现货库存、技术资料、百科信息、热点资讯,精彩尽在鼎好!

LM2598

SIMPLE SWITCHER

®

Power Converter 150 kHz

1A Step-Down Voltage Regulator, with Features

January 2001

LM2598 SIMPLE SWITCHER Power Converter 150 kHz 1A Step-Down Voltage Regulator, with

Features

General Description

The LM2598 series of regulators are monolithic integrated

circuits that provide all the active functions for a step-down

(buck) switching regulator, capable of driving a 1A load with

excellent line and load regulation. These devices are available in fixed output voltages of 3.3V, 5V, 12V, and an adjustable output version.

This series of switching regulators is similar to the LM2595

series, with additionalsupervisory and performance features

added.

Requiring a minimum number of external components, these

regulators are simple to use and include internal frequency

compensation

fixed-frequency oscillator, Shutdown /Soft-start, error flag

delay and error flag output.

The LM2598 series operates at a switching frequency of 150

kHz thus allowing smaller sized filter components than what

would be needed with lower frequency switching regulators.

Available in a standard 7-lead TO-220 package with several

different lead bend options, and a 7-lead TO-263 surface

mount package. Typically, for output voltages less than 12V,

and ambient temperatures less than 50˚C, no heat sink is

required.

A standard series of inductors (both through hole and surface mount types) are available from several different manufacturers optimized for use with the LM2598 series. This

feature greatly simplifies the design of switch-mode power

supplies.

Other features include a guaranteed

put voltage under all conditions of input voltage and output

load conditions, and

†

, improved line and load specifications,

±

4% tolerance on out-

±

15% on the oscillator frequency. Ex-

ternal shutdown is included, featuring typically 85 µA

standby current. Self protection features include a two stage

current limit for the output switch and an over temperature

shutdown for complete protection under fault conditions.

Features

n 3.3V, 5V, 12V, and adjustable output versions

n Adjustable version output voltage range, 1.2V to 37V

±

4% max over line and load conditions

n Guaranteed 1A output current

n Available in 7-pin TO-220 and TO-263 (surface mount)

package

n Input voltage range up to 40V

n Excellent line and load regulation specifications

n 150 kHz fixed frequency internal oscillator

n Shutdown /Soft-start

n Out of regulation error flag

n Error output delay

n Low power standby mode, I

n High Efficiency

n Uses readily available standard inductors

n Thermal shutdown and current limit protection

typically 85 µA

Q

Applications

n Simple high-efficiency step-down (buck) regulator

n Efficient pre-regulator for linear regulators

n On-card switching regulators

n Positive to Negative converter

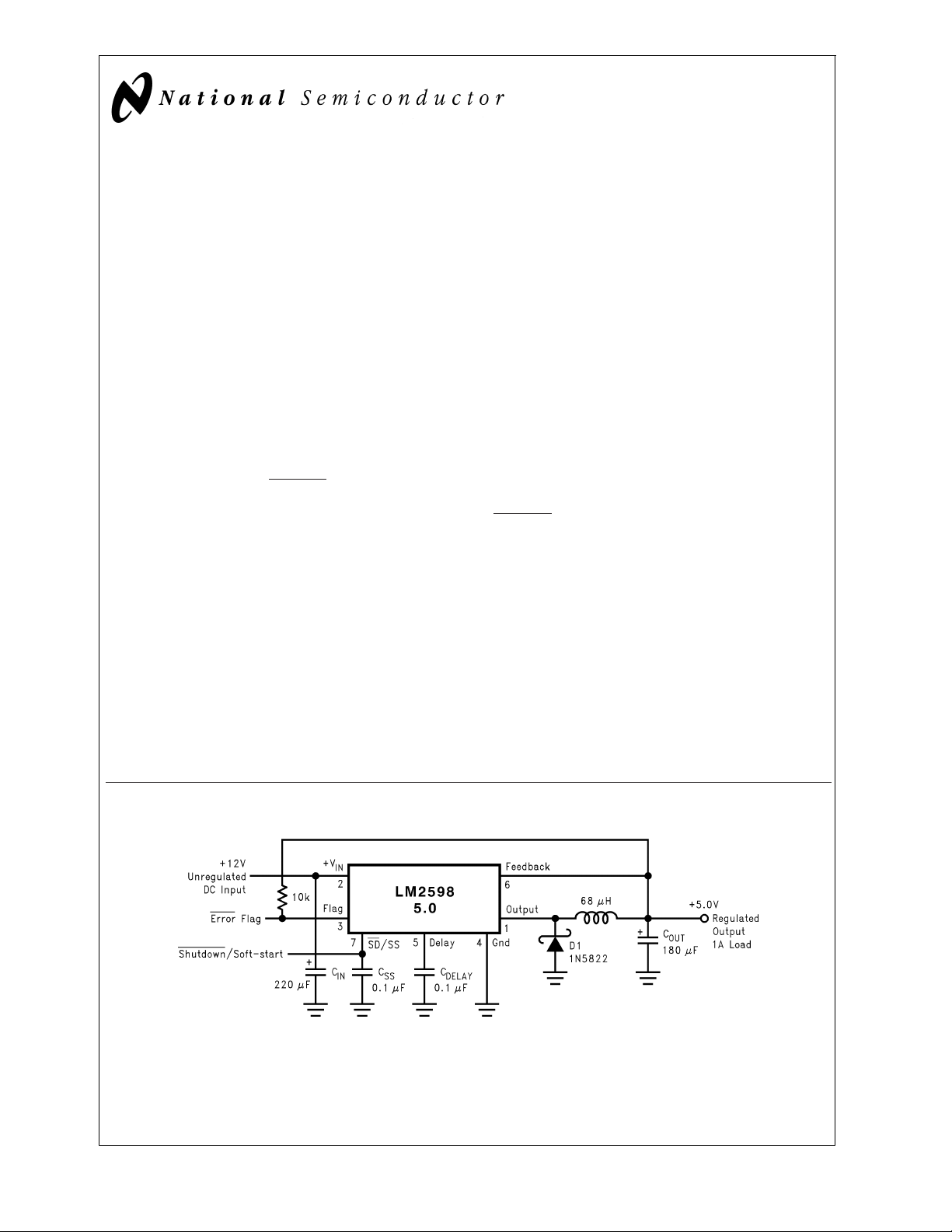

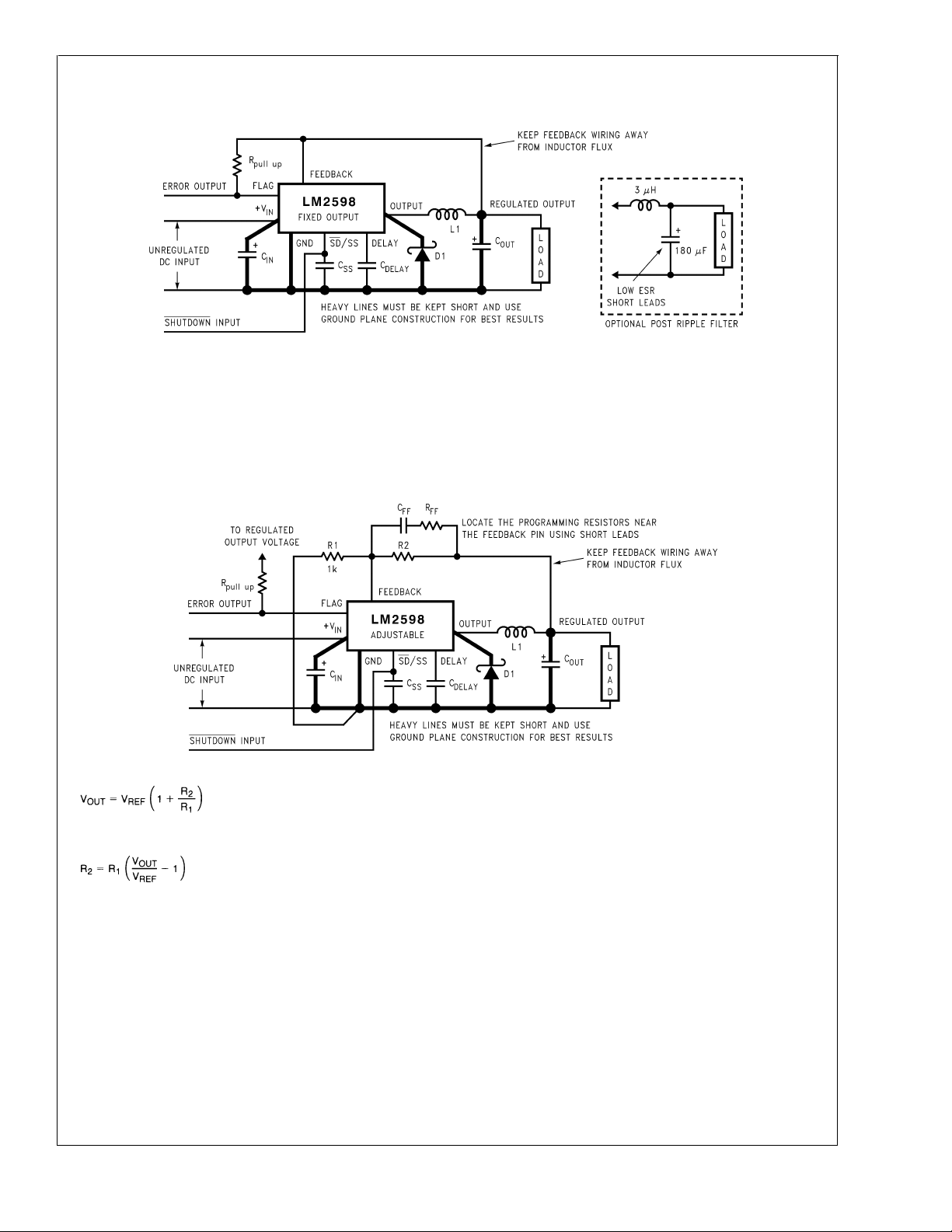

Typical Application (Fixed Output Voltage Versions)

DS012593-1

†

Patent Number 5,382,918.

SIMPLE SWITCHER

© 2001 National Semiconductor Corporation DS012593 www.national.com

®

and

Switchers Made Simple

®

are registered trademarks of National Semiconductor Corporation.

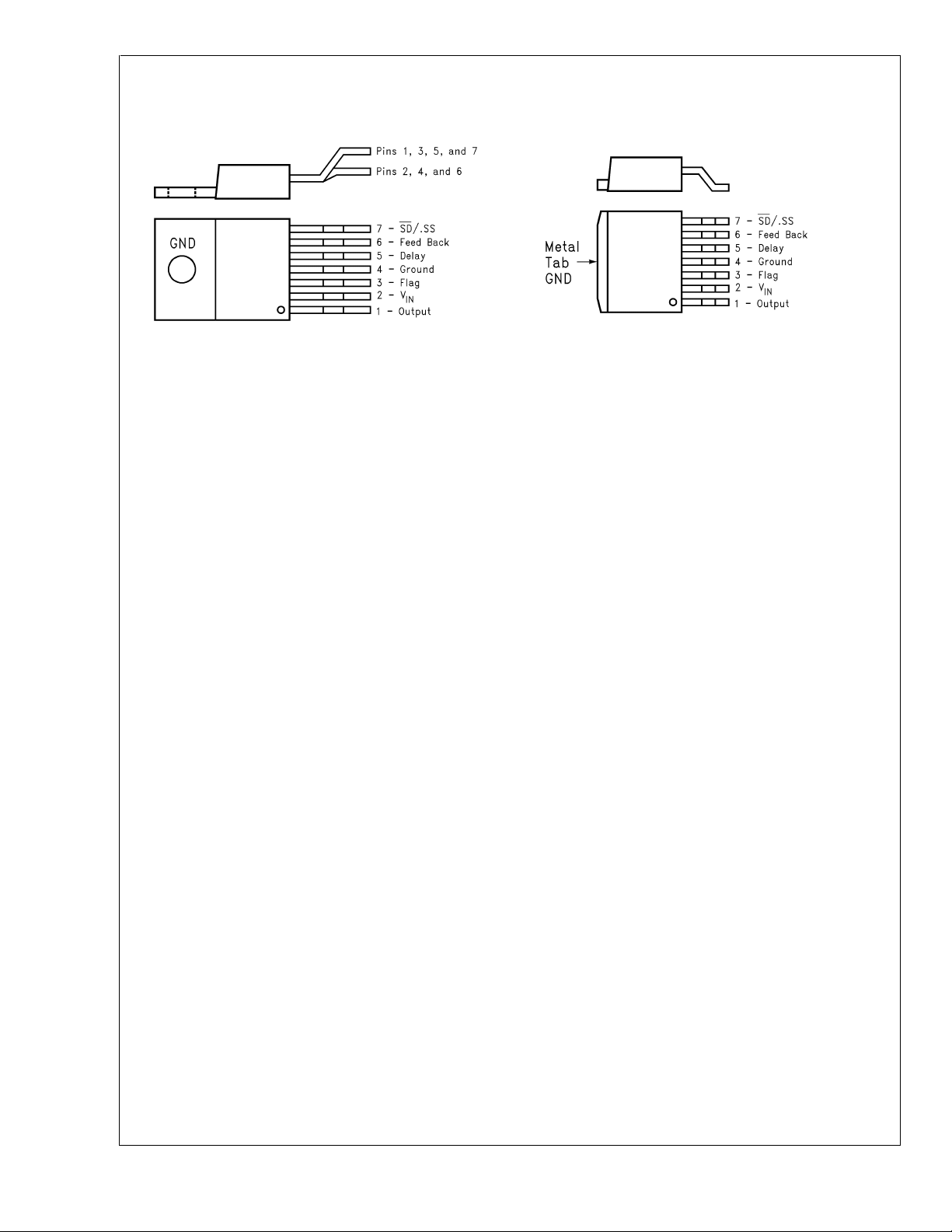

Connection Diagrams and Order Information

LM2598

Bent and Staggered Leads, Through Hole Package

7-Lead TO-220 (T)

Surface Mount Package

7-Lead TO-263 (S)

DS012593-50

Order Number LM2598T-3.3, LM2598T-5.0,

LM2598T-12 or LM2598T-ADJ

See NS Package Number TA07B

DS012593-22

Order Number LM2598S-3.3, LM2598S-5.0,

LM2598S-12 or LM2598S-ADJ

See NS Package Number TS7B

www.national.com 2

LM2598

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Maximum Supply Voltage (V

SD/SS Pin Input Voltage (Note 2)

Delay Pin Voltage (Note 2) 1.5V

Flag Pin Voltage −0.3 ≤ V ≤ +45V

Feedback Pin Voltage −0.3 ≤ V ≤ +25V

Output Voltage to Ground

(Steady State) −1V

Power Dissipation Internally limited

Storage Temperature Range −65˚C to +150˚C

) 45V

IN

6V

ESD Susceptibility

Human Body Model (Note 3) 2 kV

Lead Temperature

S Package

Vapor Phase (60 sec.) +215˚C

Infrared (10 sec.) +245˚C

T Package (Soldering, 10 sec.) +260˚C

Maximum Junction Temperature +150˚C

Operating Conditions

Temperature Range −25˚C ≤ TJ≤ +125˚C

Supply Voltage 4.5V to 40V

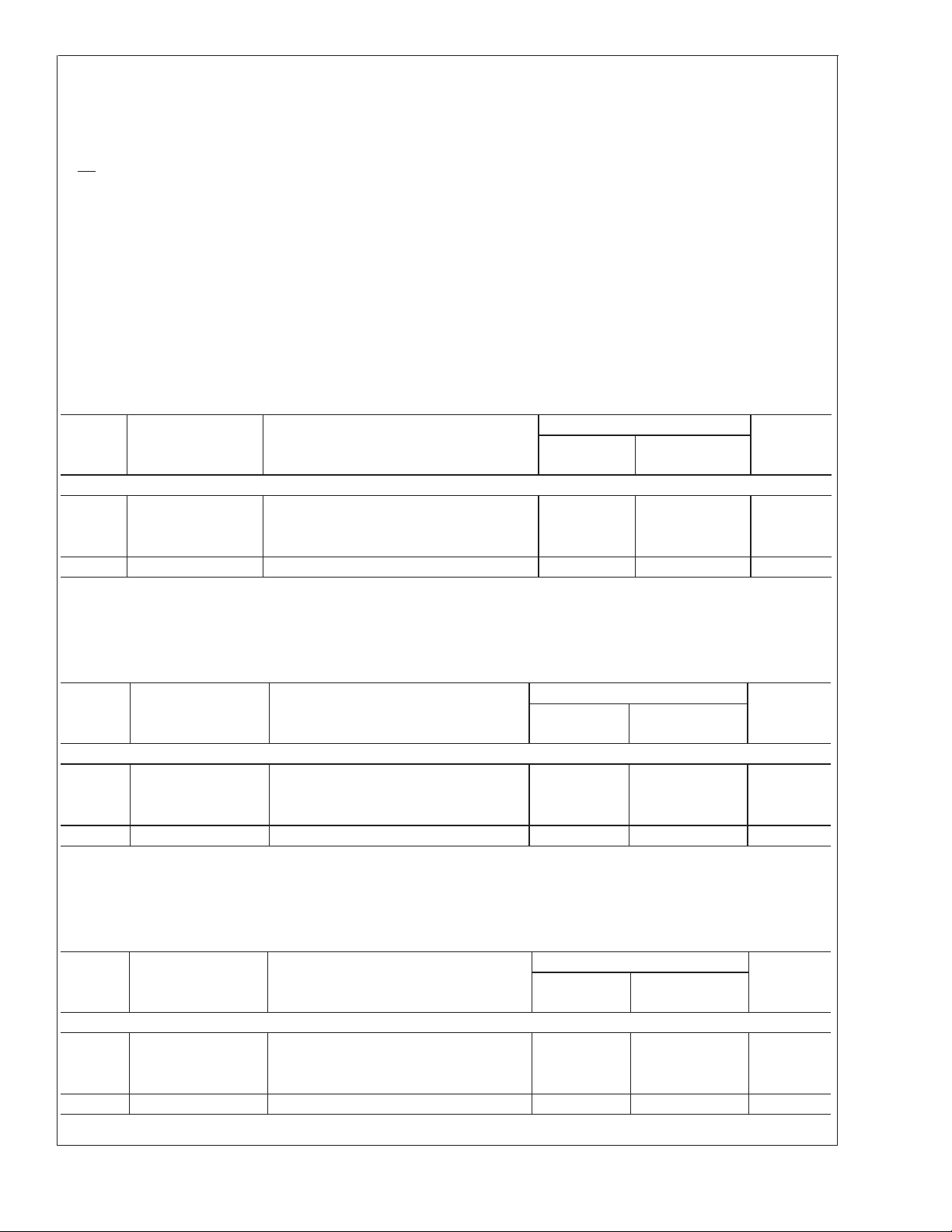

LM2598-3.3

Electrical Characteristics

Specifications with standard type face are for TJ= 25˚C, and those with boldface type apply over full Operating Temperature Range.

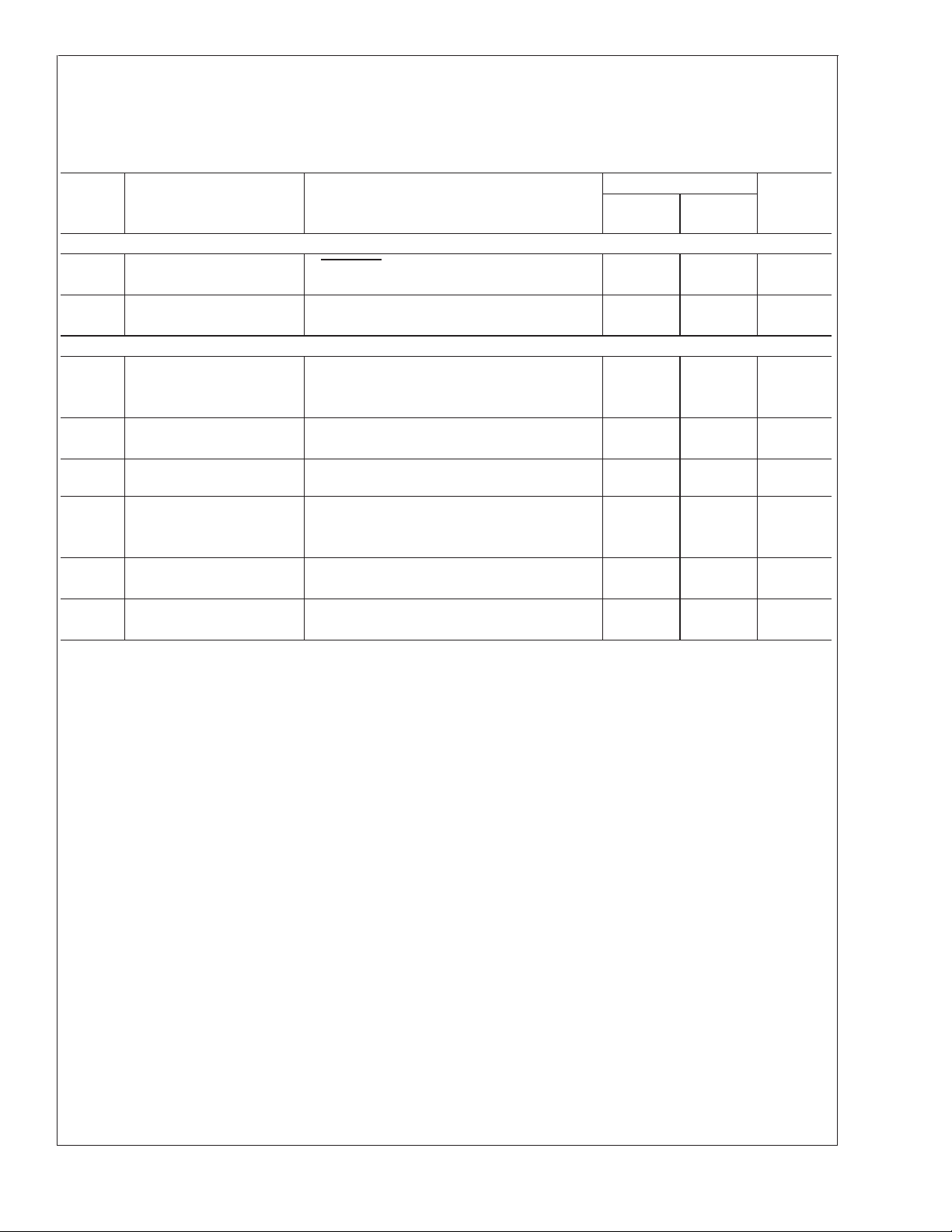

Symbol Parameter Conditions LM2598-3.3 Units

Typ Limit

(Note 4) (Note 5)

SYSTEM PARAMETERS (Note 6) Test Circuit

V

OUT

η Efficiency V

Output Voltage 4.75V ≤ VIN≤ 40V, 0.1A ≤ I

IN

= 12V, I

Figure 1

≤ 1A 3.3 V

LOAD

3.168/3.135 V(min)

3.432/3.465 V(max)

=1A 78 %

LOAD

(Limits)

LM2598-5.0

Electrical Characteristics

Specifications with standard type face are for TJ= 25˚C, and those with boldface type apply over full Operating Temperature Range.

Symbol Parameter Conditions LM2598-5.0 Units

Typ Limit

(Note 4) (Note 5)

SYSTEM PARAMETERS (Note 6) Test Circuit

V

OUT

η Efficiency V

Output Voltage 7V ≤ VIN≤ 40V, 0.1A ≤ I

IN

= 12V, I

Figure 1

≤ 1A 5 V

LOAD

4.800/4.750 V(min)

5.200/5.250 V(max)

=1A 82 %

LOAD

(Limits)

LM2598-12

Electrical Characteristics

Specifications with standard type face are for TJ= 25˚C, and those with boldface type apply over full Operating Temperature Range.

Symbol Parameter Conditions LM2598-12 Units

Typ Limit

(Note 4) (Note 5)

SYSTEM PARAMETERS (Note 6) Test Circuit

V

OUT

η Efficiency V

Output Voltage 15V ≤ VIN≤ 40V, 0.1A ≤ I

IN

= 25V, I

Figure 1

≤ 1A 12 V

LOAD

11.52/11.40 V(min)

12.48/12.60 V(max)

=1A 90 %

LOAD

(Limits)

www.national.com3

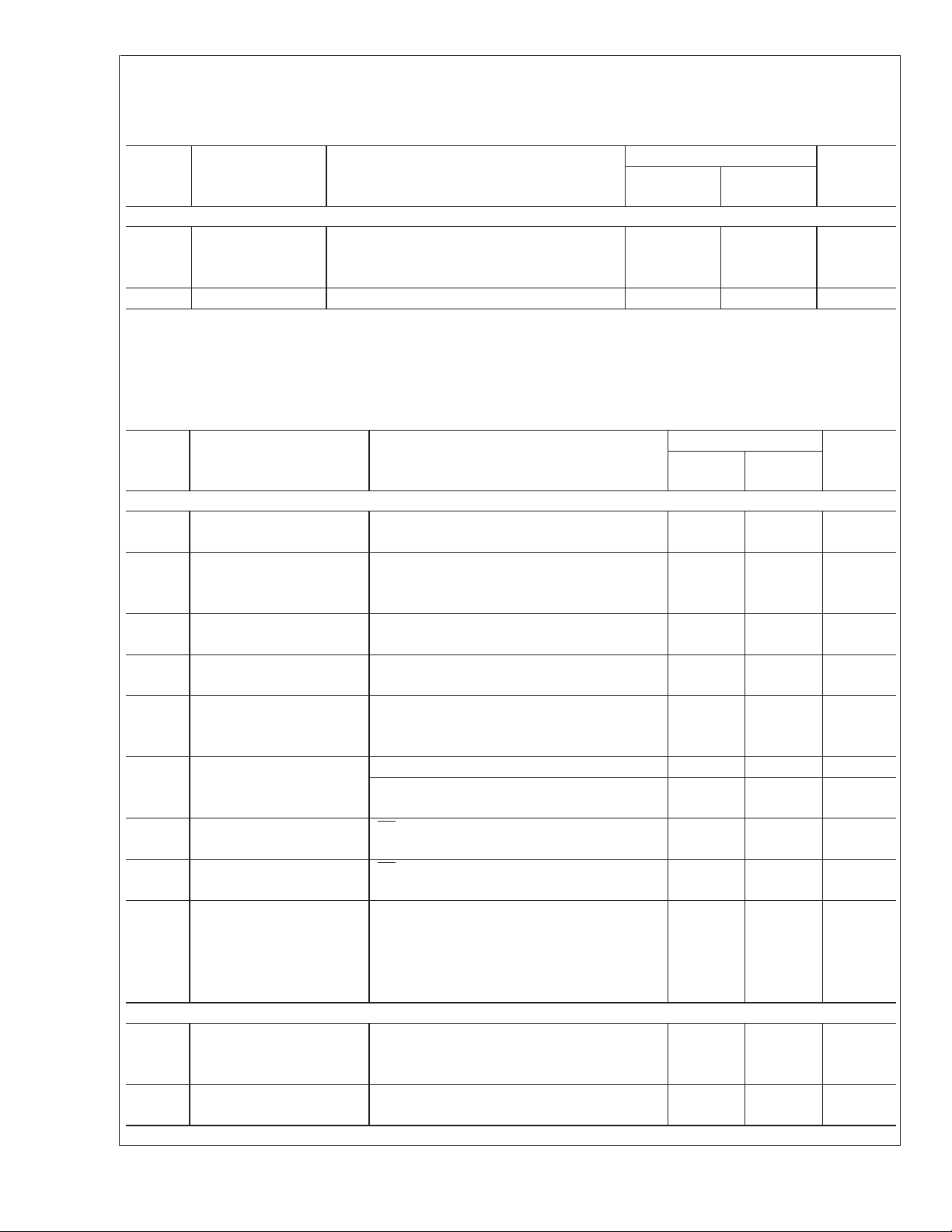

LM2598-ADJ

Electrical Characteristics

LM2598

Specifications with standard type face are for TJ= 25˚C, and those with boldface type apply over full Operating Temperature Range.

Symbol Parameter Conditions LM2598-ADJ Units

Typ Limit

(Note 4) (Note 5)

SYSTEM PARAMETERS (Note 6) Test Circuit

V

FB

Feedback Voltage 4.5V ≤ VIN≤ 40V, 0.1A ≤ I

V

OUT

Figure 1

≤ 1A 1.230 V

LOAD

programmed for 3V. Circuit of

Figure 12

. 1.193/1.180 V(min)

1.267/1.280 V(max)

η Efficiency V

= 12V, V

IN

OUT

= 3V, I

=1A 78 %

LOAD

All Output Voltage Versions

Electrical Characteristics

Specifications with standard type face are for TJ= 25˚C, and those with boldface type apply over full Operating Temperature Range. Unless otherwise specified, V

sion. I

LOAD

= 200 mA

Symbol Parameter Conditions LM2598-XX Units

DEVICE PARAMETERS

I

b

f

O

V

SAT

Feedback Bias Current Adjustable Version Only, VFB= 1.3V 10 nA

Oscillator Frequency (Note 7) 150 kHz

Saturation Voltage I

DC Max Duty Cycle (ON) (Note 9) 100 %

Min Duty Cycle (OFF) (Note 10) 0

I

CL

I

L

I

Q

Current Limit Peak Current, (Note 8) (Note 9) 1.5 A

Output Leakage Current Output = 0V (Note 9) (Note 10) (Note 11) 50 µA(max)

Operating Quiescent SD /SS Pin Open, (Note 10) 5mA

Current 10 mA(max)

I

STBY

Standby Quiescent SD /SS pin = 0V, (Note 11) 85 µA

Current 200/250 µA(max)

θ

JC

θ

JA

θ

JA

θ

JA

θ

JA

Thermal Resistance TO220 or TO263 Package, Junction to Case 2 ˚C/W

SHUTDOWN/SOFT-START CONTROL Test Circuit of

V

SD

Shutdown Threshold 1.3 V

Voltage Low, (Shutdown Mode) 0.6 V(max)

V

SS

Soft-start Voltage V

= 12V for the 3.3V, 5V, and Adjustable version and VIN= 24V for the 12V ver-

IN

Typ Limit

(Note 4) (Note 5)

50/100 nA(max)

127/110 kHz(min)

173/173 kHz(max)

= 1A (Note 8) (Note 9) 1 V

OUT

1.2/1.3 V(max)

1.2/1.15 A(min)

2.4/2.6 A(max)

Output = −1V 2 mA

15 mA(max)

TO220 Package, Junction to Ambient (Note 12) 50 ˚C/W

TO263 Package, Junction to Ambient (Note 13) 50 ˚C/W

TO263 Package, Junction to Ambient (Note 14) 30 ˚C/W

TO263 Package, Junction to Ambient (Note 15) 20 ˚C/W

Figure 1

High, (Soft-start Mode) 2 V(min)

= 20% of Nominal Output Voltage 2 V

OUT

V

= 100% of Nominal Output Voltage 3

OUT

(Limits)

(Limits)

www.national.com 4

All Output Voltage Versions

Electrical Characteristics

Specifications with standard type face are for TJ= 25˚C, and those with boldface type apply over full Operating Temperature Range. Unless otherwise specified, V

sion. I

Symbol Parameter Conditions LM2598-XX Units

SHUTDOWN/SOFT-START CONTROL Test Circuit of

I

SD

I

SS

FLAG/DELAY CONTROL Test Circuit of

VF

SAT

IF

L

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for which the device is

intended to be functional, but do not guarantee specific performance limits. For guaranteed specifications and test conditions, see the Electrical Characteristics.

Note 2: Voltage internally clamped. If clamp voltage is exceeded, limit current to a maximum of 1 mA.

Note 3: The human body model is a 100 pF capacitor discharged through a 1.5k resistor into each pin.

Note 4: Typical numbers are at 25˚C and represent the most likely norm.

Note 5: All limits guaranteed at room temperature (standard type face) and at temperature extremes (bold type face). All room temperature limits are 100%

production tested. All limits at temperature extremes are guaranteed via correlation using standard Statistical Quality Control (SQC) methods. All limits are used

to calculate Average Outgoing Quality Level (AOQL).

Note 6: External components such as the catch diode, inductor, input and output capacitors can affect switching regulator system performance. When the LM2598

is used as shown in the

Note 7: The switching frequency is reduced when the second stage current limit is activated. The amount of reduction is determined by the severity of current

overload.

Note 8: No diode, inductor or capacitor connected to output pin.

Note 9: Feedback pin removed from output and connected to 0V to force the output transistor switch ON.

Note 10: Feedback pin removed from output and connected to12Vfor the 3.3V, 5V, and theADJ. version, and 15V for the 12V version, to force theoutput transistor

switch OFF.

Note 11: V

Note 12: Junction to ambient thermal resistance (no external heat sink) forthe TO-220 package mounted vertically,with the leads soldered to a printed circuit board

with (1 oz.) copper area of approximately 1 in

Note 13: Junction to ambient thermal resistance with the TO-263 package tab soldered to a single sided printed circuit board with 0.5 in

Note 14: Junction to ambient thermal resistance with the TO-263 package tab soldered to a single sided printed circuit board with 2.5 in

Note 15: Junction to ambient thermal resistance with the TO-263 package tab soldered to a double sided printed circuit board with 3 in

the LM2598S side of the board, and approximately 16 in

Switchers Made Simple

in

= 200 mA

LOAD

Shutdown Current V

Soft-start Current V

Regulator Dropout Detector Low (Flag ON) 96 %

Threshold Voltage 92 %(min)

Flag Output Saturation I

Voltage V

Flag Output Leakage

Current

Delay Pin Threshold 1.25 V

Voltage Low (Flag ON) 1.21 V(min)

Delay Pin Source Current V

Delay Pin Saturation Low (Flag ON) 55 mV

Figure 1

test circuit, system performance will be as shown in system parameters section of Electrical Characteristics.

= 40V.

IN

®

version 4.2 software.

(Continued)

= 12V for the 3.3V, 5V, and Adjustable version and VIN= 24V for the 12V ver-

IN

SHUTDOWN

= 2.5V 1.6 µA

Soft-start

Figure 1

= 3 mA 0.3 V

SINK

= 0.5V 0.7/1.0 V(max)

DELAY

V

= 40V 0.3 µA

FLAG

High (Flag OFF) and V

= 0.5V 3 µA

DELAY

2

.

2

of copper on the other side of the p-c board. See application hints in this data sheetandthe thermal model

Typ Limit

(Limits)

(Note 4) (Note 5)

Figure 1

= 0.5V 5µA

10 µA(max)

5 µA(max)

98 %(max)

Regulated 1.29 V(max)

OUT

6 µA(max)

350/400 mV(max)

2

of (1 oz.) copper area.

2

of (1 oz.) copper area.

2

of (1 oz.) copper area on

LM2598

www.national.com5

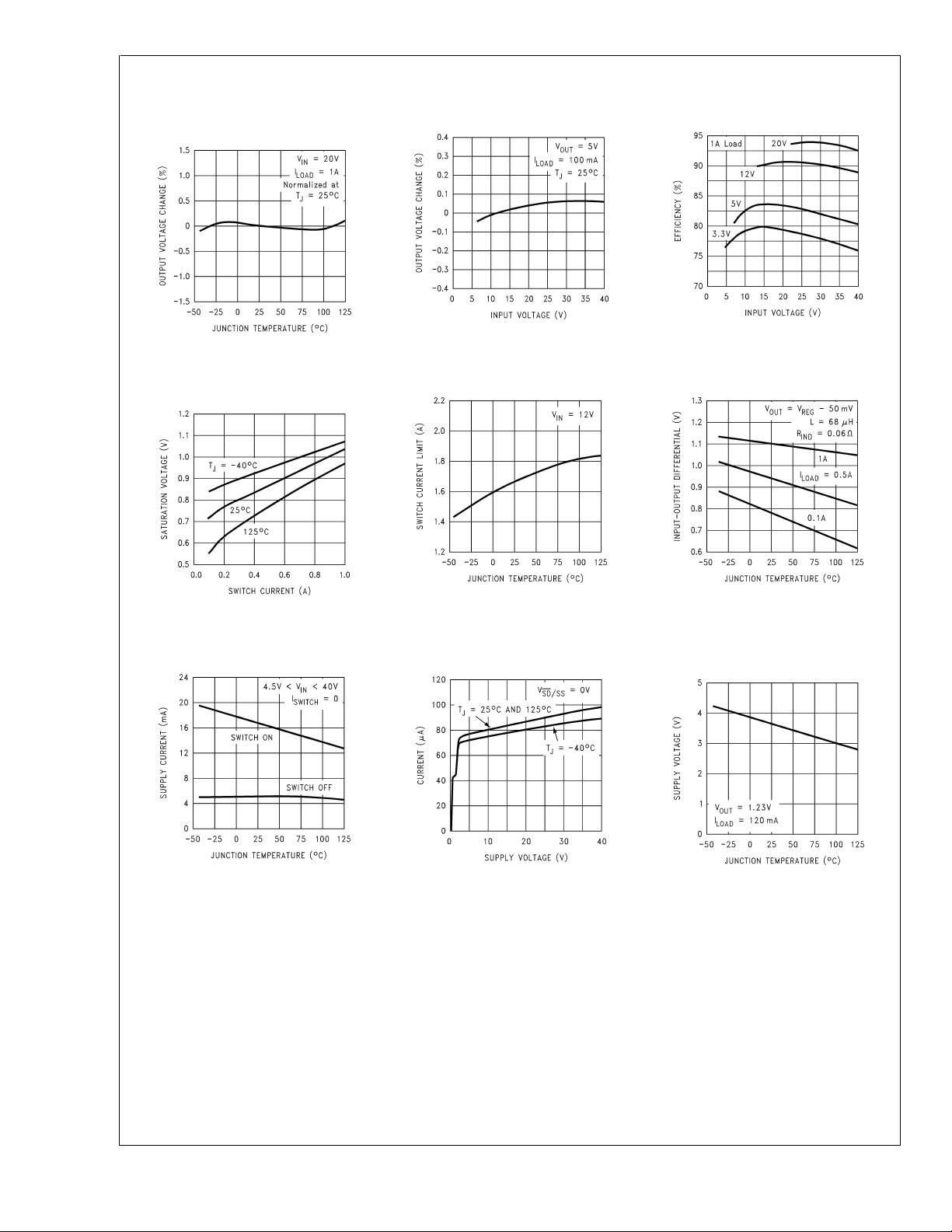

Typical Performance Characteristics (Circuit of

LM2598

Normalized

Output Voltage

Line Regulation

Figure 1

)

Efficiency

Switch Saturation

Voltage

Operating

Quiescent Current

DS012593-2

DS012593-15

Switch Current Limit

Shutdown

Quiescent Current

DS012593-3

DS012593-16

DS012593-14

Dropout Voltage

DS012593-17

Minimum Operating

Supply Voltage

DS012593-4

www.national.com 6

DS012593-5

DS012593-6

LM2598

Typical Performance Characteristics (Circuit of

Feedback Pin

Bias Current

DS012593-49

Soft-start

Flag Saturation

Voltage

Shutdown/Soft-start

Current

Figure 1

DS012593-7

) (Continued)

Switching Frequency

DS012593-8

Delay Pin Current

Soft-start Response

DS012593-9

DS012593-10

DS012593-11

Shutdown/Soft-start

Threshold Voltage

DS012593-12

DS012593-13

www.national.com7

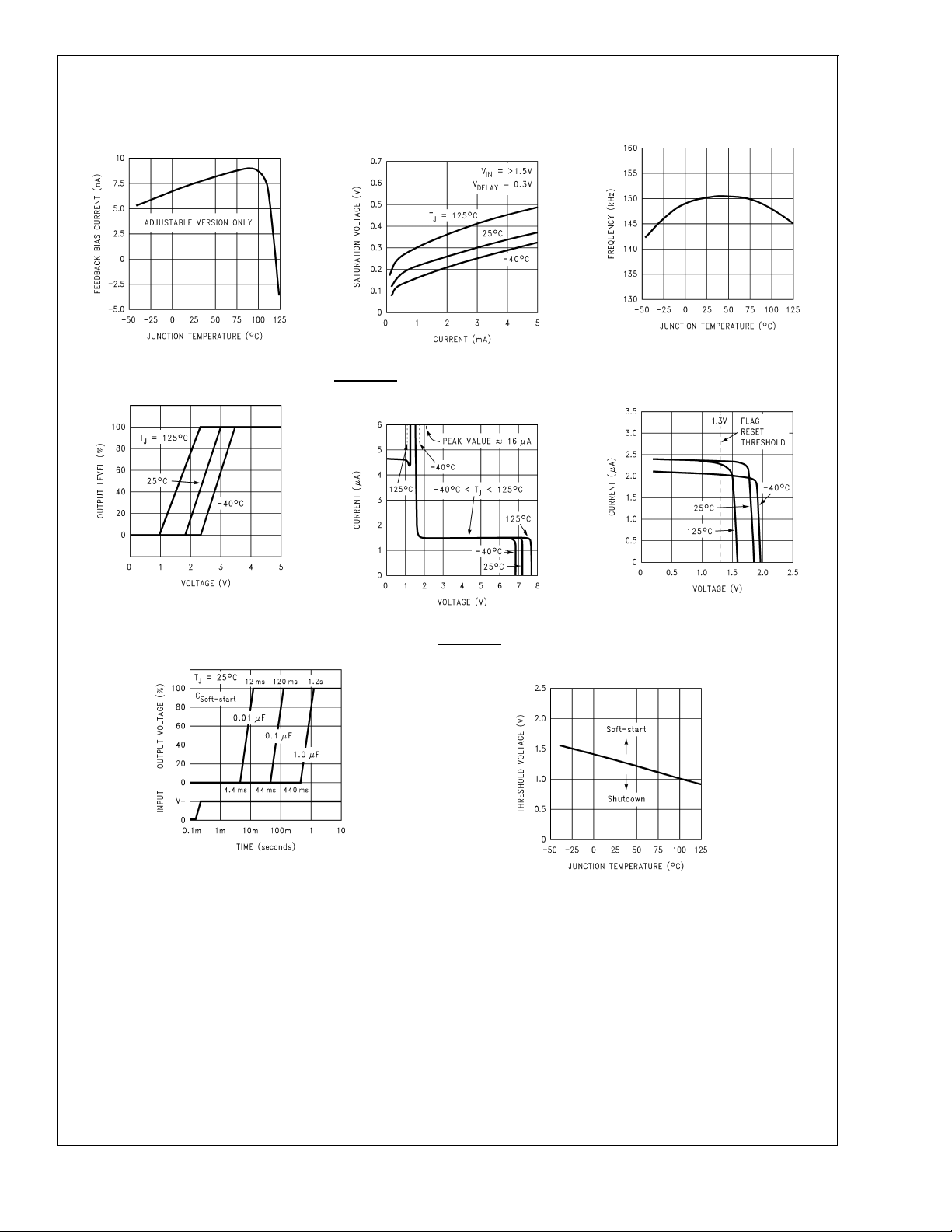

Typical Performance Characteristics (Circuit of

LM2598

Continuous Mode Switching Waveforms

V

= 20V, V

IN

L = 68 µH, C

OUT

OUT

=5V,I

LOAD

= 120 µF, C

=1A

ESR = 100 mΩ

OUT

Figure 1

)

Discontinuous Mode Switching Waveforms

= 20V, V

V

IN

L = 22 µH, C

OUT

OUT

=5V,I

LOAD

= 220 µF, C

= 600 mA

ESR=50mΩ

OUT

A: Output Pin Voltage, 10V/div.

B: Inductor Current 0.5A/div.

C: Output Ripple Voltage, 50 mV/div.

Horizontal Time Base: 2 µs/div.

Load Transient Response for Continuous Mode

V

= 20V, V

IN

L = 68 µH, C

A: Output Voltage, 100 mV/div. (AC)

B: 250 mA to 750 mA Load Pulse

OUT

OUT

=5V,I

LOAD

= 120 µF, C

= 250 mA to 750 mA

ESR = 100 mΩ

OUT

Horizontal Time Base: 100 µs/div.

DS012593-18

DS012593-20

DS012593-19

A: Output Pin Voltage, 10V/div.

B: Inductor Current 0.5A/div.

C: Output Ripple Voltage, 50 mV/div.

Horizontal Time Base: 2 µs/div.

Load Transient Response for Discontinuous Mode

= 20V, V

V

IN

L = 22 µH, C

A: Output Voltage, 100 mV/div. (AC)

B: 250 mA to 750 mA Load Pulse

OUT

OUT

=5V,I

LOAD

= 220 µF, C

= 250 mA to 750 mA

ESR=50mΩ

OUT

DS012593-21

Horizontal Time Base: 200 µs/div.

www.national.com 8

Test Circuit and Layout Guidelines

Fixed Output Voltage Versions

Component Values shown are for VIN= 15V, V

120 µF, 50V, Aluminum Electrolytic Nichicon “PL Series”

120 µF, 35V Aluminum Electrolytic, Nichicon “PL Series”

3A, 40V Schottky Rectifier, 1N5822

68 µH, L30

Typical Values

*CSS: — 0.1 µF

: — 0.1 µF

C

DELAY

: — 4.7k

R

Pull Up

OUT

=5V,I

LOAD

= 1A.

Adjustable Output Voltage Versions

LM2598

DS012593-23

where V

REF

= 1.23V

Select R1to be approximately 1kΩ, use a 1% resistor for best stability.

Component Values shown are for V

= 10V, I

V

OUT

— 120 µF, 35V,Aluminum Electrolytic Nichicon “PL Series”

C

IN

— 120 µF, 35V Aluminum Electrolytic, Nichicon “PL Series”

C

OUT

D1 —3A, 40V Schottky Rectifier, 1N5822

LOAD

= 1A.

IN

= 20V,

L1 —100 µH, L29

—1 kΩ,1%

R

1

—7.15k, 1%

R

2

—3.3 nF, See Application Information Section

C

FF

—3 kΩ, See Application Information Section

R

FF

Typical Values

CSS—0.1 µF

—0.1 µF

C

DELAY

—4.7k

R

PULL UP

FIGURE 1. Standard Test Circuits and Layout Guides

DS012593-24

www.national.com9

Test Circuit and Layout Guidelines

(Continued)

LM2598

As in any switching regulator, layout is very important. Rapidly switching currents associated with wiring inductance can

generate voltage transients which can cause problems. For

minimal inductance and ground loops, the wires indicated by

heavy lines should be wide printed circuit traces and

should be kept as short as possible. For best results,

external components should be located as close to the

If open core inductors are used, special care must be

taken as to the location and positioning of this type of inductor.Allowing the inductor flux to intersect sensitive feedback,

lC groundpath and C

wiring can cause problems.

OUT

When using the adjustable version, special care must be

taken as to the location of the feedback resistors and the

associated wiring. Physically locate both resistors near the

IC, and route the wiring away from the inductor, especially an

open core type of inductor. (See application section for more

information.)

switcher lC as possible using ground plane construction or

single point grounding.

LM2598 Series Buck Regulator Design Procedure (Fixed Output)

PROCEDURE (Fixed Output Voltage Version) EXAMPLE (Fixed Output Voltage Version)

Given:

V

= Regulated Output Voltage (3.3V, 5V or 12V)

OUT

(max) = Maximum DC Input Voltage

V

IN

I

(max) = Maximum Load Current I

LOAD

1. Inductor Selection (L1) 1. Inductor Selection (L1)

A. Select the correct inductor value selection guide from

Figures

Figure 4,Figure 5

,or

Figure 6

(Output voltages of

3.3V, 5V, or 12V respectively.) For all other voltages, see the

design procedure for the adjustable version.

B. From the inductor value selection guide, identify the inductance region intersected by the Maximum Input Voltage

line and the Maximum Load Current line. Each region is

identified by an inductance value and an inductor code

(LXX).

C. Select an appropriate inductor from the four manufacturer’s part numbers listed in

2. Output Capacitor Selection (C

Figure 8

.

) 2. Output Capacitor Selection (C

OUT

A. In the majority of applications, low ESR (Equivalent Series

Resistance) electrolytic capacitors between 47 µF and 330

µF and low ESR solid tantalum capacitors between 56 µF

and 270 µF provide the best results. This capacitor should be

located close to the IC using short capacitor leads and short

copper traces. Do not use capacitors larger than 330 µF.

For additional information, see section on output capacitors in application information section.

Given:

V

=5V

OUT

V

(max) = 12V

IN

(max) = 1A

LOAD

A. Use the inductor selection guide for the 5V version shown

in

Figure 5

.

B. From the inductor value selection guide shown in

the inductance region intersected by the 12V horizontal line

and the 1A vertical line is 68 µH, and the inductor code is

L30.

C. The inductance value required is 68 µH. From the table in

Figure 8

, go to the L30 line and choose an inductor part

number from any of the four manufacturers shown. (In most

instance, both through hole and surface mount inductors are

available.)

A. See section on output capacitors in application information section.

OUT

Figure 5

,

)

www.national.com 10

LM2598 Series Buck Regulator Design Procedure (Fixed Output) (Continued)

PROCEDURE (Fixed Output Voltage Version) EXAMPLE (Fixed Output Voltage Version)

B. To simplify the capacitor selection procedure, refer to the

quick design component selection table shown in

This table contains different input voltages, output voltages,

and load currents, and lists various inductors and output

capacitors that will provide the best design solutions.

C. The capacitor voltage rating for electrolytic capacitors

should be at least 1.5 times greater than the output voltage,

and often much higher voltage ratings are needed to satisfy

the low ESR requirements for low output ripple voltage .

D. For computer aided design software, see

™

Simple

3. Catch Diode Selection (D1) 3. Catch Diode Selection (D1)

A. The catch diode current rating must be at least 1.3 times

greater than the maximum load current. Also, if the power

supply design must withstand a continuous output short, the

diode should have a current rating equal to the maximum

current limit of the LM2598. The most stressful condition for

this diode is an overload or shorted output condition.

B. The reverse voltage rating of the diode should be at least

1.25 times the maximum input voltage.

C. This diode must be fast (short reverse recovery time) and

must be located close to the LM2598 using short leads and

short printed circuit traces. Because of their fast switching

speed and low forward voltage drop, Schottky diodes provide

the best performance and efficiency, and should be the first

choice, especially in low output voltage applications.

Ultra-fast recovery, or High-Efficiency rectifiers also provide

good results. Ultra-fast recovery diodes typically have reverse recovery times of 50 ns or less. Rectifiers such as the

1N5400 series are much too slow and should not be used.

(version 4.2 or later).

Figure 2

Switchers Made

B. From the quick design component selection table shown

in

.

Figure 2

current column, choose the load current line that is closest to

the current needed in your application, for this example, use

the 1A line. In the maximum input voltage column, select the

line that covers the input voltage needed in your application,

in this example, use the 15V line. Continuing on this line are

recommended inductors and capacitors that will provide the

best overall performance.

The capacitor list contains both through hole electrolytic and

surface mount tantalum capacitors from four different capacitor manufacturers. It is recommended that both the manufacturers and the manufacturer’s series that are listed in the

table be used.

In this example aluminum electrolytic capacitors from several

different manufacturers are available with the range of ESR

numbers needed.

C. For a 5V output, a capacitor voltage rating at least 7.5V or

more is needed. But, in this example, even a low ESR,

switching grade, 220 µF 10V aluminum electrolytic capacitor

would exhibit approximately 225 mΩ of ESR (see the curve

in

Figure 17

ESR would result in relatively high output ripple voltage. To

reduce the ripple to 1% of the output voltage, or less, a

capacitor with a higher voltage rating (lower ESR) should be

selected. A 16V or 25V capacitor will reduce the ripple voltage by approximately half.

A. Refer to the table shown in

3A, 20V, 1N5820 Schottky diode will provide the best performance, and will not be overstressed even for a shorted

output.

, locate the 5V output voltage section. In the load

220 µF 25V Panasonic HFQ Series

220 µF 25V Nichicon PL Series

for the ESR vs voltage rating). This amount of

Figure 11

. In this example, a

LM2598

www.national.com11

LM2598 Series Buck Regulator Design Procedure (Fixed Output) (Continued)

LM2598

PROCEDURE (Fixed Output Voltage Version) EXAMPLE (Fixed Output Voltage Version)

4. Input Capacitor (C

)

IN

Alow ESR aluminum or tantalum bypass capacitor is needed

between the input pin and ground to prevent large voltage

transients from appearing at the input. In addition, the RMS

current rating of the input capacitor should be selected to be

1

at least

⁄2the DC load current. The capacitor manufacturers

data sheet must be checked to assure that this current rating

is not exceeded. The curve shown in

Figure 16

RMS current ratings for several different aluminum electrolytic capacitor values.

This capacitor should be located close to the IC using short

leads and the voltage rating should be approximately 1.5

times the maximum input voltage.

If solid tantalum input capacitors are used, it is recomended

that they be surge current tested by the manufacturer.

Use caution when using ceramic capacitors for input bypassing, because it may cause severe ringing at the V

For additional information, see section on input capacitors in Application Information section.

shows typical

pin.

IN

4. Input Capacitor (C

)

IN

The important parameters for the Input capacitor are the

input voltage rating and the RMS current rating. With a

nominal input voltage of 12V, an aluminum electrolytic capacitor with a voltage rating greater than 18V (1.5 x V

IN

would be needed. The next higher capacitor voltage rating is

25V.

The RMS current rating requirement for the input capacitor in

a buck regulator is approximately

1

⁄2the DC load current. In

this example, with a 1A load, a capacitor with a RMS current

rating of at least 500 mA is needed. The curves shown in

Figure 16

can be used to select an appropriate input capacitor. From the curves, locate the 25V line and note which

capacitor values have RMS current ratings greater than 500

mA. Either a 180 µF or 220 µF,25V capacitor could be used.

For a through hole design, a 220 µF/25V electrolytic capacitor (Panasonic HFQ series or Nichicon PL series or equivalent) would be adequate. other types or other manufacturers

capacitors can be used provided the RMS ripple current

ratings are adequate.

For surface mount designs, solid tantalum capacitors are

recommended. The TPS series available from AVX, and the

593D series from Sprague are both surge current tested.

)

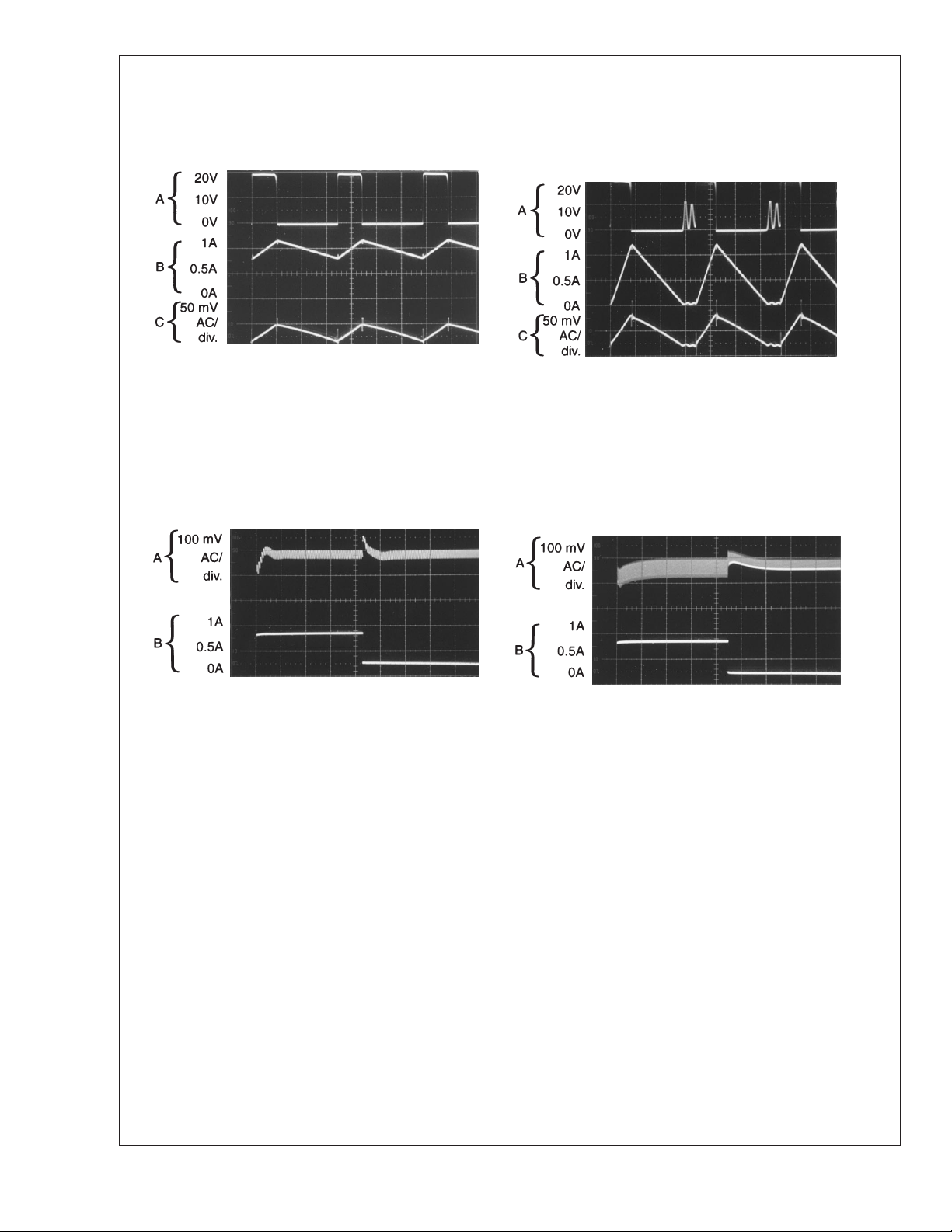

Conditions Inductor Output Capacitor

Through Hole Electrolytic Surface Mount Tantalum

Output Load Max Input Inductance Inductor Panasonic Nichicon AVX TPS Sprague

Voltage Current Voltage (µH) (

#

) HFQ Series PL Series Series 595D Series

(V) (A) (V) (µF/V) (µF/V) (µF/V) (µF/V)

3.3 1 5 22 L24 330/16 330/16 220/10 330/10

7 33 L23 270/25 270/25 220/10 270/10

10 47 L31 220/25 220/35 220/10 220/10

40 68 L30 180/35 220/35 220/10 180/10

6 47 L13 220/25 220/16 220/16 220/10

0.5 10 68 L21 150/35 150/25 100/16 150/16

40 100 L20 150/35 82/35 100/16 100/20

5 1 8 33 L28 330/16 330/16 220/10 270/10

10 47 L31 220/25 220/25 220/10 220/10

15 68 L30 180/35 180/35 220/10 150/16

40 100 L29 180/35 120/35 100/16 120/16

9 68 L21 180/16 180/16 220/10 150/16

0.5 20 150 L19 120/25 120/25 100/16 100/20

40 150 L19 100/25 100/25 68/20 68/25

12 1 15 47 L31 220/25 220/25 68/20 120/20

18 68 L30 180/35 120/25 68/20 120/20

30 150 L36 82/25 82/25 68/20 100/20

40 220 L35 82/25 82/25 68/20 68/25

15 68 L21 180/25 180/25 68/20 120/20

0.5 20 150 L19 82/25 82/25 68/20 100/20

40 330 L26 56/25 56/25 68/20 68/25

FIGURE 2. LM2598 Fixed Voltage Quick Design Component Selection Table

www.national.com 12

LM2598 Series Buck Regulator Design Procedure (Adjustable Output)

PROCEDURE (Adjustable Output Voltage Version) EXAMPLE (Adjustable Output Voltage Version)

Given:

V

= Regulated Output Voltage

OUT

V

(max) = Maximum Input Voltage

IN

I

(max) = Maximum Load Current

LOAD

F = Switching Frequency

(Fixed at a nominal 150 kHz).

1. Programming Output Voltage (Selecting R1and R2,as

shown in

Figure 1

)

Use the following formula to select the appropriate resistor

values.

Given:

V

= 20V

OUT

V

(max) = 28V

IN

I

(max) = 1A

LOAD

F = Switching Frequency

(Fixed at a nominal 150 kHz).

1. Programming Output Voltage (Selecting R1and R2,as

shown in

Select R

Figure 1

1

)

to be 1 kΩ, 1%. Solve for R2.

LM2598

Select a value for R1between 240Ω and 1.5 kΩ. The lower

resistor values minimize noise pickup in the sensitive feed-

R2= 1k (16.26 − 1) = 15.26k, closest 1% value is 15.4 kΩ.

R

2

back pin. (For the lowest temperature coefficient and the best

stability with time, use 1% metal film resistors.)

2. Inductor Selection (L1)

A. Calculate the inductor Volt

(V

µs), from the following formula:

•

where V

and V

= internal switch saturation voltage = 1V

SAT

= diode forward voltage drop = 0.5V

D

microsecond constant E•T

•

B. Use the E•T value from the previous formula and match

it with the E

Value Selection Guide shown in

T number on the vertical axis of the Inductor

•

Figure 7

.

2. Inductor Selection (L1)

A. Calculate the inductor Volt

(E

B. E

C. on the horizontal axis, select the maximum load current. C. I

D. Identify the inductance region intersected by the E

•

value and the Maximum Load Current value. Each region is

identified by an inductance value and an inductor code

(LXX).

E. Select an appropriate inductor from the four manufacturer’s part numbers listed in

3. Output Capacitor Selection (C

Figure 8

.

) 3. Output Capacitor SeIection (C

OUT

A. In the majority of applications, low ESR electrolytic or solid

T

D. From the inductor value selection guide shown in

the inductance region intersected by the 35 (V

tal line and the 1A vertical line is 100 µH, and the inductor

code is L29.

E. From the table in

inductor part number from the list of manufacturers part

numbers.

A. See section on C

tantalum capacitors between 82 µF and 220 µF provide the

best results. This capacitor should be located close to the IC

using short capacitor leads and short copper traces. Do not

use capacitors larger than 220 µF. For additional informa-

tion, see section on output capacitors in application

information section.

= 15.4 kΩ.

T),

•

T = 34.8 (V•µs)

•

(max) = 1A

LOAD

microsecond constant

•

•

Figure 8

OUT

, locate line L29, and select an

)

OUT

in Application Information section.

Figure 7

µs) horizon-

,

www.national.com13

LM2598 Series Buck Regulator Design Procedure (Adjustable Output)

(Continued)

LM2598

PROCEDURE (Adjustable Output Voltage Version)

B. To simplify the capacitor selection procedure, refer to the

quick design table shown in

Figure 3

. This table contains

different output voltages, and lists various output capacitors

that will provide the best design solutions.

C. The capacitor voltage rating should be at least 1.5 times

greater than the output voltage, and often much higher voltage ratings are needed to satisfy the low ESR requirements

needed for low output ripple voltage.

4. Feedforward Capacitor (C

) (See

FF

Figure 1

)

For output voltages greater than approximately 10V, an additional capacitor is required. The compensation capacitor is

typically between 50 pF and 10 nF, and is wired in parallel

with the output voltage setting resistor, R

. It provides addi-

2

tional stability for high output voltages, low input-output voltages, and/or very low ESR output capacitors, such as solid

tantalum capacitors.

EXAMPLE (Adjustable Output Voltage Version)

B. From the quick design table shown in

output voltage column. From that column, locate the output

voltage closest to the output voltage in your application. In

this example, select the 24V line. Under the output capacitor

section, select a capacitor from the list of through hole electrolytic or surface mount tantalum types from four different

capacitor manufacturers. It is recommended that both the

manufacturers and the manufacturers series that are listed in

the table be used.

In this example, through hole aluminum electrolytic capacitors from several different manufacturers are available.

82 µF 35V Panasonic HFQ Series

82 µF 35V Nichicon PL Series

C. For a 20V output, a capacitor rating of at least 30V or

more is needed. In this example, either a 35V or 50V capacitor would work. A 35V rating was chosen although a 50V

rating could also be used if a lower output ripple voltage is

needed.

Other manufacturers or other types of capacitors may also

be used, provided the capacitor specifications (especially the

100 kHz ESR) closely match the types listed in the table.

Refer to the capacitor manufacturers data sheet for this

information.

4. Feedforward Capacitor (C

The table shown in

Figure 3

)

FF

contains feed forward capacitor

values for various output voltages. In this example,a1nF

capacitor is needed.

Figure 3

, locate the

This capacitor type can be ceramic, plastic, silver mica, etc.

(Because of the unstable characteristics of ceramic capacitors made with Z5U material, they are not recommended.)

5. Catch Diode Selection (D1)

A. The catch diode current rating must be at least 1.3 times

greater than the maximum load current. Also, if the power

supply design must withstand a continuous output short, the

diode should have a current rating equal to the maximum

current limit of the LM2598. The most stressful condition for

this diode is an overload or shorted output condition.

B. The reverse voltage rating of the diode should be at least

1.25 times the maximum input voltage.

C. This diode must be fast (short reverse recovery time) and

must be located close to the LM2598 using short leads and

short printed circuit traces. Because of their fast switching

speed and low forward voltage drop, Schottky diodes provide

the best performance and efficiency, and should be the first

choice, especially in low output voltage applications.

Ultra-fast recovery, or High-Efficiency rectifiers are also a

good choice, but some types with an abrupt turn-off characteristic may cause instability or EMl problems. Ultra-fast recovery diodes typically have reverse recovery times of 50 ns

or less. Rectifiers such as the 1N4001 series are much too

slow and should not be used.

www.national.com 14

5. Catch Diode Selection (D1)

A. Refer to the table shown in

Figure 11

. Schottky diodes

provide the best performance, and in this example a 3A, 40V,

1N5822 Schottky diode would be a good choice. The 3A

diode rating is more than adequate and will not be overstressed even for a shorted output.

LM2598 Series Buck Regulator Design Procedure (Adjustable Output)

(Continued)

LM2598

PROCEDURE (Adjustable Output Voltage Version)

6. Input Capacitor (C

)

IN

Alow ESR aluminum or tantalum bypass capacitor is needed

between the input pin and ground to prevent large voltage

transients from appearing at the input. In addition, the RMS

current rating of the input capacitor should be selected to be

1

at least

⁄2the DC load current. The capacitor manufacturers

data sheet must be checked to assure that this current rating

is not exceeded. The curve shown in

Figure 16

shows typical

RMS current ratings for several different aluminum electrolytic capacitor values.

This capacitor should be located close to the IC using short

leads and the voltage rating should be approximately 1.5

times the maximum input voltage.

If solid tantalum input capacitors are used, it is recomended

that they be surge current tested by the manufacturer.

Use caution when using a high dielectric constant ceramic

capacitor for input bypassing, because it may cause severe

ringing at the V

pin.

IN

For additional information, see section on input capacitor in application information section.

EXAMPLE (Adjustable Output Voltage Version)

6. Input Capacitor (C

)

IN

The important parameters for the Input capacitor are the

input voltage rating and the RMS current rating. With a

nominal input voltage of 28V, an aluminum electrolytic aluminum electrolytic capacitor with a voltage rating greater than

42V (1.5 x V

) would be needed. Since the the next higher

IN

capacitor voltage rating is 50V, a 50V capacitor should be

used. The capacitor voltage rating of (1.5 x V

) is a conser-

IN

vative guideline, and can be modified somewhat if desired.

The RMS current rating requirement for the input capacitor of

a buck regulator is approximately

1

⁄2the DC load current. In

this example, with a 1A load, a capacitor with a RMS current

rating of at least 500 mA is needed.

The curves shown in

Figure 16

can be used to select an

appropriate input capacitor. From the curves, locate the 50V

line and note which capacitor values have RMS current

ratings greater than 500 mA. Either a 100 µF or 120 µF, 50V

capacitor could be used.

For a through hole design, a 120 µF/50V electrolytic capacitor (Panasonic HFQ series or Nichicon PL series or equivalent) would be adequate. Other types or other manufacturers

capacitors can be used provided the RMS ripple current

ratings are adequate.

For surface mount designs, solid tantalum capacitors can be

used, but caution must be exercised with regard to the

capacitor surge current rating (seeApplication Information or

input capacitors in this data sheet). The TPS series available

from AVX, and the 593D series from Sprague are both surge

current tested.

To further simplify the buck regulator design procedure, National Semiconductor is making available computer design

software to be used with the Simple Switcher line ot switching regulators. Switchers Made Simple (version 4.2 or later)

is available on a 3

1

⁄2" diskette for IBM compatible computers.

Output

Voltage

(V)

Through Hole Electrolytic Output Capacitor Surface Mount Tantalum Output Capacitor

Panasonic Nichicon PL Feedforward AVX TPS Sprague Feedforward

HFQ Series Series Capacitor Series 595D Series Capacitor

(µF/V) (µF/V) (µF/V) (µF/V)

1.2 330/50 330/50 0 330/6.3 330/6.3 0

4 220/25 220/25 4.7 nF 220/10 220/10 4.7 nF

6 220/25 220/25 3.3 nF 220/10 220/10 3.3 nF

9 180/25 180/25 1.5 nF 100/16 180/16 1.5 nF

12 120/25 120/25 1.5 nF 68/20 120/20 1.5 nF

15 120/25 120/25 1.5 nF 68/20 100/20 1.5 nF

24 82/35 82/35 1 nF 33/25 33/35 220 pF

28 82/50 82/50 1 nF 10/35 33/35 220 pF

FIGURE 3. Output Capacitor and Feedforward Capacitor Selection Table

www.national.com15

LM2598 Series Buck Regulator Design Procedure

LM2598

INDUCTOR VALUE SELECTION GUIDES (For Continuous Mode Operation)

FIGURE 4. LM2598-3.3

FIGURE 5. LM2598-5.0

DS012593-25

DS012593-26

DS012593-27

FIGURE 6. LM2598-12

DS012593-28

FIGURE 7. LM2598-ADJ

www.national.com 16

LM2598 Series Buck Regulator Design Procedure (Continued)

LM2598

Inductance

(µH)

L4 68 0.32 67143940 67144310 RL-1284-68-43 RL1500-68 PE-53804 PE-53804-S DO1608-68

L5 47 0.37 67148310 67148420 RL-1284-47-43 RL1500-47 PE-53805 PE-53805-S DO1608-473

L6 33 0.44 67148320 67148430 RL-1284-33-43 RL1500-33 PE-53806 PE-53806-S DO1608-333

L9 220 0.32 67143960 67144330 RL-5470-3 RL1500-220 PE-53809 PE-53809-S DO3308-224

L10 150 0.39 67143970 67144340 RL-5470-4 RL1500-150 PE-53810 PE-53810-S DO3308-154

L11 100 0.48 67143980 67144350 RL-5470-5 RL1500-100 PE-53811 PE-53811-S DO3308-104

L12 68 0.58 67143990 67144360 RL-5470-6 RL1500-68 PE-53812 PE-53812-S DO3308-683

L13 47 0.70 67144000 67144380 RL-5470-7 RL1500-47 PE-53813 PE-53813-S DO3308-473

L14 33 0.83 67148340 67148450 RL-1284-33-43 RL1500-33 PE-53814 PE-53814-S DO3308-333

L15 22 0.99 67148350 67148460 RL-1284-22-43 RL1500-22 PE-53815 PE-53815-S DO3308-223

L16 15 1.24 67148360 67148470 RL-1284-15-43 RL1500-15 PE-53816 PE-53816-S DO3308-153

L17 330 0.42 67144030 67144410 RL-5471-1 RL1500-330 PE-53817 PE-53817-S DO3316-334

L18 220 0.55 67144040 67144420 RL-5471-2 RL1500-220 PE-53818 PE-53818-S DO3316-224

L19 150 0.66 67144050 67144430 RL-5471-3 RL1500-150 PE-53819 PE-53819-S DO3316-154

L20 100 0.82 67144060 67144440 RL-5471-4 RL1500-100 PE-53820 PE-53820-S DO3316-104

L21 68 0.99 67144070 67144450 RL-5471-5 RL1500-68 PE-53821 PE-53821-S DO3316-683

L22 47 1.17 67144080 67144460 RL-5471-6 — PE-53822 PE-53822-S DO3316-473

L23 33 1.40 67144090 67144470 RL-5471-7 — PE-53823 PE-53823-S DO3316-333

L24 22 1.70 67148370 67144480 RL-1283-22-43 — PE-53824 PE-53824-S DO3316-223

L26 330 0.80 67144100 67144480 RL-5471-1 — PE-53826 PE-53826-S DO5022P-334

L27 220 1.00 67144110 67144490 RL-5471-2 — PE-53827 PE-53827-S DO5022P-224

L28 150 1.20 67144120 67144500 RL-5471-3 — PE-53828 PE-53828-S DO5022P-154

L29 100 1.47 67144130 67144510 RL-5471-4 — PE-53829 PE-53829-S DO5022P-104

L30 68 1.78 67144140 67144520 RL-5471-5 — PE-53830 PE-53830-S DO5022P-683

L35 47 2.15 67144170 — RL-5473-1 — PE-53935 PE-53935-S —

Current

(A)

Schott Renco Pulse Engineering Coilcraft

Through Surface Through Surface Through Surface Surface

Hole Mount Hole Mount Hole Mount Mount

FIGURE 8. Inductor Manufacturers Part Numbers

www.national.com17

LM2598 Series Buck Regulator Design Procedure (Continued)

LM2598

Coilcraft Inc. Phone (800) 322-2645

FAX (708) 639-1469

Coilcraft Inc., Europe Phone +11 1236 730

595

FAX +44 1236 730

627

Pulse Engineering Inc. Phone (619) 674-8100

FAX (619) 674-8262

Pulse Engineering Inc., Phone +353 93 24 107

Europe FAX +353 93 24 459

Renco Electronics Inc. Phone (800) 645-5828

FAX (516) 586-5562

Schott Corp. Phone (612) 475-1173

FAX (612) 475-1786

FIGURE 9. Inductor Manufacturers Phone Numbers

Nichicon Corp. Phone (708) 843-7500

FAX (708) 843-2798

Panasonic Phone (714) 373-7857

FAX (714) 373-7102

AVX Corp. Phone (803) 448-9411

FAX (803) 448-1943

Sprague/Vishay Phone (207) 324-4140

FAX (207) 324-7223

FIGURE 10. Capacitor Manufacturers Phone Numbers

VR 1A Diodes 3A Diodes

Surface Mount Through Hole Surface Mount Through Hole

Schottky Ultra Fast Schottky Ultra Fast Schottky Ultra Fast Schottky Ultra Fast

Recovery Recovery Recovery Recovery

20V SK12 All of these 1N5817 All of these All of these IN5820 All of these

diodes are SR102 diodes are SK32 diodes are SR302 diodes are

rated to at rated to at rated to at MBR320 rated to at

30V SK13 least 50V. 1N5818 least 50V. least 50V. 1N5821 least 50V.

MBRS130 SR103 SK33 MBR330

11DQ03 31DQ03

40V SK14 1N5822

MBRS140 1N5819 SK34 SR304

10BQ040 SR104 MBRS340 MBR340

10MQ040 MURS120 11DQ04 MUR120 30WQ04 MURS320 31DQ04 MUR320

50V

MBRS160 10BF10 SR105 SK35 30WF10 SR305 30WF10

or

more

10BQ050 MBR150 MBRS360 MBR350

10MQ060 11DQ05 30WQ05 31DQ05

FIGURE 11. Diode Selection Table

www.national.com 18

Block Diagram

LM2598

FIGURE 12.

Application Information

PIN FUNCTIONS

+V

(Pin 2)—This is the positive input supply for the IC

IN

switching regulator. A suitable input bypass capacitor must

be present at this pin to minimize voltage transients and to

supply the switching currents needed by the regulator.

Ground (Pin 4)—Circuit ground.

Output (Pin 1)—Internal switch. The voltage at this pin

switches between approximately (+V

IN−VSAT

mately −0.5V, with a duty cycle of V

coupling to sensitive circuitry, the PC board copper area

connected to this pin should be kept to a minimum.

Feedback (Pin 6) —Senses the regulated output voltage to

complete the feedback loop.

Shutdown /Soft-start (Pin 7)—This dual function pin provides the following features: (a) Allows the switching regulator circuit to be shut down using logic level signals thus

dropping the total input supply current to approximately

85 µA. (b) Adding a capacitor to this pin provides a soft-start

feature which minimizes startup current and provides a controlled ramp up of the output voltage.

Error Flag (Pin 3)—Open collector output that provides a

low signal (flag transistor ON) when the regulated output

voltage drops more than 5% from the nominal output voltage. On start up, Error Flag is low until V

the nominal output voltage and a delay time determined by

the Delay pin capacitor. This signal can be used as a reset to

a microprocessor on power-up.

Delay (Pin 5)—At power-up, this pin can be used to provide

a time delay between the time the regulated output voltage

reaches 95% of the nominal output voltage, and the time the

error flag output goes high.

OUT/VIN

reaches 95% of

OUT

) and approxi. To minimize

DS012593-29

Special Note If any of the above three features (Shutdown

/Soft-start, Error Flag, or Delay) are not used, the respective

pins should be left open.

EXTERNAL COMPONENTS

SOFT-START CAPACITOR

C

—A capacitor on this pin provides the regulator with a

SS

Soft-start feature (slow start-up). When the DC input voltage

is first applied to the regulator, or when the Shutdown

/Soft-start pin is allowed to go high, a constant current

(approximately 5 µA begins charging this capacitor). As the

capacitor voltage rises, the regulator goes through four operating regions (See the bottom curve in

1. Regulator in Shutdown.

When the SD /SS pin voltage is

Figure 13

).

between 0V and 1.3V, the regulator is in shutdown, the

output voltage is zero, and the IC quiescent current is approximately 85 µA.

2. Regulator ON, but the output voltage is zero.

With the

SD /SS pin voltage between approximately 1.3V and 1.8V,

the internal regulator circuitry is operating, the quiescent

current rises to approximately 5 mA, but the output voltage is

still zero. Also, as the 1.3V threshold is exceeded, the

Soft-start capacitor charging current decreases from 5 µA

down to approximately 1.6 µA. This decreases the slope of

capacitor voltage ramp.

3. Soft-start Region.

When the SD /SS pin voltage is between 1.8V and 2.8V (@25˚C), the regulator is in a Soft-start

condition. The switch (Pin 1) duty cycle initially starts out

very low, with narrow pulses and gradually get wider as the

capacitor SD /SS pin ramps up towards 2.8V. As the duty

cycle increases, the output voltage also increases at a controlled ramp up. See the center curve in

Figure 13

. The input

supply current requirement also starts out at a low level for

www.national.com19

Application Information (Continued)

the narrow pulses and ramp up in a controlled manner. This

LM2598

is a very useful feature in some switcher topologies that

require large startup currents (such as the inverting configuration) which can load down the input power supply.

Note: The lower curve shown in

0% to 100%. This is not the duty cycle percentage, but the output

voltage percentage. Also, the Soft-start voltage range has a negative

temperature coefficient associated with it. See the Soft-start curve in

the electrical characteristics section.

4. Normal operation.

standard Pulse Width Modulated switching regulator. The

capacitor will continue to charge up until it reaches the

internal clamp voltage of approximately 7V. If this pin is

driven from a voltage source, the current must be limited to

about 1 mA.

If the part is operated with an input voltage at or below the

internal soft-start clamp voltage of approximately 7V, the

voltage on the SD/SS pin tracks the input voltage and can be

disturbed by a step in the voltage. To maintain proper function under these conditions, it is strongly recommended that

the SD/SS pin be clamped externally between the 3V maximum soft-start threshold and the 4.5V minimum input voltage.

Figure 15

is an example of an external 3.7V (approx.)

clamp that prevents a line-step related glitch but does not

interfere with the soft-start behavior of the device.

Figure 13

shows the Soft-start region from

Above 2.8V, the circuit operates as a

FIGURE 13. Soft-start, Delay, Error, Output

FIGURE 14. Timing Diagram for 5V Output

DS012593-30

DS012593-31

www.national.com 20

Application Information (Continued)

FIGURE 15. External 3.7V Soft-Start Clamp

DELAY CAPACITOR

C

upper curve in

Figure 14

between the time the regulated output voltage (when it is

increasing in value) reaches 95% of the nominal output

voltage, and the time the error flag output goes high. A 3 µA

constant current from the delay pin charges the delay capacitor resulting in a voltage ramp. When this voltage

reaches a threshold of approximately 1.3V, the open collector error flag output (or power OK) goes high. This signal can

be used to indicate that the regulated output has reached the

correct voltage and has stabilized.

If, for any reason, the regulated output voltage drops by 5%

or more, the error output flag (Pin 3) immediately goes low

(internal transistor turns on). The delay capacitor provides

very little delay if the regulated output is dropping out of

regulation. The delay time for an output that is decreasing is

approximately a 1000 times less than the delay for the rising

output. For a 0.1 µF delay capacitor, the delay time would be

approximately 50 ms when the output is rising and passes

through the 95% threshold, but the delay for the output

dropping would only be approximately 50 µs.

R

lector of a NPN transistor, with the emitter internally

grounded. To use the error flag, a pullup resistor to a positive

voltage is needed. The error flag transistor is rated up to a

maximum of 45V and can sink approximately 3 mA. If the

error flag is not used, it can be left open.

FEEDFORWARD CAPACITOR

(Adjustable Output Voltage Version)

C

Figure 1

or then C

compensation to the feedback loop and increases the phase

margin for better loop stability. For C

design procedure section.

If the output ripple is large (

voltage), this ripple can be coupled to the feedback pin

through the feedforward capacitor and cause the error comparator to trigger the error flag. In this situation, adding a

resistor, R

proximately 3 times R1, will attenuate the ripple voltage at

the feedback pin.

—Provides delay for the error flag output. See the

DELAY

Figure 13

, and also refer to timing diagrams in

. A capacitor on this pin provides a time delay

—The error flag output, (or power OK) is the col-

Pull Up

— A Feedforward Capacitor CFF, shown across R2 in

FF

is used when the output voltage is greater than 10V

has a very low ESR. This capacitor adds lead

OUT

selection, see the

FF

>

5% of the nominal output

, in series with the feedforward capacitor, ap-

FF

DS012593-65

INPUT CAPACITOR

—A low ESR aluminum or tantalum bypass capacitor is

C

IN

needed between the input pin and ground pin. It must be

located near the regulator using short leads. This capacitor

prevents large voltage transients from appearing at the input, and provides the instantaneous current needed each

time the switch turns on.

The important parameters for the Input capacitor are the

voltage rating and the RMS current rating. Because of the

relatively high RMS currents flowing in a buck regulator’s

input capacitor, this capacitor should be chosen for its RMS

current rating rather than its capacitance or voltage ratings,

although the capacitance value and voltage rating are directly related to the RMS current rating.

The RMS current rating of a capacitor could be viewed as a

capacitor’s power rating. The RMS current flowing through

the capacitors internal ESR produces power which causes

the internal temperature of the capacitor to rise. The RMS

current rating of a capacitor is determined by the amount of

current required to raise the internal temperature approximately 10˚C above an ambient temperature of 105˚C. The

ability of the capacitor to dissipate this heat to the surrounding air will determine the amount of current the capacitor can

safely sustain. Capacitors that are physically large and have

a large surface area will typically have higher RMS current

ratings. For a given capacitor value, a higher voltage electrolytic capacitor will be physically larger than a lower voltage

capacitor, and thus be able to dissipate more heat to the

surrounding air, and therefore will have a higher RMS current rating.

LM2598

www.national.com21

Application Information (Continued)

LM2598

DS012593-32

FIGURE 16. RMS Current Ratings for Low

ESR Electrolytic Capacitors (Typical)

DS012593-33

FIGURE 17. Capacitor ESR vs Capacitor Voltage Rating

(Typical Low ESR Electrolytic Capacitor)

The consequences of operating an electrolytic capacitor

above the RMS current rating is a shortened operating life.

The higher temperature speeds up the evaporation of the

capacitor’s electrolyte, resulting in eventual failure.

Selecting an input capacitor requires consulting the manufacturers data sheet for maximum allowable RMS ripple

current. For a maximum ambient temperature of 40˚C, a

general guideline would be to select a capacitor with a ripple

current rating of approximately 50% of the DC load current.

For ambient temperatures up to 70˚C, a current rating of

75% of the DC load current would be a good choice for a

conservative design. The capacitor voltage rating must be at

least 1.25 times greater than the maximum input voltage,

and often a much higher voltage capacitor is needed to

satisfy the RMS current requirements.

A graph shown in

an electrolytic capacitor value, its voltage rating, and the

RMS current it is rated for. These curves were obtained from

the Nichicon “PL” series of low ESR, high reliability electrolytic capacitors designed for switching regulator applications.

Other capacitor manufacturers offer similar types of capacitors, but always check the capacitor data sheet.

“Standard” electrolytic capacitors typically have much higher

ESR numbers, lower RMS current ratings and typically have

a shorter operating lifetime.

Because of their small size and excellent performance, surface mount solid tantalum capacitors are often used for input

Figure 16

shows the relationship between

bypassing, but several precautions must be observed. A

small percentage of solid tantalum capacitors can short if the

inrush current rating is exceeded. This can happen at turn on

when the input voltage is suddenly applied, and of course,

higher input voltages produce higher inrush currents. Several capacitor manufacturers do a 100% surge current testing on their products to minimize this potential problem. If

high turn on currents are expected, it may be necessary to

limit this current by adding either some resistance or inductance before the tantalum capacitor, or select a higher voltage capacitor. As with aluminum electrolytic capacitors, the

RMS ripple current rating must be sized to the load current.

OUTPUT CAPACITOR

C

—An output capacitor is required to filter the output

OUT

and provide regulator loop stability. Low impedance or low

ESR Electrolytic or solid tantalum capacitors designed for

switching regulator applications must be used. When selecting an output capacitor, the important capacitor parameters

are; the 100 kHz Equivalent Series Resistance (ESR), the

RMS ripple current rating, voltage rating, and capacitance

value. For the output capacitor, the ESR value is the most

important parameter.

The output capacitor requires an ESR value that has an

upper and lower limit. For low output ripple voltage, a low

ESR value is needed. This value is determined by the maximum allowable output ripple voltage, typically 1% to 2% of

the output voltage. But if the selected capacitor’s ESR is

extremely low, there is a possibility of an unstable feedback

loop, resulting in an oscillation at the output. Using the

capacitors listed in the tables, or similar types, will provide

design solutions under all conditions.

If very low output ripple voltage (less than 15 mV) is required, refer to the section on Output Voltage Ripple and

Transients for a post ripple filter.

An aluminum electrolytic capacitor’s ESR value is related to

the capacitance value and its voltage rating. In most cases,

higher voltage electrolytic capacitors have lower ESR values

(see

Figure 17

). Often, capacitors with much higher voltage

ratings may be needed to provide the low ESR values required for low output ripple voltage.

The output capacitor for many different switcher designs

often can be satisfied with only three or four different capacitor values and several different voltage ratings. See the

quick design component selection tables in

Figure 3

for typical capacitor values, voltage ratings, and

Figure 2

and

manufacturers capacitor types.

Electrolytic capacitors are not recommended for tempera-

tures below −25˚C. The ESR rises dramatically at cold temperatures and typically rises 3X

10X at −40˚C. See curve shown in

@

−25˚C and as much as

Figure 18

.

Solid tantalum capacitors have a much better ESR spec for

cold temperatures and are recommended for temperatures

below −25˚C.

CATCH DIODE

Buck regulators require a diode to provide a return path for

the inductor current when the switch turns off. This must be

a fast diode and must be located close to the LM2598 using

short leads and short printed circuit traces.

Because of their very fast switching speed and low forward

voltage drop, Schottky diodes provide the best performance,

especially in low output voltage applications (5V and lower).

Ultra-fast recovery, or High-Efficiency rectifiers are also a

good choice, but some types with an abrupt turnoff charac-

www.national.com 22

Application Information (Continued)

teristic may cause instability or EMI problems. Ultra-fast

recovery diodes typically have reverse recovery times of 50

ns or less. Rectifiers such as the 1N5400 series are much

too slow and should not be used.

DS012593-34

FIGURE 18. Capacitor ESR Change vs Temperature

INDUCTOR SELECTION

All switching regulators have two basic modes of operation;

continuous and discontinuous. The difference between the

two types relates to the inductor current, whether it is flowing

continuously, or if it drops to zero for a period of time in the

normal switching cycle. Each mode has distinctively different

operating characteristics, which can affect the regulators

performance and requirements. Most switcher designs will

operate in the discontinuous mode when the load current is

low.

The LM2598 (or any of the Simple Switcher family) can be

used for both continuous or discontinuous modes of operation.

In many cases the preferred mode of operation is the continuous mode. It offers greater output power, lower peak

switch, inductor and diode currents, and can have lower

output ripple voltage. But it does require larger inductor

values to keep the inductor current flowing continuously,

especially at low output load currents and/or high input voltages.

To simplify the inductor selection process, an inductor selection guide (nomograph) was designed (see

Figure 6

). This guide assumes that the regulator is operating

in the continuous mode, and selects an inductor that will

allow a peak-to-peak inductor ripple current to be a certain

percentage of the maximum design load current. This

peak-to-peak inductor ripple current percentage is not fixed,

but is allowed to change as different design load currents are

selected. (See

Figure 19

.)

Figure 3

through

DS012593-35

FIGURE 19. (∆I

) Peak-to-Peak Inductor

IND

Ripple Current (as a Percentage of the

Load Current) vs Load Current

By allowing the percentage of inductor ripple current to

increase for low load currents, the inductor value and size

can be kept relatively low.

When operating in the continuous mode, the inductor current

waveform ranges from a triangular to a sawtooth type of

waveform (depending on the input voltage), with the average

value of this current waveform equal to the DC output load

current.

Inductors are available in different styles such as pot core,

toroid, E-core, bobbin core, etc., as well as different core

materials, such as ferrites and powdered iron. The least

expensive, the bobbin, rod or stick core, consists of wire

wound on a ferrite bobbin. This type of construction makes

for an inexpensive inductor,but since the magnetic flux is not

completely contained within the core, it generates more

Electro-Magnetic Interference (EMl). This magnetic flux can

induce voltages into nearby printed circuit traces, thus causing problems with both the switching regulator operation and

nearby sensitive circuitry,and can give incorrect scope readings because of induced voltages in the scope probe. Also

see section on Open Core Inductors.

When multiple switching regulators are located on the same

PC board, open core magnetics can cause interference

between two or more of the regulator circuits, especially at

high currents. A torroid or E-core inductor (closed magnetic

structure) should be used in these situations.

The inductors listed in the selection chart include ferrite

E-core construction for Schott, ferrite bobbin core for Renco

and Coilcraft, and powdered iron toroid for Pulse Engineering.

Exceeding an inductor’s maximum current rating may cause

the inductor to overheat because of the copper wire losses,

or the core may saturate. If the inductor begins to saturate,

the inductance decreases rapidly and the inductor begins to

look mainly resistive (the DC resistance of the winding). This

can cause the switch current to rise very rapidly and force

the switch into a cycle-by-cycle current limit, thus reducing

the DC output load current. This can also result in overheating of the inductor and/or the LM2598. Different inductor

types have different saturation characteristics, and this

should be kept in mind when selecting an inductor.

The inductor manufacturer’s data sheets include current and

energy limits to avoid inductor saturation.

LM2598

www.national.com23

Application Information (Continued)

DISCONTINUOUS MODE OPERATION

LM2598

The selection guide chooses inductor values suitable for

continuous mode operation, but for low current applications

and/or high input voltages, a discontinuous mode design

may be a better choice. It would use an inductor that would

be physically smaller, and would need only one half to one

third the inductance value needed for a continuous mode

design. The peak switch and inductor currents will be higher

in a discontinuous design, but at these low load currents

(200 mA and below), the maximum switch current will still be

less than the switch current limit.

Discontinuous operation can have voltage waveforms that

are considerable different than a continuous design. The

output pin (switch) waveform can have some damped sinusoidal ringing present. (See Typical Perfomance Characteristics photo titled Discontinuous Mode Switching Waveforms) This ringing is normal for discontinuous operation,

and is not caused by feedback loop instabilities. In discontinuous operation, there is a period of time where neither the

switch or the diode are conducting, and the inductor current

has dropped to zero. During this time, a small amount of

energy can circulate between the inductor and the switch/

diode parasitic capacitance causing this characteristic ringing. Normally this ringing is not a problem, unless the amplitude becomes great enough to exceed the input voltage, and

even then, there is very little energy present to cause damage.

Different inductor types and/or core materials produce different amounts of this characteristic ringing. Ferrite core inductors have very little core loss and therefore produce the most

ringing. The higher core loss of powdered iron inductors

produce less ringing. If desired, a series RC could be placed

in parallel with the inductor to dampen the ringing. The

computer aided design software

(version 4.2) will provide all component values for continuous and discontinuous modes of operation.

Switchers Made Simple

ESR capacitors because they can affect the loop stability,

resulting in oscillation problems. If very low output ripple

voltage is needed (less than 20 mV), a post ripple filter is

recommended. (See

Figure 1

.) The inductance required is

typically between 1 µH and 5 µH, with low DC resistance, to

maintain good load regulation. A low ESR output filter capacitor is also required to assure good dynamic load response and ripple reduction. The ESR of this capacitor may

be as low as desired, because it is out of the regulator

feedback loop. The photo shown in

Figure 20

shows a

typical output ripple voltage, with and without a post ripple

filter.

When observing output ripple with a scope, it is essential

that a short, low inductance scope probe ground connection

be used. Most scope probe manufacturers provide a special

probe terminator which is soldered onto the regulator board,

preferable at the output capacitor. This provides a very short

scope ground thus eliminating the problems associated with

the 3 inch ground lead normally provided with the probe, and

provides a much cleaner and more accurate picture of the

ripple voltage waveform.

The voltage spikes are caused by the fast switching action of

the output switch, the diode, and the parasitic inductance of

the output filter capacitor, and its associated wiring. To minimize these voltage spikes, the output capacitor should be

designed for switching regulator applications, and the lead

lengths must be kept very short. Wiring inductance, stray

capacitance, as well as the scope probe used to evaluate

these transients, all contribute to the amplitude of these

spikes.

DS012593-36

FIGURE 20. Post Ripple Filter Waveform

OUTPUT VOLTAGE RIPPLE AND TRANSIENTS

The output voltage of a switching power supply operating in

the continuous mode will contain a sawtooth ripple voltage at

the switcher frequency, and may also contain short voltage

spikes at the peaks of the sawtooth waveform.

The output ripple voltage is a function of the inductor sawtooth ripple current and the ESR of the output capacitor. A

typical output ripple voltage can range from approximately

0.5% to 3% of the output voltage. To obtain low ripple

voltage, the ESR of the output capacitor must be low, however, caution must be exercised when using extremely low

www.national.com 24

DS012593-37

FIGURE 21. Peak-to-Peak Inductor

Ripple Current vs Load Current

When a switching regulator is operating in the continuous

mode, the inductor current waveform ranges from a triangular to a sawtooth type of waveform (depending on the input

voltage). For a given input and output voltage, the

peak-to-peak amplitude of this inductor current waveform

remains constant. As the load current increases or decreases, the entire sawtooth current waveform also rises

and falls. The average value (or the center) of this current

waveform is equal to the DC load current.

If the load current drops to a low enough level, the bottom of

the sawtooth current waveform will reach zero, and the

switcher will smoothly change from a continuous to a discontinuous mode of operation. Most switcher designs (irregardless how large the inductor value is) will be forced to run

discontinuous if the output is lightly loaded. This is a perfectly acceptable mode of operation.

Application Information (Continued)

In a switching regulator design, knowing the value of the

peak-to-peak inductor ripple current (∆I

determining a number of other circuit parameters. Parameters such as, peak inductor or peak switch current, minimum load current before the circuit becomes discontinuous,

output ripple voltage and output capacitor ESR can all be

calculated from the peak-to-peak ∆I

nomographs shown in

Figure 4

through

select an inductor value, the peak-to-peak inductor ripple

current can immediately be determined. The curve shown in

Figure 21

shows the range of (∆I

IND

for different load currents. The curve also shows how the

peak-to-peak inductor ripple current (∆I

go from the lower border to the upper border (for a given load

current) within an inductance region. The upper border represents a higher input voltage, while the lower border represents a lower input voltage (see Inductor Selection Guides).

These curves are only correct for continuous mode operation, and only if the inductor selection guides are used to

select the inductor value

Consider the following example:

V

= 5V, maximum load current of 800 mA

OUT

V

= 12V, nominal, varying between 10V and 14V.

IN

The selection guide in

Figure 5

shows that the vertical line

for a 0.8A load current, and the horizontal line for the 12V

input voltage intersect approximately midway between the

upper and lower borders of the 68 µH inductance region. A

68 µH inductor will allow a peak-to-peak inductor current

(∆I

) to flow that will be a percentage of the maximum load

IND

current. Referring to

Figure 21

, follow the 0.8A line approximately midway into the inductance region, and read the

peak-to-peak inductor ripple current (∆I

axis (approximately 300 mA p-p).

As the input voltage increases to 14V, it approaches the

upper border of the inductance region, and the inductor

ripple current increases. Referring to the curve in

it can be seen that for a load current of 0.8A, the

peak-to-peak inductor ripple current (∆I

12V in, and can range from 340 mA at the upper border (14V

in) to 225 mA at the lower border (10V in).

Once the ∆I

value is known, the following formulas can be

IND

used to calculate additional information about the switching

regulator circuit.

1. Peak Inductor or peak switch current

) can be useful for

IND

. When the inductor

IND

Figure 7

are used to

) that can be expected

) changes as you

IND

) on the left hand

IND

Figure 21

) is 300 mA with

IND

LM2598

OPEN CORE INDUCTORS

Another possible source of increased output ripple voltage or

unstable operation is from an open core inductor. Ferrite

bobbin or stick inductors have magnetic lines of flux flowing

through the air from one end of the bobbin to the other end.

These magnetic lines of flux will induce a voltage into any

wire or PC board copper trace that comes within the inductor’s magnetic field. The strength of the magnetic field, the

orientation and location of the PC copper trace to the magnetic field, and the distance between the copper trace and

the inductor, determine the amount of voltage generated in

the copper trace. Another way of looking at this inductive

coupling is to consider the PC board copper trace as one

turn of a transformer (secondary) with the inductor winding

as the primary. Many millivolts can be generated in a copper

trace located near an open core inductor which can cause

stability problems or high output ripple voltage problems.

If unstable operation is seen, and an open core inductor is

used, it’s possible that the location of the inductor with

respect to other PC traces may be the problem. To determine if this is the problem, temporarily raise the inductor

away from the board by several inches and then check

circuit operation. If the circuit now operates correctly, then

the magnetic flux from the open core inductor is causing the

problem. Substituting a closed core inductor such as a torroid or E-core will correct the problem, or re-arranging the

PC layout may be necessary. Magnetic flux cutting the IC

device ground trace, feedback trace, or the positive or negative traces of the output capacitor should be minimized.

Sometimes, locating a trace directly beneath a bobbin inductor will provide good results, provided it is exactly in the

center of the inductor (because the induced voltages cancel

themselves out), but if it is off center one direction or the

other, then problems could arise. If flux problems are

present, even the direction of the inductor winding can make

a difference in some circuits.

This discussion on open core inductors is not to frighten the

,

user, but to alert the user on what kind of problems to watch

out for when using them. Open core bobbin or “stick” inductors are an inexpensive, simple way of making a compact

efficient inductor, and they are used by the millions in many

different applications.

2. Minimum load current before the circuit becomes dis-

continuous

3. Output Ripple Voltage = (∆I

) x (ESR of C

IND

OUT

)

= 0.3A x 0.16Ω=48mVp-p

4. ESR of C

OUT