December 5, 2007

LM2756

Multi-Display Inductorless LED Driver with 32 Exponential

Dimming Steps in micro SMD

LM2756 Multi-Display Inductorless LED Driver with 32 Exponential Dimming Steps in micro SMD

General Description

The LM2756 is a highly integrated, switched-capacitor, multidisplay LED driver that can drive up to 8 LEDs in parallel with

a total output current of 180mA. Regulated internal current

sources deliver excellent current and brightness matching in

all LEDs.

The LED driver current sinks are split into three independently

controlled groups. The primary group (Group A) can be configured to drive four, five or six LEDs for use in the main phone

display, while the secondary group (Group B) can be configured to drive one, two or three LEDs for driving secondary

displays, keypads and/or indicator LEDs. An additional driver,

D1C, is provided for additional indicator lighting functions.

The device provides excellent efficiency without the use of an

inductor by operating the charge pump in a gain of 3/2 or in

Pass-Mode. The proper gain for maintaining current regulation is chosen, based on LED forward voltage, so that efficiency is maximized over the input voltage range.

The LM2756 is available in National’s tiny 20-bump, 0.4mm

pitch, thin micro SMD package.

Features

Drives up to 8 LEDs with up to 30mA of Diode Current

■

Each

32 Exponential Dimming Steps with 800:1 Dimming Ratio

■

for Group A (Up to 6 LEDs)

8 Linear Dimming States for Groups B (Up to 3 LEDs) and

■

D1C (1 LED)

Programmable Auto-Dimming Function

■

3 Independently Controlled LED Groups Via I2C

■

Compatible Interface

Up to 90% Efficiency

■

Total Solution Size < 21mm

■

Low Profile 20 Bump micro SMD Package

■

(1.615mm × 2.015mm × 0.6mm)

0.4% Accurate Current Matching

■

Internal Soft-Start Limits Inrush Current

■

True Shutdown Isolation for LED’s

■

Wide Input Voltage Range (2.7V to 5.5V)

■

Active High Hardware Enable

■

2

Applications

Dual Display LCD Backlighting for Portable Applications

■

Large Format LCD Backlighting

■

Display Backlighting with Indicator Light

■

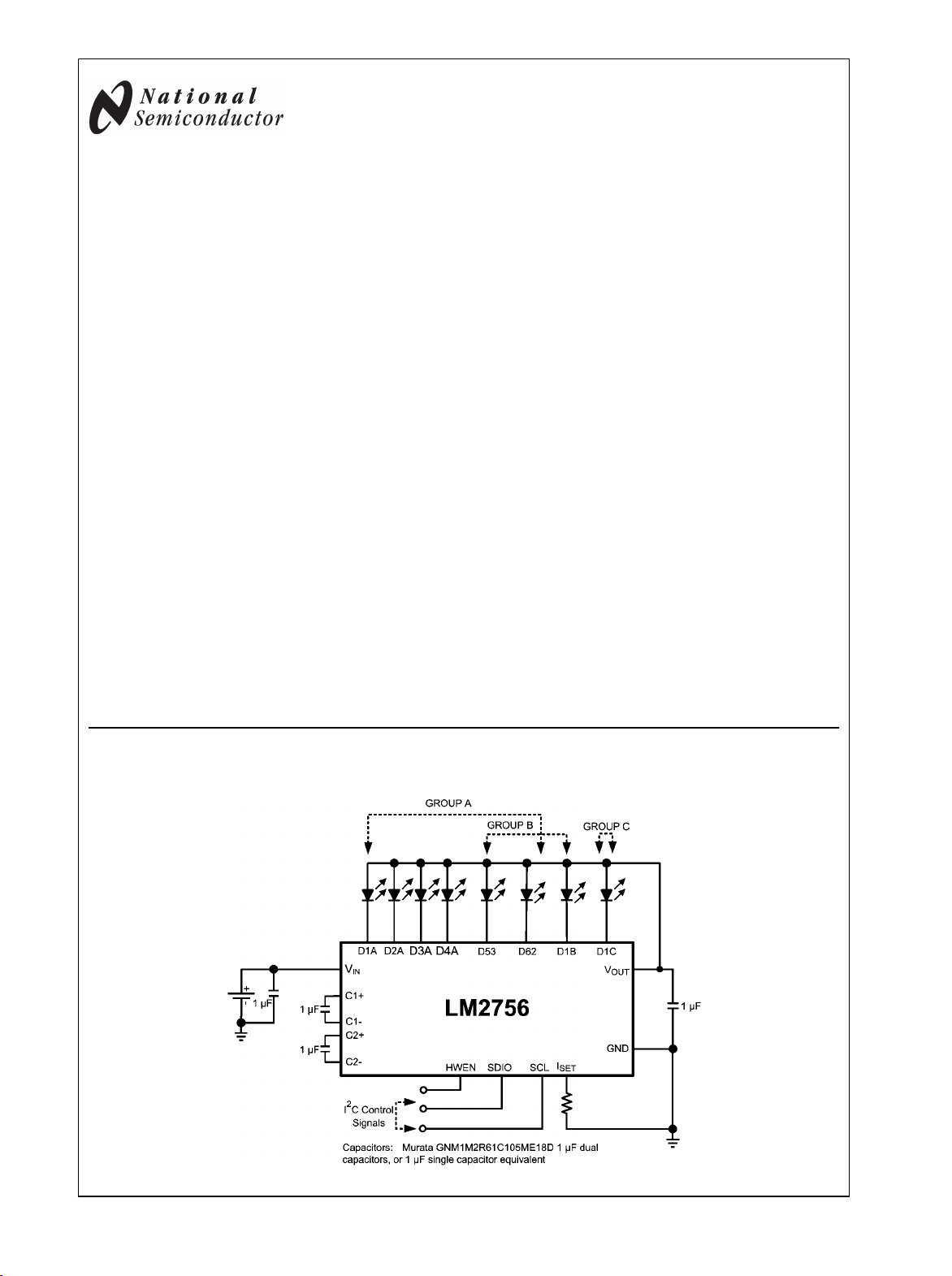

Typical Application Circuit

30009701

© 2007 National Semiconductor Corporation 300097 www.national.com

LM2756

Minimum Layout

30009741

Connection Diagram

20 Bump micro SMD Package

NS Package Number TMD20AAA

30009702

Pin Descriptions

Bump #s

TMD20AAA

A3 V

A2 V

A1, C1, B1, B2 C1+, C1-, C2+, C2- Flying Capacitor Connections

D3, E3,E4, D4 D1A-D4A LED Drivers - GroupA

C4, B4 D53, D62 LED Drivers - Configurable Current Sinks. Can be assigned to GroupA or GroupB

B3 D1B LED Drivers - GroupB

C3 D1C LED Driver - Indicator LED

D2 I

E1 HWEN Hardware Enable Pin. High = Normal Operation, Low = RESET

C2 SDIO Serial Data Input/Output Pin

E2 SCL Serial Clock Pin

A4, D1 GND Ground

Pin Names Pin Descriptions

IN

OUT

SET

Input voltage. Input range: 2.7V to 5.5V.

Charge Pump Output Voltage

Placing a resistor (R

) between this pin and GND sets the full-scale LED current for

SET

DxA , DxB, D53, D62 and D1C LEDs.

Full-Scale LED Current = 189 × (1.25V ÷ R

SET

)

Ordering Information

Order Information Package Supplied As

LM2756TM

LM2756TMX 3000 Units, Tape & Reel

www.national.com 2

TMD20AAA

250 Units, Tape & Reel

LM2756

Absolute Maximum Ratings (Notes 1, 2)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

VIN pin voltage -0.3V to 6.0V

SCL, SDIO, HWEN pin voltages -0.3V to (VIN+0.3V)

w/ 6.0V max

I

Pin Voltages -0.3V to (V

Dxx

Continuous Power Dissipation

Internally Limited

(Note 3)

Junction Temperature (T

) 150°C

J-MAX

Storage Temperature Range -65°C to +150° C

Maximum Lead Temperature

(Soldering)

ESD Rating(Note 5)

Human Body Model 2.0kV

+0.3V)

VOUT

w/ 6.0V max

(Note 4)

Operating Rating

(Notes 1, 2)

Input Voltage Range 2.7V to 5.5V

LED Voltage Range 2.0V to 4.0V

Junction Temperature (TJ) Range

Ambient Temperature (TA) Range

(Note 6)

-30°C to +105°C

-30°C to +85°C

Thermal Properties

Junction-to-Ambient Thermal

Resistance (θJA),

TMD20 Package

40°C/W

(Note 7)

ESD Caution Notice National Semiconductor

recommends that all integrated circuits be handled with

appropriate ESD precautions. Failure to observe proper ESD

handling techniques can result in damage to the device.

Electrical Characteristics (Notes 2, 8)

Limits in standard typeface are for TJ = 25°C, and limits in boldface type apply over the full operating temperature range. Unless

otherwise specified: VIN = 3.6V; V

Current; ENA, ENB, ENC Bits = “1”; SD53, SD62, 53A, 62A Bits = "0"; C1 = C2 = CIN= C

output current(s) and current setting pins (I

Symbol Parameter Condition Min Typ Max Units

Output Current Regulation

GroupA

Output Current Regulation

GroupB

I

Dxx

Output Current Regulation

IDC

Maximum Diode Current per Dxx

Output(Note 10)

Output Current Regulation

GroupA, GroupB, and GroupC

Enabled

(Note 10)

I

Dxx-

MATCH

V

DxTH

LED Current Matching(Note 11)

V

1x to 3/2x Gain Transition

Dxx

Threshold

Current sink Headroom Voltage

V

HR

Requirement

(Note 12)

R

OUT

I

Q

Open-Loop Charge Pump Output

Resistance

Quiescent Supply Current Gain = 1.5x, No Load 2.1 2.5 mA

HWEN

= VIN; V

Dxx

= V

= V

DxA

and I

DxB

) apply to GroupA and GroupB. (Note 9)

SET

= 0.4V; R

DxC

2.7V ≤ VIN ≤ 5.5V

ENA = '1', 53A = 62A = '0'', ENB = ENC = '0'

4 LEDs in GroupA

2.7V ≤ VIN ≤ 5.5V

ENA = '1', 53A = 62A = '1', ENB = ENC = '0'

6 LEDs in GroupA

2.7V ≤ VIN ≤ 5.5V

ENB = '1', 53A = 62A = '0', ENA = ENC = '0'

3 LEDs in GroupB

2.7V ≤ VIN ≤ 5.5V

ENC = '1', ENA = ENB = '0'

R

= 8.33kΩ

SET

3.2V ≤ VIN ≤ 5.5V

V

= 3.6V

LED

R

= 10.5kΩ

SET

= 11.8kΩ; GroupA = GroupB = GroupC = Fullscale

SET

= 1.0µF; Specifications related to

OUT

18.65

(-8%)

18.70

(-8.5%)

18.40

(-8%)

18.20

(-7.5%)

20.28

20.40

20.00

19.70

30 mA

22.5

DxA

22.5

DxB

22.5

DxC

GroupA (4 LEDs) 0.4 1.8

2.7V ≤ VIN ≤ 5.5V

GroupB (3 LEDs) 0.7 2.5

V

and/or V

DxA

I

= 95% ×I

Dxx

(I

(nom) ≈ 20mA)

Dxx

DxB

Dxx

Falling

(nom.)

150 mV

65 mV

Gain = 3/2 2.4

Gain = 1 0.9

21.90

(+8%)mA(%)

22.10

(+8.5%)mA(%)

21.60

(+8%)mA(%)

21.20

(+7.5%)mA(%)

mA

%GroupA (6 LEDs) 1.0 2.7

Ω

3 www.national.com

Symbol Parameter Condition Min Typ Max Units

I

SD

LM2756

V

SET

I

DxA-B-C /

I

SET

f

SW

t

START

V

HWEN

Shutdown Supply Current All ENx bits = "0" 3.7 5.5 µA

I

Pin Voltage

SET

Output Current to Current Set Ratio

GroupA, GroupB, GroupC

2.7V ≤ VIN ≤ 5.5V

189

1.25 V

Switching Frequency 1.0 1.3 1.6 MHz

V

Start-up Time

HWEN Voltage Thresholds

= 90% steady state

OUT

2.7V ≤ VIN ≤ 5.5V

250 µs

Reset 0 0.580

Normal Operation 1.075

V

IN

I2C Compatible Interface Voltage Specifications (SCL, SDIO)

V

IL

V

IH

V

OL

Input Logic Low "0"

Input Logic High "1"

Output Logic Low "0"

2.7V ≤ VIN ≤ 5.5V

2.7V ≤ VIN ≤ 5.5V

I

= 3.5mA

LOAD

0 0.710 V

1.225

V

IN

400 mV

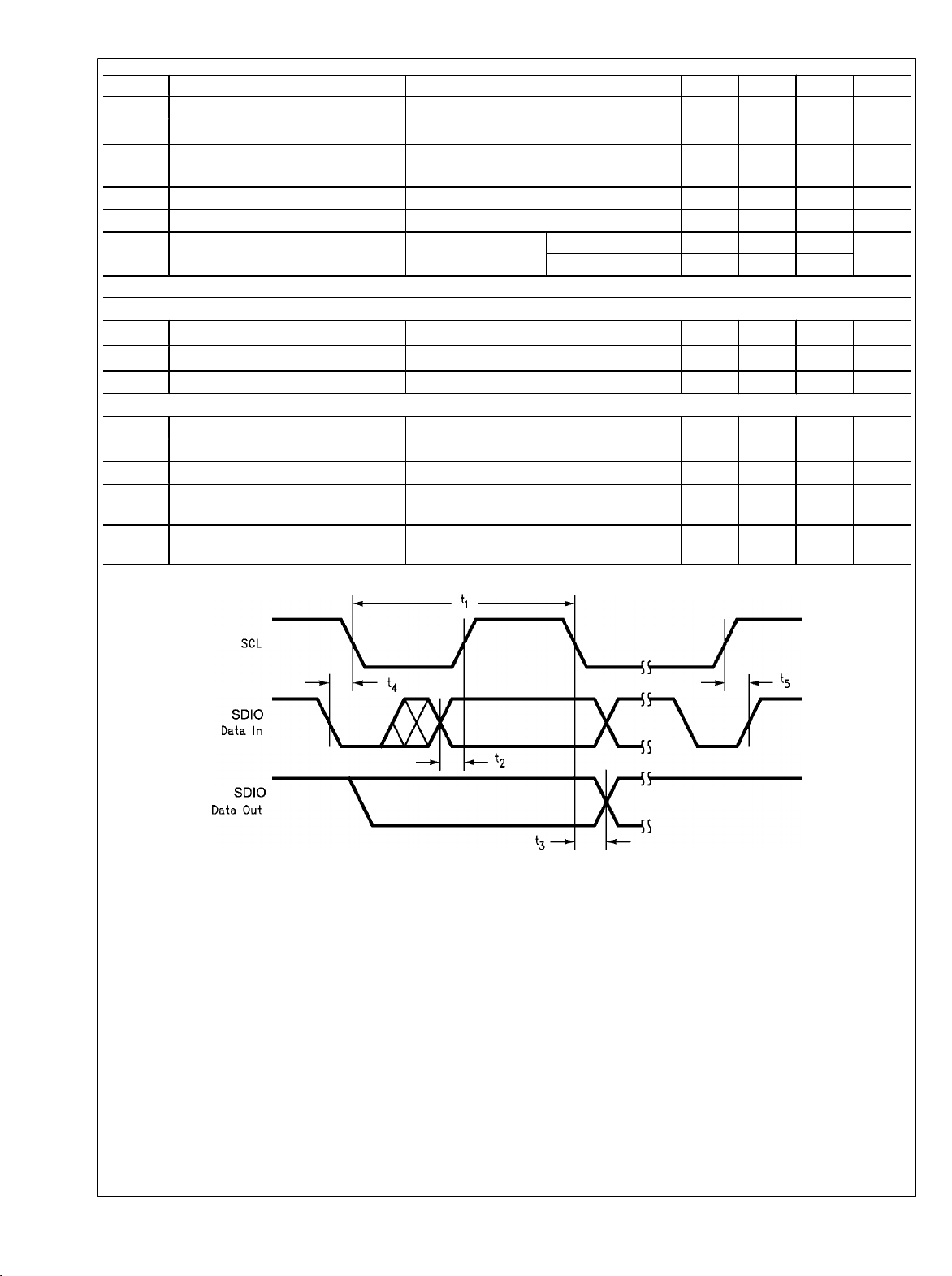

I2C Compatible Interface Timing Specifications (SCL, SDIO)(Note 13)

t

1

t

2

t

3

t

4

t

5

SCL (Clock Period) (Note 14) 294 ns

Data In Setup Time to SCL High 100 ns

Data Out stable After SCL Low 0 ns

SDIO Low Setup Time to SCL Low

(Start)

SDIO High Hold Time After SCL High

(Stop)

100 ns

100 ns

V

V

30009713

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the component may occur. Operating Ratings are conditions under which operation

of the device is guaranteed. Operating Ratings do not imply guaranteed performance limits. For guaranteed performance limits and associated test conditions,

see the Electrical Characteristics tables.

Note 2: All voltages are with respect to the potential at the GND pins.

Note 3: Internal thermal shutdown circuitry protects the device from permanent damage. Thermal shutdown engages at TJ = 160°C (typ.) and disengages at T

= 155°C (typ.).

Note 4: For detailed soldering specifications and information, please refer to National Semiconductor Application Note 1112: Micro SMD Wafer Level Chip Scale

Package (AN-1112).

Note 5: The human body model is a 100pF capacitor discharged through a 1.5kΩ resistor into each pin. (MIL-STD-883 3015.7)

Note 6: In applications where high power dissipation and/or poor package thermal resistance is present, the maximum ambient temperature may have to be

derated. Maximum ambient temperature (T

dissipation of the device in the application (P

following equation: T

Note 7: Junction-to-ambient thermal resistance is highly dependent on application and board layout. In applications where high maximum power dissipation

exists, special care must be paid to thermal dissipation issues in board design. For more information, please refer to National Semiconductor Application Note

1112: Micro SMD Wafer Level Chip Scale Package (AN-1112).

Note 8: Min and Max limits are guaranteed by design, test, or statistical analysis. Typical numbers are not guaranteed, but do represent the most likely norm.

Note 9: CIN, C

www.national.com 4

VOUT

= T

A-MAX

, C1, and C2 : Low-ESR Surface-Mount Ceramic Capacitors (MLCCs) used in setting electrical characteristics

J-MAX-OP

– (θJA × P

) is dependent on the maximum operating junction temperature (T

A-MAX

), and the junction-to ambient thermal resistance of the part/package in the application (θJA), as given by the

D-MAX

).

D-MAX

= 105°C), the maximum power

J-MAX-OP

J

Note 10: The maximum total output current for the LM2756 should be limited to 180mA. The total output current can be split among any of the three Groups

(I

= I

= I

DxA

proper current regulation. See the Maximum Output Current section of the datasheet for more information.

= 30mA Max.). Under maximum output current conditions, special attention must be given to input voltage and LED forward voltage to ensure

DxB

DxC

Note 11: For the two groups of current sinks on a part (GroupA and GroupB), the following are determined: the maximum sink current in the group (MAX), the

minimum sink current in the group (MIN), and the average sink current of the group (AVG). For each group, two matching numbers are calculated: (MAX-AVG)/

AVG and (AVG-MIN)/AVG. The largest number of the two (worst case) is considered the matching figure for the Group. The matching figure for a given part is

considered to be the highest matching figure of the two Groups. The typical specification provided is the most likely norm of the matching figure for all parts.

Note 12: For each Dxx pin, headroom voltage is the voltage across the internal current sink connected to that pin. For Group A, B, and C current sinks, V

V

-V

. If headroom voltage requirement is not met, LED current regulation will be compromised.

OUT

LED

HRx

=

Note 13: SCL and SDIO should be glitch-free in order for proper brightness control to be realized.

Note 14: SCL is tested with a 50% duty-cycle clock.

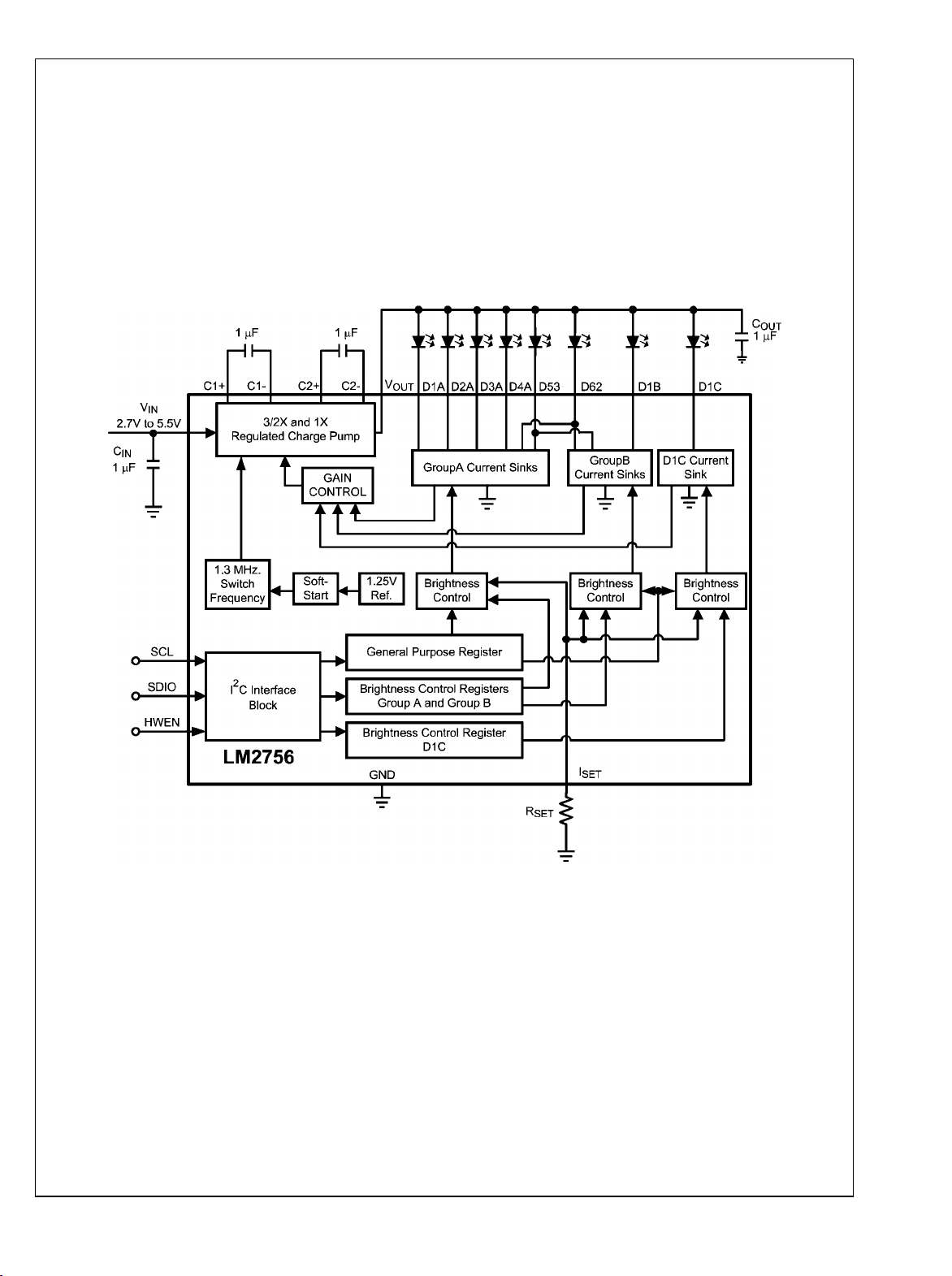

Block Diagram

LM2756

30009703

5 www.national.com

Typical Performance Characteristics Unless otherwise specified: T

V

LEDxA

LM2756

= V

LEDxB

= V

LED1C

= 3.6V; R

= 11.8kΩ; C1=C2= CIN = C

SET

LED Drive Efficiency vs Input Voltage

= 1µF; ENA = ENB = ENC = '1'.

VOUT

LED Drive Efficiency vs Input Voltage

= 25°C; VIN = 3.6V; V

A

HWEN

= VIN;

30009719

Input Current vs Input Voltage

30009720

GroupB Diode Current vs Input Voltage

30009721

GroupA Diode Current vs Input Voltage

30009726

GroupC Diode Current vs Input Voltage

30009727

www.national.com 6

30009728

LM2756

GroupA Current Matching vs Input Voltage

6 LEDs

30009716

GroupB Current Matching vs Input Voltage

3 LEDs

GroupA Current Matching vs Input Voltage

4 LEDs

30009717

GroupA Diode Current vs GroupA Brightness Code

30009718

GroupB Diode Current vs GroupB Brightness Code

30009723

30009722

GroupC Diode Current vs GroupC Brightness Code

30009724

7 www.national.com

LM2756

Quiescent Current in Gain 1.5× vs Input Voltage

Shutdown Current vs Input Voltage

30009714

30009715

www.national.com 8

LM2756

Circuit Description

OVERVIEW

The LM2756 is a white LED driver system based upon an

adaptive 3/2× - 1× CMOS charge pump capable of supplying

up to 180mA of total output current. With three separately

controlled Groups of constant current sinks, the LM2756 is an

ideal solution for platforms requiring a single white LED driver

for main display, sub display, and indicator lighting. The tightly

matched current sinks ensure uniform brightness from the

LEDs across the entire small-format display.

Each LED is configured in a common anode configuration,

with the peak drive current being programmed through the

use of an external R

is used to enable the device and vary the brightness within

the individual current sink Groups. For GroupA , 32 exponentially-spaced analog brightness control levels are available.

GroupB and GroupC have 8 linearly-spaced analog brightness levels.

CIRCUIT COMPONENTS

Charge Pump

The input to the 3/2× - 1× charge pump is connected to the

VIN pin, and the regulated output of the charge pump is connected to the V

range of the LM2756 is 2.7V to 5.5V. The device’s regulated

charge pump has both open loop and closed loop modes of

operation. When the device is in open loop, the voltage at

V

is equal to the gain times the voltage at the input. When

OUT

the device is in closed loop, the voltage at V

to 4.6V (typ.). The charge pump gain transitions are actively

selected to maintain regulation based on LED forward voltage

and load requirements.

LED Forward Voltage Monitoring

The LM2756 has the ability to switch gains (1x or 3/2x) based

on the forward voltage of the LED load. This ability to switch

gains maximizes efficiency for a given load. Forward voltage

monitoring occurs on all diode pins. At higher input voltages,

the LM2756 will operate in pass mode, allowing the V

voltage to track the input voltage. As the input voltage drops,

the voltage on the Dxx pins will also drop (V

V

). Once any of the active Dxx pins reaches a voltage

LEDx

approximately equal to 150mV, the charge pump will switch

to the gain of 3/2. This switch-over ensures that the current

through the LEDs never becomes pinched off due to a lack of

headroom across the current sinks. Once a gain transition

occurs, the LM2756 will remain in the gain of 3/2 until an

I2C write to the part occurs. At that time, the LM2756 will

re-evaluate the LED conditions and select the appropriate gain.

Only active Dxx pins will be monitored. For example, if only

GroupA is enabled, the LEDs in GroupB or GroupC will not

affect the gain transition point. If all 3 Groups are enabled, all

diodes will be monitored, and the gain transition will be based

upon the diode with the highest forward voltage.

Configurable Gain Transition Delay

To optimize efficiency, the LM2756 has a user selectable gain

transition delay that allows the part to ignore short duration

input voltage drops. By default, the LM2756 will not change

gains if the input voltage dip is shorter than 3 to 6 milliseconds.

There are four selectable gain transition delay ranges available on the LM2756. All delay ranges are set within the VF

Monitor Delay Register . Please refer to the INTERNAL REG-

resistor. An I2C compatible interface

SET

pin. The recommended input voltage

OUT

is regulated

OUT

= V

DXX

OUT

VOUT

ISTERS section of this datasheet for more information regarding the delay ranges.

HWEN Pin

The LM2756 has a hardware enable/reset pin (HWEN) that

allows the device to be disabled by an external controller

without requiring an I2C write command. Under normal operation, the HWEN pin should be held high (logic '1') to prevent

an unwanted reset. When the HWEN is driven low (logic '0'),

all internal control registers reset to the default states and the

part becomes disabled. Please see the Electrical Character-

istics section of the datasheet for required voltage thresholds.

I2C Compatible Interface

DATA VALIDITY

The data on SDIO line must be stable during the HIGH period

of the clock signal (SCL). In other words, state of the data line

can only be changed when SCL is LOW.

30009725

FIGURE 1. Data Validity Diagram

A pull-up resistor between the controller's VIO line and SDIO

must be greater than [ (VIO-VOL) / 3.5mA] to meet the V

requirement on SDIO. Using a larger pull-up resistor results

OL

in lower switching current with slower edges, while using a

smaller pull-up results in higher switching currents with faster

edges.

START AND STOP CONDITIONS

START and STOP conditions classify the beginning and the

end of the I2C session. A START condition is defined as SDIO

–

signal transitioning from HIGH to LOW while SCL line is

HIGH. A STOP condition is defined as the SDIO transitioning

from LOW to HIGH while SCL is HIGH. The I2C master always

generates START and STOP conditions. The I2C bus is considered to be busy after a START condition and free after a

STOP condition. During data transmission, the I2C master

can generate repeated START conditions. First START and

repeated START conditions are equivalent, function-wise.

30009711

FIGURE 2. Start and Stop Conditions

TRANSFERING DATA

Every byte put on the SDIO line must be eight bits long, with

the most significant bit (MSB) transferred first. Each byte of

data has to be followed by an acknowledge bit. The acknowledge related clock pulse is generated by the master. The

9 www.national.com

master releases the SDIO line (HIGH) during the acknowledge clock pulse. The LM2756 pulls down the SDIO line

during the 9th clock pulse, signifying an acknowledge. The

LM2756

LM2756 generates an acknowledge after each byte is received.

After the START condition, the I2C master sends a chip address. This address is seven bits long followed by an eighth

ack = acknowledge (SDIO pulled down by either master or slave)

id = chip address, 36h for LM2756

bit which is a data direction bit (R/W). The LM2756 address

is 36h. For the eighth bit, a “0” indicates a WRITE and a “1”

indicates a READ. The second byte selects the register to

which the data will be written. The third byte contains data to

write to the selected register.

30009712

FIGURE 3. Write Cycle

w = write (SDIO = "0")

r = read (SDIO = "1")

I2C COMPATIBLE CHIP ADDRESS

The chip address for LM2756 is 0110110, or 36h.

FIGURE 4. Chip Address

INTERNAL REGISTERS OF LM2756

Register Internal Hex

Power On Value

Address

General Purpose

10h 0000 0000

Register

Group A

A0h 1110 0000

Brightness Control

Register

Group B

B0h 1111 1000

Brightness Control

Register

Group C

C0h 1111 1000

Brightness Control

Register

Ramp Step Time

20h 1111 0000

Register

VF Monitor Delay

60h 1111 1100

Ragister

30009709

FIGURE 5. General Purpose Register Description

Internal Hex Address: 10h

Note:

ENA: Enables DxA LED drivers (Main Display)

ENB: Enables DxB LED drivers (Aux Lighting)

ENC: Enables D1C LED driver (Indicator Lighting)

SD53: Shuts down driver D53

SD62: Shuts down driver D62

53A: Configures D53 to GroupA

62A: Configures D62 to GroupA

FIGURE 6. Brightness Control Register Description

30009708

30009705

30009706

30009707

www.national.com 10

LM2756

Internal Hex Address: 0xA0 (GroupA), 0xB0 (GroupB),

0xC0 (GroupC)

Note:

DxA4-DxA0, D53, D62: Sets Brightness for DxA pins (GroupA).

11111=Fullscale

DxB2-DxB0: Sets Brightness for DxB pins (GroupB). 111=Fullscale

DxC2-DxC0: Sets Brightness for D1C pin. 111 = Fullscale

Full-Scale Current set externally by the following equation:

I

= 189 × 1.25V / R

Dxx

SET

Brightness Level Control Table (GroupA)

Brightness Code (hex) Perceived Brightness

Level (%)

00 0.125

01 0.313

02 0.625

03 1

04 1.125

05 1.313

06 1.688

07 2.063

08 2.438

09 2.813

0A 3.125

0B 3.75

0C 4.375

0D 5.25

0E 6.25

0F 7.5

10 8.75

11 10

12 12.5

13 15

14 16.875

15 18.75

16 22.5

17 26.25

18 31.25

19 37.5

1A 43.75

1B 52.5

1C 61.25

1D 70

1E 87.5

1F 100

GroupB and GroupC Brightness Levels (% of Full-Scale) =

10%, 20%, 30%, 40%, 50%, 60%, 70%, 100%

30009735

FIGURE 7. Ramp Step Time Register Description

Internal Hex Address: 20h

Note:

RS1-RS0: Sets Brightness Ramp Step Time. The Brightness ramp

settings only affect GroupA current sinks. ('00' = 100µs, '01' = 25ms,

'10' = 50ms, '11' = 100ms).

30009739

FIGURE 8. VF Monitor Delay Register Description

Internal Hex Address: 60h

Note:

VF1-VF0: Sets the Gain Transition Delay Time. The VF Monitor Delay

can be set to four different delay times. ('00' (Default) = 3-6msec., '01'

= 1.5-3msec., '10' = 0.4-0.8msec., '11' = 60-90µsec.).

Application Information

LED CONFIGURATIONS

The LM2756 has a total of 8 current sinks capable of sinking

180mA of total diode current. These 8 current sinks are configured to operate in three independently controlled lighting

regions. GroupA has four dedicated current sinks, while

GroupB and GroupC each have one. To add greater lighting

flexibility, the LM2756 has two additional drivers (D53 and

D62) that can be assigned to either GroupA or GroupB

through a setting in the general purpose register.

At start-up, the default condition is four LEDs in GroupA, three

LEDs in GroupB and a single LED in GroupC (NOTE: GroupC

only consists of a single current sink (D1C) under any configuration). Bits 53A and 62A in the general purpose register

control where current sinks D53 and D62 are assigned. By

writing a '1' to the 53A or 62A bits, D53 and D62 become assigned to the GroupA lighting region. Writing a '0' to these bits

assigns D53 and D62 to the GroupB lighting region. With this

added flexibility, the LM2756 is capable of supporting applications requiring 4, 5, or 6 LEDs for main display lighting,

while still providing additional current sinks that can be used

for a wide variety of lighting functions.

SETTING LED CURRENT

The current through the LEDs connected to DxA and DxB can

be set to a desired level simply by connecting an appropriately

sized resistor (R

GND. The DxA, DxB and D1C LED currents are proportional

to the current that flows out of the I

189 times greater than the I

of the internal amplifiers set the voltage of the I

(typ.). The statements above are simplified in the equations

below:

Once the desired R

has the ability to internally dim the LEDs using analog current

scaling. The analog current level is set through the I2C compatible interface. LEDs connected to GroupA can be dimmed

) between the I

SET

I

(A)= 189 × (V

DxA/B/C

R

(Ω)= 189 × (1.25V / I

SET

value has been chosen, the LM2756

SET

pin of the LM2756 and

SET

pin and are a factor of

SET

current. The feedback loops

SET

ISET

/ R

DxA/B/C

SET

SET

)

)

pin to 1.25V

11 www.national.com

to 32 different levels. GroupB and GroupC(D1C) have 8 analog current levels.

LM2756

Please refer to the I2C Compatible Interface section of this

datasheet for detailed instructions on how to adjust the brightness control registers.

LED CURRENT RAMPING

The LM2756 provides an internal LED current ramping function that allows the GroupA LEDs to turn on and turn off

gradually over time. The target current level is set in the

GroupA Brightness Control Register (0xA0). The total rampup/ramp-down time is determind by the GroupA brightness

level (0-31) and the user configurable ramp step time.

Bits RS1 and RS2 in the Ramp Step Time Register (0x20) set

the ramp step time to the following four times: '00' = 100µsec.,

'01' = 25msec., '10' = 50msec., '11' = 100msec.

The LM2756 will always ramp-up (upon enable) and rampdown (upon disable) through the brightness levels until the

target level is reached. At the default setting of '00', the

LM2756's current ramping feature looks more like a current

step rather than a current ramp. The following table gives the

approximate ramp-up/ramp-down times if the GroupA brightness register is set to full-scale, or brightness code 31.

Brightness Ramp-Up/Ramp-Down Times

Ramp Code

RS1-RS0

Ramp Step

Time

Total Ramp

Time

00 100µs 3.2ms

01 25ms 0.8s

10 50ms 1.6s

11 100ms 3.2s

kHR – Headroom constant. This parameter models the mini-

mum voltage required to be present across the current sinks

for them to regulate properly. This minimum voltage is proportional to the programmed LED current, so the constant has

units of mV/mA. The typical kHR of the LM2756 is 3.25mV/mA.

In equation form:

(V

– V

) > k

× I

VOUT

LEDx

HRx

(eq. 3)

LEDx

Typical Headroom Constant Values

k

= k

= k

HRA

HRB

The "I

R

OUT

ing for I

minimum input voltage and LED forward voltage. Output cur-

" equation (eq. 1) is obtained from combining the

LED-MAX

equation (eq. 2) with the k

. Maximum LED current is highly dependent on

LEDx

= 3.25 mV/mA

HRC

equation (eq. 3) and solv-

HRx

rent capability can be increased by raising the minimum input

voltage of the application, or by selecting an LED with a lower

forward voltage. Excessive power dissipation may also limit

output current capability of an application.

Total Output Current Capability

The maximum output current that can be drawn from the

LM2756 is 180mA. Each driver Group has a maximum allotted current per Dxx sink that must not be exceeded.

DRIVER TYPE MAXIMUM Dxx CURRENT

DxA 30mA per DxA Pin

DxB 30mA per DxB Pin

D1C 30mA

The 180mA load can be distributed in many different configurations. Special care must be taken when running the

LM2756 at the maximum output current to ensure proper

functionality.

MAXIMUM OUTPUT CURRENT, MAXIMUM LED VOLTAGE, MINIMUM INPUT VOLTAGE

The LM2756 can drive 8 LEDs at 22.5mA each (GroupA ,

GroupB, GroupC) from an input voltage as low as 3.2V, so

long as the LEDs have a forward voltage of 3.6V or less (room

temperature).

The statement above is a simple example of the LED drive

capability of the LM2756. The statement contains the key application parameters that are required to validate an LEDdrive design using the LM2756: LED current (I

of active LEDs (Nx), LED forward voltage (V

mum input voltage (V

IN-MIN

).

), number

LEDx

), and mini-

LED

The equation below can be used to estimate the maximum

output current capability of the LM2756:

I

I

I

ADDITIONAL

the other LED Groups.

R

OUT

losses of the charge pump that result in voltage droop at the

pump output V

is proportional to the total output current of the charge pump,

LED_MAX

LED_MAX

= [(1.5 x VIN) - V

[(Nx x R

= [(1.5 x V

IN

[(Nx x 2.4Ω) + k

OUT

) - V

LED

) + k

LED

- (I

ADDITIONAL

] (eq. 1)

HRx

- (I

ADDITIONAL

HRx

]

× R

)] /

OUT

× 2.4Ω)] /

is the additional current that could be delivered to

– Output resistance. This parameter models the internal

. Since the magnitude of the voltage droop

OUT

the loss parameter is modeled as a resistance. The output

resistance of the LM2756 is typically 2.4Ω (VIN = 3.6V, TA =

25°C). In equation form:

V

= (1.5 × VIN) – [(NA× I

VOUT

R

OUT

+ NB × I

LEDA

] (eq. 2)

LEDB

+ NC × I

LEDC

) ×

PARALLEL CONNECTED AND UNUSED OUTPUTS

Connecting the outputs in parallel does not affect internal operation of the LM2756 and has no impact on the Electrical

Characteristics and limits previously presented. The available

diode output current, maximum diode voltage, and all other

specifications provided in the Electrical Characteristics table

apply to this parallel output configuration, just as they do to

the standard LED application circuit.

All Dx current sinks utilize LED forward voltage sensing circuitry to optimize the charge-pump gain for maximum efficiency. Due to the nature of the sensing circuitry, it is not

recommended to leave any of the DxA (D1A-D4A, D53, D62)

pins open if diode GroupA is going to be used during normal

operation. Leaving DxA pins unconnected will force the

charge-pump into 3/2× mode over the entire VIN range negating any efficiency gain that could have been achieved by

switching to 1× mode at higher input voltages.

If the D1B or D1C drivers are not going to be used, make sure

that the ENB and ENC bits in the general purpose register are

set to '0' to ensure optimal efficiency.

The D53 and D62 pins can be completely shutdown through

the general purpose register by writing a '1' to the SD53 or

SD62 bits.

Care must be taken when selecting the proper R

The current on any DxX pin must not exceed the maximum

SET

value.

current rating for any given current sink pin.

POWER EFFICIENCY

Efficiency of LED drivers is commonly taken to be the ratio of

power consumed by the LEDs (P

the input of the part (PIN). With a 3/2× - 1× charge pump, the

) to the power drawn at

LED

input current is equal to the charge pump gain times the output

www.national.com 12

LM2756

current (total LED current). The efficiency of the LM2756 can

be predicted as follow:

P

LEDTOTAL

(V

LEDB

PIN = VIN × (GAIN × I

= (V

× NB × I

PIN = VIN × I

E = (P

× NA × I

LEDA

) + (V

LEDB

LEDTOTAL

LEDC

IN

LEDTOTAL

÷ PIN)

LEDA

× I

+ IQ)

) +

LEDC

)

The LED voltage is the main contributor to the charge-pump

gain selection process. Use of low forward-voltage LEDs

(3.0V- to 3.5V) will allow the LM2756 to stay in the gain of 1×

for a higher percentage of the lithium-ion battery voltage

range when compared to the use of higher forward voltage

LEDs (3.5V to 4.0V). See the LED Forward Voltage Monitor-

ing section of this datasheet for a more detailed description

of the gain selection and transition process.

For an advanced analysis, it is recommended that power consumed by the circuit (VIN x IIN) for a given load be evaluated

rather than power efficiency.

POWER DISSIPATION

The power dissipation (P

can be approximated with the equations below. PIN is the

power generated by the 3/2× - 1× charge pump, P

power consumed by the LEDs, TA is the ambient temperature,

) and junction temperature (TJ)

DISS

LED

is the

and θJA is the junction-to-ambient thermal resistance for the

micro SMD 20-bump package. VIN is the input voltage to the

LM2756, V

number of LEDs and I

P

= (GAIN × VIN × I

DISS

is the nominal LED forward voltage, N is the

I

LEDA

LED

P

DISS

) - (V

is the programmed LED current.

LED

= PIN - P

GroupA + GroupB + GroupC

× NB × I

LEDB

TJ = TA + (P

LEDA

- P

LEDB

DISS

LEDB

) - (V

x θJA)

- P

LEDC

LEDC

) - (V

× I

LEDA

LEDC

× NA ×

)

The junction temperature rating takes precedence over the

ambient temperature rating. The LM2756 may be operated

outside the ambient temperature rating, so long as the junction temperature of the device does not exceed the maximum

operating rating of 105°C. The maximum ambient temperature rating must be derated in applications where high power

dissipation and/or poor thermal resistance causes the junction temperature to exceed 105°C.

THERMAL PROTECTION

Internal thermal protection circuitry disables the LM2756

when the junction temperature exceeds 160°C (typ.). This

feature protects the device from being damaged by high die

temperatures that might otherwise result from excessive power dissipation. The device will recover and operate normally

when the junction temperature falls below 155°C (typ.). It is

important that the board layout provide good thermal conduction to keep the junction temperature within the specified

operating ratings.

CAPACITOR SELECTION

The LM2756 requires 4 external capacitors for proper operation (C1 = C2 = CIN = C

ceramic capacitors are recommended. These capacitors are

= 1µF). Surface-mount multi-layer

OUT

small, inexpensive and have very low equivalent series resistance (ESR <20mΩ typ.). Tantalum capacitors, OS-CON

capacitors, and aluminum electrolytic capacitors are not recommended for use with the LM2756 due to their high ESR,

as compared to ceramic capacitors.

For most applications, ceramic capacitors with X7R or X5R

temperature characteristic are preferred for use with the

LM2756. These capacitors have tight capacitance tolerance

(as good as ±10%) and hold their value over temperature

(X7R: ±15% over -55°C to 125°C; X5R: ±15% over -55°C to

85°C).

Capacitors with Y5V or Z5U temperature characteristic are

generally not recommended for use with the LM2756. Capacitors with these temperature characteristics typically have

wide capacitance tolerance (+80%, -20%) and vary significantly over temperature (Y5V: +22%, -82% over -30°C to

+85°C range; Z5U: +22%, -56% over +10°C to +85°C range).

Under some conditions, a nominal 1µF Y5V or Z5U capacitor

could have a capacitance of only 0.1µF. Such detrimental deviation is likely to cause Y5V and Z5U capacitors to fail to

meet the minimum capacitance requirements of the LM2756.

The recommended voltage rating for the capacitors is

10V to account for DC bias capacitance losses.

13 www.national.com

Physical Dimensions inches (millimeters) unless otherwise noted

LM2756

TMD20AAA: 20 Bump 0.4mm micro SMD

X1 = 1.615mm

X2 = 2.015mm

X3 = 0.6mm

www.national.com 14

Notes

LM2756

15 www.national.com

Notes

For more National Semiconductor product information and proven design tools, visit the following Web sites at:

Products Design Support

Amplifiers www.national.com/amplifiers WEBENCH www.national.com/webench

Audio www.national.com/audio Analog University www.national.com/AU

Clock Conditioners www.national.com/timing App Notes www.national.com/appnotes

Data Converters www.national.com/adc Distributors www.national.com/contacts

Displays www.national.com/displays Green Compliance www.national.com/quality/green

Ethernet www.national.com/ethernet Packaging www.national.com/packaging

Interface www.national.com/interface Quality and Reliability www.national.com/quality

LVDS www.national.com/lvds Reference Designs www.national.com/refdesigns

Power Management www.national.com/power Feedback www.national.com/feedback

Switching Regulators www.national.com/switchers

LDOs www.national.com/ldo

LED Lighting www.national.com/led

PowerWise www.national.com/powerwise

Serial Digital Interface (SDI) www.national.com/sdi

Temperature Sensors www.national.com/tempsensors

Wireless (PLL/VCO) www.national.com/wireless

THE CONTENTS OF THIS DOCUMENT ARE PROVIDED IN CONNECTION WITH NATIONAL SEMICONDUCTOR CORPORATION

(“NATIONAL”) PRODUCTS. NATIONAL MAKES NO REPRESENTATIONS OR WARRANTIES WITH RESPECT TO THE ACCURACY

OR COMPLETENESS OF THE CONTENTS OF THIS PUBLICATION AND RESERVES THE RIGHT TO MAKE CHANGES TO

SPECIFICATIONS AND PRODUCT DESCRIPTIONS AT ANY TIME WITHOUT NOTICE. NO LICENSE, WHETHER EXPRESS,

IMPLIED, ARISING BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS

DOCUMENT.

TESTING AND OTHER QUALITY CONTROLS ARE USED TO THE EXTENT NATIONAL DEEMS NECESSARY TO SUPPORT

NATIONAL’S PRODUCT WARRANTY. EXCEPT WHERE MANDATED BY GOVERNMENT REQUIREMENTS, TESTING OF ALL

PARAMETERS OF EACH PRODUCT IS NOT NECESSARILY PERFORMED. NATIONAL ASSUMES NO LIABILITY FOR

APPLICATIONS ASSISTANCE OR BUYER PRODUCT DESIGN. BUYERS ARE RESPONSIBLE FOR THEIR PRODUCTS AND

APPLICATIONS USING NATIONAL COMPONENTS. PRIOR TO USING OR DISTRIBUTING ANY PRODUCTS THAT INCLUDE

NATIONAL COMPONENTS, BUYERS SHOULD PROVIDE ADEQUATE DESIGN, TESTING AND OPERATING SAFEGUARDS.

EXCEPT AS PROVIDED IN NATIONAL’S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, NATIONAL ASSUMES NO

LIABILITY WHATSOEVER, AND NATIONAL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY RELATING TO THE SALE

AND/OR USE OF NATIONAL PRODUCTS INCLUDING LIABILITY OR WARRANTIES RELATING TO FITNESS FOR A PARTICULAR

PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY

RIGHT.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR

SYSTEMS WITHOUT THE EXPRESS PRIOR WRITTEN APPROVAL OF THE CHIEF EXECUTIVE OFFICER AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

Life support devices or systems are devices which (a) are intended for surgical implant into the body, or (b) support or sustain life and

whose failure to perform when properly used in accordance with instructions for use provided in the labeling can be reasonably expected

to result in a significant injury to the user. A critical component is any component in a life support device or system whose failure to perform

can be reasonably expected to cause the failure of the life support device or system or to affect its safety or effectiveness.

National Semiconductor and the National Semiconductor logo are registered trademarks of National Semiconductor Corporation. All other

brand or product names may be trademarks or registered trademarks of their respective holders.

Copyright© 2007 National Semiconductor Corporation

For the most current product information visit us at www.national.com

National Semiconductor

Americas Customer

Support Center

Email:

new.feedback@nsc.com

Tel: 1-800-272-9959

LM2756 Multi-Display Inductorless LED Driver with 32 Exponential Dimming Steps in micro SMD

www.national.com

National Semiconductor Europe

Customer Support Center

Fax: +49 (0) 180-530-85-86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +49 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor Asia

Pacific Customer Support Center

Email: ap.support@nsc.com

National Semiconductor Japan

Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

Loading...

Loading...