National Semiconductor ADC102S051, ADC082S051, ADC122S051, ADC122S021, ADC082S021 User Manual

...Page 1

National Semiconductor

Evaluation Board User's Guide

12-, 10- and 8-Bit General Purpose

Analog-to-Digital Converters with Input Multiplexer

ADC122S101 / ADC102S101 / ADC082S101

ADC122S051 / ADC102S051 / ADC082S051

ADC122S021 / ADC102S021 / ADC082S021

ADC124S101 / ADC104S101 / ADC084S101

ADC124S051 / ADC104S051 / ADC084S051

ADC124S021 / ADC104S021 / ADC084S021

August 2005

Rev -

© 2005 National Semiconductor Corporation.

1 http://www.national.com

Page 2

Table of Contents

1.0 Introduction.............................................................................................................................3

2.0 Board Assembly .....................................................................................................................3

3.0 Quick Start..............................................................................................................................3

4.0 Functional Description............................................................................................................4

4.1 Input (signal conditioning) circuitry............................................................................4

4.2 The ADC reference ...................................................................................................4

4.3 ADC clock circuit .......................................................................................................4

4.5 Digital Data Output....................................................................................................4

4.6 Power Supply Connections .......................................................................................4

4.7 Power Requirements.................................................................................................5

4.8 Analog Inputs ............................................................................................................5

5.0 Installing and Using the ADCxx1S101 Evaluation Board .......................................................5

5.1 Software Installation..................................................................................................5

5.2 Setting up the ADCxx1S101 Evaluation Board .........................................................5

5.2.1 Board Set-up .............................................................................................5

5.2.2 Quick Check of Analog Functions.............................................................5

5.2.3 Quick Check of Software and Computer Interface Operation...................5

5.2.4 Getting Consistent Readings.....................................................................6

5.2.5 Troubleshooting.........................................................................................6

6.0 Evaluation Board Specifications.............................................................................................6

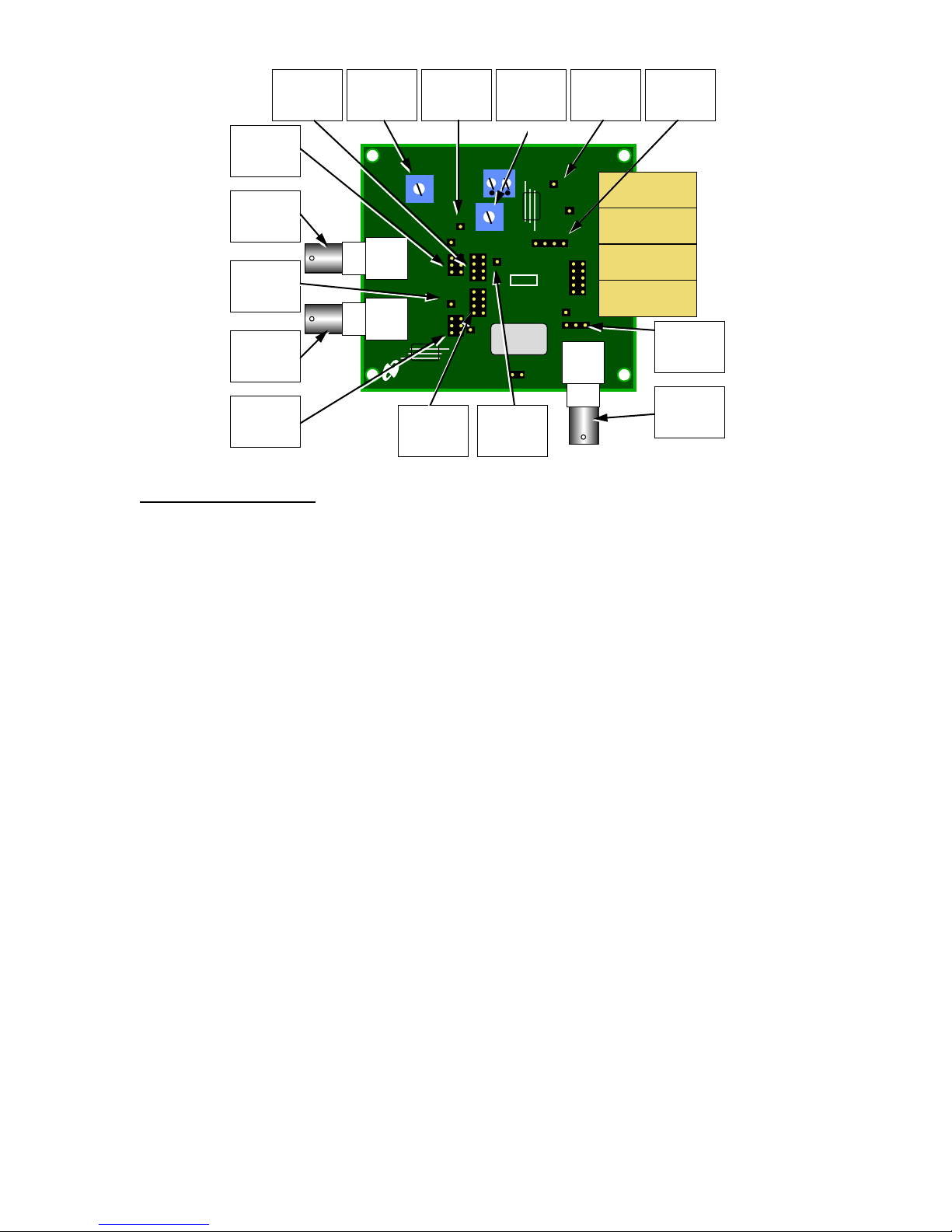

7.0 Hardware Schematic..............................................................................................................7

8.0 ADCxx1S101 Evaluation Board Bill of Materials ....................................................................8

A1 Summary Tables of Test Points and Connectors ...................................................................9

2 http://www.national.com

Page 3

1.0 Introduction

These ADC Design Kits (consisting of one of these

evaluation boards: ADC12xS101, ADC10xS101,

ADC08xS101, ADC12xS051, ADC10xS051,

ADC08xS051, ADC12xS021, ADC10xS021,

ADC08xS021 and WaveVision4 hardware, where "x" in

the device types here could be a 2 or a 4, indicating the

number of multiplexer inputs) is designed to ease

evaluation and design-in of these National

Semiconductor Analog-to-Digital Converters. These

evaluation boards allow the desivgner to evaluate product

performance in a choice of two ways: in standalone mode

with a logic analyzer and appropriate software (including

National's WaveVision software), or with a personal

computer and WaveVision4 hardware and software.

Reference in this Guide to DUT is meant to refer to the

particular device for which you have the evaluation board.

For operation with a computer system, this evaluation

board should be coupled to a WaveVision4 data capture

board (National part number WAVEVSN BRD 4.0) using

the WaveVision software operating under Microsoft

Windows. The analog signal presented to the DUT is

captured by the WaveVision4 data capture board, and

displayed on the computer screen as a dynamic

waveform, FFT, and/or histogram. The software also

computes and displays dynamic performance in the form

of SNR, SINAD, THD, SFDR, and ENOB.

Important Note: The evaluation boards for all of these ADCs

look identical. The actual device placed on your evaluation

board can be identified by the label on the board and verified

by looking at the DUT (Device Under Test) top mark. The

devices have the following top marks:

Device Top Mark

ADC082S101 X22C

ADC082S051 X04C

ADC082S021 X16C

ADC084S101 X25C

ADC084S051 X10C 8. Run the WaveVision 4 software and click on

ADC084S021 X19C

ADC102S101 X23C

ADC102S051 X05C

ADC102S021 X17C

ADC104S101 X26C

ADC104S051 X11C

ADC104S021 X20C

ADC122S101 X24C

ADC122S051 X06C

ADC122S021 X18C

ADC124S101 X27C

ADC124S051 X12C

ADC124S021 X21C

The signal at the Analog Input to the board is digitized

and is available at FutureBus connector J2.

The board inputs are provided at BNC1 and BNC2.

Jumper headers JP1 and JP3 allow these inputs to be

either a.c. or d.c. coupled to the DUT. Provision is made

to adjust the DUT supply voltage (measured at TP1) with

potentiometer VR1.

VR2 is used to set the input offset.

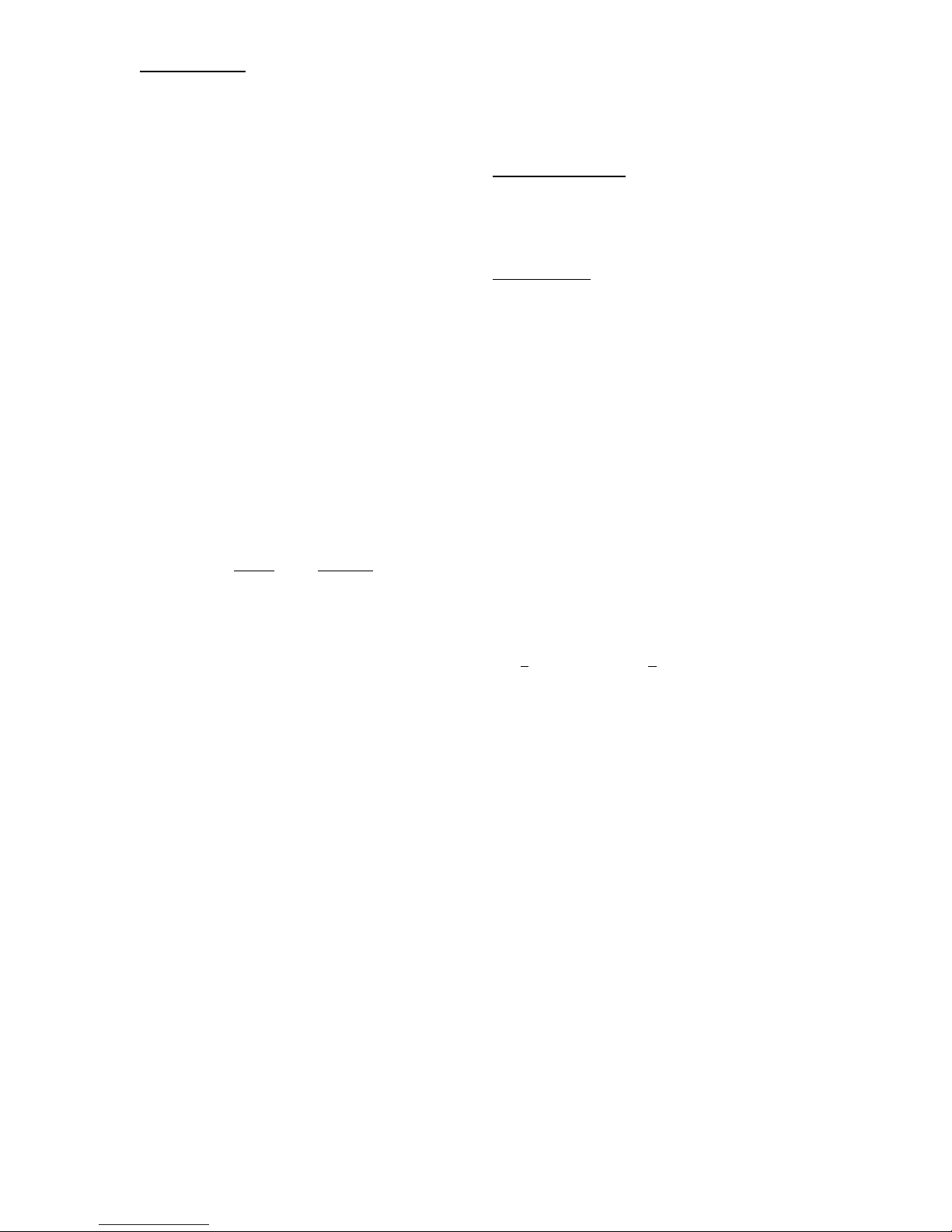

2.0 Board Assembly

These Evaluation Boards come fully assembled and

ready to use. Refer to the Bill of Materials for a

description of components, to Figure 1 for major

component placement and to Figure 2 for the Evaluation

Board schematic.

3.0 Quick Start

Refer to Figure 1 for locations of test points and major

components.

1. Connect the evaluation board to the Capture Board

(order number WAVEVSN BRD 4.0). See the

Capture Board Manual for operation of that board.

2. Connect a clean power supply to the terminals of

connector P1. Adjust power supply to a voltage of

±5.5V to ±5.7V before connecting it to the board.

3. Connect a voltmeter to TP1 and use VR1 to set the

DUT analog supply voltage for the desired value

between +2.7V and +5.0V.

4. Set the jumper to short pins 1 and 2 of JP6 and be

sure there is a clock oscillator of the appropriate

frequency at Y1.

5. Put a jumper between pins 1 and 2 of JP1 and pins

1 and 2 of JP2.

6. Connect a signal, through an appropriate bandpass

filter, to BNC1. The peak-to-peak amplitude of this

signal at TP6 should be the same as or just under

the power supply voltage setting.

7. Connect a USB cable between the WaveVision

Capture Board and the PC.

Settings, then click on Capture. Under "Board Type"

select "WaveVision 4.0 (USB)".

9. Under "Communication" press the "Test" button. If

you get a "Communication Failed" message, check

all connections and be sure the power supply is on.

10. If the appropriate sample rate (not clock rate) is not

reported, check to be sure the clock signal has

adequate amplitude and repeat the previous step.

11. Click "Accept" then gather data by pressing F1 on

the keyboard. Perform an FFT on the data by

clicking on the FFT tab.

See the WaveVision Capture Board Manual for complete

data gathering instructions.

3 http://www.national.com

Page 4

Input 1 Chan

JP1

INPUT 1

AC/DC Couple

BNC1

INPUT 1

Connection

JP2

Select

VR2

Offset

Adjust

INPUT 1

INPUT 1

Test Point

VR2

TP6

BNC1

TP7

INPUT 2

Test Point

BNC1

JP1

BNC2

JP3

BNC2

INPUT 2

Connection

JP3

INPUT 2

AC/DC Couple

BNC2

INPUT 2

National Semiconductor

G/P ADC, MSOP, Evaluation Board

Rev. 1.1

Input 1 Chan

L1

JP2

Select

Figure 1. Major Components and Test Points of the Evaluation Board

4.0 Functional Description

The Evaluation Board component locations are shown in

Figure 1. The board schematic is shown in Figure 2.

4.1 Input (signal conditioning) circuitry

The input signal to be digitized should be applied to BNC

connector BNC1 or to BNC2, or to both through (an)

appropriate filter(s). These 50 Ohm inputs are intended to

accept a low-noise sine wave signal of peak-to-peak

amplitude up to the power supply level. To accurately

evaluate the ADC dynamic performance, the input test

signal should be a single frequency passed through a

high-quality band pass filter as described in Section 5.0.

The input signal may be either a.c. or d.c. coupled to the

DUT with the setting of jumpers on J1 and JP3. See

schematic Figure 2.

4.2 The ADC reference

The reference voltage for the DUT is the device supply

voltage. Therefore, adjusting this voltage will change the

full scale range of the DUT. Since the operational supply

voltage range of the these ADCs is 2.7V to 5.25V, this is

also the range of the reference voltage.

TP6

TP7

Input2

TPG1

GND

POWER

Input1

JP2

JP4

TPG3

GND

P1

VR1

VA Supply

TP1

+V

U2, U3, U4

JP5

JP6

Clock

Select

VR1

Adjust

L2

TP2 TP5 TP4 TP3

Y1

+5.5V IN 1

TP8

TPG4

+5.5V Input

TPG2

GND

GND

JP6

BNC3

TP8

Test Point

J2

LA1

CLK INPUT

BNC3

TP2, TP3,

TP4, TP5

Serial Lines

Test Points

JP6

Clock

Select

BNC3

Ext. Clock

Connection

4.3 ADC Input Bias

To maximize ADC performance it is necessary that the

input signal swing cover nearly the entire ADC input

range. If the input biasing is not at the center of the signal

swing, it will not be possible to get maximum signal swing

without clipping of the signal, at which point there will be

excessive distortion.

VR2 is provided to allow adjustment of the input bias

point when a.c. input coupling is used. VR2 should be

adjusted to provide a d.c. voltage at TP6 and TP7 that

are one half the DUT supply voltage at TP1.

4.4 ADC clock circuit

The clock signal applied to the ADC can come from

BNC3 or from an on-board oscillator at position Y1 or Y2.

Y1 is for a through-hole TTL oscillator, while Y2 is for a

surface mounted TTL oscillator. Only one oscillator

should be mounted at a time and either an oscillator or

an external generator should be connected. JP6 is used

to select the oscillator source. Shorting pins 1 and 2 of

JP6 selects the on-board oscillator, while shorting pins 2

and 3 selects the oscillator signal at BNC3.

4 http://www.national.com

Page 5

4.5 Digital Data Output.

The digital output data from the DUT is available at

Header LA1 for connection to a logic analyzer. Data is

transferred over FutureBus J5 for use with the

WaveVision4 data capture board.

4.6 Power Supply Connections

Power to this board is supplied through power connector

J6. The only Voltage needed for the evaluation board is a

single +5.5V to +5.7V supply.

When using this evaluation Board with the WaveVision4

Capture Board, the +5V logic power supply for that

Capture board and the +5V of the DUT evaluation board

are connected together through pins A1, B1, A2 and B2

of J2. Diode D1 between P1 and the WaveVision4 board

is meant to prevent the higher voltage at DUT board P1

from getting to the WaveVision4 board. Providing the

+5.5V to +5.7V to the DUT board will provide +5V to the

WaveVision4 board through D1 and the WaveVision4

board pins A1, B1, A2 and B2 of J2.

4.7 Power Requirements

Voltage and current requirements for the DUT Evaluation

Board are

• Pin 1 of P1: +5.5V to 5.7V at 50 mA

• Pin 2 of P1: Ground

4.8 Analog Inputs

The evaluation board input channel is composed of

termination components and a user choice of a.c. or d.c.

signal coupling to the DUT, as well as a choice of DUT

multiplexer inputs that are connected to inputs BNC1 and

BNC2. Short together pins 1 and 2 of JP1 and JP3 to a.c.

couple the input signals. Short pins 5 and 6 of JP1 and

JP3 to d.c. couple the input signal to the DUT. Shorting

together pins 3 and 4 of JP1 or JP3 will ground the

corresponding ADC input.

JP2 and JP4 determine which BNC connector is

connected to which ADC input. See Figure 2 for the

device schematic.

Caution: Be sure that the input signals to the DUT do

not go more negative than -0.3V or more than 0.3V

above the DUT power supply.

5.0 Installing and Using the ADCxx1S101

Evaluation Board

The evaluation board requires a power supply as

described in Section 4.7. An appropriate signal generator

with 50 Ohm source impedance should be connected to

the Analog Input BNC1 and/or BNC2. A bandpass filter

should be inserted between the generator output and the

input to the evaluation board when evaluating sinusoidal

signals to be sure there are no unwanted frequencies

(harmonics and noise) presented to the ADC. It is

important to realize that no frequency generator or

synthesizer produces a pure enough sine wave to

evaluate an A/D Converter without the use of a good

filter. If the WaveVison4 capture board is used, a USB

cable must be connected between the WaveVision4

Capture Board and the host computer. See the

WaveVision4 Capture Board User's Guide for details.

5.1 Software Installation

The WaveVision4 software provided requires about 6

Megabytes of hard drive space, including the Java files,

and runs under Windows. See the WaveVision4 Capture

Board Users' Guide for WaveVision4 software installation

instructions.

5.2 Setting up the Evaluation Board

This evaluation package was designed to be easy and

simple to use, and to provide a quick and simple way to

evaluate the DUT. The procedures given here will help

you to properly set up the board.

5.2.1 Board Set-up

Refer to Figure 1 for locations of the major components

on the board.

1. Connect The evaluation board to a WaveVision4

Capture Board, WAVEVSN BRD 4.0.

2. Connect the desired jumper to JP1, JP2, JP3 and

JP4. (See Section 4.8).

3. Connect power to the board per requirements of

paragraph 4.7.

4. Connect a USB cable between the WaveVision4

Capture Board and a USB port on your computer.

5. Connect a clean power supply to the terminals of

connector P1. Adjust power supply to a voltage of

±5.5V to ±5.7V before connecting it to the board.

Apply power to the WaveVision4 Capture Board.

6. Connect an appropriate test signal source to

connector BNC1 and/or BNC2 of the evaluation

board through (an) appropriate filter(s).

5.2.2 Quick Check of Analog Functions

Refer to Figure 1 for locations of major components on

the board. If at any time the expected response is not

obtained, see section 5.2.5 on Troubleshooting.

1. Perform steps 1 through 6 of Section 5.2.1.

2. Adjust VR1 for the desired DUT supply voltage at

TP1.

3. Adjust VR2 for a voltage at TP6 and TP7 that are

1/2 that at TP1.

4. Apply a signal to BNC1 and scope TP6 to be sure

the input signal is present.

5. Apply a signal to BNC2 and scope TP7 to be sure

the input signal is present.

5 http://www.national.com

Page 6

This completes the testing of the analog portion of the

evaluation board.

5.2.3 Quick Check of Software and Computer

Interface Operation

1. Perform the steps of Paragraph 5.2.2, above.

2. Put a jumper between pins 1 and 2 of JP1 and

between pins 1 and 2 of JP2.

3. Apply a signal to BNC1. Adjust the signal source at

Analog Input BNC1 for a peak-to-peak signal

amplitude at TP6 that is very slightly below the value

of the d.c. voltage at TP1.

4. Be sure there is an interconnecting cable between

the Capture Board and your computer USB port.

5. Run the WaveVision4 program and click on

Settings, then click on Capture. Under "Board Type"

select "WaveVision 4.0 (USB)".

6. Under "Communication" press the "Test" button. If

you get a "Communication Failed" message, test all

connections and be sure the power supply to the

boards is turned on. Click on "Accept".

7. Acquire data by pressing the computer F1 key. Data

transfer can take a few seconds.

8. When transfer is complete, the data window should

show many sine waves. The display may show a

nearly solid area of red, which is O.K.

9. With the mouse, you may click on the magnifying

glass, then and drag (top left to bottom right) to

select a portion of the displayed waveform for better

examination.

10. Click on the FFT tab to compute the FFT and

display a frequency domain plot.

The FFT data will provide a measurement of SINAD,

SNR, THD SFDR and ENOB, simplifying the

performance verification of the DUT.

Note: Be sure to use a band pass filter between the

signal source and this board for accurate dynamic

performance measurement.

To change the selected input channel, click on the

"Settings" pull-down, then on "Product Board Settings"

and choose the selected channel. Choosing "GND" will

internally ground the ADC input. It is necessary to select

the mainWaveVision4 window before capturing data.

5.2.4 Getting Consistent Readings

Artifacts can result when we perform an FFT on a

digitized waveform, producing inconsistent results when

testing repeatedly. The presence of these artifacts means

that the ADC under test may perform better than our

measurements would indicate. Windowing is a common

method of improving FFT results of finite data.

We can eliminate the need for windowing and get more

consistent results if we observe the proper ratios between

the input and sampling frequencies, forcing the data to

cleanly "wrap around" itself, providing coherent sampling.

This eliminates the distortion that would otherwise be

present in an FFT and greatly increases its spectral

resolution. This, in turn, allows us to more accurately

evaluate the spectral response of the A/D converter.

When we do this, however, we must be sure that the

input signal has high spectral purity and stability and that

the sampling clock signal is extremely stable with

minimal jitter.

Coherent sampling of a periodic waveform occurs when

an integer number of cycles exists in the sample window.

The relationship between the number of cycles sampled

(CY), the number of samples taken (SS), the signal input

frequency (fin) and the sample rate (fs), for coherent

sampling, is

f

CY

in

=

f

SS

s

CY, the number of cycles in the data record, must be a

prime integer number and SS, the number of samples in

the record, must be a power of 2 integer.

Further, fin (signal input frequency) and fs (sampling rate)

should be locked to each other. Then, if they come from

the same generator, whatever frequency instability (jitter)

is present in the two signals will cancel each other.

Windowing (an FFT Option under WaveVision) should

not be used for coherent sampling.

5.2.5 Troubleshooting

Nothing happens when F1 is pressed

then Capture Board Settings and look at the top for

"Board Properties" If you see "No WaveVision hardware

is present", be sure that the WaveVision Capture Board

is connected to an USB port and has power, that the

evaluation board has power and is properly connected to

and seated with the WaveVision4 Capture Board.

There is no output from the DUT: perform the following:

: Select Settings,

• Be sure the appropriate input channel is selected

through the WaveVision4 software.

• Be sure that a shorting jumper is appropriately

placed on JP1 through JP4.

• Be sure that the proper voltage and polarity is

present at Power Connector J6.

• Check to see that the DUT input signal does not go

below ground or above the DUT supply voltage.

• Be sure there is a clock signal is present at TP5.

The PC displayed waveform appears to be noisy, or the

FFT plot shows nothing but noise with no apparent

signal:

• Be sure the appropriate input channel is selected

through the WaveVision4 software.

• Be sure shorting jumpers are appropriately on JP1

through JP4.

6 http://www.national.com

Page 7

• Check to see that the DUT input signal does not go

below ground or above the DUT analog supply

voltage.

• Be sure that a minimum of +2.7V is at pin 1 of TP1.

• Be sure that only one clock source (oscillator at Y1

or signal at BNC3) is active on the board.

6.0 Evaluation Board Specifications

Board Size: 3.1" x 3.8" (8.0 cm x 9.6 cm)

Power Requirements: + 5.5V to 5.7 @ 15 mA

Clock Frequency Range: 1 MHz to 20 MHz

Analog Input

Nominal Voltage: Supply peak-to-peak Voltage

Impedance: 50 Ohms

7 http://www.national.com

Page 8

7.0 Hardware Schematic

+5V

D2

1N4148

Q1

2N3904

312

VR1

1k

+5p5V

+5p5V

L1

100 uHChoke

C2

68uF

0.1uF

C1

8 MHz OSC (THROUGH-HOLE)

Y1

18

OEOUT

VDDGND

147

42

C3

0.1uF

JP5

CLK_ENABLE

1 2

Y2

8 MHz OSC (SMT)

13

OEOUT

VDDGND

JP6

123

INT

BNC3

CLK

1 2

3 4

5 6

7 8

9 1 0

LA1

Logic Analyzer Header

1

GND

TPG1

1

ADC_SCLK

TP5

1

ADC_DOUT

TP4

1

ADC_DIN

TP3

1

ADC_CS#

TP2

1

+V

TP1

+V

C5

10uF, 6.3V

R6

1k

C4

0.1uF

R5

1.8k

INPUT_OFFSET

VR2

1k

R4

0

R7

1k

312

Q2

2N3904

HEADER 3X1

EXT

R2

51.1

R3

51.1

1

2

INPUT_1

ADC_DIN

ADC_CSb

ADC_SCLK

ADC_DOUT

R12

100

R11

100

R10

100

R9

100

ADC_DIN

ADC_CSb

ADC_DOUT

ADC_SCLK

U2

1

8

9

10

MSOP10-2

DIN

CS#

SCLK

VA

DOUT

2

GND

3

VD

100

R13

AIN1

AIN2

N/C

0.1uF

C10

6

574

AIN2

AIN1

C8

0.1uF

C7

1uF

1

GND

TPG2

U1

LM4041DIZ-1.2

+1p2V

3 2

C9

0.1uF

C6

10uF, 6.3V

R8

not used

1

Input_1

TP6

5.1K

R14

C12

10uF, 6.3V

0.1uF

C11

U3

MSOP8-1

23

AIN1

AIN2

AIN3

JP2

1 2

3 4

5 6

IN2_CH_SEL

INPUT1

246

+

+

+

JP1

+

+

+

135

D.C. COUP.

A.C. COUP.

5.1K

R15

INPUT_1

BNC1

ADC_DIN

ADC_CSb

1

678

CS#

VAGND

AIN1

5

4

AIN1

AIN2

AIN4

7 8

IN1_SEL

C13

0.1uF

R16

51

1

2

AIN2 DIN

ADC_SCLK

ADC_DOUT

DOUT

SCLK

U4

ADC_DIN

ADC_CSb

ADC_DOUT

ADC_SCLK

1

8

9

10

MSOP10-1

DIN

CS#

SCLK

DOUT

VAGND

23

AIN1

AIN2

AIN4

AIN3

765

4

AIN1

AIN3

AIN2

AIN4

JP4

1 2

IN2_CH_SEL

JP3

1

Input_2

TP7

R18

R17

5.1K

5.1K

C15

10uF, 6.3V

C14

0.1uF

3 4

5 6

INPUT2

246

+

+

135

A.C. COUP.

BNC2

EEPROM_SDA

24C02/SO8

U5

5

0.1uF

C17

EEPROM_Power

7 8

+

+

+

+

IN2_SEL

D.C. COUP.

C16

0.1uF

R19

51

1

2

INPUT_2

SCLK_SEND

GND

SDA

4

VCC

8

WP

A0A1A2

SCL

123

6

7

EEPROM_Power

EEPROM_SCL

A1

A1

+5V

B1

B1

C1

C1

D1

D1

A2

A2

B2

B2

C2

C2

D2

ADC_SCLK

D2

A3

A3

B3

EEPROM_SDA

B3

C3

EEPROM_SCL

C3

D3

EEPROM_Power

D3

A4

ADC_DOUT

A4

B4

B4

C4

C4

D4

1

GND

TPG4

1

GND

TPG3

D4

A5

A5

B5

B5

C5

C5

D5

D5

A6

A6

B6

B6

C6

C6

D6

D6

A7

A7

B7

B7

C7

C7

D7

D7

A8

A8

B8

B8

C8

C8

D8

D8

A9

A9

B9

B9

C9

C9

D9

D9

A10

A10

B10

B10

C10

C10

D10

D10

A11

A11

B11

B11

C11

C11

D11

D11

A12

A12

B12

B12

C12

C12

D12

D12

A13

A13

B13

B13

C13

C13

D13

D13

A14

A14

B14

B14

C14

C14

D14

D14

A15

A15

B15

B15

C15

C15

D15

D15

A16

A16

B16

B16

C16

C16

D16

D16

A17

A17

B17

B17

C17

C17

D17

SCLK_SEND

D17

A18

A18

B18

B18

C18

C18

D18

ADC_SCLK

D18

A19

A19

B19

B19

C19

C19

D19

D19

ADC_CSb

A20

A20

B20

B20

C20

C20

D20

ADC_DIN

D20

A21

A21

B21

B21

C21

C21

D21

D21

A22

A22

B22

B22

C22

C22

D22

D22

A23

A23

B23

B23

C23

C23

D23

D23

A24

A24

B24

B24

FUTUREBUS_96

C24

+3P3V

C24

D24

D24

J2

+5p5V

0.1uF

C18

10uF, 6.3V

C19

L2

100 uHChoke

D1

1N4001

1

+5.5V_IN

TP8

+5p5V_IN

1

2

P1

POWER_IN

Figure 2. ADC12xSxx1 / ADC10xSxx1 / ADC08xSxx1 Evaluation Board Schematic

8 http://www.national.com

Page 9

8.0 ADC12/10/08xSxx1 Evaluation Board Bill of Materials

Item Qty Reference Part Source

1 12

2 1 C2 68uF Type 7343

3 5 C5, C6, C12, C15, C19 10uF, 6.3V Type 3216

4 1 C7 1uF, 6.3V or 10V Type 3216

5 3 BNC1, BNC2, BNC3 BNC Connector DigiKey # ARF1177-ND

6 1 D1 1N4001 - DO-41 Pkg Various

7 1 JP1, JP3 3x2 Pin Post Header DigiKey # 22-28-4065-ND

8 2 JP2, JP4 2x2 Pin Post Header [2 input]

9 0 JP5 not used n/a

10 1 JP6 3-pin Post Header DigiKey # A19351-ND

11 1 J2 FUTUREBUS Connector AMP/Tyco 536501-1

12 1 LA1 2 x 10 pin Post Header DigiKey # 10-89-2101-ND

13 2 L1, L2 100uH Inductor DigiKey # 445-1152-1-ND

14 1 P1 2-Pin Terminal Block DigiKey # ED1609-ND

15 2 Q1, Q2 MMBTN3904 (SOT-23) Various

16 2 R2, R3 51.1, 1%, 1/8 Watt Size 0603

17 1 R4 0 Size 0603

18 1 R5 1.8k, 5%, 1/10 W Size 0603

19 2 R6, R7 1k, 5%, 1/10 W Size 0603

20 2 VR1, VR2 1k DigiKey # 3386F-102-ND

21 0 R8 not used n/a

22 5 R9, R10, R11, R12, R13 100, 5%, 1/10 W Size 0603

23 4 R14, R15, R17, R18 5.11K, 1%, 1/10 W Size 0603

24 2 R16, R19 51, 5%, 1/8 W Size 0603

25 1

26 1 U1 LM4041DIZ-1.2 National Semiconductor

27 0 U2 not used n/a

28 1 U3 ADCxx2Sxx1 National Semiconductor

29 0 U4 ADCxx4Sxx1 National Semiconductor

30 1 U5 24C02/SO8 Various

31 1 Y1 4 MHz OSC fo 50 ksps

32 0 Y2 - optional, not provided not used n/a

33 1 OSC Socket For Y1 DigiKey # A400-ND

34 5 Shorting Jumpers For JP1, JP2, JP3, JP4, JP6 DigiKey #S9601-ND

C1, C3, C4, C8, C9, C10, C11, C13, C14, C16,

C17, C18

TP1, TP2, TP3, TP4, TP5 ,TP6, TP7, TP8,

TPG1, TPG2, TPG3, TPG4

0.1uF Type 0805

DigiKey # 10-89-9047-ND

2x4 Pin Post Header [4 input]

Breakable Header DigiKey # S1012-36-ND

20 MHz OSC for 200 ksps

20 MHz OSC for 1 Msps

DigiKey # 22-28-4085-ND

DigiKey # CTX107-ND

DigiKey # CTX114-ND

DigiKey # CTX119-ND

9 http://www.national.com

Page 10

APPENDIX

A1 Summary Tables of Test Points and Connectors

P1 Connector - Power Supply Connections

Pin Iput Voltage Function

P1-1 +5.5V to +5.7V Positive Power Supply

P1-2 GND Power Supply Ground

LA1 - Logic Analyzer Header

Pin Function

1 Ground

3 ADC Serial Data Output

5 ADC Chip Select (active low)

7 ADC serial Clock

9 ADC Serial Data Input

2 Ground

4 Ground

6 Ground

8 Ground

10 Ground

JP1 - Input 1 Select

Jumper Function

none Input 1 not connected to DUT

1 - 2 Input 1 a.c. coupled

3 - 4 Input 1 path grounded

5 - 6 Input 1 d.c. coupled

JP2 - Input 1 Channel Select

Jumper Function

none Input 1 NOT connected to DUT

1 - 2 Input 1 connected to IN1

3 - 4 Input 1 connected to IN2

5 - 6 Input 1 connected to IN3 (ADCxx4Sxx1 only)

7 - 8 Input 1 connected to IN4 (ADCxx4Sxx1 only)

JP3 - Input 2 Select

Jumper Function

none Input 2 not connected to DUT

1 - 2 Input 2 a.c. coupled

3 - 4 Input 2 path grounded

5 - 6 Input 2 d.c. coupled

10 http://www.national.com

Page 11

JP4 - Input 2 Channel Select

IN

OUT

Jumper Function

none Input 2 NOT connected to DUT

1 - 2 Input 2 connected to IN1

3 - 4 Input 2 connected to IN2

5 - 6 Input 2 connected to IN3 (ADCxx4Sxx1 only)

7 - 8 Input 2 connected to IN4 (ADCxx4Sxx1 only)

JP5 - Clock Enable

Jumper Function

none Clock at Y1 or Y2 is disabled if oscillator has enable input

1 - 2 Clock at Y1 or Y2 is enabled

Test Points on the Evaluation Board

Test Point Function

TP 1 DUT supply voltage

TP 2 ADC CSb

TP 3 ADC D

TP 4 ADC D

TP 5 SCLK

TP 6 INPUT1 Signal input to DUT

TP 7 INPUT2 Signal input to DUT

TP 8 Board +5.5V Supply Input voltage

TPG1 thru

TPG4

Ground

J10 - FutureBus Connector

Pin(s) Function

A1, B1, A2, B2 +5V from WaveVision4 Capture Board

D2 ADC Serial Clock

B3 EEPROM SDA (Data)

C3 EEPROM SCL (Clock)

D3 EEPROM Power

A4 ADC Data Output

D17 SCLK SEND

D18 ADC SCLK

D19 ADC CS#

D20 ADC Data Input

A23, B23, A24, B24 +3.3V from WaveVision4 Capture Board

All Others Ground

11 http://www.national.com

Page 12

These Evaluation Boards are intended for product evaluation purposes only and are not intended for resale to end

consumers, is not authorized for such use and is not designed for compliance with European EMC Directive 89/336/EEC.

National does not assume any responsibility for use of any circuitry or software supplied or described. No circuit patent

licenses are implied.

LIFE SUPPORT POLICY

NATIONAL'S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF NATIONAL

SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform, when properly used in

accordance with instructions for use provided in the

2. A critical component is any component in a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

labeling, can be reasonably expected to result in a

significant injury to the user.

National Semiconductor Corporation

Americas

Tel: 1-800-272-9959

Fax: 1-800-737-7018

Email: support@nsc.com

National Semiconductor Europe

Fax: +49 (0) 1 80-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 1 80-530 85 85

English Tel: +49 (0) 1 80 532 78 32

Français Tel: +49 (0) 1 80 532 93 58

Italiano Tel: +49 (0) 1 80 534 16 8

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: sea.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5620-6175

Fax: 81-3-5620-6179

www.national.com

National does not assume any responsibility for any circuitry described, no circuit patent licenses are implied and National reserves the right

at any time without notice to change said circuitry and specifications.

12 http://www.national.com

Page 13

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications, enhancements, improvements,

and other changes to its products and services at any time and to discontinue any product or service without notice. Customers should

obtain the latest relevant information before placing orders and should verify that such information is current and complete. All products are

sold subject to TI’s terms and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in accordance with TI’s standard

warranty. Testing and other quality control techniques are used to the extent TI deems necessary to support this warranty. Except where

mandated by government requirements, testing of all parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for their products and

applications using TI components. To minimize the risks associated with customer products and applications, customers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right, copyright, mask work right,

or other TI intellectual property right relating to any combination, machine, or process in which TI products or services are used. Information

published by TI regarding third-party products or services does not constitute a license from TI to use such products or services or a

warranty or endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual

property of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of TI information in TI data books or data sheets is permissible only if reproduction is without alteration and is accompanied

by all associated warranties, conditions, limitations, and notices. Reproduction of this information with alteration is an unfair and deceptive

business practice. TI is not responsible or liable for such altered documentation. Information of third parties may be subject to additional

restrictions.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that product or service voids all

express and any implied warranties for the associated TI product or service and is an unfair and deceptive business practice. TI is not

responsible or liable for any such statements.

TI products are not authorized for use in safety-critical applications (such as life support) where a failure of the TI product would reasonably

be expected to cause severe personal injury or death, unless officers of the parties have executed an agreement specifically governing

such use. Buyers represent that they have all necessary expertise in the safety and regulatory ramifications of their applications, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products

and any use of TI products in such safety-critical applications, notwithstanding any applications-related information or support that may be

provided by TI. Further, Buyers must fully indemnify TI and its representatives against any damages arising out of the use of TI products in

such safety-critical applications.

TI products are neither designed nor intended for use in military/aerospace applications or environments unless the TI products are

specifically designated by TI as military-grade or "enhanced plastic." Only products designated by TI as military-grade meet military

specifications. Buyers acknowledge and agree that any such use of TI products which TI has not designated as military-grade is solely at

the Buyer's risk, and that they are solely responsible for compliance with all legal and regulatory requirements in connection with such use.

TI products are neither designed nor intended for use in automotive applications or environments unless the specific TI products are

designated by TI as compliant with ISO/TS 16949 requirements. Buyers acknowledge and agree that, if they use any non-designated

products in automotive applications, TI will not be responsible for any failure to meet such requirements.

Following are URLs where you can obtain information on other Texas Instruments products and application solutions:

Products Applications

Audio www.ti.com/audio Automotive and Transportation www.ti.com/automotive

Amplifiers amplifier.ti.com Communications and Telecom www.ti.com/communications

Data Converters dataconverter.ti.com Computers and Peripherals www.ti.com/computers

DLP® Products www.dlp.com Consumer Electronics www.ti.com/consumer-apps

DSP dsp.ti.com Energy and Lighting www.ti.com/energy

Clocks and Timers www.ti.com/clocks Industrial www.ti.com/industrial

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Security www.ti.com/security

Power Mgmt power.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com

OMAP Mobile Processors www.ti.com/omap

Wireless Connectivity www.ti.com/wirelessconnectivity

TI E2E Community Home Page e2e.ti.com

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2012, Texas Instruments Incorporated

Loading...

Loading...