现货库存、技术资料、百科信息、热点资讯,精彩尽在鼎好!

LM1276

150 MHz I

2

C Compatible RGB Preamplifier with Internal

512 Character OSD ROM, 512 Character RAM and 4

DACs

General Description

The LM1276 pre-amp is an integrated CMOS CRT preamp

with an integrated Hi-Brite Window generator, 512 Character

OSD generator, and an auto size measurement circuit. It has

2

C compatible interface, which allows control of all the

an I

parameters necessary to directly setup and adjust the gain

and contrast in the CRT display. Brightness and bias can be

controlled through the DAC outputs, which are well matched

to the LM2479 and LM2480 integrated bias clamp ICs. The

LM1276 preamp is also designed to be compatible with the

LM247x high gain driver family.

Black level clamping of the video signal is carried out directly

on the AC coupled input signal into the high impedance

preamplifier input, thus eliminating the need for additional

clamp capacitors. Horizontal and vertical blanking of the

outputs is provided. Vertical blanking is optional and its

duration is register programmable.

The IC is packaged in an industry standard 28-lead narrow

DIP molded plastic package.

Features

n Integrated Hi-Brite Window Generator operation

independent of the Microcontroller.

n Programmable Video Emphasis Control.

n 8 Programmable Hi-Brite Windows.

n Hi-Brite Enhancement on full screen, window only, or

outside of windows.

n Fully addressable 512 Character OSD.

n Internal 512 character OSD ROM usable as either (a)

384 2-color plus 128 4-color characters, (b) 640 2-color

characters, or (c) some combination in between.

n Internal 512 character RAM.

May 2005

n Enhanced I

allow versatile Page RAM access.

n OSD Window Fade In/Fade Out.

n OSD Variable Tone Transparency.

n 3 Bit OSD Contrast.

n Video Data detection for Auto Centering & Sizing.

n 2 Bit Adjustable Burn-in screen Mode with no video

input.

n 4 DAC outputs (8-bit resolution) for bus controlled CRT

bias and brightness.

n Spot killer, which blanks the video outputs when V

falls below the specified threshold.

n Suitable for use with discrete or integrated clamp, with

software configurable brightness mixer.

n Programmable ABL Onset for Multi-Limit Applications.

n 4-Bit Programmable start position for internal Horizontal

Blanking.

n Horizontal blanking and OSD synchronization directly

from deflection signals. The blanking can be disabled, if

desired.

n Vertical blanking and OSD synchronization directly from

sync signals. The blanking width is register

programmable and can be disabled, if desired.

n Power Saving Mode with 65% power reduction.

n Matched to LM246x, LM247x drivers, and LM2479/80

bias IC’s.

2

C compatible microcontroller interface to

CC

Applications

n Ideal preamplifier IC for total Hi-Brite Solution.

n 17" and 19” bus controlled monitors with OSD.

n Low cost systems with LM247x drivers.

Character RAM and 4 DACs

LM1276 150 MHz I

2

C Compatible RGB Preamplifier with Internal 512 Character OSD ROM, 512

© 2005 National Semiconductor Corporation DS200969 www.national.com

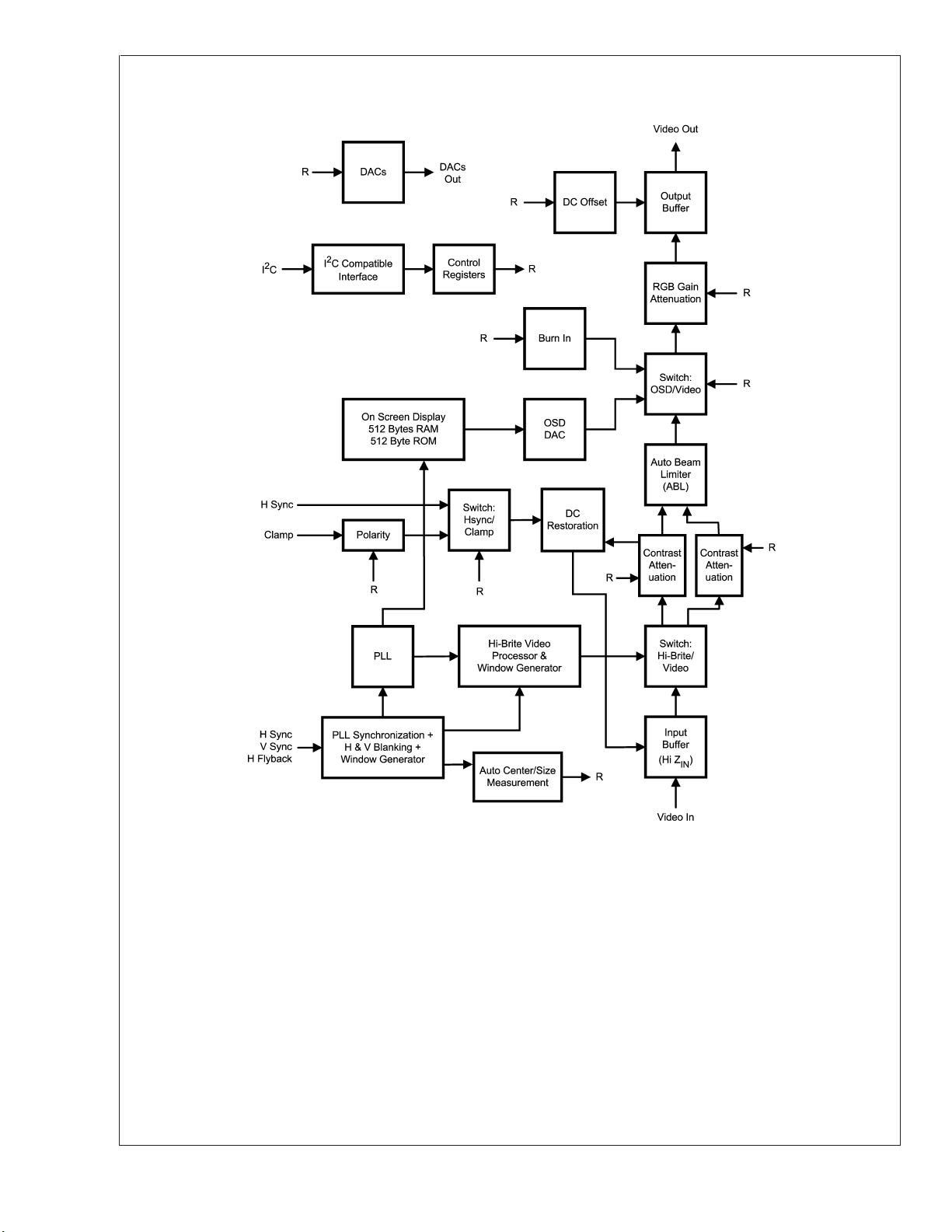

Internal Block Diagram

LM1276

FIGURE 1. Block Diagram

www.national.com 2

20096961

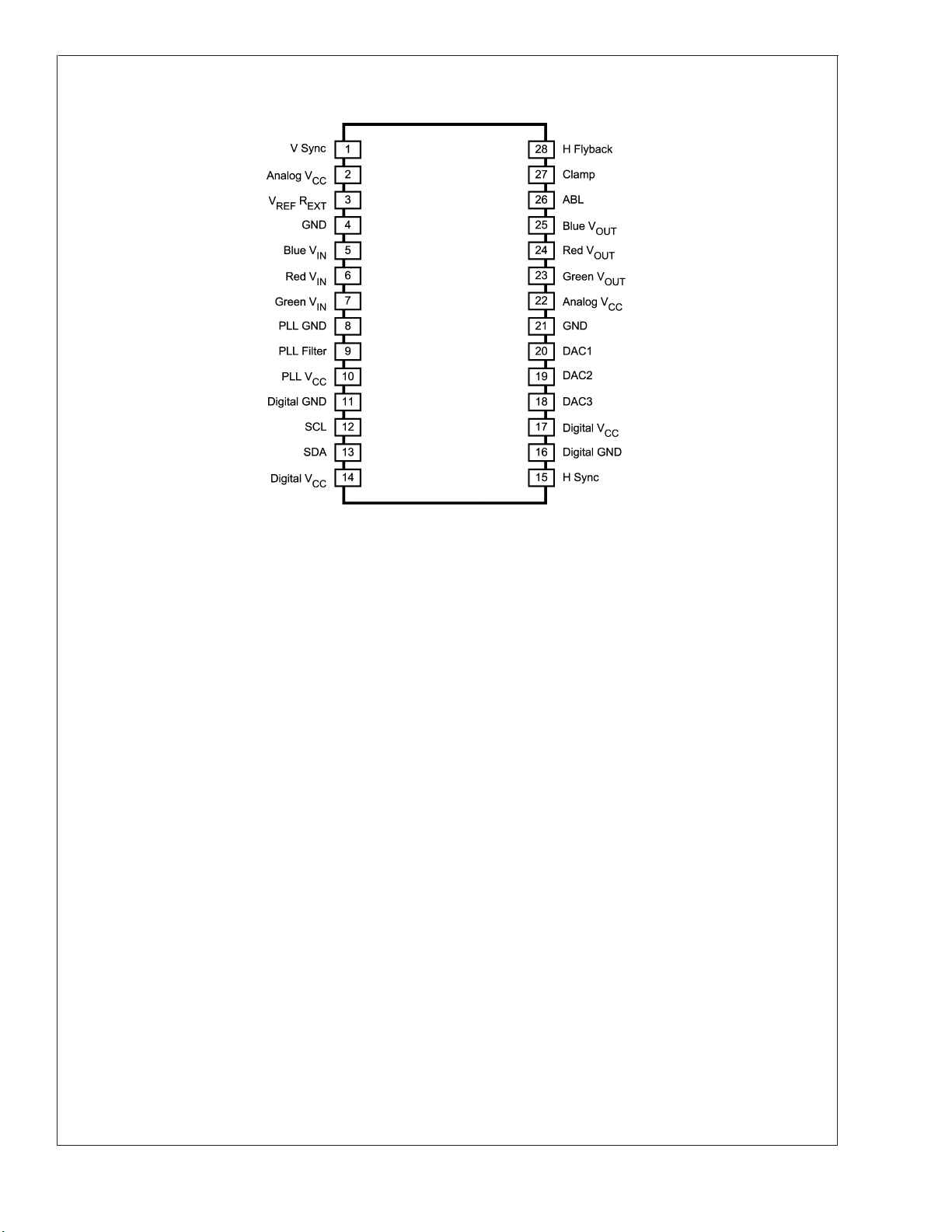

Internal Block Diagram (Continued)

LM1276

FIGURE 2. LM1276 Pinout

Order Number LM1276AAA/NA

See NS Package Number N28D

20096962

www.national.com3

Absolute Maximum Ratings (Notes 1,

3)

LM1276

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Supply Voltage V

, Pins 10, 14, 17,

CC

Thermal Resistance to Case (θ

Junction Temperature (T

) 150˚C

J

) 32˚C/W

JC

ESD Susceptibility (Note 4) 3.0 kV

ESD Machine Model (Note 13) 350V

Storage Temperature −65˚C to +150˚C

Lead Temperature (Soldering, 10 sec.) 265˚C

and 22 6.0V

Peak Video DC Output Source Current

(Any One Amp) Pins 23, 24 or 25 1.5 mA

Voltage at Any Input Pin (V

Video Inputs (pk-pk) 0.0V ≤ V

Thermal Resistance to Ambient (θ

Power Dissipation (P

) –0.5V ≤ VIN≤ VCC+0.5V

IN

) 51˚C/W

JA

)

D

IN

≤ 1.2V

Operating Ratings (Note 2)

Temperature Range 0˚C to +70˚C

Supply Voltage V

CC

Video Inputs (pk-pk) 0.0V ≤ V

4.75V ≤ VCC≤ 5.25V

(Above 25˚C Derate Based

and TJ) 2.4W

on θ

JA

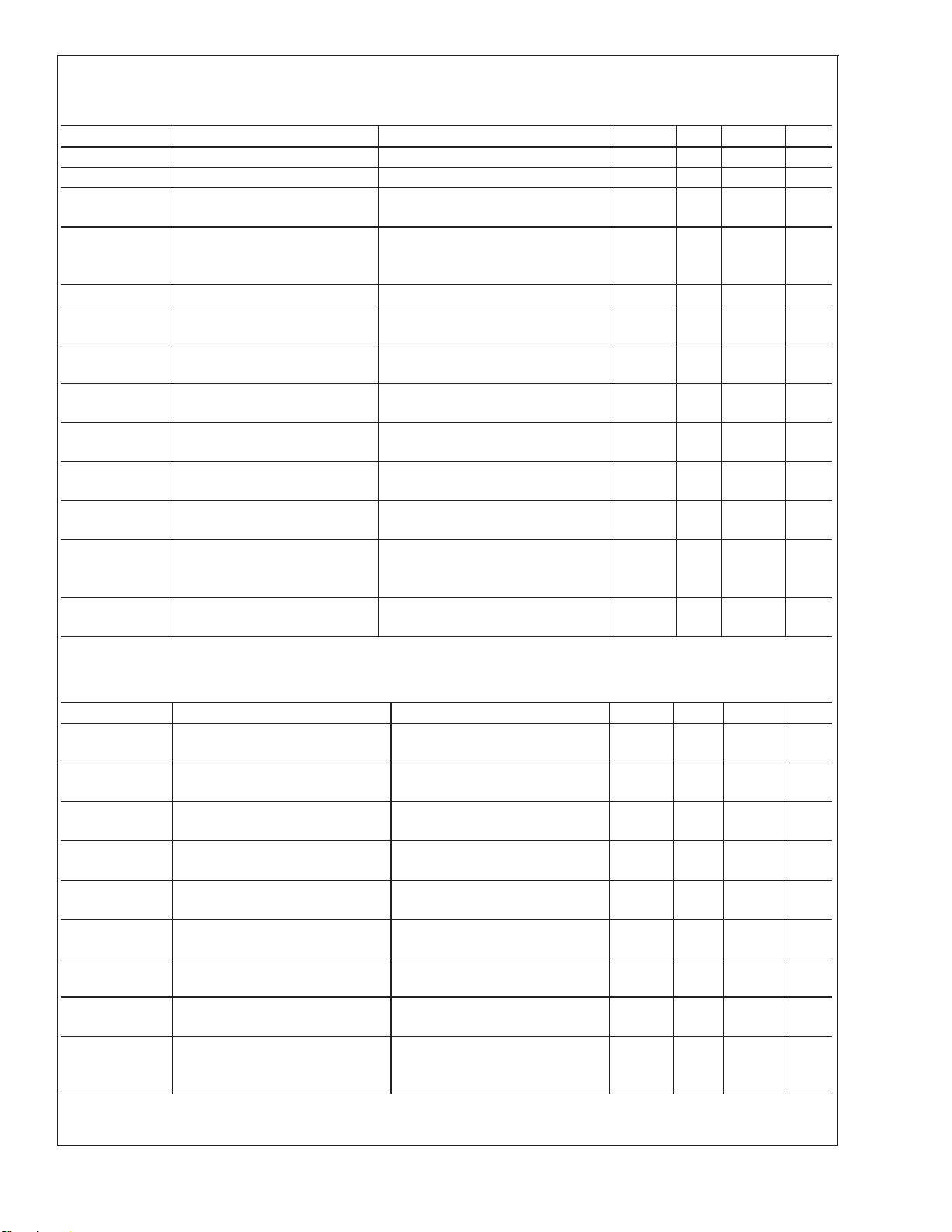

Video Signal Electrical Characteristics

Unless otherwise noted: TA= 25˚C, VCC= +5.0V, VIN= 0.70 V

P-P,VABL=VCC,CL

numbers refer to the definitions in Table 1. See (Note 7) for Min and Max parameters and (Note 6) for Typicals.

Symbol Parameter Conditions Min Typ Max Units

I

S

Supply Current Test Setting 1, both supplies, no

output loading. See (Note 8).

I

S-PS

V

O BLK A-B

Supply Current, Power Save

Mode

Typical Video Black Level

Test Setting 1, both supplies, no

output loading. See (Note 8).

No AC Input Signal

Difference between Normal Video

and Hi-Brite Video.

V

O BLK A-B, CH-CH

Typical Channel to Channel

No AC Input Signal

Video Black Level Difference

between Normal Video and

Hi-Brite Video.

V

O BLK

V

O BLK STEP

Active Video Black Level Output

Voltage

Active Video Black Level Step

Test Setting 4, no AC input signal, DC

offset register (0x8438) set to 0xD5.

Test Setting 4, no AC input signal.

Size

Max Maximum Video Output Voltage Test Setting 3, Video in = 0.70 V

V

O

LE Linearity Error Test Setting 4, staircase input signal

(see (Note 9)).

t

r

Video Rise Time (Note 5), 10% to 90%, Test Setting 4,

AC input signal.

OS

R

Rising Edge Overshoot (Note 5), Test Setting 4, AC input

signal.

t

f

Video Fall Time (Note 5), 90% to 10%, Test Setting 4,

AC input signal.

OS

F

Falling Edge Overshoot (Note 5), Test Setting 4, AC input

signal.

BW Channel Bandwidth (−3 dB) (Note 5), Test Setting 4, AC input

signal.

10 kHz Video Amplifier 10 kHz Isolation (Note 14), Test Setting 8. −60 dB

V

SEP

V

10 MHz Video Amplifier 10 MHz Isolation (Note 14), Test Setting 8. −50 dB

SEP

A

Max Maximum Voltage Gain Test Setting 8, AC input signal. 3.8 4.1 V/V

V

A

C-50% Contrast Attenuation@50% Test Setting 5, AC input signal. −5.2 dB

V

A

Min/AVMax Maximum Contrast Attenuation

V

Test Setting 2, AC input signal.

(dB)

= 8 pF, Video Outputs = 2.0 V

220 300 mA

55 85 mA

-50 0 TBD VDC

-50 0 50 VDC

1.2 VDC

100 mVDC

P-P

4.0 4.3 V

5%

3.1 ns

2%

2.9 ns

2%

150 MHz

−12 dB

IN

. Setting

P-P

≤ 1.0V

www.national.com 4

Video Signal Electrical Characteristics (Continued)

Unless otherwise noted: TA= 25˚C, VCC= +5.0V, VIN= 0.70 V

P-P,VABL=VCC,CL

numbers refer to the definitions in Table 1. See (Note 7) for Min and Max parameters and (Note 6) for Typicals.

Symbol Parameter Conditions Min Typ Max Units

G-50% Gain Attenuation@50% Test Setting 6, AC input signal. −4.0 dB

A

V

A

G-Min Maximum Gain Attenuation Test Setting 7, AC input signal. −11 dB

V

A

Match Maximum Gain Match between

V

Test Setting 3, AC input signal.

Channels

A

Track Gain Change between Channels Tracking when changing from Test

V

Setting 8 to Test Setting 5. See (Note

11).

Vid

Threshold

V

TH ABL Control Range Upper Limit (Note 12), Test Setting 4, AC input

ABL

Video Threshold Normal Operation 80 mV

signal.

V

Range ABL Gain Reduction Range (Note 12), Test Setting 4, AC input

ABL

signal.

A

V 3.5/AV Max

A

V 2.0/AV Max

I

Max ABL Input Current Sink Capability (Note 12), Test Setting 4, AC input

ABL

ABL Gain Reduction at 3.5V (Note 12), Test Setting 4, AC input

signal. V

ABL

= 3.5V

ABL Gain Reduction at 2.0V (Note 12), Test Setting 4, AC input

signal. V

ABL

= 2.0V

signal.

Max Maximum ABL Input Voltage

V

ABL

during Clamping

(Note 12), Test Setting 4, AC input

signal. I

ABL=IABL

MAX

AVABL Track ABL Gain Tracking Error (Note 9), Test Setting 4, 0.7 V

input signal, ABL voltage set to 4.5V

and 2.5V.

R

IP

Minimum Input Resistance (pins

Test Setting 4.

5, 6, 7)

= 8 pF, Video Outputs = 2.0 V

±

0.5 dB

±

0.5 dB

4.8 V

2.8 V

−2 dB

−12 dB

P-P

20 MΩ

. Setting

P-P

2.5 mA

V

+

CC

0.1

5.0 %

LM1276

V

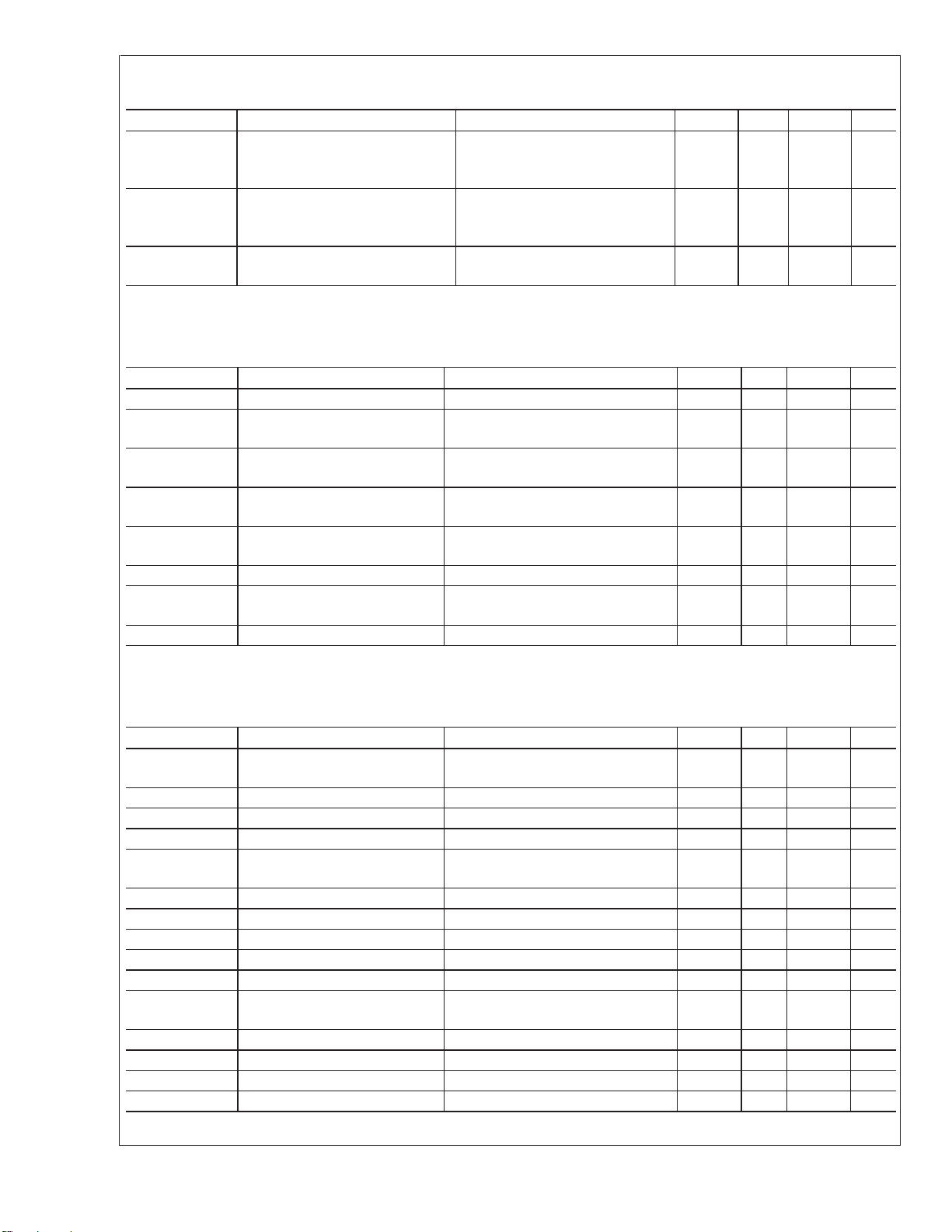

OSD Electrical Characteristics

Unless otherwise noted: TA= 25˚C, VCC= +5.0V. See (Note 7) for Min and Max parameters and (Note 6) for Typicals.

Symbol Parameter Conditions Min Typ Max Units

V

OSDHIGH

V

OSDHIGH

V

OSDHIGH

V

OSDHIGH

V

OSDHIGH

V

OSDHIGH

V

OSDHIGH

V

OSDHIGH

∆V

max Maximum OSD Level with OSD

Contrast 111

110 Maximum OSD Level with OSD

Contrast 110

101 Maximum OSD Level with OSD

Contrast 101

100 Maximum OSD Level with OSD

Contrast 100

011 Maximum OSD Level with OSD

Contrast 011

010 Maximum OSD Level with OSD

Contrast 010

001 Maximum OSD Level with OSD

Contrast 001

000 Maximum OSD Level with OSD

Contrast 000

(Black) Difference between OSD Black

OSD

Level and Video Black Level (same

channel)

Palette Set at 111, OSD Contrast =

111, Test Setting 3

Palette Set at 111, OSD Contrast =

110, Test Setting 3

Palette Set at 111, OSD Contrast =

01, Test Setting 3

Palette Set at 111, OSD Contrast =

100, Test Setting 3

Palette Set at 111, OSD Contrast =

011, Test Setting 3

Palette Set at 111, OSD Contrast =

010, Test Setting 3

Palette Set at 111, OSD Contrast =

001, Test Setting 3

Palette Set at 111, OSD Contrast =

000, Test Setting 3

Register 0x8438=0x18, Input Video

= Black, Same Channel, Test

Setting 8

3.02 V

2.91 V

2.79 V

2.67 V

2.55 V

2.43 V

2.32 V

2.20 V

±

130 mV

www.national.com5

OSD Electrical Characteristics (Continued)

Unless otherwise noted: TA= 25˚C, VCC= +5.0V. See (Note 7) for Min and Max parameters and (Note 6) for Typicals.

LM1276

Symbol Parameter Conditions Min Typ Max Units

∆V

OSD-black

(Track)

(White) Output Match between Channels Palette Set at 111, OSD Contrast =

∆V

OSD

Difference between OSD Black

Level and Video Black Level

between any 2 channels

Register 0x8438=0x18, Input Video

= Black, Same Channel, Test

Setting 8

11, Maximum difference between R,

±

115 mV

3%

G and B

V

(Track) Output Variation between Channels OSD contrast varied from max to

OSD-out

min

3%

DAC Output Electrical Characteristics

Unless otherwise noted: TA= 25˚C, VCC= +5.0V, VIN= 0.7V, V

ABL=VCC,CL

for Min and Max parameters and (Note 6) for Typicals. DAC parameters apply to all 4 DACs.

Symbol Parameter Conditions Min Typ Max Units

V

Min DAC

V

Max DAC

Mode 00

V

Max DAC

Mode 01

∆V

Max DAC

(Temp)

∆V

Max DAC(VCC

Min Output Voltage of DAC Register Value = 0x00 0.5 0.7 V

Max Output Voltage of DAC Register Value = 0xFF,

DCF[1:0] = 00b

Max Output Voltage of DAC in

DCF Mode 01

DAC Output Voltage Variation

Register Value = 0xFF,

DCF[1:0] = 01b

<T<

0

70˚C ambient

with Temperature

) DAC Output Voltage Variation

with V

CC

VCCvaried from 4.75V to 5.25V, DAC

register set to mid-range (0x7F)

Linearity Linearity of DAC over its Range 5 %

Monotonicity Monotonicity of the DAC

Excluding Dead Zones

I

MAX

Max Load Current −1.0 1.0 mA

= 8 pF, Video Outputs = 2.0 V

3.7 4.2 V

1.85 2.35 V

±

0.5 mV/˚C

50 mV

±

0.5 LSB

. See (Note 7)

P-P

System Interface Signal Characteristics

Unless otherwise noted: TA= 25˚C, VCC= +5.0V, VIN= 0.7V, V

ABL=VCC,CL

for Min and Max parameters and (Note 6) for Typicals. DAC parameters apply to all 4 DACs.

Symbol Parameter Conditions Min Typ Max Units

V

VTH+

VFLYBACK Positive Switching

Vertical Blanking triggered

Guarantee

V

SPOT

V

Ref

V

(SCL, SDA) Logic Low Input Voltage −0.5 1.5 V

IL

V

(SCL, SDA) Logic High Input Voltage

IH

Spot Killer Voltage (Note 17), VCCAdjusted to Activate 3.4 3.9 4.3 V

V

Output Voltage (pin 2) 1.25 1.45 1.65 V

Ref

IL(SCL, SDA) Logic Low Input Current SDA or SCL, Input Voltage = 0.4V

I

(SCL, SDA) Logic High Input Voltage SDA or SCL, Input Voltage = 4.5V

H

V

(SCL, SDA) Logic Low Output Voltage IO= 3 mA 0.5 V

OL

f

Min Minimum Horizontal Frequency PLL & OSD Functioning 25 kHz

H

f

Max Maximum Horizontal Frequency PLL & OSD Functioning 110 kHz

H

I

Max Horizontal Flyback Input Current Absolute Maximum during

HFB IN

Flyback

I

IN

I

HFB OUT

I

OUT

I

IN THRESHOLD

Max Horizontal Flyback Input Current Absolute Maximum during Scan −700 µA

Peak Current during Flyback Design Value 4 mA

Peak Current during Scan Not exact - Duty Cycle Dependent −550 µA

IINH-Blank Detection Threshold 0 µA

= 8 pF, Video Outputs = 2.0 V

2.0 V

3.0

±

10 µA

±

10 µA

. See (Note 7)

P-P

VCC+

0.5

5mA

V

www.national.com 6

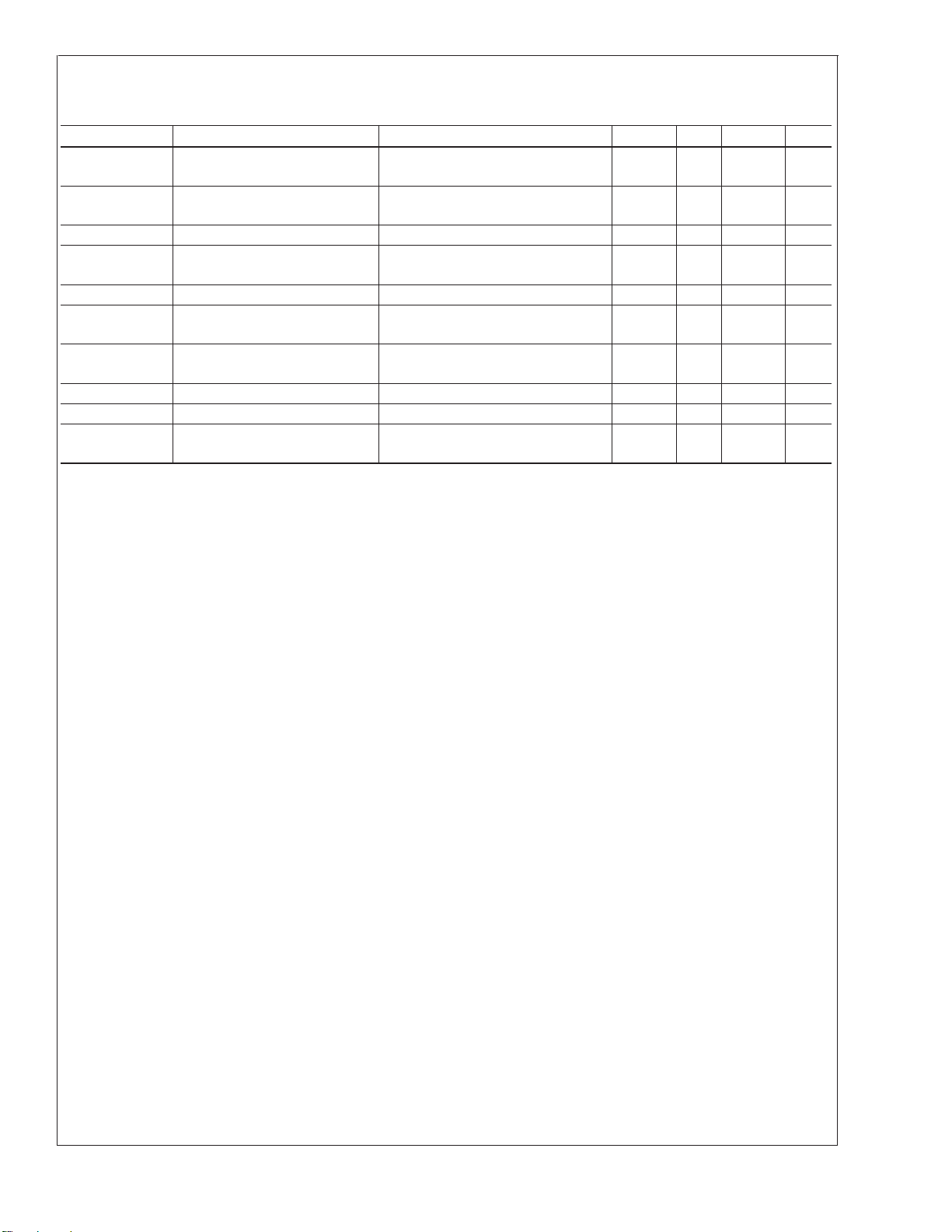

System Interface Signal Characteristics (Continued)

Unless otherwise noted: TA= 25˚C, VCC= +5.0V, VIN= 0.7V, V

ABL=VCC,CL

for Min and Max parameters and (Note 6) for Typicals. DAC parameters apply to all 4 DACs.

Symbol Parameter Conditions Min Typ Max Units

t

H-BLANK ON

H-Blank Time Delay - On + Zero crossing of I

output blanking start. I

t

H-BLANK OFF

H-Blank Time Delay - Off − Zero crossing of I

output blanking end. I

V

Max Maximum Video Blanking Level Test Setting 4, AC input signal 0 0.25 V

BLANK

f

FREERUN

Free Run H Frequency, Including

H Blank

t

PW CLAMP

V

CLAMP MAX

Minimum Clamp Pulse Width See (Note 15) 200 ns

Maximum Low Level Clamp

Video Clamp Functioning

Pulse Voltage

V

CLAMP MIN

Minimum High Level Clamp

Video Clamp Functioning

Pulse Voltage

Low Clamp Gate Low Input Current V23= 2V −0.4 µA

I

CLAMP

I

High Clamp Gate High Input Current V23= 3V 0.4 µA

CLAMP

t

CLAMP-VIDEO

Note 1: Limits of Absolute Maximum Ratings indicate below which damage to the device must not occur.

Note 2: Operating Ratings indicate conditions for which the device is functional, but do not guarantee specific performance limits.

Note 3: All voltages are measured with respect to GND, unless otherwise specified.

Note 4: Human body model, 100 pF discharged through a 1.5 kΩ resistor.

Note 5: Input from signal generator: t

Note 6: Typical specifications are specified at +25˚C and represent the most likely parametric norm.

Note 7: Datasheet min/max specification limits are guaranteed by design, test, or statistical analysis. The guaranteed specifications apply only for the test conditions

listed. Some performance characteristics may change when the device is not operated under the listed test conditions.

Note 8: The supply current specified is the quiescent current for V

therefore all the supply current is used by the pre-amp.

Note 9: Linearity Error is the maximum variation in step height of a 16 step staircase input signal waveform with a 0.7 V

with each at least 100 ns in duration.

Note 10: dt/dV

Note 11: ∆A

gain change between any two amplifiers with the contrast set to A

amplifiers’ gains might be 12.1 dB, 11.9 dB, and 11.8 dB and change to 2.2 dB, 1.9 dB and 1.7 dB respectively for contrast set to A

gain change of 10.0 dB with a tracking change of

Note 12: The ABL input provides smooth decrease in gain over the operational range of 0 dB to −5 dB: ∆A

V

ABL MIN GAIN

Note 13: Machine Model ESD test is covered by specification EIAJ IC-121-1981. A 200 pF cap is charged to the specific voltage, then discharged directly into the

IC with no external series resistor (resistance of discharge path must be under 50Ω).

Note 14: Measure output levels of the other two undriven amplifiers relative to the driven amplifier to determine channel separation. Terminate the undriven amplifier

inputs to simulate generator loading. Repeat test at f

Note 15: A minimum pulse width of 200 ns is the guaranteed minimum for a horizontal line of 15 kHz. This limit is guaranteed by design. If a lower line rate is used

then a longer clamp pulse may be required.

Note 16: Adjust input frequency from 10 MHz (A

Note 17: Once the spot killer has been activated, the LM1276 remains in the off state until V

Time from End of Clamp Pulse to

Start of Video

<

1 ns.

r,tf

= 200*(t

CC

track is a measure of the ability of any two amplifiers to track each other and quantifies the matching of the three gain stages. It is the difference in

V

). Beyond −5 dB the gain characteristics, linearity and pulse response may depart from normal values.

5.5V–t4.5V

)/ ((t

5.5V+t4.5V

)) %/V, where: t

±

0.2 dB.

= 10 MHz for V

IN

max reference level) to the −3 dB corner frequency (f

V

Referenced to Blue, Red and Green

inputs

and 5V Dig with RL=∞. Load resistors are not required and are not used in the test circuit,

CC

is the rise or fall time at VCC= 5.5V, and t

5.5V

C−50% and measured relative to the AVmax condition. For example, at AVmax the three

V

10 MHz.

SEP

= 8 pF, Video Outputs = 2.0 V

to 50% of

HFB

= +1.5mA

24

to 50% of

HFB

= −100µA

24

P-P

45 ns

85 ns

42 kHz

3.0 V

50 ns

level at the input. All 16 steps equal,

P-P

is the rise or fall time at VCC= 4.5V.

4.5V

C−50%. This yields a typical

V

= A(V

ABL

).

−3 dB

is cycled (reduced below 0.5V and then restored to 5V).

CC

ABL=VABL MAX GAIN

. See (Note 7)

2.0 V

)–A(V

ABL

LM1276

=

Hexadecimal and Binary Notation

Hexadecimal numbers appear frequently throughout this

document, representing slave and register addresses, and

register values. These appear in the format “0x...”. For example, the slave address for writing the registers of the

LM1276 is hexadecimal BA, written as 0xBA. On the other

hand, binary values, where the individual bit values are

shown, are indicated by a trailing “b”. For example, 0xBA is

equal to 10111010b. A subset of bits within a register is

referred to by the bit numbers in brackets following the

register value. For example, the OSD contrast bits are the

fourth, fifth, and sixth bits of register 0x8538. Since the first

bit is bit 0, the OSD contrast register is 0x8538[5:3].

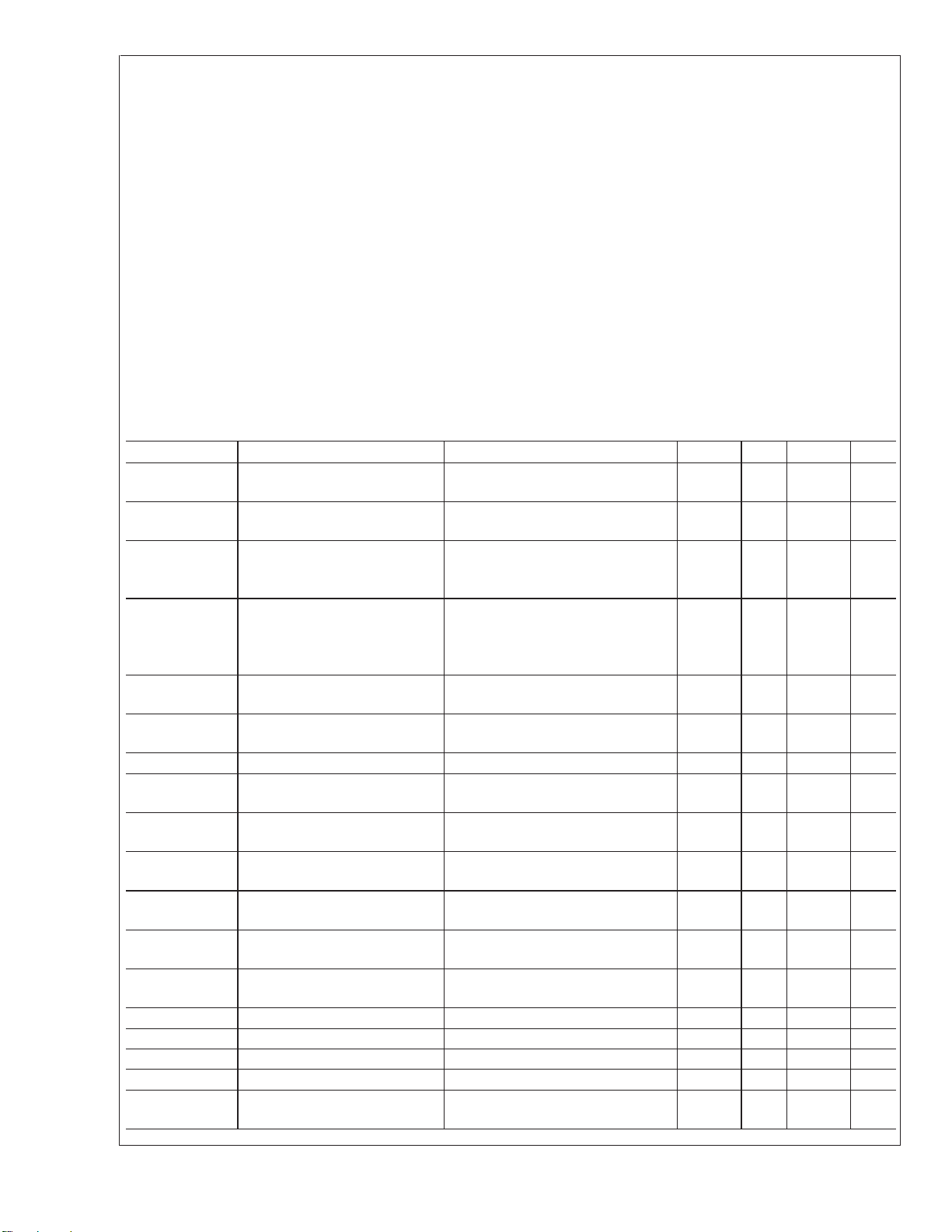

Register Test Settings

Table 1 shows the definitions of the Test Settings 1–8 referred to in the specifications sections. Each test setting is a

combination of five hexadecimal register values, Contrast,

Gain (Blue, Red, Green) and DC offset.

www.national.com7

Register Test Settings (Continued)

LM1276

Control No. of Bits

Contrast 7 0x7F

B, R, G

Gain

DC Offset 3 0x00

1234 5678

(Max)

7 0x7F

(Max)

(Min)

TABLE 1. Test Settings

0x00

Min

0x7F

(Max)

0x7F

(Max)

0x7F

(Max)

0x05 0x07

(Max)

Test Settings

0x7F

(Max)

Set V

2V

O

P-P

0x40

(50.4%)

to

0x7F

(Max)

0x7F

(Max)

0x40

(50.4%)

0x7F

(Max)

0x00

(Min)

0x05 0x05 0x05 0x05 0x05

0x7F

(Max)

0x7F

(Max)

www.national.com 8

OSD vs Video Intensity

The OSD amplitude has been increased over the LM1237

level. During monitor alignment the three gain registers are

used to achieve the desired front of screen color balance.

This also causes the OSD channels to be adjusted accordingly, since these are inserted into the video channels prior

to the gain attenuators. This provides the means to fine-tune

the intensity of the OSD relative to the video as follows. If a

typical starting point for the alignment is to have the gains at

maximum (0x7F) and the contrast at 0x55, the resultant

OSD intensity will be higher than if the starting point is with

the gains at 0x55 and the contrast at maximum (0x7F). This

LM1276

tradeoff allows the fine-tuning of the final OSD intensity

relative to the video. In addition, the OSD contrast register,

0x85C8[5:3], provides 8 major increments of intensity. Together, these allow setting the OSD intensity to the most

pleasing level.

ESD Protection

The LM1276 features a 3.0 kV ESD protection level (see

(Notes 4, 13)). This is provided by special internal circuitry,

which activates when the voltage at any pin goes beyond the

supply rails by a preset amount. This protection is applied to

all the pins, including SDA and SCL.

www.national.com9

Typical Performance Characteristics V

LM1276

= 5V, TA= 25˚C unless otherwise specified

CC

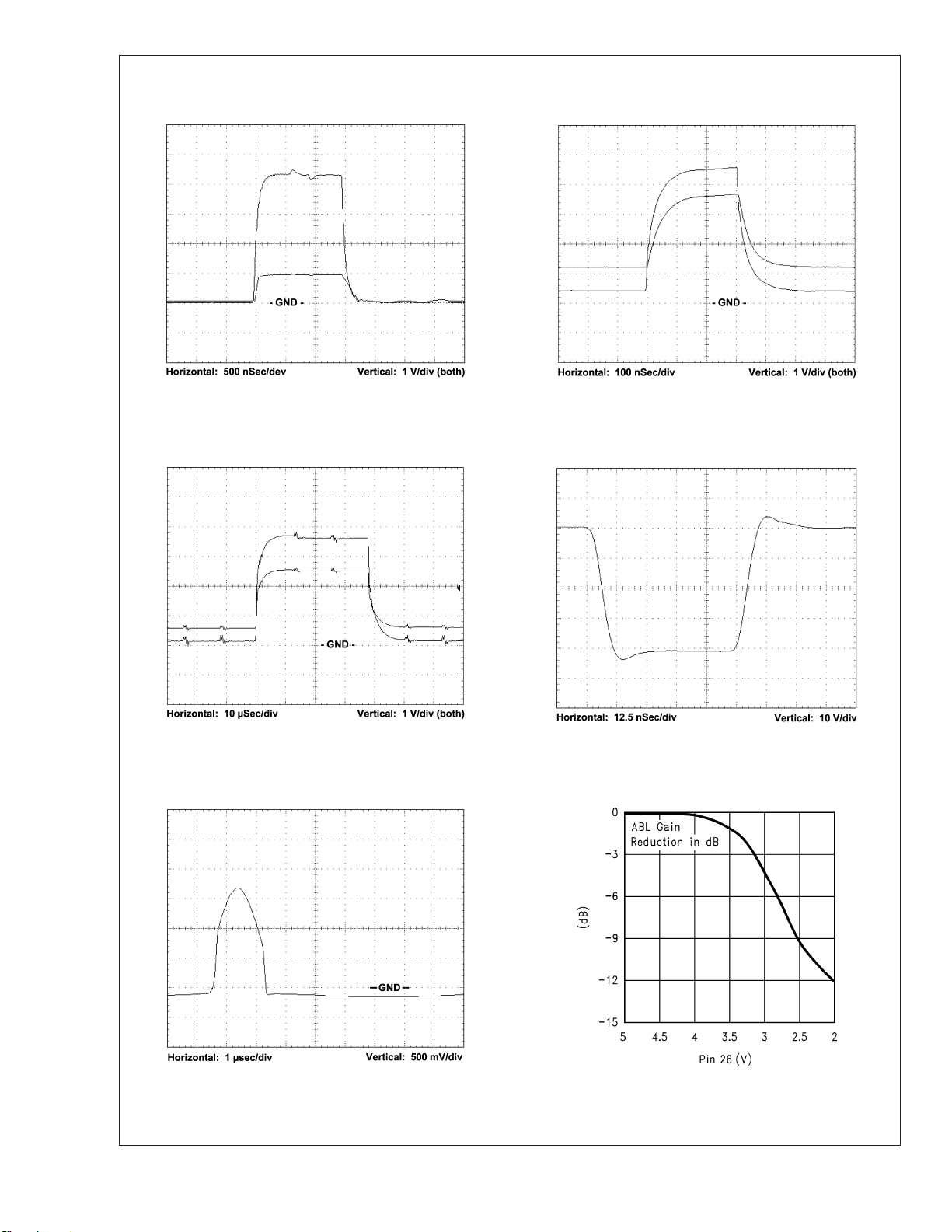

FIGURE 3. Logic Horizontal Blanking

FIGURE 4. Logic Vertical Blanking

20096902

20096903

20096906

FIGURE 6. Logic Clamp Pulse

20096907

FIGURE 7. Red Cathode Response

20096904

FIGURE 5. Deflection Horizonal Blanking

www.national.com 10

20096908

FIGURE 8. ABL Gain Reduction Curve

Typical Performance

Characteristics

otherwise specified (Continued)

SYSTEM INTERFACE SIGNALS

The Horizontal Sync, Flyback, Vertical Sync, and the Clamp

input signals are important for proper functionality of the

LM1276. Both blanking inputs must be present for OSD

synchronization. In addition, the Horizontal blanking input

also assists in setting the proper cathode black level, along

with the Clamping pulse. The Vertical blanking input initiates

a blanking level at the LM1276 outputs, which is programmable from 3 to 127 lines (at least 10 is recommended). This

input is set up to only accept a vertical sync pulse, and the

leading edge is used to start the programmable vertical

blanking signal directly. The start position of the internal

Horizontal blanking pulse is programmable from 0 to 64

pixels ahead of the start position of the Horizontal flyback

input. Both horizontal and vertical blanking can be individually disabled, if desired.

Figure 3 and Figure 4 show the Horizontal Flyback input

when it is logic level and the Vertical input (which must

always be logic level). Figure 3 shows the smaller pin 28

voltage superimposed on the horizontal blanking pulse input

to the neck board with R

where the voltage at pin 28 is clamped to about 1V when the

pin is sinking current. Figure 4 shows the smaller pin 1

voltage superimposed on the vertical blanking input to the

neck board with R

spond to the application circuit of Figure 9.

Please note that the Horizontal Flyback signal to pin 28

MUST be continuously provided to the IC, even during energy save or sleep modes. In the application, this signal

should be always generated whether the VGA cable is disconnected, the monitor is in energy save mofe, or sleep

mode.

Figure 5 show the case where the horizontal input is from

deflection. Figure 5 shows the pin 28 voltage which is derived from a horizontal flyback pulse of 35V peak to peak

with R

= 8.2K and C1jumpered.

H

Figure 6 shows the pin 27 clamp input voltage superimposed

on the neck board clamp logic input pulse.R=1kandshould

be chosen to limit the pin 27 voltage to about 2.5V peak to

peak. This corresponds to the application circuit given in

Figure 9. The clamp input pin can also be internally connected to the Horizontal Sync pin, thus eliminating the need

for a Clamp signal supplied to the neckboard. This can be

enabled with register 0x853E[4].

V

VCC= 5V, TA= 25˚C unless

= 4.7k and C1= 0.1 µF. Note

H

= 4.7k. These component values corre-

H SYNC & V SYNC

V Sync at pin 1 and H Sync at pin 15 must be supplied with

logic level signals generated by the MCU. In an application

where a logic level clamp pulse is used, the same signal can

be used for the H Sync input. It is important that both V Sync

and H Sync are always receiving signals, even during VGA

cable disconnect, energy save mode, or sleep mode.

CATHODE RESPONSE

Figure 7 shows the response at the red cathode for the

application circuit in Figures 9, 10. The input video rise time

is 1.5 ns. The resulting leading edge has a 7.1 ns rise time

and 7.6% overshoot, while the trailing edge has a 7.1 ns rise

time and 6.9% overshoot using an LM2467 driver.

ABL GAIN REDUCTION

The ABL function reduces the contrast level of the LM1276

as the voltage on pin 26 is lowered from V

to around 2V.

CC

Figure 8 shows the amount of gain reduction as the voltage

is lowered from V

until V

reaches the knee around 3.7V, where the slope

26

(5.0V) to 2V. The gain reduction is small

CC

increases. Many system designs will require about 3 dB to

5 dB of gain reduction in full beam limiting. Additional attenuation is possible, and can be used in special circumstances.

However, in this case, video performance such as video

linearity and tracking between channels will tend to depart

from normal specifications.

The onset of ABL in the LM1276 is adjustable so that the

amount of beam limiting can be varied, especially for larger

Hi-Brite window displays where the contrast level is not

desired to be reduced as much as a normal video display.

The beam current limiting is 4-bit adjustable in steps of 80 µA

each all the way up to a delta of 1.2 mA. The value of the

ABL pull up resistor (R2) to the external +80V supply must

be selected carefully such that the ABL threshold current will

be at the desired maximum (i.e. 2 mA) when register 0x85C4

is at the lowest setting, 0x00.

There are 4 different ABL current registers corresponding to

4 different ABL settings. Each setting or register (0x85C4 0x85C7) can be assigned a different ABL current threshold.

ABL current register 0 can correspond to a minimal area of

the screen being highlighted, and ABL current register 4 can

correspond to the maximum area of the screen being highlighted. This area is calculated by the HiBrite software, and

the particular ABL register that is is to be activated is selected by the software. The values of each register are

written by the MCU.

LM1276

www.national.com11

Typical Performance

Characteristics

LM1276

otherwise specified (Continued)

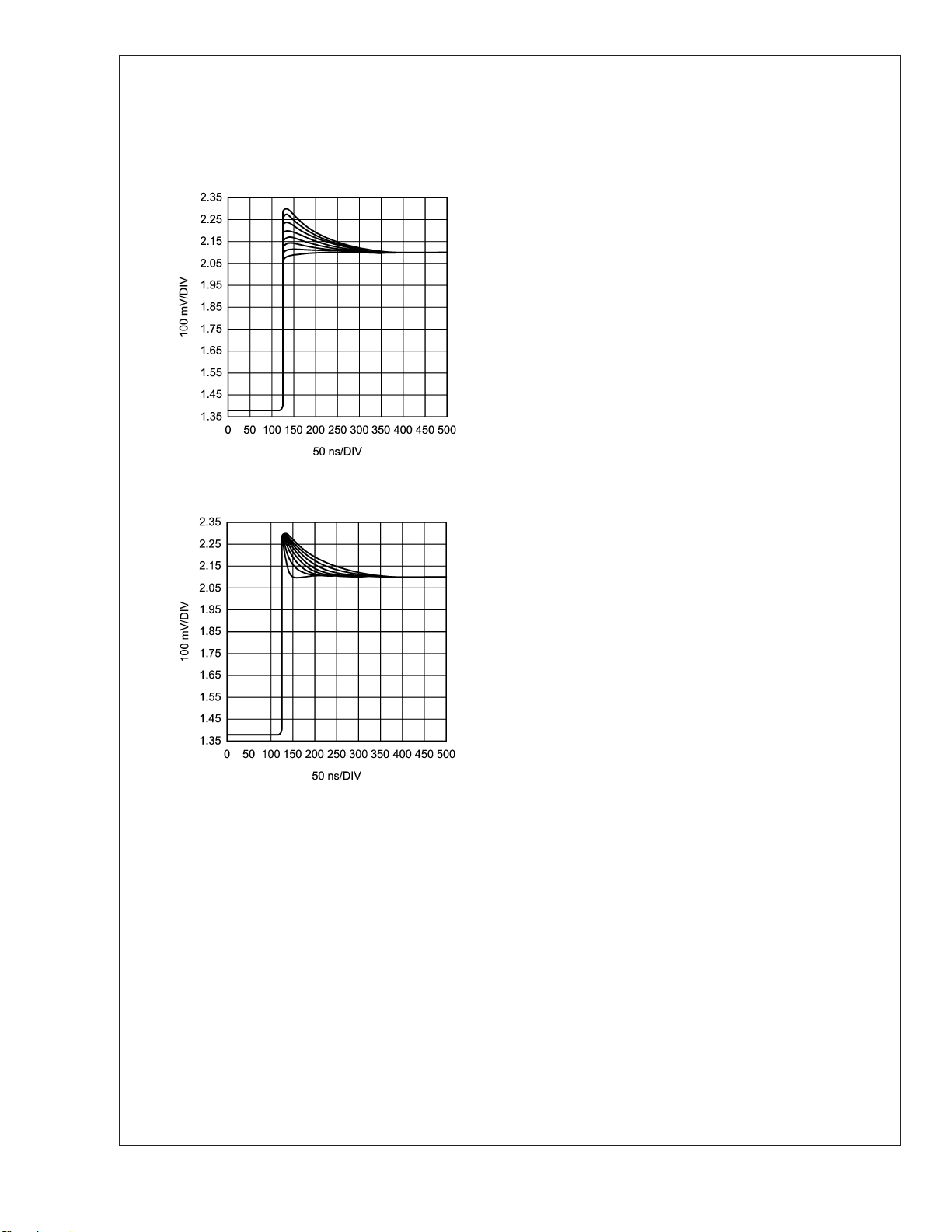

VIDEO PROCESSING

Emphasis, Center Frequency at Maximum

Center Frequency, Emphasis at Maximum

These two plots show the processing done by the LM1276

on the video input signal. There are two variables for the

video processing, emphasis and center frequency. Empha-

sis is controlled by bits 0-2 in registers 0x85C8, 0x85CA,

or 0x85CC. This gives 8 different levels of emphasis. In the

top plot the center frequency is set at its maximum level and

the 8 different levels of emphasis are measured. The video

with no emphasis is adjusted to a 0.7 V

maximum emphasis the video is increased to a 0.9 V

level at the rising edge of the video. If the falling edge was

measured it would show a similar waveform, but going in the

negative direction.

Center frequency is shown in the bottom plot. Control of the

center frequency is done with bits 4-7 in register

0x85C1. This gives 16 adjustments for this feature. Every

other adjustment is shown in the bottom plot, since showing

all 16 adjustments would have made the plot too difficult to

read. The curves closely approximate the peaking of an RC

VCC=5V,TA= 25˚C unless

P-P

20096963

20096964

level. Using

P-P

network. Therefore, the term center frequency means the

RC time constant that is approximated by each curve in the

above plot. A true RC peaking network would give very large

overshoot. The LM1276 has special circuitry to clip the very

large overshoot, yet has the complete benefit of the RC

peaking. This special circuitry allows for much more overshoot than one could do with RC peaking and still not

saturate the video channel.

Note that the video channel with the emphasis also has its

own independent contrast control. This allows the user to

adjust his monitor for a brighter picture within the Hi-Brite

window and optimize the emphasis for the resolution he is

using with the monitor. Now, the monitor user can give his

pictures or video a special “sparkle” when using the capabilities of the LM1276.

OSD PHASE LOCKED LOOP

The PLL in the LM1276 serves both the OSD as well as the

Hi-Brite Window generation. The pixels per line range for the

LM1276 OSD is from 704 to 1152 pixels per line, in increments of 64. The maximum OSD pixel frequency available is

111 MHz. For example, if the horizontal scan rate is 106 kHz,

1024 pixels per line would be acceptable to use, since the

OSD pixel frequency is:

Horizontal Scan Rate X PPL =

106kHz X 1024 = 108.5 MHz

If 1152 pixels per line is being used, the horizontal scan rate

would have to be lower than 106 kHz in order to not exceed

the maximum OSD pixel frequency of 111 MHz. The maximum number of video lines that may be used is 1536 lines as

in a 2048x1536 display. At this line rate, using a PPL setting

of 4 is recommended. The LM1276 has a PLL Auto feature,

which will automatically select an internal PLL frequency

range setting that will guarantee optimal OSD locking for any

horizontal scan rate and for improved jitter performance over

a wider temperature range. This eliminates the need for PLL

register settings determined by the user, as well as improved

PLL performance. To initialize the PLL Auto feature, set bit,

0x8439[4] to 1. This will effectively perform all necessary

calibrations and activate the PLL Auto mode, which takes

approximately 2–4 vertical scan period to complete, and

must be done while the video is blanked. Table 2 shows the

recommended horizontal scan rate ranges (in kHz) for each

pixels per line register setting, 0x8401[7:5]. These ranges

are recommended for chip ambient temperatures of 0

o

C, and the recommended PLL filter values are 6.2 kΩ,

70

o

Cto

0.01 uF, and 1000 pF. While the OSD PLL will lock for other

register combinations and at scan rates outside these

ranges, the performance of the loop will be improved if these

recommendations are followed.

PLL AUTO MODE INITIALIZATION SEQUENCE

Blank video.

•

Set 0x8539[4] to 1.

•

Wait for at least 2–4 vertical periods or vertical sync

•

pulses to pass.

Unblank Video.

•

This sequence must be done by the microcontroller at system power up, as well as each time there is a horizontal line

rate change from the video source, for the PLL Auto mode to

function properly.

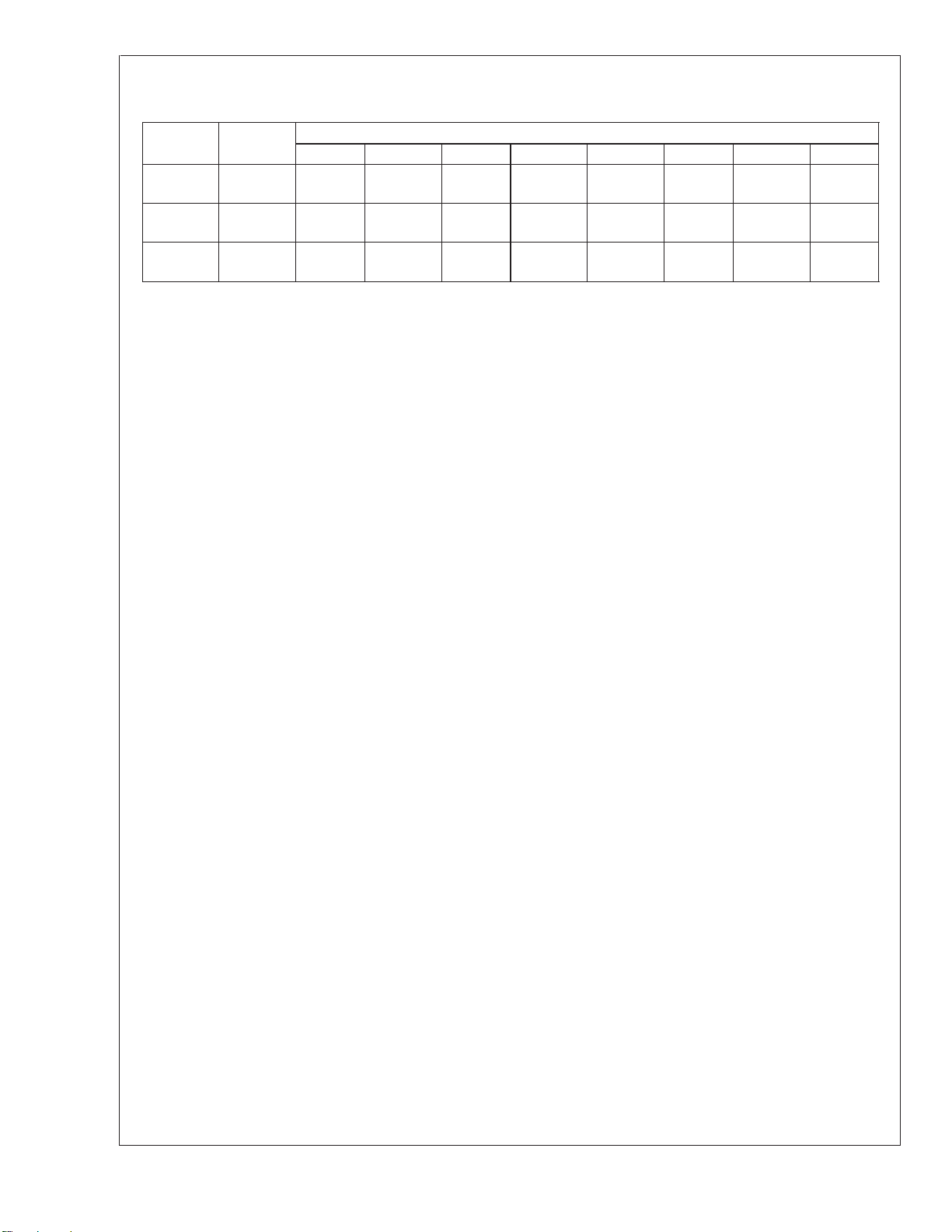

www.national.com 12

LM1276

Typical Performance Characteristics V

=5V,TA= 25˚C unless otherwise specified (Continued)

CC

TABLE 2. OSD Register Recommendations

PPL=0 PPL=1 PPL=2 PPL=3 PPL=4 PPL=5 PPL=6 PPL=7

PLL Auto 25 - 61 25 - 53 25 - 98 25 - 110 25 - 110 25 - 108 25 - 102 25 - 96

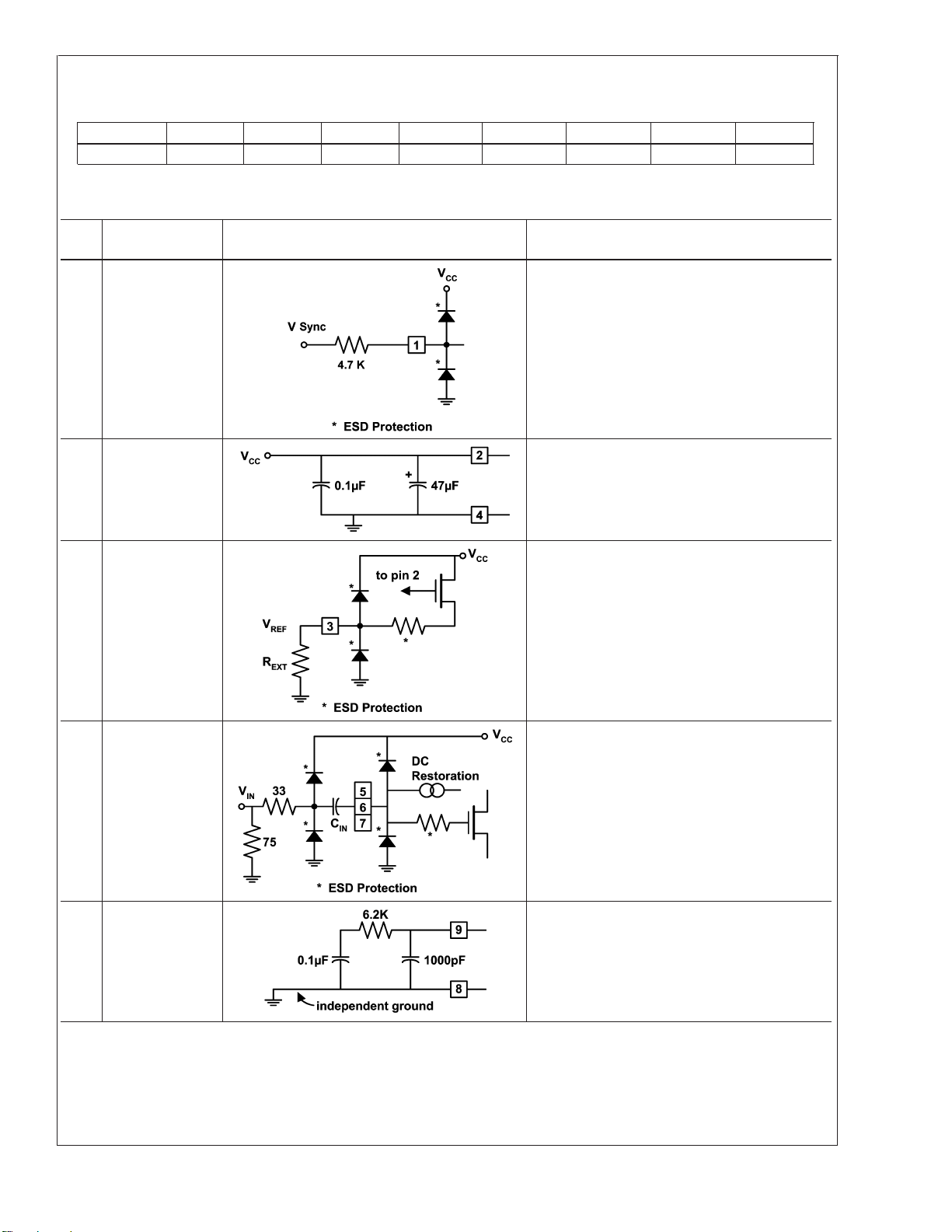

Pin Descriptions and Application Information

Pin

No.

1 V Sync Logic level vertical sync signal received from the

2

4

Pin Name Schematic Description

video card in the PC or sync stripper circuit.

Analog V

CC

Analog Ground

Ground pin and power supply pin for the input

analog portion of the LM1276. Note the

recommended charge storage and high

frequency capacitors, which should be as close

to pins 2 and 4 as possible.

3V

5

6

7

8

9

REFREXT

Blue Video In

Red Video In

Green Video In

PLL Ground

PLL Filter

External current set resistor, 10k 1%, sets the

internal bias current level for optimum

performance of the LM1276. This resistor should

be placed as close to pin 3 and the pin 4 ground

return as possible.

These video inputs must be AC coupled with a

.0047 µF cap. Internal DC restoration is done at

these inputs. A series resistor of about 33Ω and

external ESD protection diodes should also be

used for protection from ESD damage.

Recommended topology and values are shown

to the left. It is recommended that both filter

branches be bypassed to the independent

ground as close to pin 8 as possible. Great care

should be taken to prevent external signals from

2

coupling into this filter from video, I

C, etc.

www.national.com13

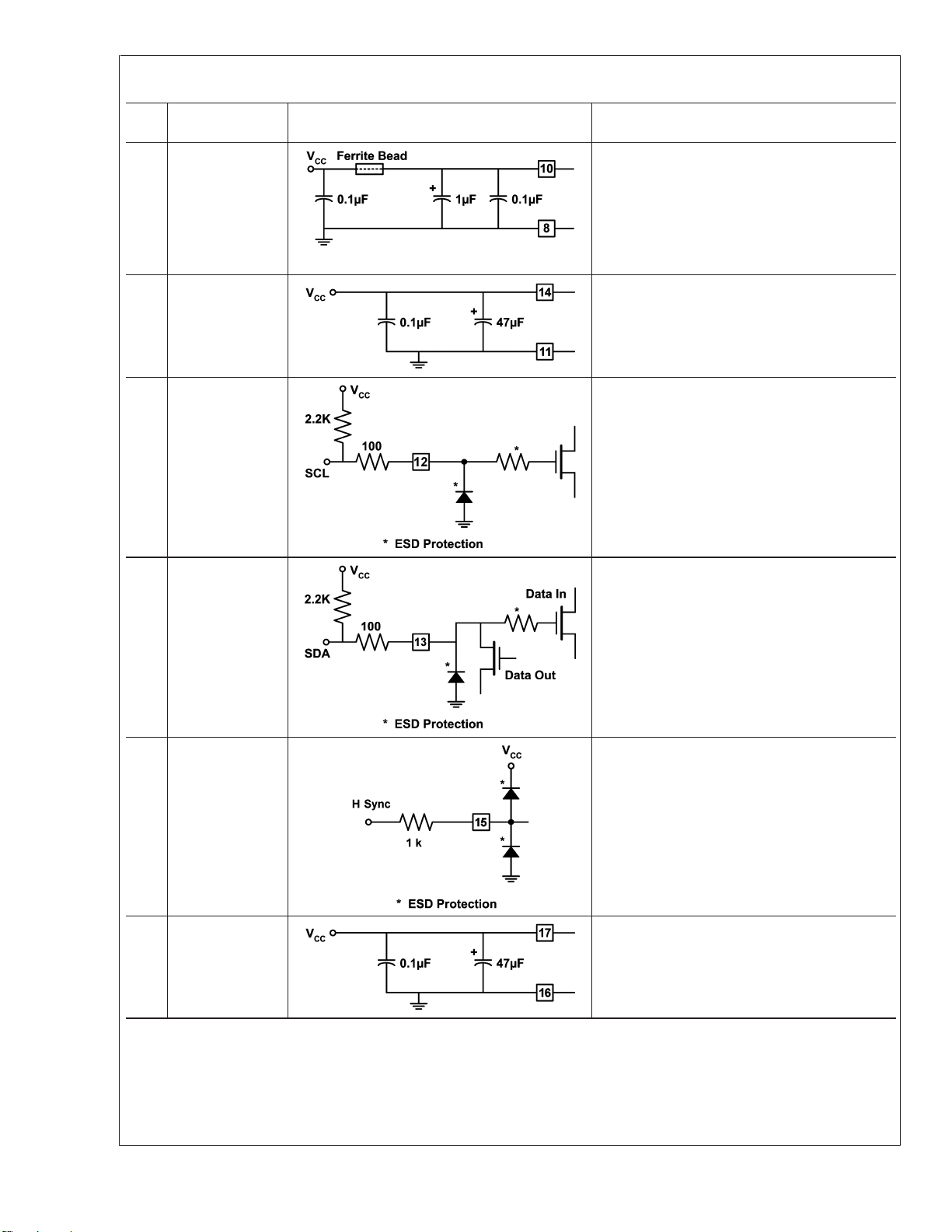

Pin Descriptions and Application Information (Continued)

LM1276

Pin

No.

10 PLL V

11

14

Pin Name Schematic Description

CC

Digital Ground

Digital V

CC

The ground pin should be connected to the rest

of the circuit ground by a short but independent

PCB trace to prevent contamination by

extraneous signals. The PLL V

isolated from the rest of the V

pin should be

CC

line by a ferrite

CC

bead and bypassed to pin 8 with an electrolytic

capacitor and a high frequency ceramic.

Ground pin and power supply pin for the digital

portion of the LM1276. Note the recommended

charge storage and high frequency capacitors,

which should be as close to pins 11 and 14 as

possible.

12 SCL

13 SDA

15 H Sync

The I2C compatible clock line. A pull-up resistor

of about 2.2 kΩ should be connected between

this pin and V

. A resistor of at least 100Ω

CC

should be connected in series with the clock line

for additional ESD protection.

The I2C compatible data line. A pull-up resistor

of about 2.2 kΩ should be connected between

this pin and V

. A resistor of at least 100Ω

CC

should be connected in series with the data line

for additional ESD protection.

Logic level horizontal sync signal received from

the MCU or sync stripper circuit. This input can

also be derived from the clamp input as long as

it is a logic level signal.

16

17

www.national.com 14

Digital Ground

Digital V

CC

Ground pin and power supply pin for the digital

portion of the LM1276. Note the recommended

charge storage and high frequency capacitors,

which should be as close to pins 16 and 17 as

possible.

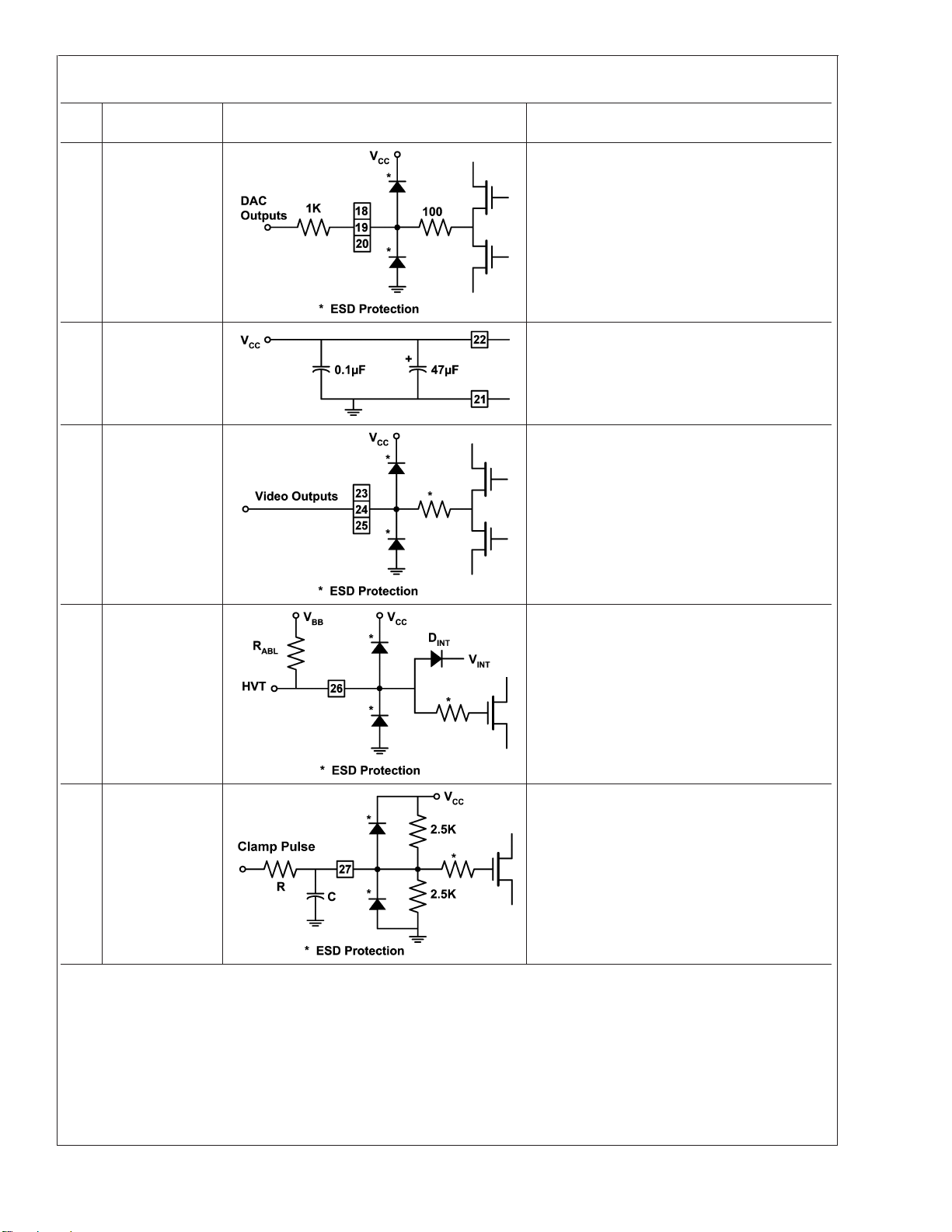

Pin Descriptions and Application Information (Continued)

LM1276

Pin

No.

18

19

20

Pin Name Schematic Description

DAC 3 Output

DAC 2 Output

DAC 1 Output

2122Analog Ground

23

24

25

Analog V

Green Output

Red Output

Blue Output

CC

DAC outputs for cathode cut-off adjustments and

brightness control. The DAC values are set

2

through the I

C compatible bus. A resistor of at

least 1kΩ should be connected in series with

these outputs for additional ESD protection.

Ground pin and power supply pin for the output

analog portion of the LM1276. Note the

recommended charge storage and high

frequency capacitors which should be as close to

pins 21 and 22 as possible.

These are the three video output pins. They are

intended to drive the LM2476 and LM246X

family of cathode drivers. Nominally, about 2V

peak to peak will produce 40V peak to peak of

cathode drive.

26 ABL

27 CLAMP

The Automatic Beam Limiter input is biased to

the desired beam current limit by R

and normally keeps D

forward biased. When

INT

ABL

and V

BB

the current resupplying the CRT capacitance

(averaged by C

) exceeds this limit, then D

ABL

INT

begins to turn off and the voltage at pin 26

begins to drop. The LM1276 then lowers the

gain of the three video channels until the beam

current reaches an equilibrium value.

This pin accepts either TTL or CMOS logic

levels. This pin can also be internally connected

to the Horizontal sync pin. The internal switching

threshold is approximately one-half of V

CC

.An

external series resistor, R, of about 1k is

recommended to avoid overdriving the input

devices. In any event, R must be large enough

to prevent the voltage at pin 27 from going

higher than V

or below GND.

CC

www.national.com15

Pin Descriptions and Application Information (Continued)

LM1276

Pin

No.

28 H Flyback Proper operation requires current reversal. R

Pin Name Schematic Description

should be large enough to limit the peak current

at pin 28 to about +4 mA during blanking, and

−500 µA during scan. C

is usually needed for

1

logic level inputs and should be large enough to

make the time constant, R

HC1

than the horizontal period. R

typically 300Ω and 330 pF when the flyback

waveform has ringing and needs filtering. C

may be needed to filter extraneous noise and

can be up to 100 pF.

significantly larger

and C2are

1

H

3

www.national.com 16

Schematic Diagram

LM1276

FIGURE 9. LM1276/LM2476 Demo Board Schematic

20096924

www.national.com17

Schematic Diagram

LM1276

FIGURE 10. LM1276/LM2476 Demo Board Schematic (continued)

www.national.com 18

20096925

PCB Layout

LM1276

FIGURE 11. LM1276/LM2476 Demo Board Layout

20096970

www.national.com19

Burn In Screen

The LM1276 provides a Burn In Screen feature, where a full

LM1276

screen of white video will be displayed without the need for

any video input. The Burn In Screen is enabled by setting bit

5 of register 0x8439 to 1. The contrast level of this Burn In

display can be adjusted with a 2 Bit DAC over the range of

65% to 85% of normal white level video. This adjustment is

made with register 0X8439[7:6].

Programmable Horizontal Blank

The leading edge position of the internal horizontal blank can

be programmed with respect to the horizontal flyback zero

crossing leading edge in steps of 1 OSD pixel up to a

maximum of 31 steps as shown below in Figure 12. This

start position of the horizontal blanking pulse is only programmable to occur before the horizontal flyback zero crossing edge, and cannot be programmed in the opposite direction. The trailing edge of the horizontal blanking pulse is

independent of the programmable leading edge, and its

relativity to the Horizontal flyback trailing edge remains unchanged. To use this feature, both Horizontal Blanking

(0x843A[0]) and Programmable Horizontal Blanking

(0x843A[2]) must be enabled. The number of steps is programmed with the bits in 0x843A[7:3]. When this feature is

disabled, please refer to the H-Blank Time Delay – On

specification (+ Zero Crossing of I

blanking end) listed under the System Interface Signal Characteristics section.

FIGURE 12. Programmable Internal H. Blank

to 50% of output

HFB

Video Detection for Auto-Sizing &

Auto-Centering

The LM1276 is capable of taking measurements necessary

for the monitor’s microcontroller to perform the auto-sizing

and auto-centering operations. The horizontal and vertical

flybacks/syncs are used as the reference for timing. Either

the flyback or sync signals may be used. In this section, the

flyback signals will be considered, although horizontal and

vertical sync can be applied similarly. The resultant outputs

are the flyback time, the position of the start of video relative

to the flyback end, and the time from the end of the active

video to the start of the flyback time. Since the total line time

20096952

is known, the microcontroller can calculate the active video

time. The microcontroller can center the video between the

start and end of flyback for best image centering, and to

calculate the duty cycle of the video with respect to the

forward scan time, thus giving a measure of the relative size

of the image.

VIDEO INPUT DETECTION

The LM1276 will detect even low-level video information to

determine the video image size and position. The video

detect logic must also find the extreme points of the displayed image during each frame with respect to the horizontal and vertical flyback pulses as measured using the internal

PLL. For best performance in the auto-sizing mode, it is

recommended that the application use the maximum pixels

per line mode is used when measurements are made. The

durations to be measured are shown generically in Figure 13

and apply to both horizontal and vertical timings. Since

measurements are made in terms of OSD pixels, the

ratio of OSD pixels per line to the video pixels per line

must be applied to the data below to attain measurements in terms of video pixels.

1. Flyback or sync period: The duration of either the sync

input or the horizontal flyback, in either horizontal lines

(vertical) or pixels (horizontal).

2. Back porch period: The duration between the trailing

edge of the sync or flyback pulse and the leading edge

of the first detected video, in either lines (vertical) or

pixels (horizontal).

3. Front porch: The duration between the trailing edge of

the last detected video and the leading edge of the sync

or flyback pulse, in either lines (vertical) or pixels (horizontal).

The video period is the duration between the leading edge of

the first detected video and the trailing edge of the last

detected video, in either lines (vertical) or OSD pixels (horizontal). This period is calculated by the microcontroller with

the measured periods above.

As the video may start and finish at different positions on the

screen, depending upon the image, the measured horizontal

porches and video time may vary from line to line. To overcome this, the periods should be measured over at least one

entire field. The hardware records the shortest back porch

and front porch periods used over the measured period. The

possible error for the above measurements are within 1 to 2

OSD pixels.

The video period is the duration between the leading edge of

the first detected video and the trailing edge of the last

detected video, in either lines (vertical) or OSD pixels (horizontal). This period is calculated by the microcontroller with

the measured periods above.

The analog front end video detection is also utilized by the

Video Data Interface for decoding of color bar data. It is

critical to note again that the threshold for video detection is 80mV above the internal V

the minimum rise time requirement of the driving PC

video card must be at least 10.0ns. Excessively slow rise

times in the PC video card will prevent the video detect

circuit from working properly.

To perform an auto size calculation, the following instruction

sequence must be done by the MCU:

voltage, and also

REF

www.national.com 20

Video Detection for Auto-Sizing & Auto-Centering (Continued)

20096953

FIGURE 13. Timing Intervals

Please see the OSD Programming section for more detailed

Auto Size Calculation Instruction Sequence

Set register bits 0xFFF8[5] and 0xFFF8[4] to high

•

Set register bits 0xFFFD[3] to low

•

Set register bit 0x8400[6] to high

•

Wait for 0x8400[7] to become high by itself

•

When 0x8400[7] is high, then read auto size data regis-

•

ters 0x8580 to 0x858F

Set register bits 0xFFFD[3] to high

•

Set register bits 0xFFF8[5] and 0xFFF8[4] to low

•

PLL Lock Detect and Horizontal

Input Select

During the monitor initialization routine by the MCU, register

bit 0xFFFD[3] must be set high. This bit is only set low during

OSD display operation and auto size calculations. Please

see the instructions above for Auto Size calculations.

The following sequence which involves register 0xFFFD and

0xFFF8 must be done by the MCU when the OSD is enabled. Register bits, 0xFFF8[5:4], control the PLL lock detect

override function.

Before writing to memory to setup the OSD, or

enabling OSD:

Set register bit 0x8400[0] to high

•

Set register bits 0xFFF8[5] and 0xFFF8[4] to high

•

Set register bits 0xFFFD[3] to low

•

Initialize OSD and write to memory

•

Set register bits 0x8400[1] and/or 0x8400[2] to high

•

Before disabling OSD:

Set register bits 0x8400[1] and/or 0x8400[2] to low

•

Set register bits 0xFFFD[3] to high

•

Set register bits 0xFFF8[5] and 0xFFF8[4] to low

•

Set register bit 0x8400[0] to low

•

information or displaying OSD pages and accessing the

RAM

Hi-Brite Video Enhancement

Functional Description

The LM1276 enables a desired area of the CRT monitor

display to be enhanced for vivid TV quality images. The

LM1276 along with the software that is provided by National

Semiconductor is fully self-sufficient and independent of the

microcontroller in generating and controlling Hi-Brite windows.

HI-BRITE VIDEO PROCESSING

The enhancement is achieved with programmable emphasis, programmable center frequency, and an additional Contrast adjustment control that is separate from the normal

Video Contrast Control of the preamp. Having an independent contrast control allows the user to adjust the video gain

normally, having the higher gain to have a “brighter” picture

within the Hi-Brite window. The emphasis control is used to

give more “sparkle” to the highlighted video. Video that is

processed by the emphasis control has peaking added to the

video. Both the amplitude and the duration of the peaking

are adjustable through the NSC software, optimizing the

emphasis for different video resolutions. Maximum peaking

is 20%.

EMPHASIS

Emphasis is the amount of overshoot on the video signal.

Referring to Figure 14 the overshoot is the ratio of the

overshoot voltage to the video level after the emphasis has

settled out of the output signal. The typical overshoot is

about 20%. The peak measurement is taken 9 ns from the

rising edge. This delay gives a more accurate peak measurement by avoiding any ringing that may occur at the rising

edge. Overshoot is defined in percent as:

LM1276

www.national.com21

Hi-Brite Video Enhancement

Functional Description

LM1276

FIGURE 14. Overshoot Measurement

Bits 0 to 2 in registers 0x85C8, 0x85CA, or 0x85CC control

the emphasis. When a “4” is programmed into these bits the

overshoot is typically 11%. A “0” will give no overshoot in the

Hi-Brite window.

CENTER FREQUENCY

Shown in Figure 15 is how the center frequency is measured. The center frequency is expressed as the time it takes

the overshoot to settle to within 5% of the DC level of the

pulse.

(Continued)

20096972

Bits 4 to 7 in register 0x85C1 control the center frequency.

When an “8” is programmed into 0x85C1[7:4] the t

Center Freq

is typically 80 ns. An “F” will give about 145 ns. A “0” will give

no emphasis in the Hi-Brite window.

HI-BRITE USER MODES

There are 3 different modes whose settings are to be preset

by the MCU. Text Mode, Movie Mode, and Picture Mode

each have their own HiBrite Contrast and Overshoot registers (See the Preamp Interface Registers Table). When the

user selects a particular mode, the preset register settings of

that mode become in effect. There is also a 4th mode, which

is the Custom Mode. The Custom Mode, however can be

adjusted by the user through the HiBrite Software, and is not

preset by the MCU. These modes can ONLY be selected or

changed from one to another through the HiBrite Software.

There is no I

2

C register to select the effective mode. The

default mode for the LM1276 is the Movie Mode. Thus, the

Contrast and Overshoot settings that will be in effect when a

window is initially drawn or when the Full Screen HiBrite

function is called will be that of the settings preset for the

Movie Mode.

FULL SCREEN HI-BRITE

The LM1276 is capable of applying HiBrite on the entire

screen without the need for Software. In the absence of

Software, this provides an alternative means of achieving

emphasis and contrast boost on the picture through I

2

C. The

contrast setting and overshoot that will be applied when this

function is enabled will be that of the previously selected

User mode, during the last instance that the software was in

operation. For example, if the user last selected the Picture

Mode in the Software preference menu, before exiting the

program, then the subsequent enabling of the Full Screen

function through I

being in effect on the full screen. The I

2

C will result in the Picture Mode settings

2

C bits that enable this

function are 0x8590[5:4]. Setting 0x8590[5] high will disable

the HiBrite Window Generation circuit that works together

with the Software, and 0x8590[4] enables the Full Screen

HiBrite. The Window Generation Circuit must be shut off by

0x8590[5] in order for 0x8590[4] to have an effect. Thus, to

activate the Full Screen feature, simply set 0x8590[5:4] to

high, and to deactivate, set 0x8590[5:4] to low.

20096973

FIGURE 15. Center Frequency Measurement

www.national.com 22

HI-BRITE WINDOW GENERATION OPTIONS

Up to 8 separate windows can be drawn and enabled simultaneously, with programmable sizes and coordinates. The

Hi-Brite video enhancement can also be applied to the entire

desktop rather than to a specific window area or it can be

applied to everything outside of the drawn window(s). All of

this window programming can be achieved with National

Semiconductor’s software, and does not require any interfacing with a microcontroller.

OSD Generator Operation

LM1276

FIGURE 16. OSD Generator Block Diagram

PAGE OPERATION

Figure 16 shows the block diagram of the OSD generator.

OSD screens are created using any of the 512 predefined

characters stored in the mask programmed ROM. The

LM1276 offers a full 9-bit character code operation, which

allows the entire 512 ROM character set to be displayed at

once. The 9-bit character code operation enables all 512

character addresses to be independently accessed on one

page.

OSD ROM CONFIGURATION

The OSD ROM is equivalent to two 256 character ROMs of

the type used in the LM1253A and LM1237. Each ROM can

be considered as a group of 3 banks, (192) two-color characters followed by 1 bank (64) four-color characters. Physically, the combined ROM is then 192x2 + 64x4 + 192x2 +

64x4.

END-OF-LINE AND END-OF-SCREEN CODES

Please refer to the LM1247 datasheet for details.

BLANK CHARACTER REQUIREMENT

Five of the 512 Character ROM should be reserved as blank.

ROM Addresses 0 and 1 are for the use of the End-OfScreen and End-Of-Line characters as mentioned above.

ROM addresses 32, 63, and 511 must be reserved for test

20096927

engineering purposes. All other ROM addresses are usable,

and any that are unused must be filled with at least a

duplicate character. Any other addresses except for those

listed above should not be left blank.

DISPLAYING AN OSD IMAGE

Consecutive lines of characters make up the displayed window. These characters are stored in the page RAM through

2

C compatible bus. Each line can contain any number of

the I

characters up to the limit of the displayable line length (dependent on the pixels per line register), although some restrictions concerning the enhanced features apply on character lines longer than 32 characters. The number of

characters across the width and height of the page can be

varied under I

2

C compatible control, but the total number of

characters that can be stored and displayed on the screen is

limited to 512 including any End-of-Line and End-of-Screen

characters. The horizontal and vertical start position can also

be programmed through the I

2

C compatible bus.

WINDOWS

Please refer to the LM1247 datasheet for details.

OSD VIDEO DAC

The Gain of the OSD DAC is now programmable bya3Bit

OSD contrast register, for 8 levels.

www.national.com23

OSD Generator Operation (Continued)

OSD VIDEO TIMING

LM1276

Please refer to the LM1247 datasheet for details.

CHARACTER CELL

Please refer to the LM1247 datasheet for details.

FOUR COLOR FONT AS TWO 2-COLOR

Please refer to the LM1247 datasheet for details.

ATTRIBUTE TABLES

Each character has an attribute value assigned to it in the

page RAM. The attribute value is 4 bits wide, making each

character entry in the page RAM 13 bits wide in total. The

attribute value acts as an address, which points to one of 16

entries in either the two-color attribute table RAM or the

four-color attribute table RAM. The attribute word in the table

contains the coding information which defines which color is

represented by color 0 and color 1 in the two color attribute

table and color 0, color 1, color 2, color 3 in the four-color

attribute table. Each color is defined by a 9-bit value, with 3

bits assigned to each channel of RGB. A dynamic look-up

table defines each of the 16 different color ‘palettes’. As the

look-up table can be dynamically coded by the microcontroller over the I

assigned to any one of 2

maximum of 64 different colors to be used within one page

using the 4-color characters, with up to 4 different colors

within any one character and 32 different colors using the

2-color characters, with 2 different colors within any one

character.

TRANSPARENT DISABLE

In addition to the 9 lines of video data, a tenth data line is

generated by the transparent disable bit. When this line is

activated, the black color code will be translated as ‘transparent’ or invisible. This allows the video information from

the PC system to be visible on the screen when this is

present. Note that this feature is enabled on any black color

in any of the first 8 attribute table entries.

VARIABLE TONE TRANSPARENCY

When the transparency is already in effect the tone of the

transparency can be adjusted. The contrast of the PC video

that is visible in the “transparent area” can be varied from

100% (fully transparent) to 0% (completely black). For example, 50% reduction in contrast would provide a semitransparent effect. Just as in the conventional transparency

mode, variable tone transparency is effective on backgrounds or foregrounds with black color codes from only the

first 8 attribute table entries. This feature is controlled by

0x85C0[6:0], and is only available when the transparency

mode is already enabled.

OSD WINDOW FADE IN/FADE OUT

The OSD window can be opened and closed with a fade

in/fade out effect. The interval for fading in and fading out the

OSD window in the horizontal and vertical direction is variable and can be set by the microcontroller. This allows the

OSD window to be opened or closed in the vertical directions, horizontal direction, or from the upper left to lower right

corner. Assuming the desired time to typically complete a full

fade in or fade out is 0.5 seconds, and if the vertical scan

frequency is for example, 60 Hz, the number of steps is:

2

C compatible interface, each color can be

9

(i.e. 512) choices. This allows a

With a typical OSD window that is 300 pixels wide and 180

video lines long, the horizontal and vertical intervals would

be:

For a smooth fade in or fade out animation from the upper

left corner to the lower right corner, the horizontal to vertical

interval ratio must be matched to the aspect ratio of the OSD

window. In the example above, the 300 pixel wide by 180

lines long OSD window has an aspect ratio of 5:3. Thus, the

horizontal to vertical interval ratio should be set to 5/3 or

10/6. With an OSD window aspect ratio of 3:2, the H/V

intervals can be set to 3/2, 6/4, 9/6, 12/8, or 15/10 for optimal

operation. If the calculated aspect ratio of an OSD window is

a non-integer ratio, the H/V interval ratio should meet or

exceed the aspect ratio. For example, if the OSD aspect

ratio is 3.7:2 (or 1.85:1), the H/V intervals should be set to

2/1, 4/2, 6/3, 8/4, 10/5, or 12/6. The fade in/out speed

increases as H/V interval settings are increased. The OSD

window can also be faded in or out in only one direction if

desired, by setting the horizontal interval to 0 for fading in/out

strictly in the vertical direction or setting the vertical interval

to 0 for fading in/out in the horizontal direction. In interlaced

video formats, it is not recommended to fade in and fade out

the OSD in the vertical direction, and should be only faded in

the horizontal direction. The fade in/out function can be

enabled/disabled with bit 5 of the frame control register,

0x8400, and the horizontal & vertical intervals are controlled

by setting register 0x8429. The OSD window fade in/out

feature can only be used with OSD window 1.

ENHANCED FEATURES

Please refer to the LM1247 datasheet for details.

Microcontroller Interface

The microcontroller interfaces to the LM1276 preamp using

2

C compatible interface. The protocol of the interface

the I

begins with a Start Pulse followed by a byte comprised of a

7-bit Slave Device Address and a Read/Write bit. Since the

first byte is composed of both the address and the read/write

bit, the address of the LM1276 for writing is 0xBA

(10111010b) and the address for reading is 0xBB

(10111011b). The development software provided by National Semiconductor will automatically take care of the difference between the read and write addresses if the target

address under the communications tab is set to 0xBA. Fig-

ures 17, 18 show a write and read sequence on the I

compatible interface.

WRITE SEQUENCE

The write sequence begins with a start condition, which

consists of the master pulling SDA low while SCL is held

high. The Slave Device Write Address, 0xBA, is sent next.

Each byte that is sent is followed by an acknowledge bit.

When SCL is high, the master will release the SDA line. The

slave must pull SDA low to acknowledge. The register to be

2

C

www.national.com 24

Microcontroller Interface (Continued)

written to is next sent in two bytes, the least significant byte

being sent first. The master can then send the data, which

consists of one or more bytes. Each data byte is followed by

an acknowledge bit. If more than one data byte is sent, the

data will increment to the next address location. See Figure

17.

READ SEQUENCE

Read sequences are comprised of two I

fer sequences: The first is a write sequence that only transfers the two byte address to be accessed. The second is a

read sequence that starts at the address transferred in the

previous address only write access and increments to the

next address upon every data byte read. This is shown in

2

C compatible trans-

LM1276

Figure 18. The write sequence consists of the Start Pulse,

the Slave Device Write Address (0xBA), and the Acknowledge bit; the next byte is the least significant byte of the

address to be accessed, followed by its Acknowledge bit.

This is then followed by a byte containing the most significant address byte, followed by its Acknowledge bit. Then a

Stop bit indicates the end of the address only write access.

Next the read data access will be performed beginning with

the Start Pulse, the Slave Device Read Address (0xBB), and

the Acknowledge bit. The next 8 bits will be the read data

driven out by the LM1276 preamp associated with the address indicated by the two address bytes. Subsequent read

data bytes will correspond to the next increment address

locations. Data should only be read from the LM1276 when

both OSD windows and the Fade In/ Fade Out are disabled.

LM1276 Address Map

20096938

FIGURE 17. I2C Compatible Write Sequence

20096939

FIGURE 18. I2C Compatible Read Sequence

www.national.com25

LM1276 Address Map (Continued)

CHARACTER ROM

LM1276

The 512 font characters from 0x0000 to 0x7FFF can be read from ROM by addressing the individual pixel rows of the desired

character. Since the characters have 12 columns, it takes two bytes to read a given row of pixels within one character. Since the

characters have 18 rows, a total of 36 bytes are needed to read the entire character. The 16-bit address for reading a row of pixels

is formed as follows:

Address = (N * 0x1000) + (I * 0x40) + (R * 0x02) + H

where: N = bank number (0x0 ≤ N ≤ 0x7)

I = Character Index within its respective bank (0x00 ≤ I ≤ 0x3F)

R = row of pixels within the character (0x00 ≤ R ≤ 0x11)

H = 0 for low byte, 1 for high byte

Note that bit 0 of the Character Font Access Register, 0x8402, needs to be set to 0 to read the 2-color fonts. In order to read the

four-color fonts, two complete reads are needed. Set bit 0 of the Character Font Access Register, 0x8402, toa0toread the least

significant plane and toa1toread the most significant plane. See Table 3.

TABLE 3. Character ROM Addressing

Address Range R/W Description 0x8402[0] N

0x0000–0x2FFF R These are the first 3 banks of two-color, read-only ROM character

fonts. There are 192 total characters in this range.

0x3000–0x3FFF R This is bank 3 of four-color, read-only ROM character fonts. There

are 64 total characters in this range.

0x4000–0x6FFF R These are banks 4, 5 and 6 of two-color, read-only ROM character

fonts. There are 192 characters in this range.

0x7000–0x7FFF R This is bank 7 of four-color, read-only ROM character fonts. There

are 64 total characters in this range.

0 0x0

0/1 0x3

0 0x4

0/1 0x7

0x1

0x2

0x5

0x6

When read back, the low byte will contain the first eight pixels of the row with data bit 0 corresponding to the left most bit in the

pixel row. The high byte will contain the remaining four pixels in the least significant nibble. The remaining 4 bits, shown as “X”,

are “don’t care” bits, and should be discarded. Bit 3 of the high byte corresponds to the right most pixel in the pixel row. This is

shown in Table 4.

TABLE 4. Character ROM Read Data

Register Address D7 D6 D5 D4 D3 D2 D1 D0

Fonts - 2 Color 0x0000–0x2FFE PIXEL[7:0]

+1 XXXX PIXEL[11:8]

Fonts - 4 Color 0x3000–0x3FFE PIXEL[7:0]

+1 XXXX PIXEL[11:8]

Fonts - 2 Color 0x4000–0x6FFE PIXEL[7:0]

+1 XXXX PIXEL[11:8]

Fonts - 4 Color 0x7000–0x7FFE PIXEL[7:0]

+1 XXXX PIXEL[11:8]

Display Page 0x8000–0x83FF X

DISPLAY PAGE RAM

Full 512 Displayable Character Access

This address range (0x8000–0x81FF) contains the 512 characters, which comprise the displayable OSD screens. There must be

at least one End-Of-Screen code (0x00) in this range to prevent unpredictable behavior. NOTE: To avoid any unpredictable

behavior, this range should be cleared by writinga0tobit3oftheFRMCTRL1 Register, 0x8400, immediately after power up.

There may also be one or more pairs of End-Of-Line and Skip Line codes. The character code is 9 bits long. The codes and

characters are written as 8-bit bytes, but are stored with their attributes in groups of 13 bits. When writing, one byte describes a

displayed character (CC), Attribute Code (AC), End-Of-Screen (EOS), End-Of-Line (EOL) or Skip Line (SL) code.

When reading characters from RAM, bit 1 of the Character Font Access Register (0x8402) determines whether the lower 8 bits

or upper 5 bits of the Page RAM are returned. Table 5 gives the lower byte read, which is the first 8 character code bits when bit

1 of the Character Font Access Register is a 0. Table 6 gives the upper byte read, which is the 9th character code bit and 4

attribute code bits when this bit is set to a 1.

CHAR_CODE[7:4] or

reserved

CHAR_CODE[3:0] or

ATTR_CODE

www.national.com 26

LM1276 Address Map (Continued)

TABLE 5. Page RAM Lower Byte Read Data

Address Range D7 D6 D5 D4 D3 D2 D1 D0

0x8000–0x81FF CHAR_CODE[7:0]

TABLE 6. Page RAM Upper Byte Read Data

Address D7 D6 D5 D4 D3 D2 D1 D0

0x8000–0x81FF X X X CC[8] ATTR_CODE[3:0]

RAM Data Format

Each of the 512 locations in the page RAM is comprised of a 13-bit code consisting of an 9-bit character or control code, and a

4-bit attribute code. Each of the characters is stored in sequence in the page RAM in bits 8:0. Special codes are used between

lines to show where one line ends and the next begins, and also to allow blank (or ‘skipped’) single scan lines to be added

between character lines. Table 7 shows the format of a character stored in RAM. Note that even though this is a 13-bit format,

reading and writing characters and codes is done in 8-bit bytes.

TABLE 7. Page RAM Format (9-bit mode)

ATTRIBUTE CODE CHARACTER CODE

ATT[3:0] CC[8:0]

Bits 8-0 determined which of the 512 characters is to be called from the character ROM. Bits 12–9 address one of the 16

attributes in the table containing the colors and enhanced features to be used for this particular character. Two separate attribute

tables are used, one for 2-color characters, and the other for 4-color characters. Note there are 16 available attributes for 2-color

characters and a different set of 16 available attributes for 4-color characters.

LM1276

End-Of-Line Code

To signify the end of a line of characters, a special End-Of-Line (EOL) code is used in place of a character code. This code, shown

in Table 8 tells the OSD generator that the character and attribute codes which follow must be placed on a new line in the

displayed window. Bits 8–1 are zeros, bit 0 is a one. The attribute that is stored in Page RAM along with this code is not used.

TABLE 8. End-Of-Line Code

ATTRIBUTE CODE END-OF-LINE CODE

ATT[3:0] 000000001

Skip-Line Code

In order to allow finer control of the vertical spacing of character lines, each displayed line of characters may have up to 15

skipped (i.e., blank) lines between it and the line beneath it. Each skipped line is treated as a single character pixel line, so

multiple scan lines may actually be displayed in order to maintain accurate size relative to the character cell.An internal algorithm

maintains vertical height proportionality (see the section on Constant Character Height Mechanism). To specify the number of

skipped lines, the first character in each new line of characters is interpreted differently than the others in the line. Its data are

interpreted as shown in Table 9, with the attribute bits setting the color of the skipped lines.

TABLE 9. Skipped-Line Code

ATTRIBUTE CODE NUMBER OF SKIPPED LINES

ATT[3:0] XXXXX SL[3:0]

Bits 8–4 are reserved and should be set to zero. Bits 3– 0 determine how many blank pixel lines will be inserted between the

present line of display characters and the next. A range of 0–15 may be selected. Bits 12– 9 determine which attribute the pixels

in the skipped lines will have, which is always called from the two-color attribute table. The pixels will have the background color

(Color 0) of the selected attribute table entry.

Note that the pixels in the first line immediately below the character may be overwritten by the pixel override system that creates

the button box. (Refer to the Button Box Formation Section for more information).

After the first line, each new line always starts with an SL code, even if the number of skipped lines to follow is zero. This means

an SL code must always follow an EOL code. An EOL code may follow an SL code if several ‘transparent’ lines are required

between sections of the window. See Example 3 in the LM1247 data sheet for a case where skipped lines of zero characters are

displayed, resulting in one window being displayed in two segments.

End-Of-Screen Code

To signify the end of the window, a special End-Of-Screen (EOS) code is used in place of a End-Of-Line (EOL) code. There must

be at least one EOS code in the Page RAM to avoid unpredictable behavior. This can be accomplished by clearing the RAM by

writinga0tobit3oftheFRMCTRL1 Register, 0x8400, immediately after power up.

www.national.com27

LM1276 Address Map (Continued)

LM1276

ATTRIBUTE CODE END-OF-SCREEN CODE

ATT[3:0] 000000000

Bits 8– 0 are all zeros. Bits 12–9 will have the previously entered AC but this is not used and so these bits are “don’t cares”.

OSD CONTROL REGISTERS

These registers, shown in Table 11, control the size, position, enhanced features and ROM bank selection of up to two

independent OSD windows. These registers are compatible to the LM1246 OSD control Registers. Any bits marked as “X”

are reserved and should be written to with zeros and should be ignored when the register is read. Additional register detail is

provided in the Control Register Definitions Section, later in this document.

Register Address Default D7 D6 D5 D4 D3 D2 D1 D0

FRMCTRL1 0x8400 0x98 ASZDN ASZEN FEN TD CDPR D2E D1E OSE

FRMCTRL2 0x8401 0x80 PIXELS_PER_LINE[2:0] BLINK_PERIOD[4:0]

CHARFONTACC 0x8402 0x00 SRST RSV RSV LIMIT VSYPOL HSYPOL ATTR FONT4

VBLANKDUR 0x8403 0x10 X VBLANK_DURATION[6:0]

CHARHTCTRL 0x8404 0x51 CHAR_HEIGHT[7:0]

BBHLCTRLB0 0x8405 0xFF G[1:0] R[2:0] B[2:0]

BBHLCTRLB1 0x8406 0x01 XXXXXXXG[2]

BBLLCTRLB0 0x8407 0x00 G[1:0] R[2:0] B[2:0]

BBLLCTRLB1 0x8408 0x00 XXXXXXXG[2]

CHSDWCTRLB0 0x8409 0x00 G[1:0] R[2:0] B[2:0]

CHSDWCTRLB1 0x840A 0x00 XXXXXXXG[2]

ROMSIGCTRL 0x840D 0x00 XXXXXXXCRS

ROMSIGDATAB0 0x840E 0x00 CRC[7:0]

ROMSIGDATAB1 0x840F 0x00 CRC[15:8]

HSTRT1 0x8410 0x62 HPOS1[7:0]

VSTRT1 0x8411 0x32 VPOS1[7:0]

W1STRTADRL 0x8412 0x00 ADDR1[7:0]

W1STRTADRH 0x8413 0x00 XXXXXXXADDR1[8]

COLWIDTH1B0 0x8414 0x00 COL1[7:0]

COLWIDTH1B1 0x8415 0x00 COL1[15:8]

COLWIDTH1B2 0x8416 0x00 COL1[23:16]

COLWIDTH1B3 0x8417 0x00 COL1[31:24]

HSTRT2 0x8418 0x56 HPOS2[7:0]

VSTRT2 0x8419 0x5B VPOS2[7:0]

W2STRTADRL 0x841A 0x00 ADDR2[7:0]

W2STRTADRH 0x841B 0x01 XXXXXXXADDR2[8]

COLWIDTH2B0 0x841C 0x00 COL2[7:0]

COLWIDTH2B1 0x841D 0x00 COL2[15:8]

COLWIDTH2B2 0x841E 0x00 COL2[23:16]

COLWIDTH2B3 0x841F 0x00 COL2[31:24]

Any registers in the range of 0x8420– 0x8426 are for National Semiconductor internal use only and should not be written to under

application conditions.

FADE_INTVL 0x8429 0x35 V_INTVL[3:0] H_INVTVL[3:0]

TABLE 10. End-Of-Screen Code

TABLE 11. OSD Control Register Detail

PREAMPLIFIER CONTROL

These registers, shown in Table 12, control the gains, DAC outputs, PLL, horizontal and vertical blanking, OSD contrast and DC

offset of the video outputs. Registers 0x8430– 0x8437 are compatible to the LM1246 Registers. Any bits marked as “X” are

reserved and should be written to with zeros and should be ignored when the register is read.Additional register detail is provided

in the Control Register Definitions Section, later in this document.

www.national.com 28

LM1276 Address Map (Continued)

TABLE 12. LM1276 Preamplifier Interface Registers

Register Address Default D7 D6 D5 D4 D3 D2 D1 D0

BGAINCTRL 0x8430 0x60 X BGAIN[6:0]

GGAINCTRL 0x8431 0x60 X GGAIN[6:0]

RGAINCTRL 0x8432 0x60 X RGAIN[6:0]

CONTRCTRL 0x8433 0x60 X CONTRAST[6:0]

DAC1CTRL 0x8434 0x80 DAC1[7:0]

DAC2CTRL 0x8435 0x80 DAC2[7:0]

DAC3CTRL 0x8436 0x80 DAC3[7:0]

DAC4CTRL 0x8437 0x80 DAC4[7:0]

DACOSDDCOFF 0x8438 0x24 DCF[1:0] OSD CONT[2:0] DC OFFSET[2:0]

GLOBALCTRL 0x8439 0x00 BI[7:6] BI_EN PLLCAL RSV RSV PS BV

AUXCTRL1 0x843A 0x03 HB_POS[4:0]

AUXCTRL2 0x843E 0x06 RSV RSV CLMP

OSD_TRANSP

TONE

EMPHASIS

CENTF

ABLCTRL0 0x85C4 0x0F RSV ABL0[3:0]

ABLCTRL1 0x85C5 0x0F RSV ABL1[3:0]

ABLCTRL2 0x85C6 0x0F RSV ABL2[3:0]

ABLCTRL3 0x85C7 0x0F RSV ABL3[3:0]

PEAKCNTLTXT 0x85C8 0x30 RSV TM_OVRSHT[2:0]

HLCONTRTXT 0x85C9 0x60 RSV HILIGHT_CONTRAST[6:0]

PEAKCNTLPIC 0x85CA 0x03 RSV PM_OVRSHT[2:0]

HLCONTRPIC 0x85CB 0x60 RSV HILIGHT_CONTRAST[6:0]

PEAKCNTLMOV 0x85CC 0x03 RSV MM_OVRSHT[2:0]

HLCONTRTMOV 0x85CD 0x60 RSV HILIGHT_CONTRAST[6:0]

0x85C0 0x7F RSV OSD TONE[6:0]

0x85C1 0x80 CENTF[3:0] RSV

CLMP

SW

OOR VB2 RSV RSV

HBPOS

_EN

RSV HBD

LM1276

TWO-COLOR ATTRIBUTE RAM

This RAM is identical to that of the LM1247. Please refer to the LM1247 datasheet for details.

FOUR-COLOR ATTRIBUTE RAM

This RAM is identical to that of the LM1247. Please refer to the LM1247 datasheet for details.

AUTO SIZE AND HI-BRITE REGISTERS

These registers, shown in Table 13 provide measured values for the Auto size function and control the Hi-Brite function.

Registers 0x8580 — 0x858A are compatible to the LM1246 Auto Size Registers. Reserved bits are for internal use and

should not be written to, and any value read should be ignored.

TABLE 13. LM1276 Auto Size Registers

Register Address Default D7 D6 D5 D4 D3 D2 D1 D0

H_FP0 0x8580 0xFF HFP[7:0]

H_FP1 0x8581 0x07 RSV HFP[10:8]

HF_S0 0x8582 0xFF HFL_HS[7:0]