LM2754

800mA Switched Capacitor Flash LED Driver with

Time-Out Protection

LM2754 800mA Switched Capacitor Flash LED Driver with Time-Out Protection

September 2006

General Description

The LM2754 is an integrated low noise, high current

switched capacitor DC/DC converter with four regulated current sinks. The device is optimized for driving 1 to 4 high

power white LEDs in parallel with a maximum current of

800mA. Maximum efficiency is achieved over the input voltage range by actively selecting the proper gain based on the

LED forward voltage and current requirements.

Two external low power resistors set the desired current for

Torch and Flash modes. The TX pin allows the device to be

forced into Torch mode during a Flash pulse, allowing for

synchronization between the RF power amplifier pulse and

Flash/Torch modes. To protect the device and Flash LEDs,

internal Time-Out circuitry turns off the LM2754 in case of a

faulty prolonged Flash mode. Internal soft-start circuitry limits the amount of inrush current during start-up.

The LM2754 is available in a small 24-pin thermally enhanced LLP package.

Features

n Up to 800mA Output Current

n Wide Operating Input Voltage Range: 2.8V to 5.5V

n Drives 1, 2, 3 or 4 LEDs in Parallel

n Ability to Disable One Current Sink Via the SEL Pin to

Accommodate 3-LED Flash Modules

n Time-Out Circuitry Limits Flash Duration to 1 Second

n TX Input Ensures Synchronization with RF Power

Amplifier Pulse

n Adaptive 1x, 1.5x and 2x Gains for Maximum Efficiency

n 1MHz Constant Frequency Operation

n Output Current Limit

n True Shutdown Output Disconnect

<

n

1µA Shutdown Current

n Internal Soft-Start Limits Inrush Current

n No Inductor Required

n Total Solution Size without LED

n Low Profile 24-Pin LLP Package (4mm x 4mm x 0.8mm)

<

28mm

2

Applications

n Camera Flash in Mobile Phones

n Flash for Digital Cameras

n Supplies for DSP’s, Microprocessors, Memory, MP3

Players, Pagers, Other Portable Devices

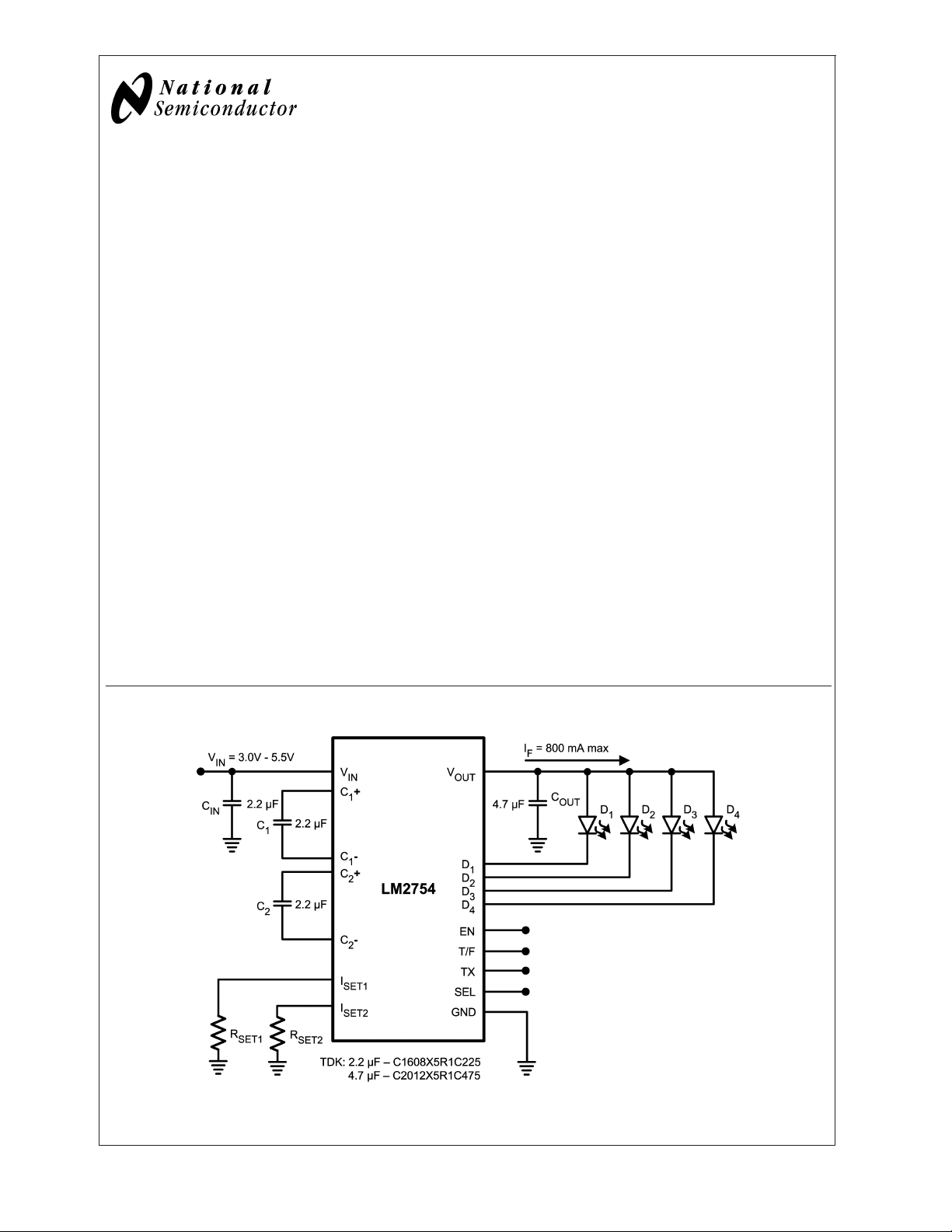

Typical Application Circuit

20202801

© 2006 National Semiconductor Corporation DS202028 www.national.com

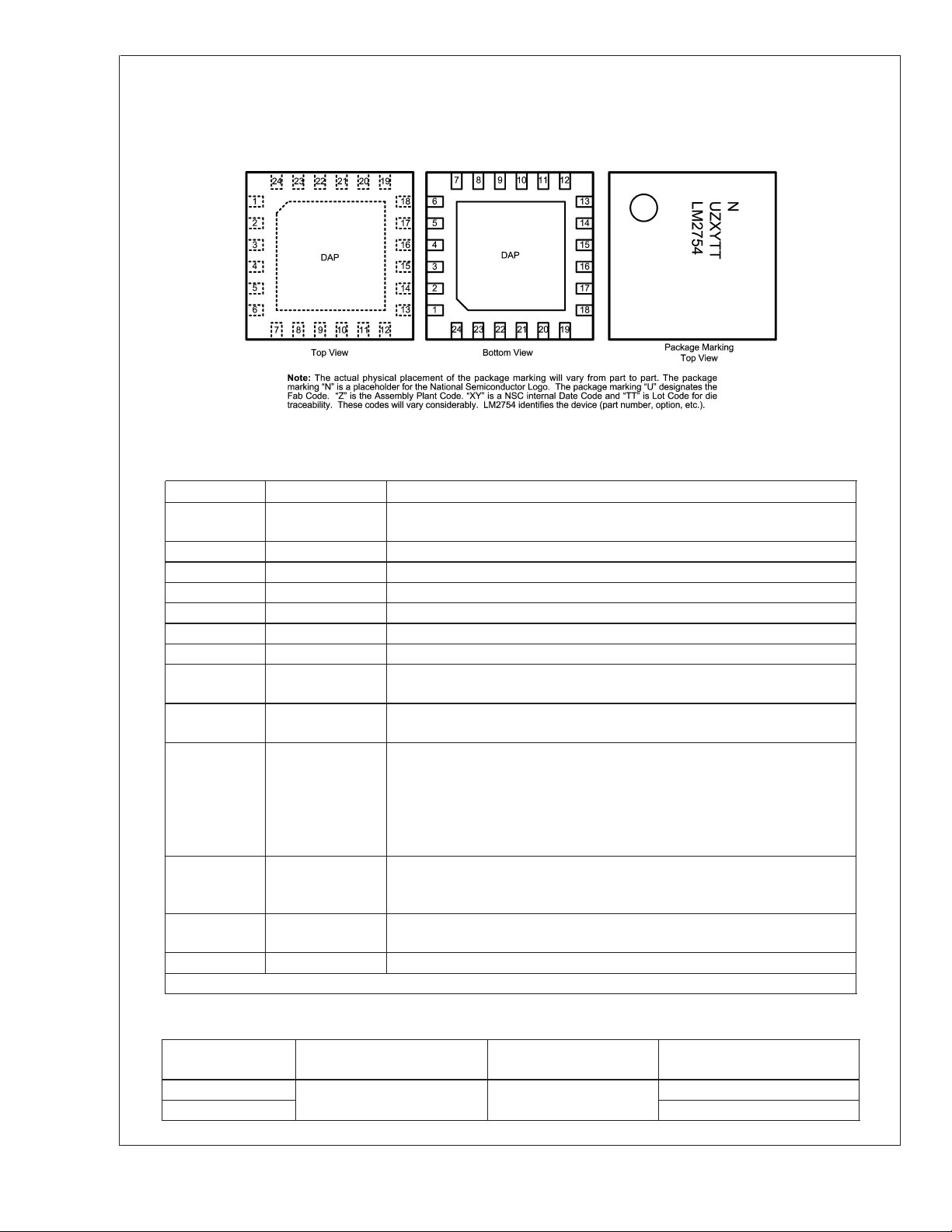

Connection Diagram

LM2754

Pin Descriptions

Pin Name Description

23,24 V

22 V

8V

12, 13, 14, 15 D1, D2, D3, D4* Regulated Current Sink Inputs. (* See SEL PIN description)

1, 2, 7, 5 C

3 GND

9, 16, 17 GND Ground Connection. Connect GND and GND

21 EN Enable Control Pin. Logic High = Normal Operation in Torch Mode.

20 T/F Torch/Flash Control Pin. Logic High = Flash Mode. Logic Low = Torch Mode.

10, 11 I

19 TX RF PA synchronization control pin. Logic High = Force Torch Mode. Logic Low

18 SEL D

4, 6 No Connect Do not connect to any node.

Note: EN, T/F, TX, and SEL pins each have a 500kΩ resistor connected internally to GND

LM2754

24-pin No-Pullback Leadless Leadframe Package (LLP-24)

4mm x 4mm x 0.8mm

NS Package Number SQA24A

INSW

Input Voltage Connection for Switch Array. Pins 23 and 24 are connected

internally on the die. Connect V

IN

OUT

+, C1-, C2+, C2- Flying Capacitor Connections.

1

SW

Input Voltage Connection. Connect VINand V

Output Voltage. Connect to LED Anodes.

Switch Array Ground Connection. Connect GND and GNDSWpins together.

Logic Low = Device Shut-Down. (See Note)

Device must be enabled for Torch or Flash to operate. (See Note)

SET1,ISET2

Current Set Resistor Connections. Connect 1% resistors to ground to set the

desired current through the LEDs. LED current is approximated by the

equation: 800 x (1.25V ÷ R). This equation corresponds to the current through

one current sink. Total LED current is equal to the sum of currents through all

current sinks connected to the LED. The equation used for Torch (I

Flash (I

) resistors are the same.

SET2

= Normal Operation. (See Applications Information section for the full

operational description) (See Note)

Control Pin. Logic Low = Normal 4-LED Operation. Logic High = Disable

4

LED Input. Connect D4to V

D

4

and V

IN

when not used. (See Note)

OUT

pins together.

INSW

INSW

SW

pins together.

pins together.

20202802

SET1

) and

Ordering Information

Order Number Package Description Package Marking Supplied as Tape and Reel

LM2754SQ No-Pullback

LM2754SQX 4500

www.national.com 2

LLP-24

UZXYTT

LM2754

(Units)

1000

LM2754

Absolute Maximum Ratings (Notes 1, 2)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

V

IN,VOUT

EN, T/F, TX, SEL pins -0.3V to (V

pins -0.3V to 6.0V

+ 0.3V)

IN

Operating Ratings (Notes 1, 2)

Input Voltage (V

Junction Temperature Range (T

Ambient Temperature Range (T

(Note 5) -40˚C to +85 ˚C

) 2.8V to 5.5V

IN

) -40˚C to +125˚C

J

)

A

w/ 6.0V max

Continuous Power Dissipation

(Note 3) Internally Limited

Junction Temperature

(T

J-MAX-ABS

) 150˚C

Thermal Information

Junction-to-Ambient Thermal Resistance,

LLP-24 Package (θ

) (Note 6) 42˚C/W

JA

Storage Temperature Range -65˚C to 150˚C

Lead Temp. (Soldering, 5 sec.) 260˚C

ESD Rating (Note 4)

Human Body Model 2kV

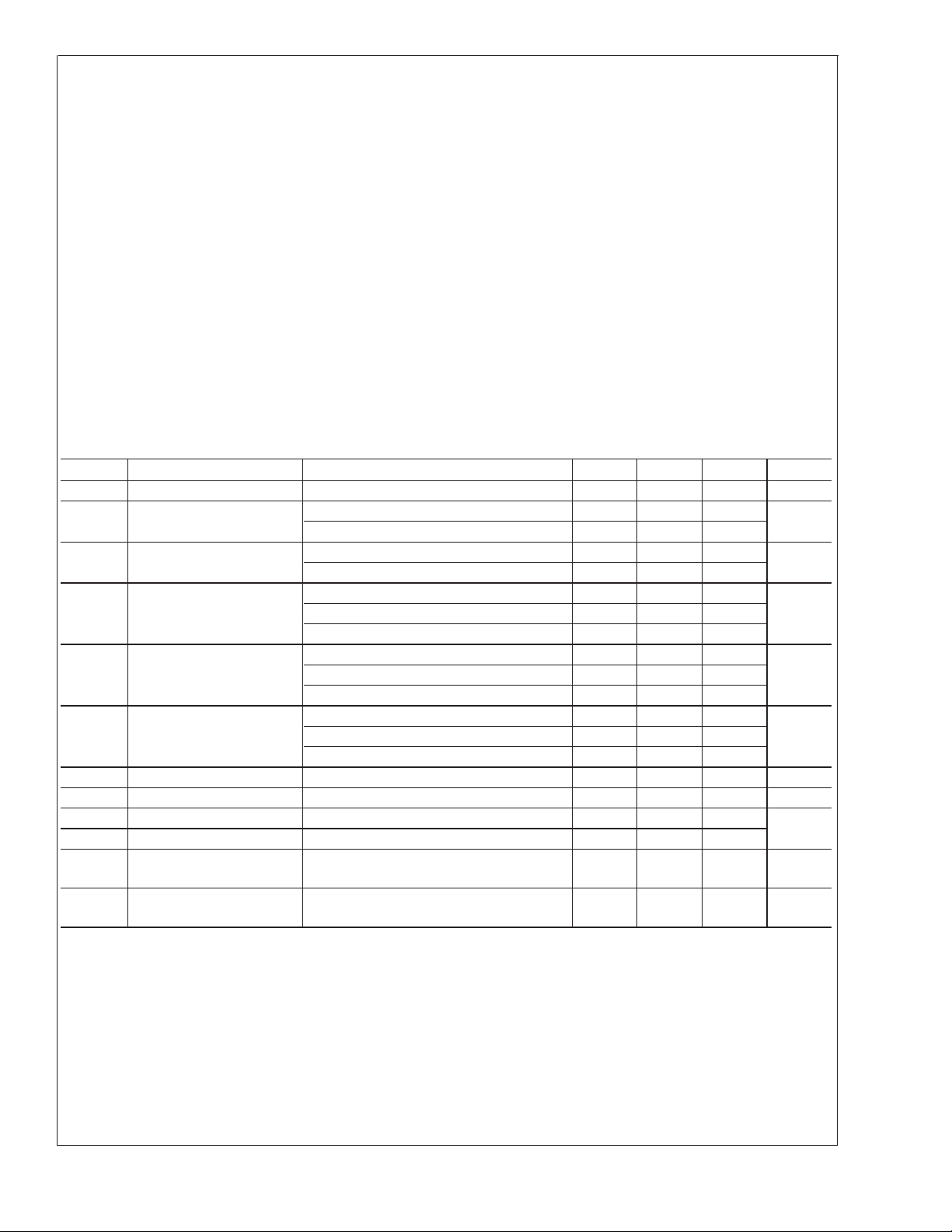

Electrical Characteristics (Notes 2, 7)

Limits in standard typeface are for TJ= 25˚C, and limits in boldface type apply over the full operating junction temperature

range (-40˚C to +125 ˚C). Unless otherwise noted, specifications apply to the LM2754 Typical Application Circuit (pg.1) with

V

(IN, INSW)

= 3.6V, VEN= 1.8V, V

Symbol Parameter Conditions Min Typ Max Units

V

SETx

I

Dx/ISETx

I

Pin Voltage R

SETx

LED Current to Set Current

Ratio (Note 11)

V

HR

Current Sink Headroom

Voltage (Note 10)

V

OUT

R

OUT

I

Q

I

SD

f

SW

V

IH

V

IL

I

IH

Output Voltage 1x Mode, IDx= 0mA 4.7 V

Output Impedance 1x Mode 0.25 Ω

Quiescent Supply Current 1x Mode, IDx= 0mA 0.7 mA

Shutdown Supply Current VEN= 0V 0.1 1 µA

Switching Frequency 0.7 1 1.3 MHz

Logic Input High Input Pins: EN, T/F, TX, SEL 1.2 V

Logic Input Low Input Pins: EN, T/F, TX, SEL 0.4

Logic Input High Current

(Note 9)

I

IL

Logic Input Low Current

(Note 9)

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the component may occur. Operating Ratings are conditions under which operation of

the device is guaranteed. Operating Ratings do not imply guaranteed performance limits. For guaranteed performance limits and associated test conditions, see the

Electrical Characteristics tables.

Note 2: All voltages are with respect to the potential at the GND pin.

Note 3: Internal thermal shutdown circuitry protects the device from permanent damage. Thermal shutdown engages at T

120˚C (typ.).

Note 4: The Human-body model is a 100 pF capacitor discharged through a 1.5kΩ resistor into each pin.

Note 5: In applications where high power dissipation and/or poor package thermal resistance is present, the maximum ambient temperature may have to be

derated. Maximum ambient temperature (T

dissipation of the device in the application (P

following equation: T

Note 6: Junction-to-ambient thermal resistance (θ

standard JESD51-7. The test board is a 4 layer FR-4 board measuring 102mm x 76mm x 1.6mm. The 2 imbedded copper layers cover roughly the same area as

the board. Thickness of copper layers are 70µm/35µm/35µm/70µm (2oz/1oz/1oz/2oz). Thermal vias are placed between the die attach pad in the 1st copper layer

A-MAX=TJ-MAX-OP

= 0V, VTX= 0V, V

T/F

SETx

IDx= 50mA to 100mA −7% 795 +7% mA/mA

I

= 200mA −11.5% 820 +11.5%

Dx

IDx= 200mA 550 mV

I

= 50mA 150

Dx

1.5x Mode, I

2x Mode, I

1.5x Mode 1.3

2x Mode 1.5

1.5x Mode, I

2x Mode, I

V

(EN, T/F, TX, SEL)

V

(EN, T/F, TX, SEL)

) is dependent on the maximum operation junction temperature (T

A-MAX

), and the junction-to ambient thermal resistance of the part/package in the application (θJA), as given by the

D-MAX

-(θJAxP

).

D-MAX

) is taken from a thermal modeling result, performed under the conditions and guidelines set forth in the JEDEC

JA

= 0V, CIN=C1=C2= 2.2µF, C

SEL

= 4.7µF. (Note 8)

OUT

= 20kΩ −3.5% 1.244 +3.5% V

= 0mA 4.7

Dx

= 0mA 5.1

Dx

= 0mA 3.4

Dx

= 0mA 6.3 8

Dx

= 1.8V 4 µA

= 0V 0.5 µA

=150˚C (typ.) and disengages at TJ=

J

= 125oC), the maximum power

J-MAX-OP

www.national.com3

Electrical Characteristics (Notes 2, 7) (Continued)

and the 2nd copper layer. Ambient temperature in simulation is 22˚C, still air. Power dissipation is 1W.

LM2754

The value of θ

conditions. In applications where high maximum power dissipation exists (high V

For more information on these topics, please refer to Application Note 1187: Leadless Leadframe Package (LLP) and the Power Efficiency and Power

Dissipation section of this datasheet..

Note 7: Min and Max limits are guaranteed by design, test, or statistical analysis. Typical numbers are not guaranteed, but do represent the most likely norm.

Note 8: C

Note 9: There is a 500kΩ resistor connected internally between each logic pin (EN, T/F, TX, SEL) and GND.

Note 10: Headroom Voltage (V

measured from V

Note 11: I

of the LM2754 in LLP-24 could fall in a range as wide as 35oC/W to 150oC/W (if not wider), depending on PWB material, layout, and environmental

JA

IN,COUT,C1,C2

Dx/ISETx

: Low-ESR Surface-Mount Ceramic Capacitors (MLCCs) used in setting electrical characteristics

) is the voltage across the current sinks (VDx) at which the current falls to 95% of the nominal programmed current. VHRis

to GND. If the headroom voltage requirement is not met, LED current regulation will be compromised.

Dx

Ratio was tested with the Charge Pump in a gain of 1x.

HR

, high Gain, high I

IN

), special care must be paid to thermal dissipation issues.

OUT

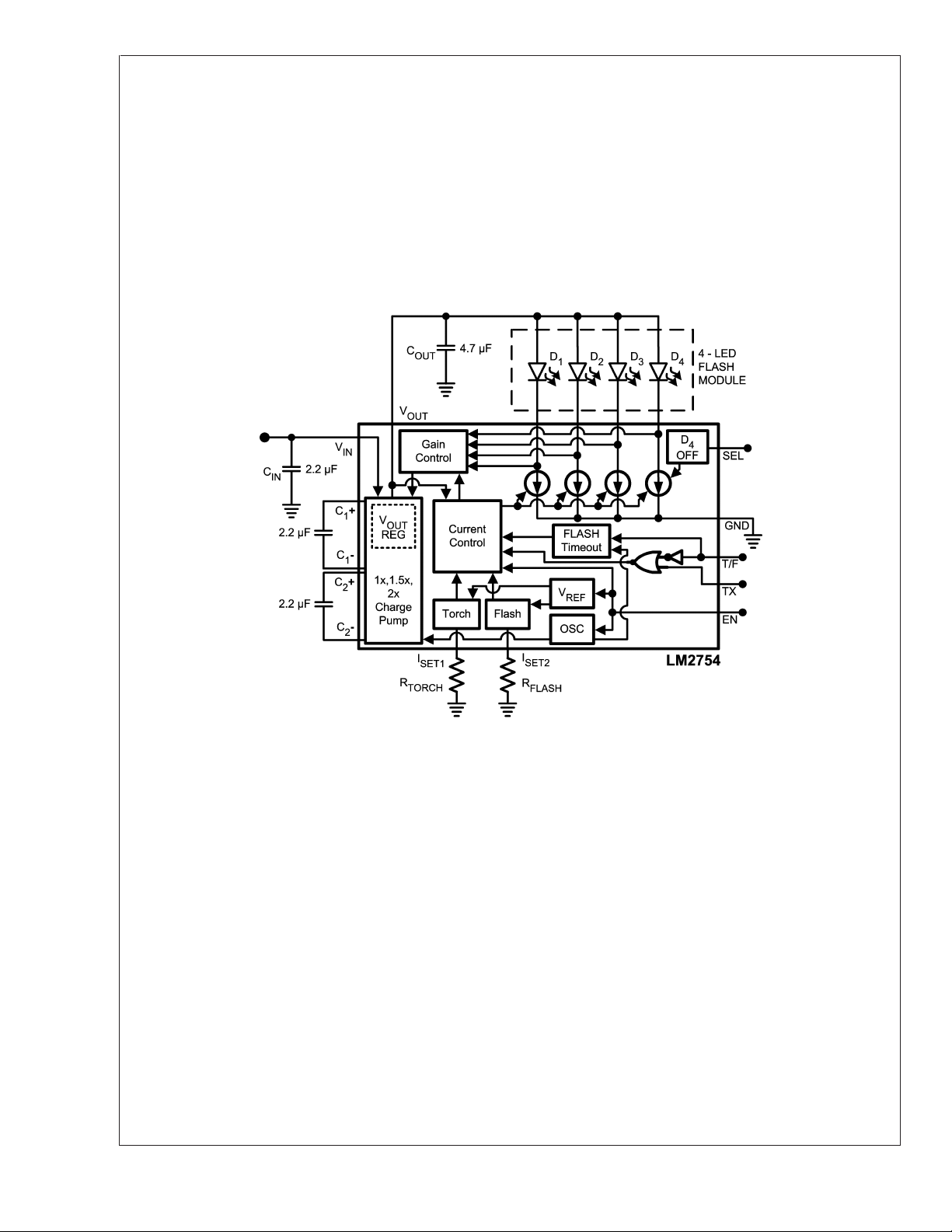

Block Diagram

www.national.com 4

20202803

LM2754

Typical Performance Characteristics Unless otherwise specified: T

3.6V, V

EN=VIN,VT/F=VTX=VSEL

capacitors (MLCC’s).

Quiescent Current vs. Input Voltage Shutdown Current vs. Input Voltage

Dx Current vs. R

= 0V, CIN=C1=C2= 2.2µF, C

SET

20202804

= 4.7µF. Capacitors are low-ESR multi-layer ceramic

OUT

Dx Current vs. Headroom Voltage

= 25˚C, VDx= 1V, V

A

(IN, INSW)

20202805

=

20202806 20202807

Efficiency vs. Input Voltage Oscillator Frequency vs. Input Voltage

20202808 20202809

www.national.com5

Typical Performance Characteristics Unless otherwise specified: T

3.6V, V

LM2754

EN=VIN,VT/F=VTX=VSEL

capacitors (MLCC’s). (Continued)

Flash Mode with TX Pulse Torch to Flash Mode

= 0V, CIN=C1=C2= 2.2µF, C

= 4.7µF. Capacitors are low-ESR multi-layer ceramic

OUT

= 25˚C, VDx= 1V, V

A

(IN, INSW)

=

VIN= 3.6V, Load = 700mA (Flash), LED = PWF1

CH1 (TOP): V

CH2 (BOTTOM): I

Time scale: 1ms/Div

; Scale: 1V/Div, DC Coupled

TX

; Scale: 200mA/Div

LED

20202810

Torch to Flash Mode

Rising Edge

VIN= 3.6V, Load = 200mA/800mA (Torch/Flash), LED = PWF1

CH1 (TOP): V

CH2 (MIDDLE): V

CH3 (BOTTOM): I

Time scale: 400µs/Div

; Scale: 1V/Div, DC Coupled

IN

; Scale: 1V/Div, DC Coupled

OUT

; Scale: 200mA/Div

IN

20202812

VIN= 3.6V, Load = 200mA/800mA (Torch/Flash), LED = PWF1

CH1 (TOP): V

CH2 (MIDDLE): V

CH3 (BOTTOM): I

Time scale: 100ms/Div

; Scale: 1V/Div, DC Coupled

IN

; Scale: 1V/Div, DC Coupled

OUT

; Scale: 200mA/Div

IN

20202811

Flash to Torch Mode

Falling Edge

VIN= 3.6V, Load = 800mA/200mA (Flash/Torch), LED = PWF1

CH1 (TOP): V

CH2 (MIDDLE): V

CH3 (BOTTOM): I

Time scale: 100µs/Div

; Scale: 1V/Div, DC Coupled

IN

; Scale: 1V/Div, DC Coupled

OUT

; Scale: 200mA/Div

IN

20202813

www.national.com 6

LM2754

Typical Performance Characteristics Unless otherwise specified: T

3.6V, V

EN=VIN,VT/F=VTX=VSEL

capacitors (MLCC’s). (Continued)

Battery Ripple, Gain = 1.5x Battery Ripple, Gain = 2x

VIN= Li-Ion Battery at 3.7V, Load = 400mA, LED = PWF1

CH1 (MID-TOP): V

CH2 (MID-BOTTOM): V

CH3 (TOP): V

CH4 (BOTTOM): I

Time scale: 1µs/Div

; Scale: 20mV/Div, AC Coupled

OUT

; Scale: 50mV/Div, AC Coupled

IN

; Scale: 1V/Div, DC Coupled

IN

; Scale: 500mA/Div

IN

Startup and Shutdown Response

Torch Mode (400mA)

= 0V, CIN=C1=C2= 2.2µF, C

20202814

= 4.7µF. Capacitors are low-ESR multi-layer ceramic

OUT

VIN= Li-Ion Battery at 3.7V, Load = 400mA, LED = PWF1

CH1 (MID-TOP): V

CH2 (MID-BOTTOM): V

CH3 (TOP): V

CH4 (BOTTOM): I

Time scale: 1µs/Div

; Scale: 1V/Div, DC Coupled

IN

IN

= 25˚C, VDx= 1V, V

A

; Scale: 20mV/Div, AC Coupled

OUT

; Scale: 50mV/Div, AC Coupled

IN

; Scale: 500mA/Div

20202815

(IN, INSW)

=

VIN= 3.6V, Load = 400mA, LED = PWF1

CH1 (TOP): V

CH4 (MIDDLE): I

CH3 (BOTTOM): I

Time scale: 100ms/Div

; Scale: 1V/Div, DC Coupled

OUT

; Scale: 200mA/Div

IN

; Scale: 200mA/Div

OUT

20202816

www.national.com7

Application Information

LM2754

CIRCUIT DESCRIPTION

The LM2754 is an adaptive 1x/1.5x/2x CMOS charge pump,

optimized for driving Flash LEDs in camera phone and other

portable applications. It provides four constant current inputs, each capable of sinking up to 200mA for Flash mode,

and 100mA for Torch mode.

Each LED is driven from V

four current sinks. LED drive current for Torch mode is

programmed by connecting a resistor, R

set pin, I

. LED drive current for Flash mode is set by

SET1

connecting a resistor, R

Torch mode is enabled by the EN pin, and the transition from

Torch to Flash mode is controlled by the T/F pin. This device

also has an option to disable the D

pin, for Flash LED modules with only 3 LEDs.

To prevent high battery load during a simultaneous RF PA

transmission pulse and Flash condition, this device has a

Flash interrupt pin (TX) to reduce the LED current to the

Torch mode level for the duration of the RF PA transmission

pulse.

CHARGE PUMP

The input to the 1x/1.5x/2x charge pump is connected to the

pin, and the loosely regulated output of the charge pump

V

IN

is connected to the V

OUT

charge pump has both open loop and closed loop modes of

operation. Under no-load conditions, open loop operation

occurs when V

is equal to the product of the input voltage

OUT

and the charge pump gain, and is less than the nominal

output regulation voltage. Over the recommended input voltage range of 3.0V to 5.5V, unloaded open loop operation will

only occur in 1x and 1.5x gains. When the LM2754 is in

closed loop operation with no-load, the voltage at V

loosely regulated to 4.7V (typ.) for the 1x and 1.5x gains, and

5.1V (typ.) for the 2x gain. When under load, the voltage at

can be less than the target regulation voltage while the

V

OUT

charge pump is still in closed loop operation. This is due to

the load regulation topology of the LM2754.

The charge pump gain transitions are actively selected to

maintain regulation based on LED forward voltage and load

requirements. The charge pump only transitions to higher

gains, from 1x to 1.5x and 1.5x to 2x. Each transition from

one gain to the next takes 125ms (typ.) for Torch mode and

2ms (typ.) for Flash mode. Once the charge pump transitions

to a higher gain, it will remain at that gain for as long as the

device remains enabled. Shutting down and then re-enabling

the device resets the gain mode to the minimum gain required to maintain the load.

SOFT START

The LM2754 contains internal soft-start circuitry to limit inrush currents when the part is enabled. Soft start is implemented internally with a controlled turn-on of the internal

voltage reference.

CURRENT LIMIT PROTECTION

The LM2754 charge pump contains current limit protection

circuitry that protects the device during V

where excessive current is drawn. Output current is limited

to 1.2A (typ.).

and connected to one of the

OUT

, to the current

SET1

, to the current set pin, I

SET2

current sink via the SEL

4

pin. The device’s loosely-regulated

fault conditions

OUT

OUT

SET2

LOGIC CONTROL PINS

There are 4 logic control pins for the LM2754. All pins are

active-High logic (High = Function ON). There is an internal

pull-down resistor (500kΩ typ.) connected between each

logic pin and GND. The operating modes for the part function

according to the Table below:

EN T/F TX SEL Mode

0 X X X Part in Shutdown

10X0

.

10X1

1100

1101

Part Enabled, Current set by

R

SET1,D1-4

Active

Part Enabled, Current set by

R

SET1,D1-3

Active, D4Disabled

Part Enabled, Current set by

R

SET2,D1-4

Active

Part Enabled, Current set by

R

SET2,D1-3

Active, D4Disabled

Part Enabled, Current set by

1110

R

, TX signal from RF PA,

SET1

Active

D

1-4

Part Enabled, Current set by

1111

, TX signal from RF PA,

R

SET1

Active, D4Disabled

D

1-3

EN PIN (TORCH)

The EN pin is the master enable pin for the part. When the

voltage on this pin is Low (

mode. In this mode, all internal circuitry is OFF, V

disconnected from the V

<

supply current (

is High (

is

regulate the output voltage to its nominal value. When the

>

1µA typ.). When the voltage on the EN pin

1.2V), the part will activate the charge pump and

<

0.4V), the part is in shutdown

, and the part consumes very little

IN

OUT

is

output voltage reaches its regulation level, the current sinks

will turn on and sink the current programmed by R

SET1

(assuming the logic on T/F is Low). Enabling the device is

also referred to as Torch Mode. For correct start-up sequencing, power must be applied to V

before a High logic

IN

signal is applied to the EN pin.

T/F PIN (FLASH) AND FLASH TIMEOUT

A logic Low (

<

0.4V) signal on the T/F pin disables the Flash

mode, defaulting the current through the LEDs to the Torch

level programmed by R

. Applying a logic High (>1.2V)

SET1

signal to T/F places the device in Flash mode, with the LED

current set by R

SET2

.

Flash Timeout Protection Circuitry disables the current sinks

when the signal on T/F is held high for more than 1 second

(typ). This prevents the device from self-heating due to the

high power dissipation during Flash conditions. During the

timeout condition, voltage will still be present on V

OUT

but

the current sinks will be shut off, resulting in no current

through the Flash LEDs. When the device goes into a timeout condition, placing a logic Low signal on EN will reset the

timeout and a subsequent logic High signal on EN will return

the device to normal operation. Flash timeout is not active

during TX mode.

TX PIN

The TX pin on the LM2754 disables the Flash operation

during a RF PAtransmission pulse, and sets the LED current

to the Torch level programmed by R

for the duration of

SET1

that pulse. At the end of each transmission interrupt pulse

www.national.com 8

Application Information (Continued)

signal on the TX pin, the LED current level returns to the

Flash current level set by R

>

typical logic High (

1.2V) and logic Low (<0.4V) signal

levels. Flash Timeout is not active during the TX mode

operation.

SEL PIN

Connecting the SEL pin to a logic Low (

the device in normal operation, with all 4 current sinks active.

To accommodate Flash LED modules with only 3 LEDs,

>

place a logic High (

the current sink D

1.2V) signal on the SEL pin to disable

. If only 3 current sinks are used, the

4

200mA per current sink recommendation still applies, and

the maximum Flash current will be 600mA. Connect D

when the logic in the SEL pin is High. Optional use of

V

OUT

the SEL pin is to reduce the LED current used for Torch or

Flash by 25% for high battery load conditions.

SETTING LED CURRENTS

The current through the LEDs connected to D

simply by connecting an appropriately sized resistor (R

between the I

mode and the I

pin of the LM2754 and GND for Torch

SET1

pin and GND for Flash Mode. The LED

SET2

currents are proportional to the current that flows out of the

pin and are a factor of approximately 800 times greater

I

SETx

than the I

current. The feedback loop of an internal

SETx

amplifier sets the voltage of the I

statements above are simplified in the equations below:

= 800 x(V

I

Dx

R

= 800 x (1.25V / IDx)

SET

The maximum recommended current through each current

sink is 100mA during Torch mode and 200mA during Flash

mode. Maximum recommended total Flash current with all 4

current sinks used is 800mA (max 200mA per current sink).

Using the part in conditions where the junction temperature

might rise above the rated maximum requires that the operating ranges and/or conditions be de-rated. The printed circuit board also must be carefully laid out to account for high

thermal dissipation in the part.

PARALLEL DX OUTPUTS FOR INCREASED CURRENT DRIVE

Outputs D

may be connected together to drive a one or

1-4

two LEDs at higher currents. In applications using a single

LED, all four parallel current sinks of equal value drive the

single LED. For this type of configuration, the LED current

should be programmed so that the current through each of

the outputs is 25% of the total desired LED current. For

example, if 200mA is the desired drive current for the single

LED, R

should be selected such that the current through

SET

each of the current sink inputs is 50mA. Similarly, if two

LEDs are to be driven by pairing up the D

), R

D

3-4

should be selected such that the current through

SET

each current sink input is 50% of the desired LED current.

Connecting the outputs in parallel does not affect internal

operation of the LM2754 and has no impact on the Electrical

Characteristics and limits previously presented. The available diode output current, maximum diode voltage, and all

other specifications provided in the Electrical Characteristics

table apply to this parallel output configuration, just as they

do to the standard 4-LED application circuit.

. The TX pin responds to the

SET2

<

0.4V) signal places

1-4

pin to 1.25V (typ.). The

SET

SET/RSET

)

inputs (i.e D

1-4

4

can be set

SETx

1-2

LM2754

Maximum recommended LED current for any configuration

is 200mA per current sink, and 800mA total. For situations

where only 3 current sinks will be used for the application,

see the SEL PIN operation section.

CAPACITOR SELECTION

The LM2754 requires 4 external capacitors for proper operation. Surface-mount multi-layer ceramic capacitors are recommended. These capacitors are small, inexpensive and

have very low equivalent series resistance (ESR

typ.). Tantalum capacitors, OS-CON capacitors, and aluminum electrolytic capacitors are not recommended for use

with the LM2754 due to their high ESR, as compared to

ceramic capacitors.

to

For most applications, ceramic capacitors with X7R or X5R

temperature characteristic are preferred for use with the

LM2754. These capacitors have tight capacitance tolerance

±

(as good as

±

(X7R:

10%) and hold their value over temperature

15% over -55˚C to 125˚C; X5R:±15% over -55˚C to

85˚C).

Capacitors with Y5V or Z5U temperature characteristic are

)

generally not recommended for use with the LM2754. Capacitors with these temperature characteristics typically

have wide capacitance tolerance (+80%, -20%) and vary

significantly over temperature (Y5V: +22%, -82% over -30˚C

to +85˚C range; Z5U: +22%, -56% over +10˚C to +85˚C

range). Under some conditions, a nominal 1µF Y5V or Z5U

capacitor could have a capacitance of only 0.1µF. Such

detrimental deviation is likely to cause Y5V and Z5U capacitors to fail to meet the minimum capacitance requirements of

the LM2754.

The voltage rating of the output capacitor should be 10V or

more. For example, a 10V 0603 4.7µF output capacitor (TDK

C1608X5R1A475) is acceptable for use with the LM2754, as

long as the capacitance on the output does not fall below a

minimum of 3µF in the intended application. All other capacitors should have a voltage rating at or above the maximum

input voltage of the application and should have a minimum

capacitance of 1µF.

POWER EFFICIENCY

Efficiency of LED drivers is commonly taken to be the ratio of

power consumed by the LEDs (P

the input of the part (P

). With a 1x/1.5x/2x charge pump,

IN

) to the power drawn at

LED

the input current is equal to the charge pump gain times the

output current (total LED current). The efficiency of the

LM2754 can be predicted as follows:

=NxV

P

LED

PIN=VINxI

PIN=VINx (GainxNxI

E=(P

LEDxILED

LED÷PIN

IN

LED+IQ

)

For a simple approximation, the current consumed by inter-

,

nal circuitry (I

) can be neglected, and the resulting effi-

Q

ciency will become:

÷(VINx Gain)

LED

Neglecting I

E=V

will result in a slightly higher efficiency predic-

Q

tion, but this impact will be negligible due to the value of I

being very low compared to the typical Torch and Flash

current levels (100-800mA). It is also worth noting that efficiency as defined here is in part dependent on LED voltage.

Variation in LED voltage does not affect power consumed by

the circuit and typically does not relate to the brightness of

the LED. For an advanced analysis, it is recommended that

power consumed by the circuit (V

) be evaluated rather

INxIIN

than power efficiency.

<

20mΩ

)

Q

www.national.com9

Application Information (Continued)

THERMAL PROTECTION

LM2754

Internal thermal protection circuitry disables the LM2754

when the junction temperature exceeds 150˚C (typ.). This

feature protects the device from being damaged by high die

temperatures that might otherwise result from excessive

power dissipation. The device will recover and operate normally when the junction temperature falls below 120˚C (typ.).

It is important that the board layout provide good thermal

conduction to keep the junction temperature within the specified operating ratings.

POWER DISSIPATION

The power dissipation (P

) can be approximated with the equations below. P

ture (T

J

DISSIPATION

is the power generated by the 1x/1.5x/2x charge pump, P

is the power consumed by the LEDs, TAis the ambient

temperature, and θ

is the junction-to-ambient thermal re-

JA

sistance for the LLP-24 package. V

the LM2754, V

is the programmed LED current.

I

LED

is the nominal LED forward voltage, and

LED

P

DISSIPATION=PIN-PLED

= [Gain x VINx(4xI

) and junction tempera-

is the input voltage to

IN

)]−(V

LED

LED

x4xI

LED

T

J=TA

+(P

DISSIPATION

x θJA)

The junction temperature rating takes precedence over the

ambient temperature rating. The LM2754 may be operated

outside the ambient temperature rating, so long as the junction temperature of the device does not exceed the maximum operating rating of 125˚C. The maximum ambient temperature rating must be derated in applications where high

power dissipation and/or poor thermal resistance causes the

junction temperature to exceed 125˚C.

PCB Layout Considerations

The LLP is a leadframe based Chip Scale Package (CSP)

with very good thermal properties. This package has an

exposed DAP (die attach pad) at the center of the package

IN

LED

)

measuring 2.6mm x 2.6mm. The main advantage of this

exposed DAP is to offer lower thermal resistance when it is

soldered to the thermal land on the PCB. For PCB layout,

National highly recommends a 1:1 ratio between the package and the PCB thermal land. To further enhance thermal

conductivity, the PCB thermal land may include vias to a

ground plane. For more detailed instructions on mounting

LLP packages, please refer to National Semiconductor Application Note AN-1187.

www.national.com 10

Physical Dimensions inches (millimeters) unless otherwise noted

LM2754 800mA Switched Capacitor Flash LED Driver with Time-Out Protection

24-Pin LLP

NS Package Number SQA24A

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves

the right at any time without notice to change said circuitry and specifications.

For the most current product information visit us at www.national.com.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS

WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL COUNSEL OF NATIONAL SEMICONDUCTOR

CORPORATION. As used herein:

1. Life support devices or systems are devices or systems

which, (a) are intended for surgical implant into the body, or

(b) support or sustain life, and whose failure to perform when

properly used in accordance with instructions for use

2. A critical component is any component of a life support

device or system whose failure to perform can be reasonably

expected to cause the failure of the life support device or

system, or to affect its safety or effectiveness.

provided in the labeling, can be reasonably expected to result

in a significant injury to the user.

BANNED SUBSTANCE COMPLIANCE

National Semiconductor follows the provisions of the Product Stewardship Guide for Customers (CSP-9-111C2) and Banned Substances

and Materials of Interest Specification (CSP-9-111S2) for regulatory environmental compliance. Details may be found at:

www.national.com/quality/green.

Lead free products are RoHS compliant.

National Semiconductor

Americas Customer

Support Center

Email: new.feedback@nsc.com

Tel: 1-800-272-9959

www.national.com

National Semiconductor

Europe Customer Support Center

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Support Center

Email: ap.support@nsc.com

National Semiconductor

Japan Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

Loading...

Loading...