查询DO3316P-472供应商

LM2747

Synchronous Buck Controller with Pre-bias Startup, and

Optional Clock Synchronization

LM2747 Synchronous Buck Controller with Pre-bias Startup, and Optional Clock Synchronization

March 2006

General Description

The LM2747 is a high-speed synchronous buck regulator

controller with a feedback voltage accuracy of

provide simple down conversion to output voltages as low as

0.6V. Though the control section of the IC is rated for 3 to 6V,

the driver section is designed to accept input supply rails as

high as 14V. The use of adaptive non-overlapping MOSFET

gate drivers helps avoid potential shoot-through problems

while maintaining high efficiency. The IC is designed for the

more cost-effective option of driving only N-channel MOSFETs in both the high-side and low-side positions. It senses

the low-side switch voltage drop for providing a simple,

adjustable current limit.

The LM2747 features a fixed-frequency voltage-mode PWM

control architecture which is adjustable from 50 kHz to 1

MHz with one external resistor. In addition, the LM2747 also

allows the switching frequency to be synchronized to an

external clock signal over the range of 250 kHz to 1 MHz.

This wide range of switching frequency gives the power

supply designer the flexibility to make better tradeoffs between component size, cost and efficiency.

Features include the ability to startup with a pre-biased load

on the output, soft-start, input undervoltage lockout (UVLO)

and Power Good (based on both undervoltage and overvoltage detection). In addition, the shutdown pin of the IC can be

used for providing startup delay, and the soft-start pin can be

used for implementing precise tracking, for the purpose of

sequencing with respect to an external rail.

±

1%. It can

Features

n±1% feedback voltage accuracy over temperature

n Switching frequency from 50 kHz to 1 MHz

n Switching frequency synchronize range 250 kHz to 1

MHz

n Startup with a pre-biased output load

n Power stage input voltage from 1V to 14V

n Control stage input voltage from 3V to 6V

n Output voltage adjustable down to 0.6V

n Power Good flag and shutdown

n Output overvoltage and undervoltage detection

n Low-side adjustable current sensing

n Adjustable soft-start

n Tracking and sequencing with shutdown and soft start

pins

n TSSOP-14 package

Applications

n Down Conversion from 3.3V

n Cable Modem, DSL and ADSL

n Laser Jet and Ink Jet Printers

n Low Voltage Power Modules

n DSP, ASIC, Core and I/O

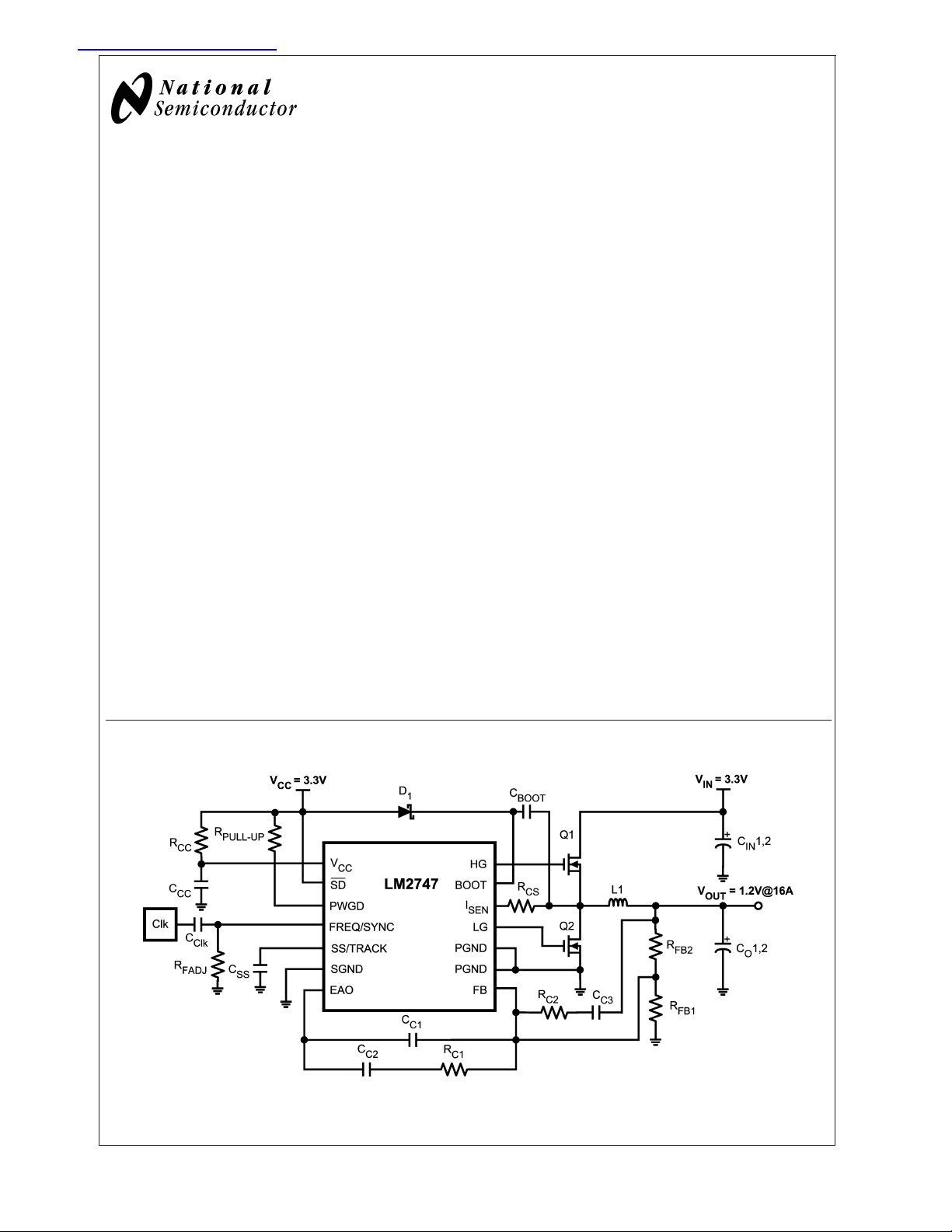

Typical Application

20150901

© 2006 National Semiconductor Corporation DS201509 www.national.com

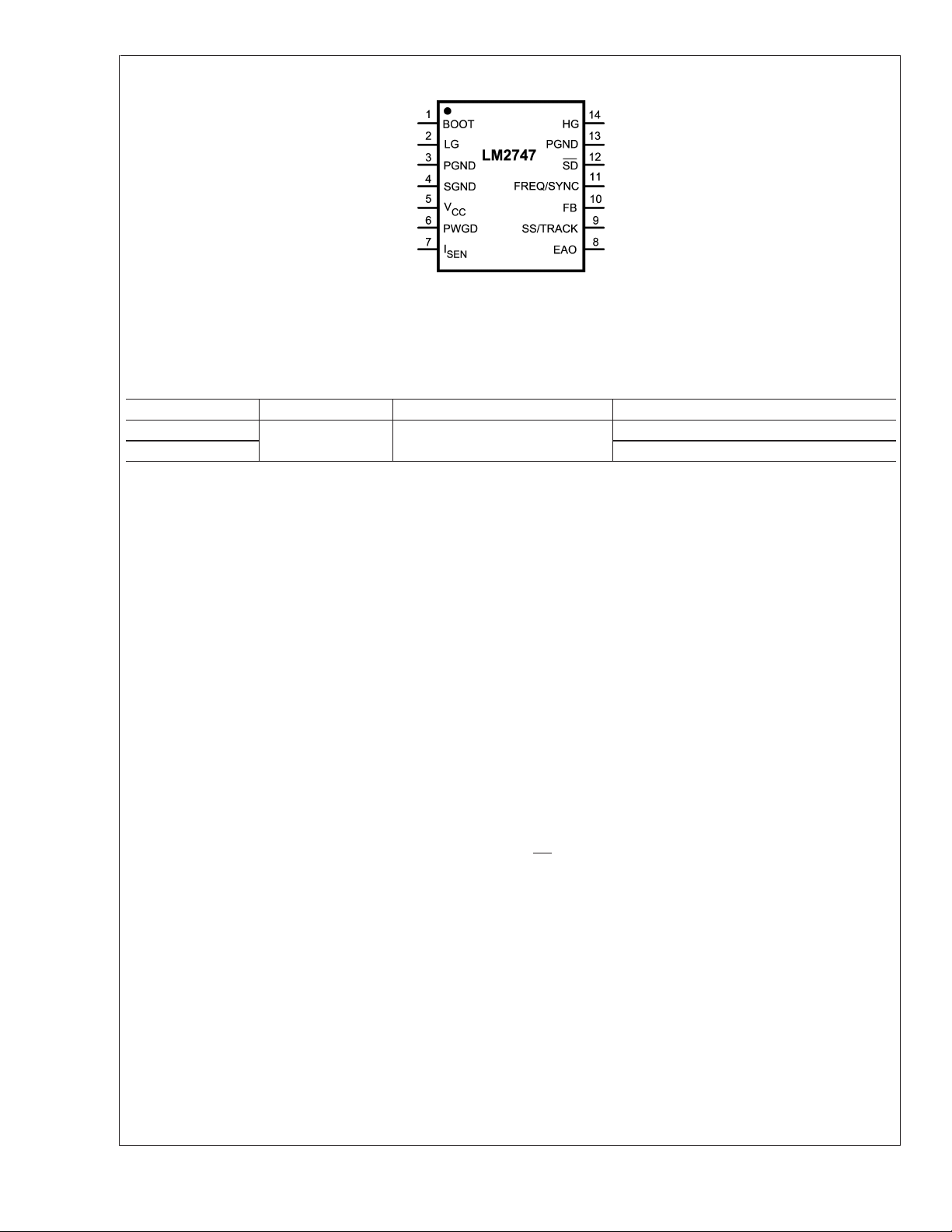

Connection Diagram

LM2747

14-Lead Plastic TSSOP

20150990

= 155˚C/W

θ

JA

NS Package Number MTC14

Ordering Information

Order Number Package Type NSC Package Drawing Supplied As

LM2747MTC

LM2747MTCX 2500 Units on Tape and Reel

Pin Description

BOOT (Pin 1) - Bootstrap pin. This is the supply rail for the

high-side gate driver. When the high-side MOSFET turns on,

the voltage on this pin should be at least one gate threshold

above the regulator input voltage V

MOSFET. See MOSFET Gate Drivers in the Application

Information section for more details on how to select MOSFETs.

LG (Pin 2) - Low-gate drive pin. This is the gate drive for the

low-side N-channel MOSFET. This signal is interlocked with

the high-side gate drive HG (Pin 14), so as to avoid shootthrough.

PGND (Pins 3, 13) - Power ground. This is also the ground

for the low-side MOSFET driver. Both the pins must be

connected together on the PCB and form a ground plane,

which is usually also the system ground.

SGND (Pin 4) - Signal ground. It should be connected

appropriately to the ground plane with due regard to good

layout practices in switching power regulator circuits.

(Pin 5) Supply rail for the control sections of the IC.

V

CC

PWGD (Pin 6) - Power Good pin. This is an open drain

output, which is typically meant to be connected to V

any other low voltage source through a pull-up resistor.

Choose the pull-up resistor so that the current going into this

pin is kept below 1 mA. A recommended value for the pull-up

resistor is 100 kΩ for most applications. The voltage on this

pin is thus pulled low under output undervoltage or overvoltage fault conditions and also under input UVLO.

(Pin 7) - Current limit threshold setting pin. This sources

I

SEN

a fixed 40 µA current. A resistor of appropriate value should

be connected between this pin and the drain of the low-side

TSSOP-14 MTC14

to properly turn on the

IN

or

CC

EAO (Pin 8) - Output of the error amplifier. The voltage level

on this pin is compared with an internally generated ramp

signal to determine the duty cycle. This pin is necessary for

compensating the control loop.

SS/TRACK (Pin 9) - Soft-start and tracking pin. This pin is

internally connected to the non-inverting input of the error

amplifier during soft-start, and in fact any time the SS/

TRACK pin voltage happens to be below the internal reference voltage. For the basic soft-start function, a capacitor of

minimum value 1 nF is connected from this pin to ground. To

track the rising ramp of another power supply’s output, connect a resistor divider from the output of that supply to this

pin as described in Application Information.

FB (Pin 10) - Feedback pin. This is the inverting input of the

error amplifier, which is used for sensing the output voltage

and compensating the control loop.

FREQ/SYNC (Pin 11) - Frequency adjust pin. The switching

frequency is set by connecting a resistor of suitable value

between this pin and ground. Some typical values (rounded

up to the nearest standard values) are 150 kΩ for 200 kHz,

100 kΩ for 300 kHz, 51.1 kΩ for 500 kHz, 18.7 kΩ for 1 MHz.

This pin is also used to synchronize to an external clock

within the range of 250kHz to 1MHz.

SD (Pin 12) - IC shutdown pin. Pull this pin to V

the IC is enabled. Connect to ground to disable the IC. Under

shutdown, both high-side and low-side drives are off. This

pin also features a precision threshold for power supply

sequencing purposes, as well as a low threshold to ensure

minimal quiescent current.

HG (Pin 14) - High-gate drive pin. This is the gate drive for

the high-side N-channel MOSFET. This signal is interlocked

with LG (Pin 2) to avoid shoot-through.

MOSFET (switch node). The minimum value for this resistor

is1kΩ.

94 Units on Rail

to ensure

CC

www.national.com 2

LM2747

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

V

CC

BOOT Voltage -0.3 to 18V

I

SEN

FREQ/SYNC Voltage -0.5 to V

All other pins -0.3 to V

Junction Temperature 150˚C

Storage Temperature −65˚C to 150˚C

-0.3 to 7V

-0.3 to 14V

+ 0.3V

CC

+ 0.3V

CC

Soldering Information

Lead Temperature (soldering, 10sec) 260˚C

Infrared or Convection (20sec) 235˚C

ESD Rating (Note 3) 2kV

Operating Ratings

Supply Voltage Range, VCC(Note 2) 3V to 6V

BOOT Voltage Range 1V to 17V

Junction Temperature Range (T

Thermal Resistance (θ

) 155˚C/W

JA

) −40˚C to +125˚C

J

Electrical Characteristics

VCC= 3.3V unless otherwise indicated. Typicals and limits appearing in plain type apply for TA=TJ= 25˚C. Limits appearing in

boldface type apply over full Operating Temperature Range. Datasheet min/max specification limits are guaranteed by design,

test, or statistical analysis.

Symbol Parameter Conditions Min Typ Max Units

V

FB

V

ON

I

Q_VCC

t

PWGD1

t

PWGD2

I

SS-ON

I

SS-OC

I

SEN-TH

I

FB

ERROR AMPLIFIER

GBW Error Amplifier Unity Gain

G Error Amplifier DC Gain 118 dB

SR Error Amplifier Slew Rate 2 V/µs

I

EAO

V

EAO

FB Pin Voltage VCC=3Vto6V 0.594 0.6 0.606 V

UVLO Thresholds VCCRising

Falling

V

CC

V

= 3.3V, VSD= 3.3V

CC

= 600 kHz

f

Operating VCCCurrent

Shutdown V

Current VCC= 3.3V, VSD=0V 1 3 µA

CC

SW

V

= 5V, VSD= 3.3V

CC

= 600 kHz

f

SW

1.1 1.7 2.3

1.3 2 2.6

2.79

2.42

PWGD Pin Response Time VFBRising 10 µs

PWGD Pin Response Time VFBFalling 10 µs

SS Pin Source Current VSS=0V 7 10 14 µA

SS Pin Sink Current During Over

Current

I

Pin Source Current Trip

SEN

Point

VSS= 2.0V

90 µA

25 40 55 µA

FB Pin Current Sourcing 20 nA

Bandwidth

EAO Pin Current Sourcing and

Sinking Capability

9 MHz

14

16

Error Amplifier Output Voltage Minimum 1 V

Maximum 2.2 V

V

mA

mA

www.national.com3

Electrical Characteristics (Continued)

VCC= 3.3V unless otherwise indicated. Typicals and limits appearing in plain type apply for TA=TJ= 25˚C. Limits appearing in

LM2747

boldface type apply over full Operating Temperature Range. Datasheet min/max specification limits are guaranteed by design,

test, or statistical analysis.

Symbol Parameter Conditions Min Typ Max Units

GATE DRIVE

I

Q-BOOT

R

HG_UP

BOOT Pin Quiescent Current V

High-Side MOSFET Driver

Pull-Up ON resistance

R

HG_DN

High-Side MOSFET Driver

Pull-Down ON resistance

R

LG_UP

Low-Side MOSFET Driver Pull-Up

ON resistance

R

LG_DN

Low-Side MOSFET Driver

Pull-Down ON resistance

OSCILLATOR

PWM Frequency

f

SW

External Synchronizing Signal

Frequency

SYNC

SYNC

D

MAX

Synchronization Signal Low

L

Threshold

Synchronization Signal High

H

Threshold

Max High-Side Duty Cycle fSW= 300 kHz

LOGIC INPUTS AND OUTPUTS

V

STBY-IH

V

STBY-IL

V

SD-IH

V

SD-IL

V

PWGD-TH-LO

V

PWGD-TH-HI

V

PWGD-HYS

Note 1: Absolute maximum ratings indicate limits beyond which damage to the device may occur. Operating ratings indicate conditions for which the device

operates correctly. Operating Ratings do not imply guaranteed performance limits.

Note 2: The power MOSFETs can run on a separate 1V to 14V rail (Input voltage, V

See the MOSFET GATE DRIVERS section under Application Information for further details.

Note 3: ESD using the human body model which is a 100pF capacitor discharged through a 1.5 kΩ resistor into each pin.

Standby High Trip Point VFB= 0.575V, V

Standby Low Trip Point VFB= 0.575V, V

SD Pin Logic High Trip Point VSDRising 1.3 V

SD Pin Logic Low Trip Point VSDFalling 0.8 V

PWGD Pin Trip Points VFBFalling 0.408 0.434 0.457 V

PWGD Pin Trip Points VFBRising 0.677 0.710 0.742 V

PWGD Hysteresis VFBFalling

= 12V, VSD=0 18 90 µA

BOOT

=5V@350 mA Sourcing 2.7 Ω

V

BOOT

350 mA Sinking 0.8 Ω

=5V@350 mA Sourcing 2.7 Ω

V

BOOT

350 mA Sinking 0.8 Ω

= 750 kΩ 50

R

FADJ

R

= 100 kΩ 300

FADJ

R

= 42.2 kΩ 475 600 725

FADJ

R

= 18.7 kΩ 1000

FADJ

Voltage Swing = 0V to V

= 250 kHz to 1 MHz 1 V

f

SW

= 250 kHz to 1 MHz 2 V

f

SW

CC

250 1000

86

= 600 kHz

f

SW

f

SW

V

SD

V

SD

= 1 MHz

Rising

Falling

BOOT

BOOT

= 3.3V

= 3.3V

0.232

78

67

60

Rising

V

FB

). Practical lower limit of VINdepends on selection of the external MOSFET.

IN

90

1.1

kHz

%

V

V

mV

www.national.com 4

Typical Performance Characteristics

LM2747

Efficiency (V

= 3.3V, fSW= 1 MHz Internal Reference Voltage vs Temperature

V

CC

OUT

= 1.2V)

20150940 20150958

Frequency vs Temperature Output Voltage vs Output Current

Switch Waveforms

= 3.3V, VIN= 5V, V

V

CC

= 3A, CSS= 12 nF, fSW= 1 MHz

I

OUT

OUT

20150960 20150956

Start-Up (Full-Load)

= 1.2V

20150946

V

= 3.3V, VIN= 5V, V

CC

= 3A, CSS= 12 nF, fSW= 1 MHz

I

OUT

OUT

= 1.2V

20150948

www.national.com5

Typical Performance Characteristics (Continued)

LM2747

Start-Up (No-Load)

V

= 3.3V, VIN= 5V, V

CC

= 12 nF, fSW= 1 MHz

C

SS

Load Transient Response

= 3.3V, VIN= 14V, V

V

CC

f

SW

= 1 MHz

OUT

OUT

Shutdown (Full-Load)

= 1.2V

20150949 20150950

= 1.2V

V

= 3.3V, VIN= 5V, V

CC

= 3A, CSS= 12 nF, fSW= 1 MHz

I

OUT

Line Transient Response (V

= 3.3V, V

V

CC

= 2A, fSW= 1 MHz

I

OUT

OUT

OUT

IN

= 1.2V

= 1.2V

=3Vto9V)

20150953 20150954

Frequency vs. Frequency Adjust Resistor

20150955

www.national.com 6

Maximum Duty Cycle vs Frequency

VCC= 3.3V

20150992

Typical Performance Characteristics (Continued)

LM2747

Maximum Duty Cycle vs V

fSW= 600 kHz

CC

Maximum Duty Cycle vs V

fSW= 1 MHz

20150993 20150994

CC

www.national.com7

Block Diagram

LM2747

Application Information

The LM2747 is a voltage-mode, high-speed synchronous

buck regulator with a PWM control scheme. It is designed for

use in set-top boxes, thin clients, DSL/Cable modems, and

other applications that require high efficiency buck converters. It has output shutdown (SD), input undervoltage lock-out

(UVLO) mode and power good (PWGD) flag (based on

overvoltage and undervoltage detection). The overvoltage

and undervoltage signals are OR-gated to drive the power

good signal and provide a logic signal to the system if the

output voltage goes out of regulation. Current limit is

achieved by sensing the voltage V

MOSFET. The LM2747 is also able to start-up with the

output pre-biased with a load and allows for the switching

frequency to be synchronized with an external clock source.

START UP/SOFT-START

When V

exceeds 2.79V and the shutdown pin (SD) sees

CC

a logic high, the soft-start period begins. Then an internal,

fixed 10 µA source begins charging the soft-start capacitor.

During soft-start the voltage on the soft-start capacitor C

connected internally to the non-inverting input of the error

amplifier. The soft-start period lasts until the voltage on the

soft-start capacitor exceeds the LM2747 reference voltage

of 0.6V. At this point the reference voltage takes over at the

non-inverting error amplifier input. The capacitance of C

determines the length of the soft-start period, and can be

approximated by:

across the low side

DS

SS

SS

20150903

Where CSSis in µF and tSSis in ms.

During soft start the Power Good flag is forced low and it is

released when the FB pin voltage reaches 70% of 0.6V. At

this point the chip enters normal operation mode, and the

output overvoltage and undervoltage monitoring starts.

SETTING THE OUTPUT VOLTAGE

The LM2747 regulates the output voltage by controlling the

duty cycle of the high side and low side MOSFETs (see

Typical Application Circuit).The equation governing output

voltage is:

is

SETTING THE SWITCHING FREQUENCY

During fixed-frequency mode of operation the PWM fre-

quency is adjustable between 50 kHz and 1 MHz and is set

by an external resistor, R

, between the FREQ/SYNC pin

FADJ

and ground. The resistance needed for a desired frequency

www.national.com 8

Application Information (Continued)

is approximated by the curve FREQUENCY vs. FREQUENCY ADJUST RESISTOR in the Typical Performance

Characteristics section.

When it is desired to synchronize the switching frequency

with an external clock source, the LM2747 has the unique

ability to synchronize from this external source within the

range of 250 kHz to 1 MHz. The external clock signal should

be AC coupled to the FREQ/SYNC pin as shown below in

Figure 1, where the R

quency is approximately within

chronizing clock frequency. An internal protection diode

clamps the low level of the synchronizing signal to approximately -0.5V. The internal clock synchrinizes to the rising

edge of the external clock.

is chosen so that the fixed fre-

FADJ

±

30% of the external syn-

switching cycle. Figure 2 shows the SW node, HG, and LG

signals during pre-bias startup. The pre-biased output voltage should not exceed V

CC+VGS

of the external High-Side

MOSFET to ensure that the High-Side MOSFET will be able

to switch during startup.

LM2747

20150989

FIGURE 1. AC Coupled Clock

It is recommended to choose an AC coupling capacitance in

the range of 50 pF to 100 pF. Exceeding the recommended

capacitance may inject excessive energy through the internal clamping diode structure present on the FREQ/SYNC

pin.

The typical trip level of the synchronization pin is 1.5V. To

ensure proper synchronization and to avoid damaging the

IC, the peak-to-peak value (amplitude) should be between

2.5V and V

. The minimum width of this pulse must be

CC

greater than 100 ns, and it’s maximum width must be 100ns

less than the period of the switching cycle.

The external clock synchronization process begins once the

LM2747 is enabled and an external clock signal is detected.

During the external clock synchronization process the internal clock initially switches at approximately 1.5 MHz and

decreases until it has matched the external clock’s frequency. The lock-in period is approximately 30 µs if the

external clock is switching at 1 MHz, and about 100 µs if the

external clock is at 200 kHz. When there is no clock signal

present, the LM2747 enters into fixed-frequency mode and

begins switching at the frequency set by the R

FADJ

resistor.

If the external clock signal is removed after frequency synchronization, the LM2747 will enter fixed-frequency mode

within two clock cycles. If the external clock is removed

within the 30 µs lock-in period, the LM2747 will re-enter

fixed-frequency mode within two internal clock cycles after

the lock-in period.

20150991

FIGURE 2. Output Pre-Bias Mode Waveforms

TRACKING A VOLTAGE LEVEL

The LM2747 can track the output of a master power supply

during soft-start by connecting a resistor divider to the SS/

TRACK pin. In this way, the output voltage slew rate of the

LM2747 will be controlled by the master supply for loads that

require precise sequencing. When the tracking function is

used no soft-start capacitor should be connected to the

SS/TRACK pin. However in all other cases, a C

value of at

SS

least 1 nF between the soft-start pin and ground should be

used.

OUTPUT PRE-BIAS STARTUP

If there is a pre-biased load on the output of the LM2747

during startup, the IC will disable switching of the low-side

MOSFET and monitor the SW node voltage during the offtime of the high-side MOSFET. There is no load current

sensing while in pre-bias mode because the low-side MOSFET never turns on. The IC will remain in this pre-bias mode

until it sees the SW node stays below 0V during the entire

high-side MOSFET’s off-time. Once it is determined that the

SW node remained below 0V during the high-side off-time,

the low-side MOSFET begins switching during the next

20150907

FIGURE 3. Tracking Circuit

One way to use the tracking feature is to design the tracking

resistor divider so that the master supply’s output voltage

) and the LM2747’s output voltage (represented sym-

(V

OUT1

bolically in Figure 3 as V

, i.e. without explicitly showing

OUT2

the power components) both rise together and reach their

www.national.com9

Application Information (Continued)

target values at the same time. For this case, the equation

LM2747

governing the values of the tracking divider resistors R

is:

R

T2

The current through RT1should be about 4 mA for precise

tracking. The final voltage of the SS/TRACK pin should be

set higher than the feedback voltage of 0.6V (say about

0.65V as in the above equation). If the master supply voltage

was 5V and the LM2747 output voltage was 1.8V, for example, then the value of R

identical soft-start times would be 150Ω. A timing diagram for

the equal soft-start time case is shown in Figure 4.

needed to give the two supplies

T1

and

T1

20150910

FIGURE 5. Tracking with Equal Slew Rates

SEQUENCING

The start up/soft-start of the LM2747 can be delayed for the

purpose of sequencing by connecting a resistor divider from

the output of a master power supply to the SD pin, as shown

in Figure 6.

20150908

FIGURE 4. Tracking with Equal Soft-Start Time

TRACKING A VOLTAGE SLEW RATE

The tracking feature can alternatively be used not to make

both rails reach regulation at the same time but rather to

have similar rise rates (in terms of output dV/dt). This

method ensures that the output voltage of the LM2747 always reaches regulation before the output voltage of the

master supply. In this case, the tracking resistors can be

determined based on the following equation:

For the example case of V

set to 150Ω as before, RT2is calculated from the above

R

T1

OUT1

= 5V and V

OUT2

= 1.8V, with

equation to be 265Ω. A timing diagram for the case of equal

slew rates is shown in Figure 5.

20150914

FIGURE 6. Sequencing Circuit

A desired delay time t

between the startup of the

DELAY

master supply output voltage and the LM2747 output voltage

can be set based on the SD pin low-to-high threshold V

SD-IH

and the slew rate of the voltage at the SD pin, SRSD:

t

DELAY=VSD-IH

/SR

SD

Note again, that in Figure 6, the LM2747’s output voltage

has been represented symbolically as V

, i.e. without

OUT2

explicitly showing the power components.

is typically 1.08V and SRSDis the slew rate of the SD

V

SD-IH

pin voltage. The values of the sequencing divider resistors

and RS2set the SRSDbased on the master supply

R

S1

output voltage slew rate, SR

, using the following equa-

OUT1

tion:

www.national.com 10

Application Information (Continued)

For example, if the master supply output voltage slew rate

was 1V/ms and the desired delay time between the startup

of the master supply and LM2747 output voltage was 5 ms,

then the desired SD pin slew rate would be (1.08V/5 ms) =

0.216V/ms. Due to the internal impedance of the SD pin, the

maximum recommended value for RS2is1kΩ. To achieve

the desired slew rate, R

diagram for this example is shown in Figure 7.

FIGURE 7. Delay for Sequencing

SD PIN IMPEDANCE

When connecting a resistor divider to the SD pin of the

LM2747 some care has to be taken. Once the SD voltage

goes above V

, a 17 µA pull-up current is activated as

SD-IH

shown in Figure 8. This current is used to create the internal

hysteresis ()170 mV); however, high external impedances

will affect the SD pin logic thresholds as well. The external

impedance used for the sequencing divider network should

preferably be a small fraction of the impedance of the SD pin

for good performance (around 1 kΩ).

would then be 274Ω. A timing

S1

20150911

20150906

FIGURE 8. SD Pin Logic

MOSFET GATE DRIVERS

The LM2747 has two gate drivers designed for driving

N-channel MOSFETs in a synchronous mode. Note that

unlike most other synchronous controllers, the bootstrap

capacitor of the LM2747 provides power not only to the

driver of the upper MOSFET, but the lower MOSFET driver

too (both drivers are ground referenced, i.e. no floating

driver).

Two things must be kept in mind here. First, the BOOT pin

has an absolute maximum rating of 18V. This must never be

exceeded, even momentarily. Since the bootstrap capacitor

is connected to the SW node, the peak voltage impressed on

the BOOT pin is the sum of the input voltage (V

) plus the

IN

voltage across the bootstrap capacitor (ignoring any forward

drop across the bootstrap diode). The bootstrap capacitor is

charged up by a given rail (called V

BOOT_DC

here) whenever

the upper MOSFET turns off. This rail can be the same as

or it can be any external ground-referenced DC rail. But

V

CC

care has to be exercised when choosing this bootstrap DC

rail that the BOOT pin is not damaged. For example, if the

desired maximum V

the same as V

, then clearly if the VCCrail is 6V, the peak

CC

is 14V, and V

IN

BOOT_DC

is chosen to be

voltage on the BOOT pin is 14V + 6V = 20V. This is unacceptable, as it is in excess of the rating of the BOOT pin. A

of 3V would be acceptable in this case. Or the VINrange

V

CC

must be reduced accordingly. There is also the option of

deriving the bootstrap DC rail from another 3V external rail,

independent of V

.

CC

The second thing to be kept in mind here is that the output of

the low-side driver swings between the bootstrap DC rail

level of V

BOOT_DC

high-side driver swings between V

and Ground, whereas the output of the

+V

IN

BOOT_DC

and

Ground. To keep the high-side MOSFET fully on when desired, the Gate pin voltage of the MOSFET must be higher

than its instantaneous Source pin voltage by an amount

equal to the ’Miller plateau’. It can be shown that this plateau

is equal to the threshold voltage of the chosen MOSFET plus

a small amount equal to Io/g. Here Io is the maximum load

current of the application, and g is the transconductance of

this MOSFET (typically about 100 for logic-level devices).

That means we must choose V

BOOT_DC

to at least exceed

LM2747

www.national.com11

Application Information (Continued)

the Miller plateau level. This may therefore affect the choice

LM2747

of the threshold voltage of the external MOSFETs, and that

in turn may depend on the chosen V

So far, in the discussion above, the forward drop across the

bootstrap diode has been ignored. But since that does affect

the output of the driver somewhat, it is a good idea to include

this drop in the following examples. Looking at the Typical

Application schematic, this means that the difference voltage

V

CC-VD1

, which is the voltage the bootstrap capacitor

charges up to, must always be greater than the maximum

tolerance limit of the threshold voltage of the upper MOSFET. Here V

is the forward voltage drop across the boot-

D1

strap diode D1. This may place restrictions on the minimum

input voltage and/or type of MOSFET used.

A basic bootstrap circuit can be built using one Schottky

diode and a small capacitor, as shown in Figure 9. The

capacitor C

serves to maintain enough voltage between

BOOT

the top MOSFET gate and source to control the device even

when the top MOSFET is on and its source has risen up to

the input voltage level. The charge pump circuitry is fed from

, which can operate over a range from 3.0V to 6.0V.

V

CC

Using this basic method the voltage applied to the gates of

both high-side and low-side MOSFETs is V

method works well when V

CC

drives will get at least 4.0V of drive voltage during the worst

case of V

CC-MIN

= 4.5V and V

MOSFETs generally specify their on-resistance at V

4.5V. When V

= 3.3V±10%, the gate drive at worst case

CC

could go as low as 2.5V. Logic level MOSFETs are not

guaranteed to turn on, or may have much higher onresistance at 2.5V. Sub-logic level MOSFETs, usually specified at V

= 2.5V, will work, but are more expensive, and

GS

tend to have higher on-resistance. The circuit in Figure 9

works well for input voltages ranging from 1V up to 14V and

=5V±10%, because the drive voltage depends only on

V

CC

.

V

CC

BOOT_DC

is 5V±10%, because the gate

= 0.5V. Logic level

D-MAX

rail.

CC-VD

. This

GS

powers both the V

and the bootstrap circuit, providing

CC

efficient drive for logic level MOSFETs. An example of this

circuit is shown in Figure 10.

20150913

FIGURE 10. LM78L05 Feeding Basic Charge Pump

=

Figure 11 shows a second possibility for bootstrapping the

MOSFET drives using a doubler. This circuit provides an

equal voltage drive of V

-3VD+VINto both the high-side

CC

and low-side MOSFET drives. This method should only be

used in circuits that use 3.3V for both V

V

IN=VCC

= 3.0V (10% lower tolerance on 3.3V) and VD=

and VIN. Even with

CC

0.5V both high-side and low-side gates will have at least

4.5V of drive. The power dissipation of the gate drive circuitry is directly proportional to gate drive voltage, hence the

thermal limits of the LM2747 IC will quickly be reached if this

circuit is used with V

or VINvoltages over 5V.

CC

20150912

FIGURE 9. Basic Charge Pump (Bootstrap)

Note that the LM2747 can be paired with a low cost linear

regulator like the LM78L05 to run from a single input rail

between 6.0 and 14V. The 5V output of the linear regulator

www.national.com 12

20150919

FIGURE 11. Charge Pump with Added Gate Drive

All the gate drive circuits shown in the above figures typically

use 100 nF ceramic capacitors in the bootstrap locations.

Application Information (Continued)

POWER GOOD SIGNAL

The open drain output on the Power Good pin needs a

pull-up resistor to a low voltage source. The pull-up resistor

should be chosen so that the current going into the Power

Good pin is less than 1 mA. A 100 kΩ resistor is recommended for most applications.

The Power Good signal is an OR-gated flag which takes into

account both output overvoltage and undervoltage conditions. If the feedback pin (FB) voltage is 18% above its

nominal value (118% x V

value (72% x V

= 0.42V) the Power Good flag goes low.

FB

The Power Good flag can be used to signal other circuits that

the output voltage has fallen out of regulation, however the

switching of the LM2747 continues regardless of the state of

the Power Good signal. The Power Good flag will return to

logic high whenever the feedback pin voltage is between

72% and 118% of 0.6V.

UVLO

The 2.79V turn-on threshold on V

of about 300 mV. If V

nitely enters UVLO mode. UVLO consists of turning off the

top and bottom MOSFETS and remaining in that condition

until V

rises above 2.79V. As with normal shutdown initi-

CC

ated by the SD pin, the soft-start capacitor is discharged

through an internal MOSFET, ensuring that the next start-up

will be controlled by the soft-start circuitry.

= 0.708V) or falls 28% below that

FB

has a built in hysteresis

CC

drops below 2.42V, the chip defi-

CC

LM2747

on. (The point of peak inductor current, see Figure 12). Note

that in normal operation mode the high-side MOSFET always turns on at the beginning of a clock cycle. In current

limit mode, by contrast, the high-side MOSFET on-pulse is

skipped. This causes inductor current to fall. Unlike a normal

operation switching cycle, however, in a current limit mode

switching cycle the high-side MOSFET will turn on as soon

as inductor current has fallen to the current limit threshold.

The LM2747 will continue to skip high-side MOSFET pulses

until the inductor current peak is below the current limit

threshold, at which point the system resumes normal operation.

CURRENT LIMIT

Current limit is realized by sensing the voltage across the

low-side MOSFET while it is on. The R

of the MOSFET

DSON

is a known value; hence the current through the MOSFET

can be determined as:

V

DS=IOUTxRDSON

The current through the low-side MOSFET while it is on is

also the falling portion of the inductor current. The current

limit threshold is determined by an external resistor, R

connected between the switching node and the I

constant current (I

, causing a fixed voltage drop. This fixed voltage is

R

CS

compared against V

) of 40 µA typical is forced through

SEN-TH

and if the latter is higher, the current

DS

SEN

CS

pin. A

limit of the chip has been reached. To obtain a more accurate

value for R

R

DSON

you must consider the operating values of

CS

and I

at their operating temperatures in your

SEN-TH

application and the effect of slight parameter differences

from part to part. R

equation using the R

can be found by using the following

CS

value of the low side MOSFET at

DSON

it’s expected hot temperature and the absolute minimum

value expected over the full temperature range for the for the

which is 25 µA:

I

SEN-TH

R

CS=RDSON-HOTxILIM/ISEN-TH

For example, a conservative 15A current limit in a 10A

design with a R

DSON-HOT

resistor. The minimum value for R

of 10 mΩ would requirea6kΩ

in any application is 1

CS

kΩ. Because current sensing is done across the low-side

MOSFET, no minimum high-side on-time is necessary. The

LM2747 enters current limit mode if the inductor current

exceeds the current limit threshold at the point where the

high-side MOSFET turns off and the low-side MOSFET turns

20150988

FIGURE 12. Current Limit Threshold

Unlike a high-side MOSFET current sensing scheme, which

limits the peaks of inductor current, low-side current sensing

is only allowed to limit the current during the converter

off-time, when inductor current is falling. Therefore in a typi-

,

cal current limit plot the valleys are normally well defined, but

the peaks are variable, according to the duty cycle. The

PWM error amplifier and comparator control the off-pulse of

the high-side MOSFET, even during current limit mode,

meaning that peak inductor current can exceed the current

limit threshold. Assuming that the output inductor does not

saturate, the maximum peak inductor current during current

limit mode can be calculated with the following equation:

Where TSWis the inverse of switching frequency fSW. The

200 ns term represents the minimum off-time of the duty

cycle, which ensures enough time for correct operation of

the current sensing circuitry.

In order to minimize the time period in which peak inductor

current exceeds the current limit threshold, the IC also discharges the soft-start capacitor through a fixed 90 µA sink.

The output of the LM2747 internal error amplifier is limited by

the voltage on the soft-start capacitor. Hence, discharging

the soft-start capacitor reduces the maximum duty cycle D of

the controller. During severe current limit this reduction in

duty cycle will reduce the output voltage if the current limit

conditions last for an extended time. Output inductor current

www.national.com13

Application Information (Continued)

will be reduced in turn to a flat level equal to the current limit

LM2747

threshold. The third benefit of the soft-start capacitor discharge is a smooth, controlled ramp of output voltage when

the current limit condition is cleared.

SHUTDOWN

If the shutdown pin is pulled low, (below 0.8V) the LM2747

enters shutdown mode, and discharges the soft-start capacitor through a MOSFET switch. The high and low-side MOSFETs are turned off. The LM2747 remains in this state as

long as V

istics table). To assure proper IC start-up the shutdown pin

should not be left floating. For normal operation this pin

should be connected directly to V

between 1.3V to V

table).

DESIGN CONSIDERATIONS

The following is a design procedure for all the components

needed to create the Typical Application Circuit shown on

the front page. This design converts 3.3V (V

(V

OUT

and a switching frequency of 300 kHz. The same procedures

can be followed to create many other designs with varying

input voltages, output voltages, and load currents.

Input Capacitor

The input capacitors in a Buck converter are subjected to

high stress due to the input current trapezoidal waveform.

Input capacitors are selected for their ripple current capability and their ability to withstand the heat generated since that

ripple current passes through their ESR. Input rms ripple

current is approximately:

Where duty cycleD=V

The power dissipated by each input capacitor is:

where n is the number of paralleled capacitors, and ESR is

the equivalent series resistance of each capacitor. The equation above indicates that power loss in each capacitor decreases rapidly as the number of input capacitors increases.

The worst-case ripple for a Buck converter occurs during full

load and when the duty cycle (D) is 0.5. For this 3.3V to 1.2V

design the duty cycle is 0.364. For a 4A maximum load the

ripple current is 1.92A.

Output Inductor

The output inductor forms the first half of the power stage in

a Buck converter. It is responsible for smoothing the square

wave created by the switching action and for controlling the

output current ripple (∆I

selecting between tradeoffs in efficiency and response time.

The smaller the output inductor, the more quickly the converter can respond to transients in the load current. However, as shown in the efficiency calculations, a smaller inductor requires a higher switching frequency to maintain the

same level of output current ripple. An increase in frequency

sees a logic low (see the Electrical Character-

SD

or to another voltage

(see the Electrical Characteristics

CC

CC

) at a maximum load of 4A with an efficiency of 89%

.

OUT/VIN

). The inductance is chosen by

OUT

) to 1.2V

IN

can mean increasing loss in the MOSFETs due to the charging and discharging of the gates. Generally the switching

frequency is chosen so that conduction loss outweighs

switching loss. The equation for output inductor selection is:

L = 1.6 µH

Here we have plugged in the values for output current ripple,

input voltage, output voltage, switching frequency, and assumed a 40% peak-to-peak output current ripple. This yields

an inductance of 1.6 µH. The output inductor must be rated

to handle the peak current (also equal to the peak switch

current), which is (I

OUT

+ (0.5 x ∆I

)) = 4.8A, for a 4A

OUT

design.

The Coilcraft DO3316P-222P is 2.2 µH, is rated to 7.4A

peak, and has a direct current resistance (DCR) of 12 mΩ.

After selecting the Coilcraft DO3316P-222P for the output

inductor, actual inductor current ripple should be recalculated with the selected inductance value, as this information is needed to select the output capacitor. Rearranging the equation used to select inductance yields the

following:

V

voltage, or 3.6V at V

is assumed to be 10% above the steady state input

IN(MAX)

= 3.3V. The re-calculated current

IN

ripple will then be 1.2A. This gives a peak inductor/switch

current will be 4.6A.

Output Capacitor

The output capacitor forms the second half of the power

stage of a Buck switching converter. It is used to control the

output voltage ripple (∆V

) and to supply load current

OUT

during fast load transients.

In this example the output current is 4A and the expected

type of capacitor is an aluminum electrolytic, as with the

input capacitors. Other possibilities include ceramic, tantalum, and solid electrolyte capacitors, however the ceramic

type often do not have the large capacitance needed to

supply current for load transients, and tantalums tend to be

more expensive than aluminum electrolytic. Aluminum capacitors tend to have very high capacitance and fairly low

ESR, meaning that the ESR zero, which affects system

stability, will be much lower than the switching frequency.

The large capacitance means that at the switching frequency, the ESR is dominant, hence the type and number of

output capacitors is selected on the basis of ESR. One

simple formula to find the maximum ESR based on the

desired output voltage ripple, ∆V

put current ripple, ∆I

OUT

, is:

and the designed out-

OUT

www.national.com 14

Application Information (Continued)

In this example, in order to maintain a 2% peak-to-peak

output voltage ripple and a 40% peak-to-peak inductor current ripple, the required maximum ESR is 20 mΩ. The Sanyo

4SP560M electrolytic capacitor will give an equivalent ESR

of 14 mΩ. The capacitance of 560 µF is enough to supply

energy even to meet severe load transient demands.

MOSFETs

Selection of the power MOSFETs is governed by a trade-off

between cost, size, and efficiency. One method is to determine the maximum cost that can be endured, and then

select the most efficient device that fits that price. Breaking

down the losses in the high-side and low-side MOSFETs and

then creating spreadsheets is one way to determine relative

efficiencies between different MOSFETs. Good correlation

between the prediction and the bench result is not guaranteed, however. Single-channel buck regulators that use a

controller IC and discrete MOSFETs tend to be most efficient

for output currents of 2 to 10A.

Losses in the high-side MOSFET can be broken down into

conduction loss, gate charging loss, and switching loss.

Conduction, or I

In the above equations the factor 1.3 accounts for the increase in MOSFET R

1.3 can be ignored and the R

using the R

datasheets.

Gate charging loss results from the current driving the gate

capacitance of the power MOSFETs, and is approximated

as:

where ‘n’ is the number of MOSFETs (if multiple devices

have been placed in parallel), V

MOSFET Gate Drivers section) and Q

of the MOSFET. If different types of MOSFETs are used, the

‘n’ term can be ignored and their gate charges simply

summed to form a cumulative Q

from conduction and switching losses in that the actual

dissipation occurs in the LM2747, and not in the MOSFET

itself.

Switching loss occurs during the brief transition period as the

high-side MOSFET turns on and off, during which both current and voltage are present in the channel of the MOSFET.

It can be approximated as:

where trand tfare the rise and fall times of the MOSFET.

Switching loss occurs in the high-side MOSFET only.

For this example, the maximum drain-to-source voltage applied to either MOSFET is 3.6V. The maximum drive voltage

at the gate of the high-side MOSFET is 3.1V, and the maximum drive voltage for the low-side MOSFET is 3.3V. Due to

the low drive voltages in this example, a MOSFET that turns

on fully with 3.1V of gate drive is needed. For designs of 5A

and under, dual MOSFETs in SO-8 provide a good trade-off

between size, cost, and efficiency.

2

R loss, is approximately:

PC=D(I

2

xR

O

DSON-HI

x 1.3)

(High-Side MOSFET)

=(1-D)x(I

P

C

2

xR

O

DSON-LO

x 1.3)

(Low-Side MOSFET)

due to heating. Alternatively, the

DSON

Vs. Temperature curves in the MOSFET

DSON

=nx(VDD)xQGxf

P

GC

=0.5xVINxIOx(tr+tf)xf

P

SW

of the MOSFET estimated

DSON

SW

is the driving voltage (see

DD

G

is the gate charge

GS

. Gate charge loss differs

SW

Support Components

C

2 - A small (0.1 to 1 µF) ceramic capacitor should be

IN

placed as close as possible to the drain of the high-side

MOSFET and source of the low-side MOSFET (dual MOSFETs make this easy). This capacitor should be X5R type

dielectric or better.

R

CC,CCC

ensure smooth DC voltage for the chip supply. R

be1to10Ω.C

C

BOOT

R

PULL-UP

- These are standard filter components designed to

should 1 µF, X5R type or better.

CC

CC

- Bootstrap capacitor, typically 100 nF.

– This is a standard pull-up resistor for the open-

should

drain power good signal (PWGD). The recommended value

is 100 kΩ connected to V

. If this feature is not necessary,

CC

the resistor can be omitted.

- A small Schottky diode should be used for the bootstrap.

D

1

It allows for a minimum drop for both high and low-side

drivers. The MBR0520 or BAT54 work well in most designs.

- Resistor used to set the current limit. Since the design

R

CS

calls for a peak current magnitude (I

OUT

+ (0.5 x ∆I

OUT

)) of

4.8A, a safe setting would be 6A. (This is below the saturation current of the output inductor, which is 7A.) Following the

equation from the Current Limit section, a 1.3 kΩ resistor

should be used.

- This resistor is used to set the switching frequency of

R

FADJ

the chip. The resistor value is approximated from the Frequency vs Frequency Adjust Resistor curve in the Typical

Performance Characteristics section. For 300 kHz operation,

a 100 kΩ resistor should be used.

- The soft-start capacitor depends on the user require-

C

SS

ments and is calculated based on the equation given in the

section titled START UP/SOFT-START. Therefore, fora7ms

delay, a 12 nF capacitor is suitable.

Control Loop Compensation

The LM2747 uses voltage-mode (‘VM’) PWM control to correct changes in output voltage due to line and load transients. VM requires careful small signal compensation of the

control loop for achieving high bandwidth and good phase

margin.

The control loop is comprised of two parts. The first is the

power stage, which consists of the duty cycle modulator,

output inductor, output capacitor, and load. The second part

is the error amplifier, which for the LM2747 isa9MHz

op-amp used in the classic inverting configuration. Figure 13

shows the regulator and control loop components.

LM2747

www.national.com15

Application Information (Continued)

LM2747

20150964

a=LCO(RO+RC)

b=L+C

c=R

O(RORL+RORC+RCRL

O+RL

)

FIGURE 13. Power Stage and Error Amp

One popular method for selecting the compensation components is to create Bode plots of gain and phase for the power

stage and error amplifier. Combined, they make the overall

bandwidth and phase margin of the regulator easy to see.

Software tools such as Excel, MathCAD, and Matlab are

useful for showing how changes in compensation or the

power stage affect system gain and phase.

The power stage modulator provides a DC gain A

DC

that is

equal to the input voltage divided by the peak-to-peak value

of the PWM ramp. This ramp is 1.0V

for the LM2747.

pk-pk

The inductor and output capacitor create a double pole at

frequency f

ate a single zero at frequency f

= 3.3V, these quantities are:

V

IN

, and the capacitor ESR and capacitance cre-

DP

. For this example, with

ESR

In the equation for fDP, the variable RLis the power stage

resistance, and represents the inductor DCR plus the on

resistance of the top power MOSFET. R

is the output

O

voltage divided by output current. The power stage transfer

function G

is given by the following equation, and Figure

PS

14 shows Bode plots of the phase and gain in this example.

20150969

20150970

FIGURE 14. Power Stage Gain and Phase

The double pole at 4.5 kHz causes the phase to drop to

approximately -130˚ at around 10 kHz. The ESR zero, at

20.3 kHz, provides a +90˚ boost that prevents the phase

from dropping to -180

o

. If this loop were left uncompensated,

the bandwidth would be approximately 10 kHz and the

phase margin 53˚. In theory, the loop would be stable, but

would suffer from poor DC regulation (due to the low DC

gain) and would be slow to respond to load transients (due to

the low bandwidth.) In practice, the loop could easily become

unstable due to tolerances in the output inductor, capacitor,

or changes in output current, or input voltage. Therefore, the

loop is compensated using the error amplifier and a few

passive components.

For this example, a Type III, or three-pole-two-zero approach

gives optimal bandwidth and phase.

In most voltage mode compensation schemes, including

Type III, a single pole is placed at the origin to boost DC gain

www.national.com 16

Application Information (Continued)

LM2747

as high as possible. Two zeroes f

and fZ2are placed at the

Z1

double pole frequency to cancel the double pole phase lag.

Then, a pole, f

A final pole f

is placed at the frequency of the ESR zero.

P1

is placed at one-half of the switching fre-

P2

quency. The gain of the error amplifier transfer function is

selected to give the best bandwidth possible without violating the Nyquist stability criteria. In practice, a good crossover

point is one-fifth of the switching frequency, or 60 kHz for this

example. The generic equation for the error amplifier transfer

function is:

In this equation the variable AEAis a ratio of the values of the

capacitance and resistance of the compensation components, arranged as shown in Figure 13.A

is selected to

EA

provide the desired bandwidth. A starting value of 80,000 for

should give a conservative bandwidth. Increasing the

A

EA

value will increase the bandwidth, but will also decrease

phase margin. Designs with 45-60˚ are usually best because

they represent a good trade-off between bandwidth and

phase margin. In general, phase margin is lowest and gain

highest (worst-case) for maximum input voltage and minimum output current. One method to select A

is to use an

EA

iterative process beginning with these worst-case conditions.

1. Increase A

EA

2. Check overall bandwidth and phase margin

3. Change V

to minimum and recheck overall bandwidth

IN

and phase margin

4. Change I

to maximum and recheck overall bandwidth

O

and phase margin

The process ends when the both bandwidth and the phase

margin are sufficiently high. For this example input voltage

can vary from 3.0 to 3.6V and output current can vary from 0

to 4A, and after a few iterations a moderate gain factor of

101dB is used.

The error amplifier of the LM2747 has a unity-gain bandwidth of 9 MHz. In order to model the effect of this limitation,

the open-loop gain can be calculated as:

20150974

20150975

FIGURE 15. Error Amp. Gain and Phase

In VM regulators, the top feedback resistor R

of the compensation. Setting R

to 10 kΩ±1%, usually

FB2

forms a part

FB2

gives values for the other compensation resistors and capacitors that fall within a reasonable range. (Capacitances

1 pF, resistances<1MΩ)CC1,CC2,CC3,RC1, and RC2are

selected to provide the poles and zeroes at the desired

frequencies, using the following equations:

>

The new error amplifier transfer function that takes into

account unity-gain bandwidth is:

The gain and phase of the error amplifier are shown in

Figure 15.

www.national.com17

Application Information (Continued)

LM2747

In practice, a good trade off between phase margin and

±

and CC2,

C1

10%

bandwidth can be obtained by selecting the closest

capacitor values above what are suggested for C

±

the closest

, and the closest±1% resistor values below the sugges-

C

C3

tions for R

10% capacitor value below the suggestion for

. Note that if the suggested value for RC2is

C1,RC2

less than 100Ω, it should be replaced by a short circuit.

Following this guideline, the compensation components will

be:

=27pF±10%, CC2= 820 pF±10%

C

C1

= 2.7 nF±10%, RC1= 39.2 kΩ±1%

C

C3

= 2.55 kΩ±1%

R

C2

The transfer function of the compensation block can be

derived by considering the compensation components as

impedance blocks Z

and ZIaround an inverting op-amp:

F

20150985

20150986

As with the generic equation, G

EA-ACTUAL

must be modified

to take into account the limited bandwidth of the error amplifier. The result is:

The total control loop transfer function H is equal to the

power stage transfer function multiplied by the error amplifier

transfer function.

H=G

PSxHEA

The bandwidth and phase margin can be read graphically

from Bode plots of H

as shown in Figure 16.

EA

FIGURE 16. Overall Loop Gain and Phase

The bandwidth of this example circuit is 59 kHz, with a phase

margin of 60˚.

EFFICIENCY CALCULATIONS

The following is a sample calculation.

A reasonable estimation of the efficiency of a switching buck

controller can be obtained by adding together the Output

Power (P

The Output Power (P

design is (1.2V x 4A) = 4.8W. The Total Power (P

) loss and the Total Power (P

OUT

) for the Typical Application Circuit

OUT

TOTAL

) loss:

TOTAL

), with

an efficiency calculation to complement the design, is shown

below.

The majority of the power losses are due to the low side and

high side MOSFET’s losses. The losses in any MOSFET are

group of switching (P

P

FET=PSW+PCND

SW

P

FET

FET Switching Loss (P

P

SW=PSW(ON)

PSW=0.5xVINxI

) and conduction losses (P

= 61.38 mW + 270.42 mW

= 331.8 mW

)

SW

+P

SW(OFF)

x(tr+tf)xf

OUT

SW

CND

).

www.national.com 18

Application Information (Continued)

P

=0.5x3.3Vx4Ax300kHzx31ns

SW

= 61.38 mW

P

SW

SW

and turn-off

r

is the

GS

The FDS6898A has a typical turn-on rise time t

fall time t

of 15 ns and 16 ns, respectively. The switching

f

losses for this type of dual N-Channel MOSFETs are

0.061W.

2

OUT

OUT

CND

xR

)

xR

DS(ON)

xkxD

DS(ON)

x k x (1-D)

of a FET due to heat-

DS(ON)

FET Conduction Loss (P

P

CND=PCND1+PCND2

P

=I

CND1

2

=I

P

CND2

R

=13mΩ and the factor is a constant value (k = 1.3)

DS(ON)

to account for the increasing R

ing.

= (4A)2x13mΩ x 1.3 x 0.364

P

CND1

= (4A)2x13mΩ x 1.3 x (1 - 0.364)

P

CND2

P

= 98.42 mW + 172 mW = 270.42 mW

CND

There are few additional losses that are taken into account:

IC Operating Loss (P

where I

is the typical operating VCCcurrent

Q-VCC

P

FET Gate Charging Loss (P

P

GATE

IC)

PIC=I

Q_VCCxVCC

= 1.7 mA x 3.3V = 5.61 mW

IC

)

GATE

=nxVCCxQGSxf

P

GATE

=2x3.3Vx3nCx300kHz

= 5.94 mW

P

GATE

,

The value n is the total number of FETs used and Q

typical gate-source charge value, which is 3 nC. For the

FDS6898A the gate charging loss is 5.94 mW.

Input Capacitor Loss (P

CAP

)

Here n is the number of paralleled capacitors, ESR is the

equivalent series resistance of each, and P

is the dissi-

CAP

pation in each. So for example if we use only one input

capacitor of 24 mΩ.

P

= 88.8 mW

CAP

IND

IND

=I

)

2

x DCR

OUT

Output Inductor Loss (P

P

where DCR is the DC resistance. Therefore, for example

P

= (4A)2x11mΩ

IND

= 176 mW

P

IND

Total System Efficiency

P

TOTAL=PFET+PIC+PGATE+PCAP+PIND

LM2747

where,

www.national.com19

Example Circuits

LM2747

FIGURE 17. 3.3V to 1.8V@2A, fSW= 300 kHz

PART PART NUMBER TYPE PACKAGE DESCRIPTION VENDOR

U1 LM2747 Synchronous

Controller

Q1 FDS6898A Dual N-MOSFET SO-8 20V, 10 mΩ

D1 MBR0520LTI Schottky Diode SOD-123

L1 DO3316P-472 Inductor 4.7 µH, 4.8Arms 18mΩCoilcraft

TSSOP-14 NSC

@

4.5V,

16nC

20150932

Fairchild

C

1 16SP100M Aluminum

IN

Electrolytic

CO1 6SP220M Aluminum

Electrolytic

C

CC,CBOOT,

VJ1206Y104KXXA Capacitor 1206 0.1 µF, 10% Vishay

CIN2, CO2

C

C3

C

SS

C

C2

C

C1

R

FB2

R

FB1

R

FADJ

R

C2

R

CS

R

CC

R

C1

R

PULL-UP

C

CLK

VJ0805Y332KXXA Capacitor 0805 3300 pF, 10% Vishay

VJ0805A123KXAA Capacitor 0805 12 nF, 10% Vishay

VJ0805A821KXAA Capacitor 0805 820 pF 10% Vishay

VJ0805A220KXAA Capacitor 0805 22 pF, 10% Vishay

CRCW08051002F Resistor 0805 10.0 kΩ 1% Vishay

CRCW08054991F Resistor 0805 4.99 kΩ1% Vishay

CRCW08051003F Resistor 0805 100 kΩ 1% Vishay

CRCW08052101F Resistor 0805 2.1 kΩ 1% Vishay

CRCW08052101F Resistor 0805 2.1 kΩ 1% Vishay

CRCW080510R0F Resistor 0805 10.0Ω 1% Vishay

CRCW08055492F Resistor 0805 54.9 kΩ 1% Vishay

CRCW08051003J Resistor 0805 100 kΩ 5% Vishay

VJ0805A560KXAA Capacitor 0805 56 pF, 10% Vishay

10mm x 6mm 100 µF, 16V,

2.89Arms

10mm x 6mm 220 µF, 6.3V

3.1Arms

Sanyo

Sanyo

www.national.com 20

Example Circuits (Continued)

FIGURE 18. 5V to 2.5V@2A, fSW= 300 kHz

LM2747

20150933

PART PART NUMBER TYPE PACKAGE DESCRIPTION VENDOR

U1 LM2747 Synchronous

TSSOP-14 NSC

Controller

Q1 FDS6898A Dual N-MOSFET SO-8 20V, 10 mΩ

@

4.5V, 16nCFairchild

D1 MBR0520LTI Schottky Diode SOD-123

L1 DO3316P-682 Inductor 6.8 µH, 4.4Arms, 27 mΩ Coilcraft

C

1 16SP100M Aluminum

IN

10mm x 6mm 100 µF, 16V, 2.89Arms Sanyo

Electrolytic

1 10SP56M Aluminum

C

O

6.3mm x 6mm 56 µF, 10V 1.7Arms Sanyo

Electrolytic

CCC,C

BOOT,

VJ1206Y104KXXA Capacitor 1206 0.1 µF, 10% Vishay

CIN2, CO2

C

C3

C

SS

C

C2

C

C1

R

FB2

R

FB1

R

FADJ

R

C2

R

CS

R

CC

R

C1

R

PULL-UP

C

CLK

VJ0805Y182KXXA Capacitor 0805 1800 pF, 10% Vishay

VJ0805A123KXAA Capacitor 0805 12 nF, 10% Vishay

VJ0805A821KXAA Capacitor 0805 820 pF 10% Vishay

VJ0805A330KXAA Capacitor 0805 33 pF, 10% Vishay

CRCW08051002F Resistor 0805 10.0 kΩ 1% Vishay

CRCW08053161F Resistor 0805 3.16 kΩ 1% Vishay

CRCW08051003F Resistor 0805 100 kΩ 1% Vishay

CRCW08051301F Resistor 0805 1.3 kΩ 1% Vishay

CRCW08052101F Resistor 0805 2.1 kΩ 1% Vishay

CRCW080510R0F Resistor 0805 10.0Ω 1% Vishay

CRCW08053322F Resistor 0805 33.2 kΩ 1% Vishay

CRCW08051003J Resistor 0805 100 kΩ 5% Vishay

VJ0805A560KXAA Capacitor 0805 56 pF, 10% Vishay

www.national.com21

Example Circuits (Continued)

LM2747

FIGURE 19. 12V to 3.3V@4A, fSW= 300kHz

PART PART NUMBER TYPE PACKAGE DESCRIPTION VENDOR

U1 LM2747 Synchronous

Controller

Q1 FDS6898A Dual N-MOSFET SO-8 20V, 10 mΩ

TSSOP-14 NSC

@

4.5V, 16nCFairchild

20150934

D1 MBR0520LTI Schottky Diode SOD-123

L1 DO3316P-332 Inductor 3.3 µH, 5.4Arms 15 mΩ Coilcraft

C

1 16SP100M Aluminum

IN

10mm x 6mm 100 µF, 16V, 2.89Arms Sanyo

Electrolytic

1 6SP220M Aluminum

C

O

10mm x 6mm 220 µF, 6.3V 3.1Arms Sanyo

Electrolytic

CCC,C

BOOT,

VJ1206Y104KXXA Capacitor 1206 0.1 µF, 10% Vishay

CIN2, CO2

C

C3

C

SS

C

C2

C

C1

R

FB2

R

FB1

R

FADJ

R

C2

R

CS

R

CC

R

C1

R

PULL-UP

C

CLK

VJ0805Y222KXXA Capacitor 0805 2200 pF, 10% Vishay

VJ0805A123KXAA Capacitor 0805 12 nF, 10% Vishay

VJ0805Y332KXXA Capacitor 0805 3300 pF 10% Vishay

VJ0805A820KXAA Capacitor 0805 82 pF, 10% Vishay

CRCW08051002F Resistor 0805 10.0 kΩ 1% Vishay

CRCW08052211F Resistor 0805 2.21 kΩ 1% Vishay

CRCW08051003F Resistor 0805 100 kΩ 1% Vishay

CRCW08052611F Resistor 0805 2.61 kΩ 1% Vishay

CRCW08054121F Resistor 0805 4.12 kΩ 1% Vishay

CRCW080510R0F Resistor 0805 10.0Ω 1% Vishay

CRCW08051272F Resistor 0805 12.7kΩ 1% Vishay

CRCW08051003J Resistor 0805 100 kΩ 5% Vishay

VJ0805A560KXAA Capacitor 0805 56 pF, 10% Vishay

www.national.com 22

Physical Dimensions inches (millimeters) unless otherwise noted

LM2747 Synchronous Buck Controller with Pre-bias Startup, and Optional Clock Synchronization

TSSOP-14

NS Package Number MTC14

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves

the right at any time without notice to change said circuitry and specifications.

For the most current product information visit us at www.national.com.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS

WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL COUNSEL OF NATIONAL SEMICONDUCTOR

CORPORATION. As used herein:

1. Life support devices or systems are devices or systems

which, (a) are intended for surgical implant into the body, or

(b) support or sustain life, and whose failure to perform when

properly used in accordance with instructions for use

2. A critical component is any component of a life support

device or system whose failure to perform can be reasonably

expected to cause the failure of the life support device or

system, or to affect its safety or effectiveness.

provided in the labeling, can be reasonably expected to result

in a significant injury to the user.

BANNED SUBSTANCE COMPLIANCE

National Semiconductor manufactures products and uses packing materials that meet the provisions of the Customer Products

Stewardship Specification (CSP-9-111C2) and the Banned Substances and Materials of Interest Specification (CSP-9-111S2) and contain

no ‘‘Banned Substances’’ as defined in CSP-9-111S2.

Leadfree products are RoHS compliant.

National Semiconductor

Americas Customer

Support Center

Email: new.feedback@nsc.com

Tel: 1-800-272-9959

www.national.com

National Semiconductor

Europe Customer Support Center

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Support Center

Email: ap.support@nsc.com

National Semiconductor

Japan Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

Loading...

Loading...