Page 1

March 24, 2006

Revision A

Development Board Instruction Manual

ADC081500DEV - Single 8-Bit, 1.5 GSPS, 1.2W A/D Converter with

Xilinx Virtex 4 (XC4VLX15) FPGA

© Copyright 2006 National Semiconductor Corporation

1 www.national.com

Page 2

ADC081500EVAL BOARD USER MANUAL – TABLE OF CONTENTS

ADC081500EVAL BOARD USER MANUAL – TABLE OF CONTENTS........................2

1.0 Introduction........................................................................................................................... 3

2.0 Board Assembly.................................................................................................................... 3

3.0 Quick Start............................................................................................................................ 4

4.0 Functional Description .......................................................................................................... 4

4.1 Input circuitry...................................................................................................................... 4

4.2 ADC reference.................................................................................................................... 4

4.3 ADC clock........................................................................................................................... 4

4.4 Digital Data Output............................................................................................................. 4

4.5 Power Requirements..........................................................................................................5

4.6 Power Supply Connections................................................................................................ 5

5.0 Obtaining Best Results ......................................................................................................... 5

5.1 Clock Jitter.......................................................................................................................... 5

6.0 Evaluation Board Specifications ........................................................................................... 5

7.0 Schematic Drawing ADC081500DEV – Onboard Clock (VCO + PLL) ................................. 6

7.1 Schematic Drawing ADC081500DEV – Analog Inputs (I,Q) & Digital Trigger Input........... 7

7.2 Schematic Drawing ADC081500DEV – ADC connected to Virtex4 FPGA ........................ 8

7.3 Schematic Drawing ADC081500DEV – USB Interface...................................................... 9

7.4 Schematic Drawing ADC081500DEV – Power Supplies 1 .............................................. 10

7.5 Schematic Drawing ADC081500DEV – Power Supplies 2 .............................................. 11

7.6 Schematic Drawing ADC081500DEV – Expansion Header Interface.............................. 12

8.0 Bill of Materials (Page 1 of 2)..............................................................................................13

8.1 Bill of Material (Page 2 of 2)............................................................................................. 14

9.0 Using the Wavevision4 software with the ADC081500DEV ............................................... 15

9.1 Getting Started................................................................................................................. 15

9.2 Control Panel.................................................................................................................... 17

9.3 Serial Control Mode.......................................................................................................... 19

9.4 Capturing Waveforms....................................................................................................... 20

10.0 Appendix A - Hardware Information.................................................................................. 20

10.1 LED functions................................................................................................................. 20

10.2 Expansion Header.......................................................................................................... 21

10.3 System Block Diagram................................................................................................... 22

11.0 Appendix B - Installing and running the Wavevision 4 software....................................... 23

11.1 Install the WaveVision Software..................................................................................... 23

11.2 Java™ Technology......................................................................................................... 23

11.3 Automatic Device Detection & Configuration ................................................................. 23

11.4 Windows Driver.............................................................................................................. 23

12.0 Appendix C - Using WaveVision Plots.............................................................................. 24

The Waveform Plot................................................................................................................. 24

The FFT Plot .......................................................................................................................... 24

FFT Options ........................................................................................................................... 25

Histogram Plots...................................................................................................................... 26

Information Viewer ................................................................................................................. 26

Data Import and Export..........................................................................................................26

2 www.national.com

Page 3

1.0 Introduction

The ADC081500DEV Board is designed to

allow quick evaluation and design development

of National Semiconductor’s ADC081500 8-bit

Analog-to-Digital Converter. This device is

specified for 1.5 GSPS operation.

This development board is designed to function

with National Semiconductor’s WaveVision

Software, for fast evaluation. It requires only 3

connections to get started: a Power Supply, a

USB Interface to PC and a Signal Source. A

1.5GHz Clock generator is provided on board

and the system also allows an external clock to

be used if alternative sample rates are required.

Analog I Channel

Input

Clock Input

The ADC connects to a Xilinx Virtex4 FPGA

which stores up to 4K of data from each

channel before transferring it through the USB

interface to the PC.

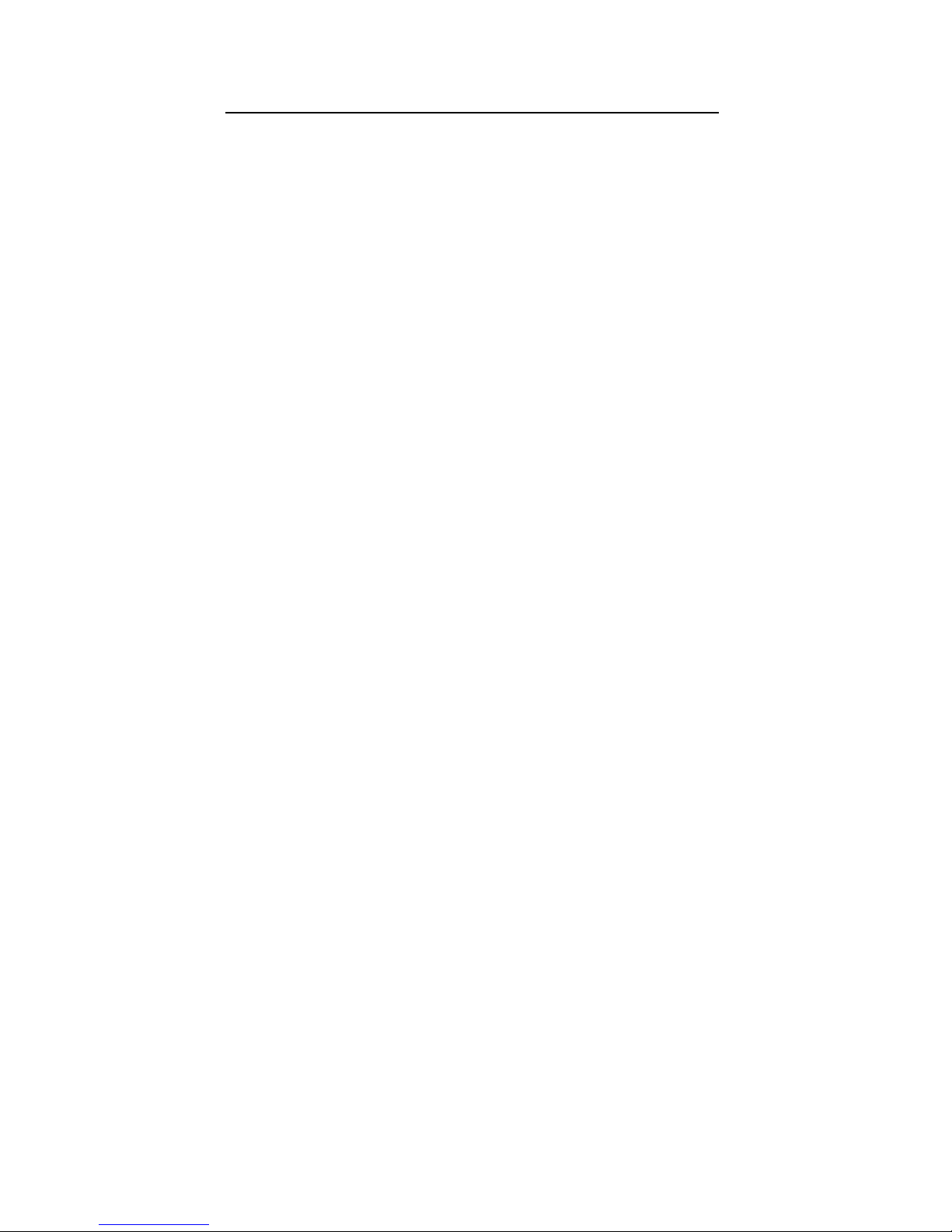

2.0 Board Assembly

The ADC081500 Development Board comes in

a low profile plastic enclosure and requires no

assisted cooling due to its low power

consumption. The ADC081500 device is

configured entirely through software and also

allows changes to easily be made to the FPGA

configuration to enable system development.

USB

E

x

p

a

n

s

i

o

n

Trigger Input

PWR

SWITCH

PWR

INPUT

Figure 1 Component Placement & Front Panel

3 www.national.com

Page 4

3.0 Quick Start

Refer to Figure 1 for locations of the power

connection, signal input and USB port.

IMPORTANT NOTE:

Install the Wavevision 4 Software before

connecting this product to the PC. See

Appendix B – Installing Wavevision.

For quick start operation:

1. Connect the 12V DC power source

(included with the development board) to the

rear Power Connector labeled (8-12V DC).

2. Connect a stable sine wave source capable

of supplying the desired input frequencies at

up to 8 dBm. Connect this signal to the front

panel SMA connector labeled “I CH.”

through a band pass filter. The exact level

needed from the generator will

depend upon

the insertion loss of the filter used.

3 Connect the USB cable (included) from the

USB port to the PC. If this is the first time

the board has been connected, Windows

may install the drivers for this product at this

time.

5. Push the Power Switch to the ON position

on the rear panel and check that the Green

LED between the switch and the power

connector illuminates.

6. Start the Wavevision 4 Software

7. Once loaded the “Firmware Download”

Progress bar should be displayed. See

Appendix B for more information.

8. Upon Firmware Download completion, the

control panel for the board should

automatically be displayed on the PC and

the CLK LED on the front panel should be

flashing.

8. Set the signal source for the analog input to

8 dBm at the desired frequency. Observe

the ‘Out of Range’ LED “OVR” on the front

panel is illuminated. If this LED is not on,

increase the input signal source until it is.

9. Reduce the input level until the ‘OVR’ LED

just turns off.

10. From the Wavevision 4 pull-down menu

select “Acquire” and then samples. The

system will then capture the input waveform

and display the results in the time domain.

11. For FFT Analysis click the FFT Tab.

4.0 Functional Description

The ADC081500 Development Board schematic

is shown in Section 7.0.

4.1 Input circuitry

The input signal(s) to be digitized should be

applied to the front panel SMA connectors

labeled “I CH.” and “Q CH.”. These 50 Ohm

inputs are intended to accept a low-noise sine

wave signals. To accurately evaluate the

dynamic performance of this converter, the input

test signals will have to be passed through a

high-quality bandpass filter with at least 10-bit

equivalent noise and distortion characteristics.

This evaluation board as delivered is set up for

operation with two single-ended analog inputs,

which are converted to differential signals on

board.

Signal transformer T2, is connected as a balun,

and provides the single-ended to differential

conversion. The differential PCB traces to the

ADC analog input pins have a characteristic

differential impedance of 100 Ohms.

No scope or other test equipment should be

connected anywhere in the signal path while

gathering data.

4.2 ADC reference

The ADC081500 has an internal reference that

can not be adjusted. However, the Full-Scale

(differential) Range may adjusted with the

Software Control Panel Refer to Section 9.0 for

more information

4.3 ADC clock

The ADC clock is supplied on board and is fixed

at 1.5GHz. An external clock signal may be

applied to the ADC through the SMA Connector

labeled “CLOCK” on the front panel. The baluntransformer (T1) converts the single ended clock

source to a differential signal to drive the ADC

clock pins

Note that it is very important that the ADC clock

should be as free of jitter as possible or the

apparent SNR of the ADC081500 will be

compromised.

4.4 Digital Data Output

The digital output data from the ADC081500 is

connected to a Xilinx 4 FPGA. Up to 4K Bytes of

data can be stored and then uploaded over the

USB interface to the Wavevision 4 software. The

FPGA logic usage is low allowing further code to

be written and tested for product development.

4 www.national.com

Page 5

4.5 Power Requirements

The power supply requirement for the

ADC081500 Evaluation Board is 12V at 800mA.

Most of the regulators on board are switching

regulators for increased power efficiency.

The board typically draws around 500mA but it

is always good practice to have extra power

reserve in the power supply over the typical

power requirements.

A Universal 100-240V AC input to 12V DC Brick

Power Supply is included with the development

board.

4.6 Power Supply Connections

Power to this board is supplied through the

power connector on the rear panel. It is advised

that only the supplied PSU is used with this

board.

The ADC081500 supply voltage has been set to

1.9V, ±50 mV.

5.0 Obtaining Best Results

Obtaining the best results with any ADC

requires both good circuit techniques and a

good PC board layout. For layout information for

this product please contact you nearest National

Semiconductor representative

5.1 Clock Jitter

When any circuitry is added after a signal

source, some jitter is almost always added to

that signal. Jitter in a clock signal, depending

upon how bad it is, can degrade dynamic

performance. We can see the effects of jitter in

the frequency domain (FFT) as "leakage" or

"spreading" around the input frequency, as seen

in Figure 2a. Compare this with the more

desirable plot of Figure 2b. Note that all dynamic

performance parameters (shown to the right of

the FFT) are improved by eliminating clock jitter.

.

Figure 2a. Jitter causes a spreading around the input

signal, as well as undesirable signal spurs.

Figure 2b. Eliminating or minimizing clock jitter results in

a more desirable FFT that is more representative of how

the ADC actually performs.

6.0 Evaluation Board

Specifications

Board Size: 168mm x 100mm

Power Requirements: +12V, 800mA

Clock Frequency Range : 200 MHz to 1.5 GHz

Analog Input Range (AC Coupled) 30MHz to 1800MHz

Nominal Analog Input Voltage: 560 mV P-P to 870 mV P-P

Impedance: 50 Ohms

5 www.national.com

Page 6

7.0 Schematic Drawing ADC081500DEV – Onboard Clock (VCO + PLL)

6 www.national.com

Page 7

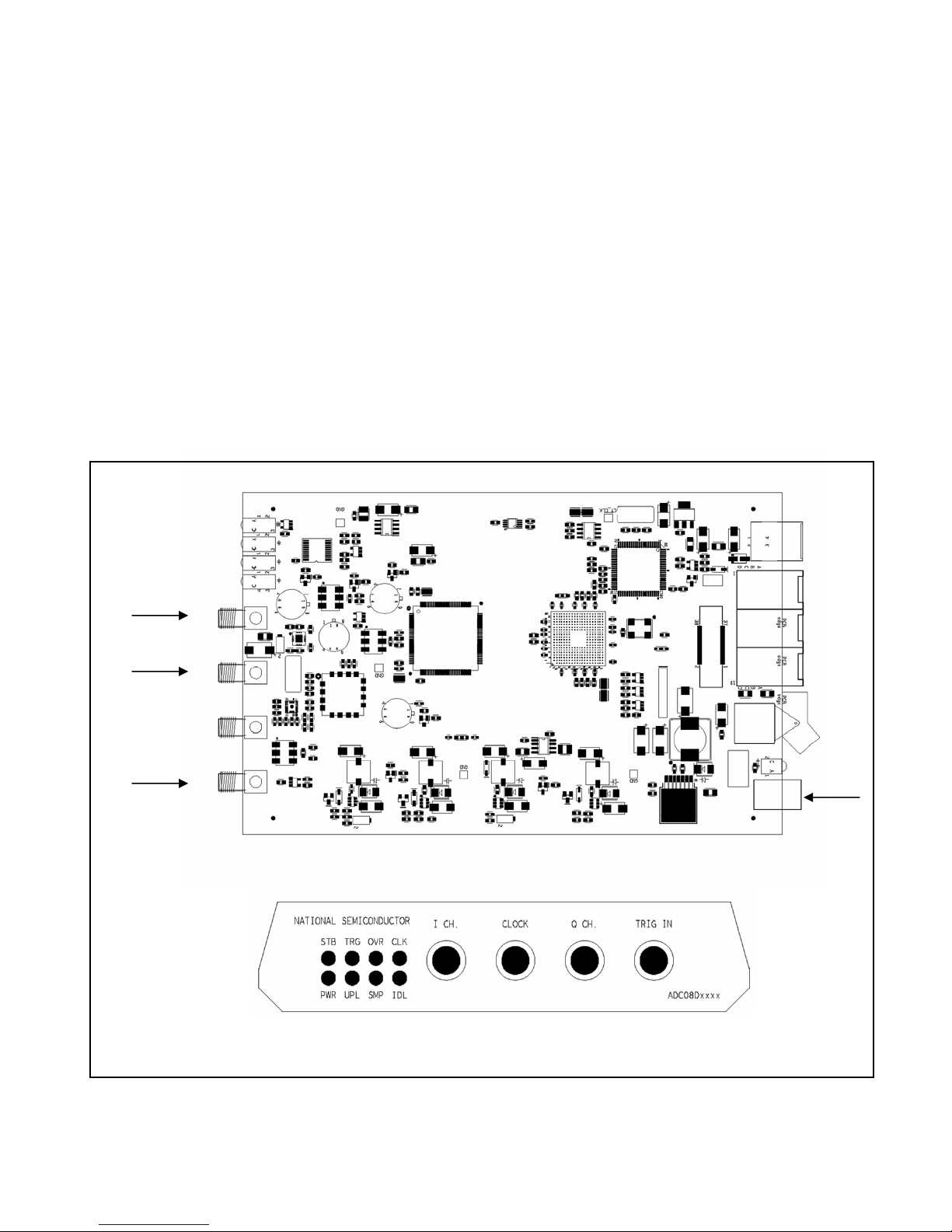

7.1 Schematic Drawing ADC081500DEV – Analog Inputs (I,Q) & Digital Trigger Input

7 www.national.com

Page 8

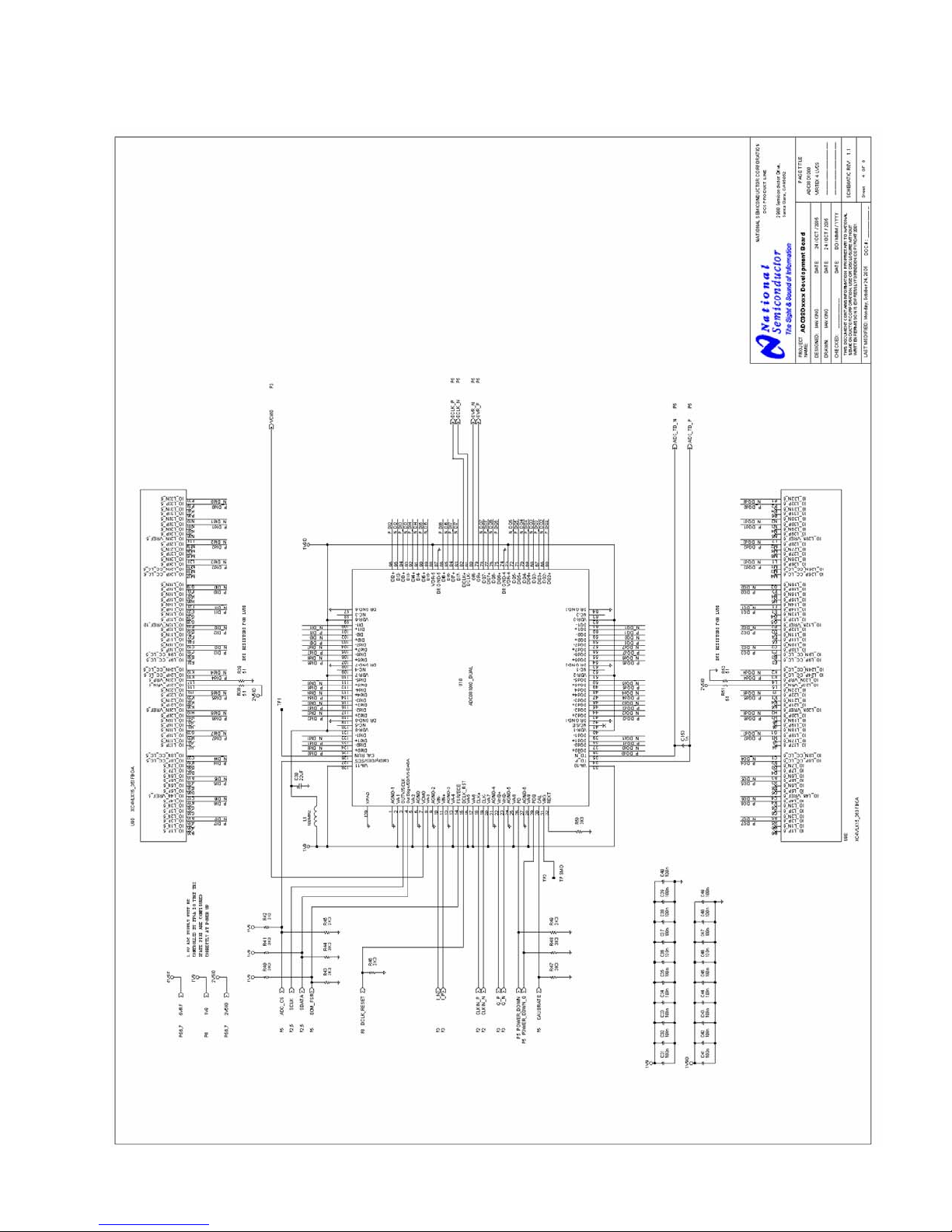

7.2 Schematic Drawing ADC081500DEV – ADC connected to Virtex4 FPGA

8 www.national.com

Page 9

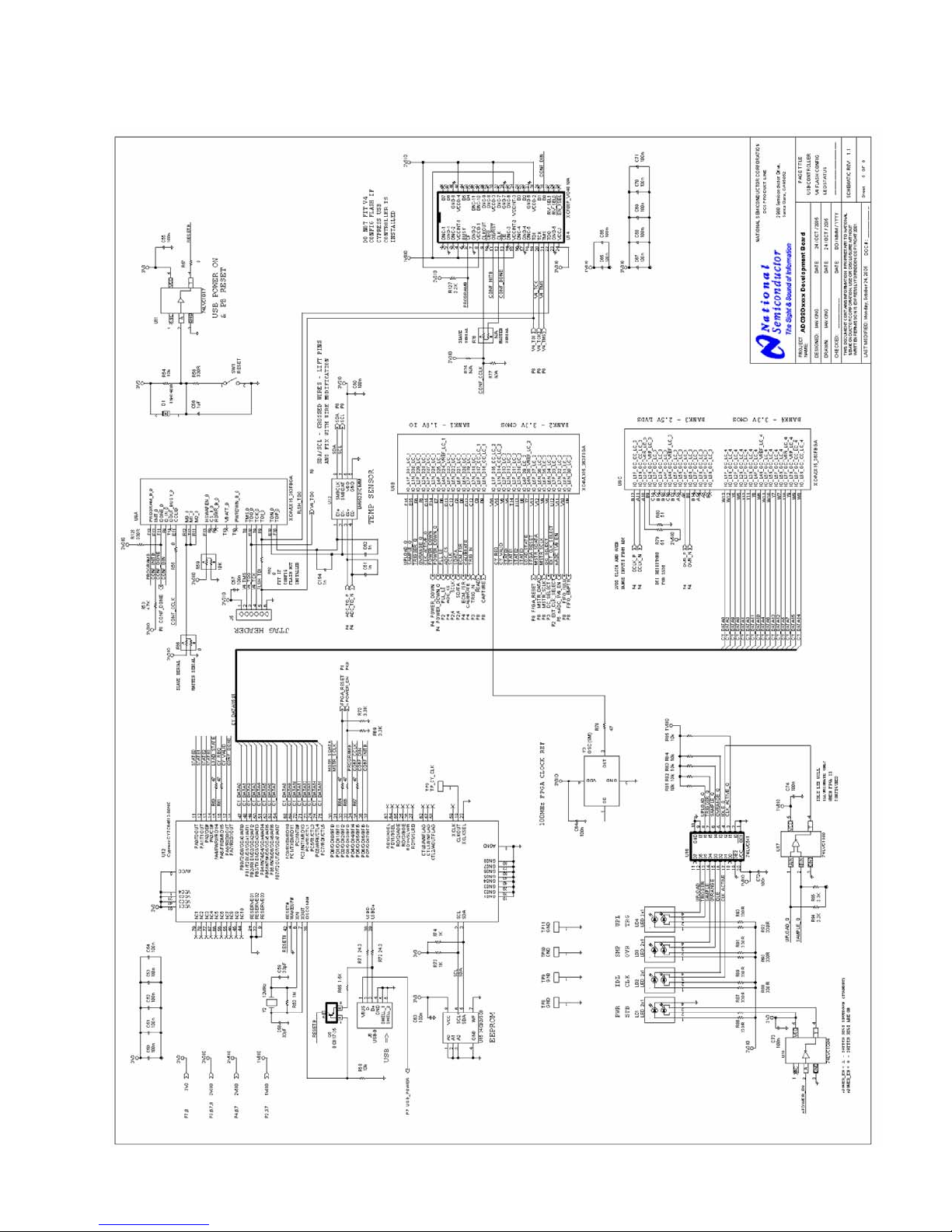

7.3 Schematic Drawing ADC081500DEV – USB Interface

9 www.national.com

Page 10

7.4 Schematic Drawing ADC081500DEV – Power Supplies 1

10 www.national.com

Page 11

7.5 Schematic Drawing ADC081500DEV – Power Supplies 2

11 www.national.com

Page 12

7.6 Schematic Drawing ADC081500DEV – Expansion Header Interface

12 www.national.com

Page 13

8.0 Bill of Materials (Page 1 of 2)

13 www.national.com

Page 14

8.1 Bill of Material (Page 2 of 2)

14 www.national.com

Page 15

9.0 Using the Wavevision4 software with the ADC081500DEV

IMPORTANT NOTE: Before connecting this board to the PC, please install the Wavevision 4

Software from the CDROM included with the development kit. (See Appendix B)

Connecting the Development Board before installation may result in the board being registered as

an unknown USB device. If this happens you will need to uninstall the device using the Windows

Device Manager before installing the Wavevision 4 Software.

9.1 Getting Started

This development board is designed to connect over a USB interface to a PC running the Wavevision 4

Software.

Ensure the board is connected to the 12V power supply (included in the package) and that the switch on

the rear panel is pushed to the “ON” position. The Green LED on the rear panel should be illuminated

Connect the USB cable between the PC which has Wavevision 4 software installed and the

ADC081500DEV board. The USB port can also be found on the rear panel (shown below).

If this is the 1

(automatic) by the Operating System. Follow the on screen instructions and use the recommended

settings.

st

time the board has been connected to the PC, Drivers may be required to be installed

Start the Wavevision 4 software (Start -> All Programs -> Wavevision -> Wavevision 4)

The software may take several seconds to initialize, but should display a welcome screen similar to the

following.

15 www.national.com

Page 16

If the board is connected correctly the following popup box should appear to indicate that the board has

been recognized and the firmware for the FPGA is being downloaded over the USB interface

If the “Downloading firmware” box does not appear automatically, click on the “Settings” pulldown menu

and then click Capture Settings as shown below.

This will display the System Settings Window which should appear as below

If the board has not been detected click the “Test” button under the Communication heading and the

development board should be found. If the communications fail, check that the USB drivers are installed

correctly, then disconnect and re-connect the USB cable. Finally restart the Wavevision 4 software See

Appendix B for more information.

16 www.national.com

Page 17

9.2 Control Panel

Once the FPGA Firmware download has completed the development board Control Panel will

automatically be displayed as shown below.

The Following section describes the Function of the pull-down selection tabs in the left hand side of the

ADC081500DEV product Control Panel

Channel Selection

I – Displays the data captured from the I Channel Only after acquiring Samples

Q- Display is not available on this board due to the ADC being single channel

I and Q – Display is not a valid selection

I/Q Interleaved – is not a valid selection

Temp Sensor

Displayed below the Channel Selection tab is the die temperature of both the FPGA and the ADC

Hardware/Serial Control

Hardware Pin Control – The ADC is controlled by the logic states on the dedicated control pins. The logic

on these pins is determined by the setting of OUTV, OUTEDGE, DDR, DES and FSR below.

Serial Register Program – The ADCs registers are accessed through the Extended Control Mode. In this

mode the hardware pin control is disabled and the programmable registers are available for fine tuning.

17 www.national.com

Page 18

Out V

Low Amplitude – LVDS output voltage amplitude is set to 510mV pk-pk

High Amplitude – LVDS output voltage amplitude is set to 710mV pk-pk

OutEdge

Falling Edge – Data outputs are changed on the falling edge of DCLK+ (Single Data rate mode only)

Rising Edge – Data output are changed on the rising edge of DCLK+ (Single Data rate mode only)

DDR

Disable Dual Data Rate – DDR Mode is disabled (data output follows OutEdge Setting)

Enable Dual Data Rate – Data is output with rising and falling edge of DCLK (Default for 1.5GHz clock)

DES

Disable Dual Edge Sample – DES Mode is disabled.

Enable Dual Edge Sample – This Feature is not available on the single channel device

FSR

650mV Full Scale – Sets the full scale range to 650mV pk-pk

870mV Full Scale – Sets the full scale range to 870mV pk-pk

The Following Pull-down Tabs are available whether the Control mode is Hardware or Serial

Standby

Disable Standby – Enable all on-board power regulators

Enable Standby – Board is put into standby mode – All power is shutdown except USB power

PDQ

Disable Q Shutdown – Q Channel is not available

Enable Q Shutdown – Q Channel is not available

PD

Disable Shutdown – The ADC is powered up and Active

Enable Shutdown – The ADC is put into low power mode. Register Settings are retained

DC_Coup

AC Coupling – The I Channel is AC coupled to the ADCs input

DC Coupling – The I Channel is DC coupled to the ADCs input (not available on AC only model)

Ext_Clock

Internal Clock – The ADC is clocked using the on-board 1.5GHz clock

External Clock – The ADC is clocked from an External clock source connected to the “CLOCK” input.

18 www.national.com

Page 19

Reset FPGA

This button resets the FPGA, and also returns all the pulldown tabs to their default values

Calibrate ADC

This button issues an on-command calibration to the ADC by toggling the ADCs calibrate pin.

9.3 Serial Control Mode

When the Hardware/Serial Control tab is selected as “Serial Register Program”, the control panel display

will be changed to the following view.

In this mode the register settings can be changed simply by clicking on the bits. Doing so will toggle the bit

value and any linear values such as Full Scale Range or Offset will automatically be updated.

The “Reset Registers” button at the bottom of the Control Panel will reset and write all the values to the

power-on default settings.

Please refer to the ADC081500 datasheet for a full description of the ADCs internal registers.

19 www.national.com

Page 20

9.4 Capturing Waveforms

When the ADC has been configured as required, the selected input(s) can be sampled by clicking the

“Acquire” pull-down menu and selecting “Samples”. Alternatively press F1 then the Escape key.

10.0 Appendix A - Hardware Information

10.1 LED functions

The function of the LEDs on the front panel of the boards is as follows

STB – STANDBY, Illuminates when the board is in standby mode.

TRG – TRIGGER EVENT, illuminates when the Trigger Input makes low to high transition

OVR – ADC OVER RANGE, Illuminates when the I or Q channel exceeds the full scale range of the ADC

CLK – CLOCK INPUT, flashes with 50% duty cycle if the ADC is receiving a good clock input.

PWR – POWER, illuminates when the external 12V is connected, and the system is not in Standby.

UPL – UPLOAD, illuminates when the FPGA is uploading sample data to the PC

SMP – SAMPLE, illuminates when the FPGA is sampling data and storing to the FIFO buffers

IDL – IDLE, Illuminates when the system is IDLE.

20 www.national.com

Page 21

10.2 Expansion Header

A 72 pin Future Bus Expansion Header is provided on the rear panel to allow easy connection to a third

party microprocessor board to allow for the reading and analysis of the data captured by the FPGA.

The signals connector to this expansion bus will be as follows

PIN DESCRIPTION PIN DESCRIPTION

A1 I2C - SDA B1 GROUND

A2 I2C - SCL B2 GROUND

A3 SSP - SERIAL DATA B3 GROUND

A4 SSP - SERIAL CLOCK B4 GROUND

A5 FPGA RESET B5 GROUND

A6 READ FIFO B6 GROUND

A7 WRITE FIFO B7 GROUND

A8 FIFO FULL B8 GROUND

A9 FIFO EMPTY B9 GROUND

A10 ADC DCLK RESET B10 GROUND

A11 FPGA CONF DONE B11 GROUND

A12 FPGA JTAG – TMS B12 GROUND

A13 FPGA JTAG - TCK B13 GROUND

A14 FPGA JTAG – TDI B14 GROUND

A15 FPGA JTAG – TDO B15 GROUND

A16 notSHUTDOWN B16 GROUND

A17 3.3V SUPPLY B17 GROUND

A18 12V SUPPLY B18 GROUND

C1 DATA BUS A P0 (LVDS or CMOS) D1 DATA BUS A N0 (LVDS or CMOS)

C2 DATA BUS A P1 (LVDS or CMOS) D2 DATA BUS A N1 (LVDS or CMOS)

C3 DATA BUS A P2 (LVDS or CMOS) D3 DATA BUS A N2 (LVDS or CMOS)

C4 DATA BUS A P3 (LVDS or CMOS) D4 DATA BUS A N3 (LVDS or CMOS)

C5 DATA BUS A P4 (LVDS or CMOS) D5 DATA BUS A N4 (LVDS or CMOS)

C6 DATA BUS A P5 (LVDS or CMOS) D6 DATA BUS A N5 (LVDS or CMOS)

C7 DATA BUS A P6 (LVDS or CMOS) D7 DATA BUS A N6 (LVDS or CMOS)

C8 DATA BUS A P7 (LVDS or CMOS) D8 DATA BUS A N7 (LVDS or CMOS)

C9 INPUT STROBE P D9 INPUT STROBE N

C10 DATA BUS B P0 (LVDS or CMOS) D10 DATA BUS B N0 (LVDS or CMOS)

C11 DATA BUS B P1 (LVDS or CMOS) D11 DATA BUS B N1 (LVDS or CMOS)

C12 DATA BUS B P2 (LVDS or CMOS) D12 DATA BUS B N2 (LVDS or CMOS)

C13 DATA BUS B P3 (LVDS or CMOS) D13 DATA BUS B N3 (LVDS or CMOS)

C14 DATA BUS B P4 (LVDS or CMOS) D14 DATA BUS B N4 (LVDS or CMOS)

C15 DATA BUS B P5 (LVDS or CMOS) D15 DATA BUS B N5 (LVDS or CMOS)

C16 DATA BUS B P6 (LVDS or CMOS) D16 DATA BUS B N6 (LVDS or CMOS)

C17 DATA BUS B P7 (LVDS or CMOS) D17 DATA BUS B N7 (LVDS or CMOS)

C18 OUTPUT STROBE P D18 OUTPUT STROBE N

The Data busses on this header can be configured as follows

• Two 8 bit busses with LVDS differential signaling, plus two LVDS strobes

• Four 8 bit busses with LVCMOS (3.3V IO) signaling plus four CMOS strobes

All control signals on pins A1 to A15 will be at LVCMOS 3.3V levels.

21 www.national.com

Page 22

10.3 System Block Diagram

22 www.national.com

Page 23

11.0 Appendix B - Installing and running the Wavevision 4 software

11.1 Install the WaveVision Software.

• Insert the WaveVision CD-ROM into your computer’s CD-ROM drive.

• The WaveVision software requires a Java™ Runtime Environment or Java™ Development Kit,

version 1.4 or higher, from Sun Microsystems, Inc. For detailed information on WaveVision’s use

of Java technology, please see below. If your computer does not have this software, the

WaveVision installer will instruct you on how to install it.

• Locate and run the WaveVision 4 Setup.exe program on the CD-ROM. Follow the on-screen

instructions to finish the install

11.2 Java™ Technology

The WaveVision software uses Sun Microsystems® Java technology. The underlying Java software must

be installed on your computer in order for the WaveVision software to run. The software can run on top of

either the Java Runtime Environment (JRE) or the Java Development Kit (JDK), version 1.4 or higher. A

suitable copy of the JRE is included on your WaveVision CD-ROM.

The WaveVision installer will first look for an existing copy of the JRE or JDK on your computer. If neither

is found, the installer will instruct you to first install a JRE. To do this, run the J2RE*.exe installer

program off the CD-ROM. Follow the on-screen instructions to finish the install.

After a suitable JRE or JDK is installed, run the WaveVision installer again. The installer will detect the

Java software and configure the WaveVision software to use it.

Java technology can allow software to run on different platforms. However, the WaveVision software

contains Windows specific hardware interface code and therefore is only currently supported under

Windows.

.

11.3 Automatic Device Detection & Configuration

The WaveVision system provides automatic hardware detection and configuration for the device under

test. The FPGA is re-programmed on the fly by the host PC when the Development board is turned on.

Normally, the configuration process is totally transparent to the user, and requires no intervention.

However, this process can be overridden if required by specifying a new Xilinx configuration image by

clicking the Xilinx Image Settings button within the Capture Setting window (Settings -> Capture Settings).

11.4 Windows Driver

The WaveVision software communicates with the WaveVision hardware through the Windows device

driver software. If you are unable to connect to the Wavevision board after installing the software, do the

following to uninstall and reinstall the driver. Go to the Windows Control Panel and select System. If you

are using Windows 2000/XP select the Hardware tab. Then click on Device Manager and go down to the

Universal Serial Bus controllers. With the WaveVision board connected, you will see it (or an unknown

device) listed. Right click on it and uninstall the driver. Then unplug and plug in the board again to reinstall

the driver

.

23 www.national.com

Page 24

12.0 Appendix C - Using WaveVision Plots

The WaveVision software provides several tools to help you interact with plots. A toolbar appears above

each plot, similar to Figure 4.

Figure 4: WaveVision Plot Tools

Seen from left to right, the following tools are available:

Plot Actions menu: This menu contains commands that pertain to this particular plot. You may export

the plot data to a file, print the plot, save it as a graphic, or change the plot’s colors.

Plot Options: This button opens a dialog box with options that pertain to this particular plot. You may turn

off labels, annotations, or other elements in this dialog. The WaveVision software maintains default

options for new plots. You may edit the default options by choosing Default Plot Options from the

Settings menu.

FFT Options: The toolbar shown in Figure 4 is from an FFT plot, and thus contains a button to edit the

options for the FFT calculation. Depending upon the type of plot, various options may be present on the

toolbar. Please consult the appropriate section below for more information about these options.

Magnifying glass tool: This tool allows you to zoom in and out to see fine details in the plot. Click and

drag a box from upper-left to lower-right to zoom in on a particular region of your plot. Click and drag a

box from lower-right to upper-left to zoom out. With the magnifying glass tool selected, click the right

mouse button to return to a normal, 100% view.

Arrow Tool: The arrow tool is used to select, move, and edit annotations. To edit an annotation, double

click it with the arrow tool. To delete an annotation, select it with the arrow tool and press the Delete key

on your keyboard.

Line Annotation Tool: To draw lines on the plot, select this tool. Drag to draw new lines. To add

arrowheads, or fix the endpoints of the line, double-click it with the arrow tool.

Text Annotation Tool: To draw labels on the plot, select this tool and click at the desired location in the

plot. To edit the justification, location, or text of an annotation, double-click it with the arrow tool.

The Waveform Plot

The Waveform plot shows you the raw samples collected from the hardware. This plot is mainly used to

verify the integrity of collected data – the waveform is the best view in which to diagnose a distorted signal,

an irregular clock, a low-amplitude signal, and many other common ADC system problems.

The Waveform plot also quickly shows you how much of the ADC’s dynamic range your signal occupies.

The FFT Plot

The WaveVision software automatically computes a Fast Fourier Transform (FFT) of the sample set, and

displays the results in an FFT plot. The FFT plot is, in many respects, the heart of the software. The FFT

shows you the frequency content of your input signal. It marks the fundamental frequency, and a

selectable number of harmonics. It also labels their order and frequencies. It shows the power in the

fundamental and harmonics. Try hovering your mouse cursor over a harmonic to get information about it.

The FFT can be used to diagnose common ADC problems such as input spectral impurity, clock phase

noise, and clock jitter. The FFT plot also shows several statistics on the quality and purity of the collected

24 www.national.com

Page 25

samples, such as SNR, SINAD, THD, SFDR, and ENOB. These statistics are to be interpreted with the

following definitions (which are repeated in every National Semiconductor ADC datasheet):

Signal to Noise Ratio (SNR) is the ratio, expressed in dB, of the RMS value of the input signal to the

RMS value of the sum of all other spectral components below one-half the sampling frequency, not

including harmonics or DC.

Signal to Noise Plus Distortion (S/N+D or SINAD) Is the ratio, expressed in dB, of the RMS value of the

input signal to the RMS value of all of the other spectral components below half the clock frequency,

including harmonics but excluding DC.

Total Harmonic Distortion (THD) is the ratio, expressed in dBc, of the RMS total of the first five harmonic

levels at the output to the level of the fundamental at the output. THD is calculated as

22

ff

log20THD

2

++=L

N

2

f

1

where f

is the RMS power of the fundamental (output) frequency and f2 through fN are the RMS power in

1

the first N harmonic frequencies.

Spurious-Free Dynamic Range (SFDR) is the difference, expressed in dB, between the RMS values of

the input signal and the peak spurious signal, where a spurious signal is any signal present in the output

spectrum that is not present at the input.

Effective Number of Bits (ENOB, or Effective Bits) is another method of specifying Signal-to-Noise and

Distortion or SINAD. ENOB is defined as (SINAD - 1.76) / 6.02 and says that the converter is equivalent to

a perfect ADC of this (ENOB) number of bits.

FFT Options

FFT plots can be configured in many different ways. Clicking the “FFT Options” button at the top of the

plot will display a dialog showing the options for that particular plot. The software also maintains default

options for new FFT plots, which are editable. You can edit the default FFT options by choosing Default

FFT Options from the Settings menu. The options are:

Windowing: You may choose from one of five different window functions. The window function is applied

to the samples before computing the FFT to compensate for the fact that the sample set may not be an

integral number of wavelengths of the input signal. In general, Flat-Top will give the best results, but you

may find it easier to compare data with other systems when the windowing functions are the same.

dB Scale: You may select to represent power on the FFT in dBc (decibels relative to carrier), in which 0

dB is taken to be the fundamental (carrier) power, or dBFS (decibels relative to full-scale), in which 0 dB is

taken to the be power contained in a signal which uses the entire dynamic range of the ADC.

Harmonics: You may select the number of harmonics recognized (and labeled) by the software. You may

also select the number of FFT bins excluded around harmonics in, for example, SNR calculations. The

exclusion region around each harmonic will be shown in a different color than the rest of the data points.

IMD Calculations: The WaveVision software is capable of performing Intermodulation Distortion

calculations. When two fundamental frequencies within 3 dBFS are present in the waveform, The

software will normally perform IMD calculations. You may inhibit this behavior by deselecting the “Allow

IMD calculation” checkbox. When IMD calculation is enabled, you may also select whether the software

will include only 2

nd

order or both 2nd and 3rd order terms.

25 www.national.com

Page 26

Histogram Plots

Histogram plots are created by counting the number of times each ADC output code appears in a dataset.

Histograms may be computed by software, or by hardware. A software histogram is computed from a

dataset which is normally 128k samples or smaller. A hardware histogram is collected directly by the

hardware, and may include millions of counts per code. The resulting histogram will show discontinuities

between comparators, gain or offset errors, and other common ADC system problems.

The Histogram plot also displays the number of codes that were never counted (missing codes), followed

by the first ten such missing codes.

Information Viewer

The information viewer is not a plot, but it displays a variety of useful information about the dataset, such

as the sampling rate, and any warnings generated by the software. You may also store comments about

the dataset here, to be saved in a WaveVision file.

Data Import and Export

The WaveVision software provides a variety of means to share data with others, in both textual and

graphical formats.

The most flexible way to import data into the software is from a tab-delimited ASCII text file. The contents

can be either a sample set or a histogram, provided with or without time information. The simplest

example of this would be a file with a single column of samples. You can open tab-delimited text files by

choosing Open from the File menu; you can interleave data from multiple columns and/or files. You can

choose ReOpen to reopen the same file later with the same settings (for example when you update the file

with new data),

There are a variety of ways to export data from the software:

• Save the file as a normal WV4 (*.wv4) file. WV4 files are ASCII, tab-delimited text files. Samples

are stored one per line in a single column. You can open a WV4 file directly in a spreadsheet

program.

• Save the file as a TXT (*.txt) file. You will produce a one- or two-column tab-delimited ASCII text

file of samples or histogram information, without the header information that is contained in a WV4

file.

• You can export the contents of an individual plot by choosing Export Data… from the plot’s

Plot Actions menu. The format of the data is always tab-delimited ASCII text.

• You can export a plot as either a GIF (*.gif) or Encapsulated Postscript (*.eps) graphic by

choosing Export Plot as Graphic from the plot’s Plot Actions menu. GIF files are

suitable for the web or for emails. Encapsulated Postscript files are high-resolution scalable files

suitable for direct publication.

26 www.national.com

Page 27

BY USING THIS PRODUCT, YOU ARE AGREEING TO BE BOUND BY THE TERMS AND CONDITIONS OF NATIONAL

SEMICONDUCTOR'S END USER LICENSE AGREEMENT. DO NOT USE THIS PRODUCT UNTIL YOU HAVE READ AND

AGREED TO THE TERMS AND CONDITIONS OF THAT AGREEMENT. IF YOU DO NOT AGREE WITH THEM, CONTACT THE

VENDOR WITHIN TEN (10) DAYS OF RECEIPT FOR INSTRUCTIONS ON RETURN OF THE UNUSED PRODUCT FOR A

REFUND OF THE PURCHASE PRICE PAID, IF ANY.

The ADC081500DEV Development Boards are intended for product evaluation purposes only and are not intended for resale to end

consumers, is not authorized for such use and is not designed for compliance with European EMC Directive 89/336/EEC, or for

compliance with any other electromagnetic compatibility requirements.

National Semiconductor Corporation does not assume any responsibility for use of any circuitry or software supplied or described. No

circuit patent licenses are implied

.LIFE SUPPORT POLICY

NATIONAL'S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR

SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF NATIONAL SEMICONDUCTOR

CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant into the

body, or (b) support or sustain life, and whose failure to

perform, when properly used in accordance with instructions

2. A critical component is any component in a life support

device or system whose failure to perform can be reasonably

expected to cause the failure of the life support device or

system, or to affect its safety or effectiveness.

for use provided in the labeling, can be reasonably expected

to result in a significant injury to the user.

BANNED SUBSTANCE COMPLIANCE

National Semiconductor certifies that the products and packing materials meet the provisions of the Customer

Products Stewardship Specification (CSP-9-111C2) and the Banned Substances and Materials of Interest

Specification (CSP-9-111S2) and contain no ‘‘Banned Substances’’ as defined in CSP-9-111S2.

National does not assume any responsibility for any circuitry described, no circuit patent licenses are

implied and National reserves the right at any time without notice to change said circuitry and

specifications.

National Semiconductor

Corporation

Americas Customer Support

Center

Tel: 1-800-272-9959

Email:

new.feedback@nsc.com

27 www.national.com

National Semiconductor Europe

Customer Support Center

Fax: +49 (0) 1 80-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 699508 6208

English Tel: +49 (0) 870 24 0

2171

Français Tel: +49 (0) 141 91 8790

National

Semiconductor

Asia Pacific

Customer

Support Center

Email:

ap.support@nsc.com

National Semiconductor

Japan Customer

Support Center

Tel: 81-3-5639-7560

Fax: 81-3-5639-7507

Email:

jpn.feedback@nsc.com

Loading...

Loading...