LM5118

Wide Voltage Range Buck-Boost Controller

LM5118 Wide Voltage Range Buck-Boost Controller

May 19, 2008

General Description

The LM5118 wide voltage range Buck-Boost switching regulator controller features all of the functions necessary to implement a high performance, cost efficient Buck-Boost

regulator using a minimum of external components. The

Buck-Boost topology maintains output voltage regulation

when the input voltage is either less than or greater than the

output voltage making it especially suitable for automotive

applications. The LM5118 operates as a buck regulator while

the input voltage is sufficiently greater than the regulated output voltage and gradually transitions to the buck-boost mode

as the input voltage approaches the output. This dual mode

approach maintains regulation over a wide range of input

voltages with optimal conversion efficiency in the buck mode

and a glitch-free output during mode transitions. This easy to

use controller includes drivers for the high side buck MOSFET

and the low side boost MOSFET. The regulator’s control

method is based upon current mode control utilizing an emulated current ramp. Emulated current mode control reduces

noise sensitivity of the pulse-width modulation circuit, allowing reliable control of the very small duty cycles necessary in

high input voltage applications. Additional protection features

include current limit, thermal shutdown and an enable input.

The device is available in a power enhanced TSSOP-20

package featuring an exposed die attach pad to aid thermal

dissipation.

Typical Application Circuit

Features

Ultra-wide input voltage range from 3V to 75V

■

Emulated peak current mode control

■

Smooth transition between step-down and step- up modes

■

Switching frequency programmable to 500KHz

■

Oscillator synchronization capability

■

Internal high voltage bias regulator

■

Integrated high and low-side gate drivers

■

Programmable soft-start time

■

Ultra low shutdown current

■

Enable input wide bandwidth error amplifier

■

1.5% feedback reference accuracy

■

Thermal shutdown

■

Package

TSSOP-20EP (Exposed pad)

30058501

© 2008 National Semiconductor Corporation 300585 www.national.com

Connection Diagram

LM5118

See NS Package Numbers MXA20A

Top View

30058502

Ordering Information

Ordering Number Package Type NSC Package Drawing Supplied As

LM5118MH TSSOP-20EP MXA20A 73 Units Per Anti-Static Tube

LM5118MHX TSSOP-20EP MXA20A 2500 units shipped as Tape & Reel

Pin Descriptions

Pin Name Description

1 VIN Input supply voltage.

2 UVLO If the UVLO pin is below 1.23V, the regulator will be in standby mode (VCC regulator running, switching

regulator disabled). When the UVLO pin exceeds 1.23V, the regulator enters the normal operating mode. An

external voltage divider can be used to set an under-voltage shutdown threshold. A fixed 5 µA current is sourced

out of the EN pin. If a current limit condition exists for 256 consecutive switching cycles, an internal switch pulls

the UVLO pin to ground and then releases.

3 RT The internal oscillator frequency is set with a single resistor between this pin and the AGND pin. The

recommended frequency range is 50 kHz to 500 kHz.

4 EN If the EN pin is below 0.5V, the regulator will be in a low power state drawing less than 10 µA from VIN. EN

must be raised above 3V for normal operation.

5 RAMP Ramp control signal. An external capacitor connected between this pin and the AGND pin sets the ramp slope

used for emulated current mode control.

6 AGND Analog ground.

7 SS Soft-Start. An external capacitor and an internal 10 µA current source set the rise time of the error amp

reference. The SS pin is held low when VCC is less than the VCC under-voltage threshold (< 3.7V), when the

UVLO pin is low (< 1.23V), when EN is low (< 0.5V) or when thermal shutdown is active.

8 FB Feedback signal from the regulated output. Connect to the inverting input of the internal error amplifier.

9 COMP Output of the internal error amplifier. The loop compensation network should be connected between COMP

and the FB pin.

10 VOUT Output voltage monitor for emulated current mode control. Connect this pin directly to the regulated output.

11 SYNC Sync input for switching regulator synchronization to an external clock.

12 CS Current sense input. Connect to the diode side of the current sense resistor.

13 CSG Current sense ground input. Connect to the ground side of the current sense resistor.

14 PGND Power Ground.

15 LO Boost MOSFET gate drive output. Connect to the gate of the external boost MOSFET.

www.national.com 2

Pin Name Description

16 VCC Output of the bias regulator. Locally decouple to PGND using a low ESR/ESL capacitor located as close to

the controller as possible.

17 VCCX Optional input for an externally supplied bias supply. If the voltage at the VCCX pin is greater than 3.9V, the

internal VCC regulator is disabled and the VCC pin is internally connected to VCCX pin supply. If VCCX is not

used, connect to AGND.

18 HB High side gate driver supply used in bootstrap operation. The bootstrap capacitor supplies current to charge

the high side MOSFET gate. This capacitor should be placed as close to the controller as possible and

connected between HB and HS.

19 HO Buck MOSFET gate drive output. Connect to the gate of the high side buck MOSFET through a short, low

inductance path.

20 HS Buck MOSFET source pin. Connect to the source terminal of the high side buck MOSFET and the bootstrap

capacitor.

EP Solder to the ground plane under the IC to aid in heat dissipation.

LM5118

3 www.national.com

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

LM5118

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

VIN, EN, VOUT to GND -0.3V to 76V

VCC, LO, VCCX, UVLO to GND (Note 5) -0.3 to 15V

HB to HS -0.3 to 15V

HO to HS -0.3 to HB+0.3V

HS to GND -4V to 76V

CSG, CS to GND -0.3V to +0.3V

RAMP, SS, COMP, FB, SYNC, RT to GND -0.3 to 7V

ESD Rating

HBM (Note 2) 2 kV

Storage Temperature Range -55°C to +150°C

Junction Temperature +150°C

Operating Ratings (Note 1)

VIN (Note 4) 3V to 75V

VCC, VCCX 4.75V to 14V

Junction Temperature -40°C to +125°C

Electrical Characteristics Limits in standard type are for T

= 25°C only; limits in boldface type apply over the

J

junction temperature range of -40°C to +125°C. Unless otherwise specified, the following conditions apply: VIN = 48V, VCCX =

0V, EN = 5V, RT = 29.11 kΩ, No load on LO and HO (Note 3).

Symbol Parameter Conditions Min Typ Max Units

VIN SUPPLY

I

BIAS

I

BIASX

I

STDBY

VIN Operating Current VCCX = 0V 4.5 5.5 mA

VIN Operating Current VCCX = 5V 1 1.85 mA

VIN Shutdown Current EN = 0V 1 10 µA

VCC REGULATOR

V

CC(REG)

V

CC(REG)

VCC Regulation VCCX = 0V 6.8 7 7.2 V

VCC Regulation VCCX = 0V, VIN = 6V 5 5.25 5.5 V

VCC Sourcing Current Limit VCC = 0 21 35 mA

VCCX Switch threshold VCCX Rising 3.68 3.85 4.02 V

VCCX Switch hysterisis 0.2 V

VCCX Switch RDS(ON) ICCX = 10 mA 5 12

VCCX Switch Leakage VCCX = 0V 0.5 1 µA

VCCCX Pull-down Resistance VCCX = 3V 70

VCC Under-Voltage Lockout

VCC Rising 3.52 3.7 3.86 V

Voltage

VCC Under-Voltage Hysterisis 0.21 V

HB DC Bias current HB-HS = 15V 205 260 µA

VC LDO Mode Turn-off 10 V

EN INPUT

V

V

IL max

IH min

EN Input Low Threshold 0.5 V

EN Input High Threshold 3.00 V

EN Input Bias Current VEN = 3V -1 1 µA

EN Input Bias Current VEN = 0.5V -1 1 µA

EN Input Bias Current VEN = 75V 50 µA

UVLO THRESHOLDS

UVLO Standby Threshold UVLO Rising 1.191 1.231 1.271 V

UVLO Threshold Hysteresis 0.105 V

UVLO Pull-up Current Source UVLO = 0V 5 µA

UVLO Pull-down R

DS(ON)

100 200

SOFT- START

SS Current Source SS = 0V 7.5 10.5 13.5 µA

SS to FB Offset FB = 1.23V 150 mV

SS Output Low Voltage Sinking 100 µA, UVLO = 0V 7 mV

ERROR AMPLIFIER

V

REF

FB Reference Voltage Measured at FB pin,

1.212 1.230 1.248 V

FB = COMP

FB Input Bias Current FB = 2V 20 200 nA

Ω

kΩ

Ω

www.national.com 4

Symbol Parameter Conditions Min Typ Max Units

COMP Sink/Source Current 3 mA

A

OL

f

BW

DC Gain 80 dB

Unity Bain Bandwidth 3 MHz

PWM COMPARATORS

t

HO(OFF)

T

ON(MIN)

Forced HO Off-time 305 400 495 ns

Minimum HO On-time 70 ns

COMP to Comparator Offset 200 mV

OSCILLATOR (RT PIN)

f

SW1

f

SW2

Frequency 1

Frequency 2

SYNC

Sync threshold falling 1.3 V

CURRENT LIMIT

V

CS(TH)

Cycle-by-cycle Sense Voltage

Threshold (CS-CSG)

V

CS(THX)

Cycle-by-cycle Sense Voltage

Threshold (CS-CSG)

CS Bias Current CS = 0V 45 60 µA

CSG Bias Current CSG = 0V 45 60 µA

Current Limit Fault Timer 256 cycles

RAMP GENERATOR

I

R1

I

R2

I

R3

RAMP Current 1 VIN = 60V, VOUT = 10V 245 305 365 µA

RAMP Current 2 VIN = 12V, VOUT = 12V 95 115 135 µA

RAMP Current 3 VIN = 5V, VOUT = 12V 65 80 95 µA

VOUT Bias Current VOUT = 48V 245 µA

LOW SIDE (LO) GATE DRIVER

V

OLL

V

OHL

LO Low-state Output Voltage ILO = 100 mA 0.095 0.14 0.23 V

LO High-state Output Voltage ILO = -100 mA

LO Rise Time C-load = 1 nF, VCC = 8V 16 ns

LO Fall Time C-load = 1 nF, VCC = 8V 14 ns

I

I

OHL

OLL

Peak LO Source Current VLO = 0V, VCC = 8V 2.2 A

Peak LO Sink Current VLO = VCC = 8V 2.7 A

HIGH SIDE (HO) GATE DRIVER

V

OLH

V

OHH

HO Low-state Output Voltage IHO = 100 mA 0.1 0.135 0.21 V

HO High-state Output Voltage IHO = -100 mA,

HO Rise Time C-load = 1 nF, VCC = 8V 14 ns

HO Fall Time C-load = 1 nF, VCC = 8V 12 ns

I

OHH

I

OLH

Peak HO Source Current VHO = 0V, VCC = 8V 2.2 V

Peak HO Sink Current VHO = VCC = 8V 3.5 V

HB-HS Under Voltage Lock-out 3 V

BUCK-BOOST CHARACTERISTICS

Buck-Boost Mode Buck Duty Cycle (Note 5) 69 75 80 %

THERMAL

T

SD

Thermal Shutdown Temp. 165 °C

Thermal Shutdown Hysterisis 25 °C

θ

JA

θ

JC

Junction to Ambient 40 °C/W

Junction to Case 4 °C/W

RT = 29.11 kΩ

RT = 9.525 kΩ

178 200 224 kHz

450 515 575 kHz

RAMP = 0 Buck Mode -103 -125 -147 mV

RAMP = 0 Buck-Boost Mode -218 -255 -300 mV

0.25 V

V

= VCC-V

OHL

LO

0.25 V

V

= VHB-V

OHH

OH

LM5118

5 www.national.com

Note 1: Absolute Maximum Ratings are limits beyond which damage to the device may occur. Operating Ratings indicate conditions for which the device is

intended to be functional, but does not guarantee specific performance limits. For guaranteed specifications and test conditions see the Electrical Characteristics.

Note 2: The human body model is a 100pF capacitor discharged through a 1.5 kΩ resistor into each pin.

LM5118

Note 3: Min and Max limits are 100% production tested at 25°C. Limits over the operating temperature range are guaranteed through correlation using Statistical

Quality Control (SQC) methods. Limits are used to calculate National’s Average Outgoing Quality Level (AOQL).

Note 4: 5V VIN is required to initially start the controller.

Note 5: : When the duty cycle exceeds 75%, the LM5118 controller gradually phases into the Buck-Boost mode.

www.national.com 6

Typical Performance Characteristics

LM5118

Efficiency vs VIN and IOUT

VOUT = 12V

VCC vs VIN

30058503

Current Limit Threshold vs VOUT/VIN

VOUT = 12V

30058504

VCC vs IVCC

Error Amplifier Gain/Phase

30058505

30058507

30058506

LO and HO Peak Gate Current vs Output Voltage

VCC = 8V

30058508

7 www.national.com

LM5118

Oscillator Frequency vs RT

30058509

www.national.com 8

Block Diagram and Typical Application Circuit

LM5118

30058510

FIGURE 1.

9 www.national.com

Detailed Operating Description

The LM5118 high voltage switching regulator features all of

LM5118

the functions necessary to implement an efficient high voltage

buck or buck-boost regulator using a minimum of external

components. The regulator switches smoothly from buck to

buck-boost operation as the input voltage approaches the

output voltage, allowing operation with the input greater than

or less than the output voltage. This easy to use regulator

integrates high-side and low-side MOSFET drivers capable

of supplying peak currents of 2 Amps. The regulator control

method is based on current mode control utilizing an emulated current ramp. Peak current mode control provides inherent

line feed-forward, cycle-by-cycle current limiting and ease of

loop compensation. The use of an emulated control ramp reduces noise sensitivity of the pulse-width modulation circuit,

allowing reliable processing of very small duty cycles necessary in high input voltage applications. The operating frequency is user programmable from 50 kHz to 500 kHz. An

oscillator synchronization pin allows multiple LM5118 regulators to self synchronize or be synchronized to an external

clock. Fault protection features include current limiting, thermal shutdown and remote shutdown capability. An undervoltage lockout input allows regulator shutdown when the

input voltage is below a user selected threshold, and a low

state at the enable pin will put the regulator into an extremely

low current shutdown state. The device is available in the

TSSOP-20EP package featuring an exposed pad to aid in

thermal dissipation.

A buck-boost regulator can maintain regulation for input voltages either higher or lower than the output voltage. The

challenge is that buck-boost power converters are not as efficient as buck regulators. The LM5118 has been designed as

a dual mode controller whereby the power converter acts as

a buck regulator while the input voltage is above the output.

As the input voltage approaches the output voltage, a gradual

transition to the buck-boost mode occurs. The dual mode approach maintains regulation over a wide range of input voltages, while maintaining the optimal conversion efficiency in

the normal buck mode. The gradual transition between

modes eliminates disturbances at the output during transitions. Figure 2 shows the basic operation of the LM5118

regulator in the buck mode. In buck mode, transistor Q1 is

active and Q2 is disabled. The inductor current ramps in proportion to the Vin - Vout voltage difference when Q1 is active

and ramps down through the re-circulating diode D1 when Q1

is off. The first order buck mode transfer function is VOUT/

VIN = D, where D is the duty cycle of the buck switch, Q1.

FIGURE 2. Buck Mode Operation

Figure 3 shows the basic operation of buck-boost mode. In

buck-boost mode both Q1 and Q2 are active for the same time

interval each cycle. The inductor current ramps up (proportional to VIN) when Q1 and Q2 are active and ramps down

www.national.com 10

30058511

through the re-circulating diode during the off time. The first

order buck-boost transfer function is VOUT/VIN = D/(1-D),

where D is the duty cycle of Q1 and Q2.

FIGURE 3. Buck-Boost Mode Operation

LM5118

30058512

FIGURE 4. Mode Dependence on Duty Cycle (VOUT =12V)

Operation Modes

Figure 4 illustrates how duty cycle affects the operational

mode and is useful for reference in the following discussions.

Initially, only the buck switch is active and the buck duty cycle

increases to maintain output regulation as VIN decreases.

When VIN is approximately equal to 15.5V, the boost switch

begins to operate with a low duty cycle. If VIN continues to

fall, the boost switch duty cycle increases and the buck switch

duty cycle decreases until they become equal at VIN = 13.2V.

Buck Mode Operation: VIN > VOUT

The LM5118 buck-boost regulator operates as a conventional

buck regulator with emulated current mode control while VIN

is greater than VOUT and the buck mode duty cycle is less

than 75%. In buck mode, the LO gate drive output to the boost

switch remains low.

30058513

Buck-Boost Mode Operation: VIN ≊ VOUT

When VIN decreases relative to VOUT, the duty cycle of the

buck switch will increase to maintain regulation. Once the duty

cycle reaches 75%, the boost switch starts to operate with a

very small duty cycle. As VIN is further decreased, the boost

switch duty cycle increases until it is the same as the buck

switch. As VIN is further decreased below VOUT, the buck

and boost switch operate together with the same duty cycle

and the regulator is in full buck-boost mode. This feature allows the regulator to transition smoothly from buck to buckboost mode. It should be noted that the regulator can be

designed to operate with VIN less than 4 volts, but VIN must

be at least 5 volts during start-up. Figure 5 presents a timing

illustration of the gradual transition from buck to buck-boost

mode when the input voltage ramps downward over a few

switching cycles.

11 www.national.com

LM5118

30058555

FIGURE 5. Buck (HO) and Boost (LO) Switch Duty Cycle vs. Time,

Illustrating Gradual Mode Change with Decreasing Input Voltage

High Voltage Start-Up Regulator

The LM5118 contains a dual mode, high voltage linear regulator that provides the VCC bias supply for the PWM controller

and the MOSFET gate driver. The VIN input pin can be connected directly to input voltages as high as 75V. For input

voltages below 10V, an internal low dropout switch connects

VCC directly to VIN. In this supply range, VCC is approximately equal to VIN. For VIN voltages greater than 10V, the

low dropout switch is disabled and the VCC regulator is enabled to maintain VCC at approximately 7V. A wide operating

range of 4V to 75V (with a startup requirement of at least 5

volts) is achieved through the use of this dual mode regulator.

The output of the VCC regulator is current limited to 35 mA,

typical. Upon power up, the regulator sources current into the

capacitor connected to the VCC pin. When the voltage at the

VCC pin exceeds the VCC under-voltage threshold of 3.7V

and the UVLO input pin voltage is greater than 1.23V, the gate

driver outputs are enabled and a soft-start sequence begins.

The gate driver outputs remain enabled until VCC falls below

3.5V or the voltage at the UVLO pin falls below 1.13V.

In many applications the regulated output voltage or an aux-

iliary supply voltage can be applied to the VCCX pin to reduce

the IC power dissipation. For output voltages between 4V and

15V, VOUT can be connected directly to VCCX. When the

voltage at the VCCX pin is greater than 3.85V, the internal

VCC regulator is disabled and an internal switch connects

VCCX to VCC, reducing the internal power dissipation.

In high voltage applications extra care should be taken to ensure the VIN pin voltage does not exceed the absolute max-

imum voltage rating of 76V. During line or load transients,

voltage ringing on the VIN line that exceeds the absolute

maximum rating can damage the IC. Both careful PC board

layout and the use of quality bypass capacitors located close

to the VIN and GND pins are essential.

30058516

FIGURE 6. VIN and VCC Sequencing

Enable

The LM5118 contains an enable function which provides a

very low input current shutdown mode. If the EN pin is pulled

below 0.5V, the regulator enters shutdown mode, drawing

less than 10 µA from the VIN pin. Raising the EN input above

www.national.com 12

LM5118

3V returns the regulator to normal operation. The EN pin can

be tied directly to the VIN pin if this function is not needed. It

must not be left floating. A 1 MΩ pull-up resistor to VIN can

be used to interface with an open collector or open drain control signal.

UVLO

An under-voltage lockout pin is provided to disable the regulator when the input is below the desired operating range. If

the UVLO pin is below 1.13V, the regulator enters a standby

mode with the outputs disabled, but with VCC regulator operating. If the UVLO input exceeds 1.23V, the regulator will

resume normal operation. A voltage divider from the input to

ground can be used to set a VIN threshold to disable the regulator in brown-out conditions or for low input faults.

If a current limit fault exists for more than 256 clock cycles,

the regulator will enter a “hiccup” mode of current limiting and

the UVLO pin will be pulled low by an internal switch. This

switch turns off when the UVLO pin approaches ground potential allowing the UVLO pin to rise. A capacitor connected

to the UVLO pin will delay the return to a normal operating

level and thereby set the off-time of the hiccup mode fault

protection. An internal 5 µA pull-up current pulls the UVLO pin

to a high state to ensure normal operation when the VIN

UVLO function is not required and the pin is left floating.

Oscillator and Sync Capability

The LM5118 oscillator frequency is set by a single external

resistor connected between the RT pin and the AGND pin.

The RT resistor should be located very close to the device and

connected directly to the pins of the IC. To set a desired oscillator frequency (f), the necessary value for the RT resistor

can be calculated from the following equation:

The SYNC pin can be used to synchronize the internal oscillator to an external clock. The external clock must be of higher

frequency than the free-running frequency set by the RT resistor. A clock circuit with an open drain output is the recommended interface from the external clock to the SYNC pin.

The clock pulse duration should be greater than 15 ns.

30058518

FIGURE 7. Sync from Multiple Devices

Multiple LM5118 devices can be synchronized together simply by connecting the SYNC pins together. In this configuration all of the devices will be synchronized to the highest

frequency device. The diagram in Figure 7 illustrates the

SYNC input/output features of the LM5118. The internal oscillator circuit drives the SYNC pin with a strong pull-down/

weak pull-up inverter. When the SYNC pin is pulled low, either

by the internal oscillator or an external clock, the ramp cycle

of the oscillator is terminated and forced 400 ns off-time is

initiated before a new oscillator cycle begins. If the SYNC pins

of several LM5118 IC’s are connected together, the IC with

the highest internal clock frequency will pull all the connected

SYNC pins low and terminate the oscillator ramp cycles of the

other IC’s. The LM5118 with the highest programmed clock

frequency will serve as the master and control the switching

frequency of all the devices with lower oscillator frequencies.

30058519

FIGURE 8. Simplified Oscillator and Block Diagram with Sync I/O Circuit

13 www.national.com

Error Amplifier and PWM Comparator

LM5118

The internal high gain error amplifier generates an error signal

proportional to the difference between the regulated output

voltage and an internal precision reference (1.23V). The output of the error amplifier is connected to the COMP pin. Loop

compensation components, typically a type II network illus-

trated in Figure 1 are connected between the COMP and FB

pins. This network creates a low frequency pole, a zero, and

a noise reducing high frequency pole. The PWM comparator

compares the emulated current sense signal from the RAMP

generator to the error amplifier output voltage at the COMP

pin. The same error amplifier is used for operation in buck and

buck-boost mode.

FIGURE 9. Composition of Emulated Current Signal

Ramp Generator

The ramp signal of a pulse-width modulator with current mode

control is typically derived directly from the buck switch drain

current. This switch current corresponds to the positive slope

portion of the inductor current signal. Using this signal for the

PWM ramp simplifies the control loop transfer function to a

single pole response and provides inherent input voltage

feed-forward compensation. The disadvantage of using the

buck switch current signal for PWM control is the large leading

edge spike due to circuit parasitics. The leading edge spike

must be filtered or blanked to avoid early termination of the

PWM pulse. Also, the current measurement may introduce

significant propagation delays. The filtering, blanking time

and propagation delay limit the minimal achievable pulse

width. In applications where the input voltage may be relatively large in comparison to the output voltage, controlling a

small pulse width is necessary for regulation. The LM5118

utilizes a unique ramp generator which does not actually

measure the buck switch current but instead creates a signal

representing or emulating the inductor current. The emulated

ramp provides signal to the PWM comparator that is free of

leading edge spikes and measurement or filtering delays. The

current reconstruction is comprised of two elements, a sample-and-hold pedestal level and a ramp capacitor which is

charged by a controlled current source. Refer to Figure 9 for

details.

The sample-and-hold pedestal level is derived from a measurement of the re-circulating current through a current sense

resistor in series with the re-circulating diode of the buck regulator stage. A small value current sensing resistor is required

between the re-circulating diode anode and ground. The CS

30058525

and CSG pins should be Kelvin connected directly to the

sense resistor. The voltage level across the sense resistor is

sampled and held just prior to the onset of the next conduction

interval of the buck switch. The current sensing and sampleand-hold provide the DC level of the reconstructed current

signal. The sample and hold of the re-circulating diode current

is valid for both buck and buck-boost modes. The positive

slope inductor current ramp is emulated by an external capacitor connected from the RAMP pin to the AGND and an

internal voltage controlled current source. In buck mode, the

ramp current source that emulates the inductor current is a

function of the VIN and VOUT voltages per the following

equation:

In buck-boost mode, the ramp current source is a function of

the input voltage VIN, per the following equation:

Proper selection of the RAMP capacitor (C

on the value of the output inductor (L) and the current sense

resistor (RS). For proper current emulation, the sample and

hold pedestal value and the ramp amplitude must have the

same relative relationship to the actual inductor current. That

is:

) depends up-

RAMP

www.national.com 14

Where gm is the ramp generator transconductance (5 µA/V)

and A is the current sense amplifier gain (10V/V). The ramp

capacitor should be located very close to the device and connected directly to the RAMP and AGND pins.

The relationship between the average inductor current and

the pedestal value of the sampled inductor current can cause

instability in certain operating conditions. This instability is

known as sub-harmonic oscillation, which occurs when the

inductor ripple current does not return to its initial value by the

start of the next switching cycle. Sub-harmonic oscillation is

normally characterized by observing alternating wide and narrow pulses at the switch node. Adding a fixed slope voltage

ramp (slope compensation) to the current sense signal prevents this oscillation. The 50µA of offset current provided from

the emulated current source adds enough slope compensation to the ramp signal for output voltages less than or equal

to 12V. For higher output voltages, additional slope compensation may be required. In such applications, the ramp capacitor can be decreased from the nominal calculated value

to increase the ramp slope compensation.

The pedestal current sample is obtained from the current

sense resistor (Rs) connected to the CS and CSG pins. It is

sometimes helpful to adjust the internal current sense amplifier gain (A) to a lower value in order to obtain the higher

current limit threshold. Adding a pair of external resistors RG

in a series with CS and CSG as shown in Figure 10 reduces

the current sense amplifier gain A according to the following

equation:

LM5118

Current Limit

In the buck mode the average inductor current is equal to the

output current (Iout). In buck-boost mode the average inductor current is approximately equal to:

Consequently, the inductor current in buck-boost mode is

much larger especially when VOUT is large relative to VIN.

The LM5118 provides a current monitoring scheme to protect

the circuit from possible over-current conditions. When set

correctly, the emulated current sense signal is proportional to

the buck switch current with a scale factor determined by the

current sense resistor. The emulated ramp signal is applied

to the current limit comparator. If the peak of the emulated

ramp signal exceeds 1.25V when operating in the buck mode,

the PWM cycle is immediately terminated (cycle-by-cycle current limiting). In buck-boost mode the current limit threshold

is increased to 2.50V to allow higher peak inductor current.

To further protect the external switches during prolonged

overload conditions, an internal counter detects consecutive

cycles of current limiting. If the counter detects 256 consecutive current limited PWM cycles, the LM5118 enters a low

power dissipation hiccup mode. In the hiccup mode, the output drivers are disabled, the UVLO pin is momentarily pulled

low, and the soft-start capacitor is discharged. The regulator

is restarted with a normal soft-start sequence once the UVLO

pin charges back to 1.23V. The hiccup mode off-time can be

programmed by an external capacitor connected from UVLO

pin to ground. This hiccup cycle will repeat until the output

overload condition is removed.

In applications with low output inductance and high input voltage, the switch current may overshoot due to the propagation

delay of the current limit comparator and control circuitry. If

an overshoot should occur, the sample-and-hold circuit will

detect the excess re-circulating diode current. If the sampleand-hold pedestal level exceeds the internal current limit

threshold, the buck switch will be disabled and will skip PWM

cycles until the inductor current has decayed below the current limit threshold. This approach prevents current runaway

conditions due to propagation delays or inductor saturation

since the inductor current is forced to decay before the buck

switch is turned on again.

FIGURE 10. Current Limit and Ramp Circuit

15 www.national.com

30058523

Maximum Duty Cycle

Each conduction cycle of the buck switch is followed by a

LM5118

forced minimum off-time of 400ns to allow sufficient time for

the re-circulating diode current to be sampled. This forced offtime limits the maximum duty cycle of the controller. The

actual maximum duty cycle will vary with the operating frequency as follows:

D

= 1 - f x 400 x 10

MAX

where f is the oscillator frequency in Hz

FIGURE 11. Maximum Duty Cycle vs Frequency

Limiting the maximum duty cycle will limit the maximum boost

ratio (VOUT/VIN) while operating in buck-boost mode. For

example, from Figure 11, at an operating frequency of 500

kHz, D

With D= 80%, solving for VOUT results in,

VOUT = 4 x VIN

With a minimum input voltage of 5 volts, the maximum pos-

sible output voltage is 20 volts at f = 500 kHz. The buck-boost

step-up ratio can be increased by reducing the operating frequency which increases the maximum duty cycle.

is 80%. Using the buck-boost transfer function.

MAX

-9

Soft-Start

The soft-start feature allows the regulator to gradually reach

the initial steady state operating point, thus reducing start-up

stresses and surges. The internal 10 µA soft-start current

source gradually charges an external soft-start capacitor connected to the SS pin. The SS pin is connected to the positive

input of the internal error amplifier. The error amplifier controls

the pulse-width modulator such that the FB pin approximately

equals the SS pin as the SS capacitor is charged. Once the

SS pin voltage exceeds the internal 1.23V reference voltage,

the error amp is controlled by the reference instead of the SS

pin. The SS pin voltage is clamped by an internal amplifier at

a level of 150 mV above the FB pin voltage. This feature provides a soft-start controlled recovery in the event a severe

overload pulls the output voltage (and FB pin) well below normal regulation but doesn’t persist for 256 clock cycles.

30058526

Various sequencing and tracking schemes can be implemented using external circuits that limit or clamp the voltage

level of the SS pin. The SS pin acts as a non-inverting input

to the error amplifier anytime SS voltage is less than the 1.23V

reference. In the event a fault is detected (over-temperature,

VCC under-voltage, hiccup current limit), the soft-start capacitor will be discharged. When the fault condition is no

longer present, a new soft-start sequence will begin.

HO Ouput

The LM5118 contains a high side, high current gate driver and

associated high voltage level shift. This gate driver circuit

works in conjunction with an internal diode and an external

bootstrap capacitor. A 0.1 µF ceramic capacitor, connected

with short traces between the HB pin and HS pin is recommended for most circuit configurations. The size of the bootstrap capacitor depends on the gate charge of the external

FET. During the off time of the buck switch, the HS pin voltage

is approximately -0.5V and the bootstrap capacitor is charged

from VCC through the internal bootstrap diode. When operating with a high PWM duty cycle, the buck switch will be

forced off each cycle for 400ns to ensure that the bootstrap

capacitor is recharged.

Thermal Protection

Internal Thermal Shutdown circuitry is provided to protect the

integrated circuit in the event the maximum junction temperature is exceeded. When activated, typically at 165°C, the

controller is forced into a low power reset state, disabling the

output driver and the bias regulator. This protection is provided to prevent catastrophic failures from accidental device

overheating.

Application Information

The procedure for calculating the external components is illustrated with the following design example. The designations

used in the design example correlate to the final schematic

shown in Figure 18. The design specifications are:

•

VOUT = 12V

•

VIN = 5V to 75V

•

F = 300 kHz

•

Minimum load current (CCM operation) = 600 mA

•

Maximum load current = 3A

R7 = R

T

RT sets the oscillator switching frequency. Generally speaking, higher operating frequency applications will use smaller

components, but have higher switching losses. An operating

frequency of 300 kHz was selected for this example as a reasonable compromise for both component size and efficiency.

The value of RT can be calculated as follows:

therefore, R7 = 18.3 kΩ

www.national.com 16

30058529

FIGURE 12. Inductor Current Waveform

INDUCTOR SELECTION

L1

The inductor value is determined based upon the operating

frequency, load current, ripple current and the input and output voltages. Refer to Figure 12 for details.

To keep the circuit in continuous conduction mode (CCM), the

maximum ripple current IRIPPLE should be less than twice

the minimum load current. For the specified minimum load of

0.6A, the maximum ripple current is 1.2A p-p. Also, the minimum value of L must be calculated both for a buck and buckboost configurations. The final value of inductance will

generally be a compromise between the two modes. It is desirable to have a larger value inductor for buck mode, but the

saturation current rating for the inductor must be large for

buck-boost mode, resulting in a physically large inductor. Additionally, large value inductors present buck-boost mode

loop compensation challenges which will be discussed in error amplifier configuration section. For the design example,

the inductor values in both modes are calculated as:

Because the inductor selected is lower than calculated for the

Buck mode, the minimum load current for CCM in buck mode

is 1.68 A at maximum VIN.

With a 10 µH inductor, the worst case peak inductor currents

can be estimated for each case, assuming a 20% inductor

value tolerance.

For this example, the two equations yield:

I

= 5.43A

1(PEAK)

I

= 13.34A

2(PEAK)

An acceptable current limit setting would be 6.7A for buck

mode since the LM5118 automatically doubles the current

limit threshold in buck-boost mode. The selected inductor

must have a saturation current rating at least as high as the

buck-boost mode cycle-by-cycle current limit threshold, in this

case at least 13.5A. A 10 µH 15 amp inductor was chosen for

this application.

R13 = R

SENSE

To select the current sense resistor value, begin by calculating the value of R

R13

(BUCK)

= 23 mΩ

For the buck-boost mode, R

for both modes of operation.

SENSE

is given by:

SENSE

LM5118

Where:

V

is the output voltage

OUT

V

is the maximum input voltage

IN1

f is the switching frequency

I

is the selected inductor peak to peak ripple current (1.2

RIPPLE

A selected for this example)

V

is the minimum input voltage

IN2

The resulting inductor values are:

L1 = 28 µH, Buck Mode

L1 = 9.8 µH Buck-Boost mode

A 10 µH inductor was selected which is a compromise be-

tween these values, while favoring the buck-boost mode. As

will be illustrated in the compensation section below, the inductor value should be as low as possible to move the buckboost right-half-plane zero to a higher frequency. The ripple

current is then rechecked with the selected inductor value using the equations above,

I

RIPPLE(BUCK)

I

RIPPLE(BUCK-BOOST)

= 3.36A

= 1.17A

R13

(BUCK-BOOST)

A R

SENSE

guarantee the required maximum output current in the buck-

= 18.7 mΩ

value of no more than 18.7 mΩ must be used to

boost mode. A value of 15 mΩ was selected for component

tolerances and is a standard value.

R13 = 15 mΩ

C15 = C

RAMP

With the inductor value selected, the value of C3 necessary

for the emulation ramp circuit is:

With the inductance value (L1) selected as 10 µH, the calculated value for C

was selected.

is 333 pF. A standard value of 330 pF

RAMP

C9 - C12 = OUTPUT CAPACITORS

In buck-boost mode, the output capacitors C9 - C12 must

supply the entire output current during the switch on-time. For

this reason, the output capacitors are chosen for operation in

buck-boost mode, the demands being much less in buck operation. Both bulk capacitance and ESR must be considered

17 www.national.com

to guarantee a given output ripple voltage. Buck-boost mode

capacitance can be estimated from:

LM5118

case 0.6V drop across the diode, the maximum diode power

dissipation can be high. The diode should have a voltage rating of VIN and a current rating of IOUT. A conservative design

would at least double the advertised diode rating since specifications between manufacturers vary. For the reference design a 100V, 10A Schottky in a D2PAK package was selected.

ESR requirements can be estimated from:

For our example, with a ΔVOUT (output ripple) of 50 mV,

C

= 141 µF

MIN

ESR

= 3.8 mΩ

MAX

If hold-up times are a consideration, the values of input/output

capacitors must be increased appropriately. Note that it is

usually advantageous to use multiple capacitors in parallel to

achieve the ESR value required. Also, it is good practice to

put a .1 µF - .47 µF ceramic capacitor directly on the output

pins of the supply to reduce high frequency noise. Ceramic

capacitors have good ESR characteristics, and are a good

choice for input and output capacitors. It should be noted that

the effective capacitance of ceramic capacitors decreases

with dc bias. For larger bulk values of capacitance, a low ESR

electrolytic is usually used. However, electrolytic capacitors

have poor tolerance, especially over temperature, and the

selected value should be selected larger than the calculated

value to allow for temperature variation. Allowing for component tolerances, the following values of Cout were chosen for

this design example:

Two 180 µF Oscon electrolytic capacitors for bulk capacitance

Two 47 µF ceramic capacitors to reduce ESR

Two 0.47 µF ceramic capacitors to reduce spikes at the out-

put .

D1

Reverse recovery currents degrade performance and decrease efficiency. For these reasons, a Schottky diode of

appropriate ratings should be used for D1. The voltage rating

of the boost diode should be equal to VOUT plus some margin. Since D1 only conducts during the buck switch off time in

either mode, the current rating required is:

I

= I

DIODE

I

DIODE

x (1-D) Buck Mode

OUT

= I

Buck-Boost Mode

OUT

D4

A Schottky type re-circulating diode is required for all LM5118

applications. The near ideal reverse recovery characteristics

and low forward voltage drop are particularly important diode

characteristics for high input voltage and low output voltage

applications. The reverse recovery characteristic determines

how long the current surge lasts each cycle when the buck

switch is turned on. The reverse recovery characteristics of

Schottky diodes minimize the peak instantaneous power in

the buck switch during the turn-on transition. The reverse

breakdown rating of the diode should be selected for the maximum VIN plus some safety margin.

The forward voltage drop has a significant impact on the conversion efficiency, especially for applications with a low output

voltage. “Rated” current for diodes vary widely from various

manufacturers. For the LM5118 this current is user selectable

through the current sense resistor value. Assuming a worst

C1 - C5 = INPUT CAPACITORS

A typical regulator supply voltage has a large source

impedance at the switching frequency. Good quality input capacitors are necessary to limit the ripple voltage at the VIN

pin while supplying most of the switch current during the buck

switch on-time. When the buck switch turns on, the current

into the buck switch steps from zero to the lower peak of the

inductor current waveform, then ramps up to the peak value,

and then drops to the zero at turn-off. The RMS current rating

of the input capacitors depends on which mode of operation

is most critical.

This value is a maximum at 50% duty cycle which corresponds to VIN = 75 volts.

Checking both modes of operation we find:

I

RMS(BUCK)

I

RMS(BUCK-BOOST)

= 1.5 Amps

= 4.7 Amps

Therefore C1 - C5 should be sized to handle 4.7A of ripple

current. Quality ceramic capacitors with a low ESR should be

selected. To allow for capacitor tolerances, four 2.2 µF, 100V

ceramic capacitors will be used. If step input voltage transients are expected near the maximum rating of the LM5118,

a careful evaluation of the ringing and possible spikes at the

device VIN pin should be completed. An additional damping

network or input voltage clamp may be required in these cases.

C20

The capacitor at the VCC pin provides noise filtering and stability for the VCC regulator. The recommended value of C20

should be no smaller than 0.1 µF, and should be a good quality, low ESR, ceramic capacitor. A value of 1 µF was selected

for this design. C20 should be 10 x C8.

If operating without VCCX, then

f

x (QCBuck + Boost) + I

OSC

LOAD(INTERNAL)

must be less than the VCC current limit.

C8

The bootstrap capacitor between the HB and HS pins supplies the gate current to charge the buck switch gate at turnon. The recommended value of C8 is 0.1 µF to 0.47 µF, and

should be a good quality, low ESR, ceramic capacitor. A value

of 0.1 µF was chosen for this design.

C16 = C

SS

The capacitor at the SS pin determines the soft-start time, i.e.

the time for the reference voltage and the output voltage, to

reach the final regulated value. The time is determined from:

www.national.com 18

and assumes a current limit>Iload + ICout

For this application, a C16 value of 0.1 µF was chosen which

corresponds to a soft-start time of about 12 ms.

R8, R9

R8 and R9 set the output voltage level, the ratio of these resistors is calculated from:

For a 12V output, the R8/R9 ratio calculates to 9.76. The resistors should be chosen from standard value resistors and a

good starting point is to select resistors within power ratings

appropriate for the output voltage. Values of 309Ω for R9 and

2.67 kΩ for R8 were selected.

R1, R3, C21

A voltage divider can be connected to the UVLO pin to set a

minimum operating voltage VIN

feature is required, the easiest approach to select the divider

for the regulator. If this

(UVLO)

resistor values is to choose a value for R1 between 10 kΩ and

100 kΩ, while observing the minimum value of R1 necessary

to allow the UVLO switch to pull the UVLO pin low. This value

is:

R1 ≥ 1000 x V

IN(MAX)

R1 ≥ 75k in our example

R3 is then calculated from

SNUBBER

A snubber network across the buck re-circulating diode reduces ringing and spikes at the switching node. Excessive

ringing and spikes can cause erratic operation and increase

noise at the regulator output. In the limit, spikes beyond the

maximum voltage rating of the LM5118 or the re-circulating

diode can damage these devices. Selecting the values for the

snubber is best accomplished through empirical methods.

First, make sure the lead lengths for the snubber connections

are very short. Start with a resistor value between 5 and 20

Ohms. Increasing the value of the snubber capacitor results

in more damping, however the snubber losses increase. Select a minimum value of the capacitor that provides adequate

clamping of the diode waveform at maximum load. A snubber

may be required for the boost diode as well. The same empirical procedure applies. Snubbers were not necessary in

this example.

Error Amplifier Configuration

R4, C18, C17

These components configure the error amplifier gain characteristics to accomplish a stable overall loop gain. One advantage of current mode control is the ability to close the loop with

only three feedback components, R4, C18 and C17. The

overall loop gain is the product of the modulator gain and the

error amplifier gain. The DC modulator gain of the LM5118 is

as follows:

The dominant, low frequency pole of the modulator is determined by the load resistance (R

(C

). The corner frequency of this pole is:

OUT

) and output capacitance

LOAD

LM5118

Since VIN

some margin in component tolerances and input ripple.

for our example is 5V, set VIN

(MIN)

(UVLO)

to 4.0V for

R1 = 75k is chosen since it is a standard value

R3 = 29.332k is calculated from the equation above. 29.4k

was used since it is a standard value.

Capacitor C21 provides filtering for the divider and the off time

of the “hiccup” duty cycle during current limit. The voltage at

the UVLO pin should never exceed 15V when using an external set-point divider. It may be necessary to clamp the

UVLO pin at high input voltages.

Knowing the desired off time during “hiccup” current limit, the

value of C21 is given by:

Notice that t

varies with V

OFF

IN

In this example, C21 was chosen to be 0.1 µF. This will set

the t

time to 956 µs with VIN = 12V.

OFF

R2

A 1M pull-up resistor connected from the EN pin to the VIN

pin is sufficient to keep enable in a high state if on-off control

is not used.

For this example, R

µF, therefore:

f

= 149 Hz

P(MOD)

DC Gain

=3.63 = 11.2 dB

(MOD)

LOAD

= 4Ω, D

= 0.294, and C

MIN

OUT

= 454

Additionally, there is a right-half plane (RHP) zero associated

with the modulator. The frequency of the RHP zero is:

f

= 7.8 kHz

RHPzero

The output capacitor ESR produces a zero given by:

ESR

ZERO

= 70 kHz

The RHP zero complicates compensation. The best design

approach is to reduce the loop gain to cross zero at about

30% of the calculated RHP zero frequency. The Type ll error

amplifier compensation provided by R4, C18 and C17 places

one pole at the origin for high DC gain. The 2nd pole should

19 www.national.com

be located close to the RHP zero. The error amplifier zero

(see below) should be placed near the dominate modulator

pole. This is a good starting point for compensation. Refer to

LM5118

the on-line LM5118 Quick-Start calculator for ready to use

equations and more details.

Components R4 and C18 configure the error amplifier as a

type II configuration which has a DC pole and a zero at

C17 introduces an additional pole used to cancel high frequency switching noise. The error amplifier zero cancels the

modulator pole leaving a single pose response at the

crossover frequency of the loop gain if the crossover frequency is much lower than the right half plane zero frequency. A

single pole response at the crossover frequency yields a very

stable loop with 90 degrees of phase margin.

For the design example, a target loop bandwidth (crossover

frequency) of 2.0 kHz was selected (about 30% of the right-

half-plane zero frequency). The error amplifier zero (fz)

should be selected at a frequency near that of the modulator

pole and much less than the target crossover frequency. This

constrains the product of R4 and C18 for a desired compensation network zero to be less than 2 kHz. Increasing R4,

while proportionally decreasing C18 increases the error amp

gain. Conversely, decreasing R4 while proportionally increasing C18 decreases the error amp gain. For the design example C18 was selected for 4.7 nF and R4 was selected to be

10 kΩ. These values set the compensation network zero at

149 Hz. The overall loop gain can be predicted as the sum (in

dB) of the modulator gain and the error amp gain.

If a network analyzer is available, the modulator gain can be

measured and the error amplifier gain can be configured for

the desired loop transfer function. If a network analyzer is not

available, the error amplifier compensation components can

be designed with the guidelines given. Step load transient

tests can be performed to verify acceptable performance. The

step load goal is minimal overshoot with a damped response.

FIGURE 13. Modulator Gain and Phase

FIGURE 14. Error Amplifier Gain and Phase

www.national.com 20

30058548

30058549

30058550

FIGURE 15. Overall Loop Gain and Phase

LM5118

The plots shown in Figures 13, 14 and 15 illustrate the gain

and phase diagrams of the design example. The overall bandwidth is lower in a buck-boost application due the compensation challenges associated with the right-half-plane zero.

For a pure buck application, the bandwidth could be much

higher. The LM5116 datasheet is a good reference for compensation design of a pure buck mode regulator.

Bias Power Dissipation Reduction

Buck or Buck-boost regulators operating with high input voltage can dissipate an appreciable amount of power while

supplying the required bias current of the IC. The VCC regulator must step-down the input voltage VIN to a nominal VCC

level of 7V. The large voltage drop across the VCC regulator

translates into high power dissipation in the VCC regulator.

There are several techniques that can significantly reduce this

bias regulator power dissipation. Figures 16 and 17 depict two

methods to bias the IC, one from the output voltage and one

from a separate bias supply. In the first case, the internal VCC

regulator is used to initially bias the VCC pin. After the output

voltage is established, the VCC pin bias current is supplied

through the VCCX pin, which effectively disables the internal

VCC regulator. Any voltage greater than 4.0V can supply

VCC bias through the VCCX pin. However, the voltage applied to the VCCX pin should never exceed 15V. The voltage

supplied through VCCX must be large enough to drive the

switching MOSFETs into full saturation.

FIGURE 16. VCC Bias from VOUT 4V < VOUT < 15V

21 www.national.com

30058551

LM5118

30058552

FIGURE 17. VCC Bias with Additional Bias Supply

PCB Layout and Thermal Considerations

In a buck-boost regulator, there are two loops where currents

are switched very fast. The first loop starts from the input capacitors, and then to the buck switch, the inductor, the boost

switch then back to the input capacitor. The second loop starts

from the inductor, and then to the output diode, the output

capacitor, the re-circulating diode, and back to the inductor.

Minimizing the PC board area of these two loops reduces the

stray inductance and minimizes noise and the possibility of

erratic operation. A ground plane in the PC board is recommended as a means to connect the input filter capacitors to

the output filter capacitors and the PGND pins of the LM5118.

Connect all of the low current ground connections (CSS, RT,

C

) directly to the regulator AGND pin. Connect the AGND

RAMP

and PGND pins together through topside copper area covering the entire underside of the device. Place several vias in

this underside copper area to the ground plane of the input

capacitors.

The highest power dissipating components are the two power

MOSFETs, the re-circulating diode, and the output diode. The

easiest way to determine the power dissipated in the MOSFETs is to measure the total conversion losses (PIN - P

then subtract the power losses in the Schottky diodes, output

OUT

inductor and any snubber resistors. An approximation for the

re-circulating Schottky diode loss is:

P = (1-D) x I

OUT

x V

FWD

.

The boost diode loss is

P = I

OUT

x V

FWD

.

If a snubber is used, the power loss can be estimated with an

oscilloscope by observation of the resistor voltage drop at

both turn-on and turn-off transitions. The LM5118 package

has an exposed thermal pad to aid power dissipation. Selecting diodes with exposed pads will aid the power dissipation of

the diodes as well. When selecting the MOSFETs, pay careful

attention to R

FETs with low gate charge will result in lower switching loss-

at high temperature. Also, selecting MOS-

DS(ON)

es.

),

www.national.com 22

30058553

LM5118

FIGURE 18. 12V, 3A Typical Application Schematic

23 www.national.com

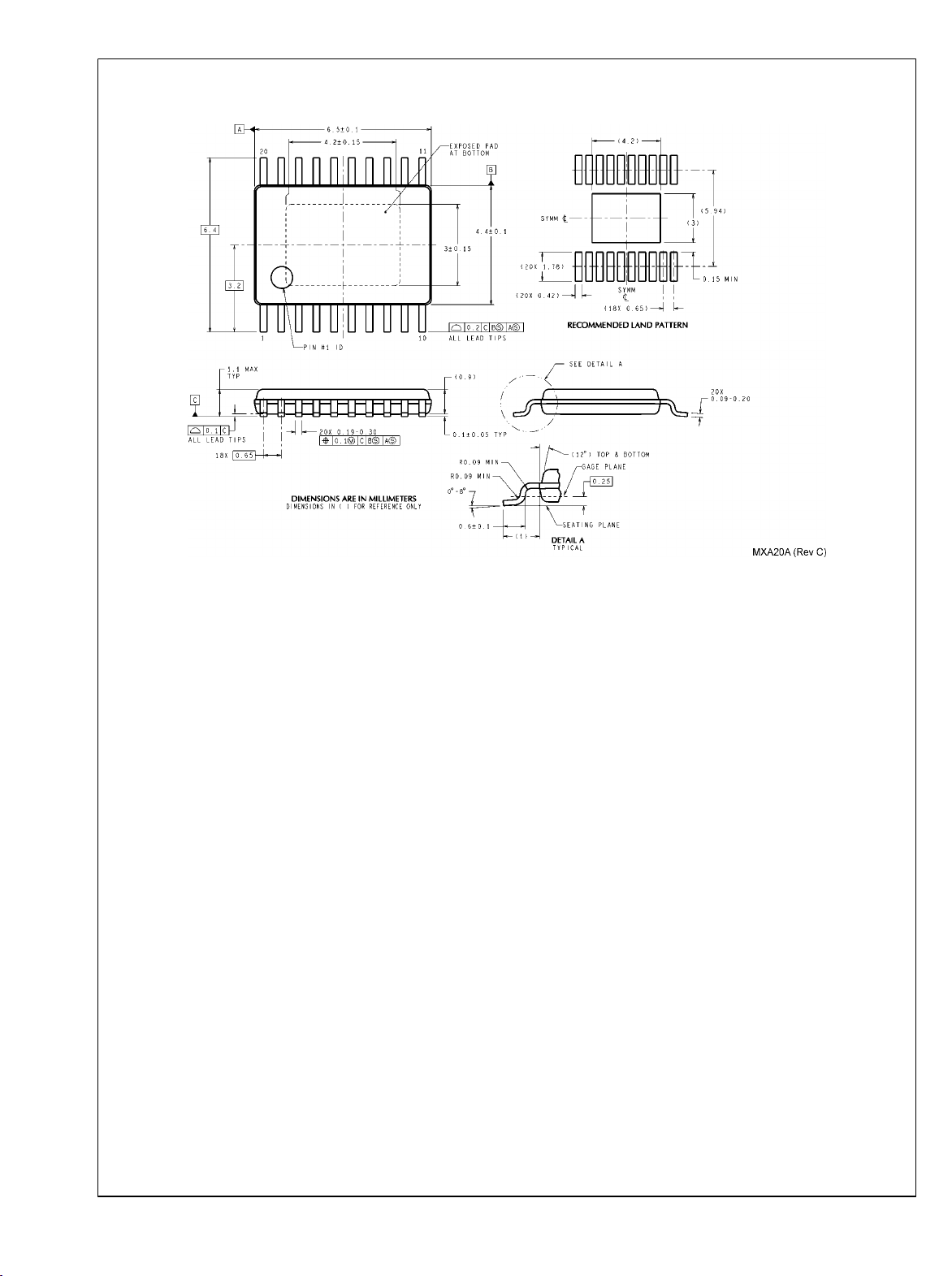

Physical Dimensions inches (millimeters) unless otherwise noted

LM5118

TSSOP-20EP Outline Drawing

NS Package Number MXA20A

www.national.com 24

Notes

LM5118

25 www.national.com

Notes

For more National Semiconductor product information and proven design tools, visit the following Web sites at:

Products Design Support

Amplifiers www.national.com/amplifiers WEBENCH www.national.com/webench

Audio www.national.com/audio Analog University www.national.com/AU

Clock Conditioners www.national.com/timing App Notes www.national.com/appnotes

Data Converters www.national.com/adc Distributors www.national.com/contacts

Displays www.national.com/displays Green Compliance www.national.com/quality/green

Ethernet www.national.com/ethernet Packaging www.national.com/packaging

Interface www.national.com/interface Quality and Reliability www.national.com/quality

LVDS www.national.com/lvds Reference Designs www.national.com/refdesigns

Power Management www.national.com/power Feedback www.national.com/feedback

Switching Regulators www.national.com/switchers

LDOs www.national.com/ldo

LED Lighting www.national.com/led

PowerWise www.national.com/powerwise

Serial Digital Interface (SDI) www.national.com/sdi

Temperature Sensors www.national.com/tempsensors

Wireless (PLL/VCO) www.national.com/wireless

THE CONTENTS OF THIS DOCUMENT ARE PROVIDED IN CONNECTION WITH NATIONAL SEMICONDUCTOR CORPORATION

(“NATIONAL”) PRODUCTS. NATIONAL MAKES NO REPRESENTATIONS OR WARRANTIES WITH RESPECT TO THE ACCURACY

OR COMPLETENESS OF THE CONTENTS OF THIS PUBLICATION AND RESERVES THE RIGHT TO MAKE CHANGES TO

SPECIFICATIONS AND PRODUCT DESCRIPTIONS AT ANY TIME WITHOUT NOTICE. NO LICENSE, WHETHER EXPRESS,

LM5118 Wide Voltage Range Buck-Boost Controller

IMPLIED, ARISING BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS

DOCUMENT.

TESTING AND OTHER QUALITY CONTROLS ARE USED TO THE EXTENT NATIONAL DEEMS NECESSARY TO SUPPORT

NATIONAL’S PRODUCT WARRANTY. EXCEPT WHERE MANDATED BY GOVERNMENT REQUIREMENTS, TESTING OF ALL

PARAMETERS OF EACH PRODUCT IS NOT NECESSARILY PERFORMED. NATIONAL ASSUMES NO LIABILITY FOR

APPLICATIONS ASSISTANCE OR BUYER PRODUCT DESIGN. BUYERS ARE RESPONSIBLE FOR THEIR PRODUCTS AND

APPLICATIONS USING NATIONAL COMPONENTS. PRIOR TO USING OR DISTRIBUTING ANY PRODUCTS THAT INCLUDE

NATIONAL COMPONENTS, BUYERS SHOULD PROVIDE ADEQUATE DESIGN, TESTING AND OPERATING SAFEGUARDS.

EXCEPT AS PROVIDED IN NATIONAL’S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, NATIONAL ASSUMES NO

LIABILITY WHATSOEVER, AND NATIONAL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY RELATING TO THE SALE

AND/OR USE OF NATIONAL PRODUCTS INCLUDING LIABILITY OR WARRANTIES RELATING TO FITNESS FOR A PARTICULAR

PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY

RIGHT.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR

SYSTEMS WITHOUT THE EXPRESS PRIOR WRITTEN APPROVAL OF THE CHIEF EXECUTIVE OFFICER AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

Life support devices or systems are devices which (a) are intended for surgical implant into the body, or (b) support or sustain life and

whose failure to perform when properly used in accordance with instructions for use provided in the labeling can be reasonably expected

to result in a significant injury to the user. A critical component is any component in a life support device or system whose failure to perform

can be reasonably expected to cause the failure of the life support device or system or to affect its safety or effectiveness.

National Semiconductor and the National Semiconductor logo are registered trademarks of National Semiconductor Corporation. All other

brand or product names may be trademarks or registered trademarks of their respective holders.

Copyright© 2008 National Semiconductor Corporation

For the most current product information visit us at www.national.com

www.national.com

National Semiconductor

Americas Technical

Support Center

Email: support@nsc.com

Tel: 1-800-272-9959

National Semiconductor Europe

Technical Support Center

Email: europe.support@nsc.com

German Tel: +49 (0) 180 5010 771

English Tel: +44 (0) 870 850 4288

National Semiconductor Asia

Pacific Technical Support Center

Email: ap.support@nsc.com

National Semiconductor Japan

Technical Support Center

Email: jpn.feedback@nsc.com

Loading...

Loading...