查询LM70供应商

LM70

LM70 SPI/MICROWIRE10-Bit plus Sign Digital Temperature Sensor

July 2000

SPI/MICROWIRE

™

10-Bit plus Sign Digital Temperature

Sensor

General Description

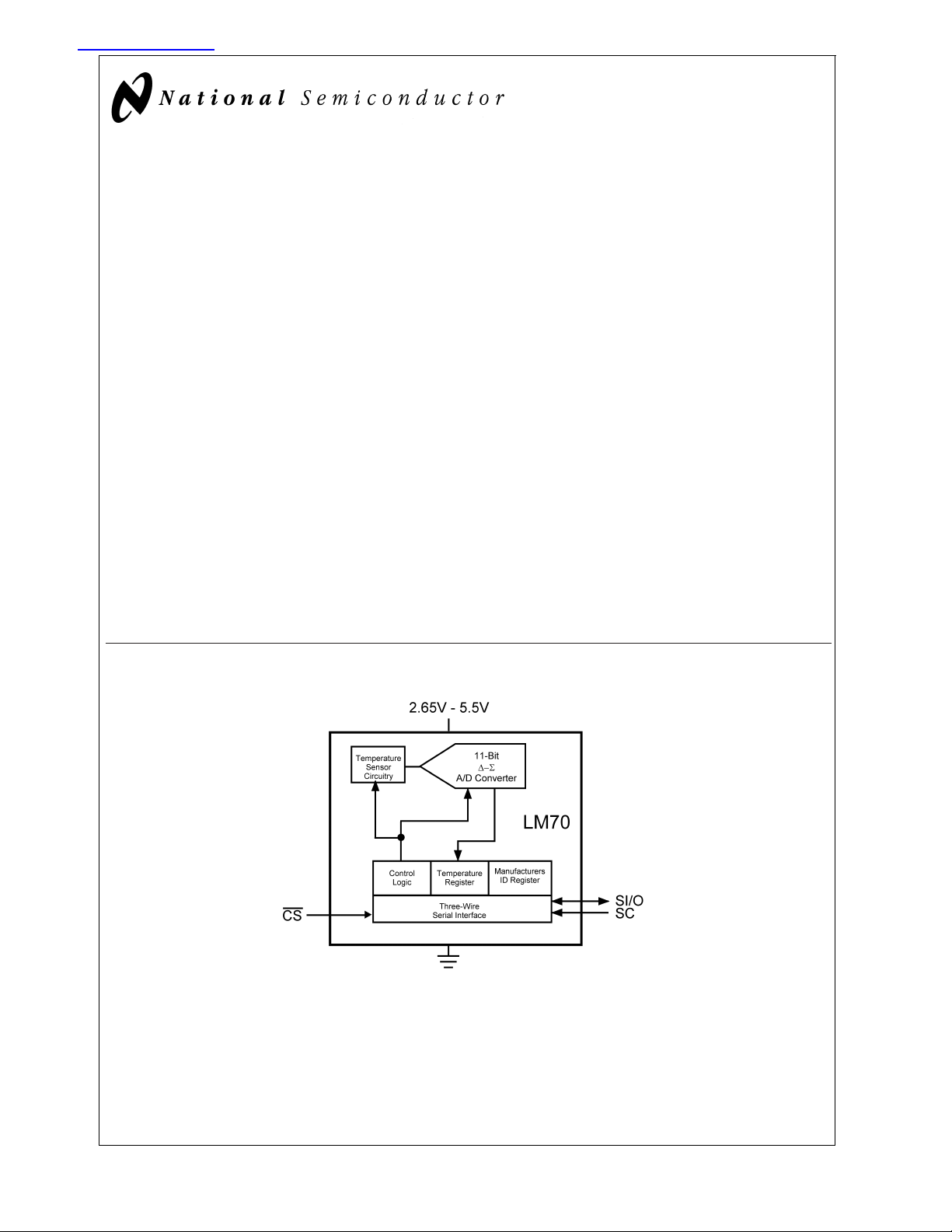

The LM70 is a temperature sensor, Delta-Sigma

analog-to-digital converter with an SPI and MICROWIRE

compatible interface available in LLP and MSOP 8-pin packages. The host can query the LM70 at any time to read temperature. A shutdown mode decreases power consumption

to less than10µA. This mode is useful in systems where low

average power consumption is critical.

The LM70 has 10-bit plus sign temperature resolution

(0.25˚C per LSB) while operating over a temperature range

of −55˚C to +150˚C.

The LM70’s 2.65V to 5.5V supply voltage range, low supply

current and simple SPI interface make it ideal for a wide

range of applications. These include thermal management

and protection applications in hard disk drives, printers, electronic test equipment, and office electronics.

Applications

n System Thermal Management

n Personal Computers

n Disk Drives

n Office Electronics

n Electronic Test Equipment

Features

n 0.25˚C temperature resolution.

n Shutdown mode conserves power between temperature

reading

n SPI and MICROWIRE Bus interface

n MSOP-8 and LLP-8 packages save space

Key Specifications

j

Supply Voltage 2.65V to 5.5V

j

Supply Current operating 260µA (typ)

490µA (max)

shutdown 12µA (typ)

j

Temperature

Accuracy

−40˚C to 85˚C

−10˚C to 65˚C +1.5/−2˚C(max)

−55˚C to 125˚C +3/−2˚C(max)

−55˚C to 150˚C +3.5/−2˚C(max)

±

2˚C(max)

Simplified Block Diagram

DS101223-1

MICROWIRE®is a registered trademark of National Semiconductor Corporation.

© 2000 National Semiconductor Corporation DS101223 www.national.com

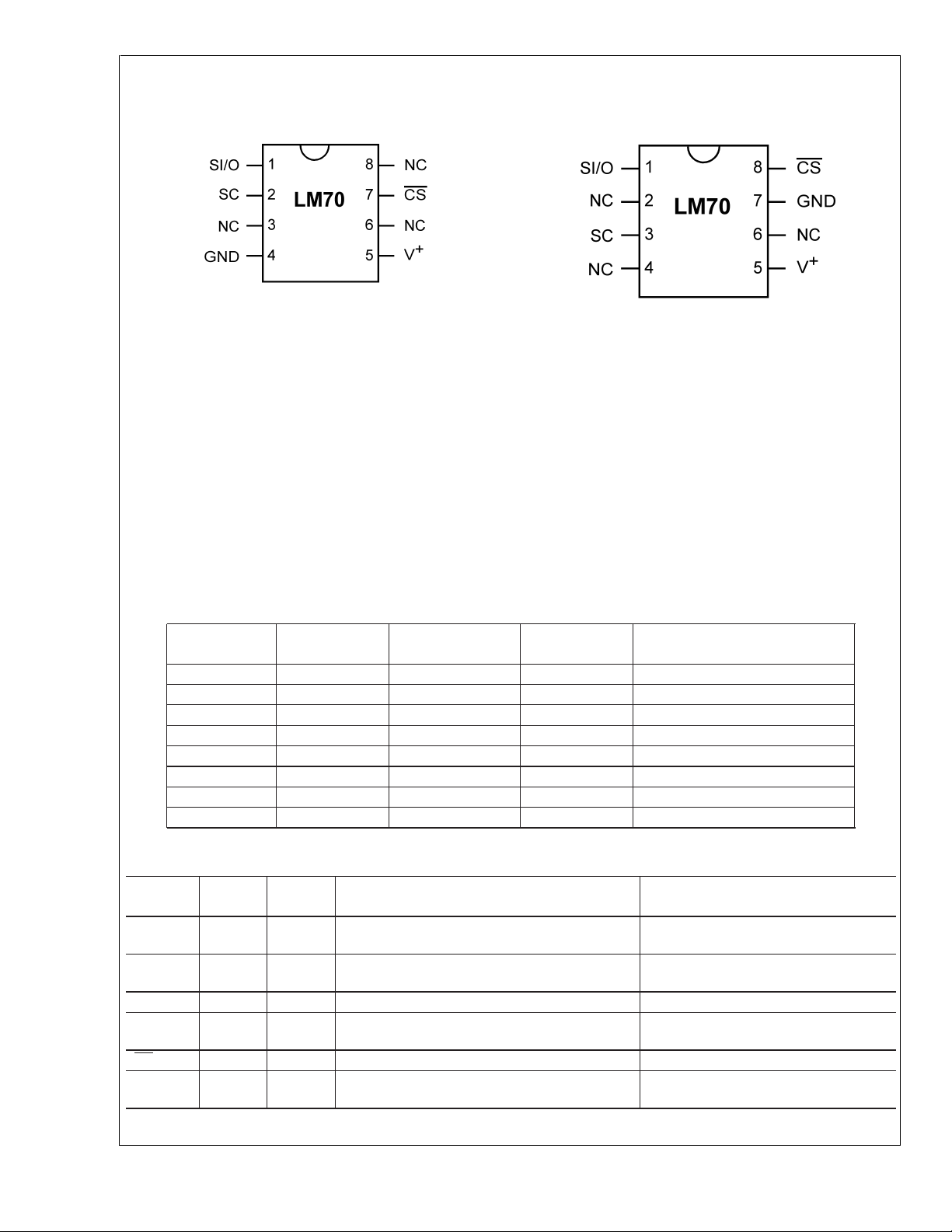

Connection Diagrams

LM70

MSOP-8

DS101223-2

TOP VIEW

NS Package Number MUA08A

LLP-8

DS101223-25

TOP VIEW

NS Package Number LDA08A

Ordering Information

Order Number

LM70CILD-3 T33 LLP-8, LDA08A 2.65V to 3.6V _ Units in Rail

LM70CILDX-3 T33 LLP-8, LDA08A 2.65V to 3.6V _ Units in Rail

LM70CILD-5 T35 LLP-8, LDA08A 4.5V to 5.5V _ Units in Tape and Reel

LM70CILDX-5 T35 LLP-8, LDA08A 4.5V to 5.5V _ Units in Tape and Reel

LM70CIMM-3 T04C MSOP-8, MUA08A 2.65V to 3.6V 250 Units in Rail

LM70CIMMX-3 T04C MSOP-8, MUA08A 2.65V to 3.6V 3500 Units in Tape and Reel

LM70CIMM-5 T03C MSOP-8, MUA08A 4.5V to 5.5V 250 Units in Rail

LM70CIMMX-5 T03C MSOP-8, MUA08A 4.5V to 5.5V 3500 Units in Tape and Reel

Package

Marking

NS Package

Number

Supply Voltage Transport Media

Pin Descriptions

Label SOP-8

Pin

SI/O 1 1 Input/Output - Serial bus bi-directional data

SC 2 3 Clock - Serial bus clock Schmitt trigger input

GND 4 7 Power Supply Ground Ground

+

V

CS

NC 3, 6, 8 2, 4, 6 No Connect These pins are not connected to the

5 5 Positive Supply Voltage Input DC Voltage from 2.65V to 5.5V. Bypass

7 8 Chip Select input. From Controller

LLP-8

#

Pin

#

line. Schmitt trigger input.

line.

Function Typical Connection

From and to Controller

From Controller

with a 0.1 µF ceramic capacitor.

LM70 die in any way.

www.national.com 2

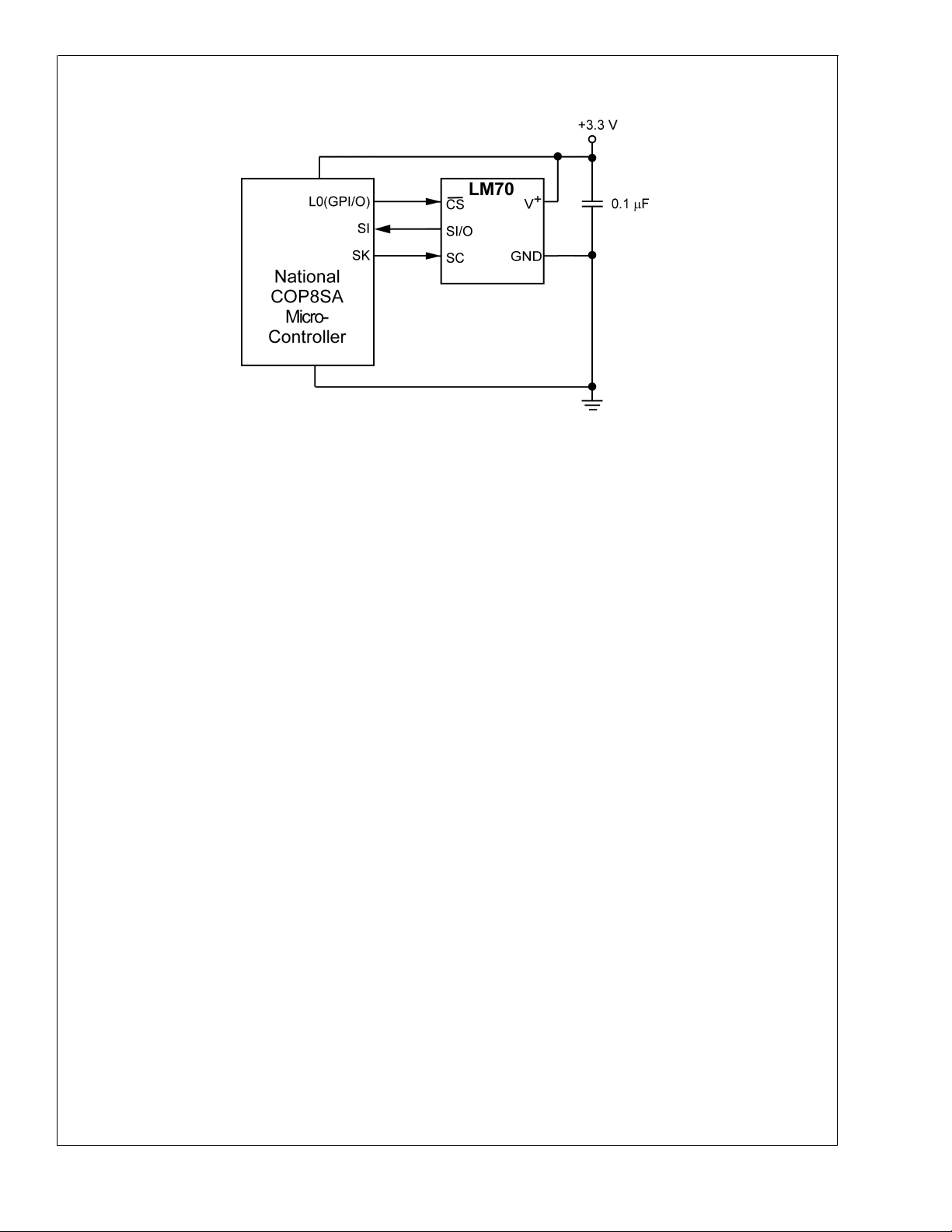

Typical Application

LM70

DS101223-3

FIGURE 1. COP Microcontroller Interface

www.national.com3

Absolute Maximum Ratings (Note 1)

LM70

Supply Voltage −0.3V to 6.0V

Voltage at any Pin −0.3V to V

Input Current at any Pin (Note 2) 5 mA

Package Input Current (Note 2) 20 mA

Storage Temperature −65˚C to +150˚C

Soldering Information, Lead Temperature

MSOP-8 and LLP-8 Packages

+

+ 0.3V

ESD Susceptibility (Note 4)

Human Body Model 3000V

Machine Model 300V

Operating Ratings

Specified Temperature Range T

(Note 5) −55˚C to +150˚C

Supply Voltage Range (+V

) +2.65V to +5.5V

S

(Note 3)

Vapor Phase (60 seconds)

Infrared (15 seconds)

215˚C

220˚C

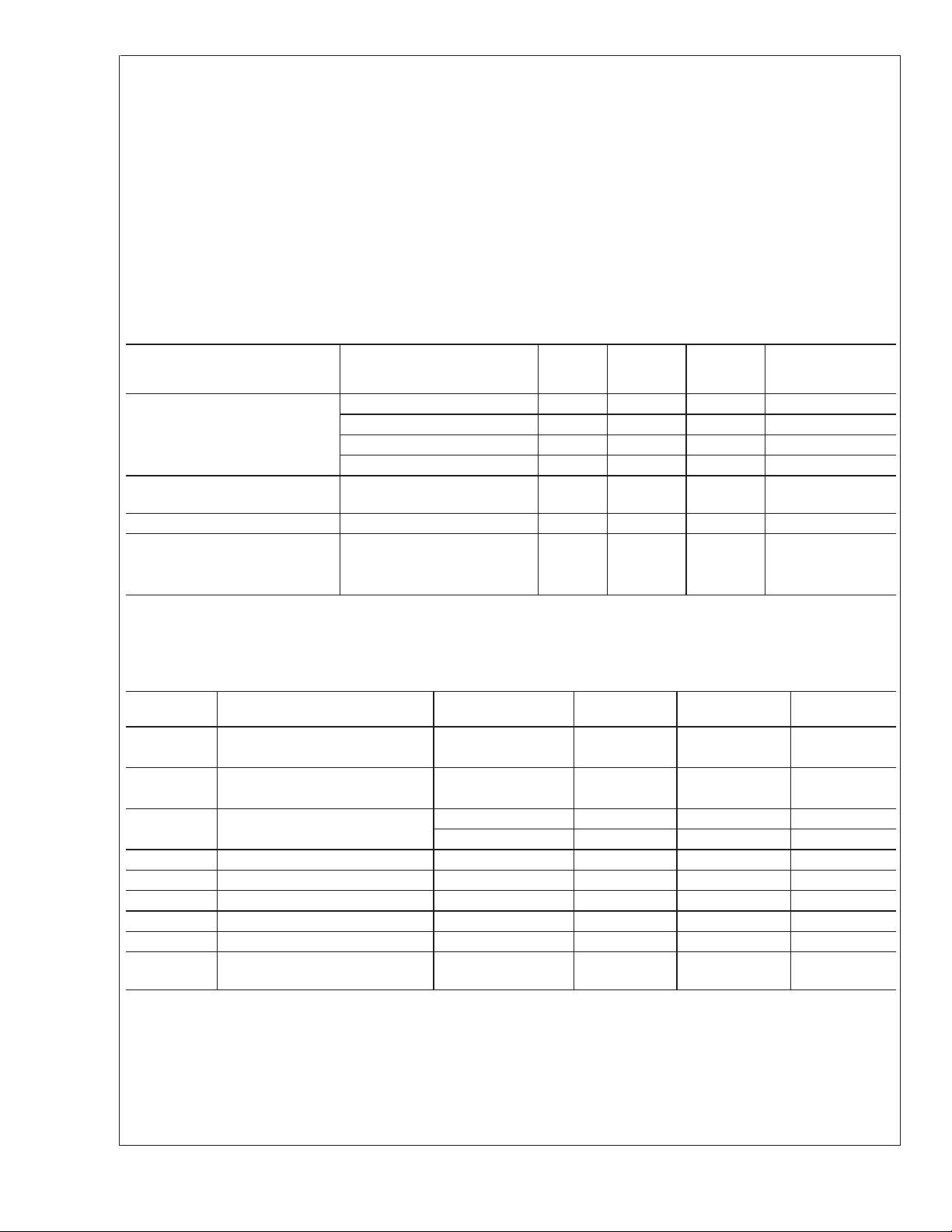

Temperature-to-Digital Converter Characteristics

Unless otherwise noted, these specifications apply for V+= 2.65V to 3.6V for the LM70-3 and V+= 4.5V to 5.5V for the LM70-5

(Note 6). Boldface limits apply for TA=TJ=T

Parameter Conditions

Temperature Error (Note 6) T

= −10˚C to +65˚C +1.5/−2.0 +1.5/−2.0 ˚C (max)

A

T

= −40˚C to +85˚C

A

T

= −55˚C to +125˚C +3.0/−2.0 +3.0/−2.0 ˚C (max)

A

T

= −55˚C to +150˚C +3.5/−2.0 +3.5/−2.0 ˚C (max)

A

Resolution 11

Temperature Conversion Time (Note 9) 140 210 210 ms (max)

Quiescent Current Serial Bus Inactive 260 490 490 µA (max)

Serial Bus Active 260 µA

Shutdown Mode 12 µA

MIN

to T

; all other limits TA=TJ=+25˚C, unless otherwise noted.

MAX

Typical

(Note 7)

LM70-5

Limits

(Note 8)

±

2.0

LM70-3

Limits

(Note 8)

±

2.0 ˚C (max)

0.25

(Limit)

MIN

Units

Bits

˚C

to T

MAX

Logic Electrical Characteristics

DIGITAL DC CHARACTERISTICS

Unless otherwise noted, these specifications apply for V+= 2.65V to 3.6V for the LM70-3 and V+= 4.5V to 5.5V for the

LM70-5. Boldface limits apply for T

A=TJ=TMIN

Symbol Parameter Conditions

V

IN(1)

V

IN(0)

Logical “1” Input Voltage V+x 0.7 V (min)

Logical “0” Input Voltage −0.3 V (min)

Input Hysteresis Voltage V

I

IN(1)

I

IN(0)

C

IN

V

OH

V

OL

I

O_TRI-STATE

Logical “1” Input Current VIN=V

Logical “0” Input Current VIN= 0V −0.005 −3.0 µA (min)

All Digital Inputs 20 pF

High Level Output Voltage IOH= −400 µA 2.4 V (min)

Low Level Output Voltage IOL=+2mA 0.4 V (max)

TRI-STATE Output Leakage

Current

to T

V

VO= GND

V

; all other limits TA=TJ=+25˚C, unless otherwise noted.

MAX

Typical

(Note 7)

+

= 2.65V to 3.6V 0.8 0.27 V (min)

+

= 4.5V to 5.5V 0.8 0.35 V (min)

O

=V

+

+

0.005 3.0 µA (max)

Limits

(Note 8)

+

V

+ 0.3 V (max)

+

V

x 0.3 V (max)

−1

+1

Units

(Limit)

µA (min)

µA(max)

www.national.com 4

Logic Electrical Characteristics (Continued)

SERIAL BUS DIGITAL SWITCHING CHARACTERISTICS

Unless otherwise noted, these specifications apply for V+= 2.65V to 3.6V for the LM70-3 and V+= 4.5V to 5.5V for the

LM70-5, C

T

MIN

Symbol Parameter Conditions

t

1

t

2

t

3

t

4

t

5

t

6

t

7

(load capacitance) on output lines = 100 pF unless otherwise specified. Boldface limits apply for TA=TJ=

L

to T

; all other limits TA=TJ= +25˚C, unless otherwise noted.

MAX

Typical

(Note 7)

Limits

(Note 8)

SC (Clock) Period 0.16

DC

CS Low to SC (Clock) High Set-Up Time 100 ns (max)

CS Low to Data Out (SO) Delay 70 ns (max)

SC (Clock) Low to Data Out (SO) Delay 70 ns (max)

CS High to Data Out (SO) TRI-STATE 200 ns (min)

SC (Clock) High to Data In (SI) Hold Time 60 ns (min)

Data In (SI) Set-Up Time to SC (Clock) High 30 ns (min)

LM70

Units

(Limit)

µs (min)

(max)

FIGURE 2. Data Output Timing Diagram

FIGURE 3. TRI-STATE Data Output Timing Diagram

DS101223-4

DS101223-5

FIGURE 4. Data Input Timing Diagram

DS101223-6

www.national.com5

Logic Electrical Characteristics (Continued)

LM70

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur.DC andAC electrical specifications do not apply when operating

the device beyond its rated operating conditions.

Note 2: When the input voltage (V

maximum package input current rating limits the number of pins that can safely exceed the power supplies with an input current of 5 mA to four.

Note 3: See AN-450 “Surface Mounting Methods and Their Effect on Product Reliability” or the section titled “Surface Mount” found in a current National Semicon-

ductor Linear Data Book for other methods of soldering surface mount devices.

Note 4: Human body model, 100 pF discharged through a 1.5 kΩ resistor. Machine model, 200 pF discharged directly into each pin.

Note 5: The life expectancy of the LM70 will be reduced when operating at elevated temperatures. LM70 θ

tached to a printed circuit board with 2 oz. foil is summarized in the table below:

) at any pin exceeds the power supplies (V

I

Device Number

<

GND or V

I

NS Package

Number

>

+VS) the current at that pin should be limited to 5 mA. The 20 mA

I

(thermal resistance, junction-to-ambient) when at-

JA

Thermal

Resistance (θ

)

JA

LM70CILD LDA08A 51.3˚C/W

LM70CIMM MUA08A 200˚C/W

Note 6: Both part numbers of the LM70 will operate properly over the V+supply voltage range of 2.65V to 5.5V. The temperature error for temperature ranges of

−10˚C to +65˚C, −40˚C to +85˚C, −55˚C to +125˚C and −55˚C to +150˚C include error induced by power supply variation of

ture error will increase by

Note 7: Typicals are at T

Note 8: Limits are guaranteed to National’s AOQL (Average Outgoing Quality Level).

Note 9: This specification is provided only to indicate how often temperature data is updated. The LM70 can be read at any time without regard to conversion state

(and will yield last conversion result). A conversion in progress will not be interrupted. The output shift register will be updated at the completion of the read and a

new conversion restarted.

Note 10: For best accuracy,minimize output loading. Higher sink currents can affect sensor accuracy with internal heating. This can cause an error of 0.64˚C at full

rated sink current and saturation voltage based on junction-to-ambient thermal resistance.

±

0.3˚C for a power supply voltage (V+) variation of±10% from the nominal value.

= 25˚C and represent most likely parametric norm.

A

±

5% from the nominal value. Tempera-

www.national.com 6

Electrical Characteristics

FIGURE 5. Temperature-to-Digital Transfer Function (Non-linear scale for clarity)

LM70

DS101223-8

TRI-STATE Test Circuit

DS101223-7

www.national.com7

Typical Performance Characteristics

LM70

Average Power-On Reset Voltage

vs Temperature

Static Supply Current vs

Temperature

Temperature Error

DS101223-23

1.0 Functional Description

The LM70 temperature sensor incorporates a band-gap type

temperature sensor and 10-bit plus sign ∆Σ ADC

(Delta-Sigma Analog-to-Digital Converter). Compatibility of

the LM70’s three wire serial interface with SPI and MICROWIRE allows simple communications with common microcontrollers and processors. Shutdown mode can be used

to optimize current drain for different applications. A manufacture’s ID register identifies the LM70 as National Semiconductor product.

1.1 POWER UP AND POWER DOWN

The LM70 always powers up in a known state. The power up

default condition is continuous conversion mode. Immediatly

after power up the LM70 will output an erroneous code until

the first temperature conversion has completed.

When the supply voltage is less than about 1.6V (typical),

the LM70 is considered powered down. As the supply voltage rises above the nominal 1.6V power up threshold, the internal registers are reset to the power up default state described above.

1.2 SERIAL BUS INTERFACE

The LM70 operates as a slave and is compatible with SPI or

MICROWIRE bus specifications. Data is clocked out on the

falling edge of the serial clock (SC), while data is clocked in

on the rising edge of SC. A complete transmit/receive communication will consist of 32 serial clocks. The first 16 clocks

comprise the transmit phase of communication, while the

second 16 clocks are the receive phase.

When CS is high SI/O will be in TRISTATE

should be initiated by taking chip select (CS) low. This

should not be done when SC is changing from a low to high

state. Once CS is low the serial I/O pin (SI/O) will transmit

the first bit of data. The master can then read this bit with the

rising edge of SC. The remainder of the data will be clocked

out by the falling edge of SC. Once the 14 bits of data (one

sign bit, ten temperature bits and 3 high bits) are transmitted

the SI/O line will go into TRI-STATE. CS can be taken high at

any time during the transmit phase. If CS is brought low in

the middle of a conversion the LM70 will complete the conversion and the output shift register will be updated after CS

is brought back high.

The receive phase of a communication starts after 16 SC periods. CS can remain low for 32 SC cycles. The LM70 will

read the data available on the SI/O line on the rising edge of

the serial clock. Input data is to an 8-bit shift register. The

®

. Communication

DS101223-21

part will detect the last eight bits shifted into the register.The

receive phase can last up to 16 SC periods.All ones must be

shifted in order to place the part into shutdown. A zero in any

location will take the LM70 out of shutdown. The following

codes only should be transmitted to the LM70:

00 hex (normal operation)

•

01 hex (normal operation)

•

03 hex (normal operation)

•

07 hex (normal operation)

•

0F hex (normal operation)

•

1F hex (normal operation)

•

3F hex(normal operation)

•

7F hex(normal operation)

•

FF hex (Shutdown, transmit manufacturer’s ID)

•

.

any others may place the part into a Test Mode. Test Modes

are used by National Semiconductor to thoroughly test the

function of the LM70 during production testing. Only eight

bits have been defined above since only the last eight transmitted, before CS is taken HIGH, are detected by the LM70

The following communication can be used to determine the

Manufacturer’s/Device ID and then immediately place the

part into continuous conversion mode. With CS continuously

low:

Read 16 bits of temperature data

•

Write 16 bits of data commanding shutdown

•

Read 16 bits of Manufacture’s/Device ID data

•

Write 8 to 16 bits of data commanding Conversion Mode

•

Take CS HIGH.

•

Note that 250 ms will have to pass for a conversion to complete before the LM70 actually transmits temperature data.

DS101223-22

www.national.com 8

1.0 Functional Description (Continued)

1.3 TEMPERATURE DATA FORMAT

Temperature data is represented by a 11-bit, two’s complement word with an LSB (Least Significant Bit) equal to

0.25˚C:

Temperature Digital Output

Binary Hex

+150˚C 0100 1011 0001 1111 4B 1Fh

+125˚C 0011 1110 1001 1111 3E 9Fh

+25˚C 0000 1100 1001 1111 0B 9Fh

+0.25˚C 0000 0000 0011 1111 00 3Fh

0˚C 0000 0000 0001 1111 00 1Fh

−0.25˚C 1111 1111 1111 1111 FF FFh

−25˚C 1111 0011 1001 1111 F3 9Fh

−55˚C 1110 0100 1001 1111 E4 9Fh

1.5 INTERNAL REGISTER STRUCTURE

The LM70 has three registers, the temperature register, the configuration register and the manufacturer’s/device identification

register.The temperature and manufacturer’s/device identification registers are read only. The configuration register is write only.

1.5.1 CONFIGURATION REGISTER

(Selects shutdown or continuous conversion modes):

Note: The last two bits are TRI-STATE and depicted as one

in the table.

The first data byte is the most significant byte with most significant bit first, permitting only as much data as necessary to

be read to determine temperature condition. For instance, if

the first four bits of the temperature data indicate an overtemperature condition, the host processor could immediately

take action to remedy the excessive temperatures.

1.4 SHUTDOWN MODE/MANUFACTURER’S ID

Shutdown mode is enabled by writing XX FF to the LM70 as

shown in

bus is still active when the LM70 is in shutdown. Current

draw drops to less than 10 µA between serial communications. When in shutdown mode the LM70 always will output

1000 0001 0000 00XX. This is the manufacturer’s ID/Device

ID information. The first 5-bits of the field (1000 0XXX) are

reserved for manufacturer’s ID.

Figure 7

c and discussed in Section 1.2. The serial

LM70

(Write Only):

D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

XXXXXXXX Shutdown

D0-D15 set to XX FF hex enables shutdown mode.

D0-D15 set to XX 00 hex enables continuous conversion mode.

Note: setting D0-D15 to any other values may place the LM70 into a manufacturer’s test mode, upon which the LM70 will stop

responding as described. These test modes are to be used for National Semiconductor production testing only. See Section 1.2

Serial Bus Interface for a complete discussion.

1.5.2 TEMPERATURE REGISTER

(Read Only):

D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

MSB Bit 9 Bit 8 Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 LSB 1 1 1 X X

D0–D1: Undefined. TRI-STATE will be output on SI/0.

D2–D4: Always set high.

D5–D15: Temperature Data. One LSB = 0.25˚C. Two’s complement format.

1.5.3 MANUFACTURER’S/DEVICE ID REGISTER

(Read Only):

D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

10000001000000XX

D0–D1: Undefined. TRI-STATE will be output on SI/0.

D2-D4: Always set LOW.

D5–D15: Manufacturer’s ID Data. This register is accessed whenever the LM70 is in shutdown mode.

www.national.com9

2.0 Serial Bus Timing Diagrams

LM70

a) Reading Continuous Conversion - Single Eight-Bit Frame

b) Reading Continuous Conversion - Two Eight-Bit Frames

DS101223-14

DS101223-15

c) Writing Shutdown Control

FIGURE 7. Timing Diagrams

3.0 Application Hints

To get the expected results when measuring temperature

with an integrated circuit temperature sensor like the LM70,

it is important to understand that the sensor measures its

own die temperature. For the LM70, the best thermal path

between the die and the outside world is through the LM70’s

pins. In the MSOP-8 package the ground pin is connected to

the back side of the LM70 die and thus has the most effect

on the die temperature. Although the other pins will also

have some effect on the LM70die temperature and therefore

should not be discounted. The LM70 will provide an accurate

measurement of the temperature of the printed circuit board

on which it is mounted, because the pins represent a good

thermal path to the die. A less efficient thermal path exists

DS101223-18

between the plastic package and the LM70 die. If the ambient air temperature is significantly different from the printed

circuit board temperature, it will have a small effect on the

measured temperature.

In probe-type applications, the LM70 can be mounted inside

a sealed-end metal tube, and can then be dipped into a bath

or screwed into a threaded hole in a tank. As with any IC, the

LM70 and accompanying wiring and circuits must be kept insulated and dry, to avoid leakage and corrosion. This is especially true if the circuit may operate at cold temperatures

where condensation can occur. Printed-circuit coatings and

varnishes such as Humiseal and epoxy paints or dips are often used to insure that moisture cannot corrode the LM70 or

its connections.

www.national.com 10

4.0 Typical Applications

FIGURE 8. Temperature monitor using Intel 196 processor

LM70

DS101223-20

DS101223-19

FIGURE 9. LM70 digital input control using micro-controller’s general purpose I/O.

www.national.com11

Physical Dimensions inches (millimeters) unless otherwise noted

LM70

8-Lead Molded Mini Small Outline Package (MSOP)

(JEDEC REGISTRATION NUMBER M0-187)

Order Number LM70CIMM-3, LM70CIMMX-3, LM70CIMM-5 or LM70CIMMX-5

NS Package Number MUA08A

www.national.com 12

Physical Dimensions inches (millimeters) unless otherwise noted (Continued)

LM70 SPI/MICROWIRE10-Bit plus Sign Digital Temperature Sensor

8-Lead Molded Lead Less Package

Order Number LM70CILD-3, LM70CILDX-3, LM70CILD-5 or LM70CILDX-5

NS Package Number LDA08A

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

labeling, can be reasonably expected to result in a

significant injury to the user.

National Semiconductor

Corporation

Americas

Tel: 1-800-272-9959

Fax: 1-800-737-7018

Email: support@nsc.com

www.national.com

National Semiconductor

Europe

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: ap.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5639-7560

Fax: 81-3-5639-7507

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

Loading...

Loading...