LM3502

Step-Up Converter for White LED Applications

LM3502 Step-Up Converter for White LED Applications

August 2006

General Description

The LM3502 is a white LED driver for lighting applications.

For dual display or large single white LED string backlighting

applications, the LM3502 provides a complete solution. The

LM3502 contains two internal white LED current bypass

FET(Field Effect Transitor) switches that are ideal for controlling dual display applications. The white LED current can

be adjusted with a PWM signal directly from a microcontroller without the need of an RC filter network.

With no external compensation, cycle-by-cycle current limit,

over-voltage protection, and under-voltage protection, the

LM3502 offers superior performance over other application

specific standard product step-up white LED drivers.

Typical Application

Features

n Drive up to 4, 6, 8 or 10 white LEDs for Dual Display

Backlighting

>

n

80% efficiency

n Output Voltage Options: 16V , 25V , 35V, and 44V

n Input Under-Voltage Protection

n Internal Soft Start Eliminating Inrush Current

n 1 MHz Constant Switching Frequency

n Wide Input Voltage: 2.5V to 5.5V

n Small External Components

n Low Profile Packages:

-10 Bump MicroSMD

-16 Pin LLP

<

1 mm Height

Applications

n Dual Display Backlighting in Portable Devices

n Cellular Phones and PDAs

20131701

FIGURE 1. Blacklight Configuration with 10 White LEDs

© 2006 National Semiconductor Corporation DS201317 www.national.com

Connection Diagrams

LM3502

10-Bump Thin MicroSMD

Package (TLP10)

16-Lead Thin Leadless Leadframe

Package (SQA16A)

TOP VIEW

20131702

Pin Descriptions/Functions

Bump # Pin # Name Description

A1 9 Cntrl Shutdown Control Connection

B1 7 Fb Feedback Voltage Connection

TOP VIEW

C1 6 V

D1 4 V

OUT2

OUT1

D2 2 and 3 Sw Drain Connection of The Power NMOS Switch (Figure 2: N1)

D3 15 and 16 PGND Power Ground Connection

C3 14 AGND Analog Ground Connection

B3 13 V

A3 12 En2 NMOS FET Switch Control Connection

A2 10 En1 PMOS FET Switch Control Connection

1 NC No Connection

5 NC No Connection

8 NC No Connection

11 NC No Connection

DAP DAP Die Attach Pad (DAP), must be soldered to the printed circuit board’s ground plane for

Drain Connections of The NMOS and PMOS Field Effect Transistor (FET) Switches

(Figure 2: N2 and P1)

Over-Voltage Protection (OVP) and Source Connection of The PMOS FET Switch

(Figure 2: P1)

Supply or Input Voltage Connection

IN

enhanced thermal dissipation.

20131703

Cntrl (Bump A1): Shutdown control pin. When V

1.4V, the LM3502 is enabled or ON. When V

Cntrl

is ≥

Cntrl

is ≤ 0.3V,

the LM3502 will enter into shutdown mode operation. The

LM3502 has an internal pull down resistor on the Cntrl pin,

thus the device is normally in the off state or shutdown mode

of operation.

Fb (Bump B1): Output voltage feedback connection. The

white LED string network current is set/programmed using a

resistor from this pin to ground.

(Bump C1): Drain connections of the internal PMOS

V

OUT2

and NMOS FET switches. (Figure 2: P1 and N2). It is recommended to connect 100nF at V

and LM3502-44 versions if V

(Bump D1): Source connection of the internal PMOS

V

OUT1

OUT2

for the LM3502-35V

OUT2

is not used.

FET switch (Figure 2: P1) and OVP sensing node. The

output capacitor must be connected as close to the device

www.national.com 2

as possible, between the V

pin and ground plane. Also

OUT1

connect the Schottky diode as close as possible to the

pin to minimize trace resistance and EMI radiation.

V

OUT1

Sw (Bump D2): Drain connection of the internal power

NMOS FET switch. (Figure 2: N1) Minimize the metal trace

length and maximize the metal trace width connected to this

pin to reduce EMI radiation and trace resistance.

PGND (Bump D3): Power ground pin. Connect directly to

the ground plane.

AGND (Bump C3): Analog ground pin. Connect the analog

ground pin directly to the PGND pin.

(Bump B3): Supply or input voltage connection pin. The

V

IN

capacitor should be as close to the device as possible,

C

IN

between the V

pin and ground plane.

IN

En2 (Bump A3): Enable pin for the internal NMOS FET

switch (Figure 2: N2) during device operation. When V

En2

is

Pin Descriptions/Functions

(Continued)

≤ 0.3V, the internal NMOS FET switch turns on and the SUB

display turns off. When V

FET switch turns off and the SUB display turns on. The En2

pin has an internal pull down resistor, thus the internal

NMOS FET switch is normally in the on state of operation

with the SUB display turned off.

and V

If V

En1

will enter a low I

are ≤ 0.3V and V

En2

shutdown mode of operation where all the

Q

internal FET switches are off. If V

is ≥ 1.4V, the internal NMOS

En2

is ≥ 1.4V, the LM3502

Cntrl

is not used, En2 must

OUT2

En1 (Bump A2): Enable pin for the internal PMOS FET

switch (Figure 2: P1) during device operation. When V

≤ 0.3V, the internal PMOS FET switch turns on and the MAIN

display is turned off. When V

is ≥ 1.4V, the internal PMOS

En1

FET switch turns off and the MAIN display is turned on. The

En1 pin has an internal pull down resistor, thus the internal

PMOS FET switch is normally in the on state of operation

with the MAIN display turned off. If V

and V

is ≥ 1.4V, the LM3502 will enter a low IQshutdown

Cntrl

En1

mode of operation where all the internal FET switches are

off. If V

is not used, En2 must be grounded and use En1

OUT2

a long with Cntrl, to enable the device.

be grounded or floating and use En1 along with Cntrl, to

enable the device.

Ordering Information

Voltage Option Order Number Package Marking Supplied As

16 LM3502ITL-16 SANB 250 units, Tape-and-Reel

16 LM3502ITLX-16 SANB 3000 units, Tape-and-Reel

16 LM3502SQ-16 L00048B 250 units, Tape-and-Reel

16 LM3502SQX-16 L00048B 3000 units, Tape-and-Reel

25 LM3502ITL-25 SAPB 250 units, Tape-and-Reel

25 LM3502ITLX-25 SAPB 3000 units, Tape-and-Reel

25 LM3502SQ-25 L00049B 250 units, Tape-and-Reel

25 LM3502SQX-25 L00049B 3000 units, Tape-and-Reel

35 LM3502ITL-35 SARB 250 units, Tape-and-Reel

35 LM3502ITLX-35 SARB 3000 units, Tape-and-Reel

35 LM3502SQ-35 L00044B 250 units, Tape-and-Reel

35 LM3502SQX-35 L00044B 3000 units, Tape-and-Reel

44 LM3502ITL-44 SDLB 250 units, Tape-and-Reel

44 LM3502ITLX-44 SDLB 3000 units, Tape-and-Reel

44 LM3502SQ-44 L00050B 250 units, Tape-and-Reel

44 LM3502SQX-44 L00050B 3000 units, Tape-and-Reel

and V

are ≤ 0.3V

En2

En1

LM3502

is

www.national.com3

Absolute Maximum Ratings (Notes 6, 1)

If Military/Aerospace specified devices are required,

LM3502

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Pin −0.3V to +5.5V

V

IN

Sw Pin −0.3V to +48V

Fb Pin −0.3V to +5.5V

Cntrl Pin −0.3V to +5.5V

V

Pin −0.3V to +48V

OUT1

V

Pin −0.3V to V

OUT2

En1 −0.3V to +5.5V

En2 −0.3V to +5.5V

Continuous Power Dissipation Internally Limited

Maximum Junction Temperature

(T

J-MAX)

Storage Temperature Range −65˚C to +150˚C

OUT1

+150˚C

ESD Rating (Note 2)

Human Body Model:

Machine Model:

2kV

200V

Operating Conditions (Notes 1, 6)

Junction Temperature (T

Ambient Temperature (T

Input Voltage, V

IN

Cntrl, En1, and En2 Pins 0V to 5.5V

) Range −40˚C to +125˚C

J

) Range −40˚C to +85˚C

A

Pin 2.5V to 5.5V

Thermal Properties (Note 4)

Junction-to-Ambient Thermal Resistance (θ

Micro SMD Package 65˚C/W

Leadless Leadframe Package 49˚C/W

)

JA

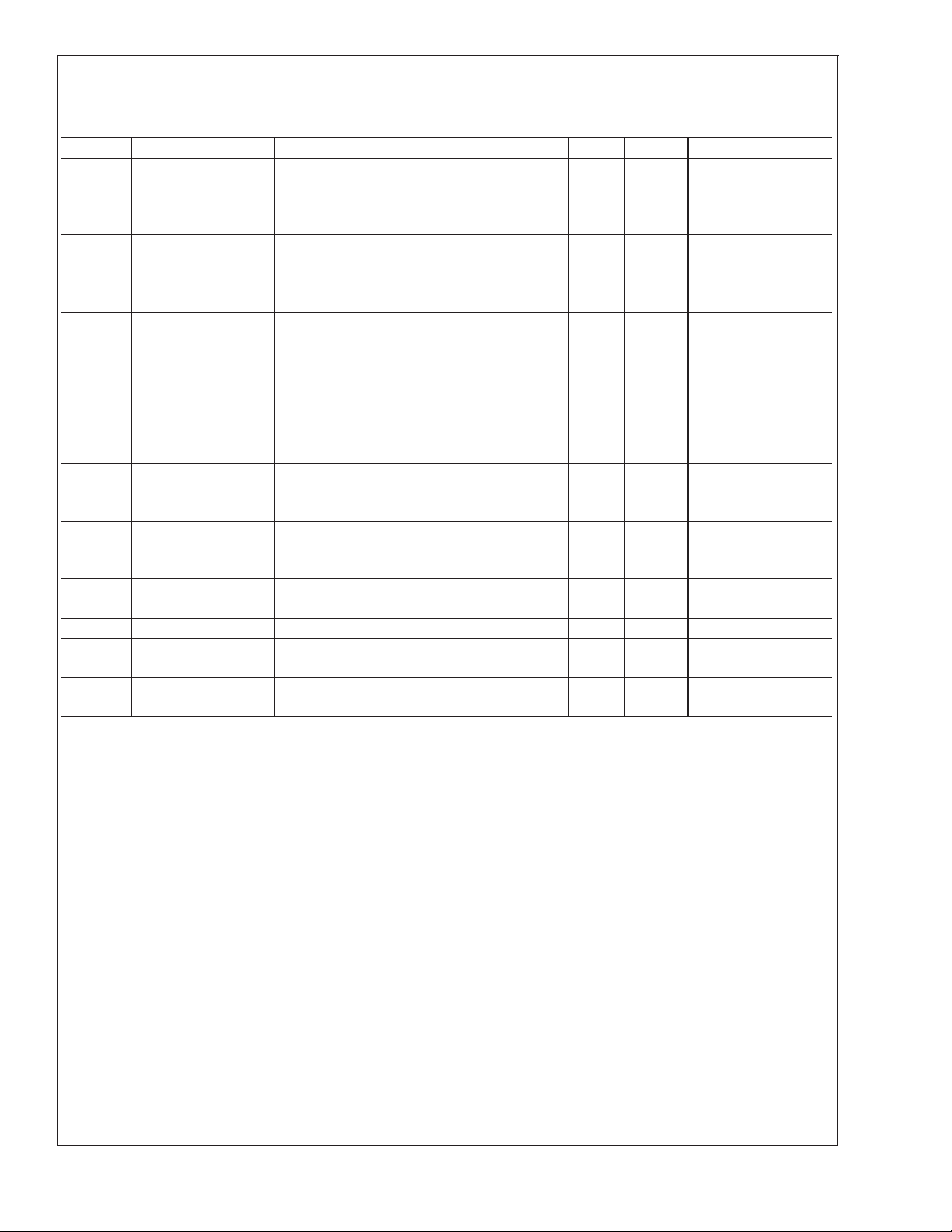

Preliminary Electrical Characteristics (Notes 6, 7) Limits in standard typeface are for T

Limits in bold typeface apply over the full operating junction temperature range (−40˚C ≤ T

specified, V

= 2.5V.

IN

≤ +125˚C). Unless otherwise

J

= 25˚C.

J

Symbol Parameter Conditions Min Typ Max Units

V

IN

I

Q

V

Fb

I

CL

I

Fb

F

S

R

DS(ON)

Input Voltage 2.5 5.5 V

Non-Switching

Switching

Shutdown

Shutdown

Low I

Q

>

0.25V

Fb

Fb = 0V, Sw Is Floating

Cntrl = 0V

Cntrl = 1.5V, En1 = En2 = 0V

0.5

1.9

0.1

6

1

3

3

15

Feedback Voltage 0.18 0.25 0.3 V

NMOS Power Switch

Current Limit

Feedback Pin Bias

Current (Note 8)

−16, Fb = 0V

−25, Fb = 0V

−35, Fb = 0V

−44, Fb = 0V

Fb = 0.25V

250

400

450

450

400

600

750

750

650

800

1050

1050

64 500 nA

Switching Frequency 0.8 1 1.2 MHz

NMOS Power Switch

ON Resistance

= 500 mA

I

Sw

0.55 1.1 Ω

(Figure 2: N1)

R

PDS(ON)

PMOS ON Resistance

of V

OUT1/VOUT2

Switch

= 20 mA, En1 = 0V, En2 = 1.5V

I

PMOS

5 10 Ω

(Figure 2: N1)

R

NDS(ON)

NMOS ON Resistance

OUT2

/Fb Switch

of V

= 20 mA, En1 = 1.5V, En2 = 0V

I

NMOS

2.5 5 Ω

(Figure 2: N2)

D

I

I

I

MAX

Cntrl

Sw

V

OUT1

Maximum Duty Cycle Fb = 0V 90 95 %

Cntrl Pin Input Bias

Current (Note 3)

Sw Pin Leakage

Current (Note 3)

(OFF) V

OUT1

Current (Note 3)

Pin Leakage

Cntrl = 2.5V

Cntrl = 0V

Sw = 42V, Cntrl = 0V

V

= 14V, Cntrl = 0V (16)

OUT1

= 23V, Cntrl = 0V (25)

V

OUT1

= 32V, Cntrl = 0V (35)

V

OUT1

= 42V, Cntrl = 0V (44)

V

OUT1

7

0.1

0.01 5 µA

0.1

0.1

0.1

0.1

14

3

3

3

3

mA

mA

µA

µA

mA

µA

µA

www.national.com 4

LM3502

Preliminary Electrical Characteristics (Notes 6, 7) Limits in standard typeface are for T

Limits in bold typeface apply over the full operating junction temperature range (−40˚C ≤ T

specified, V

= 2.5V. (Continued)

IN

≤ +125˚C). Unless otherwise

J

= 25˚C.

J

Symbol Parameter Conditions Min Typ Max Units

I

(ON) V

V

OUT1

I

V

OUT2

UVP Under-Voltage

OVP Over-Voltage

V

En1

Pin Bias

OUT1

Current (Note 3)

V

Pin Leakage

OUT2

Current (Note 3)

Protection

Protection (Note 5)

PMOS FET Switch

Enabling Threshold

V

= 14V, Cntrl = 1.5V (16)

OUT1

= 23V, Cntrl = 1.5V (25)

V

OUT1

= 32V, Cntrl = 1.5V (35)

V

OUT1

= 42V, Cntrl = 1.5V (44)

V

OUT1

Fb = 0V, Cntrl = 0V, V

OUT2

= 42V

On Threshold

Off Threshold 2.2

On Threshold (16)

Off Threshold (16)

On Threshold (25)

Off Threshold (25)

On Threshold (35)

Off Threshold (35)

On Threshold (44)

Off Threshold (44)

14.5

14.0

22.5

21.5

32.0

31.0

40.5

39.0

Off Threshold (Display Lighting)

On Threshold (Display Lighting) 1.4

40

50

50

85

80

100

100

140

0.1 3 µA

2.4

2.5

2.3

15.5

15

24

23

34

33

42

41

0.8

16.5

16.0

25.5

24.5

35.0

34.0

43.5

42.0

0.3

0.8

(Figure 2: P1)

V

En2

NMOS FET Switch

Enabling Threshold

Off Threshold (Display Lighting)

On Threshold (Display Lighting) 1.4

0.8

0.8

0.3

(Figure 2: N2)

V

T

I

En1

I

En2

Cntrl

SHDW

Device Enabling

Threshold

Shutdown Delay Time 8 12 16 ms

En1 Pin Input Bias

Current

En2 Pin Input Bias

Current

Off Threshold

OnThreshold 1.4

En1 = 2.5V

En1=0V

En2 = 2.5V

En2=0V

0.8

0.8

0.1

0.1

0.3

7

7

14

14

µA

V

V

V

V

V

µA

µA

Note 1: Absolute maximum ratings indicate limits beyond which damage to the device may occur. Electrical characteristic specifications do not apply when

operating the device outside of its rated operating conditions.

Note 2: The human body model is a 100 pF capacitor discharged through a 1.5 kΩ resistor into each pin. The machine model is a 200 pF capacitor discharged

directly into each pin.

Note 3: Current flows into the pin.

Note 4: The maximum allowable power dissipation is a function of the maximum junction temperature, T

and the ambient temperature, T

calculated using: P

on this topic, please refer to Application Note 1187: Leadless Leadframe Package (LLP) and Application Note 1112 (AN1112) for microSMD chip scale package.

Note 5: The on threshold indicates that the LM3502 is no longer switching or regulating LED current, while the off threshold indicates normal operation.

Note 6: All voltages are with respect to the potential at the GND pin.

Note 7: Min and Max limits are guaranteed by design, test, or statistical analysis. Typical numbers are not guaranteed, but do represent the most likely norm.

Note 8: Current flows out of the pin.

(MAX) = (TJ(MAX) – TA)/θJA. Exceeding the maximum allowable power dissipation will cause excessive die temperature. For more information

D

. See Thermal Properties for the thermal resistance. The maximum allowable power dissipation at any ambient temperature is

A

(MAX), the junction-to-ambient thermal resistance, θJA,

J

www.national.com5

Block Diagram

LM3502

FIGURE 2. Block Diagram

www.national.com 6

20131704

Detailed Description of Operation

The LM3502 utilizes an asynchronous current mode pulsewidth-modulation (PWM) control scheme to regulate the

feedback voltage over specified load conditions. The DC/DC

converter behaves as a controlled current source for white

LED applications. The operation can best be understood by

referring to the block diagram in Figure 2 for the following

operational explanation. At the start of each cycle, the oscillator sets the driver logic and turns on the internal NMOS

power device, N1, conducting current through the inductor

and reverse biasing the external diode. The white LED current is supplied by the output capacitor when the internal

NMOS power device, N1, is turned on. The sum of the error

amplifier’s output voltage and an internal voltage ramp are

compared with the sensed power NMOS, N1, switch voltage.

Once these voltages are equal, the PWM comparator will

then reset the driver logic, thus turning off the internal NMOS

power device, N1, and forward biasing the external diode.

The inductor current then flows through the diode to the

white LED load and output capacitor. The inductor current

recharges the output capacitor and supplies the current for

the white LED load. The oscillator then resets the driver logic

again repeating the process. The output voltage of the error

amplifier controls the current through the inductor. This voltage will increase for larger loads and decrease for smaller

loads limiting the peak current in the inductor and minimizing

EMI radiation. The duty limit comparator is always operational, it prevents the internal NMOS power switch, N1, from

being on for more than one oscillator cycle and conducting

large amounts of current. The light load comparator allows

the LM3502 to properly regulate light/small white LED load

currents, where regulation becomes difficult for the

LM3502’s primary control loop. Under light load conditions,

the LM3502 will enter into a pulse skipping pulse-frequencymode (PFM) of operation where the switching frequency will

vary with the load.

The LM3502 has 2 control pins, En1 and En2, used for

selecting which segment of a single white LED string network is active for dual display applications. En1 controls the

main display (MAIN) segment of the single string white LED

network between pins V

OUT1

and V

sub display (SUB) segment of the single string white LED

. En2 controls the

OUT2

network between the V

and Fb. For a quick review of

OUT2

the LM3502 control pin operational characteristics, see Fig-

ure 3.

When the Cntrl pin is ≥ 1.4V, the LM3502 will enter in low I

state if both En1 and En2 ≤ 0.3V. At this time, both the P1

and N2 FETs will turn off. The output voltage will be a diode

drop below the supply voltage and the soft-start will be reset

limiting the peak inductor current at the next start-up.

The LM3502 is designed to control the LED current with a

PWM signal without the use of an external RC filter. Utilizing

special circuitry, the LM3502 can operate over a large range

of PWM frequencies without restarting the soft-start allowing

for fast recovery at high PWM frequencies. Figure 4

reprsents a PWM signal driving the Cntrl pin where t

L

defined as the low time of the signal. The following is true:

<

If t

•

12ms (typical): The device will stop switching

L

during this time and the soft-start will not be reset allowing LED current PWM control.

>

If t

•

12ms (typical): The device will shutdown and the

L

soft-start will reset to prevent high peak currents at the

next startup. Both the N2 and P1 switches will turn off.

The LM3502 has dedicated protection circuitry active during

normal operation to protect the integrated circuit (IC) and

external components. The thermal shutdown circuitry turns

off the internal NMOS power device, N1, when the internal

semiconductor junction temperature reaches excessive levels. The LM3502 has a under-voltage protection (UVP) comparator that disables the internal NMOS power device when

battery voltages are too low, thus preventing an on state

where the internal NMOS power device conducts large

amounts of current. The over-voltage protection (OVP) comparator prevents the output voltage from increasing beyond

the protection limit when the white LED string network is

removed or if there is a white LED failure. OVP allows for the

use of low profile ceramic capacitors at the output. The

current though the internal NMOS power device, N1, is

monitored to prevent peak inductor currents from damaging

the IC. If during a cycle (cycle=1/switching frequency) the

peak inductor current exceeds the current limit for the

LM3502, the internal NMOS power device will be turned off

for the remaining duration of that cycle.

LM3502

Q

is

www.national.com7

LM3502

20131705

FIGURE 3. Operational Characteristics Table

20131706

FIGURE 4. Control Signal Waveform

www.national.com 8

Typical Performance Characteristics ( Circuit in Figure 1: L = DO1608C-223 and D = MBRM140T3.

Efficiency: η =P

OUT/PIN

= [(V

OUT–VFb

(Non-Switching) vs V

I

Q

)*I

]/[VIN*IIN]. TA= 25˚C, unless otherwise stated.)

OUT

IN

20131707

Switching Frequency vs Temperature

20131708

LM3502

IQ(Switching) vs V

IN

20131709

IQ(Switching) vs Temperature

10 LED Efficiency vs LED Current 8 LED Efficiency vs LED Current

20131710

20131711

20131712

www.national.com9

Typical Performance Characteristics ( Circuit in Figure 1: L = DO1608C-223 and D = MBRM140T3.

Efficiency: η =P

LM3502

OUT/PIN

= [(V

OUT–VFb

6 LED Efficiency vs LED Current 4 LED Efficiency vs LED Current

)*I

]/[VIN*IIN]. TA= 25˚C, unless otherwise stated.) (Continued)

OUT

20131713

20131714

Cntrl Pin Current vs Cntrl Pin Voltage Maximum Duty Cycle vs Temperature

20131715

20131716

En1 Pin Current vs En1 Pin Voltage En2 Pin Current vs En2 Pin Voltage

20131717

www.national.com 10

20131718

Typical Performance Characteristics ( Circuit in Figure 1: L = DO1608C-223 and D = MBRM140T3.

Efficiency: η =P

V

OUT1

OUT/PIN

= [(V

OUT–VFb

Pin Current vs V

)*I

]/[VIN*IIN]. TA= 25˚C, unless otherwise stated.) (Continued)

OUT

Pin Voltage Power NMOS R

OUT1

20131719 20131720

(Figure 2: N1) vs V

DS(ON)

IN

LM3502

NMOS R

(Figure 2: N2) vs V

DS(ON)

Feedback Voltage vs Temperature

IN

20131721

PMOS R

(Figure 2: P1) vs V

DS(ON)

IN

20131722

20131725

www.national.com11

Typical Performance Characteristics ( Circuit in Figure 1: L = DO1608C-223 and D = MBRM140T3.

Efficiency: η =P

LM3502

OUT/PIN

= [(V

OUT–VFb

Current Limit (LM3502-16) vs V

)*I

]/[VIN*IIN]. TA= 25˚C, unless otherwise stated.) (Continued)

OUT

IN

Current Limit (LM3502-16) vs Temperature

20131754

Current Limit (LM3502-25) vs V

IN

20131756

Current Limit (LM3502-25) vs Temperature

Current Limit (LM3502-35/44) vs Temperature Current Limit (LM3502-35/44) vs V

20131755

20131757

IN

20131758

www.national.com 12

20131729

Application Information

WHITE LED CURRENT SETTING

The LED current is set using the following equation:

20131730

I

: White LED Current.

LED

: Feedback Pin Voltage. VFb= 0.25V, Typical.

V

Fb

R1: Currrent Setting Resistor.

WHITE LED DIMMING

For dimming the white LED string with a pulse-widthmodulated (PWM) signal on the Cntrl pin, care must taken to

balance the tradeoffs between audible noise and white LED

LM3502

brightness control. For best PWM duty cycle vs. white LED

current linearity, the PWM frequency should be between

200Hz and 500Hz. Other PWM frequencies can be used, but

the linearity over input voltage and duty cycle variation will

not be as good as what the 200Hz to 500Hz PWM frequency

spectrum provides. To minimize audible noise interference, it

is recommended that a output capacitor with minimal susceptibility to piezoelectric induced stresses be used for the

particular applications that require minimal or no audible

noise interference.

If V

is not used , En2 must be grounded

OUT2

20131735

FIGURE 5.

www.national.com13

Application Information (Continued)

LM3502

FIGURE 6. Inductor Current Waveform

CONTINUOUS AND DISCONTINUOUS MODES OF OPERATION

Since the LM3502 is a constant frequency pulse-widthmodulated step-up regulator, care must be taken to make

sure the maximum duty cycle specification is not violated.

The duty cycle equation depends on which mode of operation the LM3502 is in. The two operational modes of the

LM3502 are continuous conduction mode (CCM) and discontinuous conduction mode (DCM). Continuous conduction

mode refers to the mode of operation where during the

switching cycle, the inductor current never goes to and stays

at zero for any significant amount of time during the switching cycle. Discontinuous conduction mode refers to the

mode of operation where during the switching cycle, the

inductor current goes to and stays at zero for a significant

amount of time during the switching cycle. Figure 6 illustrates the threshold between CCM and DCM operation. In

Figure 6, the inductor current is right on the CCM/DCM

operational threshold. Using this as a reference, a factor can

be introduced to calculate when a particular application is in

CCM or DCM operation. R is a CCM/DCM factor we can use

to compute which mode of operation a particular application

is in. If R is ≥ 1, then the application is operating in CCM.

Conversely, if R is

The R factor inequalities are a result of the components that

make up the R factor. From Figure 6, the R factor is equal to

the average inductor current, I

inductor ripple current, ∆i

equation can be used to compute R factor:

<

1, the application is operating in DCM.

(avg), divided by half the

L

. Using Figure 6 the following

L

20131736

20131739

20131740

VIN: Input Voltage.

: Output Voltage.

V

OUT

Eff: Efficiency of the LM3502.

Fs: Switching Frequency.

: White LED Current/Load Current.

I

OUT

L: Inductance Magnitude/Inductor Value.

D: Duty Cycle for CCM Operation.

: Inductor Ripple Current

∆i

L

(avg): Average Inductor Current

I

L

For CCM operation, the duty cycle can be computed with:

20131741

20131737

20131738

www.national.com 14

20131742

D: Duty Cycle for CCM Operation.

: Output Voltage.

V

OUT

: Input Voltage.

V

IN

For DCM operation, the duty cycle can be computed with:

20131743

Application Information (Continued)

20131744

D: Duty Cycle for DCM Operation.

: Output Voltage.

V

OUT

: Input Voltage.

V

IN

I

: White LED Current/Load Current.

OUT

Fs: Switching Frequency.

L: Inductor Value/Inductance Magnitude.

INDUCTOR SELECTION

In order to maintain inductance, an inductor used with the

LM3502 should have a saturation current rating larger than

the peak inductor current of the particular application. Inductors with low DCR values contribute decreased power losses

and increased efficiency. The peak inductor current can be

computed for both modes of operation: CCM and DCM.

The cycle-by-cycle peak inductor current for CCM operation

can be computed with:

20131745

20131746

VIN: Input Voltage.

Eff: Efficiency of the LM3502.

Fs: Switching Frequency.

: White LED Current/Load Current.

I

OUT

L: Inductance Magnitude/Inductor Value.

D: Duty Cycle for CCM Operation.

: Peak Inductor Current.

I

PEAK

: Inductor Ripple Current.

∆i

L

(avg): Average Inductor Current.

I

L

The cycle-by-cycle peak inductor current for DCM operation

can be computed with:

20131747

VIN: Input Voltage.

Fs: Switching Frequency.

L: Inductance Magnitude/Inductor Value.

D: Duty Cycle for DCM Operation.

: Peak Inductor Current.

I

PEAK

The minimum inductance magnitude/inductor value for the

LM3502 can be calculated using the following, which is only

valid when the duty cycle is

>

0.5:

20131748

D: Duty Cycle.

D: 1– D.

: NMOS Power Switch ON Resistance.

R

DS(ON)

: Input Voltage.

V

IN

L: Inductance Magnitude/Inductor Value.

This equation gives the value required to prevent subharmonic oscillations. The result of this equation and the inductor average and ripple current should be accounted for when

choosing an inductor value.

Some recommended inductor manufacturers included but

are not limited to:

CoilCraft

DO1608C-223

DT1608C-223

www.coilcraft.com

CAPACITOR SELECTION

Multilayer ceramic capacitors are the best choice for use

with the LM3502. Multilayer ceramic capacitors have the

lowest equivalent series resistance (ESR). Applied voltage

or DC bias, temperature, dielectric material type (X7R, X5R,

Y5V, etc), and manufacturer component tolerance have an

affect on the true or effective capacitance of a ceramic

capacitor. Be aware of how your application will affect a

particular ceramic capacitor by analyzing the aforementioned factors of your application. Before selecting a capacitor always consult the capacitor manufacturer’s data curves

to verify the effective or true capacitance in your application.

INPUT CAPACITOR SELECTION

The input capacitor serves as an energy reservoir for the

inductor. In addition to acting as an energy reservoir for the

inductor the input capacitor is necessary for the reduction in

input voltage ripple and noise experienced by the LM3502.

The reduction in input voltage ripple and noise helps ensure

the LM3502’s proper operation, and reduces the effect of the

LM3502 on other devices sharing the same supply voltage.

To ensure low input voltage ripple, the input capacitor must

have an extremely low ESR. As a result of the low input

voltage ripple requirement multilayer ceramic capacitors are

the best choice.A minimum capacitance of 2.0 µF is required

for normal operation, so consult the capacitor manufacturer’s data curves to verify whether the minimum capacitance

requirement is going to be achieved for a particular application.

OUTPUT CAPACITOR SELECTION

The output capacitor serves as an energy reservoir for the

white LED load when the internal power FET switch (Figure

2: N1) is on or conducting current. The requirements for the

output capacitor must include worst case operation such as

when the load opens up and the LM3502 operates in overvoltage protection (OVP) mode operation. A minimum capacitance of 0.5µF is required to ensure normal operation.

Consult the capacitor manufacturer’s data curves to verify

whether the minimum capacitance requirement is going to

be achieved for a particular application.

Some recommended capacitor manufacturers included but

are not limited to:

LM3502

www.national.com15

Application Information (Continued)

LM3502

Taiyo

Yuden

muRata GRM40-035X7R105K

TDK C3216X7R1H105KT

AVX 08053D105MAT

DIODE SELECTION

To maintain high efficiency it is recommended that the average current rating (I

larger than the peak inductor current (I

mum, the average current rating of the diode should be

larger than the maximum LED current. To maintain diode

integrity the peak repetitive forward current (I

greater than or equal to the peak inductor current (I

Diodes with low forward voltage ratings (V

capacitance magnitudes (C

high efficiency. The chosen diode must have a reverse

breakdown voltage rating (V

than the output voltage (V

is chosen, Schottky or not, certain selection criteria must be

followed:

1. V

R

2. IFor IO≥ I

3. I

FRM

Some recommended diode manufacturers included but are

not limited to:

Vishay SS12(1A/20V) www.vishay.com

On

Semiconductor

Central

Semiconductor

SHUTDOWN AND START-UP

On startup, the LM3502 contains special circuitry that limits

the peak inductor current which prevents large current

spikes from loading the battery or power supply. When Cntrl

≥ 1.4V and both the En1 and En2 signals are less than 0.3V,

the LM3502 will enter a low I

During this low I

below the supply voltage and the soft-start will be reset to

GMK212BJ105MD

(0805/35V)

(0805/50V)

(1206/50V)

C3216X7R1C475K

(1206/16V)

(0805/25V)

08056D475KAT

(0805/6.3V)

1206ZD475MAT

(1206/10V)

and V

RRM

LOAD

≥ I

Lpeak

Q

www.t-yuden.com

www.murata.com

www.tdktca.com

www.avxcorp.com

or IO) of the selected diode should be

F

or CTor CD) are conducive to

J

and/or V

R

). No matter what type of diode

out

>

V

OUT

or I

OUT

). At the mini-

Lpeak

) and low junction

F

) that is larger

RRM

SS14(1A/40V)

SS16(1A/60V)

MBRM120E

www.onsemi.com

(1A/20V)

MBRS1540T3

(1.5A/40V)

MBR240LT

(2A/40V)

CMSH1- 40M

www.centralsemi.com

(1A/40V)

state and regulation will end.

Q

mode the output voltage is a diode drop

) must be

FRM

Lpeak

limit the peak inductor current at the next startup. When both

En1 and En2 are less than 0.3V, the P1 PMOS and N2

NMOS switches will turn off.

When Cntrl

<

0.3V for more than 12ms, typicaly, the LM3502

will shutdown and the output voltage will be a diode drop

below the supply voltage. If the Cntrl pin is low for more than

12ms, the soft-start will reset to limit the peak inductor current at the next startup.

<

When Cntrl is

0.3 but for less than 12ms, typically, the

device will not shutdown and reset the soft-start but shut off

the NMOS N1 Power Device to allow for PWM contrl of the

LED current.

THERMAL SHUTDOWN

The LM3502 stops regulating when the internal semiconductor junction temperature reaches approximately 140˚C. The

internal thermal shutdown has approximately 20˚C of hysteresis which results in the LM3502 turning back on when the

internal semiconductor junction temperature reaches 120˚C.

When the thermal shutdown temperature is reached, the

softstart is reset to prevent inrush current when the die

temperature cools.

UNDER VOLTAGE PROTECTION

The LM3503 contains protection circuitry to prevent operation for low input supply voltages. When Vin drops below

2.3V, typically the LM3502 will no longer regulate. In this

).

mode, the output volage will be one diode drop below Vin

and the softstart will be reset. When Vin increases above

2.4V, typically, the device will begin regulating again.

OVER VOLTAGE PROTECTION

The LM3502 contains dedicated circuitry for monitoring the

output voltage. In the event that the LED network is disconnected from the LM3502, the output voltage will increase

and be limited to 15.5V(typ.) for the 16V version , 24V(typ.)

for the 25V version, 34V(typ.) for the 35V version and

42V(typ.) for the 44V version (see eletrical table for more

details). In the event that the network is reconnected, regulation will resume at the appropriate output voltage.

LAYOUT CONSIDERATIONS

All components, except for the white LEDs, must be placed

as close as possible to the LM3502. The die attach pad

(DAP) must be soldered to the ground plane.

The input bypass capacitor C

be placed close to the IC and connect between the V

, as shown in Figure 1, must

IN

IN

and

PGND pins. This will reduce copper trace resistance which

effects input voltage ripple of the IC. For additional input

voltage filtering, a 100nF bypass capacitor can be placed in

parallel with C

ground. The output capacitor, C

the IC and be connected between the V

pins. Any copper trace connections for the C

to shunt any high frequency noise to

IN

, must be placed close to

OUT

OUT1

OUT

and PGND

capacitor

can increase the series resistance, which directly effects

output voltage ripple and efficiency. The current setting resistor, R1, should be kept close to the Fb pin to minimize

copper trace connections that can inject noise into the system. The ground connection for the current setting resistor

network should connect directly to the PGND pin. The AGND

pin should be tied directly to the PGND pin. Trace connections made to the inductor should be minimized to reduce

power dissipation and increase overall efficiency while reducing EMI radiation. For more details regarding layout

guidelines for switching regulators, refer to Applications Note

AN-1149.

www.national.com 16

Physical Dimensions inches (millimeters) unless otherwise noted

LM3502

16-Lead Thin Leadless Leadframe Package

NS Package Number SQA16A

TLP10: 10-Bump Thin Micro SMD

X1 = 1.958 mm

X2 = 2.135 mm

X3 = 0.6 mm

NS Package No. TLP10

www.national.com17

Notes

LM3502 Step-Up Converter for White LED Applications

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves

the right at any time without notice to change said circuitry and specifications.

For the most current product information visit us at www.national.com.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS

WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL COUNSEL OF NATIONAL SEMICONDUCTOR

CORPORATION. As used herein:

1. Life support devices or systems are devices or systems

which, (a) are intended for surgical implant into the body, or

(b) support or sustain life, and whose failure to perform when

properly used in accordance with instructions for use

provided in the labeling, can be reasonably expected to result

in a significant injury to the user.

BANNED SUBSTANCE COMPLIANCE

National Semiconductor follows the provisions of the Product Stewardship Guide for Customers (CSP-9-111C2) and Banned Substances

and Materials of Interest Specification (CSP-9-111S2) for regulatory environmental compliance. Details may be found at:

www.national.com/quality/green.

Lead free products are RoHS compliant.

National Semiconductor

Americas Customer

Support Center

Email: new.feedback@nsc.com

Tel: 1-800-272-9959

www.national.com

National Semiconductor

Europe Customer Support Center

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

2. A critical component is any component of a life support

device or system whose failure to perform can be reasonably

expected to cause the failure of the life support device or

system, or to affect its safety or effectiveness.

National Semiconductor

Asia Pacific Customer

Support Center

Email: ap.support@nsc.com

National Semiconductor

Japan Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

Loading...

Loading...