ADC083000

8-Bit, 3 GSPS, High Performance, Low Power A/D

Converter

ADC083000 8-Bit, 3 GSPS, High Performance, Low Power A/D Converter

May 2007

General Description

The ADC083000 is a single, low power, high performance

CMOS analog-to-digital converter that digitizes signals to 8

bits resolution at sampling rates up to 3.4 GSPS. Consuming

a typical 1.9 Watts at 3 GSPS from a single 1.9 Volt supply,

this device is guaranteed to have no missing codes over the

full operating temperature range. The unique folding and interpolating architecture, the fully differential comparator design, the innovative design of the internal sample-and-hold

amplifier and the self-calibration scheme enable a very flat

response of all dynamic parameters up to Nyquist, producing

a high 7.0 Effective Number Of Bits, (ENOB) with a 748 MHz

input signal and a 3 GHz sample rate while providing a 10

Bit Error Rate, (BER). The ADC083000 achieves a 3 GSPS

sampling rate by utilizing both the rising and falling edge of a

1.5 GHz input clock. Output formatting is offset binary and the

LVDS digital outputs are compatible with IEEE 1596.3-1996,

with the exception of an adjustable common mode voltage

between 0.8V and 1.15V.

The ADC has a 1:4 demultiplexer that feeds four LVDS buses

and reduces the output data rate on each bus to a quarter of

the sampling rate.

The converter typically consumes less than 25 mW in the

Power Down Mode and is available in a 128-lead, thermally

enhanced exposed pad LQFP and operates over the Industrial (-40°C ≤ TA ≤ +85°C) temperature range.

-18

Features

Internal Sample-and-Hold

■

Single +1.9V ±0.1V Operation

■

Choice of SDR or DDR output clocking

■

Guaranteed No Missing Codes

■

Serial Interface for Extended Control

■

Adjustment of Input Full-Scale Range and Offset

■

Duty Cycle Corrected Sample Clock

■

Test pattern

■

Key Specifications

Resolution 8 Bits

■

Max Conversion Rate 3 GSPS (min)

■

Bit Error Rate (BER) 10

■

ENOB @ 748 MHz Input 7.0 Bits (typ)

■

SNR @ 748 MHz 44.5 dB (typ)

■

Full Power Bandwidth 3 GHz (typ)

■

Power Consumption

■

Operating 1.9 W (typ)

—

Power Down Mode 25 mW (typ)

—

Applications

Direct RF Down Conversion

■

Digital Oscilloscopes

■

Satellite Set-top boxes

■

Communications Systems

■

Test Instrumentation

■

-18

(typ)

Ordering Information

Industrial Temperature Range

(-40°C < TA < +85°C)

ADC083000CIYB 128-Pin Exposed Pad LQFP

ADC08x3000EB Development Board

© 2007 National Semiconductor Corporation 201932 www.national.com

NS Package

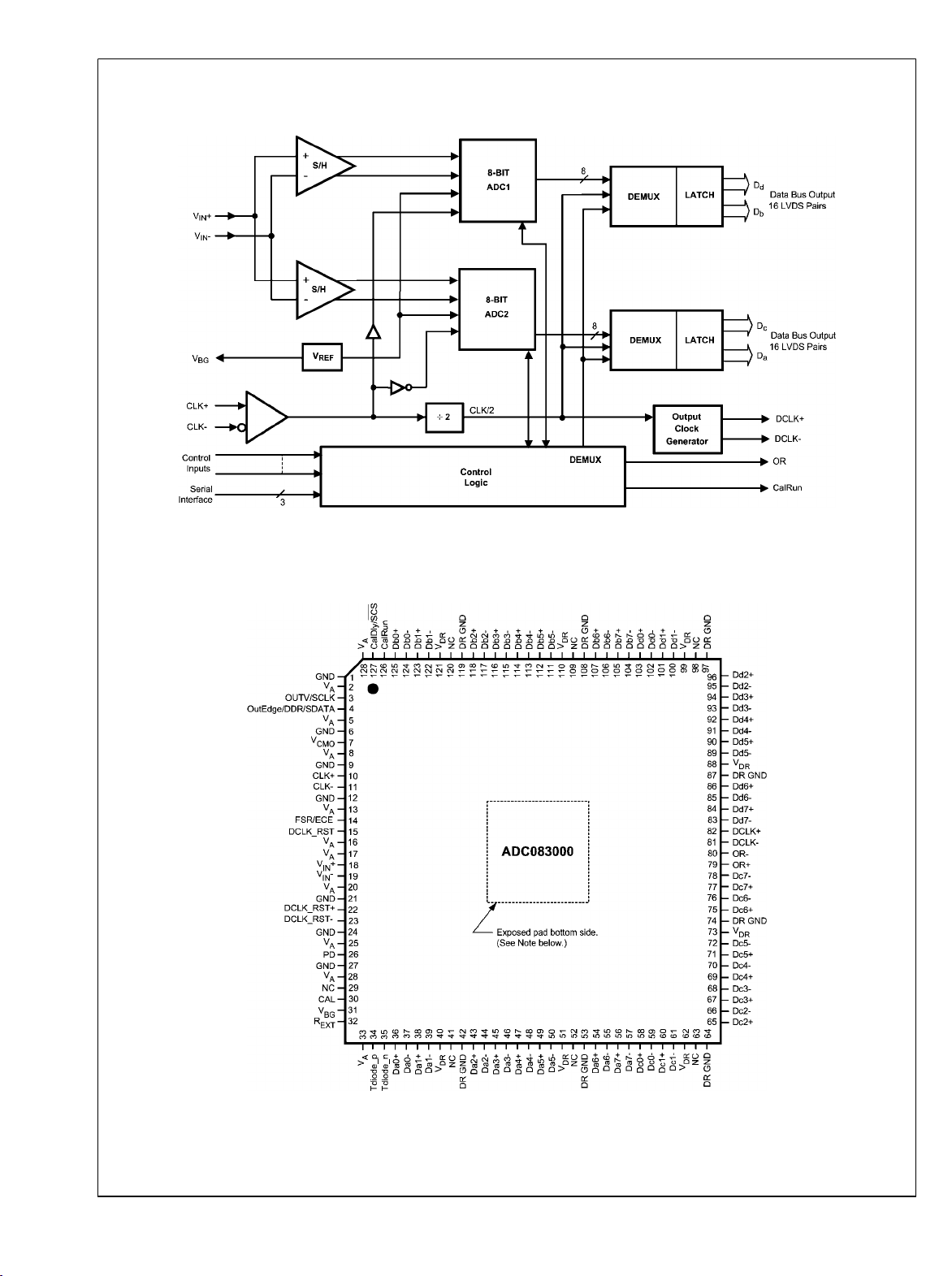

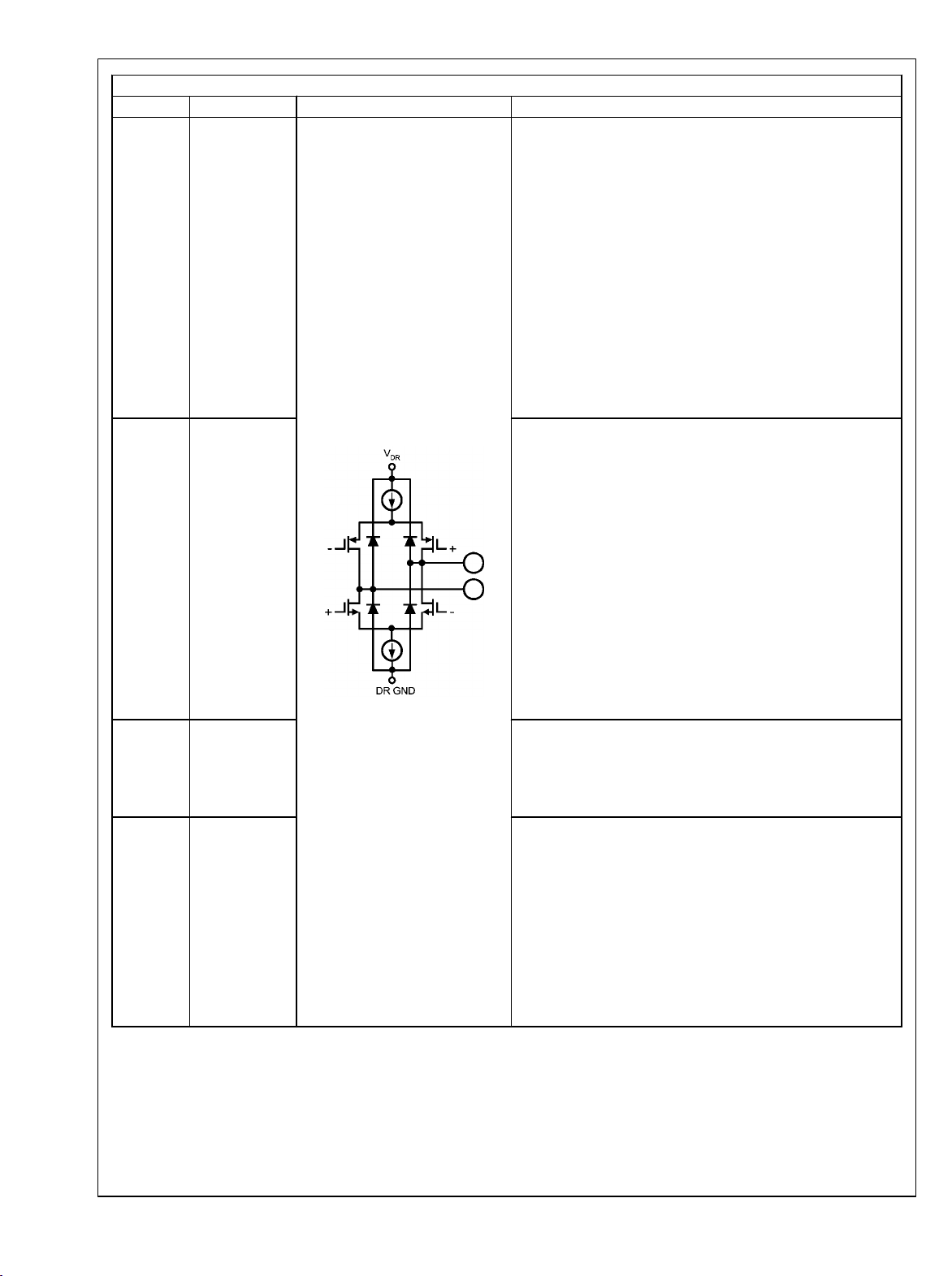

Block Diagram

ADC083000

Pin Configuration

20193253

20193201

Note: The exposed pad on the bottom of the package must be soldered to a ground plane to ensure rated performance.

www.national.com 2

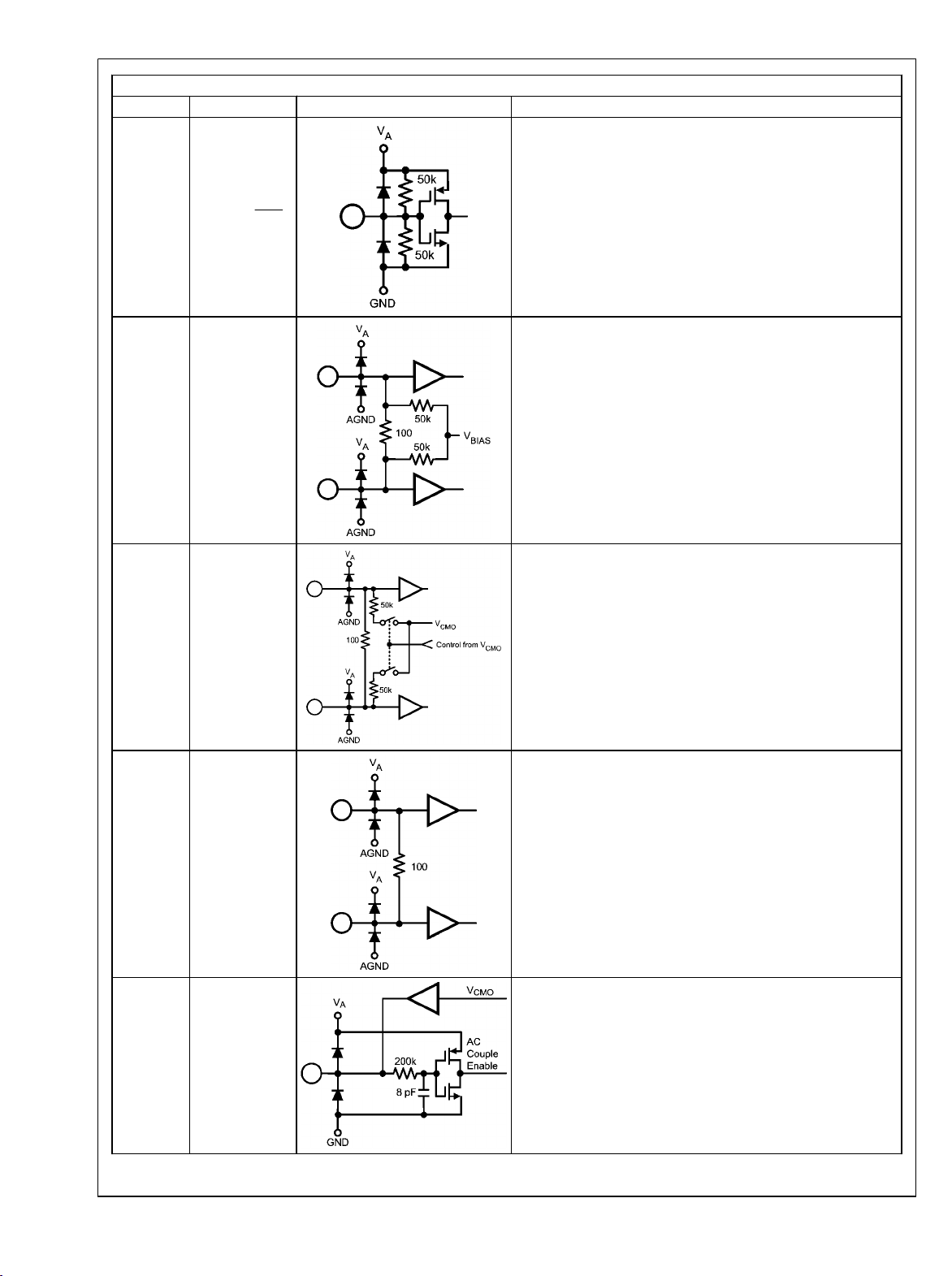

Pin Descriptions and Equivalent Circuits

Pin Functions

Pin No. Symbol Equivalent Circuit Description

Output Voltage Amplitude / Serial Interface Clock

(Input):LVCMOS Tie this pin high for normal differential DCLK

and data amplitude. Ground this pin for a reduced differential

3 OutV / SCLK

OutEdge / DDR /

4

SDATA

output amplitude and reduced power consumption. See Section

1.1.6. When the extended control mode is enabled, this pin

functions as the SCLK input which clocks in the serial data. See

Section 1.2 for details on the extended control mode. See

Section 1.3 for description of the serial interface.

Edge Select / Double Data Rate / Serial Data

(Input):LVCMOS This input sets the output edge of DCLK+ at

which the output data transitions. (See Section 1.1.5.2). When

this pin is floating or connected to 1/2 the supply voltage, DDR

clocking is enabled. When the extended control mode is enabled,

this pin functions as the SDATA input. See Section 1.2 for details

on the extended control mode. See Section 1.3 for description of

the serial interface.

ADC083000

15 DCLK_RST

26 PD

30 CAL

14 FSR/ECE

DCLK Reset

(Input):LVCMOS A positive pulse on this pin is used to reset

and synchronize the DCLK outs of multiple converters. See

Section 1.5 for detailed description. When bit 14 in the

Configuration Register (address 1h) is set to 0b, this singleended DCLK_RST pin is selected.

Power Down

(Input):LVCMOS A logic high on the PD pin puts the entire

device into the Power Down Mode.

Calibration Cycle Initiate

(Input):LVCMOS A minimum 80 input clock cycles logic low

followed by a minimum of 80 input clock cycles high on this pin

initiates the calibration sequence. See Section 2.4.2 for an

overview of self-calibration and Section 2.4.2.2 for a description

of on-command calibration.

Full Scale Range Select / Extended Control Enable

(Input):LVCMOS In non-extended control mode, a logic low on

this pin sets the full-scale differential input range to 600 mV

A logic high on this pin sets the full-scale differential input range

to 820 mV

mode, whereby the serial interface and control registers are

employed, allow this pin to float or connect it to a voltage equal

to VA/2. See Section 1.2 for information on the extended control

mode.

. See Section 1.1.4. To enable the extended control

P-P

P-P

.

3 www.national.com

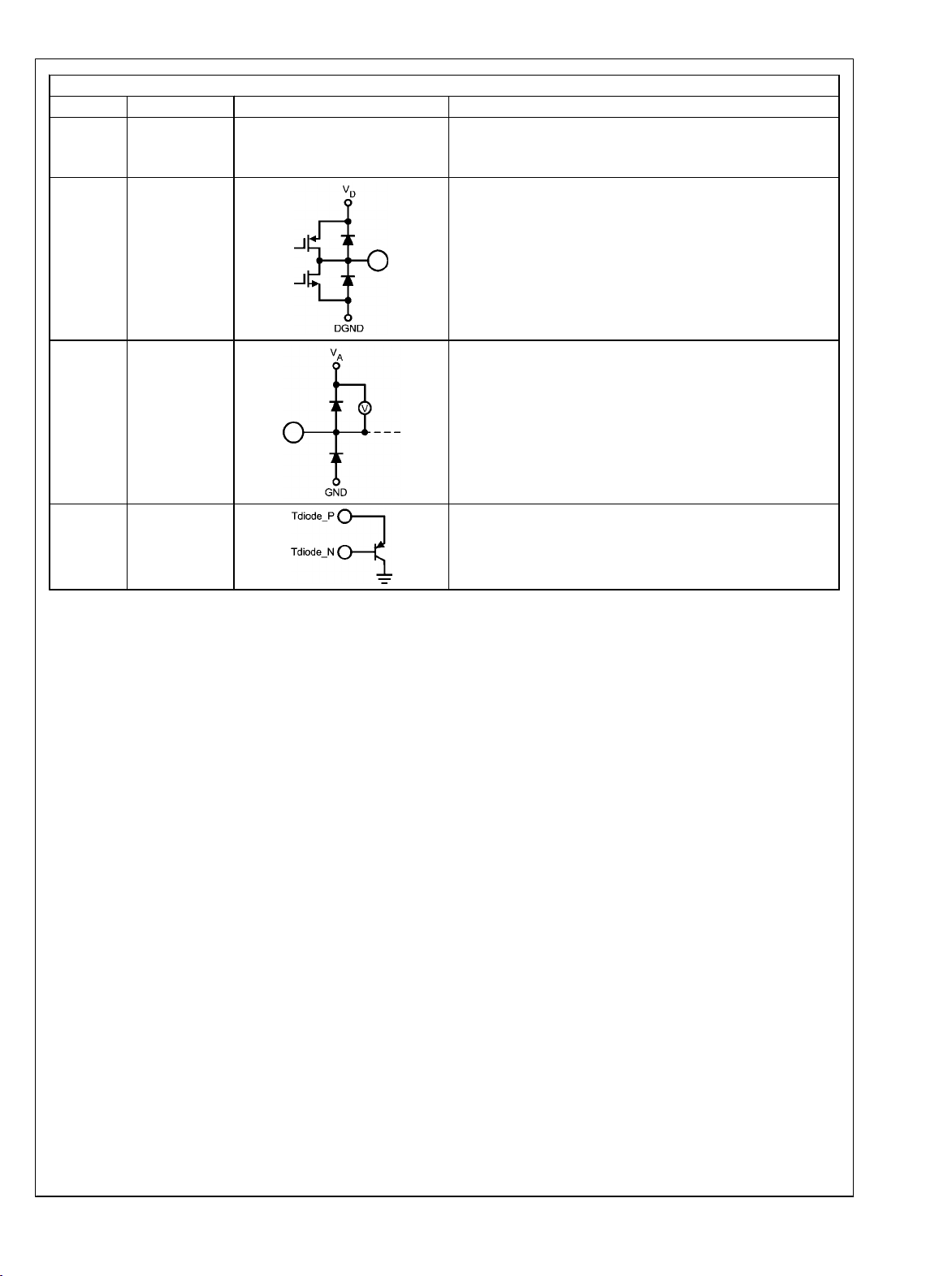

Pin Functions

Pin No. Symbol Equivalent Circuit Description

ADC083000

127 CalDly / SCS

10

11

18

19

CLK+

CLK-

VIN+

VIN−

Calibration Delay / Serial Interface Chip Select

(Input):LVCMOS With a logic high or low on pin 14, this pin

functions as Calibration Delay and sets the number of input clock

cycles after power up before calibration begins (See Section

1.1.1). With pin 14 floating, this pin acts as the enable pin for the

serial interface input and the CalDly value becomes "0" (short

delay with no provision for a long power-up calibration delay).

Sampling Clock Input

(Input):LVDS The differential clock signal must be a.c. coupled

to these pins. The input signal is sampled on the rising and falling

edge of CLK. See Section 1.1.2 for a description of acquiring the

input and Section 2.3 for an overview of the clock inputs.

Signal Input

(Input):Analog The differential full-scale input range is 600

mV

when the FSR pin is low, or 820 mV

P-P

when the FSR pin

P-P

is high.

22

23

7

www.national.com 4

DCLK_RST+

DCLK_RST-

V

CMO

Sample Clock Reset

(Input):LVDS A positive pulse on this pin is used to reset and

synchronize the DCLK outs of multiple converters. See Section

1.5 for detailed description. When bit 14 in the Configuration

Register (address 1h) is set to 1b, these differential DCLK_RST

pins are selected.

Common Mode Voltage

(Output):Analog - The voltage output at this pin is required to

be the common mode input voltage at VIN+ and VIN− when d.c.

coupling is used. This pin should be grounded when a.c. coupling

is used at the analog input. This pin is capable of sourcing or

sinking 100μA and can drive a load up to 80 pF. See Section 2.2.

Pin Functions

Pin No. Symbol Equivalent Circuit Description

Bandgap Output Voltage

31

V

BG

(Output):Analog - Capable of 100 μA source/sink and can drive

a load up to 80 pF.

Calibration Running

126 CalRun

(Output):LVCMOS - This pin is at a logic high when calibration

is running.

External Bias Resistor Connection

32

R

EXT

Analog - Nominal value is 3.3k-Ohms (±0.1%) to ground. See

Section 1.1.1.

ADC083000

34

35

Tdiode_P

Tdiode_N

Temperature Diode

Analog - Positive (Anode) and Negative (Cathode) for die

temperature measurements. See Section 2.6.2.

5 www.national.com

Pin Functions

Pin No. Symbol Equivalent Circuit Description

36 / 37

38 / 39

ADC083000

43 / 44

45 / 46

47 / 48

49 / 50

54 / 55

56 / 57

58 / 59

60 / 61

65 / 66

67 / 68

69 / 70

71 / 72

75 / 76

77 / 78

83 / 84

85 / 86

89 / 90

91 / 92

93 / 94

95 / 96

100 / 101

102 / 103

104 / 105

106 / 107

111 / 112

113 / 114

115 / 116

117 / 118

122 / 123

124 / 125

79

80

82

81

Da0+ / Da0Da1+ / Da1-

Da2+ / Da2−

Da3+ / Da3-

Da4+ / Da4−

Da5+ / Da5-

Da6+ / Da6−

Da7+ / Da7-

Dc0+ / Dc0Dc1+ / Dc1-

Dc2+ / Dc2−

Dc3+ / Dc3-

Dc4+ / Dc4−

Dc5+ / Dc5-

Dc6+ / Dc6−

Dc7+ / Dc7-

Dd7− / Dd7+

Dd6- / Dd6+

Dd5− / Dd5+

Dd4- / Dd4+

Dd3- / Dd3+

Dd2- / Dd2+

Dd1− / Dd1+

Dd0- / Dd0+

Db7- / Db7+

Db6- / Db6+

Db5− / Db5+

Db4- / Db4+

Db3− / Db3+

Db2- / Db2+

Db1− / Db1+

Db0- / Db0+

OR+

OR-

DCLK+

DCLK-

A and C Data

(Output):LVDS Data Outputs from the first internal converter.

The data should be extracted in the order ABCD These outputs

should always be terminated with a 100Ω differential resistor.

B and D Data

(Output):LVDS Data Outputs from the second internal

converter. The data should be extracted in the order ABCD

These outputs should always be terminated with a 100Ω

differential resistor.

Out Of Range

(Output):LVDS - A differential high at these pins indicates that

the differential input is out of range (outside the range ±325 mV

or ±435 mV as defined by the FSR pin). These outputs should

always be terminated with a 100Ω differential resistor.

Differential Clock

(Output):LVDS - The Differential Clock outputs are used to latch

the output data. Delayed and non-delayed data outputs are

supplied synchronous to this signal. DCLK is 1/2 the sample

clock rate in SDR mode and 1/4 the sample clock rate in the DDR

mode. These outputs should always be terminated with a 100Ω

differential resistor. The DCLK outputs are not active during the

calibration cycle depending on the setting of Configuration

Register (address 1h), bit- 14 (RTD). DCLK is continuously

present during the calibration cycle when bit-14 is set high (1b)

and is not active during the calibration cycle when set low (0b).

www.national.com 6

Pin Functions

Pin No. Symbol Equivalent Circuit Description

2, 5, 8, 13,

16, 17, 20,

25, 28, 33,

V

A

Analog power supply pins

(Power) - Bypass these pins to ground.

128

40, 51 ,62,

73, 88, 99,

110, 121

1, 6, 9, 12,

21, 24, 27

V

DR

GND

Output Driver power supply pins

(Power) - Bypass these pins to DR GND.

(Gnd) - Ground return for VA.

42, 53, 64,

74, 87, 97,

DR GND

(Gnd) - Ground return for VDR.

108, 119

29,41,52,

63, 98, 109,

NC No Connection Make no connection to these pins

120

ADC083000

7 www.national.com

Absolute Maximum Ratings

(Notes 1, 2)

If Military/Aerospace specified devices are required,

ADC083000

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Supply Voltage (VA, VDR)

Supply Difference

VA - V

DR

Voltage on Any Input Pin −0.15V to (VA + 0.15V)

Ground Difference

|GND - DR GND| 0V to 100 mV

Input Current at Any Pin (Note 3) ±25 mA

Package Input Current (Note 3) ±50 mA

Power Dissipation at TA ≤ 85°C

ESD Susceptibility (Note 4)

Human Body Model

Machine Model

Storage Temperature −65°C to +150°C

0V to -100mV

2.2V

2.3 W

2500V

250V

Operating Ratings (Notes 1, 2)

Ambient Temperature Range

Supply Voltage (VA)

Driver Supply Voltage (VDR) +1.8V to V

Analog Input Common Mode Voltage V

VIN+, VIN- Voltage Range

(Maintaining Common Mode)

Ground Difference

(|GND - DR GND|) 0V

CLK Pins Voltage Range 0V to V

Differential CLK Amplitude 0.4V

−40°C ≤ TA ≤ +85°C

+1.8V to +2.0V

CMO

200mV to V

to 2.0V

P-P

Package Thermal Resistance

Package

128-Lead

Exposed Pad

LQFP

θ

θ

JA

JC (Top of

Package)

26°C / W 10°C / W 2.8°C / W

θ

(Thermal Pad)

Soldering process must comply with National

Semiconductor’s Reflow Temperature Profile specifications.

Refer to www.national.com/packaging. (Note 5)

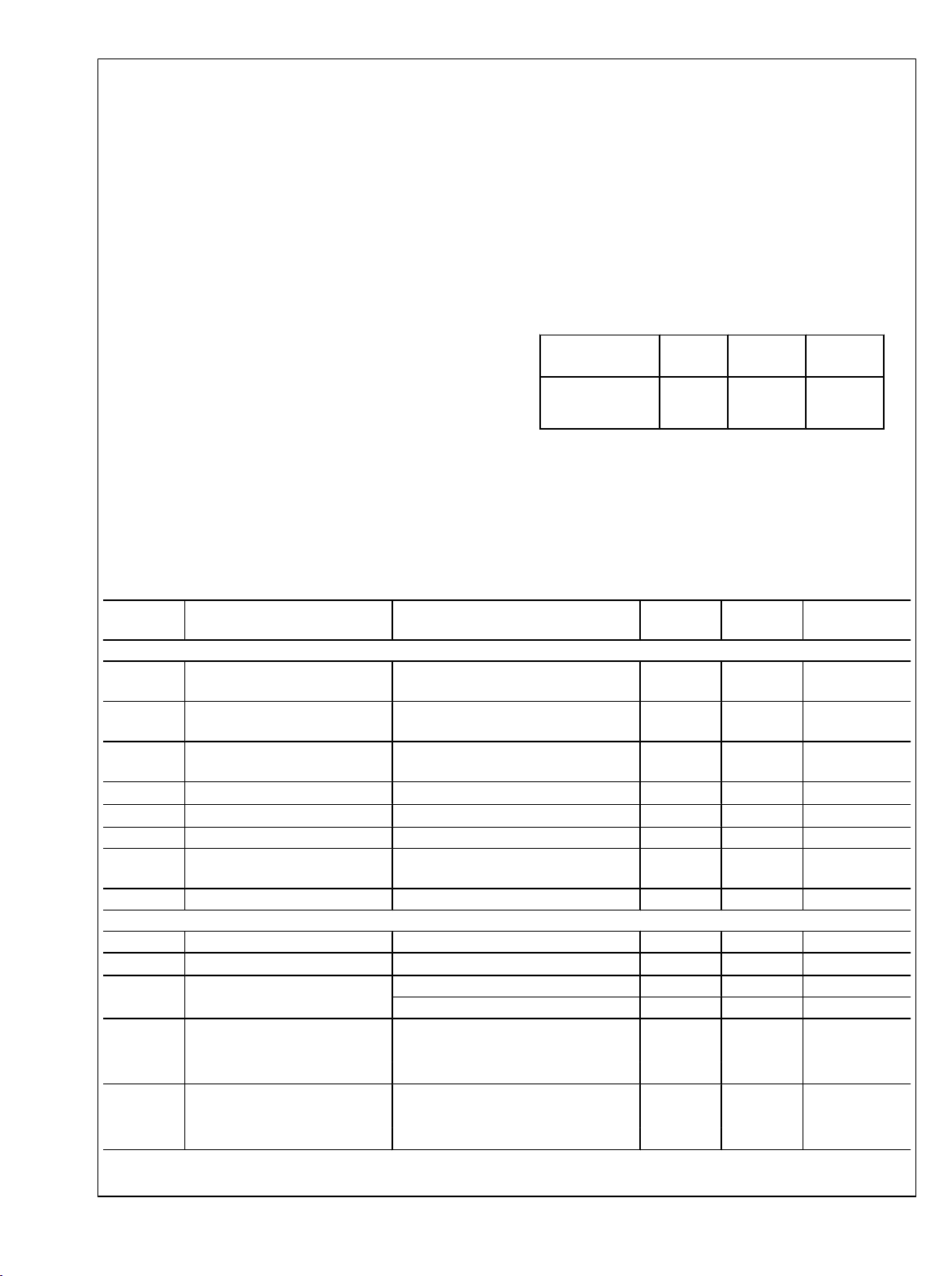

Converter Electrical Characteristics

The following specifications apply after calibration for VA = VDR = +1.9VDC, OutV = 1.9V, VIN FSR (a.c. coupled) = differential

820mV

Non-Extended Control Mode, SDR Mode, R

limits apply for TA = T

Symbol Parameter Conditions

STATIC CONVERTER CHARACTERISTICS

INL Integral Non-Linearity (Best fit)

DNL Differential Non-Linearity

V

OFF

V

OFF

PFSE Positive Full-Scale Error (Note 9) −1.6 ±25 mV (max)

NFSE

FS_ADJ Full-Scale Adjustment Range Extended Control Mode ±20 ±15 %FS

DYNAMIC CONVERTER CHARACTERISTICS

FPBW Full Power Bandwidth 3 GHz

B.E.R. Bit Error Rate

Gain Flatness

ENOB Effective Number of Bits

SINAD

, CL = 10 pF, Differential, a.c. coupled Sinewave Input Clock, f

P-P

MIN

to T

. All other limits TA = 25°C, unless otherwise noted. (Notes 6, 7)

MAX

= 3300Ω ±0.1%, Analog Signal Source Impedance = 100Ω Differential. Boldface

EXT

DC Coupled, 1MHz Sine Wave Over

Ranged

DC Coupled, 1MHz Sine Wave Over

Ranged

Resolution with No Missing

Codes

8 Bits

Offset Error -0.20 LSB

_ADJ

Input Offset Adjustment Range Extended Control Mode ±45 mV

Negative Full-Scale Error (Note

9)

−1.00 ±25 mV (max)

d.c. to 750 MHz ±0.42 dBFS

d.c. to 1500 MHz ±0.83 dBFS

fIN = 373 MHz, VIN = FSR − 0.5 dB

fIN = 748 MHz, VIN = FSR − 0.5 dB

fIN = 1498 MHz, VIN = FSR − 0.5 dB

Signal-to-Noise Plus Distortion

Ratio

fIN = 373 MHz, VIN = FSR − 0.5 dB

fIN = 748 MHz, VIN = FSR − 0.5 dB

fIN = 1498 MHz, VIN = FSR − 0.5 dB

= 1.5GHz at 0.5V

CLK

with 50% duty cycle, VBG = Floating,

P-P

Typical

(Note 8)

Limits

(Note 8)

±0.35 ±0.9 LSB (max)

±0.20 ±0.6 LSB (max)

-18

10

Error/Sample

7.2 6.85 Bits (min)

7.0 6.6 Bits (min)

6.5 Bits

45 42.2 dB (min)

44.2 40.8 dB (min)

41.1 dB

A

±50mV

A

A

P-P

J-PAD

Units

(Limits)

www.national.com 8

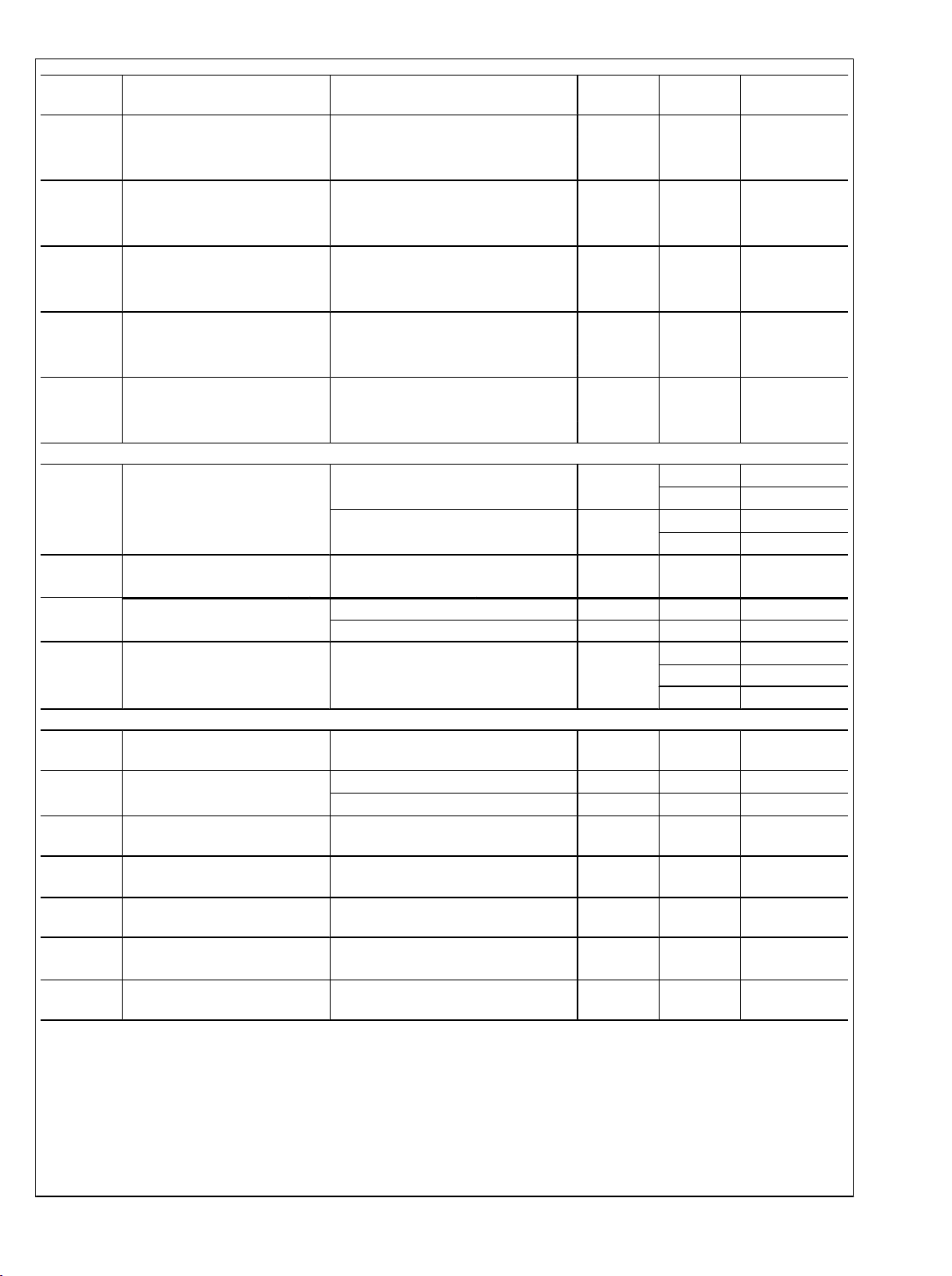

ADC083000

Symbol Parameter Conditions

fIN = 373 MHz, VIN = FSR − 0.5 dB

SNR Signal-to-Noise Ratio

fIN = 748 MHz, VIN = FSR − 0.5 dB

fIN = 1498 MHz, VIN = FSR − 0.5 dB

fIN = 373 MHz, VIN = FSR − 0.5 dB

THD Total Harmonic Distortion

fIN = 748 MHz, VIN = FSR − 0.5 dB

fIN = 1498 MHz, VIN = FSR − 0.5 dB

fIN = 373 MHz, VIN = FSR − 0.5 dB

2nd Harm Second Harmonic Distortion

fIN = 748 MHz, VIN = FSR − 0.5 dB

fIN = 1498 MHz, VIN = FSR − 0.5 dB

fIN = 373 MHz, VIN = FSR − 0.5 dB

3rd Harm Third Harmonic Distortion

fIN = 748 MHz, VIN = FSR − 0.5 dB

fIN = 1498 MHz, VIN = FSR − 0.5 dB

fIN = 373 MHz, VIN = FSR − 0.5 dB

SFDR Spurious-Free dynamic Range

fIN = 748 MHz, VIN = FSR − 0.5 dB

fIN = 1498 MHz, VIN = FSR − 0.5 dB

ANALOG INPUT AND REFERENCE CHARACTERISTICS

FSR pin 14 Low 600

V

IN

Full Scale Analog Differential

Input Range

FSR pin 14 High 820

V

CMI

C

IN

R

IN

Analog Input Common Mode

Voltage

Analog Input Capacitance (Notes

10, 11)

Differential Input Resistance 100

Differential 1.08 pF

Each input pin to ground 2.2 pF

ANALOG OUTPUT CHARACTERISTICS

V

CMO

V

CMO_LVL

TC V

CMO

C

LOAD VCMO

V

BG

TC V

BG

C

LOAD VBG

Common Mode Output Voltage

V

input threshold to set DC

CMO

Coupling mode

Common Mode Output Voltage

Temperature Coefficient

Maximum V

CMO

load

Capacitance

Bandgap Reference Output

Voltage

Bandgap Reference Voltage

Temperature Coefficient

Maximum Bandgap Reference

load Capacitance

I

= ±100 µA

CMO

VA = 1.8V

VA = 2.0V

TA = −40°C to +85°C

80 pF

IBG = ±100 µA

TA = −40°C to +85°C,

IBG = ±100 µA

80 pF

Typical

(Note 8)

Limits

(Note 8)

Units

(Limits)

45.3 43.2 dB (min)

44.5 41.7 dB (min)

41.8 dB

-57 -49 dB (max)

-56 -48 dB (max)

-49.5 dB

−68 dB

−66 dB

−56 dB

−64 dB

−58 dB

−52 dB

57 49 dB (min)

54.5 48 dB (min)

52.0 dB

mV

P-P

mV

P-P

mV

P-P

mV

P-P

mV (min)

mV (max)

Ω (min)

V

CMO

550

650

770

870

V

− 50

CMO

V

+ 50

CMO

95

1.26

105

0.95

1.45

Ω (max)

V (min)

V (max)

0.60 V

0.66 V

118 ppm/°C

1.26

1.20

1.33

V (min)

V (max)

28 ppm/°C

(min)

(max)

(min)

(max)

9 www.national.com

Symbol Parameter Conditions

TEMPERATURE DIODE CHARACTERISTICS

ADC083000

ΔV

BE

Temperature Diode Voltage

192 µA vs. 12 µA,

TJ = 25°C

192 µA vs. 12 µA,

TJ = 85°C

LVDS INPUT CHARACTERISTICS

Sine Wave Clock 0.6

V

ID

Differential Clock Input Level

Square Wave Clock 0.6

I

I

C

IN

Input Current

Input Capacitance (Notes 10, 11)

VIN = 0 or VIN = V

Differential 0.02 pF

Each input to ground 1.5 pF

LVDS OUTPUT CHARACTERISTICS

Measured differentially, OutV = VA, V

V

OD

LVDS Differential Output Voltage

= Floating (Note 15)

Measured differentially, OutV = GND,

VBG = Floating (Note 15)

Δ V

V

V

Δ V

I

OS

Z

O

OS

OS

O DIFF

OS

Change in LVDS Output Swing

Between Logic Levels

Output Offset Voltage,

see Figure 1

Output Offset Voltage,

see Figure 1

Output Offset Voltage Change

Between Logic Levels

Output Short Circuit Current Output+ & Output- connected to 0.8V ±4 mA

Differential Output Impedance 100 Ohms

±1 mV

VBG = Floating

VBG = VA (Note 15)

±1 mV

LVCMOS INPUT CHARACTERISTICS

V

IH

V

IL

C

IN

Logic High Input Voltage (Note 12)

Logic Low Input Voltage (Note 12)

Input Capacitance (Notes 11, 13) Each input to ground 1.2 pF

LVCMOS OUTPUT CHARACTERISTICS

V

OH

V

OL

CMOS H level output

CMOS L level output

IOH = -400uA (Note 12)

IOH = 400uA (Note 12)

POWER SUPPLY CHARACTERISTICS

I

A

I

DR

P

D

Analog Supply Current PD = Low 734 810 mA (max)

Output Driver Supply Current PD = Low 300 410 mA (max)

Power Consumption

PD = Low 1.9 2.3 W (max)

PD = High 25 mW

Typical

(Note 8)

Limits

(Note 8)

Units

(Limits)

71.23 mV

85.54 mV

V

V

V

mV

mV

mV

mV

V

P-P

P-P

P-P

P-P

P-P

P-P

P-P

P-P

(min)

(max)

(min)

(max)

(min)

(max)

(min)

(max)

0.4

2.0

0.4

2.0

A

BG

±1 µA

680

520

470

920

380

720

800 mV

1150 mV

0.85 x V

0.15 x V

A

A

V (min)

V (max)

1.65 1.5 V

0.15 0.3 V

www.national.com 10

ADC083000

Symbol Parameter Conditions

Typical

(Note 8)

Limits

(Note 8)

Units

(Limits)

AC ELECTRICAL CHARACTERISTICS - Sampling Clock

f

CLK1

f

CLK2

t

CYC

t

LC

t

HC

DCLK Duty Cycle (Note 11) 50

t

AD

t

AJ

t

OD

Maximum Input Clock Frequency Sampling rate is 2x clock input 1.7 1.5 GHz (min)

Minimum Input Clock Frequency Sampling rate is 2x clock input 500 MHz

Input Clock Duty Cycle

500MHz ≤ Input clock frequency ≤ 1.5

GHz (Note 12)

50

20

80

% (min)

% (max)

Input Clock Low Time (Note 11) 333 133 ps (min)

Input Clock High Time (Note 11) 333 133 ps (min)

Sampling (Aperture) Delay

Input CLK transition to Acquisition of

Data

45

55

1.4 ns

% (min)

% (max)

Aperture Jitter 0.55 ps rms

Input Clock to Data Output Delay

(in addition to Pipeline Delay)

50% of Input Clock transition to 50% of

Data transition

3.7 ns

Dd Outputs 13

Pipeline Delay (Latency)

(Notes 11, 14)

Db Outputs 14

Dc Outputs 13.5

Input Clock

Cycles

Da Outputs 14.5

AC ELECTRICAL CHARACTERISTICS - Output Clock and Data (Note 16)

t

t

LHT

HLT

LH Transition Time - Differential 10% to 90% 150 ps

HL Transition Time - Differential 10% to 90% 150 ps

50% of DCLK transition to 50% of Data

t

SKEWO

DCLK to Data Output Skew

transition, SDR Mode

±50 ps (max)

and DDR Mode, 0° DCLK (Note 11)

t

OSU

t

OH

Data to DCLK Set-Up Time DDR Mode, 90° DCLK (Note 12) 570 ps

DCLK to Data Hold Time DDR Mode, 90° DCLK (Note 12) 555 ps

AC ELECTRICAL CHARACTERISTICS - Serial Interface Clock

f

SCLK

t

SS

t

HS

Serial Clock Frequency (Note 11) 67 MHz

Data to Serial Clock Setup Time (Note 11) 2.5 ns (min)

Data to Serial Clock Hold Time (Note 11) 1 ns (min)

Serial Clock Low Time 6 ns (min)

Serial Clock High Time 6 ns (min)

AC ELECTRICAL CHARACTERISTICS - General Signals

t

SR

t

HR

t

PWR

t

WU

t

CAL

t

CAL_L

t

CAL_H

t

CalDly

t

CalDly

Setup Time DCLK_RST±

Hold Time DCLK_RST± 30 ps

(Note 12)

90 ps

Pulse Width DCLK_RST± (Note 11) 4 CLK± Cyc. (min)

PD low to Rated Accuracy

Conversion (Wake-Up Time)

Calibration Cycle Time

(Note 11) 1 µs

5

1.4 x 10

CLK± Cyc.

CAL Pin Low Time See Figure 8 (Note 11) 80 CLK± Cyc. (min)

CAL Pin High Time See Figure 8 (Note 11) 80 CLK± Cyc.(min)

Calibration delay determined by

pin 127

Calibration delay determined by

pin 127

See Section 1.1.1, Figure 8, (Note 11)

See Section 1.1.1, Figure 8, (Note 11)

25

2

2

31

CLK± Cyc.(min)

CLK± Cyc.(max)

11 www.national.com

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. There is no guarantee of operation at the Absolute Maximum

Ratings. Operating Ratings indicate conditions for which the device is functional, but do not guarantee specific performance limits. For guaranteed specifications

and test conditions, see the Electrical Characteristics. The guaranteed specifications apply only for the test conditions listed. Some performance characteristics

may degrade when the device is not operated under the listed test conditions.

Note 2: All voltages are measured with respect to GND = DR GND = 0V, unless otherwise specified.

ADC083000

Note 3: When the input voltage at any pin exceeds the power supply limits (that is, less than GND or greater than VA), the current at that pin should be limited to

25 mA. The 50 mA maximum package input current rating limits the number of pins that can safely exceed the power supplies with an input current of 25 mA to

two. This limit is not placed upon the power, ground and digital output pins.

Note 4: Human body model is 100 pF capacitor discharged through a 1.5 kΩ resistor. Machine model is 220 pF discharged through ZERO Ohms.

Note 5: Reflow temperature profiles are different for lead-free and non-lead-free packages.

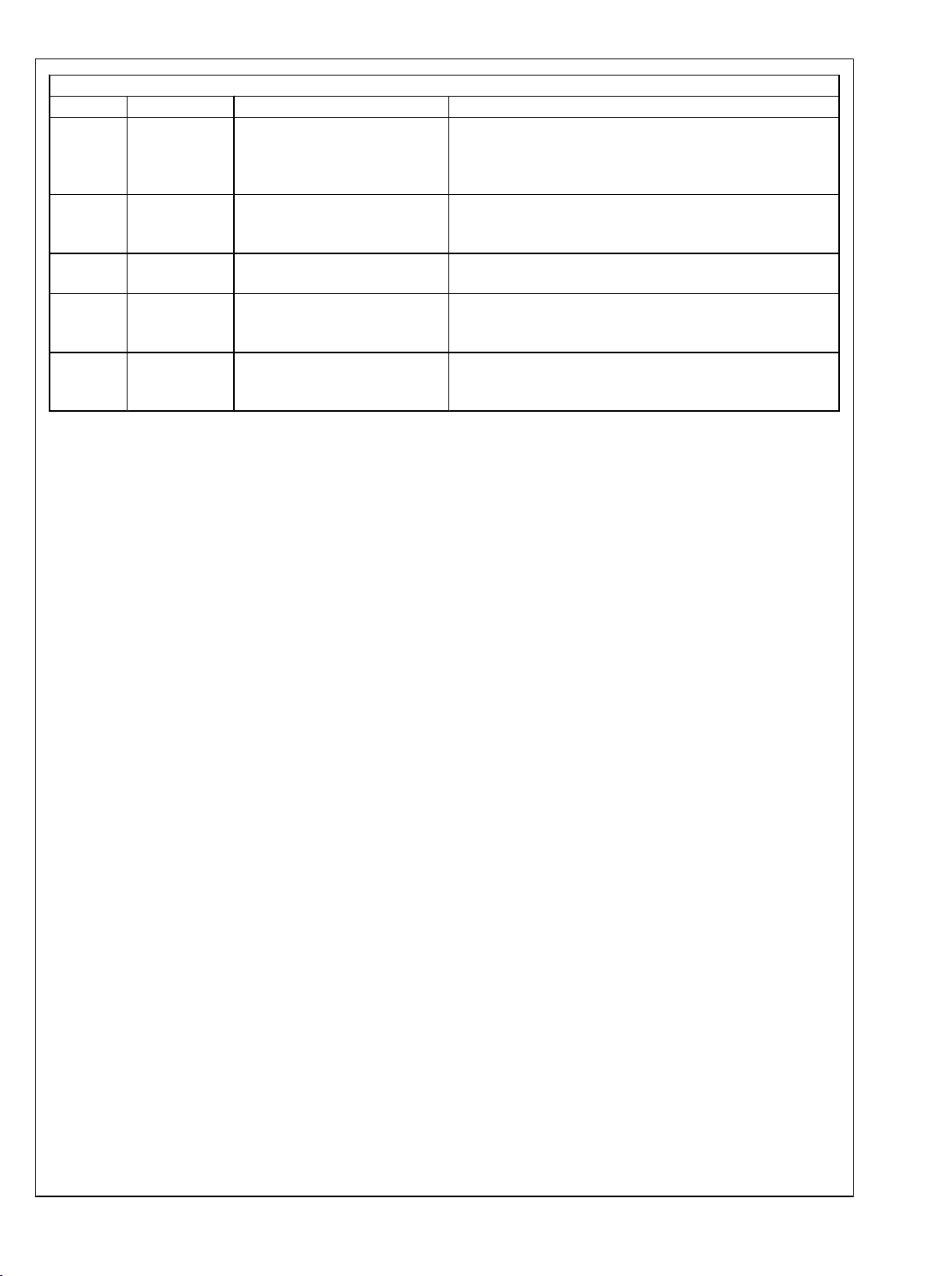

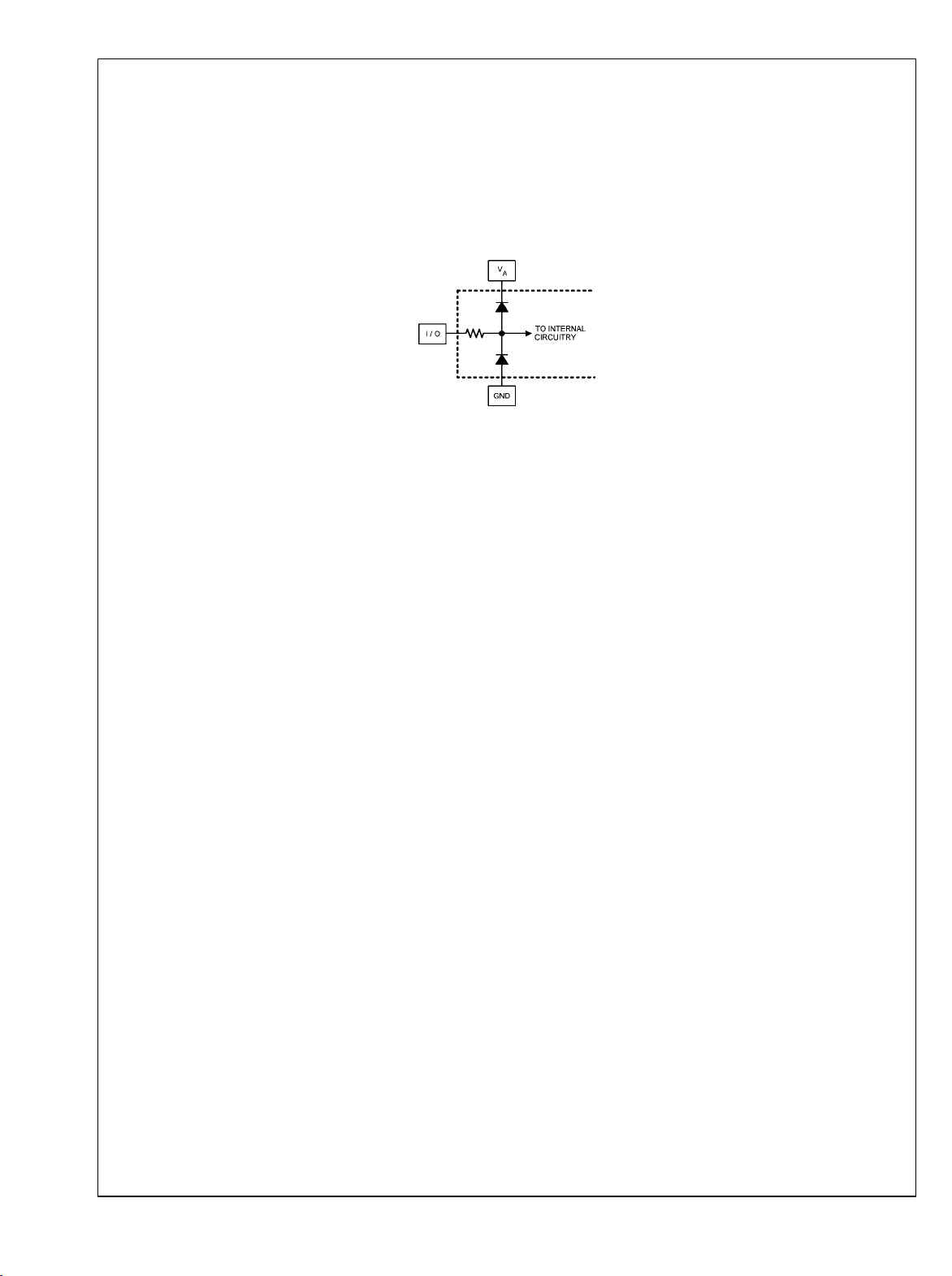

Note 6: The analog inputs are protected as shown below. Input voltage magnitudes beyond the Absolute Maximum Ratings may damage this device.

20193204

Note 7: To guarantee accuracy, it is required that VA and VDR be well bypassed. Each supply pin must be decoupled with separate bypass capacitors. Additionally,

achieving rated performance requires that the backside exposed pad be well grounded.

Note 8: Typical figures are at TA = 25°C, and represent most likely parametric norms. Test limits are guaranteed to National's AOQL (Average Outgoing Quality

Level).

Note 9: Calculation of Full-Scale Error for this device assumes that the actual reference voltage is exactly its nominal value. Full-Scale Error for this device,

therefore, is a combination of Full-Scale Error and Reference Voltage Error. See Figure 2. For relationship between Gain Error and Full-Scale Error, see

Specification Definitions for Gain Error.

Note 10: The analog and clock input capacitances are die capacitances only. Additional package capacitances of 0.65 pF differential and 0.95 pF each pin to

ground are isolated from the die capacitances by lead and bond wire inductances.

Note 11: This parameter is guaranteed by design and is not tested in production.

Note 12: This parameter is guaranteed by design and/or characterization and is not tested in production.

Note 13: The digital control pin capacitances are die capacitances only. Additional package capacitance of 1.6 pF each pin to ground are isolated from the die

capacitances by lead and bond wire inductances.

Note 14: Each of the two converters of the ADC083000 has two LVDS output buses, which each clock data out at one quarter the sample rate. Bus Db has a

pipeline latency that is one Input Clock cycle less than the latency of bus Dd. Likewise, bus Da has a pipeline latency that is one Input Clock cycle less than the

latency of bus Dc.

Note 15: Tying VBG to the supply rail will increase the output offset voltage (VOS) by 400mv (typical), as shown in the VOS specification above. Tying VBG to the

supply rail will also affect the differential LVDS output voltage (VOD), causing it to increase by 40mV (typical).

Note 16: All parameters are measured through a transmission line and 100Ω termination using a 0.33pF load oscilloscope probe.

Specification Definitions

APERTURE (SAMPLING) DELAY is the amount of delay,

measured from the sampling edge of the Clock input, after

which the signal present at the input pin is sampled inside the

device.

APERTURE JITTER (tAJ) is the variation in aperture delay

from sample to sample. Aperture jitter shows up as input

noise.

Bit Error Rate (B.E.R.) is the probability of error and is defined as the probable number of errors per unit of time divided

by the number of bits seen in that amount of time. A B.E.R. of

-18

10

corresponds to a statistical error in one bit about every

four (4) years.

CLOCK DUTY CYCLE is the ratio of the time that the clock

wave form is at a logic high to the total time of one clock period.

DIFFERENTIAL NON-LINEARITY (DNL) is the measure of

the maximum deviation from the ideal step size of 1 LSB.

Measured at 3 GSPS with a ramp input.

EFFECTIVE NUMBER OF BITS (ENOB, or EFFECTIVE

BITS) is another method of specifying Signal-to-Noise and

Distortion Ratio, or SINAD. ENOB is defined as (SINAD −

1.76) / 6.02 and says that the converter is equivalent to a per-

FULL POWER BANDWIDTH (FPBW) is a measure of the

frequency at which the reconstructed output fundamental

drops 3 dB below its low frequency value for a full scale input.

GAIN ERROR is the deviation from the ideal slope of the

transfer function. It can be calculated from Offset and FullScale Errors:

Positive Gain Error = Offset Error − Positive Full-Scale

Error

Negative Gain Error = −(Offset Error − Negative FullScale Error)

Gain Error = Negative Full-Scale Error − Positive FullScale Error = Positive Gain Error + Negative Gain Error

INTEGRAL NON-LINEARITY (INL) is a measure of the deviation of each individual code from a straight line through the

input to output transfer function. The deviation of any given

code from this straight line is measured from the center of that

code value. The best fit method is used.

INTERMODULATION DISTORTION (IMD) is the creation of

additional spectral components as a result of two sinusoidal

frequencies being applied to the ADC input at the same time.

It is defined as the ratio of the power in the second and third

order intermodulation products to the power in one of the

original frequencies. IMD is usually expressed in dBFS.

fect ADC of this (ENOB) number of bits.

www.national.com 12

ADC083000

LSB (LEAST SIGNIFICANT BIT) is the bit that has the small-

est value or weight of all bits. This value is

n

VFS / 2

where VFS is the differential full-scale amplitude of VIN as set

by the FSR input (pin-14) and "n" is the ADC resolution in bits,

which is 8 for the ADC083000.

LVDS DIFFERENTIAL OUTPUT VOLTAGE (VOD) is the absolute value of the difference between the VD+ & VD- outputs;

each measured with respect to Ground.

20193246

FIGURE 1.

LVDS OUTPUT OFFSET VOLTAGE (VOS) is the midpoint

between the D+ and D- pins output voltage; ie., [(VD+) +

( VD-)]/2.

MISSING CODES are those output codes that are skipped

and will never appear at the ADC outputs. These codes cannot be reached with any input value.

MSB (MOST SIGNIFICANT BIT) is the bit that has the largest

value or weight. Its value is one half of full scale.

NEGATIVE FULL-SCALE ERROR (NFSE) is a measure of

how far the last code transition is from the ideal 1/2 LSB above

a differential -VIN / 2. For the ADC083000 the reference voltage is assumed to be ideal, so this error is a combination of

full-scale error and reference voltage error.

OFFSET ERROR (V

scale point is from the ideal zero voltage differential input.

) is a measure of how far the mid-

OFF

Offset Error = Actual Input causing average of 8k samples to result in an average code of 127.5.

OUTPUT DELAY (tOD) is the time delay from 50% point of the

input clock transition, CLK, to the 50% point of the updated

data transition at the output pins.

OVER-RANGE RECOVERY TIME is the time required after

the differential input voltages goes from ±1.2V to 0V for the

converter to recover and make a conversion with its rated accuracy.

PIPELINE DELAY (LATENCY) is the number of input clock

cycles between initiation of conversion and when that data is

presented to the output driver stage. New data is available at

every clock cycle, but the data lags the conversion by the

Pipeline Delay plus the tOD.

POSITIVE FULL-SCALE ERROR (PFSE) is a measure of

how far the last code transition is from the ideal 1-1/2 LSB

below a differential +VIN / 2. For the ADC083000 the reference

voltage is assumed to be ideal, so this error is a combination

of full-scale error and reference voltage error.

POWER SUPPLY REJECTION RATIO (PSRR) can be one

of two specifications. PSRR1 (DC PSRR) is the ratio of the

change in full-scale error that results from a power supply

voltage change from 1.8V to 2.0V. PSRR2 (AC PSRR) is a

measure of how well an a.c. signal riding upon the power

supply is rejected from the output and is measured with a 248

MHz, 50 mV

ratio of the output amplitude of that signal at the output to its

signal riding upon the power supply. It is the

P-P

amplitude on the power supply pin. PSRR is expressed in dB.

SIGNAL TO NOISE RATIO (SNR) is the ratio, expressed in

dB, of the rms value of the input signal at the output to the rms

value of the sum of all other spectral components below onehalf the sampling frequency, not including harmonics or d.c.

SIGNAL TO NOISE PLUS DISTORTION (S/(N+D) or

SINAD) is the ratio, expressed in dB, of the rms value of the

input signal at the output to the rms value of all of the other

spectral components below half the input clock frequency, including harmonics but excluding d.c.

SPURIOUS-FREE DYNAMIC RANGE (SFDR) is the difference, expressed in dB, between the rms values of the input

signal at the output and the peak spurious signal, where a

spurious signal is any signal present in the output spectrum

that is not present at the input, excluding d.c.

TOTAL HARMONIC DISTORTION (THD) is the ratio expressed in dB, of the rms total of the first nine harmonic levels

at the output to the level of the fundamental at the output. THD

is calculated as

where Af1 is the RMS power of the fundamental (output) frequency and Af2 through A

harmonic frequencies in the output spectrum.

are the RMS power of the first 9

f10

– Second Harmonic Distortion (2nd Harm) is the difference, expressed in dB, between the RMS power in the input

frequency seen at the output and the power in its 2nd harmonic level at the output.

– Third Harmonic Distortion (3rd Harm) is the difference

expressed in dB between the RMS power in the input frequency seen at the output and the power in its 3rd harmonic

level at the output.

13 www.national.com

Transfer Characteristic

ADC083000

FIGURE 2. Input / Output Transfer Characteristic

20193222

www.national.com 14

Timing Diagrams

ADC083000

20193214

FIGURE 3. ADC083000 Timing — SDR Clocking

FIGURE 4. ADC083000 Timing — DDR Clocking

15 www.national.com

20193259

ADC083000

20193220

FIGURE 5. Clock Reset Timing in DDR Mode

FIGURE 6. Clock Reset Timing in SDR Mode with OUTEDGE Low

FIGURE 7. Clock Reset Timing in SDR Mode with OUTEDGE High

20193223

20193224

www.national.com 16

FIGURE 8. Calibration and On-Command Calibration Timing

ADC083000

20193225

FIGURE 9. Serial Interface Timing

20193219

17 www.national.com

Typical Performance Characteristics V

A=VDR

=1.9V, F

=1500MHz, TA=25°C unless otherwise stated.

CLK

ADC083000

DNL vs. TEMPERATURE

ENOB vs. TEMPERATURE

20193268

POWER DISSIPATION vs. SAMPLE RATE

20193269

ENOB vs. SUPPLY VOLTAGE

20193270

ENOB vs. SAMPLE RATE

20193272

www.national.com 18

20193271

ENOB vs. INPUT FREQUENCY

20193273

ADC083000

SNR vs. TEMPERATURE

SNR vs. SAMPLE RATE

20193274

SNR vs. SUPPLY VOLTAGE

20193275

SNR vs. INPUT FREQUENCY

THD vs. TEMPERATURE

20193276

20193278

20193277

THD vs. SUPPLY VOLTAGE

20193279

19 www.national.com

ADC083000

THD vs. SAMPLE RATE

THD vs. INPUT FREQUENCY

SFDR vs. TEMPERATURE

SFDR vs. SAMPLE RATE

20193280

20193282

20193281

SFDR vs. SUPPLY VOLTAGE

20193283

SFDR vs. INPUT FREQUENCY

20193284

www.national.com 20

20193285

ADC083000

Spectral Response at FIN = 748 MHZ

FULL POWER BANDWIDTH

20193287

Spectral Response at FIN = 1497 MHZ

20193288

20193290

21 www.national.com

1.0 Functional Description

The ADC083000 is a versatile A/D Converter with an innovative architecture permitting very high speed operation. The

controls available ease the application of the device to circuit

ADC083000

solutions. Optimum performance requires adherence to the

provisions discussed here and in the Applications Information

Section.

While it is generally poor practice to allow an active pin to float,

pins 4 and 14 of the ADC083000 are designed to be left floating without jeopardy. In all discussions throughout this data

sheet, whenever a function is called by allowing a control pin

to float, connecting that pin to a potential of one half the V

supply voltage will have the same effect as allowing it to float.

1.1 OVERVIEW

The ADC083000 uses a calibrated folding and interpolating

architecture that achieves over 7.2 effective bits. The use of

folding amplifiers greatly reduces the number of comparators

and power consumption. Interpolation reduces the number of

front-end amplifiers required, minimizing the load on the input

signal and further reducing power requirements. In addition

to other things, on-chip calibration reduces the INL bow often

seen with folding architectures. The result is an extremely

fast, high performance, low power converter.

The analog input signal that is within the converter's input

voltage range is digitized to eight bits at speeds of 1.0 GSPS

to 3.0 GSPS, typical. Differential input voltages below negative full-scale will cause the output word to consist of all

zeroes. Differential input voltages above positive full-scale

will cause the output word to consist of all ones. Either of

these conditions at the analog input will cause the OR (Out of

Range) output to be activated. This single OR output indicates

when the output code from the converter is below negative

full scale or above positive full scale.

The ADC083000 demultiplexes the data at 1:4 and is output

on all four output busses at a quarter of the ADC sampling

rate. The outputs must be interleaved by the user to provide

output words at the full conversion rate.

The output levels may be selected to be normal or reduced

voltage. Using reduced levels saves power but could result in

erroneous data capture of some or all of the bits, especially

at higher sample rates and in marginally designed systems.

1.1.1 Calibration

A calibration is performed upon power-up and can also be

invoked by the user upon command. Calibration trims the

100Ω analog input differential termination resistor and minimizes full-scale error, offset error, DNL and INL, resulting in

maximizing SNR, THD, SINAD (SNDR) and ENOB. Internal

bias currents are also set with the calibration process. All of

this is true whether the calibration is performed upon power

up or is performed upon command. Running the calibration is

an important part of this chip's functionality and is required in

order to obtain adequate performance. In addition to the requirement to be run at power-up, calibration must be re-run

by the user whenever the state of the FSR pin is changed. For

best performance, we recommend an on command calibration be run after initial power up and the device has reached

a stable temperature. Also, we recommend that an on command calibration be run whenever the operating temperature

changes significantly relative to the specific system performance requirements. See Section 2.4.2.2 for more information. Calibration can not be initiated or run while the device is

in the power-down mode. See Section 1.1.7 for information

on the interaction between Power Down and Calibration.

In normal operation, calibration is performed just after application of power and whenever a valid calibration command is

given, which is holding the CAL pin low for at least 80 input

clock cycles, then hold it high for at least another 80 input

clock cycles. The time taken by the calibration procedure is

specified in the A.C. Characteristics Table. Holding the CAL

pin high upon power up will prevent the calibration process

from running until the CAL pin experiences the above-mentioned 80 input clock cycles low followed by 80 cycles high.

CalDly (pin 127) is used to select one of two delay times after

the application of power to the start of calibration. This calibration delay is 225 input clock cycles (about 22 ms at 3

A

GSPS) with CalDly low, or 231 input clock cycles (about 1.4

seconds at 3 GSPS) with CalDly high. These delay values

allow the power supply to come up and stabilize before calibration takes place. If the PD pin is high upon power-up, the

calibration delay counter will be disabled until the PD pin is

brought low. Therefore, holding the PD pin high during power

up will further delay the start of the power-up calibration cycle.

The best setting of the CalDly pin depends upon the poweron settling time of the power supply.

Calibration Operation Notes:

•

During the calibration cycle, the OR output may be active

as a result of the calibration algorithm. All data on the

output pins and the OR output are invalid during the

calibration cycle.

•

During the power-up calibration and during the oncommand calibration when Resistor Trim Disable

(address: 1h, bit 13) is not active (0b) , all clocks are halted

on chip, including internal clocks and DCLK, while the

input termination resistor is trimmed to a value that is equal

to R

/ 33. This is to reduce noise during the input

EXT

resistor calibration portion of the calibration cycle. See

Section 2.4.2.2 for information on maintaining DCLK

operation during on-command calibration.

This external resistor is located between pin 32 and

ground. R

input termination resistor is trimmed to be 100 Ω. Because

R

is also used to set the proper current for the Track

EXT

and Hold amplifier, for the preamplifiers and for the

comparators, other values of R

•

The CalRun output is high whenever the calibration

must be 3300 Ω ±0.1%. With this value, the

EXT

should not be used.

EXT

procedure is running. This is true whether the calibration

is done at power-up or on-command.

1.1.2 Acquiring the Input

Data is acquired at the rising and falling edge of CLK+ (pin

10) and the digital equivalent of that data is available at the

digital outputs 13 input clock cycles later for the Dd output

bus, 13.5 input clock cycles later for Dc output bus, 14 input

clock cycles later for the Db output bus and 14.5 input clock

cycles later for the Da output bus. See Table 1. There is an

additional internal delay called tOD before the data is available

at the outputs. See Figure 3 and Figure 4. The ADC083000

will convert as long as the input clock signal is present. The

fully differential comparator design and the innovative design

of the sample-and-hold amplifier, together with calibration,

enables a very flat SINAD/ENOB response beyond 1.5 GHz.

The ADC083000 output data signaling is LVDS and the output

format is offset binary.

1.1.3 Control Modes

Much of the user control can be accomplished with several

control pins that are provided. Examples include initiation of

the calibration cycle, power down mode and full scale range

setting. However, the ADC083000 also provides an Extended

www.national.com 22

ADC083000

Control mode whereby a serial interface is used to access

register-based control of several advanced features. The Extended Control mode is not intended to be enabled and

disabled dynamically. Rather, the user is expected to employ

either the normal control mode or the Extended Control mode

at all times. When the device is in the Extended Control mode,

pin-based control of several features is replaced with registerbased control and those pin-based controls are disabled.

These pins are OutV (pin 3), OutEdge/DDR (pin 4), FSR (pin

14). See Section 1.2 for details on the Extended Control

mode.

1.1.4 The Analog Inputs

The ADC083000 must be driven with a differential input signal. Operation with a single-ended signal is not recommended. It is important that the input signals are either a.c. coupled

to the inputs with the V

the V

equal to the V

is used.

pin left floating. An input common mode voltage

CMO

output must be provided when d.c. coupling

CMO

pin grounded, or d.c. coupled with

CMO

Two full-scale range settings are provided with pin 14 (FSR).

A high on pin 14 causes an input full-scale range setting of

820 mV

range setting of 600 mV

, while grounding pin 14 causes an input full-scale

P-P

P-P

.

In the Extended Control mode, the full-scale input range can

be set to values between 560 mV

a serial interface. See Section 2.2

and 840 mV

P-P

through

P-P

1.1.5 Clocking

The ADC083000 sampling clock (CLK+/CLK-) must be driven

with an a.c. coupled, differential clock signal. Section 2.3 de-

scribes the use of the clock input pins. A differential LVDS

output clock (DCLK) is available for use in latching the ADC

output data into whatever device is used to receive the data.

The ADC083000 offers options for CLK+/CLK- and DCLK

clocking. For DCLK, the clock edge on which output data

transitions, and a choice of Single Data Rate (SDR) or Double

Data Rate (DDR) outputs are available.

The sampling clock CLK has optional duty cycle correction as

part of its circuit. This feature is enabled by default and provides improved ADC clocking. This circuitry allows the ADC

to be clocked with a signal source having a duty cycle ratio of

80 / 20 % (worst case).

1.1.5.1 Output Demultiplexer

The ADC083000 utilizes both the rising and falling edge of the

input clock resulting in the overall sample rate being twice the

input clock frequency, or 3GSPS with a 1.5 GHz input clock.

The demultiplexer outputs data on each of the four output

busses at 750MHz with a 1.5GHz input clock.

All data is available in parallel at the output. The four bytes of

parallel data that are output with each clock is in the following

sampling order, from the earliest to the latest: Da, Db, Dc, Dd.

Table 1 indicates what the outputs represent for the various

sampling possibilities.

The ADC083000 includes an automatic clock phase background calibration feature which automatically and continuously adjusts the phase of the ADC input clock. This feature

removes the need to manually adjust the clock phase and

provides optimal ENOB performance.

TABLE 1. Input Channel Samples Produced at Data Outputs

Data Outputs* Input/Output Relationship

Dd ADC1 sampled with the fall of CLK, 13 cycles earlier

Db ADC1 sampled with the fall of CLK, 14 cycles earlier

Dc ADC2 sampled with the rise of CLK, 13.5 cycles earlier

Da ADC2 sampled with the rise of CLK, 14.5 cycles earlier

* Always sourced with respect to fall of DCLK

1.1.5.2 OutEdge Setting

To help ease data capture in the SDR mode, the output data

may be caused to transition on either the positive or the negative edge of the output data clock (DCLK). This is chosen

with the OutEdge input (pin 4). A high on the OutEdge input

pin causes the output data to transition on the rising edge of

DCLK, while grounding this input causes the output to transition on the falling edge of DCLK. See Section 2.4.3.

1.1.5.3 Double Data Rate

A choice of single data rate (SDR) or double data rate (DDR)

output is offered. When the device is in DDR mode, address

1h, bit-8 must be set to 0b. With single data rate the output

clock (DCLK) frequency is the same as the data rate of the

two output buses. With double data rate the DCLK frequency

is half the data rate and data is sent to the outputs on both

edges of DCLK. DDR clocking is enabled in non-Extended

Control mode by allowing pin 4 to float.

1.1.6 The LVDS Outputs

The data outputs, the Out Of Range (OR) and DCLK, are

LVDS. Output current sources provide 3 mA of output current

to a differential 100 Ohm load when the OutV input (pin 3) is

high or 2.2 mA when the OutV input is low. For short LVDS

lines and low noise systems, satisfactory performance may

be realized with the OutV input low, which results in lower

power consumption. If the LVDS lines are long and/or the

system in which the ADC083000 is used is noisy, it may be

necessary to tie the OutV pin high.

The LVDS data outputs have a typical common mode voltage

of 800mV when the VBG pin is unconnected and floating. This

common mode voltage can be increased to 1.150V by tying

the VBG pin to VA if a higher common mode is required.

IMPORTANT NOTE: Tying the VBG pin to VA will also in-

crease the differential LVDS output voltage (VOD) by up to

40mV.

1.1.7 Power Down

The ADC083000 is in the active state when the Power Down

pin (PD) is low. When the PD pin is high, the device is in the

power down mode. In this power down mode the data output

pins (positive and negative) including DCLK+/- and OR +/- are

put into a high impedance state and the devices power consumption is reduced to a minimal level.

If the PD input is brought high while a calibration is running,

the device will not go into power down until the calibration

sequence is complete. However, if power is applied and PD

23 www.national.com

is already high, the device will not begin the calibration sequence until the PD input goes low. If a manual calibration is

requested while the device is powered down, the calibration

will not begin at all. That is, the manual calibration input is

completely ignored in the power down state.

ADC083000

1.2 NORMAL/EXTENDED CONTROL

The ADC083000 may be operated in one of two modes. In

the Normal Mode, the user affects available configuration and

Feature Normal Control Mode Extended Control Mode

SDR or DDR Clocking Selected with pin 4

DDR Clock Phase Not Selectable (0° Phase Only)

SDR Data transitions with rising or falling

DCLK edge

Selected with pin 4

LVDS output level Selected with pin 3

Power-On Calibration Delay Delay Selected with pin 127 Short delay only.

Options (600 mV

Full-Scale Range

selected with pin 14. Selected range

applies to both channels.

Input Offset Adjust Not possible

Sampling Clock Phase Adjustment

The Clock Phase is adjusted

automatically

Test Pattern Not Possible

Resistor Trim Disable Not possible

control of the device through several control pins. The "extended control mode" provides additional configuration and

control options through a serial interface and a set of 6 registers. The two control modes are selected with pin 14 (FSR/

ECE: Extended Control Enable). The choice of control modes

is required to be a fixed selection and is not intended to be

switched dynamically while the device is operational.

Table 2 shows how several of the device features are affected

by the control mode chosen.

TABLE 2. Features and Modes

or 820 mV

P-P

P-P

)

Selected with nDE in the Configuration

Register (1h; bit-10). When the device is

in DDR mode, address 1h, bit-8 must be

set to 0b.

Selected with DCP in the Configuration

Register (1h; bit-11).

Selected with OE in the Configuration

Register (1h; bit-8).

Selected with the OV in the

Configuration Register (1h; bit-9).

Up to 512 step adjustments over a

nominal range of 560 mV to 840 mV in

the Configuration Register (3h; bits-7

thru 15).

Up to ±45 mV adjustments in 512 steps

in the Configuration Register (2h; bits-7

thru 15).

The clock phase can be adjusted

manually through the Fine & Coarse

registers (Dh and Eh).

A test pattern can be made present at the

data outputs by selecting TPO in the

Configuration Register (Fh; bit-11).

The DCLK outputs will continuously be

present when RTD is selected in the

Configuration Register (1h; bit-13)

www.national.com 24

ADC083000

The default state of the Extended Control Mode is set upon

power-on reset (internally performed by the device) and is

shown in Table 3.

TABLE 3. Extended Control Mode Operation (Pin 14

Floating)

Feature

Extended Control Mode

Default State

SDR or DDR Clocking DDR Clocking

DDR Clock Phase

LVDS Output Amplitude

Data changes with DCLK

edge (0° phase)

Normal amplitude

(710 mV

P-P

)

Calibration Delay Short Delay

Full-Scale Range

Input Offset Adjust

700 mV nominal for both

channels

No adjustment for either

channel

Trim enabled, DCLK not

Resistor Trim Disable

continuously present at

output

Test Pattern Not present at output

1.3 THE SERIAL INTERFACE

The 3-pin serial interface is enabled only when the device is

in the Extended Control mode. The pins of this interface are

Serial Clock (SCLK), Serial Data (SDATA) and Serial Interface Chip Select (SCS) Eight write only registers are accessible through this serial interface.

SCS: This signal should be asserted low while accessing a

register through the serial interface. Setup and hold times with

respect to the SCLK must be observed.

SCLK: Serial data input is accepted with the rising edge of

this signal.

SDATA: Each register access requires a specific 32-bit pattern at this input. This pattern consists of a header, register

address and register value. The data is shifted in MSB first.

Setup and hold times with respect to the SCLK must be observed. SeeFigure 9.

Each Register access consists of 32 bits, as shown in Figure

9 of the Timing Diagrams. The fixed header pattern is 0000

0000 0001 (eleven zeros followed by a 1). The loading sequence is such that a "0" is loaded first. These 12 bits form

the header. The next 4 bits are the address of the register that

is to be written to and the last 16 bits are the data written to

the addressed register. The addresses of the various registers are indicated in Table 4.

Refer to the Register Description (Section 1.4) for information

on the data to be written to the registers.

Subsequent register accesses may be performed immediately, starting with the 33rd SCLK. This means that the SCS input

does not have to be de-asserted and asserted again between

register addresses. It is possible, although not recommended,

to keep the SCS input permanently enabled (at a logic low)

when using extended control.

IMPORTANT NOTE: The Serial Interface should not be used

when calibrating the ADC. Doing so will impair the performance of the device until it is re-calibrated correctly. Programming the serial registers will also reduce dynamic

performance of the ADC for the duration of the register access

time.

TABLE 4. Register Addresses

4-Bit Address

Loading Sequence:

A3 loaded after H0, A0 loaded last

A3 A2 A1 A0 Hex Register Addressed

0 0 0 0 0h Reserved

0 0 0 1 1h Configuration

0 0 1 0 2h Offset

0 0 1 1 3h Full-Scale Voltage

Adjust

0 1 0 0 4h Reserved

0 1 0 1 5h Reserved

0 1 1 0 6h Reserved

0 1 1 1 7h Reserved

1 0 0 0 8h Reserved

1 0 0 1 9h Reserved

1 0 1 0 Ah Reserved

1 0 1 1 Bh Reserved

1 1 0 0 Ch Reserved

1 1 0 1 Dh Extended Clock

Phase adjust fine

1 1 1 0 Eh Extended Clock

Phase adjust coarse

1 1 1 1 Fh Test Pattern

25 www.national.com

1.4 REGISTER DESCRIPTION

Eight write-only registers provide several control and configuration options in the Extended Control Mode. These registers have no effect when the device is in the Normal Control

ADC083000

Mode. Each register description below also shows the PowerOn Reset (POR) state of each control bit.

Configuration Register

Addr: 1h (0001b) W only (0xB2DF)

D15 D14 D13 D12 D11 D10 D9 D8

1 DRE RTD DCS DCP nDE OV OE

D7 D6 D5 D4 D3 D2 D1 D0

1 1 1 1 1 1 1 1

Bit 15 Must be set to 1b

Bit 14 DRE: Differential Reset Enable. When this bit

is set to 0b , it enables the single-ended

DCLK_RST input. When this bit is set to 1b , it

enables the differential DCLK_RST input.

POR State: 0b

Bit 13 RTD: Resistor Trim Disable. When this bit is

set to 1b, the input termination resistor is not

trimmed during the calibration cycle and the

DCLK output remains enabled. Note that the

ADC is calibrated regardless of this setting.

POR State: 0b

Bit 12 DCS: Duty Cycle Stabilizer. When this bit is set

to 1b , a duty cycle stabilization circuit is

applied to the clock input. When this bit is set

to 0b the stabilization circuit is disabled.

POR State: 1b

Bit 11 DCP: DDR Clock Phase. This bit only has an

effect in the DDR mode. When this bit is set to

0b, the DCLK edges are time-aligned with the

data bus edges ("0° Phase"). When this bit is

set to 1b, the DCLK edges are placed in the

middle of the data bit-cells ("90° Phase"),

using the one-half speed DCLK shown in

Figure 4 as the phase reference.

POR State: 0b

Bit 10 nDE: DDR Enable. When this bit is set to 0b,

data bus clocking follows the DDR (Dual Data

Rate) mode whereby a data word is output

with each rising and falling edge of DCLK.

When the device is in DDR mode, address 1h,

bit-8 must be set to 0b. When this bit is set to

a 1b, data bus clocking follows the SDR (single

data rate) mode whereby each data word is

output with either the rising or falling edge of

DCLK , as determined by the OutEdge bit.

POR State: 0b

Bit 9 OV: Output Voltage. This bit determines the

LVDS outputs' voltage amplitude and has the

same function as the OutV pin that is used in

the normal control mode. When this bit is set

to 1b, the standard output amplitude of 680

mV

is used. When this bit is set to 0b, the

P-P

reduced output amplitude of 520 mV

P-P

is

used.

POR State: 1b

Bit 8 OE: Output Edge. This bit has two functions.

When the device is in SDR mode, this bit

selects the DCLK edge with which the data

words transition and has the same effect as

the OutEdge pin in the normal control mode.

When this bit is set to 1b, the data outputs

change with the rising edge of DCLK+. When

this bit is set to 0b, the data output changes

with the falling edge of DCLK+. When the

device is in DDR mode, this bit must be set to

0b.

POR State: 0b

Bits 7:0 Must be set to 1b

Offset Adjust

Addr: 2h (0010b) W only (0x007F)

D15 D14 D13 D12 D11 D10 D9 D8

(MSB) Offset Value (LSB)

D7 D6 D5 D4 D3 D2 D1 D0

Sign 1 1 1 1 1 1 1

Bits 15:8 Offset Value. The input offset of the ADC is

adjusted linearly and monotonically by the

value in this field. 00h provides a nominal zero

offset, while FFh provides a nominal 45 mV of

offset. Thus, each code step provides 0.176

mV of offset.

POR State: 0000 0000 b (no adjustment)

Bit 7 Sign bit. 0b gives positive offset, 1b gives

negative offset.

POR State: 0b

Bit 6:0 Must be set to 1b

www.national.com 26

ADC083000

Full-Scale Voltage Adjust

Addr: 3h (0011b) W only (0x807F)

D15 D14 D13 D12 D11 D10 D9 D8

(MSB) Adjust Value

D7 D6 D5 D4 D3 D2 D1 D0

(LSB) 1 1 1 1 1 1 1

Bit 15:7 Full Scale Voltage Adjust Value. The input full-

scale voltage or gain of the ADC is adjusted

linearly and monotonically with a 9 bit data

value. The adjustment range is ±20% of the

nominal 700 mV

0000 0000 0 560mV

1000 0000 0

differential value.

P-P

P-P

700mV

P-P

Default Value

1111 1111 1 840mV

P-P

For best performance, it is recommended that

the value in this field be limited to the range of

0110 0000 0b to 1110 0000 0b. i.e., limit the

amount of adjustment to ±15%. The remaining

±5% headroom allows for the ADC's own full

scale variation. A gain adjustment does not

require ADC re-calibration.

POR State: 1000 0000 0b

Bits 6:0 Must be set to 1b

Extended Clock Phase Adjust Fine

Addr: Dh (1101b) W only (0x3FFF)

D15 D14 D13 D12 D11 D10 D9 D8

(MSB) FAM

D7 D6 D5 D4 D3 D2 D1 D0

(LSB) 1 1 1 1 1 1 1

Bit 15:7 Fine Adjust Magnitude. With all bits set, total

adjust = 110ps of non-linear clock adjust.

Refer to Section 2.3.1.

POR State: 000 0000 0b

Bit 6:0 Must be set to 1b

Extended Clock Phase Adjust Coarse

Addr: Eh (1110b) W only (0x07FF)

D15 D14 D13 D12 D11 D10 D9 D8

ENA CAM LFS 1 1

D7 D6 D5 D4 D3 D2 D1 D0

1 1 1 1 1 1 1 1

Bit 15 Enable, default is 0b

Bit 14:11 Coarse Adjust Magnitude. Each LSB results in

approximately 70ps of clock adjust. Refer to

Section 2.3.1.

POR State: 0000b

Bit 10 Low Frequency Sample clock. When this bit is

set 1b, the dynamic performance of the device

is improved when the sample clock is less than

900MHz.

POR State: 0b

Bits 9:0 Must be set to 1b

Test Pattern Register

Addr: Fh (1111b) W only (0xF7FF)

D15 D14 D13 D12 D11 D10 D9 D8

1 1 1 1 TPO 1 1 1

D7 D6 D5 D4 D3 D2 D1 D0

1 1 1 1 1 1 1 1

Bits 15:12 Must be set to 1b

Bit 11 TPO: Test Pattern Output enable. When this

bit is set 1b, the ADC is disengaged and a test

pattern generator is connected to the outputs

including OR. This test pattern will work with

the device in the SDR and DDR modes.

POR State: 0b

Bit 10:0 Must be set to 1b

27 www.national.com

1.4.1 Note Regarding Extended Mode Offset Correction

When using the Offset Adjust register, the following information should be noted.

For offset values of +0000 0000 and -0000 0000, the actual

ADC083000

offset is not the same. By changing only the sign bit in this

case, an offset step in the digital output code of about 1/10th

of an LSB is experienced. This is shown more clearly in the

Figure below.

FIGURE 10. Extended Mode Offset Behavior

1.5 MULTIPLE ADC SYNCHRONIZATION

The ADC083000 has the capability to precisely reset its sampling clock (CLK) to synchronize its output clock (DCLK) and

data with multiple ADCs in a system. This allows multiple ADCs in a system to have their DCLK (and data) outputs transition at the same time with respect to the shared CLK input

that they all use for sampling.

The ADC083000 has been designed to accommodate systems which require a single-ended (LVCMOS) DCLK_RST or

a differential (LVDS) DCLK_RST.

Single-Ended (LVCMOS) DCLK_RST: The Power on Reset

state of DCLK_RST is to have single-ended DCLK_RST activated. Bit 14, (DRE) in the Configuration Register is asserted

low, 0b. When not using singled-ended DCLK_RST, the input

should be grounded.

Differential (LVDS) DCLK_RST: Activated by asserting bit

14, (DRE) in the configuration register high, 1b. When the dif-

20193230

ferential DCLK_RST is not activated, the inputs should be

grounded. Differential DCLK_RST has an internal 100 ohm

termination resistor and should not be AC coupled.

The DCLK_RST signal must observe some timing requirements that are shown in Figure 5, Figure 6 and Figure 7 of the

Timing Diagrams. The DCLK_RST pulse must be of a minimum width and its deassertion edge must observe setup and

hold times with respect to the CLK input rising edge. These

times are specified in the AC Electrical Characteristics Table.

The DCLK_RST signal can be asserted asynchronous to the

input clock. If DCLK_RST is asserted, the DCLK output is held

in a designated state. The state in which DCLK is held during

the reset period is determined by the mode of operation (SDR/

DDR) and the setting of the Output Edge configuration pin or

bit. (Refer to Figure 5, Figure 6 and Figure 7 for the DCLK

reset state conditions). Therefore, depending upon when the

DCLK_RST signal is asserted, there may be a narrow pulse

on the DCLK line during this reset event. When the

DCLK_RST signal is de-asserted in synchronization with the

CLK rising edge, the next CLK falling edge synchronizes the

DCLK output with those of other ADC083000s in the system.

The DCLK output is enabled again after a constant delay (relative to the input clock frequency) which is equal to the CLK

input to DCLK output delay (tSD). The device always exhibits

this delay characteristic in normal operation.

If the device is not programmed to allow DCLK to run continuously, DCLK will become inactive during a calibration cycle.

Therefore, it is strongly recommended that DCLK only be

used as a data capture clock and not as a system clock.

The DCLK_RST pin should NOT be brought high while the

calibration process is running (while CalRun is high). Doing

so could cause a digital glitch in the digital circuitry, resulting

in corruption and invalidation of the calibration.

1.6 ADC TEST PATTERN

To aid in system debug, the ADC083000 has the capability of

providing a test pattern at the four output ports completely

independent of the input signal. The test pattern is selected

by setting bit-11 (TPO) in the Test Pattern Register (address

Fh). The test pattern will appear at the digital output about 10

DCLK cycles after the last write to the Test Pattern Register.

The ADC is disengaged and a test pattern generator is connected to the outputs including OR. Each port is given a

unique 8-bit word, alternating between 1's and 0's as described in theTable 5.

TABLE 5. Test Pattern by Output Port

Time Da Db Dc Dd OR Comments

T0 01h 02h 03h 04h 0

T1 FEh FDh FCh FBh 1

T2 01h 02h 03h 04h 0

T3 FEh FDh FCh FBh 1

T4 01h 02h 03h 04h 0

T5 01h 02h 03h 04h 0

T6 FEh FDh FCh FBh 1

T7 01h 02h 03h 04h 0

T8 FEh FDh FCh FBh 1

T9 01h 02h 03h 04h 0

T10 01h 02h 03h 04h 0

T11 ... ... ... ... ...

Note: The same bit pattern repeats when the test pattern sequence is concatenated.

www.national.com 28

Pattern Sequence n

Pattern Sequence n+1

Pattern Sequence n+2

ADC083000

2.0 Applications Information

2.1 THE REFERENCE VOLTAGE

The voltage reference for the ADC083000 is derived from a

1.254V bandgap reference, a buffered version of which is

made available at pin 31, VBG for user convenience and has

an output current capability of ±100 μA. This reference voltage should be buffered if more current is required.

The internal bandgap-derived reference voltage has a nominal value of 600 mV or 820 mV, as determined by the FSR

pin and described in Section 1.1.4.

There is no provision for the use of an external reference voltage, but the full-scale input voltage can be adjusted through

a Configuration Register in the Extended Control mode, as

explained in Section 1.2.

Differential input signals up to the chosen full-scale level will

be digitized to 8 bits. Signal excursions beyond the full-scale

range will be clipped at the output. These large signal excursions will also activate the OR output for the time that the

signal is out of range. See Section 2.2.2.

One extra feature of the VBG pin is that it can be used to raise

the common mode voltage level of the LVDS outputs. The

output offset voltage (VOS) is typically 800mV when the V

pin is used as an output or left unconnected. To raise the

LVDS offset voltage to a typical value of 1150mV the VBG pin

can be connected directly to the supply rails.

2.2 THE ANALOG INPUT

The analog input is a differential one to which the signal

source may be a.c. coupled or d.c. coupled. The full-scale

input range is selected with the FSR pin to be 600 mV

820 mV

560 mV

through the Serial Interface. For best performance, it is rec-

, or can be adjusted to values between

P-P

and 840 mV

P-P

in the Extended Control mode

P-P

ommended that the full-scale range be kept

between 595 mV

mode.

and 805 mV

P-P

in the Extended Control

P-P

Table 6 gives the input to output relationship with the FSR pin

high and the normal (non-extended) mode is used. With the

FSR pin grounded, the millivolt values in Table 6 are reduced

to 75% of the values indicated. In the Enhanced Control

Mode, these values will be determined by the full scale range

and offset settings in the Control Registers.

TABLE 6. DIFFERENTIAL INPUT TO OUTPUT

RELATIONSHIP (Non-Extended Control Mode, FSR High)

VIN+ VIN−

VCM − 205mV VCM + 205mV

VCM − 102.5 mV VCM + 102.5 mV

V

CM

V

CM

Output Code

0000 0000

0100 0000

0111 1111 /

1000 0000

VCM + 102.5 mV VCM −102.5 mV 1100 0000

VCM + 205mV VCM − 205mV 1111 1111

The buffered analog inputs simplify the task of driving these

inputs and the RC pole that is generally used at sampling ADC

inputs is not required. If it is desired to use an amplifier circuit

before the ADC, use care in choosing an amplifier with adequate noise and distortion performance and adequate gain at

the frequencies used for the application.

The Input impedance of V

(V

pin not grounded) consists of a precision 100Ω resistor

CMO

across the inputs and a capacitance from each of these inputs

IN+

/ V

in the d.c. coupled mode

IN-

to ground. In the a.c. coupled mode, the input appears the

P-P

BG

or

same except there is also a resistor of 50KΩ between each

analog input pin and the on-chip V

When the inputs are a.c. coupled, the V

grounded, as shown in Figure 11. This causes the on-chip

V

voltage to be connected to the inputs through on-chip

CMO

50KΩ resistors.

potential.

CMO

output must be

CMO

20193244

FIGURE 11. Differential Data Input Connection

When the d.c. coupled mode is used, a precise common

mode voltage must be provided at the differential inputs. This

common mode voltage should track the V

that the V

The common mode output of the driving device should track

output potential will change with temperature.

CMO

output pin. Note

CMO

this change.

Full-scale distortion performance falls off rapidly as the

input common mode voltage deviates from V

a direct result of using a very low supply voltage to min-

CMO

. This is

imize power. Keep the input common voltage within 50

mV of V

CMO

.

Performance is as good in the d.c. coupled mode as it is

in the a.c. coupled mode, provided the input common

mode voltage at both analog inputs remain within 50 mV

of V

CMO

.

2.2.1 Handling Single-Ended Input Signals

There is no provision for the ADC083000 to adequately process single-ended input signals. The best way to handle

single-ended signals is to convert them to differential signals

before presenting them to the ADC.

2.2.1.1 A.C. Coupled Input

The easiest way to accomplish single-ended a.c. input to differential a.c. signal is with an appropriate balun-connected

transformer, as shown in Figure 12.

20193243

FIGURE 12. Single-Ended to Differential signal

conversion with a balun-connected transformer

Figure 12 is a generic depiction of a single-ended to differential signal conversion using a balun. The circuitry specific to

the balun will depend on the type of balun selected and the

overall board layout. It is recommended that the system designer contact the manufacturer of the balun they have selected to aid in designing the best performing single-ended to

differential conversion circuit using that particular balun.

29 www.national.com

When selecting a balun, it is important to understand the input

of the ADC. The ADC083000 has an on-chip 100 Ohm differential input termination resistor. The range of this input termination resistor is described in the electrical table as the

specification RIN. Also, as a result of the ADC architecture,

ADC083000

the phase and amplitude balance are critical. The lowest possible phase and amplitude imbalance is desired when selecting a balun. The ADC can tolerate no more than ±2.5° of

phase imbalance and the amplitude imbalance should be limited to less than 1dB at the desired input frequency. Since the

ADC architecture is based on interleaving, if the phase and

amplitude imbalance are greater than what the ADC can tolerate, interleaving spurs will appear in the FFT spectrum and

degrade the dynamic performance of the device. Finally,

when selecting a balun, the VSWR and insertion loss of the

balun should also be considered. The VSWR aids in determining the overall transmission line termination capability of

the balun when interfacing to the ADC input. The insertion

loss should be considered so that the signal at the balun output is within the specified input range of the ADC as described

in the electrical table as the specification VIN.

2.2.1.2 D.C. Coupled Input

When d.c. coupling to the ADC083000 analog inputs is required, single-ended to differential conversion may be easily

accomplished with the LMH6555. An example of this type of

circuit is shown in Figure 13. In such applications, the

LMH6555 performs the task of single-ended to differential

conversion while delivering low distortion and noise, as well

as output balance, that supports the operation of the

ADC083000. Connecting the ADC083000 V

V

will ensure that the common mode input voltage is as needed

pin of the LMH6555, through the appropriate buffer,

CM_REF

CMO

for optimum performance of the ADC083000. The LMV321

was chosen to buffer V

reasonable offset voltage.

Be sure that the current drawn from the V

exceed 100 μA.

for its low voltage operation and

CMO

output does not

CMO

FIGURE 13. Example of Servoing the Analog Input with

V

CMO

pin to the

20193255

TABLE 7. D.C. Coupled Offset Adjustment

Unadjusted Offset

Resistor Value

Reading

0mV to 10mV no resistor needed

11mV to 30mV

31mV to 50mV

51mV to 70mV

71mV to 90mV

91mV to 110mV

20.0kΩ

10.0kΩ

6.81kΩ

4.75kΩ

3.92kΩ

2.2.2 Out Of Range (OR) Indication

When the conversion result is clipped the Out of Range output

is activated such that OR+ goes high and OR- goes low. This

output is active as long as accurate data on either or both of

the buses would be outside the range of 00h to FFh. During

a calibration cycle, the OR output is invalid. Refer to 1.1

OVERVIEW for more details.

2.2.3 Full-Scale Input Range

As with all A/D Converters, the input range is determined by

the value of the ADC's reference voltage. The reference voltage of the ADC083000 is derived from an internal band-gap