CLC031A

SMPTE 292M/259M Digital Video Deserializer /

Descrambler with Video and Ancillary Data FIFOs

General Description

The CLC031A SMPTE 292M / 259M Digital Video

Deserializer/Descrambler with Video and Ancillary Data

FIFOs is a monolithic integrated circuit that deserializes and

decodes SMPTE 292M, 1.485Gbps (or 1.483Gbps) serial

component video data, to 20-bit parallel data with a synchronized parallel word-rate clock. It also deserializes and decodes SMPTE 259M, 270Mbps, 360Mbps and

SMPTE 344M (proposed) 540Mbps serial component video

data, to 10-bit parallel data. Functions performed by the

CLC031A include: clock/data recovery from the serial data,

serial-to-parallel data conversion, SMPTE standard data decoding, NRZI-to-NRZ conversion, parallel data clock generation, word framing, CRC and EDH data checking and handling, Ancillary Data extraction and automatic video format

determination. The parallel video output features a variabledepth FIFO which can be adjusted to delay the output data

up to 4 parallel data clock periods. Ancillary Data may be

selectively extracted from the parallel data through the use

of masking and control bits in the configuration and control

registers and stored in the on-chip FIFO. Reverse LSB dithering is also implemented.

The unique multi-functional I/O port of the CLC031A provides external access to functions and data stored in the

configuration and control registers. This feature allows the

designer greater flexibility in tailoring the CLC031A to the

desired application. The CLC031A is auto-configured to a

default operating condition at power-on or after a reset command. Separate power pins for the PLL, deserializer and

other functional circuits improve power supply rejection and

noise performance.

The CLC031A has a unique Built-In Self-Test (BIST) and

video Test Pattern Generator (TPG). The BIST enables comprehensive testing of the device by the user. The BIST uses

the TPG as input data and includes SD and HD component

video test patterns, reference black, PLL and EQ pathologicals and a 75% saturation, 8 vertical colour bar pattern, for

all implemented rasters. The colour bar pattern has optional

transition coding at changes in the chroma and luma bar

data. The TPG data is output via the parallel data port.

The CLC030, SMPTE 292M / 259M Digital Video Serializer

with Ancillary Data FIFO and Integrated Cable Driver, is the

ideal complement to the CLC031A.

The CLC031A’s internal circuitry is powered from +2.5 Volts

and the I/O circuitry from a +3.3 Volt supply. Power dissipation is typically 850mW. The device is packaged in a 64-pin

TQFP.

Features

n SDTV/HDTV serial digital video standard compliant

n Supports 270 Mbps, 360 Mbps, 540 Mbps, 1.483 Gbps

and 1.485 Gbps serial video data rates with

auto-detection

n LSB de-dithering option

n Uses low-cost 27MHz crystal or clock oscillator

reference

n Fast VCO lock time:

n Built-in self-test (BIST) and video test pattern generator

(TPG)*

n Automatic EDH/CRC word and flag processing

n Ancillary Data FIFO with extensive packet handling

options

n Adjustable, 4-deep parallel output video data FIFO

n Flexible control and configuration I/O port

n LVCMOS compatible control inputs and clock and data

outputs

n LVDS and ECL-compatible, differential, serial inputs

n 3.3V I/O power supply and 2.5V logic power supply

operation

n Low power: typically 850mW

n 64-pin TQFP package

n Commercial temperature range 0˚C to +70˚C

* Patent applications made or pending.

<

500 µs at 1.485 Gbps

Applications

n SDTV/HDTV serial-to-parallel digital video interfaces for:

— Video editing equipment

— VTRs

— Standards converters

— Digital video routers and switchers

— Digital video processing and editing equipment

— Video test pattern generators and digital video test

equipment

— Video signal generators

September 2004

CLC031A SMPTE 292M/259M Digital Video Deserializer / Descrambler with Video and Ancillary

Data FIFOs

Ordering Information

Order Number Package Type NS Package Number

CLC031AVEC 64-Pin TQFP VEC-64A

© 2004 National Semiconductor Corporation DS200201 www.national.com

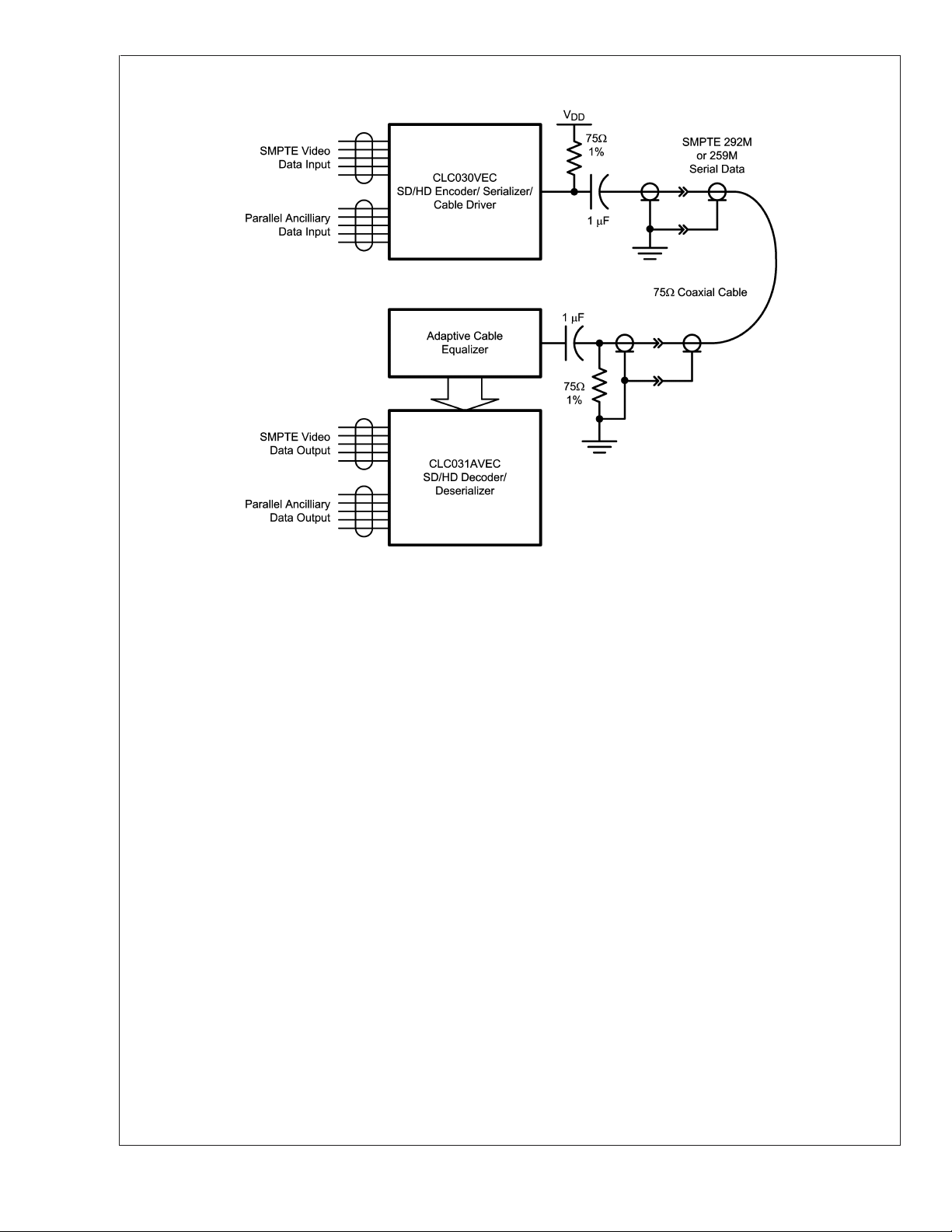

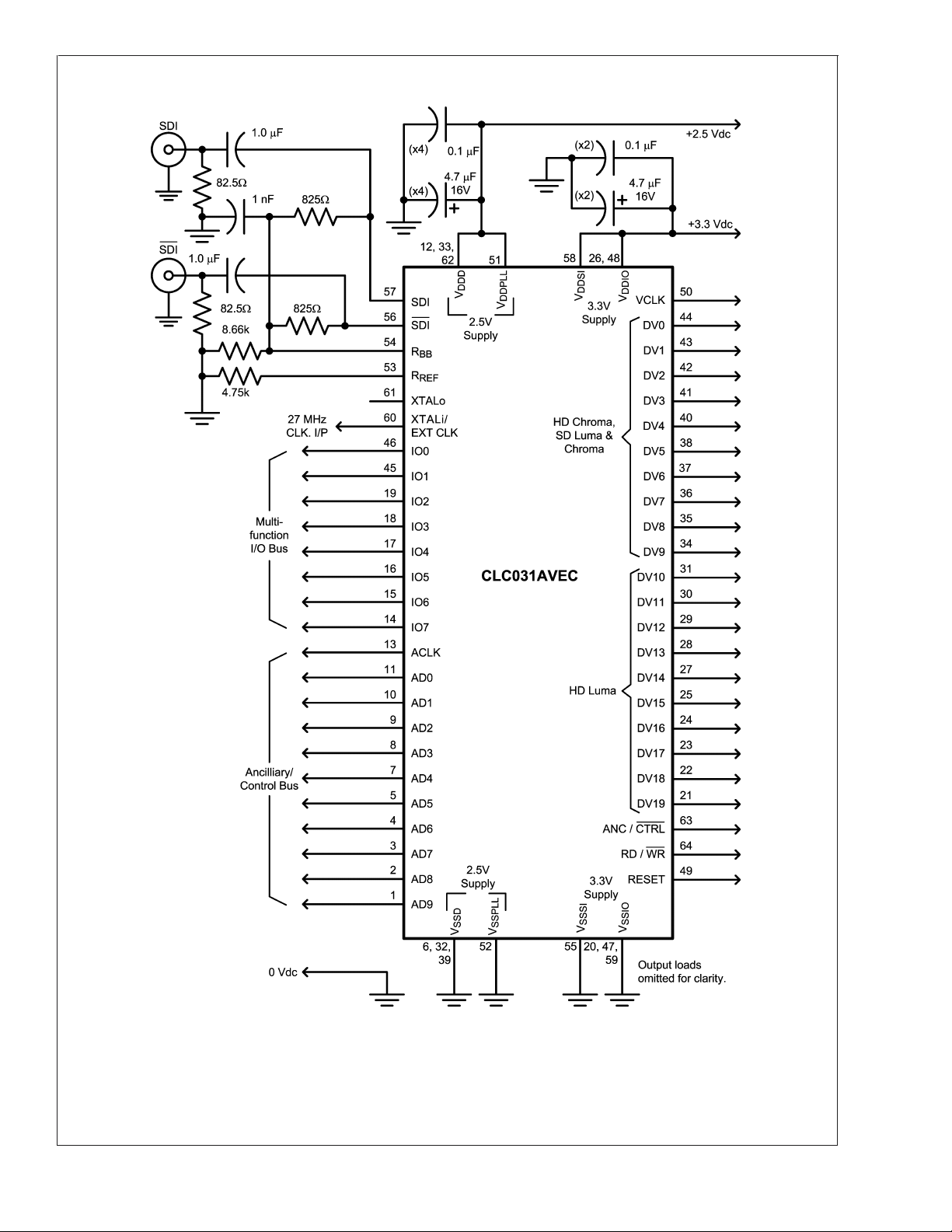

Typical Application

CLC031A

20020101

www.national.com 2

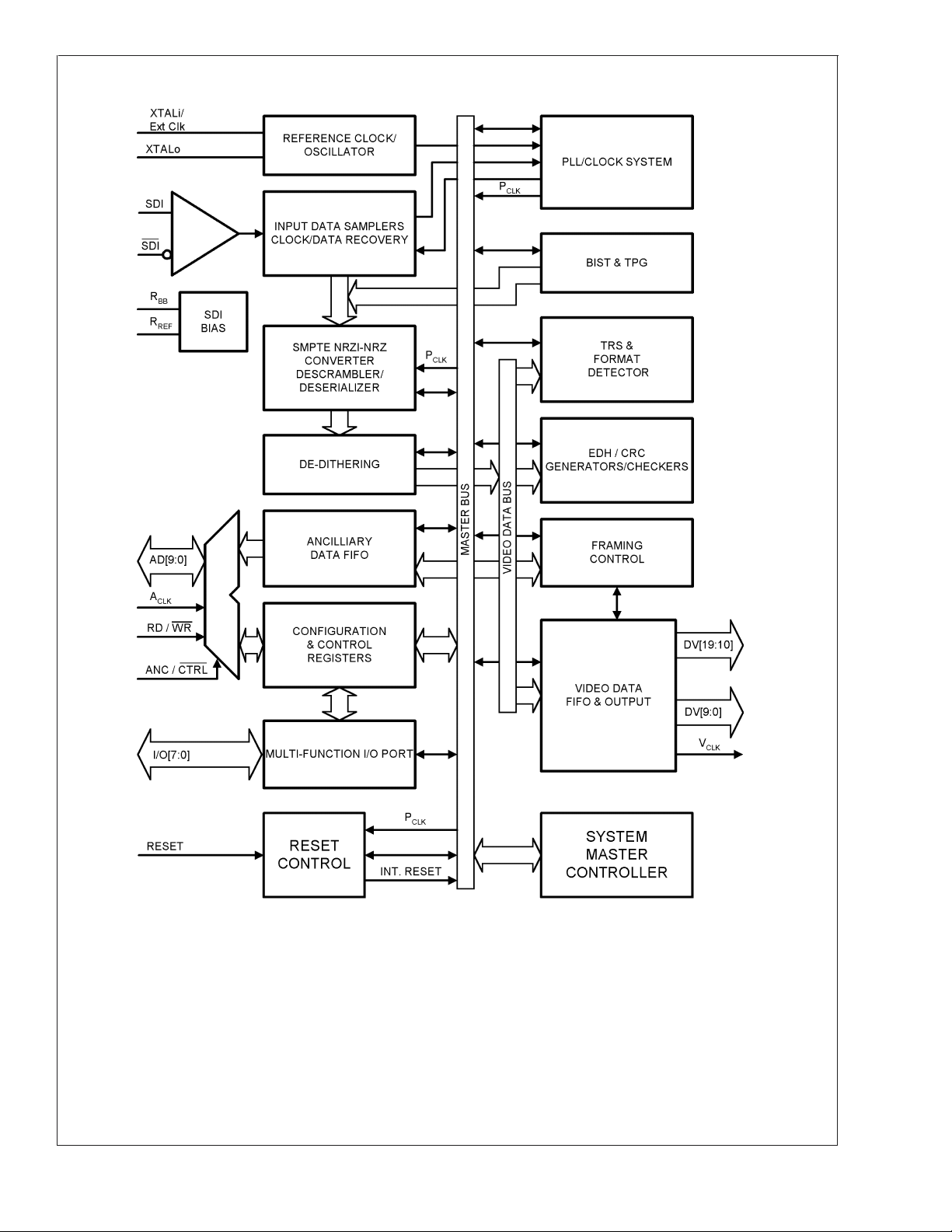

Block Diagram

CLC031A

20020102

www.national.com3

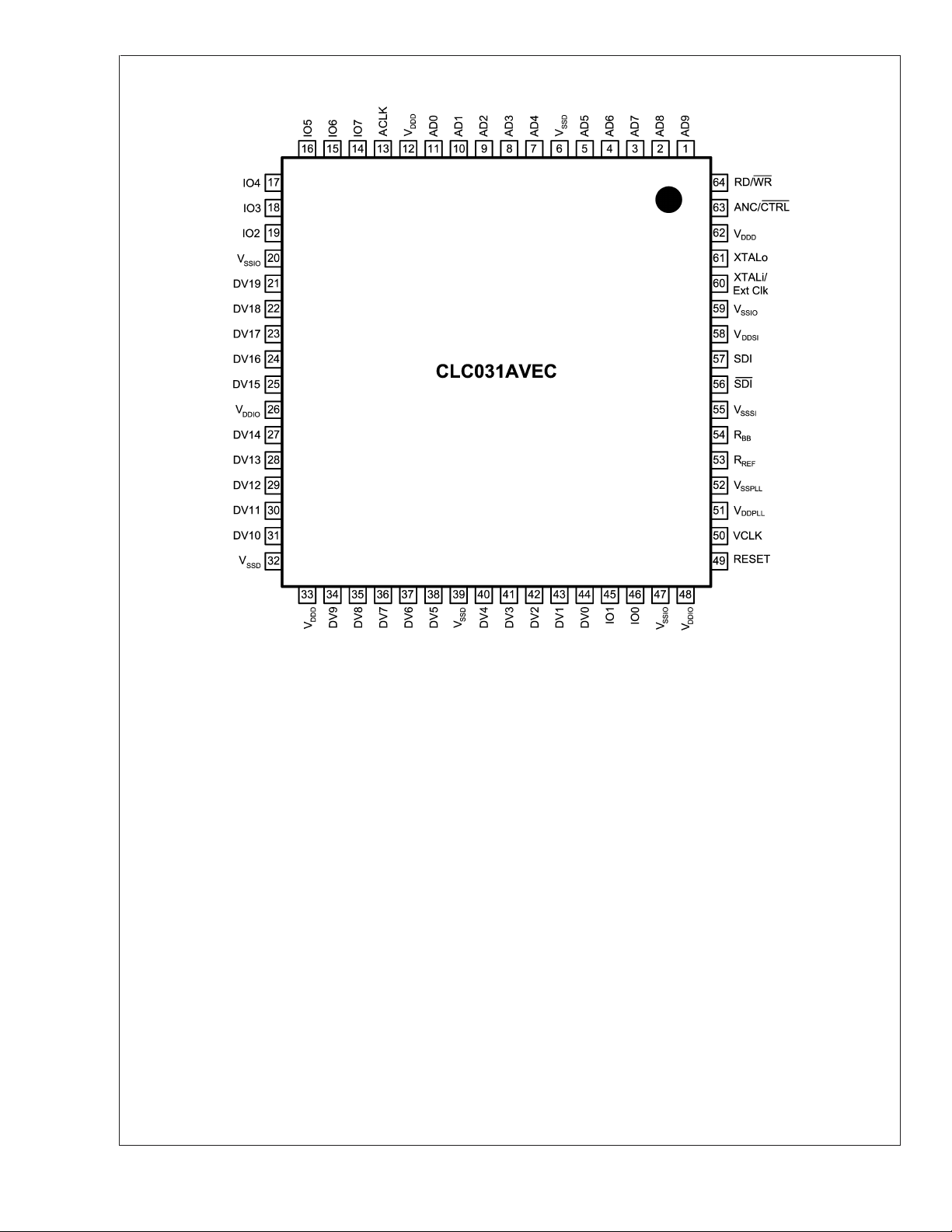

Connection Diagram

CLC031A

64-Pin TQFP

Order Number CLC031AVEC

See NS Package Number VEC-64A

20020103

www.national.com 4

CLC031A

Absolute Maximum Ratings (Note 1)

It is anticipated that this device will not be offered in

a military qualified version. If Military/Aerospace speci-

fied devices are required, please contact the National

Semiconductor Sales Office / Distributors for availability

and specifications.

CMOS I/O Supply Voltage

(V

DDIO–VSSIO

SDI Supply Voltage

(V

DDSI–VSSSI

Digital Logic Supply Voltage

(V

DDD–VSSD

PLL Supply Voltage

(V

DDPLL–VSSPLL

CMOS Input Voltage

(Vi):

CMOS Output Voltage

(Vo):

): 4.0V

): 4.0V

): 3.0V

): 3.0V

V

−0.15V to

SSIO

+0.15V

V

DDIO

V

−0.15V to

SSIO

+0.15V

V

DDIO

CMOS Input Current (single input):

Vi=V

Vi=V

CMOS Output Source/Sink Current:

I

Output Current: +300 µA

BB

I

Output Current: +300 µA

REF

SDI Input Voltage

(Vi):

−0.15V: −5 mA

SSIO

+0.15V: +5 mA

DDIO

V

SSSI

V

±

−0.15V to

+0.15V

DDSI

6mA

Package Thermal Resistance

@

θ

0 LFM Airflow 40.1˚C/W

JA

@

θ

500 LFM Airflow 24.5˚C/W

JA

θ

JC

5.23˚C/W

Storage Temp. Range: −65˚C to +150˚C

Junction Temperature: +150˚C

Lead Temperature (Soldering 4

Sec): +260˚C

ESD Rating (HBM): 6.0 kV

ESD Rating (MM): 400 V

Recommended Operating Conditions

Symbol Parameter Conditions Reference Min Typ Max Units

V

V

V

V

T

DDIO

DDSD

DDD

DDPLL

A

CMOS I/O Supply Voltage V

SDI Supply Voltage V

Digital Logic Supply

Voltage

PLL Supply Voltage V

Operating Free Air

Temperature

DDIO−VSSIO

DDSI−VSSSI

V

DDD–VSSD

DDPLL–VSSPLL

3.150 3.300 3.450 V

2.375 2.500 2.625 V

0 +70 ˚C

Required Input Conditions

(Note 9)

Symbol Parameter Conditions Reference Min Typ Max Units

V

IN

t

r,tf

BR

V

CM(SDI)

V

IN(SDI)

V

IN(SDI)

tr,t

SDI

f

Input Voltage Range

Rise Time, Fall Time 10%–90% 1.0 1.5 3.0 ns

All LVCMOS

Inputs

SMPTE 259M, Level C

V

SSIO

V

DDIO

270

SMPTE 259M, Level D 360

Serial Input Data Rate

SMPTE 344M 540

SDI, SDI

M

SMPTE 292M 1,483

SMPTE 292M 1,485

Common Mode Voltage VIN= 125 mV

SDI Serial Input Voltage,

Single-ended

SDI Serial Input Voltage,

Differential

20%–80%, SMPTE 259M

Rise Time, Fall Time

Data Rates

20%–80%, SMPTE 292M

Data Rates

P-P

SDI, SDI

V

SSSI

+1.0V

125 800 880 mV

125 800 880 mV

0.4 1.0 1.5 ns

V

DDSI

−0.05V

270 ps

V

BPS

V

P-P

P-P

www.national.com5

Required Input Conditions (Continued)

Symbol Parameter Conditions Reference Min Typ Max Units

CLC031A

f

ACLK

DC

ACLK

tr,t

f

Ancillary / Control Data

Clock Frequency

Duty Cycle, Ancillary Clock 45 50 55 %

Ancillary / Control Clock

and Data Rise Time, Fall

10%–90% 1.0 1.5 3.0 ns

A

CLK

V

CLK

Time

t

S

t

H

R

REF

f

EXT CLK

f

XTAL

Setup Time, ADNto A

or IONto A

CLK

Edge

Hold Time, Rising Edge

to ADNor A

A

CLK

IO

N

Bias Supply Reference

Resistor

External Clock Frequency Ext Clk

Crystal Frequency Figure 6 XTALo, XTALi

Rising

CLK

CLK

3.0 1.5 ns

Control Data Input or

I/O Bus Input

to

IO

,ADN,A

N

CLK

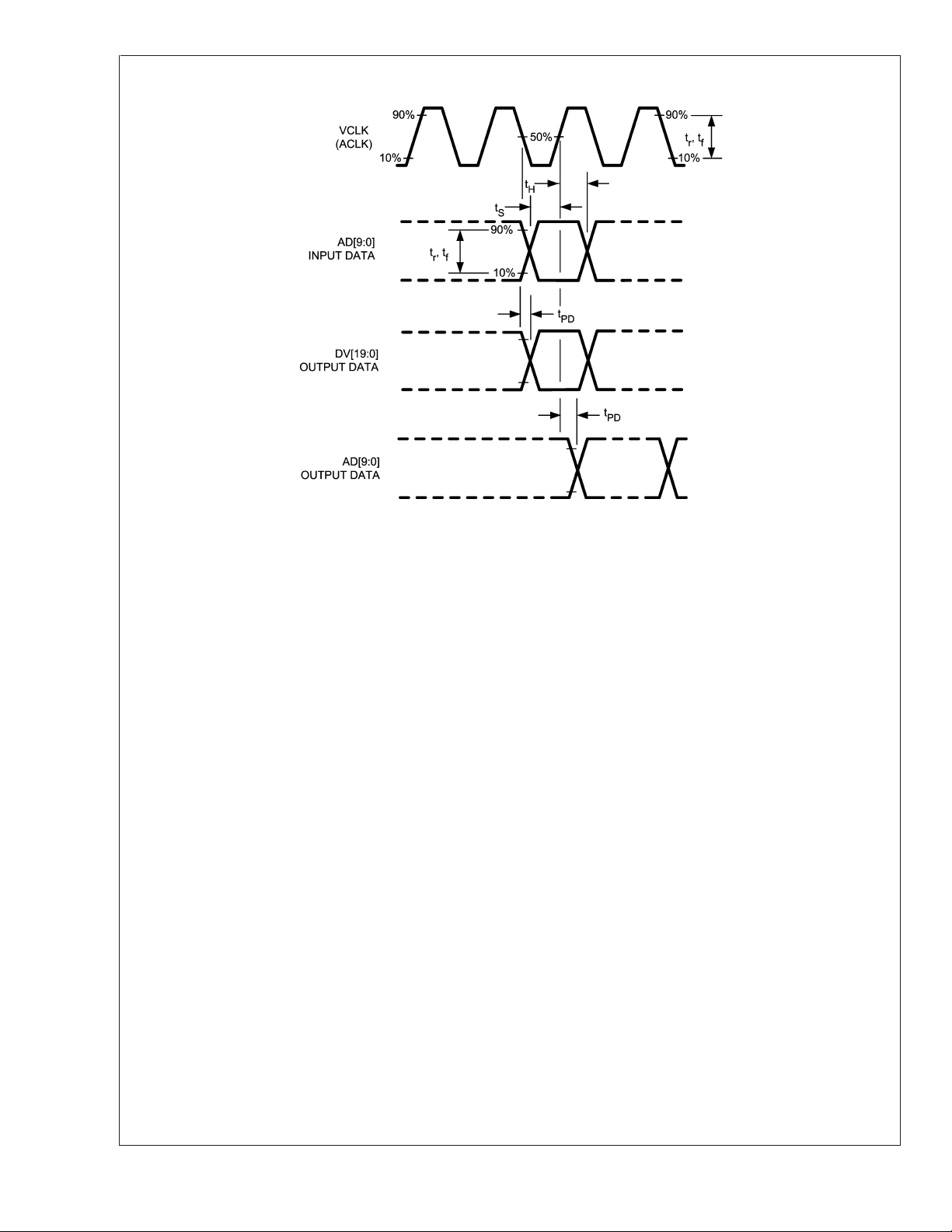

Timing Diagram

3.0 1.5 ns

Tolerance 1% 4.75k Ω

−100

ppm

27.0

+100

ppm

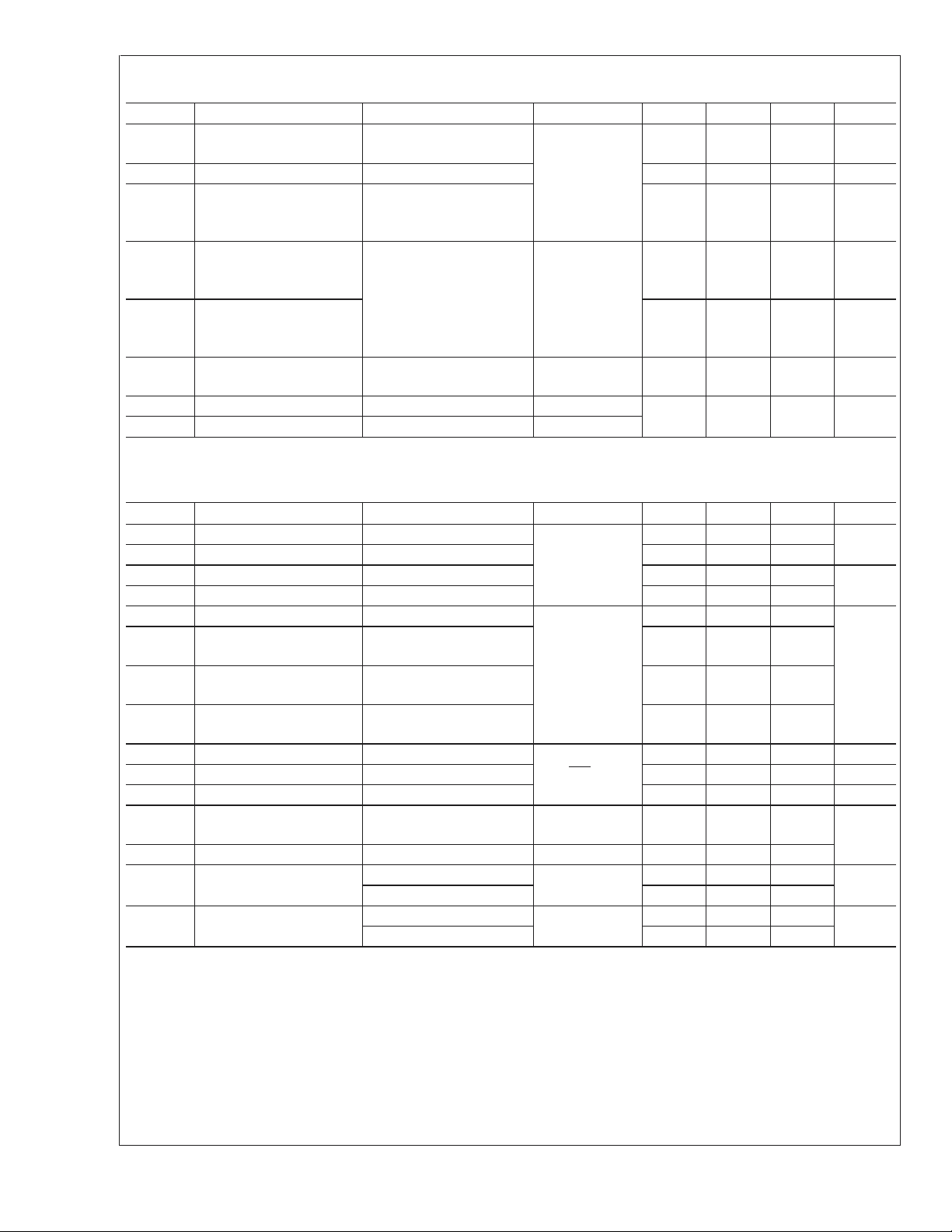

DC Electrical Characteristics

Over Supply Voltage and Operating Temperature ranges, unless otherwise specified (Notes 2, 3).

Symbol Parameter Conditions Reference Min Typ Max Units

V

V

I

I

V

V

V

V

V

I

V

I

I

I

I

IH

IL

IH

IL

OH

OL

OHV

OLP

SDI

SDI

TH

BB

REF

DD

DD

(3.3V)

(2.5V)

Input Voltage High Level

Input Voltage Low Level V

Input Current High Level VIH=V

Input Current Low Level VIL=V

(Note 8) +85 +150

DDIO

SSIO

All LVCMOS

Inputs

Output Voltage High Level IOH=−2mA

Output Voltage Low Level IOL=+2mA V

All LVCMOS

Outputs

Minimum Dynamic V

Maximum Dynamic V

OH

OL

IOH=−2mA

(Note 6)

IOL=+2mA

(Note 6)

Serial Data Input Voltage

Serial Data Input Current

SDI, SDI

Input Thereshold Over VCM range

Bias Supply Output

Current

Reference Output Current R

Power Supply Current,

3.3V Supply, Total

Power Supply Current,

2.5V Supply, Total

= 8.66kΩ 1% −220 −188

R

BB

= 4.75kΩ 1% −290 −262

REF

270M

1,485M

270M

1,485M

Data Rate

BPS

Data Rate 47.0 50.0

BPS

Data Rate

BPS

Data Rate 220 340

BPS

V

DDIO,VDDSI

V

DDD,VDDPLL

2.0 V

SSIO

DDIO

0.8

−1 −20

2.4 2.7 V

V

SSIO

+0.3

V

DDIO

SSIO

DDIO

V

SSIO

+0.5V

−0.5

V

SSIO

+0.4

125 800 880 mV

±

1

<

100 mV

±

10 µA

38.0 45.0

80 120

MHz

MHz

V

µA

V

P-P

µA

mA

mA

www.national.com 6

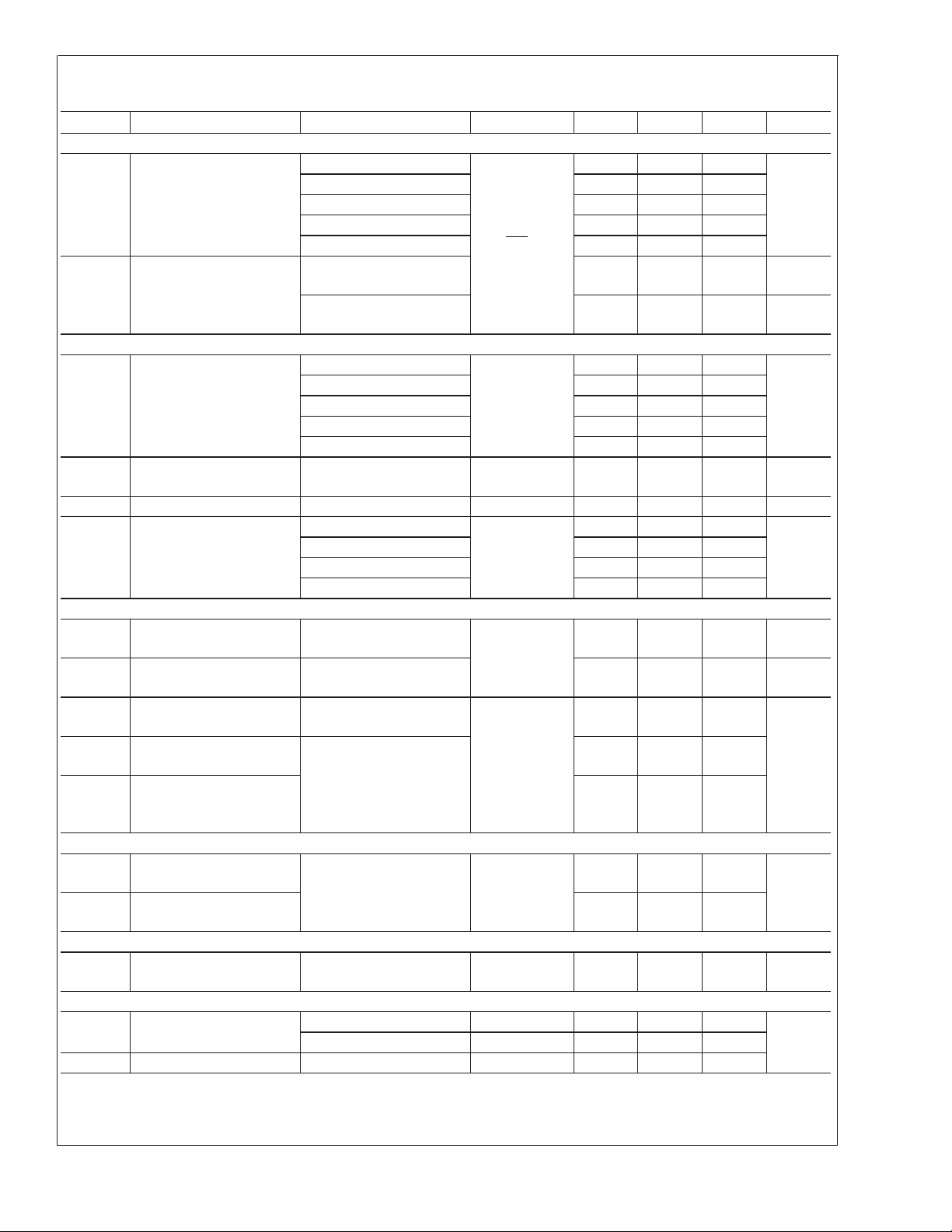

AC Electrical Characteristics

Over Supply Voltage and Operating Temperature ranges, unless otherwise specified (Note 3).

Symbol Parameter Conditions Reference Min Typ Max Units

Serial Video Data Inputs

SMPTE 259M, Level C

SMPTE 259M, Level D 360

BR

SDI

Serial Input Data Rate

SMPTE 344M 540

SMPTE 292M 1,483

SDI, SDI

0.4 1.0 1.5 pns

t

r,tf

Rise Time, Fall Time

SMPTE 292M 1,485

20%–80%, SMPTE 259M

Data Rates

20%–80%, SMPTE 292M

Data Rates

Parallel Video Data Outputs

f

VCLK

t

pd

DC

SMPTE 259M, 270M

Video Output Clock

Frequency

SMPTE 267M, 360M

SMPTE 344M, 540M

SMPTE 292M, 1,483M

SMPTE 292M, 1,485M

Propagation Delay, Video

Clock to Video Data Valid

V

Duty Cycle, Video Clock V

50%–50%

BPS

BPS

BPS

V

BPS

BPS

V

Timing Diagram

CLK

CLK

CLK

to DV

N

27MHz

t

JIT

Video Data Output Clock

Jitter

36MHz 1.4

54MHz 1.0

V

CLK

74.25MHz 0.5

Parallel Ancillary / Control Data Inputs, Multi-function Parallel Bus Inputs

f

ACLK

DC

t

r,tf

t

S

t

H

A

Ancillary / Control Data

Clock Frequency

Duty Cycle, Ancillary Data

Clock

Output Rise Time, Fall

Time

Setup Time, ADNto A

or IONto A

CLK

CLK

Rising Edge

Hold Time, Rising Edge

A

IO

CLK

N

to ADNor A

CLK

to

ANC Data clock

(Note 7)

10%–90%

Control Data Input or I/O

Bus Input

A

CLK

,ADN,A

IO

N

CLK

Timing Diagram

45 50 55 %

1.0 1.5 3.0

3.0 1.5

3.0 1.5

Parallel Ancillary / Control Data Outputs

t

pd

t

pd

Propagation Delay, Clock

to Control Data

Propagation Delay, Clock

to Ancillary Data

50%–50%

to AD

A

CLK

N

Timing Diagram

Multi-function Parallel I/O Bus

t

r,tf

Rise Time, Fall Time 10%–90%

IO0–IO7

Timing Diagram

1.0 1.5 3.0 ns

PLL/CDR, Format Detect

t

LOCK

t

FORMAT

Note 1: “Absolute Maximum Ratings” are those parameter values beyond which the life and operation of the device cannot be guaranteed. The stating herein of

these maximums shall not be construed to imply that the device can or should be operated at or beyond these values. The table of “Electrical Characteristics”

specifies acceptable device operating conditions.

Lock Detect Time

Format Detect Time All Rates 20

SD Rates (Note 5) 0.32 1.0

270

M

270 ps

27.0

36.0

54.0

MHz

74.176

74.25

0.5 2.0 ns

50±5%

2.0

ns

V

CLK

MHz

8.5

11.5

CLC031A

BPS

P-P

ns

ns

msHD Rates (Note 5) 0.26 1.0

www.national.com7

AC Electrical Characteristics (Continued)

Note 2: Current flow into device pins is defined as positive. Current flow out of device pins is defined as negative. All voltages are referenced to V

V

=0V.

SSSI

CLC031A

Note 3: Typical values are stated for V

Note 4: Spec. is guaranteed by design.

Note 5: Measured from rising-edge of first SDI cycle until Lock Detect bit goes high (true). Lock time includes CDR phase acquisition time plus PLL lock time.

Note 6: V

simultaneous output switching conditions. V

conditions.

Note 7: When used to clock control data into or from the CLC031A, the duty cycle restriction does not apply.

Note 8: I

Note 9: Required Input Conditions are the electrical signal conditions or component values which shall be supplied by the circuit in which this device is used in order

for it to produce the specified DC and AC electrical output characteristics.

Note 10: Functional and certain other parametric tests utilize a CLC030 as the input source to the SDI inputs of the CLC031A. The CLC030 is DC coupled to the

inputs of the CLC031A. Typical V

and V

OHV

includes static current required by input pull-down devices.

IH

are measured with respect to reference ground. V

OLP

DDIO=VDDSI

= 800 mV, VCM= 2.9 V.

IN

= +3.3V, V

is the lowest output HIGH voltage or output droop that may occur under dynamic simultaneous output switching

OHV

DDD=VDDPLL

= +2.5V and TA= +25˚C.

is the peak output LOW voltage or ground bounce that may occur under dynamic

OLP

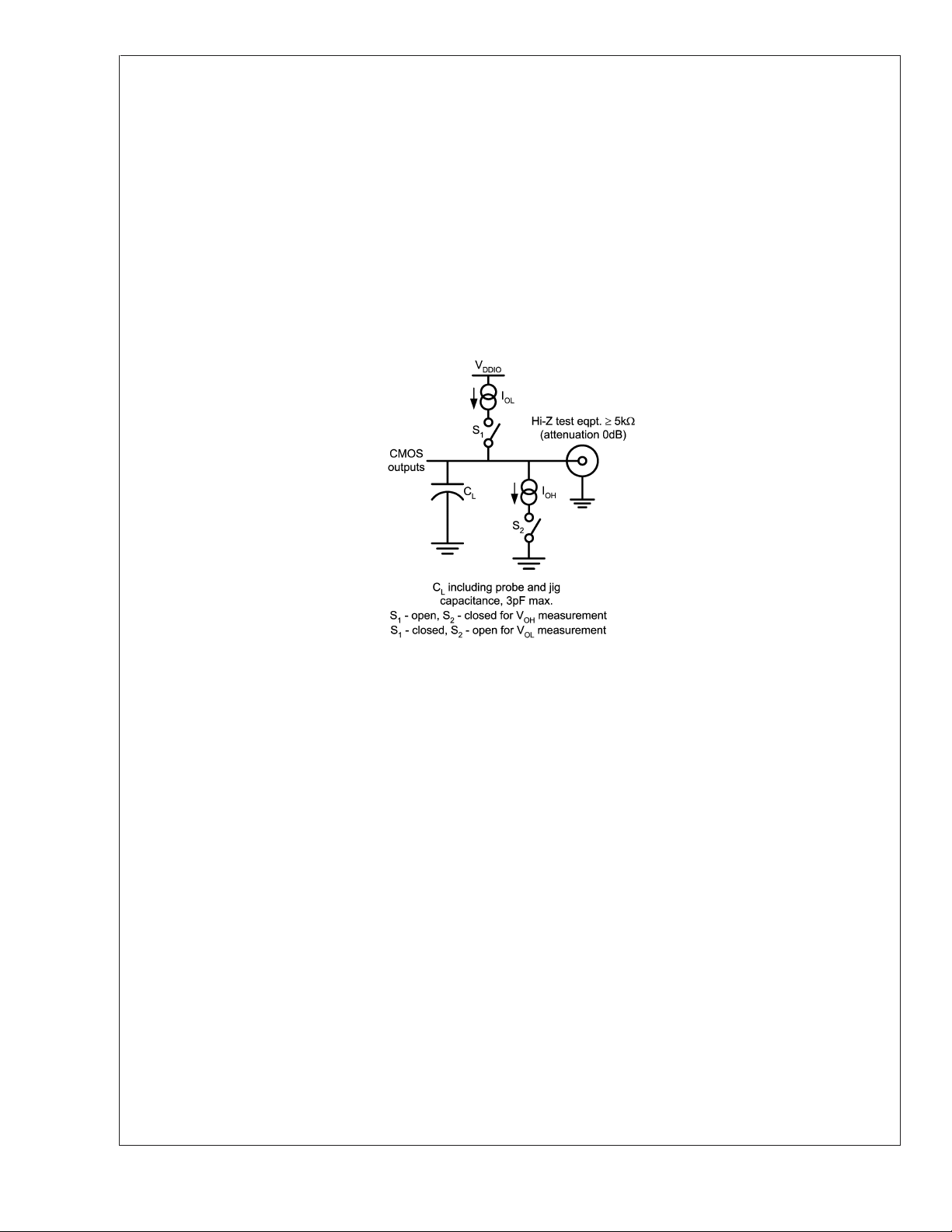

Test Loads

SSIO=VSSD

=

20020104

www.national.com 8

Test Circuit

CLC031A

20020107

www.national.com9

Timing Diagram

CLC031A

20020108

Device Operation

INTRODUCTION

The CLC031A SMPTE 292M/259M Digital Video

Deserializer/Decoder is used in digital video signal origination and destination equipment: cameras, video tape recorders, telecines, editors, standards converters, video test and

other equipment. It decodes and converts serial SDTV or

HDTV component digital video signals into parallel format.

The CLC031A decoder/deserializer processes serial digital

video (SDV) signals conforming to SMPTE 259M, SMPTE

344M (proposed) or SMPTE 292M and operates at serial

data rates of 270 Mbps, 360 Mbps, 540 Mbps, 1.483 Gbps

and 1.485 Gbps. Corresponding parallel output data rates

are 27.0 MHz, 36.0 MHz, 54.0 MHz, 74.176MHz and

74.25 MHz.

The CLC031A accepts ECL or LVDS serial data input sig-

nals. Outputs signals are compatible with LVCMOS logic

devices.

Note: In the following explanations, these logical equivalences are observed: ON

≡

and OFF

Disabled≡Reset≡False≡Logic_0.

≡

Enabled≡Set≡True≡Logic_1

VIDEO DATA PATH

The Serial Data Inputs (SDI) accept serial video data at

SMPTE 259M standard definition, SMPTE 344M (proposed)

or SMPTE 292M high-definition data rates. These inputs

accept standard ECL or LVDS signal levels and may be used

single-ended or differentially. Inputs may be DC or AC

coupled, as required, to devices and circuits supplying the

data. Recommended operating conditions and all input DC

and AC voltage and current specifications shall be observed

when designing the input coupling circuits.

For convenience, a reference bias source, pin name R

REF

sets the reference current available from the input bias

source, pin name R

is 4.75kΩ, 1%. RBBis provided so that the SDI inputs

R

REF

. The recommended nominal value of

BB

may be supplied DC bias voltage via external resistors when

the inputs are AC-coupled. The bias source should be

loaded with a resistance to the V

current available at R

input biasing scheme using R

is 200µA. Figure 1 shows a typical

BB

BB

supply. The source

SS

and R

REF

.

,

www.national.com 10

Device Operation (Continued)

20020106

FIGURE 1. Optional Input Biasing Scheme

The SMPTE descrambler receives NRZI serial data, converts it to NRZ, then decodes it to either 10-bit standard

definition or 20-bit high definition parallel video data using

the reverse polynomial X

respective standard: SMPTE 259M, SMPTE 344M (proposed) or SMPTE 292M. The data reception bit order is

LSB-first. All data processing is done at the parallel rate.

The CLC031A incorporates circuitry that implements a

method for handling data that has been subjected to LSB

dithering. When so enabled, data from the de-scrambler is

routed for de-dithering. The De-Dither Enable bit in the

VIDEO INFO 0 control register enables this function. Dedithering of data present in the vertical blanking interval can

be selectively enabled by use of the V De-Dither Enable bit

in the VIDEO INFO 0 control register. The initial condition of

De-Dither Enable and V De-Dither Enable is OFF.

The descrambler supplies signals to theTRS character de-

tector which identifies the presence of the valid video data.

The TRS character detector processes the timing reference signals which control raster framing. TRS (sync) characters are detected and the video is aligned on word boundaries. Data is re-synchronized with the parallel word-rate

9

+X4+ 1 as specified in the

clock. Interraction and operation of the character alignment

control signals and indicators Framing Mode, Framing En-

able and NSP (New Sync Position) is described later in this

datasheet.

The CLC031A implements TRS character LSB-clipping as

prescribed in ITU-R BT.601. LSB-clipping causes all TRS

characters with a value between 000h and 003h to be forced

to 000h and all TRS characters with a value between 3FCh

and 3FFh to be forced to 3FFh. Clipping is done after descrambling and de-dithering.

Once the PLL attains lock, the video format detector processes the received data to determine the raster characteristics (video data format) and configure the CLC031A to

handle it. This assures that the parallel output data will be

properly formatted, that the correct data rate is selected and

that Ancillary Data and CRC/EDH data are correctly detected and checked. Supported parallel data formats or subformats may belong to any one of several component standards: SMPTE 125M, SMPTE 267M, SMPTE 260M, 274M,

295M or 296M. Refer to Table 4 for the supported formats.

(See also the Section Application Information section for

handling of other raster formats or format extensions developed after this device was designed). The detected video

standard information is passed to the device control system

and saved in the control registers from whence it may be

read by the user.

The CLC031A may be configured to operate in a single video

format by loading the appropriate FORMAT SET[4:0] control

data into the FORMAT 0 control register. Also, the CLC031A

may be configured to handle only the standard-definition

data formats by setting the SD ONLY bit or only the highdefinition data formats by setting the HD ONLY bit in the

FORMAT 0 control register. When both bits are reset, the

default condition, the part automatically detects the data rate

and range.

Aligned and de-processed parallel data passes into a

variable-depth video FIFO prior to output. Video FIFO depth

from 0 to 4 registers is set by a 3-bit word written into the

VIDEO FIFO Depth[2:0] bits in the ANC 0 control register.

The video FIFO permits adjustment of the parallel video data

output timing or delay at a parallel word rate. The occurence

of corresponding TRS indicator bits, EAV, SAV and NSP, in

the control register corresponds to the input register position

of the FIFO. This positioning permits a look-ahead function

in which the alignment status of the video data can be

determined up to four parallel clock periods prior to the

appearance of that data at the parallel data output.

The parallel video data is output on DV[19:0]. The 20-bit

parallel video data is organized so that for HDTV data, the

upper-order 10 bits DV[19:10] are luminance (luma) information and the lower 10 bits DV[9:0] are colour difference

(chroma) information. SDTV data use the lower-order 10-bits

DV[9:0] for both luma and chroma information. (The SDTV

parallel data is also duplicated on DV[19:10]). V

parallel output word rate clock signal. The frequency of V

CLK

is the

CLK

is appropriate to either the HD or SD data being processed.

Data is valid between the falling edges of a V

cycle. Data

CLK

may be clocked into external devices on the rising-edge of

. The DV[19:0] and V

V

CLK

signals are LVCMOS-

CLK

compatible.

CLC031A

www.national.com11

Device Operation (Continued)

ANCILLARY/CONTROL DATA PATH

CLC031A

The 10-bit ancillary and Control Data Port AD[9:0] serves

two functions in the CLC031A. Ancillary Data from the An-

cillary Data FIFO is output from this port after its recovery

from the video data stream. The utilization and flow of Ancillary Data from the device is managed by a system of control

bits, masks and IDs stored in the control data registers. This

port also provides read/write access to contents of the configuration and control registers. The signals RD/WR, ANC/

CTRL and A

CONTROL DATA FUNCTIONS

Control data is input to and output from the CLC031A using

the lower-order 8 bits AD[7:0] of the ancillary/Control Data

Port. This control data initializes, monitors and controls operation of the CLC031A. The upper two bits AD[9:8] of the

port function as handshaking signals with the device accessing the port. When either a control register read or write

address is being written to the port, AD[9:8] must be driven

as 00b (0XXh, where XX are AD[7:0]). When control data is

being written to the port, AD[9:8] must be driven as 11b

(3XXh, where XX are AD[7:0]). When control data is being

read from the port, the CLC031A will output AD[9:8] as 10b

(2XXh, where XX are output data AD[7:0]) and may be

ignored by the monitoring system.

Note: After either a manual or power-on reset, A

toggled three (3) times to complete initiallization of the An-

cillary and Control Data Port.

The sequence of clock and control signals for reading control

data from the ancillary/control data port is shown in Figure 2.

Control data read mode is invoked by making the ANC/

CTRL input low and the RD/WR input high. The 8-bit ad-

dress of the control register set to be accessed is input to the

port on bits AD[7:0]. To identify the data as an address,

AD[9:8] must be driven as 00b. The complete address word

will be 0XXh, where 0 is AD[9:8] and XX are AD[7:0]. The

address is captured on the rising edge of A

control data is being read from the port, the CLC031A will

output AD[9:8] as 10b (2XXh, where XX are output data

AD[7:0]) and may be ignored by the monitoring system. Data

being output from the selected register is driven by the port

immediately following the rising edge of A

address signal is removed. For optimum system timing, the

signals driving the address to the port should be removed

control data flow through the port.

CLK

CLK

must be

CLK

. When

CLK

or when the

immediately after the address is clocked into the port and

before or simultaneously with the falling edge of A

CLK

at the

end of that address cycle. Output data remains stable until

the next rising edge of A

and may be written into external

CLK

devices at any time after the removal of the address signal.

This second clock resets the port from drive to receive and

readies the port for another access cycle.

Example: Read the Full-field Flags via the AD port.

1. Set ANC/CTRL to a logic-low.

2. Set RD/WR to a logic-high.

3. Present 001h to AD[9:0] as the register address.

4. Toggle A

CLK

.

5. Release the bus driving the AD port.

6. Read the data present on the AD port. The Full-field

Flags are bits AD[4:0].

7. Toggle A

to release the AD port.

CLK

Figure 3 shows the sequence of clock and control signals for

writing control data to the ancillary/control data port. The

control data write mode is similar to the read mode. Control data write mode is invoked by making the ANC/CTRL

input low and the RD/WR input low. The 8-bit address of the

control register set to be accessed is input to the port on bits

AD[7:0]. When a control register write address is being

written to the port, AD[9:8] must be driven as 00b (0XXh,

where XX areAD[7:0]). The address is captured on the rising

edge of A

edge of A

. The address data is removed on the falling

CLK

. Next, the control data is presented to the port

CLK

bits AD[7:0] and written into the selected register on the next

rising edge of A

. When control data is being written to the

CLK

port, AD[9:8] must be driven as 11b (3XXh, where XX are

AD[7:0]). Control data written into the registers may be read

out non-destructively in most cases.

Example: Setup (without enabling) the TPG Mode via the

AD port using the 1125 line, 30 frame, 74.25MHz, interlaced

component (SMPTE 274M) colour bars as test pattern. The

TPG may be enabled after setup using the Multi-function I/O

port or by the control registers.

1. Set ANC/CTRL to a logic-low.

2. Set RD/WR to a logic-low.

3. Present 00Dh to AD[9:0] as the Test 0 register address.

4. Toggle A

CLK

.

5. Present 027h to AD[9:0] as the register data.

6. Toggle A

CLK

.

www.national.com 12

Device Operation (Continued)

FIGURE 2. Control Data Read Timing (2 read and 1 write cycle shown)

CLC031A

20020109

FIGURE 3. Control Data Write Timing

Ancillary Data Functions

The CLC031A can recover Ancillary Data from the serial

data stream. This Ancillary Data and related control characters are defined in the relevant SMPTE standards and may

reside in the horizontal and vertical blanking intervals. The

data can consist of different types of message packets including audio data. The serial Ancillary Data space must be

formatted according to SMPTE 291M. The CLC031A sup-

ports Ancillary Data in the chrominance channel (C’r/

C’b) only for high-definition operation. Ancillary Data for

standard definition follows the requirements of SMPTE

125M.

The Ancillary Data FIFO is sized to handle a maximum

length ANC data Type 1 or Type 2 packet without the ANC

Flag, 259 words. Defined in SMPTE 291M, the packet con-

20020110

sists of the Ancillary Data Flag, a 3-word Data ID and Data

Count, 255 8- or 10-bit User Data Words and a Checksum.

The design of the CLC031A Ancillary Data FIFO also allows

storage of up to 8 shorter length messages with total length

not exceeding 259 words including all ID information. Ancil-

lary Data is copied from the data stream into the Ancillary

Data FIFO. The parallel Ancillary Data will still be present in

the parallel chroma output DV[9:0]. ancillary flag information

is not extracted into the FIFO.

Copying of ANC data from the video data into the FIFO is

controlled by the ANC Mask and ANC ID bits in the control

registers. A system of flags, ANC FIFO Empty, ANC FIFO

90% Full, ANC FIFO Full and ANC FIFO Overrun are used

to monitor FIFO status. The details and functions of these

and other control words are explained later in this datasheet.

www.national.com13

Device Operation (Continued)

Figure 4 shows the relationship of clock, data and control

CLC031A

signals for reading Ancillary Data from the port AD[9:0].In

Ancillary Data read mode, 10-bit Ancillary Data is routed

from the Ancillary Data FIFO and read from the port

AD[9:0] at a rate determined by A

Ancillary Data read (output) mode is invoked by making the

ANC/CTRL input high and the RD/WR input high. Ancillary

Data is clocked from the FIFO on the L-H transition of A

Data may be read from the port on rising edges of A

after the specified propagation delay, until the FIFO is emp-

.

CLK

FIGURE 4. Ancillary Data Read Timing

CLK

CLK

tied. Data may only be read from the port when in the

Ancillary Data mode. Ancillary Data cannot be written to the

port.

To conserve power when the Ancillary Data function is not

being used, the internal Ancillary Data FIFO clock is disabled. This clock must be enabled before Ancillary Data may

be replicated into the FIFO for output. This internal FIFO

clock is controlled by FIFO CLOCK ENABLE, bit-6 of the

ANC 5 register (address 17h). The default condition of FIFO

.

,

CLOCK ENABLE is OFF. After enabling the internal FIFO

clock by turning this bit ON, A

must be toggled three (3)

CLK

times to propagate the enable to the clock tree.

20020111

MULTI-FUNCTION I/O PORT

The multi-function I/O port can be configured to provide

immediate access to many control and indicator functions

that are stored within the CLC031A’s configuration and control registers. The individual pins comprising this port are

assigned as input or output for selected functions stored in

the control data registers.

The multi-function I/O port is configured by way of an 8x6-bit

register bank consisting of registers I/O pin 0 CONFIG

through I/O pin 7 CONFIG. The contents of these registers

determine whether the port bits function as inputs or outputs

and to which control function or indicator each port bit is

assigned. Port bits may be assigned to access different

functions and indicators or any or all port bits may be assigned to access the same function or indicator (output

mode only). The same indicator or function should not be

assigned to more than one port bit as an input. Controls and

indicators that are accessible by the port and their corresponding selection addresses are given in the I/O Pin Configuration Register Addresses, Table 6. Table 2 gives the

control register bit assignments.

Data resulting from device operation will be sent to the

selected I/O port bit. This same data is also stored in the

configuration and control registers. Mapping the control and

indicator functions in this manner means that device operation will be immediately reflected at the I/O port pins thereby

ensuring more reliable real-time operation of the device

within and by the host system.

When a multifunction I/O port bit is used as input to a control

register bit, data must be presented to the I/O port bit and

clocked into the register bit using A

as shown in Figure 5.

CLK

Port timing for bit write operations is the same as for the

ANC/CTRL port operation.

20020112

FIGURE 5. I/O Port Data Write Timing

Example: Program multi-function I/O port bit-0 as the CRC

Luma Error bit output.

1. Set ANC/CTRL to a logic-low.

2. Set RD/WR to a logic-low.

3. Present 00Fh to AD[9:0] as the I/O PIN 0 CONFIG

register address.

4. Toggle A

CLK

.

5. Present 310h to AD[9:0] as the register data.

6. Toggle A

CLK

.

EDH/CRC SYSTEM The CLC031A has EDH and CRC character generation

and checking circuitry. The EDH system functions as de-

scribed in SMPTE Recommended Practice RP-165. The

CRC system functions as specified in SMPTE 292M. The

EDH/CRC polynomial generators/checkers accept parallel data from the de-serializing system and generate the

EDH and CRC check words for comparison with those received in the data.

The EDH Enable bit in the control register enables the EDH

generation and checking system. Incoming SDTV data is

checked for errors and the EDH flags are updated automati-

www.national.com 14

Device Operation (Continued)

cally. EDH errors are reported in the EDH0, EDH1, and

EDH2 register sets of the configuration and control registers.

Updated or new EDH check words and flags may be generated and inserted in the data. EDH check words are generated using the polynomial X

RP165. Generation and automatic insertion of new or corrected EDH check words is controlled by EDH Force and

EDH Enable bits in the control registers. EDH check words

and status flags are inserted in the parallel data at the

correct positions in the Ancillary Data space and formatted

per SMPTE 291M. After a reset, the initial state of all EDH

and CRC check characters is 00h.

The SMPTE 292M high definition video standard employs

CRC (cyclic redundancy check codes) error checking instead of EDH. The CRC consists of two 18-bit words generated using the polynomial X

292M. One CRC is used for luminance and one for chrominance data. The CRCs appear in the data stream following

the EAV and line number characters. The CRCs are checked

and errors are reported in the EDH0, EDH1, and EDH2

register sets of the configuration and control registers.

PHASE-LOCKED LOOP / CLOCK-DATA RECOVERY SYSTEM

The phase-locked loop and clock-data recovery (PLL/

CDR) system generates all internal timing and data rate

clocks for the CLC031A. The PLL/CDR system consists of

five main functional blocks: 1) the input buffer which receives

the incoming data, 2) input data samplers which oversample

the data coming from the input buffer, 3) a PLL (VCO, divider

chain, phase-frequency detector and internal loop filter)

which generates sampling and other system clocks, 4) a

digital CDR system to recover the oversampled serial input

data from the samplers and the digital system control and 5)

a rate detect controller which sequences the PLL to find the

data rate.

Using an oversampling technique, the timing information

encoded in the serial data is extracted and used to synchronize the recovered clock and data. The parallel data rate and

other clock signals are derived from the regenerated serial

clock. The parallel data rate clock is 1/10th of the serial data

rate clock for standard definition or 1/20th of the serial data

clock frequency for high definition. The data interface between the CDR and the digital processing block uses 10-bit

data plus the required clocks.

The PLL is held in coarse frequency lock by an external

27MHz clock signal, EXT CLK, or by an external 27MHz

crystal and internal oscillator. Upon power-on, EXT CLK is

the default reference. The internal oscillator and an external

crystal may be used as the reference by setting the OSCEN

bit in the CDR register. The reference clock reduces lock

latency and enhances format and auto-rate detection robust-

16+X12+X6

18+X5+X4

+ 1 per SMPTE

+ 1 per SMPTE

ness. PLL acquisition, data phase alignment and format

detection time is 20ms or less at 1.485Mbps. The VCO has

separate V

DDPLL

and V

power supply feeds, pins 51

SSPLL

and 52, which may be supplied power via an external lowpass filter, if desired.

20020105

FIGURE 6. Crystal and Load Circuit

A 27MHz crystal and load circuit may be used to provide the

reference clock. A fundamental mode crystal with the following parameters is used: frequency 27MHz, frequency toler-

±

30ppm, load capacitance 18pF, maximum drive level

ance

100µW, equivalent series resistance

<

50Ω, operating temperature range 0˚C to 70˚C. Refer to Figure 6 for a typical

load circuit and connection information.

The CLC031A indicates that the PLL is locked to the incoming data rate and that the CDR has acquired a phase of the

serial data by setting the Lock Detect bit in the Video Info 0

control register. Indication of the standard being processed

is retained in the FORMAT[4:0] bits in the FORMAT 1 control data register. Format data from this register can be

programmed for output on the multi-function I/O port. The

power-on default assigns Lock Detect as I/O Port bit 4.

POWER SUPPLIES, POWER-ON-RESET AND RESET INPUT

The CLC031A requires two power supplies, 2.5V for the core

logic functions and 3.3V for the I/O functions. The supplies

must be applied to the device in proper sequence. The 3.3V

supply must be applied prior to or coincident with the 2.5V

supply. Application of the 2.5V supply must not precede the

3.3V supply. It is recommended that the 3.3V supply be

configured or designed so as to control application of the

2.5V supply in order to satisfy this sequencing requirement.

The CLC031A has an automatic, power-on-reset circuit.

Reset initializes the device and clears TRS detection circuitry, all latches, registers, counters and polynomial

generators/checkers and resets the EDH/CRC characters to

00h. An active-HIGH-true, manual reset input is available at

pin 49. The reset input has an internal pull-down device and

may be considered inactive when unconnected.

Important: When power is first applied to the device or

following a reset, the ancillary and Control Data Port must

be initialized to receive data. This is done by toggling A

CLK

three times.

CLC031A

www.national.com15

Device Operation (Continued)

TEST PATTERN GENERATOR (TPG) AND BUILT-IN

CLC031A

SELF-TEST (BIST)

The CLC031A includes an on-board, parallel video test pat-

tern generator (TPG). Four test pattern types are available

in both HD and SD formats, NTSC and PAL standards, and

4x3 and 16x9 raster sizes. The test patterns are: flat-field

black, PLL pathological, equalizer (EQ) pathological and a

75%, 8-colour vertical bar pattern. The pathologicals follow

recommendations contained in SMPTE RP 178-1996 regarding the test data used. The colour bar pattern has optional bandwidth limiting coding in the chroma and luma data

transitions between bars. The VPG FILTER ENABLE bit in

the VIDEO INFO 0 control register enables the colour bar

filter function. The test pattern data is available at the video

data outputs, DV[19:0] with a corresponding parallel rate

clock, VCLK, appropriate to the particular standard and

format selected.

The TPG also functions as a built-in self-test (BIST) which

can be used to verify device functionality. The BIST function

performs a comprehensive go/no-go test of the device. The

test may be run using any of the HD colour bar patterns or

one of two SD patterns, either the 270 Mb/s NTSC colour bar

or the PAL PLL pathological, as the test data pattern. Data is

input from the digital processing block, processed through

the device and tested for errors using either the EDH system

for SD or the CRC system for HD. Clock signals from the

CDR block supply timing for the test data. The CDR must be

supplied a 27MHz reference clock via the XTALi/Ext Clk

input (or using the internal oscillator and crystal) during the

TPG or BIST function. A go/no-go indication is logged in the

Pass/Fail bit of the TEST 0 control register set. This bit may

be assigned as an output on the multifunction I/O port.

TPG and BIST operation is initiated by loading the code for

the desired test pattern into the Test Pattern Select[5:0] bits

and by setting the TPG Enable bit of the TEST 0 register.

Note that when attempting to use the TPG or BIST immediately after the device has been reset or powered on, the TPG

defaults to the 270Mbps SD rate. The device must be configured for the desired test pattern by loading the appropriate

code in to the TEST 0 register. If HD operation is desired,

selection of the desired HD test pattern is sufficient to enable

the device to configure itself to run at the correct rate and

generate valid data. Table 5 gives the available test patterns

and codes.

The Pass/Fail bit in the control register gives the device test

status indication. If no errors have been detected, this bit will

be set to logic-1 approximately 2 field intervals after TPG

Enable is set. If errors have been detected in the internal

circuitry of the CLC031A, Pass/Fail will remain reset to a

logic-0. TPG or BIST operation is stopped by resetting the

TPG Enable bit. Parallel output data is present at the

DV[19:0] outputs during TPG or BIST operation.

Example: Enable the TPG Mode to use the NTSC 270Mbps

colour bars as the BIST and TPG pattern. Enable TPG

operation using the I/O port.

1. Set ANC/CTRL to a logic-low.

2. Set RD/WR to a logic-low.

3. Present 00Dh to AD[9:0] as the TEST 0 register address.

4. Toggle A

CLK

.

5. Present 343h to AD[9:0] as the register data (525 line,

30 frame, 27MHz, NTSC 4x3, colour bars (SMPTE

125M)).

6. Toggle A

CLK

.

7. The PASS/FAIL indicator, TEST 0 register, Bit 7, should

be read for the result of the test. Alternatively, this bit

may be mapped to a convenient bit of the Multi-function

I/O bus. The test pattern data and clock is available at

the DV[19:0] and V

CLK

outputs.

CONFIGURATION AND CONTROL REGISTERS

The configuration and control registers store data which

determines the operational modes of the CLC031A or which

result from its operation. Many of these registers may be

assigned as external I/O functions which are then available

on the multi-function I/O bus. These functions are summarized in Table 1 and detailed in Table 2. The power-on default

condition for the multi-function I/O port is indicated in Table 1

and detailed in Table 6.

www.national.com 16

Device Operation (Continued)

TABLE 1. Configuration and Control Data Register Summary

Register Function Bits Read or Write Initial Condition

EDH and CRC Operations

CRC Error (SD/HD) 1 R Reset Output (Note 11) I/O 5

CRC Error Luma 1 R Reset Output

CRC Error Chroma 1 R Reset Output

CRC Replace 1 R/W OFF No (Note 13)

Full-Field Flags 5 R Reset No

Active Picture Flags 5 R Reset No

ANC Flags 5 R Reset No

EDH Force 1 R/W OFF Input

EDH Enable 1 R/W ON Input

F/F Flag Error 1 R Reset Output

A/P Flag Error 1 R Reset Output

ANC Flag Error 1 R Reset Output

Ancillary Data Operations

ANC Checksum Force 1 R/W OFF Input

ANC Checksum Error 1 R Reset Output

ANC FIFO Empty 1 R Set Output (Note 11) I/O 6

ANC FIFO 90% Full 1 R Reset Output

ANC FIFO Full 1 R Reset Output

ANC FIFO Overrun 1 R Reset Output

ANC ID 16 R/W 0000h No

ANC Mask 16 R/W FFFFh No

MSG Track 1 R/W OFF No

MSG Flush Static 1 R/W OFF No

FIFO Flush Static 1 R/W OFF No

Full MSG Available 1 R OFF Output

Short MSG Detect 1 R OFF Output

FIFO Clock Enable 1 R/W OFF No

FIFO Extract Enable 1 R/W OFF Input

Video FIFO Operation

Video FIFO Depth 3 R/W 000b No

Video Format Operations

Format Set 5 R/W 00000B No

SD Only 1 R/W OFF No

HD Only 1 R/W OFF No

Format 5 R Output Format [4] (Note 11)

H 1 R Output (Note 11) I/O 2

V 1 R Output (Note 11) I/O 1

F 1 R Output (Note 11) I/O 0

Framing Mode 1 R/W ON No

Framing Enable 1 R/W ON Input

New Sync Position (NSP) 1 R Output

SAV 1 R Output

EAV 1 R Output (Note 11) I/O 7

De-scramble Enable 1 R/W ON No

NRZI Enable 1 R/W ON No

Available on

I/O Bus

Notes

I/O 3

CLC031A

www.national.com17

Device Operation (Continued)

CLC031A

Register Function Bits Read or Write Initial Condition

LSB Clipping Enable 1 R/W ON No

Sync Detect Enable 1 R/W ON No

De-Dither Enable 1 R/W OFF Input

Vert. De-Dither Enable 1 R/W OFF Input

Lock Detect 1 R Output (Note 11) I/O 4

Unscrambled

Video Data Out

TPG and BIST Operations

Test Pattern Select 6 R/W 000000b Input 525/27 MHz/Black

TPG Enable 1 R/W OFF Input

Pass/Fail 1 R Output

VPG Filter Enable 1 R/W OFF Input

Reference Clock Operations

Reference Clock 2 R/W 00b No EXT CLK Enabled

External Vclk 1 R/W OFF No (Note 13)

Multifunction I/O Bus Operations

I/O Bus Pin Config. 48 R/W See Table 6 No

Note 11: Connected to multifunction I/O port at power-on.

Note 12: ON = SET = logic-1, OFF = RESET = logic-0 (positive logic).

Note 13: Special or restricted functionality. Refer to text for details.

TABLE 1. Configuration and Control Data Register Summary (Continued)

Available on

I/O Bus

1 R/W OFF No (Note 13)

Notes

TABLE 2. Control Register Bit Assignments

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

EDH 0 (register address 01h)

CRC ERROR EDH FORCE EDH ENABLE F/F UES F/F IDA F/F IDH F/F EDA F/F EDH

EDH 1 (register address 02h)

CRC

REPLACE

EDH 2 (register address 03h)

F/F FLAG

ERROR

ANC 0 (register address 04h)

VIDEO

FIFO-DEPTH(2)

ANC 1 (register address 05h)

ANC ID(7) ANC ID(6) ANC ID(5) ANC ID(4) ANC ID(3) ANC ID(2) ANC ID(1) ANC ID(0)

ANC 2 (register address 06h)

ANC ID(15) ANC ID(14) ANC ID(13) ANC ID(12) ANC ID(11) ANC ID(10) ANC ID(9) ANC ID(8)

ANC 3 (register address 07h)

ANC MASK(7) ANC MASK(6) ANC MASK(5)

ANC 4 (register address 08h)

ANC

MASK(15)

ANC 5 (register address 17h)

FIFO

EXTRACT

ENABLE

CRC ERROR

LUMA

A/P FLAG

ERROR

VIDEO

FIFO-DEPTH(1)

ANC MASK(14) ANC MASK(13)

FIFO CLOCK

ENABLE

CRC ERROR

CHROMA

ANC FLAG

ERROR

VIDEO

FIFO-DEPTH(0)

FULL MSG

AVAILABLE

A/P UES A/P IDA A/P IDH A/P EDA A/P EDH

ANC UES ANC IDA ANC IDH ANC EDA ANC EDH

ANC FIFO

OVERRUN

ANC

MASK(4)

ANC

MASK(12)

reserved

ANC FIFO

EMPTY

ANC

MASK(3)

ANC

MASK(11)

FIFO FLUSH

STATIC

ANC FIFO

FULL

ANC

MASK(2)

ANC

MASK(10)

reserved

ANC CHECKSUM ERROR

ANC

MASK(1)

ANC

MASK(9)

MSG FLUSH

STATIC

ANC CHECK-

SUM FORCE

ANC

MASK(0)

ANC

MASK(8)

MSG TRACK

www.national.com 18

Device Operation (Continued)

TABLE 2. Control Register Bit Assignments (Continued)

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

ANC 6 (register address 18h)

ANC FIFO

90% FULL

FORMAT 0 (register address 0Bh)

FRAMING

MODE

FORMAT 1 (register address 0Ch)

F V H FORMAT(4) FORMAT(3) FORMAT(2) FORMAT(1) FORMAT(0)

TEST 0 (register address 0Dh)

PASS/FAIL TPG ENABLE

VIDEO INFO 0 (register address 0Eh)

DE-DITHER

ENABLE

VIDEO CONTROL 0 (register address 55h)

reserved

REFERENCE CLOCK (register address 67h)

reserved reserved reserved reserved reserved INT_OSC EN CLK EN

MULTI-FUNCTION I/O BUS PIN CONFIGURATION

I/O PIN 0 CONFIG (register address 0Fh)

reserved reserved PIN 0 SEL[5] PIN 0 SEL[4] PIN 0 SEL[3] PIN 0 SEL[2] PIN 0 SEL[1] PIN 0 SEL[0]

I/O PIN 1 CONFIG (register address 10h)

reserved reserved PIN 1 SEL[5] PIN 1 SEL[4] PIN 1 SEL[3] PIN 1 SEL[2] PIN 1 SEL[1] PIN 1 SEL[0]

I/O PIN 2 CONFIG (register address 11h)

reserved reserved PIN 2 SEL[5] PIN 2 SEL[4] PIN 2 SEL[3] PIN 2 SEL[2] PIN 2 SEL[1] PIN 2 SEL[0]

I/O PIN 3 CONFIG (register address 12h)

reserved reserved PIN 3 SEL[5] PIN 3 SEL[4] PIN 3 SEL[3] PIN 3 SEL[2] PIN 3 SEL[1] PIN 3 SEL[0]

I/O PIN 4 CONFIG (register address 13h)

reserved reserved PIN 4 SEL[5] PIN 4 SEL[4] PIN 4 SEL[3] PIN 4 SEL[2] PIN 4 SEL[1] PIN 4 SEL[0]

I/P PIN 5 CONFIG (register address 14h)

reserved reserved PIN 5 SEL[5] PIN 5 SEL[4] PIN 5 SEL[3] PIN 5 SEL[2] PIN 5 SEL[1] PIN 5 SEL[0]

I/O PIN 6 CONFIG (register address 15h)

reserved reserved PIN 6 SEL[5] PIN 6 SEL[4] PIN 6 SEL[3] PIN 6 SEL[2] PIN 6 SEL[1] PIN 6 SEL[0]

I/O PIN 7 CONFIG (register address 16h)

reserved reserved PIN 7 SEL[5] PIN 7 SEL[4] PIN 7 SEL[3] PIN 7 SEL[2] PIN 7 SEL[1] PIN 7 SEL[0]

SHORT MSG

DETECT

SD ONLY HD ONLY

VERT.

DE-DITHER

ENABLE

EXTERNAL

V

CLK

ANC PARITY

MASK

TEST

PATTERN

SELECT(5)

VPG FILTER

ENABLE

SYNC DETECT

ENABLE

reserved reserved reserved reserved VANC

FORMAT

SET(4)

TEST

PATTERN

SELECT(4)

LOCK

DETECT

LSB CLIP

ENABLE

FORMAT

SET(3)

TEST

PATTERN

SELECT(3)

EAV SAV NSP

reserved

FORMAT

SET(2)

TEST

PATTERN

SELECT(2)

NRZI

ENABLE

FORMAT

SET(1)

TEST

PATTERN

SELECT(1)

DE-Scramble

ENABLE

FORMAT

SET(0)

TEST

PATTERN

SELECT(0)

FRAMING

ENABLE

reserved

reserved

CLC031A

www.national.com19

Device Operation (Continued)

CLC031A

EDH 0 (register 01h)

The EDH Full-Field flags F/F UES, F/F IDA, F/F IDH, F/F

EDA andF/F EDH are defined in SMPTE RP 165. The flags

are updated automatically when the EDH function is enabled

and data is being received.

The EDH ENABLE bit, when set, enables operation of the

EDH generator function during SD operation. The default

condition of this bit is set (ON).

The EDH FORCE bit, when set, causes updated EDH packets to be inserted in the parallel output data regardless of the

previous condition of EDH checkwords and flags in the input

serial data. This function may be used in situations where

video content has been edited thus making the previous

EDH information invalid. The default condition of this bit is

reset (OFF).

The CRC ERROR bit indicates that errors in either the EDH

checksums (SD) or CRC checkwords (HD) were detected in

the serial input data. This bit is a combined function which

indicates the presence of either EDH errors during SD operation or CRC errors during HD operation.

EDH 1 (register 02h)

The EDH Active Picture flags A/P UES, A/P IDA, A/P IDH,

A/P EDA andA/P EDH are defined in SMPTE RP 165. The

flags are updated automatically when the EDH function is

enabled and data is being received.

TABLE 3. Control Register Addresses

Register Name

EDH 0 01

EDH 1 02

EDH 2 03

ANC 0 04

ANC 1 05

ANC 2 06

ANC 3 07

ANC 4 08

ANC 5 17

ANC 6 18

FORMAT 0 0B

FORMAT 1 0C

TEST 0 0D

VIDEO INFO 0 0E

I/O PIN 0 CONFIG 0F

I/O PIN 1 CONFIG 10

I/O PIN 2 CONFIG 11

I/O PIN 3 CONFIG 12

I/O PIN 4 CONFIG 13

I/O PIN 5 CONFIG 14

I/O PIN 6 CONFIG 15

I/O PIN 7 CONFIG 16

VIDEO CONTROL 0 55

VIDEO CONTROL 1 56

REFERENCE CLOCK 67

Address

Hexadecimal

Specific types of CRC errors in incoming HD serial data are

reported in the CRC ERROR LUMA and CRC ERROR

CHROMA bits.

The CRC REPLACE bit, when set, causes the CRCs in the

incoming data to be replaced with CRCs calculated by the

CLC031A. The bit is normally reset (OFF).

EDH 2 (register 03h)

The EDH Ancillary Data flags ANC UES, ANC IDA, ANC

IDH, ANC EDA andANC EDH are defined in SMPTE RP

165. The flags are updated automatically when the EDH

function is enabled and data is being received.

The status of EDH flag errors in incoming SD serial data are

reported in the ffFlagError, apFlagError and ancFlagError

bits. Each of these bits is the logical-OR of the corresponding EDH and EDA flags.

ANC 0 (Address 04h)

The V FIFO Depth[2:0] bits control the depth of the video

FIFO which preceeds the parallel output data drivers. The

depth can be set from 0 to 4 stages by writing the corresponding binary code into these bits. For example: to set the

Video FIFO depth at two registers, load 11010XXXXXb into

the ANC 0 control register (where X represents the other

functional bits of this register).

Note: When changing some but not all bits in a register and

to retain unchanged other data previously stored in the

register, read the register’s contents and logically-OR this

with the new data. Then write the modified data back into the

register.

Flags for ANC FIFO EMPTY, ANC FIFO 90% FULL, ANC

FIFO FULL and ANC FIFO OVERRUN are available in the

configuration and control register set. These flags can also

be assigned as outputs on the multi-function I/O port. ANC

FIFO EMPTY when set indicates that the FIFO contains no

data. ANC FIFO 90% FULL indicates when the FIFO is at

90% of capacity. Since it is virtually impossible for the host

processor to begin extracting data from the FIFO after it has

been flagged as full without the possibility of an overrun

condition occurring, ANC FIFO 90% FULL is used as an

advanced command to the host to begin extracting data from

the FIFO. To be used properly, ANC FIFO 90% FULL should

be assigned as an output on the multi-function I/O port and

monitored by the host system. Otherwise, inadvertent loss of

ancillary packet data could occur. ANC FIFO FULL when set

indicates that the FIFO registers are completely filled with

data.

The ANC FIFO OVERRUN flag indicates that an attempt to

write data into a full FIFO has occurred. ANC FIFO OVER-

RUN can be reset by reading the bit’s status via the ancillary/

Control port. If an overrun occurrs, the status of the FIFO

message tracking will be invalidated. In this event, the FIFO

should be flushed to reset the message tracking pointers.

Any messages then in the FIFO will be lost.

The ANC Checksum Force bit, under certain conditions,

enables the overwriting of Ancillary Data checksums received in the data. Calculation and insertion of new Ancillary

Data checksums is controlled by the ANC Checksum Force

bit. If a checksum error is detected (calculated and received

checksums do not match) and the ANC Checksum Force

bit is set, the ANC Checksum Error bit is set and a new

checksum is inserted in the Ancillary Data replacing the

previous one. If a checksum error is detected and the ANC

Checksum Force bit is not set, the checksum mismatch is

www.national.com 20

Device Operation (Continued)

reported via the ANC Checksum Error bit. ANC Checksum

Error is available as an output on the multifunction I/O port.

ANC 1 AND 2 (Addresses 05h and 06h)

The extraction of Ancillary Data packets from video data into

the FIFO is controlled by the ANC MASK[15:0] and ANC

ID[15:0] bits in the control registers. The ANC ID[7:0] register normally is set to a valid 8-bit code used for component

Ancillary Data packet DID identification as specified in

SMPTE 291M-1998. Similarly, ANC ID[15:8] normally is set

to a valid 8-bit code used for component Ancillary Data

packet SDID/DBN identification.

ANC 3 AND 4 (Addresses 07h and 08h)

The ANC MASK[7:0] is an 8-bit word that can be used to

selectively control extraction of packets with specific DIDs

(or DID ranges) into the FIFO. When the ANC MASK[7:0] is

set to FFh, packets with any DID can be extracted into the

FIFO. When any bit or bits of the ANC MASK[7:0] are set to

a logic-1, the corresponding bit or bits of the ANC ID[7:0] are

a don’t-care when matching DIDs of packets being extracted. When the ANC MASK[7:0] is set to 00h, the ANC

DID of incoming packets must match exactly, bit-for-bit the

ANC ID[7:0] set in the control register for the packets to be

extracted into the FIFO. The initial value of the ANC

MASK[7:0] is FFh and the ANC ID[7:0] is 00h.

Similarly, ANC MASK[15:8] is an 8-bit word that can be

used to selectively control extraction of packets with specific

SDID/DBN (or SDID/DBN ranges) into the FIFO. Operation

and use of these bits is the same as for ANC MASK[7:0]

previously discussed.

ANC 5 (Address 17h)

The FIFO EXTRACT ENABLE bit in the control registers

enables the device to extract or copy Ancillary Data from the

video data stream and place it in the ANC FIFO. From there

data may be output via the parallel ancillary port. Data

extraction is enabled when this bit is set to a logic-1. This bit

can be used to delay automatic extraction and therefore the

output of parallel Ancillary Data. FIFO EXTRACT ENABLE

should be asserted during an SAV or EAV to avoid timing

problems with Ancillary Data extraction. Access to data in the

FIFO is controlled by the RD/WR, ANC/CTRL and A

control signals.

To conserve power when the Ancillary Data function is not

being used, the internal Ancillary Data FIFO clock is disabled. This clock must be enabled before Ancillary Data may

be replicated into the FIFO for output. FIFO CLOCK EN-

ABLE, bit-6 of the ANC 5 register (address 17h), when set,

enables this clock to propagate to the FIFO. The default

condition of FIFO CLOCK ENABLE is OFF. After enabling

the internal FIFO clock by turning this bit ON, A

CLK

toggled three (3) times to propagate the enable to the clock

tree. A

should remain running at all times when the ANC

CLK

FIFO is in use. Otherwise, message tracking and related

functions will not operate correctly.

The CLC031A can keep track of up to 8 ANC data packets in

the ANC FIFO. Incoming packet length versus available

space in the FIFO is also tracked. The MSG TRACK bit in

the control registers, when set, enables tracking of packets

in the FIFO. Other functions for control of packet traffic in the

CLK

must be

CLC031A

FIFO are FIFO FLUSH STAT and MSG FLUSH STAT.Ifthe

user wishes to handle more than 8 messages, the MSG

TRACK bit should be turned off (reset). The operation FIFO

FLUSH STAT will no longer work and the function FULL

MSG AVAILABLE will no longer be a reliable indicator that

messages are available in the FIFO. The user may still

effectively use the FIFO by monitoring the states of ANC

FIFO EMPTY, ANC FIFO FULL, ANC FIFO 90%FULL and

ANC FIFO OVERRUN.

Setting the FIFO FLUSH STAT bit to a logic-1 flushes the

FIFO. FIFO FLUSH STAT may not be set while the FIFO is

being accessed (Read or Write). FIFO FLUSH STAT is

automatically reset after this operation is complete.

When MSG FLUSH STAT is set to a logic-1, the oldest

message packet in the FIFO is flushed when data is not

being written to the FIFO. MSG FLUSH STAT is automati-

cally reset after this operation is complete.

The FULL MSG AVAILABLE bit in the control registers,

when set, notifies the host system that complete packets

reside in the Ancillary Data FIFO. When this bit is not set, the

messages in the FIFO are incomplete or partial. This function is not affected by MSG TRACK. The FULL MSG AVAIL-

ABLE function is most useful when mapped to the multifunction I/O port as an output.

ANC 6 (Address 18h)

The ANC FIFO 90% FULL flag bit indicates when the ANC

FIFO is 90% full. This bit may be mapped to the multifunction I/O port. The purpose of this flag is to provide a

signal which gives the host system time to begin reading

from the FIFO before it has the chance to overflow. This was

done because it is virtually impossible to monitor the FIFO

FULL flag and begin extracting from the FIFO before an

overrun condition occurs.

The SHORT MSG DETECT flag bit indicates when short

ANC messages have been detected. i.e. An ANC header

was detected before the last full message was recovered.

This bit may be mapped to the multi-function I/O port.

The ANC PARITY MASK bit when set disables parity checking for DID and SDID words in the ANC data packet. When

reset, parity checking is enabled; and, if a parity error occurs,

the packet will not be extracted.

The VANC bit, when set, enables extraction of ANC data

present in the vertical blanking interval (both active video

and horizontal blanking portions of the line).

FORMAT 0 (Address 0Bh)

The CLC031A may be set to process a single video format

by writing the appropriate data into the FORMAT 0 register.

The Format Set[4:0] bits confine the CLC031A to recognize

and process only one of the fourteen specified type of SD or

HD formats defined by a particular SMPTE specification. The

Format Set[4:0] bits may not be used to confine device

operation to a range of standards. The available formats and

codes are detailed in Table 4. Generally speaking, the For-

mat Set[4:0] codes indicate or group the formats as follows:

Format Set[4] is set for the HD data formats, reset for SD

data formats. Format Set[3] is set for PAL data formats (with

the exception of the SMPTE 274M 24-frame progressive

format), reset for NTSC data formats. Format Set[2:0] further sub-divide the standards as given in the table.

www.national.com21

Device Operation (Continued)

CLC031A

Format

Code

[4,3,2,1,0]

00001 SDTV, 54 RP 174 60I 525 507/487* 3432 2880

00010 SDTV, 36 SMPTE 267 60I 525 507/487* 2288 1920

00011 SDTV, 27 SMPTE 125 60I 525 507/487* 1716 1440

01001 SDTV, 54 ITU-R BT 601.5 50I 625 577 3456 2880

01010 SDTV, 36 ITU-R BT 601.5 50I 625 577 2304 1920

01011 SDTV, 27 ITU-R BT 601.5 50I 625 577 1728 1440

10001 HDTV, 74.25 SMPTE 260 30I 1125 1035 2200 1920

10010 HDTV, 74.25 SMPTE 274 30I 1125 1080 2200 1920

10011 HDTV, 74.25 SMPTE 274 30P 1125 1080 2200 1920

11001 HDTV, 74.25 SMPTE 274 25I 1125 1080 2640 1920

11010 HDTV, 74.25 SMPTE 274 25P 1125 1080 2640 1920

11100 HDTV, 74.25 SMPTE 295 25I 1250 1080 2376 1920

11101 HDTV, 74.25 SMPTE 274 24P 1125 1080 2750 1920

10100 HDTV, 74.25 SMPTE 296 (1, 2) 60P 750 720 1650 1280

The HD Only bit when set to a logic-1 locks the CLC031A

into the high definition data range and frequency. In systems

designed to handle only high definition signals, enabling HD

Only reduces the time required for the CLC031A to establish

frequency lock and determine the HD format being processed.

The SD Only bit when set to a logic-1 locks the CLC031A

into the standard definition data ranges and frequencies. In

systems designed to handle only standard definition signals,

enabling SD Only reduces the time required for the

CLC031A to establish frequency lock and determine the

format being processed. When SD Only and HD Only are

set to logic-0, the device operates in SD/HD mode.

The Framing Mode bit in the Format 0 register and Fram-

ing Enable in the Video Info 0 register combine with Framing Enable to control the manner in which the CLC031A

aligns framing. When Framing Mode and Framing Enable

are both reset, the CLC031A aligns on the first valid TRS

character. If another TRS occurs that is not on a word

boundary, the NSP bit is set until the next TRS that is on a

word boundary occurs. When Framing Mode is set to a

logic-1, the CLC031A operates similarly to the CLC011 when

NSP is tied to FE. An alternative configuration that operates

identically can be achieved with the CLC031A by mapping

NSP as an output and Framing Enable as an input on the

Multifunction I/O bus and externally connecting them. In this

case Framing Mode should be reset to a logic-0. When

Framing Mode is reset and Framing Enable is set, the

CLC031A realigns on every valid TRS. The initial state of

Framing Mode is set following a reset or at power-on.

FORMAT 1 (Address 0Ch)

The CLC031A automatically determines the format of the

incoming serial data. The result of this operation is stored in

the FORMAT 1 register. The Format[4:0] bits identify which

Format Spec.

TABLE 4. Video Raster Format Parameters

Frame

Rate

Lines Active Lines Samples

of the many possible video data standards that the CLC031A

can process is being received. These format codes follow

the same arrangement as for the Format Set[4:0] bits.

These formats and codes are given in Table 4. Bit Format[4]

when set indicates that HD data is being processed. When

reset, SD data is indicated. Format[3] when set indicates

that PAL data is being processed. When reset NTSC data is

being processed. Format[2:0] correspond with one of the

sub-standards given in the table. Note that the CLC031A

does not distinguish or log the data rate differences between

HD data at 74.25Mhz and 74.25MHz/1.001.

The H, V, and F bits correspond to input TRS data bits 6, 7

and 8, respectively. The meaning and function of this data is

the same for both standard definition (SMPTE 125M) and

high definition (SMPTE 292M luminance and colour difference) video data. Polarity is logic-1 equals HIGH-true. These

bits are registered for the duration of the applicable field.

TEST 0 REGISTER (Address 0Dh)

The Test Pattern Select bits determine which test pattern is

output when the Test Pattern Generator (TPG) mode or the

Built-in Self-Test (BIST) mode is enabled. Table 5 gives the

codes corresponding to the various test patterns. All HD

colour bar test patterns are inherently BIST data. BIST test

patterns for SD are: NTSC, 27MHz, 4x3 Colour Bars and

PAL, 27MHz, 4x3 PLL Pathological.

The TPG Enable bit when set to a logic-1 enables the Test

Pattern Generator function and built-in self-test (BIST).

The Pass/Fail bit indicates the result of the built-in self-test.

This bit is a logic-1 for a pass condition.

Active

Samples

www.national.com 22

Device Operation (Continued)

TABLE 5. Test Pattern Selection Codes

Test Pattern Select Word Bits

Video Raster Standard

1125 Line, 74.25 MHz, 30 Frame Interlaced Component (SMPTE 260M)

Ref. Black 1 0 0000

PLL Path. 1 0 0001

EQ Path. 1 0 0010

Colour Bars 1 0 0011

1125 Line, 74.25 MHz, 30 Frame Interlaced Component (SMPTE 274M)

Ref. Black 1 0 0100

PLL Path. 1 0 0101

EQ Path. 1 0 0110

Colour Bars 1 0 0111

1125 Line, 74.25 MHz, 25 Frame Interlaced Component (SMPTE 274M)

Ref. Black 1 0 1000

PLL Path. 1 0 1001

EQ Path. 1 0 1010

Colour Bars 1 0 1011

1125 Line, 74.25 MHz, 25 Frame Interlaced Component (SMPTE 295M)

Ref. Black 1 0 1100

PLL Path. 1 0 1101

EQ Path. 1 0 1110

Colour Bars 1 0 1111

1125 Line, 74.25 MHz, 30 Frame Progressive Component (SMPTE 274M)

Ref. Black 1 1 0000

PLL Path. 1 1 0001

EQ Path. 1 1 0010

Colour Bars 1 1 0011

1125 Line, 74.25 MHz, 25 Frame Progressive Component (SMPTE 274M)

Ref. Black 1 1 0100

PLL Path. 1 1 0101

EQ Path. 1 1 0110

Colour Bars 1 1 0111

1125 Line, 74.25 MHz, 24 Frame Progressive Component (SMPTE 274M)

Ref. Black 1 1 1000

PLL Path. 1 1 1001

EQ Path. 1 1 1010

Colour Bars 1 1 1011

750 Line, 74.25 MHz, 60 Frame Progressive Component (SMPTE 296M)

Ref. Black 1 1 1100

PLL Path. 1 1 1101

EQ Path. 1 1 1110

Colour Bars 1 1 1111

>

Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

1=HD 1=Progressive

0=Interlaced

0=SD 1=PAL

0=NTSC

CLC031A

00=Black

01=PLL Path.

10=EQ Path.

11=Colour Bars

www.national.com23

Device Operation (Continued)

CLC031A

Test Pattern Select Word Bits

525 Line, 30 Frame, 27 MHz, NTSC 4x3 (SMPTE 125M)

Ref. Black 0 0 0000

PLL Path. 0 0 0001

EQ Path. 0 0 0010

Colour Bars (SD BIST) 0 0 0011

625 Line, 25 Frame, 27 MHz, PAL 4x3 (ITU-T BT.601)

Ref. Black 0 1 0000

PLL Path. (SD BIST) 0 1 0001

EQ Path. 0 1 0010

Colour Bars 0 1 0011

525 Line, 30 Frame, 36 MHz, NTSC 16x9 (SMPTE 125M)

Ref. Black 0 0 0100

PLL Path. 0 0 0101

EQ Path. 0 0 0110

Colour Bars 0 0 0111

625 Line, 25 Frame, 36 MHz, PAL 16x9 (ITU-T BT.601)

Ref. Black 0 1 0100

PLL Path. 0 1 0101

EQ Path. 0 1 0110

Colour Bars 0 1 0111

525 Line, 30 Frame, 54 MHz (NTSC)

Ref. Black 0 0 1000

PLL Path. 0 0 1001

EQ Path. 0 0 1010

Colour Bars 0 0 1011

625 Line, 25 Frame, 54 MHz (PAL)

Ref. Black 0 1 1000

PLL Path. 0 1 1001

EQ Path. 0 1 1010

Colour Bars 0 1 1011

Note: BIST test patterns for SD are: NTSC 4x3 Colour Bars and PAL 4x3 PLL Pathological.

TABLE 5. Test Pattern Selection Codes (Continued)

>

Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

VIDEO INFO 0 REGISTER (Address 0Eh)

Re-synchronization of the parallel video output data with the

parallel rate clock is controlled by the functions Framing

Enable, Framing Mode and NSP. For operating details

about these control bits, refer to the preceeding section

about Format Registers 0 and 1 and the Format Mode bit.

Framing Enable may be assigned as an input on the multifunction I/O port.

The NSP (New Sync Position) bit indicates that a new or

out-of-place TRS character has been detected in the input

data. This bit is set to a logic-1 and remains set for at least

one horizontal line period or unless re-activated by a subsequent new or out-of-place TRS. It is reset by an EAV TRS

character.

The EAV (end of active video) and SAV (start of active video)

bits track the occurrence of the corresponding TRS characters.

The Lock Detect is a logic-1 when the loop is locked and the

CDR has acquired a phase of the incoming serial data. This

www.national.com 24

bit may be programmed as an output on the multi-function

I/O bus. This bit is mapped to I/O port bit 4 in the default

condition.

The VPG Filter Enable bit when set enables operation of the

Video Pattern Generator filter. Operation of this filter causes

the insertion of transition codes in the chroma and luma data

of colour bar test patterns where these patterns change from

one bar to the next. This filter reduces the magnitude of

out-of-band frequency products which are produced by

abrupt transitions in the chroma and luma data when fed to

D-to-A converters and picture monitors.

The CLC031A incorporates circuitry that implements a

method for handling data that has been subjected to LSB

dithering. Data from the de-scrambler is routed for dedithering. Control of this circuitry is via the De-Dither Enable

bit in the VIDEO INFO 0 control register. Recovery of data

that has been dithered during the vertical blanking interval

can be selectively enabled by use of the V De-Dither Enable

bit in the VIDEO INFO 0 control register. The initial condition

of De-Dither Enable and V De-Dither Enable is OFF.

Device Operation (Continued)

VIDEO CONTROL 0 (register address 55h)

The EXTERNAL V

which enables use of an external VCXO as a substitute for

the internally generated V

within the CLC031A which provides phase-frequency detection and control voltage output for the VCXO. An external

loop filter and voltage amplifier are required to interface the

control voltage output to the VCXO frequency control input.

When this function is used, the R

changed from the bias supply output to the control voltage

output of the phase-frequency detector. The V

changes function, becoming the input for the VCXO signal.

Use of this function and required external support circuitry is

explained in the Section Application Information section.

The SYNC DETECT ENABLE bit, when set, enables detection of TRS characters. This bit is normally set (ON).

The LSB CLIP ENABLE bit, when set, causes the two LSBs

of TRS characters to be set to 00b as described in ITU-R

BT.601. This function is normally set (ON).

The NRZI ENABLE bit, when set, enables data to be converted from NRZI to NRZ. This bit is normally set (ON).

The DE-SCRAMBLE ENABLE bit, when set, enables descrambling of the incoming data according to requirements

of SMPTE 259M or SMPTE 292M. This bit is normally set

(ON).

CAUTION: The default state of this register is 36h. If any of

the normal operating features of the descrambler are turned

off, this register’s default data must be restored to resume

normal device operation.

REFERENCE CLOCK REGISTER (Address 67h)

The Reference Clock register controls operation of the CDR

reference clock source. The CLKEN bit when reset to a

logic-0 enables the oscillator signal to be used by the

bit is a special application function

CLK

. Additional circuitry is enabled

CLK

output function is

BB

CLK

output

CLC031A as a reference. The default state of this bit at

power-on is enabled. In general, this function and bit should

not be disabled. The INT_OSC EN bit enables the internal

crystal oscillator amplifier. By default this bit is a logic-0 and

is therefore inactive at power-on. The device expects an

external 27MHz reference reference clock source to be connected to the XTALi/Ext Clk pin and activated at power-on.

I/O PIN 0 THROUGH 7 CONFIGURATION REGISTERS (Addresses 0Fh through 16h)

The I/O Pin Configuration Registers are used to map

individual bits of the multi-function I/O port to selected bits of

the Configuration and Control Registers. Table 6 gives the

pin select codes for the Configuration and Control register

functions that may be mapped to the port. Pin[n] Select [5]

controls whether the port pin is input or output. The port pin