LM2524D/LM3524D

Regulating Pulse Width Modulator

General Description

The LM3524D family is an improved version of the industry

standard LM3524. It has improved specifications and additional features yet is pin for pin compatible with existing 3524

families. New features reduce the need for additional external

circuitry often required in the original version.

The LM3524D has a ±1% precision 5V reference. The current

carrying capability of the output drive transistors has been

raised to 200 mA while reducing V

breakdown to 60V. The common mode voltage range of the

error-amp has been raised to 5.5V to eliminate the need for

a resistive divider from the 5V reference.

In the LM3524D the circuit bias line has been isolated from

the shut-down pin. This prevents the oscillator pulse amplitude and frequency from being disturbed by shut-down. Also

at high frequencies (≃300 kHz) the max. duty cycle per output

has been improved to 44% compared to 35% max. duty cycle

in other 3524s.

In addition, the LM3524D can now be synchronized externally, through pin 3. Also a latch has been added to insure one

and increasing V

CEsat

pulse per period even in noisy environments. The LM3524D

includes double pulse suppression logic that insures when a

shut-down condition is removed the state of the T-flip-flop will

change only after the first clock pulse has arrived. This feature

prevents the same output from being pulsed twice in a row,

thus reducing the possibility of core saturation in push-pull

designs.

Features

CE

Fully interchangeable with standard LM3524 family

■

±1% precision 5V reference with thermal shut-down

■

Output current to 200 mA DC

■

60V output capability

■

Wide common mode input range for error-amp

■

One pulse per period (noise suppression)

■

Improved max. duty cycle at high frequencies

■

Double pulse suppression

■

Synchronize through pin 3

■

LM2524D/LM3524D Regulating Pulse Width Modulator

May 2, 2008

Connection Diagram

Order Number LM2524DN or LM3524DN

Top View

See NS Package Number N16E

Order Number LM3524DM

See NS Package Number M16A

865002

© 2008 National Semiconductor Corporation 8650 www.national.com

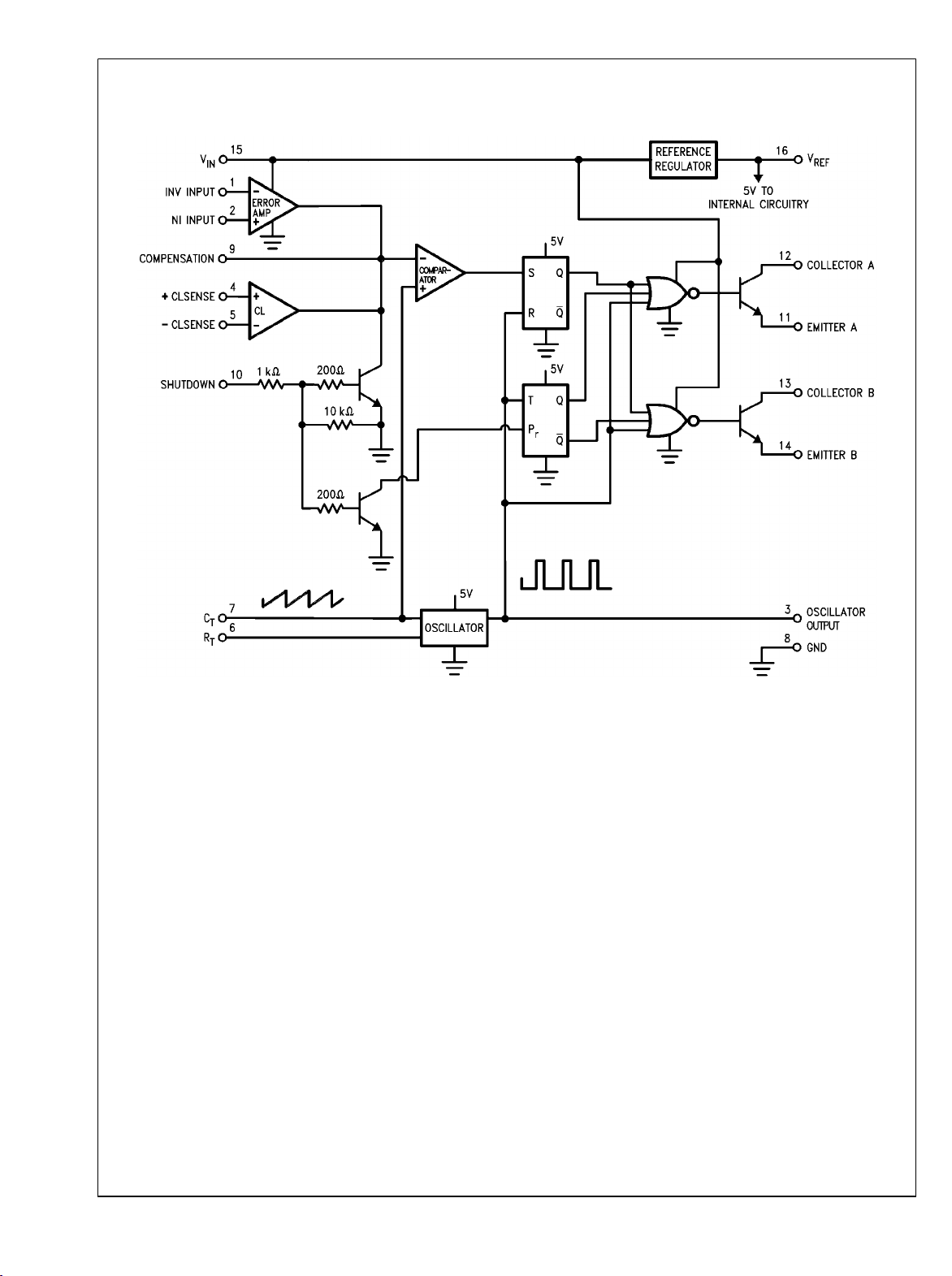

Block Diagram

LM2524D/LM3524D

865001

www.national.com 2

LM2524D/LM3524D

Absolute Maximum Ratings (Note 5)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Supply Voltage 40V

Collector Supply Voltage

(LM2524D) 55V

(LM3524D) 40V

Output Current DC (each) 200 mA

Internal Power Dissipation 1W

Operating Junction Temperature

Range (Note 2)

LM2524D −40°C to +125°C

LM3524D 0°C to +125°C

Maximum Junction Temperature 150°

Storage Temperature Range −65°C to +150°C

Lead Temperature (Soldering 4 sec.)

M, N Pkg. 260°C

Oscillator Charging Current (Pin 7) 5 mA

Electrical Characteristics

(Note 1)

LM2524D LM3524D

Symbol Parameter Conditions

Typ Limit Limit Typ Limit Limit

REFERENCE SECTION

V

REF

Output Voltage

V

V

RLine

RLoad

Line Regulation VIN = 8V to 40V 10 15 30 10 25 50 mV

Load Regulation IL = 0 mA to 20 mA 10 15 25 10 25 50 mV

Ripple Rejection f = 120 Hz 66 66 dB

Tested Design Tested Design

(Note 3) (Note 4)

4.85 4.80

5

5.15 5.20

(Note 3) (Note 4)

4.75 V

5

5.25 V

Units

Min

Max

Max

Max

I

OS

Short Circuit V

= 0 25 25 mA Min

REF

Current 50 50

180 200 mA Max

N

O

Output Noise

10 Hz ≤ f ≤ 10 kHz

Long Term TA = 125°C

40 100 40 100

20

20

Stability

OSCILLATOR SECTION

f

OSC

Max. Freq.

RT = 1k, CT = 0.001 μF

550

500 350

(Note 7)

f

OSC

Initial

RT = 5.6k, CT = 0.01 μF

17.5 17.5 kHz

Accuracy (Note 7) 20 20

22.5 22.5 kHz

RT = 2.7k, CT = 0.01 μF

34 30 kHz

(Note 7) 38 38

42 46 kHz

Δf

OSC

with V

Δf

OSC

Freq. Change VIN = 8 to 40V

IN

0.5 1

Freq. Change TA = −55°C to +125°C

0.5 1.0

with Temp. at 20 kHz RT = 5.6k, 5 5 %

V

OSC

Output Amplitude

CT = 0.01 μF

RT = 5.6k, CT = 0.01 μF

3 2.4

3 2.4

(Pin 3) (Note 8)

t

PW

Output Pulse

RT = 5.6k, CT = 0.01 μF

0.5 1.5

0.5 1.5

Width (Pin 3)

Sawtooth Peak

RT = 5.6k, CT = 0.01 μF

3.4 3.6 3.8

3.8

Voltage

μV

rms Max

mV/kHr

kHz

%

Max

V

Min

μs

Max

V

Max

Min

Min

Max

Min

Max

3 www.national.com

LM2524D LM3524D

Symbol Parameter Conditions

Tested Design Tested Design

Typ Limit Limit Typ Limit Limit

Sawtooth Valley

RT = 5.6k, CT = 0.01 μF

(Note 3) (Note 4)

1.1 0.8 0.6

(Note 3) (Note 4)

0.6

Voltage

LM2524D/LM3524D

ERROR-AMP SECTION

V

IO

Input Offset VCM = 2.5V

2 8 10 2 10

mV

Voltage

I

IB

Input Bias VCM = 2.5V

1 8 10 1 10

Current

I

IO

Input Offset VCM = 2.5V

0.5 1.0 1 0.5 1

Current

I

COSI

Compensation V

IN(I)

− V

= 150 mV 65 65

IN(NI)

Current (Sink) 95 95

125 125

I

COSO

Compensation V

IN(NI)

− V

= 150 mV −125 −125

IN(I)

Current (Source) −95 −95

−65 −65

A

VOL

Open Loop Gain

RL = ∞, VCM = 2.5 V

80 74 60 80 70 60 dB

VCMR Common Mode 1.5 1.4 1.5 V

Input Voltage

5.5 5.4 5.5 V

Range

CMRR Common Mode

90 80

90 80

dB

Rejection Ratio

G

BW

Unity Gain A

= 0 dB, VCM = 2.5V

VOL

3

2

Bandwidth

V

O

Output Voltage

RL = ∞

0.5 0.5 V

Swing 5.5 5.5 V

PSRR Power Supply VIN = 8 to 40V

80

70 80 65

db

Rejection Ratio

COMPARATOR SECTION

V

COMPZ

Minimum Duty Pin 9 = 0.8V,

Cycle

[RT = 5.6k, CT = 0.01 μF]

Maximum Duty Pin 9 = 3.9V,

Cycle

[RT = 5.6k, CT = 0.01 μF]

Maximum Duty Pin 9 = 3.9V,

Cycle

[RT = 1k, CT = 0.001 μF]

Input Threshold Zero Duty Cycle

0 0

49 45

44 35

1

0 0

49 45

44 35

1

%

%

%

(Pin 9)

V

COMPM

Input Threshold Maximum Duty Cycle

3.5

3.5

(Pin 9)

I

IB

Input Bias

−1

−1

Current

CURRENT LIMIT SECTION

V

SEN

Sense Voltage

V

(Pin 2)

− V

(Pin 1)

≥

180 180 mV

150 mV 200 200

220 220 mV

TC-V

sense

Sense Voltage T.C. 0.2 0.2 mV/°C

Units

V

Min

Max

μA

Max

μA

Max

μA

Min

μA

Max

μA

Min

μA

Max

Min

Min

Max

Min

MHz

Min

Max

Min

Max

Min

Min

V

V

μA

Min

Max

www.national.com 4

LM2524D LM3524D

Symbol Parameter Conditions

Tested Design Tested Design

Units

Typ Limit Limit Typ Limit Limit

(Note 3) (Note 4)

(Note 3) (Note 4)

Common Mode −0.7 −0.7 V

Voltage Range V5 − V4 = 300 mV 1 1 V

SHUT DOWN SECTION

V

SD

High Input

V

(Pin 2)

− V

(Pin 1)

≥

1

0.5

0.5 V

1

Voltage 150 mV 1.5 1.5 V

I

SD

High Input I

(pin 10)

1

1

mA

Current

OUTPUT SECTION (EACH OUTPUT)

V

CES

Collector Emitter

IC ≤ 100 μA

55

40

V

Voltage Breakdown

I

CES

V

CESAT

V

EO

Collector Leakage VCE = 60V

Current

VCE = 55V 0.1 50

VCE = 40V 0.1 50

Saturation IE = 20 mA 0.2 0.5 0.2 0.7

Voltage

Emitter Output IE = 50 mA

IE = 200 mA 1.5 2.2 1.5 2.5

18 17

18 17

μA

V

V

Voltage

t

R

Rise Time VIN = 20V,

IE = −250 μA

200 200 ns

RC = 2k

t

F

Fall Time RC = 2k 100 100 ns

SUPPLY CHARACTERISTICS SECTION

V

IN

Input Voltage After Turn-on 8 8 V

Range 40 40 V

T Thermal Shutdown (Note 2) 160 160 °C

Temp.

I

IN

Note 1: Unless otherwise stated, these specifications apply for TA = TJ = 25°C. Boldface numbers apply over the rated temperature range: LM2524D is −40° to

85°C and LM3524D is 0°C to 70°C. VIN = 20V and f

Note 2: For operation at elevated temperatures, devices in the N package must be derated based on a thermal resistance of 86°C/W, junction to ambient. Devices

in the M package must be derated at 125°C/W, junction to ambient.

Note 3: Tested limits are guaranteed and 100% tested in production.

Note 4: Design limits are guaranteed (but not 100% production tested) over the indicated temperature and supply voltage range. These limits are not used to

calculate outgoing quality level.

Note 5: Absolute maximum ratings indicate limits beyond which damage to the device may occur. DC and AC electrical specifications do not apply when operating

the device beyond its rated operating conditions.

Note 6: Pins 1, 4, 7, 8, 11, and 14 are grounded; Pin 2 = 2V. All other inputs and outputs open.

Note 7: The value of a Ct capacitor can vary with frequency. Careful selection of this capacitor must be made for high frequency operation. Polystyrene was used

in this test. NPO ceramic or polypropylene can also be used.

Note 8: OSC amplitude is measured open circuit. Available current is limited to 1 mA so care must be exercised to limit capacitive loading of fast pulses.

Stand By Current VIN = 40V (Note 6) 5 10 5 10 mA

= 20 kHz.

OSC

LM2524D/LM3524D

Min

Max

Min

Max

Min

Max

Max

Min

Min

Max

5 www.national.com

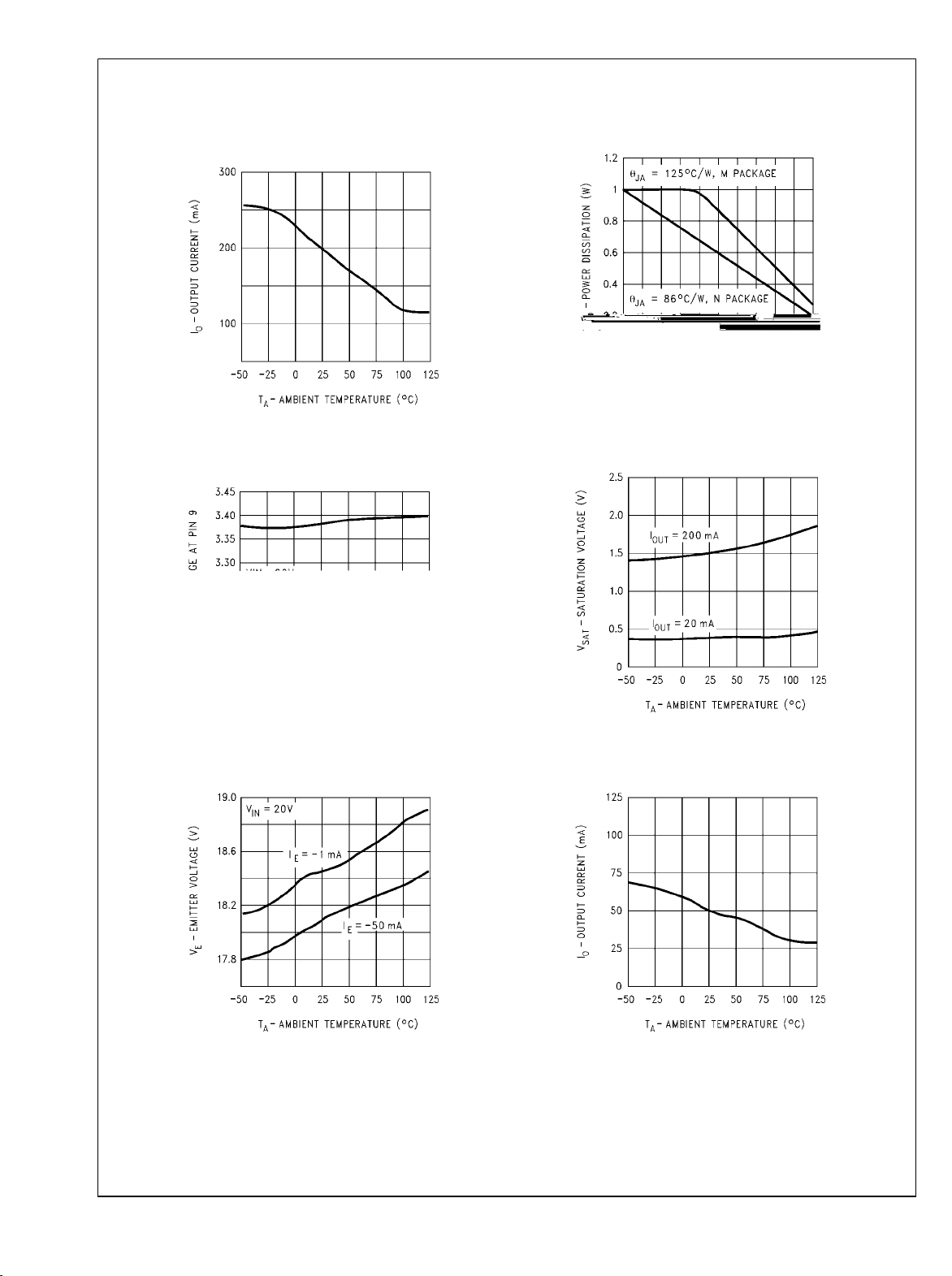

Typical Performance Characteristics

LM2524D/LM3524D

Switching Transistor

Peak Output Current

vs Temperature

Maximum & Minimum

Duty Cycle Threshold

Voltage

Maximum Average Power

Dissipation (N, M Packages)

865029

865028

Output Transistor

Saturation Voltage

Output Transistor Emitter

Voltage

865030

865032

865031

Reference Transistor

Peak Output Current

865033

www.national.com 6

LM2524D/LM3524D

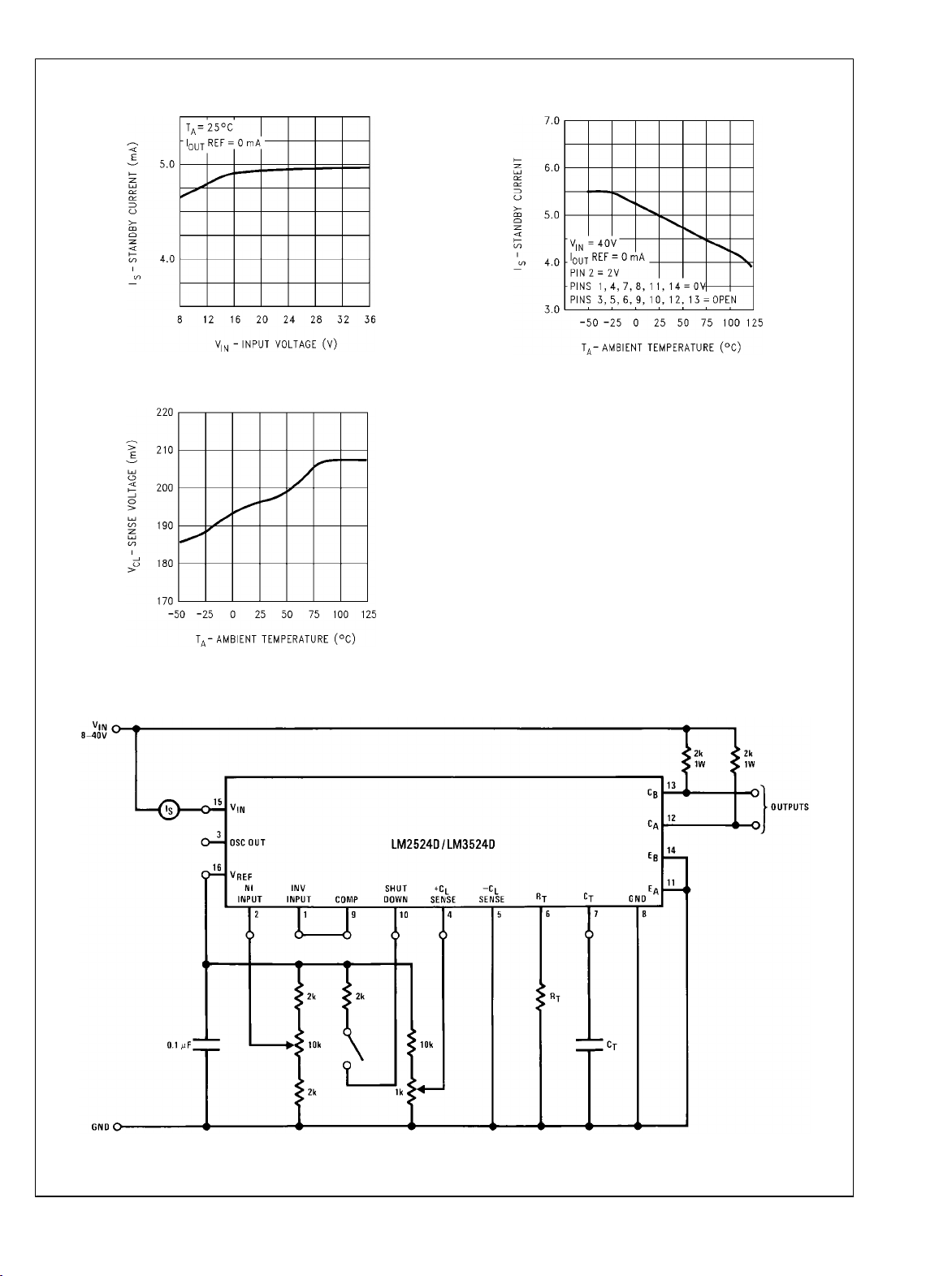

Standby Current

vs Voltage

Current Limit Sense Voltage

865034

Standby Current

vs Temperature

865035

Test Circuit

865036

865004

7 www.national.com

Functional Description

INTERNAL VOLTAGE REGULATOR

The LM3524D has an on-chip 5V, 50 mA, short circuit protected voltage regulator. This voltage regulator provides a

supply for all internal circuitry of the device and can be used

as an external reference.

For input voltages of less than 8V the 5V output should be

LM2524D/LM3524D

shorted to pin 15, VIN, which disables the 5V regulator. With

these pins shorted the input voltage must be limited to a maximum of 6V. If input voltages of 6V–8V are to be used, a preregulator, as shown in Figure 1, must be added.

865005

FIGURE 2.

*Minimum CO of 10 μF required for stability.

865010

FIGURE 1.

OSCILLATOR

The LM3524D provides a stable on-board oscillator. Its frequency is set by an external resistor, RT and capacitor, CT. A

graph of RT, CT vs oscillator frequency is shown is Figure 2.

The oscillator's output provides the signals for triggering an

internal flip-flop, which directs the PWM information to the

outputs, and a blanking pulse to turn off both outputs during

transitions to ensure that cross conduction does not occur.

The width of the blanking pulse, or dead time, is controlled by

the value of CT, as shown in Figure 3. The recommended

values of RT are 1.8 kΩ to 100 kΩ, and for CT, 0.001 μF to 0.1

μF.

If two or more LM3524D's must be synchronized together, the

easiest method is to interconnect all pin 3 terminals, tie all pin

7's (together) to a single CT, and leave all pin 6's open except

one which is connected to a single RT. This method works well

unless the LM3524D's are more than 6≃ apart.

A second synchronization method is appropriate for any circuit layout. One LM3524D, designated as master, must have

its RTCT set for the correct period. The other slave LM3524D

(s) should each have an RTCT set for a 10% longer period. All

pin 3's must then be interconnected to allow the master to

properly reset the slave units.

The oscillator may be synchronized to an external clock

source by setting the internal free-running oscillator frequency 10% slower than the external clock and driving pin 3 with

a pulse train (approx. 3V) from the clock. Pulse width should

be greater than 50 ns to insure full synchronization.

865006

FIGURE 3.

ERROR AMPLIFIER

The error amplifier is a differential input, transconductance

amplifier. Its gain, nominally 86 dB, is set by either feedback

or output loading. This output loading can be done with either

purely resistive or a combination of resistive and reactive

components. A graph of the amplifier's gain vs output load

resistance is shown in Figure 4.

www.national.com 8

865007

FIGURE 4.

LM2524D/LM3524D

The output of the amplifier, or input to the pulse width modulator, can be overridden easily as its output impedance is very

high (ZO ≃ 5 MΩ). For this reason a DC voltage can be applied

to pin 9 which will override the error amplifier and force a particular duty cycle to the outputs. An example of this could be

a non-regulating motor speed control where a variable voltage was applied to pin 9 to control motor speed. A graph of

the output duty cycle vs the voltage on pin 9 is shown in Figure

5.

The duty cycle is calculated as the percentage ratio of each

output's ON-time to the oscillator period. Paralleling the outputs doubles the observed duty cycle.

CURRENT LIMITING

The function of the current limit amplifier is to override the

error amplifier's output and take control of the pulse width.

The output duty cycle drops to about 25% when a current limit

sense voltage of 200 mV is applied between the +CL and

−CLsense terminals. Increasing the sense voltage approximately 5% results in a 0% output duty cycle. Care should be

taken to ensure the −0.7V to +1.0V input common-mode

range is not exceeded.

In most applications, the current limit sense voltage is produced by a current through a sense resistor. The accuracy of

this measurement is limited by the accuracy of the sense resistor, and by a small offset current, typically 100 μA, flowing

from +CL to −CL.

OUTPUT STAGES

The outputs of the LM3524D are NPN transistors, capable of

a maximum current of 200 mA. These transistors are driven

180° out of phase and have non-committed open collectors

and emitters as shown in Figure 6.

865008

FIGURE 5.

The amplifier's inputs have a common-mode input range of

1.5V–5.5V. The on board regulator is useful for biasing the

inputs to within this range.

865009

FIGURE 6.

9 www.national.com

Typical Applications

LM2524D/LM3524D

865011

FIGURE 7. Positive Regulator, Step-Up Basic Configuration (I

IN(MAX)

FIGURE 8. Positive Regulator, Step-Up Boosted Current Configuration

= 80 mA)

865012

www.national.com 10

865013

LM2524D/LM3524D

FIGURE 9. Positive Regulator, Step-Down Basic Configuration (I

11 www.national.com

IN(MAX)

= 80 mA)

LM2524D/LM3524D

865014

FIGURE 10. Positive Regulator, Step-Down Boosted Current Configuration

FIGURE 11. Boosted Current Polarity Inverter

www.national.com 12

865015

LM2524D/LM3524D

BASIC SWITCHING REGULATOR THEORY AND APPLICATIONS

The basic circuit of a step-down switching regulator circuit is

shown in Figure 12, along with a practical circuit design using

the LM3524D in Figure 15.

865016

FIGURE 12. Basic Step-Down Switching Regulator

The circuit works as follows: Q1 is used as a switch, which

has ON and OFF times controlled by the pulse width modulator. When Q1 is ON, power is drawn from VIN and supplied

to the load through L1; VA is at approximately VIN, D1 is reverse biased, and Co is charging. When Q1 turns OFF the

inductor L1 will force VA negative to keep the current flowing

in it, D1 will start conducting and the load current will flow

through D1 and L1. The voltage at VAis smoothed by the L1,

Co filter giving a clean DC output. The current flowing through

L1 is equal to the nominal DC load current plus some ΔI

which is due to the changing voltage across it. A good rule of

thumb is to set ΔI

≃ 40% × Io.

LP-P

865017

L

FIGURE 13. Relation of Switch Timing to Inductor Current in Step-Down Regulator

−

+

;

Neglecting V

, VD, and settling ΔI

SAT

L

= ΔI

L

where T = Total Period

The above shows the relation between VIN, Vo and duty cycle.

as Q1 only conducts during tON.

ηMAX will be further decreased due to switching losses in Q1.

For this reason Q1 should be selected to have the maximum

possible fT, which implies very fast rise and fall times.

CALCULATING INDUCTOR L1

−

Since ΔIL+ = ΔI

= 0.4I

L

o

Solving the above for L1

The efficiency, η, of the circuit is:

where: L1 is in Henrys

f is switching frequency in Hz

13 www.national.com

Also, see LM1578 data sheet for graphical methods of inductor selection.

CALCULATING OUTPUT FILTER CAPACITOR Co:

Figure 13 shows L1's current with respect to Q1's tON and

t

times (VA is at the collector of Q1). This curent must flow

OFF

to the load and Co. Co's current will then be the difference

between IL, and Io.

LM2524D/LM3524D

Ico = IL − I

o

From Figure 13 it can be seen that current will be flowing into

Co for the second half of tON through the first half of t

time, tON/2 + t

The resulting ΔVc or ΔVo is described by:

/2. The current flowing for this time is ΔIL/4.

OFF

OFF

, or a

865019

FIGURE 14. Inductor Current Slope in Step-Down

Regulator

A complete step-down switching regulator schematic, using

the LM3524D, is illustrated in Figure 15. Transistors Q1 and

Q2 have been added to boost the output to 1A. The 5V regulator of the LM3524D has been divided in half to bias the

error amplifier's non-inverting input to within its commonmode range. Since each output transistor is on for half the

period, actually 45%, they have been paralleled to allow

longer possible duty cycle, up to 90%. This makes a lower

possible input voltage. The output voltage is set by:

where VNI is the voltage at the error amplifier's non-inverting

input.

Resistor R3 sets the current limit to:

For best regulation, the inductor's current cannot be allowed

to fall to zero. Some minimum load current Io, and thus inductor current, is required as shown below:

Figures 16, 17 and show a PC board layout and stuffing diagram for the 5V, 1A regulator of Figure 15. The regulator's

performance is listed in Table 1.

www.national.com 14

LM2524D/LM3524D

*Mounted to Staver Heatsink No. V5-1.

Q1 = BD344

Q2 = 2N5023

L1 = >40 turns No. 22 wire on Ferroxcube No. K300502 Torroid core.

FIGURE 15. 5V, 1 Amp Step-Down Switching Regulator

865020

15 www.national.com

LM2524D/LM3524D

TABLE 1.

Parameter Conditions Typical

Characteristics

Output Voltage VIN = 10V, Io = 1A 5V

Switching Frequency VIN = 10V, Io = 1A 20 kHz

Short Circuit VIN = 10V

1.3A

Current Limit

Load Regulation VIN = 10V

3 mV

Io = 0.2 − 1A

Line Regulation

ΔVIN = 10 − 20V,

6 mV

Io = 1A

Efficiency VIN = 10V, Io = 1A 80%

Output Ripple VIN = 10V, Io = 1A 10 mVp-p

FIGURE 16. 5V, 1 Amp Switching Regulator, Foil Side

FIGURE 17. Stuffing Diagram, Component Side

865021

865022

www.national.com 16

THE STEP-UP SWITCHING REGULATOR

Figure 18 shows the basic circuit for a step-up switching regulator. In this circuit Q1 is used as a switch to alternately apply

VIN across inductor L1. During the time, tON, Q1 is ON and

energy is drawn from VIN and stored in L1; D1 is reverse biased and Io is supplied from the charge stored in Co. When

Q1 opens, t

where D1 turns ON. The output current is now supplied

, voltage V1 will rise positively to the point

OFF

through L1, D1 to the load and any charge lost from Co during

tON is replenished. Here also, as in the step-down regulator,

the current through L1 has a DC component plus some ΔIL.

ΔIL is again selected to be approximately 40% of IL. Figure

19 shows the inductor's current in relation to Q1's ON and

OFF times.

LM2524D/LM3524D

865023

FIGURE 18. Basic Step-Up Switching Regulator

FIGURE 19. Relation of Switch Timing to Inductor Current in Step-Up Regulator

Since ΔIL+ = ΔIL−, VINtON = Vot

and neglecting V

SAT

and V

− VINt

OFF

D1

OFF

,

The above equation shows the relationship between VIN, V

and duty cycle.

In calculating input current I

DC current, assume first 100% efficiency:

, which equals the inductor's

IN(DC)

865024

This equation shows that the input, or inductor, current is

larger than the output current by the factor (1 + tON/t

this factor is the same as the relation between Vo and VIN, I

can also be expressed as:

(DC)

OFF

). Since

IN

So far it is assumed η = 100%, where the actual efficiency or

η

will be somewhat less due to the saturation voltage of

MAX

Q1 and forward on voltage of D1. The internal power loss due

to these voltages is the average IL current flowing, or IIN,

through either V

o

loss becomes I

or VD1. For V

SAT

(1V). η

IN(DC)

MAX

= VD1 = 1V this power

SAT

is then:

for η = 100%, P

OUT

= P

IN

This equation assumes only DC losses, however η

ther decreased because of the switching time of Q1 and D1.

17 www.national.com

MAX

is fur-

In calculating the output capacitor Co it can be seen that C

supplies Io during tON. The voltage change on Co during this

time will be some ΔVc = ΔVo or the output ripple of the regulator. Calculation of Co is:

LM2524D/LM3524D

where: Co is in farads, f is the switching frequency,

ΔVo is the p-p output ripple

Calculation of inductor L1 is as follows:

o

where: L1 is in henrys, f is the switching frequency in Hz

To apply the above theory, a complete step-up switching reg-

ulator is shown in Figure 20. Since VIN is 5V, V

VIN. The input voltage is divided by 2 to bias the error

is tied to

REF

amplifier's inverting input. The output voltage is:

The network D1, C1 forms a slow start circuit.

This holds the output of the error amplifier initially low thus

reducing the duty-cycle to a minimum. Without the slow start

circuit the inductor may saturate at turn-on because it has to

supply high peak currents to charge the output capacitor from

0V. It should also be noted that this circuit has no supply rejection. By adding a reference voltage at the non-inverting

input to the error amplifier, see Figure 21, the input voltage

variations are rejected.

The LM3524D can also be used in inductorless switching

regulators. Figure 22 shows a polarity inverter which if connected to Figure 20 provides a −15V unregulated output.

VIN is applied across L1

www.national.com 18

LM2524D/LM3524D

L1 = > 25 turns No. 24 wire on Ferroxcube No. K300502 Toroid core.

FIGURE 20. 15V, 0.5A Step-Up Switching Regulator

FIGURE 21. Replacing R3/R4 Divider in Figure 20 with Reference Circuit Improves Line Regulation

865025

865026

865027

FIGURE 22. Polarity Inverter Provides Auxiliary −15V Unregulated Output from Circuit of Figure 20

19 www.national.com

Physical Dimensions inches (millimeters) unless otherwise noted

LM2524D/LM3524D

Molded Surface-Mount Package (M)

Order Number LM3524DM

NS Package Number M16A

www.national.com 20

Molded Dual-In-Line Package (N)

Order Number LM2524DN or LM3524DN

NS Package Number N16E

LM2524D/LM3524D

21 www.national.com

Notes

For more National Semiconductor product information and proven design tools, visit the following Web sites at:

Products Design Support

Amplifiers www.national.com/amplifiers WEBENCH www.national.com/webench

Audio www.national.com/audio Analog University www.national.com/AU

Clock Conditioners www.national.com/timing App Notes www.national.com/appnotes

Data Converters www.national.com/adc Distributors www.national.com/contacts

Displays www.national.com/displays Green Compliance www.national.com/quality/green

Ethernet www.national.com/ethernet Packaging www.national.com/packaging

Interface www.national.com/interface Quality and Reliability www.national.com/quality

LVDS www.national.com/lvds Reference Designs www.national.com/refdesigns

Power Management www.national.com/power Feedback www.national.com/feedback

Switching Regulators www.national.com/switchers

LDOs www.national.com/ldo

LED Lighting www.national.com/led

PowerWise www.national.com/powerwise

Serial Digital Interface (SDI) www.national.com/sdi

Temperature Sensors www.national.com/tempsensors

Wireless (PLL/VCO) www.national.com/wireless

THE CONTENTS OF THIS DOCUMENT ARE PROVIDED IN CONNECTION WITH NATIONAL SEMICONDUCTOR CORPORATION

(“NATIONAL”) PRODUCTS. NATIONAL MAKES NO REPRESENTATIONS OR WARRANTIES WITH RESPECT TO THE ACCURACY

OR COMPLETENESS OF THE CONTENTS OF THIS PUBLICATION AND RESERVES THE RIGHT TO MAKE CHANGES TO

SPECIFICATIONS AND PRODUCT DESCRIPTIONS AT ANY TIME WITHOUT NOTICE. NO LICENSE, WHETHER EXPRESS,

IMPLIED, ARISING BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS

DOCUMENT.

LM2524D/LM3524D Regulating Pulse Width Modulator

TESTING AND OTHER QUALITY CONTROLS ARE USED TO THE EXTENT NATIONAL DEEMS NECESSARY TO SUPPORT

NATIONAL’S PRODUCT WARRANTY. EXCEPT WHERE MANDATED BY GOVERNMENT REQUIREMENTS, TESTING OF ALL

PARAMETERS OF EACH PRODUCT IS NOT NECESSARILY PERFORMED. NATIONAL ASSUMES NO LIABILITY FOR

APPLICATIONS ASSISTANCE OR BUYER PRODUCT DESIGN. BUYERS ARE RESPONSIBLE FOR THEIR PRODUCTS AND

APPLICATIONS USING NATIONAL COMPONENTS. PRIOR TO USING OR DISTRIBUTING ANY PRODUCTS THAT INCLUDE

NATIONAL COMPONENTS, BUYERS SHOULD PROVIDE ADEQUATE DESIGN, TESTING AND OPERATING SAFEGUARDS.

EXCEPT AS PROVIDED IN NATIONAL’S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, NATIONAL ASSUMES NO

LIABILITY WHATSOEVER, AND NATIONAL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY RELATING TO THE SALE

AND/OR USE OF NATIONAL PRODUCTS INCLUDING LIABILITY OR WARRANTIES RELATING TO FITNESS FOR A PARTICULAR

PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY

RIGHT.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR

SYSTEMS WITHOUT THE EXPRESS PRIOR WRITTEN APPROVAL OF THE CHIEF EXECUTIVE OFFICER AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

Life support devices or systems are devices which (a) are intended for surgical implant into the body, or (b) support or sustain life and

whose failure to perform when properly used in accordance with instructions for use provided in the labeling can be reasonably expected

to result in a significant injury to the user. A critical component is any component in a life support device or system whose failure to perform

can be reasonably expected to cause the failure of the life support device or system or to affect its safety or effectiveness.

National Semiconductor and the National Semiconductor logo are registered trademarks of National Semiconductor Corporation. All other

brand or product names may be trademarks or registered trademarks of their respective holders.

Copyright© 2008 National Semiconductor Corporation

For the most current product information visit us at www.national.com

www.national.com

National Semiconductor

Americas Technical

Support Center

Email: support@nsc.com

Tel: 1-800-272-9959

National Semiconductor Europe

Technical Support Center

Email: europe.support@nsc.com

German Tel: +49 (0) 180 5010 771

English Tel: +44 (0) 870 850 4288

National Semiconductor Asia

Pacific Technical Support Center

Email: ap.support@nsc.com

National Semiconductor Japan

Technical Support Center

Email: jpn.feedback@nsc.com

Loading...

Loading...