LMK02000

Precision Clock Conditioner with Integrated PLL

LMK02000 Precision Clock Conditioner with Integrated PLL

September 2007

General Description

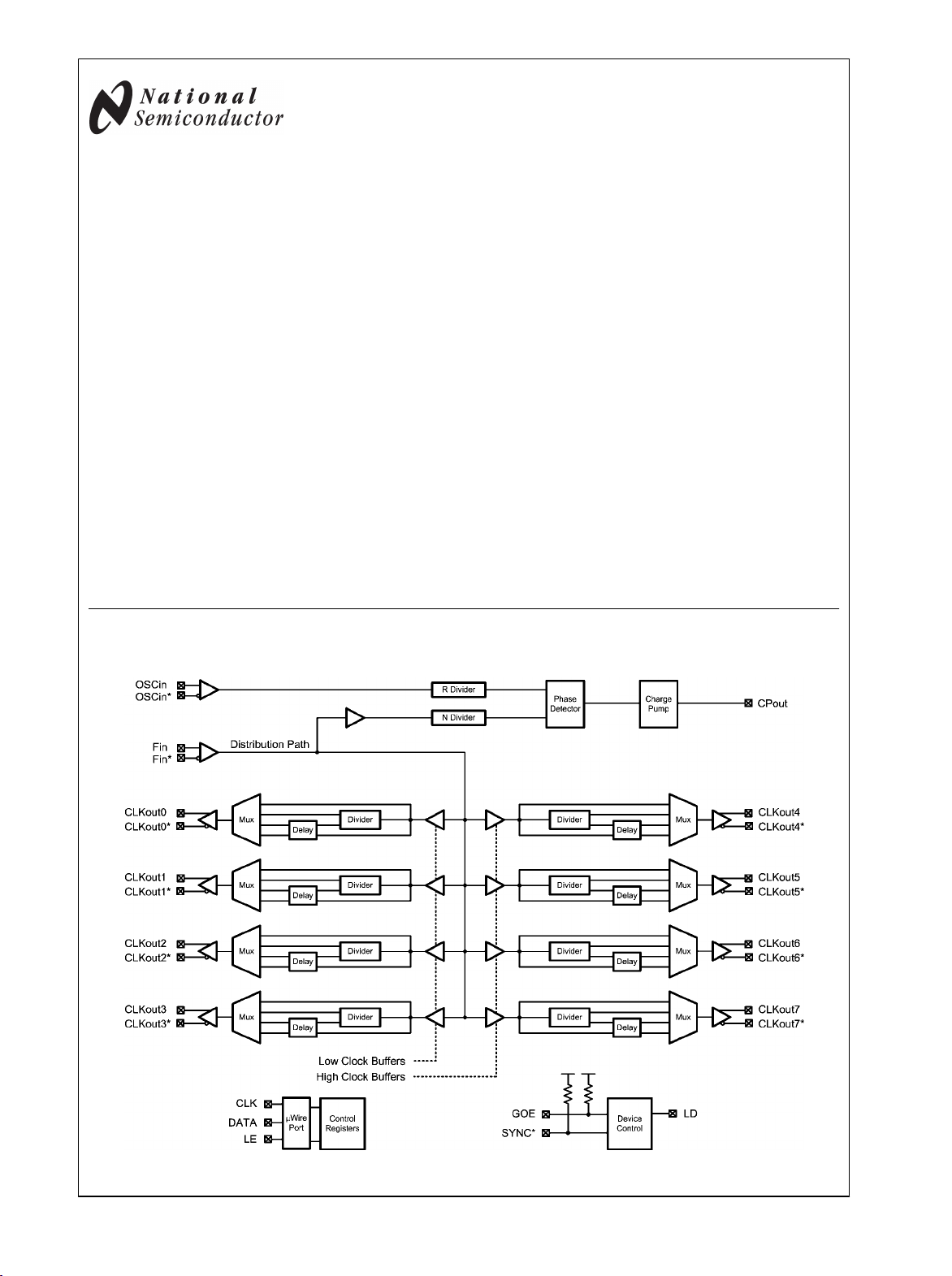

The LMK02000 precision clock conditioner combines the

functions of jitter cleaning/reconditioning, multiplication, and

distribution of a reference clock. The device integrates a high

performance Integer-N Phase Locked Loop (PLL), three

LVDS, and five LVPECL clock output distribution blocks.

Each clock distribution block includes a programmable divider, a phase synchronization circuit, a programmable delay,

a clock output mux, and an LVDS or LVPECL output buffer.

This allows multiple integer-related and phase-adjusted

copies of the reference to be distributed to eight system components.

The clock conditioner comes in a 48-pin LLP package and is

footprint compatible with other clocking devices in the same

family.

Functional Block Diagram

Features

20 fs additive jitter

■

Integrated Integer-N PLL with outstanding normalized

■

phase noise contribution of -224 dBc/Hz

Clock output frequency range of 1 to 800 MHz

■

3 LVDS and 5 LVPECL clock outputs

■

Dedicated divider and delay blocks on each clock output

■

Pin compatible family of clocking devices

■

3.15 to 3.45 V operation

■

Package: 48 pin LLP (7.0 x 7.0 x 0.8 mm)

■

Target Applications

Data Converter Clocking

■

Networking, SONET/SDH, DSLAM

■

Wireless Infrastructure

■

Medical

■

Test and Measurement

■

Military / Aerospace

■

TRI-STATE® is a registered trademark of National Semiconductor Corporation.

© 2007 National Semiconductor Corporation 202165 www.national.com

20216501

Connection Diagram

LMK02000

48-Pin LLP Package

www.national.com 2

20216502

Pin Descriptions

Pin # Pin Name I/O Description

1, 25 GND - Ground

2, 7 NC - No Connection to these pins

3, 8, 13, 16, 19, 22, 26,

30, 31, 33, 37, 40, 43, 46

4 CLKuWire I MICROWIRE Clock Input

5 DATAuWire I MICROWIRE Data Input

6 LEuWire I MICROWIRE Latch Enable Input

9, 10 LDObyp1, LDObyp2 - LDO Bypass

11 GOE I Global Output Enable

12 LD O Lock Detect and Test Output

14, 15 CLKout0, CLKout0* O LVDS Clock Output 0

17, 18 CLKout1, CLKout1* O LVDS Clock Output 1

20, 21 CLKout2, CLKout2* O LVDS Clock Output 2

23, 24 CLKout3, CLKout3* O LVPECL Clock Output 3

27 SYNC* I Global Clock Output Synchronization

28, 29 OSCin, OSCin* I Oscillator Clock Input; Must be AC coupled

32 CPout O Charge Pump Output

34, 35 Fin, Fin* I Frequency Input; Must be AC coupled

36 Bias I Bias Bypass

38, 39 CLKout4, CLKout4* O LVPECL Clock Output 4

41, 42 CLKout5, CLKout5* O LVPECL Clock Output 5

44, 45 CLKout6, CLKout6* O LVPECL Clock Output 6

47, 48 CLKout7, CLKout7* O LVPECL Clock Output 7

DAP DAP - Die Attach Pad is Ground

Vcc1, Vcc2, Vcc3, Vcc4, Vcc5, Vcc6, Vcc7,

Vcc8, Vcc9, Vcc10, Vcc11, Vcc12, Vcc13, Vcc14

LMK02000

- Power Supply

3 www.national.com

Absolute Maximum Ratings (Notes 1, 2)

If Military/Aerospace specified devices are required, please contact the National Semiconductor Sales Office/ Distributors

for availability and specifications.

LMK02000

Parameter Symbol Ratings Units

Power Supply Voltage

Input Voltage

Storage Temperature Range

Lead Temperature (solder 4 s)

Junction Temperature

V

CC

V

IN

T

STG

T

L

T

J

-0.3 to 3.6 V

-0.3 to (VCC + 0.3)

-65 to 150 °C

+260 °C

125 °C

Recommended Operating Conditions

Parameter Symbol Min Typ Max Units

Ambient Temperature

Power Supply Voltage

Note 1: "Absolute Maximum Ratings" indicate limits beyond which damage to the device may occur, including inoperability and degradation of device reliability

and/or performance. Functional operation of the device and/or non-degradation at the Absolute Maximum Ratings or other conditions beyond those indicated in

the Recommended Operating Conditions is not implied. The Recommended Operating Conditions indicate conditions at which the device is functional and the

device should not be operated beyond such conditions.

Note 2: This device is a high performance integrated circuit with ESD handling precautions. Handling of this device should only be done at ESD protected work

stations. The device is rated to a HBM-ESD of > 2 kV, a MM-ESD of > 200 V, and a CDM-ESD of > 1.2 kV.

T

A

V

CC

-40 25 85 °C

3.15 3.3 3.45 V

Package Thermal Resistance

V

Package

θ

JA

θ

J-PAD (Thermal Pad)

48-Lead LLP (Note 3) 27.4° C/W 5.8° C/W

Note 3: Specification assumes 16 thermal vias connect the die attach pad to the embedded copper plane on the 4-layer JEDEC board. These vias play a key

role in improving the thermal performance of the LLP. It is recommended that the maximum number of vias be used in the board layout.

Electrical Characteristics (Note 4)

(3.15 V ≤ Vcc ≤ 3.45 V, -40 °C ≤ TA ≤ 85 °C, Differential Inputs/Outputs; except as specified. Typical values represent most likely

parametric norms at Vcc = 3.3 V, TA = 25 °C, and at the Recommended Operation Conditions at the time of product characterization

and are not guaranteed).

Symbol Parameter Conditions Min Typ Max Units

Current Consumption

I

CC

ICCPD

f

OSCin

V

OSCin

f

Fin

SLEW

DUTY

P

Fin

square

square

Fin

Fin

Entire device; CLKout0 & CLKout4

Power Supply Current

(Note 5)

enabled in Bypass Mode

Entire device; All Outputs Off (no

emitter resistors placed)

Power Down Current POWERDOWN = 1 1 mA

Reference Oscillator

Reference Oscillator Input Frequency

Range for Square Wave

Square Wave Input Voltage for OSCin and

AC coupled; Differential (VOD)

OSCin*

Frequency Input

Frequency Input Frequency Range 1 800 MHz

Frequency Input Slew Rate (Notes 6, 10) 0.5 V/ns

Frequency Input Duty Cycle 40 60 %

Input Power Range for Fin or Fin* AC coupled -13 8 dBm

145.8

70

1 200 MHz

0.2 1.6 Vpp

mA

www.national.com 4

Symbol Parameter Conditions Min Typ Max Units

PLL

f

COMP

I

CPout

SRCE

I

CPout

SINK

I

TRI Charge Pump TRI-STATE® Current 0.5 V < V

CPout

I

%MIS

CPout

I

VTUNE

CPout

I

TEMP

CPout

PN10kHz

PN1Hz

Phase Detector Frequency 40 MHz

V

Charge Pump Source Current

Charge Pump Sink Current

Magnitude of Charge Pump

Sink vs. Source Current Mismatch

Magnitude of Charge Pump

Current vs. Charge Pump Voltage

Variation

Magnitude of Charge Pump Current vs.

Temperature Variation

PLL 1/f Noise at 10 kHz Offset (Note 7)

Normalized to 1 GHz Output Frequency

Normalized Phase Noise Contribution

(Note 8)

= Vcc/2, PLL_CP_GAIN = 1x

CPout

V

= Vcc/2, PLL_CP_GAIN = 4x

CPout

V

= Vcc/2, PLL_CP_GAIN = 16x

CPout

V

= Vcc/2, PLL_CP_GAIN = 32x

CPout

V

= Vcc/2, PLL_CP_GAIN = 1x

CPout

V

= Vcc/2, PLL_CP_GAIN = 4x

CPout

V

= Vcc/2, PLL_CP_GAIN = 16x

CPout

V

= Vcc/2, PLL_CP_GAIN = 32x

CPout

< Vcc - 0.5 V

CPout

V

= Vcc / 2

CPout

TA = 25°C

0.5 V < V

< Vcc - 0.5 V

CPout

TA = 25°C

4 %

PLL_CP_GAIN = 1x -117

PLL_CP_GAIN = 32x -122

PLL_CP_GAIN = 1x -219

PLL_CP_GAIN = 32x -224

100

400

1600

3200

-100

-400

-1600

-3200

2 10 nA

3 %

4 %

Clock Distribution Section (Note 9) - LVDS Clock Outputs (CLKout0 to CLKout2)

Jitter

ADD

Additive RMS Jitter (Note 9)

RL = 100 Ω

Distribution Path =

800 MHz

Bandwidth =

12 kHz to 20 MHz

CLKoutX_MUX

= Bypass

CLKoutX_MUX

= Divided

CLKoutX_DIV =

4

20

75

Equal loading and identical clock

t

SKEW

CLKoutX to CLKoutY (Note 10)

configuration

-30 ±4 30 ps

RL = 100 Ω

V

ΔV

V

ΔV

I

SA

I

SB

I

SAB

OD

OD

OS

OS

Differential Output Voltage

Change in magnitude of VOD for

complementary output states

Output Offset Voltage

Change in magnitude of VOS for

complementary output states

Clock Output Short Circuit Current

single ended

Clock Output Short Circuit Current

differential

RL = 100 Ω

RL = 100 Ω

RL = 100 Ω

RL = 100 Ω

250 350 450 mV

-50 50 mV

1.070 1.25 1.370 V

-35 35 mV

Single ended outputs shorted to GND -24 24 mA

Complementary outputs tied together -12 12 mA

LMK02000

µA

μA

dBc/Hz

dBc/Hz

fs

5 www.national.com

Symbol Parameter Conditions Min Typ Max Units

Clock Distribution Section (Note 9) - LVPECL Clock Outputs (CLKout3 to CLKout7)

LMK02000

Jitter

ADD

Additive RMS Jitter (Note 9)

RL = 100 Ω

Distribution Path =

800 MHz

Bandwidth =

12 kHz to 20 MHz

CLKoutX_MUX

= Bypass

CLKoutX_MUX

= Divided

CLKoutX_DIV =

4

20

75

Equal loading and identical clock

t

SKEW

CLKoutX to CLKoutY (Note 10)

configuration

-30 ±3 30 ps

Termination = 50 Ω to Vcc - 2 V

V

OH

V

OL

V

OD

Output High Voltage

Output Low Voltage

Termination = 50 Ω to Vcc - 2 V

Differential Output Voltage 660 810 965 mV

Vcc -

0.98

Vcc -

1.8

Digital LVTTL Interfaces (Note 11)

V

IH

V

IL

I

IH

I

IL

V

OH

V

OL

High-Level Input Voltage 2.0 Vcc V

Low-Level Input Voltage 0.8 V

High-Level Input Current

Low-Level Input Current

High-Level Output Voltage

Low-Level Output Voltage

VIH = Vcc

VIL = 0

IOH = +500 µA

IOL = -500 µA

-5.0 5.0 µA

-40.0 5.0 µA

Vcc -

0.4

V

0.4 V

Digital MICROWIRE Interfaces (Note 12)

V

IH

V

IL

I

IH

I

IL

High-Level Input Voltage 1.6 Vcc V

Low-Level Input Voltage 0.4 V

High-Level Input Current

Low-Level Input Current

VIH = Vcc

VIL = 0

-5.0 5.0 µA

-5.0 5.0 µA

MICROWIRE Timing

t

CS

t

CH

t

CWH

t

CWL

t

ES

t

CES

t

EWH

Note 4: The Electrical Characteristics tables list guaranteed specifications under the listed Recommended Operating Conditions except as otherwise modified

or specified by the Electrical Characteristics Conditions and/or Notes. Typical specifications are estimations only and are not guaranteed.

Note 5: See 3.4 for more current consumption / power dissipation calculation information.

Note 6: For all frequencies the slew rate, SLEW

Note 7: A specification in modeling PLL in-band phase noise is the 1/f flicker noise, L

dB/decade slope. PN10kHz is normalized to a 10 kHz offset and a 1 GHz carrier frequency. PN10kHz = L

(f) is the single side band phase noise of only the flicker noise's contribution to total noise, L(f). To measure L

slope close to the carrier. A high phase detector frequency and a clean crystal are important to isolating this noise source from the total phase noise, L(f). L

(f) can be masked by the reference oscillator performance if a low power or noisy source is used. The total PLL inband phase noise performance is the sum of

L

PLL_flicker

Note 8: A specification in modeling PLL in-band phase noise is the Normalized Phase Noise Contribution, L

L

PLL_flat

detector frequency of the synthesizer. L

smaller then the loop bandwidth of the PLL, and yet large enough to avoid a substantial noise contribution from the reference and flicker noise. L

masked by the reference oscillator performance if a low power or noisy source is used.

Note 9: The Clock Distribution Section includes all parts of the device except the PLL section. Typical Additive Jitter specifications apply to the clock distribution

section only.

Note 10: Specification is guaranteed by characterization and is not tested in production.

Note 11: Applies to GOE, LD, and SYNC*.

Data to Clock Set Up Time See Data Input Timing 25 ns

Data to Clock Hold Time See Data Input Timing 8 ns

Clock Pulse Width High See Data Input Timing 25 ns

Clock Pulse Width Low See Data Input Timing 25 ns

Clock to Enable Set Up Time See Data Input Timing 25 ns

Enable to Clock Set Up Time See Data Input Timing 25 ns

Enable Pulse Width High See Data Input Timing 25 ns

, is measured between 20% and 80%.

(f) and L

(f) – 20log(N) – 10log(f

PLL_flat

(f).

COMP

Fin

). L

(f) is the single side band phase noise measured at an offset frequency, f, in a 1 Hz Bandwidth and f

PLL_flat

(f) contributes to the total noise, L(f). To measure L

PLL_flat

(f), which is dominant close to the carrier. Flicker noise has a 10

PLL_flicker

PLL_flat

(10 kHz) - 20log(Fout / 1 GHz), where L

PLL_flicker

(f) the offset frequency, f, must be chosen sufficiently

(f) it is important to be on the 10 dB/decade

PLL_flicker

(f), of the PLL and is defined as PN1Hz =

PLL_flat

COMP

V

V

PLL_flicker

PLL_flicker

is the phase

(f) can be

PLL_flat

fs

www.national.com 6

Note 12: Applies to CLKuWire, DATAuWire, and LEuWire.

Serial Data Timing Diagram

20216503

Data bits set on the DATAuWire signal are clocked into a shift register, MSB first, on each rising edge of the CLKuWire signal. On

the rising edge of the LEuWire signal, the data is sent from the shift register to the addressed register determined by the LSB bits.

After the programming is complete the CLKuWire, DATAuWire, and LEuWire signals should be returned to a low state.

LMK02000

7 www.national.com

Charge Pump Current Specification Definitions

LMK02000

20216531

I1 = Charge Pump Sink Current at V

I2 = Charge Pump Sink Current at V

I3 = Charge Pump Sink Current at V

I4 = Charge Pump Source Current at V

I5 = Charge Pump Source Current at V

I6 = Charge Pump Source Current at V

= Vcc - ΔV

CPout

= Vcc/2

CPout

= ΔV

CPout

CPout

CPout

CPout

= Vcc - ΔV

= Vcc/2

= ΔV

ΔV = Voltage offset from the positive and negative supply rails. Defined to be 0.5 V for this device.

Charge Pump Output Current Magnitude Variation vs. Charge Pump Output Voltage

20216532

Charge Pump Sink Current vs. Charge Pump Output Source Current Mismatch

20216533

Charge Pump Output Current Magnitude Variation vs. Temperature

www.national.com 8

20216534

LMK02000

1.0 Functional Description

The LMK02000 precision clock conditioner combines the

functions of jitter cleaning/reconditioning, multiplication, and

distribution of a reference clock. The device integrates a high

performance Integer-N Phase Locked Loop (PLL), three

LVDS, and five LVPECL clock output distribution blocks.

Each clock distribution block includes a programmable divider, a phase synchronization circuit, a programmable delay,

a clock output mux, and an LVDS or LVPECL output buffer.

This allows multiple integer-related and phase-adjusted

copies of the reference to be distributed to eight system components.

The clock conditioner comes in a 48-pin LLP package and is

footprint compatible with other clocking devices in the same

family.

1.1 BIAS PIN

To properly use the device, bypass Bias (pin 36) with a low

leakage 1 µF capacitor connected to Vcc. This is important

for low noise performance.

1.2 LDO BYPASS

To properly use the device, bypass LDObyp1 (pin 9) with a

10 µF capacitor and LDObyp2 (pin 10) with a 0.1 µF capacitor.

1.3 OSCILLATOR INPUT PORT (OSCin, OSCin*)

The purpose of OSCin is to provide the PLL with a reference

signal. The OSCin port must be AC coupled, refer to the System Level Diagram in the Application Information section. The

OSCin port may be driven single endedly by AC grounding

OSCin* with a 0.1 µF capacitor.

1.4 FREQUENCY INPUT PORT (Fin, Fin*)

The purpose of Fin is to provide the PLL with a feedback signal from an external oscillator. The Fin port may be driven

single endedly by AC grounding Fin*.

1.5 CLKout DELAYS

Each individual clock output includes a delay adjustment.

Clock output delay registers (CLKoutX_DLY) support a 150

ps step size and range from 0 to 2250 ps of total delay.

1.6 LVDS/LVPECL OUTPUTS

Each LVDS or LVPECL output may be disabled individually

by programming the CLKoutX_EN bits. All the outputs may

be disabled simultaneously by pulling the GOE pin low or

programming EN_CLKout_Global to 0.

1.7 GLOBAL CLOCK OUTPUT SYNCHRONIZATION

The SYNC* pin synchronizes the clock outputs. When the

SYNC* pin is held in a logic low state, the divided outputs are

also held in a logic low state. When the SYNC* pin goes high,

the divided clock outputs are activated and will transition to a

high state simultaneously. Clocks in the bypassed state are

not affected by SYNC* and are always synchronized with the

divided outputs.

The SYNC* pin must be held low for greater than one clock

cycle of the Frequency Input port, also known as the distribution path. Once this low event has been registered, the outputs will not reflect the low state for four more cycles. Similarly

once the SYNC* pin becomes high, the outputs will not simultaneously transition high until four more distribution path

clock cycles have passed. See the timing diagram below for

further detail. In the timing diagram below the clocks are pro-

grammed as CLKout0_MUX = Bypassed, CLKout1_MUX =

Divided, CLKout1_DIV = 2, CLKout2_MUX = Divided, and

CLKout2_DIV = 4.

SYNC* Timing Diagram

20216504

The SYNC* pin provides an internal pull-up resistor as shown

on the functional block diagram. If the SYNC* pin is not terminated externally the clock outputs will operate normally. If

the SYNC* function is not used, clock output synchronization

is not guaranteed.

1.8 CLKout OUTPUT STATES

Each clock output may be individually enabled with the

CLKoutX_EN bits. Each individual output enable control bit is

gated with the Global Output Enable input pin (GOE) and the

Global Output Enable bit (EN_CLKout_Global).

All clock outputs can be disabled simultaneously if the GOE

pin is pulled low by an external signal or EN_CLKout_Global

is set to 0.

CLKoutX

_EN bit

1 1 Low Low

Don't care 0 Don't care Off

0 Don't care Don't care Off

1 1

When an LVDS output is in the Off state, the outputs are at a

voltage of approximately 1.5 volts. When an LVPECL output

is in the Off state, the outputs are at a voltage of approximately

1 volt.

1.9 GLOBAL OUTPUT ENABLE AND LOCK DETECT

The GOE pin provides an internal pull-up resistor. If it is not

terminated externally, the clock output states are determined

by the Clock Output Enable bits (CLKoutX_EN) and the

EN_CLKout_Global bit.

By programming the PLL_MUX register to Digital Lock Detect

Active High (See 2.5.2), the Lock Detect (LD) pin can be connected to the GOE pin in which case all outputs are set low

automatically if the synthesizer is not locked.

1.10 POWER ON RESET

When supply voltage to the device increases monotonically

from ground to Vcc, the power on reset circuit sets all registers

to their default values, see 2.3.1 for more information on default register values. Voltage should be applied to all Vcc pins

simultaneously.

EN_CLKout

_Global bit

GOE pin Clock X

Output State

High / No

Connect

Enabled

9 www.national.com

2.0 General Programming Information

The LMK02000 device is programmed using several 32-bit

LMK02000

registers which control the device's operation. The registers

consist of a data field and an address field. The last 4 register

bits, ADDR[3:0] form the address field. The remaining 28 bits

form the data field DATA[27:0].

During programming, LEuWire is low and serial data is

clocked in on the rising edge of clock (MSB first). When

LEuWire goes high, data is transferred to the register bank

selected by the address field. Only registers R0 to R7, R11,

R14, and R15 need to be programmed for proper device operation.

It is required to program register R14.

2.1 RECOMMENDED PROGRAMMING SEQUENCE

The recommended programming sequence involves programming R0 with the reset bit set (RESET = 1) to ensure the

device is in a default state. It is not necessary to program R0

again, but if R0 is programmed again, the reset bit is programmed clear (RESET = 0). Registers are programmed in

order with R15 being the last register programmed. An example programming sequence is shown below.

•

Program R0 with the reset bit set (RESET = 1). This

ensures the device is in a default state. When the reset bit

is set in R0, the other R0 bits are ignored.

If R0 is programmed again, the reset bit is programmed

—

clear (RESET = 0).

•

Program R0 to R7 as necessary with desired clocks with

appropriate enable, mux, divider, and delay settings.

•

Program R11 with DIV4 setting if necessary.

•

Program R14 with global clock output bit, power down

setting, PLL mux setting, and PLL R divider. It is required

to program register R14.

R14 must be programmed in accordance with the

—

register map as shown in the register map (see 2.2).

•

Program R15 with PLL charge pump gain, and PLL N

divider.

www.national.com 10

LMK02000

0 0 0 0

[3:0]

CLKout0_DLY

[7:0]

CLKout0_DIV

CLKout0_EN

0 0 0 1

[3:0]

CLKout1_DLY

[7:0]

CLKout1_DIV

CLKout1_EN

0 0 1 0

[3:0]

CLKout2_DLY

[7:0]

CLKout2_DIV

CLKout2_EN

0 0 1 1

[3:0]

CLKout3_DLY

[7:0]

CLKout3_DIV

CLKout3_EN

0 1 0 0

[3:0]

CLKout4_DLY

[7:0]

CLKout4_DIV

CLKout4_EN

0 1 0 1

[3:0]

CLKout5_DLY

[7:0]

CLKout5_DIV

CLKout5_EN

0 1 1 0

[3:0]

CLKout6_DLY

[7:0]

CLKout6_DIV

CLKout6_EN

0 1 1 1

[3:0]

CLKout7_DLY

[7:0]

CLKout7_DIV

CLKout7_EN

[1:0]

_MUX

CLKout0

0 0 0 0 0 0 0 0 0 0 0 0

31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Register

Data [27:0] A3 A2 A1 A0

2.2 LMK02000 REGISTER MAP

RESET

R0

[1:0]

_MUX

CLKout1

R1 0 0 0 0 0 0 0 0 0 0 0 0 0

_MUX

CLKout2

R2 0 0 0 0 0 0 0 0 0 0 0 0 0

[1:0]

[1:0]

_MUX

CLKout3

R3 0 0 0 0 0 0 0 0 0 0 0 0 0

[1:0]

_MUX

CLKout4

R4 0 0 0 0 0 0 0 0 0 0 0 0 0

[1:0]

_MUX

CLKout5

R5 0 0 0 0 0 0 0 0 0 0 0 0 0

[1:0]

_MUX

CLKout6

R6 0 0 0 0 0 0 0 0 0 0 0 0 0

[1:0]

_MUX

CLKout7

R7 0 0 0 0 0 0 0 0 0 0 0 0 0

11 www.national.com

LMK02000

0 0 0 0 0 0 0 0 0 0 0 1 0 1 1

DIV4

0 0 0 0 1 1 1 0

[11:0]

PLL_R

0 0 0 0 1 1 1 1

[17:0]

PLL_N

[3:0]

PLL_MUX

PLL_CP_POL

TRI-STATE

POWERDOWN

EN_CLKout_Global

0 0 0 0

CP_

GAIN

R15

[1:0]

31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Register

R11 0 0 0 0 0 0 0 0 1 0 0 0 0 0 1 0

www.national.com 12

R14 0 0 1 0

PLL_

LMK02000

2.3 REGISTER R0 to R7

Registers R0 through R7 control the eight clock outputs. Register R0 controls CLKout0, Register R1 controls CLKout1, and

so on. There is one additional bit in register R0 called RESET.

Aside from this, the functions of these bits are identical. The

X in CLKoutX_MUX, CLKoutX_DIV, CLKoutX_DLY, and

CLKoutX_EN denote the actual clock output which may be

from 0 to 7.

Bit Name

RESET 0 No reset, normal operation Reset to power on defaults R0 31

CLKoutX_MUX 0 Bypassed CLKoutX mux mode

CLKoutX_EN 0 Disabled CLKoutX enable 16

CLKoutX_DIV 1 Divide by 2 CLKoutX clock divide 15:8

CLKoutX_DLY 0 0 ps CLKoutX clock delay 7:4

DIV4 0

EN_CLKout_Global 1 Normal - CLKouts normal Global clock output enable

POWERDOWN 0 Normal - Device active Device power down 26

PLL_CP_TRI 0 Normal - PLL active TRI-STATE PLL charge pump 25

PLL_CP_POL 0 Negative Polarity CP Polarity of charge pump 24

PLL_MUX 0 Disabled Multiplexer control for LD pin 23:20

PLL_R 10 R divider = 10 PLL R divide value 19:8

PLL_CP_GAIN 0 100 uA Charge pump current

PLL_N 760 N divider = 760 PLL N divide value 25:8

Default

Bit Value

Bit State Bit Description Register

PDF ≤ 20 MHz

2.3.1 RESET Bit -- R0 only

This bit is only in register R0. The use of this bit is optional

and it should be set to '0' if not used. Setting this bit to a '1'

forces all registers to their power on reset condition and therefore automatically clears this bit. If this bit is set, all other R0

bits are ignored and R0 needs to be programmed again if

used with its proper values and RESET = 0.

Bit

Location

18:17

R0 to R7

Phase Detector Frequency R11 15

27

R14

R15

31:30

2.3.2 CLKoutX_MUX[1:0] -- Clock Output Multiplexers

These bits control the Clock Output Multiplexer for each clock

output. Changing between the different modes changes the

blocks in the signal path and therefore incurs a delay relative

to the bypass mode. The different MUX modes and associated delays are listed below.

CLKoutX_MUX

[1:0]

0 Bypassed (default) 0 ps

1 Divided 100 ps

2 Delayed

3

Mode Added Delay

Divided and

Delayed

Relative to

Bypass Mode

400 ps

(In addition to the

programmed

delay)

500 ps

(In addition to the

programmed

delay)

13 www.national.com

2.3.3 CLKoutX_DIV[7:0] -- Clock Output Dividers

These bits control the clock output divider value. In order for

these dividers to be active, the respective CLKoutX_MUX

(See 2.3.2) bit must be set to either "Divided" or "Divided and

LMK02000

Delayed" mode. After all the dividers are programed, the

SYNC* pin must be used to ensure that all edges of the clock

outputs are aligned (See 1.7). By adding the divider block to

the output path a fixed delay of approximately 100 ps is incurred.

The actual Clock Output Divide value is twice the binary value

programmed as listed in the table below.

CLKoutX_DIV[7:0] Clock Output

Divider value

0 0 0 0 0 0 0 0 Invalid

0 0 0 0 0 0 0 1 2 (default)

0 0 0 0 0 0 1 0 4

0 0 0 0 0 0 1 1 6

0 0 0 0 0 1 0 0 8

0 0 0 0 0 1 0 1 10

. . . . . . . . ...

1 1 1 1 1 1 1 1 510

2.3.4 CLKoutX_DLY[3:0] -- Clock Output Delays

These bits control the delay stages for each clock output. In

order for these delays to be active, the respective

CLKoutX_MUX (See 2.3.2) bit must be set to either "Delayed"

or "Divided and Delayed" mode. By adding the delay block to

the output path a fixed delay of approximately 400 ps is incurred in addition to the delay shown in the table below.

CLKoutX_DLY[3:0] Delay (ps)

0 0 (default)

1 150

2 300

3 450

4 600

5 750

6 900

7 1050

8 1200

9 1350

10 1500

11 1650

12 1800

13 1950

CLKoutX_DLY[3:0] Delay (ps)

14 2100

15 2250

2.3.5 CLKoutX_EN bit -- Clock Output Enables

These bits control whether an individual clock output is enabled or not. If the EN_CLKout_Global bit (See 2.5.4) is set

to zero or if GOE pin is held low, all CLKoutX_EN bit states

will be ignored and all clock outputs will be disabled. See 1.8

for more information on CLKout states.

CLKoutX_EN bit Conditions CLKoutX State

0 EN_CLKout_Global

bit = 1

1 Enabled

2.4 REGISTER R11

This register only has one bit and only needs to be programmed in the case that the phase detector frequency is

greater than 20 MHz and digital lock detect is used. Otherwise, it is automatically defaulted to the correct values.

2.4.1 DIV4

This bit divides the frequency presented to the digital lock detect circuitry by 4. It is necessary to get a reliable output from

the digital lock detect output in the case of a phase detector

frequency greater than 20 MHz.

DIV4 Digital Lock Detect Circuitry Mode

0 Not divided; Phase detector

1 Divided by 4; Phase detector

2.5 REGISTER R14

The LMK02000 requires register R14 to be programmed as

shown in the register map (see 2.2).

2.5.1 PLL_R[11:0] -- R Divider Value

These bits program the PLL R Divider and are programmed

in binary fashion.

0 0 0 0 0 0 0 0 0 0 0 0 Invalid

0 0 0 0 0 0 0 0 0 0 0 1 1

0 0 0 0 0 0 0 0 0 0 1 0 2

. . . . . . . . . . . . ...

0 0 0 0 0 0 0 0 1 0 1 0 10 (default)

. . . . . . . . . . . . ...

1 1 1 1 1 1 1 1 1 1 1 1 4095

GOE pin = High / No

Connect 1

frequency ≤ 20 MHz (default)

frequency > 20 MHz

PLL_R[11:0] PLL R Divide

Disabled (default)

Value

www.national.com 14

LMK02000

2.5.2 PLL_MUX[3:0] -- Multiplexer Control for LD Pin

These bits set the output mode of the LD pin. The table below

lists several different modes.

PLL_MUX[3:0] Output Type LD Pin Function

0 Hi-Z Disabled (default)

1 Push-Pull Logic High

2 Push-Pull Logic Low

3 Push-Pull Digital Lock Detect

(Active High)

4 Push-Pull Digital Lock Detect

(Active Low)

5 Push-Pull Analog Lock

Detect

6 Open Drain NMOS Analog Lock

Detect

7 Open Drain PMOS Analog Lock

Detect

8 Invalid

9 Push-Pull N Divider Output/2

(50% Duty Cycle)

10 Invalid

11 Push-Pull R Divider Output/2

(50% Duty Cycle)

12 to 15 Invalid

2.5.3 POWERDOWN Bit -- Device Power Down

This bit can power down the device. Enabling this bit powers

down the entire device and all blocks, regardless of the state

of any of the other bits or pins.

POWERDOWN bit Mode

0 Normal Operation (default)

1 Entire Device Powered Down

2.5.4 EN_CLKout_Global Bit -- Global Clock Output Enable

This bit overrides the individual CLKoutX_EN bits (See 2.3.5).

When this bit is set to 0, all clock outputs are disabled, regardless of the state of any of the other bits or pins. See 1.8

for more information on CLKout states.

EN_CLKout_Global

Clock Outputs

bit

0 All Off

1 Normal Operation (default)

2.5.5 PLL_CP_TRI Bit -- PLL Charge Pump TRI-STATE

This bit sets the PLL charge pump TRI-STATE.

PLL_CP_TRI PLL Charge Pump

0 Normal operation (default)

1 TRI-STATE

2.5.6 PLL_CP_POLBbit -- PLL Charge Pump Polarity

This bit sets the polarity of the charge pump to either negative

or positive. A negative charge pump is used with a VCO or

VCXO which decreases frequency with increasing tuning voltage. A positive charge pump is used with a VCO or VCXO

which increases frequency with increasing tuning voltage.

PLL_CP_POL PLL Charge Pump Polarity

0 Negative (default)

1 Positive

2.6 Register R15

2.6.1 PLL_N[17:0] -- PLL N Divider

These bits program the divide value for the PLL N Divider.

The PLL N Divider precedes the PLL phase detector. The

VCO or VCXO frequency is calculated as, f

N Divider / PLL R Divider. Since the PLL N divider is a pure

VCO

= f

OSCin

× PLL

binary counter, there are no illegal divide values for PLL_N

[17:0] except for 0.

PLL_N[17:0] PLL N

Divider

Value

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 Invalid

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1

. . . . . . . . . . . . . . . . . . ...

0 0 0 0 0 0 0 0 1 0 1 1 1 1 1 0 0 0 760

(default)

. . . . . . . . . . . . . . . . . . ...

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 262143

2.6.2 PLL_CP_GAIN[1:0] -- PLL Charge Pump Gain

These bits set the charge pump gain of the PLL.

PLL_CP_GAIN[1:0] Charge Pump Gain

0 1x (default)

1 4x

2 16x

3 32x

15 www.national.com

3.0 Application Information

3.1 SYSTEM LEVEL DIAGRAM

LMK02000

The following shows the LMK02000 in a typical application.

In this setup the clock may be multiplied, reconditioned, and

redistributed.

FIGURE 1. Typical Application

3.2 BIAS PIN

To properly use the device, bypass Bias (pin 36) with a low

leakage 1 µF capacitor connected to Vcc. This is important

for low noise performance.

www.national.com 16

20216570

3.3 LDO BYPASS

To properly use the device, bypass LDObyp1 (pin 9) with a

10 µF capacitor and LDObyp2 (pin 10) with a 0.1 µF capacitor.

LMK02000

3.4 CURRENT CONSUMPTION / POWER DISSIPATION CALCULATIONS

calculate estimated current consumption of the LMK02000.

Unless otherwise noted Vcc = 3.3 V, TA = 25 °C.

Due to the myriad of possible configurations the following table serves to provide enough information to allow the user to

Table 3.4 - Block Current Consumption

Block Condition

Entire device,

core current

Low clock buffer

(internal)

High clock buffer

(internal)

All outputs off; No LVPECL emitter resistors

connected

The low clock buffer is enabled anytime one of

CLKout0 through CLKout3 are enabled

The high clock buffer is enabled anytime one of

the CLKout4 through CLKout7 are enabled

Current

Consumption at

3.3 V (mA)

70 231 -

9 29.7 -

9 29.7 -

Power

Dissipated in

device (mW)

Power Dissipated in

LVPECL emitter

resistors (mW)

LVDS output, bypass mode 17.8 58.7 -

Output buffers

Divide circuitry

per output

Delay circuitry

per output

LVPECL output, bypass mode (includes 120 Ω

emitter resistors)

LVPECL output, disabled mode (includes 120

Ω emitter resistors)

LVPECL output, disabled mode. No emitter

resistors placed; open outputs

Divide enabled, divide = 2 5.3 17.5 -

Divide enabled, divide > 2 8.5 28.0 -

Delay enabled, delay < 8 5.8 19.1 -

Delay enabled, delay > 7 9.9 32.7 -

40 72 60

17.4 38.3 19.1

0 0 -

Entire device CLKout0 & CLKout4 enabled in bypass mode 145.8 421.1 60

From Table 3.4 the current consumption can be calculated in

any configuration. For example, the current for the entire device with 1 LVDS (CLKout0) & 1 LVPECL (CLKout4) output

in bypass mode can be calculated by adding up the following

blocks: core current, low clock buffer, high clock buffer, one

LVDS output buffer current, and one LVPECL output buffer

current. There will also be one LVPECL output drawing emitter current, but some of the power from the current draw is

dissipated in the external 120 Ω resistors which doesn't add

to the power dissipation budget for the device. If delays or

divides are switched in, then the additional current for these

stages needs to be added as well.

For power dissipated by the device, the total current entering

the device is multiplied by the voltage at the device minus the

power dissipated in any emitter resistors connected to any of

the LVPECL outputs. If no emitter resistors are connected to

the LVPECL outputs, this power will be 0 watts. For example,

in the case of 1 LVDS (CLKout0) & 1 LVPECL (CLKout4) operating at 3.3 volts, we calculate 3.3 V × (70 + 9 + 9 + 17.8 +

40) mA = 3.3 V × 145.8 mA = 481.1 mW. Because the

LVPECL output (CLKout4) has the emitter resistors hooked

up and the power dissipated by these resistors is 60 mW, the

total device power dissipation is 481.1 mW - 60 mW = 421.1

mW.

When the LVPECL output is active, ~1.9 V is the average

voltage on each output as calculated from the LVPECL Voh

& Vol typical specification. Therefore the power dissipated in

each emitter resistor is approximately (1.9 V)2 / 120 Ω = 30

mW. When the LVPECL output is disabled, the emitter resistor voltage is ~1.07 V. Therefore the power dissipated in each

emitter resistor is approximately (1.07 V)2 / 120 Ω = 9.5 mW.

3.5 THERMAL MANAGEMENT

Power consumption of the LMK02000 can be high enough to

require attention to thermal management. For reliability and

performance reasons the die temperature should be limited

to a maximum of 125 °C. That is, as an estimate, TA (ambient

temperature) plus device power consumption times θ

should not exceed 125 °C.

The package of the device has an exposed pad that provides

the primary heat removal path as well as excellent electrical

grounding to the printed circuit board. To maximize the removal of heat from the package a thermal land pattern including multiple vias to a ground plane must be incorporated

on the PCB within the footprint of the package. The exposed

pad must be soldered down to ensure adequate heat conduction out of the package. A recommended land and via

pattern is shown in Figure 2. More information on soldering

LLP packages can be obtained at www.national.com.

JA

17 www.national.com

LMK02000

20216573

FIGURE 2.

To minimize junction temperature it is recommended that a

simple heat sink be built into the PCB (if the ground plane

layer is not exposed). This is done by including a copper area

of about 2 square inches on the opposite side of the PCB from

the device. This copper area may be plated or solder coated

to prevent corrosion but should not have conformal coating (if

possible), which could provide thermal insulation. The vias

shown in Figure 2 should connect these top and bottom copper layers and to the ground layer. These vias act as “heat

pipes” to carry the thermal energy away from the device side

of the board to where it can be more effectively dissipated.

www.national.com 18

Physical Dimensions inches (millimeters) unless otherwise noted

LMK02000

Leadless Leadframe Package (Bottom View)

48 Pin LLP (SQA48A) Package

Order Number Package Marking Packing LVDS Outputs LVPECL

Outputs

LMK02000ISQ K02000 I 250 Unit Tape and Reel 3 5

LMK02000ISQX K02000 I 2500 Unit Tape and Reel 3 5

19 www.national.com

Notes

THE CONTENTS OF THIS DOCUMENT ARE PROVIDED IN CONNECTION WITH NATIONAL SEMICONDUCTOR CORPORATION

(“NATIONAL”) PRODUCTS. NATIONAL MAKES NO REPRESENTATIONS OR WARRANTIES WITH RESPECT TO THE ACCURACY

OR COMPLETENESS OF THE CONTENTS OF THIS PUBLICATION AND RESERVES THE RIGHT TO MAKE CHANGES TO

SPECIFICATIONS AND PRODUCT DESCRIPTIONS AT ANY TIME WITHOUT NOTICE. NO LICENSE, WHETHER EXPRESS,

IMPLIED, ARISING BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS

DOCUMENT.

TESTING AND OTHER QUALITY CONTROLS ARE USED TO THE EXTENT NATIONAL DEEMS NECESSARY TO SUPPORT

NATIONAL’S PRODUCT WARRANTY. EXCEPT WHERE MANDATED BY GOVERNMENT REQUIREMENTS, TESTING OF ALL

PARAMETERS OF EACH PRODUCT IS NOT NECESSARILY PERFORMED. NATIONAL ASSUMES NO LIABILITY FOR

APPLICATIONS ASSISTANCE OR BUYER PRODUCT DESIGN. BUYERS ARE RESPONSIBLE FOR THEIR PRODUCTS AND

APPLICATIONS USING NATIONAL COMPONENTS. PRIOR TO USING OR DISTRIBUTING ANY PRODUCTS THAT INCLUDE

LMK02000 Precision Clock Conditioner with Integrated PLL

NATIONAL COMPONENTS, BUYERS SHOULD PROVIDE ADEQUATE DESIGN, TESTING AND OPERATING SAFEGUARDS.

EXCEPT AS PROVIDED IN NATIONAL’S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, NATIONAL ASSUMES NO

LIABILITY WHATSOEVER, AND NATIONAL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY RELATING TO THE SALE

AND/OR USE OF NATIONAL PRODUCTS INCLUDING LIABILITY OR WARRANTIES RELATING TO FITNESS FOR A PARTICULAR

PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY

RIGHT.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR

SYSTEMS WITHOUT THE EXPRESS PRIOR WRITTEN APPROVAL OF THE CHIEF EXECUTIVE OFFICER AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

Life support devices or systems are devices which (a) are intended for surgical implant into the body, or (b) support or sustain life and

whose failure to perform when properly used in accordance with instructions for use provided in the labeling can be reasonably expected

to result in a significant injury to the user. A critical component is any component in a life support device or system whose failure to perform

can be reasonably expected to cause the failure of the life support device or system or to affect its safety or effectiveness.

National Semiconductor and the National Semiconductor logo are registered trademarks of National Semiconductor Corporation. All other

brand or product names may be trademarks or registered trademarks of their respective holders.

Copyright© 2007 National Semiconductor Corporation

For the most current product information visit us at www.national.com

www.national.com

National Semiconductor

Americas Customer

Support Center

Email:

new.feedback@nsc.com

Tel: 1-800-272-9959

National Semiconductor Europe

Customer Support Center

Fax: +49 (0) 180-530-85-86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +49 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor Asia

Pacific Customer Support Center

Email: ap.support@nsc.com

National Semiconductor Japan

Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

Loading...

Loading...