LM6588

TFT-LCD Quad, 16V RRIO High Output Current

Operational Amplifier

LM6588 TFT-LCD Quad, 16V RRIO High Output Current Operational Amplifier

July 2005

General Description

The LM6588 is a low power, high voltage, rail-to-rail inputoutput amplifier ideally suited for LCD panel V

gamma buffer applications. The LM6588 contains four unity

gain stable amplifiers in one package. It provides a common

mode input ability of 0.5V beyond the supply rails, as well as

an output voltage range that extends to within 50mV of either

supply rail. With these capabilities, the LM6588 provides

maximum dynamic range at any supply voltage. Operating

on supplies ranging from 5V to 16V, while consuming only

750µA per amplifier, the LM6588 has a bandwidth of 24MHz

(−3dB).

The LM6588 also features fast slewing and settling times,

along with a high continuous output capability of 75mA. This

output stage is capable of delivering approximately 200mA

peak currents in order to charge or discharge capacitive

loads. These features are ideal for use in TFT-LCDs.

The LM6588 is available in the industry standard 14-pin SO

package and in the space-saving 14-pin TSSOP package.

The amplifiers are specified for operation over the full −40˚C

to +85˚C temperature range.

COM

driver and

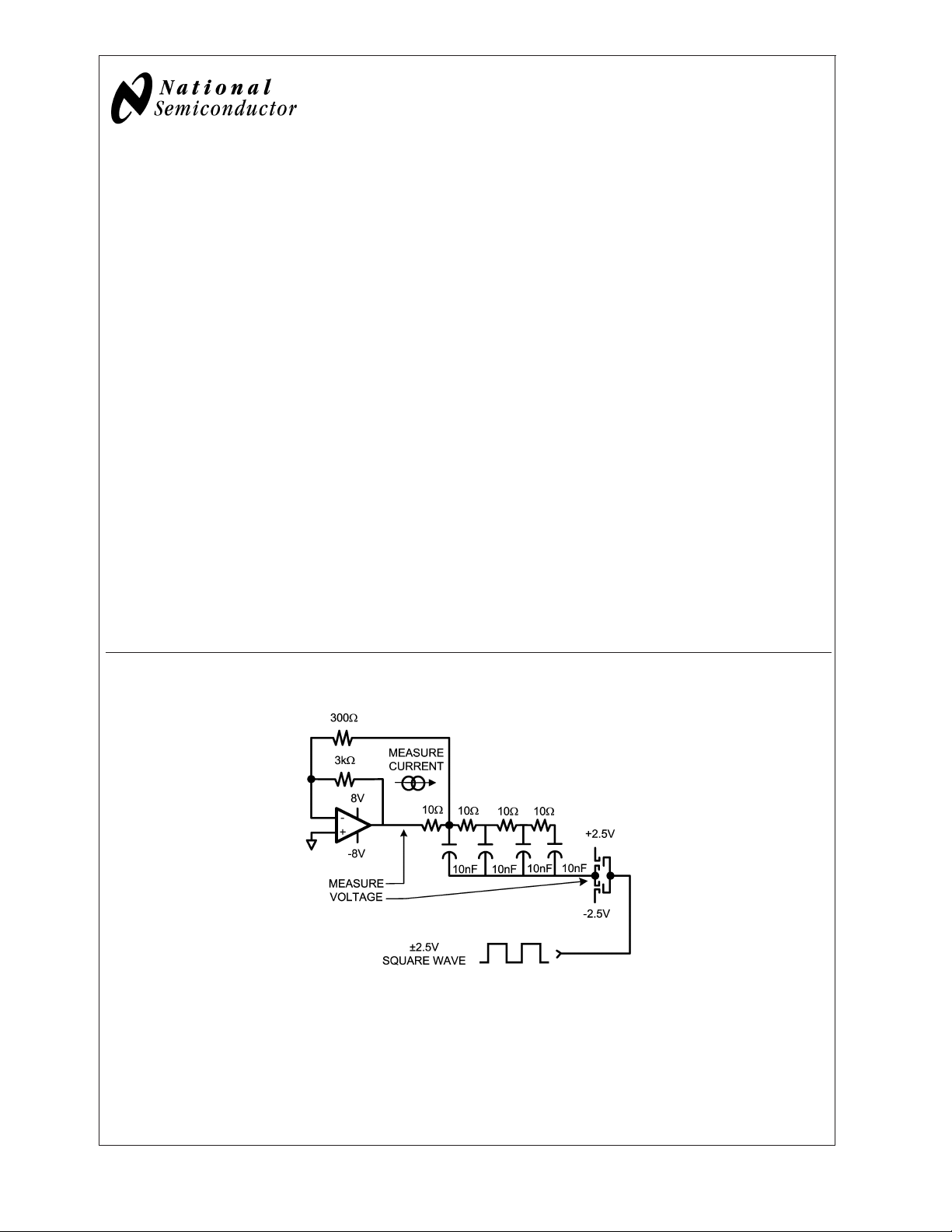

Test Circuit Diagram

Features

(VS=5V,TA= 25˚C typical values unless specified)

n Input common mode voltage 0.5V beyond rails

n Output voltage swing (R

n Output short circuit current

n Continuous output current 75mA

n Supply current (per amp, no load) 750µA

n Supply voltage range 5V to 16V

n Unity gain stable

n −3dB bandwidth (A

n Slew rate 11V/µSec

n Settling time 270ns

n SO-14 and TSSOP-14 package

n Manufactured in National Semiconductor’s

state-of-the-art bonded wafer, trench isolated

complementary bipolar VIP10

performance at low power levels

=2kΩ) 50mV from rails

L

= +1) 24MHz

V

™

technology for high

±

200mA

Applications

n LCD panel V

n LCD panel gamma buffer

n LCD panel repair amp

COM

driver

20073401

© 2005 National Semiconductor Corporation DS200734 www.national.com

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

LM6588

please contact the National Semiconductor Sales Office/

Input Common Mode Voltage V

Junction Temperature (Note 4) 150˚C

Distributors for availability and specifications.

Operating Ratings (Note 1)

ESD Tolerance (Note 2)

Human Body Model 2.5KV

Machine Model 250V

+-V−

Supply Voltage (V

Differential Input Voltage

) 18V

±

5.5V

Output Short Circuit to Ground (Note 3) Continuous

Storage Temperature Range −65˚C to 150˚C

Supply Voltage 4V ≤ V

Temperature Range −40˚C to +85˚C

Thermal Resistance (θ

)

JA

SOIC-14 145˚C/W

TSSOP-14 155˚C/W

16V DC Electrical Characteristics (Note 13)

Unless otherwise specified, all limits guaranteed for at TJ= 25˚C, VCM=1⁄2VSand RL=2kΩ. Boldface limits apply at the tem-

perature extremes.

Symbol Parameter Conditions Min

(Note 6)

V

OS

TC V

Input Offset Voltage 0.7 4

Input Offset Voltage Average

OS

Drift

I

B

I

OS

R

IN

Input Bias Current −0.3/+0.3

Input Offset Current 16 150

Input Resistance Common Mode 20

Differential Mode 0.5

CMRR Common Mode Rejection

V

= 0 to +16V 75

CM

Ratio

= 0 to 14.5V 78

V

CM

PSRR Power Supply Rejection Ratio V

CMVR Input Common-Mode Voltage

=±1V 80

CM

>

CMRR

50dB

Range

A

V

Large Signal Voltage Gain

RL=2kΩ,VO= 0.5 to +15.5V 80

(Note 7)

V

I

SC

I

CONT

I

S

O

Output Swing High RL=2kΩ 15.8

Output Swing Low R

Output Short Circuit Current

(Note 11)

Continuous Output Current

(Note 12)

=2kΩ 0.100 0.200

L

Sourcing 170 230

Sinking 170 230

Sourcing 40

Sinking 40

Supply Current (per Amp) 800 1200

70

72

75

16.2

75

15.6

Typ

(Note 5)

Max

(Note 6)

6

5

±

1

±

7

300

103

103

103 dB

0

−0.2 V

16

108 dB

15.9

1500

−

≤ 16V

S

Units

mV

µV/˚C

µA

nA

MΩ

dB

V

mA

mA

µA

to V

+

16V AC Electrical Characteristics (Note 13)

Unless otherwise specified, all limits guaranteed for at TJ= 25˚C, VCM=1⁄2VSand RL=2kΩ. Boldface limits apply at the tem-

perature extremes.

Symbol Parameter Conditions Min

SR Slew Rate (Note 9) A

www.national.com 2

= +1, VIN= 10V

V

PP

(Note 6)

8 15 V/µs

Typ

(Note 5)

Max

(Note 6)

Units

16V AC Electrical Characteristics (Note 13) (Continued)

Unless otherwise specified, all limits guaranteed for at TJ= 25˚C, VCM=1⁄2VSand RL=2kΩ. Boldface limits apply at the tem-

perature extremes.

Symbol Parameter Conditions Min

(Note 6)

Typ

(Note 5)

Max

(Note 6)

Units

Unity Gain Bandwidth Product 15.4 MHz

−3dB Frequency A

Φ

m

t

s

t

p

HD2 2

Phase Margin 61 deg

Settling Time (0.1%) AV= −1, AO=±5V, RL= 500Ω 780 ns

Propagation Delay AV= −2, VIN=±5V, RL= 500Ω 20 ns

nd

Harmonic Distortion

= 1MHz (Note 10)

F

IN

HD3 3rd Harmonic Distortion

= 1MHz (Note 10)

F

IN

e

n

Input-Referred Voltage Noise f = 10kHz 23 nV/

= +1 10 24 MHz

V

V

=2V

OUT

V

OUT

=2V

PP

PP

−53 dBc

−40 dBc

5V DC Electrical Characteristics (Note 13)

Unless otherwise specified, all limits guaranteed for at TJ= 25˚C, VCM=1⁄2VSand RL=2kΩ. Boldface limits apply at the tem-

perature extremes.

Symbol Parameter Conditions Min

(Note 6)

V

OS

TC V

Input Offset Voltage 0.7 4

Input Offset Voltage Average

OS

Drift

I

B

I

OS

R

IN

Input Bias Current −0.3/+0.3

Input Offset Current 20 150

Input Resistance Common Mode 20

Differential Mode 0.5

CMRR Common Mode Rejection

V

Stepped from 0 to 5V 70

CM

Ratio

VCMStepped from 0 to 3.5V 75

PSRR Power Supply Rejection Ratio V

CMVR Input Common-Mode Voltage

S=VCC

CMRR

= 3.5V to 5.5V 80

>

50dB

Range

A

V

Large Signal Voltage Gain

RL=2kΩ,VO= 0 to 5V 80

(Note 7)

V

O

Output Swing High RL=2kΩ 4.85

Output Swing Low RL=2kΩ 0.05 0.15

I

SC

I

CONT

I

S

Output Short Circuit Current

(Note 11)

Continuous Output Current

(Note 12)

Sourcing 160 200

Sinking 160 200

Sourcing 75

Sinking 75

Supply Current (per Amp) 750 1000

66

70

75

5.2

75

4.7

Typ

(Note 5)

Max

(Note 6)

6

10

±

1

±

7

300

105

105

92

0.0

−0.2 V

5.0

106 dB

4.95

1250

Units

µV/˚C

LM6588

mV

µA

nA

MΩ

dB

dB

V

mA

mA

µA

www.national.com3

5V AC Electrical Characteristics (Note 13)

Unless otherwise specified, all limits guaranteed for at TJ= 25˚C, VCM=1⁄2VSand RL=2kΩ. Boldface limits apply at the tem-

LM6588

perature extremes.

Symbol Parameter Conditions Min

(Note 6)

SR Slew Rate (Note 9) A

= +1, VIN= 3.5V

V

PP

Unity Gain Bandwidth Product 15.3 MHz

−3dB Frequency A

Φ

m

t

s

t

p

HD2 2

Phase Margin 56 deg

Settling Time (0.1%) AV= −1, VO=±1V, RL= 500Ω 270 ns

Propagation Delay AV= −2, VIN=±1V, RL= 500Ω 21 ns

nd

Harmonic Distortion

= 1MHz (Note 10)

F

IN

HD3 3rd Harmonic Distortion

= 1MHz (Note 10)

F

IN

e

n

Note 1: Note 1: Absolute maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for which the

device is intended to be functional, but specific performance is not guaranteed. For guaranteed specifications and the test conditions, see the Electrical

Characteristics.

Note 2: For testing purposes, ESD was applied using human body model, 1.5kΩ in series with 100pF.

Note 3: Applies to both single-supply and split-supply operation. Continuous short circuit operation at elevated ambient temperature can result in exceeding the

maximum allowed junction temperature of 150˚C

Note 4: The maximum power dissipation is a function of T

P

D

Note 5: Typical values represent the most likely parametric norm.

Note 6: All limits are guaranteed by testing or statistical analysis.

Note 7: Large signal voltage gain is the total output swing divided by the input signal required to produce that swing.

Note 8: The open loop output current is guaranteed, by the measurement of the open loop output voltage swing.

Note 9: Slew rate is the average of the raising and falling slew rates.

Note 10: Harmonics are measured with A

Note 11: Continuous operation at these output currents will exceed the power dissipation ability of the device

Note 12: Power dissipation limits may be exceeded if all four amplifiers source or sink 40mA. Voltage across the output transistors and their output currents must

be taken into account to determine the power dissipation of the device

Note 13: Electrical table values apply only for factory testing conditions at the temperature indicated. Factory testing conditions result in very limited self-heating of

the device such that T

See applications section for information on temperature de-rating of this device.

Input-Referred Voltage Noise f = 10kHz 23 nV/

=(T

J(MAX)-TA

)/ θJA. All numbers apply for packages soldered directly onto a PC board.

= +2 and RL= 100Ω and VIN=1VPPto give V

V

. No guarantee of parametric performance is indicated in the electrical tables under conditions of internal self heating where T

J=TA

= +1 10 24 MHz

V

V

=2V

OUT

V

OUT

PP

=2V

PP

, θJA, and TA. The maximum allowable power dissipation at any ambient temperature is

J(MAX)

=2VPP.

OUT

Typ

(Note 5)

Max

(Note 6)

11 V/µs

−53 dBc

−40 dBc

Units

>

J

TA.

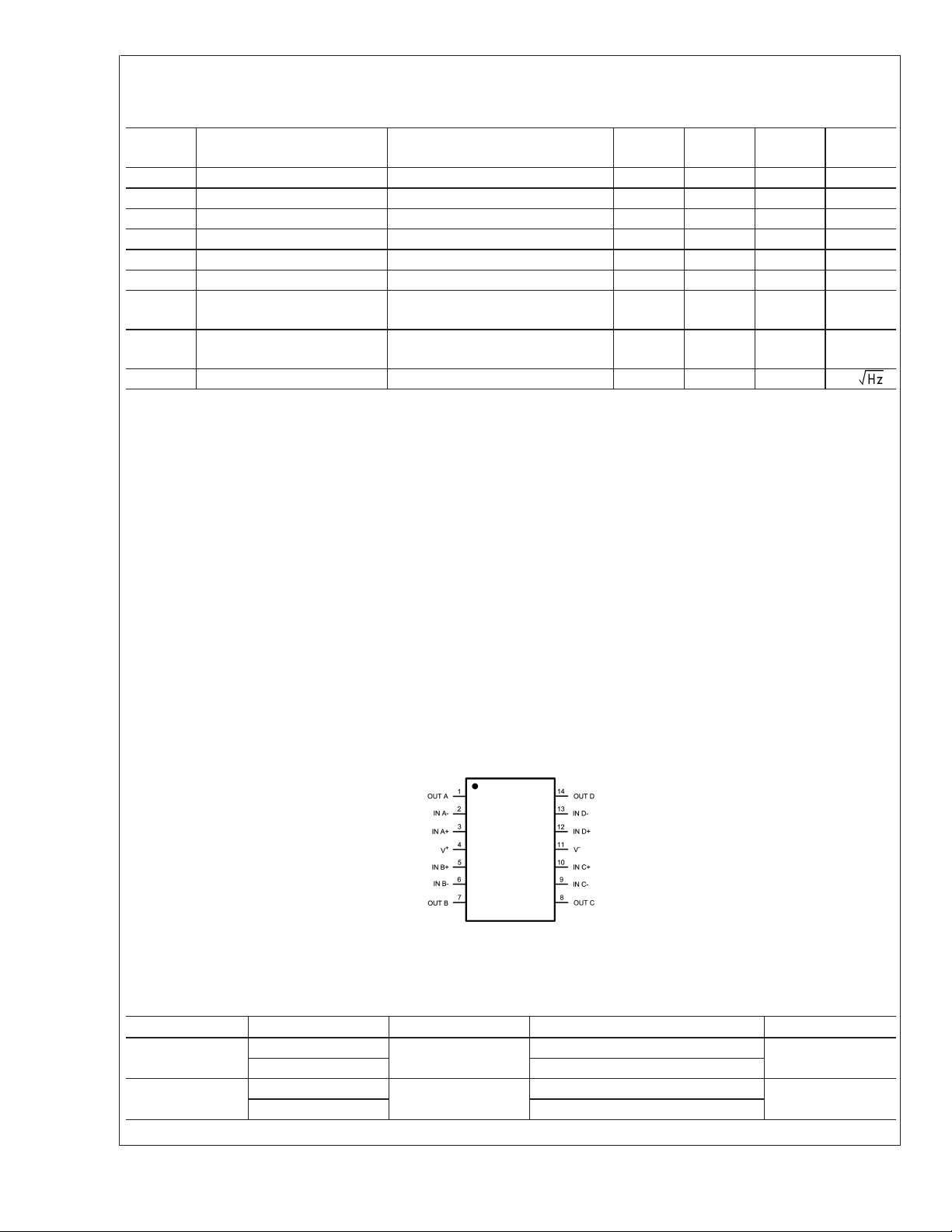

Connection Diagram

14-Pin SOIC/TSSOP

Top View

20073402

Ordering Information

Package Part Number Package Marking Transport Media NSC Drawing

14-Pin SOIC

14-Pin TSSOP

www.national.com 4

LM6588MA

LM6588MAX 2.5k Units Tape and Reel

LM6588MT

LM6588MTX 2.5k Units Tape and Reel

LM6588MA

LM6588MT

95 Units/Rail

95 Units/Rail

M14A

MTC14

LM6588

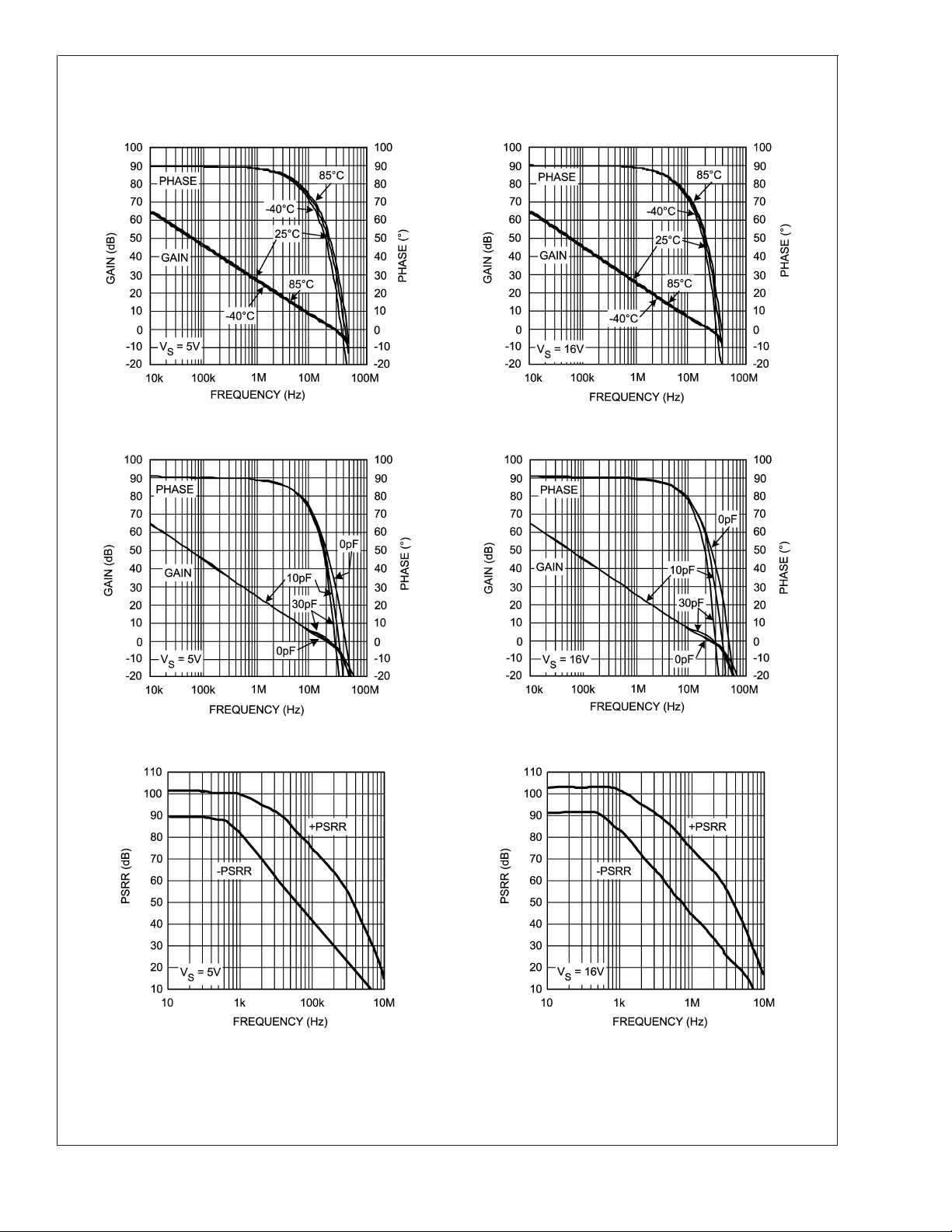

Typical Performance Characteristics Unless otherwise specified, all limits guaranteed for T

= 1/2VSand RL=2kΩ.

V

CM

Gain Phase vs. Temperature (V

Gain Phase vs. Capacitive Loading (VS= 5V) Gain Phase vs. Capacitive Loading (VS= 16V)

= 5V) Gain Phase vs. Temperature (VS= 16V)

S

20073403

= 25˚C,

J

20073404

20073405

PSRR (VS= 5V) PSRR (VS= 16V)

20073407 20073408

20073406

www.national.com5

Typical Performance Characteristics Unless otherwise specified, all limits guaranteed for T

= 1/2VSand RL=2kΩ. (Continued)

V

CM

LM6588

CMRR (V

Settling Time vs. Input Step Amplitude

(Output Slew and Settle Time)

= 5V) CMRR (VS= 16V)

S

20073409 20073410

Settling Time vs. Capacitive Loading

(Output Slew and Settle Time)

= 25˚C,

J

20073411

Crosstalk Rejection vs. Frequency

(Output to Output) Input Voltage Noise vs. Frequency

20073413

www.national.com 6

20073412

20073414

LM6588

Typical Performance Characteristics Unless otherwise specified, all limits guaranteed for T

= 1/2VSand RL=2kΩ. (Continued)

V

CM

Stability vs. Capacitive Load Unity Gain (V

Small Signal Step Response Small Signal Step Response

= 16V) Large Signal Step Response

S

20073415

20073416

= 25˚C,

J

20073417 20073418

Closed Loop Output Impedance vs. Frequency (AV= +1) I

20073419

vs. Common Mode Voltage (VS=±5V)

SUPPLY

20073420

www.national.com7

Typical Performance Characteristics Unless otherwise specified, all limits guaranteed for T

= 1/2VSand RL=2kΩ. (Continued)

V

CM

LM6588

V

vs. Common Mode Voltage (VS= 16V) VOSvs. V

OS

(Typical Unit), (VS= 10V)

OUT

= 25˚C,

J

V

OUT

I

SUPPLY

from V+vs. I

SOURCE

vs. Supply Voltage

20073421

V

from V−vs. I

OUT

20073423 20073424

SINK

20073422

20073425

www.national.com 8

Application Notes

CIRCUIT DESCRIPTION GENERAL & SPEC

The LM6588 is a bipolar process operational amplifier. It has

an exceptional output current capability of 200mA. The part

has both rail to rail inputs and outputs. It has a −3dB bandwidth of 24MHz. The part has input voltage noise of 23nV/

, and 2ndand 3rdharmonic distortion of −53dB and

−40dB respectively.

INPUT SECTION

The LM6588 has rail to rail inputs and thus has an input

range over which the device may be biased of V

0.5V, and V

+

plus 0.5V. The ultimate limit on input voltage

excursion is the ESD protection diodes on the input pins.

The most important consideration in Rail-to-Rail input op

amps is to understand the input structure. Most Rail-to-Rail

input amps use two differential input pairs to achieve this

function. This is how the LM6588 works. A conventional PNP

differential transistor pair provides the input gain from 0.5V

below the negative rail to about one volt below the positive

rail. At this point internal circuitry activates a differential NPN

transistor pair that allows the part to function from 1 volt

below the positive rail to 0.5V above the positive rail. The

effect on the inputs pins is as if there were two different op

amps connected to the inputs. This has several unique

implications.

The input offset voltage will change, sometimes from

•

positive to negative as the inputs transition between the

two stages at about a volt below the positive rail. this

effect is seen in the V

vs. VCMchart in the Typical

OS

Performance Characteristics section of this datasheet.

The input bias currents can be either positive or negative.

•

Do not expect a consistent flow in or out of the pins.

The part will have different specifications depending on

•

whether the NPN or PNP stage is operating.

There is a little more input capacitance then a single

•

stage input although the ESD diodes often swamp out the

added base capacitance.

Since the input offset voltages can change from positive

•

to negative the output may not be monotonic when the

inputs are transitioning between the two stages and the

part is in a high gain configuration.

It should be remembered that swinging the inputs across the

input stage transition may cause output distortion and accuracy anomalies. It is also worth noting that anytime any amps

inputs are swung near the rails THD and other specs are

sure to suffer.

OUTPUT SECTION

Current Rating

The LM6588 has an output current rating, sinking or sourcing, of 200mA. The LM6588 is ideally suited to loads that

require a high value of peak current but only a reduced value

of average current. This condition is typical of driving the

gate of a MOSFET. While the output drive rating is 200mA

peak, and the output structure supports rail-to-rail operation,

the attainable output current is reduced when the gain and

drive conditions are such that the output voltage approaches

either rail.

−

minus

Output Power

Because of the increased output drive capability, internal

heat dissipation must be held to a level that does not increase the junction temperature above its maximum rated

value of 150˚ C.

Power Requirements

+

±

and

2.5V

The LM6588 operates from a voltage supply, of V

ground, or from a V

−

and V+split supply. Single-ended

voltage range is +5V to +16V and split supply range is

±

8.0V.

to

APPLICATION HINTS POWER SUPPLIES

Sequencing

Best practice design technique for operational amplifiers

includes careful attention to power sequencing. Although the

LM6588 is a bipolar op amp, recommended op amp turn on

power sequencing of ground (or V

−

), followed by V+, followed by input signal should be observed. Turn off power

sequence should be the reverse of the turn-on sequence.

Depending on how the amp is biased the outputs may swing

to the rails on power-on or power-off. Due to the high output

currents and rail to rail output stage in the LM6588 the output

may oscillate very slightly if the power is slowly raised between 2V and 4V The part is unconditionally stable at 5V.

Quick turn-off and turn-on times will eliminate oscillation

problems.

PSRR and Noise

Care should be taken to minimize the noise in the power

supply rails. The figure of merit for an op amp’s ability to

keep power supply noise out of the signal is called Power

Supply Rejection Ratio (PSRR). Observe from the PSRR

charts in the Typical Performance Characteristics section

that the PSRR falls of dramatically as the frequency of the

noise on the power supply line goes up. This is one of the

reasons switching power supplies can cause problems. It

should also be noticed from the charts that the negative

supply pin is far more susceptible to power noise. The design engineer should determine the switching frequencies

and ripple voltages of the power supplies in the system. If

required, a series resistor or in the case of a high current op

amp like the LM6588, a series inductor can be used to filter

out the noise.

Transients

In addition to the ripple and noise on the power supplies

there are also transient voltage changes. This can be

caused by another device on the same power supply suddenly drawing current or suddenly stopping a current draw.

The design engineer should insure that there are no damaging transients induced on the power supply lines when the op

amp suddenly changes current delivery.

LAYOUT

Ground Planes

Do not assume the ground (or more properly, the common or

return) of the power supply is an ocean of zero impedance.

The thinner the trace, the higher the resistance. Thin traces

cause tiny inductances in the power lines. These can react

against the large currents the LM6588 is capable of delivering to cause oscillations, instability, overshoot and distortion.

A ground plane is the most effective way of insuring the

LM6588

www.national.com9

Application Notes (Continued)

ground is a uniform low impedance. If a four layer board

LM6588

cannot be used, consider pouring a plane on one side of a

two layer board. If this cannot be done be sure to use as

wide a trace as practicable and use extra decoupling capacitors to minimize the AC variations on the ground rail.

Decoupling

A high-speed, high-current amp like the LM6588 must have

generous decoupling capacitors. They should be as close to

the power pins as possible. Putting them on the back side

opposite the power pins may give the tightest layout. If

ground and power planes are available, the placement of the

decoupling caps are not as critical.

Breadboards

The high currents and high frequencies the LM6588 operates at, as well as thermal considerations, require that prototyping of the design be done on a circuit board as opposed

to a “Proto-Board” style breadboard.

STABILITY

General:

High speed parts with large output current capability require

special care to insure lack of oscillations. Keep the ”+” pin

isolated from the output to insure stability. As noted above

care should be take to insure the large output currents do not

appear in the ground or ground plane and then get coupled

into the “+” pin. As always, good tight layout is essential as is

adequate use of decoupling capacitors on the power supplies.

Unity Gain

The unity gain or voltage-follower configuration is the most

subject to oscillation. If a part is stable at unity gain it is

almost certain to work in other configurations. In certain

applications where the part is setting a reference voltage or

is being used as a buffer greater stability can be achieved by

configuring the part as a gain of −1 or −2 or +2.

Phase Margin

The phase margin of an op amps gain-phase plot is an

indication of the stability of the amp. It is desirable to have at

least 45˚C of phase margin to insure stability in all cases.

The LM6588 has 60˚C of phase margin even with it’s large

output currents and Rail-to-Rail output stage, which are

generally more prone to stability issues.

Capacitive Load

The LM6588 can withstand 30pF of capacitive load in a unity

gain configuration before stability issues arise. At very large

capacitances, the load capacitor will attenuate the gain like

any other heavy load and the part becomes stable again.

The LM6588 will be stable at 330nF and higher load capacitance. Refer to the chart in the Typical Performance Characteristics section.

OUTPUT

Swing vs. Current

The LM6588 will get to about 25mV or 30mV of either rail

when there is no load. The LM6588 can sink or source

hundreds of milliamperes while remaining less then 0.5V

away from the rail. It should be noted that if the outputs are

driven to the rail and the part can no longer maintain the

feedback loop, the internal circuitry will deliver large base

currents into the huge output transistors, trying to get the

outputs to get past the saturation voltage. The base currents

will approach 16 milliamperes and this will appear as an

increase in power supply current. Operating at this power

dissipation level for extended periods will damage the part,

especially in the higher thermal resistance TSSOP package.

Because of this phenomenon, unused parts should not have

the inputs strapped to either rail, but should have the inputs

biased at the midpoint or at least a diode drop (0.6V) within

the rails.

Self Heating

As discussed above the LM6588 is capable of significant

power by virtue of its 200mA current handling capability. A

TSSOP package cannot sustain these power levels for more

then a brief period.

TFT Display Application

INTRODUCTION

In today’s high-resolution TFT displays, op amps are used

for the following three functions:

1. V

2. Gamma Buffer

3. Panel Repair Buffer

All of these functions utilize op amps as non-inverting, unity-

gain buffers. The V

that supply a well regulated DC voltage. A Panel Repair

Buffer, on the other hand, provides a high frequency signal

that contains part of the display’s visual image.

In an effort to reduce production costs, display manufacturers use a minimum variety of different parts in their TFT

displays. As a result, the same type of op amp will be used

for the V

To perform all these functions, such an op amp must have

the following characteristics:

1. Large output current drive

2. Rail to rail input common mode range

3. Rail to rail output swing

4. Medium speed gain bandwidth and slew rate

The LM6588 meets these requirements. It has a rail-to-rail

input and output, typical gain bandwidth and slew rate of

15MHz and 15V/µs, and it can supply up to 200mA of output

current. The following sections will describe the operation of

V

COM

showing how the LM6588 is well suited for each of these

functions.

BRIEF OVERVIEW OF TFT DISPLAY

To better understand these op amp applications, let’s first

review a few basic concepts of how a TFT display operates.

Figure 1 is a simplified illustration of an LCD pixel. The top

and bottom plates of each pixel consist of Indium-Tin oxide

(ITO), which is a transparent, electrically conductive material. ITO lies on the inner surfaces of two glass substrates

that are the front and back glass panels of a TFT display.

Sandwiched between the two ITO plates is an insulating

material (liquid crystal) that alters the polarization of light to a

lesser a greater amount, depending on how much voltage

(V

PIXEL

placed on the outer surfaces of the two glass substrates,

which in combination with the liquid crystal create a variable

Driver

COM

Driver and Gamma Buffer are buffers

COM

Driver, Gamma Buffer, and Panel Repair Buffer.

COM

Drivers, Gamma Buffers, and Panel Repair Buffers,

) is applied across the two plates. Polarizers are

www.national.com 10

TFT Display Application (Continued)

light filter that modulates light transmitted from the back to

the front of a display. A pixel’s bottom plate lies on the

backside of a display where a light source is applied, and the

top plate lies on the front, facing the viewer. On a Twisted

Neumatic (TN) display, which is typical of most TFT displays,

a pixel transmits the greatest amount of light when V

±

0.5V, and it becomes less transparent as this voltage

less

increases with either a positive or negative polarity. In short,

an LCD pixel can be thought of as a capacitor, through

which, a controlled amount of light is transmitted by varying

.

V

PIXEL

FIGURE 1. Individual LCD Pixel

PIXEL

20073426

LM6588

the Column Drivers supply this voltage via the column lines.

Column Drivers ‘write’ this voltage to the pixels one row at a

time, and this is accomplished by having the Row Drivers

select an individual row of pixels when their voltage levels

are transmitted by the Column Drivers. The Row Drivers

sequentially apply a large positive pulse (typically 25V to

35V) to each row line. This turns-on NMOS transistors con-

is

nected to an individual row, allowing voltages from the column lines to be transmitted to the pixels.

V

DRIVER

COM

The V

driver supplies a common voltage (V

COM

the pixels in a TFT panel. V

is a constant DC voltage that

COM

COM

)toall

lies in the middle of the column drivers’ output voltage range.

As a result, when the column drivers write to a row of pixels,

they apply voltages that are either positive or negative with

respect to V

. In fact, the polarity of a pixel is reversed

COM

each time its row is selected. This allows the column drivers

to apply an alternating voltage to the pixels rather than a DC

signal, which can ‘burn’ a pattern into an LCD display.

When column drivers write to the pixels, current pulses are

injected onto the V

ing stray capacitance between V

line. These pulses result from charg-

COM

and the column lines

COM

(see Figure 2), which ranges typically from 16pF to 33pF per

column. Pixel capacitance contributes very little to these

pulses because only one pixel at a time is connected to a

column, and the capacitance of a single pixel is on the order

of only 0.5pF. Each column line has a significant amount of

series resistance (typically 2kΩ to 40kΩ), so the stray capacitance is distributed along the entire length of a column.

This can be modeled by the multi-segment RC network

shown in Figure 3. The total capacitance between V

COM

and

the column lines can range from 25nF to 100nF, and charging this capacitance can result in positive or negative current

pulses of 100mA, or more. In addition, a similar distributed

capacitance of approximately the same value exists between V

and the row lines. Therefore, the V

COM

COM

driver’s

load is the sum of these distributed RC networks with a total

capacitance of 50nF to 200nF, and this load can modeled

like the circuit in Figure 3.

20073427

FIGURE 2. TFT Display

Figure 2 is a simplified block diagram of a TFT display,

showing how individual pixels are connected to the row,

column, and V

lines. Each pixel is represented by ca-

COM

pacitor with an NMOS transistor connected to its top plate.

Pixels in a TFT panel are arranged in rows and columns.

Row lines are connected to the NMOS gates, and column

lines to the NMOS sources. The back plate of every pixel is

connected to a common voltage called V

. Pixel bright-

COM

ness is controlled by voltage applied to the top plates, and

20073428

FIGURE 3. Model of Impedance between V

COM

and

Column Lines

AV

driver is essentially a voltage regulator that can

COM

source and sink current into a large capacitive load. To

simplify the analysis of this driver, the distributed RC network

of Figure 3 has been reduced to a single RC load in Figure

4. This load places a large capacitance on the V

COM

driver

output, resulting in an additional pole in the op amp’s feedback loop. However, the op amp remains stable because

and R

C

LOAD

pole. The range of C

create a zero that cancels the effect of this

ESR

is 50nF to 200nF and R

LOAD

ESR

is 20Ω

to 100Ω, so this zero will have a frequency in the range of

www.national.com11

TFT Display Application (Continued)

8KHz to 160KHz, which is much lower than the gain band-

LM6588

width of most op amps. As a result, the V

little phase lag when op amp loop gain is unity, and this

allows the V

Driver to remain stable. This was verified by

COM

measuring the small-signal bandwidth of the LM6588 with

the RC load of Figure 4. When driving an RC load of 50nF

and 20Ω, the LM6588 has a unity gain frequency of 6.12MHz

with 41.5˚C of phase margin. If the load capacitor is increased to 200nF and the resistance remains 20Ω, the unity

gain frequency is virtually unchanged: 6.05MHz with 42.9˚C

of phase margin.

load adds very

COM

20073429

Figure 5 is a common test circuit used for measuring V

COM

driver response time. The RC network of RL1to RL3and C

to C4models the distributed RC load of a V

line. This RC

COM

network is a gross simplification of what the actual impedance is on a TFT panel. However, it does provide a useful

test for measuring the op amp’s transient response when

driving a large capacitive load. A low impedance MOSFET

driver applies a 5V square wave to V

, generating large

SW

current pulses in the RC network. Scope photos from this

circuit are shown in Figure 6 and Figure 7. Figure 6 shows

the test circuit generates positive and negative voltage

spikes with an amplitude of

3.2V at the V

COM

node, and

±

both transients settle-out in approximately 2µs. As mentioned before, the speed at which these transients settle-out

is a function of the op amp’s peak output current. The I

OUT

trace in Figure 7 shows that the LM6588 can sink and source

peak currents of −200mA and 200mA. This ability to supply

large values of output current makes the LM6588 extremely

well suited for V

Driver applications.

COM

1

AV

COM

FIGURE 4. V

Driver’s large-signal response time is determined by

Driver with Simplified Load

COM

the op amp’s maximum output current, not by its slew rate.

This is easily shown by calculating how much output current

is required to slew a 50nF load capacitance at the LM6588

slew rate of 14V/µs:

= 14V/µs x 50nF

I

OUT

= 700mA

700mA exceeds the maximum current specification for the

LM6588 and almost all other op amps, confirming that a

driver’s speed is limited by its peak output current. In

V

COM

order to minimize V

Driver must supply large values of output current.

V

COM

transients, the op amp used as a

COM

FIGURE 6. VSWand V

Waveforms from V

COM

20073431

COM

20073430

FIGURE 5. V

www.national.com 12

Driver Test Circuit

COM

FIGURE 7. VSWand I

Waveforms from V

OUT

Circuit

20073432

COM

Test

TFT Display Application (Continued)

GAMMA BUFFER

Illumination in a TFT display, also referred to as grayscale, is

set by a series of discrete voltage levels that are applied to

each LCD pixel. These voltage levels are generated by

resistive DAC networks that reside inside each of the column

driver ICs. For example, a column driver with 64 Grayscale

levels has a two 6 bit resistive DACs. Typically, the two

DACs will have their 64 resistors grouped into four segments, as shown in Figure 8. Each of these segments is

connected to external voltage lines, VGMA1 to VGMA10,

which are the Gamma Levels. VGMA1 to VGMA5 set grayscale voltage levels that are positive with respect to V

(high polarity gamma levels). VGMA6 to VGMA10 set grayscale voltages negative with respect to V

(low polarity

COM

gamma levels).

COM

LM6588

20073434

FIGURE 9. Basic Gamma Buffer Configuration

Another important specification for Gamma Buffers is small

signal bandwidth and slew rate. When column drivers select

which voltage levels are written to a row of pixels, their

internal DACs inject current spikes into the Gamma Lines.

This generates voltage transients at the Gamma Buffer outputs, and they should settle-out in less than 1µs to insure a

steady output voltage from the column drivers. Typically,

these transients have a maximum amplitude of 2V, so a

gamma buffer must have sufficient bandwidth and slew rate

to recover from a 2V transient in 1µs or less.

20073433

FIGURE 8. Simplified Schematic of Column Driver IC

Figure 9 shows how column drivers in a TFT display are

connected to the gamma levels. VGMA1, VGMA5, VGMA6,

and VGMA10 are driven by the Gamma Buffers. These

buffers serve as low impedance voltage sources that generate the display’s gamma levels. The Gamma Buffers’ outputs

are set by a simple resistive ladder, as shown in Figure 9.

Note that VGMA2 to VGMA4 and VGMA7 to VGMA9 are

usually connected to the column drivers even though they

are not driven by external buffers. Doing so, forces the

gamma levels in all the column drivers to be identical, minimizing grayscale mismatch between column drivers. Referring again to Figure 9, the resistive load of a column driver

DAC (i.e. resistance between GMA1 to GMA5) is typically

10kΩ to 15kΩ. On a typical display such as XGA, there can

be up to 10 column drivers, so the total resistive load on a

Gamma Buffer output can be as low as 1kΩ. The voltage

between VGMA1 and VGMA5 can range from 3V to 6V,

depending on the type of TFT panel. Therefore, maximum

load current supplied by a Gamma Buffer is approximately

6V/1kΩ = 6mA, which is a relatively light load for most op

amps. In many displays, VGMA1 can be less than 500mV

below V

, and VGMA10 can be less than 500mV above

DD

ground. Under these conditions, an op amp used for the

Gamma Buffer must have rail-to-rail inputs and outputs, like

the LM6588.

20073435

FIGURE 10. Large Signal Transient Response of an

Operational Amplifier

Figure 10 illustrates how an op amp responds to a largesignal transient. When such a transient occurs att=0,the

output does not start changing until T

, which is the op

PD

amp’s propagation delay time (typically 20ns for the

LM6588). The output then changes at the op amp’s slew rate

from t = T

to its final value (V

to TSR.Fromt=TSRto TSET, the output settles

PD

) at a speed determined by the op amp’s

F

small-signal frequency response. Although propagation de-

www.national.com13

TFT Display Application (Continued)

lay and slew limited response time (t=0toT

LM6588

calculated from data sheet specifications, the small signal

to T

settling time (T

SR

amp’s gain vs. frequency has multiple poles, and as a result,

small-signal settling time can not be calculated as a simple

function of the op amp’s gain bandwidth. Therefore, the only

accurate method for determining op amp settling time is to

measure it directly.

FIGURE 11. Gamma Buffer Settling Time Test Circuit

The test circuit in Figure 11 was used to measure LM6588

settling time for a 2V pulse and 1kΩ load, which represents

the maximum transient amplitude and output load for a

gamma buffer. With this test system, the LM6588 settled to

±

within

30mV of 2V pulse in approximately 170ns. Settling

time fora0to–2Vpulse was slightly less, 150ns. These

values are much smaller than the desired response time of

1µs, so the LM6588 has sufficient bandwidth and slew rate

for regulating gamma line transients.

) cannot. This is because an op

SET

) can be

SR

20073436

rails. Therefore, op amps used as panel repair buffers should

have rail-to-rail input and stages. Otherwise, they may clip

the column driver signal.

The signal from a panel repair buffer is stored by a pixel

when the pixel’s row is selected. In high-resolution displays,

each row is selected for as little as 11µs. To insure that a

pixel has adequate time to settle-out during this brief period,

a panel repair buffer should settle to within 1% of its final

value approximately 1µs after a row is selected. This is

hardest to achieve when transmitting a column line’s maximum voltage swing, which is the difference between the

upper and lower gamma levels (i.e. voltage between VGMA1

and VGMA10). For a LM6588, the most demanding application occurs in displays that operate from a 16V supply. In

these displays, voltage difference between the top and bottom gamma levels can be as large as 15V, so the LM6588

±

needs to transmit a

15V pulse and settle to within 60mV of

its final value in approximately 1µs (60mV is approximately

1% of the dynamic range of the high or low polarity gamma

levels). LM6588 settling times for 15V and –15V pulses were

measured in a test circuit similar to the one in Figure 11.V

and V−were set to 15.5V and –0.5V, respectively, when

measuring settling time for a 0V to 15V pulse. Likewise, V

and V−were set to 0.5V and –15.5V when measuring settling time for a 0V to –15V pulse. In both cases, the LM6588

output was connected to a series RC load of 51Ω and 200pF.

When tested this way, the LM6588 settled to within 60mV of

15V or –15V in approximately 1.1µs. These observed values

are very close to the desired 1µs specification, demonstrating that the LM6588 has the bandwidth and slew rate required for repair buffers in high-resolution TFT displays.

+

+

PANEL REPAIR BUFFER

It is not uncommon for a TFT panel to be manufactured with

an open in one or two of its column or row lines. In order to

repair these opens, TFT panels have uncommitted repair

lines that run along their periphery. When an open line is

identified during a panel’s final assembly, a repair line reroutes its signal past the open. Figure 12 illustrates how a

column is repaired. The column driver’s output is sent to the

other end of an open column via a repair line, and the repair

line is driven by a panel repair buffer. When a column or row

line is repaired, the capacitance on that line increases substantially. For instance, a column typically has 50pF to

100pF of line capacitance, but a repaired column can have

up to 200pF. Column drivers are not designed to drive this

extra capacitance, so a panel repair buffer provides additional output current to the repaired column line. Note that

there is typically a 20Ω to 100Ω resistor in series with the

buffer output. This resistor isolates the output from the

200pF of capacitance on a repaired column line, ensuring

that the buffer remains stable. A pole is created by this

resistor and capacitance, but its frequency will be in the

range of 8MHz to 40MHz, so it will have only a minor effect

on the buffer’s transient response time. Panel repair buffers

transmit a column driver signal, and as mentioned in the

gamma buffer section, this signal is set by the gamma levels.

It was also mentioned that many displays have upper and

lower gamma levels that are within 500mV of the supply

20073437

FIGURE 12. Panel Repair Buffer

SUMMARY

This application note provided a basic explanation of how op

amps are used in TFT displays, and it also presented the

specifications required for these op amps. There are three

major op amp applications in a display: V

COM

Driver,

Gamma Buffer, and Panel Repair Buffer, and the LM6588

can be used for all of them. As a V

can supply large values of output current to regulate V

Driver, the LM6588

COM

COM

load transients. It has rail-to-rail input common-mode range

and output swing required for gamma buffers and panel

repair buffers. It also has the necessary gain bandwidth and

slew-rate for regulating gamma levels and driving column

repair lines. All these features make the LM6588 very well

suited for use in TFT displays.

www.national.com 14

Physical Dimensions inches (millimeters) unless otherwise noted

14-Pin SOIC

NS Package Number M14A

LM6588

14-Pin TSSOP

NS Package Number MTC14

www.national.com15

Notes

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves

the right at any time without notice to change said circuitry and specifications.

For the most current product information visit us at www.national.com.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS

WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL COUNSEL OF NATIONAL SEMICONDUCTOR

CORPORATION. As used herein:

1. Life support devices or systems are devices or systems

which, (a) are intended for surgical implant into the body, or

LM6588 TFT-LCD Quad, 16V RRIO High Output Current Operational Amplifier

(b) support or sustain life, and whose failure to perform when

properly used in accordance with instructions for use

2. A critical component is any component of a life support

device or system whose failure to perform can be reasonably

expected to cause the failure of the life support device or

system, or to affect its safety or effectiveness.

provided in the labeling, can be reasonably expected to result

in a significant injury to the user.

BANNED SUBSTANCE COMPLIANCE

National Semiconductor manufactures products and uses packing materials that meet the provisions of the Customer Products

Stewardship Specification (CSP-9-111C2) and the Banned Substances and Materials of Interest Specification (CSP-9-111S2) and contain

no ‘‘Banned Substances’’ as defined in CSP-9-111S2.

Leadfree products are RoHS compliant.

National Semiconductor

Americas Customer

Support Center

Email: new.feedback@nsc.com

Tel: 1-800-272-9959

www.national.com

National Semiconductor

Europe Customer Support Center

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Support Center

Email: ap.support@nsc.com

National Semiconductor

Japan Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

Loading...

Loading...