August 2007

LMP7732

2.9 nV/sqrt(Hz) Low Noise, Precision, RRIO Amplifier

General Description

The LMP7732 is a dual low noise, low offset voltage, rail-torail input and output, low voltage precision amplifier. The

LMP7732 is part of the LMP® precision amplifier family and is

ideal for precision and low noise applications with low voltage

requirements.

This operational amplifier offers low voltage noise of 2.9 nV/

with a 1/f corner of only 3 Hz and low DC offset with a

maximum value of ±40 µV, targeting high accuracy, low frequency applications. The LMP7732 has bipolar junction input

stages with a bias current of only 1.5 nA. This low input bias

current, complemented by the very low AC and DC levels of

voltage noise, makes the LMP7732 an excellent choice for

photometry applications.

The LMP7732 provides a wide GBW of 22 MHz while consuming only 4 mA of current. This high gain bandwidth along

with the high open loop gain of 130 dB enables accurate signal conditioning in applications with high closed loop gain

requirements.

The LMP7732 has a supply voltage range of 1.8V to 5.5V,

making it an ideal choice for battery operated portable applications.

The LMP7732 is offered in an 8-pin SOIC.

The LMP7731 is the single version of this product and is of-

fered in an 5-Pin SOT23 package.

Features

(Typical values, TA = 25°C, VS = 5V)

■

Input voltage noise

—

f = 3 Hz 3.3 nV/√Hz

—

f = 1 kHz 2.9 nV/√Hz

■

Offset voltage (max) ±40 µV

■

Offset voltage drift (max) ±1.3 µV/°C

■

CMRR 130 dB

■

Open loop gain 130 dB

■

GBW 22 MHz

■

Slew rate 2.4 V/µs

■

THD @ f = 10 kHz, AV = 1, RL = 2 kΩ 0.001%

■

Supply current 4.4 mA

■

Supply voltage range 1.8V to 5.5V

■

Operating temperature range −40°C to 125°C

■

Input bias current ±1.5 nA

■

RRIO

■

8-Pin SOIC package

Applications

■

Thermopile amplifier

■

Gas analysis instruments

■

Photometric instrumentation

■

Medical instrumentation

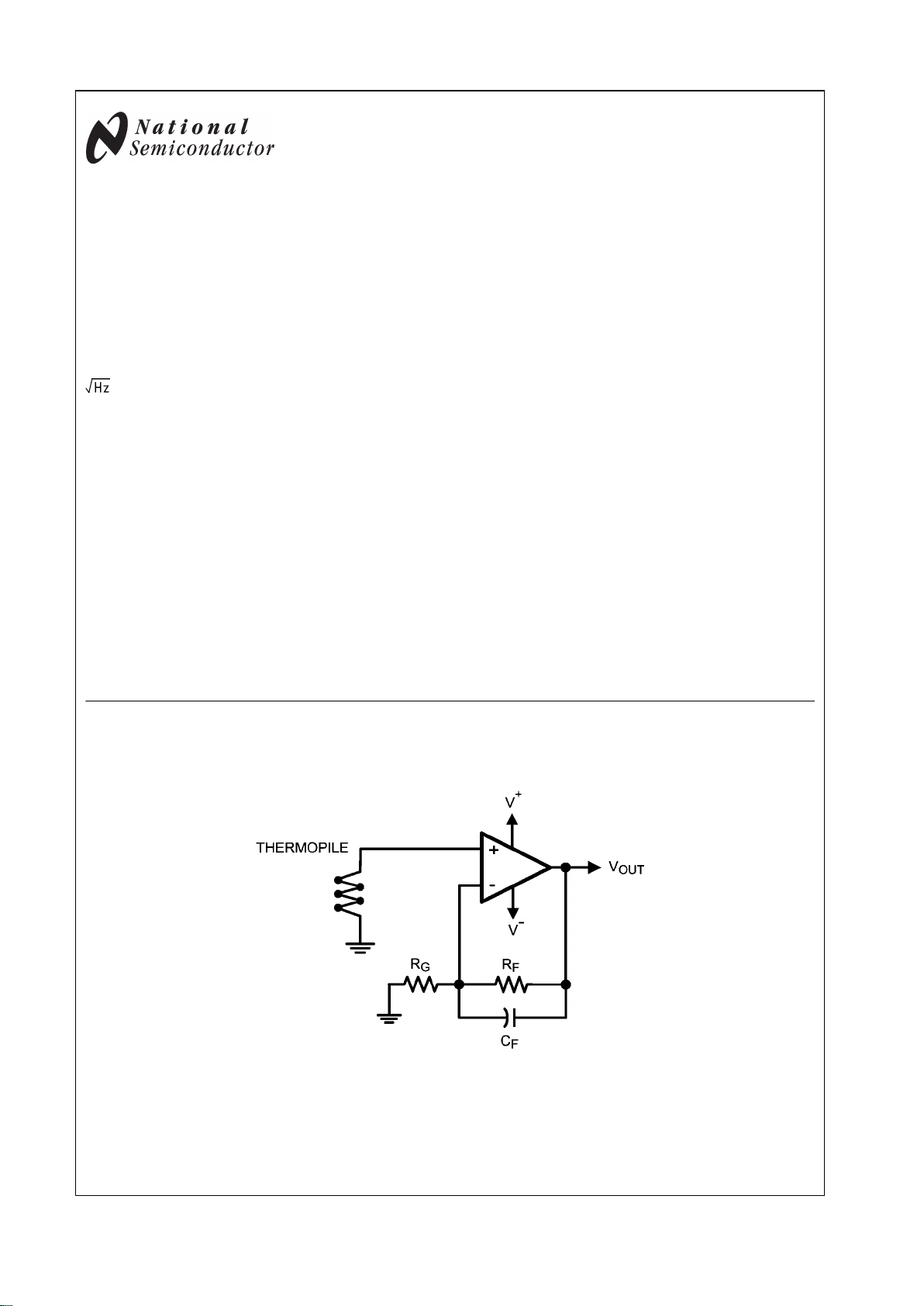

Typical Application

Thermopile Signal Amplifier

30015001

LMP® is a registered trademark of National Semiconductor Corporation.

© 2007 National Semiconductor Corporation 300150 www.national.com

LMP7732 Low Noise, Precision, RRIO Amplifier

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

ESD Tolerance (Note 2)

Human Body Model

For inputs pins only 2000V

For all other pins 2000V

Machine Model 200V

Charge Device Model 1000V

VIN Differential

±2V

Supply Voltage (VS = V+ – V−)

6.0V

Storage Temperature Range −65°C to 150°C

Junction Temperature (Note 3) +150°C max

Soldering Information

Infrared or Convection (20 sec) 235°C

Wave Soldering Lead Temp. (10 sec) 260°C

Operating Ratings (Note 1)

Temperature Range −40°C to 125°C

Supply Voltage (VS = V+ – V–)

1.8V to 5.5V

Package Thermal Resistance (θJA)

8-Pin SOIC 190 °C/W

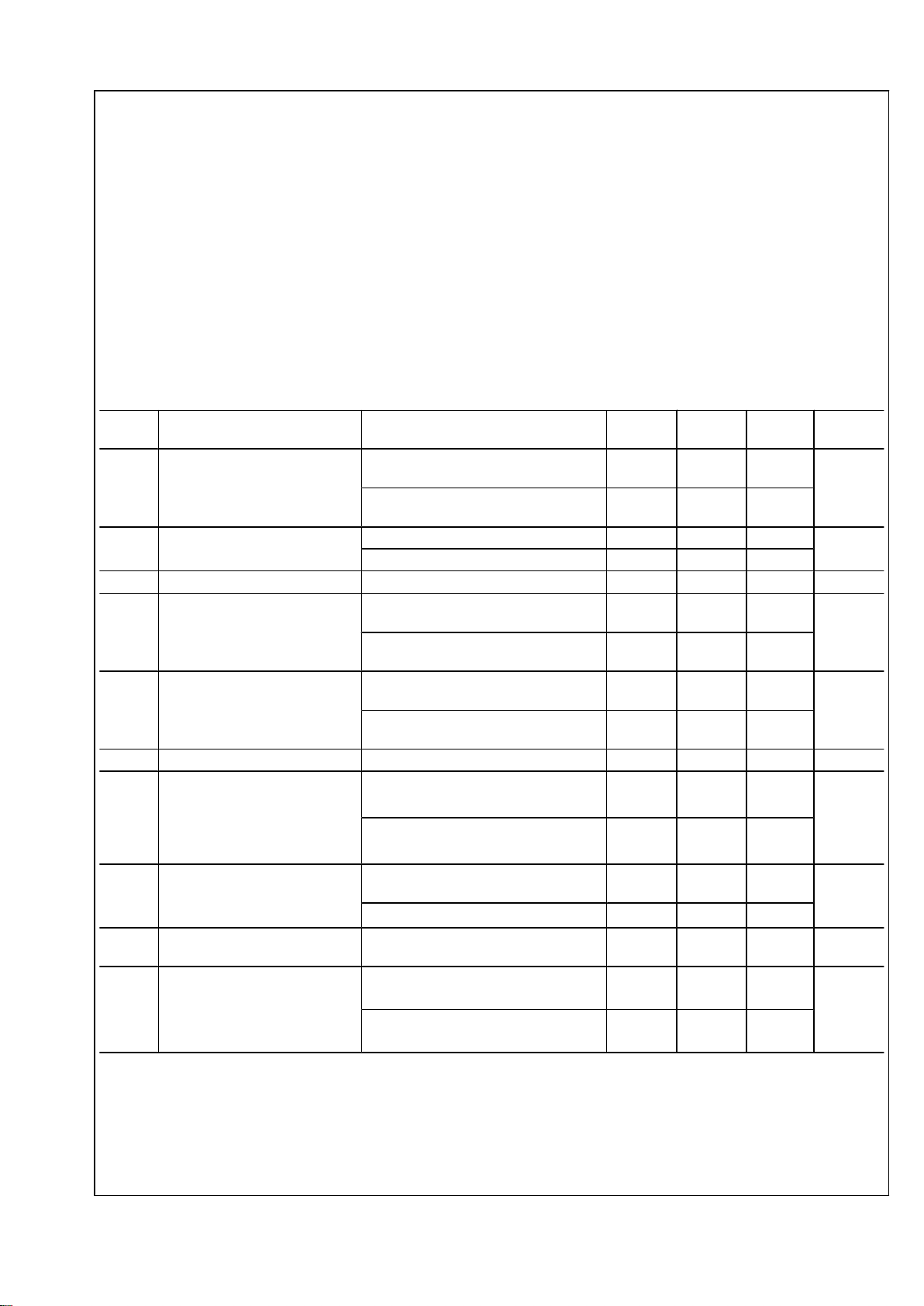

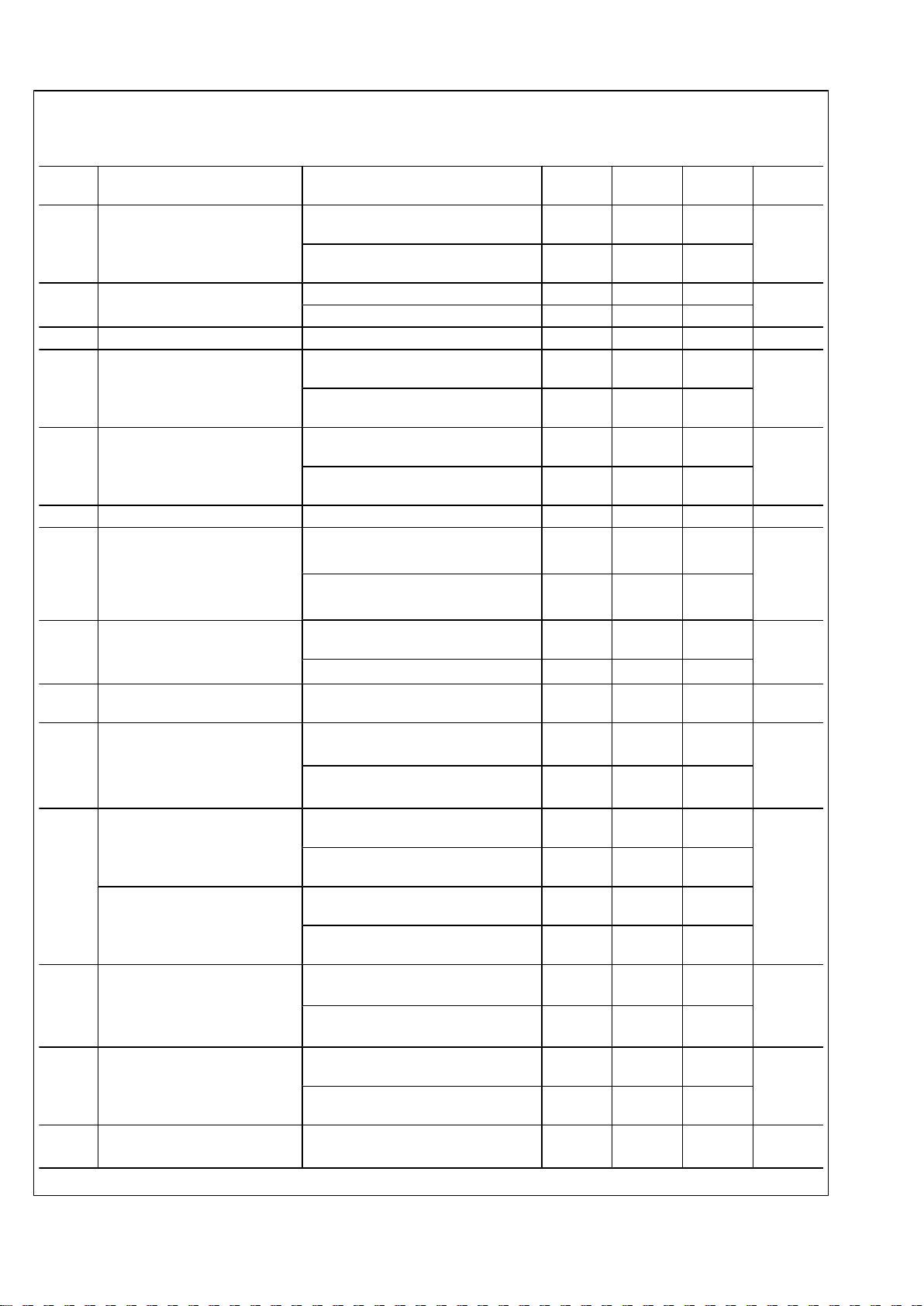

2.5V Electrical Characteristics (Note 4)

Unless otherwise specified, all limits are guaranteed for TA = 25°C, V+ = 2.5V, V− = 0V, VCM = V+/2, RL >10 kΩ to V+/2. Boldface limits apply at the temperature extremes.

Symbol Parameter Conditions Min

(Note 6)

Typ

(Note 5)

Max

(Note 6)

Units

V

OS

Input Offset Voltage

(Note 7)

VCM = 2.0V ±9 ±50

±150

μV

VCM = 0.5V ±9 ±40

±125

TCV

OS

Input Offset Voltage Drift VCM = 2.0V ±0.5 ±1.3

μV/°C

VCM = 0.5V ±0.2 ±0.8

Input Offset Voltage Time Drift VCM = 0.5V and VCM = 2.0V 0.35

μV/month

I

B

Input Bias Current VCM = 2.0V ±1 ±30

±45

nA

VCM = 0.5V ±12 ±50

±75

I

OS

Input Offset Current VCM = 2.0V ±1 ±50

±75

nA

VCM = 0.5V ±11 ±60

±80

TCI

OS

Input Offset Current Drift VCM = 0.5V and VCM = 2.0V 0.0474 nA/°C

CMRR Common Mode Rejection Ratio

0.15V ≤ VCM ≤ 0.7V

0.23V ≤ VCM ≤ 0.7V

101

89

120

dB

1.5V ≤ VCM ≤ 2.35V

1.5V ≤ VCM ≤ 2.27V

105

99

129

PSRR Power Supply Rejection Ratio

2.5V ≤ V+ ≤ 5V

111

105

129

dB

1.8V ≤ V+ ≤ 5.5V

117

CMVR Input Common-Mode Voltage

Range

Large Signal CMRR ≥ 80 dB

0

2.5 V

A

VOL

Large Signal Voltage Gain

RL = 10 kΩ to V+/2

VO = 0.5V to 2.0V

112

104

130

dB

RL = 2 kΩ to V+/2

VO = 0.5V to 2.0V

109

90

119

www.national.com 2

LMP7732

Symbol Parameter Conditions Min

(Note 6)

Typ

(Note 5)

Max

(Note 6)

Units

V

O

Output Swing High

RL = 10 kΩ to V+/2

4 50

75

mV

from either

rail

RL = 2 kΩ to V+/2

13 50

75

Output Swing Low

RL = 10 kΩ to V+/2

6 50

75

RL = 2 kΩ to V+/2

9 50

75

I

O

Output Short Circuit Current Sourcing, VO = V+/2

VIN (diff) = 100 mV

22

12

31

mA

Sinking, VO = V+/2

VIN (diff) = −100 mV

15

10

44

I

S

Supply Current VCM = 2.0V 4.0 5.4

6.8

mA

VCM = 0.5V 4.6 6.2

7.8

SR Slew Rate

AV = +1, CL = 10 pF, RL = 10 kΩ to V+/2

VO = 2 V

PP

2.4

V/μs

GBW Gain Bandwidth Product

CL = 20 pF, RL = 10 kΩ to V+/2

21 MHz

G

M

Gain Margin

CL = 20 pF, RL = 10 kΩ to V+/2

14 dB

Φ

M

Phase Margin

CL = 20 pF, RL = 10 kΩ to V+/2

60 deg

R

IN

Input Resistance Differential Mode 38

kΩ

Common Mode 151

MΩ

THD Total Harmonic Distortion AV = 1, fO = 1 kHz, Amplitude = 1V 0.002

%

e

n

Input-Referred Voltage Noise f = 1 kHz, VCM = 2.0V 3.0

nV/

f = 1 kHz, VCM = 0.5V 3.0

0.1 Hz to 10 Hz 75 nV

PP

i

n

Input-Referred Current Noise f = 1 kHz, VCM = 2.0V 1.1

pA/

f = 1 kHz, VCM = 0.5V 2.3

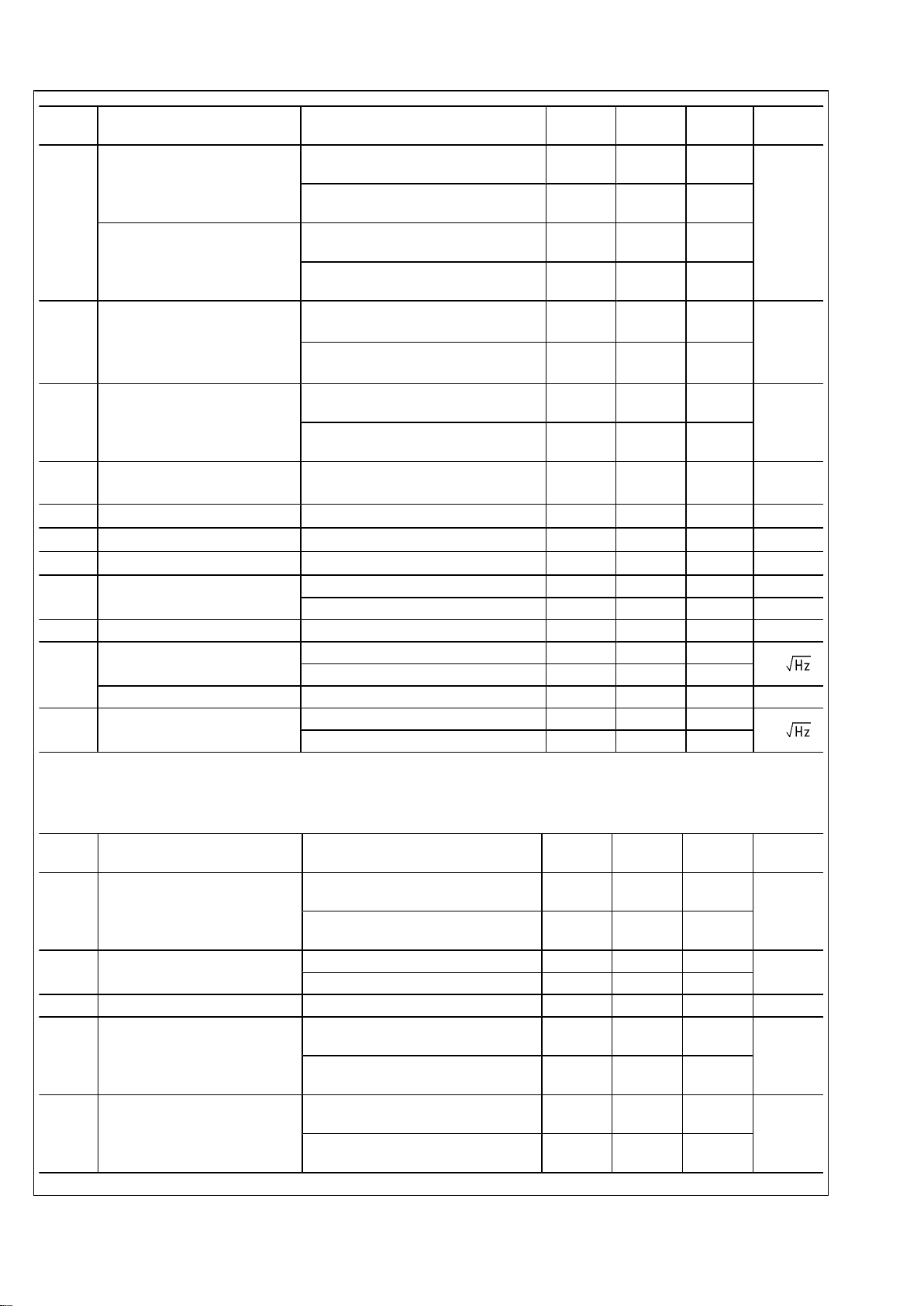

3.3V Electrical Characteristics (Note 4)

Unless otherwise specified, all limits are guaranteed for TA = 25°C, V+ = 3.3V, V− = 0V, VCM = V+/2, RL > 10 kΩ to V+/2. Boldface limits apply at the temperature extremes.

Symbol Parameter Conditions Min

(Note 6)

Typ

(Note 5)

Max

(Note 6)

Units

V

OS

Input Offset Voltage

(Note 7)

VCM = 2.5V ±6 ±50

±150

μV

VCM = 0.5V ±6 ±40

±125

TCV

OS

Input Offset Voltage Drift VCM = 2.5V ±0.5 ±1.3

μV/°C

VCM = 0.5V ±0.2 ±0.8

Input Offset Voltage Time Drift VCM = 0.5V and VCM = 2.5V 0.35

μV/month

I

B

Input Bias Current VCM = 2.5V ±1.5 ±30

±45

nA

VCM = 0.5V ±13 ±50

±77

I

OS

Input Offset Current VCM = 2.5V ±1 ±50

±70

nA

VCM = 0.5V ±11 ±60

±80

3 www.national.com

LMP7732

Symbol Parameter Conditions Min

(Note 6)

Typ

(Note 5)

Max

(Note 6)

Units

TCI

OS

Input Offset Current Drift VCM = 0.5V and VCM = 2.5V 0.048 nA/°C

CMRR Common Mode Rejection Ratio

0.15V ≤ VCM ≤ 0.7V

0.23V ≤ VCM ≤ 0.7V

101

89

120

dB

1.5V ≤ VCM ≤ 3.15V

1.5V ≤ VCM ≤ 3.07V

105

99

130

PSRR Power Supply Rejection Ratio

2.5V ≤ V+ ≤ 5.0V

111

105

129

dB

1.8V ≤ V+ ≤ 5.5V

117

CMVR Input Common-Mode Voltage

Range

Large Signal CMRR ≥ 80 dB

0

3.3 V

A

VOL

Large Signal Voltage Gain

RL = 10 kΩ to V+/2

VO = 0.5V to 2.8V

112

104

130

dB

RL = 2 kΩ to V+/2

VO = 0.5V to 2.8V

110

92

119

V

O

Output Swing High

RL = 10 kΩ to V+/2

5 50

75

mV

from either

rail

RL = 2 kΩ to V+/2

14 50

75

Output Swing Low

RL = 10 kΩ to V+/2

9 50

75

RL = 2 kΩ to V+/2

13 50

75

I

O

Output Short Circuit Current Sourcing, VO = V+/2

VIN (diff) = 100 mV

28

22

45

mA

Sinking, VO = V+/2

VIN (diff) = −100 mV

25

20

48

I

S

Supply Current VCM = 2.5V 4.2 5.6

7.0

mA

VCM = 0.5V 4.8 6.4

8.0

SR Slew Rate

AV = +1, CL = 10 pF, RL = 10 kΩ to V+/2

VO = 2 V

PP

2.4

V/μs

GBW Gain Bandwidth Product

CL = 20 pF, RL = 10 kΩ to V+/2

22 MHz

G

M

Gain Margin

CL = 20 pF, RL = 10 kΩ to V+/2

14 dB

Φ

M

Phase Margin

CL = 20 pF, RL = 10 kΩ to V+/2

62 deg

THD Total Harmonic Distortion AV = 1, fO = 1 kHz, Amplitude = 1V 0.002

%

R

IN

Input Resistance Differential Mode 38

kΩ

Common Mode 151

MΩ

e

n

Input-Referred Voltage Noise f = 1 kHz, VCM = 2.5V

2.9

nV/

f = 1 kHz, VCM = 0.5V

2.9

0.1 Hz to 10 Hz 75 nV

PP

i

n

Input-Referred Current Noise f = 1 kHz, VCM = 2.5V 1.1

pA/

f = 1 kHz, VCM = 0.5V 2.1

www.national.com 4

LMP7732

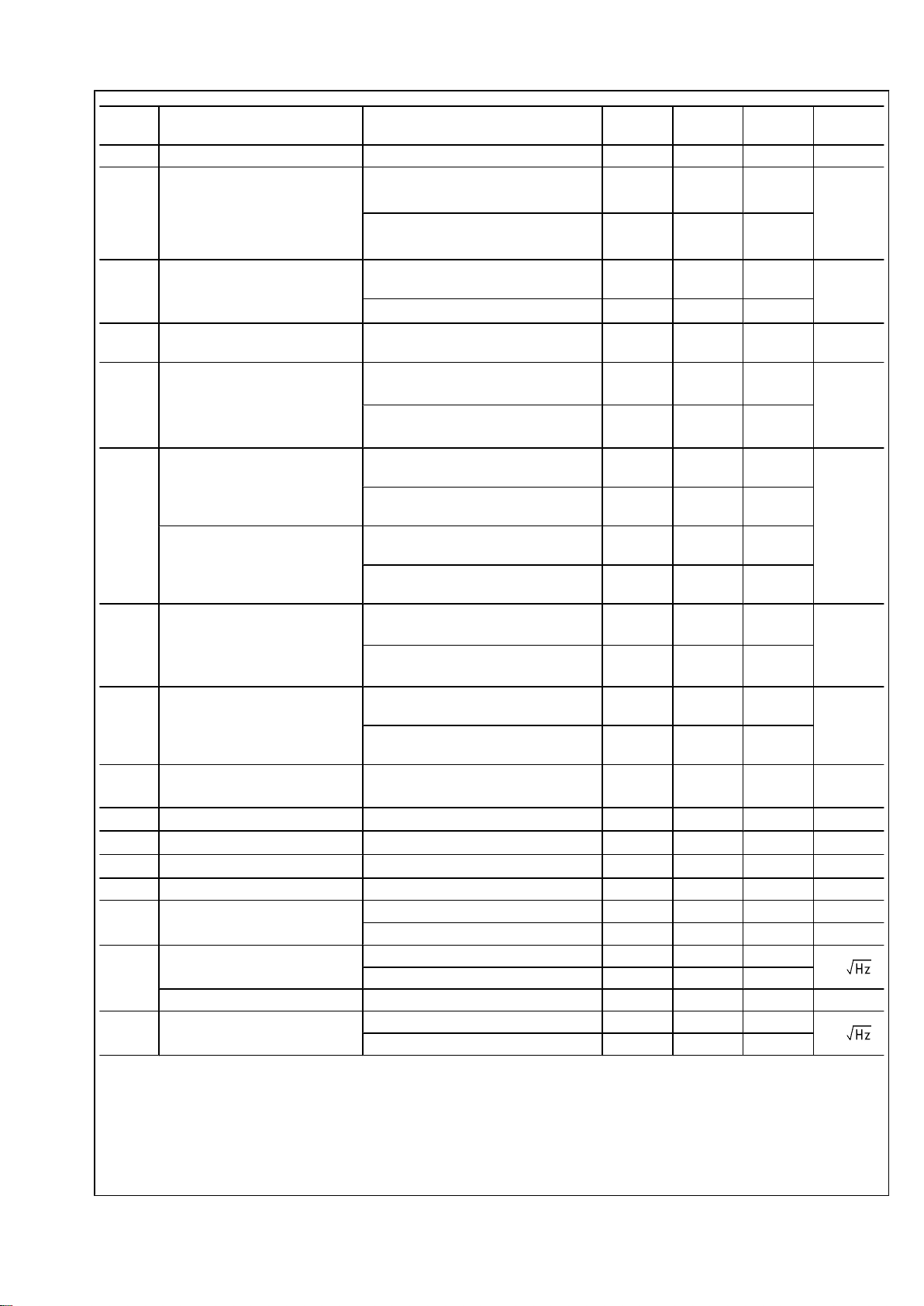

5V Electrical Characteristics (Note 4)

Unless otherwise specified, all limits are guaranteed for TA = 25°C, V+ = 5V, V− = 0V, VCM = V+/2, RL > 10 kΩ to V+/2. Boldface

limits apply at the temperature extremes.

Symbol Parameter Conditions Min

(Note 6)

Typ

(Note 5)

Max

(Note 6)

Units

V

OS

Input Offset Voltage

(Note 7)

VCM = 4.5V ±6 ±50

±150

μV

VCM = 0.5V ±6 ±40

±125

TCV

OS

Input Offset Voltage Drift VCM = 4.5V ±0.5 ±1.3

μV/°C

VCM = 0.5V ±0.2 ±0.8

Input Offset Voltage Time Drift VCM = 0.5V and VCM = 4.5V 0.35

μV/month

I

B

Input Bias Current VCM = 4.5V ±1.5 ±30

±50

nA

VCM = 0.5V ±14 ±50

±85

I

OS

Input Offset Current VCM = 4.5V ±1 ±50

±70

nA

VCM = 0.5V ±11 ±65

±80

TCI

OS

Input Offset Current Drift VCM = 0.5V and VCM = 4.5V 0.0482 nA/°C

CMRR Common Mode Rejection Ratio

0.15V ≤ VCM ≤ 0.7V

0.23V ≤ VCM ≤ 0.7V

101

89

120

dB

1.5V ≤ VCM ≤ 4.85V

1.5V ≤ VCM ≤ 4.77V

105

99

130

PSRR Power Supply Rejection Ratio

2.5V ≤ V+ ≤ 5V

111

105

129

dB

1.8V ≤ V+ ≤ 5.5V

117

CMVR Input Common-Mode Voltage

Range

Large Signal CMRR ≥ 80 dB

0

5 V

A

VOL

Large Signal Voltage Gain

RL = 10 kΩ to V+/2

VO = 0.5V to 4.5V

112

104

130

dB

RL = 2 kΩ to V+/2

VO = 0.5V to 4.5V

110

94

119

V

O

Output Swing High

RL = 10 kΩ to V+/2

8 50

75

mV

from either

rail

RL = 2 kΩ to V+/2

24 50

75

Output Swing Low

RL = 10 kΩ to V+/2

9 50

75

RL = 2 kΩ to V+/2

23 50

75

I

O

Output Short Circuit Current Sourcing, VO = V+/2

VIN (diff) = 100 mV

33

27

47

mA

Sinking, VO = V+/2

VIN (diff) = −100 mV

30

25

49

I

S

Supply Current VCM = 4.5V 4.4 6.0

7.4

mA

VCM = 0.5V 5.0 6.8

8.4

SR Slew Rate

AV = +1, CL = 10 pF, RL = 10 kΩ to V+/2

VO = 2 V

PP

2.4

V/μs

5 www.national.com

LMP7732

Symbol Parameter Conditions Min

(Note 6)

Typ

(Note 5)

Max

(Note 6)

Units

GBW Gain Bandwidth Product

CL = 20 pF, RL = 10 kΩ to V+/2

22 MHz

G

M

Gain Margin

CL = 20 pF, RL = 10 kΩ to V+/2

12 dB

Φ

M

Phase Margin

CL = 20 pF, RL = 10 kΩ to V+/2

65 deg

R

IN

Input Resistance Differential Mode 38

kΩ

Common Mode 151

MΩ

THD Total Harmonic Distortion AV = 1, fO = 1 kHz, Amplitude = 1V 0.001

%

e

n

Input-Referred Voltage Noise f = 1 kHz, VCM = 4.5V

2.9

nV/

f = 1 kHz, VCM = 0.5V

2.9

0.1 Hz to 10 Hz 75 nV

PP

i

n

Input-Referred Current Noise f = 1 kHz, VCM = 4.5V

1.1

pA/

f = 1 kHz, VCM = 0.5V

2.2

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for which the device is

intended to be functional, but specific performance is not guaranteed. For guaranteed specifications and the test conditions, see the Electrical Characteristics

Tables.

Note 2: Human Body Model, applicable std. MIL-STD-883, Method 3015.7. Machine Model, applicable std. JESD22-A115-A (ESD MM std. of JEDEC) FieldInduced Charge-Device Model, applicable std. JESD22-C101-C (ESD FICDM std. of JEDEC).

Note 3: The maximum power dissipation is a function of T

J(MAX)

, θJA, and TA. The maximum allowable power dissipation at any ambient temperature is

PD = (T

J(MAX)

- TA)/ θJA. All numbers apply for packages soldered directly onto a PC board.

Note 4: Electrical Table values apply only for factory testing conditions at the temperature indicated. Factory testing conditions result in very limited self-heating

of the device such that TJ = TA. No guarantee of parametric performance is indicated in the electrical tables under conditions of internal self-heating where TJ >

TA. Absolute maximum Ratings indicate junction temperature limits beyond which the device maybe permanently degraded, either mechanically or electrically.

Note 5: Typical values represent the most likely parametric norm as determined at the time of characterization. Actual typical values may vary over time and will

also depend on the application and configuration. The typical values are not tested and are not guaranteed on shipped production material.

Note 6: All limits are guaranteed by testing, statistical analysis or design.

Note 7: Ambient production test is performed at 25°C with a variance of ±3°C.

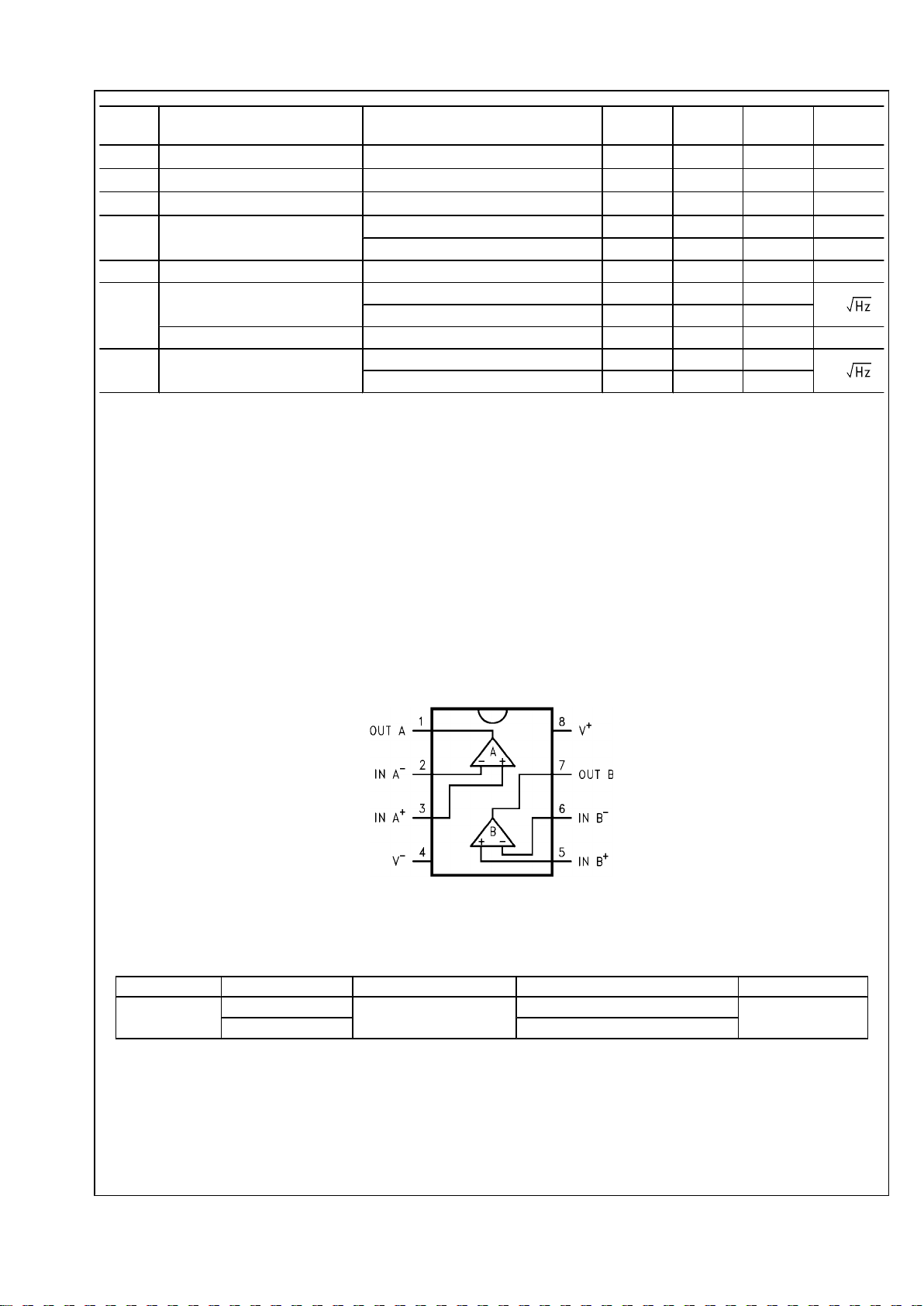

Connection Diagram

8-Pin SOIC

30015003

Top View

Ordering Information

Package Part Number Package Marking Transport Media NSC Drawing

8-Pin SOIC

LMP7732MA

LMP7732MA

95 units/Rails

M08A

LMP7732MAX 2.5k Units Tape and Reel

www.national.com 6

LMP7732

Typical Performance Characteristics Unless otherwise noted: T

A

= 25°C, RL > 10 kΩ, VCM = VS/2.

Offset Voltage Distribution

30015071

TCVOS Distribution

30015076

Offset Voltage Distribution

30015073

TCVOS Distribution

30015074

Offset Voltage Distribution

30015070

TCVOS Distribution

30015077

7 www.national.com

LMP7732

Offset Voltage Distribution

30015072

TCVOS Distribution

30015075

Offset Voltage vs. Temperature

30015082

Offset Voltage vs. Temperature

30015083

PSRR vs. Frequency

30015029

CMRR vs. Frequency

30015062

www.national.com 8

LMP7732

Offset Voltage vs. Supply Voltage

30015053

Offset Voltage vs. V

CM

30015054

Offset Voltage vs. V

CM

30015055

Offset Voltage vs. V

CM

30015056

Input Offset Voltage Time Drift

30015080

Slew Rate vs. Supply Voltage

30015020

9 www.national.com

LMP7732

Input Voltage Noise vs. Frequency

30015063

Input Current Noise vs. Frequency

30015064

Time Domain Voltage Noise

30015067

Time Domain Voltage Noise

30015065

Time Domain Voltage Noise

30015066

Output Voltage vs. Output Current

30015057

www.national.com 10

LMP7732

Input Bias Current vs. V

CM

30015025

Input Bias Current vs. V

CM

30015026

Input Bias Current vs. V

CM

30015027

Open Loop Frequency Response Over Temperature

30015018

Open Loop Frequency Response

30015019

Open Loop Frequency Response

30015028

11 www.national.com

LMP7732

THD+N vs. Frequency

30015085

THD+N vs. Output Voltage

30015069

Large Signal Step Response

30015022

Small Signal Step Response

30015021

Large Signal Step Response

30015024

Small Signal Step Response

30015023

www.national.com 12

LMP7732

Supply Current vs. Supply Voltage

30015081

Output Swing High vs. Supply Voltage

30015058

Output Swing Low vs. Supply Voltage

30015059

Sinking Current vs, Supply Voltage

30015060

Sourcing Current vs. Supply Voltage

30015061

13 www.national.com

LMP7732

Application Notes

LMP7732

The LMP7732 is a dual low noise, low offset voltage, rail-torail input and output, low voltage precision amplifier.

The low input voltage noise of only 2.9 nV/

with a 1/f corner at 3 Hz makes the LMP7732 ideal for sensor applications

where DC accuracy is of importance.

The LMP7732 has very low guaranteed offset voltage of only

±40 µV. This low offset voltage along with the very low input

voltage noise allows higher signal integrity and higher signal

to noise ratios since the error contribution by the amplifier is

at a minimum.

The LMP7732 has high gain bandwidth of 22 MHz. This wide

bandwidth enables the use of the amplifier at higher gain settings while retaining ample usable bandwidth for the application. This is particularly beneficial when system designers

need to use sensors with very limited output voltage range as

it allows larger gains in one stage which in turn increases signal to noise ratio.

The LMP7732 has a proprietary input bias cancellation circuitry on the input stages. This allows the LMP7732 to have

only about 1.5 nA bias current with a bipolar input stage. This

low input bias current, paired with the inherent lower input

voltage noise of bipolar input stages makes the LMP7732 an

excellent choice for precision applications. The combination

of low input bias current, low input offset voltage, and low input

voltage noise enables the user to achieve unprecedented accuracy and higher signal integrity.

National Semiconductor is heavily committed to precision

amplifiers and the market segment they serve. Technical support and extensive characterization data is available for sensitive applications or applications with a constrained error

budget.

The LMP7732 comes in the 8-pin SOIC package. This small

package is an ideal solution for area constrained PC boards

and portable electronics.

INPUT BIAS CURRENT CANCELLATION

The LMP7732 has proprietary input bias current cancellation

circuitry on its input stage.

The LMP7732 has rail-to-rail input. This is achieved by having

a p-input and n-input stage in parallel. Figure 1 only shows

one of the input stages as the circuitry is symmetrical for both

stages.

Figure 1 shows that as the common mode voltage gets closer

to one of the extreme ends, current I1 significantly increases.

This increased current shows as an increase in voltage drop

across resistor R1 equal to I1*R1 on IN+ of the amplifier. This

voltage contributes to the offset voltage of the amplifier. When

common mode voltage is in the mid-range, the transistors are

operating in the linear region and I1 is significantly small. The

voltage drop due to I1 across R1 can be ignored as it is orders

of magnitude smaller than the amplifier's input offset voltage.

As the common mode voltage gets closer to one of the rails,

the offset voltage generated due to I1 increases and becomes

comparable to the amplifiers offset voltage.

30015006

FIGURE 1. Input Bias Current Cancellation

INPUT VOLTAGE NOISE MEASUREMENT

The LMP7732 has very low input voltage noise. The peak-topeak input voltage noise of the LMP7732 can be measured

using the test circuit shown in Figure 2

30015079

FIGURE 2. 0.1 Hz to 10 Hz Noise Test Circuit

www.national.com 14

LMP7732

The frequency response of this noise test circuit at the 0.1 Hz

corner is defined by only one zero. The test time for the

0.1 Hz to 10 Hz noise measurement using this configuration

should not exceed 10 seconds, as this time limit acts as an

additional zero to reduce or eliminate the contributions of

noise from frequencies below 0.1 Hz.

Figure 3 shows typical peak-to-peak noise for the LMP7732

measured with the circuit in Figure 2.

30015066

FIGURE 3. 0.1 Hz to 10 Hz Input Voltage Noise

Measuring the very low peak-to-peak noise performance of

the LMP7732, requires special testing attention. In order to

achieve accurate results, the device should be warmed up for

at least five minutes. This is so that the input offset voltage of

the op amp settles to a value. During this warm up period, the

offset can typically change by a few µV because the chip

temperature increases by about 30°C. If the 10 seconds of

the measurement is selected to include this warm up time,

some of this temperature change might show up as the measured noise.Figure 4 shows the start-up drift of five typical

LMP7732 units.

30015080

FIGURE 4. Start-Up Input Offset Voltage Drift

During the peak-to-peak noise measurement, the LMP7732

must be shielded. This prevents offset variations due to airflow. Offset can vary by a few nV due to this airflow and that

can invalidate measurements of input voltage noise with a

magnitude which is in the same range. For similar reasons,

sudden motions must also be restricted in the vicinity of the

test area. The feed-through which results from this motion

could increase the observed noise value which in turn would

invalidate the measurement.

DIODES BETWEEN THE INPUTS

The LMP7732 has a set of anti-parallel diodes between their

input pins, as shown in Figure 5. These diodes are present to

protect the input stage of the amplifiers. At the same time,

they limit the amount of differential input voltage that is allowed on the input pins. A differential signal larger than the

voltage needed to turn on the diodes might cause damage to

the diodes. The differential voltage between the input pins

should be limited to ±3 diode drops or the input current needs

to be limited to ±20 mA.

30015004

FIGURE 5. Anti-Parallel Diodes between Inputs

15 www.national.com

LMP7732

DRIVING AN ADC

Analog to Digital Converters, ADCs, usually have a sampling

capacitor on their input. When the ADC's input is directly connected to the output of the amplifier a charging current flows

from the amplifier to the ADC. This charging current causes

a momentary glitch that can take some time to settle. There

are different ways to minimize this effect. One way is to slow

down the sampling rate. This method gives the amplifier sufficient time to stabilize its output. Another way to minimize the

glitch, caused by the switch capacitor, is to have an external

capacitor connected to the input of the ADC. This capacitor is

chosen so that its value is much larger than the internal

switching capacitor and it will hence provide the charge needed to quickly and smoothly charge the ADC's sampling capacitor. Since this large capacitor will be loading the output of

the amplifier as well, an isolation resistor is needed between

the output of the amplifier and this capacitor. The isolation

resistor, R

ISO

, separates the additional load capacitance from

the output of the amplifier and will also form a low-pass filter

and can be designed to provide noise reduction as well as

anti-aliasing. The draw back of having R

ISO

is that it reduces

signal swing since there is some voltage drop across it.

Figure 6 (a) shows the ADC directly connected to the ampli-

fier. To minimize the glitch in this setting, a slower sample rate

needs to be used. Figure 6 (b) shows R

ISO

and an external

capacitor used to minimize the glitch.

30015005

FIGURE 6. Driving An ADC

THERMOPILE AMPLIFIER

Thermopile Sensors

Thermopiles are arrays of interconnected thermocouples

which can detect surface temperature of an object through

radiation rather than direct contact. The hot and cold junctions

of the thermocouples are thermally isolated. The hot junctions

are exposed to IR radiation emitted from the measurement

surface and the cold junctions are connected to a heat sink.

The incident IR changes the temperature of the hot junctions

of the thermopile and produces an output voltage proportional

to this change.

The hot junction of the thermopile is covered with a highly

emissive coating. The IR radiation incident to this highly emissive material changes the temperature of this coating. The

temperature change is converted to a voltage by the thermopile. Emissivity represents the radiation or absorption efficiency of a material relative to a black body. An ideal black

body has an emissivity of 1.0. Excluding shiny metals, most

objects have emissivities above 0.85. As a practical matter,

shiny metals are not good candidates for IR sensing because

of their low emissivity. The low emissivity means that the material is highly reflective. Reflective materials often “reflect”

the surrounding environment's temperature rather than their

own heat radiation. This makes them not suitable for thermopile applications.

The output voltage of a thermopile is related to temperature

and emissivity by the following formula:

Where:

V

OUT

: Output voltage of the thermopile

K : Proportionality constant

ε

OBJ

: Emissivity of object being measured

T

OBJ

: Temperature of object being measured

δ : Correction factor. This is needed since thermopile filters

do not allow all wavelengths to enter the sensor

εTP: Emissivity of the thermopile

TTP: Temperature of the thermopile

As mentioned above, the IR radiation generates a static volt-

age across the pyroelectric material. If the illumination is

constant, the signal level detection declines. This is why the

radiation needs to be periodically refreshed. This task is usually achieved by the means of a mechanical chopper in front

of the detector.

Thermopiles offer much faster response time compared to

other temperature measurement devices. Packaged thermistors and thermocouples have response times that can range

up to a few seconds, where as packaged thermopiles can

easily achieve response times in the order of tens of milliseconds. Thermopiles also provide superior thermal isolation

compared to their contact temperature measurement counterparts. Physical contact disturbs the systems temperature

and also creates temperature gradients.

Figure 7 shows a simplified schematic of a thermopile. The

cold junctions are connected to a heat sink, and the absorber

material covers the hot junction. The output voltage resulting

from temperature difference between the two junctions is

measured at the two ends of the array of thermocouples. As

is evident in Figure 7, increasing the number of thermocouples in a thermopile increases the output voltage range. This

also increases the active area of the thermopile sensor.

www.national.com 16

LMP7732

30015007

FIGURE 7. Thermopile

Thermopiles have very wide temperature ranges of -100°C to

1000°C

When choosing a thermopile for a certain application, one

must pay attention to several parameters. Some of these parameters are discussed below:

Thermopiles' sensitivity, or responsivity, is determined by the

ratio of output voltage to the absorbed input signal power and

is usually specified in V/W. Typical sensitivity of thermopiles

ranges from 10s of V/W to about 100 V/W. Generally, higher

values of sensitivity are desirable. Sensitivity is dependent on

the absorber's area and number of thermocouples used in the

sensor. Sensitivity is often represented by S where:

S = V

OUT/PIN

The sensitivity of a thermopile changes with change in temperature. This change is usually specified as the Temperature

Coefficient, TC, of sensitivity. Lower numbers are desired for

this parameter.

Resistance of the thermopile is usually specified in the

datasheet. This is the impedance which will be seen by the

input of the amplifier used to process the thermopile's output

signal. Typical values for thermopile resistance, RTP, range

from 10s of kilo-ohms to about 100 kΩ. This resistance is also

a function of temperature. The temperature coefficient of the

resistance is usually specified in a thermopile's datasheet. As

with any other parameter, minimum variation with temperature is desired.

The dominant noise source for a thermopile is its resistance.

Noise spectral density of a resistor is calculated by:

Where k is the Boltzman constant and T is absolute temperature. Unit of noise spectral density is: V/

For the thermopile sensor, this noise is usually represented

by V

NOISE

where:

Typical values for this voltage noise are in the order of a few

tens of nV/ .

The Noise Equivalent Power, NEP, is often used to specify

the minimum detectable signal level per square root band-

width. A smaller NEP is desired, however NEP is dependent

on the thermopile active area, AD. For a thermopile:

And

As it is shown above, one cannot just compare the NEP of

two thermopiles without considering the corresponding active

areas.

A better way to compare thermopiles is to look at their specific

detectivity, D*. Specific detectivity includes both the device

noise and its sensitivity. It is normalized with respect to the

detector's active area and also noise bandwidth. D* is given

by:

Unit of D* is cm / W. Typical values for specific detectivity

range from 108 to 3*108 cm / W.

After receiving radiation, the thermopile takes some time before it comes to thermal equilibrium. The time it takes for the

sensor to achieve this equilibrium is called response time or

time constant of the sensor. Clearly, lower time constants are

very desirable.

Precision Amplifier

Since the output of thermopiles are usually very small and at

most in the order of only a few millivolts, the first part of the

signal conditioning path should involve amplification. In

choosing an amplifier for this purpose, a few different sensor

characteristics and the way they interface with the amplifier

should be considered. These are:

Sensor's Impedance and Opamp's Input Bias Current

The input bias current causes a voltage drop across the sen-

sor and the amount of this voltage is equal to the sensor's

impedance multiplied by the magnitude of bias current. The

higher the sensor's input impedance, the more accentuated

the effect of amplifier's input bias current will be. For very high

impedance sensors, it is imperative that opamps with very low

input bias currents be used. Thermopiles have input

impedances in the range of 100 kΩ, so input bias current is

not as critical as in some other applications.

Sensor's output voltage range:

The output signal of the sensor is fed into the opamp where

it will be amplified or otherwise conditioned, (e.g. level shifted,

buffered.) It is important to pay attention to different parameters of this output signal.

One important aspect is the lowest expected level of the

sensor's output and compare that with different parameters

contributing to the amplifier's total input noise. If the sensor's

output level is in the same order of magnitude or smaller than

the opamp's total input noise, then signal integrity at the

opamp's output and the ADC's input will be compromised.

17 www.national.com

LMP7732

30015078

FIGURE 8. Thermopile Amplifier

Figure 8 shows the LMP7732 used as a thermopile amplifier.

The LMP7732 is a great choice for use with thermopile sensors. The LMP7732 provides unprecedented accuracy and

precision because of its very low input voltage noise and the

very low 1/f corner frequency. The 1/f noise is one of the main

sources of error in DC operating mode. Since thermopiles and

most other sensors operate on DC signals, signal integrity at

the DC level is very important. The LMP7732 also has very

low offset voltage and offset voltage drift which greatly reduces the effects of input offset voltage of the amplifier on the

thermopile signal. The thermopile used in this circuit is

TPS332 from PerkinElmer Optoelectronics, PKI. This thermopile has an internal resistance, RTP, of 75 kΩ. The output

voltage of the thermopile is represented with a DC voltage

source. The TPS332 has a thermistor integrated in the package. The thermistor is used to measure the ambient temperature of the thermopile at the time of measurement. The

thermistor's resistance at room temperature is 30 kΩ. More

information about this thermopile and other sensors from PKI

can be found on http://www.perkinelmer.com/

The circuit in Figure 8 shows how the LMP7732 is connected

to the thermopile. This circuit is comprised of two LMP7732

amplifiers, the LM4140A-2.5 which is a precision voltage reference, the ADC122S021 which is a two channel Analog to

Digital converter, and the thermopile sensor. Note that the two

amplifiers used in this circuit are numbered for ease of refer-

ence. The LMP7732 amplifiers are referred to as amplifier 1

and amplifier 2 per Figure 8.

In Figure 8the LM4140A is providing a precision voltage reference of 2.5V. This reference voltage is applied to the thermistor via the 30 kΩ resistor. The thermistor's resistance is

converted to a voltage using this set up. This voltage is fed

into the ADC's channel one. The ADC uses this voltage and

the thermistor's look up table to convert this voltage to temperature. The 2.5V reference is also fed into amplifier 1, which

is configured as a buffer. This LMP7732 transfers the 2.5V

signal to both inputs of amplifier 2. This means the 2.5V will

show up on the output of amplifier 2. Having an output level

that is mid-supply is important since the thermopile sensor

has a bipolar output signal and this way the amplifier can accurately gain the thermopile voltage, whether its polarity is

positive or negative. It is also important because the output

signal of amplifier 2 is only positive. ADCs can only handle

positive signals on their inputs. Amplifier 2 is used to gain and

filter the thermopile signal. The low pass filter ensures that AC

noise will not be gained up and, as a result, the output signal

will be cleaner. The output of amplifier 2 is fed into the ADC's

channel 0. The ADC uses the ambient temperature, which

was calculated using the voltage on Channel 1 and the

thermistor's look up table, along with the thermopiles' gained

output voltage available on channel 0 and the thermopile's

look up table to determine the object's temperature.

www.national.com 18

LMP7732

Physical Dimensions inches (millimeters) unless otherwise noted

8-Pin SOIC

NS Package Number M08A

19 www.national.com

LMP7732

Notes

LMP7732 Low Noise, Precision, RRIO Amplifier

THE CONTENTS OF THIS DOCUMENT ARE PROVIDED IN CONNECTION WITH NATIONAL SEMICONDUCTOR CORPORATION

(“NATIONAL”) PRODUCTS. NATIONAL MAKES NO REPRESENTATIONS OR WARRANTIES WITH RESPECT TO THE ACCURACY

OR COMPLETENESS OF THE CONTENTS OF THIS PUBLICATION AND RESERVES THE RIGHT TO MAKE CHANGES TO

SPECIFICATIONS AND PRODUCT DESCRIPTIONS AT ANY TIME WITHOUT NOTICE. NO LICENSE, WHETHER EXPRESS,

IMPLIED, ARISING BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS

DOCUMENT.

TESTING AND OTHER QUALITY CONTROLS ARE USED TO THE EXTENT NATIONAL DEEMS NECESSARY TO SUPPORT

NATIONAL’S PRODUCT WARRANTY. EXCEPT WHERE MANDATED BY GOVERNMENT REQUIREMENTS, TESTING OF ALL

PARAMETERS OF EACH PRODUCT IS NOT NECESSARILY PERFORMED. NATIONAL ASSUMES NO LIABILITY FOR

APPLICATIONS ASSISTANCE OR BUYER PRODUCT DESIGN. BUYERS ARE RESPONSIBLE FOR THEIR PRODUCTS AND

APPLICATIONS USING NATIONAL COMPONENTS. PRIOR TO USING OR DISTRIBUTING ANY PRODUCTS THAT INCLUDE

NATIONAL COMPONENTS, BUYERS SHOULD PROVIDE ADEQUATE DESIGN, TESTING AND OPERATING SAFEGUARDS.

EXCEPT AS PROVIDED IN NATIONAL’S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, NATIONAL ASSUMES NO

LIABILITY WHATSOEVER, AND NATIONAL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY RELATING TO THE SALE

AND/OR USE OF NATIONAL PRODUCTS INCLUDING LIABILITY OR WARRANTIES RELATING TO FITNESS FOR A PARTICULAR

PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY

RIGHT.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR

SYSTEMS WITHOUT THE EXPRESS PRIOR WRITTEN APPROVAL OF THE CHIEF EXECUTIVE OFFICER AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

Life support devices or systems are devices which (a) are intended for surgical implant into the body, or (b) support or sustain life and

whose failure to perform when properly used in accordance with instructions for use provided in the labeling can be reasonably expected

to result in a significant injury to the user. A critical component is any component in a life support device or system whose failure to perform

can be reasonably expected to cause the failure of the life support device or system or to affect its safety or effectiveness.

National Semiconductor and the National Semiconductor logo are registered trademarks of National Semiconductor Corporation. All other

brand or product names may be trademarks or registered trademarks of their respective holders.

Copyright© 2007 National Semiconductor Corporation

For the most current product information visit us at www.national.com

National Semiconductor

Americas Customer

Support Center

Email:

new.feedback@nsc.com

Tel: 1-800-272-9959

National Semiconductor Europe

Customer Support Center

Fax: +49 (0) 180-530-85-86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +49 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor Asia

Pacific Customer Support Center

Email: ap.support@nsc.com

National Semiconductor Japan

Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

www.national.com

Loading...

Loading...