LM3590

Series White LED Driver

LM3590 Series White LED Driver

November 2003

General Description

The LM3590 is a White LED constant current driver capable

of supplying up to 3 White LEDs connected in series with

20mA. This device operates over a wide 6V-12.6V input

voltage range. The output can accomodate LEDs with a

combined forward voltage of up to 11.5V, from a 12V input

supply. The LED drive current is programmed by using an

external resistor on the I

LED brightness can be linearly varied up to the programmed

LED current by applying a Pulse Width Modulated (PWM)

signal to the EN pin of the device. The LED output current of

the LM3590 is tightly controlled over temperature and voltage. LED Current matching is guaranteed due to the series

configuration of the LEDs. The series topology also simplifies the connection between the White LEDs in the display

module and the LM3590 since only one connection is required.

The LM3590 typically draws only 50µA when operating in the

no-load condition and draws less than 0.1µA when the device is shut down.

The LM3590 is available in a small 5-pin SOT23 package.

SET

pin.

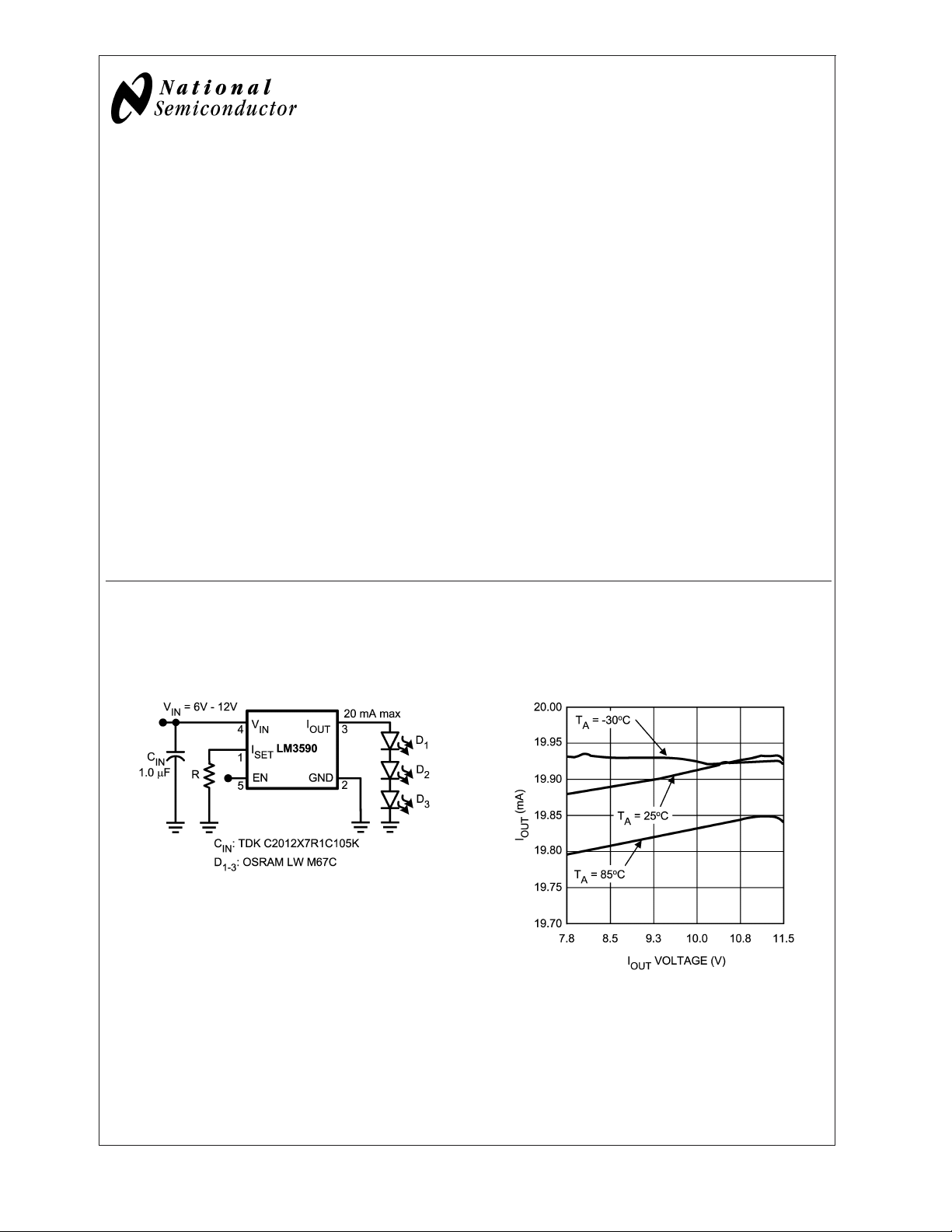

Typical Application Circuit

Features

n Drives up to 3 stacked white LEDs

n 6.0V-12.6V input voltage range

n Up to 20mA LED output current

n Excellent LED current matching guaranteed by series

configuration

n Single connection to the White LEDs in the display

module

n Tightly controlled programmable current source

n Low shutdown current (0.1µA typ.)

n PWM brightness control

n Very small solution size

n SOT23-5 package: 3mm x 3mm x 1.0mm (LxWxH)

Applications

n White LED Display Backlights

n Keypad Backlights

n General purpose constant current driver for high

forward-voltage LEDs

20081301

20081305

© 2003 National Semiconductor Corporation DS200813 www.national.com

Connection Diagram

LM3590

Ordering Information

Order Number Package Description Package Marking Supplied As

LM3590MF SOT23-5 SABB

LM3590MFX SOT23-5 SABB

Pin Description

#

Pin

1I

2 GND Ground Connection

3I

4V

5 EN Device Enable

20081302

¢Z¢1¢

*

¢Z¢1¢

*

Name Function

SET

Programmable LED current Input. The LED current has the following relationship with the

resistor used:

OUT

= 100 x (125 ÷ I

R

SET

Constant Current LED Output

IN

Power Supply Voltage Input. Input voltage range: 6V-12.6V

OUT

)

Tape and Reel

X 250 Units, Tape

and Reel

X 3000 Units, Tape

and Reel

www.national.com 2

LM3590

Absolute Maximum Ratings (Notes 1,

2)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

V

IN

EN −0.3 to (V

−0.3 to 13.0V Max

+0.3V) w/

IN

13.0V max

Operating Conditions

Input Voltage Range 6.0V to 12.6V

EN Voltage Range 0V to V

Ambient Temperature (TA)

Range

(Note 4)

Junction Temperature (T

Range

)

J

−40˚C to +85˚C

−40˚C to +110˚C

Maximum Junction Temperature

) 150˚C

(T

JMAX

Storge Temperature −65˚C to +150˚C

Maximum Lead Temperature

260˚C

(Soldering, 5 sec.)

ESD Rating (Note 3)

Thermal Information

Junction-to-Ambient Thermal

Resistance,

SOT23-5 Package (θ

) (Note 5) 220˚C/W

JA

Human Body Model 1.5kV

Machine Model 200V

Electrical Characteristics (Notes 2, 6)

Limits in standard typeface are for TJ= 25˚C and limits in boldface type apply over the full Operating Junction Temperature

Range (−40˚C ≤ T

≤ +110˚C). Unless otherwise specified, CIN= 1 µF, VIN= 12.0V, VEN= 3.0V, R

J

10.8V.

Symbol Parameter Conditions Min Typ Max Units

I

OUT

Output Current Capability VIN= 12V

7.5V ≤ V

V

= 10.8V

IOUT

11.3V ≤ V

R

= 8.35kΩ 15

SET

R

= 12.5kΩ 10

SET

IOUT

IN

≤ 11.5V

≤ 12.6V

19

(−5%)

19

(−5%)

Output Current Programming 125 ÷

I

ratio to I

OUT

I

Q

I

SD

V

ISET

V

HR

Quiescent Supply Current 11.3V ≤ VIN≤ 12.6V

Shutdown Supply Current VIN= 12.6V

I

Reference Voltage 1.25 V

SET

Minimum Current Source

Voltage Headroom (V

V

IOUT

V

IH

V

IL

I

EN

t

ON

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings are conditions under which operation of the

device is guaranteed. Operating Ratings do not imply guaranteed performance limits. For guaranteed performance limits and associated test conditions, see the

Electrical Characteristics table.

Note 2: All voltages are with respect to the potential at the GND pin.

Note 3: The human-body model is a 100pF capacitor discharged through a 1.5kΩ resistor into each pin. The machine model is a 220pF capacitor discharged

directly into each pin.

Note 4: Maximum ambient temperature (T

dissipation of the device in the application (P

following equation: T

outside the listed T

Note 5: Junction-to-ambient thermal resistance is highly application and board-layout dependent. In applications where high maximum power dissipation exists,

special care must be paid to thermal dissipation issues. For more information on these topics, please refer to the Power Dissipation section of this datasheet.

Logic Input EN: High level 1.1 V

Logic Input EN: Low level 0 0.3 V

Enable Pin Input Current(Note 8) 6 µA

Turn-On Time I

A-MAX=TJ-MAX-OP

rating, so long as the junction temperature of the device does not exceed the maximum operating rating of 110oC.

A

)(Note 7)

SET

= OPEN

R

SET

= OPEN

I

OUT

=0V

V

EN

= 95% nominal 300 mV

I

OUT

−

IN

= 90% of steady state 50 µs

OUT

) is dependent on the maximum operating junction temperature (T

A-MAX

), and the junction-to-ambient thermal resistance of the part/package in the application (θJA), as given by the

D-MAX

-(θJAxP

). The ambient temperature operating rating is provided merely for convenience. This part may be operated

D-MAX

J-MAX-OP

= 6.19kΩ,V

SET

IOUT

20 21

(+5%)

20 21

(+5%)

R

SET

100:1

50 75 µA

0.1 1 µA

IN

=110oC), the maximum power

IN

=

mA

A

V

www.national.com3

Electrical Characteristics (Notes 2, 6) (Continued)

Note 6: All room temperature limits are 100% tested or guaranteed through statistical analysis. All limits at temperature extremes are guaranteed by correlation

LM3590

using standard Statistical Quality Control methods (SQC). All limits are used to calculate Average Outgoing Quality Level (AOQL). Typical numbers are not

guaranteed, but do represent the most likely norm.

Note 7: The current source is connected internally between V

For the current source to regulate properly, a minimum headroom voltage must be present across it. Minimum required headroom voltage is proportional to the

current flowing through the current source, as dictated by this equation: V

Note 8: An internal 500kΩ pull-down resistor is connected between the EN and GND pins.

IN

and V

. The voltage across the current source, [VIN−V

IOUT

HR-MIN

= 300mV x (I

OUT

÷ 20mA).

], is referred to as headroom voltage.

IOUT

Functional Block Diagram

www.national.com 4

20081314

LM3590

Typical Performance Characteristics Unless otherwise specified, C

3.0V, V

IOUT

= 10.8V, R

= 6.19kΩ,TA= 25˚C. CINis a low ESR multi-layer ceramic capacitor (MLCC).

SET

I

I

OUT

OUT

vs V

vs R

IN

20081304

SET

I

OUT

= 1µF, VIN= 12.0V, VEN=

IN

vs V

IOUT

IQvs V

IN

20081305

20081306

V

SET

vs V

IN

20081308

Shutdown Supply Current vs V

20081307

IN

20081309

www.national.com5

Typical Performance Characteristics Unless otherwise specified, C

3.0V, V

LM3590

IOUT

= 10.8V, R

Shutdown Threshold vs V

= 6.19kΩ,TA= 25˚C. CINis a low ESR multi-layer ceramic capacitor (MLCC). (Continued)

SET

IN

20081310

= 1µF, VIN= 12.0V, VEN=

IN

Startup

20081311

www.national.com 6

Application Information

CIRCUIT DESCRIPTION

The LM3590 is a constant current series White-LED Driver,

providing up to 20mA from an input voltage between 7.5V to

12.6V. To set the LED drive current, the LM3590 uses a

resistor connected to the I

This reference current is then multiplied and mirrored to the

constant current output, I

controlled by applying a PWM (Pulse Width Modulation)

signal to the Enable pin (EN). (see PWM BRIGHTNESS

CONTROL PROCEDURES section).

ENABLE MODE

The Enable pin (EN) disables the part and reduces the

quiescent current to 0.1µA (typ.). The LM3590 has an activehigh enable pin (LOW = shut down, HIGH = operating). The

LM3590 EN pin can be driven with a low-voltage CMOS logic

signal (1.5V logic, 1.8V logic, etc). There is an internal

500kΩ pull-down between the EN and GND pins of the

LM3590.

CAPACITOR SELECTION

Although not required for normal operation, a capacitor can

be added to the voltage input of the LM3590 to reduce line

noise. A surface-mount multi-layer ceramic capacitor

(MLCC) is recommended. MLCCs are small, inexpensive

and have very low equivalent series resistance (ESR,

≤15mΩ typ.). MLCCs with a X5R or X7R temperature characteristic are preferred for use with the LM3590. Table 1.

Ceramic Capacitor Manufacturers lists suggested capacitor

suppliers for the typical application circuit.

pin to set a reference current.

SET

. The LED brightness can be

OUT

required headroom voltage is proportional to the current

flowing through the current source, as dictated by the equation:

V

HR-MIN=kHRxIOUT

The parameter kHR, typically 15mV/mA in the LM3590, is a

proportionality constant that represents the ON-resistance of

the internal current mirror transistors. For worst-case design

calculations, using a k

of 20mV/mA is recommended.

HR

(Worst-case recommendation accounts for parameter shifts

from part-to-part variation and applies over the full operating

temperature range). Figure 1 shows how output current of

the LM3590 varies with respect to headroom voltage.

LM3590

TABLE 1. Ceramic Capacitor Manufacturers

Manufacturer Contact

TDK www.component.tdk.com

Murata www.murata.com

Taiyo Yuden www.t-yuden.com

LED SELECTION

The LM3590 is designed to drive up to 3 LEDs with the

combined forward voltages of the LEDs being no greater

than 11.5V, when using a 12V input supply. The typical and

maximum diode forward voltage depends highly on the

manufacturer and their technology. Table 2. White LED Se-

lection lists two suggested manufacturers. LED Forward current matching is guaranteed by design, due to the series

LED configuration of the LM3590.

TABLE 2. White LED Selection

Manufacturer Contact

Osram www.osram-os.com

Nichia www.nichia.com

LED HEADROOM VOLTAGE (V

)

HR

A single current source is connected internally between V

and I

V

. The voltage across the current source, (VIN−

OUT

), is referred to as headroom voltage (VHR). The cur-

IOUT

rent source requires a sufficient amount of headroom voltage

to be present across it in order to regulate properly. Minimum

20081312

FIGURE 1. I

VHR=VIN−V

OUT

vs V

IOUT

HR

VIN= 12.0V

On the flat part of the graph, the current is regulated properly

as there is sufficient headroom voltage for regulation. On the

sloping part of the graph the headroom voltage is too small,

the current source is squeezed, and the current drive capability is limited. Thus, operating the LM3590 with insufficient

headroom voltage across the current source should be

avoided.

PIN

I

SET

An external resistor, R

, connected to the I

SET

pin sets the

SET

output current. The internal current mirror sets the series

LED output current with a 100:1 ratio to the current through

. The current matching through each LED is guaranteed

R

SET

by the series LED drive topology. The following equation

approximates the LED current:

= 100 x (1.25V ÷ R

I

OUT

SET

) (Amps)

PWM BRIGHTNESS CONTROL PROCEDURES

The brightness of the LEDs can be linearly varied from zero

up to the maximum programmed current level by applying a

IN

Pulse-Width-Modulated signal to the EN pin of the LM3590.

The following procedures illustrate how to program the LED

drive current and adjust the output current level using a

PWM signal.

1. Determine the maximum desired I

equation to calculate R

I

OUT

SET

current. Use the

OUT

www.national.com7

Application Information (Continued)

2. Brightness control can be implemented by pulsing a

LM3590

signal at the EN pin. LED brightness is proportional to

the duty cycle (D) of the PWM signal. For linear brightness control over the full duty cycle adjustment range,

the PWM frequency (f) should be limited to accommodate the turn-on time (T

D x (1/f)

f

MAX=DMIN÷TON

= 50µs) of the device.

ON

>

T

ON

If the PWM frequency is much less than 100Hz, flicker

may be seen in the LEDs. For the LM3590, zero duty

cycle will turn off the LEDs and a 50% duty cycle will

result in an average I

LED current. For example, if R

being half of the programmed

OUT

is set to program

SET

15mA, a 50% duty cycle will result in an average I

7.5mA.

POWER DISSIPATION

The power dissipation (P

) can be approximated with the equations below. P

ture (T

J

DISSIPATION

) and junction tempera-

is the product of the input current and input voltage, P

Application Circuits

Figure 2 shows how to program the LED current to four

different DC levels using two digital logic signals. The programmed LED current is a function of the equivalent resis-

LED

IOUT

the power consumed by the LEDs, T

perature, and θ

is the junction-to-ambient thermal resis-

JA

tance for the SOT23-5 package. V

the LM3590, V

LEDs connected to the I

is the sum of the forward voltages of

IOUT

OUT

pin, and I

is the ambient tem-

A

is the input voltage to

IN

is the programmed

OUT

LED current.

P

DISSIPATION=PIN-PIOUT

=(VINxI

T

J=TA

OUT

+(P

)−(V

IOUTxIOUT

DISSIPATION

)

x θJA)

The junction temperature rating takes precedence over the

ambient temperature rating. The LM3590 may be operated

outside the ambient temperature rating, so long as the junction temperature of the device does not exceed the maximum operating rating of 110˚C. The maximum ambient tem-

of

perature rating must be derated in applications where high

power dissipation and/or poor thermal resistance causes the

junction temperature to exceed 110˚C.

IN

is

tance on the I

SET

pin (R

), resulting from the logic signals

ISET

on SET1 and SET2. Example values for R1, R2, and RSET

an the resulting 4 current levels are shown below.

FIGURE 2. Example: R1= 15.8kΩ,R2= 31.6kΩ,R

TABLE 3. Digital LED Current Programming

EN SET1 SET2 R

ISET

0 X X Shutdown Shutdown Shutdown

111 R

110 R

101 R

100 R

www.national.com 8

SETiR1iR2

SETiR1

SETiR2

SET

20081313

= 31.6kΩ

SET

Example R

ISET

Example I

31.6kΩi15.kΩi31.6kΩ 16mA

31.6kΩi15.kΩ 12mA

31.6kΩi31.6kΩ 8mA

31.6kΩ 4mA

OUT

Physical Dimensions inches (millimeters) unless otherwise noted

LM3590 Series White LED Driver

5 Lead Small Outline Package (SOT23-5)

NS Package Number MF05A

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

labeling, can be reasonably expected to result in a

significant injury to the user.

BANNED SUBSTANCE COMPLIANCE

National Semiconductor certifies that the products and packing materials meet the provisions of the Customer Products

Stewardship Specification (CSP-9-111C2) and the Banned Substances and Materials of Interest Specification

(CSP-9-111S2) and contain no ‘‘Banned Substances’’ as defined in CSP-9-111S2.

National Semiconductor

Americas Customer

Support Center

Email: new.feedback@nsc.com

Tel: 1-800-272-9959

www.national.com

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

National Semiconductor

Europe Customer Support Center

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Support Center

Email: ap.support@nsc.com

National Semiconductor

Japan Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

Loading...

Loading...