January 2007

LM5022

60V Low Side Controller for Boost and SEPIC

General Description

The LM5022 is a high voltage low-side N-channel MOSFET

controller ideal for use in boost and SEPIC regulators. It contains all of the features needed to implement single ended

primary topologies. Output voltage regulation is based on

current-mode control, which eases the design of loop compensation while providing inherent input voltage feed-forward.

The LM5022 includes a start-up regulator that operates over

a wide input range of 6V to 60V. The PWM controller is designed for high speed capability including an oscillator frequency range up to 2 MHz and total propagation delays less

than 100 ns. Additional features include an error amplifier,

precision reference, line under-voltage lockout, cycle-by-cycle current limit, slope compensation, soft-start, external synchronization capability and thermal shutdown. The LM5022 is

available in the MSOP-10 package.

Features

■

Internal 60V Startup Regulator

■

1A Peak MOSFET Gate Driver

■

VIN Range 6V to 60V

■

Duty Cycle Limit of 90%

■

Programmable UVLO with Hysteresis

■

Cycle-by-Cycle Current Limit

■

External Synchronizable (AC-coupled)

■

Single Resistor Oscillator Frequency Set

■

Slope Compensation

■

Adjustable Soft-start

■

MSOP-10 Package

Applications

■

Boost Converter

■

SEPIC Converter

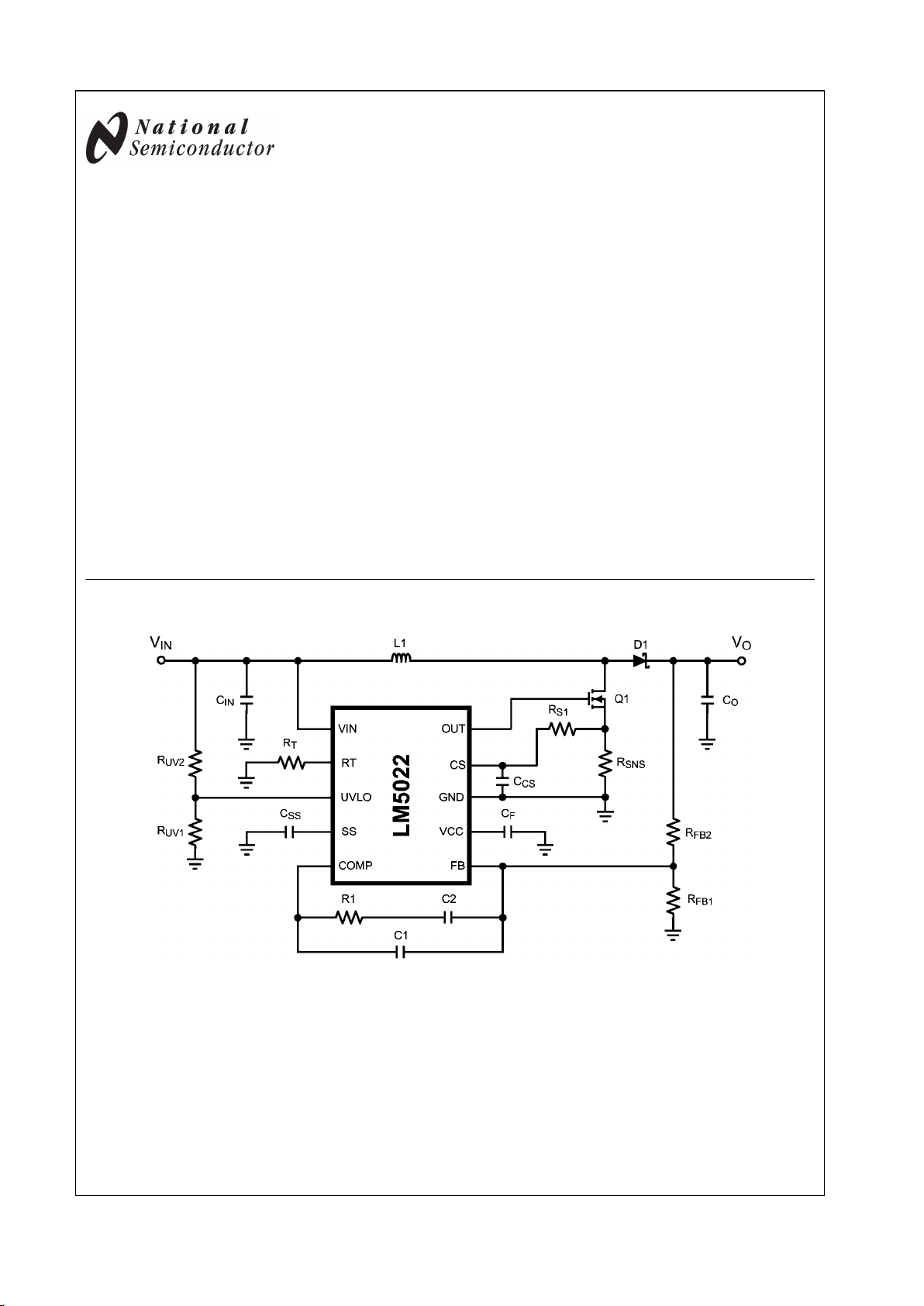

Typical Application

20212201

© 2007 National Semiconductor Corporation 202122 www.national.com

LM5022 60V Low Side Controller for Boost and SEPIC

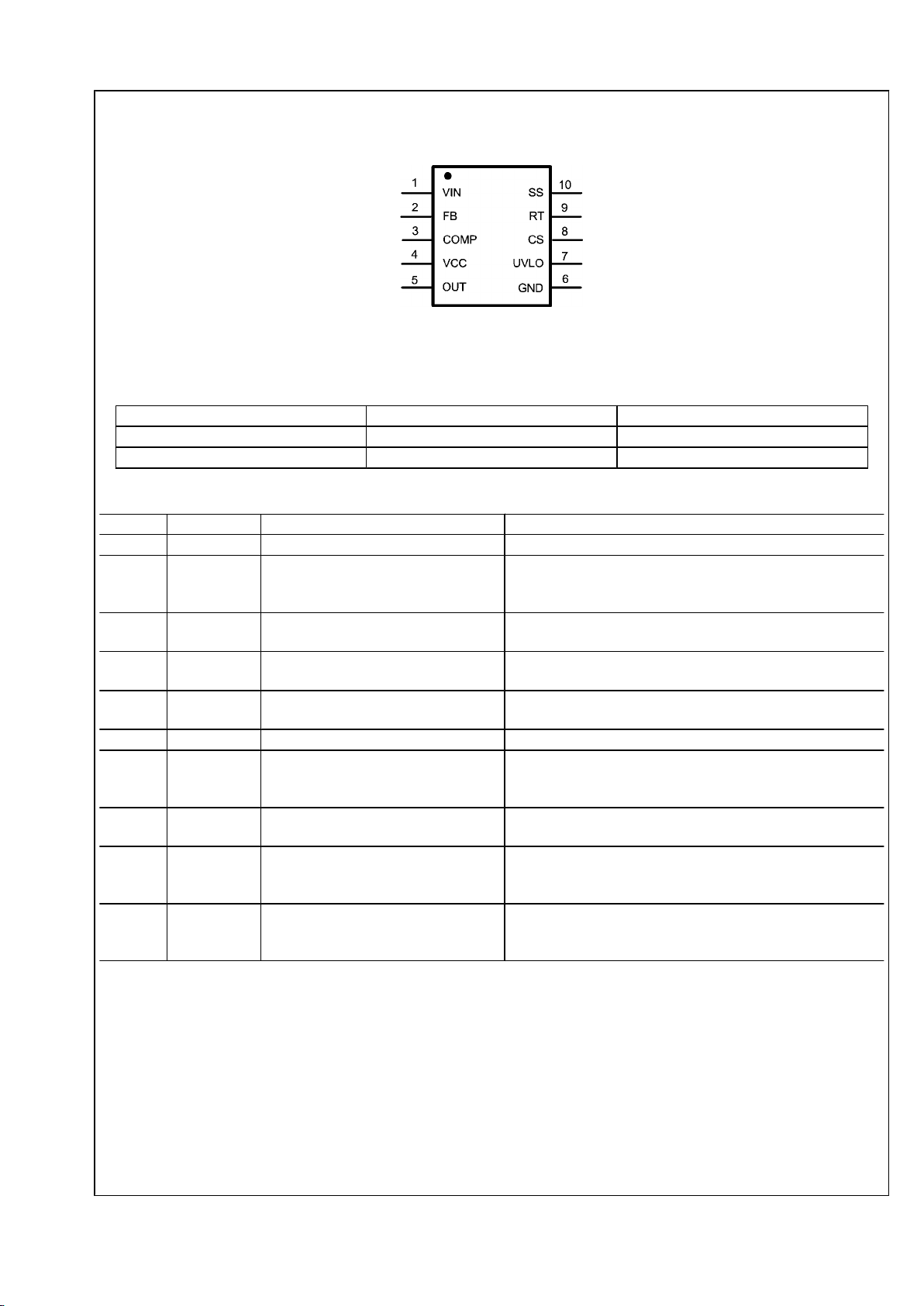

Connection Diagram

20212253

10-Lead MSOP

NS Package Number MUB10A

Ordering Information

Part Number NS Package Drawing Supplied As

LM5022MM MUB10A 1000 Units on Tape and Reel

LM5022MMX MUB10A 3500 Units on Tape and Reel

Pin Descriptions

Pin(s) Name Description Application Information

1 VIN Source input voltage Input to the start-up regulator. Operates from 6V to 60V.

2 FB Feedback pin

Inverting input to the internal voltage error amplifier. The noninverting input of the error amplifier connects to a 1.25V

reference.

3 COMP

Error amplifier output and PWM

comparator input

The control loop compensation components connect between

this pin and the FB pin.

4 VCC

Output of the internal, high voltage linear

regulator.

This pin should be bypassed to the GND pin with a ceramic

capacitor.

5 OUT Output of MOSFET gate driver Connect this pin to the gate of the external MOSFET. The gate

driver has a 1A peak current capability.

6 GND System ground

7 UVLO Input Under-Voltage Lock-out

Set the start-up and shutdown levels by connecting this pin to the

input voltage through a resistor divider. A 20 µA current source

provides hysteresis.

8 CS

Current Sense input Input for the switch current used for current mode control and for

current limiting.

9 RT/SYNC

Oscillator frequency adjust pin and

synchronization input

An external resistor connected from this pin to GND sets the

oscillator frequency. This pin can also accept an AC-coupled

input for synchronization from an external clock.

10 SS Soft-start pin

An external capacitor placed from this pin to ground will be

charged by a 10 µA current source, creating a ramp voltage to

control the regulator start-up.

www.national.com 2

LM5022

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

VIN to GND -0.3V to 65V

VCC to GND -0.3V to 16V

RT/SYNC to GND -0.3V to 5.5V

OUT to GND -1.5V for < 100 ns

All other pins to GND -0.3V to 7V

Power Dissipation Internally Limited

Junction Temperature 150°C

Storage Temperature -65°C to +150°C

Soldering Information

Vapor Phase (60 sec.) 215°C

Infrared (15 sec.) 220°C

ESD Rating

Human Body Model (Note 2) 2 kV

Operating Ranges (Note 4)

Supply Voltage 6V to 60V

External Volatge at V

CC

7.5V to 14V

Junction Temperature Range -40°C to +125°C

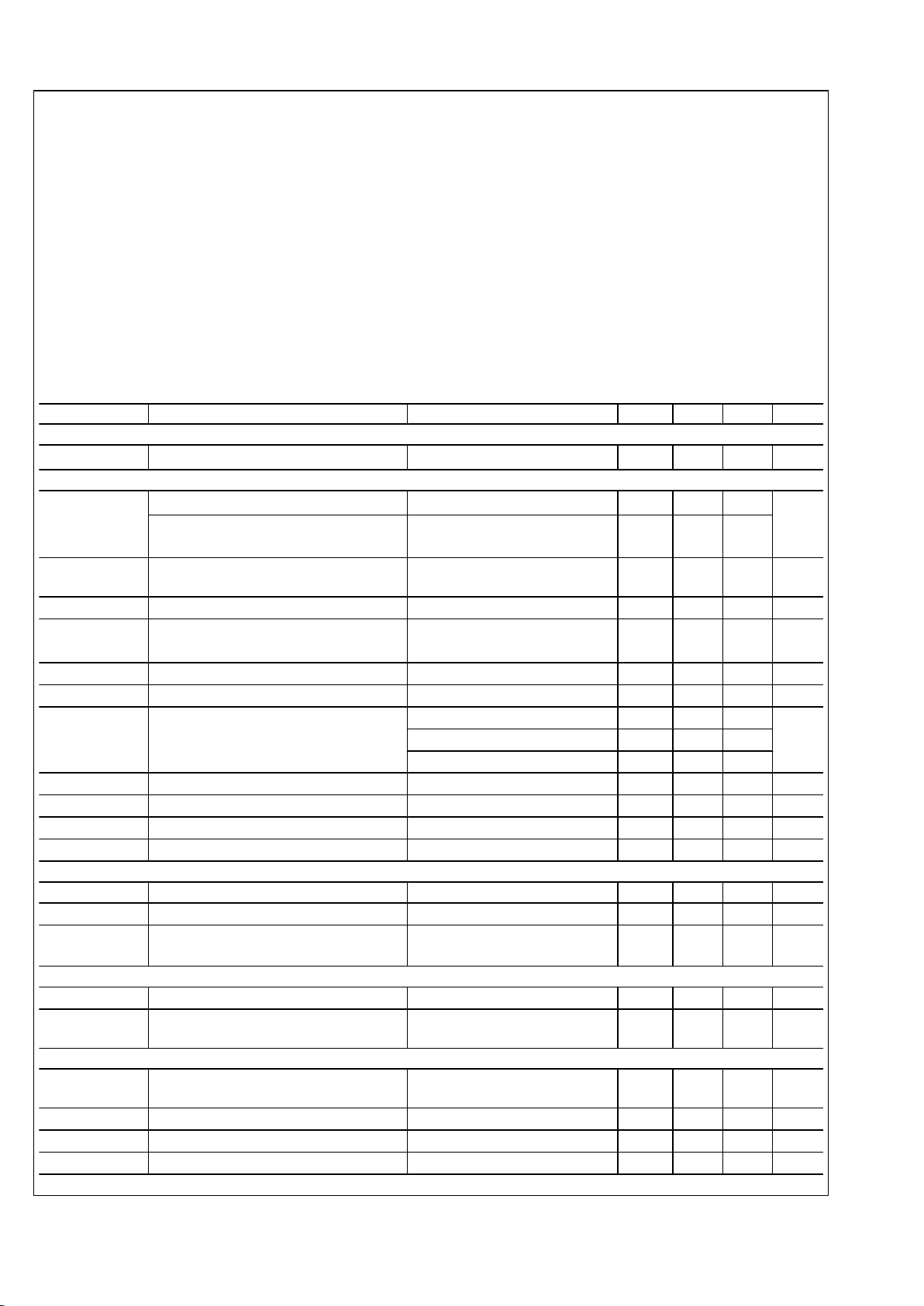

Electrical Characteristics Limits in standard type are for T

J

= 25°C only; limits in boldface type apply over the

junction temperature (TJ) range of -40°C to +125°C. Minimum and Maximum limits are guaranteed through test, design, or statistical

correlation. Typical values represent the most likely parametric norm at TJ = 25°C, and are provided for reference purposes only.

VIN = 24V and RT = 27.4 kΩ unless otherwise indicated. (Note 3)

Symbol Parameter Conditions Min Typ Max Units

SYSTEM PARAMETERS

V

FB

FB Pin Voltage

-40°C ≤ T

J

≤ 125°C

1.225 1.250 1.275 V

START-UP REGULATOR

VCC

VCC Regulation

9V ≤ VIN ≤ 60V, ICC = 1 mA

6.6 7 7.4

V

VCC Regulation

6V ≤ VIN < 9V, VCC Pin Open

Circuit

5

I

CC

Supply Current

OUT Pin Capacitance = 0

VCC = 10V

3.5 4

mA

I

CC-LIM

VCC Current Limit VCC = 0V, (Note 4, 6) 15 35 mA

VIN - VCC

Dropout Voltage Across Bypass Switch

ICC = 0 mA, fSW < 200 kHz

6V ≤ VIN ≤ 8.5V

200

mV

V

BYP-HI

Bypass Switch Turn-off Threshold VIN increasing 8.7 V

V

BYP-HYS

Bypass Switch Threshold Hysteresis VIN Decreasing 260 mV

Z

VCC

VCC Pin Output Impedance

0 mA ≤ ICC ≤ 5 mA

VIN = 6.0V 58

Ω

VIN = 8.0V 53

VIN = 24.0V 1.6

VCC

-HI

VCC Pin UVLO Rising Threshold 5 V

VCC

-HYS

VCC Pin UVLO Falling Hysteresis 300 mV

I

VIN

Start-up Regulator Leakage VIN = 60V 150 500 µA

I

IN-SD

Shutdown Current V

UVLO

= 0V, VCC = Open Circuit 350 450 µA

ERROR AMPLIFIER

GBW Gain Bandwidth 4 MHz

A

DC

DC Gain 75 dB

I

COMP

COMP Pin Current Sink Capability

VFB = 1.5V

V

COMP

= 1V

5 17

mA

UVLO

V

SD

Shutdown Threshold 1.22 1.25 1.28 V

I

SD-HYS

Shutdown

Hysteresis Current Source

16 20 24

µA

CURRENT LIMIT

t

LIM-DLY

Delay from ILIM to Output

CS steps from 0V to 0.6V

OUT transitions to 90% of VCC

30

ns

V

CS

Current Limit Threshold Voltage 0.45 0.5 0.55 V

t

BLK

Leading Edge Blanking Time 65 ns

R

CS

CS Pin Sink Impedance Blanking active 40 75

Ω

3 www.national.com

LM5022

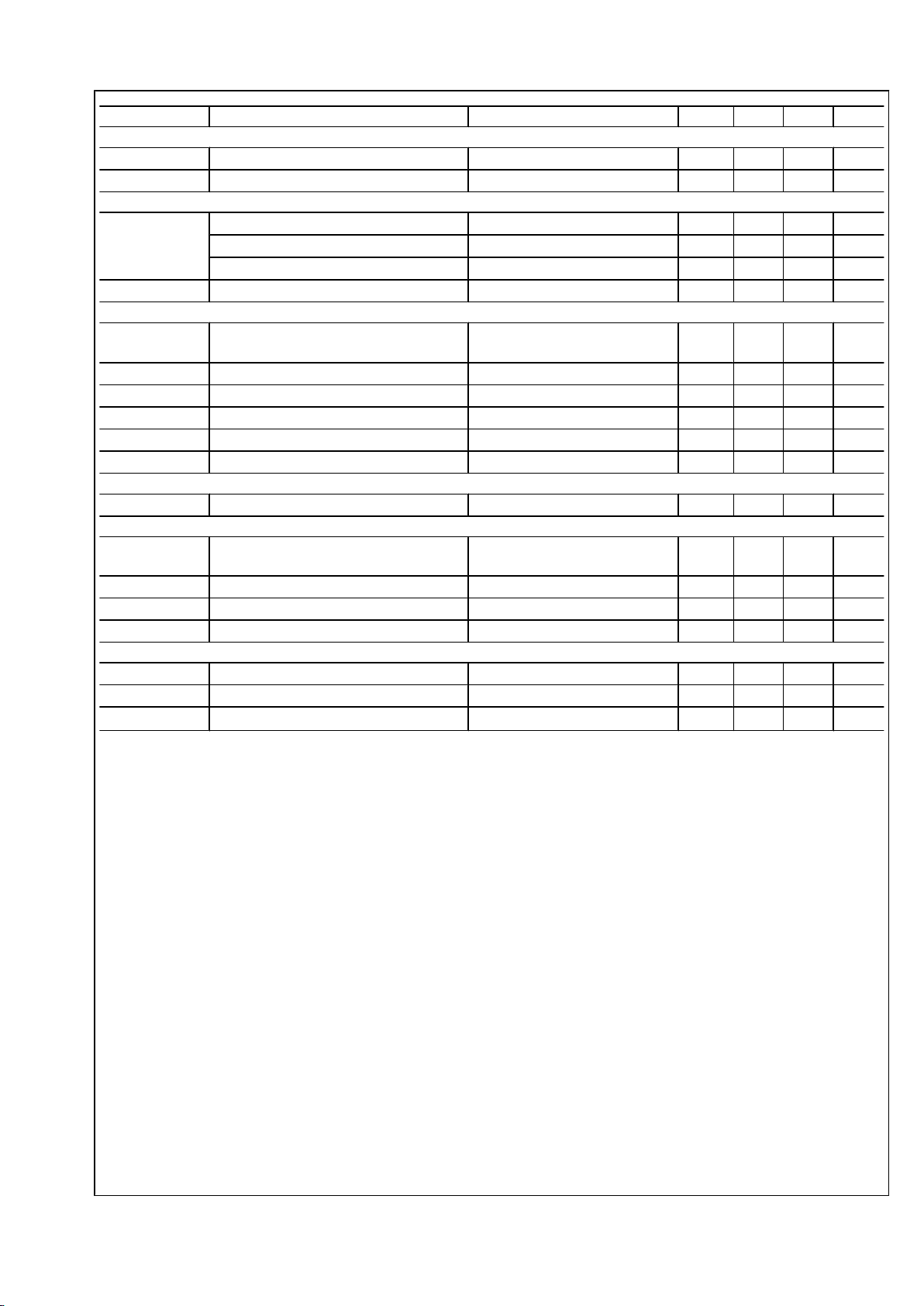

Symbol Parameter Conditions Min Typ Max Units

SOFT-START

I

SS

Soft-start Current Source 7 10 13 µA

V

SS-OFF

Soft-start to COMP Offset 0.35 0.55 0.75 V

OSCILLATOR

f

SW

RT to GND = 84.5 kΩ

(Note 5) 170 200 230 kHz

RT to GND = 27.4 kΩ

(Note 5) 525 600 675 kHz

RT to GND = 16.2 kΩ

(Note 5) 865 990 1115 kHz

V

SYNC-HI

Synchronization Rising Threshold 3.8 V

PWM COMPARATOR

t

COMP-DLY

Delay from COMP to OUT Transition

V

COMP

= 2V

CS stepped from 0V to 0.4V

25

ns

D

MIN

Minimum Duty Cycle V

COMP

= 0V 0 %

D

MAX

Maximum Duty Cycle 90 95 %

A

PWM

COMP to PWM Comparator Gain 0.33 V/V

V

COMP-OC

COMP Pin Open Circuit Voltage VFB = 0V 4.3 5.2 6.1 V

I

COMP-SC

COMP Pin Short Circuit Current V

COMP

= 0V, VFB = 1.5V 0.6 1.1 1.5 mA

SLOPE COMPENSATION

V

SLOPE

Slope Compensation Amplitude 80 105 130 mV

MOSFET DRIVER

V

SAT-HI

Output High Saturation Voltage (VCC –

VOUT)

I

OUT

= 50 mA 0.25 0.75 V

V

SAT-LO

Output Low Saturation Voltage (VOUT) I

OUT

= 100 mA 0.25 0.75 V

t

RISE

OUT Pin Rise Time OUT Pin load = 1 nF 18 ns

t

FALL

OUT Pin Fall Time OUT Pin load = 1 nF 15 ns

THERMAL CHARACTERISTICS

T

SD

Thermal Shutdown Threshold 165 °C

T

SD-HYS

Thermal Shutdown Hysteresis 25 °C

θ

JA

Junction to Ambient Thermal Resistance MUB-10A Package 200 °C/W

Note 1: Absolute Maximum Ratings are limits beyond which damage to the device may occur. The Recommended Operating Limits define the conditions within

which the device is intended to be functional. For guaranteed specifications and test conditions, see the Electrical Characteristics.

Note 2: The human body model is a 100 pF capacitor discharged through a 1.5kΩ resistor into each pin.

Note 3: Min and Max limits are 100% production tested at 25°C. Limits over the operating temperature range are guaranteed through correlation using Statistical

Quality Control (SQC) methods. Limits are used to calculate National’s Average Outgoing Quality Level (AOQL).

Note 4: Device thermal limitations may limit usable range.

Note 5: Specification applies to the oscillator frequency.

Note 6: VCC provides bias for the internal gate drive and control circuits.

www.national.com 4

LM5022

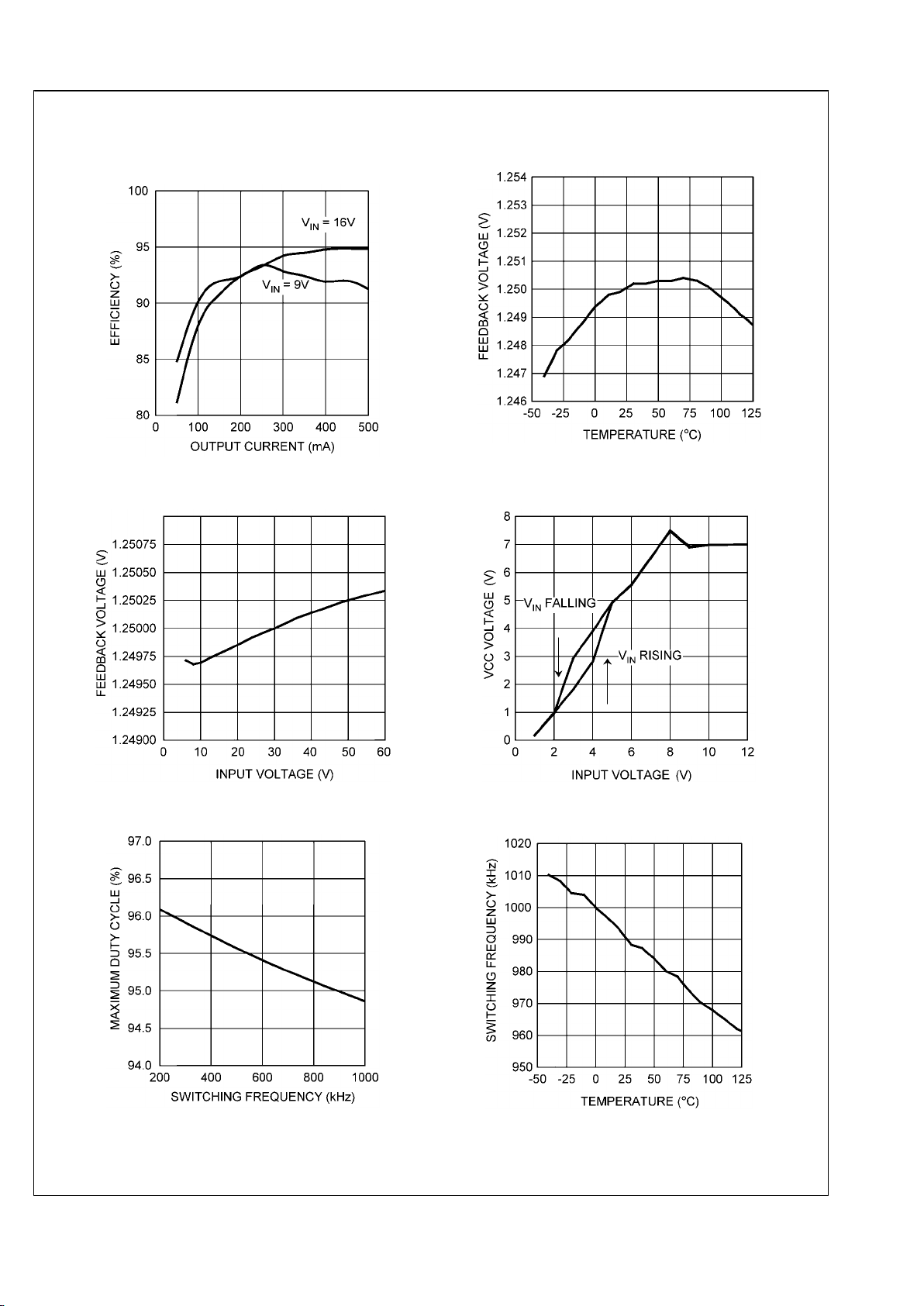

Typical Performance Characteristics

Efficiency, VO = 40V

Example Circuit BOM

20212255

VFB vs. Temp (VIN = 24V)

20212203

VFB vs. VIN (TA = 25°C)

20212204

VCC vs. VIN (TA = 25°C)

20212205

Max Duty Cycle vs. fSW (TA = 25°C)

20212206

fSW vs. Temperature (RT = 16.2 kΩ)

20212207

5 www.national.com

LM5022

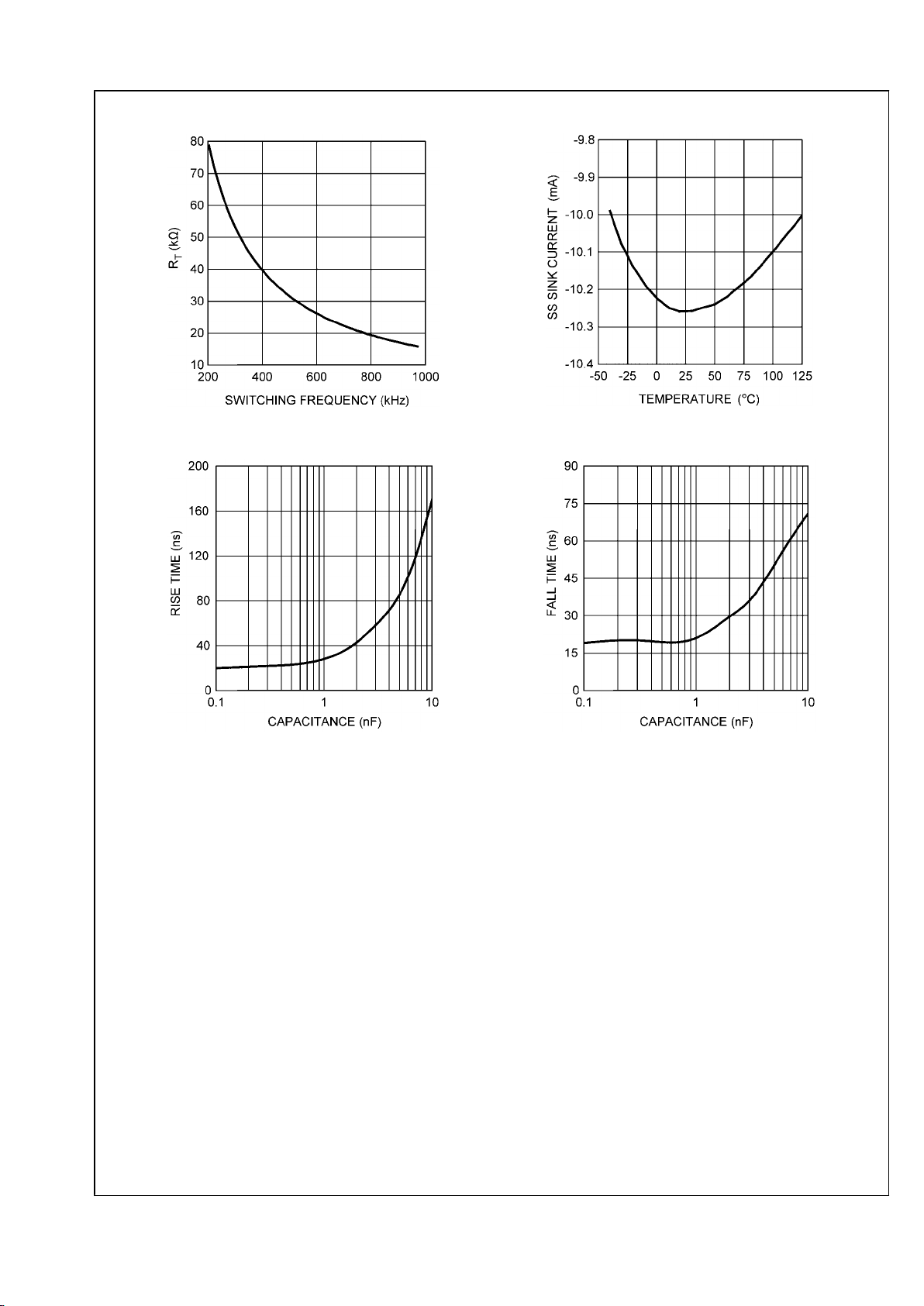

RT vs. fSW (TA = 25°C)

20212208

SS vs. Temperature

20212209

OUT Pin t

RISE

vs. Gate Capacitance

20212210

OUT Pin t

FALL

vs. Gate Capacitance

20212211

www.national.com 6

LM5022

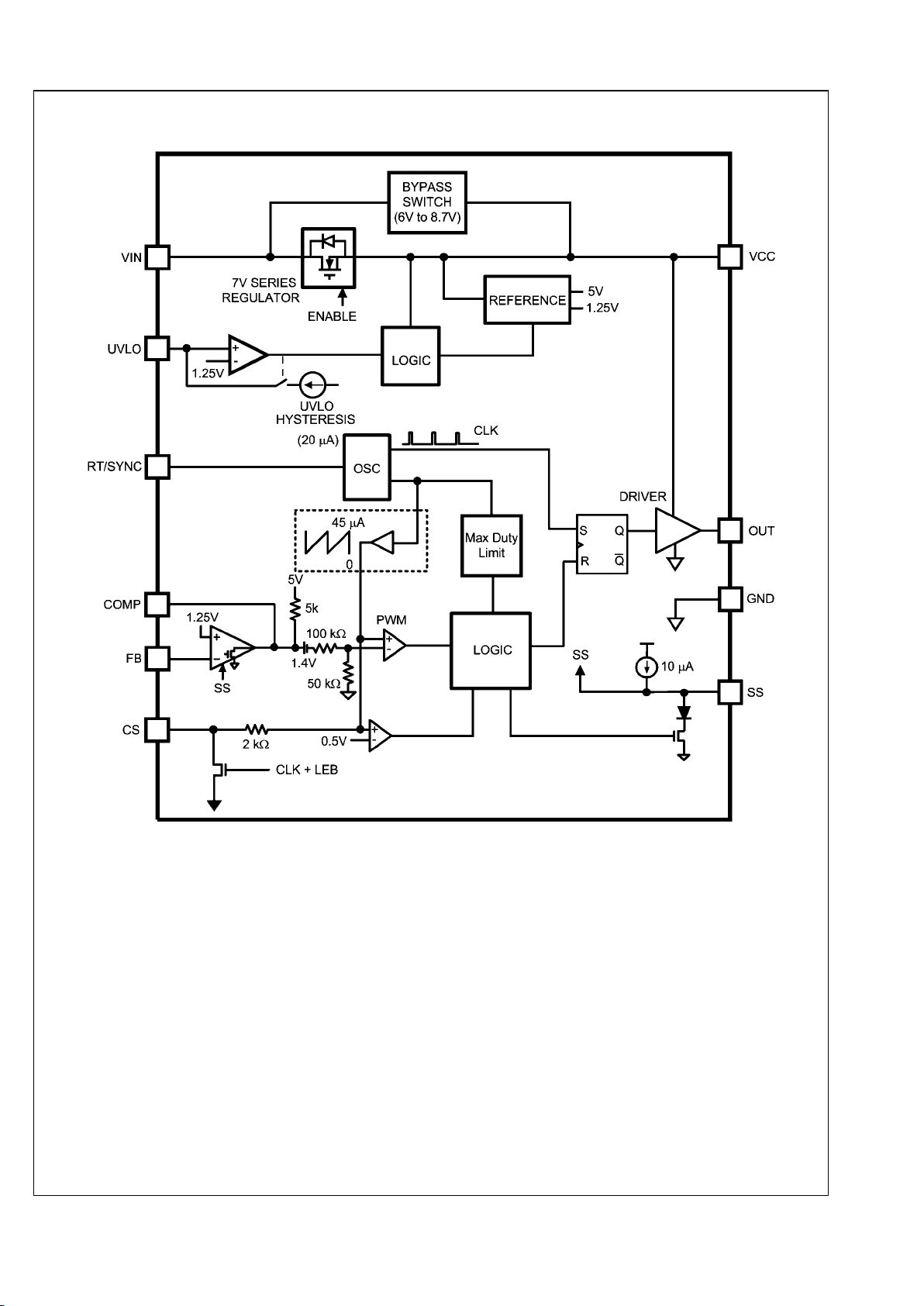

Block Diagram

20212212

7 www.national.com

LM5022

Example Circuit

20212213

FIGURE 1. Design Example Schematic

Applications Information

OVERVIEW

The LM5022 is a low-side N-channel MOSFET controller that

contains all of the features needed to implement single ended

power converter topologies. The LM5022 includes a highvoltage startup regulator that operates over a wide input

range of 6V to 60V. The PWM controller is designed for high

speed capability including an oscillator frequency range up to

2 MHz and total propagation delays less than 100 ns. Additional features include an error amplifier, precision reference,

input under-voltage lockout, cycle-by-cycle current limit, slope

compensation, soft-start, oscillator sync capability and thermal shutdown.

The LM5022 is designed for current-mode control power converters that require a single drive output, such as boost and

SEPIC topologies. The LM5022 provides all of the advantages of current-mode control including input voltage feedforward, cycle-by-cycle current limiting and simplified loop

compensation.

HIGH VOLTAGE START-UP REGULATOR

The LM5022 contains an internal high-voltage startup regulator that allows the VIN pin to be connected directly to line

voltages as high as 60V. The regulator output is internally

current limited to 35 mA (typical). When power is applied, the

regulator is enabled and sources current into an external capacitor, CF, connected to the VCC pin. The recommended

capacitance range for CF is 0.1 µF to 100 µF. When the voltage on the VCC pin reaches the rising threshold of 5V, the

controller output is enabled. The controller will remain enabled until VCC falls below 4.7V. In applications using a

transformer, an auxiliary winding can be connected through

a diode to the VCC pin. This winding should raise the VCC

pin voltage to above 7.5V to shut off the internal startup regulator. Powering VCC from an auxiliary winding improves

conversion efficiency while reducing the power dissipated in

the controller. The capacitance of CF must be high enough

that it maintains the VCC voltage greater than the VCC UVLO

falling threshold (4.7V) during the initial start-up. During a fault

condition when the converter auxiliary winding is inactive, external current draw on the VCC line should be limited such

that the power dissipated in the start-up regulator does not

exceed the maximum power dissipation capability of the controller.

An external start-up or other bias rail can be used instead of

the internal start-up regulator by connecting the VCC and the

VIN pins together and feeding the external bias voltage (7.5V

to 14V) to the two pins.

INPUT UNDER-VOLTAGE DETECTOR

The LM5022 contains an input Under Voltage Lock Out (UVLO) circuit. UVLO is programmed by connecting the UVLO

pin to the center point of an external voltage divider from VIN

to GND. The resistor divider must be designed such that the

voltage at the UVLO pin is greater than 1.25V when VIN is in

the desired operating range. If the under voltage threshold is

not met, all functions of the controller are disabled and the

controller remains in a low power standby state. UVLO hysteresis is accomplished with an internal 20 µA current source

that is switched on or off into the impedance of the set-point

divider. When the UVLO threshold is exceeded, the current

source is activated to instantly raise the voltage at the UVLO

pin. When the UVLO pin voltage falls below the 1.25V threshold the current source is turned off, causing the voltage at the

UVLO pin to fall. The UVLO pin can also be used to implement

a remote enable / disable function. If an external transistor

pulls the UVLO pin below the 1.25V threshold, the converter

will be disabled. This external shutdown method is shown in

Figure 2.

www.national.com 8

LM5022

20212214

FIGURE 2. Enable/Disable Using UVLO

ERROR AMPLIFIER

An internal high gain error amplifier is provided within the

LM5022. The amplifier’s non-inverting input is internally set to

a fixed reference voltage of 1.25V. The inverting input is connected to the FB pin. In non-isolated applications such as the

boost converter the output voltage, VO, is connected to the FB

pin through a resistor divider. The control loop compensation

components are connected between the COMP and FB pins.

For most isolated applications the error amplifier function is

implemented on the secondary side of the converter and the

internal error amplifier is not used. The internal error amplifier

is configured as an open drain output and can be disabled by

connecting the FB pin to ground. An internal 5 kΩ pull-up resistor between a 5V reference and COMP can be used as the

pull-up for an opto-coupler in isolated applications.

CURRENT SENSING AND CURRENT LIMITING

The LM5022 provides a cycle-by-cycle over current protection function. Current limit is accomplished by an internal

current sense comparator. If the voltage at the current sense

comparator input exceeds 0.5V, the MOSFET gate drive will

be immediately terminated. A small RC filter, located near the

controller, is recommended to filter noise from the current

sense signal. The CS input has an internal MOSFET which

discharges the CS pin capacitance at the conclusion of every

cycle. The discharge device remains on an additional 65 ns

after the beginning of the new cycle to attenuate leading edge

ringing on the current sense signal.

The LM5022 current sense and PWM comparators are very

fast, and may respond to short duration noise pulses. Layout

considerations are critical for the current sense filter and

sense resistor. The capacitor associated with the CS filter

must be located very close to the device and connected directly to the pins of the controller (CS and GND). If a current

sense transformer is used, both leads of the transformer secondary should be routed to the sense resistor and the current

sense filter network. The current sense resistor can be located between the source of the primary power MOSFET and

power ground, but it must be a low inductance type. When

designing with a current sense resistor all of the noise sensitive low-power ground connections should be connected together locally to the controller and a single connection should

be made to the high current power ground (sense resistor

ground point).

OSCILLATOR, SHUTDOWN AND SYNC

A single external resistor, RT, connected between the RT/

SYNC and GND pins sets the LM5022 oscillator frequency.

To set the switching frequency, fSW, RT can be calculated

from:

The LM5022 can also be synchronized to an external clock.

The external clock must have a higher frequency than the free

running oscillator frequency set by the RT resistor. The clock

signal should be capacitively coupled into the RT/SYNC pin

with a 100 pF capacitor as shown in Figure 3. A peak voltage

level greater than 3.8V at the RT/SYNC pin is required for

detection of the sync pulse. The sync pulse width should be

set between 15 ns to 150 ns by the external components. The

RT resistor is always required, whether the oscillator is free

running or externally synchronized. The voltage at the RT/

SYNC pin is internally regulated to 2V, and the typical delay

from a logic high at the RT/SYNC pin to the rise of the OUT

pin voltage is 120 ns. RT should be located very close to the

device and connected directly to the pins of the controller (RT/

SYNC and GND).

20212254

FIGURE 3. Sync Operation

PWM COMPARATOR AND SLOPE COMPENSATION

The PWM comparator compares the current ramp signal with

the error voltage derived from the error amplifier output. The

error amplifier output voltage at the COMP pin is offset by

1.4V and then further attenuated by a 3:1 resistor divider. The

PWM comparator polarity is such that 0V on the COMP pin

will result in a zero duty cycle at the controller output. For duty

cycles greater than 50%, current mode control circuits can

experience sub-harmonic oscillation. By adding an additional

fixed-slope voltage ramp signal (slope compensation) this oscillation can be avoided. Proper slope compensation damps

the double pole associated with current mode control (see the

Control Loop Compensation section) and eases the design of

the control loop compensator. The LM5022 generates the

slope compensation with a sawtooth-waveform current

source with a slope of 45 µA x fSW, generated by the clock.

(See Figure 4) This current flows through an internal 2 kΩ

9 www.national.com

LM5022

resistor to create a minimum compensation ramp with a slope

of 100 mV x fSW (typical). The slope of the compensation ramp

increases when external resistance is added for filtering the

current sense (RS1) or in the position RS2. As shown in Figure

4 and the block diagram, the sensed current slope and the

compensation slope add together to create the signal used

for current limiting and for the control loop itself.

20212216

FIGURE 4. Slope Compensation

In peak current mode control the optimal slope compensation

is proportional to the slope of the inductor current during the

power switch off-time. For boost converters the inductor current slope while the MOSFET is off is (VO - VIN) / L. This

relationship is combined with the requirements to set the peak

current limit and is used to select R

SNS

and RS2 in the Design

Considerations section.

SOFT-START

The soft-start feature allows the power converter output to

gradually reach the initial steady state output voltage, thereby

reducing start-up stresses and current surges. At power on,

after the VCC and input under-voltage lockout thresholds are

satisfied, an internal 10 µA current source charges an external

capacitor connected to the SS pin. The capacitor voltage will

ramp up slowly and will limit the COMP pin voltage and the

switch current.

MOSFET GATE DRIVER

The LM5022 provides an internal gate driver through the OUT

pin that can source and sink a peak current of 1A to control

external, ground-referenced N-channel MOSFETs.

THERMAL SHUTDOWN

Internal thermal shutdown circuitry is provided to protect the

LM5022 in the event that the maximum junction temperature

is exceeded. When activated, typically at 165°C, the controller

is forced into a low power standby state, disabling the output

driver and the VCC regulator. After the temperature is reduced (typical hysteresis is 25°C) the VCC regulator will be

re-enabled and the LM5022 will perform a soft-start.

Design Considerations

The most common circuit controlled by the LM5022 is a nonisolated boost regulator. The boost regulator steps up the

input voltage and has a duty ratio D of:

(VD is the forward voltage drop of the output diode)

The following is a design procedure for selecting all the components for the boost converter circuit shown in Figure 1. The

application is "in-cabin" automotive, meaning that the operating ambient temperature ranges from -20°C to 85°C. This

circuit operates in continuous conduction mode (CCM),

where inductor current stays above 0A at all times, and delivers an output voltage of 40.0V ±2% at a maximum output

current of 0.5A. Additionally, the regulator must be able to

handle a load transient of up to 0.5A while keeping VO within

±4%. The voltage input comes from the battery/alternator

system of an automobile, where the standard range 9V to 16V

and transients of up to 32V must not cause any malfunction.

SWITCHING FREQUENCY

The selection of switching frequency is based on the tradeoffs

between size, cost, and efficiency. In general, a lower frequency means larger, more expensive inductors and capacitors will be needed. A higher switching frequency generally

results in a smaller but less efficient solution, as the power

MOSFET gate capacitances must be charged and discharged more often in a given amount of time. For this application, a frequency of 500 kHz was selected as a good

compromise between the size of the inductor and efficiency.

PCB area and component height are restricted in this application. Following the equation given for RT in the Applications

Information section, a 33.2 kΩ 1% resistor should be used to

switch at 500 kHz.

MOSFET

Selection of the power MOSFET is governed by tradeoffs between cost, size, and efficiency. Breaking down the losses in

the MOSFET is one way to determine relative efficiencies between different devices. For this example, the SO-8 package

provides a balance of a small footprint with good efficiency.

Losses in the MOSFET can be broken down into conduction

loss, gate charging loss, and switching loss.

Conduction, or I2R loss, PC, is approximately:

www.national.com 10

LM5022

The factor 1.3 accounts for the increase in MOSFET on resistance due to heating. Alternatively, the factor of 1.3 can be

ignored and the maximum on resistance of the MOSFET can

be used.

Gate charging loss, PG, results from the current required to

charge and discharge the gate capacitance of the power

MOSFET and is approximated as:

PG = VCC x QG x f

SW

QG is the total gate charge of the MOSFET. Gate charge loss

differs from conduction and switching losses because the actual dissipation occurs in the LM5022 and not in the MOSFET

itself. If no external bias is applied to the VCC pin, additional

loss in the LM5022 IC occurs as the MOSFET driving current

flows through the VCC regulator. This loss, P

VCC

, is estimated

as:

P

VCC

= (VIN – VCC) x QG x f

SW

Switching loss, PSW, occurs during the brief transition period

as the MOSFET turns on and off. During the transition period

both current and voltage are present in the channel of the

MOSFET. The loss can be approximated as:

PSW = 0.5 x VIN x [IO / (1 – D)] x (tR + tF) x f

SW

Where tR and tF are the rise and fall times of the MOSFET

For this example, the maximum drain-to-source voltage applied across the MOSFET is VO plus the ringing due to parasitic inductance and capacitance. The maximum drive voltage

at the gate of the high side MOSFET is VCC, or 7V typical.

The MOSFET selected must be able to withstand 40V plus

any ringing from drain to source, and be able to handle at least

7V plus ringing from gate to source. A minimum voltage rating

of 50V

D-S

and 10V

G-S

MOSFET will be used. Comparing the

losses in a spreadsheet leads to a 60V

D-S

rated MOSFET in

SO-8 with an R

DSON

of 22 mΩ (the maximum vallue is 31

mΩ), a gate charge of 27 nC, and rise and falls times of 10 ns

and 12 ns, respectively.

OUTPUT DIODE

The boost regulator requires an output diode D1 (see Figure

1) to carrying the inductor current during the MOSFET off-

time. The most efficient choice for D1 is a Schottky diode due

to low forward drop and near-zero reverse recovery time. D1

must be rated to handle the maximum output voltage plus any

switching node ringing when the MOSFET is on. In practice,

all switching converters have some ringing at the switching

node due to the diode parasitic capacitance and the lead inductance. D1 must also be rated to handle the average output

current, IO.

The overall converter efficiency becomes more dependent on

the selection of D1 at low duty cycles, where the boost diode

carries the load current for an increasing percentage of the

time. This power dissipation can be calculating by checking

the typical diode forward voltage, VD, from the I-V curve on

the diode's datasheet and then multiplying it by IO. Diode

datasheets will also provide a typical junction-to-ambient thermal resistance, θJA, which can be used to estimate the operating die temperature of the Schottky. Multiplying the power

dissipation (PD = IO x VD) by θJA gives the temperature rise.

The diode case size can then be selected to maintain the

Schottky diode temperature below the operational maximum.

In this example a Schottky diode rated to 60V and 1A will be

suitable, as the maximum diode current will be 0.5A. A small

case such as SOD-123 can be used if a small footprint is critical. Larger case sizes generally have lower θJA and lower

forward voltage drop, so for better efficiency the larger SMA

case size will be used.

BOOST INDUCTOR

The first criterion for selecting an inductor is the inductance

itself. In fixed-frequency boost converters this value is based

on the desired peak-to-peak ripple current, ΔiL, which flows in

the inductor along with the average inductor current, IL. For a

boost converter in CCM IL is greater than the average output

current, IO. The two currents are related by the following expression:

IL = IO / (1 – D)

As with switching frequency, the inductance used is a tradeoff

between size and cost. Larger inductance means lower input

ripple current, however because the inductor is connected to

the output during the off-time only there is a limit to the reduction in output ripple voltage. Lower inductance results in

smaller, less expensive magnetics. An inductance that gives

a ripple current of 30% to 50% of IL is a good starting point for

a CCM boost converter. Minimum inductance should be calculated at the extremes of input voltage to find the operating

condition with the highest requirement:

By calculating in terms of amperes, volts, and megahertz, the

inductance value will come out in micro henries.

In order to ensure that the boost regulator operates in CCM

a second equation is needed, and must also be evaluated at

the corners of input voltage to find the minimum inductance

required:

By calculating in terms of volts, amps and megahertz the inductance value will come out in µH.

For this design ΔiL will be set to 40% of the maximum IL. Duty

cycle is evaluated first at V

IN(MIN)

and at V

IN(MAX)

. Second, the

average inductor current is evaluated at the two input voltages. Third, the inductor ripple current is determined. Finally,

the inductance can be calculated, and a standard inductor

value selected that meets all the criteria.

Inductance for Minimum Input Voltage

D

VIN(MIN)

= (40 – 9.0 + 0.5) / (40 + 0.5) = 78%

I

L-VIN(MIN)

= 0.5 / (1 – 0.78) = 2.3A

ΔiL = 0.4 x 2.3A = 0.92A

11 www.national.com

LM5022

Inductance for Maximum Input Voltage

D

VIN(MAX)

= (40 - 16 + 0.5) / (40 + 0.5) = 60%

I

L-VIN(MIAX)

= 0.5 / (1 – 0.6) = 1.25A

ΔiL = 0.4 x 1.25A = 0.5A

Maximum average inductor current occurs at V

IN(MIN)

, and the

corresponding inductor ripple current is 0.92A

P-P

. Selecting

an inductance that exceeds the ripple current requirement at

V

IN(MIN)

and the requirement to stay in CCM for V

IN(MAX)

provides a tradeoff that allows smaller magnetics at the cost of

higher ripple current at maximum input voltage. For this example, a 33 µH inductor will satisfy these requirements.

The second criterion for selecting an inductor is the peak current carrying capability. This is the level above which the

inductor will saturate. In saturation the inductance can drop

off severely, resulting in higher peak current that may overheat the inductor or push the converter into current limit. In a

boost converter, peak current, IPK, is equal to the maximum

average inductor current plus one half of the ripple current.

First, the current ripple must be determined under the conditions that give maximum average inductor current:

Maximum average inductor current occurs at V

IN(MIN)

. Using

the selected inductance of 33 µH yields the following:

ΔiL = (9 x 0.78) / (0.5 x 33) = 425 mA

P-P

The highest peak inductor current over all operating conditions is therefore:

IPK = IL + 0.5 x ΔiL = 2.3 + 0.213 = 2.51A

Hence an inductor must be selected that has a peak current

rating greater than 2.5A and an average current rating greater

than 2.3A. One possibility is an off-the-shelf 33 µH ±20% inductor that can handle a peak current of 3.2A and an average

current of 3.4A. Finally, the inductor current ripple is recalculated at the maximum input voltage:

Δi

L-VIN(MAX)

= (16 x 0.6) / (0.5 x 33) = 0.58A

P-P

OUTPUT CAPACITOR

The output capacitor in a boost regulator supplies current to

the load during the MOSFET on-time and also filters the AC

portion of the load current during the off-time. This capacitor

determines the steady state output voltage ripple, ΔVO, a critical parameter for all voltage regulators. Output capacitors are

selected based on their capacitance, CO, their equivalent series resistance (ESR) and their RMS or AC current rating.

The magnitude of ΔVO is comprised of three parts, and in

steady state the ripple voltage during the on-time is equal to

the ripple voltage during the off-time. For simplicity the analysis will be performed for the MOSFET turning off (off-time)

only. The first part of the ripple voltage is the surge created

as the output diode D1 turns on. At this point inductor/diode

current is at the peak value, and the ripple voltage increase

can be calculated as:

ΔVO1 = IPK x ESR

The second portion of the ripple voltage is the increase due

to the charging of CO through the output diode. This portion

can be approximated as:

ΔVO2 = (IO / CO) x (D / fSW)

The final portion of the ripple voltage is a decrease due to the

flow of the diode/inductor current through the output

capacitor’s ESR. This decrease can be calculated as:

ΔVO3 = ΔiL x ESR

The total change in output voltage is then:

ΔVO = ΔVO1 + ΔVO2 - ΔV

O3

The combination of two positive terms and one negative term

may yield an output voltage ripple with a net rise or a net fall

during the converter off-time. The ESR of the output capacitor

(s) has a strong influence on the slope and direction of ΔVO.

Capacitors with high ESR such as tantalum and aluminum

electrolytic create an output voltage ripple that is dominated

by ΔVO1 and ΔVO3, with a shape shown in Figure 5. Ceramic

capacitors, in contrast, have very low ESR and lower capacitance. The shape of the output ripple voltage is dominated by

ΔVO2, with a shape shown in Figure 6.

20212226

FIGURE 5. ΔVO Using High ESR Capacitors

www.national.com 12

LM5022

20212227

FIGURE 6. ΔVO Using Low ESR Capacitors

For this example the small size and high temperature rating

of ceramic capacitors make them a good choice. The output

ripple voltage waveform of Figure 6 is assumed, and the capacitance will be selected first. The desired ΔVO is ±2% of

40V, or 0.8V

P-P

. Beginning with the calculation for ΔVO2, the

required minimum capacitance is:

C

O-MIN

= (IO / ΔVO) x (D

MAX

/ fSW)

C

O-MIN

= (0.5 / 0.8) x (0.77 / 5 x 105) = 0.96 µF

The next higher standard 20% capacitor value is 1.0 µF, however to provide margin for component tolerance and load

transients two capacitors rated 4.7 µF each will be used. Ceramic capacitors rated 4.7 µF ±20% are available from many

manufacturers. The minimum quality dielectric that is suitable

for switching power supply output capacitors is X5R, while

X7R (or better) is preferred. Careful attention must be paid to

the DC voltage rating and case size, as ceramic capacitors

can lose 60% or more of their rated capacitance at the maximum DC voltage. This is the reason that ceramic capacitors

are often de-rated to 50% of their capacitance at their working

voltage. The output capacitors for this example will have a

100V rating in a 2220 case size.

The typical ESR of the selected capacitors is 3 mΩ each, and

in parallel is approximately 1.5 mΩ. The worst-case value for

ΔVO1 occurs during the peak current at minimum input volt-

age:

ΔVO1 = 2.5 x 0.0015 = 4 mV

The worst-case capacitor charging ripple occurs at maximum

duty cycle:

ΔVO2 = (0.5 / 9.4 x 10-6) x (0.77 / 5 x 105) = 82 mV

Finally, the worst-case value for ΔVO3 occurs when inductor

ripple current is highest, at maximum input voltage:

ΔVO3 = 0.58 x 0.0015 = 1 mV (negligible)

The output voltage ripple can be estimated by summing the

three terms:

ΔVO = 4 mV + 82 mV - 1 mV = 85 mV

The RMS current through the output capacitor(s) can be estimated using the following, worst-case equation:

The highest RMS current occurs at minimum input voltage.

For this example the maximum output capacitor RMS current

is:

I

O-RMS(MAX)

= 1.13 x 2.3 x (0.78 x 0.22)

0.5

= 1.08A

RMS

These 2220 case size devices are capable of sustaining RMS

currents of over 3A each, making them more than adequate

for this application.

VCC DECOUPLING CAPACITOR

The VCC pin should be decoupled with a ceramic capacitor

placed as close as possible to the VCC and GND pins of the

LM5022. The decoupling capacitor should have a minimum

X5R or X7R type dielectric to ensure that the capacitance remains stable over voltage and temperature, and be rated to

a minimum of 470 nF. One good choice is a 1.0 µF device

with X7R dielectric and 1206 case size rated to 25V.

INPUT CAPACITOR

The input capacitors to a boost regulator control the input

voltage ripple, ΔVIN, hold up the input voltage during load

transients, and prevent impedance mismatch (also called

power supply interaction) between the LM5022 and the inductance of the input leads. Selection of input capacitors is

based on their capacitance, ESR, and RMS current rating.

The minimum value of ESR can be selected based on the

maximum output current transient, I

STEP

, using the following

expression:

For this example the maximum load step is equal to the load

current, or 0.5A. The maximum permissable ΔVIN during load

transients is 4%

P-P

. ΔVIN and duty cycle are taken at minimum

input voltage to give the worst-case value:

ESR

MIN

= [(1 – 0.77) x 0.36] / (2 x 0.5) = 83 mΩ

The minimum input capacitance can be selected based on

ΔVIN, based on the drop in VIN during a load transient, or

based on prevention of power supply interaction. In general,

the requirement for greatest capacitance comes from the

power supply interaction. The inductance and resistance of

the input source must be estimated, and if this information is

not available, they can be assumed to be 1 µH and 0.1Ω, re-

spectively. Minimum capacitance is then estimated as:

As with ESR, the worst-case, highest minimum capacitance

calculation comes at the minimum input voltage. Using the

default estimates for LS and RS, minimum capacitance is:

13 www.national.com

LM5022

The next highest standard 20% capacitor value is 6.8 µF, but

because the actual input source impedance and resistance

are not known, two 4.7 µF capacitors will be used. In general,

doubling the calculated value of input capacitance provides a

good safety margin. The final calculation is for the RMS current. For boost converters operating in CCM this can be

estimated as:

I

RMS

= 0.29 x Δi

L(MAX)

From the inductor section, maximum inductor ripple current is

0.58A, hence the input capacitor(s) must be rated to handle

0.29 x 0.58 = 170 mA

RMS

.

The input capacitors can be ceramic, tantalum, aluminum, or

almost any type, however the low capacitance requirement

makes ceramic capacitors particularly attractive. As with the

output capacitors, the minimum quality dielectric used should

X5R, with X7R or better preferred. The voltage rating for input

capacitors need not be as conservative as the output capacitors, as the need for capacitance decreases as input voltage

increases. For this example, the capacitor selected will be 4.7

µF ±20%, rated to 50V, in the 1812 case size. The RMS current rating of these capacitors is over 2A each, more than

enough for this application.

CURRENT SENSE FILTER

Parasitic circuit capacitance, inductance and gate drive current create a spike in the current sense voltage at the point

where Q1 turns on. In order to prevent this spike from terminating the on-time prematurely, every circuit should have a

low-pass filter that consists of CCS and RS1, shown in Figure

1. The time constant of this filter should be long enough to

reduce the parasitic spike without significantly affecting the

shape of the actual current sense voltage. The recommended

range for RS1 is between 10Ω and 500Ω, and the recommended range for CCS is between 100 pF and 2.2 nF. For this

example, the values of RS1 and CCS will be 100Ω and 1 nF,

respectively.

R

SNS

, RS2 AND CURRENT LIMIT

The current sensing resistor R

SNS

is used for steady state

regulation of the inductor current and to sense over-current

conditions. The slope compensation resistor is used to ensure

control loop stability, and both resistors affect the current limit

threshold. The R

SNS

value selected must be low enough to

keep the power dissipation to a minimum, yet high enough to

provide good signal-to-noise ratio for the current sensing circuitry. R

SNS

, and RS2 should be set so that the current limit

comparator, with a threshold of 0.5V, trips before the sensed

current exceeds the peak current rating of the inductor, without limiting the output power in steady state.

For this example the peak current, at V

IN(MIN)

, is 2.5A, while

the inductor itself is rated to 3.2A. The threshold for current

limit, I

LIM

, is set slightly between these two values to account

for tolerance of the circuit components, at a level of 3.0A. The

required resistor calculation must take into account both the

switch current through R

SNS

and the compensation ramp cur-

rent flowing through the internal 2 kΩ, RS1 and RS2 resistors.

R

SNS

should be selected first because it is a power resistor

with more limited selection. The following equation should be

evaluated at V

IN(MIN)

, when duty cycle is highest:

L in µH, fSW in MHz

The closest 5% value is 100 mΩ. Power dissipation in R

SNS

can be estimated by calculating the average current. The

worst-case average current through R

SNS

occurs at minimum

input voltage/maximum duty cycle and can be calculated as:

PCS = [(0.5 / 0.22)2 x 0.1] x 0.78 = 0.4W

For this example a 0.1Ω ±1%, thick-film chip resistor in a 1210

case size rated to 0.5W will be used.

With R

SNS

selected, RS2 can be determined using the follow-

ing expression:

The closest 1% tolerance value is 3.57 kΩ.

CONTROL LOOP COMPENSATION

The LM5022 uses peak current-mode PWM control to correct

changes in output voltage due to line and load transients.

Peak current-mode provides inherent cycle-by-cycle current

limiting, improved line transient response, and easier control

loop compensation.

The control loop is comprised of two parts. The first is the

power stage, which consists of the pulse width modulator,

output filter, and the load. The second part is the error amplifier, which is an op-amp configured as an inverting amplifier.

Figure 7 shows the regulator control loop components.

www.national.com 14

LM5022

20212234

FIGURE 7. Power Stage and Error Amp

One popular method for selecting the compensation components is to create Bode plots of gain and phase for the power

stage and error amplifier. Combined, they make the overall

bandwidth and phase margin of the regulator easy to determine. Software tools such as Excel, MathCAD, and Matlab

are useful for observing how changes in compensation or the

power stage affect system gain and phase.

The power stage in a CCM peak current mode boost converter consists of the DC gain, APS, a single low frequency

pole, f

LFP

, the ESR zero, f

ZESR

, a right-half plane zero, f

RHP

,

and a double pole resulting from the sampling of the peak

current. The power stage transfer function (also called the

Control-to-Output transfer function) can be written:

Where the DC gain is defined as:

Where:

RO = VO / I

O

The system ESR zero is:

The low frequency pole is:

The right-half plane zero is:

The sampling double pole quality factor is:

The sampling double corner frequency is:

ωn = π x f

SW

The natural inductor current slope is:

Sn = R

SNS

x VIN / L

The external ramp slope is:

Se = 45 µA x (2000 + RS1 + RS2)] x f

SW

In the equation for APS, DC gain is highest when input voltage

and output current are at the maximum. In this the example

those conditions are VIN = 16V and IO = 500 mA.

DC gain is 44 dB. The low frequency pole fP = 2πωP is at

423Hz, the ESR zero fZ = 2πωZ is at 5.6 MHz, and the righthalf plane zero f

RHP

= 2πω

RHP

is at 61 kHz. The sampling

double-pole occurs at one-half of the switching frequency.

Proper selection of slope compensation (via RS2) is most evident the sampling double pole. A well-selected RS2 value

eliminates peaking in the gain and reduces the rate of change

of the phase lag. Gain and phase plots for the power stage

are shown in Figure 8.

20212241

15 www.national.com

LM5022

20212297

FIGURE 8. Power Stage Gain and Phase

The single pole causes a roll-off in the gain of -20 dB/decade

at lower frequency. The combination of the RHP zero and

sampling double pole maintain the slope out to beyond the

switching frequency. The phase tends towards -90° at lower

frequency but then increases to -180° and beyond from the

RHP zero and the sampling double pole. The effect of the

ESR zero is not seen because its frequency is several

decades above the switching frequency. The combination of

increasing gain and decreasing phase makes converters with

RHP zeroes difficult to compensate. Setting the overall control loop bandwidth to 1/3 to 1/10 of the RHP zero frequency

minimizes these negative effects, but requires a compromise

in the control loop bandwidth. If this loop were left uncompensated, the bandwidth would be 89 kHz and the phase

margin -54°. The converter would oscillate, and therefore is

compensated using the error amplifier and a few passive

components.

The transfer function of the compensation block, GEA, can be

derived by treating the error amplifier as an inverting op-amp

with input impedance ZI and feedback impedance ZF. The

majority of applications will require a Type II, or two-pole onezero amplifier, shown in Figure 7. The LaPlace domain transfer function for this Type II network is given by the following:

Many techniques exist for selecting the compensation component values. The following method is based upon setting

the mid-band gain of the error amplifier transfer function first

and then positioning the compensation zero and pole:

1.

Determine the desired control loop bandwidth: The

control loop bandwidth, f

0dB

, is the point at which the total

control loop gain (H = GPS x GEA) is equal to 0 dB. For

this example, a low bandwidth of 10 kHz, or

approximately 1/6th of the RHP zero frequency, is

chosen because of the wide variation in input voltage.

2.

Determine the gain of the power stage at f

0dB

: This

value, A, can be read graphically from the gain plot of

GPS or calculated by replacing the ‘s’ terms in GPS with

‘2πf

0dB

’. For this example the gain at 10 kHz is

approximately 16 dB.

3.

Calculate the negative of A and convert it to a linear

gain: By setting the mid-band gain of the error amplifier

to the negative of the power stage gain at f

0dB

, the control

loop gain will equal 0 dB at that frequency. For this

example, -16 dB = 0.15V/V.

4.

Select the resistance of the top feedback divider

resistor R

FB2

: This value is arbitrary, however selecting

a resistance between 10 kΩ and 100 kΩ will lead to

practical values of R1, C1 and C2. For this example,

R

FB2

= 20 kΩ 1%.

5.

Set R1 = A x R

FB2

: For this example: R1 = 0.15 x 20000

= 3 kΩ

6.

Select a frequency for the compensation zero, fZ1:

The suggested placement for this zero is at the low

frequency pole of the power stage, f

LFP

= ωLFP / 2π. For

this example, fZ1 = f

LFP

= 423Hz

7.

Set

For this example, C2 = 125 nF

8.

Select a frequency for the compensation pole, fP1:

The suggested placement for this pole is at one-fifth of

the switching frequency. For this example, fP1 = 100 kHz

9.

Set

For this example, C1 = 530 pF

10.

Plug the closest 1% tolerance values for R

FB2

and R1,

then the closest 10% values for C1 and C2 into G

EA

and model the error amp: The open-loop gain and

bandwidth of the LM5022’s internal error amplifier are 75

dB and 4 MHz, respectively. Their effect on GEA can be

modeled using the following expression:

ADC is a linear gain, the linear equivalent of 75 dB is

approximately 5600V/V. C1 = 560 pF 10%, C2 = 120 nF

10%, R1 = 3.01 kΩ 1%

11.

Plot or evaluate the actual error amplifier transfer

function:

www.national.com 16

LM5022

20212248

20212298

FIGURE 9. Error Amplifier Gain and Phase

12. Plot or evaluate the complete control loop transfer

function: The complete control loop transfer function is ob-

tained by multiplying the power stage and error amplifier

functions together. The bandwidth and phase margin can

then be read graphically or evaluated numerically.

20212249

20212299

FIGURE 10. Overall Loop Gain and Phase

The bandwidth of this example circuit at VIN = 16V is 10.5 kHz,

with a phase margin of 66°.

13. Re-evaluate at the corners of input voltage and output

current: Boost converters exhibit significant change in their

loop response when VIN and IO change. With the compensation fixed, the total control loop gain and phase should be

checked to ensure a minimum phase margin of 45° over both

line and load.

Efficiency Calculations

A reasonable estimation for the efficiency of a boost regulator

controlled by the LM5022 can be obtained by adding together

the loss is each current carrying element and using the equation:

The following shows an efficiency calculation to complement

the circuit design from the Design Considerations section.

Output power for this circuit is 40V x 0.5A = 20W. Input voltage

is assumed to be 13.8V, and the calculations used assume

that the converter runs in CCM. Duty cycle for VIN = 13.8V is

66%, and the average inductor current is 1.5A.

CHIP OPERATING LOSS

This term accounts for the current drawn at the VIN pin. This

current, IIN, drives the logic circuitry and the power MOSFETs.

The gate driving loss term from the power MOSFET section

of Design Considerations is included in the chip operating

loss. For the LM5022, IIN is equal to the steady state operating

current, ICC, plus the MOSFET driving current, IGC. Power is

lost as this current passes through the internal linear regulator

of the LM5022.

IGC = QG X f

SW

IGC = 27 nC x 500 kHz = 13.5 mA

ICC is typically 3.5 mA, taken from the Electrical Characteristics table. Chip Operating Loss is then:

PQ = VIN X (IQ + IGC)

17 www.national.com

LM5022

PQ = 13.8 X (3.5m + 13.5m) = 235 mW

MOSFET SWITCHING LOSS

PSW = 0.5 x VIN x IL x (tR + tF) x f

SW

PSW = 0.5 x 13.8 x 1.5 x (10 ns + 12 ns) x 5 x 105 = 114 mW

MOSFET AND R

SNS

CONDUCTION LOSS

PC = D x (I

L

2

x (R

DSON

x 1.3 + R

SNS

))

PC = 0.66 x (1.52 x (0.029 + 0.1)) = 192 mW

OUTPUT DIODE LOSS

The average output diode current is equal to IO, or 0.5A. The

estimated forward drop, VD, is 0.5V. The output diode loss is

therefore:

PD1 = IO x V

D

PD1 = 0.5 x 0.5 = 0.25W

INPUT CAPACITOR LOSS

This term represents the loss as input ripple current passes

through the ESR of the input capacitor bank. In this equation

‘n’ is the number of capacitors in parallel. The 4.7 µF input

capacitors selected have a combined ESR of approximately

1.5 mΩ, and ΔiL for a 13.8V input is 0.55A:

I

IN-RMS

= 0.29 x ΔiL = 0.29 x 0.55 = 0.16A

P

CIN

= [0.162 x 0.0015] / 2 = 0.02 mW (negligible)

OUTPUT CAPACITOR LOSS

This term is calculated using the same method as the input

capacitor loss, substituting the output capacitor RMS current

for VIN = 13.8V. The output capacitors' combined ESR is also

approximately 1.5 mΩ.

I

O-RMS

= 1.13 x 1.5 x (0.66 x 0.34)

0.5

= 0.8A

PCO = [0.8 x 0.0015] / 2 = 0.6 mW

BOOST INDUCTOR LOSS

The typical DCR of the selected inductor is 40 mΩ.

P

DCR

= I

L

2

x DCR

P

DCR

= 1.52 x 0.04 = 90 mW

Core loss in the inductor is estimated to be equal to the DCR

loss, adding an additional 90 mW to the total inductor loss.

TOTAL LOSS

P

LOSS

= Sum of All Loss Terms = 972 mW

EFFICIENCY

η = 20 / (20 + 0.972) = 95%

Layout Considerations

To produce an optimal power solution with the LM5022, good

layout and design of the PCB are as important as the component selection. The following are several guidelines to aid

in creating a good layout.

FILTER CAPACITORS

The low-value ceramic filter capacitors are most effective

when the inductance of the current loops that they filter is

minimized. Place C

INX

as close as possible to the VIN and

GND pins of the LM5022. Place COX close to the load, and

CF next to the VCC and GND pins of the LM5022.

SENSE LINES

The top of R

SNS

should be connected to the CS pin with a

separate trace made as short as possible. Route this trace

away from the inductor and the switch node (where D1, Q1,

and L1 connect). For the voltage loop, keep R

FB1/2

close to

the LM5022 and run a trace from as close as possible to the

positive side of COX to R

FB2

. As with the CS line, the FB line

should be routed away from the inductor and the switch node.

These measures minimize the length of high impedance lines

and reduce noise pickup.

COMPACT LAYOUT

Parasitic inductance can be reduced by keeping the power

path components close together and keeping the area of the

loops that high currents travel small. Short, thick traces or

copper pours (shapes) are best. In particular, the switch node

should be just large enough to connect all the components

together without excessive heating from the current it carries.

The LM5022 (boost converter) operates in two distinct cycles

whose high current paths are shown in Figure 11:

20212252

FIGURE 11. Boost Converter Current Loops

www.national.com 18

LM5022

The dark grey, inner loops represents the high current paths

during the MOSFET on-time. The light grey, outer loop represents the high current path during the off-time.

GROUND PLANE AND SHAPE ROUTING

The diagram of Figure 11 is also useful for analyzing the flow

of continuous current vs. the flow of pulsating currents. The

circuit paths with current flow during both the on-time and offtime are considered to be continuous current, while those that

carry current during the on-time or off-time only are pulsating

currents. Preference in routing should be given to the pulsating current paths, as these are the portions of the circuit most

likely to emit EMI. The ground plane of a PCB is a conductor

and return path, and it is susceptible to noise injection just as

any other circuit path. The continuous current paths on the

ground net can be routed on the system ground plane with

less risk of injecting noise into other circuits. The path between the input source, input capacitor and the MOSFET and

the path between the output capacitor and the load are examples of continuous current paths. In contrast, the path

between the grounded side of the power switch and the negative output capacitor terminal carries a large pulsating current. This path should be routed with a short, thick shape,

preferably on the component side of the PCB. Multiple vias in

parallel should be used right at the negative pads of the input

and output capacitors to connect the component side shapes

to the ground plane. Vias should not be placed directly at the

grounded side of the MOSFET (or R

SNS

) as they tend to inject

noise into the ground plane. A second pulsating current loop

that is often ignored but must be kept small is the gate drive

loop formed by the OUT and VCC pins, Q1, R

SNS

and capac-

itor CF.

19 www.national.com

LM5022

BOM for Example Circuit

ID Part Number Type Size Parameters Qty Vendor

U1 LM5022 Low-Side Controller MSOP-10 60V 1 NSC

Q1 Si4850EY MOSFET SO-8

60V, 31mΩ, 27nC

1 Vishay

D1 CMSH2-60M Schottky Diode SMA 60V, 2A 1 Central Semi

L1 SLF12575T-M3R2 Inductor 12.5 x 12.5 x 7.5 mm

33µH, 3.2A, 40mΩ

1 TDK

Cin1, Cin2 C4532X7R1H475M Capacitor 1812

4.7µF, 50V, 3mΩ

2 TDK

Co1, Co2 C5750X7R2A475M Capacitor 2220

4.7µF,100V, 3mΩ

2 TDK

Cf C2012X7R1E105K Capacitor 0805 1µF, 25V 1 TDK

Cinx

Cox

C2012X7R2A104M Capacitor 0805 100nF, 100V 2 TDK

C1 VJ0805A561KXXAT Capacitor 0805 560pF 10% 1 Vishay

C2 VJ0805Y124KXXAT Capacitor 0805 120nF 10% 1 Vishay

Css VJ0805Y103KXXAT Capacitor 0805 10nF 10% 1 Vishay

Ccs VJ0805Y102KXXAT Capacitor 0805 1nF 10% 1 Vishay

R1 CRCW08053011F Resistor 0805

3.01kΩ 1%

1 Vishay

Rfb1 CRCW08056490F Resistor 0805

649Ω 1%

1 Vishay

Rfb2 CRCW08052002F Resistor 0805

20kΩ 1%

1 Vishay

Rs1 CRCW0805101J Resistor 0805

100Ω 5%

1 Vishay

Rs2 CRCW08053571F Resistor 0805

3.57kΩ 1%

1 Vishay

Rsns ERJL14KF10C Resistor 1210

100mΩ, 1%, 0.5W

1 Panasonic

Rt CRCW08053322F Resistor 0805

33.2kΩ 1%

1 Vishay

Ruv1 CRCW08052611F Resistor 0805

2.61kΩ 1%

1 Vishay

Ruv2 CRCW08051002F Resistor 0805

10kΩ 1%

1 Vishay

www.national.com 20

LM5022

Physical Dimensions inches (millimeters) unless otherwise noted

10-Lead MSOP Package

NS Package Number MUB10A

21 www.national.com

LM5022

Notes

LM5022 60V Low Side Controller for Boost and SEPIC

THE CONTENTS OF THIS DOCUMENT ARE PROVIDED IN CONNECTION WITH NATIONAL SEMICONDUCTOR CORPORATION

(“NATIONAL”) PRODUCTS. NATIONAL MAKES NO REPRESENTATIONS OR WARRANTIES WITH RESPECT TO THE ACCURACY

OR COMPLETENESS OF THE CONTENTS OF THIS PUBLICATION AND RESERVES THE RIGHT TO MAKE CHANGES TO

SPECIFICATIONS AND PRODUCT DESCRIPTIONS AT ANY TIME WITHOUT NOTICE. NO LICENSE, WHETHER EXPRESS,

IMPLIED, ARISING BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS

DOCUMENT.

TESTING AND OTHER QUALITY CONTROLS ARE USED TO THE EXTENT NATIONAL DEEMS NECESSARY TO SUPPORT

NATIONAL’S PRODUCT WARRANTY. EXCEPT WHERE MANDATED BY GOVERNMENT REQUIREMENTS, TESTING OF ALL

PARAMETERS OF EACH PRODUCT IS NOT NECESSARILY PERFORMED. NATIONAL ASSUMES NO LIABILITY FOR

APPLICATIONS ASSISTANCE OR BUYER PRODUCT DESIGN. BUYERS ARE RESPONSIBLE FOR THEIR PRODUCTS AND

APPLICATIONS USING NATIONAL COMPONENTS. PRIOR TO USING OR DISTRIBUTING ANY PRODUCTS THAT INCLUDE

NATIONAL COMPONENTS, BUYERS SHOULD PROVIDE ADEQUATE DESIGN, TESTING AND OPERATING SAFEGUARDS.

EXCEPT AS PROVIDED IN NATIONAL’S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, NATIONAL ASSUMES NO

LIABILITY WHATSOEVER, AND NATIONAL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY RELATING TO THE SALE

AND/OR USE OF NATIONAL PRODUCTS INCLUDING LIABILITY OR WARRANTIES RELATING TO FITNESS FOR A PARTICULAR

PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY

RIGHT.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR

SYSTEMS WITHOUT THE EXPRESS PRIOR WRITTEN APPROVAL OF THE CHIEF EXECUTIVE OFFICER AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

Life support devices or systems are devices which (a) are intended for surgical implant into the body, or (b) support or sustain life and

whose failure to perform when properly used in accordance with instructions for use provided in the labeling can be reasonably expected

to result in a significant injury to the user. A critical component is any component in a life support device or system whose failure to perform

can be reasonably expected to cause the failure of the life support device or system or to affect its safety or effectiveness.

National Semiconductor and the National Semiconductor logo are registered trademarks of National Semiconductor Corporation. All other

brand or product names may be trademarks or registered trademarks of their respective holders.

Copyright© 2007 National Semiconductor Corporation

For the most current product information visit us at www.national.com

National Semiconductor

Americas Customer

Support Center

Email:

new.feedback@nsc.com

Tel: 1-800-272-9959

National Semiconductor Europe

Customer Support Center

Fax: +49 (0) 180-530-85-86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +49 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor Asia

Pacific Customer Support Center

Email: ap.support@nsc.com

National Semiconductor Japan

Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

www.national.com

Loading...

Loading...