March 7, 2008

LM3433

Common Anode Capable High Brightness LED Driver with

High Frequency Dimming

LM3433 Common Anode Capable High Brightness LED Driver with High Frequency Dimming

General Description

The LM3433 is an adaptive constant on-time DC/DC buck

(step-down) constant current controller (a true current

source). The LM3433 provides a constant current for illuminating high power LEDs. The output configuration allows the

anodes of multiple LEDs to be tied directly to the ground referenced chassis for maximum heat sink efficacy. The high

frequency capable architecture allows the use of small external passive components and no output capacitor while maintaining low LED ripple current. Two control inputs are used to

modulate LED brightness. An analog current control input is

provided so the LM3433 can be adjusted to compensate for

LED manufacturing variations and/or color temperature correction. The other input is a logic level PWM control of LED

current. The PWM functions by shorting out the LED with a

parallel switch allowing high PWM dimming frequencies. High

frequency PWM dimming allows digital color temperature

control, interference blanking, field sequential illumination,

and brightness control. Additional features include thermal

shutdown, VCC under-voltage lockout, and logic level shutdown mode. The LM3433 is available in a low profile LLP-24

package.

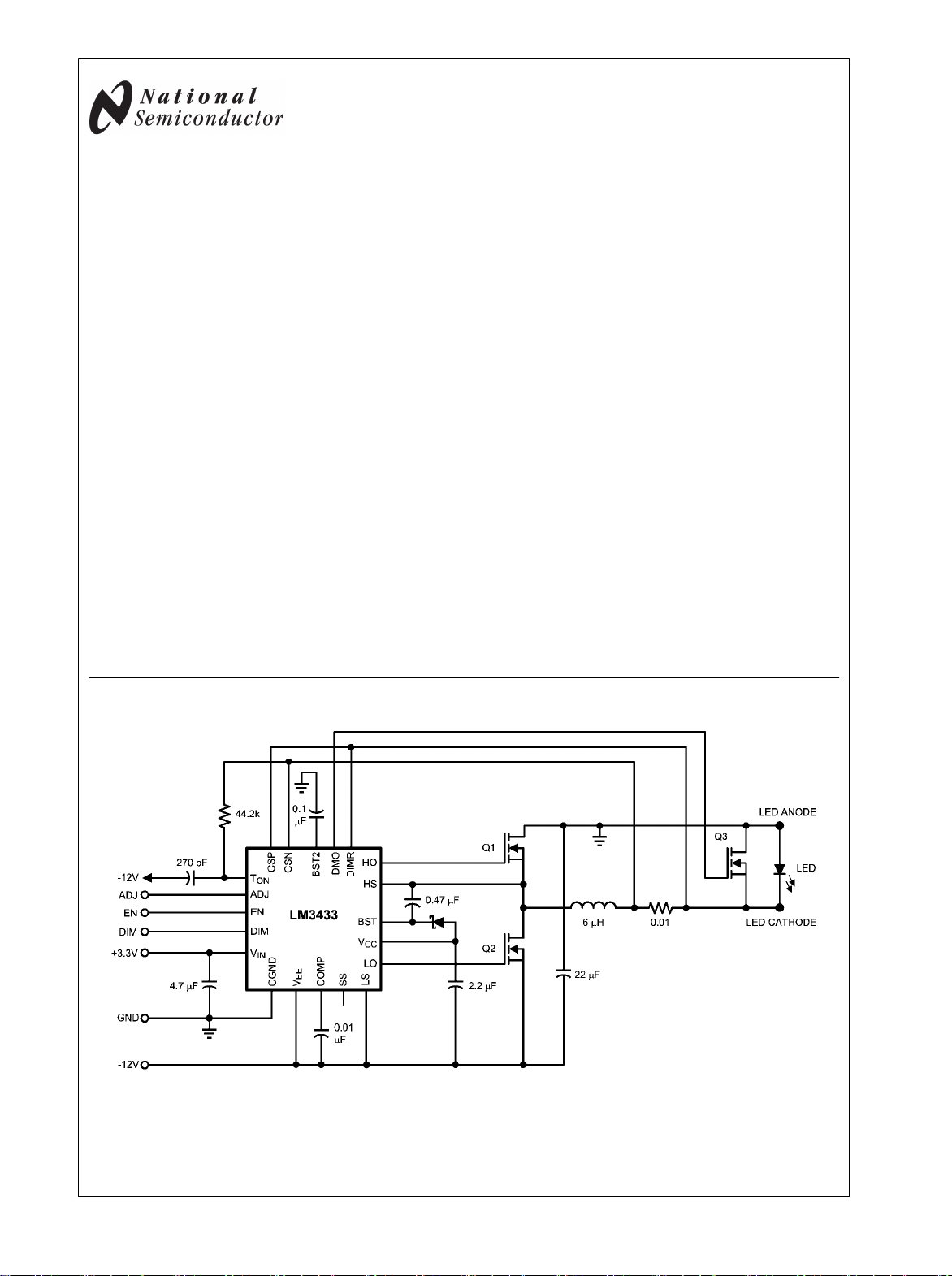

Typical Application Circuit

Features

Operating input voltage range of -9V to -14V w.r.t. LED

■

anode

Control inputs are referenced to the LED anode

■

Output current greater than 6A

■

Greater than 30kHz PWM frequency capable

■

Negative output voltage capability allows LED anode to be

■

tied directly to chassis for maximum heat sink efficacy

No output capacitor required

■

Up to 1MHz switching frequency

■

Low IQ, 1mA typical

■

Soft start

■

Adaptive programmable ON time allows for constant ripple

■

current

LLP-24 package

■

Applications

LCD backlighting

■

Projection systems

■

Solid state lighting

■

Automotive lighting

■

30031531

© 2008 National Semiconductor Corporation 300315 www.national.com

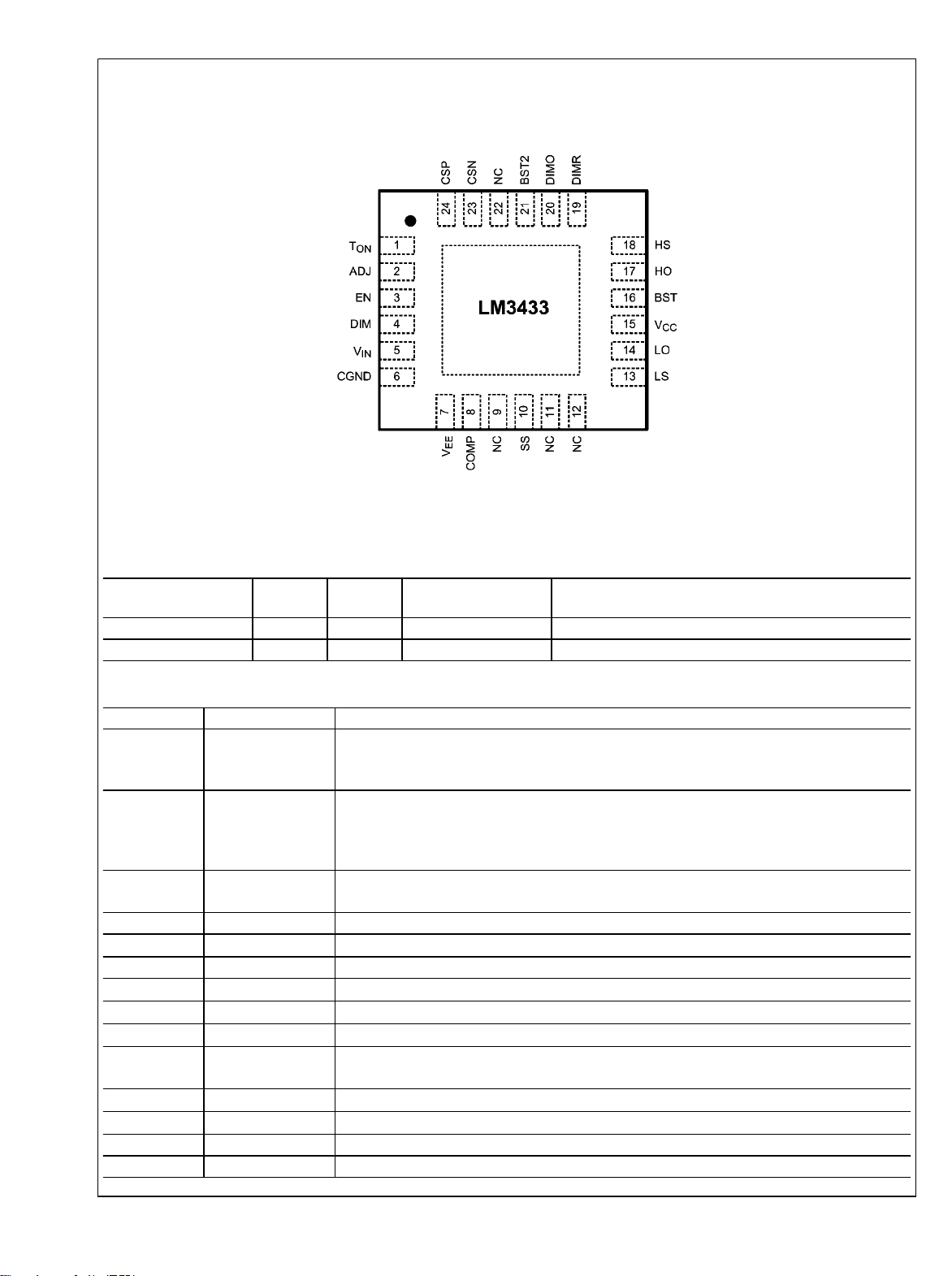

Connection Diagram

LM3433

Top View

NS Package Number SQA24A

24-Lead LLP

30031504

Ordering Information

Order Number Spec. Package

Type

LM3433SQ NOPB LLP-24 SQA24A 1000 Units, Tape and Reel

LM3433SQX NOPB LLP-24 SQA24A 4500 Units, Tape and Reel

NSC Package

Drawing

Supplied As

Pin Descriptions

Pin Name Function

On-time programming pin. Tie an external resistor (RON) from TON to CSN, and a capacitor

1

2 ADJ

3 EN

4 DIM Logic level input for LED PWM dimming. DIM is internally tied to CGND through a 100k resistor.

5 V

6 CGND Chassis ground connection.

7 V

8 COMP

9 NC No internal connection. Tie to VEE or leave open.

10 SS

11 NC No internal connection. Tie to VEE or leave open.

12 NC No internal connection. Tie to VEE or leave open.

13 LS Low side FET gate drive return pin.

14 LO Low side FET gate drive output. Low in shutdown.

T

ON

IN

EE

(CON) from TON to VEE. This sets the nominal operating frequency when the LED is fully

illuminated.

Analog LED current adjust. Tie to VIN for fixed 60mV average current sense resistor voltage. Tie

to an external reference to adjust the average current sense resistor voltage (programmed output

current). Refer to the "V

Characteristics section and the Design Procedure section of the datasheet.

Enable pin. Connect this pin to logic level HI or VIN for normal operation. Connect this pin to

CGND for low current shutdown. EN is internally tied to VIN through a 100k resistor.

Logic power input: Connect to positive voltage between +3.0V and +5.8V w.r.t. CGND.

Negative voltage power input: Connect to voltage between –14V to –9V w.r.t. CGND.

Compensation pin. Connect a capacitor between this pin and VEE.

Soft Start pin. Tie a capacitor from SS to VEE to reduce input current ramp rate. Leave pin open

if function is not used. The SS pin is pulled to VEE when the device is not enabled.

vs. ADJ Voltage" graphs in the Typical Performance

SENSE

www.national.com 2

Pin Name Function

15

V

CC

Low side FET gate drive power bypass connection and boost diode anode connection. Tie a

2.2µF capacitor between VCC and VEE.

16 BST High side "synchronous" FET drive bootstrap rail.

17 HO High side "synchronous" FET gate drive output. Pulled to HS in shutdown.

18 HS Switching node and high side "synchronous" FET gate drive return.

19 DIMR LED dimming FET gate drive return. Tie to LED cathode.

20 DIMO LED dimming FET gate drive output. DIMO is a driver that switches between DIMR and BST2.

21 BST2 DIMO high side drive supply pin. Tie a 0.1µF between BST2 and CGND.

22 NC No internal connection. Tie to VEE or leave open.

23 CSN Current sense amplifier inverting input. Connect to current sense resistor negative terminal.

24 CSP Current sense amplifier non-inverting input. Connect to current sense resistor positive terminal.

EP

V

EE

Exposed Pad on the underside of the device. Connect this pad to a PC board plane connected

to VEE.

Block Diagram

LM3433

30031503

3 www.national.com

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

LM3433

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

VIN, EN, DIM, ADJ to CGND

COMP, SS to V

BST to HS -0.3V to +7V

VCC to V

CGND, DIMR, CSP, CSN,

TON to V

HS to VEE (Note 2)

LS to V

EE

HO output HS-0.3V to BST+0.3V

DIMO to DIMR -0.3V to +7V

LO output LS-0.3V to VCC +0.3V

BST2 to V

Maximum Junction

EE

EE

EE

EE

-0.3V to +7.5V

-0.3V to +16V

-0.3V to +16V

-0.3V to +0.3V

-0.3V to 22.0V

-0.3V to +7V

-0.3V to +7V

150°C

Power Dissipation(Note 3) Internally Limited

ESD Susceptibility

(Note 4)

Human Body Model 2kV

Machine Model 200V

Charge Device Model 1kV

Operating Conditions

Operating Junction

Temperature Range (Note 5) −40°C to +125°C

Storage Temperature −65°C to +150°C

Input Voltage VIN w.r.t. CGND 3.0V to 5.8V

Input Voltage VEE w.r.t. CGND -9V to -14V

ADJ Input Voltage Range to

CGND

CSP, CSN Common Mode

Range With Respect to CGND

Temperature

Electrical Characteristics

Specifications in standard type face are for TJ = 25°C and those with boldface type apply over the full Operating Temperature

Range ( TJ = −40°C to +125°C). Minimum and Maximum limits are guaranteed through test, design, or statistical correlation. Typical

values represent the most likely parametric norm at TJ = +25ºC, and are provided for reference purposes only. Unless otherwise

stated the following conditions apply: VEE = -12.0V and VIN = +3.3V with respect to CGND.

Symbol Parameter Conditions

SUPPLY CURRENT

IINV

EE

VEE Quiescent Current EN = CGND 3 19 µA

EN = VIN, Not Switching 1.0 mA

IINV

IN

VIN Quiescent Current EN = VIN, Not Switching 300

EN = CGND 35 71

OUTPUT CURRENT CONTROL

V

CS

G

ADJ

I

CSN

I

CSP

Gm CS to COMP

Current sense target voltage;

VCS = V

I

ADJ

(V

CNP-VCSN

– V

CSP

Gain = (V

)

CSN

-CGND)/

ADJ

Isense Input Current V

Isense Input Current V

V

= V

ADJ

IN

VIN = 3.3V, V

ADJ

w.r.t. CGND

= 1V w.r.t. CGND -50

ADJ

V

= V

ADJ

IN

= V

ADJ

IN

V

= 1V w.r.t. CGND 1

ADJ

Transconductance; Gm =

I

/ (V

– V

- V

COMP

CSP

CSN

ADJ

/

16.67)

ON TIME CONTROL

T

ONTH

On time threshold V

- VEE at terminate ON time

T

ON

event

GATE DRIVE AND INTERNAL REGULATOR

V

CCOUT

V

CCILIM

R

OLH

R

OHH

R

OLL

R

OHL

VCC output regulation w.r.t. VEEICC = 0mA to 20mA

VCC current limit VCC = V

EE

HO output low resistance I = 50mA source

HO output high resistance I = 50mA sink

LO output low resistance I = 50mA source

LO output high resistance I = 50mA sink

= 0.5V or 1.5V

Min(Note 5) Typ(Note 6) Max(Note 5)

57 60 63 mV

15 16.67 18 V/V

10

60

0.6 1.3 2.2 mS

230 287 334 mV

6.3 6.75 7.1 V

33 53 mA

2

3

2

3

0V to V

-6V to 0V

Units

µA

µA

µA

Ω

Ω

IN

www.national.com 4

LM3433

Symbol Parameter Conditions

R

OLP

R

OHP

DIMO output low resistance I = 5mA source

DIMO output high resistance I = 5mA sink

FUNCTIONAL CONTROL

V

INUVLO

V

CCUVLO

V

EN

R

EN

V

DIM

VIN undervoltage lockout With respect to CGND 1.4 V

VCC - VEE undervoltage lockout

thresholds

Enable threshold, with respect

to CGND

On Threshold 6.0 6.6 7.0

Off threshold 4.9 5.4 5.8

Device on w.r.t. CGND 1.6

Device off w.r.t. CGND 0.6

Enable pin pullup resistor 100

DIM logic input threshold DIM rising threshold w.r.t.

CGND

DIM falling threshold w.r.t.

CGND

R

I

I

R

DIM

ADJ

SS

SS

DIM pin pulldown resistor 100

ADJ pin current -1.0

SS pin source current

SS pin pulldown resistance EN = CGND

AC SPECIFICATIONS

T

DTD

LO and HO dead time LO falling to HO rising dead

time

HO falling to LO rising dead

time

T

PDIM

DIM to DIMO propagation

delay

DIM rising to DIMO rising delay 68 124

DIM falling to DIMO falling

delay

THERMAL SPECIFICATIONS

T

JLIM

Junction temperature thermal

limit

T

JLIM(hyst)

θ

JA

Thermal limit hysteresis 20

LLP-24 package thermal

JEDEC 4 layer board

resistance

Min(Note 5) Typ(Note 6) Max(Note 5)

20

30

1.6

0.6

10

1.0

26

28

58 160

175 °C

39 °C/W

Units

Ω

V

V

kΩ

V

kΩ

1.0 µA

µA

kΩ

ns

ns

°C

Note 1: Absolute maximum ratings are limits beyond which damage to the device may occur. Operating Ratings are conditions for which the device is intended

to be functional, but device parameter specifications may not be guaranteed. For guaranteed specifications and test conditions, see the Electrical Characteristics.

Note 2: The HS pin can go to -6V with respect to VEE for 30ns and +22V with respect to VEE for 50ns without sustaining damage.

Note 3: The maximum allowable power dissipation is a function of the maximum junction temperature, TJ(MAX), the junction-to-ambient thermal resistance,

θJA, and the ambient temperature, TA. The maximum allowable power dissipation at any ambient temperature is calculated using: PD (MAX) = (T

θJA. Exceeding the maximum allowable power dissipation will cause excessive die temperature, and the regulator will go into thermal shutdown. Internal thermal

shutdown circuitry protects the device from permanent damage. Thermal shutdown engages at TJ=175°C (typ.) and disengages at TJ=155°C (typ).

Note 4: Human Body Model, applicable std. JESD22-A114-C. Machine Model, applicable std. JESD22-A115-A. Field Induced Charge Device Model, applicable

std. JESD22-C101-C.

Note 5: All limits guaranteed at room temperature (standard typeface) and at temperature extremes (bold typeface). All room temperature limits are 100%

production tested. All limits at temperature extremes are guaranteed via correlation using standard Statistical Quality Control (SQC) methods. All limits are used

to calculate Average Outgoing Quality Level (AOQL).

Note 6: Typical numbers are at 25°C and represent the most likely norm.

5 www.national.com

J(MAX)

− TA)/

Typical Performance Characteristics

LM3433

Efficiency vs. LED Forward Voltage

(V

CGND-VEE

= 9V)

Efficiency vs. LED Forward Voltage

(V

CGND-VEE

= 14V)

30031523

Efficiency vs. LED Forward Voltage

(V

CGND-VEE

V

SENSE

= 12V)

vs. V

(VIN = 3.3V)

ADJ

30031522

30031521

V

vs. V

SENSE

(VIN = 5.0V)

www.national.com 6

ADJ

30031519

V

vs. Temperature

SENSE

(ADJ = VIN)

30031518

30031524

V

vs. Temperature

SENSE

(ADJ = 1.0V)

Average LED Current vs. DIM Duty Cycle

(30kHz dimming, I

= 6A nominal)

LED

LM3433

30031525

Startup Waveform

I

= 6A nominal, VIN = 3.3V, VEE = -12V, V

LED

Top trace: EN input, 2V/div, DC

Middle trace: VEE input current, 2A/div, DC

Bottom trace: I

, 2A/div, DC

LED

T = 100µs/div

LED

30031567

= 3V, SS = open

30kHz PWM Dimming Waveform Showing Inductor Ripple

Current

Shutdown Waveform

I

= 6A nominal, VIN = 3.3V, VEE = -12V, V

LED

Top trace: EN input, 2V/div, DC

Middle trace: VEE input current, 2A/div, DC

Bottom trace: I

T = 100µs/div

, 2A/div, DC

LED

= 3V, SS = open

LED

30031520

30031568

I

= 6A nominal, VIN = 3.3V, VEE = -12V

LED

Top trace: DIM input, 2V/div, DC

Bottom trace: I

, 2A/div, DC

LED

T = 10µs/div

30031566

7 www.national.com

Operation

LM3433

CURRENT REGULATOR OPERATION

The LM3433 is a controller for a Continuous Conduction Buck

Converter. Because of its buck topology and operation in the

continuous mode, the output current is very well controlled. It

only varies within a switching frequency cycle by the inductor

ripple current. This ripple current is normally set at 10% of the

DC current. Setting the ripple current lower than 10% is a

useful tradeoff of inductor size for less LED light output ripple.

Additional circuitry can be added to achieve any LED light

ripple desired.

The LED current is set by the voltage across a sense resistor.

This sense voltage is nominally 60mV but can be programmed higher or lower by an external control voltage.

The running frequency of the converter is programmed by an

external RC network in conjunction with the LED's forward

voltage. The frequency is nominally set around 200kHz to

500khz. Fast PWM control is available by shorting the output

of the current source by a MOSFET in parallel with the LED.

During the LED OFF time the running frequency is determined

by the RC network and the parasitic resistance of the output

circuit including the DIM FET R

The LM3433 system has been evaluated to be a very accurate, high compliance current source. This is manifest in its

high output impedance and accurate current control. The current is measured to vary less than 6mA out of 6A when

transitioning from LED OFF (output shorted) to LED ON (output ~6V).

PROTECTION

The LM3433 has dedicated protection circuitry running during

normal operation. The thermal shutdown circuitry turns off all

power devices when the die temperature reaches excessive

levels. The VCC undervoltage lockout (UVLO) comparator

protects the power devices during power supply startup and

shutdown to prevent operation at voltages less than the minimum operating input voltage. The VCC pin is short circuit

protected to VEE. The LM3433 also features a shutdown mode

which decreases the supply current to approximately 35µA.

The ADJ, EN, and DIM pins are capable of sustaining up to

+/-2mA. If the voltages on these pins will exceed either VIN or

CGND by necessity or by a potential fault, an external resistor

is recommended for protection. Size this resistor to limit pin

current to under 2mA. A 10k resistor should be sufficient. This

resistor may be used in any application for added protection

without any impact on function or performance.

DESIGN PROCEDURE

This section presents guidelines for selecting external components.

DSON

.

FIXED LED CURRENT

The ADJ pin sets V

internal reference for V

current based on the following equation:

. Tie ADJ to VIN to use a fixed 60mV

SENSE

SENSE

. Select R

to fix the LED

SENSE

ADJUSTABLE LED CURRENT

When tied to an external voltage the ADJ pin sets V

based on the following equation:

When the reference on ADJ is adjustable, V

can be adjusted within the linear range of the ADJ pin. This

SENSE

SENSE

and I

LED

range has the following limitations:

When V

anteed by design to be less than or equal to 0.3V/16.667.

When V

VIN - 1V, V

equal to V

V

SENSE

is less than this linear range the V

ADJ

is greater than this linear range and less than

ADJ

switches to 60mV.

is guaranteed by design to be less than or

SENSE

/16.667. If V

ADJ

is greater than VIN - 1V,

ADJ

SENSE

is guar-

INPUT CAPACITOR SELECTION

A low ESR ceramic capacitor is needed to bypass the MOSFETs. This capacitor is connected between the drain of the

synchronous FET (CGND) and the source of the main switch

(VEE). This capacitor prevents large voltage transients from

appearing at the VEE pin of the LM3433. Use a 22µF value

minimum with X5R or X7R dielectric. In addition to the FET

bypass capacitors, additional bypass capacitors should be

placed near the VEE and VIN pins and should be returned to

CGND.

The input capacitor must also be sized to handle the dimming

frequency input ripple when the DIM function is used. This

ripple may be as high as 85% of the nominal DC input current

(at 50% duty cycle). When dimming this input capacitor

should be selected to handle the input ripple current.

RECOMMENDED OPERATING FREQUENCY AND ON TIME "TIMEON" CALCULATION

Although the switching frequency can be set over a wide

range, the following equation describes the recommended

frequency selection given inexpensive magnetic materials

available today:

SETTING LED CURRENT CONTROL

LM3433 uses average current mode control to regulate the

current delivered to the LED (I

resistor (R

I

into a voltage that is sensed by the LM3433 at the CSP

LED

and CSN pins. CSP and CSN are the inputs to an error am-

) in series with the LED is used to convert

SENSE

plifier with a programmed input offset voltage (V

V

is used to regulate I

SENSE

tion:

www.national.com 8

). An external current sense

LED

based on the following equa-

LED

SENSE

).

In the above equation A=1.2 for powdered iron core inductors

and A=0.9 or less for ferrite core inductors. This difference

takes into account the fact that ferrite cores generally become

more lossy at higher frequencies. Given the switching frequency f calculated above, TIMEON can be calculated. If

V

is the forward voltage drop of the LED that is being driv-

LED

en, TIMEON can be calculated with the following equation:

LM3433

TIMING COMPONENTS (RON and CON)

Using the calculated value for TIMEON, the timing components RON and CON can be selected. CON should be large

enough to dominate the parasitic capacitance of the TON pin.

A good CON value for most applications is 1nF. Based on calculated TIMEON, CON, and the nominal VEE and V

RON can be calculated based on the following equation:

voltages,

LED

INDUCTOR SELECTION

The most critical inductor parameters are inductance, current

rating, and DC resistance. To calculate the inductance, use

the desired peak to peak LED ripple current (I

and CON. A reasonable value for I

inductor value is calculated using the following equation:

For all V

and is only dependent on the passive external compo-

and VEE voltages, I

LED

is 10% of I

RIPPLE

remains constant

RIPPLE

RIPPLE

), RON,

. The

LED

nents RON, CON, and L.

The I2R loss caused by the DC resistance of the inductor is

an important parameter affecting the efficiency. Lower DC resistance inductors are larger. A good tradeoff point between

the efficiency and the core size is letting the inductor I2R loss

equal 1% to 2% of the output power. The inductor should have

a current rating greater than the peak current for the application. The peak current is I

plus 1/2 I

LED

RIPPLE

.

POWER FET SELECTION

FETs should be chosen so that the I2R

1% of the total output power. Analysis shows best efficiency

with around 8mΩ of R

application. All of the switching loss is in the main switch FET.

and 15nC of gate charge for a 6A

DSON

loss is less than

DSON

An additional important parameter for the synchronous FET

is reverse recovery charge (QRR). High QRR adversely affects

the transient voltages seen by the IC. A low QRR FET should

be used.

DIM FET SELECTION

Choose a DIM FET with the lowest R

cieny and low input current draw during the DIM cycle. The

for maximum effi-

DSON

output voltage during DIM will determine the switching frequency. A lower output voltage results in a lower switching

frequency. If the lower frequency during DIM must be bound,

choose a FET with a higher R

quency higher during the DIM cycle.

to force the switching fre-

DSON

BOOTSTRAP CAPACITORS

The LM3433 uses two bootstrap capacitors and a bypass capacitor on VCC to generate the voltages needed to drive the

external FETs. A 2.2µF ceramic capacitor or larger is recommended between the VCC and LS pins. A 0.47µF is recommended between the HS and BST pins. A 0.1µF is

recommended between BST2 and CGND.

SOFT-START CAPACITOR

The LM3433 integrates circuitry that, when used in conjunction with the SS pin, will slow the current ramp on start-up.

The SS pin is used to tailor the soft-start for a specific application. A capacitor value of 0.1µF on the SS pin will yield a

12mS soft start time. For most applications soft start is not

needed.

ENABLE OPERATION

The EN pin of the LM3433 is designed so that it may be controlled using a 1.6V or higher logic signal. If the enable function is not used, the EN pin may be tied to VIN or left open.

This pin is pulled to VIN internally through a 100k pull up resistor.

PWM DIM OPERATION

The DIM pin of the LM3433 is designed so that it may be controlled using a 1.6V or higher logic signal. The PWM frequency easily accomodates more than 40kHz dimming and can be

much faster if needed. If the PWM DIM pin is not used, tie it

to CGND or leave it open. The DIM pin is tied to CGND internally through a 100k pull down resistor.

LAYOUT CONSIDERATIONS

The LM3433 is a high performance current driver so attention

to layout details is critical to obtain maximum performance.

The most important PCB board design consideration is minimizing the loop comprised by the main FET, synchronous

FET, and their associated decoupling capacitor(s). Place the

VCC bypass capacitor as near as possible to the LM3433.

Place the PWM dimming/shunt FET as close to the LED as

possible. A ground plane should be used for power distribution to the power FETs. Use a star ground between the

LM3433 circuitry, the synchronous FET, and the decoupling

capacitor(s). The EP contact on the underside of the package

must be connected to VEE. The two lines connecting the sense

resistor to CSN and CSP must be routed as a differential pair

directly from the resistor. A Kelvin connection is recommended. It is good practice to route the DIMO/DIMR, HS/HO, and

LO/LS lines as differential pairs. The most important PCB

board design consideration is minimizing the loop comprised

by the main FET, synchronous FET, and their associated decoupling capacitor(s). Optimally this loop should be orthogonal to the ground plane.

9 www.national.com

Application Information

LM3433

30031516

FIGURE 1. 2A to 6A Output Application Circuit

FIGURE 2. 2A to 14A Output Application Circuit

www.national.com 10

30031517

Some Recommended Inductors (Others May Be Used)

Manufacturer Inductor Contact Information

Coilcraft GA3252-AL and SER1360 series www.coilcraft.com

800-322-2645

Coiltronics HCLP2 series www.coiltronics.com

Pulse PB2020 series www.pulseeng.com

Some Recommended Input/Bypass Capacitors (Others May Be Used)

Manufacturer Capacitor Contact Information

Vishay Sprague 293D, 592D, and 595D series tantalum www.vishay.com

407-324-4140

Taiyo Yuden High capacitance MLCC ceramic www.t-yuden.com

408-573-4150

Cornell Dubilier

MuRata High capacitance MLCC ceramic www.murata.com

Manufacturer Inductor Contact Information

Siliconix Si7386DP (Main FET, DIM FET)

ON Semiconductor NTMFS4841NHT1G (Main FET, Synchronous FET, DIM

ESRD seriec Polymer Aluminum Electrolytic

SPV and AFK series V-chip series

Some Recommended MOSFETs (Others May Be Used)

Si7668ADP (Synchronous FET)

FET)

www.cde.com

www.vishay.com/company/brands/

siliconix/

www.onsemi.com

LM3433

11 www.national.com

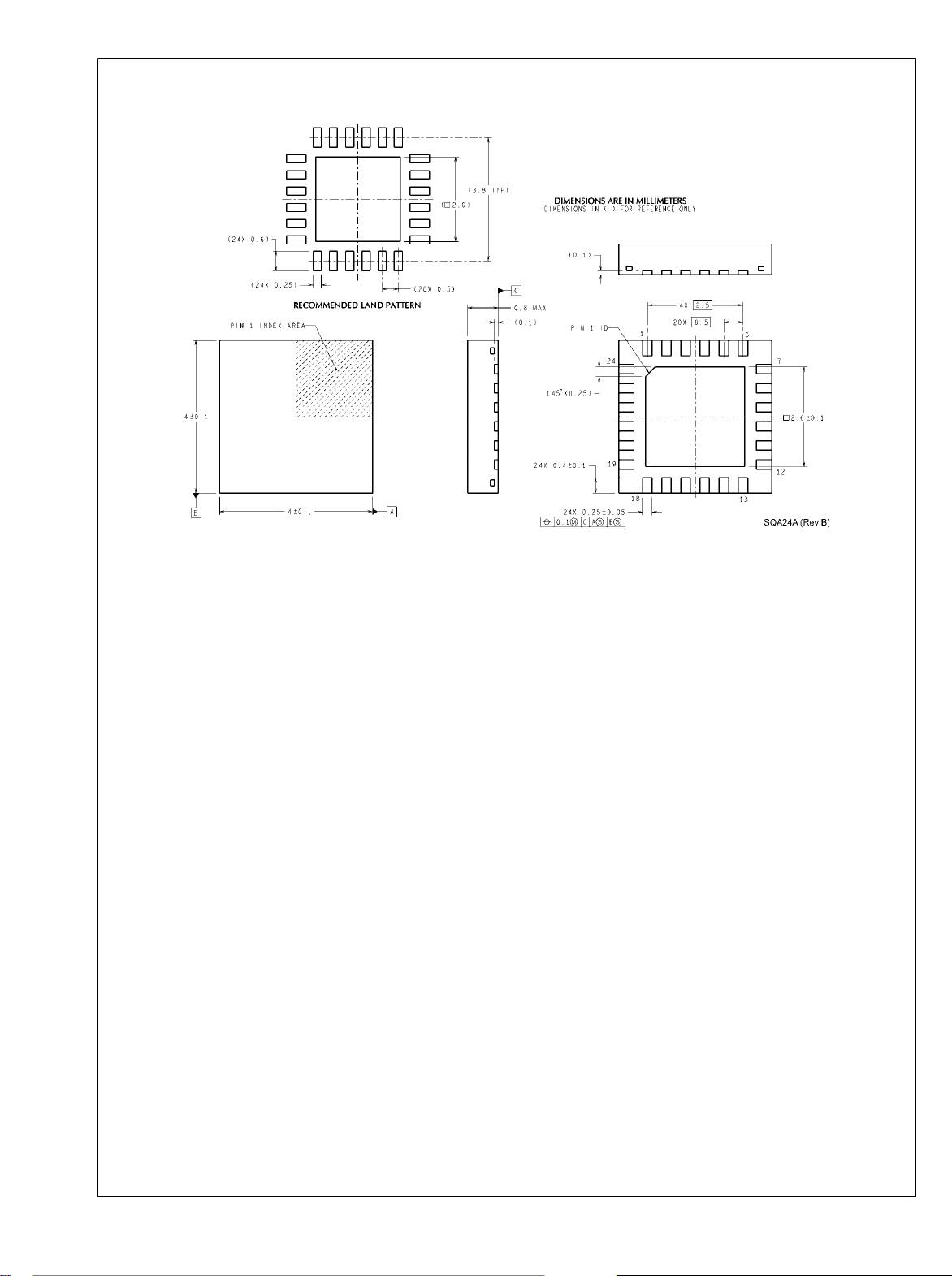

Physical Dimensions inches (millimeters) unless otherwise noted

LM3433

For Ordering, Refer to Ordering Information Table

LLP-24 Pin Package (SQA)

NS Package Number SQA24A

www.national.com 12

Notes

LM3433

13 www.national.com

Notes

For more National Semiconductor product information and proven design tools, visit the following Web sites at:

Products Design Support

Amplifiers www.national.com/amplifiers WEBENCH www.national.com/webench

Audio www.national.com/audio Analog University www.national.com/AU

Clock Conditioners www.national.com/timing App Notes www.national.com/appnotes

Data Converters www.national.com/adc Distributors www.national.com/contacts

Displays www.national.com/displays Green Compliance www.national.com/quality/green

Ethernet www.national.com/ethernet Packaging www.national.com/packaging

Interface www.national.com/interface Quality and Reliability www.national.com/quality

LVDS www.national.com/lvds Reference Designs www.national.com/refdesigns

Power Management www.national.com/power Feedback www.national.com/feedback

Switching Regulators www.national.com/switchers

LDOs www.national.com/ldo

LED Lighting www.national.com/led

PowerWise www.national.com/powerwise

Serial Digital Interface (SDI) www.national.com/sdi

Temperature Sensors www.national.com/tempsensors

Wireless (PLL/VCO) www.national.com/wireless

THE CONTENTS OF THIS DOCUMENT ARE PROVIDED IN CONNECTION WITH NATIONAL SEMICONDUCTOR CORPORATION

(“NATIONAL”) PRODUCTS. NATIONAL MAKES NO REPRESENTATIONS OR WARRANTIES WITH RESPECT TO THE ACCURACY

OR COMPLETENESS OF THE CONTENTS OF THIS PUBLICATION AND RESERVES THE RIGHT TO MAKE CHANGES TO

SPECIFICATIONS AND PRODUCT DESCRIPTIONS AT ANY TIME WITHOUT NOTICE. NO LICENSE, WHETHER EXPRESS,

IMPLIED, ARISING BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS

DOCUMENT.

TESTING AND OTHER QUALITY CONTROLS ARE USED TO THE EXTENT NATIONAL DEEMS NECESSARY TO SUPPORT

NATIONAL’S PRODUCT WARRANTY. EXCEPT WHERE MANDATED BY GOVERNMENT REQUIREMENTS, TESTING OF ALL

PARAMETERS OF EACH PRODUCT IS NOT NECESSARILY PERFORMED. NATIONAL ASSUMES NO LIABILITY FOR

APPLICATIONS ASSISTANCE OR BUYER PRODUCT DESIGN. BUYERS ARE RESPONSIBLE FOR THEIR PRODUCTS AND

APPLICATIONS USING NATIONAL COMPONENTS. PRIOR TO USING OR DISTRIBUTING ANY PRODUCTS THAT INCLUDE

NATIONAL COMPONENTS, BUYERS SHOULD PROVIDE ADEQUATE DESIGN, TESTING AND OPERATING SAFEGUARDS.

EXCEPT AS PROVIDED IN NATIONAL’S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, NATIONAL ASSUMES NO

LIABILITY WHATSOEVER, AND NATIONAL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY RELATING TO THE SALE

AND/OR USE OF NATIONAL PRODUCTS INCLUDING LIABILITY OR WARRANTIES RELATING TO FITNESS FOR A PARTICULAR

PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY

RIGHT.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR

SYSTEMS WITHOUT THE EXPRESS PRIOR WRITTEN APPROVAL OF THE CHIEF EXECUTIVE OFFICER AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

Life support devices or systems are devices which (a) are intended for surgical implant into the body, or (b) support or sustain life and

whose failure to perform when properly used in accordance with instructions for use provided in the labeling can be reasonably expected

to result in a significant injury to the user. A critical component is any component in a life support device or system whose failure to perform

can be reasonably expected to cause the failure of the life support device or system or to affect its safety or effectiveness.

National Semiconductor and the National Semiconductor logo are registered trademarks of National Semiconductor Corporation. All other

brand or product names may be trademarks or registered trademarks of their respective holders.

Copyright© 2008 National Semiconductor Corporation

For the most current product information visit us at www.national.com

National Semiconductor

Americas Technical

Support Center

LM3433 Common Anode Capable High Brightness LED Driver with High Frequency Dimming

www.national.com

Email:

new.feedback@nsc.com

Tel: 1-800-272-9959

National Semiconductor Europe

Technical Support Center

Email: europe.support@nsc.com

German Tel: +49 (0) 180 5010 771

English Tel: +44 (0) 870 850 4288

National Semiconductor Asia

Pacific Technical Support Center

Email: ap.support@nsc.com

National Semiconductor Japan

Technical Support Center

Email: jpn.feedback@nsc.com

Loading...

Loading...