Page 1

LM27961

Dual-Display White LED Driver with 3/2x Switched

Capacitor Boost

LM27961 Dual-Display White LED Driver with 3/2x Switched Capacitor Boost

November 2004

General Description

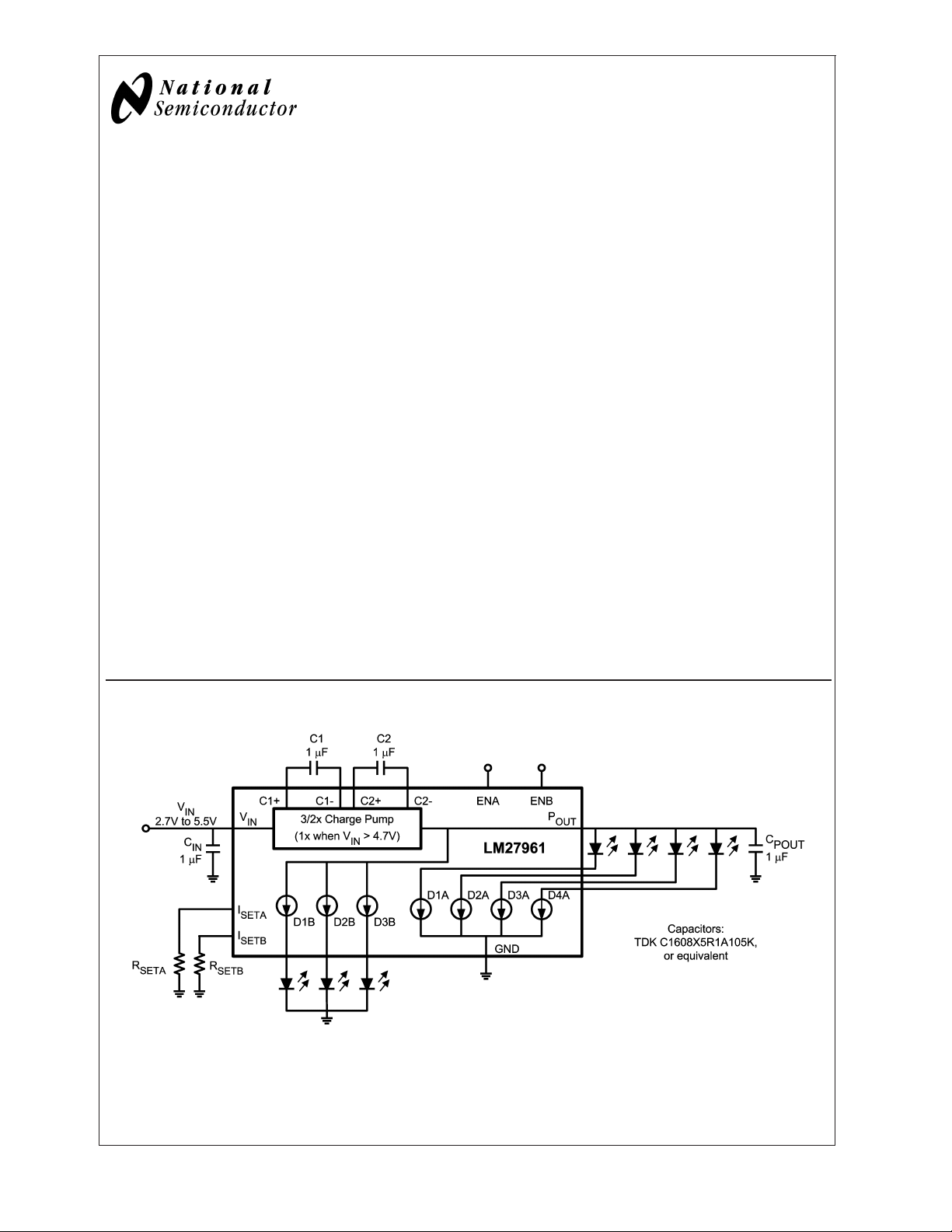

The LM27961 is a charge-pump-based white-LED driver that

is ideal for mobile phone display backlighting. It is intended

to drive 4 LEDs for a main phone display backlight and 3

LEDs for a sub-display backlight. Regulated internal current

sources deliver excellent current and brightness matching in

all LEDs.

The LED driver current sources are split into two independently controlled groups. The primary group (Group A) can

be used to backlight a main phone display with up to 4 LEDs.

The low-side current drivers of Group A accommodate

common-anode-type LEDs. The second group (Group B)

can backlight a secondary display with up to 3 LEDs. The

high-side current drivers of Group B accommodate commoncathode-type LEDs. Both Group A and Group B can also

drive standard two-terminal LEDs, and provide other general

lighting functions (keypad lighting, fun lighting, etc). The

brightness of the two LED groups can be adjusted independently with external resistors.

The LM27961 works off an extended Li-Ion input voltage

range (2.7V to 5.5V). Voltage boost is achieved with a highefficiency 3/2x-gain charge pump.

The LM27961 is available in National’s chip-scale 18-bump

micro SMD package.

Features

n Drives 4 Individual Common-Anode LEDs with up to

20mA each for a Main Display Backlight

n Drives 3 Individual Common-Cathode LEDs with up to

20mA each for a Sub-Display Backlight

n Independent Resistor-Programmable Current Setting

n Excellent Current and Brightness Matching

n High-Efficiency 3/2x Charge Pump

n Extended Li-Ion Input: 2.7V to 5.5V

n PWM Brightness Control: 100Hz - 1kHz

n 18-bump Thin Micro SMD Package:

(2.1mm x 2.4mm x 0.6mm)

Applications

n Mobile Phone Display Lighting

n Mobile Phone Keypad Lighting

n PDAs

n General LED Lighting

Typical Application Circuit

20127901

© 2004 National Semiconductor Corporation DS201279 www.national.com

Page 2

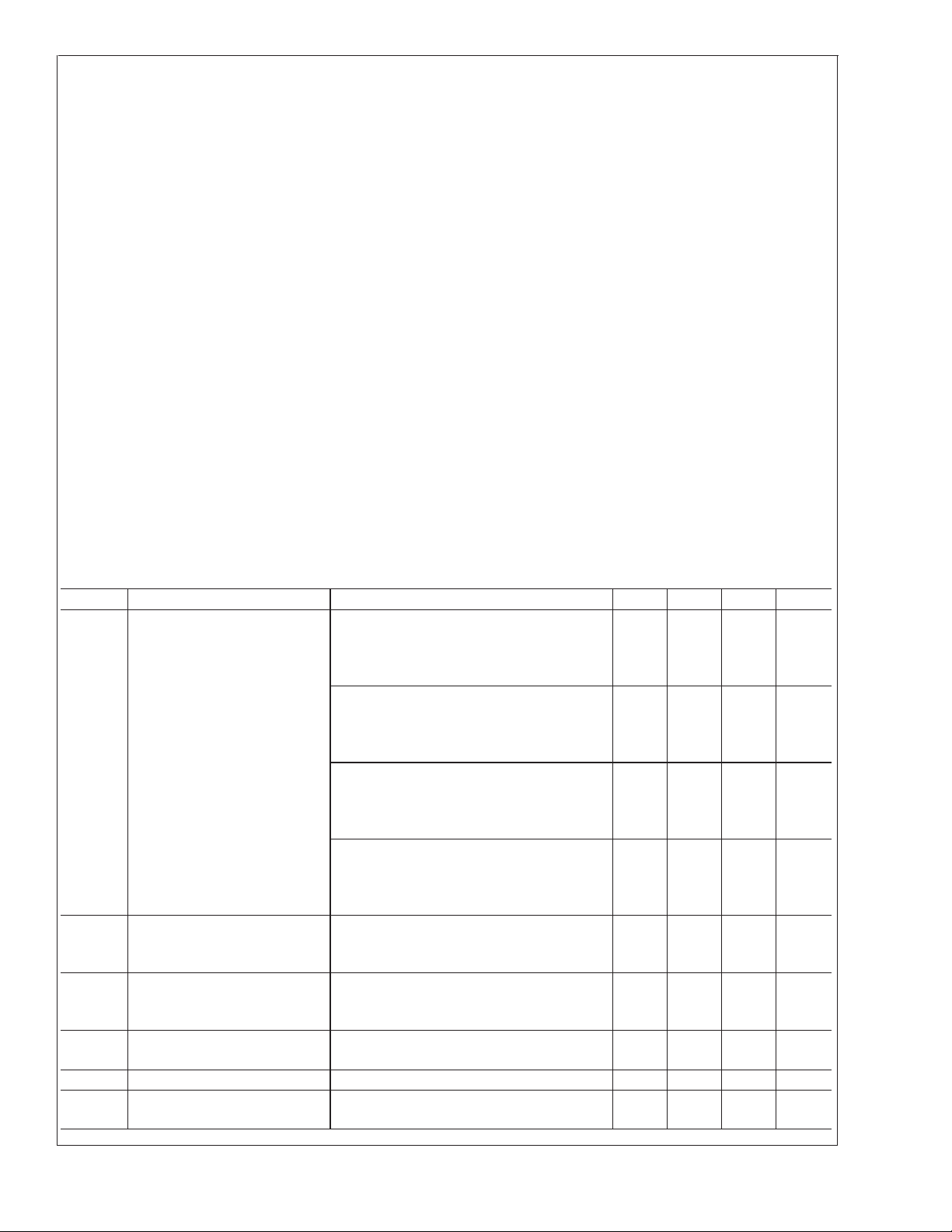

Connection Diagram

LM27961

Pin Description

Pin #s Pin Names Pin Descriptions

C1 V

D2 GND Ground

A3 P

A1, B2, A5, E1 C1+, C1-, C2+,

D6, E5, D4, E3 D1A, D2A, D3A,

C5, B4, C3 D1B, D2B, D3B LED Outputs - Group B

B6 EN-A Enable for Group-A LEDs (current outputs). Logic input.

A7 EN-B Enable for Group-B LEDs (current outputs). Logic input.

E7 I

C7 I

18-Bump Thin Micro SMD Package, Large Bump

NS Package Number TLA18

IN

OUT

Input voltage. Input range: 2.7V to 5.5V.

Charge pump output. Approximately 1.5xV

Flying capacitor connections.

C2-

LED Outputs - Group A

D4A

High = Group-A LEDs ON. Low = Group A LEDs OFF.

Pulsing this pin with a PWM signal (100Hz-1kHz) can be used to dim LEDs.

High = Group-B LEDs ON. Low = Group B LEDs OFF.

Pulsing this pin with a PWM signal (100Hz-1kHz) can be used to dim LEDs.

SETA

Placing a resistor (R

SETA

Group A LEDs. LED Current = 100 x (1.25V ÷ R

SETB

Placing a resistor (R

SETB

Group B LEDs. LED Current = 100 x (1.25V ÷ R

20127902

IN

) between this pin and GND sets the LED current for

).

SETA

) between this pin and GND sets the LED current for

).

SETB

Operational States

ENA ENB Mode of Operation

L L Shutdown

H L Enabled. Group A LEDs ON. Group B LEDs OFF

L H Enabled. Group B LEDs ON. Group A LEDs OFF

H H Invalid for normal operation

Ordering Information

Order Information Package Supplied As

LM27961TL TLA18 Micro SMD 250 Units, Tape & Reel

LM27961TLX 3000 Units, Tape & Reel

www.national.com 2

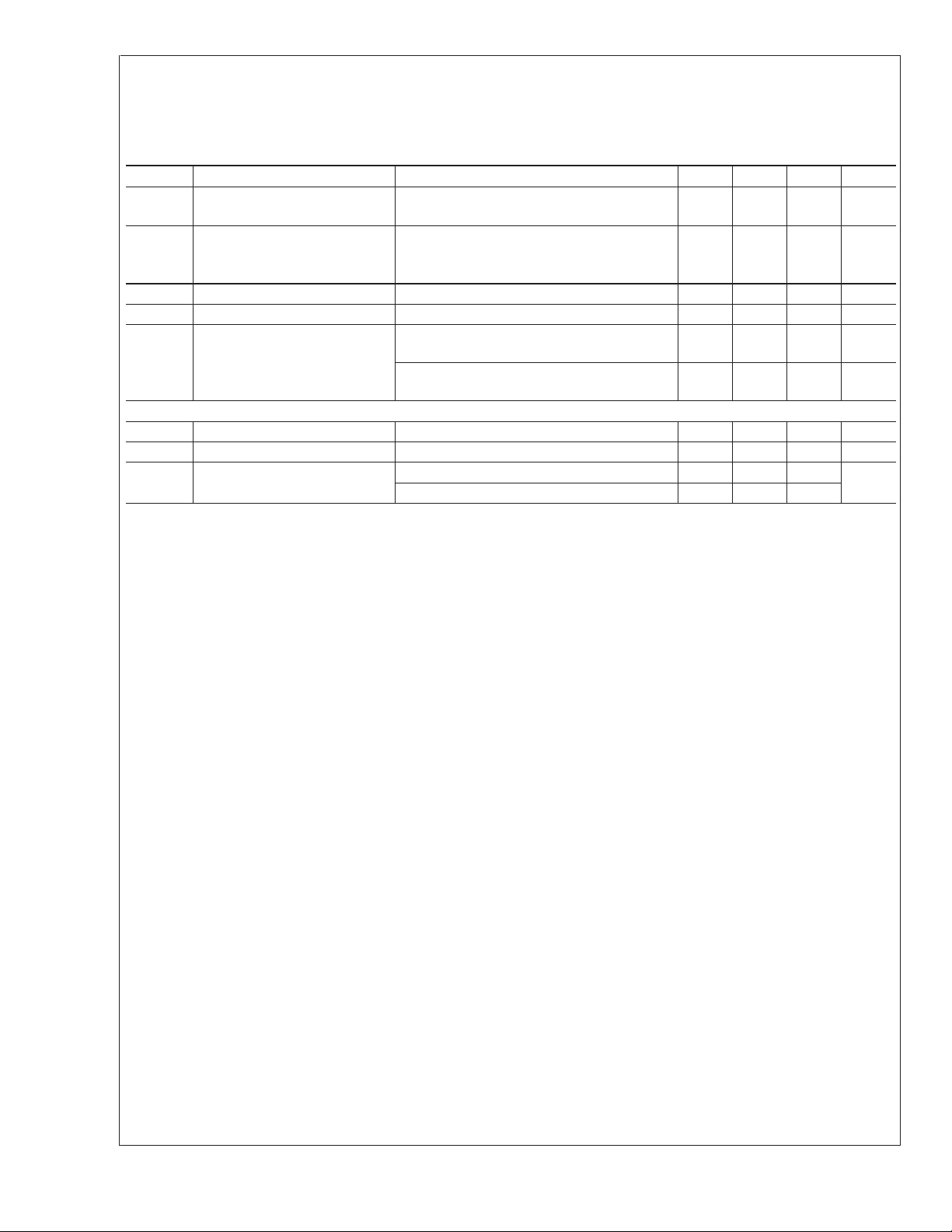

Page 3

LM27961

Absolute Maximum Ratings (Notes 1, 2)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

pin voltage -0.3V to 7.1V

V

IN

ENA, ENB pin voltages -0.3V to (V

+0.3V)

IN

Operating Rating (Notes 1, 2)

Input Voltage Range 2.7V to 5.5V

Junction Temperature (T

Ambient Temperature (T

(Note 5)

) Range -30˚C to +125˚C

J

) Range

A

-30˚C to +85˚C

w/ 6.0V max

Pin Voltages -0.3V to

I

Dxx

(V

POUT

w/ 6.0V max

Continuous Power Dissipation

Internally Limited

+0.3V)

Thermal Properties

Juntion-to-Ambient Thermal

Resistance (θ

), (Note 6)

JA

100˚C/W

(Note 3)

Junction Temperature (T

Storage Temperature Range -65

Maximum Lead Temperature

) 150oC

J-MAX

o

C to +150oC

265

o

C

(Soldering, 10 sec.)

ESD Rating (Note 4)

Human Body Model - I

Human Body Model - All other Pins:

Machine Model - I

Dxx

Machine Model - All Other Pins:

Dxx

Pins:

Pins:

1.0kV

2.0kV

100V

200V

Electrical Characteristics (Notes 2, 7)

Limits in standard typeface are for TJ= 25˚C, and limits in boldface type apply over the full operating temperature range. Unless otherwise specified: V

1.5V; R

SETA=RSETB

pins (I

Dxx

and I

) apply to both Group A and Group B. (Note 8)

SETx

= 3.6V; V

IN

= 8.35kΩ;CIN,C1,C2, and C

Symbol Parameter Condition Min Typ Max Units

I

Dxx

I

Dxx-MATCH

Output Current Regulation

Current Matching Between Any

Two Group A Outputs or Group

B Outputs

I

Q

I

SD

V

SET

I

Dxx/ISET

Quiescent Supply Current 2.7V ≤ VIN≤ 4.2V;

Shutdown Supply Current 2.7V ≤ VIN≤ 5.5V,

I

Pin Voltage 2.7V ≤ VIN≤ 5.5V 1.25 V

SET

Output Current to Current Set

Ratio

= 0.6V; V

DxA

DxB

POUT

3.0V ≤ V

0.45V ≤ V

2.5V ≤ V

= 8.35kΩ

R

SET

3.0V ≤ V

0.6V ≤ V

2.5V ≤ V

= 6.25kΩ

R

SET

3.0V ≤ V

0.3V ≤ V

2.5V ≤ V

= 12.5kΩ

R

SET

2.7V ≤ V

0.45V ≤ V

2.5V ≤ V

= 8.35kΩ

R

SET

= 3.0V (Note 9) 0.6 %

V

IN

No Load Current,

ENA or ENB = ON

ENA and ENB = OFF

= 3.6V; ENA = 1.5V and ENB = GND, or ENA = GND and ENB =

= 1µF. Specifications related to output current(s) and current setting

≤ 4.2V, and VIN= 5.5V

IN

DxA

DxB

≤ 5.5V;

IN

DxA

DxB

≤ 5.5V;

IN

DxA

DxB

≤ 3.0V;

IN

DxA

DxB

≤ 3.8V or

≤ 3.8V;

≤ 3.8V or

≤ 3.8V;

≤ 3.8V or

≤ 3.8V;

≤ 3.8V or

≤ 3.8V;

13.5

(-10%)

15

16.5

(+10%)mA(%)

20 mA

10 mA

15 mA

4.4 6.75 mA

2.3 5 µA

100

www.national.com3

Page 4

Electrical Characteristics (Notes 2, 7) (Continued)

Limits in standard typeface are for TJ= 25˚C, and limits in boldface type apply over the full operating temperature range. Un-

LM27961

less otherwise specified: V

Dxx

SETA

=R

and I

SETB

) apply to both Group A and Group B. (Note 8)

SETx

1.5V; R

pins (I

Symbol Parameter Condition Min Typ Max Units

R

OUT

Charge Pump Output Resistance

(Note 10)

V

HR

Current Source Headroom

Voltage Requirement (Note 11)

f

SW

t

START

Switching Frequency 3.0V ≤ VIN≤ 4.2V 375 500 625 kHz

Start-up Time IDx= 90% steady state 350 µs

1.5x/1x Charge pump gain cross-over:

Gain = 1.5 when VINis below

threshold. Gain = 1 when V

above threshold.

Logic Pin Specifications: EN, ENA, ENB

V

IL

V

IH

I

LEAK

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the component may occur. Operating Ratings are conditions under which operation of

the device is guaranteed. Operating Ratings do not imply guaranteed performance limits. For guaranteed performance limits and associated test conditions, see the

Electrical Characteristics tables.

Note 2: All voltages are with respect to the potential at the GND pin.

Note 3: Internal thermal shutdown circuitry protects the device from permanent damage. Thermal shutdown engages at T

120˚C (typ.). The thermal shutdown function is guaranteed by design.

Note 4: The Human body model is a 100pF capacitor discharged through a 1.5kΩ resistor into each pin. The machine model is a 200pF capacitor discharged

directly into each pin. MIL-STD-883 3015.7

Note 5: In applications where high power dissipation and/or poor package thermal resistance is present, the maximum ambient temperature may have to be

derated. Maximum ambient temperature (T

dissipation of the device in the application (P

following equation: T

Note 6: Junction-to-ambient thermal resistance is highly dependent on application and board layout. In applications where high maximum power dissipation exists,

special care must be paid to thermal dissipation issues in board design.

Note 7: Min and Max limits are guaranteed by design, test, or statistical analysis. Typical numbers are not guaranteed, but do represent the most likely norm.

Note 8: C

Note 9: For the two groups of outputs on a part (GroupA and Group B), the following are determined: the maximum output current in the group (MAX), the minimum

output current in the group (MIN), and the average output current of the group (AVG). For each group, two matching numbers are calculated: (MAX-AVG)/AVG and

(AVG-MIN)/AVG. The largest number of the two (worst case) is considered the matching figure for the group. The matching figure for a given part is considered to

be the highest matching figure of the two groups. The typical specification provided is the most likely norm of the matching figure for all parts.

Note 10: Output resistance (R

V

Pout

equation applies when the charge pump is operating with a gain of 3/2 (V

Note 11: Headroom voltage: V

Note 12: There is a 300kΩ(typ.) pull-down resistor connected internally between each enable pin (ENA, ENB) and GND.

Input Logic Low 2.7V ≤ VIN≤ 5.5V 0 0.5 V

Input Logic High 2.7V ≤ VIN≤ 5.5V 1.1 V

Input Leakage Current V

A-MAX=TJ-MAX-OP

IN,CPOUT,C1

=(1.5xVIN)–(R

, and C2: Low-ESR Surface-Mount Ceramic Capacitors (MLCCs) used in setting electrical characteristics

OUTxIOUT

= 3.6V; V

IN

= 8.35kΩ;CIN,C1,C2, and C

DxA

= 0.6V; V

DxB

POUT

VIN= 3.0V 2.7 Ω

I

=95%XI

Dxx

= 8.35kΩ

R

SET

(nom) ≈ 15mA)

(I

Dxx

1.5x to 1x Threshold 4.75 V

is

1x to 1.5x Threshold 4.55 V

IN

= 0V 0.1 µA

ENx

V

= 3V (Note 12) 10

ENx

) is dependent on the maximum operating junction temperature (T

A-MAX

), and the junction-to ambient thermal resistance of the part/package in the application (θJA), as given by the

D-MAX

–(θJAxP

) models all voltage losses in the charge pump. R

OUT

). In the equation, I

HR=VPout–VLEDx

).

D-MAX

is the total output current: the sum of all active Dxx output currents and all current drawn from P

OUT

. If headroom voltage requirement is not met, LED current regulation will be compromised.

= 3.6V; ENA = 1.5V and ENB = GND, or ENA = GND and ENB =

= 1µF. Specifications related to output current(s) and current setting

(nom)

Dxx

≤ 4.75V typ.).

IN

J

J-MAX-OP

can be used to estimate the voltage at the charge pump output (P

OUT

320 mV

IN

= 160˚C (typ.) and disengages at TJ=

= 125˚C), the maximum power

OUT

V

OUT

. The

):

www.national.com 4

Page 5

LM27961

Typical Performance Characteristics Unless otherwise specified: V

= 3.6V; ENA = VINand ENB = GND, or ENA = GND and ENB = VIN;R

1µF.

LED Current (D1A, D2A,D3A, D4A)

vs. Input Voltage LED Current (DxA) vs. Input Voltage

20127904 20127905

Quiescent Current vs. Input Voltage,

SETA=RSETB

= 8.35kΩ;CIN,C1,C2, and C

Charge Pump Output Voltage

vs. Output Current

= 3.6V; V

IN

LEDxA

= 3.6V; V

POUT

LEDxB

=

20127906

20127907

www.national.com5

Page 6

Typical Performance Characteristics Unless otherwise specified: V

= 3.6V; ENA = VINand ENB = GND, or ENA = GND and ENB = VIN;R

1µF. (Continued)

LM27961

SETA=RSETB

= 3.6V; V

IN

LEDxA

= 3.6V; V

= 8.35kΩ;CIN,C1,C2, and C

POUT

LEDxB

=

Charge Pump Output Voltage

vs. Output Current

Input Current vs. Input Voltage

20127910

Charge Pump Output Voltage

vs. Input Voltage (No Load Current)

20127908

Charge Pump Output Resistance

vs Output Current

20127909

www.national.com 6

20127911

Page 7

LM27961

Typical Performance Characteristics Unless otherwise specified: V

= 3.6V; ENA = VINand ENB = GND, or ENA = GND and ENB = VIN;R

1µF. (Continued)

Charge Pump Switching Frequency

vs. Input Voltage

20127912

Diode Current (DxB)

vs. Headroom Voltage (DxB)

SETA=RSETB

vs. PWM Duty Cycle (ENA or ENB)

= 8.35kΩ;CIN,C1,C2, and C

Diode Current (DxA)

vs. Headroom Voltage (DxA)

Diode Current (DxA or DxB)

= 3.6V; V

IN

LEDxA

= 3.6V; V

POUT

20127913

LEDxB

=

20127914

20127915

www.national.com7

Page 8

Typical Performance Characteristics Unless otherwise specified: V

= 3.6V; ENA = VINand ENB = GND, or ENA = GND and ENB = VIN;R

1µF. (Continued)

LM27961

SETA=RSETB

= 3.6V; V

IN

LEDxA

= 3.6V; V

= 8.35kΩ;CIN,C1,C2, and C

POUT

LEDxB

=

Diode Current (DxA)

vs. R

SETx

20127916

ENx Signal (Top)

and Charge Pump Start-Up (Bottom) Waveforms

Input Voltage (Top)

and Output Voltage (Bottom) Waveforms

20127917

Vertical Scale = (100mV/div),

Horizontal Scale = 1µs/div)

Vertical Scale = (2V/div),

20127918

Horizontal Scale = 100µs/div)

www.national.com 8

Page 9

Block Diagram

LM27961

Circuit Description

OVERVIEW

The LM27961 is primarily intended for Lithium-Ion battery

driven white-LED drive applications, and is well suited to

drive white LEDs that are used for backlighting small-format

displays. The part has seven matched constant-current outputs, each capable of driving up to 20mA (or more) through

white LEDs. The well-matched current sources ensure the

current through all the LEDs is virtually identical. This keeps

brightness of all LEDs matched to near perfection so that

they can provide a consistent backlight over the entire display.

CHARGE PUMP

The core of the LM27961 is a 1.5x/1x dual-mode charge

pump. The input of the charge pump is connected to the V

pin. The recommended input voltage range of the LM27961

is 2.7V to 5.5V. The output of the charge pump is the P

pin (“Pump OUTput”). The output voltage of the charge

pump is unregulated and varies with input voltage and load

current.

The charge pump operates in the 1.5x mode when the input

voltage is below 4.75V (typ.). In this mode, the input-to-

OUT

20127903

output voltage gain of the charge pump is 1.5, and the

voltage at the output of the charge pump will be approximately 1.5x the input voltage (V(P

) ≈ 1.5*VIN). When in

OUT

the 1.5x mode, the charge pump provides the voltage boost

that is required to drive white LEDs from a Li-Ion battery.

(White LEDs typically have a forward voltage in the range of

3.3V to 4.0V. A Li-Ion battery typically is not considered to be

fully discharged until the battery voltage falls to 3.0V (approx.) )

The charge pump operates in the 1x mode when the input

voltage is above 4.75V (typ.). In these conditions, voltage

boost is not required to drive the LEDs, so the charge pump

merely passes the input voltage to P

OUT

(V(P

OUT

) ≈ VIN).

This reduces the input current and the power dissipation of

the LM27961 when the input voltage is high.

REGULATED CURRENT OUTPUTS

IN

The matched current outputs are generated with a precision

current mirror that is biased off the charge pump output.

Matched currents are ensured with the use of tightly

matched internal devices and internal mismatch cancellation

circuitry.

There are seven regulated current outputs. These seven

outputs are split into two groups, a group of 4 common

www.national.com9

Page 10

Circuit Description (Continued)

anode outputs and a group of 3 common cathode outputs.

LM27961

There is an ON/OFF control pin for each group (ENA and

ENB).

The DC current through the LEDs is programmed with an

external resistor. Changing currents on-the-fly can be

achieved with the use of digital pulse (PWM) signals.

ENABLE PINS: ENA, ENB

The LM27961 has 2 enable pins. Both are active-high logic

(HIGH = ON). There are internal pull-down resistors (300kΩ

typ.) that are connected internally between each of the enable pins and GND.

ENA and ENB can both enable and disable the part. When

the voltage on both pins are low (

shutdown mode. All internal circuitry is OFF and the part

consumes very little supply current when the LM27961 is

shutdown. When the voltage on either ENx pin is high

>

1.1V), the part is active. The charge pump is ON, and the

(

corresponding output current drivers are active.

ENA and ENB are used to turn the output currents ON and

OFF. ENA activates/deactivates the four GroupA outputs

(D1A-D4A). ENB activates/deactivates the three GroupB

outputs (D1B-D3B).

SETTING LED CURRENTS

The output currents of the LM27961 can be set to a desired

value simply by connecting an appropriately sized resistor

) between the I

(R

SETx

sets the current for the GroupA outputs and R

R

SETA

pins of the LM27961 and GND.

SETx

sets the current for the GroupB outputs. The output currents

(LED currents) are proportional to the current that flows out

of the I

greater than the I

pins. The output currents are a factor of 100

SETx

current. The feedback loop of an

SETx

internal amplifier sets the voltage of the I

(typ.). Placing a resistor between I

the I

current, and thus the LED currents. The statements

SETx

above are simplified in the equations below:

=100x(V

I

Dxx

= 100 x (1.25V / I

R

SETx

MAXIMUM OUTPUT CURRENT, MAXIMUM LED VOLTAGE, MINIMUM INPUT VOLTAGE

The LM27961 can drive 4 LEDs at 15mA each from an input

voltage as low as 2.7V, so long as the LEDs have a forward

voltage of 3.5V or less (room temperature).

The statement above is a simple example of the LED drive

capabilities of the LM27961. The statement contains the key

application parameters that are required to validate an LEDdrive design using the LM27961: LED current (I

ber of active LEDs (N), LED forward voltage (V

minimum input voltage (V

IN-MIN

The equation below can be used to estimate the total output

current capability of the LM27961:

I

LED_MAX

I

LED_MAX

R

= ((1.5 x VIN)-V

= ((1.5 x VIN)-V

– Output resistance. This parameter models the inter-

OUT

LED

LED

nal losses of the charge pump that result in voltage droop at

the pump output P

. Since the magnitude of the voltage

OUT

droop is proportional to the total output current of the charge

pump, the loss parameter is modeled as a resistance. The

output resistance of the LM27961 is typically 2.7Ω (V

3.0V, T

= 25˚C). In equation form:

A

<

0.5V), the part is in

SETx

and GND programs

SETx

Dxx

)

)

SETx/RSETx

).

)/((NxR

)+kHR) (eq. 1)

OUT

) / ((N x 2.7Ω) + 22mV/mA)

SETB

pin to 1.25V

), num-

LEDx

), and

LED

IN

V

= 1.5xVIN– NxI

POUT

– Headroom constant. This parameter models the mini-

k

HR

LEDxROUT

(eq. 2)

mum voltage required to be present across the current

sources for them to regulate properly. This minimum voltage

is proportional to the programmed LED current, so the constant has units of mV/mA. The typical k

of the LM27961 is

HR

22mV/mA. In equation form:

The "I

LED-MAX

the R

OUT

solving for I

(V

POUT–VLED

)>kHRxI

" equation (eq. 1) is obtained from combining

equation (eq. 2) with the kHRequation (eq. 3) and

. Maximum LED current is highly dependent

LED

LED

(eq. 3)

on minimum input voltage and LED forward voltage. Output

current capability can be increased by raising the minimum

input voltage of the application, or by selecting an LED with

a lower forward voltage. Excessive power dissipation may

also limit output current capability of an application.

PARALLEL Dx OUTPUTS FOR INCREASED CURRENT CAPABILITY

Outputs D1A through D4A, or D1B through D3B may be

connected together in any combination to drive higher currents through fewer LEDs. For example in Figure 1, outputs

D1A and D2A are connected together to drive one LED. D3A

and D4A are connected to drive a second LED.

20127919

FIGURE 1. Two Parallel Connected LEDs

With this configuration, two parallel current sources of equal

value provide current to one of the LEDs. R

SET

should

therefore be chosen so that the current through each output

is programmed to 50% of the desired current through the

parallel connected LED. For example, if 40mA is the desired

drive current for the parallel connected LED, R

SETx

should

be selected so that the current through each of the outputs is

20mA. Other combinations of parallel outputs may be implemented in similar fashions, such as in Figure 2.

=

www.national.com 10

Page 11

Circuit Description (Continued)

20127920

FIGURE 2. One Parallel Connected LED

Connecting outputs in parallel does not affect internal operation of the LM27961 and has no impact on the Electrical

Characteristics and limits previously presented. The available diode output current, maximum diode voltage, and all

other specifications provided in the Electrical Characteristics

table apply to parallel output configurations, just as they do

to the standard application circuit on pg1 of the datasheet.

SOFT START

The LM27961 contains internal soft-start circuitry to limit

input inrush currents when the part is enabled. Soft start is

implemented with a controlled turn-on of the internal voltage

reference. During soft start, the current through the LED

outputs rise at the rate of the reference voltage ramp. Due to

the soft-start circuitry, turn-on time of the LM27961 is approximately 350µs (typ.).

THERMAL PROTECTION

Internal thermal protection circuitry disables the LM27961

when the junction temperature exceeds 160˚C (typ.). This

feature protects the device from being damaged by high die

temperatures that might otherwise result from excessive

power dissipation. The device will recover and operate normally when the junction temperature falls below 120˚C (typ.).

It is important that the board layout provides good thermal

conduction. This will help to keep the junction temperature

within specified operating ratings.

Applications Information

POWER EFFICIENCY

Efficiency of LED drivers is commonly taken to be the ratio of

power consumed by the LEDs (P

the input of the part (P

current is approximately 1.5x the output current (total LED

current). For a simple approximation, the current consumed

by internal circuitry can be neglected and the efficiency of

the LM27961 can be predicted as follows:

). With a 1.5x charge pump, the input

IN

) to the power drawn at

LED

Neglecting IQwill result in a slightly higher efficiency prediction, but this impact will be no more than a few percentage

points when several LEDs are driven at full power.

ADJUSTING LED BRIGHTNESS (PWM control)

Perceived LED brightness can be adjusted using a PWM

control signal to turn the LM27961 current sources ON and

OFF at a rate faster than perceptible by the eye. When this

is done, the total brightness perceived is proportional to the

duty cycle (D) of the PWM signal (D = the percentage of time

that the LED is on in every PWM cycle). A simple example: if

the LEDs are driven at 15mA each with a PWM signal that

has a 50% duty cycle, perceived LED brightness will be

about half as bright as compared to when the LEDs are

driven continuously with 15mA. A PWM signal thus provides

brightness (dimming) control for the solution.

The minimum recommended PWM frequency is 100Hz. Frequencies below this may be visibly noticeable as flicker or

blinking. The maximum recommended PWM frequency is

1kHz. Frequencies above this may cause interference with

internal current driver circuitry.

In cases where a PWM signal must be connected to the ENx

pins, measures can be taken to reduce the magnitude of the

charge-pump turn-on voltage spikes. More input capacitance, series resistors and/or ferrite beads may provide benefits.

If the current and voltage spikes can be tolerated, connecting the PWM signal to the EN pin does provide a benefit:

lower supply current when the PWM signal is active. When

the PWM signal is low, the LM27961 will be shutdown and

input current will only be a few micro-amps. This results in a

lower time-averaged input current.

CAPACITOR SELECTION

The LM27961 requires 4 external capacitors for proper operation. Surface-mount multi-layer ceramic capacitors are

recommended. These capacitors are small, inexpensive and

have very low equivalent series resistance (ESR

typ.). Tantalum capacitors, OS-CON capacitors, and aluminum electrolytic capacitors are not recommended for use

with the LM27961 due to their high ESR, as compared to

ceramic capacitors.

For most applications, ceramic capacitors with X7R or X5R

temperature characteristic are preferred for use with the

LM27961. These capacitors have tight capacitance tolerance (as good as

ture (X7R:

-55˚C to 85˚C).

Capacitors with Y5V or Z5U temperature characteristic are

generally not recommended for use with the LM27961. Capacitors with these temperature characteristics typically

have wide capacitance tolerance (+80%, -20%) and vary

significantly over temperature (Y5V: +22%, -82% over -30˚C

to +85˚C range; Z5U: +22%, -56% over +10˚C to +85˚C

range). Under some conditions, a nominal 1µF Y5V or Z5U

capacitor could have a capacitance of only 0.1µF. Such

detrimental deviation is likely to cause Y5V and Z5U capacitors to fail to meet the minimum capacitance requirements of

the LM27961.

±

10%) and hold their value over tempera-

±

15% over -55˚C to 125˚C; X5R:±15% over

<

20mW

LM27961

www.national.com11

Page 12

Applications Information (Continued)

The voltage rating of the output capacitor should be 10V or

LM27961

more. All other capacitors should have a voltage rating at or

above the maximum input voltage of the application.

CIRCUIT BOARD LAYOUT

For optimal, low-noise performance, all capacitors (C

, C1, C2) should be placed very close to the LM27961.

C

POUT

A solid ground plane should be used for IC and component

GND connections. Refer to the LM27961 Evaluation Board

for an example layout.

MICRO SMD MOUNTING

The LM27961 is an 18-bump micro SMD with a bump size of

approximately 300 micron diameter. The micro SMD package requires specific mounting techniques detailed in National Semiconductor Application Note 1112 (AN-1112).

,

IN

www.national.com 12

Page 13

Physical Dimensions inches (millimeters) unless otherwise noted

LM27961 Dual-Display White LED Driver with 3/2x Switched Capacitor Boost

TLA18EHA: 18-Bump Thin Micro SMD, Large Bump

±

X1 = 2.098

X2 = 2.403mm

X3 = 0.600mm

0.030mm

±

0.030

±

0.075mm

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves

the right at any time without notice to change said circuitry and specifications.

For the most current product information visit us at www.national.com.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS

WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL COUNSEL OF NATIONAL SEMICONDUCTOR

CORPORATION. As used herein:

1. Life support devices or systems are devices or systems

which, (a) are intended for surgical implant into the body, or

(b) support or sustain life, and whose failure to perform when

properly used in accordance with instructions for use

2. A critical component is any component of a life support

device or system whose failure to perform can be reasonably

expected to cause the failure of the life support device or

system, or to affect its safety or effectiveness.

provided in the labeling, can be reasonably expected to result

in a significant injury to the user.

BANNED SUBSTANCE COMPLIANCE

National Semiconductor certifies that the products and packing materials meet the provisions of the Customer Products Stewardship

Specification (CSP-9-111C2) and the Banned Substances and Materials of Interest Specification (CSP-9-111S2) and contain no ‘‘Banned

Substances’’ as defined in CSP-9-111S2.

National Semiconductor

Americas Customer

Support Center

Email: new.feedback@nsc.com

Tel: 1-800-272-9959

www.national.com

National Semiconductor

Europe Customer Support Center

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Support Center

Email: ap.support@nsc.com

National Semiconductor

Japan Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

Loading...

Loading...