Page 1

April 2, 2008

LM2854

4A 500 kHz / 1 MHz PowerWise® Synchronous SIMPLE

SWITCHER® Buck Regulator

LM2854 4A 500 kHz / 1 MHz PowerWise® Synchronous SIMPLE SWITCHER® Buck Regulator

General Description

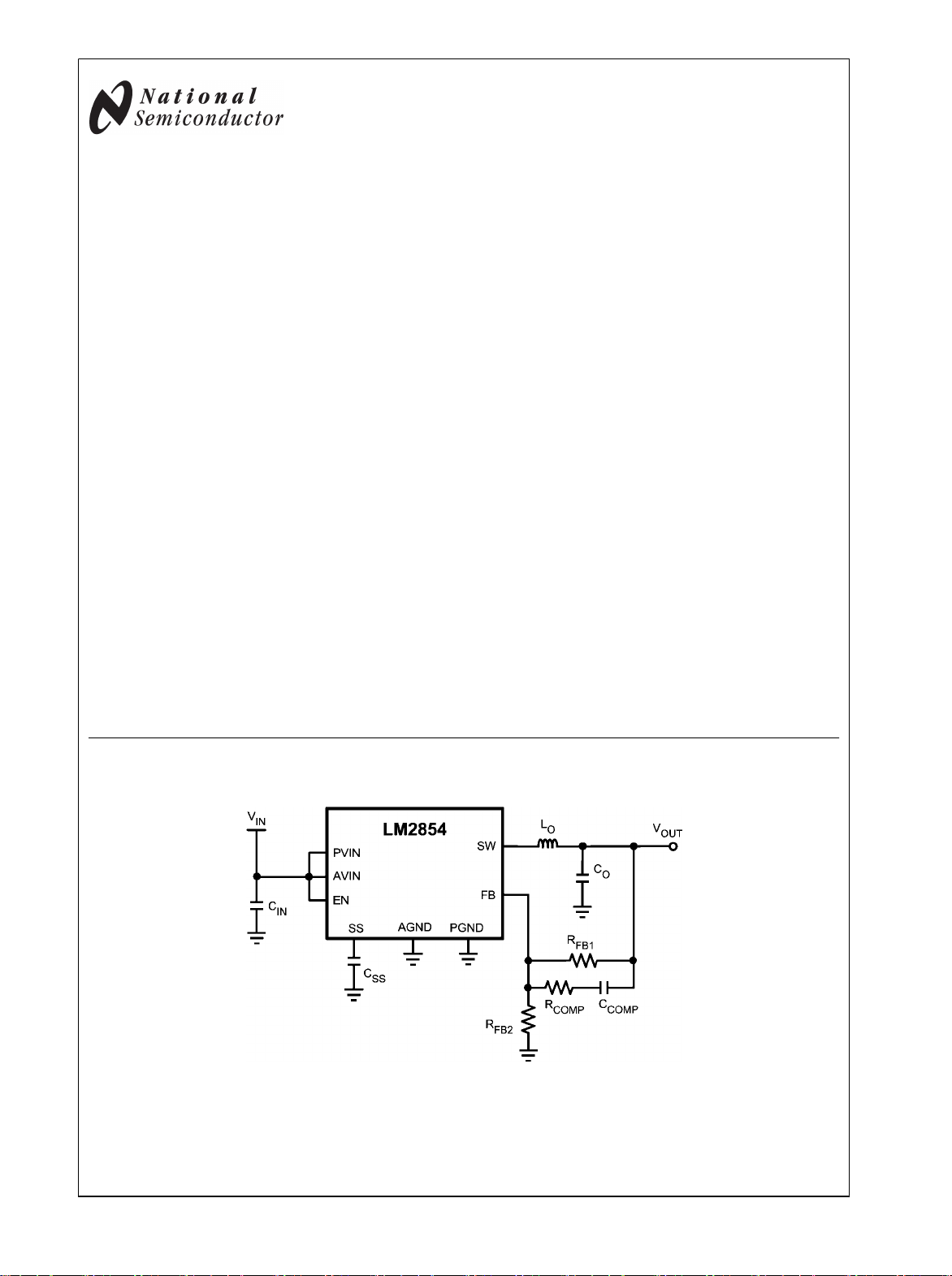

The LM2854 PowerWise® SIMPLE SWITCHER® buck regulator is a 500 kHz or 1 MHz step-down switching voltage

regulator capable of driving up to a 4A load with exceptional

power conversion efficiency, line and load regulation, and

output accuracy. The LM2854 can accept an input voltage rail

between 2.95V and 5.5V and deliver an adjustable and highly

accurate output voltage as low as 0.8V. Externally established soft-start with a small capacitor facilitates controlled

start-up, and the LM2854 is capable of starting gracefully into

a pre-biased output voltage. Partial internal compensation reduces the number of external passive components and PC

board space typically necessary in a voltage mode buck converter application, yet preserving flexibility to deal with ceramic and/or electrolytic based load capacitors. Lossless

cycle-by-cycle peak current limit is used to protect the load

from an overcurrent or short-circuit fault, and an enable comparator simplifies sequencing applications. The LM2854 is

available in an exposed pad TSSOP-16 package that enhances the thermal performance of the regulator.

Features

Input voltage range of 2.95V to 5.5V

■

Maximum load current of 4A

■

Wide bandwidth voltage mode control loop, partial internal

■

compensation

Fixed switching frequency of 500 kHz or 1 MHz

■

35 mΩ integrated MOSFET switches

■

Adjustable output voltage down to 0.8V

■

Optimized reference voltage initial accuracy and

■

temperature drift

External soft-start control with tracking capability

■

Enable pin with hysteresis

■

Low standby current of 230 µA

■

Pre-biased load startup capability

■

Integrated UVLO, OCP and thermal shutdown

■

100% duty cycle capability

■

eTSSOP-16 exposed pad package

■

Applications

Low Voltage POL Regulation from 5V or 3.3V Rail

■

Local Solution for FPGA/DSP/ASIC/µP Core or I/O Power

■

Broadband Networking and Communications

■

Infrastructure

Portable Computing

■

Typical Application Circuit

30052801

SIMPLE SWITCHER® is a Registered Trademark of National Semiconductor Corporation.

© 2008 National Semiconductor Corporation 300528 www.national.com

Page 2

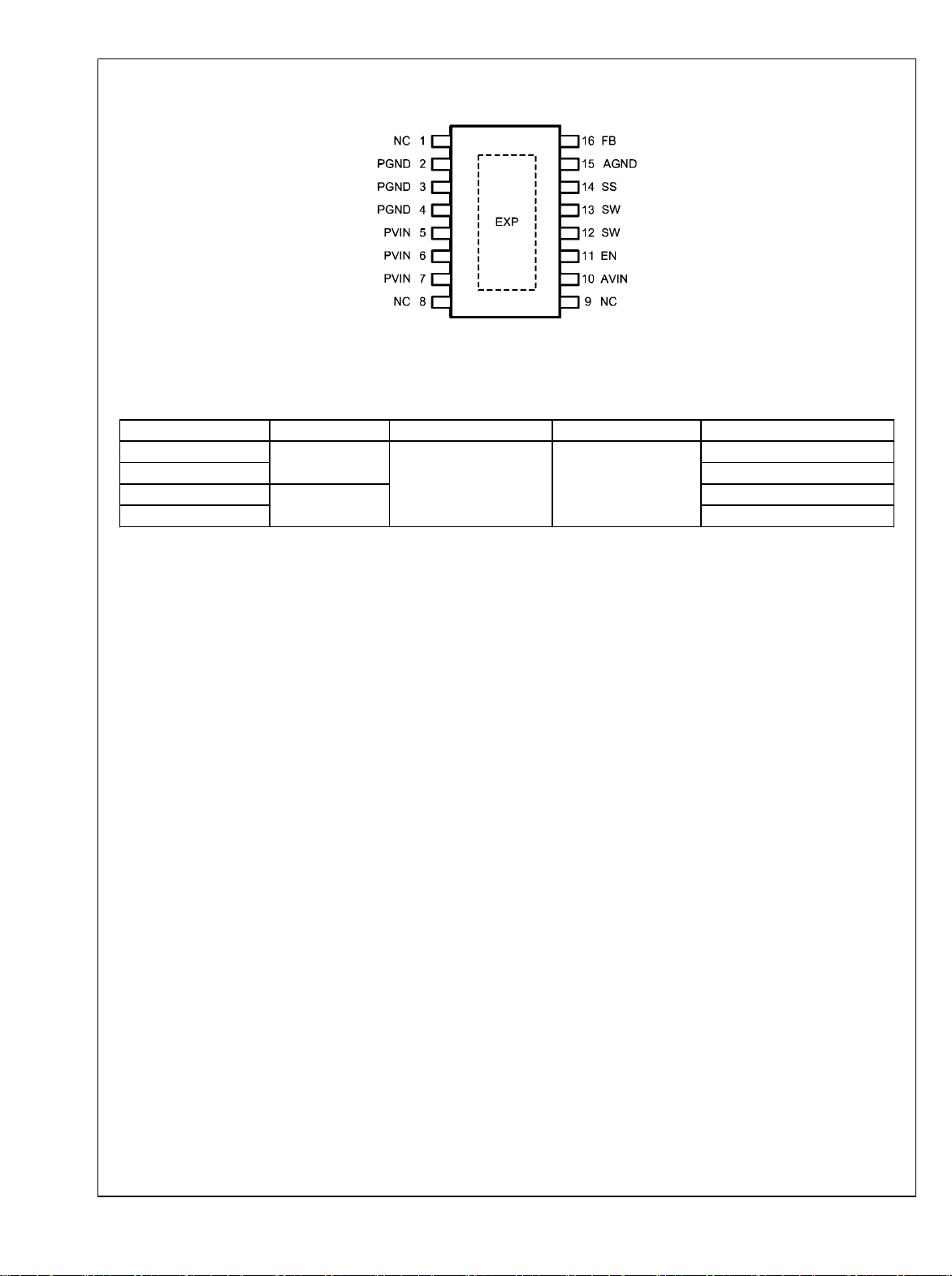

Connection Diagram

LM2854

Top View

16-Lead eTSSOP

30052802

Ordering Information

Order Number Frequency Package Type Package Drawing Supplied As

LM2854MH-500 500 kHz

LM2854MHX-500 2500 Units, Tape and Reel

LM2854MH-1000 1 MHz 92 Units, Rail

LM2854MHX-1000 2500 Units, Tape and Reel

TSSOP-16 exposed pad MXA16A

92 Units, Rail

www.national.com 2

Page 3

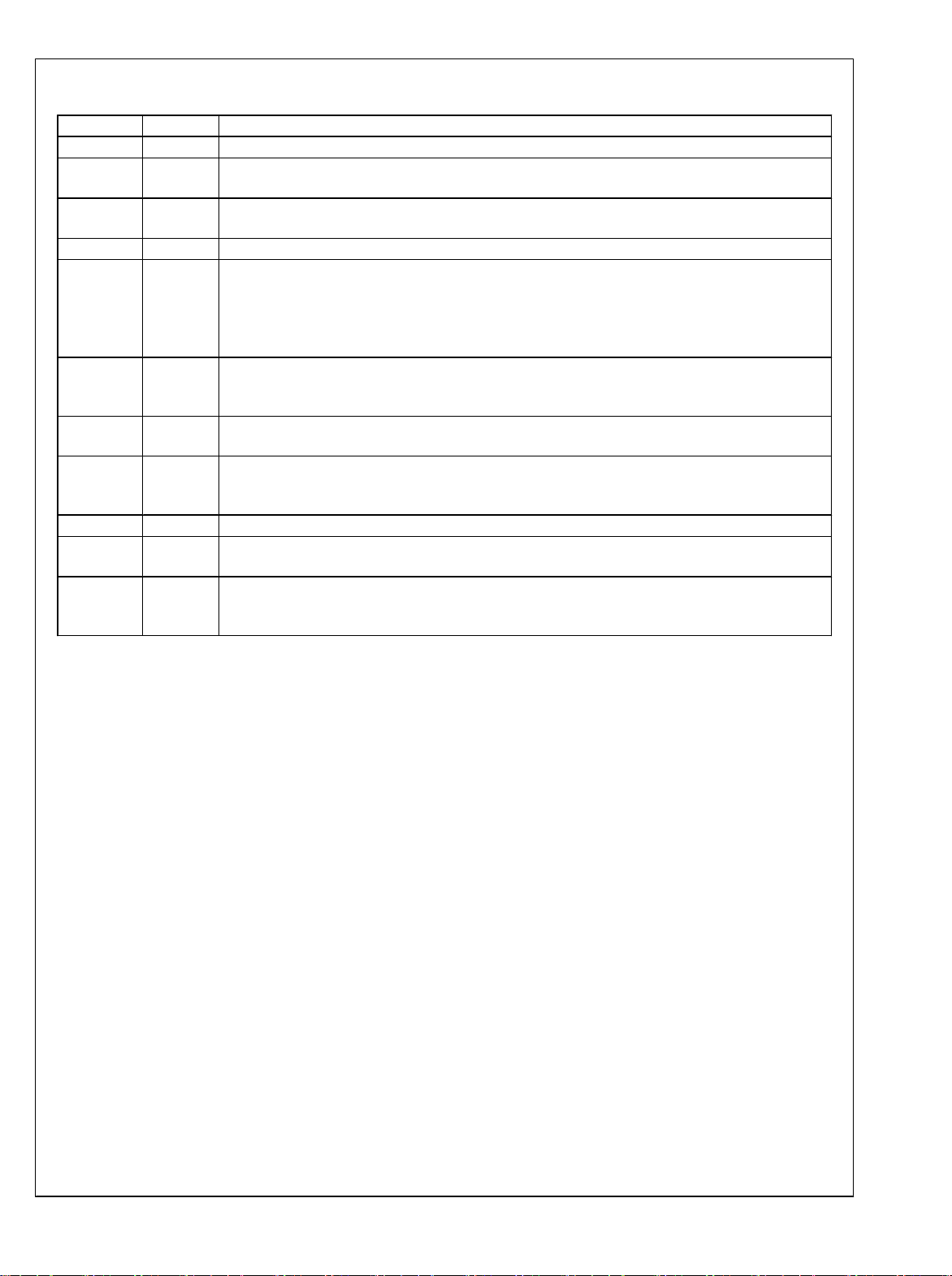

Pin Descriptions

Pin Number Name Description

1 NC Reserved for factory use, this pin should be connected to GND to ensure proper operation.

2,3,4 PGND Power ground pins for the internal power switches. These pins should be connected together locally

at the device and tied to the PC board ground plane.

5,6,7 PVIN Input voltage to the power switches inside the device. These pins should be connected together at the

device. A low ESR input capacitance should be located as close as possible to these pins.

8,9 NC Reserved for factory use, these pins should be connected to GND to ensure proper operation.

10 AVIN Analog input voltage supply that generates the internal bias. The UVLO circuit derives its input from

this pin also. Thus, if the voltage on AVIN falls below the UVLO threshold, both internal FETs are turned

off. It is recommended to connect PVIN to AVIN through a low pass RC filter to minimize the influence

of input rail ripple and noise on the analog control circuitry. The series resistor should be 1Ω and the

bypass capacitor should be a X7R ceramic type 0.1 µF to 1.0 µF.

11 EN Active high enable input for the device. Typically, turn-on threshold is 1.23V with 0.15V hysteresis. An

external resistor divider from PVIN can be used to effectively increase the UVLO turn-on threshold. If

not used, the EN pin should be connected to PVIN.

12,13 SW Switch node pins. This is the PWM output of the internal MOSFET power switches. These pins should

be tied together locally and connected to the filter inductor.

14 SS Soft-start control pin. An internal 2 µA current source charges an external capacitor connected between

this pin and AGND to set the output voltage ramp rate during startup. This pin can also be used to

configure the tracking feature.

15 AGND Quiet analog ground for the internal bias circuitry.

16 FB Feedback pin is connected to the inverting input of the voltage loop error amplifier. A 0.8V bandgap

reference is connected to the non-inverting input of the error amplifier.

EXP Exposed

Pad

Exposed metal pad on the underside of the package with a weak electrical connection to PGND. It is

recommended to connect this pad to the PC board ground plane in order to improve thermal

dissipation.

LM2854

3 www.national.com

Page 4

Absolute Maximum Ratings (Notes 1, 6)

If Military/Aerospace specified devices are required,

LM2854

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

PVIN, AVIN, SW, EN, FB, SS to GND -0.3V to 6.0V

ESD Susceptibility (Note 2) ±2 kV

Power Dissipation Internally Limited

Junction Temperature 150°C

Storage Temperature Range −65°C to +150°C

Lead Temperature

Soldering (10 sec) 260°C

Vapor Phase (60 sec) 215°C

Infrared 220°C

Operating Ratings (Note 6)

PVIN to GND 2.95V to 5.5V

AVIN to GND 2.95V to 5.5V

Junction Temperature −40°C to +125°C

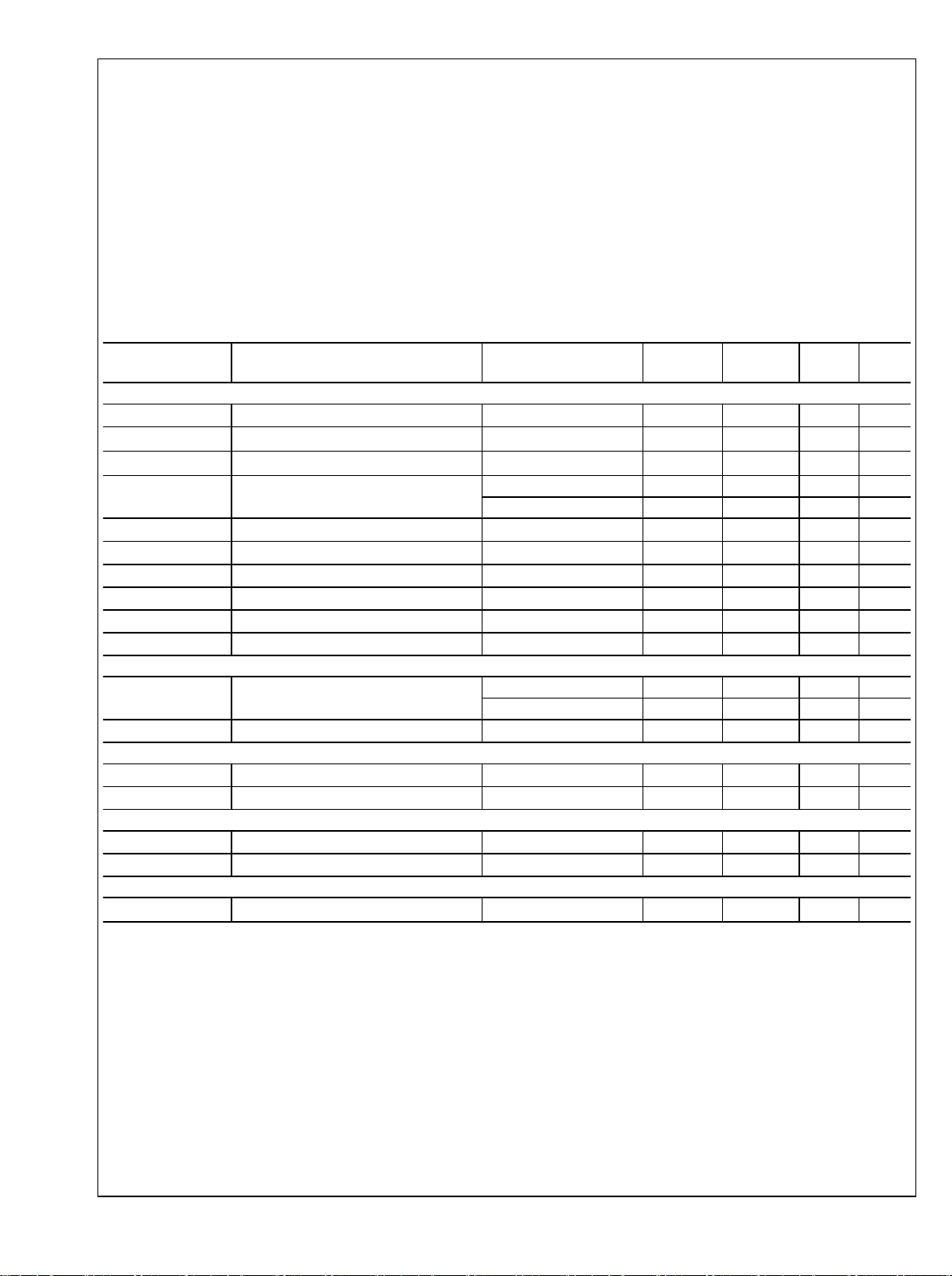

Electrical Characteristics Specifications with standard typeface are for T

= 25°C only; limits in bold face type

J

apply over the Operating Junction Temperature Range TJ range of -40°C to 125°C. Minimum and maximum limits are guaranteed

through test, design, or statistical correlation. Typical values represent the most likely parametric norm at TJ = 25°C, and are

provided for reference purposes only. AVIN = PVIN = EN = 5.0V, unless otherwise indicated in the Conditions column.

Symbol Parameter Conditions Min

(Note 3)

Typ

(Note 4)

Max

(Note 3)

SYSTEM PARAMETERS

ΔV

ΔV

V

REF

REF

V

REF

/ΔAVIN

/ΔI

ON

Reference Voltage (Note 5) Measured at the FB pin 0.790 0.8 0.808 V

Line Regulation (Note 5)

Load Regulation Normal operation 0.25 mV/A

O

ΔAVIN = 2.95V to 5.50V

0.04 0.6 %

UVLO Threshold (AVIN) Rising 2.6 2.95 V

Falling hysteresis 25 170 375 mV

R

DS(ON)-P

R

DS(ON)-N

I

SS

I

CL

I

I

SD

Q

PFET On Resistance ISW = 4A 35 65

NFET On Resistance ISW = 4A 34 65

Soft-Start Current 2 µA

Peak Current Limit Threshold 4.5 6.0 6.7 A

Operating Current Non-switching 1.7 3 mA

Shut Down Quiescent Current EN = 0V 230 500 µA

PWM SECTION

f

SW

Switching Frequency 1 MHz option 800 1050 1160 kHz

500 kHz option 400 525 580 kHz

D

range

PWM Duty Cycle Range 0 100 %

ENABLE CONTROL

V

V

EN(HYS)

IH

EN Pin Rising Threshold 0.8 1.23 1.65 V

EN Pin Hysteresis 150 mV

THERMAL CONTROL

T

T

SD-HYS

SD

TJ for Thermal Shutdown 165 °C

Hysteresis for Thermal Shutdown 10 °C

THERMAL RESISTANCE

θ

JA

Junction to Ambient MXA16A 35 °C/W

Units

mΩ

mΩ

Note 1: Absolute Maximum Ratings are limits beyond which damage to the device may occur. Operating Ratings are conditions under which operation of the

device is intended to be functional. For guaranteed specifications and test conditions, see the Electrical Characteristics.

Note 2: The human body model is a 100 pF capacitor discharged through a 1.5 kΩ resistor into each pin. Test method is per JESD22-AI14.

Note 3: Min and Max limits are 100% production tested at 25°C. Limits over the operating temperature range are guaranteed through correlation using Statistical

Quality Control (SQC) methods. Limits are used to calculate National’s Average Outgoing Quality Level (AOQL).

Note 4: Typical numbers are at 25°C and represent the most likely parametric norm.

Note 5: V

Note 6: PGND and AGND are electrically connected together on the PC board and the resultant net is termed GND.

www.national.com 4

measured in a non-switching, closed-loop configuration.

REF

Page 5

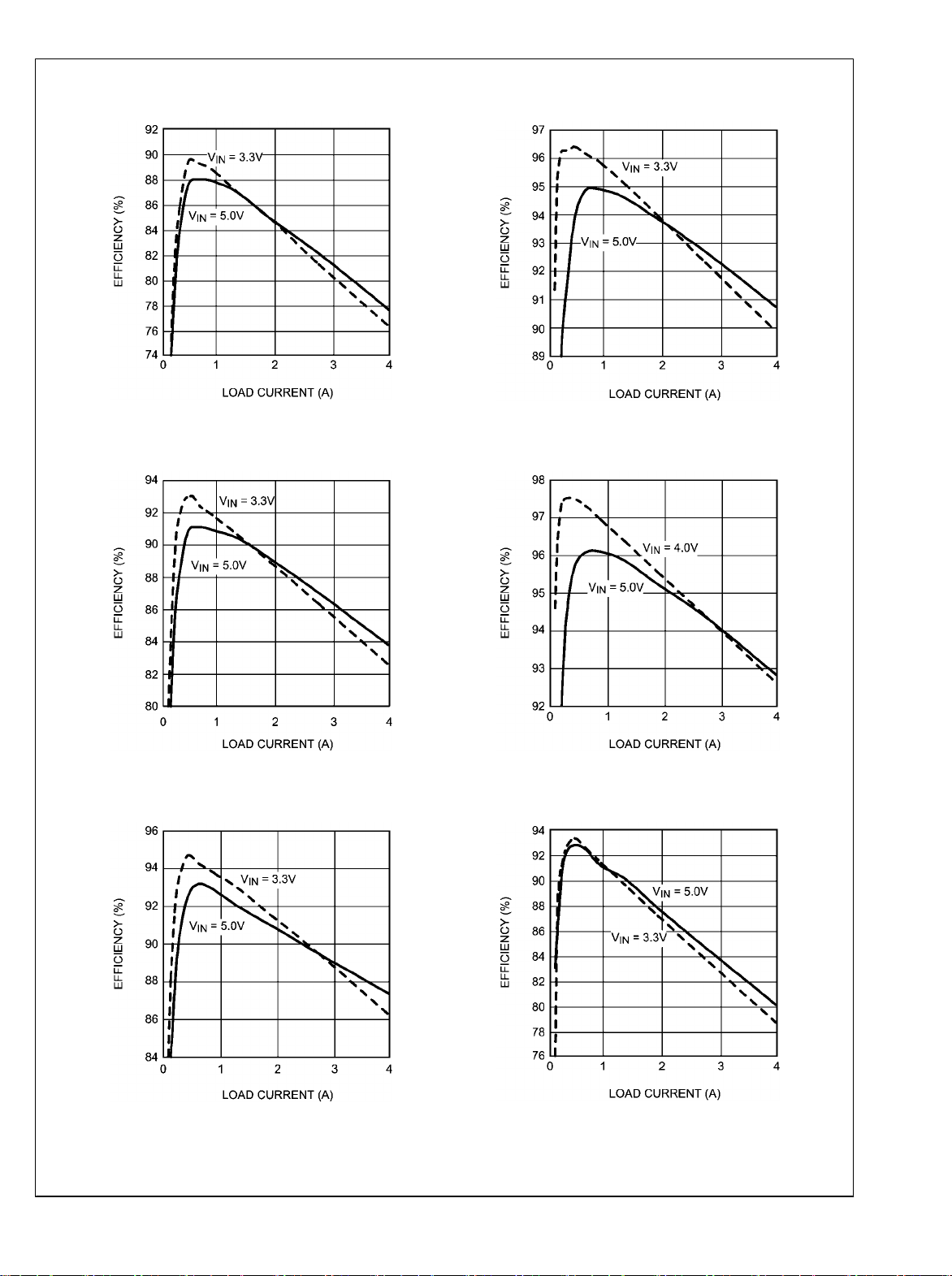

Typical Performance Characteristics Unless otherwise specified, the following conditions apply: VIN =

PVIN = AVIN = EN = 5.0V, CIN is 47 µF 10V X5R ceramic capacitor, LO is from TDK SPM6530T family; T

curves, bode plots and waveforms, and TJ = 25°C for all others.

= 25°C for efficiency

AMBIENT

LM2854

Feedback Voltage vs. Temperature

Soft Start Current vs Temperature

30052803

UVLO Threshold vs. Temperature

30052804

Enable Threshold vs. Temperature

30052805

Switching Frequency vs. Temperature

30052807

30052806

PMOS R

5 www.national.com

vs. Temperature

DS(ON)

30052808

Page 6

LM2854

NMOS R

vs. Temperature

DS(ON)

IQ (operating) vs. VIN and Temperature

30052809

Peak Current Limit vs. Temperature

30052811

IQ (disabled) vs. VIN and Temperature, EN = 0V

Feedback Voltage vs. V

Switching Frequency vs. V

30052810

IN

30052812

IN

30052813

www.national.com 6

30052814

Page 7

LM2854

LM2854 1 MHz Efficiency vs. I

V

= 0.8V, LO = 0.47 µH, 3.3 mΩ DCR

OUT

LM2854 1 MHz Efficiency vs. I

V

= 1.2V, LO = 0.68 µH, 4.9 mΩ DCR

OUT

OUT

OUT

30052815

LM2854 1 MHz Efficiency vs. I

V

= 2.5V, LO = 1.0 µH, 7.1 mΩ DCR

OUT

LM2854 1 MHz Efficiency vs. I

V

= 3.3V, LO = 1.0 µH, 7.1 mΩ DCR

OUT

OUT

30052816

OUT

LM2854 1 MHz Efficiency vs. I

V

= 1.8V, LO = 1.0 µH, 7.1 mΩ DCR

OUT

OUT

30052817

30052819

30052818

LM2854 500 kHz Efficiency vs. I

V

= 0.8V, LO = 1.0 µH, 7.1 mΩ DCR

OUT

OUT

30052820

7 www.national.com

Page 8

LM2854

LM2854 500 kHz Efficiency vs. I

V

= 2.5V, LO = 2.2 µH, 16 mΩ DCR

OUT

OUT

LM2854 500 kHz Efficiency vs. I

V

= 1.2V, LO = 1.5 µH, 9.7 mΩ DCR

OUT

OUT

LM2854 500 kHz Efficiency vs. I

V

= 3.3V, LO = 1.5 µH, 9.7 mΩ DCR

OUT

LM2854 1 MHz Bode Plot

R

= 150 kΩ, R

FB1

L

OUT

VIN = 3.3V, V

= 0.82 µH, C

= 1.8V, I

OUT

= 1 kΩ, C

COMP

= 100 µF ceramic

OUT

OUT

COMP

30052821

OUT

30052823

= 4A

= 100 pF,

LM2854 500 kHz Efficiency vs. I

V

= 1.8V, LO = 1.5 µH, 9.7 mΩ DCR

OUT

LM2854 500 kHz Bode Plot

R

= 250 kΩ, R

FB1

L

OUT

VIN = 3.3V, V

= 1.5 µH, C

= 1.8V, I

OUT

= 1 kΩ, C

COMP

= 100 µF ceramic

OUT

OUT

COMP

30052822

OUT

30052824

= 4A

= 47 pF,

30052825

www.national.com 8

30052826

Page 9

LM2854

R

= 150 kΩ, R

FB1

R

= 150 kΩ, R

FB1

L

OUT

LM2854 1 MHz Bode Plot

VIN = 5.0V, V

L

= 0.82 µH, C

OUT

OUT

COMP

= 1.8V, I

= 1 kΩ, C

OUT

LM2854 1 MHz Bode Plot

VIN = 5.0V, V

= 0.82 µH, C

= 3.3V, I

OUT

= 1 kΩ, C

COMP

= 100 µF ceramic

OUT

= 4A

OUT

COMP

= 100 µF

= 4A

OUT

COMP

= 100 pF,

30052827

= 68 pF,

R

= 250 kΩ, R

FB1

L

OUT

R

= 250 kΩ, R

FB1

L

OUT

LM2854 500 kHz Bode Plot

VIN = 5.0V, V

= 1.5 µH, C

= 1.8V, I

OUT

= 1 kΩ, C

COMP

= 100 µF ceramic

OUT

LM2854 500 kHz Bode Plot

VIN = 5.0V, V

= 1.5 µH, C

= 3.3V, I

OUT

= 1 kΩ, C

COMP

= 100 µF ceramic

OUT

OUT

COMP

OUT

COMP

= 4A

= 47 pF,

30052828

= 4A

= 33 pF,

LM2854 500 kHz Power On Characteristic

VIN = 5.0V, V

= 1.8V, I

OUT

= 4A, CSS = 220 pF

OUT

30052829

30052831

LM2854 500 kHz Power On via Enable

VIN = 5.0V, V

= 1.8V, I

OUT

= 4A, CSS = 220 pF

OUT

30052830

30052832

9 www.national.com

Page 10

LM2854

LM2854 500 kHz Power Off Characteristic

VIN = 5.0V, V

= 1.8V, I

OUT

= 4A, CSS = 220 pF

OUT

30052833

LM2854 1 MHz Load Transient Response

VIN = 5.0V, V

OUT

= 3.3V, I

= 0.5A to 4A to 0.5A step

OUT

di/dt ≊ 4A/µs, CO = 100 µF ceramic

30052834

LM2854 500 kHz Switch Node Voltage

(oscilloscope set at infinite persistence)

VIN = 5.0V, V

OUT

= 2.5V, I

OUT

= 4A

30052835

LM2854 500 kHz Pre-Biased Startup Waveform

(oscilloscope set at infinite persistence)

V

OUT

= 2.5V, I

OUT

= 0A, V

PRE-BIAS

= 1.25V

LM2854 500 kHz Startup Waveform

V

= 2.5V, I

OUT

OUT

= 0A

30052856

30052855

www.national.com 10

Page 11

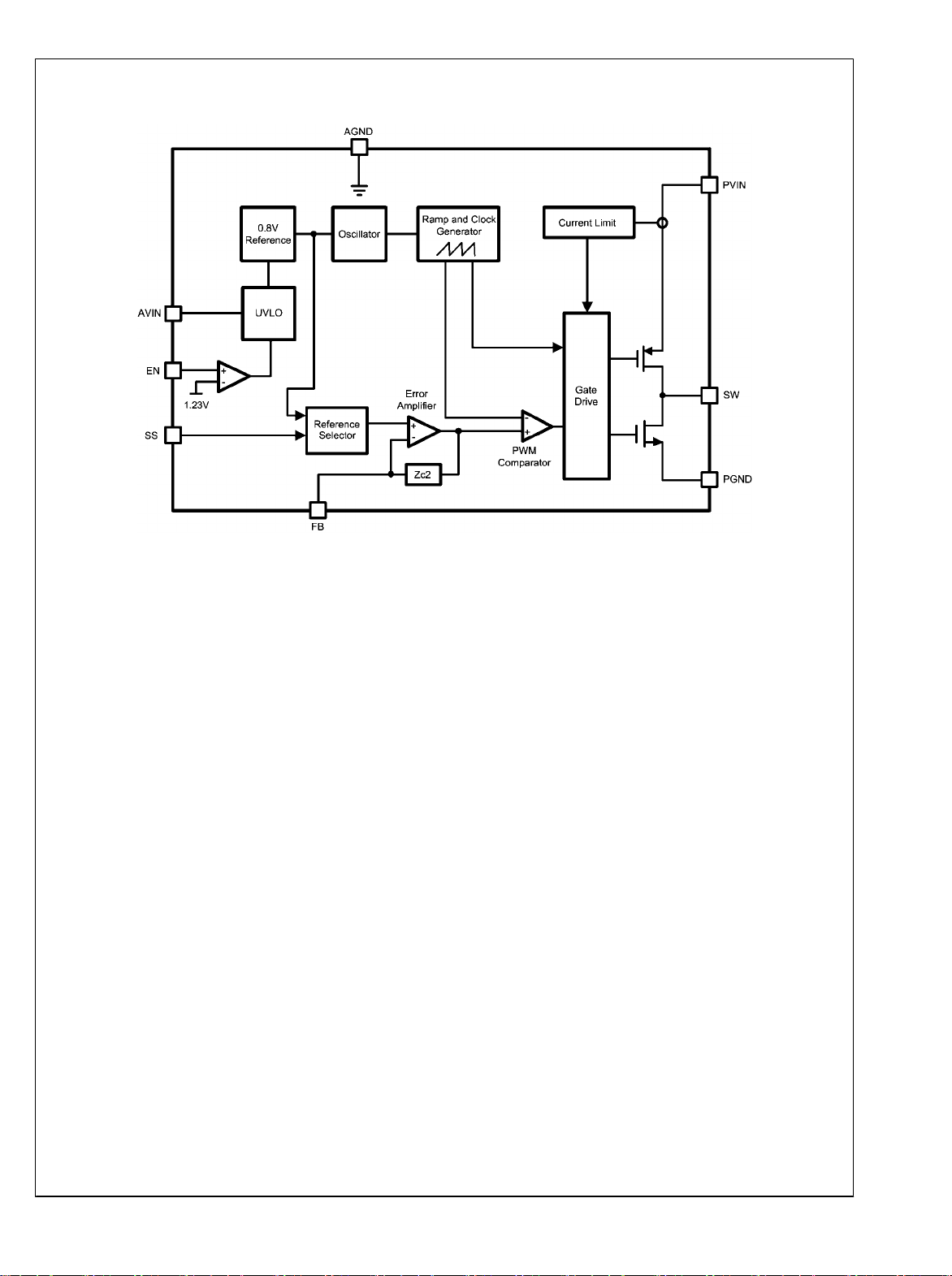

Block Diagram

LM2854

Applications Information

GENERAL

The LM2854 PowerWise® synchronous DC-DC buck regulator belongs to the National Semiconductor SIMPLE

SWITCHER® family of switching regulators. Integration of the

power MOSFETs and associated drivers, compensation component network and the PWM controller reduces the number

of external components necessary for a complete power supply design, without sacrificing performance.

Operation Description

SWITCHING FREQUENCY

The LM2854 is available in two switching frequency options,

500 kHz and 1 MHz. Generally, a higher switching frequency

allows for faster transient response and a reduction in the

footprint area and volume of the external power stage components, while a lower switching frequency affords better

efficiency. These factors should be considered when selecting the appropriate switching frequency for a given application.

ENABLE

The LM2854 features a enable (EN) pin and associated comparator to allow the user to easily sequence the LM2854 from

an external voltage rail, or to manually set the input UVLO

threshold. The turn-on or rising threshold and hysteresis for

this comparator are typically 1.23V and 0.15V respectively.

The precise reference for the enable comparator allows the

user to guarantee that the LM2854 will be disabled when the

system demands it to be.

30052836

spectively. A controlled soft-start eliminates inrush currents

during start-up and allows the user more control and flexibility

when sequencing the LM2854 with other power supplies. An

external soft-start capacitor is used to control the LM2854

start-up time. During soft-start, the voltage on the feedback

pin is connected internally to the non-inverting input of the

error amplifier. The soft-start period lasts until the voltage on

the soft-start pin exceeds the LM2854 reference voltage of

0.8V. At this point, the reference voltage takes over at the noninverting amplifier input.

In the event of either AVIN or EN decreasing below the falling

UVLO or enable threshold respectively, the voltage on the

soft-start pin is collapsed by discharging the soft-start capacitor through a 5 kΩ transistor to ground.

TRACKING

The LM2854 can track the output of a master power supply

during soft-start by connecting a resistor divider to the SS pin.

In this way, the output voltage slew rate of the LM2854 will be

controlled by a master supply for loads that require precise

sequencing. When the tracking function is used, a small value

soft-start capacitor can be connected to the SS pin to alleviate

output voltage overshoot when recovering from a current limit

fault.

SOFT-START

The LM2854 begins to operate when both the AVIN and EN

voltages exceed the rising UVLO and enable thresholds, re-

11 www.national.com

Page 12

LM2854

PRE-BIASED STARTUP CAPABILITY

The LM2854 is in a pre-biased state when the device starts

up with an output voltage greater than zero. This often occurs

in many multi-rail applications such as when powering an FPGA, ASIC, or DSP. The output can be pre-biased in these

applications through parasitic conduction paths from one supply rail to another. Even though the LM2854 is a synchronous

converter, it will not pull the output low when a pre-bias condition exists. The LM2854 will not sink current during start up

until the soft-start voltage exceeds the voltage on the FB pin.

Since the device can not sink current it protects the load from

damage that might otherwise occur if current is conducted

through the parasitic paths of the load.

FEEDBACK VOLTAGE ACCURACY

The FB pin is connected to the inverting input of the voltage

loop error amplifier and during closed loop operation its reference voltage is 0.8V. The FB voltage is accurate to within

-1.25% / +1.0% over temperature. Additionally, the LM2854

contains error nulling circuitry to substantially eliminate the

feedback voltage over temperature drift as well as the long

term aging effects of the internal amplifiers. In addition, the 1/

f noise of the bandgap amplifier and reference are dramatically reduced. The manifestation of this circuit action is that

the duty cycle will have two slightly different but distinct operating points, each evident every other switching cycle. The

oscilloscope plot shown previously of the SW pin with infinite

persistence set shows this behavior. No discernible effect is

evident on the output due to LC filter attenuation. For further

information, a National Semiconductor white paper is available on this topic.

POSITIVE CURRENT LIMIT

The LM2854 employs lossless cycle-by-cycle high-side current limit circuitry to limit the peak current through the highside FET. The peak current limit threshold, denoted ICL, is

nominally set at 6A internally. When a current greater than

ICL is sensed through the PFET, its on-time is immediately

terminated and the NFET is activated. The NFET stays on for

the entire next four switching cycles (effectively four PFET

pulses are skipped). During these skipped pulses, the voltage

on the soft-start pin is reduced by discharging the soft-start

capacitor by a current sink on the soft-start pin of nominally 6

µA or 14 µA for the 500 kHz or 1 MHz options, respectively.

Subsequent over-current events will drain more and more

charge from the soft-start capacitor, effectively decreasing

the reference voltage as the output droops due to the pulse

skipping. Reactivation of the soft-start circuitry ensures that

when the over-current situation is removed, the part will resume normal operation smoothly.

NEGATIVE CURRENT LIMIT

The LM2854 implements negative current limit detection circuitry to prevent large negative current in the inductor. When

30052857

the negative current sensed in the low-side NFET is below

approximately -0.4A, the present switching cycle is immediately terminated and both FETs are turned off. When both

FETs are off, the negative inductor current originally flowing

in the low-side NFET and into the SW pin commutates to the

high-side PFET’s body diode and ramps back to zero. At this

point, the SW pin becomes a high impedance node and ringing can be observed on the SW node as the stored energy in

the inductor is dissipated while resonating with the parasitic

nodal capacitance.

OVER-TEMPERATURE PROTECTION

When the LM2854 senses a junction temperature greater

than 165°C, both switching FETs are turned off and the part

enters a sleep state. Upon sensing a junction temperature

below 155°C, the part will re-initiate the soft-start sequence

and begin switching once again. This feature is provided to

prevent catastrophic failure due to excessive thermal dissipation.

LOOP COMPENSATION

The LM2854 preserves flexibility by integrating the control

components around the error amplifier while utilizing three

small external compensation components from V

An integrated type II (two pole, one zero) voltage-mode com-

OUT

to FB.

pensation network is featured. To ensure stability, an external

resistor and small value capacitor can be added across the

upper feedback resistor as a pole-zero pair to complete a type

III (three pole, two zero) compensation network. For correct

selection of these components, see the design section of this

datasheet.

Design Guidelines

INPUT FILTER CAPACITOR

Fast switching currents place a large strain on the input supply

to a buck regulator. A capacitor placed close to the PVIN and

PGND pins of the LM2854 helps to supply the instantaneous

charge required when the regulator demands a pulse of current every switching cycle. In fact, the input capacitor conducts a square-wave current of peak-to-peak amplitude equal

to I

. With this high AC current present in the input capac-

OUT

itor, the RMS current rating becomes an important parameter.

The necessary RMS current rating of the input capacitor to a

buck regulator can be estimated by

where the PWM duty cycle, D, is given by

Neglecting capacitor ESR, the resultant input capacitor AC

ripple voltage is a triangular waveform with peak-to-peak amplitude specified as follows

The maximum input capacitor ripple voltage and RMS current

occur at 50% duty cycle. A 22 µF or 47 µF high quality dielectric (X5R, X7R) ceramic capacitor with adequate voltage

rating is typically sufficient as an input capacitor to the

www.national.com 12

Page 13

LM2854. The input capacitor should be placed as close as

possible to the PVIN and PGND pins to substantially eliminate

the parasitic effects of any stray inductance or resistance on

the PC board and supply lines. Additional bulk capacitance

with higher ESR may be required to damp any resonance effects of the input capacitance and parasitic inductance.

AVIN FILTERING COMPONENTS

In addition to the large input filter capacitor, a smaller ceramic

capacitor such as a 0.1 µF or 1.0 µF is recommended between

AVIN and AGND to filter high frequency noise present on the

PVIN rail from the quiet AVIN supply. For additional filtering

in noisy environments, a small RC filter can be used on the

AVIN pin as shown below.

30052840

In general, RF is typically selected between 1Ω and 10Ω so

that the steady state voltage drop across the resistor due to

the AVIN bias current does not affect the UVLO level. Recommended filter capacitor, CF, is 1.0 µF in X5R or X7R

dielectric.

The above equation includes an offset voltage to ensure that

the final value of the SS pin voltage exceeds the reference

voltage of the LM2854. This offset will cause the LM2854 output voltage to reach regulation slightly before the master

supply. A value of 33 kΩ 1% is recommended for RT2 as a

compromise between high precision and low quiescent current through the divider while minimizing the effect of the 2 µA

soft-start current source.

For example, If the master supply voltage V

the LM2854 output voltage was 1.8V, then the value of R

is 3.3V and

OUT1

needed to give the two supplies identical soft-start times

would be 14.3 kΩ. A timing diagram for this example, the

equal soft-start time case, is shown below.

LM2854

T1

SOFT-START CAPACITOR

When the LM2854 is enabled, the output voltage will ramp up

linearly in the time dictated by the following relationship

where V

ISS is the soft-start charging current (nominally 2 µA) and

is the internal reference voltage (nominally 0.8V),

REF

CSS is the external soft-start capacitance. Rearranging this

equation allows for the necessary soft-start capacitor for a

given startup time to be calculated as follows

Thus, the required soft start capacitor per unit output voltage

startup time is given by

CSS = 2.5 nF / ms

For example, a 10 nF soft-start capacitor will yield a 4 ms softstart time.

TRACKING - EQUAL SOFT-START TIME

One way to use the tracking feature is to design the tracking

resistor divider so that the master supply output voltage,

V

, and the LM2854 output voltage, V

OUT1

gether and reach their target values at the same time. This is

, both rise to-

OUT2

termed ratiometric startup. For this case, the equation governing the values of tracking divider resistors RT1 and RT2 is

given by

30052859

TRACKING - EQUAL SLEW RATES

Alternatively, the tracking feature can be used to have similar

output voltage ramp rates. This is referred to as simultaneous

startup. In this case, the tracking resistors can be determined

based on the following equation

and to ensure proper overdrive of the SS pin

V

< 0.8 V

OUT2

For the example case of V

RT2 set to 33 kΩ as before, RT1 is calculated from the above

= 5V and V

OUT1

OUT1

= 2.5V, with

OUT2

equation to be 15.5 kΩ. A timing diagram for the case of equal

slew rates is shown below.

13 www.national.com

Page 14

LM2854

ENABLE AND UVLO

Using a resistor divider from VIN to EN as shown in the

schematic diagram below, the input voltage at which the part

begins switching can be increased above the normal input

UVLO level according to

For example, suppose that the required input UVLO level is

3.69V. Choosing R

kΩ.

= 10 kΩ, then we calculate R

EN2

30052861

EN1

= 20

R

is defined based on the voltage loop requirements and

FB1

R

is then selected for the desired output voltage. These

FB2

resistors are normally selected as 0.5% or 1% tolerance.

COMPENSATION COMPONENT SELECTION

The power stage transfer function of a voltage mode buck

converter has a complex double pole related to the LC output

filter and a left half plane zero due to the output capacitor

ESR, denoted R

given respectively by

. The locations of these singularities are

ESR

where CO is the output capacitance value appropriately derated for applied voltage and operating temperature, RL is the

effective load resistance and R

sistance associated with the inductor and power switches.

is the series damping re-

DCR

30052844

Alternatively, the EN pin can be driven from another voltage

source to cater for system sequencing requirements commonly found in FPGA and other multi-rail applications. The

following schematic shows an LM2854 that is sequenced to

start based on the voltage level of a master system rail.

30052845

OUTPUT VOLTAGE SETTING

A divider resistor network from V

the desired output voltage as follows

www.national.com 14

to the FB pin determines

OUT

30052848

The conventional compensation strategy employed with voltage mode control is to use two compensator zeros to offset

the LC double pole, one compensator pole located to cancel

the output capacitor ESR zero and one compensator pole located between one third and one half switching frequency for

high frequency noise attenuation.

The LM2854 internal compensation components are designed to locate a pole at the origin and a pole at high

frequency as mentioned above. Furthermore, a zero is located at 8.8 kHz or 17.6 kHz for the 500 kHz or 1 MHz options,

respectively, to approximately cancel the likely location of one

LC filter pole.

The three external compensation components, R

and C

pole location and a pole to cancel the ESR zero. The voltage

loop crossover frequency, f

one tenth to one fifth of the switching frequency

, are selected to position a zero at or below the LC

COMP

, is usually selected between

loop

0.1fSW ≤ f

loop

≤ 0.2f

SW

FB1

, R

COMP

A simple solution for the required external compensation capacitor, C

expressed as

, with type III voltage mode control can be

COMP

Page 15

where the constant α is nominally 0.038 or 0.075 for the 500

kHz or 1 MHz options, respectively. This assumes a compensator pole cancels the output capacitor ESR zero. Furthermore, since the modulator gain is proportional to VIN, the

loop crossover frequency increases with VIN. Thus, it is recommended to design the loop at maximum expected VIN.

The upper feedback resistor, R

equate mid-band gain and to locate a zero at or below the LC

pole frequency. The series resistor, R

cate a pole at the ESR zero frequency. Thus

Note that the lower feedback resistor, R

the control loop from an AC standpoint since the FB pin is the

, is selected to provide ad-

FB1

, is selected to lo-

COMP

, has no impact on

FB2

input to an error amplifier and effectively at AC ground.

Hence, the control loop can be designed irrespective of output

voltage level. The only caveat here is the necessary derating

of the output capacitance with applied voltage. Having chosen

R

as above, R

FB1

voltage.

is then selected for the desired output

FB2

Table 1 and Table 2 list inductor and ranges of capacitor values that work well with the LM2854, along with the associated

compensation components to ensure stable operation. Values different than those listed may be used, but the compensation components may need to be recalculated to avoid

degradation in phase margin. Note that the capacitance

ranges specified refer to in-circuit values where the nominal

capacitance value is adequately derated for applied voltage.

FILTER INDUCTOR AND OUTPUT CAPACITOR SELECTION

In a buck regulator, selection of the filter inductor and capacitor will affect many key system parameters, including stability, transient response and efficiency The LM2854 can

accommodate relatively wide ranges of output capacitor and

filter inductor values in a typical application and still achieve

excellent load current transient performance and low output

voltage ripple.

The inductance is chosen such that the peak-to-peak inductor

current ripple, ΔiL, is approximately 25 to 40% of I

lows

OUT

as fol-

Note that the peak inductor current is the DC output current

plus half the ripple current and reaches its highest level at

lowest duty cycle (or highest VIN). It is recommended that the

inductor should have a saturation current rating in excess of

the current limit level.

Table 3 lists examples of off-the-shelf powdered iron and ferrite based inductors that are suitable for use with the LM2854.

The output capacitor can be of ceramic or electrolytic chemistry. The chosen output capacitor requires sufficient DC voltage rating and RMS ripple current handling capability.

The output capacitor RMS current and peak-to-peak output

ripple are given respectively by

In general, 22 µF to 100 µF of ceramic output capacitance is

sufficient for both LM2854 frequency options given the optimal high frequency characteristics and low ESR of ceramic

dielectric. It is advisable to consult the manufacturer’s derating curves for capacitance voltage coefficient as the in-circuit

capacitance may drop significantly with applied voltage.

Tantalum or organic polymer electrolytic capacitance may be

suitable with the LM2854 500 kHz option, particularly in applications where substantial bulk capacitance per unit volume

is required. However, the high loop bandwidth achievable with

the LM2854 obviates the necessity for large bulk capacitance

during transient loading conditions.

Table 4 lists some examples of commercially available capacitors that can be used with the LM2854.

LM2854

TABLE 1. LM2854 500 kHz Compensation Component Values

VIN (V) LO (µH) CO (µF)

ESR (mΩ) R

FB1

(kΩ)

C

COMP

(pF)

R

Min Max Min Max

5.0 1.5 40 100 2 10 150 47 1

1.5 100 200 1 5 150 100 1

1.5 100 220 15 25 150 120 25

2.2 40 100 2 10 150 68 1

2.2 100 200 1 5 150 120 1

2.2 100 220 15 25 120 120 15

3.3 1.5 40 100 2 10 150 68 1

1.5 100 200 1 5 100 150 1

1.5 100 220 15 25 100 150 15

2.2 40 100 2 10 150 100 1

2.2 100 200 1 5 100 220 1

2.2 100 220 15 25 100 220 10

15 www.national.com

COMP

(kΩ)

Page 16

TABLE 2. LM2854 1 MHz Compensation Component Values

LM2854

VIN (V) LO (µH) CO (µF)

ESR (mΩ) R

FB1

(kΩ)

C

COMP

(pF)

Min Max Min Max

5.0 0.68 20 60 2 10 120 33 1

0.68 60 150 1 5 75 100 1

0.68 100 220 15 25 100 100 20

1.0 20 60 2 10 100 56 1

1.0 60 150 1 5 75 150 1

1.0 100 220 15 25 75 150 15

3.3 0.68 20 60 2 10 75 56 1

0.68 60 150 1 5 50 150 1

0.68 100 220 15 25 50 150 12

1.0 20 60 2 10 75 82 1

1.0 60 150 1 5 50 220 1

1.0 100 220 15 25 33 330 10

TABLE 3. Recommended Filter Inductors

R

COMP

(kΩ)

Inductance (µH)

DCR (mΩ)

Manufacturer Manufacturer P/N Case Size (mm)

0.47 14.5 Vishay Dale IHLP1616BZERR47M11 4.06 x 4.45 x 2.00

1.0 24.0 Vishay Dale IHLP1616BZER1R0M11 4.06 x 4.45 x 2.00

0.47 8.4 Vishay Dale IHLP2525AHERR47M01 6.47 x 6.86 x 1.80

0.47 6.0 Vishay Dale IHLP2525BDERR47M01 6.47 x 6.86 x 2.40

0.68 8.7 Vishay Dale IHLP2525BDERR68M01 6.47 x 6.86 x 2.40

0.82 10.6 Vishay Dale IHLP2525BDERR82M01 6.47 x 6.86 x 2.40

1.0 13.1 Vishay Dale IHLP2525BDER1R0M01 6.47 x 6.86 x 2.40

1.5 18.5 Vishay Dale IHLP2525BDER1R5M01 6.47 x 6.86 x 2.40

2.2 15.7 Vishay Dale IHLP2525CZER2R2M11 6.47 x 6.86 x 3.00

0.47 3.5 Sumida CDMC6D28NP-R47M 6.50 x 7.25 x 3.00

0.68 4.5 Sumida CDMC6D28NP-R68M 6.50 x 7.25 x 3.00

1.0 17.3 Sumida CDMC6D28NP-1R0M 6.50 x 7.25 x 3.00

1.5 10.4 Sumida CDMC6D28NP-1R5M 6.50 x 7.25 x 3.00

2.2 16.1 Sumida CDMC6D28NP-2R2M 6.50 x 7.25 x 3.00

0.56 10 Coilcraft DO1813H-561ML 6.10 x 8.89 x 5.00

0.47 3.3 Coilcraft HA3619-471ALC 7.0 x 7.0 x 3.0

0.68 4.8 Coilcraft HA3619-681ALC 7.0 x 7.0 x 3.0

1.0 7.5 Coilcraft HA3619-102ALC 7.0 x 7.0 x 3.0

1.2 9.4 Coilcraft HA3619-122ALC 7.0 x 7.0 x 3.0

1.5 11.5 Coilcraft HA3619-152ALC 7.0 x 7.0 x 3.0

1.8 16.5 Coilcraft HA3619-182ALC 7.0 x 7.0 x 3.0

0.47 3.3 TDK SPM6530T-R47M170 7.1 x 6.5 x 3.0

0.68 4.9 TDK SPM6530T-R68M140 7.1 x 6.5 x 3.0

1.0 7.1 TDK SPM6530T-1R0M120 7.1 x 6.5 x 3.0

1.5 9.7 TDK SPM6530T-1R5M100 7.1 x 6.5 x 3.0

0.47 14 Cyntec PCMC042T-0R47MN 4.0 x 4.5 x 2.0

1.0 9 Cyntec PCMC063T-1R0MN 6.5 x 6.9 x 3.0

1.5 14 Cyntec PCMC063T-1R5MN 6.5 x 6.9 x 3.0

www.national.com 16

Page 17

TABLE 4. Recommended Filter Capacitors

LM2854

Capacitance

(µF)

22 6.3, < 5 Ceramic, X5R TDK C3216X5R0J226M 1206

47 6.3, < 5 Ceramic, X5R TDK C3216X5R0J476M 1206

47 6.3, < 5 Ceramic, X5R TDK C3225X5R0J476M 1210

47 10.0, < 5 Ceramic, X5R TDK C3225X5R1A476M 1210

100 6.3, < 5 Ceramic, X5R TDK C3225X5R0J107M 1210

100 6.3, 50 Tantalum AVX TPSD157M006#0050 D, 7.5 x 4.3 x 2.9 mm

100 6.3, 25 Organic Polymer Sanyo 6TPE100MPB2 B2, 3.5 x 2.8 x 1.9 mm

150 6.3, 18 Organic Polymer Sanyo 6TPE150MIC2 C2, 6.0 x 3.2 x 1.8 mm

330 6.3, 18 Organic Polymer Sanyo 6TPE330MIL D3L, 7.3 x 4.3 x 2.8 mm

470 6.3, 23 Niobium Oxide AVX NOME37M006#0023 E, 7.3 x 4.3 x 4.1 mm

Voltage (V), ESR

(mΩ)

Chemistry Manufacturer Manufacturer P/N Case Size

17 www.national.com

Page 18

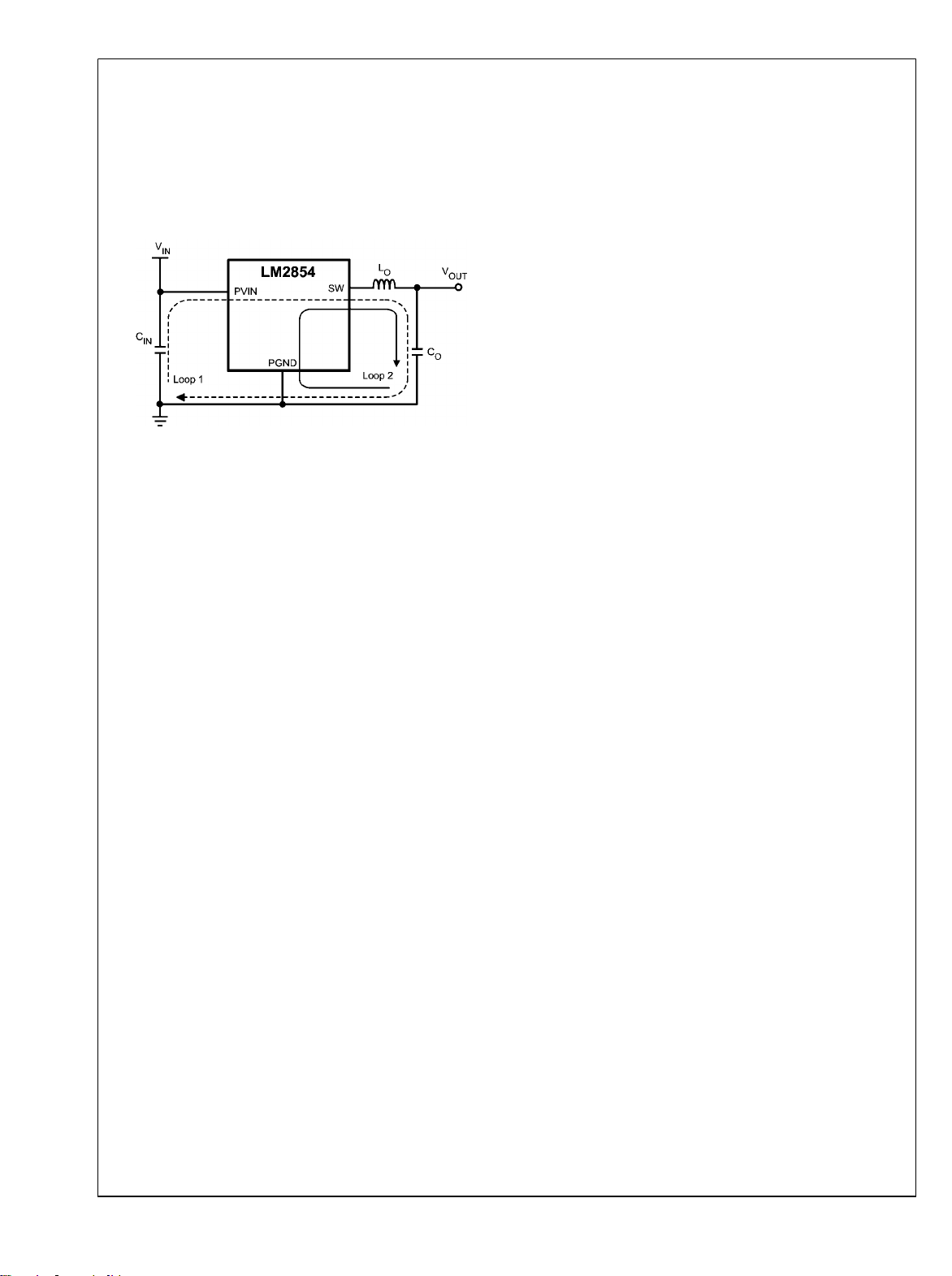

PC Board Layout Guidelines

PC board layout is an important part of DC-DC converter de-

LM2854

sign. Poor board layout can disrupt the performance of a DCDC converter and surrounding circuitry by contributing to EMI,

ground bounce and resistive voltage drop in the traces. These

can send erroneous signals to the DC-DC converter resulting

in poor regulation or instability. Good layout can be implemented by following a few simple design rules.

1. Minimize area of switched current loops.

There are two loops where currents are switched at high di/

dt slew rates in a buck regulator. The first loop represents the

path taken by AC current flowing during the high side PFET

on time. This current flows from the input capacitor to the regulator PVIN pins, through the high side FET to the regulator

SW pin, filter inductor, output capacitor and returning via the

PCB ground plane to the input capacitor.

The second loop represents the path taken by AC current

flowing during the low side NFET on time. This current flows

from the output capacitor ground to the regulator PGND pins,

through the NFET to the inductor and output capacitor. From

an EMI reduction standpoint, it is imperative to minimize this

loop area during PC board layout by physically locating the

input capacitor close to the LM2854. Specifically, it is advantageous to place CIN as close as possible to the LM2854 PVIN

and PGND pins. Grounding for both the input and output capacitor should consist of a localized top side plane that connects to PGND and the exposed die attach pad (DAP). The

inductor should be placed close to the SW pin and output capacitor.

30052853

2. Minimize the copper area of the switch node.

The LM2854 has two SW pins optimally located on one side

of the package. In general the SW pins should be connected

to the filter inductor on the top PCB layer. The inductor should

be placed close to the SW pins to minimize the copper area

of the switch node.

3. Have a single point ground for all device analog

grounds located under the DAP.

The ground connections for the Feedback, Soft-start, Enable

and AVIN components should be routed to the AGND pin of

the device. The AGND pin should connect to PGND under the

DAP. This prevents any switched or load currents from flowing in the analog ground traces. If not properly handled, poor

grounding can result in degraded load regulation or erratic

switching behavior.

4. Minimize trace length to the FB pin.

Since the feedback (FB) node is high impedance, the trace

from the output voltage setpoint resistor divider to FB pin

should be as short as possible. This is most important as relatively high value resistors are used to set the output voltage.

The FB trace should be routed away from the SW pin and

inductor to avoid noise pickup from the SW pin. Both feedback

resistors, R

R

COMP

and C

FB1

and R

COMP

, and the compensation components,

FB2

, should be located close to the FB pin.

5. Make input and output bus connections as wide as

possible.

This reduces any voltage drops on the input or output of the

converter and maximizes efficiency. To optimize voltage accuracy at the load, ensure that a separate feedback voltage

sense trace is made to the load. Doing so will correct for voltage drops and provide optimum output accuracy.

6. Provide adequate device heat-sinking.

Use an array of heat-sinking vias to connect the DAP to the

ground plane on the bottom PCB layer. If the PCB has a plurality of copper layers, these thermal vias can also be employed to make connection to inner layer heat-spreading

ground planes. For best results use a 5 x 3 via array with

minimum via diameter of 10 mils. Ensure enough copper area

is used to keep the junction temperature below 125°C.

www.national.com 18

Page 19

LM2854 Application Circuit Schematic and BOMs

This section provides several application solutions with an

associated bill of materials. All bill of materials reference the

schematic below. The compensation for each solution was

optimized to work over the full input range. Many applications

have a fixed input voltage rail. It is possible to modify the

compensation to obtain a faster transient response for a given

input voltage operating point.

LM2854

30052854

TABLE 5. LM2854 500kHz Bill of Materials, VIN = 5V, V

= 3.3V, I

OUT

OUT(MAX)

= 4A, Optimized for Efficiency

Ref Des Description Case Size Manufacturer Manufacturer P/N

U1 Synchronous Buck

eTSSOP-16 National Semiconductor LM2854MHX-500

Regulator

R

R

R

C

C

IN

C

O

L

O

FB1

FB2

COMP

R

F

COMP

C

SS

C

F

47 µF, X5R, 10V 1210 TDK C3225X5R1A476M

100 µF, X5R, 6.3V 1210 TDK C3225X5R0J107M

1.5 µH, 9.7 mΩ, 10A

249 kΩ

80.6 kΩ

1.0 kΩ

1.0Ω

7.1 x 6.5 x 3.0 mm TDK SPM6530T-1R5M100

0603 Vishay Dale CRCW06032493F-e3

0603 Vishay Dale CRCW060328062F-e3

0603 Vishay Dale CRCW06031001F-e3

0603 Vishay Dale CRCW06031R0F-e3

33 pF, ±5%, C0G, 50V 0603 TDK C1608C0G1H330J

10 nF, ±10%, X7R, 16V 0603 Murata GRM188R71C103KA01

1.0 µF, ±10%, X7R, 10V 0603 Murata GRM188R71A105KA61

19 www.national.com

Page 20

TABLE 6. LM2854 1 MHz Bill of Materials, VIN = 3.3V to 5V, V

LM2854

Ref Des Description Case Size Manufacturer Manufacturer P/N

U1 Synchronous Buck Regulator eTSSOP-16 National Semiconductor LM2854MHX-1000

R

R

R

C

C

IN

C

O

L

O

FB1

FB2

COMP

R

F

COMP

C

SS

C

F

150 µF, 6.3V, 18 mΩ

330 µF, 6.3V, 18 mΩ

2.2 µH, 16 mΩ, 7A

100 kΩ

47.5 kΩ

15 kΩ

1.0Ω

330 pF, ±5%, C0G, 50V 0603 TDK C1608C0G1H331J

10 nF, ±10%, X7R, 16V 0603 Murata GRM188R71C103KA01

1.0 µF,±10%, X7R, 10V 0603 Murata GRM188R71A105KA61

= 2.5V, I

Output Capacitance

OUT

OUT (MAX)

= 4A, Optimized for Electrolytic Input and

C2, 6.0 x 3.2 x 1.8 mm Sanyo 6TPE150MIC2

D3L, 7.3 x 4.3 x 2.8 mm Sanyo 6TPE330MIL

6.47 x 6.86 x 3.00 mm Vishay Dale IHLP2525CZER2R2M11

0603 Vishay Dale CRCW06031003F-e3

0603 Vishay Dale CRCW060324752F-e3

0603 Vishay Dale CRCW06031502F-e3

0603 Vishay Dale CRCW06031R0F-e3

TABLE 7. LM2854 1 MHz Bill of Materials, VIN = 3.3V, V

= 0.8V, I

OUT

Response

OUT (MAX)

= 4A, Optimized for Solution Size and Transient

Ref Des Description Case Size Manufacturer Manufacturer P/N

U1 Synchronous Buck Regulator eTSSOP-16 National Semiconductor LM2854MHX-1000

R

C

C

C

L

R

FB1

COMP

R

COMP

C

SS

C

IN

O

O

F

F

47 µF, X5R, 6.3V 1206 TDK C3216X5R0J476M

47 µF, X5R, 6.3V 1206 TDK C3216X5R0J476M

0.47 µH, 14.5 mΩ, 7A

110 kΩ

1.0 kΩ

1.0Ω

4.06 x 4.45 x 2.00 mm Vishay Dale IHLP1616BZER0R47M11

0402 Vishay Dale CRCW04021103F-e3

0402 Vishay Dale CRCW04021001F-e3

0402 Vishay Dale CRCW04021R0F-e3

27 pF, ±5%, C0G, 50V 0402 Murata GRM1555C1H270JZ01

10 nF, ±10%, X7R, 16V 0402 Murata GRM155R71C103KA01

1.0 µF, ±10%, X7R, 10V 0402 Murata GRM155R61A105KE15

www.national.com 20

Page 21

Physical Dimensions inches (millimeters) unless otherwise noted

LM2854

16-Lead eTSSOP Package

NS Package Number MXA16A

21 www.national.com

Page 22

Notes

For more National Semiconductor product information and proven design tools, visit the following Web sites at:

Products Design Support

Amplifiers www.national.com/amplifiers WEBENCH www.national.com/webench

Audio www.national.com/audio Analog University www.national.com/AU

Clock Conditioners www.national.com/timing App Notes www.national.com/appnotes

Data Converters www.national.com/adc Distributors www.national.com/contacts

Displays www.national.com/displays Green Compliance www.national.com/quality/green

Ethernet www.national.com/ethernet Packaging www.national.com/packaging

Interface www.national.com/interface Quality and Reliability www.national.com/quality

LVDS www.national.com/lvds Reference Designs www.national.com/refdesigns

Power Management www.national.com/power Feedback www.national.com/feedback

Switching Regulators www.national.com/switchers

LDOs www.national.com/ldo

LED Lighting www.national.com/led

PowerWise www.national.com/powerwise

Serial Digital Interface (SDI) www.national.com/sdi

Temperature Sensors www.national.com/tempsensors

Wireless (PLL/VCO) www.national.com/wireless

THE CONTENTS OF THIS DOCUMENT ARE PROVIDED IN CONNECTION WITH NATIONAL SEMICONDUCTOR CORPORATION

(“NATIONAL”) PRODUCTS. NATIONAL MAKES NO REPRESENTATIONS OR WARRANTIES WITH RESPECT TO THE ACCURACY

OR COMPLETENESS OF THE CONTENTS OF THIS PUBLICATION AND RESERVES THE RIGHT TO MAKE CHANGES TO

SPECIFICATIONS AND PRODUCT DESCRIPTIONS AT ANY TIME WITHOUT NOTICE. NO LICENSE, WHETHER EXPRESS,

IMPLIED, ARISING BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS

DOCUMENT.

TESTING AND OTHER QUALITY CONTROLS ARE USED TO THE EXTENT NATIONAL DEEMS NECESSARY TO SUPPORT

NATIONAL’S PRODUCT WARRANTY. EXCEPT WHERE MANDATED BY GOVERNMENT REQUIREMENTS, TESTING OF ALL

PARAMETERS OF EACH PRODUCT IS NOT NECESSARILY PERFORMED. NATIONAL ASSUMES NO LIABILITY FOR

APPLICATIONS ASSISTANCE OR BUYER PRODUCT DESIGN. BUYERS ARE RESPONSIBLE FOR THEIR PRODUCTS AND

APPLICATIONS USING NATIONAL COMPONENTS. PRIOR TO USING OR DISTRIBUTING ANY PRODUCTS THAT INCLUDE

NATIONAL COMPONENTS, BUYERS SHOULD PROVIDE ADEQUATE DESIGN, TESTING AND OPERATING SAFEGUARDS.

EXCEPT AS PROVIDED IN NATIONAL’S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, NATIONAL ASSUMES NO

LIABILITY WHATSOEVER, AND NATIONAL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY RELATING TO THE SALE

AND/OR USE OF NATIONAL PRODUCTS INCLUDING LIABILITY OR WARRANTIES RELATING TO FITNESS FOR A PARTICULAR

PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY

RIGHT.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR

SYSTEMS WITHOUT THE EXPRESS PRIOR WRITTEN APPROVAL OF THE CHIEF EXECUTIVE OFFICER AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

Life support devices or systems are devices which (a) are intended for surgical implant into the body, or (b) support or sustain life and

whose failure to perform when properly used in accordance with instructions for use provided in the labeling can be reasonably expected

to result in a significant injury to the user. A critical component is any component in a life support device or system whose failure to perform

can be reasonably expected to cause the failure of the life support device or system or to affect its safety or effectiveness.

National Semiconductor and the National Semiconductor logo are registered trademarks of National Semiconductor Corporation. All other

brand or product names may be trademarks or registered trademarks of their respective holders.

Copyright© 2008 National Semiconductor Corporation

For the most current product information visit us at www.national.com

National Semiconductor

Americas Technical

Support Center

Email:

LM2854 4A 500 kHz / 1 MHz PowerWise® Synchronous SIMPLE SWITCHER® Buck Regulator

www.national.com

new.feedback@nsc.com

Tel: 1-800-272-9959

National Semiconductor Europe

Technical Support Center

Email: europe.support@nsc.com

German Tel: +49 (0) 180 5010 771

English Tel: +44 (0) 870 850 4288

National Semiconductor Asia

Pacific Technical Support Center

Email: ap.support@nsc.com

National Semiconductor Japan

Technical Support Center

Email: jpn.feedback@nsc.com

Loading...

Loading...