October 24, 2008

LMV1089

Dual Input, Clarisound™ Far Field Noise Suppression

Microphone Amplifier with Automatic Calibration

Capability

LMV1089 Dual Input, Clarisound™ Far Field Noise Suppression Microphone Amplifier with

Automatic Calibration Capability

General Description

The LMV1089 is a fully analog dual differential input, differential output, microphone array amplifier designed to reduce

background acoustic noise, while delivering superb speech

clarity in voice communication applications.

The LMV1089 preserves near-field voice signals within 4cm

of the microphones while rejecting far-field acoustic noise

greater than 50cm from the microphones. Up to 20dB of farfield rejection is possible in a properly configured and calibrated system.

Part of the Powerwise™ family of energy efficient solutions,

the LMV1089 consumes only 1.1mA of supply current providing superior performance over DSP solutions consuming

greater than ten times the power.

A quick calibration during the manufacturing test process of

a product containing the LMV1089 compensates the entire

microphone system. This calibration compensates for mismatch in microphone gain and frequency response, as well

as acoustical path variances. The LMV1089 stores the calibration coefficients in the on-chip EEPROM. The calibration

is initiated by an I2C command or by a logic pin control.

The dual microphone inputs and the processed signal output

are differential to provide excellent noise immunity. The microphones are biased with an internal low-noise bias supply.

Key Specifications

Far Field Noise Suppression Electrical 33dB

■

Supply voltage 2.7V to 5.5V

■

Supply current 1.1mA (typ)

■

Standby current

■

Signal-to-Noise Ratio (A-weighted) 65dB (typ)

■

Total Harmonic Distortion + Noise 0.1% (typ)

■

PSRR (217Hz) 96dB (typ)

■

0.7μA (typ)

Features

Low power consumption

■

Shutdown function

■

No added processing delay

■

Differential outputs

■

Automatic calibration

■

Adjustable 6 - 48dB gain

■

Excellent RF immunity

■

Space-saving 36–bump micro SMD package

■

Applications

Headset and Boom microphones

■

Mobile and handheld two-way radios

■

Bluetooth and other powered headsets

■

Hand-held voice microphones

■

Equalized stereo microphone preamplifier

■

30047240

FIGURE 1.

© 2008 National Semiconductor Corporation 300472 www.national.com

Typical Application

LMV1089

30047201

www.national.com 2

FIGURE 2. Typical Dual Microphone Far Field noise Cancelling Application

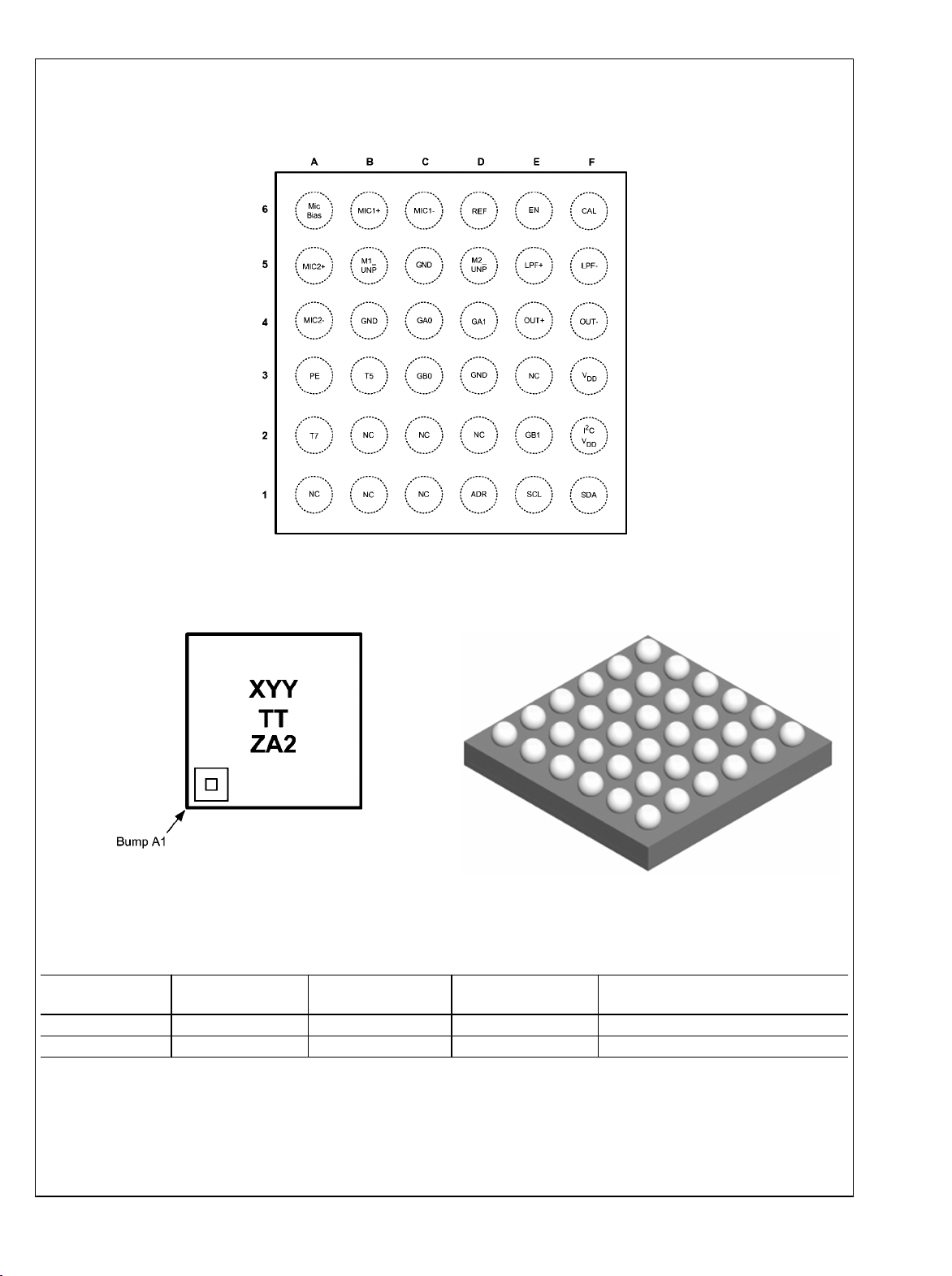

Connection Diagrams

LMV1089

36–Bump micro SMD package

Top View

30047230

Order Number LMV1089RL

See NS Package Number RLA36TTA

36–Bump micro SMD Marking

Top View

X = Plant Code

YY = Date Code

30047231

micro SMD Package View

Bottom View

TT = Die Tracability

ZA2 = LMV1089RL

Ordering Information

Order Number Package

Package Drawing

Number

Device Marking Transport Media

LMV1089RL 36 Bump µSMD RLA36TTA XYYTTZA2 250 units on tape and reel

LMV1089RLX 36 Bump µSMD RLA36TTA XYYTTZA2 1000 units on tape and reel

30047233

3 www.national.com

TABLE 1. Pin Name and Function

LMV1089

Bump Number Pin Name Pin Function Pin Type

A1 NC No connect No Connect

A2 T7

Auxiliary Control Manual Calibration = GND Auto Calibration = V

DD

Digital Input

A3 PE Program Enable EEPROM Digital Input

A4 MIC2– microphone 2 negative input Analog Input

A5 MIC2+ microphone 2 positive input Analog Input

A6 Mic Bias Microphone Bias Analog Output

B1 NC No Connect No Connect

B2 NC No Connect No Connect

B3 T5 Float (do not connect to GND) Production Test

B4 GND amplifier ground Ground

B5 M1_UNP microphone 1 unprocessed output Analog Output

B6 MIC1+ microphone 1 positive input Analog Input

C1 NC No Connect No Connect

C2 NC No Connect No Connect

C3 GB0 default Post Amp Gain 0 Digital Input

C4 GA0 default Pre Amp Gain 0 Digital Input

C5 GND amplifier ground Ground

C6 MIC1– amplifier ground Analog Input

D1 ADR I2C Address select Digital Input

D2 NC No Connect No Connect

D3 GND amplifier ground Ground

D4 GA1 default Pre Amp Gain 1 Digital Input

D5 M2_UNP microphone 2 unprocessed output Analog Output

D6 REF reference voltage de-coupling Analog Reference

E1 SCL I2C clock Digital Input

E2 GB1 default Post Amp Gain 1 Digital Input

E3 NC No Connect No Connect

E4 OUT+ positive optimized audio output Analog Output

E5 LPF+ Low Pass Filter for positive output Analog Input

E6 EN chip enable Digital Input

F1 SDA I2C data Digital Input/Output

F2

F3

I2CV

V

DD

DD

I2C power supply

Supply

power supply Supply

F4 OUT- negative optimized audio output Analog Output

F5 LPF- Low Pass Filter for negative output Analog Input

F6 CAL calibration enable Digital Input

www.national.com 4

LMV1089

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Supply Voltage 6.0V

Storage Temperature -85°C to +150°C

Power Dissipation (Note 3) Internally Limited

ESD Rating (Note 4) 2000V

ESD Rating (Note 5) 200V

Junction Temperature (T

Mounting Temperature

) 150°C

JMAX

235°C

Thermal Resistance

θJA (microSMD)

70°C/W

Soldering Information See AN-112 “microSMD Wafers Level

Chip Scale Package.”

Operating Ratings (Note 2)

Supply Voltage

I2CV

DD

Supply Voltage (Note 8)

Temperature Range −40°C to 85°C

T

≤ TA ≤ T

MIN

MAX

2.7V ≤ V

DD

≤ 5.5V

1.7V ≤ I2CVDD ≤ 5.5V

−40°C ≤ TA ≤ +85°C

Infrared or Convection (20 sec.)

Electrical Characteristics 3.3V (Note 1)

Unless otherwise specified, all limits guaranteed for TJ = 25°C, VDD = 3.3V, VIN = 18mV

(Note 8), Pre Amp gain = 20dB, Post Amp gain = 6dB, RL = 100kΩ, and CL = 4.7pF, C

Symbol Parameter Conditions

SNR Signal-to-Noise Ratio

f = 1kHz, V

f = 1kHz, VIN = 18mV

= 18mV

IN

P-P

, A-Weighted

P-P

voice band (300 – 3400Hz)

Input Referred Noise level A-weighted 5

e

N

VINMaximum Input Signal THD+N < 1%, Pre Amp Gain = 6dB 910 870 mV

Maximum AC Output Voltage

V

OUT

f = 1kHz, Differential Out+, Out-

THD+N < 1%

DC Level at Outputs Out+, Out- 800 mV

THD+N Total Harmonic Distortion + Noise Differential Out+ and Out- 0.1 0.2 % (max)

Z

Input Impedance 155

IN

Z

Z

Output Impedance 300

OUT

Load Impedance (Out+, Out-) R

LOAD

C

LOAD

LOAD

AMMicrophone Preamplifier Gain Range

Microphone Preamplifier Gain Adjustment

A

MR

A

P

A

PR

A

CR

A

MD

X

Talk

T

CAL

FFNS

SNRI

Resolution

Post Amplifier Gain Range Pass Through Mode and Summing Mode 6 – 18 dB

Post Amplifier Gain Resolution 3

Gain Compensation Range ±3 dB

Maximum Gain Matching Difference After

Calibration

Crosstalk Attenuation between Mic1 and Mic2 Measured at M1_UNP and M2_UNP 52 41 dB (min)

Calibration Duration 790

Far Field Noise Suppression Electrical

E

Signal-to-Noise Ratio Improvement Electrical

E

f = 1kHz 2

f = 300Hz

f = 1kHz

f = 3kHz

f = 1kHz (See Test Method)

f = 300Hz (See Test Method)

f = 1kHz (See Test Method)

f = 300Hz (See Test Method)

Input Referred, Input AC grounded

PSRR Power Supply Rejection Ratio

RIPPLE

f

RIPPLE

= 217Hz (V

= 1kHz (V

RIPPLE

RIPPLE

= 100mV

= 100mV

f

CMRR Common Mode Rejection Ratio f = 1kHz 60 dB

, f = 1kHz, EN = VDD, pass through mode

P-P

= 10nF

REF

LMV1089

Typical

(Note 6)

Limits

(Note 7)

(Limits)

63 dB

65 dB

1.2 1.1

10

6 – 36

1.75

2.25

0.5

V

RMS

120

190

kΩ (min)

kΩ (max)

kΩ (min)

100

pF (max)

dB (min)

dB (max)

2.6

3.4

dB (min)

dB (max)

dB

0.25

0.5

ms (max)

27

dBV

33

24

dBV

28

P-P

P-P

)

)

96 85 dB (min)

91 80 dB (min)

Units

μV

RMS

P-P

(min)

Ω

dB

dB

dB

dBV

dBV

(min)

5 www.national.com

V

BM

e

LMV1089

VBM

I

BM

I

DDQ

I

DD

I

SD

I

DDCP

Microphone Bias Supply Voltage

10nF capacitor on V

pin A-Weighted, 10nF cap at V

REF

Total available Microphone Bias Current

Supply Quiescent Current VIN = 0V

Supply Current

Shut Down Current

Supply Current during Calibration and

Programming

I

BIAS

VIN = 25mV

mode

EN pin = GND

Calibrating or Programming EEPROM 30 40 mA (max)

IDDI2C I2C supply current I2C Idle Mode

T

ON

T

OFF

Turn On Time

Turn Off Time

= 1mA

pin 10

REF

both inputs, Noise cancelling

P-P

2.0

1.85

2.15

V (min)

V (max)

μV

RMS

1.2 mA (min)

1.1 1.5 mA (max)

1.1 mA

0.7 1

μA (max)

25 100 nA (max)

40 ms (max)

60 ms (max)

www.national.com 6

Electrical Characteristics 5.0V (Note 1)

Unless otherwise specified, all limits guaranteed for TJ = 25°C, VDD = 5V, VIN = 18mV

Pre Amp gain = 20dB, Post Amp gain = 6dB, RL = 100kΩ, and CL = 4.7pF.

Symbol Parameter Conditions

SNR Signal-to-Noise Ratio

f = 1kHz, V

f = 1kHz, VIN = 18mV

= 18mV

IN

P-P

, A-Weighted

P-P

voice band (300 – 3400Hz)

e

Input Referred Noise level A-weighted 5

N

VINMaximum Input Signal f = 1kHz, THD+N < 1% 918 870 mV

Maximum AC Output Voltage

V

OUT

f = 1kHz, THD+N < 1%

between differential output

DC Output Voltage 800 mV

THD+N

FFNS

SNRI

Total Harmonic Distortion + Noise f = 1kHz VIN = 18mV

Z

Input Impedance 155

IN

Z

Output Impedance 300

OUT

AMMicrophone Preamplifier Gain Range

Microphone Preamplifier Gain Adjustment

A

MR

Resolution

A

Post Amplifier Gain Range

P

Post Amplifier Gain Adjustment Resolution

A

PR

A

Gain Compensation Range f = 1kHz ±3 dB

CR

Maximum Gain Matching Difference After

A

MD

Calibration

T

Calibration Duration 790 ms (max)

CAL

Far Field Noise Suppression Electrical

E

Signal-to-Noise Ratio Improvement Electrical

E

f = 1kHz 6 – 36 dB

f = 1kHz 2

f = 1kHz Pass Through Mode and Summing

Mode

f = 1kHz 3

f = 300Hz

f = 2kHz

f = 3kHz

f = 1kHz (See Test Method)

f = 300Hz (See Test Method)

f = 1kHz (See Test Method)

f = 300Hz (See Test Method)

P-P

Input Referred, Input AC grounded

PSRR Power Supply Rejection Ratio

RIPPLE

f

RIPPLE

= 217Hz (V

= 1kHz (V

RIPPLE

RIPPLE

= 100mV

= 100mV

f

CMRR Common Mode Rejection Ratio f = 1kHz 62 dB

V

Microphone Bias Supply Voltage

BM

10nF capacitor on V

e

VBM

I

Total Available Microphone Bias Current

BM

I

Supply Quiescent Current VIN = 0V

DDQ

Supply Current during Calibration and

I

DDCP

Programming

I

Supply Current

DD

I

Shut Down Current EN pin = GND 1.6

SD

T

Turn On Time

ON

T

Turn Off Time

OFF

pin A-Weighted 10

REF

I

= 1mA

BIAS

Calibrating or Programming EEPROM 30 40 mA (max)

VIN = 25mV

both inputs, Noise cancelling

P-P

mode

, EN = VDD, pass through mode (Note 8),

P-P

LMV1089

Typical Limit

(Limits)

(Note 6) (Note 7)

63 dB

65 dB

1.2 1.1

V

RMS

0.1 0.2 % (max)

120

190

1.75

2.25

kΩ (min)

kΩ (max)

dB (min)

dB (max)

6 – 18 dB

2.6

3.4

dB (min)

dB (max)

0.5

0.25

0.5

27

dBV

33

24

dBV

27

P-P

P-P

)

)

96 85 dB (min)

91 80 dB (min)

2.0 V

1.2 mA (min)

1.1 1.5 mA (max)

1.1 mA (max)

40 ms (max)

60 ms (max)

Units

μV

P-P

dBV

dBV

μV

LMV1089

RMS

(min)

(min)

Ω

dB

dB

dB

RMS

μA

7 www.national.com

Digital Interface Characteristics (Notes 1, 8)

Unless otherwise specified, all limits guaranteed for TJ = 25°C, I2CVDD within the Operating Rating (Note 8)

LMV1089

Symbol Parameter Conditions

V

V

ts

th

ts

PEC

th

PEC

Note 1: “Absolute Maximum Ratings” indicate limits beyond which damage to the device may occur, including inoperability and degradation of device reliability

and/or performance. Functional operation of the device and/or non-degradation at the Absolute Maximum Ratings or other conditions beyond those indicated in

the Recommended Operating Conditions is not implied. The Recommended Operating Conditions indicate conditions at which the device is functional and the

device should not be operated beyond such conditions. All voltages are measured with respect to the ground pin, unless otherwise specified.

Note 2: The Electrical Characteristics tables list guaranteed specifications under the listed Recommended Operating Conditions except as otherwise modified

or specified by the Electrical Characteristics Conditions and/or Notes. Typical specifications are estimations only and are not guaranteed.

Note 3: The maximum power dissipation must be de-rated at elevated temperatures and is dictated by T

allowable power dissipation is P

150°C and the typical θJA for this microSMD package is 70°C/W and for the LLP package θJA is 64°C/W Refer to the Thermal Considerations section for more

information.

Note 4: Human body model, applicable std. JESD22-A114C.

Note 5: Machine model, applicable std. JESD22-A115-A.

Note 6: Typical values represent most likely parametric norms at TA = +25°C, and at the Recommended Operation Conditions at the time of product

characterization and are not guaranteed.

Note 7: Datasheet min/max specification limits are guaranteed by test, or statistical analysis.

Note 8: The voltage at I2CVDD must not exceed the voltage on VDD.

Logic High Input Level

IH

Logic Low Input Level

IL

CAL Setup Time 2 ms

CAL

CAL Hold time until calibration is

CAL

finished

PE Setup Time 2 ms

PE Hold until calibration is finished 790 ms (min)

= (T

DMAX

– TA) / θJA or the number given in the Absolute Maximum Ratings, whichever is lower. For the LMV1089, T

JMAX

EN, TM, SCL, SDA, ADR, CAL, PE

GA0, GA1, GB0, GB1

EN, TM, SCL, SDA, ADR, CAL, PE

GA0, GA1, GB0

790 ms (min)

, θJC, and the ambient temperature TA. The maximum

JMAX

Typical

(Note 6)

LMV1089

(Note 7)

0.75xI2CV

0.6xV

0.25xI2CV

0.4xV

Limit

DD

DD

DD

DD

Units

(Limits)

V (min)

V (max)

=

JMAX

www.national.com 8

Test Methods

LMV1089

30047212

FIGURE 3. FFNSE, NFSLE, SNRIE Test Circuit

FAR FIELD NOISE SUPPRESSION (FFNSE)

For optimum noise suppression the far field noise should be

in a broadside array configuration from the two microphones

(see Figure 15). Which means the far field sound source is

equidistance from the two microphones. This configuration

allows the amplitude of the far field signal to be equal at the

two microphone inputs, however a slight phase difference

may still exist. To simulate a real world application a slight

phase delay was added to the FFNSE test. The block diagram

from Figure 3 is used with the following procedure to measure

the FFNSE.

1.

A sine wave with equal frequency and amplitude

(25mV

generator, the phase of Mic 2 is delayed by 1.1° when

) is applied to Mic1 and Mic2. Using a signal

P-P

compared with Mic1.

2.

Measure the output level in dBV (X)

3.

Mute the signal from Mic2

4.

Measure the output level in dBV (Y)

5.

FFNSE = Y - X dB

NEAR FIELD SPEECH LOSS (NFSLE)

For optimum near field speech preservation, the sound

source should be in an endfire array configuration from the

two microphones (see Figure 16). In this configuration the

speech signal at the microphone closest to the sound source

will have greater amplitude than the microphone further away.

Additionally the signal at microphone further away will experience a phase lag when compared with the closer microphone. To simulate this, phase delay as well as amplitude

shift was added to the NFSLE test. The schematic from Figure

3 is used with the following procedure to measure the NFSLE.

1.

A 25mV

applied to Mic1 and Mic2 respectively. Once again, a

and 17.25mV

P-P

(0.69*25mV

P-P

) sine wave is

P-P

signal generator is used to delay the phase of Mic2 by

15.9° when compared with Mic1.

2.

Measure the output level in dBV (X)

3.

Mute the signal from Mic2

4.

Measure the output level in dBV (Y)

5.

NFSLE = Y - X dB

SINGLE TO NOISE RATIO IMPROVEMENT ELECTRICAL

(SNRIE)

The SNRIE is the ratio of FFNSE to NFSLE and is defined as:

SNRIE = FFNSE - NFSL

E

9 www.national.com

Typical Performance Characteristics Unless otherwise specified, T

= 18mV

LMV1089

, f =1 kHz, pass through mode (Note 8), Pre Amp gain = 20dB, Post Amp gain = 6dB, RL = 100kΩ, and CL = 4.7pF.

P-P

THD+N vs Frequency

Mic1 = AC GND, Mic2 = 36mV

Noise Canceling Mode

P-P

Mic2 = AC GND, Mic1 = 36mV

= 25°C, VDD = 3.3V, Input Voltage

J

THD+N vs Frequency

Noise Canceling Mode

P-P

THD+N vs Frequency

Mic1 = 36mV

Mic1 Pass Through Mode

P-P

THD+N vs Input Voltage

Mic1 = AC GND, f = 1kHz

Mic2 Noise Canceling Mode

30047248

30047249

THD+N vs Frequency

Mic2 = 36mV

Mic2 Pass Through Mode

P-P

THD+N vs Input Voltage

Mic2 = AC GND, f = 1kHz

Mic1 Noise Canceling Mode

30047247

30047250

30047252

www.national.com 10

30047251

LMV1089

THD+N vs Input Voltage

f = 1kHz

Mic1 Pass Through Mode

30047253

PSRR vs Frequency

Pre Amp Gain = 20dB, Post Amp Gain = 6dB

V

= 100mV

RIPPLE

Mic1 Pass Through Mode

, Mic1 = Mic2 = AC GND

P-P

THD+N vs Input Voltage

f = 1kHz

Mic2 Pass Through Mode

30047254

PSRR vs Frequency

Pre Amp Gain = 20dB, Post Amp Gain = 6dB

V

= 100mV

RIPPLE

Mic2 Pass Through Mode

, Mic1 = Mic2 = AC GND

P-P

30047244

PSRR vs Frequency

Pre Amp Gain = 20dB, Post Amp Gain = 6dB

V

RIPPLE

= 100mV

Noise Canceling Mode

, Mic1 = Mic2 = AC GND

P-P

30047245

30047245

Far Field Noise Suppression Electrical vs Frequency

30047255

11 www.national.com

LMV1089

Signal-to-Noise Ratio Electrical vs Frequency

30047256

www.national.com 12

LMV1089

Application Data

INTRODUCTION

The LMV1089 is a fully analog single chip solution to reduce

the far field noise picked up by microphones in a communi-

FIGURE 4. Simplified Block Diagram of the LMV1089

The output signal of the microphones is amplified by a preamplifier with adjustable gain between 6dB and 36dB. In the

analog noise cancelling processor the gain and frequency response of the microphones and acoustical effects of the

enclosure are matched through the auto-calibration function.

After the signals are matched the analog noise cancelling

suppresses the far field noise signal. The output of the analog

noise cancelling processor is amplified in the post amplifier

with adjustable gain between 6dB and 18dB. For optimum

noise and EMI immunity, the microphones have a differential

connection to the LMV1089 and the output of the LMV1089

is also differential. The adjustable gain functions can be controlled via I2C and four control pins. Both methods are described later in the application section.

Power Supply Circuits

A low drop-out (LDO) voltage regulator in the LMV1089 allows

the device to be independent of supply voltage variations.

The Power On Reset (POR) circuitry in the LMV1089 requires

the supply voltage to rise from 0V to VDD in less than 100ms.

The Mic Bias output is provided as a low noise supply source

for the electret microphones. The noise voltage on the Mic

Bias microphone supply output pin depends on the noise voltage on the internal the reference node. The de-coupling

capacitor on the V

internal reference. This capacitor should be larger than 1nF;

having a larger capacitor value will result in a lower noise

voltage on the Mic Bias output.

Most of the logic levels for the digital control interface are relative to I2CVDD voltage. This eases interfacing to the micro

controller of the application containing the LMV1089. The

supply voltage on the I2CVDD pin must never exceed the voltage on the V

Only the four pins that determine the default power up gain

(as described in SETTING ADJUSTABLE GAIN) have logic

levels relative to VDD.

DD

pin determines the noise voltage on this

REF

pin.

Shutdown Function

As part of the Powerwise™ family, the LMV1089 consumes

only 1.1mA of current. In many applications the part does not

need to be continuously operational. To further reduce the

power consumption in the inactive period, the LMV1089 pro-

cation system. A simplified block diagram is provided in

Figure 4.

30047224

vides two individual microphone power down functions. When

either one of the shutdown functions is activated the part will

go into shutdown mode consuming only a few μA of supply

current.

SHUTDOWN VIA HARDWARE PIN

The hardware shutdown function is operated via the EN pin.

In normal operation the EN pin must be at a 'high' level

(VDD). Whenever a 'low' level (GND) is applied to the EN pin

the part will go into shutdown mode disabling all internal circuits.

SHUTDOWN VIA I2C

The LMV1089 offers an additional shutdown function by reprogramming an I2C register (see Table 6). The LMV1089 will

only consume power in a mode where it can perform its normal functions. So at least one of the microphone amplifier

circuits must be enabled ('1'). Writing '0' to the both bit 4 and

bit 5 of the I2C 'A' register (address 0x01h) of the LMV1089

will force the part into shutdown mode, even if the EN pin is

'High', the only part that remains active in this state is the I2C,

which consumes neglectible power when compared to the

standby current.

Adjustable Gain

The LMV1089 has two gain stages where the gain can be

adjusted to meet the requirements for the application. There

is a preamplifier and a post amplifier that can be varied independent of each other. In most applications the gain will be

set via the I2C interface, see Table 6.

SETTING ADJUSTABLE GAIN

The LMV1089 provides four pins to set the default gain settings during power up of the device, which is convenient for

applications without a micro controller . The default gain of the

preamplifier is controlled by the GA0 and GA1 pins and can

be set by wiring those pins to either VDD or GND. In this way,

one of the four possible values in the 12dB to 36dB range (see

Table 2) can be chosen. The default post amplifier gain is set

in the same way by connecting the GB0 and GB1 pins to either VDD or GND to select a gain between 6dB and 15dB (see

Table 3). Setting the gain of the preamplifier and post amplifier

13 www.national.com

via the I2C interface (see Table 6) will override this default

gain.

The default gain is only set during power up of the device.

LMV1089

Toggling the logic level of the enable pin (EN) will not change

the current gain setting of the part. Any gain setting done via

the I2C interface will remain valid during activation of the function.

TABLE 2. Default preamplifier gain

GA1 GA0 Gain

0 0 12dB

0 1 20dB (Note 9)

1 0 28dB

1 1 36dB

Gain Balance and Gain Budget

In systems where input signals have a high dynamic range,

critical noise levels or where the dynamic range of the output

voltage is also limited, careful gain balancing is essential for

the best performance. Too low of a gain setting in the preamplifier can result in higher noise levels while too high of a gain

TABLE 3. Default post amplifier gain

GB1 GB0 Gain

0 0 6dB (Note 9)

0 1 9dB

1 0 12dB

1 1 15dB

Note 9: Default value used for performance measurements

setting in the preamplifier will result in clipping and saturation

in the noise cancelling processor and output stages.

The gain ranges and maximum signal levels for the different

functional blocks are shown in Figure 5. Two examples are

given as a guideline on how to select proper gain settings.

FIGURE 5. Maximum Signal Levels

Example 1

An application using microphones with 50mV

output voltage, and a baseband chip after the LMV1089 with

1.5V

maximum input voltage.

P-P

maximum

P-P

For optimum noise performance, the gain of the input stage

should be set to the maximum.

1.

50mV

2.

3.1V

the Noise Cancelling Processor (NCP). This means a

+36 dB = 3.1V

P-P

is higher than the maximum 1.4V

P-P

P-P

.

allowed for

P-P

gain lower than 28.9dB should be selected.

3.

Select the nearest lower gain from the gain settings

shown in Table 2, 28dB is selected. This will prevent the

NCP from being overloaded by the microphone. With this

setting, the resulting output level of the Pre Amplifier will

be 1.26V

4.

The NCP can have a maximum processing gain of 9dB

P-P

.

(depending on the calibration result) which will result in

www.national.com 14

30047241

3.5V

at the output of the LMV1089. This level is higher

P-P

then maximum level that is allowed at the input of the post

amp of the LMV1089. Therefore the preamp gain has to

be reduced, to 1.4V

the preamp gain to a maximum of 20dB.

5.

The baseband chip limits the maximum output voltage to

1.5V

with the minimum of 6dB post amp gain, this

P-P

results in requiring a lower level at the input of the post

amp of 0.75V

NCP gain of 9dB the output of the preamp must be

<266mV

6.

Calculating the new gain for the preamp will result in

P-P

P-P

.

minus 9dB = 0.5V

P-P

. This limits

P-P

. Now calculating this for a maximum

<1.4dB gain.

7.

The nearest lower gain will be 14dB.

So using preamp gain = 14dB and postamp gain = 6dB is the

optimum for this application.

Example 2

An application using microphones with 10mV

output voltage, and a baseband chip after the LMV1089 with

3.3V

maximum input voltage.

P-P

maximum

P-P

For optimum noise performance we would like to have the

maximum gain at the input stage.

1.

10mV

2.

This is lower than the maximum 1.4V

3.

The NCP can have a maximum processing gain of 9dB

+ 36dB = 631mV

P-P

P-P

.

so this is OK.

P-P

(depending on the calibration result) which will result in

3.5V

at the output of the LMV1089. This level is higher

P-P

then maximum level that is allowed at the input of the

Post Amp of the LMV1089. Therefore the Pre Amp gain

has to be reduced, to 1.4V

limits the Pre Amp gain to a maximum of 34dB.

4.

With a Post Amp gain setting of 6dB the output of the

Post Amp will be 2.8V

5.

The nearest lower Post Amp gain will be 6dB.

minus 9dB = 0.5V

P-P

which is OK for the baseband.

P-P

P-P

. This

So using preamp gain = 34dB and postamp gain = 6dB is

optimum for this application.

Unprocessed Output Pins

The LMV1089 provides two single ended output pins

M1_UNP and M2_UNP. These pins provide the amplified

output signal from the two differential microphone input amplifiers Mic1 and Mic2. When the application containing the

LMV1089 is in a calibrated state the output level of the two

microphone paths are matched. This makes these outputs

suitable for stereo applications like video camera webcams

and photo cameras. Low cost microphones with wider gain

tolerance can be used because gain differences of the microphones will be compensated by the calibration system of

the LMV1089. In this situation the default gain of the Pre Amplifiers is set by GA0 and GA1 as described in Table 2. This

gain can be changed via I2C by writing register A as described

in the I2C Compatible Interface section.

I2C Compatible Interface

I2C SIGNALS

The LMV1089 pin Serial Clock (SCL) pin is used for the I2C

clock and the Serial Data (SDA) pin is used for the I2C data.

Both these signals need a pull-up resistor according to I2C

specification. The LMV1089 can be controlled through two

slave addresses. The digital I2C address pin selects the I2C

address for LMV1089 as shown inTable 4 .

TABLE 4. Chip Address

D7 D6 D5 D4 D3 D2 D1 D0

1st Chip

Address

I2C

Adress='0'

2nd Chip

Address

I2C

Adress='1'

1 1 0 0 1 1 0 W/R

1 1 0 0 1 1 1 W/R

I2C Signals: Data Validity

300472q1

I2C START AND STOP CONDITIONS

START and STOP bits classify the beginning and the end of

the I2C data transmission session. START condition is defined as the SDA signal transitioning from HIGH to LOW while

SCL line is HIGH. STOP condition is defined as the SDA transitioning from LOW to HIGH while SCL is HIGH. The I2C

master always generates START and STOP bits. The I2C bus

is considered to be busy after START condition and free after

STOP condition. During data transmission, I2C master can

generate repeated START conditions. First START and repeated START conditions are equivalent, function-wise.(Note

10)

I2C Start Stop Conditions

Note 10: The master should issue STOP after no acknowledgment.

300472q2

TRANSFERRING DATA

Every byte put on the SDA line must be eight bits long, with

the most significant bit (MSB) being transferred first. Each

byte of data has to be followed by an acknowledge bit. The

acknowledge related clock pulse is generated by the master.

The transmitter releases the SDA line (HIGH) during the acknowledge clock pulse. The receiver must pull down the SDA

line during the 9th clock pulse, signifying an acknowledge

(ACK). A receiver which has been addressed must generate

an acknowledge after each byte has been received.

After the START condition, the I2C master sends a chip address. This address is seven bits long followed by an eighth

bit which is a data direction bit (R/W). The LMV1089 address

is 110011002 or 110011102. For the eighth bit, a “0” indicates

a WRITE and a “1” indicates a READ. The second byte selects the register to which the data will be written. The third

byte contains data to write to the selected register.

LMV1089

I2C DATA VALIDITY

The data on SDA line must be stable during the HIGH period

of the clock signal (SCL). In other words, the state of the data

line can only be changed when SCL is LOW.

I2C Chip Address

15 www.national.com

300472q3

Register changes take effect at the SCL rising edge during

the last ACK from slave.

LMV1089

In Figure 6, a write example is shown, for a device with a randomly chosen address'001101002'.

w = write (SDA = “0”)

r = read (SDA = “1”)

ack = acknowledge (SDA pulled down by slave)

rs = repeated start

FIGURE 6. Example I2C Write Cycle

When a READ function is to be accomplished, a WRITE function must precede the READ function, as shown in the Read

FIGURE 7. Example I2C Read Cycle

300472q5

Cycle waveform. Figure 7 shows this read example for a randomly chosen address'001101012.

300472q6

FIGURE 8. I2C Timing Diagram

www.national.com 16

300472q9

TABLE 5. I2C Timing Paramters

LMV1089

Symbol Parameter

Limit

Min Max

1 Hold Time (repeated) START Condition 0.6 µs

2 Clock Low Time 1.3 µs

3 Clock High Time 600 ns

4 Setup Time for a Repeated START Condition 600 ns

5 Data Hold Time (Output direction, delay generated by LMV1089) 300 1100 ns

5 Data Hold Time (Input direction, delay generated by the Master) 0 1100 ns

6 Data Setup Time 300 ns

7 Rise Time of SDA and SCL 20 300 ns

8 Fall Time of SDA and SCL 15 300 ns

9 Set-up Time for STOP condition 600 ns

10 Bus Free Time between a STOP and a START Condition 1.3 µs

C

NOTE: Data guaranteed by design

Capacitive Load for Each Bus Line 10 200 pF

b

TABLE 6. I2C Register Description

Address Reg. Bits Description Default

Microphone preamplifier gain from 6dB up to 36dB in 2dB steps.

0000 6dB

0001 8dB

0010 10dB

0011 12dB

0100 14dB

0101 16dB

0110 18dB

A [3:0]

0111 20dB

1000 22dB

0x01h

1001 24dB

1010 26dB

1011 28dB

1100 30dB

1101 32dB

1110 34dB

1111 36dB

A [5:4]

A [7:6]

A4 = mute mic1 and A5 = mute mic2.

( 0 = microphone on)

Mic enable bits, A6 = enable Mic1, A7 = enable Mic2

(1 = enable), A6 and A7 both 0 = Shutdown Mode

Units

See Table 2

00(on)

11(on)

17 www.national.com

Address Reg. Bits Description Default

LMV1089

Gain setting for the post amplifier from (3dB steps)

000 6db

001 9dB

010 12dB

B [2:0]

0x02h

B [4:3]

B [7:5] Not Used 000

0x0Ch L [7:0] reads the output of the EEPROM read only

0x0Dh M [7:0] reads the output of the EEPROM read only

N [6:0] reads the output of the EEPROM read only

0x0Efh

N [7]

011 15dB

100 18dB

101 18dB

110 18dB

111 18dB

Mic select bits

0 0 Noise cancelling mode

0 1 Only Mic1 enabled

1 0 Only Mic2 enabled

1 1 Mic1 + Mic2

Reads the “ready” signal. This give the status of the program cycle.

1 = ready ; 0 = program cycle in progress

See Table 3

00

read only

www.national.com 18

Address Reg. Bits Description Default

[3:0] Control the gain compensation between the two mics at 3kHz

0000 (0) 0.0dB

0001 (1) 0.5dB

0010 (2) 1.0dB

0011 (3) 1.5dB

0100 (4) 2.0dB

0101 (5) 2.5dB

0110 (6) 3.0dB

0x0Fh O

0111 (7) 3.0dB

1000 (8) 0dB

1001 (9) –0.5dB

1010 (A) –1.0dB

1011 (B) –1.5dB

1100 (C) –2.0dB

1110 (D) –2.5dB

1110 (E) –3.0dB

1111 (F) –3.0dB

[7:4] Control the gain compensation between the two mics at 300Hz

0000 (0) 0.0dB

0001 (1) 0.5dB

0010 (2) 0.0dB

0011 (3) 1.5dB

0100 (4) 2.0dB

0101 (5) 2.5dB

0110 (6) 3.0dB

0111 (7) 3.0dB

1000 (8) 0dB

1001 (9) –0.5dB

1010 (A) –1.0dB

1011 (B) –1.5dB

1100 (C) –2.0dB

1101 (D) –2.5dB

1110 (E) –3.0dB

1111 (F) –3.0dBd

0000

0000

LMV1089

19 www.national.com

Address Reg. Bits Description Default

LMV1089

0x10h P

0x11h Q

0x12h R

[3:0] Control compensation gain for left channel at ALL frequencies

0000 (0) –3.0dB

0001 (1) –3.0dB

0010 (2) –2.5dB

0011 (3) –2.0dB

0100 (4) –1.5dB

0101 (5) –1.0dB

0110 (6) –0.5dB

0111 (7) 0.0dB

1000 (8) 0.0dB

1001 (9) 0.5dB

1010 (A) 1.0dB

1011 (B) 1.5dB

1100 (C) 2.0dB

1101 (D) 2.5dB

1110 (E) 3.0dB

1111 (F) 3.0dB

[7:4] Control compensation gain for right channel at ALL frequencies

0000 (0) –3.0dB

0001 (1) –3.0dB

0010 (2) –2.5dB

0011 (3) –2.0dB

0100 (4) –1.5dB

0101 (5) –1.0dB

0110 (6) –0.5dB

0111 (7) 0.0dB

1000 (8) 0.0dB

1001 (9) 0.5dB

1010 (A) 1.0dB

1011 (B) 1.5dB

1100 (C) 2.0dB

1101 (D) 2.5dB

1110 (E) 3.0dB

1111 (F) 3.0dB

[6:0] Values are clocked into EEPROM registers once “newdata” pulse is generated

StoreBar signal

[7]

StoreBar = 0 enables EEPROM programming

StoreBar = 1 data clock into EEPROM registers

[0] Start Calibration via I2C ‘0’ to ‘1’ = start calibration (keep ‘1’ during calibration) 0

[7] Internal test 0000000

1111

1111

1

www.national.com 20

LMV1089

Calibration

Automatic calibration should only be required once, when the

product containing the LMV1089 has completed manufacture, and prior to application packaging. The product containing the LMV1089 will be calibrated to the microphones, the

microphone spacings, and the acoustical properties of the final design.

The compensation or calibration technology is achieved via

memory stored coefficients when the FFNS circuitry activates

the calibration sequence. The purpose of the calibration sequence is to choose the optimized coefficients for the FFNS

circuitry for the given microphones, spacing, and acoustical

design of the product containing the LMV1089.

A basic calibration can be performed with a single 1kHz tone,

however to take full advantage of this calibration feature a

three tone calibration (See PERFORMING A THREE TONE

CALIBRATION) is preferred .

The automatic calibration process can be initiated from either

a digital interface CALIBRATE pin (CAL) or via the I2C interface.

The logic level at the PROGRAM ENABLE (PE) pin determines if the result of the calibration is volatile or permanent.

To make the result of the calibration permanent (stored in the

EEPROM) the PROGRAM ENABLE (PE) pin must be high

during the automatic calibration process.

AUTOMATIC CALIBRATION VIA CAL PIN

To initiate the automatic calibration via the CAL pin, the following procedure is required. See timing diagram Figure 11:

•

From the initial condition where both PE and CAL are at

'low' level

•

bring PE to a 'high' level (enable EEprom write)

•

bring CAL to a 'high' level to start Calibration

•

Apply Audio stimulus (single tone 1kHz or three tone

sequence as described in PERFORMING A THREE

TONE CALIBRATION) (see Figure 12).

•

Hold CAL 'high' for at least 790ms

•

Remove Audio stimulus

•

bring CAL to a 'low' level to stop Calibration

•

bring PE to a 'low' level (disable EEprom write)

A tone may be applied prior to the rising of CAL and PE. Signals applied to the microphone inputs before rising of CAL

and PE are ignored by the calibration system.

FIGURE 9. Automatic Calibration via CAL pin

Note:

When the I2C is operated, make sure that register 'R' (address

0x12) bit 0 is '0' before operating the CAL pin (default value for

this bit). When this bit is set '1' the calibration engine of the

LMV1089 is started and will remain active with a higher supply

300472r1

current than normal operation. The state of the calibration remains active until this bit is reset, '0”. With the bit set the 'low'

to' high' transfer of the CAL pin will be ignored.

21 www.national.com

AUTOMATIC CALIBRATION VIA I2C COMMAND

To initiate the automatic calibration via the I2C interface, the

following procedure is required:

LMV1089

•

From the initial condition where PE is 'low' level

•

Bring PE to a 'high' level (enable EEprom write)

•

Write '1' into I2C register 'R' (address 0x12) bit 0 to start

calibration

•

Apply Audio stimulus (single tone 1kHz or three tone

sequence as described in PERFORMING A THREE

TONE CALIBRATION)

•

•

•

•

A tone may be applied prior to the rising of PE or setting the

I2C calibration bit . Signals applied to the microphone inputs

before rising of PE or setting the I2C calibration bit are ignored

by the calibration system.

FIGURE 10.

Wait at least 790ms

Remove Audio stimulus

Write '0' into I2C to finish calibration

Bring PE to a 'low' level (disable EEprom write)

300472r2

PERFORMING THE AUTOMATIC CALIBRATION

Automatic calibration can be performed as 'one tone' or as

'three tone' calibration. Three tone calibration is preferred because the three tone calibration not only compensates for

differences in the gain between the two microphones, but this

function also corrects for differences in the frequency response between in the two microphones and compensates

for the acoustical effects of the enclosure.

The one tone calibration only compensates for the gain difference between the two microphones at 1kHz and can lead

to less far field noise reduction when compared to three tone

calibration.

PERFORMING A ONE TONE CALIBRATION

The easiest way to perform an automatic calibration with the

LMV1089 uses a 1kHz tone. This tone can be a steady state

tone or a 1kHz tone that is switched on and off using the timing

from Figure 11.

To perform a one tone calibration, a 1kHz test tone is required

right after the PE and CAL inputs are brought to a logic high

level and that tone should be stable during the time as indicated in Table 7. At the end of this sequence the calibration

data is automatically stored in the internal EEPROM (see Figure 12).

A tone may be applied prior to the rising of CAL start signal

and PE. Signals applied to the microphone outside the limits

shown in Figure 11 and Table 7 are ignored by the calibration

system.

FIGURE 11. One Tone Calibration Timing

www.national.com 22

300472r4

LMV1089

PERFORMING A THREE TONE CALIBRATION

In a system with two microphones in an enclosure there will

always be a difference in the transfer function in both gain and

frequency response between the two channels. The

LMV1089 has the capability to perform an automatic calibration function to minimize these differences. To perform this

calibration, a test sequence of three tones is required right

after the PE and CAL inputs are brought to a logic high level.

At the end of this sequence the calibration data is automatically stored in the internal EEPROM.

The three tones have to be applied as follows (see Figure 12):

•

A first tone with a frequency of 1kHz

•

A second tone with a frequency of 300Hz

•

A third tone with a frequency of 3kHz

A tone may be applied prior to the rising of CAL start signal

and PE. Signals applied to the microphone outside the limits

shown in Figure 12 and Table 7 are ignored by the calibration

system.

Between each tone pair there is a small time, indicated by a

cross, to change the frequency. During that time the input tone

is ignored by the calibration system.

The total calibration sequence requires less than 790ms.

TABLE 7. Automatic Calibration Timing Parameters

Symbol Parameter

t

ST1

t

ET1

t

ST2

t

ET2

t

ST3

t

ET3

t

CC

NOTE: Data guaranteed by design

Calibration Start Tone 1 10 ms

Calibration End Tone 1 200 ms

Calibration Start Tone 2 210 ms

Calibration End Tone 2 400 ms

Calibration Start Tone 3 410 ms

Calibration End Tone 3 600 ms

Calibration Complete 790 ms

FIGURE 12. Calibration Timing

Limits

Min Max

300472r3

Unitis

23 www.national.com

AUTOMATIC CALIBRATION SETUP

A calibration test setup consists of a test room (acoustical

box) with a loudspeaker (acoustical source) driven with the

LMV1089

test tone sequence from Figure 12. The test setup is shown

in Figure 13. The distances between the source and microphone 1 and microphone 2 must be equal and the sound must

travel without any obstacle from source to both microphones.

The sound will travel with the limited speed of 300m/s from

the loudspeaker source to the microphones. When creating

the calibration signals this time should not be ignored, 30cm

distance will cause 1ms delay.

For an optimum automatic calibration the output level of the

microphones and preamp gain must be set so that the resulting signal at the output of the preamplifier is 100mV

P-P

± 6dB

FIGURE 13. Calibration Test setup

MANUAL CALIBRATION

You can manually program the gain compensation of the two

mic inputs on the LMV1089 using the I2C interface. Table 5

shows the control bits for I2C Register O and P with the corresponding gains. This can be easily done by doing the

following:

1) READ contents of the I2C register N immediately after

powering up.

2) Set PE pin and T7 pin to Vdd.

3) WRITE to I2C register O and P to choose the calibration

settings.

30047235

Bits O<7:4> control the two mics at 300Hz and bits

O<3:0> control the two mics at 3kHz.

Bits P<7:4> control the right channel gain and bits

P<3:0> control the left channel gain

4) WRITE a ‘0’ to I2C register Q<7> bit (storeBar) and the

bits from I2C register N<6:0> to I2C register Q<6:0>

5) When I2C register N<7> (ready) goes high, then the

EEPROM programming is complete. Now PE pin and T7 pin

should be set to GND and I2C register Q<7> (storeBar) should

be returned to ‘1’.

www.national.com 24

LMV1089

SUPPLY CURRENT DURING CALIBRATION

The calibration function performs two main tasks in a sequence. First the AC characteristics of the microphones are

matched. Then in the second stage, if the PE pin is high, the

on-chip EEPROM is programmed.

During the first stage of this sequence the supply current on

the LMV1089 will increase to about 2.5mA. During the writing

of the EEPROM the supply current will rise for about 215 ms

to about 30mA. This increased current is used for the on chip

charge pump which generates the high voltages that are required for programming the EEPROM.

30047236

Microphone Placement

Because the LMV1089 is a microphone array Far Field Noise

Reduction solution, proper microphone placement is critical

for optimum performance. Two things need to be considered:

The spacing between the two microphones and the position

of the two microphones relative to near field source

If the spacing between the two microphones is too small, near

field speech will be canceled along with the far field noise.

Conversely, if the spacing between the two microphones is

large, the far field noise reduction performance will be degraded. The optimum spacing between Mic 1 and Mic 2 is

1.5-2.5cm. This range provides a balance of minimal near

field speech loss and maximum far field noise reduction.

If the spacing between the two microphones is too small near

field speech will be canceled along with the far field noise.

Conversely, if the spacing between the two microphones is

large, the far field noise reduction performance will be degraded. The optimum spacing between Mic 1 and Mic 2 is

1.5-2.5cm. This range provides a balance of minimal near

field speech loss and maximum far field noise reduction. The

microphones should be in line with the desired sound source

'near speech' and configured in an endfire array (seeFigure

16) orientation from the sound source. If the 'near speech' (desired sound source) is equidistant to the source like a broadside array (seeFigure 15) the result will be a great deal of near

field speech loss.

FIGURE 14. Supply current during calibration and

programming

FIGURE 15. Broadside Array (WRONG)

30047243

25 www.national.com

LMV1089

30047242

FIGURE 16. Endfire Array (CORRECT)

Low-Pass Filter At The Output

At the output of the LMV1089 there is a provision to create a

1st order low-pass filter (only enabled in 'Noise Cancelling'

mode). This low-pass filter can be used to compensate for the

change in frequency response that results from the noise

cancellation process. The change in frequency response resembles a first-order high-pass filter, and for many of the

applications it can be compensated by a first-order low-pass

filter with cutoff frequency between 1.5kHz and 2.5kHz.

The transfer function of the low-pass filter is derived as:

This low-pass filter is created by connecting a capacitor between the LPF pin and the OUT pin of the LMV1089. The

value of this capacitor also depends on the selected output

gain. For different gains the feedback resistance in the lowpass filter network changes as shown in Table 8.

TABLE 8. Low-Pass Filter Internal Impedance

Post Amplifier Gain

Setting (dB )in Pass

Through mode

6 20

9 29

12 40

15 57

18 80

This will result in the following values for a cutoff frequency of

2000 Hz:

Feedback Resistance R

(kΩ)

f

Measurement Setup

Because of the nature of the calibration system it is not possible to predict the absolute gain in the two microphone

channels of the Far Field Noise Cancelling System. This is

because, after the calibration function has been operated, the

noise cancelling circuit will compensate for the difference in

gain between the microphones. In Noise Cancelling mode,

this can result in a final gain offset of max 3dB between the

gain set in the registers (A[3:0] and B[2:0]) and the actual

measured gain between input and output of the LMV1089.

After performing a calibration the frequency characteristic of

the microphone channels will be matched for the two microphones. As a result of this matching there can be a slight slope

in the frequency characteristic in one or both amplifiers.

A-WEIGHTED FILTER

The human ear is sensitive for acoustic signals within a frequency range from about 20Hz to 20kHz. Within this range

the sensitivity of the human ear is not equal for each frequency. To approach the hearing response, weighting filters are

introduced. One of those filters is the A-weighted filter.

The A-weighted filter is used in signal to noise measurements,

where the wanted audio signal is compared to device noise

and distortion.

The use of this filter improves the correlation of the measured

values to the way these ratios are perceived by the human

ear.

TABLE 9. Low-Pass Filter Capacitor For 2kHz

Post Amplifier Gain Setting (dB)

6 20 3.9

9 29 2.7

12 40 2.0

15 57 1.3

18 80 1.0

www.national.com 26

Rf (kΩ)

Cf (nF)

FIGURE 17. A-Weighted Filter

LMV1089

MEASURING NOISE AND SNR

The overall noise of the LMV1089 is measured within the frequency band from 10Hz to 22kHz using an A-weighted filter.

The Mic+ and Mic- inputs of the LMV1089 are AC shorted

between the input capacitors, see Figure 18.

30047210

FIGURE 18. Noise Measurement Setup

For the signal to noise ratio (SNR) the signal level at the output is measured with a 1kHz input signal of 18mV

A-weighted filter. This voltage represents the output voltage

using an

P-P

of a typical electret condenser microphone at a sound pressure level of 94dB SPL, which is the standard level for these

measurements. The LMV1089 is programmed for 26dB of to-

Revision History

Rev Date Description

1.0 09/24/08 Initial release.

1.01 09/30/08 Text edits.

1.02 10/14/08 Text edits.

1.03 10/24/08 Text edits.

30047211

tal gain (20dB preamplifier and 6dB postamplifier) with only

Mic1 or Mic2 used. (See also I2C Compatible Interface).

The input signal is applied differentially between the Mic+ and

Mic-. Because the part is in Pass Through mode the low-pass

filter at the output of the LMV1089 is disabled.

27 www.national.com

Physical Dimensions inches (millimeters) unless otherwise noted

LMV1089

36 Bump micro SMD Technology

X1 = 3.459±0.03(mm), X2 = 3.459(mm)±0.03, X3 = 0.66±0.075(mm)

NS Package Number RLA36TTA

www.national.com 28

LMV1089

29 www.national.com

Notes

For more National Semiconductor product information and proven design tools, visit the following Web sites at:

Products Design Support

Amplifiers www.national.com/amplifiers WEBENCH www.national.com/webench

Audio www.national.com/audio Analog University www.national.com/AU

Clock Conditioners www.national.com/timing App Notes www.national.com/appnotes

Data Converters www.national.com/adc Distributors www.national.com/contacts

Displays www.national.com/displays Green Compliance www.national.com/quality/green

Ethernet www.national.com/ethernet Packaging www.national.com/packaging

Interface www.national.com/interface Quality and Reliability www.national.com/quality

LVDS www.national.com/lvds Reference Designs www.national.com/refdesigns

Power Management www.national.com/power Feedback www.national.com/feedback

Automatic Calibration Capability

Switching Regulators www.national.com/switchers

LDOs www.national.com/ldo

LED Lighting www.national.com/led

PowerWise www.national.com/powerwise

Serial Digital Interface (SDI) www.national.com/sdi

Temperature Sensors www.national.com/tempsensors

Wireless (PLL/VCO) www.national.com/wireless

THE CONTENTS OF THIS DOCUMENT ARE PROVIDED IN CONNECTION WITH NATIONAL SEMICONDUCTOR CORPORATION

(“NATIONAL”) PRODUCTS. NATIONAL MAKES NO REPRESENTATIONS OR WARRANTIES WITH RESPECT TO THE ACCURACY

OR COMPLETENESS OF THE CONTENTS OF THIS PUBLICATION AND RESERVES THE RIGHT TO MAKE CHANGES TO

SPECIFICATIONS AND PRODUCT DESCRIPTIONS AT ANY TIME WITHOUT NOTICE. NO LICENSE, WHETHER EXPRESS,

IMPLIED, ARISING BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS

DOCUMENT.

TESTING AND OTHER QUALITY CONTROLS ARE USED TO THE EXTENT NATIONAL DEEMS NECESSARY TO SUPPORT

NATIONAL’S PRODUCT WARRANTY. EXCEPT WHERE MANDATED BY GOVERNMENT REQUIREMENTS, TESTING OF ALL

PARAMETERS OF EACH PRODUCT IS NOT NECESSARILY PERFORMED. NATIONAL ASSUMES NO LIABILITY FOR

APPLICATIONS ASSISTANCE OR BUYER PRODUCT DESIGN. BUYERS ARE RESPONSIBLE FOR THEIR PRODUCTS AND

APPLICATIONS USING NATIONAL COMPONENTS. PRIOR TO USING OR DISTRIBUTING ANY PRODUCTS THAT INCLUDE

NATIONAL COMPONENTS, BUYERS SHOULD PROVIDE ADEQUATE DESIGN, TESTING AND OPERATING SAFEGUARDS.

EXCEPT AS PROVIDED IN NATIONAL’S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, NATIONAL ASSUMES NO

LIABILITY WHATSOEVER, AND NATIONAL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY RELATING TO THE SALE

AND/OR USE OF NATIONAL PRODUCTS INCLUDING LIABILITY OR WARRANTIES RELATING TO FITNESS FOR A PARTICULAR

PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY

RIGHT.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR

SYSTEMS WITHOUT THE EXPRESS PRIOR WRITTEN APPROVAL OF THE CHIEF EXECUTIVE OFFICER AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

Life support devices or systems are devices which (a) are intended for surgical implant into the body, or (b) support or sustain life and

whose failure to perform when properly used in accordance with instructions for use provided in the labeling can be reasonably expected

to result in a significant injury to the user. A critical component is any component in a life support device or system whose failure to perform

can be reasonably expected to cause the failure of the life support device or system or to affect its safety or effectiveness.

National Semiconductor and the National Semiconductor logo are registered trademarks of National Semiconductor Corporation. All other

brand or product names may be trademarks or registered trademarks of their respective holders.

Copyright© 2008 National Semiconductor Corporation

For the most current product information visit us at www.national.com

LMV1089 Dual Input, Clarisound™ Far Field Noise Suppression Microphone Amplifier with

www.national.com

National Semiconductor

Americas Technical

Support Center

Email: support@nsc.com

Tel: 1-800-272-9959

National Semiconductor Europe

Technical Support Center

Email: europe.support@nsc.com

German Tel: +49 (0) 180 5010 771

English Tel: +44 (0) 870 850 4288

National Semiconductor Asia

Pacific Technical Support Center

Email: ap.support@nsc.com

National Semiconductor Japan

Technical Support Center

Email: jpn.feedback@nsc.com

Loading...

Loading...