LM628/LM629

Precision Motion Controller

LM628/LM629 Precision Motion Controller

January 2003

General Description

The LM628/LM629 are dedicated motion-control processors

designed for use with a variety of DC and brushless DC

servo motors, and other servomechanisms which provide a

quadrature incremental position feedback signal. The parts

perform the intensive, real-time computational tasks required

for high performance digital motion control. The host control

software interface is facilitated by a high-level command set.

The LM628 has an 8-bit output which can drive either an

8-bit or a 12-bit DAC. The components required to build a

servo system are reduced to the DC motor/actuator, an

incremental encoder, a DAC, a power amplifier, and the

LM628. An LM629-based system is similar, except that it

provides an 8-bit PWM output for directly driving H-switches.

The parts are fabricated in NMOS and packaged in a 28-pin

dual in-line package or a 24-pin surface mount package

(LM629 only). Both 6 MHz and 8 MHz maximum frequency

versions are available with the suffixes -6 and -8, respectively, used to designate the versions. They incorporate an

SDA core processor and cells designed by SDA.

Features

n 32-bit position, velocity, and acceleration registers

n Programmable digital PID filter with 16-bit coefficients

n Programmable derivative sampling interval

n 8- or 12-bit DAC output data (LM628)

n 8-bit sign-magnitude PWM output data (LM629)

n Internal trapezoidal velocity profile generator

n Velocity, target position, and filter parameters may be

changed during motion

n Position and velocity modes of operation

n Real-time programmable host interrupts

n 8-bit parallel asynchronous host interface

n Quadrature incremental encoder interface with index

pulse input

n Available in a 28-pin dual in-line package or a 24-pin

surface mount package (LM629 only)

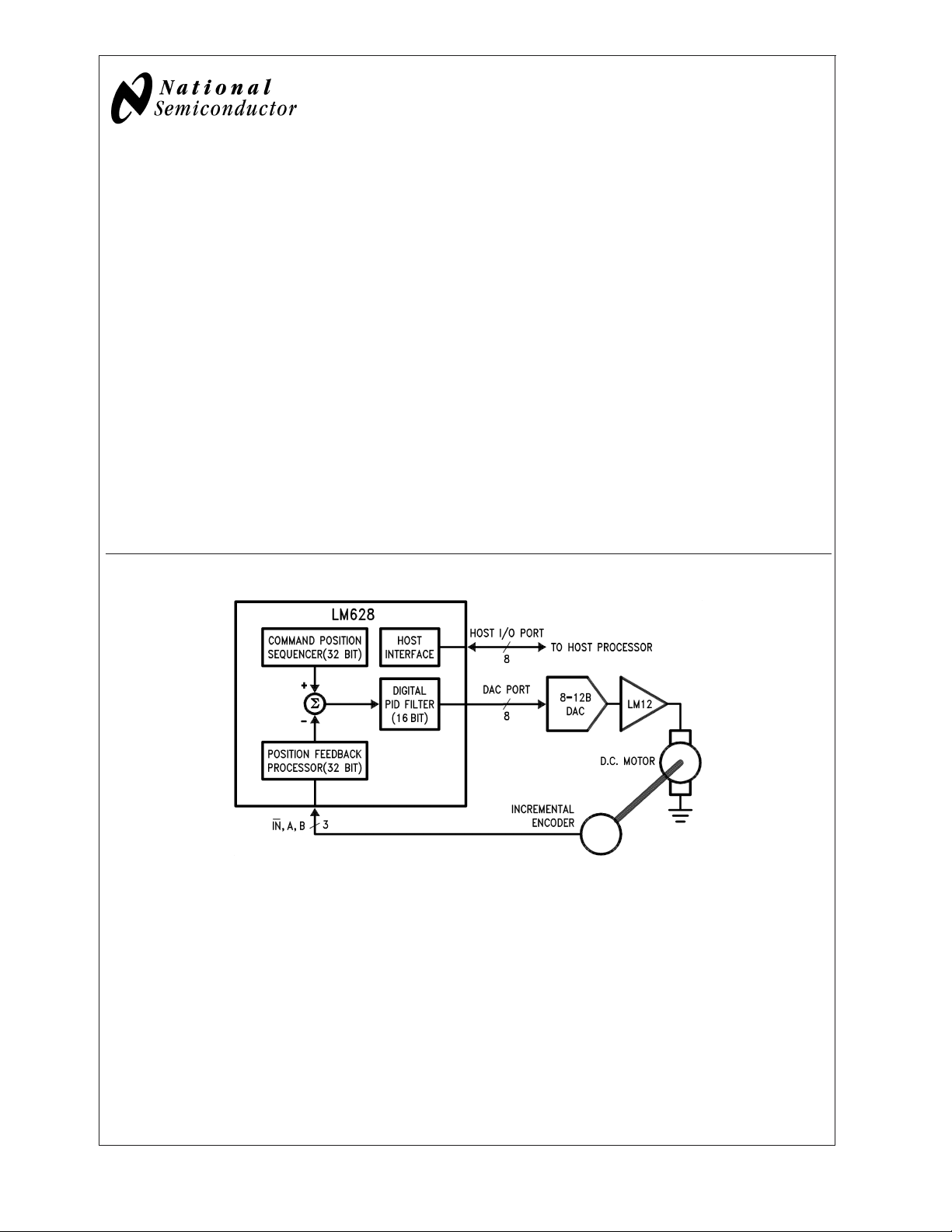

00921901

FIGURE 1. Block Diagram

TRISTATE&®is a registered trademark of National Semiconductor Corporation.

© 2003 National Semiconductor Corporation DS009219 www.national.com

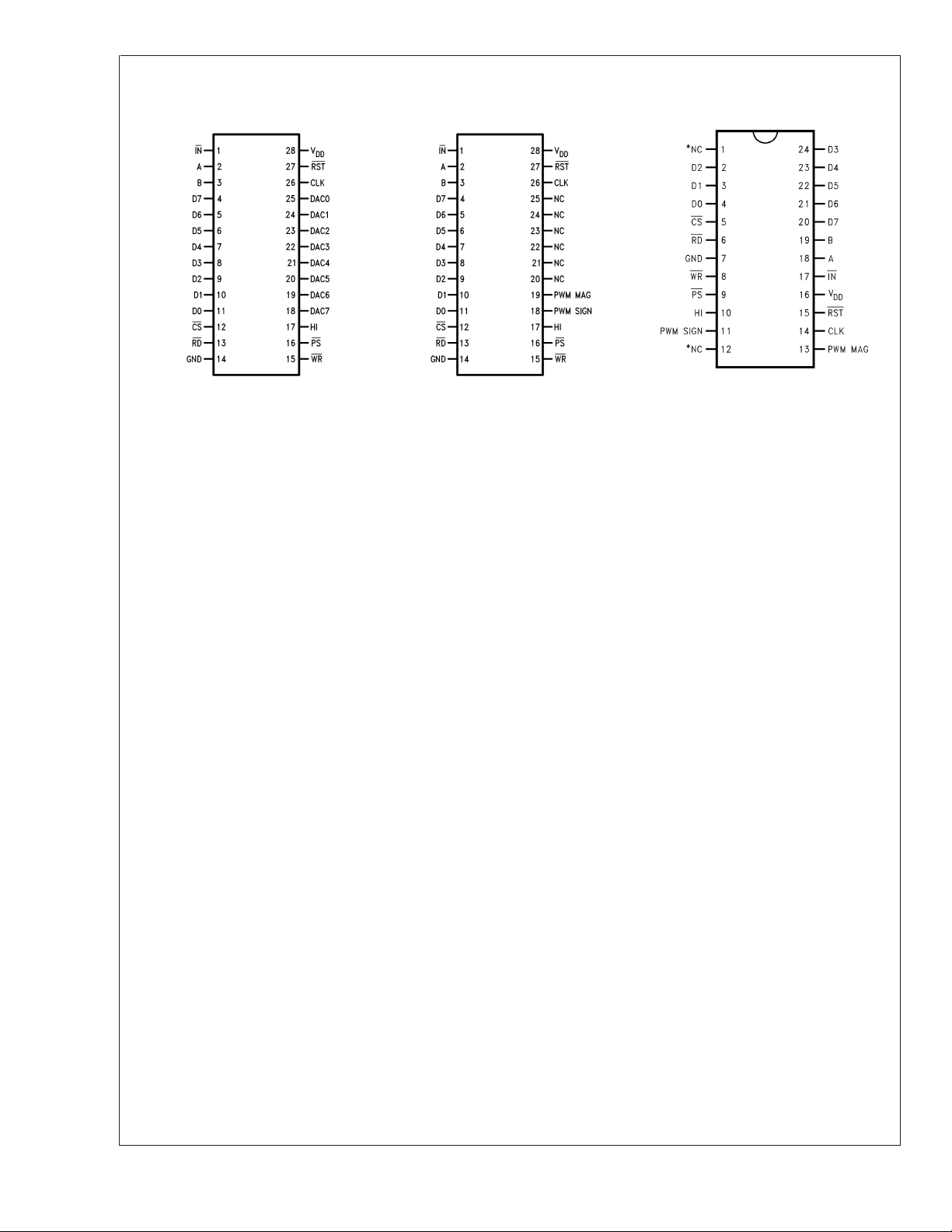

Connection Diagrams

LM628N LM629N LM629M

LM628/LM629

00921902 00921903

*Do not connect.

Order Number LM629M-6, LM629M-8, LM628N-6, LM628N-8, LM629N-6 or LM629N-8

See NS Package Number M24B or N28B

00921921

www.national.com 2

LM628/LM629

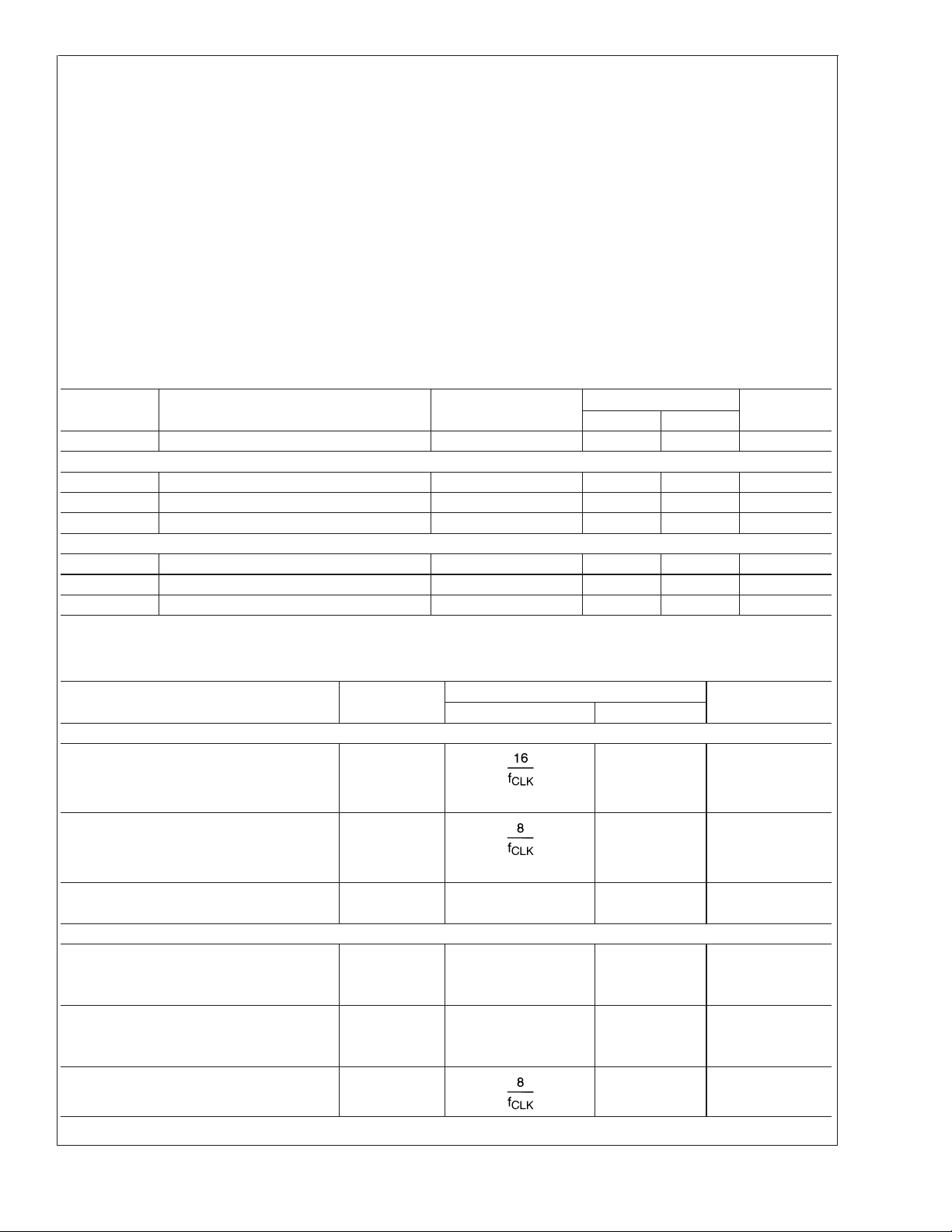

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Voltage at Any Pin with

(T

≤ 85˚C, (Note 2) 605 mW

A

ESD Tolerance

(C

= 120 pF, R

ZAP

= 1.5k) 1000V

ZAP

Operating Ratings

Respect to GND −0.3V to +7.0V

Ambient Storage Temperature −65˚C to +150˚C

Lead Temperature

28-pin Dual In-Line

Package (Soldering, 4 sec.) 260˚C

24-pin Surface Mount

Package (Soldering, 10 sec.) 300˚C

Maximum Power Dissipation

Temperature Range −40˚C<T

Clock Frequency:

LM628N-6, LM629N-6,

LM629M-6 1.0 MHz

LM628N-8, LM629N-8,

LM629M-8 1.0 MHz

V

Range 4.5V<V

DD

A

<

<

f

CLK

<

<

f

CLK

DD

DC Electrical Characteristics

(VDDand TAper Operating Ratings; f

Symbol Parameter Conditions Tested Limits Units

I

DD

Supply Current Outputs Open 110 mA

INPUT VOLTAGES

V

IH

V

IL

I

IN

Logic 1 Input Voltage 2.0 V

Logic 0 Input Voltage 0.8 V

Input Currents 0 ≤ VIN≤ V

OUTPUT VOLTAGES

V

V

I

OH

OL

OUT

Logic 1 IOH= −1.6 mA 2.4 V

Logic 0 IOL= 1.6 mA 0.4 V

TRI-STATE®Output Leakage Current 0 ≤ V

CLK

= 6 MHz)

OUT

≤ V

Min Max

DD

DD

−10 10 µA

−10 10 µA

<

+85˚C

6.0 MHz

8.0 MHz

<

5.5V

AC Electrical Characteristics

(VDDand TAper Operating Ratings; f

Timing Interval T

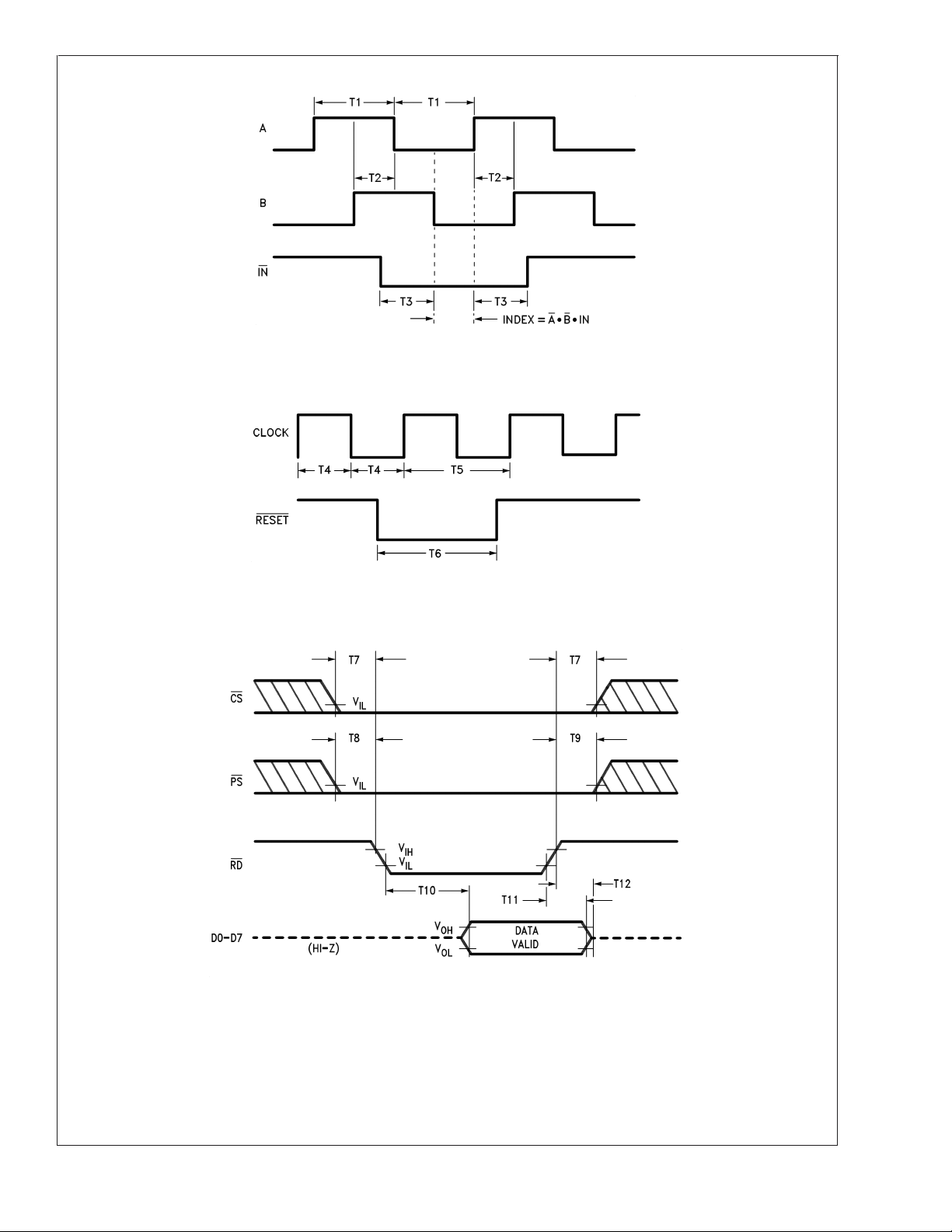

ENCODER AND INDEX TIMING (See Figure 2)

Motor-Phase Pulse Width T1

Dwell-Time per State T2

Index Pulse Setup and Hold T3 0 µs

(Relative to A and B Low)

CLOCK AND RESET TIMING (See Figure 3)

Clock Pulse Width

LM628N-6, LM629N-6, LM629M-6 T4 78 ns

LM628N-8, LM629N-8, LM629M-8 T4 57 ns

Clock Period

LM628N-6, LM629N-6, LM629M-6 T5 166 ns

LM628N-8, LM629N-8, LM629M-8 T5 125 ns

Reset Pulse Width T6

= 6 MHz; C

CLK

= 50 pF; Input Test Signal tr=tf= 10 ns)

LOAD

#

Tested Limits Units

Min Max

µs

µs

µs

www.national.com3

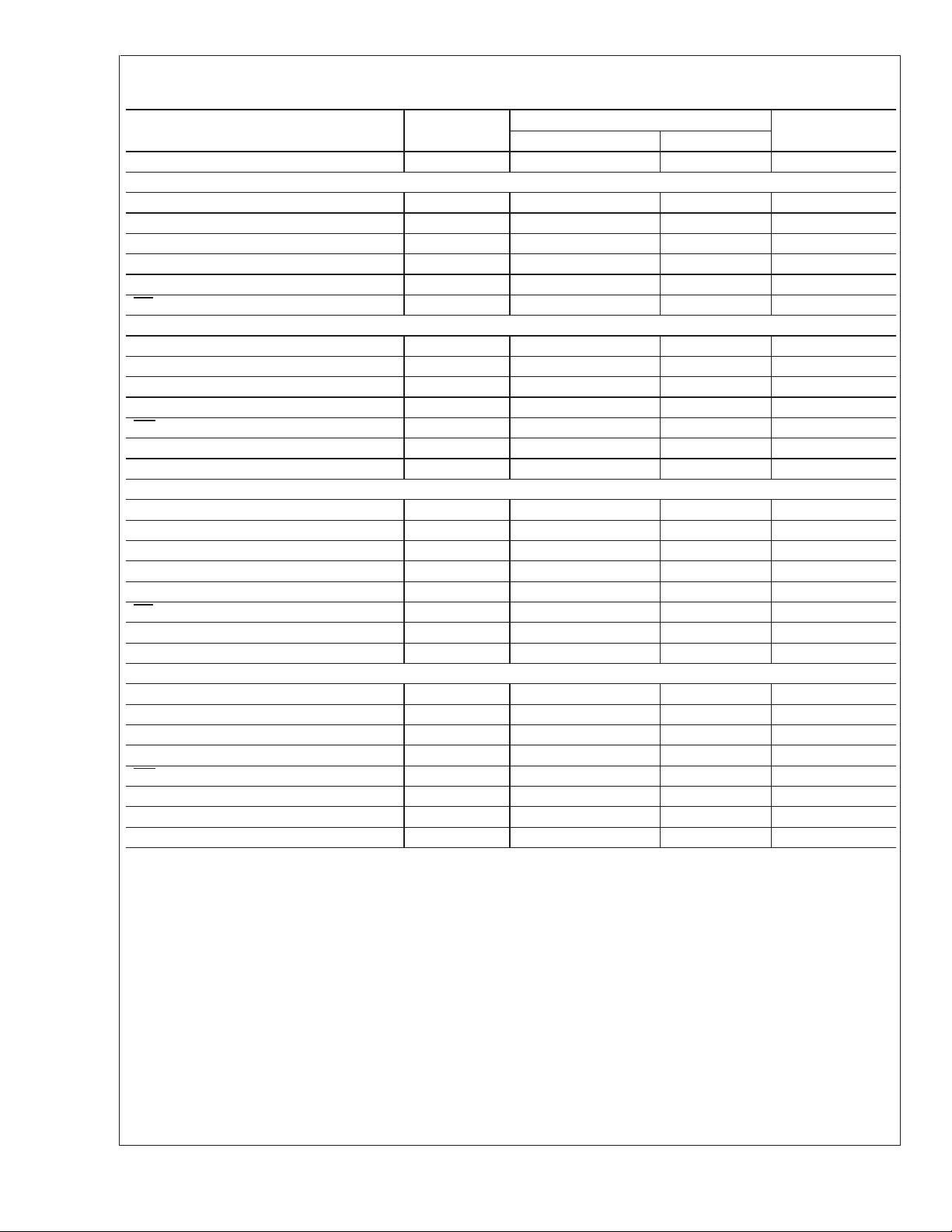

AC Electrical Characteristics (Continued)

(VDDand TAper Operating Ratings; f

Timing Interval T

LM628/LM629

STATUS BYTE READ TIMING (See Figure 4)

Chip-Select Setup/Hold Time T7 0 ns

Port-Select Setup Time T8 30 ns

Port-Select Hold Time T9 30 ns

Read Data Access Time T10 180 ns

Read Data Hold Time T11 0 ns

RD High to Hi-Z Time

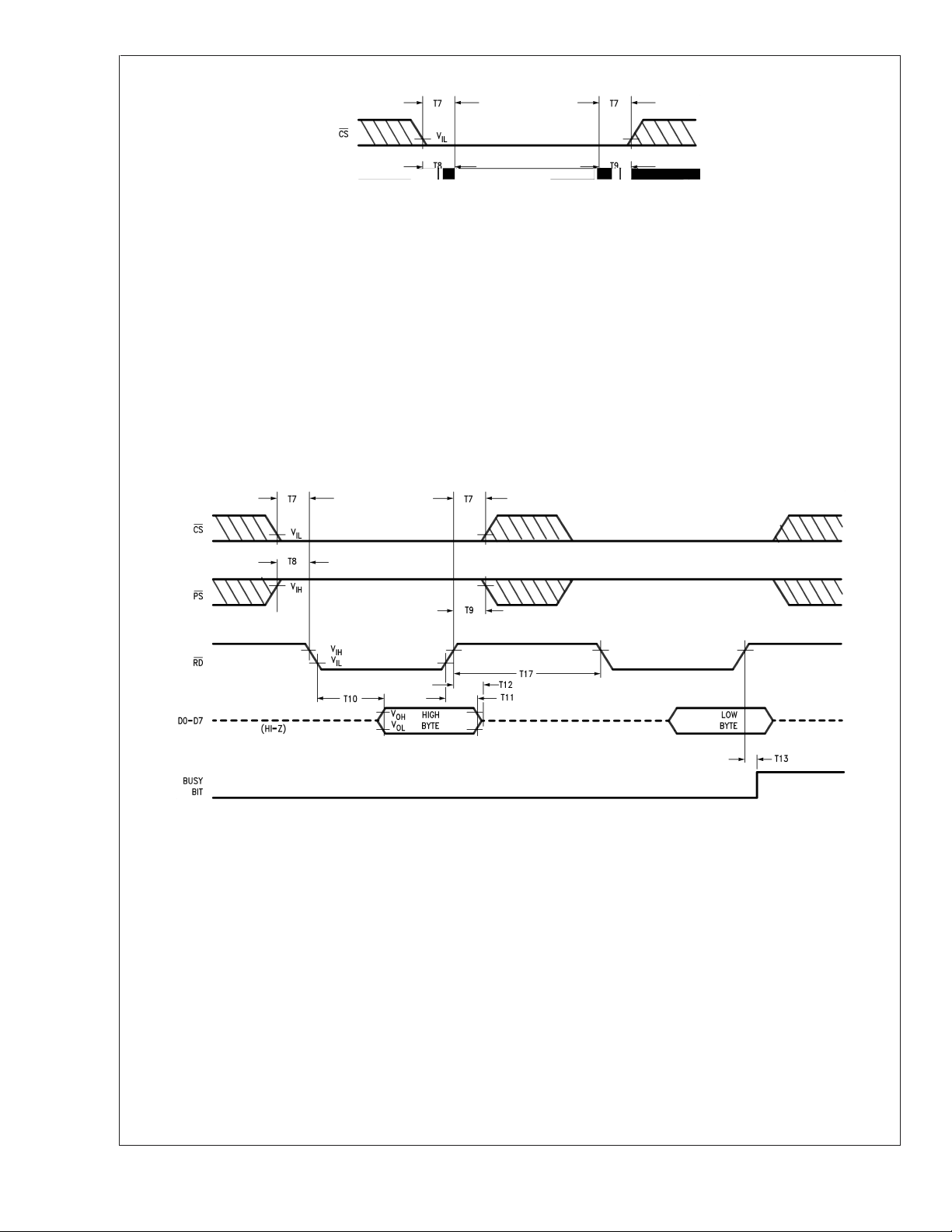

COMMAND BYTE WRITE TIMING (See Figure 5)

Chip-Select Setup/Hold Time T7 0 ns

Port-Select Setup Time T8 30 ns

Port-Select Hold Time T9 30 ns

Busy Bit Delay T13 (Note 3) ns

WR Pulse Width

Write Data Setup Time T15 50 ns

Write Data Hold Time T16 120 ns

DATA WORD READ TIMING (See Figure 6)

Chip-Select Setup/Hold Time T7 0 ns

Port-Select Setup Time T8 30 ns

Port-Select Hold Time T9 30 ns

Read Data Access Time T10 180 ns

Read Data Hold Time T11 0 ns

RD High to Hi-Z Time

Busy Bit Delay T13 (Note 3) ns

Read Recovery Time T17 120 ns

DATA WORD WRITE TIMING (See Figure 7)

Chip-Select Setup/Hold Time T7 0 ns

Port-Select Setup Time T8 30 ns

Port-Select Hold Time T9 30 ns

Busy Bit Delay T13 (Note 3) ns

WR Pulse Width

Write Data Setup Time T15 50 ns

Write Data Hold Time T16 120 ns

Write Recovery Time T18 120 ns

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. DC and AC electrical specifications do not apply when operating

the device beyond the above Operating Ratings.

Note 2: When operating at ambient temperatures above 70˚C, the device must be protected against excessive junction temperatures. Mounting the package on a

printed circuit board having an area greater than three square inches and surrounding the leads and body with wide copper traces and large, uninterrupted areas

of copper, such as a ground plane, suffices. The 28-pin DIP (N) and the 24-pin surface mount package (M) are molded plastic packages with solid copper lead

frames. Most of the heat generated at the die flows from the die, through the copper lead frame, and into copper traces on the printed circuit board.The copper traces

act as a heat sink. Double-sided or multi-layer boards provide heat transfer characteristics superior to those of single-sided boards.

Note 3: In order to read the busy bit, the status byte must first be read. The time required to read the busy bit far exceeds the time the chip requires to set the busy

bit. It is, therefore, impossible to test actual busy bit delay. The busy bit is guaranteed to be valid as soon as the user is able to read it.

= 6 MHz; C

CLK

= 50 pF; Input Test Signal tr=tf= 10 ns)

LOAD

#

Tested Limits Units

Min Max

T12 180 ns

T14 100 ns

T12 180 ns

T14 100 ns

www.national.com 4

FIGURE 2. Quadrature Encoder Input Timing

LM628/LM629

00921904

FIGURE 3. Clock and Reset Timing

FIGURE 4. Status Byte Read Timing

00921905

00921906

www.national.com5

LM628/LM629

00921907

FIGURE 5. Command Byte Write Timing

FIGURE 6. Data Word Read Timing

www.national.com 6

00921908

Pinout Description

(See Connection Diagrams) Pin numbers for the 24-pin surface mount package are indicated in parentheses.

Pin 1 (17), Index (IN) Input: Receives optional index pulse

from the encoder. Must be tied high if not used. The index

position is read when Pins 1, 2, and 3 are low.

Pins 2 and 3 (18 and 19), Encoder Signal (A, B) Inputs:

Receive the two-phase quadrature signals provided by the

incremental encoder. When the motor is rotating in the positive (“forward”) direction, the signal at Pin 2 leads the signal

at Pin 3 by 90 degrees. Note that the signals at Pins 2 and 3

must remain at each encoder state (See Figure 9) for a

minimum of 8 clock periods in order to be recognized. Because of a four-to-one resolution advantage gained by the

method of decoding the quadrature encoder signals, this

corresponds to a maximum encoder-state capture rate of 1.0

MHz (f

= 8.0 MHz) or 750 kHz (f

CLK

other clock frequencies the encoder signals must also remain at each state a minimum of 8 clock periods.

Pins 4 to 11 (20 to 24 and 2 to 4), Host I/O Port (D0 to D7):

Bi-directional data port which connects to host computer/

processor. Used for writing commands and data to the

LM628, and for reading the status byte and data from the

LM628, as controlled by CS (Pin 12), PS (Pin 16), RD (Pin

13), and WR (Pin 15).

= 6.0 MHz). For

CLK

Pinout Description (Continued)

within 1.5 ms. If the status word has not changed from hex

“00” to “84” or “C4” within 1.5 ms, perform another reset and

repeat the above steps. To be certain that the reset was

LM628/LM629

properly performed, execute a RSTI command. If the chip

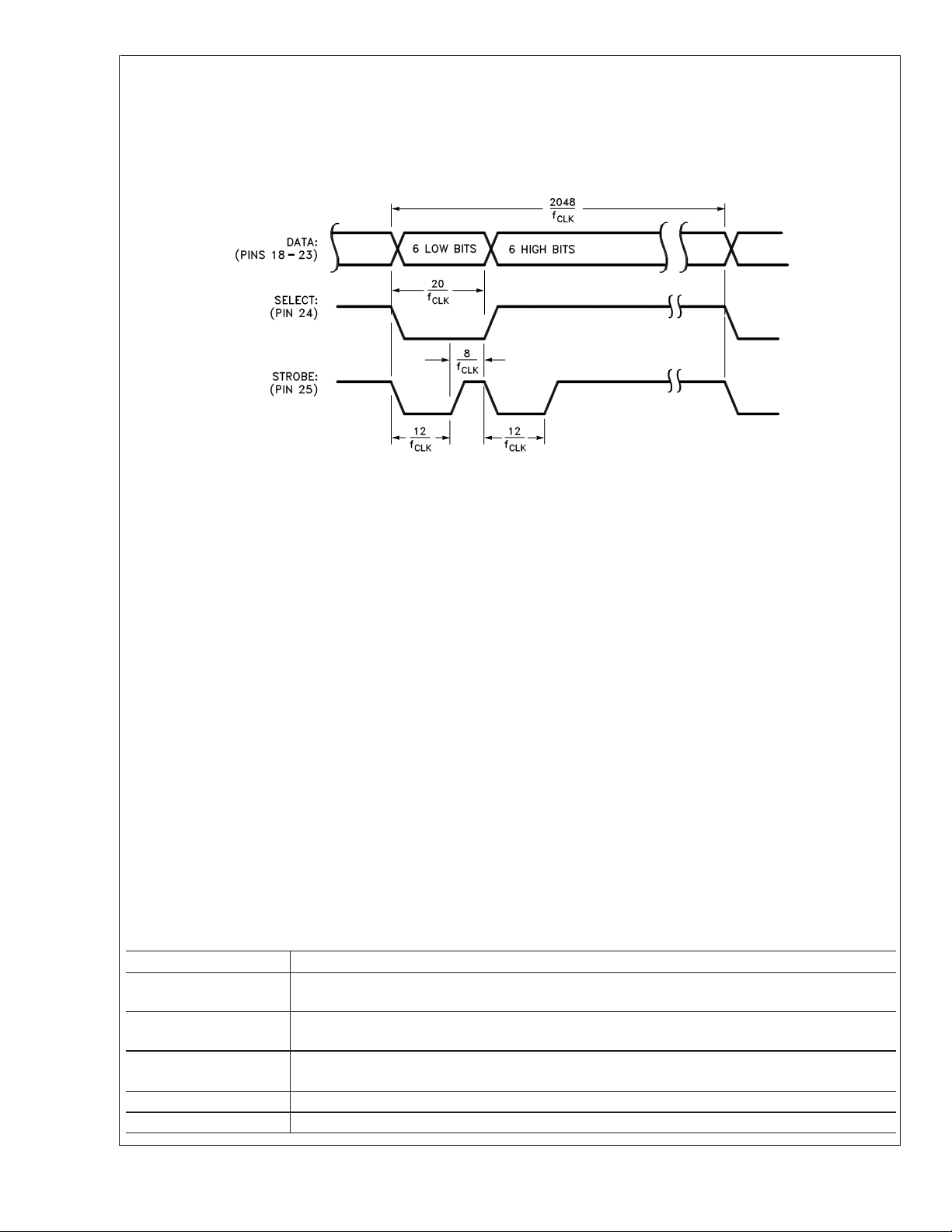

FIGURE 8. 12-Bit Multiplexed Output Timing

has reset properly, the status byte will change from hex “84”

or “C4” to hex “80” or “C0”. If this does not occur, perform

another reset and repeat the above steps.

Pin 28 (16), Supply Voltage (V

): Power supply voltage

DD

(+5V).

00921910

Theory of Operation

INTRODUCTION

The typical system block diagram (See Figure 1) illustrates a

servo system built using the LM628. The host processor

communicates with the LM628 through an I/O port to facilitate programming a trapezoidal velocity profile and a digital

compensation filter. The DAC output interfaces to an external digital-to-analog converter to produce the signal that is

power amplified and applied to the motor. An incremental

encoder provides feedback for closing the position servo

loop. The trapezoidal velocity profile generator calculates the

required trajectory for either position or velocity mode of

operation. In operation, the LM628 subtracts the actual position (feedback position) from the desired position (profile

generator position), and the resulting position error is processed by the digital filter to drive the motor to the desired

position. Table 1 provides a brief summary of specifications

offered by the LM628/LM629:

keep track of the absolute position of the motor. Each time a

logic transition occurs at one of the quadrature inputs, the

LM628 internal position register is incremented or decremented accordingly. This provides four times the resolution

over the number of lines provided by the encoder. See

Figure 9. Each of the encoder signal inputs is synchronized

with the LM628 clock.

The optional index pulse output provided by some encoders

assumes the logic-low state once per revolution. If the

LM628 is so programmed by the user, it will record the

absolute motor position in a dedicated register (the index

register) at the time when all three encoder inputs are logic

low.

If the encoder does not provide an index output, the LM628

index input can also be used to record the home position of

the motor. In this case, typically, the motor will close a switch

which is arranged to cause a logic-low level at the index

input, and the LM628 will record motor position in the index

register and alert (interrupt) the host processor. Permanently

grounding the index input will cause the LM628 to malfunc-

POSITION FEEDBACK INTERFACE

tion.

The LM628 interfaces to a motor via an incremental encoder.

Three inputs are provided: two quadrature signal inputs, and

an index pulse input. The quadrature signals are used to

TABLE 1. System Specifications Summary

Position Range −1,073,741,824 to 1,073,741,823 counts

Velocity Range 0 to 1,073,741,823/2

16

counts/sample; ie, 0 to 16,383 counts/sample, with a resolution of 1/2

counts/sample

Acceleration Range 0 to 1,073,741,823/2

resolution of 1/2

16

counts/sample/sample; ie, 0 to 16,383 counts/sample/sample, with a

16

counts/sample/sample

Motor Drive Output LM628: 8-bit parallel output to DAC, or 12-bit multiplexed output to DAC

LM629: 8-bit PWM sign/magnitude signals

Operating Modes Position and Velocity

Feedback Device Incremental Encoder (quadrature signals; support for index pulse)

16

www.national.com 8

Theory of Operation (Continued)

TABLE 1. System Specifications Summary (Continued)

Control Algorithm Proportional Integral Derivative (PID) (plus programmable integration limit)

Sample Intervals Derivative Term: Programmable from 2048/f

65,536 µs for an 8.0 MHz clock).

Proportional and Integral: 2048/f

CLK

FIGURE 9. Quadrature Encoder Signals

to (2048*256)/f

CLK

00921911

in steps of 2048/f

CLK

CLK

LM628/LM629

(256 to

FIGURE 10. Typical Velocity Profiles

VELOCITY PROFILE (TRAJECTORY) GENERATION

The trapezoidal velocity profile generator computes the desired position of the motor versus time. In the position mode

of operation, the host processor specifies acceleration, maximum velocity, and final position. The LM628 uses this information to affect the move by accelerating as specified until

the maximum velocity is reached or until deceleration must

begin to stop at the specified final position. The deceleration

rate is equal to the acceleration rate. At any time during the

move the maximum velocity and/or the target position may

be changed, and the motor will accelerate or decelerate

accordingly. Figure 10 illustrates two typical trapezoidal ve-

00921912

locity profiles. Figure 10(a) shows a simple trapezoid, while

Figure 10(b) is an example of what the trajectory looks like

when velocity and position are changed at different times

during the move.

When operating in the velocity mode, the motor accelerates

to the specified velocity at the specified acceleration rate and

maintains the specified velocity until commanded to stop.

The velocity is maintained by advancing the desired position

at a constant rate. If there are disturbances to the motion

during velocity mode operation, the long-time average velocity remains constant. If the motor is unable to maintain the

specified velocity (which could be caused by a locked rotor,

www.national.com9

Theory of Operation (Continued)

for example), the desired position will continue to be increased, resulting in a very large position error. If this condition goes undetected, and the impeding force on the motor

LM628/LM629

is subsequently released, the motor could reach a very high

velocity in order to catch up to the desired position (which is

still advancing as specified). This condition is easily detected; see commands LPEI and LPES.

All trajectory parameters are 32-bit values. Position is a

signed quantity. Acceleration and velocity are specified as

16-bit, positive-only integers having 16-bit fractions. The

integer portion of velocity specifies how many counts per

sampling interval the motor will traverse. The fractional portion designates an additional fractional count per sampling

interval. Although the position resolution of the LM628 is

limited to integer counts, the fractional counts provide increased average velocity resolution. Acceleration is treated

in the same manner. Each sampling interval the commanded

acceleration value is added to the current desired velocity to

generate a new desired velocity (unless the command velocity has been reached).

One determines the trajectory parameters for a desired

move as follows. If, for example, one has a 500-line shaft

encoder, desires that the motor accelerate at one revolution

per second per second until it is moving at 600 rpm, and then

decelerate to a stop at a position exactly 100 revolutions

from the start, one would calculate the trajectory parameters

as follows:

let P = target position (units = encoder counts)

*

let R = encoder lines

*

then R = 500

and P = 2000

P = 2000

P (coding) = 00030D40 (hex code written to LM628)

let V = velocity (units = counts/sample)

let T = sample time (seconds) = 341 µs (with 6 MHz clock)

let C = conversion factor = 1 minute/60 seconds

then V = R

and V = 2000

V = 6.82 counts/sample

V (scaled) = 6.82

V (rounded) = 446,956 (value to load)

V (coding) = 0006D1EC (hex code written to LM628)

let A = acceleration (units = counts/sample/sample)

A=R

then A = 2000

and A = 2.33E−4 counts/sample/sample

A (scaled) = 2.33E−4*65,536 = 15.24

A (rounded) = 15 (value to load)

A (coding) = 0000000F (hex code written to LM628)

The above position, velocity, and acceleration values must

be converted to binary codes to be loaded into the LM628.

The values shown for velocity and acceleration must be

multiplied by 65,536 (as shown) to adjust for the required

integer/fraction format of the input data. Note that after scaling the velocity and acceleration values, literal fractional data

cannot be loaded; the data must be rounded and converted

to binary. The factor of four increase in system resolution is

due to the method used to decode the quadrature encoder

signals, see Figure 9.

4 = 2000

*

desired number of revolutions

*

100 revs = 200,000 counts (value to load)

*T*C*

*

341E−6*1/60*600 rpm

*T*T*

*

341E−6*341E-6*1 rev/sec/sec

4 (system resolution)

desired rpm

*

65,536 = 446,955.52

desired acceleration (rev/sec/sec)

PID COMPENSATION FILTER

The LM628 uses a digital Proportional Integral Derivative

(PID) filter to compensate the control loop. The motor is held

at the desired position by applying a restoring force to the

motor that is proportional to the position error, plus the

integral of the error, plus the derivative of the error. The

following discrete-time equation illustrates the control performed by the LM628:

(1)

where u(n) is the motor control signal output at sample time

n, e(n) is the position error at sample time n, n'

indicates sampling at the derivative sampling rate,

and kp, ki, and kd are the discrete-time filter parameters loaded by the users.

The first term, the proportional term, provides a restoring

force porportional to the position error, just as does a spring

obeying Hooke’s law. The second term, the integration term,

provides a restoring force that grows with time, and thus

ensures that the static position error is zero. If there is a

constant torque loading, the motor will still be able to achieve

zero position error.

The third term, the derivative term, provides a force proportional to the rate of change of position error. It acts just like

viscous damping in a damped spring and mass system (like

a shock absorber in an automobile). The sampling interval

associated with the derivative term is user-selectable; this

capability enables the LM628 to control a wider range of

inertial loads (system mechanical time constants) by providing a better approximation of the continuous derivative. In

general, longer sampling intervals are useful for low-velocity

operations.

In operation, the filter algorithm receives a 16-bit error signal

from the loop summing-junction. The error signal is saturated

at 16 bits to ensure predictable behavior. In addition to being

multiplied by filter coefficient kp, the error signal is added to

an accumulation of previous errors (to form the integral

signal) and, at a rate determined by the chosen derivative

sampling interval, the previous error is subtracted from it (to

form the derivative signal). All filter multiplications are 16-bit

operations; only the bottom 16 bits of the product are used.

The integral signal is maintained to 24 bits, but only the top

16 bits are used. This scaling technique results in a more

usable (less sensitive) range of coefficient ki values. The 16

bits are right-shifted eight positions and multiplied by filter

coefficient ki to form the term which contributes to the motor

control output. The absolute magnitude of this product is

compared to coefficient il, and the lesser, appropriately

signed magnitude then contributes to the motor control signal.

The derivative signal is multiplied by coefficient kd each

derivative sampling interval. This product contributes to the

motor control output every sample interval, independent of

the user-chosen derivative sampling interval.

The kp, limited ki, and kd product terms are summed to form

a 16-bit quantity. Depending on the output mode (wordsize),

either the top 8 or top 12 bits become the motor control

output signal.

www.national.com 10

Theory of Operation (Continued)

LM628 READING AND WRITING OPERATIONS

The host processor writes commands to the LM628 via the

host I/O port when Port Select (PS ) input (Pin 16) is logic

low. The desired command code is applied to the parallel

port line and the Write (WR ) input (Pin 15) is strobed. The

command byte is latched into the LM628 on the rising edge

of the WR input. When writing command bytes it is necessary to first read the status byte and check the state of a flag

called the “busy bit” (Bit 0). If the busy bit is logic high, no

command write may take place. The busy bit is never high

longer than 100 µs, and typically falls within 15 µs to 25 µs.

The host processor reads the LM628 status byte in a similar

manner: by strobing the Read (RD ) input (Pin 13) when PS

(Pin 16) is low; status information remains valid as long as

RD is low.

Writing and reading data to/from the LM628 (as opposed to

writing commands and reading status) are done with PS (Pin

16) logic high. These writes and reads are always an integral

number (from one to seven) of two-byte words, with the first

byte of each word being the more significant. Each byte

requires a write (WR ) or read (RD ) strobe. When transferring data words (byte-pairs), it is necessary to first read the

status byte and check the state of the busy bit. When the

busy bit is logic low, the user may then sequentially transfer

both bytes comprising a data word, but the busy bit must

again be checked and found to be low before attempting to

LM628/LM629

transfer the next byte pair (when transferring multiple

words). Data transfers are accomplished via LM628-internal

interrupts (which are not nested); the busy bit informs the

host processor when the LM628 may not be interrupted for

data transfer (or a command byte). If a command is written

when the busy bit is high, the command will be ignored.

The busy bit goes high immediately after writing a command

byte, or reading or writing a second byte of data (See Figure

5 thru Figure 7).

MOTOR OUTPUTS

The LM628 DAC output port can be configured to provide

either a latched eight-bit parallel output or a multiplexed

12-bit output. The 8-bit output can be directly connected to a

flow-through (non-input-latching) D/A converter; the 12-bit

output can be easily demultiplexed using an external 6-bit

latch and an input-latching 12-bit D/A converter. The DAC

output data is offset-binary coded; the 8-bit code for zero is

80 hex and the 12-bit code for zero is 800 hex. Values less

than these cause a negative torque to be applied to the

motor and, conversely, larger values cause positive motor

torque. The LM628, when configured for 12-bit output, provides signals which control the demultiplexing process. See

for details.

The LM629 provides 8-bit, sign and magnitude PWM output

signals for directly driving switch-mode motor-drive amplifiers. Figure 11 shows the format of the PWM magnitude

output signal.

00921913

FIGURE 11. PWM Output Signal Format (Sign output (pin 18) not shown)

TABLE 2. LM628 User Command Set

Command Type Description Hex Data Note

Bytes

RESET Initialize Reset LM628 00 0 1

PORT8 Initialize Select 8-Bit Output 05 0 2

PORT12 Initialize Select 12-Bit Output 06 0 2

DFH Initialize Define Home 02 0 1

SIP Interrupt Set Index Position 03 0 1

LPEI Interrupt Interrupt on Error 1B 2 1

LPES Interrupt Stop on Error 1A 2 1

SBPA Interrupt Set Breakpoint, Absolute 20 4 1

www.national.com11

Theory of Operation (Continued)

TABLE 2. LM628 User Command Set (Continued)

Command Type Description Hex Data Note

Bytes

SBPR Interrupt Set Breakpoint, Relative 21 4 1

MSKI Interrupt Mask Interrupts 1C 2 1

RSTI Interrupt Reset Interrupts 1D 2 1

LFIL Filter Load Filter Parameters 1E 2 to 10 1

UDF Filter Update Filter 04 0 1

LTRJ Trajectory Load Trajectory 1F 2 to 14 1

STT Trajectory Start Motion 01 0 3

RDSTAT Report Read Status Byte None 1 1, 4

RDSIGS Report Read Signals Register 0C 2 1

RDIP Report Read Index Position 09 4 1

RDDP Report Read Desired Position 08 4 1

RDRP Report Read Real Position 0A 4 1

RDDV Report Read Desired Velocity 07 4 1

RDRV Report Read Real Velocity 0B 2 1

RDSUM Report Read Integration Sum 0D 2 1

Note 4: Commands may be executed “On the Fly” during motion.

Note 5: Commands not applicable to execution during motion.

Note 6: Command may be executed during motion if acceleration parameter was not changed.

Note 7: Command needs no code because the command port status-byte read is totally supported by hardware.

User Command Set

GENERAL

The following paragraphs describe the user command set of

the LM628. Some of the commands can be issued alone and

some require a supporting data structure. As examples, the

command STT (STarT motion) does not require additional

data; command LFIL (Load FILter parameters) requires additional data (derivative-term sampling interval and/or filter

parameters).

Commands are categorized by function: initialization, interrupt control, filter control, trajectory control, and data reporting. The commands are listed in Table 2 and described in the

following paragraphs. Along with each command name is its

command-byte code, the number of accompanying data

bytes that are to be written (or read), and a comment as to

whether the command is executable during motion.

Initialization Commands

The following four LM628 user commands are used primarily

to initialize the system for use.

RESET COMMAND: RESET THE LM628

Command Code: 00 Hex

Data Bytes: None

Executable During Motion: Yes

This command (and the hardware reset input, Pin 27) results

in setting the following data items to zero: filter coefficients

and their input buffers, trajectory parameters and their input

buffers, and the motor control output. A zero motor control

output is a half-scale, offset-binary code: (80 hex for the 8-bit

output mode; 800 hex for 12-bit mode). During reset, the

DAC port outputs 800 hex to “zero” a 12-bit DAC and reverts

to 80 hex to “zero” an 8-bit DAC. The command also clears

five of the six interrupt masks (only the SBPA/SBPR interrupt

is masked), sets the output port size to 8 bits, and defines

Initialization Commands (Continued)

DFH COMMAND: DEFINE HOME

Command Code: 02 Hex

Data Bytes: None

Executable During Motion: Yes

This command declares the current position as “home”, or

absolute position 0 (Zero). If DFH is executed during motion

it will not affect the stopping position of the on-going move

unless command STT is also executed.

Interrupt Control Commands

The following seven LM628 user commands are associated

with conditions which can be used to interrupt the host

computer. In order for any of the potential interrupt conditions to actually interrupt the host via Pin 17, the corresponding bit in the interrupt mask data associated with command

MSKI must have been set to logic high (the non-masked

state).

The identity of all interrupts is made known to the host via

reading and parsing the status byte. Even if all interrupts are

masked off via command MSKI, the state of each condition

is still reflected in the status byte. This feature facilitates

polling the LM628 for status information, as opposed to

interrupt driven operation.

SIP COMMAND: SET INDEX POSITION

Command Code: 03 Hex

Data Bytes: None

Executable During Motion: Yes

After this command is executed, the absolute position which

corresponds to the occurrence of the next index pulse input

will be recorded in the index register, and bit 3 of the status

byte will be set to logic high. The position is recorded when

both encoder-phase inputs and the index pulse input are

logic low. This register can then be read by the user (see

description for command RDIP) to facilitate aligning the definition of home position (see description of command DFH)

with an index pulse. The user can also arrange to have the

LM628 interrupt the host to signify that an index pulse has

occurred. See the descriptions for commands MSKI and

RSTI.

LPEI COMMAND: LOAD POSITION ERROR FOR INTERRUPT

Command Code: 1B Hex

Data Bytes: Two

Data Range: 0000 to 7FFF Hex

Executable During Motion: Yes

An excessive position error (the output of the loop summing

junction) can indicate a serious system problem; e.g., a

stalled rotor. Instruction LPEI allows the user to input a

threshold for position error detection. Error detection occurs

when the absolute magnitude of the position error exceeds

the threshold, which results in bit 5 of the status byte being

set to logic high. If it is desired to also stop (turn off) the

motor upon detecting excessive position error, see command LPES, below. The first byte of threshold data written

with command LPEI is the more significant. The user can

have the LM628 interrupt the host to signify that an excessive position error has occurred. See the descriptions for

commands MSKI and RSTI.

LM628/LM629

LPES COMMAND: LOAD POSITION ERROR FOR STOPPING

Command Code: 1A Hex

Data Bytes: Two

Data Range: 0000 to 7FFF Hex

Executable During Motion: Yes

Instruction LPES is essentially the same as command LPEI

above, but adds the feature of turning off the motor upon

detecting excessive position error. The motor drive is not

actually switched off, it is set to half-scale, the offset-binary

code for zero.As with command LPEI, bit 5 of the status byte

is also set to logic high. The first byte of threshold data

written with command LPES is the more significant. The user

can have the LM628 interrupt the host to signify that an

excessive position error has occurred. See the descriptions

for commands MSKI and RSTI.

SBPA COMMAND:

Command Code: 20 Hex

Data Bytes: Four

Data Range: C0000000 to 3FFFFFFF Hex

Executable During Motion: Yes

This command enables the user to set a breakpoint in terms

of absolute position. Bit 6 of the status byte is set to logic

high when the breakpoint position is reached. This condition

is useful for signaling trajectory and/or filter parameter updates. The user can also arrange to have the LM628 interrupt the host to signify that a breakpoint position has been

reached. See the descriptions for commands MSKI and

RSTI.

SBPR COMMAND:

Command Code: 21 Hex

Data Bytes: Four

Data Range: See Text

Executable During Motion: Yes

This command enables the user to set a breakpoint in terms

of relative position. As with command SBPA, bit 6 of the

status byte is set to logic high when the breakpoint position

(relative to the current commanded target position) is

reached. The relative breakpoint input value must be such

that when this value is added to the target position the result

remains within the absolute position range of the system

(C0000000 to 3FFFFFFF hex). This condition is useful for

signaling trajectory and/or filter parameter updates. The user

can also arrange to have the LM628 interrupt the host to

signify that a breakpoint position has been reached. See the

descriptions for commands MSKI and RSTI.

MSKI COMMAND: MASK INTERRUPTS

Command Code: 1C Hex

Data Bytes: Two

Data Range: See Text

Executable During Motion: Yes

The MSKI command lets the user determine which potential

interrupt condition(s) will interrupt the host. Bits 1 through 6

of the status byte are indicators of the six conditions which

are candidates for host interrupt(s). When interrupted, the

host then reads the status byte to learn which condition(s)

occurred. Note that the MSKI command is immediately followed by two data bytes. Bits 1 through 6 of the second (less

significant) byte written determine the masked/unmasked

status of each potential interrupt. Any zero(s) in this 6-bit

www.national.com13

Interrupt Control Commands

(Continued)

field will mask the corresponding interrupt(s); any one(s)

enable the interrupt(s). Other bits comprising the two bytes

LM628/LM629

have no effect. The mask controls only the host interrupt

process; reading the status byte will still reflect the actual

conditions independent of the mask byte. See Table 3.

TABLE 3. Mask and Reset Bit Allocations for Interrupts

Bit Position Function

Bits 15 thru 7 Not Used

Bit 6 Breakpoint Interrupt

Bit 5 Position-Error Interrupt

Bit 4 Wrap-Around Interrupt

Bit 3 Index-Pulse Interrupt

Bit 2 Trajectory-Complete Interrupt

Bit 1 Command-Error Interrupt

Bit 0 Not Used

(see Eq. 1) to values equal to or less than a user-defined

maximum value; this capability minimizes integral or reset

“wind-up” (an overshooting effect of the integral action). The

positive-only input value is compared to the absolute magnitude of the integration term; when the magnitude of integration term value exceeds il, the il value (with appropriate

sign) is substituted for the integration term value.

The derivative-term sampling interval is also programmable

via this command. After writing the command code, the first

two data bytes that are written specify the derivative-term

sampling interval and which of the four filter parameters

is/are to be written via any forthcoming data bytes. The first

byte written is the more significant. Thus the two data bytes

constitute a filter control word that informs the LM628 as to

the nature and number of any following data bytes. See

Table 4.

RSTI COMMAND: RESET INTERRUPTS

Command Code: 1D Hex

Data Bytes: Two

Data Range: See Text

Executable During Motion: Yes

When one of the potential interrupt conditions of Table 3

occurs, command RSTI is used to reset the corresponding

interrupt flag bit in the status byte. The host may reset one or

all flag bits. Resetting them one at a time allows the host to

service them one at a time according to a priority programmed by the user. As in the MSKI command, bits 1

through 6 of the second (less significant) byte correspond to

the potential interrupt conditions shown in Table 3. Also see

description of RDSTAT command. Any zero(s) in this 6-bit

field reset the corresponding interrupt(s). The remaining bits

have no effect.

Filter Control Commands

The following two LM628 user commands are used for setting the derivative-term sampling interval, for adjusting the

filter parameters as required to tune the system, and to

control the timing of these system changes.

LFIL COMMAND: LOAD FILTER PARAMETERS

Command Code: 1E Hex

Data Bytes: Two to Ten

Data Ranges…

Filter Control Word: See Text

Filter Coefficients: 0000 to 7FFF Hex (Pos Only)

Integration Limit: 0000 to 7FFF Hex (Pos Only)

Executable During Motion: Yes

The filter parameters (coefficients) which are written to the

LM628 to control loop compensation are: kp, ki, kd, and il

(integration limit). The integration limit (il) constrains the

contribution of the integration term

TABLE 4. Filter Control word Bit Allocation

Bit Position Function

Bit 15 Derivative Sampling Interval Bit 7

Bit 14 Derivative Sampling Interval Bit 6

Bit 13 Derivative Sampling Interval Bit 5

Bit 12 Derivative Sampling Interval Bit 4

Bit 11 Derivative Sampling Interval Bit 3

Bit 10 Derivative Sampling Interval Bit 2

Bit 9 Derivative Sampling Interval Bit 1

Bit 8 Derivative Sampling Interval Bit 0

Bit 7 Not Used

Bit 6 Not Used

Bit 5 Not Used

Bit 4 Not Used

Bit 3 Loading kp Data

Bit 2 Loading ki Data

Bit 1 Loading kd Data

Bit 0 Loading il Data

Bits 8 through 15 select the derivative-term sampling interval. See Table 5. The user must locally save and restore

these bits during successive writes of the filter control word.

Bits 4 through 7 of the filter control word are not used.

Bits 0 to 3 inform the LM628 as to whether any or all of the

filter parameters are about to be written. The user may

choose to update any or all (or none) of the filter parameters.

Those chosen for updating are so indicated by logic one(s) in

the corresponding bit position(s) of the filter control word.

The data bytes specified by and immediately following the

filter control word are written in pairs to comprise 16-bit

words. The order of sending the data words to the LM628

corresponds to the descending order shown in the above

description of the filter control word; i.e., beginning with kp,

then ki, kd and il. The first byte of each word is the moresignificant byte. Prior to writing a word (byte pair) it is necessary to check the busy bit in the status byte for readiness.

The required data is written to the primary buffers of a

double-buffered scheme by the above described operations;

www.national.com 14

Filter Control Commands (Continued)

it is not transferred to the secondary (working) registers until

the UDF command is executed. This fact can be used advantageously; the user can input numerous data ahead of

their actual use. This simple pipeline effect can relieve potential host computer data communications bottlenecks, and

facilitates easier synchronization of multiple-axis controls.

UDF COMMAND: UPDATE FILTER

Command Code: 04 Hex

Data Bytes: None

Executable During Motion: Yes

The UDF command is used to update the filter parameters,

the specifics of which have been programmed via the LFIL

command. Any or all parameters (derivative-term sampling

interval, kp, ki, kd, and/or il) may be changed by the appropriate command(s), but command UDF must be executed to

affect the change in filter tuning. Filter updating is synchronized with the calculations to eliminate erratic or spurious

behavior.

Trajectory Control Commands

The following two LM628 user commands are used for setting the trajectory control parameters (position, velocity, ac-

TABLE 5. Derivative-Term Sampling Interval Selection Codes

Bit Position Selected Derivative

15 14 13 12 11 10 9 8 Sampling Interval

00000000256µs

00000001512µs

00000010768µs

000000111024 µs, etc…

LM628/LM629

celeration), mode of operation (position or velocity), and

direction (velocity mode only) as required to describe a

desired motion or to select the mode of a manually directed

stop, and to control the timing of these system changes.

LTRJ COMMAND: LOAD TRAJECTORY PARAMETERS

Command Code: 1F Hex

Data Bytes: Two to Fourteen

Data Ranges…

Trajectory Control

Word: See Text

Position: C0000000 to 3FFFFFFF Hex

Velocity: 00000000 to 3FFFFFFF Hex

(Pos Only)

Acceleration: 00000000 to 3FFFFFFF Hex

(Pos Only)

Executable During

Motion: Conditionally, See Text

thru 1111111165,536 µs

Note 8: Sampling intervals shown are when using an 8.0 MHz clock. The 256 corresponds to 2048/8 MHz; sample intervals must be scaled for other clock

frequencies.

The trajectory control parameters which are written to the

LM628 to control motion are: acceleration, velocity, and position. In addition, indications as to whether these three

parameters are to be considered as absolute or relative

inputs, selection of velocity mode and direction, and manual

stopping mode selection and execution are programmable

via this command. After writing the command code, the first

two data bytes that are written specify which parameter(s)

is/are being changed. The first byte written is the more

significant. Thus the two data bytes constitute a trajectory

control word that informs the LM628 as to the nature and

number of any following data bytes. See Table 6.

TABLE 6. Trajectory Control Word Bit Allocation

Bit Position Function

Bit 15 Not Used

Bit 14 Not Used

Bit 13 Not Used

Bit 12 Forward Direction (Velocity Mode Only)

Bit 11 Velocity Mode

Bit 10 Stop Smoothly (Decelerate as

Programmed)

Bit Position Function

Bit 9 Stop Abruptly (Maximum Deceleration)

Bit 8 Turn Off Motor (Output Zero Drive)

Bit 7 Not Used

Bit 6 Not Used

Bit 5 Acceleration Will Be Loaded

Bit 4 Acceleration Data Is Relative

Bit 3 Velocity Will Be Loaded

Bit 2 Velocity Data Is Relative

Bit 1 Position Will Be Loaded

Bit 0 Position Data Is Relative

Bit 12 determines the motor direction when in the velocity

mode. Alogic one indicates forward direction. This bit has no

effect when in position mode.

Bit 11 determines whether the LM628 operates in velocity

mode (Bit 11 logic one) or position mode (Bit 11 logic zero).

Bits 8 through 10 are used to select the method of manually

stopping the motor. These bits are not provided for one to

merely specify the desired mode of stopping, in position

mode operations, normal stopping is always smooth and

www.national.com15

Trajectory Control Commands

(Continued)

occurs automatically at the end of the specified trajectory.

Under exceptional circumstances it may be desired to manu-

LM628/LM629

ally intervene with the trajectory generation process to affect

a premature stop. In velocity mode operations, however, the

normal means of stopping is via bits 8 through 10 (usually bit

10). Bit 8 is set to logic one to stop the motor by turning off

motor drive output (outputting the appropriate offset-binary

code to apply zero drive to the motor); bit 9 is set to one to

stop the motor abruptly (at maximum available acceleration,

by setting the target position equal to the current position);

and bit 10 is set to one to stop the motor smoothly by using

the current user-programmed acceleration value. Bits 8

through 10 are to be used exclusively; only one bit should be

a logic one at any time.

Bits 0 through 5 inform the LM628 as to whether any or all of

the trajectory controlling parameters are about to be written,

and whether the data should be interpreted as absolute or

relative. The user may choose to update any or all (or none)

of the trajectory parameters. Those chosen for updating are

so indicated by logic one(s) in the corresponding bit position(s). Any parameter may be changed while the motor is in

motion; however, if acceleration is changed then the next

STT command must not be issued until the LM628 has

completed the current move or has been manually stopped.

The data bytes specified by and immediately following the

trajectory control word are written in pairs which comprise

16-bit words. Each data item (parameter) requires two 16-bit

words; the word and byte order is most-to-least significant.

The order of sending the parameters to the LM628 corresponds to the descending order shown in the above description of the trajectory control word; i.e., beginning with acceleration, then velocity, and finally position.

Acceleration and velocity are 32 bits, positive only, but range

only from 0 (00000000 hex) to [2

bottom 16 bits of both acceleration and velocity are scaled

as fractional data; therefore, the least-significant integer data

bit for these parameters is bit 16 (where the bits are numbered 0 through 31). To determine the coding for a given

velocity, for example, one multiplies the desired velocity (in

counts per sample interval) times 65,536 and converts the

result to binary. The units of acceleration are counts per

sample per sample. The value loaded for acceleration must

not exceed the value loaded for velocity. Position is a signed,

32-bit integer, but ranges only from −[2

30

]−1 (3FFFFFFF Hex).

[2

The required data is written to the primary buffers of a

double-buffered scheme by the above described operations;

it is not transferred to the secondary (working) registers until

the STT command is executed. This fact can be used advantageously; the user can input numerous data ahead of

their actual use. This simple pipeline effect can relieve potential host computer data communications bottlenecks, and

facilitates easier synchronization of multiple-axis controls.

STT COMMAND: START MOTION CONTROL

Command Code: 01 Hex

Data Bytes: None

Executable During Motion: Yes, if acceleration has not

The STT command is used to execute the desired trajectory,

the specifics of which have been programmed via the LTRJ

command. Synchronization of multi-axis control (to within

30

]−1 (3FFFFFFF hex). The

30

] (C0000000 hex) to

been changed

one sample interval) can be arranged by loading the required trajectory parameters for each (and every) axis and

then simultaneously issuing a single STT command to all

axes. This command may be executed at any time, unless

the acceleration value has been changed and a trajectory

has not been completed or the motor has not been manually

stopped. If STT is issued during motion and acceleration has

been changed, a command error interrupt will be generated

and the command will be ignored.

Data Reporting Commands

The following seven LM628 user commands are used to

obtain data from various registers in the LM628. Status,

position, and velocity information are reported. With the

exception of RDSTAT, the data is read from the LM628 data

port after first writing the corresponding command to the

command port.

RDSTAT COMMAND: READ STATUS BYTE

Command Code: None

Byte Read: One

Data Range: See Text

Executable During Motion: Yes

The RDSTAT command is really not a command, but is listed

with the other commands because it is used very frequently

to control communications with the host computer. There is

no identification code; it is directly supported by the hardware and may be executed at any time. The single-byte

status read is selected by placing CS , PS and RD at logic

zero. See Table 7.

TABLE 7. Status Byte Bit Allocation

Bit Position Function

Bit 7 Motor Off

Bit 6 Breakpoint Reached [Interrupt]

Bit 5 Excessive Position Error [Interrupt]

Bit 4 Wraparound Occurred [Interrupt]

Bit 3 Index Pulse Observed [Interrupt]

Bit 2 Trajectory Complete [Interrupt]

Bit 1 Command Error [Interrupt]

Bit 0 Busy Bit

Bit 7, the motor-off flag, is set to logic one when the motor

drive output is off (at the half-scale, offset-binary code for

zero). The motor is turned off by any of the following conditions: power-up reset, command RESET, excessive position

error (if command LPES had been executed), or when command LTRJ is used to manually stop the motor via turning

the motor off. Note that when bit 7 is set in conjunction with

command LTRJ for producing a manual, motor-off stop, the

actual setting of bit 7 does not occur until command STT is

issued to affect the stop. Bit 7 is cleared by command STT,

except as described in the previous sentence.

Bit 6, the breakpoint-reached interrupt flag, is set to logic one

when the position breakpoint loaded via command SBPA or

SBPR has been exceeded. The flag is functional independent of the host interrupt mask status. Bit 6 is cleared via

command RSTI.

Bit 5, the excessive-position-error interrupt flag, is set to

logic one when a position-error interrupt condition exists.

This occurs when the error threshold loaded via command

www.national.com 16

LM628/LM629

Data Reporting Commands

(Continued)

LPEI or LPES has been exceeded. The flag is functional

independent of the host interrupt mask status. Bit 5 is

cleared via command RSTI.

Bit 4, the wraparound interrupt flag, is set to logic one when

a numerical “wraparound” has occurred. To “wraparound”

means to exceed the position address space of the LM628,

which could occur during velocity mode operation. If a wraparound has occurred, then position information will be in

error and this interrupt helps the user to ensure position data

integrity. The flag is functional independent of the host interrupt mask status. Bit 4 is cleared via command RSTI.

Bit 3, the index-pulse acquired interrupt flag, is set to logic

one when an index pulse has occurred (if command SIP had

been executed) and indicates that the index position register

has been updated. The flag is functional independent of the

host interrupt mask status. Bit 3 is cleared by command

RSTI.

Bit 2, the trajectory complete interrupt flag, is set to logic one

when the trajectory programmed by the LTRJ command and

initiated by the STT command has been completed. Because of overshoot or a limiting condition (such as commanding the velocity to be higher than the motor can

achieve), the motor may not yet be at the final commanded

position. This bit is the logical OR of bits 7 and 10 of the

Signals Register, see command RDSIGS below. The flag

functions independently of the host interrupt mask status. Bit

2 is cleared via command RSTI.

Bit 1, the command-error interrupt flag, is set to logic one

when the user attempts to read data when a write was

appropriate (or vice versa). The flag is functional independent of the host interrupt mask status. Bit 1 is cleared via

command RSTI.

Bit 0, the busy flag, is frequently tested by the user (via the

host computer program) to determine the busy/ready status

prior to writing and reading any data. Such writes and reads

may be executed only when bit 0 is logic zero (not busy). Any

command or data writes when the busy bit is high will be

ignored. Any data reads when the busy bit is high will read

the current contents of the I/O port buffers, not the data

expected by the host. Such reads or writes (with the busy bit

high) will not generate a command-error interrupt.

RDSIGS COMMAND: READ SIGNALS REGISTER

Command Code: 0C Hex

Bytes Read: Two

Data Range: See Text

Executable During Motion: Yes

The LM628 internal “signals” register may be read using this

command. The first byte read is the more significant. The

less significant byte of this register (with the exception of bit

0) duplicates the status byte. See Table 8.

Bit Position Function

Bit 10 On Target

Bit 9 Turn Off upon Excessive Position Error

Bit 8 Eight-Bit Output Mode

Bit 7 Motor Off

Bit 6 Breakpoint Reached [Interrupt]

Bit 5 Excessive Position Error [Interrupt]

Bit 4 Wraparound Occurred [Interrupt]

Bit 3 Index Pulse Acquired [Interrupt]

Bit 2 Trajectory Complete [Interrupt]

Bit 1 Command Error [Interrupt]

Bit 0 Acquire Next Index (SIP Executed)

Bit 15, the host interrupt flag, is set to logic one when the

host interrupt output (Pin 17) is logic one. Pin 17 is set to

logic one when any of the six host interrupt conditions occur

(if the corresponding interrupt has not been masked). Bit 15

(and Pin 17) are cleared via command RSTI.

Bit 14, the acceleration-loaded flag, is set to logic one when

acceleration data is written to the LM628. Bit 14 is cleared by

the STT command.

Bit 13, the UDF-executed flag, is set to logic one when the

UDF command is executed. Because bit 13 is cleared at the

end of the sampling interval in which it has been set, this

signal is very short-lived and probably not very profitable for

monitoring.

Bit 12, the forward direction flag, is meaningful only when the

LM628 is in velocity mode. The bit is set to logic one to

indicate that the desired direction of motion is “forward”; zero

indicates “reverse” direction. Bit 12 is set and cleared via

command LTRJ. The actual setting and clearing of bit 12

does not occur until command STT is executed.

Bit 11, the velocity mode flag, is set to logic one to indicate

that the user has selected (via command LTRJ) velocity

mode. Bit 11 is cleared when position mode is selected (via

command LTRJ). The actual setting and clearing of bit 11

does not occur until command STT is executed.

Bit 10, the on-target flag, is set to logic one when the

trajectory generator has completed its functions for the lastissued STT command. Bit 10 is cleared by the next STT

command.

Bit 9, the turn-off on-error flag, is set to logic one when

command LPES is executed. Bit 9 is cleared by command

LPEI.

Bit 8, the 8-bit output flag, is set to logic one when the LM628

is reset, or when command PORT8 is executed. Bit 8 is

cleared by command PORT12.

Bits 0 through 7 replicate the status byte (see ), with the

exception of bit 0. Bit 0, the acquire next index flag, is set to

logic one when command SIP is executed; it then remains

set until the next index pulse occurs.

TABLE 8. Signals Register Bit Allocation

Bit Position Function

Bit 15 Host Interrupt

Bit 14 Acceleration Loaded (But Not Updated)

Bit 13 UDF Executed (But Filter Not yet Updated)

Bit 12 Forward Direction

Bit 11 Velocity Mode

RDIP COMMAND: READ INDEX POSITION

Command Code: 09 Hex

Bytes Read: Four

Data Range: C0000000 to 3FFFFFFF Hex

Executable During Motion: Yes

This command reads the position recorded in the index

register. Reading the index register can be part of a system

error checking scheme. Whenever the SIP command is executed, the new index position minus the old index position,

www.national.com17

Data Reporting Commands

(Continued)

divided by the incremental encoder resolution (encoder lines

times four), should always be an integral number. The RDIP

LM628/LM629

command facilitates acquiring these data for host-based

calculations. The command can also be used to identify/

verify home or some other special position. The bytes are

read in most-to-least significant order.

RDDP COMMAND: READ DESIRED POSITION

Command Code: 08 Hex

Bytes Read: Four

Data Range: C0000000 to 3FFFFFFF Hex

Executable During Motion: Yes

This command reads the instantaneous desired (current

temporal ) position output of the profile generator. This is the

“setpoint” input to the position-loop summing junction. The

bytes are read in most-to-least significant order.

RDRP COMMAND: READ REAL POSITION

Command Code: 0A Hex

Bytes Read: Four

Data Range: C0000000 to 3FFFFFFF Hex

Executable During Motion: Yes

This command reads the current actual position of the motor.

This is the feedback input to the loop summing junction. The

bytes are read in most-to-least significant order.

RDDV COMMAND: READ DESIRED VELOCITY

Command Code: 07 Hex

Bytes Read: Four

Data Range: C0000001 to 3FFFFFFF

Executable During Motion: Yes

This command reads the integer and fractional portions of

the instantaneous desired (current temporal ) velocity, as

used to generate the desired position profile. The bytes are

read in most-to-least significant order. The value read is

properly scaled for numerical comparison with the usersupplied (commanded) velocity; however, because the two

least-significant bytes represent fractional velocity, only the

two most-significant bytes are appropriate for comparison

with the data obtained via command RDRV (see below).

Also note that, although the velocity input data is constrained

to positive numbers (see command LTRJ), the data returned

by command RDDV represents a signed quantity where

negative numbers represent operation in the reverse direction.

RDRV COMMAND: READ REAL VELOCITY

Command Code: 0B Hex

Bytes Read: Two

Data Range: C000 to 3FFF Hex, See Text

Executable During Motion: Yes

This command reads the integer portion of the instantaneous actual velocity of the motor. The internally maintained

fractional portion of velocity is not reported because the

reported data is derived by reading the incremental encoder,

which produces only integer data. For comparison with the

result obtained by executing command RDDV (or the usersupplied input value), the value returned by command RDRV

must be multiplied by 2

16

(shifted left 16 bit positions). Also,

as with command RDDV above, data returned by command

RDRVisasigned quantity, with negative values represent-

ing reverse-direction motion.

RDSUM COMMAND: READ INTEGRATION-TERM SUMMATION VALUE

Command Code: 0D Hex

Bytes Read: Two

Data Range: 00000 Hex to

Value of the Integration Limit

Executable During Motion: Yes

This command reads the value to which the integration term

has accumulated. The ability to read this value may be

helpful in initially or adaptively tuning the system.

±

the Current

Typical Applications

PROGRAMMING LM628 HOST HANDSHAKING (INTERRUPTS)

A few words regarding the LM628 host handshaking will be

helpful to the system programmer. As indicated in various

portions of the above text, the LM628 handshakes with the

host computer in two ways: via the host interrupt output (Pin

17), or via polling the status byte for “interrupt” conditions.

When the hardwired interrupt is used, the status byte is also

read and parsed to determine which of six possible conditions caused the interrupt.

When using the hardwired interrupt it is very important that

the host interrupt service routine does not interfere with a

command sequence which might have been in progress

when the interrupt occurred. If the host interrupt service

routine were to issue a command to the LM628 while it is in

the middle of an ongoing command sequence, the ongoing

command will be aborted (which could be detrimental to the

application).

Two approaches exist for avoiding this problem. If one is

using hardwired interrupts, they should be disabled at the

host prior to issuing any LM628 command sequence, and

re-enabled after each command sequence. The second approach is to avoid hardwired interrupts and poll the LM628

status byte for “interrupt” status. The status byte always

reflects the interrupt-condition status, independent of

whether or not the interrupts have been masked.

TYPICAL HOST COMPUTER/PROCESSOR INTERFACE

The LM628 is interfaced with the host computer/processor

via an 8-bit parallel bus. Figure 12 shows such an interface

and a minimum system configuration.

As shown in Figure 12, the LM628 interfaces with the host

data, address and control lines. The address lines are decoded to generate the LM628 CS input; the host address

LSB directly drives the LM628 PS input. Figure 12 also

shows an 8-bit DAC and an LM12 Power Op Amp interfaced

to the LM628.

LM628 AND HIGH PERFORMANCE CONTROLLER (HPC)INTERFACE

Figure 13 shows the LM628 interfaced to a National HPC

High Performance Controller. The delay and logic associated

with the WR line is used to effectively increase the write-data

hold time of the HPC (as seen at the LM628) by causing the

WR pulse to rise early. Note that the HPC CK2 output

www.national.com 18

Typical Applications (Continued)

provides the clock for the LM628. The 74LS245 is used to

decrease the read-data hold time, which is necessary when

interfacing to fast host busses.

INTERFACING A 12-BIT DAC

Figure 14 illustrates use of a 12-bit DAC with the LM628. The

74LS378 hex gated-D flip-flop and an inverter demultiplex

the 12-bit output. DAC offset must be adjusted to minimize

DAC linearity and monotonicity errors. Two methods exist for

making this adjustment. If the DAC1210 has been socketed,

remove it and temporarily connect a 15 kΩ resistor between

Pins 11 and 13 of the DAC socket (Pins 2 and 6 of the

LF356) and adjust the 25 kΩ potentiometer for 0V at Pin 6 of

the LF356.

If the DAC is not removable, the second method of adjustment requires that the DAC1210 inputs be presented an

all-zeros code. This can be arranged by commanding the

appropriate move via the LM628, but with no feedback from

the system encoder. When the all-zeros code is present,

adjust the pot for 0V at Pin 6 of the LF356.

A MONOLITHIC LINEAR DRIVE USING LM12 POWER OP AMP

Figure 15 shows a motor-drive amplifier built using the LM12

Power Operational Amplifier. This circuit is very simple and

can deliver up to 8A at 30V (using the LM12L/LM12CL).

Resistors R1 and R2 should be chosen to set the gain to

provide maximum output voltage consistent with maximum

input voltage. This example provides a gain of 2.2, which

allows for amplifier output saturation at

input, assuming power supply voltages of

fier gain should not be higher than necessary because the

system is non-linear when saturated, and because gain

should be controlled by the LM628. The LM12 can also be

configured as a current driver, see 1987 Linear Databook,

Vol. 1, p. 2–280.

±

22V with a±10V

±

30V. The ampli-

LM628/LM629

TYPICAL PWM MOTOR DRIVE INTERFACES

Figure 16 shows an LM18298 dual full-bridge driver interfaced to the LM629 PWM outputs to provide a switch-mode

power amplifier for driving small brush/commutator motors.

Incremental Encoder Interface

The incremental (position feedback) encoder interface consists of three lines: Phase A (Pin 2), Phase B (Pin 3), and

Index (Pin 1). The index pulse output is not available on

some encoders. The LM628 will work with both encoder

types, but commands SIP and RDIP will not be meaningful

without an index pulse (or alternative input for this input …

be sure to tie Pin 1 high if not used).

Some consideration is merited relative to use in high

Gaussian-noise environments. If noise is added to the encoder inputs (either or both inputs) and is such that it is not

sustained until the next encoder transition, the LM628 decoder logic will reject it. Noise that mimics quadrature counts

or persists through encoder transitions must be eliminated

by appropriate EMI design.

Simple digital “filtering” schemes merely reduce susceptibility to noise (there will always be noise pulses longer than the

filter can eliminate). Further, any noise filtering scheme reduces decoder bandwidth. In the LM628 it was decided

(since simple filtering does not eliminate the noise problem)

to not include a noise filter in favor of offering maximum

possible decoder bandwidth. Attempting to drive encoder

signals too long a distance with simple TTL lines can also be

a source of “noise” in the form of signal degradation (poor

risetime and/or ringing). This can also cause a system to

lose positional integrity. Probably the most effective countermeasure to noise induction can be had by using balancedline drivers and receivers on the encoder inputs. Figure 17

shows circuitry using the DS26LS31 and DS26LS32.

www.national.com19

Typical Applications (Continued)

LM628/LM629

Note:

00921914

FIGURE 12. Host Interface and Minimum System Configuration

www.national.com 20

Typical Applications (Continued)

LM628/LM629

00921915

FIGURE 13. LM628 and HPC Interface

www.national.com21

LM628/LM629

00921916

Typical Applications (Continued)

www.national.com 22

DAC offset must be adjusted to minimize DAC linearity and monotonicity errors. See text.

*

FIGURE 14. Interfacing a 12-Bit DAC and LM628

Typical Applications (Continued)

LM628/LM629

00921917

FIGURE 15. Driving a Motor with the LM12 Power Op Amp

FIGURE 16. PWM Drive for Brush/Commutator Motors

00921918

www.national.com23

Typical Applications (Continued)

LM628/LM629

FIGURE 17. Typical Balanced-Line Encoder Input Circuit

00921920

www.national.com 24

Physical Dimensions inches (millimeters) unless otherwise noted

LM628/LM629

24-Lead Small Outline Package (M)

Order Number LM629M-6 or LM629M-8

NS Package Number M24B

28 Lead Molded Dual-In-Line Package (N)

Order Number LM628N-6, LM628N-8, LM629N-6 or LM629N-8

NS Package Number N28B

www.national.com25

LM628/LM629 Precision Motion Controller

Notes

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

labeling, can be reasonably expected to result in a

significant injury to the user.

National Semiconductor

Americas Customer

Support Center

Email: new.feedback@nsc.com

Tel: 1-800-272-9959

www.national.com

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

National Semiconductor

Europe Customer Support Center

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Support Center

Fax: 65-6250 4466

Email: ap.support@nsc.com

Tel: 65-6254 4466

National Semiconductor

Japan Customer Support Center

Fax: 81-3-5639-7507

Email: nsj.crc@jksmtp.nsc.com

Tel: 81-3-5639-7560

Loading...

Loading...