LM3509

High Efficiency Boost for White LED's and/or OLED

Displays with Dual Current Sinks and I2C Compatible

Brightness Control

May 2007

LM3509 High Efficiency Boost for White LED's and/or OLED Displays with Dual Current Sinks

and I

2

C Compatible Brightness Control

General Description

The LM3509 current mode boost converter offers two separate outputs. The first output (MAIN) is a constant current sink

for driving series white LED’s. The second output (SUB/FB)

is configurable as a constant current sink for series white LED

bias, or as a feedback pin to set a constant output voltage for

powering OLED panels.

When configured as a dual output white LED bias supply, the

LM3509 adaptively regulates the supply voltage of the LED

strings to maximize efficiency and insure the current sinks remain in regulation. The maximum current per output is set via

a single external low power resistor. An I2C compatible interface allows for independent adjustment of the LED current in

either output from 0 to max current in 32 exponential steps.

When configured as a white LED + OLED bias supply the

LM3509 can independently and simultaneously drive a string

of up to 5 white LED’s and deliver a constant output voltage

of up to 21V for OLED panels.

Output over-voltage protection shuts down the device if

V

rises above 21V allowing for the use of small sized low

OUT

voltage output capacitors. The LM3509 is offered in a small

10-pin thermally- enhanced LLP package and operates over

the -40°C to +85°C temperature range.

Typical Application Circuits

Features

Integrated OLED Display Power Supply and LED Driver

■

Drives up to 10 LED’s at 30mA

■

Drives up to 5 LED’s at 20mA and delivers up to 21V at

■

40mA

Over 90% Efficient

■

32 Exponential Dimming Steps

■

0.15% Accurate Current Matching Between Strings

■

Internal Soft-Start Limits Inrush Current

■

True Shutdown Isolation for LED’s

■

Wide 2.7V to 5.5V Input Voltage Range

■

21V Over-Voltage Protection

■

1.27MHz Fixed Frequency Operation

■

Low Profile 10-pin LLP Package (3mm x 3mm x 0.8mm)

■

General Purpose I/O

■

Active Low Hardware Reset

■

Applications

Dual Display LCD Backlighting for Portable Applications

■

Large Format LCD Backlighting

■

OLED Panel Power Supply

■

30004361

© 2007 National Semiconductor Corporation 300043 www.national.com

LM3509

30004301

www.national.com 2

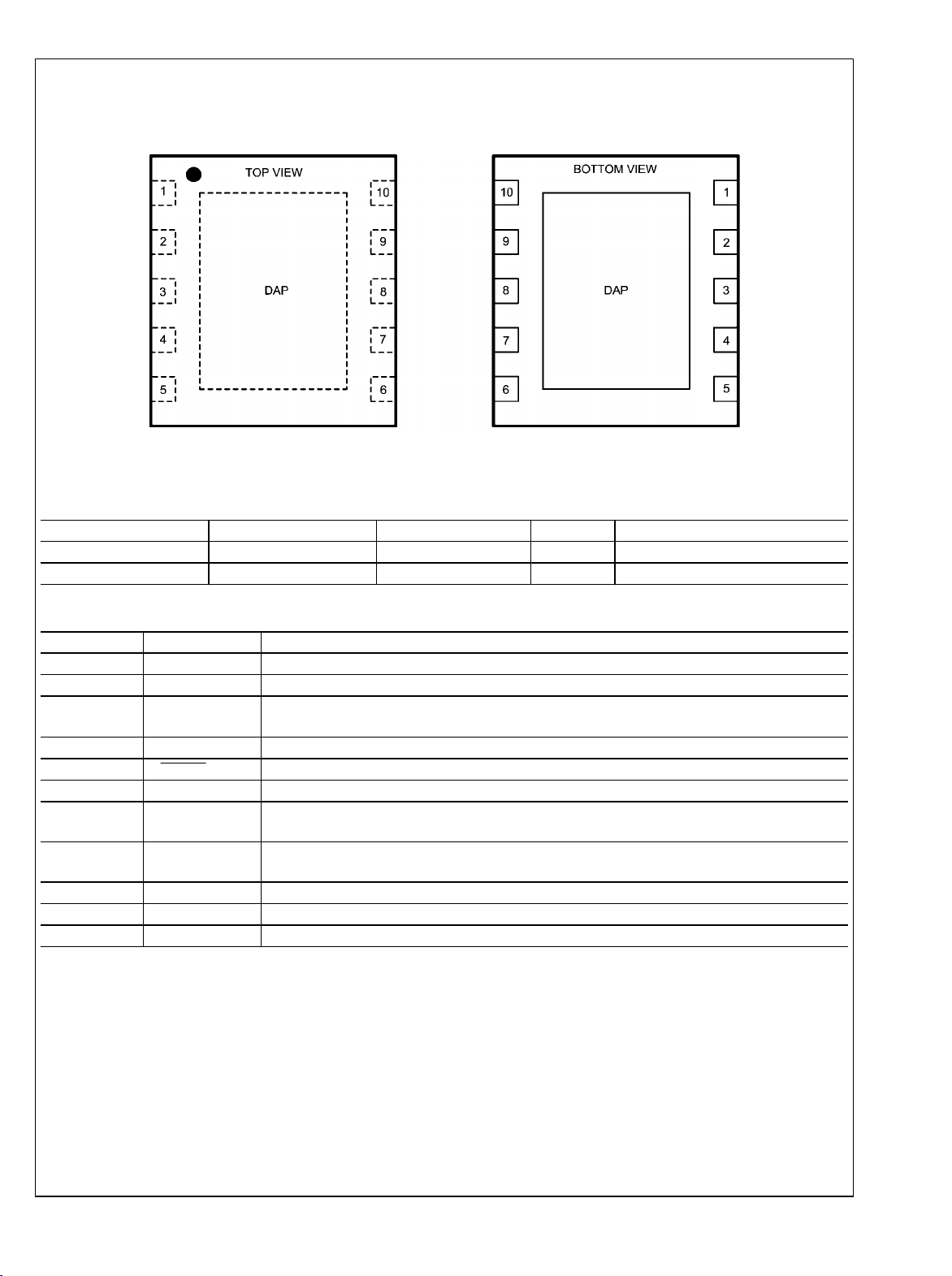

Connection Diagram

LM3509

Top View

10-Pin LLP (3mm × 3mm × 0.8mm)

30004302

Ordering Information

Order Number Package Type NSC Package Drawing Top Mark Supplied As

LM3509SD 10-Pin LLP SDA010A L3509 1000 units, Tape-and-Reel, No-Lead

LM3509SDX 10-Pin LLP SDA010A L3509 4500 units, Tape-and-Reel, No Lead

Pin Descriptions/Functions

Pin Name Function

1 MAIN Main Current Sink Input.

2 SUB/FB Secondary Current Sink Input or 1.25V Feedback Connection for Constant Voltage Output.

3 SET LED Current Setting Connection. Connect a resistor from SET to GND to set the maximum LED

current into MAIN or SUB/FB (when in LED mode), where I

4 VIO Logic Voltage Level Input

5 RESET/GPIO Active Low Hardware Reset and Programmable General Purpose I/O.

6 SW Drain Connection for Internal NMOS Switch

7 OVP Over-Voltage Protection Sense Connection. Connect OVP to the positive terminal of the output

capacitor.

8 IN Input Voltage Connection. Connect IN to the input supply, and bypass to GND with a 1µF ceramic

capacitor.

9 SDA Serial Data Input/Output

10 SCL Serial Clock Input

DAP GND Ground

LED_MAX

= 192×1.244V/R

SET

.

3 www.national.com

Absolute Maximum Ratings (Notes 1, 2)

If Military/Aerospace specified devices are required,

LM3509

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

V

IN

VSW, V

V

SUB/FB

V

SCL

V

SET

Continuous Power Dissipation Internally Limited

Junction Temperature (T

Storage Temperature Range -65ºC to +150º C

, V

OVP

, V

SDA

,

MAIN

, V

RESET\GPIO

, VIO ,

J-MAX

−0.3V to 25V

−0.3V to 23V

)

−0.3V to 6V

−0.3V to 6V

+150ºC

Operating Ratings (Notes 1, 2)

V

IN

VSW, V

V

SUB/FB

OVP

, V

,

MAIN

Junction Temperature Range

(TJ)(Note 4)

Ambient Temperature Range

(TA)(Note 5)

Thermal Properties

Junction to Ambient Thermal

Resistance (θJA)(Note 6)

-40ºC to +110ºC

-40ºC to +85ºC

Maximum Lead Temperature

(Soldering, 10s)(Note 3) +300°C

ESD Rating(Note 10)

Human Body Model 2.5kV

ESD Caution Notice

National Semiconductor recommends that all integrated circuits be handled with appropriate ESD precautions. Failure to

observe proper ESD handling techniques can result in damage to the device.

Electrical Characteristics

Specifications in standard type face are for TA = 25°C and those in boldface type apply over the Operating Temperature Range

of TA = −40°C to +85°C. Unless otherwise specified VIN = 3.6V, VIO = 1.8V, V

RESET/GPIO

12.0kΩ, OLED = ‘0’, ENM = ENS = ‘1’, BSUB = BMAIN = Full Scale.(Notes 2, 7)

Symbol Parameter Conditions Min Typ Max Units

I

LED

I

LED-MATCH

Output Current Regulation

MAIN or SUB/FB Enabled

Maximum Current Per

Current Sink

I

MAIN

to I

SUB/FB

Current

UNI = ‘0’, or ‘1’

R

= 8.0kΩ

SET

UNI = ‘1’ (Note 11)

Matching

V

SET

I

LED/ISET

SET Pin Voltage 3.0V < VIN < 5V

I

Current to I

LED

SET

Current

Ratio

V

REG_CS

Regulated Current Sink

Headroom Voltage

V

REG_OLED

V

Regulation Voltage

SUB/FB

3.0V < VIN < 5.5V, OLED = ‘1’

in OLED Mode

V

HR

Current Sink Minimum

I

= 95% of nominal

LED

Headroom Voltage

R

DSON

NMOS Switch On

ISW = 100mA

Resistance

I

CL

V

OVP

f

SW

D

MAX

D

MIN

I

Q

NMOS Switch Current Limit VIN = 3.0V

Output Over-Voltage

Protection

ON Threshold 21.2 22 22.9

OFF Threshold 19.7 20.6 21.2

Switching Frequency

Maximum Duty Cycle

Minimum Duty Cycle

Quiescent Current, Device

Not Switching

V

MAIN

V

REG_CS

and V

, BSUB = BMAIN =

SUB/FB

>

0x00

V

SUB/FB

> V

REG_OLED

,

OLED=’1’, ENM=ENS=’0’

I

SHDN

Shutdown Current ENM = ENS = OLED = '0'

= VIN, V

18.6

= V

SUB/FB

= 0.5V, R

MAIN

20 21.8

30

0.15 1 %

1.244 V

192

500 mV

1.172 1.21 1.239 V

300 mV

0.58

650 770 875 A

1.0 1.27 1.4 MHz

90 %

10 %

400 440

250 305

3.6 5 µA

2.7V to 5.5V

0V to 23V

0V to 21V

54°C/W

=

SET

mA

Ω

V

µA

www.national.com 4

Symbol Parameter Conditions Min Typ Max Units

RESET/GPIO Pin Voltage Specifications

V

IL

V

IH

V

OL

Input Logic Low 2.7V < VIN <5.5V, MODE bit

= 0

Input Logic High 2.7V < VIN < 5.5V, MODE bit

= 0

Output Logic Low I

=3mA, MODE bit = 1

LOAD

0.5 V

1.1 V

400 mV

I2C Compatible Voltage Specifications (SCL, SDA, VIO)

V

IO

V

IL

V

IH

V

OL

Serial Bus Voltage Level 2.7V < VIN < 5.5V (Note 9)

Input Logic Low 2.7V < VIN < 5.5V

Input Logic High 2.7V < VIN < 5.5V

Output Logic Low I

LOAD

= 3mA

1.4

0.7×V

IO

V

IN

0.36×V

V

IO

IO

400 mV

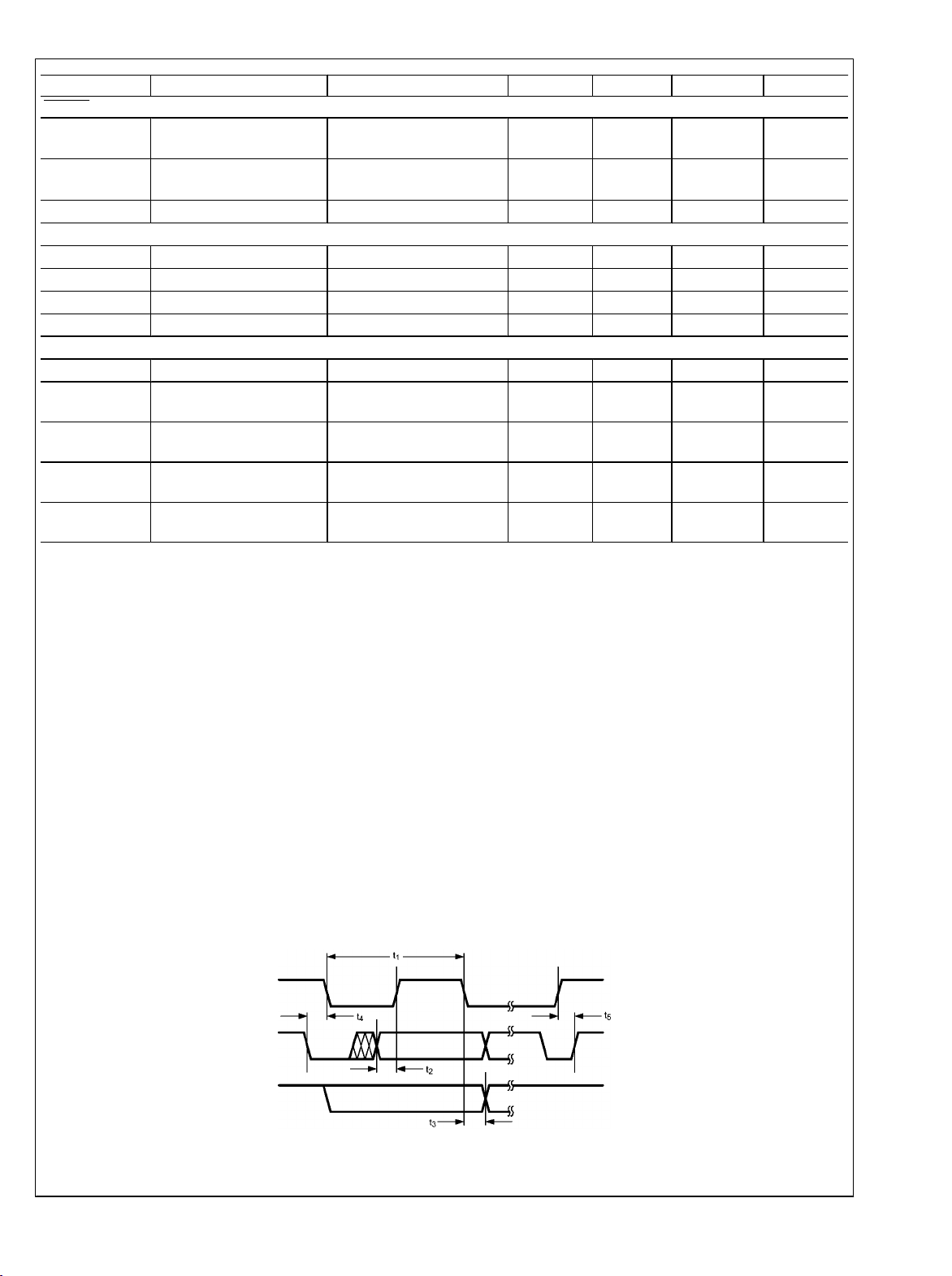

I2C Compatible Timing Specifications (SCL, SDA, VIO, see Figure 1) (Notes 8, 9)

t

1

t

2

t

3

t

4

t

5

SCL Clock Period

Data In Setup Time to SCL

High

Data Out Stable After SCL

Low

SDA Low Setup Time to

SCL Low (Start)

SDA High Hold Time After

SCL High (Stop)

2.5 µs

100 ns

0 ns

100 ns

100 ns

LM3509

V

V

V

Note 1: Absolute maximum ratings are limits beyond which damage to the device may occur. Operating Ratings are conditions for which the device is intended

to be functional, but device parameter specifications may not be guaranteed. For guaranteed specifications and test conditions, see the Electrical Characteristics.

Note 2: All voltages are with respect to the potential at the GND pin.

Note 3: For detailed soldering specifications and information, please refer to National Semiconductor Application Note 1187: Leadless Lead frame Package

(AN-1187).

Note 4: Internal thermal shutdown circuitry protects the device from permanent damage. Thermal shutdown engages at TJ=150ºC (typ.) and disengages at

TJ=140ºC (typ.).

Note 5: In applications where high power dissipation and/or poor package thermal resistance is present, the maximum ambient temperature may have to be

derated. Maximum ambient temperature (T

dissipation of the device in the application (P

following equation: T

Note 6: Junction-to-ambient thermal resistance (θJA) is taken from a thermal modeling result, performed under the conditions and guidelines set forth in the

JEDEC standard JESD51-7. The test board is a 4-layer FR-4 board measuring 114mm x 76mm x 1.6mm with a 2x1 array of thermal vias. The ground plane on

the board is 113mm x 75mm. Thickness of copper layers are 71.5µm/35µm/35µm/71.5µm (2oz/1oz/1oz/2oz). Ambient temperature in simulation is 22°C, still air.

Power dissipation is 1W. The value of θJA of this product in the LLP package could fall in a range as wide as 50ºC/W to 150ºC/W (if not wider), depending on

board material, layout, and environmental conditions. In applications where high maximum power dissipation exists special care must be paid to thermal dissipation

issues. For more information on these topics, please refer to Application Note 1187: Leadless Leadframe Package (LLP) and the Power Efficiency and Power

Dissipation section of this datasheet.

Note 7: Min and Max limits are guaranteed by design, test, or statistical analysis. Typical (Typ) numbers are not guaranteed, but represent the most likely norm.

Note 8: SCL and SDA must be glitch-free in order for proper brightness control to be realized.

Note 9: SCL and SDA signals are referenced to VIO and GND for minimum VIO voltage testing.

Note 10: The human body model is a 100pF capacitor discharged through 1.5kΩ resistor into each pin. (MIL-STD-883 3015.7).

Note 11: The matching specification between MAIN and SUB is calculated as 100 × ((I

100 × (I

MAIN

- I

SUB

)/(I

A-MAX

MAIN

+ I

= T

J-MAX-OP

SUB

– (θJA × P

).

) is dependent on the maximum operating junction temperature (TJ-MAX-OP = +105ºC), the maximum power

A-MAX

), and the junction-to ambient thermal resistance of the part/package in the application (θJA), as given by the

D-MAX

).

D-MAX

or I

) - I

) / I

MAIN

SUB

. This simplifies out to be

AVE

AVE

FIGURE 1. I2C Timing

5 www.national.com

30004303

Typical Performance Characteristics V

Mode), C

LM3509

I

SUB

+ I

= 2.2µF (OLED Mode), CIN = 1µF, L = TDK VLF4012AT-100MR79, (RL = 0.3Ω), R

OUT

, TA = +25°C unless otherwise specified.

MAIN

= 3.6V, LEDs are OSRAM (LW M67C), C

IN

= 8.06kΩ, UNI = '1', I

SET

= 1µF (LED

OUT

LED

=

10 LED Efficiency vs I

(2 Strings of 5LEDs)

6 LED Efficiency vs I

(2 Strings of 3LEDs)

LED

LED

30004308

8 LED Efficiency vs I

(2 Strings of 4LEDs)

4 LED Efficiency vs I

(2 Strings of 2LEDs)

LED

30004309

LED

30004310

LED Efficiency vs V

(L = TDK VLF3012AT-100MR49, RL = 0.36Ω, I

www.national.com 6

IN

LED

30004357

= 40mA)

LED Efficiency vs V

IN

(L = TDK VLF5014AT-100MR92, RL = 0.2Ω, I

30004311

LED

30004358

= 60mA)

LM3509

18V OLED Efficiency vs I

LED Line Regulation

(UNI = '0')

OUT

30004304

12V OLED Efficiency vs I

OLED Line Regulation

I

= 60mA

OLED

OUT

30004305

OLED Line Regulation

I

= 60mA

OLED

30004359

30004306

OLED Load Regulation

V

= 18V

OLED

30004307

30004313

7 www.national.com

LM3509

OLED Load Regulation

V

= 12V

OLED

Peak Current Limit vs. V

IN

Over Voltage Limit vs. V

Switching Frequency vs. V

IN

30004312

30004315

IN

Switch On-Resistance vs. V

Maximum Duty Cycle vs. V

30004314

IN

30004317

IN

30004318

www.national.com 8

30004319

LM3509

Shutdown Current vs. V

IN

30004320

LED Current Matching vs. CODE (Note 11)

(UNI = '1', R

= 12kΩ, TA = -40°C to +85°C)

SET

Switching Supply Current vs. V

LED Current Accuracy vs CODE

(R

= 12kΩ±0.05%)

SET

IN

30004321

(I

LED Current vs CODE

, I

SUB

, I

IDEAL

MAIN

, R

= 12kΩ±0.05%)

SET

30004322

30004324

I

vs Current Source Headroom Voltage

LED

(VIN = 3V, UNI = '0')

30004323

30004360

9 www.national.com

LM3509

Start-Up Waveform (LED Mode)

(2 × 5 LEDs, 30mA per string)

Start-Up Waveform (OLED Mode)

(V

OUT

= 18V, I

= 60mA)

OUT

Channel 1: SDA (5V/div)

Channel 2: V

Channel 3: I

(10V/div)

OUT

(50mA/div)

LED

Channel 4: IIN (500mA/div)

Time Base: 400µs/div

Load Step (OLED Mode)

(V

Channel 1: V

Channel 2: I

Time Base: 200µs/div

(AC Coupled, 500mV/div)

OUT

(20mA/div)

OUT

Transition From OLED to OLED + 1 × 4 LED)

(V

= 18V, I

OUT

OUT

= 18V, C

OUT

= 40mA, I

= 2.2µF)

OUT

= 20mA, C

LED

30004325

OUT

30004326

= 2.2µF)

Channel 1: SDA (5V/div)

Channel 2: V

Channel 3: I

(10V/div)

OUT

(50mA/div)

OUT

Channel 4: IIN (500mA/div)

Time Base: 400µs/div

Line Step (LED Mode)

(2 × 5 LEDs, 30mA per String, C

Channel 1: V

Channel 2: VIN (AC Coupled, 500mV/div)

Time Base: 200µs/div

(AC Coupled, 500mV/div)

OUT

RESET Functionality

30004327

OUT

= 1µF)

30004354

Channel 3: SDA (2V/div)

30004328

Channel 1: V

Channel 2: I

(AC Coupled, 200mV/div)

OUT

(20mA/div)

MAIN

Time Base: 400µs/div

www.national.com 10

Channel 2: I

Channel R1: I

(20mA/div)

SUB

MAIN

(20mA/div)

Channel 1: RESET (2V/div)

Time Base: 200ns/div

30004352

LM3509

(GPIO Configured as OUTPUT, f

GPIO Functionality

Channel 2: GPIO (2V/div)

Channel 3: SDA (2V/div)

Channel 1:SCL (2V/div)

Time Base: 40µs/div

Ramp Rate Functionality

(RMP1, RMP0 = '01')

= 200kHz)

SCL

30004353

Channel 3: SDA (2V/div)

Channel 1: I

Channel 4: I

(10mA/div)

MAIN

(10mA/div)

SUB

Time Base: 40µs/div

Ramp Rate Functionality

(RMP1, RMP0 = '00')

30004330

Ramp Rate Functionality

(RMP1, RMP0 = '10')

Channel 3: SDA (2V/div)

Channel 1: I

Channel 4: I

(10mA/div)

MAIN

(10mA/div)

SUB

Time Base: 100ms/div

Channel 1:I

Channel 4: I

(10mA/div)

MAIN

(10mA/div)

SUB

Time Base: 400ms/div

Ramp Rate Functionality

(RMP1, RMP0 = '11')

30004355

30004351

Channel 1:I

Channel 4: I

(10mA/div)

MAIN

(10mA/div)

SUB

Time Base: 200ms/div

30004356

11 www.national.com

Block Diagram

LM3509

FIGURE 2. LM3509 Block Diagram

Operation Description

The LM3509 Current Mode PWM boost converter operates

from a 2.7V to 5.5V input and provides two regulated outputs

for White LED and OLED display biasing. The first output,

MAIN, provides a constant current of up to 30mA to bias up

to 5 series white LED’s. The second output, SUB/FB, can be

configured as a current source for up to 5 series white LED’s

at at 30mA, or as a feedback voltage pin to regulate a constant

output voltage of up to 21V. When both MAIN and SUB/FB

are configured for white LED bias the current for each LED

string is controlled independently or in unison via an I2C compatible interface. When MAIN is configured for white LED bias

and SUB/FB is configured as a feedback voltage pin, the current into MAIN is controlled via the I2C compatible interface

and SUB/FB becomes the middle tap of a resistive divider

used to regulate the output voltage of the boost converter.

The core of the LM3509 is a Current Mode Boost converter.

Operation is as follows. At the start of each switching cycle

the internal oscillator sets the PWM converter. The converter

turns the NMOS switch on, allowing the inductor current to

www.national.com 12

30004333

ramp while the output capacitor supplies power to the white

LED’s and/or OLED panel. The error signal at the output of

the error amplifier is compared against the sensed inductor

current. When the sensed inductor current equals the error

signal, or when the maximum duty cycle is reached, the

NMOS switch turns off causing the external Schottky diode to

pick up the inductor current. This allows the inductor current

to ramp down causing its stored energy to charge the output

capacitor and supply power to the load. At the end of the clock

period the PWM controller is again set and the process repeats itself.

ADAPTIVE REGULATION

When biasing dual white led strings (White LED mode) the

LM3509 maximizes efficiency by adaptively regulating the

output voltage. In this configuration the 500mV reference is

connected to the non-inverting input of the error amplifier via

mux S2 (see Figure 2, Block Diagram). The lowest of either

V

or V

MAIN

error amplifier via mux S1. This ensures that V

are at least 500mV, thus providing enough voltage head-

FB

is then applied to the inverting input of the

SUB/FB

MAIN

and V

SUB/

LM3509

room at the input to the current sinks for proper current

regulation.

In the instance when there are unequal numbers of LEDs or

unequal currents from string to string, the string with the highest voltage will be the regulation point.

UNISON/NON-UNISON MODE

Within White LED mode there are two separate modes of operation, Unison and Non-Unison. Non-Unison mode provides

for independent current regulation, while Unison mode gives

up independent regulation for more accurate matching between LED strings. When in Non-Unison mode the LED currents I

registers BMAIN and BSUB respectively (see Brightness

MAIN

and I

are independently controlled via

SUB/FB

Registers (BMAIN and BSUB) section). When in Unison

mode BSUB is disabled and both I

trolled via BMAIN only.

MAIN

and I

SUB/FB

are con-

START-UP

The LM3509 features an internal soft-start, preventing large

inrush currents during start-up that can cause excessive voltage ripple on the input. For the typical application circuits

when the device is brought out of shutdown the average input

current ramps from zero to 450mA in 1.2ms. See Start Up

Plots in the Typical Performance Characteristics.

OLED MODE

When the LM3509 is configured for a single White LED bias

+ OLED display bias (OLED mode), the non-inverting input of

the error amplifier is connected to the internal 1.21V reference

via MUX S2. MUX S1 switches SUB/FB to the inverting input

of the error amplifier while disconnecting the internal current

sink at SUB/FB. The voltage at MAIN is not regulated in OLED

mode so when the application requires white LED + OLED

panel biasing, ensure that at least 300mV of headroom is

maintained at MAIN to guarantee proper regulation of I

(see the Typical Performance Characteristics for a plot of

I

vs Current Source Headroom Voltage)

LED

MAIN

PEAK CURRENT LIMIT

The LM3509’s boost converter has a peak current limit for the

internal power switch of 770mA typical (650mA minimum).

When the peak switch current reaches the current limit the

duty cycle is terminated resulting in a limit on the maximum

output current and thus the maximum output power the

LM3509 can deliver. Calculate the maximum LED current as

a function of VIN, V

OUT

, L and I

PEAK

as:

21.2V. In White LED mode during output open circuit conditions the output voltage will rise to the over voltage protection

threshold (V

troller will stop switching causing V

output voltage drops below 19.7V (min) the device will resume

= 21.2V min). When this happens the con-

OVP

to droop. When the

OUT

switching. If the device remains in an over voltage condition

the LM3509 will repeat the cycle causing the output to cycle

between the high and low OVP thresholds. See waveform for

OVP condition in the Typical Performance Characteristics.

OUTPUT CURRENT ACCURACY AND CURRENT MATCHING

The LM3509 provides both precise current accuracy (% error

from ideal value) and accurate current matching between the

MAIN and SUB/FB current sinks. Two modes of operation affect the current matching between I

mode (Non-Unison mode) is set by writing a 0 to bit 2 of the

MAIN

and I

SUB/FB

. The first

General Purpose register (UNI bit). Non-Unison mode allows

for independent programming of I

BMAIN and BSUB respectively. In this mode typical matching

MAIN

and I

SUB/FB

via registers

between current sinks is 1%.

Writing a 1 to UNI configures the device for Unison mode. In

Unison mode, BSUB is disabled and I

controlled via register BMAIN. In this mode typical matching

MAIN

and I

SUB/FB

are both

is 0.15%.

LIGHT LOAD OPERATION

The LM3509 boost converter operates in three modes; continuous conduction, discontinuous conduction, and skip mode

operation. Under heavy loads when the inductor current does

not reach zero before the end of the switching period the device switches at a constant frequency. As the output current

decreases and the inductor current reaches zero before the

end of the switching cycle, the device operates in discontinuous conduction. At very light loads the LM3509 will enter skip

.

mode operation causing the switching period to lengthen and

the device to only switch as required to maintain regulation at

the output.

ACTIVE LOW RESET/GENERAL PURPOSE I/O (RESET \GPIO)

The RESET/GPIO serves as an active low reset input or as a

general-purpose logic input/output. Upon power-up of the device RESET/GPIO defaults to the active low reset mode. The

functionality of RESET/GPIO is set via the GPIO register and

is detailed in Table 6. When configured as an active low reset

input, (Bit 0 = 0), pulling RESET/GPIO low automatically programs all registers of the LM3509 with 0x00. Their state

cannot be changed until RESET/GPIO is pulled high. The

General Purpose I/O (GPIO) register is used to enable the

GPIO function of the RESET/GPIO pin. The GPIO register is

an 8-bit register with only the 3 LSB’s active. The 5 MSB’s are

not used. When configured as an output, RESET/GPIO is

open drain and requires an external pull-up resistor.

ƒSW = 1.27MHz. Typical values for efficiency and I

be found in the efficiency and I

formance Characteristics.

curves in the Typical Per-

PEAK

OVER VOLTAGE PROTECTION

The LM3509's output voltage (V

by the Output Over-Voltage Protection Threshold (V

) is limited on the high end

OUT

PEAK

OVP

THERMAL SHUTDOWN

The LM3509 offers a thermal shutdown protection. When the

can

die temperature reaches +140°C the device will shutdown

and not turn on again until the die temperature falls below

+120°C.

) of

13 www.national.com

I2C COMPATIBLE INTERFACE

The LM3509 is controlled via an I2C compatible interface.

LM3509

START and STOP conditions classify the beginning and the

end of the I2C session. A START condition is defined as SDA

transitioning from HIGH to LOW while SCL is HIGH. A STOP

condition is defined as SDA transitioning from LOW to HIGH

while SCL is HIGH. The I2C master always generates START

and STOP conditions. The I2C bus is considered busy after a

FIGURE 3. Start and Stop Sequences

START condition and free after a STOP condition. During data transmission, the I2C master can generate repeated

START conditions. A START and a repeated START conditions are equivalent function-wise. The data on SDA must be

stable during the HIGH period of the clock signal (SCL). In

other words, the state of SDA can only be changed when SCL

is LOW.

30004337

I2C COMPATIBLE ADDRESS

The chip address for the LM3509 is 0110110 (36h). After the

START condition, the I2C master sends the 7-bit chip address

followed by a read or write bit (R/W). R/W= 0 indicates a

FIGURE 4. Chip Address

TRANSFERRING DATA

Every byte on the SDA line must be eight bits long, with the

most significant bit (MSB) transferred first. Each byte of data

must be followed by an acknowledge bit (ACK). The acknowledge related clock pulse (9th clock pulse) is generated by the

master. The master releases SDA (HIGH) during the 9th clock

WRITE and R/W = 1 indicates a READ. The second byte following the chip address selects the register address to which

the data will be written. The third byte contains the data for

the selected register.

30004338

pulse. The LM3509 pulls down SDA during the 9th clock

pulse, signifying an acknowledge. An acknowledge is generated after each byte has been received. Figure 5 is an example of a write sequence to the General Purpose register of the

LM3509.

FIGURE 5. Write Sequence to the LM3509

www.national.com 14

30004339

REGISTER DESCRIPTIONS

There are 4, 8 bit registers within the LM3509 as detailed in Table 1.

TABLE 1. LM3509 Register Descriptions

Register Name Hex Address Power -On-Value

General Purpose (GP) 10 0xC0

Brightness Main (BMAIN) A0 0xE0

Brightness Sub (BSUB) B0 0xE0

General Purpose

I/O (GPIO)

80 0XF8

LM3509

GENERAL PURPOSE REGISTER (GP)

The General Purpose register has four functions. It controls

the on/off state of MAIN and SUB/FB, it selects between Unison or Non-Unison mode, provides for control over the rate of

change of the LED current (see Brightness Rate of Change

Description), and selects between White LED and OLED

mode. Figure 6 and Table 2 describes each bit available within the General Purpose Register.

30004340

FIGURE 6. General Purpose Register Description

TABLE 2. General Purpose Register Bit Function

Bit Name Function Power-On-Value

0 ENM Enable MAIN. Writing a 1 to this bit enables the main current sink (MAIN).

Writing a 0 to this bit disables the main current sink and forces MAIN high

impedance.

1 ENS Enable SUB/FB. Writing a 1 to this bit enables the secondary current sink (SUB/

FB). Writing a 0 to this bit disables the secondary current sink and forces SUB/

FB high impedance.

2 UNI Unison Mode Select. Writing a 1 to this bit disables the BSUB register and

causes the contents of BMAIN to set the current in both the MAIN and SUB/

FB current sinks. Writing a 0 to this bit allows the current into MAIN and SUB/

FB to be independently controlled via the BMAIN and BSUB registers

respectively.

3 RMP0 Brightness Rate of Change. Bits RMP0 and RMP1 set the rate of change of

4 RMP1 0

the LED current into MAIN and SUB/FB in response to changes in the contents

of registers BMAIN and BSUB (see brightness rate of change description).

5 OLED OLED = 0 places the LM3509 in White LED mode. In this mode both the MAIN

and SUB/FB current sinks are active. The boost converter ensures there is at

least 500mV at V

MAIN

and V

SUB/FB

.

OLED = 1 places the LM3509 in OLED mode. In this mode the boost converter

regulates V

SUB/FB

to 1.25V. V

is unregulated and must be > 400mV for the

MAIN

MAIN current sink to maintain current regulation.

6 Don't Care These are non-functional read only bits. They will always read back as a 1. 1

7

0

0

0

0

0

15 www.national.com

TABLE 3. Operational Truth Table

LM3509

UNI OLED ENM ENS Result

X 0 0 0 LM3509 Disabled

1 0 1 X MAIN and SUB/FB current sinks enabled. Current levels set by

1 0 0 X MAIN and SUB/FB Disabled

0 0 0 1 SUB/FB current sink enabled. Current level set by BSUB.

0 0 1 0 MAIN current sink enabled. Current level set by BMAIN.

0 0 1 1 MAIN and SUB/FB current sinks enabled. Current levels set by

X 1 1 X SUB/FB current sink disabled (SUB/FB configured as a feedback

X 1 0 X SUB/FB current sink disabled (SUB/FB configured as a feedback

contents of BMAIN.

contents of BMAIN and BSUB respectively.

pin). MAIN current sink enabled current level set by BMAIN.

pin). MAIN current sink disabled.

* ENM ,ENS, or OLED high enables analog circuitry.

BRIGHTNESS REGISTERS (BMAIN and BSUB)

With the UNI bit (General Purpose register) set to 0 (NonUnison mode) both brightness registers (BMAIN and BSUB)

independently control the LED currents I

spectively. BMAIN and BSUB are both 8 bit, but with only the

MAIN

and I

SUB/FB

re-

5 LSB’s controlling the current. The three MSB’s are don’t

cares. The LED current control is designed to approximate an

exponentially increasing response of the LED current vs increasing code in either BMAIN or BSUB (see Figure 9).

Program I

to GND, where:

by connecting a resistor (RSET) from SET

LED_MAX

FIGURE 7. Brightness MAIN Register Description

. With the UNI bit (General Purpose register) set to 1 (Unison

mode), BSUB is disabled and BMAIN sets both I

. This prevents the independent control of I

FB

, however matching between current sinks goes from typi-

FB

cally 1%(with UNI = 0) to typically 0.15% (with UNI = 1). Figure

MAIN

MAIN

and I

and I

SUB/

SUB/

7 and Figure 8 show the register descriptions for the Brightness MAIN and Brightness SUB registers. Table 4 and Figure

9 show I

age of I

and/or I

MAIN

LED_MAX

vs. brightness data as a percent-

SUB/FB

.

30004342

FIGURE 8. Brightness SUB Register Description

www.national.com 16

30004343

LM3509

TABLE 4. I

BMAIN or BSUB Brightness

00000 0.000% 10000 8.750%

00001 0.125% 10001 10.000%

00010 0.625% 10010 12.500%

00011 1.000% 10011 15.000%

00100 1.125% 10100 16.875%

00101 1.313% 10101 18.750%

00110 1.688% 10110 22.500%

00111 2.063% 10111 26.250%

01000 2.438% 11000 31.250%

01001 2.813% 11001 37.500%

01010 3.125% 11010 43.750%

01011 3.750% 11011 52.500%

01100 4.375% 11100 61.250%

01101 5.250% 11101 70.000%

01110 6.250% 11110 87.500%

01111 7.500% 11111 100.000%

vs. Brightness Register Data

LED

Data

% of ILED_MAX BMAIN or BSUB Brightness Data % of ILED_MAX

FIGURE 9. I

MAIN

30004344

or I

vs BMAIN or BSUB Data

SUB

17 www.national.com

BRIGHTNESS RATE OF CHANGE DESCRIPTION

RMP0 and RMP1 control the rate of change of the LED cur-

LM3509

rent I

or BSUB. There are 4 user programmable LED current rates

MAIN

and I

in response to changes in BMAIN and /

SUB/FB

of change settings for the LM3509 (see Table 5).

TABLE 5. Rate of Change Bits

RMP0 RMP1 Change Rate

(t

STEP

0 0 51µs/step

0 1 13ms/step

1 0 26ms/step

1 1 52ms/step

For example, if R

contents of BMAIN set to 0x1F (I

contents of BMAIN are changed to 0x00 resulting in (I

0mA). With RMP0 =1 and RMP1 = 1 (52ms/step), I

change from 20mA to 0mA in 31 steps with 52ms elapsing

between steps, excluding the step from 0x1F to 0x1E, resulting in a full scale current change in 1560ms. The total time to

transition from one brightness code to another is:

The following 3 additional examples detail possible scenarios

when using the brightness register in conjunction with the rate

of change bits and the enable bits.

Example 1:

Step 1: Write to BMAIN a value corresponding to I

mA.

= 12kΩ then I

SET

= 20mA. With the

LED_MAX

= 20mA), suppose the

MAIN

Step 2: Write 1 to ENM (turning on MAIN)

Step 3: I

RMP1. (RMP0 and RMP1 bits set the duration spent at one

ramps to 20mA with a rate set by RMP0 and

MAIN

brightness code before incrementing to the next).

Step 4: ENM is set to 0 before 20mA is reached, thus the LED

current fades off at a rate given by RMP0 and RMP1 without

I

going up to 20mA.

MAIN

Example 2:

)

Step 1: ENM is 1, and BMAIN has been programmed with

code 0x01. This results in a small current into MAIN.

Step 2: BMAIN is programmed with 0x1F (full scale current).

MAIN

MAIN

will

This causes I

ed by RMP0 and RMP1.

Step 3: Before I

with 0x09. I

Step 4: When I

=

down to the current corresponding to 0x09 at a rate set by

RMP0 and RMP1.

to ramp toward full-scale at the rate select-

MAIN

reaches full-scale BMAIN is programmed

MAIN

will continue to ramp to full scale.

MAIN

has reached full-scale value it will ramp

MAIN

Example 3:

Step 1: Write to BMAIN a value corresponding to I

mA.

MAIN

= 20-

Step 2: Write a 1 to both RMP0 and RMP1.

Step 3: Write 1 to ENM (turning on MAIN).

Step 4: I

RMP1. (RMP0 and RMP1 bits set the duration spent at one

ramps toward 20mA with a rate set by RMP0 and

MAIN

brightness code before incrementing to the next).

Step 5: After 1.04s I

(0.16875 × 20mA = 3.375mA). Simultaneously, RMP0 and

has ramped to 16.875% of I

MAIN

LED_MAX

RMP1 are both programmed with 0.

MAIN

= 20-

Step 6: I

at a new ramp rate of 51µs/step.

continues ramping from 3.375mA to 20mA, but

MAIN

TABLE 6. GPIO Register Function

Bits 7 – 3 Data (Bit 2) Mode (Bit 1) Enable GPIO (Bit 0) Function

X X X 0 RESET/GPIO is configured as an active low reset

input. This is the default power on state.

X Logic Input 0 1 RESET/GPIO is configured as a logic input. The logic

level applied to RESET/GPIO can be read via bit 2 of

the GPIO register.

X Logic Output 1 1 RESET/GPIO is configured as a logic output. A 0 in

bit 2 forces RESET/GPIO low. A 1 in bit 2 forces

RESET/GPIO high impedance.

30004346

FIGURE 10. GPIO Register Description

SHUTDOWN AND OUTPUT ISOLATION

The LM3509 provides a true shutdown for either MAIN or

SUB/FB when configured as a White LED bias supply. Write

a 0 to ENM (bit 1) of the General Purpose register to turn off

the MAIN current sink and force MAIN high impedance. Write

a 0 to ENS (bit 2) of the General Purpose register to turn off

the SUB/FB current sink and force SUB/FB high impedance.

Writing a 1 to ENM or ENS turns on the MAIN and SUB/FB

current sinks respectively. When in shutdown the leakage

current into MAIN or SUB/FB is typically 3.6µA. See Typical

Performance Plots for start-up responses of the LM3509 using the ENM and ENS bits in White LED and OLED modes.

www.national.com 18

LM3509

Application Information

LED CURRENT SETTING/MAXIMUM LED CURRENT

Connect a resistor (R

maximum LED current (I

R

SET

to I

LED_MAX

relationship is:

where SET provides the constant 1.244V output.

OUTPUT VOLTAGE SETTING (OLED MODE)

Connect Feedback resistors from the converters output to

SUB/FB to GND to set the output voltage in OLED mode (see

R1 and R2 in the Typical Application Circuit (OLED Panel

Power Supply). First select R2 < 100kΩ then calculate R1

such that:

In OLED mode the MAIN current sink continues to regulate

the current through MAIN, however, V

lated. To avoid dropout and ensure proper current regulation

the application must ensure that V

OUTPUT CAPACITOR SELECTION

The LM3509’s output capacitor supplies the LED current during the boost converters on time. When the switch turns off

the inductor energy is discharged through the diode supplying

power to the LED’s and restoring charge to the output capacitor. This causes a sag in the output voltage during the on time

and a rise in the output voltage during the off time. The output

capacitor is therefore chosen to limit the output ripple to an

acceptable level depending on LED or OLED panel current

requirements and input/output voltage differentials. For proper operation ceramic output capacitors ranging from 1µF to

2.2µF are required.

As with the input capacitor, the output voltage ripple is com-

posed of two parts, the ripple due to capacitor discharge (delta

VQ) and the ripple due to the capacitors ESR (delta V

continuous conduction mode, the ripple components are

found by:

) from SET to GND to program the

SET

) into MAIN or SUB/FB. The

LED_MAX

is no longer regu-

MAIN

> 0.3V.

MAIN

ESR

). For

INPUT CAPACITOR SELECTION

Choosing the correct size and type of input capacitor helps

minimize the input voltage ripple caused by the switching of

the LM3509’s boost converter. For continuous inductor current operation the input voltage ripple is composed of 2 primary components, the capacitor discharge (delta VQ) and the

capacitor’s equivalent series resistance (delta V

ripple components are found by:

ESR

). These

In the typical application circuit a 1µF ceramic input capacitor

works well. Since the ESR in ceramic capacitors is typically

less than 5mΩ and the capacitance value is usually small, the

input voltage ripple is primarily due to the capacitive discharge. With larger value capacitors such as tantalum or

aluminum electrolytic the ESR can be greater than 0.5Ω. In

this case the input ripple will primarily be due to the ESR.

Table 7 lists different manufacturers for various capacitors

and their case sizes that are suitable for use with the LM3509.

When configured as a dual output LED driver a 1µF output

capacitor is adequate. In OLED mode for output voltages

above 12V a 2.2µF output capacitor is required (see Low

Output Voltage Operation (OLED) Section).

19 www.national.com

TABLE 7. Recommended Output Capacitors

LM3509

Manufacturer Part Number Value Case Size Voltage Rating

TDK C1608X5R1E105M 1µF 0603 25V

Murata GRM39X5R105K25D53

9

TDK C2012X5R1E225M 2.2µF 0805 25V

Murata GRM219R61E225KA12 2.2µF 0805 25V

INDUCTOR SELECTION

The LM3509 is designed for use with a 10µH inductor, however 22µH are suitable providing the output capacitor is increased 2×'s. When selecting the inductor ensure that the

saturation current rating (I

enough and the inductor is large enough such that at the

maximum LED current the peak inductor current is less than

the LM3509’s peak switch current limit. This is done by choosing:

) for the chosen inductor is high

SAT

1µF 0603 25V

Values for I

vs. VIN in the Typical Performance Characteristics graphs.

Table 8 shows possible inductors, as well as their corresponding case size and their saturation current ratings.

can be found in the plot of peak current limit

PEAK

TABLE 8. Recommended Inductors

Manufacturer Part Number Value Dimensions I

TDK VLF3012AT-100M

R49

TDK VLF4012AT-100M

R79

TOKO A997AS-100M 10µH 3.8mm×3.8mm×1.

DIODE SELECTION

The output diode must have a reverse breakdown voltage

greater than the maximum output voltage. The diodes average current rating should be high enough to handle the

LM3509’s output current. Additionally, the diodes peak current rating must be high enough to handle the peak inductor

current. Schottky diodes are recommended due to their lower

10µH 2.6mm×2.8mm×1

mm

10µH 3.5mm×3.7mm×1.

2mm

8mm

forward voltage drop (0.3V to 0.5V) compared to (0.6V to

0.8V) for PN junction diodes. If a PN junction diode is used,

ensure it is the ultra-fast type (trr < 50ns) to prevent excessive

loss in the rectifier. For Schottky diodes the B05030WS (or

equivalent) work well for most designs. See Table 9 for a list

of other Schottky Diodes with similar performance.

SAT

490mA

800mA

580mA

TABLE 9. Recommended Schottky Diodes

Manufacturer Part Number Package Reverse Breakdown

Voltage

Diodes Inc. B05030WS SOD-323 30V 0.5A

Philips BAT760 SOD-323 23V 1A

ON Semiconductor NSR0320MW2T SOD-323 30V 1A

Average Current Rating

DC Resistance

0.36Ω

0.3Ω

0.18Ω

www.national.com 20

LM3509

OUTPUT CURRENT RANGE (OLED MODE)

The maximum output current the LM3509 can deliver in OLED

mode is limited by 4 factors (assuming continuous conduction); the peak current limit of 770mA (typical), the inductor

value, the input voltage, and the output voltage. Calculate the

maximum output current (I

tion:

For the typical application circuit with V

ing 70% efficiency, the maximum output current at VIN = 2.7V

) using the following equa-

OUT_MAX

= 18V and assum-

OUT

will be approximately 70mA. At 4.2V due to the shorter on

times and lower average input currents the maximum output

current (at 70% efficiency) jumps to approximately 105mA.

Figure 11 shows a plot of I

equation, assuming 80% efficiency. In reality factors such as

vs. VIN using the above

OUT_MAX

current limit and efficiency will vary over VIN, temperature, and

component selection. This can cause the actual I

be higher or lower.

30004362

OUT_MAX

to

FIGURE 11. Typical Maximum Output Current in OLED

Mode

OUTPUT VOLTAGE RANGE (OLED MODE)

The LM3509's output voltage is constrained by 2 factors. On

the low end it is limited by the minimum duty cycle of 10%

(assuming continuous conduction) and on the high end it is

limited by the over voltage protection threshold (V

(typical). In order to maintain stability when operating at dif-

OVP

) of 22V

ferent output voltages the output capacitor and inductor must

be changed. Refer to Table 10 for different V

L combinations.

OUT

, C

OUT

, and

TABLE 10. Component Values for Output Voltage Selection

V

OUT

18V

15V

12V

9V

7V

5V

LAYOUT CONSIDERATIONS

The LLP is a leadless package with very good thermal properties. This package has an exposed DAP (die attach pad) at

the underside center of the package measuring 1.6mm x

2.0mm. The main advantage of this exposed DAP is to offer

low thermal resistance when soldered to the thermal ground

pad on the PCB. For good PCB layout a 1:1 ratio between the

package and the PCB thermal land is recommended. To further enhance thermal conductivity, the PCB thermal ground

pad may include vias to a 2nd layer ground plane. For more

detailed instructions on mounting LLP packages, please refer

to National Semiconductor Application Note AN-1187.

The high switching frequencies and large peak currents make

the PCB layout a critical part of the design. The proceeding

steps must be followed to ensure stable operation and proper

current source regulation.

1, Divide ground into two planes, one for the return terminals

of C

, CIN and the I2C Bus, the other for the return terminals

OUT

of R

and the feedback network. Connect both planes to the

SET

exposed PAD, but nowhere else.

2, Connect the inductor and the anode of D1 as close together

as possible and place this connection as close as possible to

the SW pin. This reduces the inductance and resistance of

the switching node which minimizes ringing and excess voltage drops. This will improve efficiency and decrease noise

that can get injected into the current sources.

3, Connect the return terminals of the input capacitor and the

output capacitor as close as possible to the exposed PAD and

through low impedance traces.

4, Bypass IN with at least a 1µF ceramic capacitor. Connect

the positive terminal of this capacitor as close as possible to

IN.

5, Connect C

This reduces the inductance and resistance of the output bypass node which minimizes ringing and the excess voltage

drops. This will improving efficiency and decrease noise that

can get injected into the current sources.

6, Route the traces for R

from the SW node to minimize noise injection.

7, Do not connect any external capacitance to the SET pin.

C

OUT

L VIN Range

2.2µF 10µH 2.7V to

2.2µF 10µH 2.7V to

4.7µF 10µH 2.7V to

10µF 10µH 2.7V to

10µF 4.7µH 2.7V to

22µF 4.7µH 2.7V to

as close as possible to the cathode of D1.

OUT

and the feedback divider away

SET

5.5V

5.5V

5.5V

5.5V

5.5V

4.5V

21 www.national.com

Physical Dimensions inches (millimeters) unless otherwise noted

LM3509

For Ordering, Refer to Ordering Information Table

NS Package Number SDA10A

X1 = 3mm (±0.1mm), X2 = 3mm (±0.1mm), X3 = 0.8mm

10 Pin LLP

www.national.com 22

Notes

LM3509

23 www.national.com

Notes

C Compatible Brightness Control

2

and I

THE CONTENTS OF THIS DOCUMENT ARE PROVIDED IN CONNECTION WITH NATIONAL SEMICONDUCTOR CORPORATION

(“NATIONAL”) PRODUCTS. NATIONAL MAKES NO REPRESENTATIONS OR WARRANTIES WITH RESPECT TO THE ACCURACY

OR COMPLETENESS OF THE CONTENTS OF THIS PUBLICATION AND RESERVES THE RIGHT TO MAKE CHANGES TO

SPECIFICATIONS AND PRODUCT DESCRIPTIONS AT ANY TIME WITHOUT NOTICE. NO LICENSE, WHETHER EXPRESS,

IMPLIED, ARISING BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS

DOCUMENT.

TESTING AND OTHER QUALITY CONTROLS ARE USED TO THE EXTENT NATIONAL DEEMS NECESSARY TO SUPPORT

NATIONAL’S PRODUCT WARRANTY. EXCEPT WHERE MANDATED BY GOVERNMENT REQUIREMENTS, TESTING OF ALL

PARAMETERS OF EACH PRODUCT IS NOT NECESSARILY PERFORMED. NATIONAL ASSUMES NO LIABILITY FOR

APPLICATIONS ASSISTANCE OR BUYER PRODUCT DESIGN. BUYERS ARE RESPONSIBLE FOR THEIR PRODUCTS AND

APPLICATIONS USING NATIONAL COMPONENTS. PRIOR TO USING OR DISTRIBUTING ANY PRODUCTS THAT INCLUDE

NATIONAL COMPONENTS, BUYERS SHOULD PROVIDE ADEQUATE DESIGN, TESTING AND OPERATING SAFEGUARDS.

EXCEPT AS PROVIDED IN NATIONAL’S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, NATIONAL ASSUMES NO

LIABILITY WHATSOEVER, AND NATIONAL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY RELATING TO THE SALE

AND/OR USE OF NATIONAL PRODUCTS INCLUDING LIABILITY OR WARRANTIES RELATING TO FITNESS FOR A PARTICULAR

PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY

RIGHT.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR

SYSTEMS WITHOUT THE EXPRESS PRIOR WRITTEN APPROVAL OF THE CHIEF EXECUTIVE OFFICER AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

Life support devices or systems are devices which (a) are intended for surgical implant into the body, or (b) support or sustain life and

whose failure to perform when properly used in accordance with instructions for use provided in the labeling can be reasonably expected

to result in a significant injury to the user. A critical component is any component in a life support device or system whose failure to perform

can be reasonably expected to cause the failure of the life support device or system or to affect its safety or effectiveness.

National Semiconductor and the National Semiconductor logo are registered trademarks of National Semiconductor Corporation. All other

brand or product names may be trademarks or registered trademarks of their respective holders.

Copyright© 2007 National Semiconductor Corporation

For the most current product information visit us at www.national.com

National Semiconductor

Americas Customer

Support Center

Email:

new.feedback@nsc.com

LM3509 High Efficiency Boost for White LED's and/or OLED Displays with Dual Current Sinks

www.national.com

Tel: 1-800-272-9959

National Semiconductor Europe

Customer Support Center

Fax: +49 (0) 180-530-85-86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +49 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor Asia

Pacific Customer Support Center

Email: ap.support@nsc.com

National Semiconductor Japan

Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

Loading...

Loading...