查询LM12434CIWM供应商

July 1995

LM12434/LM12

with Serial I/O and Self-Calibration

LM12434/LM12ÀLÓ438 12-Bit

a

Sign Data Acquisition

System with Serial I/O and Self-Calibration

General Description

The LM12434 and LM12ÀLÓ438 are highly integrated Data

Acquisition Systems. Operating on 3V to 5V, they combine a

fully-differential self-calibrating (correcting linearity and zero

errors) 13-bit (12-bit

(ADC) and sample-and-hold (S/H) with extensive analog

and digital functionality. Up to 32 consecutive conversions,

using two’s complement format, can be stored in an internal

32-word (16-bit wide) FIFO data buffer. An internal 8-word

instruction RAM can store the conversion sequence for up

to eight acquisitions through the LM12

multiplexer. The LM12434 has a four-channel multiplexer, a

differential multiplexer output, and a differential S/H input.

The LM12434 and LM12

a

sign resolution and in a supervisory ‘‘watchdog’’ mode

that compares an input signal against two programmable

limits.

Acquisition times and conversion rates are programmable

through the use of internal clock-driven timers. The differential reference voltage inputs can be externally driven for absolute or ratiometric operation.

All registers, RAM, and FIFO are directly accessible through

the high speed and flexible serial I/O interface bus. The

serial interface bus is user selectable to interface with the

following protocols with zero glue logic: MICROWIRE/

TM

PLUS

, Motorola’s SPI/QSPI, Hitachi’s SCI, 8051 Family’s

Serial Port (Mode 0), I

Port.

An evaluation kit for demonstrating the LM12434 and

ÀLÓ

LM12

438 is available.

TRI-STATEÉis a registered trademark of National Semiconductor Corporation.

MICROWIRE/PLUS

Windows

TM

is a registered trademark of Microsoft Corporation.

É

a

sign) analog-to-digital converter

ÀLÓ

438’s eight-input

ÀLÓ

438 can also operate with 8-bit

2

C and the TMS320 Family’s Serial

is a trademark of National Semiconductor Corporation.

Key Specifications

e

f

8 MHzÀL, f

CLK

Y

Resolution 12-bitasign or 8-bitasign

Y

13-bit conversion time 5.5 msÀ7.3 msÓ(max)

Y

9-bit conversion time 2.6 msÀ3.5 msÓ(max)

Y

13-bit Through-put rate

Y

Comparison time (‘‘watchdog’’ mode)

Y

Serial Clock 10 MHzÀ6 MHzÓ(max)

Y

Integral Linearity Error

Y

VINrange GND to V

Y

Power dissipation 45 mWÀ20 mWÓ(max)

Y

Stand-by mode

power dissipation 25 mW

Y

Supply voltage LM12L438 3.3Vg10%

Features

Y

Three operating modes: 12-bitasign, 8-bitasign,

and ‘‘watchdog’’ comparison mode

Y

Single-ended or differential inputs

Y

Built-in Sample-and-Hold

Y

Instruction RAM and event sequencer

Y

8-channel (LM12ÀLÓ438) or 4-channel (LM12434)

multiplexer

Y

32-word conversion FIFO

Y

Programmable acquisition times and conversion rates

Y

Self-calibration and diagnostic mode

Y

Power down output for system power management

Y

Read while convert capability for maximum through-put

e

CLK

140k samples/s

LM12434/8 5V

rate

Applications

Y

Data Logging

Y

Portable Instrumentation

Y

Process Control

Y

Energy Management

Y

Robotics

6 MHz

Ó

À

105k sample/sÓ(min)

À

1.4 ms

1.8 msÓ(max)

g

1 LSB (max)

À

16.5 mWÓ(typ)

g

A

10%

À

L

Ó

438 12-Bit

a

a

Sign Data Acquisition System

Connection Diagrams

28-Pin PLCC Package

*Pin names in ( ) apply to the LM12434

TL/H/11879– 1

Order Number LM12434CIWM, LM12438CIWM, or

Order Number LM12434CIV, LM12438CIV, or

LM12L438CIV

See NS Package Number V28A

C

1995 National Semiconductor Corporation RRD-B30M85/Printed in U. S. A.

TL/H/11879

28-Pin Wide Body SO Package

TL/H/11879– 2

LM12L438CIWM

See NS Package Number M28B

Table of Contents

1.0 FUNCTIONAL DIAGRAMS АААААААААААААААААААААААА3

2.0 ELECTRICAL SPECIFICATIONS АААААААААААААААААА5

2.1 Ratings ААААААААААААААААААААААААААААААААААААААА5

2.1.1 Absolute Maximum Ratings ААААААААААААААААА5

2.1.2 Operating Ratings ААААААААААААААААААААААААА5

2.2 Performance Characteristics ААААААААААААААААААААА5

2.2.1 Converter Static Characteristics ААААААААААААА5

2.2.2 Converter Dynamic Characteristics АААААААААА6

2.2.3 DC CharacteristicsААААААААААААААААААААААААА8

2.2.4 Digital DC CharacteristicsААААААААААААААААААА9

2.3 Digital Switching Characteristics ААААААААААААААААА10

2.3.1 Standard Interface Mode АААААААААААААААААА10

2.3.2 8051 Interface ModeАААААААААААААААААААААА11

2.3.3 TMS320 Interface ModeААААААААААААААААААА12

2

2.3.4 I

C Bus Interface ААААААААААААААААААААААААА13

2.4 Notes on Specifications АААААААААААААААААААААААА14

3.0 ELECTRICAL CHARACTERISTICS ААААААААААААААА15

4.0 TYPICAL PERFORMANCE CHARACTERISTICS ÀÀÀ19

5.0 PIN DESCRIPTIONS АААААААААААААААААААААААААААА23

6.0 OPERATIONAL INFORMATION АААААААААААААААААА27

6.1 Functional Description ААААААААААААААААААААААААА27

6.2 Internal User-Accessible Registers АААААААААААААА31

6.2.1 Instruction RAM АААААААААААААААААААААААААА31

6.2.2 Configuration Register АААААААААААААААААААА38

6.2.3 InterruptsАААААААААААААААААААААААААААААААА38

6.2.4 Interrupt Enable Register АААААААААААААААААА39

6.2.5 Interrupt Status Register АААААААААААААААААА39

6.2.6 Limit Status Register АААААААААААААААААААААА40

6.2.7 Timer ААААААААААААААААААААААААААААААААААА40

6.2.8 FIFOАААААААААААААААААААААААААААААААААААА40

6.3 Instruction SequencerАААААААААААААААААААААААААА41

7.0 DIGITAL INTERFACE ААААААААААААААААААААААААААА43

7.1 Standard Interface Mode ААААААААААААААААААААААА43

7.1.1 Examples of Interfacing to the HPC 46XXX’s

MICROWIRE/PLUS

TM

and 68HC11’s SPI ÀÀÀ50

7.2 8051 Interface ModeААААААААААААААААААААААААААА59

7.2.1 Example of Interfacing to the 8051АААААААААА62

7.3 TMS320 Interface ModeАААААААААААААААААААААААА66

7.3.1 Example of Interfacing to the TMS320C3x ÀÀÀ69

2

7.4 I

C Bus Interface АААААААААААААААААААААААААААААА74

7.4.1 Example of Interfacing to an I

2

C ControllerÀÀÀ76

8.0 ANALOG CONSIDERATIONS АААААААААААААААААААА77

8.1 Reference Voltage АААААААААААААААААААААААААААА77

8.2 Input Range АААААААААААААААААААААААААААААААААА77

8.3 Input Current ААААААААААААААААААААААААААААААААА77

8.4 Input Source Resistance ААААААААААААААААААААААА77

8.5 Input Bypass Capacitance АААААААААААААААААААААА77

8.6 Input Noise ААААААААААААААААААААААААААААААААААА77

8.7 Power Supply Consideration АААААААААААААААААААА77

8.8 PC Board Layout and Grounding ConsiderationÀÀÀÀ78

2

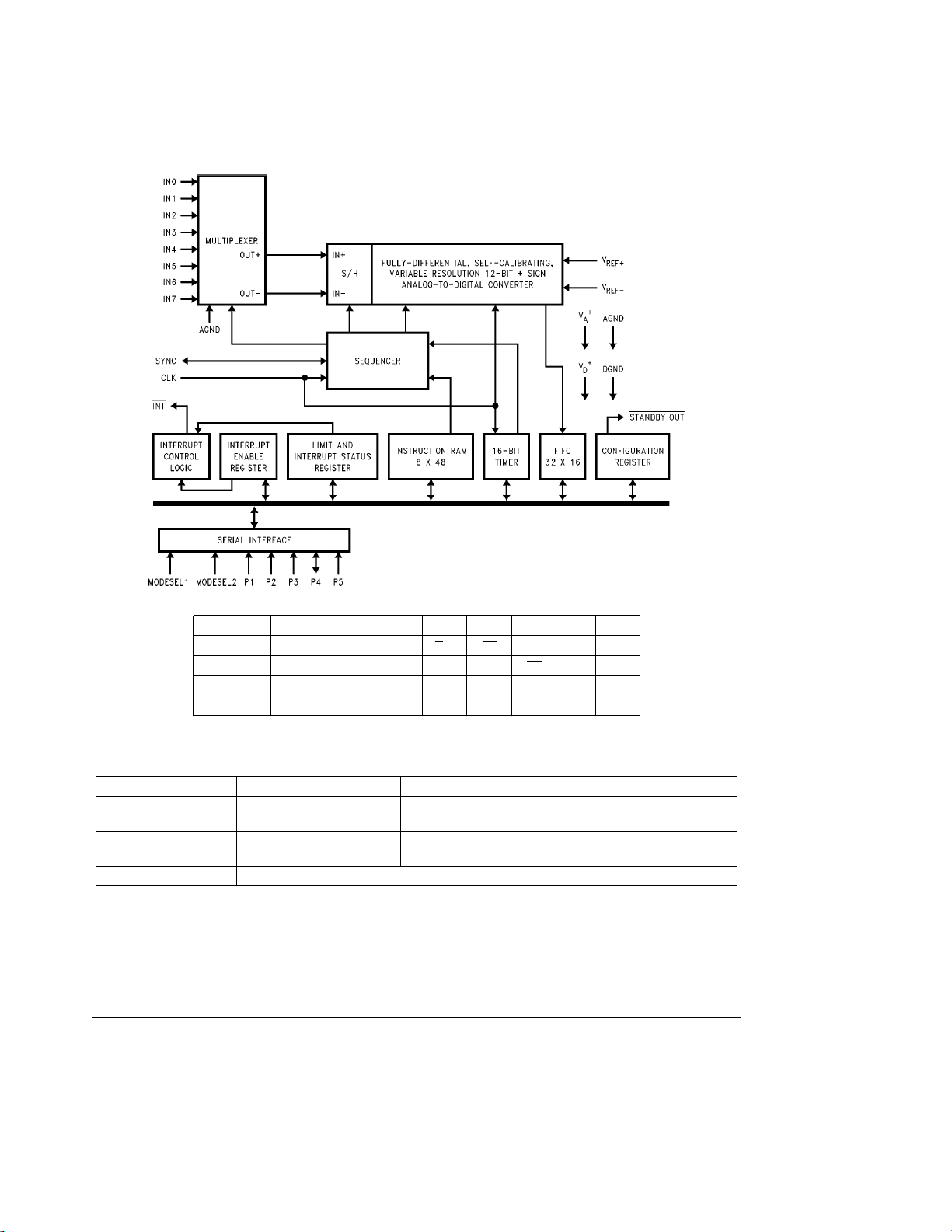

1.0 Functional Diagrams

LM12434

INTERFACE MODESEL1 MODESEL2 P1 P2 P3 P4 P5

Standard 0 1 R

8051 0 0 1* 1* CS RXD TXD

I2C 1 0 SAD0 SAD1 SAD2 SDA SCL

TMS320 1 1 FSR FSX DX DR SCLK

*Internal pull-up

/F CS

DI DO SCLK

Ordering Information (LM12434)

Part Number Package Type NSC Package Number Temperature Range

LM12434CIV 28-Pin PLCC V28A

LM12434CIWM 28-Pin Wide Body SO M28B

3

b

40§Ctoa85§C

b

40§Ctoa85§C

TL/H/11879– 3

1.0 Functional Diagrams (Continued)

LM12

ÀLÓ

438

INTERFACE MODESEL1 MODESEL2 P1 P2 P3 P4 P5

Standard 0 1 R/F CS DI DO SCLK

8051 0 0 1* 1* CS RXD TXD

I2C 1 0 SAD0 SAD1 SAD2 SDA SCL

TMS320 1 1 FSR FSX DX DR SCLK

*Internal pull-up

Ordering Information (LM12ÀLÓ438)

Part Number Package Type NSC Package Number Temperature Range

LM12438CIV 28-Pin PLCC V28A

LM12L438CIV

LM12438CIWM 28-Pin Wide Body SO M28B

LM12L438CIWM

LM12438 Eval Evaluation Board and WindowsÉbased software

4

b

40§Ctoa85§C

b

40§Ctoa85§C

TL/H/11879– 4

2.0 Electrical Specifications

2.1 RATINGS

2.1.1 Absolute Maximum Ratings (Notes1&2)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales

Office/Distributors for availability and specifications.

Supply Voltage (V

a

A

Voltage at Input and Output Pins

except IN0–IN3 (LM12434)

and IN0 – IN7 (LM12

Voltage at Analog Inputs IN0– IN3 (LM12434)

and IN0–IN7 (LM12

a

a

b

V

V

l

A

AGNDbDGND

l

l

D

l

Input Current at Any Pin (Note 3)

Package Input Current (Note 3)

Power Dissipation (T

V Package

a

and V

) 6.0V

D

ÀLÓ

438)

ÀLÓ

438) GNDb5V to V

e

25§C) (Note 4)

A

b

0.3V to V

a

a

a

300 mV

300 mV

g

g

0.3V

a

5V

5mA

20 mA

WM Package

Storage Temperature

b

65§Ctoa150§C

Soldering Information, Lead Temperature (Note 19)

V Package, Vapor Phase (60 seconds)

Infrared (15 seconds)

WM Package, Vapor Phase (60 seconds)

Infrared (15 seconds)

ESD Susceptibility (Note 5) 1.5 kV

2.2 PERFORMANCE CHARACTERISTICS All specifications apply to the LM12434, LM12438, and LM12L438 unless otherwise

noted. Specifications in braces

2.2.1 Converter Static Characteristics The following specifications apply to the LM12434 and LM12

a

e5VÀ

V

D

8.0 MHzÀ6 MHzÓ,R

À

1.25VÓcommon-mode voltage, and minimum acquisition time unless otherwise specified. Boldface limits apply for T

T

J

3.3VÓ, AGNDeDGNDe0V, V

e

T

to T

MIN

MAX

ÀÓ

apply only to the LM12L438.

e

25X, source impedance for V

S

; all other limits T

e

T

A

e

4.096VÀ2.5VÓ,V

a

REF

e

25§C. (Notes 6, 7, 8 and 9)

J

Symbol Parameter Conditions

ILE Positive and Negative Integral After Auto-Cal (Notes 12, 17)

Linearity Error

TUE Total Unadjusted Error After Auto-Cal (Note 12)

Resolution with No Missing Codes After Auto-Cal (Note 12) 13 Bits

DNL Differential Non-Linearity After Auto-Cal

Zero Error After Auto-Cal (Notes 13, 17)

Positive Full-Scale Error After Auto-Cal (Notes 12, 17)

Negative Full-Scale Error After Auto-Cal (Notes 12, 17)

DC Common Mode Error (Note 14)

ILE 8-BitaSign and ‘‘Watchdog’’ (Note 12)

Mode Positive and Negative

Integral Linearity Error

TUE 8-BitaSign and ‘‘Watchdog’’ Mode After Auto-Zero

Total Unadjusted Error

8-BitaSign and ‘‘Watchdog’’ Mode

Resolution with No Missing Codes

2.1.2 Operating Ratings (Notes1&2)

Temperature Range (T

LM12434CIV/LM12

ÀLÓ

LM12434CIWM, LM12

Supply Voltage

a

a

V

,V

A

D

a

a

b

V

V

l

A

AGDNDbDGND

l

l

D

l

Analog Inputs Range GND

V

Input Voltage 1VsV

a

REF

V

Input Voltage 0VsV

b

REF

b

REF

a

V

V

and V

V

a

REF

Common Mode

REF

Range (Note 16) 0.1 V

REF

REF

b

REF

e

0V, 12-bitasign conversion mode, f

b

s

25X, fully-differential input with fixed 2.048V

b

Typical Limits Units

(Note 10) (Note 11) (Limit)

g

g

g

s

T

min

438CIV

ÀLÓ

438CIWMb40§CsT

b

40§CsT

3.0V to 5.5V

s

V

IN

REF

s

V

b

REF

a

s

A

0.35

g

1 LSB

g

0.2

g

0.2

g

0.2

g

0.2

g

2

0.15

1/2

g

g

g

g

g

g

À

g

g

g

REF

1VsV

REF

s

V

REFCM

ÀLÓ

438 for V

1 LSB (max)

1 LSB (max)

1 LSB (max)

2 LSB (max)

2 LSB (max)

3.5 LSB (max)

Ó

4.0

1/2 LSB (max)

1/2 LSB (max)

9 Bits (max)

A

s

s

a

a

s

A

A

a

0.6 V

T

max

s

85§C

s

85§C

100 mV

100 mV

s

V

s

V

b

s

V

a

A

CLK

A

)

a

A

a

A

1V

a

A

a

A

e

e

e

5

2.0 Electrical Specifications (Continued)

2.2.1 Converter Static Characteristics The following specifications apply to the LM12434 and LM12

a

e5VÀ

V

D

8.0 MHzÀ6 MHzÓ,R

À

1.25VÓcommon-mode voltage, and minimum acquisition time unless otherwise specified. Boldface limits apply for T

e

T

J

3.3VÓ, AGNDeDGNDe0V, V

T

to T

MIN

e

25X, source impedance for V

S

; all other limits T

MAX

e

A

Symbol Parameter Conditions

DNL 8-BitaSign and ‘‘Watchdog’’ Mode

Differential Non-Linearity

8-BitaSign and ‘‘Watchdog’’ Mode After Auto-Zero

Zero Error

e

4.096VÀ2.5VÓ,V

a

REF

e

T

25§C. (Notes 6, 7, 8 and 9) (Continued)

J

REF

a

and V

REF

REF

b

e

0V, 12-bitasign conversion mode, f

b

s

25X, fully-differential input with fixed 2.048V

Typical Limits Units

(Note 10) (Note 11) (Limit)

g

g

8-BitaSign and ‘‘Watchdog’’ Positive

and Negative Full-Scale Error

8-BitaSign and ‘‘Watchdog’’ Mode

DC Common Mode Error

Multiplexer Channel-to-Channel

Matching

V

a

IN

V

b

IN

b

V

a

IN

b

V

a

IN

Non-Inverting GND V (min)

Input Range

Inverting GND V (min)

Input Range

V

Differential Input Voltage Range

b

IN

V

Common Mode Input Voltage Range GND V (min)

b

IN

g

g

2

a

a

e

PSS Power Supply Zero Error V

Sensitivity Full-Scale Error V

(Note 15) Linearity Error

C

REF

C

IN

2.2.2 Converter Dynamic Characteristics The following specifications apply only to the LM12434 and LM12438 for V

a

V

D

throughput rate

2.048V

for T

V

/V

REF

a

Input Capacitance 85 pF

b

REF

Selected Multiplexer Channel Input

Capacitance

e

5V, AGNDeDGNDe0V, V

e

T

J

133.3 kHz, R

e

T

MIN

to T

À

1.25VÓcommon-mode voltage, and minimum acquisition time unless otherwise specified. Boldface limits apply

e

A

e

S

; all other limits T

MAX

e

a

REF

25X, source impedance for V

4.096V, V

e

T

A

J

A

REF

REF

e

25§C. (Notes 6, 7, 8 and 9)

Symbol Parameter Conditions

e

V

5Vg10%,

D

e

4.096V, V

a

e

0V, 12-bitasign conversion mode, f

b

REF

a

and V

REF

REF

e

b

b

Typical Limits Units

(Note 10) (Note 11) (Limit)

g

GNDg0.25

s

25X, fully-differential input with fixed

CLK Duty Cycle 50 %

40 % (min)

60 % (max)

t

C

t

A

Conversion Time 13-Bit Resolution,

Sequencer State S5

9-Bit Resolution,

Sequencer State S5

Acquisition Time Sequencer State S7

(Figure 10)

(Figure 10)

(Figure 10)

44 (t

21 (t

(Programmable) Minimum for 13-Bits 9 (t

Maximum for 13-Bits (D

Minimum for 9-Bits

e

15) 39 (t

(Figure 10)

2(t

Maximum for 9-Bits (De15) 2 (t

) 44 (t

CLK

) 21 (t

CLK

) 9(t

CLK

) 39 (t

CLK

) 2(t

CLK

) 32 (t

CLK

)a50 ns (max)

CLK

)a50 ns (max)

CLK

)a50 ns (max)

CLK

)a50 ns (max)

CLK

)a50 ns (max)

CLK

)a50 ns (max)

CLK

ÀLÓ

438 for V

0.1

g

1/2 LSB (max)

g

1/2 LSB (max)

g

1/2 LSB (max)

0.15

0.05

g

1/8 LSB

0.05 LSB

a

V

A

a

V

A

a

b

V

A

a

V

A

a

V

A

0.05

g

g

1.0 LSB (max)

g

1.5 LSB (max)

0.2 LSB

75 pF

CLK

e

t

CLK

A

CLK

V (max)

V (max)

V (min)

V (max)

V (max)

A

e

8.0 MHz,

CLK Period

a

e

e

e

A

a

e

6

2.0 Electrical Specifications (Continued)

2.2.2 Converter Dynamic Characteristics The following specifications apply only to the LM12434 and LM12438 for V

a

e

V

5V, AGNDeDGNDe0V, V

D

throughput rate

2.048V common-mode voltage, and minimum acquisition time unless otherwise specified. Boldface limits apply for T

e

T

T

J

MIN

to T

e

MAX

133.3 kHz, R

; all other limits T

e

25X, source impedance for V

S

Symbol Parameter Conditions

t

t

Auto-Zero Time Sequencer State S2

Z

Full Calibration Time Sequencer State S2

CAL

Throughput Rate (Note 18)

t

‘‘Watchdog’’ Mode Comparison Time Sequencer States S6, S4,

WD

SNR Signal-to-Noise Ratio, V

Differential Input f

SNR Signal-to-Noise Ratio, V

Single-Ended Input f

SINAD Signal-to-NoiseaDistortion Ratio, V

Differential Input f

SINAD Signal-to-NoiseaDistortion Ratio, V

Single-Ended Input f

THD Total Harmonic Distortion, V

Differential Input f

THD Total Harmonic Distortion, V

Distortion, Single-Ended Input f

ENOB Effective Number of Bits, V

Differential Input f

ENOB Effective Number of Bits, V

Single-Ended Input f

SFDR Spurious Free Dynamic Range, V

Differential Input f

SFDR Spurious Free Dynamic Range, V

Single-Ended Input f

A

REF

e

4.096V, V

a

e

e

T

25§C. (Notes 6, 7, 8 and 9) (Continued)

J

REF

e

b

REF

(Figure 10)

(Figure 10)

(Figure 10)

and S5

e

g

4.096V (Note 20)

IN

e

1 kHz 79 dB

IN

e

f

10 kHz 79 dB

IN

e

f

62 kHz 70 dB

IN

e

4.096 V

IN

e

IN

e

f

IN

e

f

IN

e

IN

e

IN

e

f

IN

e

f

IN

e

IN

e

IN

e

f

IN

e

f

IN

e

IN

e

IN

e

f

IN

e

f

IN

e

IN

e

IN

e

f

IN

e

f

IN

e

IN

e

IN

e

f

IN

e

f

IN

e

IN

e

IN

e

f

IN

e

f

IN

e

IN

e

IN

e

f

IN

e

f

IN

e

IN

e

IN

e

f

IN

e

f

IN

p-p

1 kHz 71 dB

10 kHz 71 dB

62 kHz 67 dB

g

4.096V (Note 20)

1 kHz 79 dB

10 kHz 78 dB

62 kHz 67 dB

4.096 V

p-p

1 kHz 71 dB

10 kHz 70 dB

62 kHz 64 dB

g

4.096V (Note 20)

1 kHz

10 kHz

62 kHz

4.096 V

p-p

1 kHz

10 kHz

62 kHz

g

4.096V (Note 20)

1 kHz 12.6 Bits

10 kHz 12.2 Bits

62 kHz 12.1 Bits

4.096 V

p-p

1 kHz 11.3 Bits

10 kHz 11.2 Bits

62 kHz 10.8 Bits

g

4.096V (Note 20)

1 kHz 90 dBc

10 kHz 86 dBc

62 kHz 76 dBc

4.096V V

1 kHz 90 dBc

p-p

10 kHz 85 dBc

62 kHz 72 dBc

0V, 12-bitasign conversion mode, f

and V

a

s

25X, fully-differential input with fixed

b

REF

Typical Limits Units

(Note 10) (Note 11) (Limit)

76 (t

4944 (t

) 76 (t

CLK

) 4944 (t

CLK

)a50 ns (max)

CLK

CLK

142 140

11 (t

) 11 (t

CLK

b

90 dBc

b

85 dBc

b

71 dBc

b

88 dBc

b

82 dBc

b

67 dBc

)a50 ns (max)

CLK

e

CLK

)a50 ns (max)

a

A

8.0 MHz,

A

kHz

(min)

e

e

7

2.0 Electrical Specifications (Continued)

2.2.2 Converter Dynamic Characteristics The following specifications apply only to the LM12434 and LM12438 for V

a

e

V

5V, AGNDeDGNDe0V, V

D

throughput rate

2.048V common-mode voltage, and minimum acquisition time unless otherwise specified. Boldface limits apply for T

e

T

T

J

MIN

to T

e

MAX

133.3 kHz, R

; all other limits T

e

S

Symbol Parameter Conditions

IMD Two Tone Intermodulation Distortion V

Differential Input f

IMD Two Tone Intermodulation Distortion V

Single Ended Input f

Multiplexer Channel-to-Channel Crosstalk V

t

PU

t

WU

2.2.3 DC Characteristics The following specifications apply to the LM12434 and LM12ÀLÓ438 for V

AGND

otherwise specified. Boldface limits apply for T

Power-Up Time 10 ms

Wake-Up Time (Note 22) 2 ms

e

DGNDe0V, V

REF

a

e

4.096VÀ2.5VÓ,V

and 8)

Symbol Parameter Conditions

a

I

D

a

I

A

I

ST

a

V

Supply Current f

D

a

V

Supply Current f

A

Stand-By Supply Current (I

D

Multiplexer ON-Channel Leakage Current V

Multiplexer OFF-Channel Leakage Current V

e

4.096V, V

a

REF

25X, source impedance for V

e

e

T

A

25§C. (Notes 6, 7, 8 and 9) (Continued)

J

b

REF

e

IN

e

19.190 kHz

1

e

f

19.482 kHz

2

e

IN

e

19.190 kHz

1

e

f

19.482 kHz

2

e

IN

e

f

IN

f

CROSSTALK

LM12434 MUXOUT Only

and LM12438 MUX

plus Converter (Note 21)

e

0V, f

b

REF

e

e

T

A

a

a

a

I

) Stand-By Mode Selected

A

T

J

e

8 MHzÀ6 MHz

CLK

e

f

SCLK

e

f

SCLK

e

8 MHzÀ6 MHz

CLK

e

f

SCLK

e

f

Stopped 5À5

CLK

e

f

8 MHzÀ6 MHz

CLK

e

f

SCLK

e

f

Stopped 1.4À0.8

CLK

e

f

8 MHzÀ6 MHz

CLK

a

e

5.5V

A

ON-Channel

OFF-Channel

ON-Channel

OFF-Channel

a

e

5.5VÀ3.3V

A

ON-Channele5.5VÀ3.3V

OFF-Channele0V 0.1 1.0À3.0ÓmA (max)

ON-Channel

OFF-Channel

e

0V, 12-bitasign conversion mode, f

and V

a

REF

s

25X, fully-differential input with fixed

b

REF

CLK

Typical Limits Units

(Note 10) (Note 11) (Limit)

g

4.096V (Note 20)

4.096 V

pp

4.096 V

PP

5 kHz

e

40 kHz

e

8.0 MHzÀ6 MHzÓand minimum acquisition time unless

CLK

to T

MIN

; all other limits T

MAX

b

82 dBc

b

80 dBc

b

90 dBc

a

e

V

A

D

e

e

T

A

25§C. (Notes 6, 7

J

Typical Limits Units

(Note 10) (Note 11) (Limit)

Ó

Stopped 2.0À1.4

10 MHzÀ8 MHz

Ó

Ó

4.0À2.0

2.8À2.2

Ó

Ó

5.0À2.5ÓmA (max)

Ó

4.0À3.5ÓmA (max)

Stopped

Ó

10 MHzÀ8 MHz

e

e

e

e

e

e

Ó

Ó

5.5V

0V 0.1 1.0À3.0ÓmA (max)

0V

5.5V 1.0À3.0ÓmA (max)

Ó

Ó

0V

5.5VÀ3.3V

Ó

120À50

1.4À0.8

Ó

Ó

Ó

Ó

1.0À3.0ÓmA (max)

a

e

e5VÀ

a

A

8.0 MHz,

A

3.3V],

mA (max)

mA (max)

mA (max)

mA (max)

mA (max)

e

e

8

2.0 Electrical Specifications (Continued)

2.2.3 DC Characteristics The following specifications apply to the LM12434 and LM12

e

AGND

DGNDe0V, V

otherwise specified. Boldface limits apply for T

and 8) (Continued)

REF

a

e

4.096VÀ2.5VÓ,V

REF

A

e

b

e

T

J

0V, f

e

e

8.0 MHzÀ6 MHzÓand minimum acquisition time unless

CLK

T

to T

MIN

MAX

Symbol Parameter Conditions

R

ON

Multiplexer ON-Resistance LM12434

e

V

5V 650 1000 X(max)

IN

e

V

2.5V 700 1000 X(max)

IN

e

V

0V 630 1000 X(max)

IN

ÀLÓ

438 for V

; all other limits T

Typical Limits Units

(Note 10) (Note 11) (Limit)

Multiplexer Channel-to-Channel LM12434

R

matching V

ON

2.2.4 Digital DC Characteristics The following specifications apply to the LM12434 and LM12ÀLÓ438 for V

À

3.3VÓ, AGNDeDGNDe0V, unless otherwise specified. Boldface limits apply for T

e

limits T

e

T

A

25§C. (Notes 6, 7 and 8)

J

e

5V

IN

e

V

2.5V

IN

e

V

0V

IN

Symbol Parameter Conditions

a

a

e

V

IN(1)

V

IN(0)

I

IN(1)

I

IN(0)

C

IN

V

OUT(1)

V

OUT(0)

I

OUT

Logical ‘‘1’’ Input Voltage V

Logical ‘‘0’’ Input Voltage V

Logical ‘‘1’’ Input Current V

Logical ‘‘0’’ Input Current V

A

a

A

IN

IN

All Digital Inputs 6 pF

Logical ‘‘1’’ Output Voltage V

Logical ‘‘0’’ Output Voltage V

TRI-STATEÉOutput Leakage Current V

I

OUT

I

OUT

I

OUT

V

a

A

a

A

OUT

OUT

e

V

5.5VÀ3.6V

D

a

e

e

V

4.5VÀ3.0V

D

e5VÀ

e

e

eb

eb

e

e

e

e5VÀ

Ó

3.3V

0V

a

e

V

4.5VÀ3.0V

D

360 mA 2.4 V (min)

10 mA 4.25À2.9

a

e

V

4.5VÀ3.0V

D

1.6 mA

0V

Ó

3.3V

g

1.0%

g

1.0%

g

1.0%

A

Typical Limits Units

(Note 10) (Note 11) (Limit)

Ó

Ó

0.005 1.0 mA (max)

b

0.005

Ó

Ó

b

0.05

0.05 3.0 mA (max)

a

A

e

T

A

g

g

g

e

e

T

T

J

MIN

a

e

e5VÀ

V

D

e

25§C. (Notes 6, 7

J

3.3V],

3.0% (max)

3.0% (max)

3.0% (max)

a

a

e

e

V

A

D

to T

; all other

MAX

2.0 V (min)

0.8 V (max)

b

1.0 mA (max)

Ó

V (min)

0.4 V (max)

b

3.0 mA (max)

5V

9

2.0 Electrical Specifications (Continued)

2.3 DIGITAL SWITCHING CHARACTERISTICS The following specifications apply to the LM12434 and LM12

ae5VÀ

e

V

D

Boldface limits apply for T

2.3.1 Standard Mode Interface (MICROWIRE/PLUS

Symbol

(See

Figure

t

1

t

2

t

3

t

4

t

5

t

6

t

7

t

8

*CLK is the main clock input to the device, pin number 24 in PLCC package or pin number 2 in SO package.

3.3VÓ, AGNDeDGNDe0V, CL(load capacitance) on output linese80 pF unless otherwise specified.

Below) (Note 10) (Note 11) (Limit)

e

e

T

T

A

J

MIN

to T

, all other limits for T

MAX

TM

, SCI and SPI/QSPI)

Parameter Conditions

e

e

T

A

25§C. (Notes 6, 7, and 9)

J

Typical Limits Units

SCLK (Serial Clock) Period 100À125

CS Set-Up Time to First

Clock Transition

DI Valid Set-Up Time to Data

Capture Transition of SCLK

DI Valid Hold Time to Data

Capture Transition of SCLK

DO Hold Time from Data Shift

Transition of SCLK

À30Ó

25

0 ns (min)

40 ns (min)

À

70

120

CS Hold Time from Last SCLK

Transition in a Read or Write Cycle 25 ns (min)

(Excluding Burst Read Cycle)

CS Inactive to CS Active Again

3

SCLK Idle Time between the

End of the Command Byte

Transfer and the Start of the (min)*

3

Data Transfer in Read Cycles

ÀLÓ

Ó

Ó

438 for V

ns (min)

ns (min)

ns (max)

CLK Cycle

(min)*

CLK Cycle

a

A

TL/H/11879– 18

10

2.0 Electrical Specifications (Continued)

2.3 DIGITAL SWITCHING CHARACTERISTICS The following specifications apply to the LM12434 and LM12

ae5VÀ

e

V

D

Boldface limits apply for T

2.3.2 8051 Interface Mode

Symbol

(See

Figure

t

9

t

10

t

11

t

12

t

13

t

14

t

15

t

16

*CLK is the main clock input to the device, pin number 24 in PLCC package or pin number 2 in SO package.

3.3VÓ, AGNDeDGNDe0V, CL(load capacitance) on output linese80 pF unless otherwise specified.

Below) (Note 10) (Note 11) (Limit)

e

e

T

T

to T

A

J

MIN

, all other limits for T

MAX

Parameter Conditions

e

e

T

A

25§C. (Notes 6, 7, and 9) (Continued)

J

Typical Limits Units

TXD (Serial Clock Period) 125À250

CS Set-Up Time to First

Clock Transition

Data in Valid Set-Up Time to

TXD Clock High

Data in Valid Hold Time

from TXD Clock High

Data Out Hold Time

from TXD Clock High

À40Ó

25

40 ns (min)

À90Ó

40

À

70

120

CS Hold Time from Last TXD

High in a Read or Write Cycle 25À50

Ó

(Excluding Burst Read Cycle)

CS Inactive to CS Active Again

3

SCLK Idle Time between the

End of the Command Byte

Transfer and the Start of the (min)*

3

Data Transfer in Read Cycles

Ó

Ó

ÀLÓ

438 for V

ns (min)

ns (min)

ns (min)

ns (max)

ns (min)

CLK Cycle

(min)*

CLK Cycle

a

A

TL/H/11879– 21

11

2.0 Electrical Specifications (Continued)

2.3 DIGITAL SWITCHING CHARACTERISTICS The following specifications apply to the LM12434 and LM12

ae5VÀ

e

V

D

Boldface limits apply for T

2.3.3 TMS320 Interface Mode

Symbol

(See

Figure

t

22

t

23

t

24

t

25

t

26

t

27

t

28

t

29

3.3VÓ, AGNDeDGNDe0V, CL(load capacitance) on output linese80 pF unless otherwise specified.

Below) (Note 10) (Note 11) (Limit)

e

e

T

T

to T

A

J

MIN

, all other limits for T

MAX

Parameter Conditions

e

e

T

A

25§C. (Notes 6, 7, and 9) (Continued)

J

Typical Limits Units

SCLK (Serial Clock) Period 125À167

FSX Set-Up Time to SCLK High 30À50

FSX Hold Time from SCLK High 10 ns (min)

Data in (DX) Set-Up

Time to SCLK Low

Data in DX Hold Time from

SCLK Low

0 ns (min)

À

30

120

FSR High from SCLK High 80À100

FSR Low from SCLK Low 120 ns (max)

SCLK High to Data

Out (DR) Change

90 ns (max)

ÀLÓ

Ó

Ó

Ó

Ó

438 for V

ns (min)

ns (min)

ns (min)

ns (max)

a

A

TL/H/11879– 23

12

2.0 Electrical Specifications (Continued)

2.3 DIGITAL SWITCHING CHARACTERISTICS The following specifications apply to the LM12434 and LM12

ae5VÀ

e

V

D

Boldface limits apply for T

2

2.3.4 I

C Bus Interface

The switching characteristics of the LM12434/8 for I2C bus interface fully meets or exceeds the published specifications of the

2

I

C bus. The following parameters given here are the timing relationships between SCL and SDA signals related to the

LM12434/8. They are not the I

Symbol

(See

Figure

t

17

t

18

t

19

t

20

t

21

3.3VÓ, AGNDeDGNDe0V, CL(load capacitance) on output linese80 pF unless otherwise specified.

Below) (Note 10) (Note 11) (Limit)

e

e

T

T

to T

A

J

MIN

2

C bus specifications.

, all other limits for T

MAX

Parameter Conditions

e

e

T

A

25§C. (Notes 6, 7, and 9) (Continued)

J

Typical Limits Units

SCL (Clock) Period 2500À10000

Data in Set-Up Time to SCL High 30 ns (min)

Data Out Stable after SCL Low 900À1400

SDA Low Set-Up Time to SCL

Low (Start Condition)

SDA High Hold Time after SCL

High (Stop Condition)

ÀLÓ

438 for V

Ó

ns (min)

Ó

ns (max)

40 ns (min)

40 ns (min)

a

A

TL/H/11879– 22

13

2.0 Electrical Specifications (Continued)

2.4 NOTES ON SPECIFICATIONS

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for which the device is

functional, but do not guarantee specific performance limits. For guaranteed specifications and test conditions, see the Electrical Characteristics. The guaranteed

specifications apply only for the test conditions listed. Some performance characteristics may degrade when the device is not operated under the listed test

conditions.

Note 2: All voltages are measured with respect to GND, unless otherwise specified. GND specifies either AGND and/or DGND and V

a

.

or V

D

Note 3: When the input voltage (V

5 mA. The 20 mA maximum package input current rating allows the voltage at any four pins, with an input current of 5 mA, to simultaneously exceed the power

supply voltages.

Note 4: The maximum power dissipation must be derated at elevated temperatures and is dictated by T

junction to ambient thermal resistance), and T

or the number given in the Absolute Maximum Ratings, whichever is lower. For this device, T

H

JA

package, when board mounted, is 70

) at any pin exceeds the power supply rails (V

IN

(ambient temperature). The maximum allowable power dissipation at any temperature is PD

A

C/W and in the WM package, when board mounted, is 60§C/W.

§

IN

k

GND or V

a

IN

Jmax

l

e

a

(V

or V

)), the current at that pin should be limited to

A

D

(maximum junction temperature), HJA(package

Jmax

150§C, and the typical thermal resistance (HJA) of the V

Note 5: Human body model, 100 pF discharged through a 1.5 kX resistor.

Note 6: Two on-chip diodes are tied to each analog input through a series resistor, as shown below. Input voltage magnitude up to 5V above V

GND will not damage the part. However, errors in the A/D conversion can occur if these diodes are forward biased by more than 100 mV. As an example, if V

, the full-scale input voltage must bes4.6 VDCto ensure accurate conversions.

4.5 V

DC

a

specifies either V

e

max

(T

Jmax

a

or 5V below

A

a

and/

A

b

TA)/

a

A

is

a

Note 7: V

conversion/comparison accuracy. Refer to Section 8.0 for a detailed discussion on grounding the DAS.

Note 8: Accuracy is guaranteed when operating the LM12434/LM12

Note 9: With the test condition for V

Note 10: Typicals are at T

Note 11: Limits are guaranteed to National’s AOQL (Average Output Quality Level).

Note 12: Positive integral linearity error is defined as the deviation of the analog value, expressed in LSBs, from the straight line that passes through positive full-

scale and zero. For negative integral linearity error the straight line passes through negative full-scale and zero. (See

Note 13: Zero error is a measure of the deviation from the mid-scale voltage (a code of zero), expressed in LSB. It is the average value of the code transitions

b

between

Note 14: The DC common-mode error is measured with both the inverted and non-inverted inputs shorted together and driven from 0V to 5V

measured value is referred to the resulting output value when the inputs are driven with a 2.5V

a

and V

A

must be connected together to the same power supply voltage and bypassed with separate capacitors at each Vapin to assure

D

e

A

1to0and0toa1 (see

ÀLÓ

b

V

a

REF(VREF

25§C and represent most likely parametric norm.

Figure 6

).

) given asa4.096V, the 12-bit LSB is 1 mV and the 8-bit/‘‘Watchdog’’ LSB is 19 mV.

b

REF

438 at f

CLK

e

8 MHzÀ6 MHzÓ.

À

1.65VÓsignal.

Note 15: Power Supply Sensitivity is measured after Auto-Zero and/or Auto-Calibration cycle has been completed with V

Note 16: V

Note 17: The device self-calibration technique ensures linearity and offset errors as specified, but noise inherent in the self-calibration process will result in a

repeatability uncertainty of

Note 18: The Throughput Rate is for a single instruction repeated continuously while reading data during conversions with a serial clock frequency f

À

8 MHzÓ. Sequencer states 0 (1 clock cycle), 1 (1 clock cycle), 7 (9 clock cycles) and 5 (44 clock cycles) are used (see

conversion. The Throughput Rate is f

Note 19: See AN-450 ‘‘Surface Mounting Methods and their Effect on Product Reliability’’ for other methods of soldering surface mount devices.

Note 20: Each input referenced to the other input sees a

done by applying two sine waves with 180

Note 21: Multiplexer channel-to-channel crosstalk is measured by placing a sinewave with a frequency of f

frequency of f

generated by doing a FFT on these samples. The crosstalk is then calculated by subtracting the amplitude of the frequency component at 40 kHz from the

amplitude of the fundamental frequency at 5 kHz.

Note 22: Interrupt 7 is set to return an out-of-standby flag 10 ms (typ) after the device is requested to come out of standby mode. However, characterization has

shown the devices will perform to their rated specifications in 2 ms.

(Reference Voltage Common Mode Range) is defined as (V

REFCM

g

0.10 LSB.

(MHz)/N, where N is the number of clock cycles/conversion.

CLK

g

4.096V (8.192 V

CROSSTALK

phase shift and 4.096 V

§

e

40 kHz on the remaining channels. 8192 conversions are performed on the channel with the 5 kHz signal. A special response is

(between GND and V

p-p

a

V

REF

b

A

)/2. See

a

) to the inputs.

a

REF

) sine wave. However the voltage at each input stays within the supply rails. This is

p-p

TL/H/11879– 5

Figures 5b

and5c).

a

a

and V

and4.

A

Figures 3

Figure 10

e

5 kHz on one channel and another sinewave with a

IN

at the specified extremes.

D

) for a total of 56 clock cycles per

SCLK

À

3.3VÓ. The

e

10 MHz

14

3.0 Electrical Characteristics

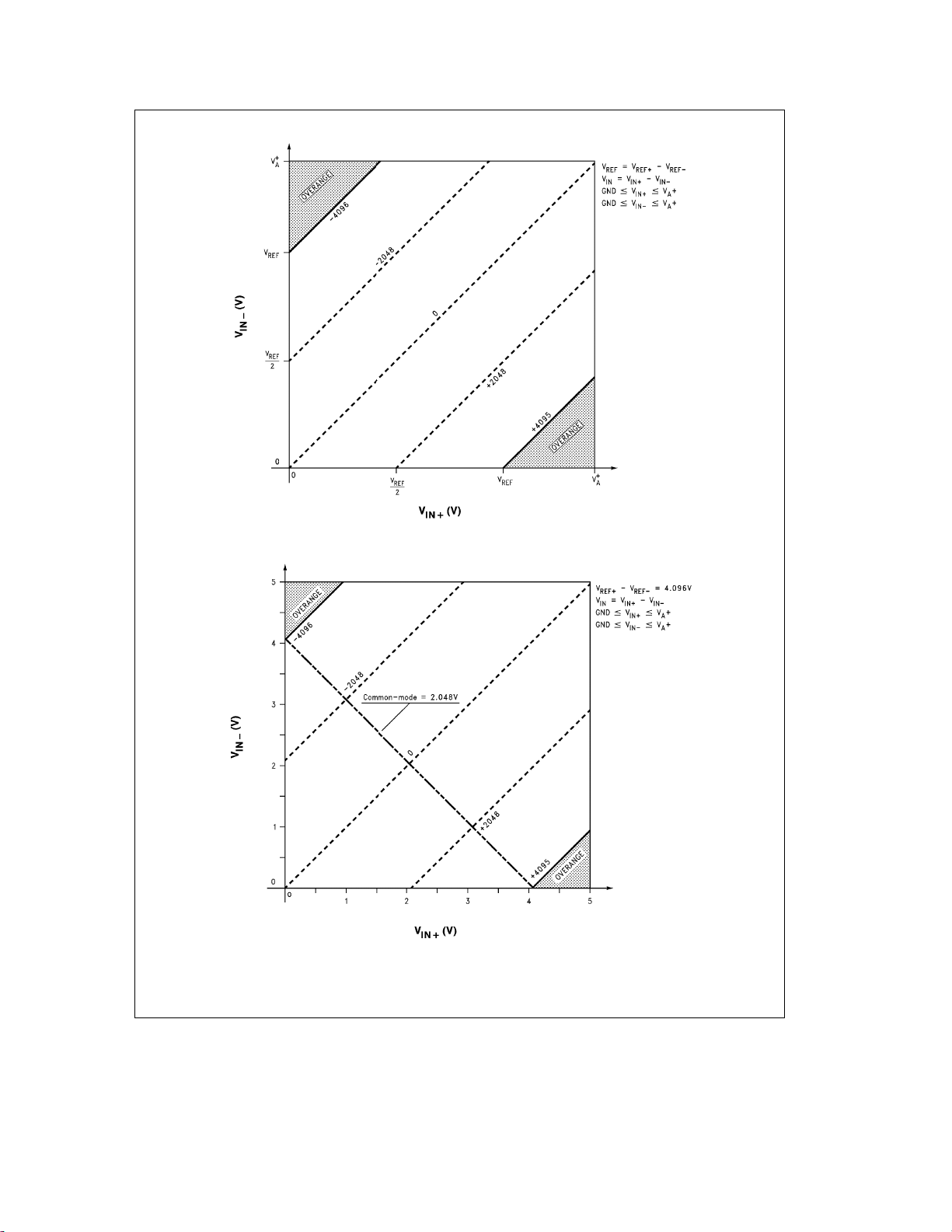

FIGURE 1. Output Digital Code vs the Operating Input Voltage Range (General Case)

FIGURE 2. Output Digital Code vs the Operating Input Voltage Range for V

REF

e

TL/H/11879– 6

TL/H/11879– 7

4.096V

15

3.0 Electrical Characteristics (Continued)

FIGURE 3. V

FIGURE 4. V

Operating Range (General Case)

REF

Operating Range for V

REF

TL/H/11879– 8

a

e

5V

A

TL/H/11879– 9

16

3.0 Electrical Characteristics (Continued)

FIGURE 5a. Transfer Characteristic

FIGURE 5b. Simplified Error Curve vs Output Code without Auto-Calibration or Auto-Zero Cycles

TL/H/11879– 10

TL/H/11879– 11

17

3.0 Electrical Characteristics (Continued)

FIGURE 5c. Simplified Error Curve vs Output Code after Auto-Calibration Cycle

TL/H/11879– 13

FIGURE 6. Offset or Zero Error Voltage

TL/H/11879– 12

18

4.0 Typical Performance Characteristics

The following curves apply for 12-bitasign mode after auto-calibration unless otherwise specified. The performance for 8-bit

sign and ‘‘watchdog’’ modes is equal to or better than shown. (Note 9)

Linearity Error Change

vs CLK Frequency

Linearity Error Change

vs Temperature

Linearity Error Change

vs Reference Voltage

a

Linearity Error Change

vs Supply Voltage

Full-Scale Error Change

vs Reference Voltage

Zero Error Change

vs Temperature

Full-Scale Error Change

vs CLK Frequency

Full-Scale Error

vs Supply Voltage

Zero Error Change

vs Reference Voltage

Full-Scale Error Change

vs Temperature

Zero Error Change

vs CLK Frequency

Zero Error Change

vs Supply Voltage

TL/H/11879– 14

19

4.0 Typical Performance Characteristics (Continued)

a

The following curves apply for 12-bit

sign and ‘‘watchdog’’ modes is equal to or better than shown. (Note 9)

sign mode after auto-calibration unless otherwise specified. The performance for 8-bit

a

Analog Supply Current

vs Temperature

The following curves apply to the LM12L438 in 12-bitasign mode after auto-calibration unless otherwise specified. R

e

T

A

100 kHz.

25§C, V

a

a

e

e

V

A

3.3V, V

D

REF

e

Unipolar Spectral Response with

10 kHz Sine Wave at 0 dB

*Digital Supply Current

vs Clock Frequency

*Free-running conversion and SPI mode data

read at 200 ns SCLK period.

2.5V, f

CLK

e

6 MHz, f

SCLK

e

8 MHz, V

Unipolar Spectral Response with

20 kHz Sine Wave at 0 dB

*Digital Supply Current

vs Temperature

e

2.5Vx0 dB, Sampling Rate

IN

TL/H/11879– 15

e

50X,

S

e

The following curves apply for 12-bitasign mode after auto-calibration unless otherwise specified. R

a

a

e

V

A

e

V

5V, V

D

e

4.096V, f

REF

CLK

Unipolar Special Response

with 41.2 kHz Sine Wave

at 0 dB Reading Data

during Conversion f

e

8 MHz, f

SCLK

SCLK

e

e

10 MHz, V

10 MHz

e

4.096Vx0 dB, Sampling Ratee100 kHz.

IN

Unipolar Special Response

with 41.2 kHz Sine Wave

at 0 dB Reading Data

between Conversions

20

TL/H/11879– 84

e

50X,T

S

TL/H/11879– 55

e

25§C,

A

4.0 Typical Performance Characteristics (Continued)

a

The following curves apply for 12-bit

e

R

S

Sampling Rate

50X,T

e

A

e

133.3 kHz.

25§C, V

a

A

Unipolar Signal-to-Noise Ratio

vs Input Frequency

sign mode after auto-calibration unless otherwise specified.

a

e

e

V

5V, V

D

e

4.096V, f

REF

Unipolar Signal-to-Noise

a

CLK

Distortion

e

8 MHz, f

vs Input Frequency

SCLK

e

10 MHz, V

Unipolar Total

Harmonic Distortion

vs Input Frequency

e

4.096Vx0 dB,

IN

Unipolar Spurious Free

Dynamic Range

vs Input Frequency

Unipolar Spectral Response

with 40.283 kHz

Sine Wave at 0 dB

Unipolar Spectral Response

with 62.256 kHz

Sine Wave at 0 dB

Unipolar Spectral Response

with 1.025 kHz

Sine Wave at 0 dB

Unipolar Spectral Response

with 40.283 kHz

Sine Wave at

Unipolar Two Tone Spectral

Response with f1

e

f2

b

0.5 dB

e

19.190 kHz and

19.482 kHz Sine Wave

Unipolar Spectral Response

with 10.010 kHz

Sine Wave at 0 dB

Unipolar Spectral Response

with 40.283 kHz

Sine Wave at

b

1.0 dB

TL/H/11879– 17

TL/H/11879– 24

21

4.0 Typical Performance Characteristics (Continued)

a

The following curves apply for 12-bit

e

R

S

Sampling Rate

50X,T

e

A

e

133.3 kHz.

25§C, V

a

A

Bipolar Signal-to-Noise Ratio

vs Input Frequency

sign mode after auto-calibration unless otherwise specified.

a

e

e

V

5V, V

D

e

4.096V, f

REF

Bipolar Signal-to-Noise

a

Distortion vs

CLK

e

8 MHz, f

Input Frequency

SCLK

e

10 MHz, V

e

g

IN

Bipolar Total Harmonic

Distortion vs Input Frequency

4.096Vx0 dB,

Bipolar Spurious Free

Dynamic Range

vs Input Frequency

Bipolar Spectral Response

with 40.283 kHz

Sine Wave at 0 dB

Bipolar Spectral Response

with 62.25 kHz

Sine Wave at 0 dB

Bipolar Spectral Response

with 1.025 kHz

Sine Wave at 0 dB

Bipolar Spectral Response

with 40.283 kHz

Sine Wave at

Bipolar Two Tone Spectral

Response with f1

e

f2

b

0.5 dB

e

19.190 kHz and

19.482 kHz Sine Waves

Bipolar Spectral Response

with 10.010 kHz

Sine Wave at 0 dB

Bipolar Spectral Response

with 40.283 kHz

Sine Wave at

b

1.0 dB

TL/H/11879– 25

TL/H/11879– 26

22

5.0 Pin Descriptions

TABLE I. LM12ÀLÓ438 Pin Description

Pin Number

PLCC SO

Pkg. Pkg.

1 7 DGND Digital ground. This is the device’s digital supply ground connection. It should be connected

2 8 IN0 These are the eight analog inputs to the multiplexer. For each conversion to be performed, the

3 9 IN1 active channels are selected according to the instruction RAM programming. Any individual

4 10 IN2 channel can be selected for a single-ended conversion referenced to AGND, or any pair of

5 11 IN3 channels, whether adjacent or non adjacent, can be selected as a fully differential input pairs.

6 12 IN4

7 13 IN5

8 14 IN6

9 15 IN7

10 16 V

11 17 V

12 18 AGND Analog ground. This is the device’s analog supply ground connection. It should be connected

13 19 V

14 20 DGND Digital ground. See above definition.

15 21 V

16 22 voltage range is

17 23 P5 P1 –P5 are the multi-function serial interface input or output pins that have different assignments

18 24 P4 Serial interface input/output: Standard: DO

19 25 P3 Serial interface input: Standard: DI

Pin Name Description

through a low resistance and low inductance ground return to the system power supply.

a

REF

Positive reference input. The operating voltage range for this input is 1VsV

Figures 3

and4). In order to achieve 12-bit performance this pin should be by passed to AGND

at least with a parallel combination of a 10 mF and a 0.1 mF (ceramic) capacitor. The capacitors

should be placed as close to the part as possible.

b

REF

Negative reference input. The operating voltage range for this input is 0 VsV

b

1V (See

Figures 3

and4). In order to achieve 12-bit performance, this pin should be bypassed

to AGND at least with a parallel combination of a 10 mF and a 0.1 mF (ceramic) capacitor. The

capacitors should be placed as close to the part as possible.

through a low resistance and low inductance ground return to the system power supply.

a

A

Analog supply. This is the supply connection for the analog circuitry. The device operating supply

voltage range is

a

3.0V toa5.5V. Accuracy is guaranteed only if the V

connected to the same potential. In order to achieve 12-bit performance, this pin should be

bypassed to AGND at least with a parallel combination of a 10 mF and a 0.1 mF (ceramic)

capacitor. The capacitors should be placed as close to the part as possible.

a

D

Digital supply. This is the supply connection for the analog circuitry. The device operating supply

a

3.0V toa5.5V. The device accuracy is guaranteed only if the V

are connected to the same potential. In order to achieve 12-bit performance this pin should be

by passed to DGND at least with a parallel combination of a 10 mF and a 0.1 mF (ceramic)

capacitor. The capacitors should be placed as close to the part as possible.

depending on the selected mode.

Serial interface input: Standard: SCLK

8051: TXD

2

I

C: SCL

TMS320: DR

8051: RXD

I2C: SDA

TMS320: DR

8051: CS

2

I

C: SAD2

TMS320: DX

a

a

s

V

REF

a

and V

A

REF

A

b

s

V

REF

a

are

D

a

and V

A

(See

a

D

a

23

5.0 Pin Descriptions (Continued)

TABLE I. LM12

Pin Number

PLCC SO

Pin Name Description

Pkg. Pkg.

20 26 P2 Serial interface input: Standard: CS

21 27 P1 Serial interface input: Standard: R/F (Clock rise/fall)

22 28 MODESEL2 Serial mode selection inputs. The logic states of these inputs determine the operation of

23 1 MODESEL1 the serial mode as shown below. The standard mode covers the National’s MICROWIRE,

Motorola’s SPI and Hitachi’s SCl protocols.

MODESEL1, MODESEL2: 01 Standard mode

24 2 CLK The device main clock input. The operating range of clock frequency is 0.05 MHz to

10.0 MHz. The device accuracy is guaranteed only for the clock frequencies indicated in

the specification tables.

25 3 INT Interrupt output. This is an active low output. An interrupt is generated any time a non-

masked interrupt condition takes place. There are seven different conditions that can

generate an interrupt. (Refer to Section 6.2.4). The interrupt is set high (inactive) by reading

the interrupt status register. This output can drive up to 100 pF of capacitive loads. An

external buffer should be used for driving higher capacitive loads.

26 4 SYNC Synchronization input/output. SYNC is an input if the Configuration Register’s SYNC I/O bit

is ‘‘0’’ and output when the bit is ‘‘1’’. When sync is an input, a rising edge on this pin

causes the internal S/H to hold the input signal and a conversion cycle or a comparison

cycle (depending on the programmed instruction) to be started. (The conversion or

comparison actually begins on the rising edge of the CLK immediately following the rising

edge of sync.) When output, it goes high at the start of a conversion or a comparison cycle

and returns low when the cycle is completed. At power up the SYNC pin is set as an input.

When used as an output it can drive up to 100 pF of capacitive loads. An external buffer

should be used for driving higher capacitive loads.

27 5 STANDBYOUT Stand-by output. This is an active low output. STANDBYOUT will be activated when the

LM12ÀLÓ438 is put into stand-by mode through the Configuration Register’s stand-by bit. It

is used to force any other devices in the system (signal conditioning circuitry, for example)

to go into power-down mode. This is done by connecting the ‘‘shutdown’’, ‘‘powerdown’’,

‘‘standby’’, etc. pins of the other ICs to STANDBYOUT

ICs do not have the power-down inputs, STANDBYOUT

through an electronic switch. Note that the logic polarity of the STANDBYOUT

opposite to that of the stand-by bit in the Configuration Register.

28 6 V

a

D

Digital supply. See above definition.

LM12434 Pin Description. (Same as LM12

LM12434 Pin Description (Same As LM12

6 12 MUXOUT

7 13 MUXOUT

8 14 S/H IN

9 15 S/H IN

b

b

a

Multiplexer outputs. These are the LM12434’s externally available analog MUX output pins.

a

Analog inputs are directed to these outputs based on the Instruction RAM programming.

Sample-and-hold inputs. These are the inverting and non-inverting inputs of the sampleand-hold. LM12434 allows external analog signal conditioning circuits to be placed

between MUX outputs and S/H inputs.

ÀLÓ

438 Pin Description (Continued)

8051: 1

2

I

C: SAD1

TMS320: FSX

8051: 1

2

I

C: SAD0

TMS320: FSR

00 8051

10 I

2

11 TMS320

ÀLÓ

438 with the exceptions of the following pins.)

ÀLÓ

438 with the exception of the following pins.)

C

. In those cases where the peripheral

can be used to turn off their power

is the

24

6.0 Operational Information

6.1 FUNCTIONAL DESCRIPTION

ÀLÓ

The LM12434 and LM12

Acquisition Systems that include a fully differential 12-bitplus-sign self-calibrating analog-to-digital converter (ADC)

with a two’s-complement output format, an 8-channel

ÀLÓ

(LM12

438) or a 4-channel (LM12434) analog multiplexer, a first-in-first-out (FIFO) register that can store 32 conversion results, and an Instruction RAM that can store as

many as eight instructions to be sequentially executed. The

LM12434 also has a differential multiplexer output and a

differential S/H input. All of this circuitry operates on only a

a

single

5V power supply. For simplicity, the DAS (Data Acquisition System) abbreviation is used as a generic name for

the members of the LM12434 and LM12

thoughout this discussion.

Figure 7

illustrates the functional block diagram or user programming model of the DAS. Note that this diagram is not

meant to reflect the actual implementation of the internal

building blocks. The model consists of the following blocks:

Ð A flexible analog multiplexer with differential output at

the front end of the device.

Ð A fully-differential, self-calibrating 12-bit

converter with sample and hold.

Ð A 32-word FIFO register as the output data buffer.

Ð An 8-word instruction RAM that can be programmed to

repeatedly perform a series of conversions and comparisons on selected input channels.

Ð A series of registers for overall control and configuration

of DAS operation and indication of internal operational

status.

Ð Interrupt generation logic to request service from the

processor under specified conditions.

Ð Serial interface logic for input/output operations be-

tween the DAS and the processor. All the registers

shown in the diagram can be read and most of them can

also be written to by the user through the input/output

block.

Ð A controller unit that manages the interactions of the

different blocks inside the DAS and controls the conversion, comparison and calibration sequences.

The DAS has 3 different modes of operation:

Ð 12-bit

a

sign conversion

Ð 8-bitasign conversion

Ð 8-bitasign comparison (also called ‘‘watchdog’’ mode)

The fully differential 12-bit-plus-sign ADC uses a charge redistribution topology that includes calibration capabilities.

Charge re-distribution ADCs use a capacitor ladder in place

of a resistor ladder to form an internal DAC. The DAC is

used by a successive approximation register to generate

intermediate voltages between the voltages applied to

b

V

and V

REF

pared against the sampled analog input voltage as each bit

a

. These intermediate voltages are com-

REF

is charged.

Conversion accuracy is ensured by an internal auto-calibration system. Two different calibration modes are available;

one compensates for offset voltage, or zero error, while the

other corrects the ADC’s linearity and offset errors.

When correcting offset only, the offset error is measured

once and a correction coefficient is created. During the full

calibration, the offset error is measured eight times, aver-

438 are multi-functional Data

ÀLÓ

438 family

a

sign ADC

aged, and a correction coefficient is created. After completion of either calibration mode, the offset correction coefficient is stored in an internal offset correction register.

The LM12434 and LM12

ÀLÓ

438’s overall linearity correction

is achieved by correcting the internal DAC’s capacitor mismatch. Each capacitor is compared eight times against all

remaining smaller value capacitors and any errors are averaged. A correction coefficient is then created and stored in

one of the thirteen linearity correction registers. A state machine, using patterns stored in 16-bit x 8-bit ROM, executes

each calibration algorithm.

Once the converter has been calibrated, an arithmetic logic

unit (ALU) uses the offset correction coefficient and the 13

linearity correction coefficients to reduce the conversion’s

offset error and linearity error, in the background, during the

a

12-bit

‘‘watchdog’’ comparisons use only the offset coefficient. An

8-bit

needed for a 12-bit

sign conversion. 8-bitasign conversions and

a

sign conversion requires less than half the time

a

sign conversion.

Diagnostic Mode

A diagnostic mode is available that allows verification of the

ÀLÓ

LM12

438’s operation. The diagnostic mode is disabled

in the LM12434. This mode internally connects the voltages

present at the V

b

and V

IN

Diagnostic bit (Bit 11) in the Configuration register to a ‘‘1’’.

a

and V

REF

S/H inputs. This mode is activated by setting the

b

pins to the internal V

REF

IN

More information concerning this mode of operation can be

found in Section 6.2.2.

Watchdog Mode

In the watchdog mode no conversion is performed, but the

DAS samples an input and compares it with the values of

the two limits stored in the Instruction RAM. If the input

voltage is above or below the limits (as defined by the user)

an interrupt can be generated to indicate a fault condition.

The LM12434 and LM

ÀLÓ

438’s ‘‘watchdog’’ mode is used

to monitor a single-ended or differential signal’s amplitude

and generate an output if the signal’s amplitude falls outsidde of a programmable ’‘window’’. Each watchdog instruction includes two limits. An interrupt can be generated if the

input signal is above or below either of the two limits. This

allows interrupt to be generated when analog voltage inputs

are ‘‘outside the window’’. After a ‘‘watchdog’’ mode interrupt, the processor can then request a conversion on the

input signal and read the signal’s magnitude.

Analog Input Multiplexer

The analog input multiplexer can be configured for any combination of single-ended or fully differential operation. Each

input is referenced to AGND when a multiplexer channel

operates in the single-ended mode. Fully differential analog

input channels are formed by pairing any two channels together.

The LM12434’s multiplexer outputs and S/H inputs

(MUXOUT

a

, MUXOUTband S/H INa, S/H INb) provide

the option for additional analog signal processing after the

multiplexer. Fixed-gain amplifiers, programmable-gain amplifiers, filters, and other processing circuits can operate on

the multiplexer output signals before they are applied to the

ADC’s S/H inputs. If external processing is not used, connect MUXOUT

a

to S/H INaand MUXOUTbto S/H INb.

a

25

6.0 Operational Information (Continued)

FIGURE 7. The LM12

(a) The LM12ÀLÓ438

ÀLÓ

438 and LM12434 Functional Block Diagram (Programming Model)

(b) The LM12434

TL/H/11879– 27

TL/H/11879– 28

26

6.0 Operational Information (Continued)

Acquisition Time

The LM12434 and LM12

to operate at its minimum acquisition time (1.125[1.5

for a 12-bit

ance, R

MHz). When 60À80ÓXkR

nal S/H’s acquisition time can be increased to a maximum

of 4.88

a

, is less than or equal to 60À80ÓX (f

S

À

6.5Óms (12asign bits, f

provide sufficient time for the sampling capacitor to charge.

See Section 6.2.1 (Instruction RAM ‘‘00’’) Bits 12–15 for

more information.

Instruction Register

The INSTRUCTION RAM is divided into 8 separate words,

each with 48 (3 x 16) bit length. Each word is separated into

three 16-bit sections. Each word has a unique address and

different sections of the instruction word are selected by the

2-bit RAM pointer (RP) in the configuration register. As

shown in

Figure 7

Instructions, Limits

tion holds operational (12-bit

dog) information such as the input channels to be selected,

the mode of operation to be performed for each instruction,

and the duration of the acquisition period. The other two

sections are used in the watchdog mode and the userdefined limits are stored in them. Each watchdog instruction

has 2 limits associated with it (usually a low limit and a high

limit, but two low limits or two high limits may be programmed instead). The DAS starts executing from instruction 0 and moves through the next instructions up to any

user-specified instruction and then ‘‘loop back’’ to instruction 0. It is not necessary to execute all 8 instructions in the

instruction loop. The cycle may be repeatedly executed until

stopped by the user. The processor should access the Instruction RAM only when the instruction sequencer is

stopped.

FIFO Register

The FIFO Register stores the conversion results. This register is ‘‘Read only’’ and all the locations are accessed

through a single address. Each time a conversion is performed the result is stored in the FIFO and the FIFO’s internal write pointer points to the next location. The pointer rolls

back to location 1 after a Write to location 32. The same

flow occurs when reading from the FIFO. The internal FIFO

Writes and the external FIFO Reads do not affect each other’s pointer locations.

ÀLÓ

438’s internal S/H is designed

sign conversion) when the source imped-

s

4.17À5.56ÓkX, the inter-

S

e8À6Ó

CLK

CLK

Ó

s

8À6

MHz) to

ms

, the Instruction RAM sections are labeled

Ý

1 and LimitsÝ2. The Instruction sec-

a

sign, 8-bitasign or watch-

Microprocessor overhead is reduced through the use of the

internal conversion FIFO. Thirty-two consecutive conversions can be completed and stored in the FIFO without any

microprocessor intervention. The microprocessor can, at

any time, interrogate the FIFO and retrieve its contents. It

Ó

can also wait for the LM12434 and LM12

interrupt when the FIFO is full or after any number (

conversions have been stored.

Configuration Register

The CONFIGURATION Register is the main ‘‘control panel’’

of the DAS. Writing 1s and 0s to the different bits of the

Configuration Register commands the DAS start or stop the

sequencer, reset the pointers and flags, go into ‘‘standby’’

mode for low power consumption, calibrate offset and linearity, and select sections of the RAM.

Other Registers

The INTERRUPT ENABLE Register lets the user activate up

to 7 sources for interrupt generation (refer to Section 6.2.3).

It also holds two user-programmable values. One is the

number of conversions to be stored in the FIFO register

before the generation of the Data Ready interrupt. The other

value is the instruction number that generates an interrupt

when the sequencer reaches that instruction.

The INTERRUPT STATUS and LIMIT STATUS Registers

are ‘‘Read only’’ registers. They are used as vectors to indicate which conditions have generated the interrupt and

what watchdog limit boundaries have been passed. Note

that the bits are set in the status registers upon occurrence

of their corresponding interrupt conditions, regardless of

whether the condition is enabled for external interrupt generation.

The TIMER Register can be programmed to insert a delay

before execution of each instruction. A bit in the instruction

register enables or disables the insertion of the delay before

the execution of an instruction.

Serial I/O

A very flexible serial synchronous interface is provided to

facilitate reading from and writing to the LM12434 and

ÀLÓ

LM12

438’s registers. The communication between the

LM12434 and LM12

ÀLÓ

438 and microcontrollers, microprocessors and other circuitry is accomplished through this

serial interface. The serial interface is designed to directly

communicate with the synchronous serial interfaces of the

most popular microprocessors with no extra hardware requirement. The interface has been also designed to simplify

software development.

ÀLÓ

438 to issue an

s

32) of

27

6.0 Operational Information (Continued)

Instruction RAM (Read/Write)

e

RP

10 RPe01 RPe00

Ý

Limits

2 LimitsÝ1 Instructions

ADDe0000 ADDe0000 ADDe0000

ADDe0001 ADDe0001 ADDe0001

ADDe0010 ADDe0010 ADDe0010

ADDe0011 ADDe0011 ADDe0011

ADDe0100 ADDe0100 ADDe0100

ADDe0101 ADDe0101 ADDe0101

ADDe0110 ADDe0110 ADDe0110

ADDe0111 ADDe0111 ADDe0111

RPeRAM Pointer

ADDeA3, A2, A1, A0 CONFIGURATION REGISTER ADDe1000

INTERRUPT ENABLE REGISTER ADDe1001

INTERRUPT STATUS REGISTER ADDe1010

TIMER REGISTER ADDe1011

CONVERSION FIFO ADDe1100

(32 Locations, 1 address) ----------------------------

LIMIT STATUS REGISTER ADDe1101

FIGURE 8. LM12434 and LM12ÀLÓ438 User Accessible Registers

----------------------------

----------------------------

(Read/Write)

(Read/Write)

(Read Only)

(Read/Write)

(Read Only)

(Read Only)

28

6.0 Operational Information (Continued)

6.2 INTERNAL USER-ACCESSIBLE REGISTERS

Figure 8

shows the LM12434 and LM12ÀLÓ438 internal user

accessible registers.

each register. All the registers are accessible through the

serial interface bus. Following are the descriptions of the

registers and their bit assignments.

6.2.1 Instruction RAM

The instruction RAM holds up to eight sequentially executable instructions. Each 48-bit long instruction is divided into

three 16-bit sections. READ and WRITE operations can be

issued to each 16-bit section using the instruction’s address

and the 2-bit ‘‘RAM pointer’’ in the Configuration register.

The eight instructions are located at addresses 0000

through 0111. They can be accessed and programmed in

random order.

Read/Write Operations

Any Instruction RAM READ or WRITE can affect the sequencer’s operation.

Therefore, the Sequencer should be stopped by setting the

RESET bit to a ‘‘1’’ or by resetting the START bit in the

Configuration Register and waiting for the current instruction

to finish execution before any Instruction RAM READ or

WRITE is initiated.

A soft RESET should be issued by writing a ‘‘1’’ to the Configuration Register’s RESET bit after any READ or WRITE to

the Instruction RAM.

The three sections in the Instruction RAM are selected by

the Configuration Register’s 2-bit ‘‘RAM Pointer’’, bits D8

and D9. The first 16-bit Instruction RAM section is selected

with the RAM Pointer equal to ‘‘00’’. This section can be

programmed for multiplexer channel selection, conversion

resolution, watchdog mode operation, timer or external

SYNC use, pause in instruction and loop bit as described

later. The second 16-bit section holds ‘‘watchdog’’ limit

its sign, and a bit that determines whether an interrupt can

be generated when the input is greater than or less than

Ý

limit

1. The third 16-bit section holds ‘‘watchdog’’ limitÝ2,

its sign, and the ‘‘greater than/less than’’ selection bit.

Instruction RAM, Bank 1, RP

Bit 0 is the LOOP bit. After an instruction with Bit 0 set to a

‘’1’’ is executed, the sequencer will loop back to instruction

0. The next instruction to be executed will be instruction 0.

Bit 1 is the PAUSE bit. When the PAUSE bit is set (‘‘1’’), the

Sequencer will stop after reading the current instruction.

The instruction will not execute at this point, and the START

bit in the Configuration register will reset to ‘‘0’’. Setting the

PAUSE also causes an interrupt to be issued. The Sequencer is restarted by placing a ‘‘1’’ in the Configuration register’s Bit 0 (Start bit).

After the Instruction RAM has been programmed and the

RESET bit is set to ‘‘1’’, the Sequencer retrieves Instruction

0, decodes it, and waits for a ‘‘1’’ to be placed in the Configuration register’s START bit. The START bit value of ‘‘1’’

‘‘overrides’’ the action of Instruction 0’s PAUSE bit when

the Sequencer is started. Once started, the Sequencer executes Instruction 0 and retrieves, decodes, and executes

Figure 9

shows the bit assignment for

e

00

Ý

each of the remaining instructions. With the PAUSE bit set

to ‘‘1’’ in instruction 0, no PAUSE Interrupt (INT 5) is generated the first time the Sequencer executes Instruction 0.

When the Sequencer encounters a LOOP bit or completes

all eight instructions, Instruction 0 is retrieved and decoded.

A set PAUSE bit in Instruction 0 now halts the Sequencer

before the instruction is executed. If Pause

tion loop continues to execute.

Bits 2 –4 select which of the eight input channels (IN0 – IN7)

will be the non-inverting inputs to the LM12

(See Table III.) They select which of the four input channels

(for IN0– IN3) will be the non-inverting inputs to the

LM12434’s ADC. (See Table IV.)

Bits 5–7 select which of the seven input channels (IN1 to

IN7) will be the inverting inputs to the LM12

(See Table III.) They select which of the three input channels (IN1 –IN4) will be the inverting inputs to the LM12434’s

ADC. (See Table IV.) Fully differential operation is created

by selecting two multiplexer channels, one non-inverting

and the other inverting. A code of ‘‘000’’ selects ground as

the inverting input for single ended operation.

Bit 8 is the SYNC bit. Setting Bit 8 to ‘‘1’’ causes the Sequencer to hold operation at the internal S/H’s acquisition

cycle and to wait until a rising edge appears at the SYNC

pin. When a rising edge appears, the S/H goes into the

‘‘Hold’’ mode and the ADC begins to perform a conversion

on the next rising edge of CLK. To make the SYNC pin

serve as an input, the Configuration register’s ‘‘SYNC I/O’’

bit (Bit 7) must be set to a ‘‘0’’. With SYNC configured as an

input, it is possible to synchronize the start of a conversion

to external events. When SYNC pin is defined as an output

(SYNC I/O bit

e

1) the SYNC bit in the instruction registers

must not be set to 1.

When the LM12434 and LM12

‘‘watchdog’’ mode with external synchronization, two rising

1,

edges on the SYNC input are required to initiate the two

ÀLÓ

438 are used in the

comparisons that are performed during a watchdog instruction. The first rising edge initiates the comparison of the

selected analog input signal with Limit

tion RAM ‘‘01’’) and the second rising edge initiates the

comparison of the same analog input signal with Limit

(found in Instruction RAM ‘‘10’’).

Bit 9 is the TIMER bit. When Bit 9 is set to ‘‘1’’, the Sequencer will halt until the internal 16-bit Timer counts down

to zero. During this time interval, no ‘‘watchdog’’ comparisons or analog-to-digital conversions will be performed.

Bit 10 selects the ADC conversion resolution. Setting Bit 10

to ‘‘1’’ selects 8-bit

a

bit

sign.

a

sign and resetting to ‘‘0’’ selects 12-

Bit 11 is the ‘‘watchdog’’ comparison mode enable bit.

When operating in the ‘‘watchdog’’ comparison mode, the

selected analog input signal is compared with the programmable values stored in Limit

Ý

1 and LimitÝ2 (see Instruction RAM ‘‘01’’ and Instruction RAM ‘‘10’’). Setting Bit 11 to

‘‘1’’ causes two comparisons of the selected analog input

signal, one with each of the two stored limits. When Bit 11 is

reset to ‘‘0’’, an 8-bit

a

sign or 12-bitasign (depending on

the state of Bit 10 of Instruction RAM ‘‘00’’) conversion of

the input signal can take place.

e

0, the instruc-

ÀLÓ

438’s ADC.

ÀLÓ

438 ADC.

Ý

1 (found in Instruc-

Ý

2

29

6.0 Operational Information (Continued)

A4 A3 A2 A1 Purpose Type D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

0000

0111

0000

0111

0000

0111

1000

1001

1010

1011

1100

1101

*LM12434 (Refer to Table IV).

²

LM12ÀLÓ438 only. Must be set to ‘‘0’’ for the LM12434.

X No interrupt is associated with this bit. When programming the interrupt Enable Register, bit-6 is a don’t care condition.

to

to

to

Instruction RAM

(RAM Pointer

Instruction RAM

(RAM Pointer

Instruction RAM

(RAM Pointer

Configuration R/W

Register

Interrupt Enable