LMD18400

Quad High Side Driver

LMD18400 Quad High Side Driver

June 1996

General Description

The LMD18400 is a fully protected quad high side driver. It

contains four common-drain DMOS N-channel power

switches, each capable of switching a continuous 1 Amp

>

3 Amps transient) to a common positive power sup-

load (

ply. The switches are fully protected from excessive voltage,

current and temperature. An instantaneous power sensing

circuit calculates the product of the voltage across and the

current through each DMOS switch and limits the power to a

safe level. The device can be disabled to produce a “sleep”

condition reducing the supply current to less than 10 µA.

Separate ON/OFF control of each switch is provided through

standard LSTLL/CMOS logic compatible inputs.

™

A MICROWIRE

to provide extensive diagnostic information. This information

includes switch status readback, output load fault conditions

and thermal and overvoltage shutdown status. There are

also two direct-output error flags to provide an immediate

indication of a general system fault and an indication of

excessive operating temperature.

The LMD18400 is packaged in a special power dissipating

leadframe that reduces the junction to case thermal resistance to approximately 20˚C/W.

compatible serial data interface is built in

Features

n Four independent outputs with>3A peak, 1A continuous

current capability

n 1.3Ω maximum ON resistance over temperature

n True instantaneous power limit for each switch

n High survival voltage (60 V

n Shorted load (to ground and supply) protection

n Overvoltage shutdown at V

n LS TTL/CMOS compatible logic inputs and outputs

<

n

10 µA supply current in “sleep” mode

n −5V output clamp for discharging inductive loads

n Serial data interface for 11 diagnostic checks:

— Switch ON/OFF status

— Open or shorted load

— Operating temperature

— Excessive supply voltage

n Two direct-output error flags

, 80V transient)

DC

>

35V

CC

Applications

n Relay and solenoid drivers

n High impedance automotive fuel injector drivers

n Lamp drivers

n Power supply switching

n Motor drivers

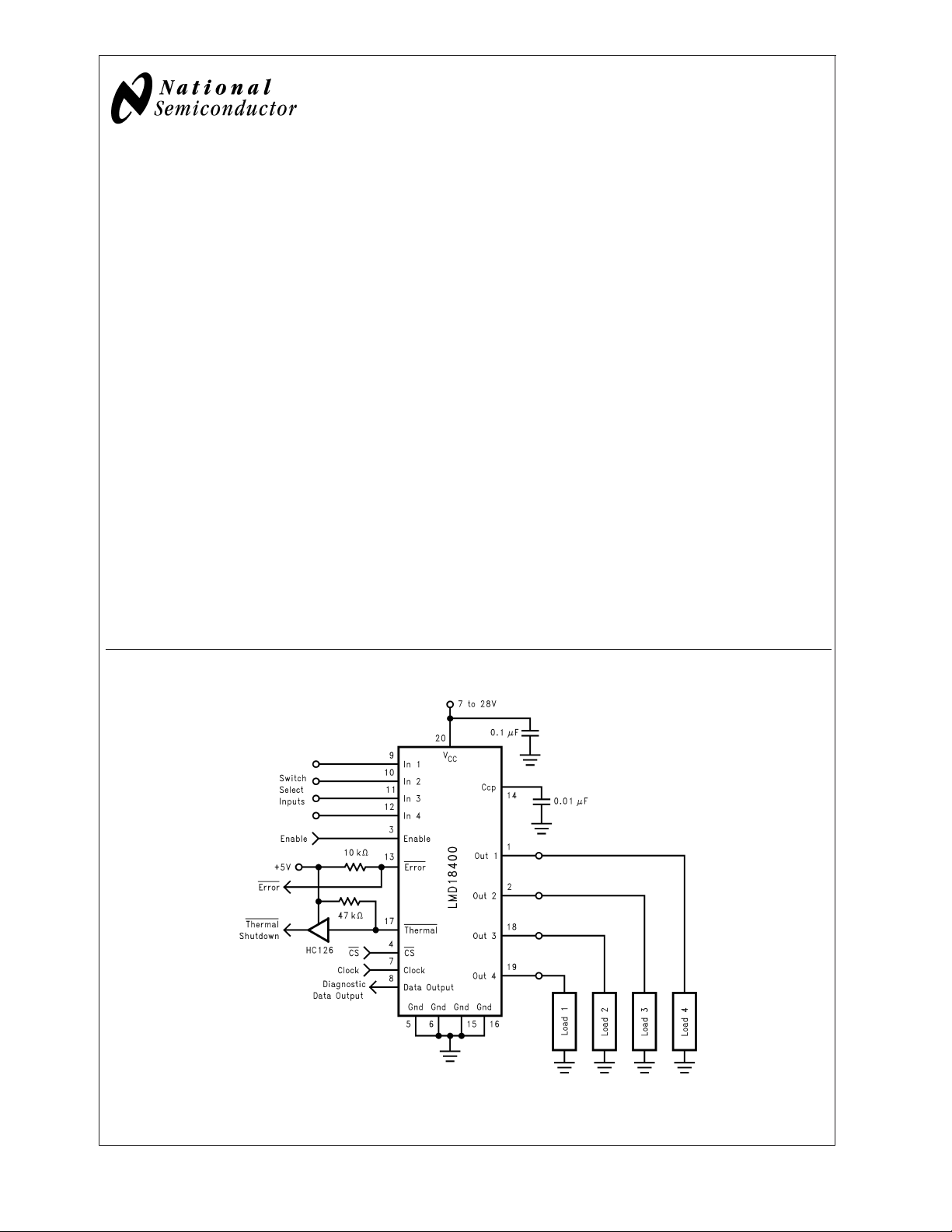

Typical Application

01102601

© 2004 National Semiconductor Corporation DS011026 www.national.com

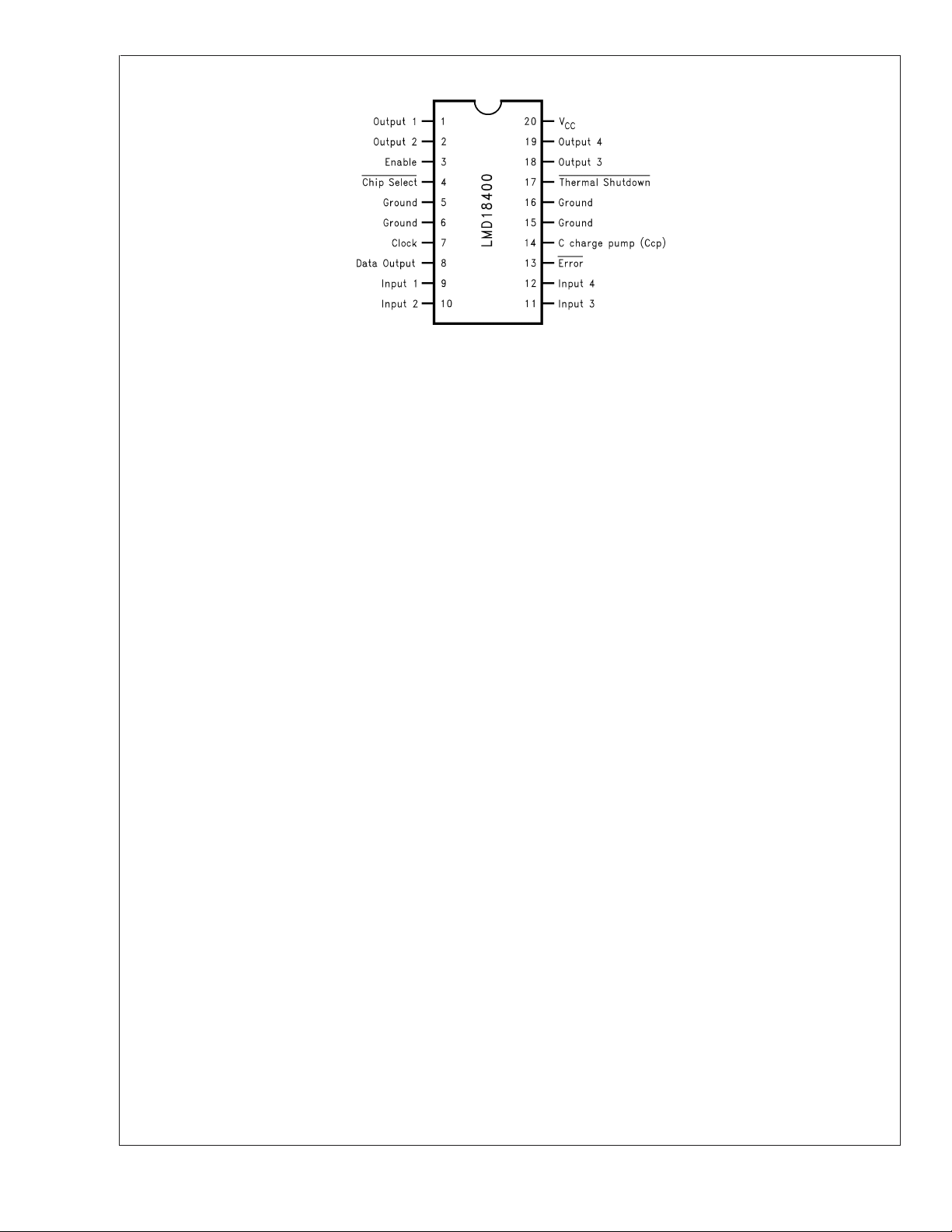

Connection Diagram

LMD18400

Order Number LMD18400N

See NS Package Number N20A

01102602

www.national.com 2

LMD18400

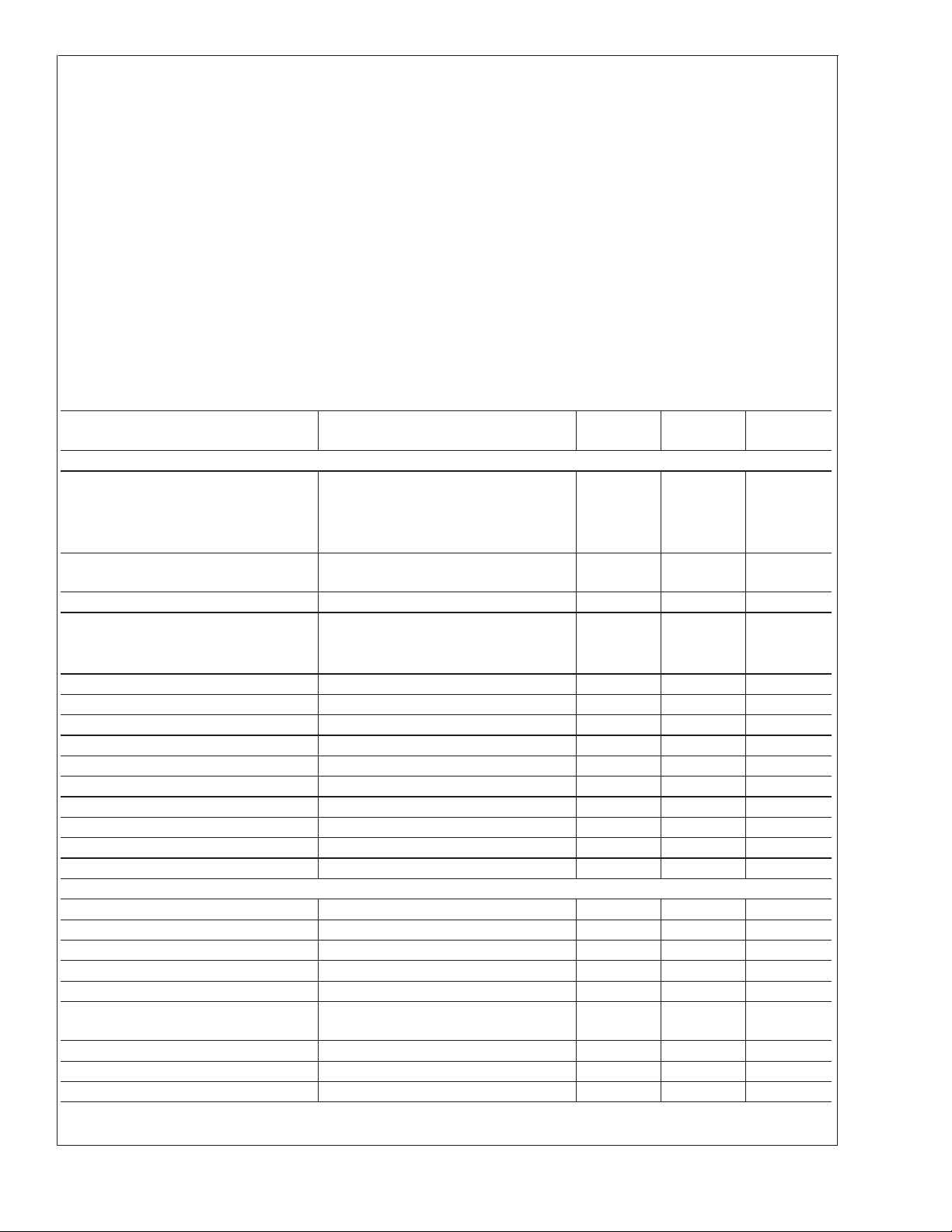

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Supply Survival Voltage (Pin 20)

Transient (t = 10 ms) 80V

Continuous −0.5V to +60V

Output Transient Current (Each Switch) 3.75A

Logic Input Voltage (Pins 4, 7) −0.3V to +6V

Error Flag Voltage 16V

ESD Susceptibility (Note 2) 2000V

Power Dissipation (Note 3) 5W

Internally Limited

Junction Temperature (T

150˚C) 150˚C

J

MAX

Storage Temperature Range −65˚C to +150˚C

Lead Temperature (Soldering, 10 sec.) +260˚C

Output Transient Current

(Total, All Switches) 6A

Operating Ratings (Note 1)

Output Steady State Current

(Each Switch) 1A

Logic Input Voltage

Ambient Temperature Range (T

Supply Voltage Range 7V to 28V

) −25˚C to +85˚C

A

(Pins 3, 9, 10, 11, 12) −0.3V to +16V

Electrical Characteristics V

over the entire operating temperature range, −25˚C ≤ T

Parameter Conditions

= 12V, CCP= 0.01 µFd, unless otherwise indicated. Boldface limits apply

CC

≤ +85˚C, all other limits are for TA=TJ= +25˚C.

A

Typical

(Note 4)

Limit

(Note 5)

Units

(Limit)

DC CHARACTERISTICS

Supply Current Enable Input = 0V 0.04 10 µA (Max)

Enable Input = 5V, Inputs = 0V 7.5 15 mA (Max)

Enable Input = 5V, Inputs = 5V

Open Loads 7.5 15 mA (Max)

Output Leakage Enable Input = 0V, Inputs = 0V

(Pins 1, 2, 18, 19)

Rds ON I

Short Circuit Current V

Maximum Output Current V

= 1A, (Note 6) 0.8 1.3 Ω (Max)

OUT

= 12V, (Note 6) 1.2 0.6 A (Min)

CC

V

= 7V, (Note 6) 2.4 A

CC

V

= 28V, (Note 6) 0.6 A

CC

CC−VO

= 4V, (Note 6) 3.75 A

0.01 300 µA (Max)

Lead Error Threshold Voltage Pins 1, 2, 18, 19 4.1 V

Open Load Detection Current Pins 1, 2, 18, 19 150 µA

Negative Clamp Output Voltage I

= 1A, (Note 6) −5 V

O

Overvoltage Shutdown Threshold 31 40 V (Max)

Overvoltage Shutdown Hysteresis 0.75 V

Error Output Leakage Current V

Thermal Warning Temperature V

Thermal Shutdown Temperature V

Thermal Warning Temperature V

= 12V 0.001 10 µA (Max)

PIN 13

<

PIN 13

PIN 17

PIN 13

0.8V 145 ˚C

<

0.8V 170 ˚C

<

0.8V 145 ˚C

AC CHARACTERISTICS

Switch Turn-On Delay (t

Switch Turn-On Rise Time (t

Switch Turn-Off Delay (t

Switch Turn-Off Fall Time (t

Enable Time (t

) Measured with Switch 1, Pin9=5V 30 50 µs(Max)

EN

Error Reporting Delay (t

Data Setup Time (t

TRI-STATE

DS

®

Control (t1H,tOH) Pin 8, Hi-Z Enable Time 2 µs

) Enable (Pin 3) = 5V, I

d(ON)

)I

ON

) Enable (Pin 3) = 5V, I

d(OFF)

)I

OFF

) Enable (Pin 3) = 5V, Switch 1 Load

Error

= 1A 7 15 µs (Max)

OUT

= 1A 0.15 1 µs (Max)

OUT

Opened

)C

= 30 pF 200 500 ns (Min)

L

= 1A 5 10 µs (Max)

OUT

= 1A 0.5 2 µs (Max)

OUT

75 150 µs (Max)

Data Clock Frequency 3 1 MHz (Max)

www.national.com3

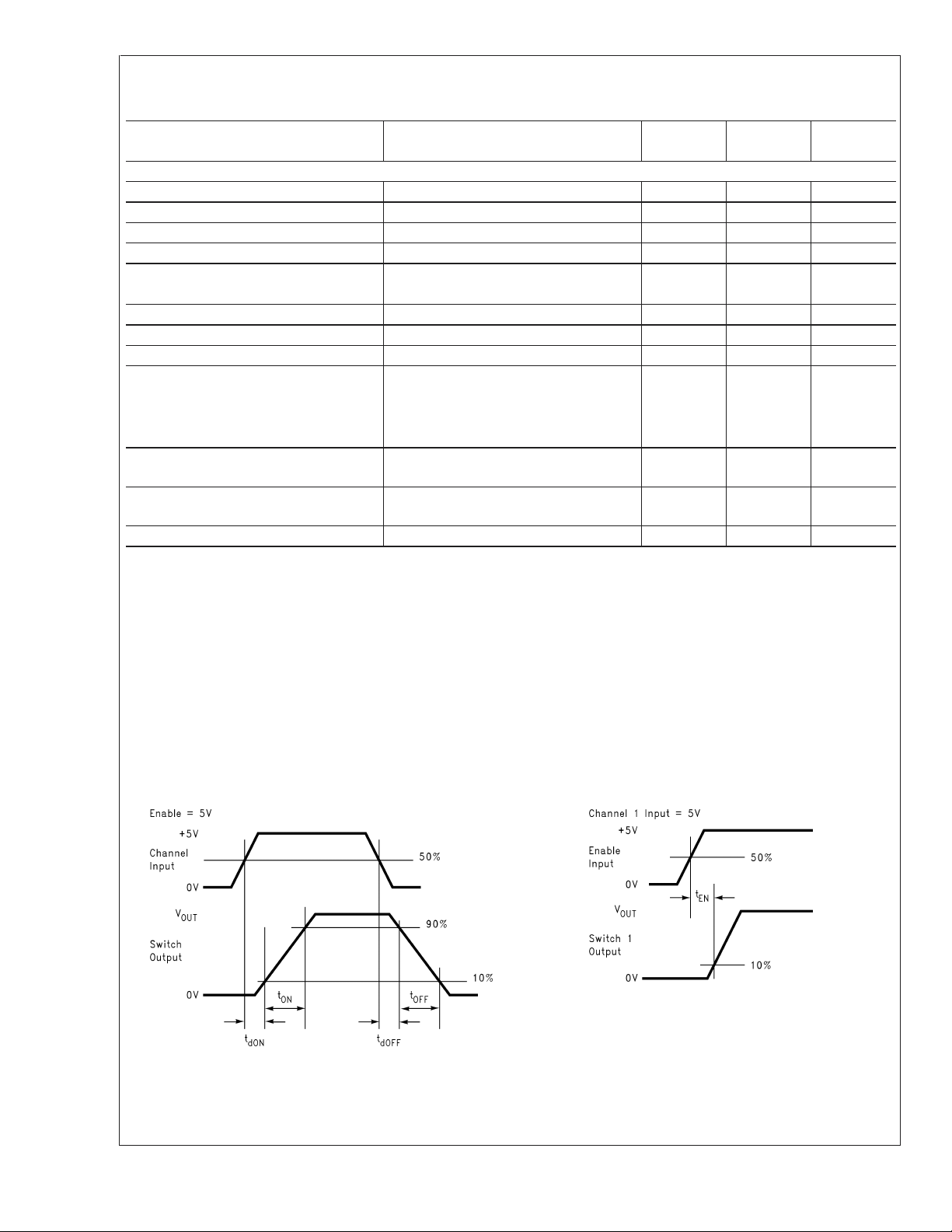

Electrical Characteristics V

= 12V, CCP= 0.01 µFd, unless otherwise indicated. Boldface limits apply over

CC

the entire operating temperature range, −25˚C ≤ T

≤ +85˚C, all other limits are for TA=TJ= +25˚C. (Continued)

A

LMD18400

Parameter Conditions

Typical

(Note 4)

Limit

(Note 5)

DIGITAL CHARACTERISTICS

Logic “1” Input Voltage Pins 3, 4, 7, 9, 10, 11, 12 2.0 V (Min)

Logic “0” Input Voltage Pins 3, 4, 7, 9, 10, 11, 12 0.8 V (Max)

Logic “1” Input Current Pins 4, 7 0.001 1 µA (Max)

Logic “0” Input Current Pins 4, 7 −0.001 −1 µA (Max)

TRI-STATE Output Current Pin 8, Pin4=5V 0.05 10 µA (Max)

Pin8=0V −0.05 −10 µA (Max)

Enable Input Current Pin 3 = 2.4V 12 25 µA (Max)

Channel Input Resistance Pins 9, 10, 11, 12 75 15 kΩ (Min)

Error Output Sink Current Pin 13 = 0.8V 4 1.6 mA (Min)

Logic “1” Output Voltage Pin 8

I

= −360 µA 4.4 2.4 V (Min)

OUT

I

= −10 µA 5.1 4.5 V (Min)

OUT

I

= −10 µA 5.5 V (Min)

OUT

Logic “0” Output Voltage Pin 8

I

OUT

Thermal Shutdown Output Source

Pin 17 = 2.4V

Current

= 100 µA

5 3 µA (Min)

0.4 V (Max)

Thermal Shutdown Output Sink Current Pin 17 = 0.8V 360 250 µA (Min)

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for which the device is

intended to be functional, but do not guarantee specific performance limits. For guaranteed specifications and test conditions, see the Electrical Characteristics.

Note 2: Human body model; 100 pF discharge through a 1.5 kΩ resistor. All pins except pins 8 and 13 which are protected to 1000V and pins 1, 2, 18 and 19 which

are protected to 500V.

Note 3: The maximum power dissipation is a function of T

ambient temperature is P

shutdown. For the LMD18400 the junction-to-ambient thermal resistance, θ

the package will be, I

Note 4: Typical values are at T

Note 5: All limits are 100% production tested at +25˚C. Limits at temperature extremes are guaranteed through correlation and accepted Statistical Quality Control

(SQC) methods.

Note 6: Pulse Testing techniques used. Pulse width is

=(T

D

DC

MAX

–TA)/θJA. If this dissipation is exceeded, the die temperature will rise above 150˚C and the device will eventually go into thermal

J

MAX

2

xR

J

x 4 switches 1A2x 1.3Ω x 4 = 5.2W).

ON

(MAX)

= +25˚C and represent the most likely parametric norm.

, θJA, and TAand is limited by thermal shutdown. The maximum allowable power dissipation at any

J

MAX

, is 60˚C/W. With sufficient heatsinking the maximum continuous power dissipation for

JA

<

5 ms with a duty cycle<1%.

Units

(Limit)

Timing Specification Definitions

Switching Turn ON/OFF Enable Turn-On

01102603

www.national.com 4

01102604

Timing Specification Definitions (Continued)

Error Reporting Delay Data Setup Time

LMD18400

01102605

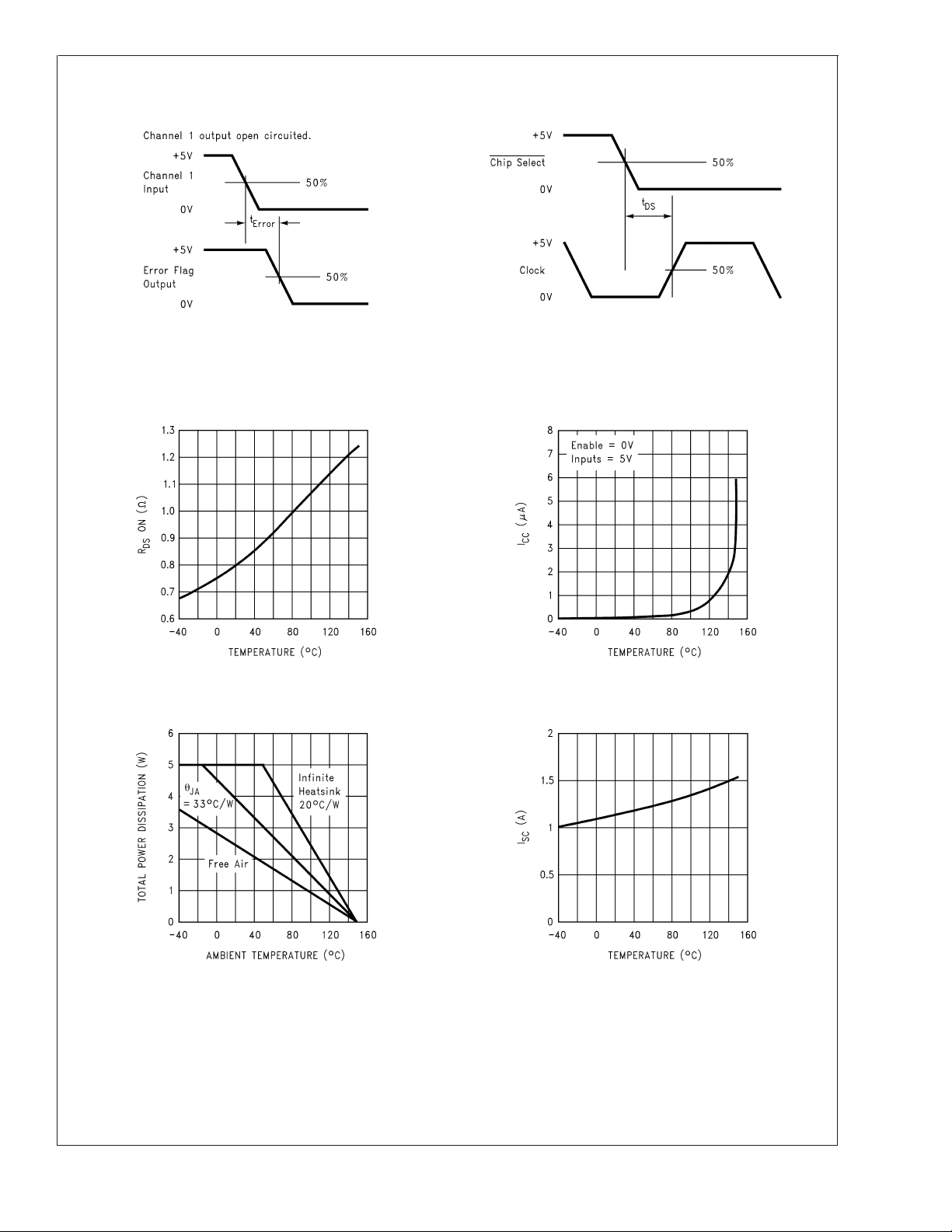

Typical Performance Characteristics For all curves, V

perature unless otherwise noted.

Switch ON Resistance

vs Temperature

01102631

Maximum Power Dissipation

vs Ambient Temperature

= 12V, Temperature is the junction tem-

CC

“Sleep Mode” Supply Current

vs Temperature

01102632

Short Circuit Current

vs Temperature

01102606

01102633

01102634

www.national.com5

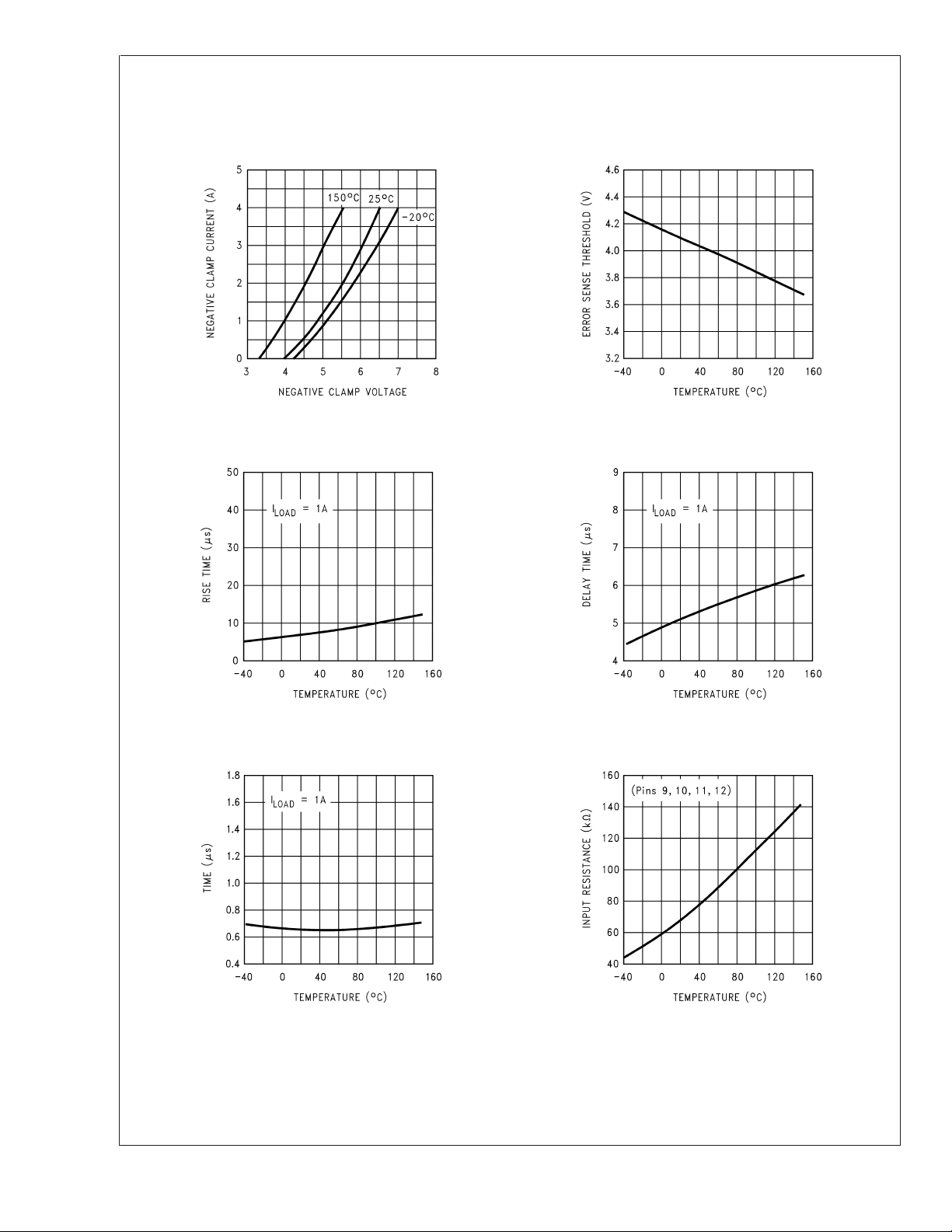

Typical Performance Characteristics For all curves, V

temperature unless otherwise noted. (Continued)

= 12V, Temperature is the junction

CC

LMD18400

Clamp Characteristics

vs Temperature

Turn ON Rise Time

vs Temperature

01102635

Error Sense Threshold

Voltage vs Temperature

01102636

Turn ON Delay Time

vs Temperature

Turn OFF Time

vs Temperature

01102637 01102638

Switch Select Logic Input

Resistance vs Temperature

01102639

01102640

www.national.com 6

LMD18400

Typical Performance Characteristics For all curves, V

temperature unless otherwise noted. (Continued)

Enable Threshold Voltage

vs Temperature

01102641 01102642

Functional Block Diagram

= 12V, Temperature is the junction

CC

Error Output Voltage

vs Sink Current

01102608

www.national.com7

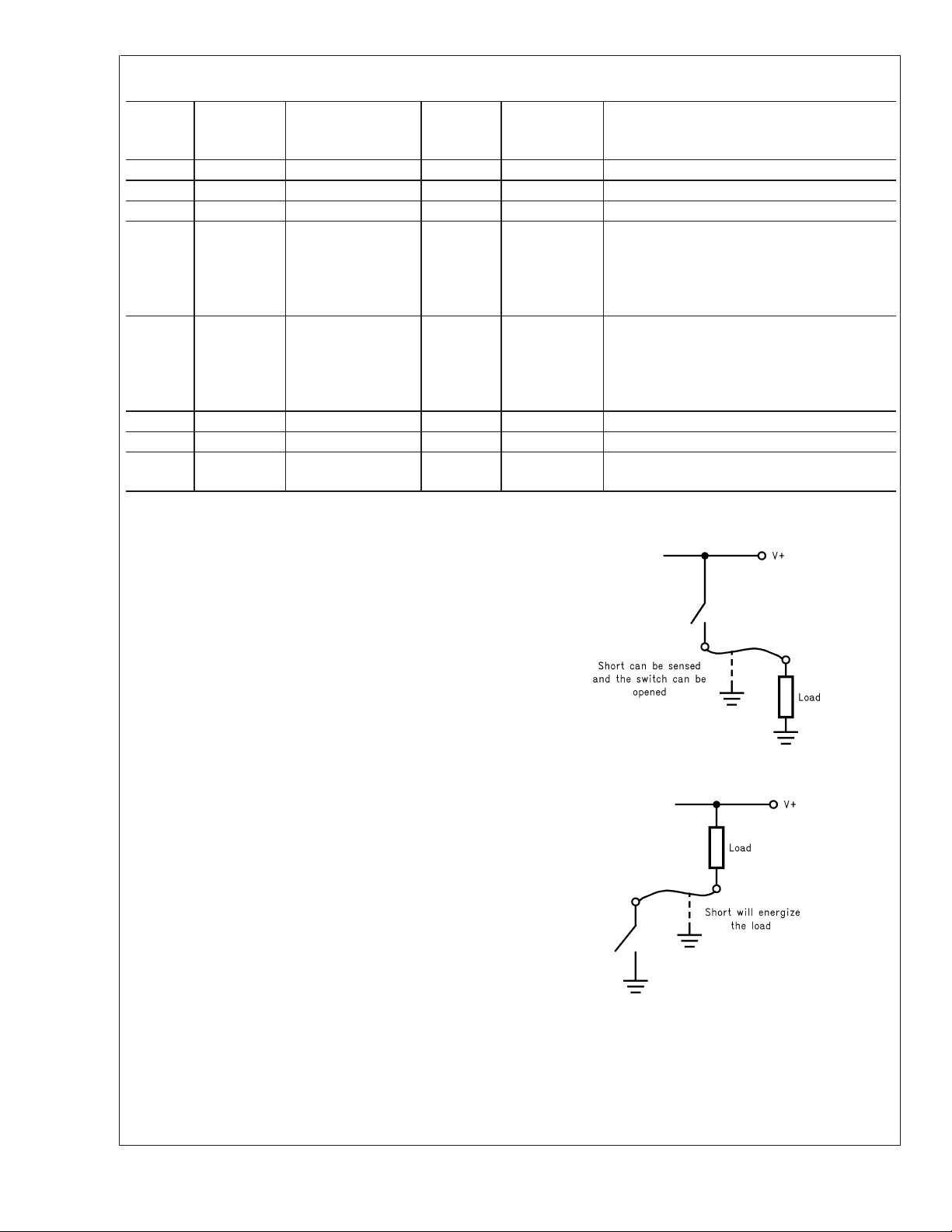

Truth Table

Enable

LMD18400

Input

(Pin 3)

Chip Select

Input

(Pin 4)

Switch Control

Input

(Pins 9, 10, 11, 12)

0 X X 1 0 “Sleep” Mode, I

1 X 0 1 1 Selected Switch is OFF

1 X 1 1 1 Selected Switch is ON, Normal Operation

1 X 0 0 1 Switch is OFF but:

1 X 1 0 1 Switch is ON, but:

1X 1 0 0T

1 1 X X X Data Output Pin is TRI-STATE

1 0 X X X Data Output Pin is Enabled and Ready to

Applications Information

BASIC OPERATION

High-side drivers are used extensively in automotive and

industrial applications to switch power to ground referred

loads. The major advantage of using high-side drive, as

opposed to low-side drive, is to protect the load from being

energized in the event that the load drive wire is inadvertently shorted to ground as shown in Figure 1. A high-side

driver can sense a shorted condition and open the power

switch to disable the load and eliminate the excessive current drain on the power supply. The LMD18400 can control

and protect up to four separate ground referenced loads.

Error

Output

(Pin 13)

Thermal SD

Output

(Pin 17)

Conditions

<

SUPPLY

10 µA

a. Load is Open Circuited, or

b. Load is Shorted to V

>

c. T

d. V

+145˚C, or

J

>

CC

+35V

,or

CC

a. Load is Shorted to Ground, or

b. Switch is in Power Limit, or

>

c. T

d. V

J

+145˚C, or

J

>

+35V and Switch is Actually OFF

CC

>

+170˚C, All Switches are OFF

Output Diagnostic Information

High Side Drive

www.national.com 8

01102609

Low Side Drive

01102610

FIGURE 1. High-Side vs Low-Side Drive

The LMD18400 combines low voltage CMOS logic control

circuitry with a high voltage DMOS process. Each DMOS

power switch has an individual ON/OFF control input. When

commanded ON, the output of the switch will connect the

load to the V

supply through a maximum resistance of

CC

Applications Information (Continued)

1.3Ω (the ON resistance of the DMOS switch). The voltage

applied to the load will depend upon the load current and the

designed current capability of the LMD18400. When a switch

is commanded OFF, the load will be disconnected from the

supply except for a small leakage current of typically less

than 0.01 µA.

The LMD18400 can be continually connected to a live power

source, a car battery for example, while drawing less than

10 µA from the power source when put into a “sleep” condition. This “sleep” mode is enacted by taking the Enable Input

(pin 3) low. During this mode the supply current for the

device is typically only 0.04 µA. Special low current consumption standby circuitry is used to hold the DMOS

switches OFF to eliminate the possibility of supply voltage

transients from turning on any of the loads (a common

problem with MOS power devices). When in the “sleep”

mode, all diagnostic and logic circuitry is inactive. When the

Enable Input is taken to a logic 1, the switches become

“armed” and ready to respond to their control input after a

short, 30 µs, enable delay time. This delay interval prevents

the switches from transient turn-on. Figure 2 shows the

switch control logic.

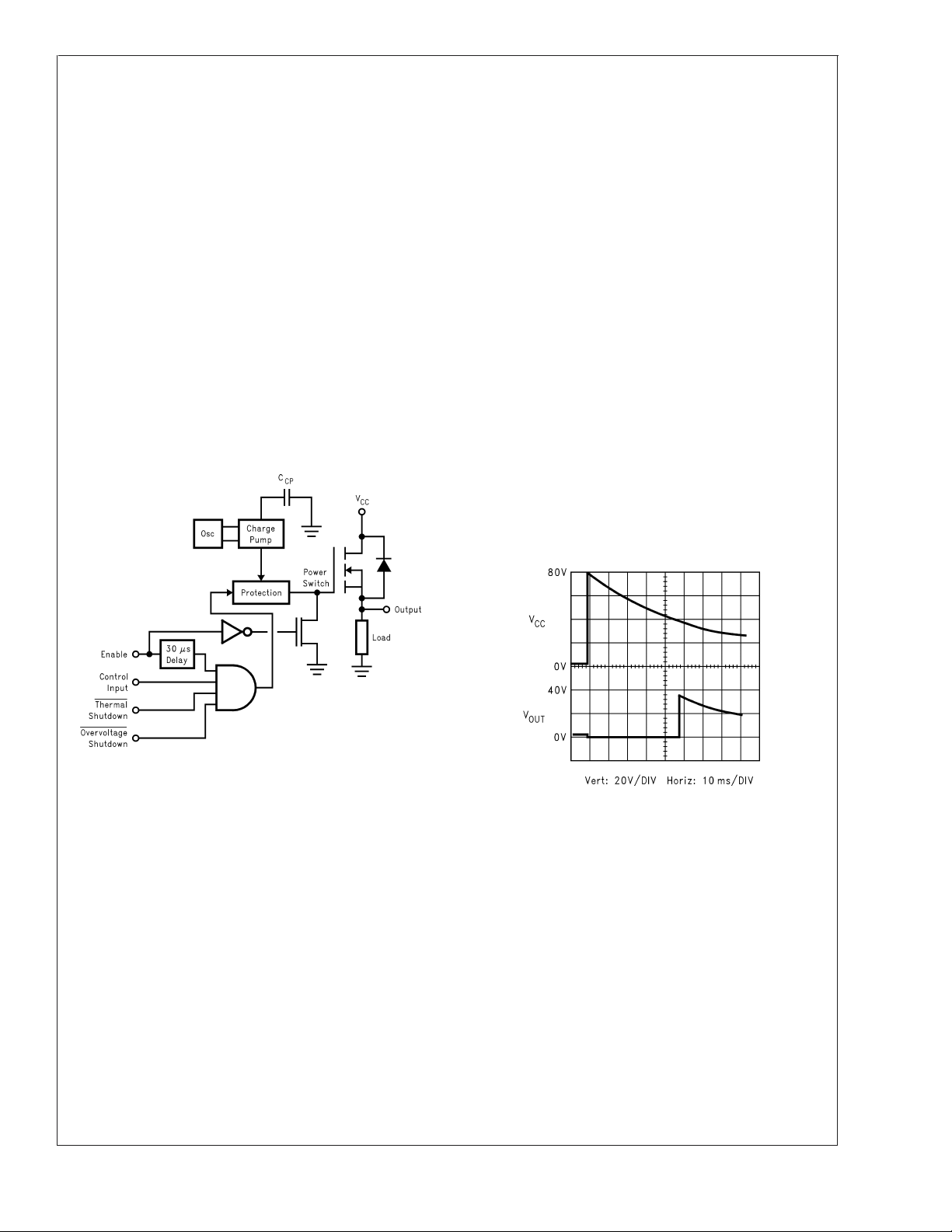

PROTECTION CIRCUITRY

The LMD18400 has extensive protection circuitry built in.

With any power device, protection against excessive voltage, current and temperature conditions is essential. To

achieve a “fail-safe” system implementation, the loads are

deactivated automatically by the LMD18400 in the event of

any detected overvoltage or over-temperature fault conditions.

Voltage Protection

The V

supply can range from −0.5V to +60 VDCwithout

CC

any damage to the LMD18400. The CMOS logic circuitry is

biased from an internal 5.1V regulator which protects these

lower voltage transistors from the higher V

potentials. In

CC

order to protect the loads connected to the switch outputs

however, an overvoltage shutdown circuit is employed.

Should the V

potential exceed 35V all of the switches are

CC

turned OFF thereby disconnecting the loads. This 35V

threshold has 750 mV of hysteresis to prevent potential

oscillations.

Additionally, there is an undervoltage lockout feature built in.

With V

less than 5V it becomes uncertain whether the

CC

logic circuitry can hold the switches in their commanded

state. To avoid this uncertainty, all of the switches are turned

OFF when V

illustrates the shutoff of an output during a 0V to 80V V

drops below approximately 5V. Figure 3

CC

CC

supply transient.

LMD18400

01102611

FIGURE 2. Control Logic for Each Power Switch

Each DMOS switch is turned ON when its gate is driven

approximately 3.5V more positive than its source voltage.

Because the source of the switch is the output terminal to the

load it can be taken to a voltage very near the V

CC

supply

potential. To ensure that there is sufficient voltage available

to drive the gates of the DMOS device a charge pump circuit

is built in. This circuit is controlled by an internal 300 kHz

oscillator and using an external 10 nF capacitor connected

from pin 14 to ground generates a voltage that is approximately 20V greater than the V

supply voltage. This pro-

CC

vides sufficient gate voltage drive for each of the switches

which is applied under command of standard 5V logic input

levels.

The turn-on time for each switch is approximately 12 µs

when driving a 1A load current. This relatively slow switching

time is beneficial in minimizing electromagnetic interference

(EMI) related problems created from switching high current

levels.

Over/Under

Voltage Shutdown

01102612

FIGURE 3. Overvoltage/Undervoltage Shutdown

The LMD18400 has been designed to drive all types of

loads. When driving a ground referenced inductive load such

as a relay or solenoid, the voltage across the load will

reverse in polarity as the field in the inductor collapses when

the power switch is turned OFF. This will pull the output pin

of the LMD18400 below ground. This negative transient

voltage is clamped at approximately −5V to protect the IC.

This clamping action is not done with diodes but rather the

power DMOS switch turning back on momentarily to conduct

the inductor current as it de-energizes as shown in Figure 4.

www.national.com9

Applications Information (Continued)

LMD18400

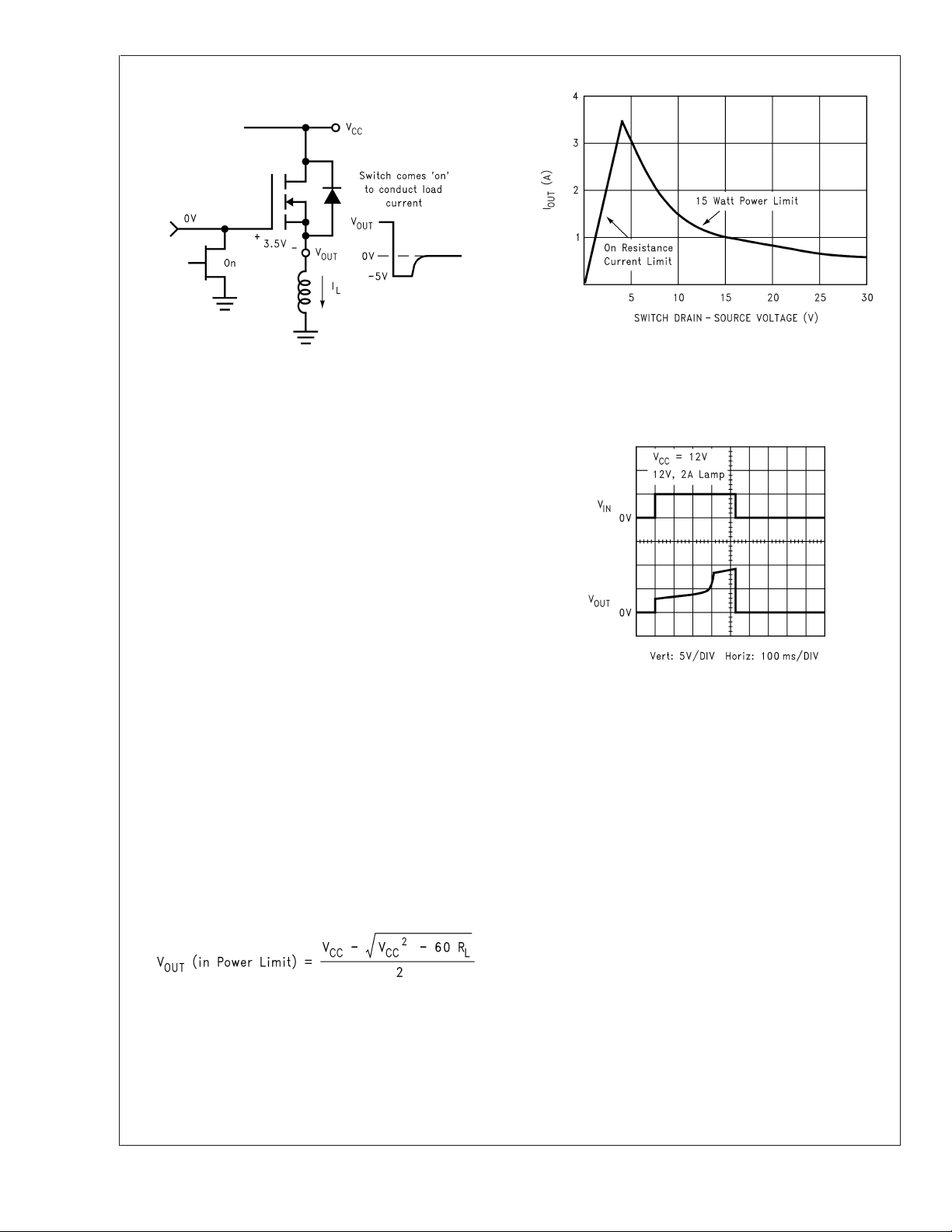

FIGURE 4. Turn-OFF Conditions with an Inductive

Load

01102614

01102613

FIGURE 5. Maximum Output Current with

Instantaneous Power Limiting

When the output inductance produces a negative voltage,

the gate of the DMOS transistor is clamped at 0V. At −3.5V,

the source of the power device is less than the gate by

enough to cause the switch to turn ON again. During this

negative transient condition the power limiting circuitry to

protect the switch is disabled due to the gate being held at

0V. The maximum current during this clamping interval,

which is equal to the steady state ON current through the

inductor, should be kept less than 1A. Another concern

during this interval has to do with the size of an inductive

load and the amount of time required to de-energize it. With

larger inductors it may be possible for the additional power

dissipation to cause the die temperature to exceed the thermal shutdown limit. If this occurs all of the other switches will

turn OFF momentarily (see section on Thermal Management).

Power Limiting

The LMD18400 utilizes a true instantaneous power limit

circuit rather than simple current limiting to protect each

switch. This provides a higher transient current capability

while still maintaining a safe power dissipation level. The

power dissipation in each switch (the product of the Drainto-Source voltage and the output current, V

dsxIOUT

)is

continually monitored and limited to 15W by varying the gate

voltage and therefore the ON resistance of the switch. Basically the ON resistance will be as low as possible until 15W

is being dissipated. To maintain 15W, the ON resistance

increases to reduce the load current. This results in a decrease of the output voltage. For resistive loads, the output

voltage when in power limit will be:

This provides a maximum transient current, and drain-tosource voltage characteristic as shown in Figure 5.

Driving a Lamp

01102615

FIGURE 6. Soft Turn-On of a Lamp Load

The steady state current to the load is limited by the package

power dissipation, ambient temperature and the ON resistance of the switch which has a positive temperature coefficient as shown in the Typical Performance Characteristics.

This dynamic current limiting of the switches is beneficial

when driving lamp and large capacitive loads. Lamps require

a large inrush current, on the order of 10 times the normal

operating current, when first switched on with a cold filament. The LMD18400 will limit this initial current to the level

where 15W is dissipated in the switch. As the filament warms

up the voltage across the lamp increases thereby decreasing the voltage across the switch which permits more current

to fully light the lamp. With limited inrush current the lifetime

of a lamp load is increased significantly. Figure 6 illustrates

the soft turn-on of a lamp load.

The same principle of increasing output current as the voltage across the load increases allows large capacitive loads

to be charged more quickly by an LMD18400 driver than as

opposed to a driver with a fixed 1A current limit protection

scheme. Figure 7 shows the output response while driving a

large capacitive load.

www.national.com 10

Applications Information (Continued)

Thermal Protection

The die temperature of the LMD18400 is continually monitored. Should any conditions cause the die temperature to

rise to +170˚C, all of the power switches are turned OFF

automatically to reduce the power dissipation. It is important

to realize that the thermal shutdown affects all four of the

switches together. That is, if just one switch load is enough to

heat the die to the thermal shutdown threshold, all of the

other switches, regardless of their power dissipation conditions, will be switched OFF. All of the switches will be reenabled when the die temperature has cooled to approximately +160˚C. Until the high temperature forcing conditions

have been removed the switches will cycle ON and OFF thus

maintaining an average die temperature of +165˚C. The

LMD18400 will signal that excessive temperatures exist

through several diagnostic output signals (see Diagnostics).

Driving a Large

Capacitive Load

01102616

FIGURE 7. Driving a Large Capacitive Load

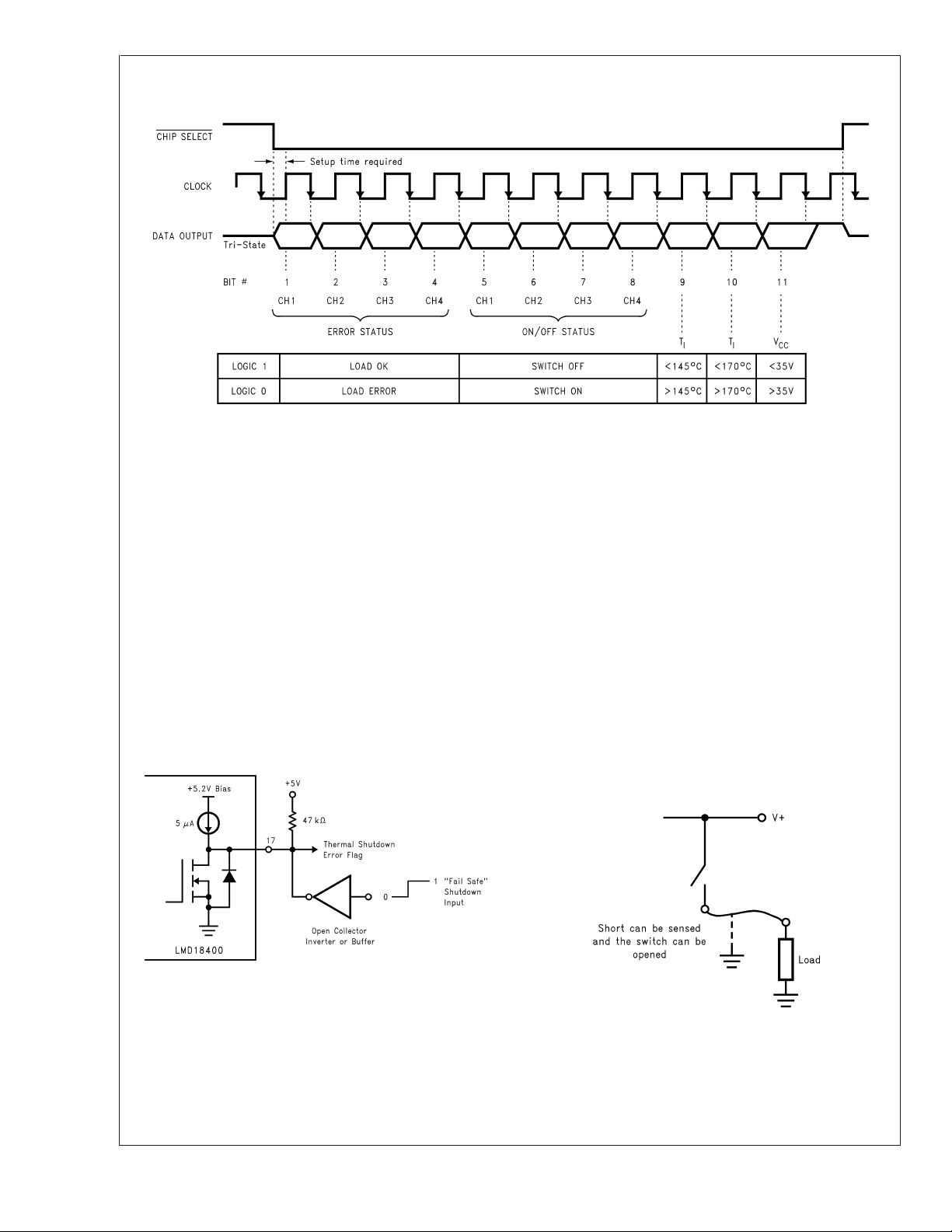

DIAGNOSTICS

The LMD18400 has extensive circuit diagnostic information

reporting capability. Use of this information can produce

systems with intelligent feedback of switch status as well as

load fault conditions for troubleshooting purposes. All of the

diagnostic information is contained in an 11-bit word. This

data can be clocked out of the LMD18400 in a serial fashion

as shown in Figure 8. The shift register is parallel loaded with

the diagnostic data whenever the Chip Select input is at a

Logic 1 and changes to the serial shift mode when Chip

Select is taken to a Logic 0. The Data Output line (pin 8) is

biased internally from a 5.1V regulator which sets the Logic

1 output voltage. This pin has low current sourcing capability

so any load on this pin will reduce the Logic 1 output level

which is guaranteed to be at least 2.4V with a 360 µA load.

The data interface is MICROWIRE compatible in that data is

clocked out of the LMD18400 on the falling edge of the clock,

to be clocked into the controlling microprocessor on the

rising edge. Any number of devices can share a common

data output line because the data output pin is held in a high

impedance (TRI-STATE) condition until the device is se-

lected by taking its Chip Select Input low. Following Chip

Select going low there is a short data setup time interval

(500 ns Min) required. This is necessary to allow the first

data bit of information to be established on the data output

line prior to the first rising clock edge which will input the data

bit into the controller. When all 11 bits of diagnostic data

have been shifted out the data output goes to a Logic 1 level

until the Chip Select line is returned high.

Figure 8 also indicates the significance of the diagnostic data

bits. The first 4 bits indicate an output load error condition,

one for each channel in succession (see Load Error Detec-

tion).

Bits 5 through 8 provide a readback of the commanded

ON/OFF status of each switch.

A unique feature of the LMD18400 is that it provides an early

warning of excessive operating temperature. Should the die

temperature exceed +145˚C, bit 9 will be set to a Logic 0.

Acting on this information a system can be programmed to

take corrective action, shutting OFF specific loads perhaps,

while the LMD18400 is still operating normally (not yet in

thermal shutdown). If this early warning is ignored and the

device continues to rise in temperature, the thermal shut-

down circuitry will come into action at a die temperature of

+170˚C. Should this occur bit 10 of the diagnostic data

stream will be set to a Logic 0 indicating that the device is in

thermal shutdown and all of the outputs have been shut OFF.

The final data bit, bit 11, indicates an overvoltage condition

on the V

indicates that all of the drivers are OFF.

The diagnostic data can be read periodically by a controller

or only in the event of a general system error indication to

determine the cause of any system problem. This general

indication of a fault is provided by an Error Flag output (pin

13). This pin goes low whenever any type of error is de-

tected. There is a built-in delay of approximately 75 µs from

the time an error is detected until pin 13 is taken low. This is

to help mask short duration error conditions such as may be

caused by driving highly capacitive loads (

load may generate a shorted load error for several hundred

milliseconds as it turns on which should be ignored.

supply (VCCis greater than 35V) and again

CC

>

2 µF). A lamp

LMD18400

www.national.com11

Applications Information (Continued)

LMD18400

FIGURE 8. Serial Diagnostic Data Assignments

01102617

The Error Flag output pin is an open drain transistor which

requires a pull-up resistor to a positive voltage of up to 16V.

Typically this pull-up is to the same 5V supply which is

biasing the Enable input and any other external logic circuitry. The Error Flag pins of several LMD18400 packages

can be connected together with just one pull-up resistor to

provide an all-encompassing general system error indication. Upon detection of an error, each device could then be

polled for diagnostic information to determine the source of

the fault condition.

A second direct output error flag is for an indication of

Thermal Shutdown (pin 17). This active low flag provides an

immediate indication that the die temperature has reached

+170˚C and that the drive to all four switches has been

removed. This output is pulled up to the internal 5.1V logic

regulator through a small (5 µA) current source so use of a

buffer on this pin is recommended.

under any sort of externally detected system fault condition.

The diagnostic logic however does not distinguish between

normal thermal shutdown or the fact that pin 17 has been

driven low. As such, various switch errors and an overtemperature indication will be reported in the diagnostic data

stream.

Figure 9 illustrates the use of pin 17 as both an output

thermal shutdown flag and as an input to shut down only the

switches. Directly tying pin 17 to +5V will prevent the internal

thermal shutdown circuitry from disabling the switches. For

reliability purposes however this is not recommended as

there will then be no limit to the maximum die temperature.

Refer to the Truth Table for a summary of the action of these

direct-output error flags.

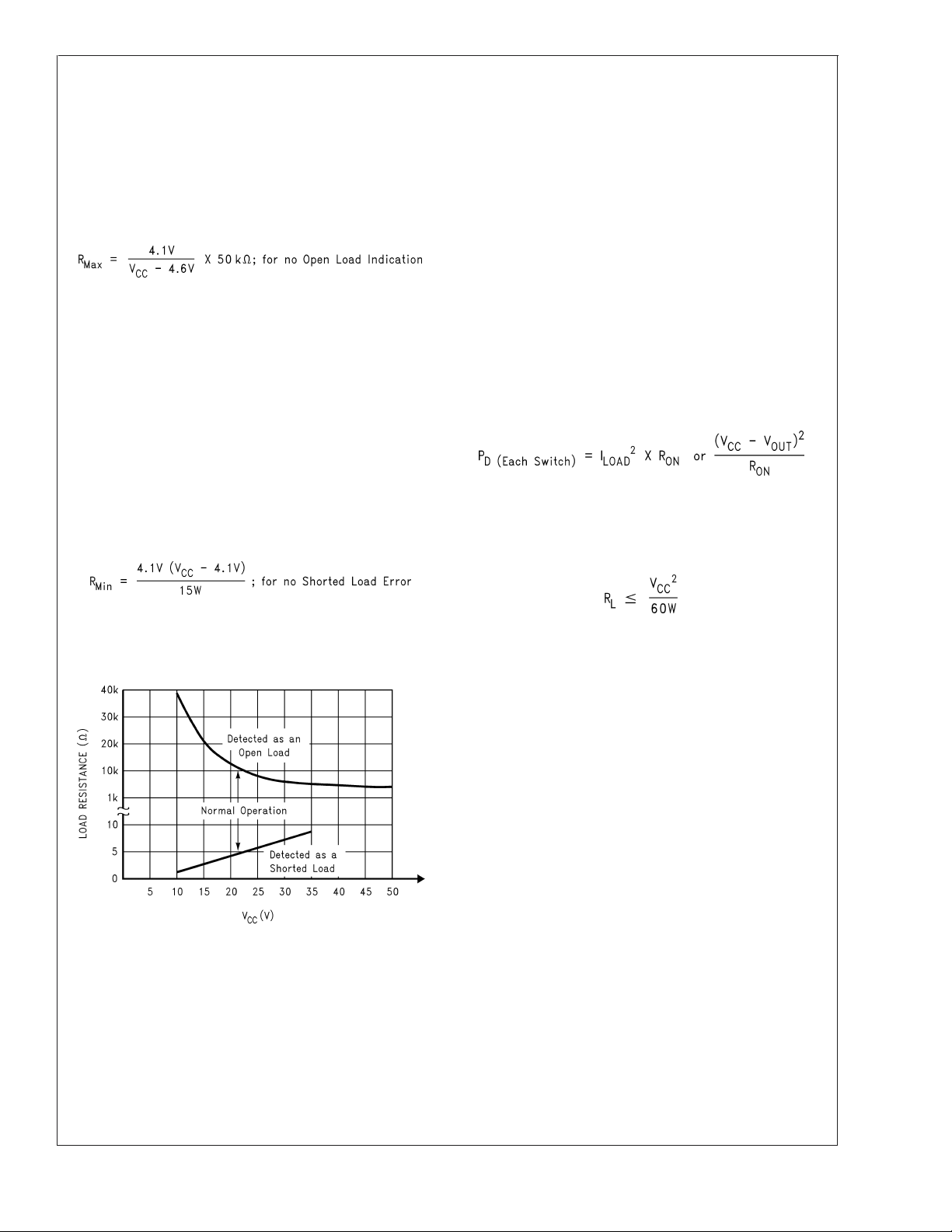

LOAD ERROR DETECTION

An important feature of the LMD18400 is the ability to detect

open or shorted load connections. Figure 10 illustrates the

detection circuit used with each of the drivers.

01102618

FIGURE 9. Thermal Shutdown Flag and Shutdown

Input

A useful feature of pin 17 is that it can also be used as a

shutdown input. Driving this pin low immediately switches all

of the drivers OFF, just the same as if thermal shutdown

temperatures has been reached, yet all of the control logic

and diagnostic circuits remain active. This is useful in designing “fail-safe” systems where the loads can be disabled

www.national.com 12

01102609

FIGURE 10. Detection Circuitry for Open/Shorted

Loads

A voltage comparator monitors the voltage to the load and

compares it to a fixed 4.1V reference level. When a switch is

OFF, the ground referenced load should have no voltage

LMD18400

Applications Information (Continued)

across it. Under this condition, an internal 50 kΩ resistor

connected to V

the load. If the load resistance is large enough to create a

voltage greater than 4.1V an Open Load Error will be indicated for that switch. The maximum load resistance that will

not generate an Open Load Error when a switch is OFF can

be found by:

To make this Open Load Error threshold more sensible, an

external pull-up resistor can be added from the output to the

supply.

V

CC

Also when a switch is commanded OFF, should the load be

shorted to the V

indicate an error.

When a switch is commanded ON, the load is expected to

have a voltage across it that approaches the V

the output voltage is less than the 4.1V threshold an error will

again be reported, indicating that the load is either shorted to

ground or that the driver is in power limit and not able to pull

the output voltage any closer to V

resistance that will not generate a Shorted Load Error when

a switch is ON can be found by:

will provide a small amount of current to

CC

supply, this same circuitry will again

CC

potential. If

CC

. The minimum load

CC

THERMAL MANAGEMENT

It is particularly important to consider the total amount of

power being dissipated by all four switches in the LMD18400

at all times. Any combination of the switches driving loads

will cause an increase in the die temperature. Should the die

temperature reach the thermal shutdown threshold of

+170˚C, all of the switches will be disabled.

Careful calculation of the worst case total power dissipation

required at any point in time, together with providing suffi-

cient heatsinking will prevent this from occurring.

The LMD18400 is packaged with a special leadframe that

helps dissipate heat through the two ground pins on each

side of the package. The thermal resistance from junction-

to-case (θ

thermal resistance from junction-to-ambient (θ

) for this package is approximately 20˚C/W. The

JC

), without

JA

any heatsinking, is approximately 60˚C/W. Figure 12 illus-

trates how the copper foil of a printed circuit board can be

designed to provide heatsinking and reduce the overall

junction-to-ambient thermal resistance.

The power dissipation in each switch is equal to:

where RONis the ON resistance of the switch (1.3Ω maxi-

mum). These equations hold true until the power dissipation

reaches the maximum limit of 15W. With resistive loads, the

15W power limit threshold will be reached when:

Figure 11 indicates the range of load resistance for normal

operation, open load, and shorted load or power limit indication.

01102620

FIGURE 11. Load Resistance Detected as Errors

Inductive loads will create additional power dissipation when

switched OFF. Figure 13 shows the idealized voltage and

current waveforms for an inductive load.

www.national.com13

Applications Information (Continued)

LMD18400

Maximum Power Dissipated

and Junction to Ambient

Thermal Resistance vs Size

01102622

01102621

FIGURE 12. Recommended PC Board Layout to Reduce the Thermal Resistance from Junction-to-Ambient

for the time interval, t

. which is the time required for the

CLAMP

inductor current to fall to zero:

01102623

FIGURE 13. Switching an Inductive Load

When switched ON, the worst case power dissipation is:

The steady-state ON current of the inductor should be kept

less than 1A per power switch.

The additional power dissipation during turn-off, as the inductor is de-energized and the voltage across the inductor is

clamped to −5V, can be found by:

The size of the inductor will determine the time duration for

this additional power dissipation interval. Even though the

peak current is kept less than 1A, the switch during this

interval will see a voltage across it of V

+ 5V with no power

CC

limit protection. If the inductor is too large, the time interval

may be long enough to heat the die temperature to +170˚C

thereby shutting OFF all other loads on the package.

The total average power dissipation during a full ON/OFF

switching cycle of an inductive load will be:

Due to the common cut-off of all loads forced by thermal

shutdown, the thermal time constants of the package become a concern. Figure 14 provides an indication of the time

it takes to heat the die to thermal shutdown with a step

increase in package power dissipation from an initial junction

temperature of +25˚C. This data was measured using a PC

board layout providing a thermal resistance from junction to

ambient of approximately 35˚C/W. Less heatsinking will, of

course, result in faster thermal shutdown of the power

switches.

www.national.com 14

Applications Information (Continued)

01102624

FIGURE 14. Approximate time required for the die to reach the 170˚C thermal shutdown point from 25˚C for different

total package power dissipation levels.

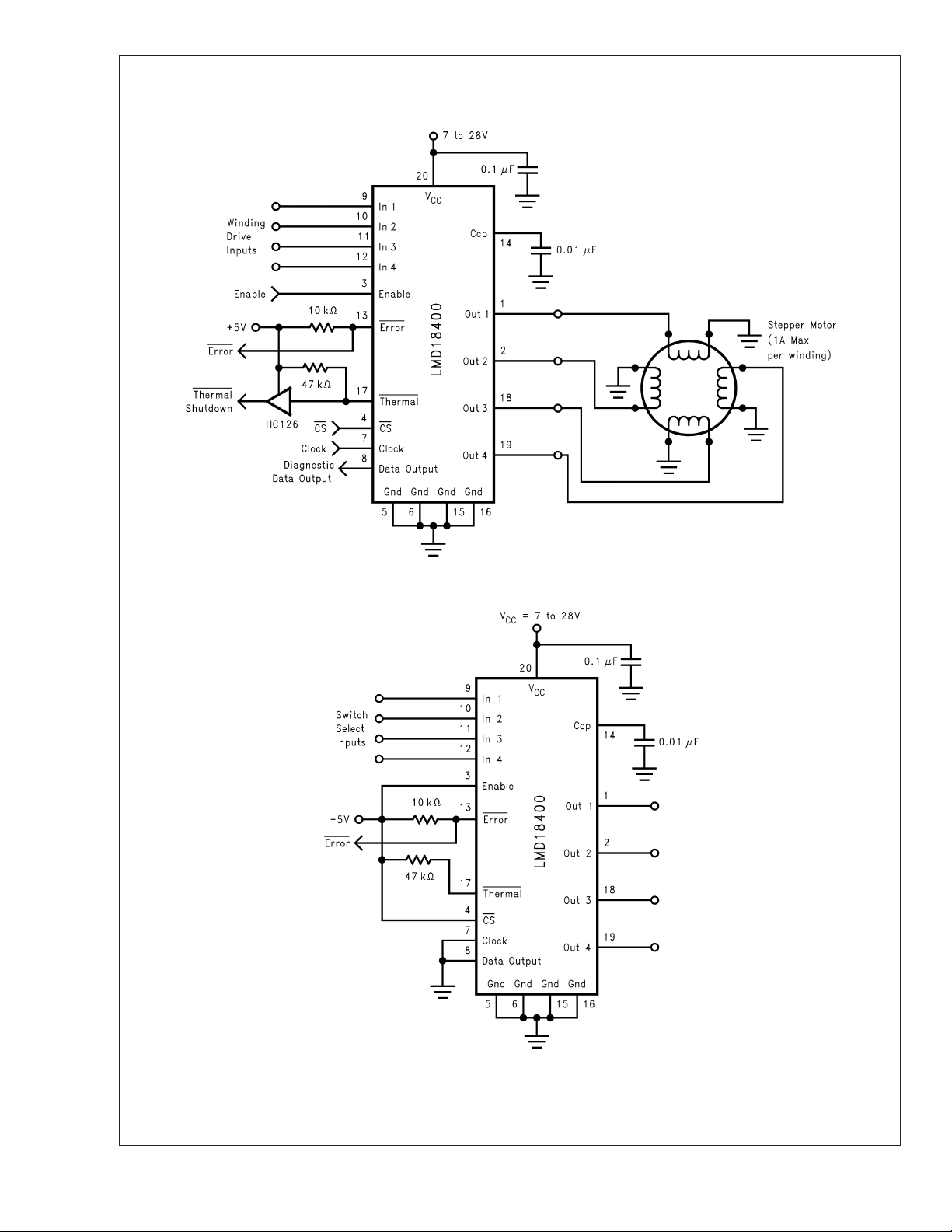

ON/OFF Switching of Multiple Voltage Regulated Circuit Loads

LMD18400

www.national.com15

01102625

Applications Information (Continued)

LMD18400

Unipolar Drive for a 4-Phase Stepper Motor

01102626

Recommended Connection If No Diagnostics are Required

www.national.com 16

01102627

Applications Information (Continued)

Simple protection of the LMD18400 against supply voltage reversal. Loads will be energized through the intrinsic

diodes in parallel with the power switches. The Schottky diode will add approximately 0.2V to the logic input

switching thresholds and the logic output low levels.

LMD18400

Simple Light “Chaser”

01102628

01102629

www.national.com17

Applications Information (Continued)

LMD18400

Paralleling switches for higher current capability. Positive temperature coefficient of the switch ON resistance

provides ballasting to evenly share the load current between the switches. Any combination of switches can be

paralleled. Required peak load current will depend upon the motor load. Motor speed control can be provided by a

PWM signal of up to 20 kHz applied to the motor drive input lines.

01102630

www.national.com 18

Physical Dimensions inches (millimeters) unless otherwise noted

Order Number LMD18400N

NS Package Number N20A

LMD18400 Quad High Side Driver

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

labeling, can be reasonably expected to result in a

significant injury to the user.

BANNED SUBSTANCE COMPLIANCE

National Semiconductor certifies that the products and packing materials meet the provisions of the Customer Products

Stewardship Specification (CSP-9-111C2) and the Banned Substances and Materials of Interest Specification

(CSP-9-111S2) and contain no ‘‘Banned Substances’’ as defined in CSP-9-111S2.

National Semiconductor

Americas Customer

Support Center

Email: new.feedback@nsc.com

Tel: 1-800-272-9959

www.national.com

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

National Semiconductor

Europe Customer Support Center

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Support Center

Email: ap.support@nsc.com

National Semiconductor

Japan Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

Loading...

Loading...