Page 1

December 2003

LM3500

Synchronous Step-up DC/DC Converter for White LED

Applications

Synchronous Step-up DC/DC Converter for White LED Applications

General Description

The LM3500 is a fixed frequency synchronous step-up

DC/DC converter in a small 8-bump thin micro SMD package. The LM3500 is ideal for white LED applications for

cellular phone back-lighting requiring low current and high

efficiency. Its fixed 1MHz operating frequency allows the use

of small, low ESR capacitors as well as a more predictable

frequency spectrum, which is important in cellular phone

applications. The LM3500 can drive 2 to 4 white LEDs in

series from a single Li-Ion battery or 3 cell NiMH with no

external rectification diode. For white LED applications, a

single external resistor is used to set the maximum LED

current. The white LED current can easily be adjusted using

a pulse width modulated (PWM) signal on the shutdown pin.

The LM3500 uses special protection circuitry on the output

to prevent an overvoltage event if the primary white LED

network should be disconnected eliminating the need of an

extra protection Zener diode. In shutdown, the LM3500 disconnects the input and output creating a true isolation preventing any LED light from emitting over the full input operating voltage range and temperature.

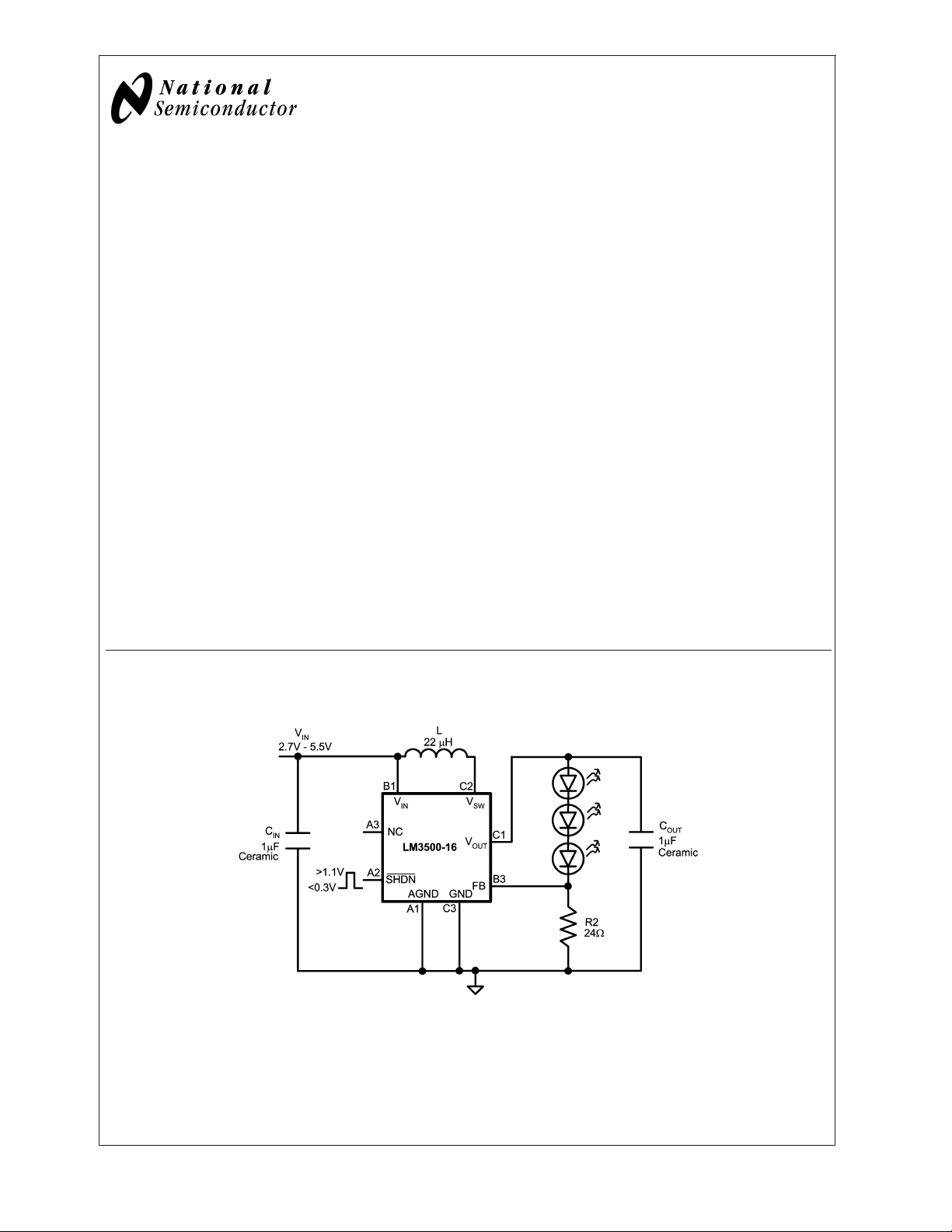

Typical Application Circuit

Features

n Synchronous rectification, high efficiency and no

external schottky diode required

n Uses small surface mount components

n Can drive up to 3 (or 4 low V

n 2.7V to 7V input range

n True shutdown isolation

n Input undervoltage lockout

n Output overvoltage protection, no external zener diode

required

n Requires only a small 16V ceramic capacitor at the

output

n Thermal Shutdown

n 0.1µA shutdown current

n Small 8-bump thin micro SMD package

) white LEDs in series

F

Applications

n LCD Bias Supplies

n White LED Back-Lighting

n Handheld Devices

n Digital Cameras

n Portable Applications

20065701

FIGURE 1. Typical 3 LED Application

© 2003 National Semiconductor Corporation DS200657 www.national.com

Page 2

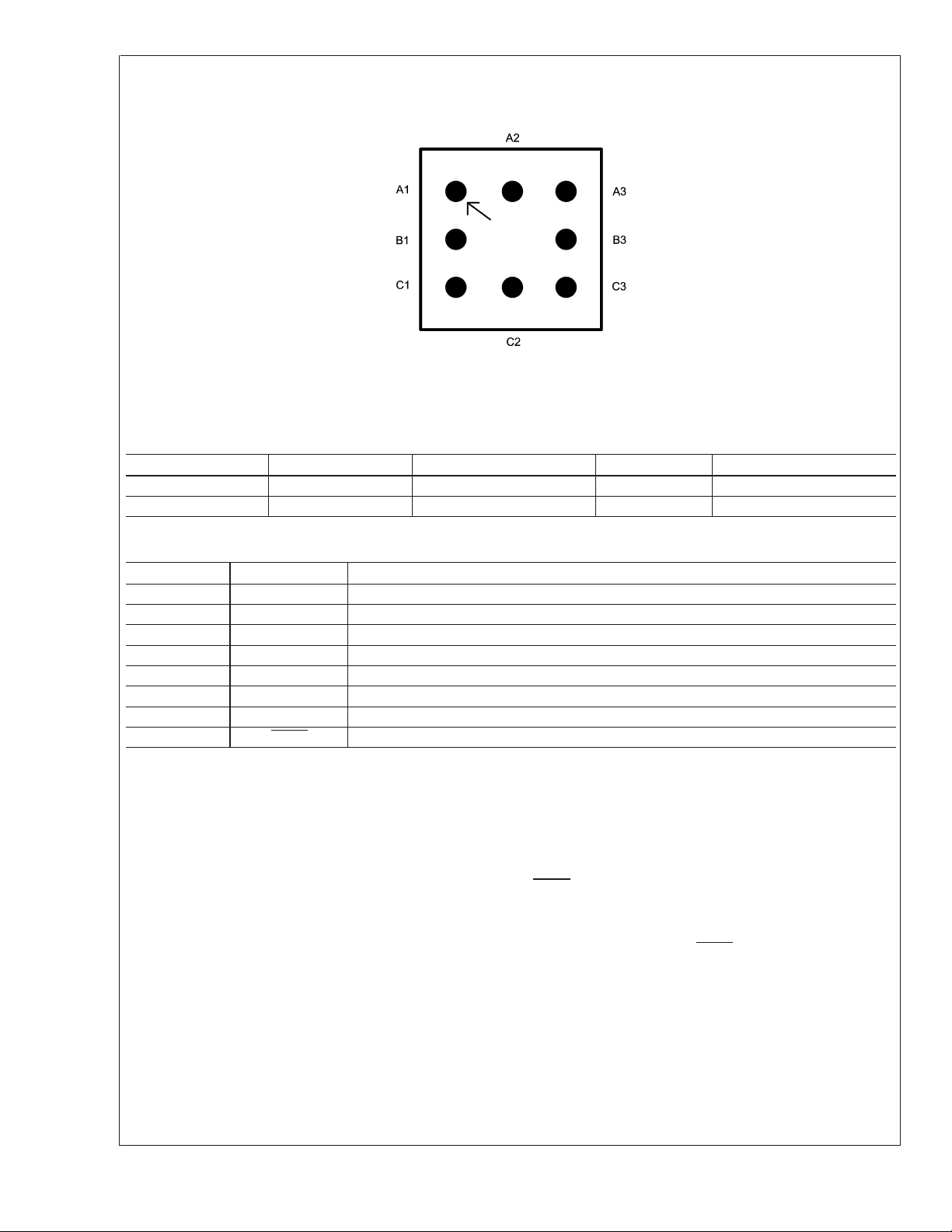

Connection Diagram

LM3500

Top View

8-bump micro SMD

20065702

T

= 125˚C, θJA= 220˚C/W (Note 3)

J(MAX)

Ordering Information

Order Number Package Type NSC Package Drawing Top Mark Supplied As

LM3500TL-16 micro SMD TL08SSA C18 250 Units, Tape and Reel

LM3500TLX-16 micro SMD TL08SSA C18 3000 Units, Tape and Reel

Pin Description/Functions

Pin Name Function

A1 AGND Analog ground.

B1 V

C1 V

C2 V

IN

OUT

SW

C3 GND Power Ground.

B3 FB Output voltage feedback connection.

A3 NC No internal connection made to this pin.

A2 SHDN

AGND(pin A1): Analog ground pin. The analog ground pin

should tie directly to the GND pin.

V

(pin B1): Analog and Power supply pin. Bypass this pin

IN

with a capacitor, as close to the device as possible, connected between the V

(pin C1): Source connection of internal PMOS power

V

OUT

and GND pins.

IN

device. Connect the output capacitor between the V

GND pins as close as possible to the device.

(pin C2): Drain connection of internal NMOS and PMOS

V

SW

switch devices. Keep the inductor connection close to this

pin to minimize EMI radiation.

GND(pin C3): Power ground pin. Tie directly to ground

plane.

Analog and Power supply input.

PMOS source connection for synchronous rectification.

Switch pin. Drain connections of both NMOS and PMOS power devices.

Shutdown control pin.

FB(pin B3): Output voltage feedback connection. Set the

primary White LED network current with a resistor from the

FB pin to GND. Keep the current setting resistor close to the

device and connected between the FB and GND pins.

NC(pin A3): No internal connection is made to this pin. The

maximum allowable voltage that can be applied to this pin is

OUT

and

7.5V.

SHDN(pin A2): Shutdown control pin. Disable the device

with a voltage less than 0.3V and enable the device with a

voltage greater than 1.1V. The white LED current can be

controlled using a PWM signal at this pin. There is an

internal pull down on the SHDN pin, the device is in a

normally off state.

www.national.com 2

Page 3

LM3500

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

V

IN

V

(Note 2) −0.3V to 16V

OUT

V

(Note 2) −0.3V to V

SW

FB Voltage −0.3V to 7.5V

SHDN Voltage

−0.3V to 7.5V

+0.3V

OUT

−0.3V to 7.5V

ESD Ratings (Note 4)

Human Body Model 2kV

Machine Model 200V

Operating Conditions

Junction Temperature

(Note 3) −40˚C to +125˚C

Supply Voltage 2.7V to 7V

NC −0.3V to 7.5V

Maximum Junction Temperature 150˚C

Lead Temperature

(Soldering 10 sec.) 300˚C

Vapor Phase

Thermal Properties

Junction to Ambient Thermal

Resistance (θ

SMD package (Note 3)

), 8-pin micro

JA

220˚C/W

(60 sec.) 215˚C

Infrared

(15 sec.) 220˚C

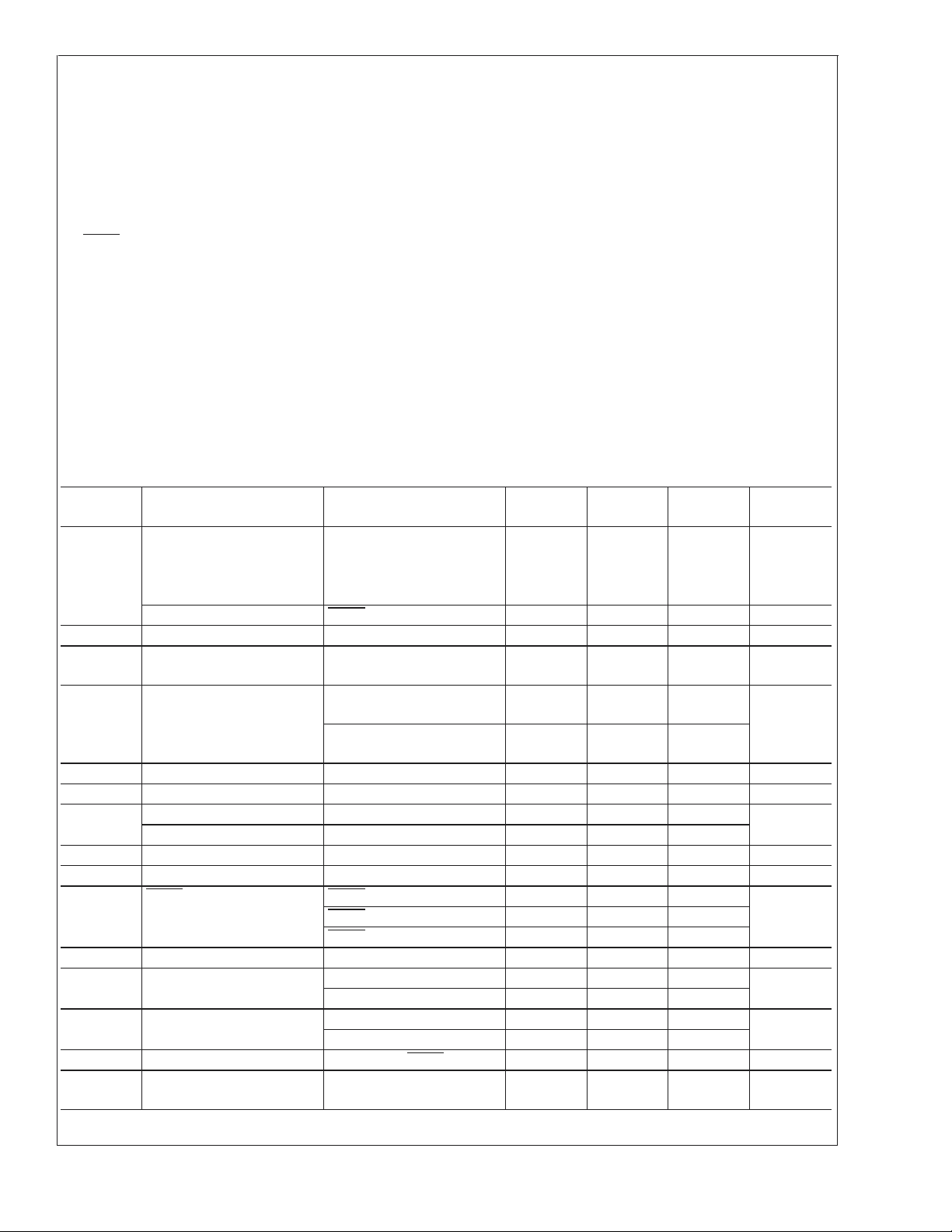

Electrical Characteristics

Specifications in standard type face are for TA= 25˚C and those in boldface type apply over the Operating Temperature

Range of T

Symbol Parameter Conditions

I

Q

V

FB

∆V

FB

I

CL

I

B

V

IN

R

DSON

D

Limit

F

SW

I

SD

I

L

UVP Input Undervoltage Lockout ON Threshold 2.4 2.5 2.6

OVP Output Overvoltage

I

Vout

I

VL

= −10˚C to +85˚C. Unless otherwise specified VIN=2.7V.

A

Quiescent Current, Device

FB>0.54V

Not Switching

Quiescent Current, Device

FB=0V

Switching

Shutdown SHDN = 0V

Min

(Note 5)

Typ

(Note 6)

Max

(Note 5)

0.95 1.2

1.8 2.5

0.1 2 µA

FeedbackVoltage VIN= 2.7V to 7V 0.47 0.5 0.53 V

FeedbackVoltage Line

Regulation

Switch Current Limit VIN= 2.7V, Duty Cycle =

VIN= 2.7V to 7V

80%

= 3.0V, Duty Cycle =

V

IN

70%

0.1 0.4 %/V

275 400 480

255 400 530

FB Pin Bias Current FB = 0.5V (Note 7) 45 200 nA

Input Voltage Range 2.7 7.0 V

NMOS Switch R

PMOS Switch R

DSON

DSON

VIN= 2.7V, ISW= 300mA 0.43

V

= 6V, ISW= 300mA 1.1 2.3

OUT

Duty Cycle Limit FB = 0V 80 87 %

Switching Frequency 0.85 1.0 1.15 MHz

SHDN Pin Current (Note 8) SHDN = 5.5V 18 30

9 16

SHDN = GND

0.1

Switch Leakage Current VSW= 15V 0.01 0.5 µA

OFF Threshold 2.3 2.4 2.5

ON Threshold 15 15.5 16

Protection

V

Bias Current V

OUT

PMOS Switch Leakage

Current

OFF Threshold 14 14.6 15

= 15V, SHDN = V

OUT

V

= 15V, VSW=0V

OUT

IN

260 400 µA

0.01 3 µA

Units

mA

mA

Ω

µASHDN = 2.7V

V

V

www.national.com3

Page 4

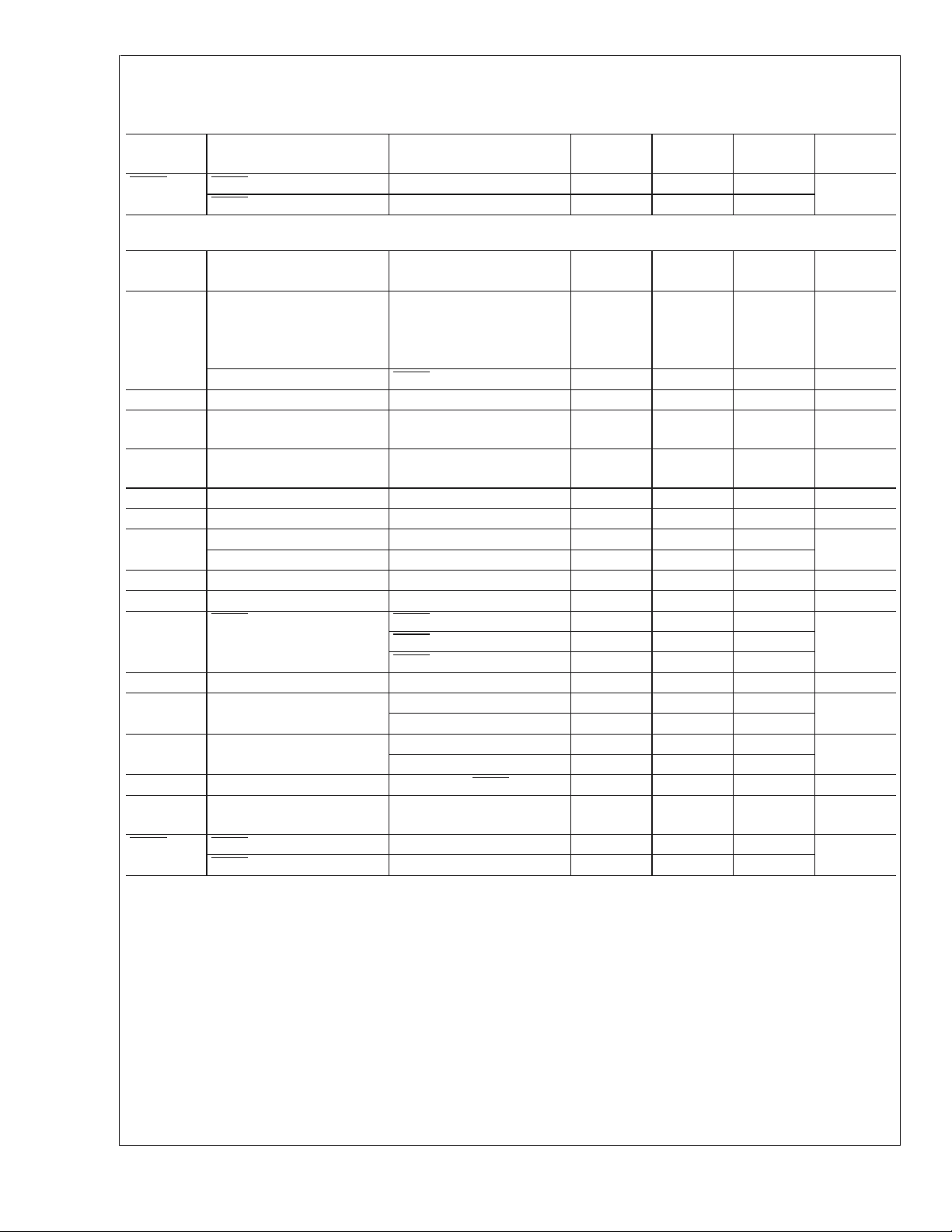

Electrical Characteristics (Continued)

Specifications in standard type face are for TA= 25˚C and those in boldface type apply over the Operating Temperature

LM3500

Range of T

Symbol Parameter Conditions

SHDN

Threshold

Specifications in standard type face are for TJ= 25˚C and those in boldface type apply over the full Operating Temperature

Range (T

Symbol Parameter Conditions

I

Q

V

FB

∆V

FB

I

CL

I

B

V

IN

R

DSON

D

Limit

F

SW

I

SD

I

L

UVP Input Undervoltage Lockout ON Threshold 2.4 2.5 2.6

OVP Output Overvoltage

I

Vout

I

VL

SHDN

Threshold

Note 1: Absolute maximum ratings are limits beyond which damage to the device may occur. Operating Ratings are conditions for which the device is intended to

be functional, but device parameter specifications may not be guaranteed. For guaranteed specifications and test conditions, see the Electrical Characteristics.

Note 2: This condition applies if V

Note 3: The maximum allowable power dissipation is a function of the maximum operating junction temperature, T

resistance, θ

temperature is calculated using: P

Note 4: The human body model is a 100 pF capacitor discharged through a 1.5 kΩ resistor into each pin. The machine model is a 200 pF capacitor discharged

directly into each pin.

Note 5: All limits guaranteed at room temperature (standard typeface) and at temperature extremes (bold typeface). All room temperature limits are production

tested, guaranteed through statistical analysis or guaranteed by design. All limits at temperature extremes are guaranteed via correlation using standard Statistical

Quality Control (SQC) methods. All limits are used to calculate Average Outgoing Quality Level (AOQL).

Note 6: Typical numbers are at 25˚C and represent the most likely norm.

Note 7: Feedback current flows out of the pin.

Note 8: Current flows into the pin.

= −10˚C to +85˚C. Unless otherwise specified VIN=2.7V.

A

SHDN low

SHDN High

= −40˚C to +125˚C). Unless otherwise specified VIN=2.7V.

J

Quiescent Current, Device

FB>0.54V

Not Switching

Quiescent Current, Device

FB=0V

Switching

Shutdown SHDN = 0V

Min

(Note 5)

1.1 0.65

Min

(Note 5)

Typ

(Note 6)

Max

(Note 5)

0.65 0.3

Typ

(Note 6)

Max

(Note 5)

0.95 1.2

1.8 2.5

0.1 2 µA

FeedbackVoltage VIN= 2.7V to 7V 0.47 0.5 0.53 V

FeedbackVoltage Line

Regulation

Switch Current Limit VIN= 3.0V, Duty Cycle =

VIN= 2.7V to 7V

70%

0.1 0.4 %/V

400 mA

FB Pin Bias Current FB = 0.5V (Note 7) 45 200 nA

Input Voltage Range 2.7 7.0 V

NMOS Switch R

PMOS Switch R

DSON

DSON

VIN= 2.7V, ISW= 300mA 0.43

V

= 6V, ISW= 300mA 1.1 2.3

OUT

Duty Cycle Limit FB = 0V 87 %

Switching Frequency 0.8 1.0 1.2 MHz

SHDN Pin Current (Note 8) SHDN = 5.5V 18 30

9 16

SHDN = GND

0.1

Switch Leakage Current VSW= 15V 0.01 0.5 µA

OFF Threshold 2.3 2.4 2.5

ON Threshold 15 15.5 16

Protection

V

Bias Current V

OUT

PMOS Switch Leakage

Current

SHDN low

SHDN High

<

V

IN

OUT

, and the ambient temperature, TA. See Thermal Properties for the thermal resistance. The maximum allowable power dissipation at any ambient

JA

(MAX) = (T

D

OFF Threshold 14 14.6 15

= 15V, SHDN = V

OUT

V

= 15V, VSW=0V

OUT

IN

260 400 µA

0.01 3 µA

0.65 0.3

1.1 0.65

>

.IfV

V

IN

J(MAX)−TA

, a voltage greater than VIN+ 0.3V should not be applied to the V

OUT

)/θJA. Exceeding the maximum allowable power dissipation will cause excessive die temperature.

or VSWpins.

OUT

, the junction-to-ambient thermal

J(MAX)

Units

V

Units

mA

Ω

µASHDN = 2.7V

V

V

V

www.national.com 4

Page 5

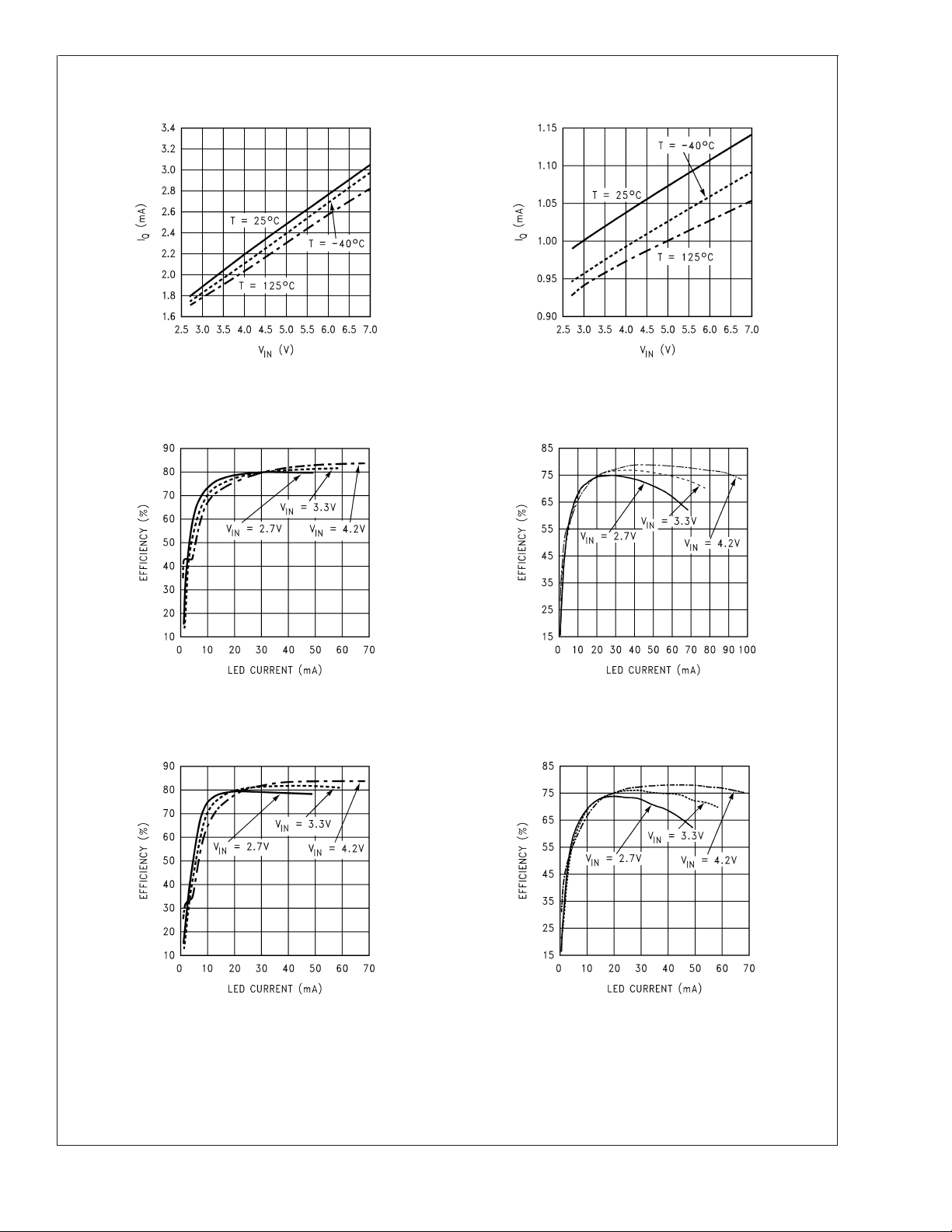

Typical Performance Characteristics

LM3500

Switching Quiescent Current vs V

20065755 20065756

2 LED Efficiency vs LED Current

L = Coilcraft DT1608C-223,

Efficiency = 100*(P

IN

/(2V

LED*ILED

IN

Non-Switching Quiescent Current vs V

IN

2 LED Efficiency vs LED Current

L = TDK VLP4612T-220MR34,

))

Efficiency = 100*(PIN/(2V

LED*ILED

))

3 LED Efficiency vs LED Current

L = Coilcraft DT1608C-223,

Efficiency = 100*(P

IN

/(3V

LED*ILED

20065757

))

20065758

3 LED Efficiency vs LED Current

L = TDK VLP4612T-220MR34,

Efficiency = 100*(PIN/(3V

LED*ILED

20065779

))

20065780

www.national.com5

Page 6

Typical Performance Characteristics (Continued)

LM3500

4 LED Efficiency vs LED Current

L = Coilcraft DT1608C-223,

Efficiency = 100*(P

2 LED Efficiency vs V

IN

/(4V

LED*ILED

IN

L = Coilcraft DT1608C-223,

Efficiency = 100*(P

IN

/(2V

LED*ILED

))

20065759

))

4 LED Efficiency vs LED Current

L = TDK VLP4612T-220MR34,

Efficiency = 100*(PIN/(4V

3 LED Efficiency vs V

LED*ILED

IN

L = Coilcraft DT1608C-223,

Efficiency = 100*(P

IN

/(3V

LED*ILED

))

20065781

))

20065769 20065770

4 LED Efficiency vs V

IN

L = Coilcraft DT1608C-223,

Efficiency = 100*(P

www.national.com 6

IN

/(4V

LED*ILED

))

20065773

Output Power vs V

IN

(L = Coilcraft DT1608C-223)

20065784

Page 7

Typical Performance Characteristics (Continued)

Output Power vs Temperature

(L = Coilcraft DT1608C-223) SHDN Pin Current vs SHDN Pin Voltage

20065785 20065761

LM3500

Switch Current Limit vs V

IN

Switch Current Limit vs Temperature (V

Switch Current Limit vs Temperature (V

20065762

=12V) Oscillator Frequency vs V

OUT

20065763

IN

OUT

=8V)

20065776

20065764

www.national.com7

Page 8

Typical Performance Characteristics (Continued)

LM3500

V

DC Bias vs V

OUT

FB Voltage vs V

Voltage FB Voltage vs Temperature

OUT

20065765

NMOS R

IN

DSON

(ISW= 300mA)

vs V

20065766

IN

PMOS R

20065767

vs Temperature Typical VINRipple

DSON

20065775

3 LEDs, R

1) SW, 10V/div, DC

, 100mA/div, DC

3) I

L

4) V

IN

T = 250ns/div

=22Ω,VIN= 3.0V

LED

, 100mV/div, AC

20065774

20065768

www.national.com 8

Page 9

Typical Performance Characteristics (Continued)

Start-Up SHDN Pin Duty Cycle Control Waveforms

LM3500

3 LEDs, R

1) SHDN, 1V/div, DC

2) IL, 100mA/div, DC

3) I

LED

T = 100µS/div

V

OUT

3) V

OUT

T = 1mS/div

=22Ω,VIN= 3.0V

LED

, 20mA/div, DC

Typical V

open circuit and equals approx. 15V DC, VIN= 3.0V

, 200mV/div, AC

Ripple, OVP Functioning

OUT

20065771

20065782

3 LEDs, R

1) SHDN, 1V/div, DC

2) IL, 100mA/div, DC

3) I

LED

4) V

OUT

T = 1mS/div

=22Ω,VIN= 3.0V, SHDN frequency = 200Hz

LED

, 20mA/div, DC

, 10V/div, DC

20065772

www.national.com9

Page 10

Operation

LM3500

20065704

FIGURE 2. LM3500 Block Diagram

The LM3500 utilizes a synchronous Current Mode PWM

control scheme to regulate the feedback voltage over almost

all load conditions. The DC/DC controller acts as a controlled

current source ideal for white LED applications. The LM3500

is internally compensated preventing the use of any external

compensation components providing a compact overall solution. The operation can best be understood referring to the

block diagram in Figure 2. At the start of each cycle, the

oscillator sets the driver logic and turns on the NMOS power

device conducting current through the inductor and turns off

the PMOS power device isolating the output from the V

SW

pin. The LED current is supplied by the output capacitor

when the NMOS power device is active. During this cycle,

the output voltage of the EAMP controls the current through

the inductor. This voltage will increase for larger loads and

decrease for smaller loads limiting the peak current in the

inductor minimizing EMI radiation. The EAMP voltage is

compared with a voltage ramp and the sensed switch voltage. Once this voltage reaches the EAMP output voltage,

the PWM COMP will then reset the logic turning off the

NMOS power device and turning on the PMOS power device. The inductor current then flows through the PMOS

power device to the white LED load and output capacitor.

The inductor current recharges the output capacitor and

supplies the current for the white LED branches. The oscillator then sets the driver logic again repeating the process.

The Duty Limit Comp is always operational preventing the

NMOS power switch from being on more than one cycle and

conducting large amounts of current.

The LM3500 has dedicated protection circuitry active during

normal operation to protect the IC and the external components. The Thermal Shutdown circuitry turns off both the

NMOS and PMOS power devices when the die temperature

reaches excessive levels. The LM3500 has a UVP Comp

that disables both the NMOS and PMOS power devices

when battery voltages are too low preventing an on state of

the power devices which could conduct large amounts of

current. The OVP Comp prevents the output voltage from

increasing beyond 15.5V when the primary white LED network is removed or if there is an LED failure, allowing the use

of small 16V ceramic capacitors at the output. This comparator has a 0.9V hysteresis that will regulate the output voltage

between 15.5V and 14.6V typically. The LM3500 features a

shutdown mode that reduces the supply current to 0.1uAand

isolates the input and output of the converter.

www.national.com 10

Page 11

Application Information

ADJUSTING LED CURRENT

The White LED current is set using the following equation:

The LED current can be controlled using a PWM signal on

the SHDN pin with frequencies in the range of 100Hz

(greater than visible frequency spectrum) to 1kHz. For controlling LED currents down to the µA levels, it is best to use

a PWM signal frequency between 200-500Hz. The LM3500

LED current can be controlled with PWM signal frequencies

above 1kHz but the controllable current decreases with

higher frequency. The maximum LED current would be

achieved using the equation above with 100% duty cycle, ie.

the SHDN pin always high.

The minimum number of LEDs the LM3500 can drive is 2 in

series and the maximum is 4. The LM3500 can also drive

multiple strings of white LEDs, see typical applications for

suggestions. When driving 4 LEDs in series the application

should use lower forward voltage drop white LEDs to prevent

the OVP function from activating during normal operation.

OUTPUT OVERVOLTAGE PROTECTION

The LM3500 contains dedicated circuitry for monitoring the

output voltage. In the event that the primary LED network is

disconnected the output will increase and be limited to

15.5V. There is a 900mV hysteresis associated with this

circuitry which will cause the output to fluctuate between

15.5V and 14.6V if the primary network is disconnected. In

the event that the network is reconnected regulation will

begin at the appropriate output voltage. The 15.5V limit

allows the use of 16V 1µF ceramic output capacitors creating an overall small solution for white LED applications.

RELIABILITY AND THERMAL SHUTDOWN

The maximum continuous pin current for the 8 pin thin micro

SMD package is 535mA. When driving the device near its

power output limits the V

than 535mA (see INDUCTOR SELECTION section for average switch current). To preserve the long term reliability of

the device the average switch current should not exceed

535mA.

The LM3500 has an internal thermal shutdown function to

protect the die from excessive temperatures. The thermal

shutdown trip point is typically 150˚C. There is a hysteresis

of typically 35˚C so the die temperature must decrease to

approximately 115˚C before the LM3500 will return to normal

operation.

INDUCTOR SELECTION

The inductor used with the LM3500 must have a saturation

current greater than the cycle by cycle peak inductor current

(see Typical Peak Inductor Currents table below). Choosing

inductors with low DCR decreases power losses and increases efficiency.

The minimum inductor value required for the LM3500 can be

calculated using the following equation:

pin can see a higher DC current

SW

where L is in µH, VINis the input supply of the chip in Volts,

is the ON resistance of the NMOS power switch

R

DSON

found in the Typical Performance Characteristics section in

ohms and D is the duty cycle of the switching regulator. The

above equation is only valid for D greater than 0.5. For

applications where the minimum duty cycle is less than or

equal to 0.5, use 0.51 for the inductor equation above. The

duty cycle, D, is given by the following equation:

where V

is the voltage at pin C1.

OUT

Typical Peak Inductor Currents (mA)

#

V

(V)

LEDs

IN

(in

15mA20mA30mA40mA50mA60

series)

LED Current

mA

2.7 2 82 100 134 160 204 234

3 118 138 190 244 294 352

4 142 174 244 322 X X

3.3 2 76 90 116 136 172 198

3 110 126 168 210 250 290

4 132 158 212 270 320 X

4.2 2 64 76 96 116 142 162

3 102 116 148 180 210 246

4 122 146 186 232 272 318

CIN=C

L = 22 µH, 160 mΩ DCR max. Coilcraft DT1608C-223

LED V

applications.

LED V

=1µF

OUT

= 3.77V at 20mA and room temperature for the 2 and 3 LED

F

= 3.41V at 20mA and room temperature for the 4 LED application.

F

The typical cycle-by-cycle peak inductor current can be calculated from the following equation:

where I

is the total load current, FSWis the switching

OUT

frequency, L is the inductance and η is the converter efficiency of the total driven load. A good typical number to use

for η is 0.8. The value of η can vary with load and duty cycle.

The average inductor current, which is also the average V

SW

pin current, is given by the following equation:

LM3500

www.national.com11

Page 12

Application Information (Continued)

The maximum output current capability of the LM3500 can

LM3500

be estimated with the following equation:

where ICLis the current limit. Some recommended inductors

include but are not limited to:

Coilcraft DT1608C series

Coilcraft DO1608C series

TDK VLP4612 series

TDK VLP5610 series

TDK VLF4012A series

CAPACITOR SELECTION

Choose low ESR ceramic capacitors for the output to minimize output voltage ripple. Multilayer X7R or X5R type ceramic capacitors are the best choice. For most applications,

a 1µF ceramic output capacitor is sufficient.

Local bypassing for the input is needed on the LM3500.

Multilayer X7R or X5R ceramic capacitors with low ESR are

a good choice for this as well. A 1µF ceramic capacitor is

sufficient for most applications. However, for some applications at least a 4.7µF ceramic capacitor may be required for

proper startup of the LM3500. Using capacitors with low

ESR decreases input voltage ripple. For additional bypassing, a 100nF ceramic capacitor can be used to shunt high

frequency ripple on the input. Some recommended capacitors include but are not limited to:

TDK C2012X7R1C105K

Taiyo-Yuden EMK212BJ105 G

LAYOUT CONSIDERATIONS

The input bypass capacitor C

, as shown in Figure 2, must

IN

be placed close to the device and connect between the V

and GND pins. This will reduce copper trace resistance

which effects the input voltage ripple of the IC. For additional

input voltage filtering, a 100nF bypass capacitor can be

placed in parallel with C

to ground. The output capacitor, C

to shunt any high frequency noise

IN

, should also be placed

OUT

close to the LM3500 and connected directly between the

and GND pins. Any copper trace connections for the

V

OUT

capacitor can increase the series resistance, which

C

OUT

directly effects output voltage ripple and efficiency. The current setting resistor, R

, should be kept close to the FB pin

LED

to minimize copper trace connections that can inject noise

into the system. The ground connection for the current setting resistor should connect directly to the GND pin. The

AGND pin should connect directly to the GND pin. Not

connecting the AGND pin directly, as close to the chip as

possible, may affect the performance of the LM3500 and

limit its current driving capability. Trace connections made to

the inductor should be minimized to reduce power dissipation, EMI radiation and increase overall efficiency. It is good

practice to keep the V

routing away from sensitive pins

SW

such as the FB pin. Failure to do so may inject noise into the

FB pin and affect the regulation of the device. See Figure 3

and Figure 4 for an example of a good layout as used for the

LM3500 evaluation board.

IN

FIGURE 3. Evaluation Board Layout (2X Magnification)

Top Layer

www.national.com 12

20065777

Page 13

Application Information (Continued)

LM3500

20065778

FIGURE 4. Evaluation Board Layout (2X Magnification)

Bottom Layer (as viewed from the top)

FIGURE 5. 2 White LED Application

20065709

www.national.com13

Page 14

Application Information (Continued)

LM3500

20065754

FIGURE 6. Multiple 2 LED String Application

FIGURE 7. Multiple 3 LED String Application

www.national.com 14

20065783

Page 15

Physical Dimensions inches (millimeters) unless otherwise noted

Synchronous Step-up DC/DC Converter for White LED Applications

8-Bump Micro SMD Package (TL)

For Ordering, Refer to Ordering Information Table

NS Package Number TLA08SSA

±

X1 = 1.92mm (

0.03mm), X2 = 1.92mm (±0.03mm), X3 = 0.6mm (±0.075mm)

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

labeling, can be reasonably expected to result in a

significant injury to the user.

BANNED SUBSTANCE COMPLIANCE

National Semiconductor certifies that the products and packing materials meet the provisions of the Customer Products

Stewardship Specification (CSP-9-111C2) and the Banned Substances and Materials of Interest Specification

(CSP-9-111S2) and contain no ‘‘Banned Substances’’ as defined in CSP-9-111S2.

National Semiconductor

Americas Customer

Support Center

Email: new.feedback@nsc.com

Tel: 1-800-272-9959

www.national.com

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

National Semiconductor

Europe Customer Support Center

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Support Center

Email: ap.support@nsc.com

National Semiconductor

Japan Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

Loading...

Loading...