LM2734Z/LM2734ZQ

Thin SOT23 1A Load Step-Down DC-DC Regulator

LM2734Z/LM2734ZQ Thin SOT23 1A Load Step-Down DC-DC Regulator

June 12, 2008

General Description

The LM2734Z regulator is a monolithic, high frequency, PWM

step-down DC/DC converter assembled in a 6-pin Thin

SOT23 and LLP non pull back package. It provides all the

active functions to provide local DC/DC conversion with fast

transient response and accurate regulation in the smallest

possible PCB area.

With a minimum of external components and online design

support through WEBENCH®™, the LM2734Z is easy to use.

The ability to drive 1A loads with an internal 300mΩ NMOS

switch using state-of-the-art 0.5µm BiCMOS technology results in the best power density available. The world class

control circuitry allows for on-times as low as 13ns, thus supporting exceptionally high frequency conversion over the entire 3V to 20V input operating range down to the minimum

output voltage of 0.8V. Switching frequency is internally set

to 3MHz, allowing the use of extremely small surface mount

inductors and chip capacitors. Even though the operating frequency is very high, efficiencies up to 85% are easy to

achieve. External shutdown is included, featuring an ultra-low

stand-by current of 30nA. The LM2734Z utilizes current-mode

control and internal compensation to provide high-performance regulation over a wide range of operating conditions.

Additional features include internal soft-start circuitry to reduce inrush current, pulse-by-pulse current limit, thermal

shutdown, and output over-voltage protection.

Features

Thin SOT23-6 package, or 6 lead LLP package

■

3.0V to 20V input voltage range

■

0.8V to 18V output voltage range

■

1A output current

■

3MHz switching frequency

■

300mΩ NMOS switch

■

30nA shutdown current

■

0.8V, 2% internal voltage reference

■

Internal soft-start

■

Current-Mode, PWM operation

■

Thermal shutdown

■

LM2734ZQ is AEC-Q100 Grade 1 qualified and is

■

manufactured on an Automotive Grade Flow

Applications

DSL Modems

■

Local Point of Load Regulation

■

Battery Powered Devices

■

USB Powered Devices

■

Automotive

■

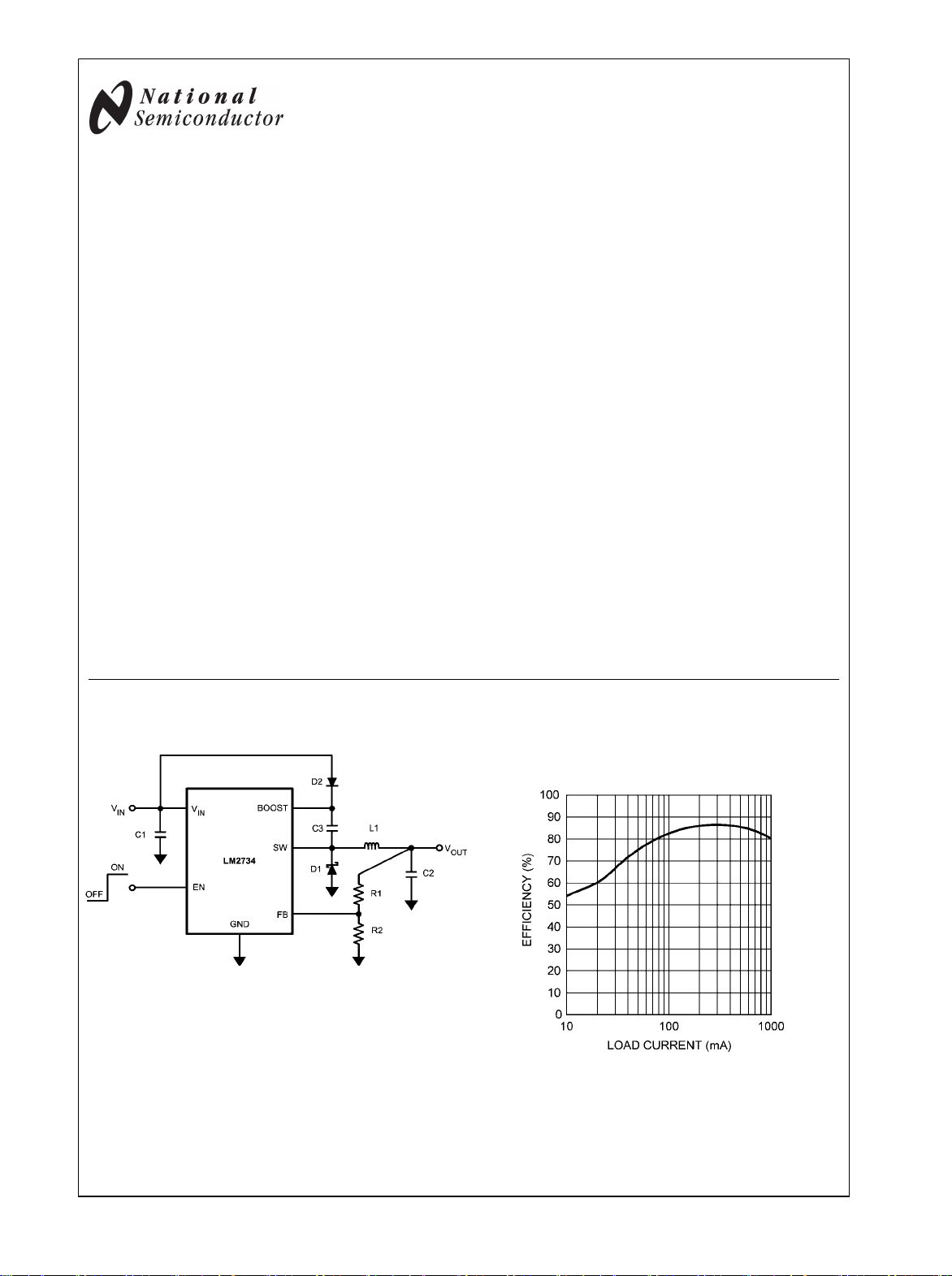

Typical Application Circuit

WEBENCH™ is a trademark of Transim.

20130301

Efficiency vs Load Current

VIN = 5V, V

OUT

= 3.3V

20130345

© 2008 National Semiconductor Corporation 201303 www.national.com

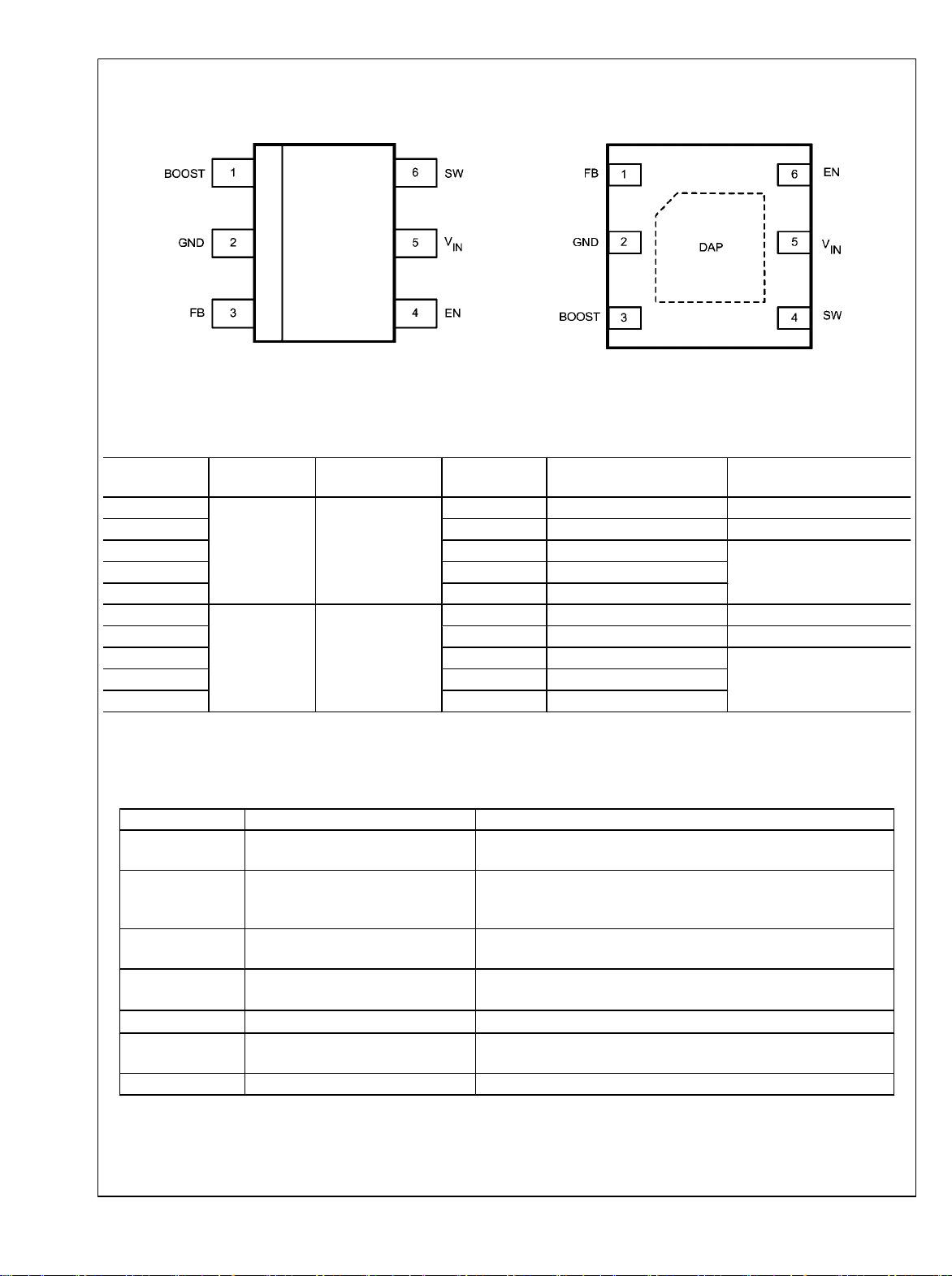

Connection Diagrams

LM2734Z/LM2734ZQ

NS Package Number MK06A

6-Lead TSOT

20130305

6-Lead LLP (3mm x 3mm)

NS Package Number SDE06A

20130360

Ordering Information

Order Number Package Type NSC Package

Drawing

LM2734ZMK

LM2734ZMKX SFTB 3000 Units on Tape and Reel

LM2734ZQMKE SVBB 250 Units on Tape and Reel AEC-Q100 Grade 1

TSOT-6 MK06A

LM2734ZQMK SVBB 1000 Units on Tape and Reel

LM2734ZQMKX SVBB 3000 Units on Tape and Reel

LM2734ZSD

LM2734ZSDX L163B 4500 Units on Tape and Reel

LM2734ZQSDE L238B 250 Units on Tape and Reel AEC-Q100 Grade 1

6-Lead LLP SDE06A

LM2734ZQSD L238B 1000 Units on Tape and Reel

LM2734ZQSDX L238B 4500 Units on Tape and Reel

*Automotive Grade (Q) product incorporates enhanced manufacturing and support processes for the automotive market, including defect detection methodologies.

Reliability qualification is compliant with the requirements and temperature grades defined in the AEC-Q100 standard. Automotive grade products are identified

with the letter Q. For more information go to http://www.national.com/automotive.

Package

Supplied As Features

Marking

SFTB 1000 Units on Tape and Reel

Qualified. Automotive-Grade

Production Flow*

L163B 1000 Units on Tape and Reel

Qualified. Automotive-Grade

Production Flow*

Pin Descriptions

Pin Name Function

1 BOOST Boost voltage that drives the internal NMOS control switch. A

bootstrap capacitor is connected between the BOOST and SW pins.

2 GND Signal and Power ground pin. Place the bottom resistor of the

feedback network as close as possible to this pin for accurate

regulation.

3 FB Feedback pin. Connect FB to the external resistor divider to set output

voltage.

4 EN Enable control input. Logic high enables operation. Do not allow this

pin to float or be greater than V

5 V

IN

Input supply voltage. Connect a bypass capacitor to this pin.

6 SW Output switch. Connects to the inductor, catch diode, and bootstrap

capacitor.

DAP GND The Die Attach Pad is internally connected to GND

+ 0.3V.

IN

www.national.com 2

LM2734Z/LM2734ZQ

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Soldering Information

Infrared/Convection Reflow (15sec) 220°C

Wave Soldering Lead Temp. (10sec) 260°C

Distributors for availability and specifications.

V

IN

-0.5V to 24V

SW Voltage -0.5V to 24V

Boost Voltage -0.5V to 30V

Boost to SW Voltage -0.5V to 6.0V

FB Voltage -0.5V to 3.0V

EN Voltage -0.5V to (VIN + 0.3V)

Junction Temperature 150°C

ESD Susceptibility (Note 2) 2kV

Operating Ratings (Note 1)

V

IN

SW Voltage -0.5V to 20V

Boost Voltage -0.5V to 25V

Boost to SW Voltage 1.6V to 5.5V

Junction Temperature Range −40°C to +125°C

Thermal Resistance θJA (Note 3)

TSOT23–6 118°C/W

3V to 20V

Storage Temp. Range -65°C to 150°C

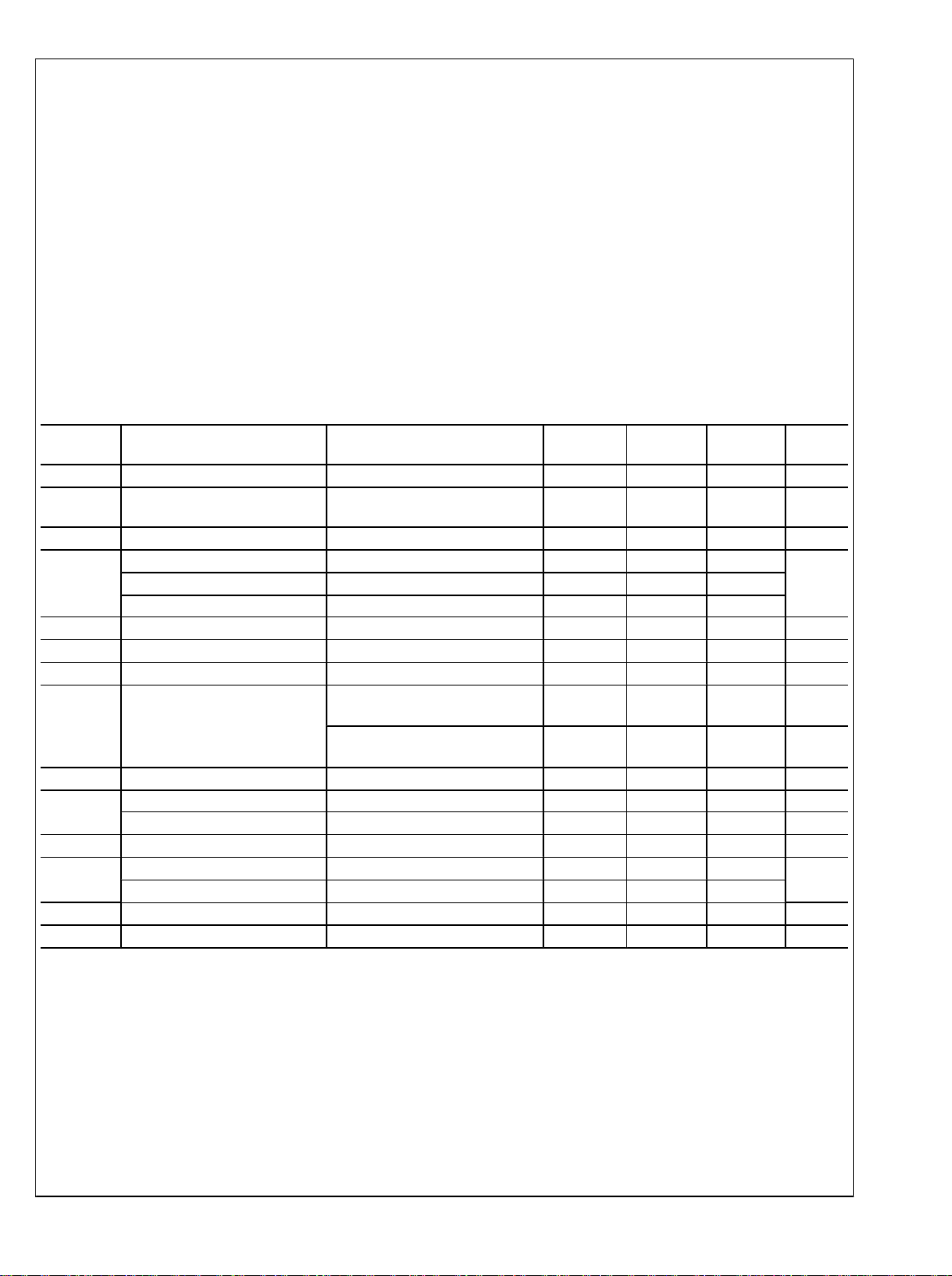

Electrical Characteristics

Specifications with standard typeface are for TJ = 25°C, and those in boldface type apply over the full Operating Temperature

Range (TJ = -40°C to 125°C). VIN = 5V, V

guaranteed by design, test, or statistical analysis.

Symbol Parameter Conditions

V

ΔVFB/ΔV

I

Feedback Voltage

FB

Feedback Voltage Line

IN

Regulation

Feedback Input Bias Current

FB

Undervoltage Lockout

UVLO

Undervoltage Lockout

UVLO Hysteresis 0.30 0.44 0.62

F

D

D

R

DS(ON)

MAX

I

I

Switching Frequency

SW

Maximum Duty Cycle

Minimum Duty Cycle

MIN

Switch ON Resistance

Switch Current Limit V

CL

Quiescent Current Switching 1.5 2.5 mA

Q

Quiescent Current (shutdown) VEN = 0V

I

BOOST

V

EN_TH

I

EN

I

SW

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for which the device is

intended to be functional, but specific performance is not guaranteed. For guaranteed specifications and the test conditions, see Electrical Characteristics.

Note 2: Human body model, 1.5kΩ in series with 100pF.

Note 3: Thermal shutdown will occur if the junction temperature exceeds 165°C. The maximum power dissipation is a function of T

maximum allowable power dissipation at any ambient temperature is PD = (T

board with 2oz. copper on 4 layers in still air. For a 2 layer board using 1 oz. copper in still air, θJA = 204°C/W.

Note 4: Guaranteed to National’s Average Outgoing Quality Level (AOQL).

Note 5: Typicals represent the most likely parametric norm.

Boost Pin Current

Shutdown Threshold Voltage VEN Falling

Enable Threshold Voltage VEN Rising 1.8

Enable Pin Current Sink/Source

Switch Leakage

- VSW = 5V unless otherwise specified. Datasheet min/max specification limits are

BOOST

VIN = 3V to 20V

Sink/Source

VIN Rising

VIN Falling

Min

(Note 4)

0.784 0.800 0.816 V

0.01 % / V

10 250 nA

2.74 2.90

2.0 2.3

2.2 3.0 3.6 MHz

78 85 %

Typ

(Note 5)

Max

(Note 4)

8

V

- VSW = 3V

BOOST

(TSOT Package)

V

- VSW = 3V

BOOST

(LLP Package)

- VSW = 3V 1.2 1.7 2.5 A

BOOST

(Switching)

300 600

340 650

30

4.25 6 mA

0.4

– TA)/θJA . All numbers apply for packages soldered directly onto a 3” x 3” PC

J(MAX)

10

40

, θJA and TA . The

J(MAX)

Units

V

%

mΩ

mΩ

nA

V

nA

nA

3 www.national.com

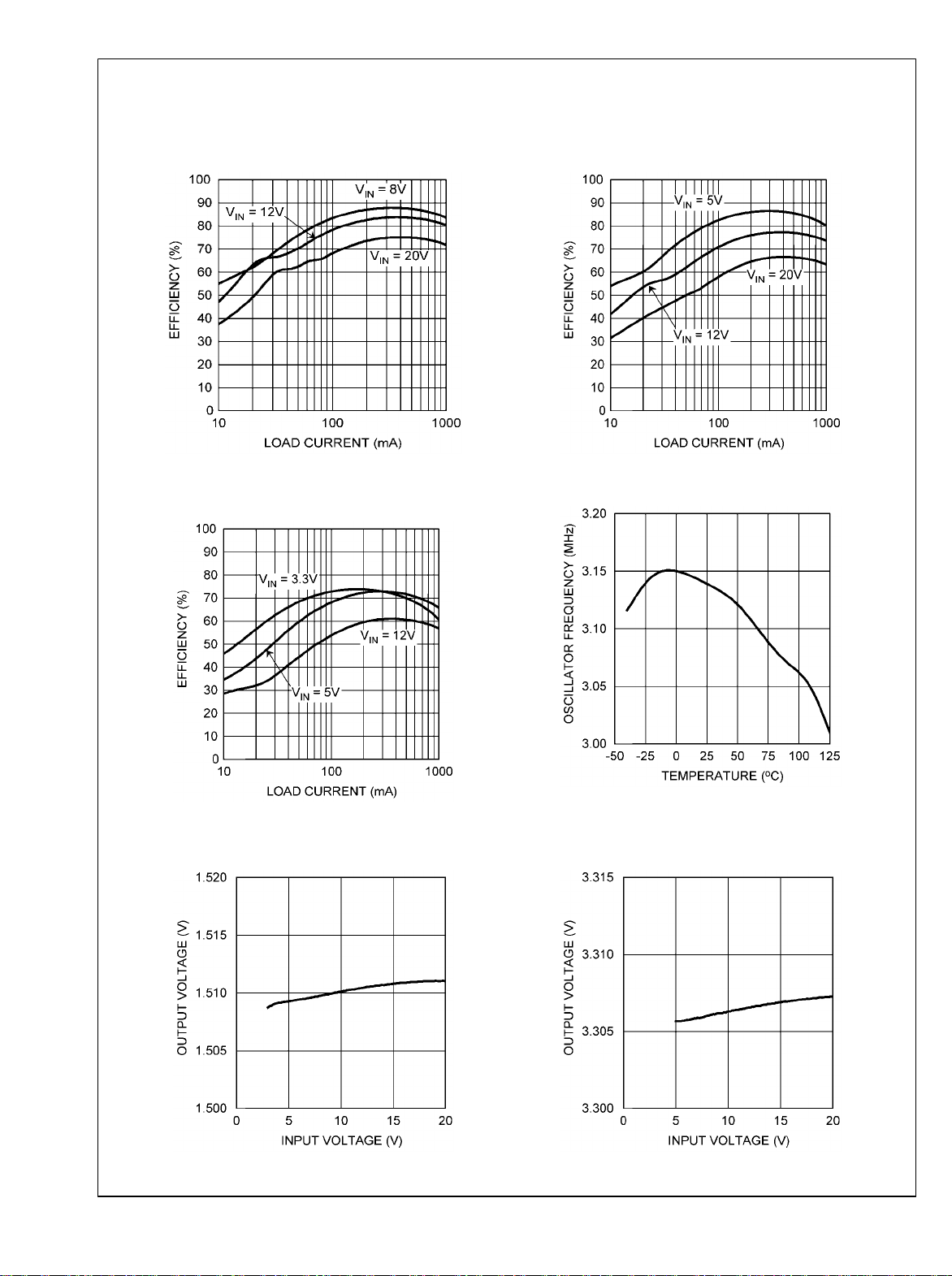

Typical Performance Characteristics All curves taken at V

TA = 25°C, unless specified otherwise.

= 5V, V

IN

- VSW = 5V, L1 = 2.2 µH and

BOOST

Efficiency vs Load Current

LM2734Z/LM2734ZQ

Efficiency vs Load Current

V

V

OUT

OUT

= 1.5V

= 5V

20130336

Efficiency vs Load Current

V

= 3.3V

OUT

20130351

Oscillator Frequency vs Temperature

20130337

Line Regulation

V

= 1.5V, I

OUT

www.national.com 4

= 500mA

OUT

20130354

Line Regulation

V

= 3.3V, I

OUT

= 500mA

OUT

20130327

20130355

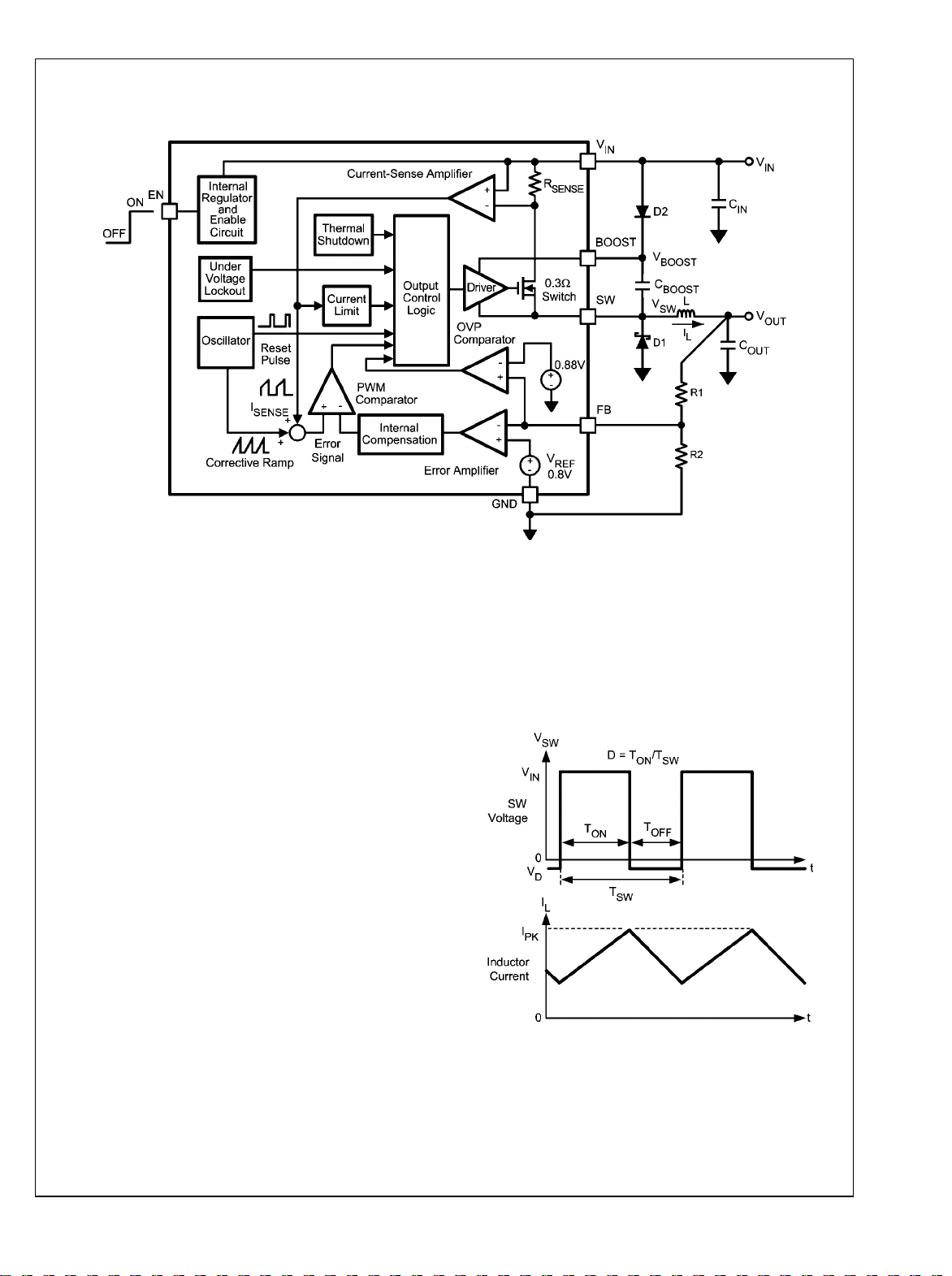

Block Diagram

LM2734Z/LM2734ZQ

Application Information

THEORY OF OPERATION

The LM2734Z is a constant frequency PWM buck regulator

IC that delivers a 1A load current. The regulator has a preset

switching frequency of 3MHz. This high frequency allows the

LM2734Z to operate with small surface mount capacitors and

inductors, resulting in a DC/DC converter that requires a minimum amount of board space. The LM2734Z is internally

compensated, so it is simple to use, and requires few external

components. The LM2734Z uses current-mode control to regulate the output voltage.

The following operating description of the LM2734Z will refer

to the Simplified Block Diagram (Figure 1) and to the waveforms in Figure 2. The LM2734Z supplies a regulated output

voltage by switching the internal NMOS control switch at constant frequency and variable duty cycle. A switching cycle

begins at the falling edge of the reset pulse generated by the

internal oscillator. When this pulse goes low, the output control logic turns on the internal NMOS control switch. During

this on-time, the SW pin voltage (VSW) swings up to approximately VIN, and the inductor current (IL) increases with a linear

slope. IL is measured by the current-sense amplifier, which

generates an output proportional to the switch current. The

sense signal is summed with the regulator’s corrective ramp

and compared to the error amplifier’s output, which is proportional to the difference between the feedback voltage and

V

. When the PWM comparator output goes high, the out-

REF

put switch turns off until the next switching cycle begins.

20130306

FIGURE 1.

During the switch off-time, inductor current discharges

through Schottky diode D1, which forces the SW pin to swing

below ground by the forward voltage (VD) of the catch diode.

The regulator loop adjusts the duty cycle (D) to maintain a

constant output voltage.

20130307

FIGURE 2. LM2734Z Waveforms of SW Pin Voltage and

Inductor Current

5 www.national.com

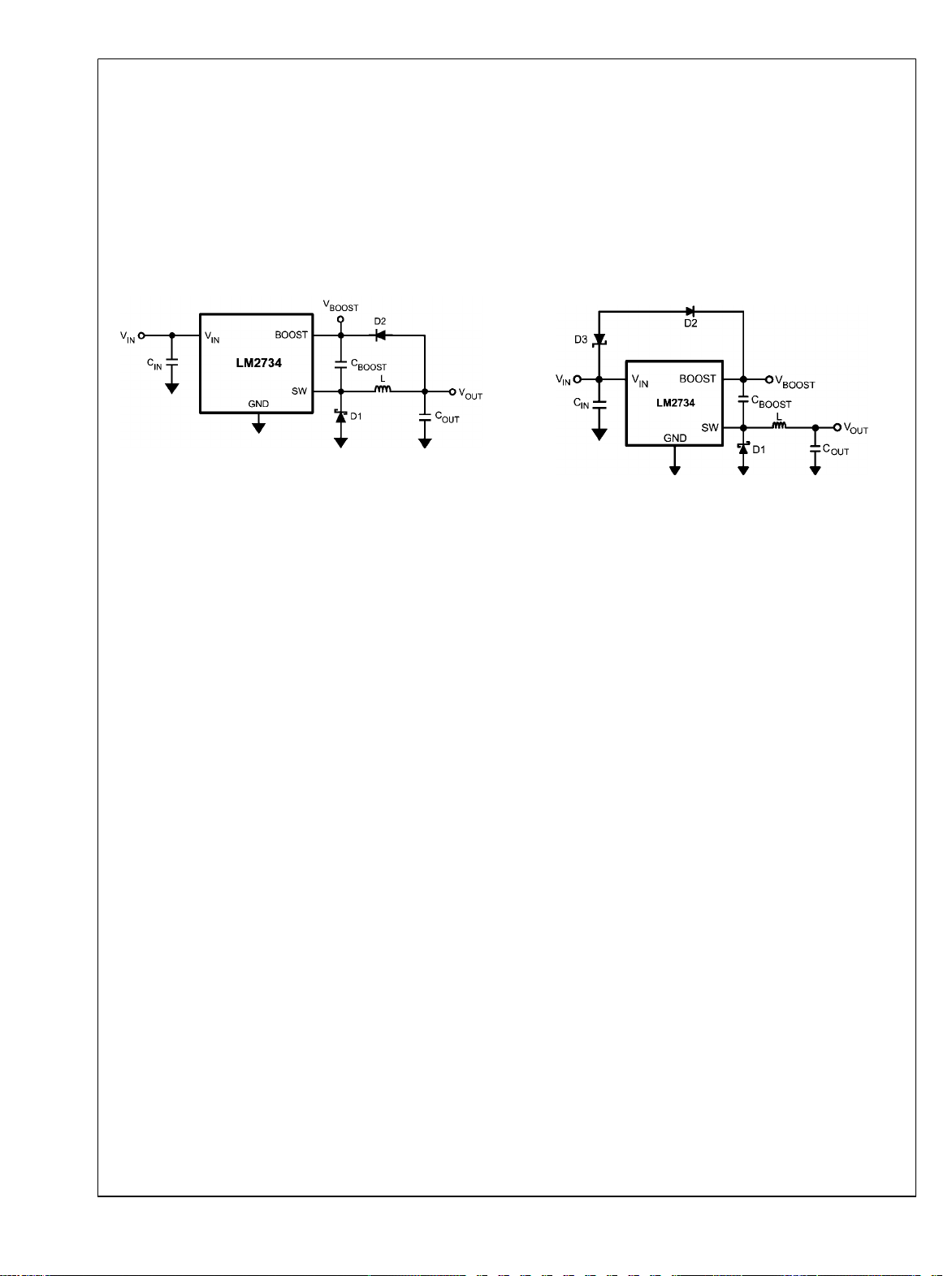

BOOST FUNCTION

Capacitor C

erate a voltage V

to the internal NMOS control switch. To properly drive the internal NMOS switch during its on-time, V

least 1.6V greater than VSW. Although the LM2734Z will op-

and diode D2 in Figure 3 are used to gen-

BOOST

BOOST

. V

- VSW is the gate drive voltage

BOOST

needs to be at

BOOST

erate with this minimum voltage, it may not have sufficient

gate drive to supply large values of output current. Therefore,

it is recommended that V

LM2734Z/LM2734ZQ

VSW for best efficiency. V

maximum operating limit of 5.5V.

5.5V > V

– VSW > 2.5V for best performance.

BOOST

FIGURE 3. V

be greater than 2.5V above

BOOST

– VSW should not exceed the

BOOST

Charges C

OUT

BOOST

When the LM2734Z starts up, internal circuitry from the

BOOST pin supplies a maximum of 20mA to C

current charges C

switch on. The BOOST pin will continue to source current to

C

until the voltage at the feedback pin is greater than

BOOST

0.76V.

There are various methods to derive V

1.

From the input voltage (VIN)

2.

From the output voltage (V

3.

From an external distributed voltage rail (V

4.

From a shunt or series zener diode

to a voltage sufficient to turn the

BOOST

:

BOOST

)

OUT

In the Simplifed Block Diagram of Figure 1, capacitor

C

and diode D2 supply the gate-drive current for the

BOOST

NMOS switch. Capacitor C

VIN. During a normal switching cycle, when the internal NMOS

control switch is off (T

VIN minus the forward voltage of D2 (V

OFF

current in the inductor (L) forward biases the Schottky diode

D1 (V

). Therefore the voltage stored across C

FD1

V

- VSW = VIN - V

BOOST

is charged via diode D2 by

BOOST

) (refer to Figure 2), V

), during which the

FD2

+ V

FD2

FD1

When the NMOS switch turns on (TON), the switch pin rises

to

forcing V

V

BOOST

VSW = VIN – (R

to rise thus reverse biasing D2. The voltage at

BOOST

is then

V

= 2VIN – (R

BOOST

DSON

x IL),

DSON

x IL) – V

FD2

+ V

which is approximately

2VIN - 0.4V

for many applications. Thus the gate-drive voltage of the

NMOS switch is approximately

VIN - 0.2V

An alternate method for charging C

the output as shown in Figure 3. The output voltage should

is to connect D2 to

BOOST

be between 2.5V and 5.5V, so that proper gate voltage will be

BOOST

)

EXT

BOOST

BOOST

FD1

20130308

. This

equals

is

applied to the internal switch. In this circuit, C

a gate drive voltage that is slightly less than V

In applications where both VIN and V

5.5V, or less than 3V, C

these voltages. If VIN and V

C

can be charged from VIN or V

BOOST

age by placing a zener diode D3 in series with D2, as shown

cannot be charged directly from

BOOST

OUT

are greater than

OUT

are greater than 5.5V,

minus a zener volt-

OUT

BOOST

OUT

provides

.

in Figure 4. When using a series zener diode from the input,

ensure that the regulation of the input supply doesn’t create

a voltage that falls outside the recommended V

(V

– VD3) < 5.5V

INMAX

(V

– VD3) > 1.6V

INMIN

FIGURE 4. Zener Reduces Boost Voltage from V

BOOST

voltage.

20130309

IN

An alternative method is to place the zener diode D3 in a

shunt configuration as shown in Figure 5. A small 350mW to

500mW 5.1V zener in a SOT-23 or SOD package can be used

for this purpose. A small ceramic capacitor such as a 6.3V,

0.1µF capacitor (C4) should be placed in parallel with the

zener diode. When the internal NMOS switch turns on, a pulse

of current is drawn to charge the internal NMOS gate capacitance. The 0.1 µF parallel shunt capacitor ensures that the

V

voltage is maintained during this time.

BOOST

Resistor R3 should be chosen to provide enough RMS current

to the zener diode (D3) and to the BOOST pin. A recommended choice for the zener current (I

current I

of the NMOS control switch and varies typically according to

into the BOOST pin supplies the gate current

BOOST

) is 1 mA. The

ZENER

the following formula:

I

= (D + 0.5) x (V

BOOST

where D is the duty cycle, V

I

is in milliamps. V

BOOST

anode of the boost diode (D2), and VD2 is the average forward

ZENER

is the voltage applied to the

ZENER

voltage across D2. Note that this formula for I

ical current. For the worst case I

by 25%. In that case, the worst case boost current will be

I

BOOST-MAX

= 1.25 x I

– VD2) mA

ZENER

and VD2 are in volts, and

gives typ-

BOOST

, increase the current

BOOST

BOOST

R3 will then be given by

R3 = (VIN - V

For example, let VIN = 10V, V

= 1mA, and duty cycle D = 50%. Then

I

= (0.5 + 0.5) x (5 - 0.7) mA = 4.3mA

BOOST

ZENER

) / (1.25 x I

ZENER

BOOST

+ I

ZENER

)

= 5V, VD2 = 0.7V, I

ZENER

R3 = (10V - 5V) / (1.25 x 4.3mA + 1mA) = 787Ω

www.national.com 6

Loading...

Loading...