Page 1

USER GUIDE

U

NIVERSAL

Contents

M

OTION INTERFACE

This user guide describes how to use the UMI-7764, UMI-4A, UMI-Flex6,

and UMI-Flex4 accessories.

Introduction.............................................................................................2

What You Need to Get Started ...............................................................2

UMI-7764................................................................................................4

Motion I/O Terminal Block.............................................................5

Amplifier/Driver Terminal Block....................................................5

Encoder Terminal Block..................................................................6

Limit Switch Terminal Block..........................................................8

Analog Input Terminal Block..........................................................9

Breakpoint Output/Trigger Input Terminal Block...........................9

Shutdown/Inhibit All Terminal Block.............................................10

Power Input Terminal Block............................................................ 10

UMI-7764 Specifications........................................................................11

UMI-4A...................................................................................................13

Amplifier/Driver Terminal Block....................................................13

Encoder Terminal Block..................................................................15

Limit Switch Terminal Block..........................................................16

Digital I/O Terminal Blocks............................................................17

Power Input Terminal Block............................................................ 18

UMI-4A Specifications........................................................... ................19

UMI-Flex6 ..............................................................................................21

Amplifier/Driver Terminal Block....................................................21

Encoder Terminal Block..................................................................22

Limit Switch Terminal Block..........................................................24

Analog Input Terminal Blocks ........................................................25

Breakpoint Output Terminal Block .................................................26

Power Input Terminal Block............................................................ 26

UMI-Flex6 Specifications................................ .......................................27

UMI-Flex4 ..............................................................................................28

Amplifier/Driver Terminal Block....................................................28

Encoder Terminal Block..................................................................30

Limit Switch Terminal Block..........................................................32

Analog Input Terminal Block..........................................................32

Breakpoint Output Terminal Block .................................................33

Power Input Terminal Block............................................................ 33

UMI-Flex4 Specifications................................ .......................................34

(UMI) A

CCESSORY

FlexMotion ™ and ValueMotion ™ are trademarks of National Instruments Corporation. Product and company names mentioned herein are

trademarks or trade names of their respective companies.

321941B-01 © Copyright 1998, 1999 National Instruments Corp. All rights reserved. August 1999

Page 2

Introduction

Note

Throughout this document, overlined text indicates that a signal is active-low.

The UMI products are connectivity accessories you can use with your

motion control boards for up to four or six axes of simultaneous or

independent control. Ideally suited to industrial and laboratory

applications, UMI accessories connect power supplies, servo amplifiers

or stepper drivers, motors, encoders, and limit switches to National

Instruments plug-in motion control boards.

A UMI accessory simplifies field wiring with separate encoder, limit

switch, and amplifier/driver terminal blocks per axis. All terminal blocks

are industry standard and do not require any special tools for wire

installation. The UMI accessory connects to the motion controller via a

single interface cable. The UMI accessory has a host bus monitor power

interlock that automatically disables the amplifiers if the host computer is

shut down or the interface cable is disconnected.

The UMI-4A and UMI-Flex4 come with an integrated DIN-rail mounting

base. The UMI-Flex6 is encased in metal and comes with attached rubber

feet for desktop use; a DIN-rail mounting kit is available separately. The

UMI-7764 is encased in a metal box with a hinged lid and comes with

attached rubber feet for desktop use.

What You Need to Get Started

To set up and use your UMI accessory, you will need the following items:

❑ One of the following UMI accessories:

–UMI-7764

–UMI-4A

–UMI-Flex6

–UMI-Flex4

❑ Universal Motion Interface (UMI) Accessory User Guide

UMI Accessory User Guide 2 www.natinst.com

Page 3

❑ One of the following National Instruments cables:

UMI Accessory Cable Motion Controller

UMI-7764 SH68-C68-S All 7344 controllers,

PCI-7324, PCI-7314

UMI-7764 SH68-68-S PXI-7324, PXI-7 314

UMI-4A SH50-50 , NB1 50-pin ValueMotion

controllers

UMI-Flex6,

UMI-Flex4

SH-Flex-100 100-pin FlexMotion

controllers

❑ +5 V power supply

❑ (Optional) Auxiliary power supply (UMI-4A only)

❑ (Optional) ISO power supply (UMI-Flex4 and UMI-Flex6 only)

Detailed specifications for each of the UMI accessories are in the

Specifications section for each device.

© National Instruments Corporation 3 UMI Accessory User Guide

Page 4

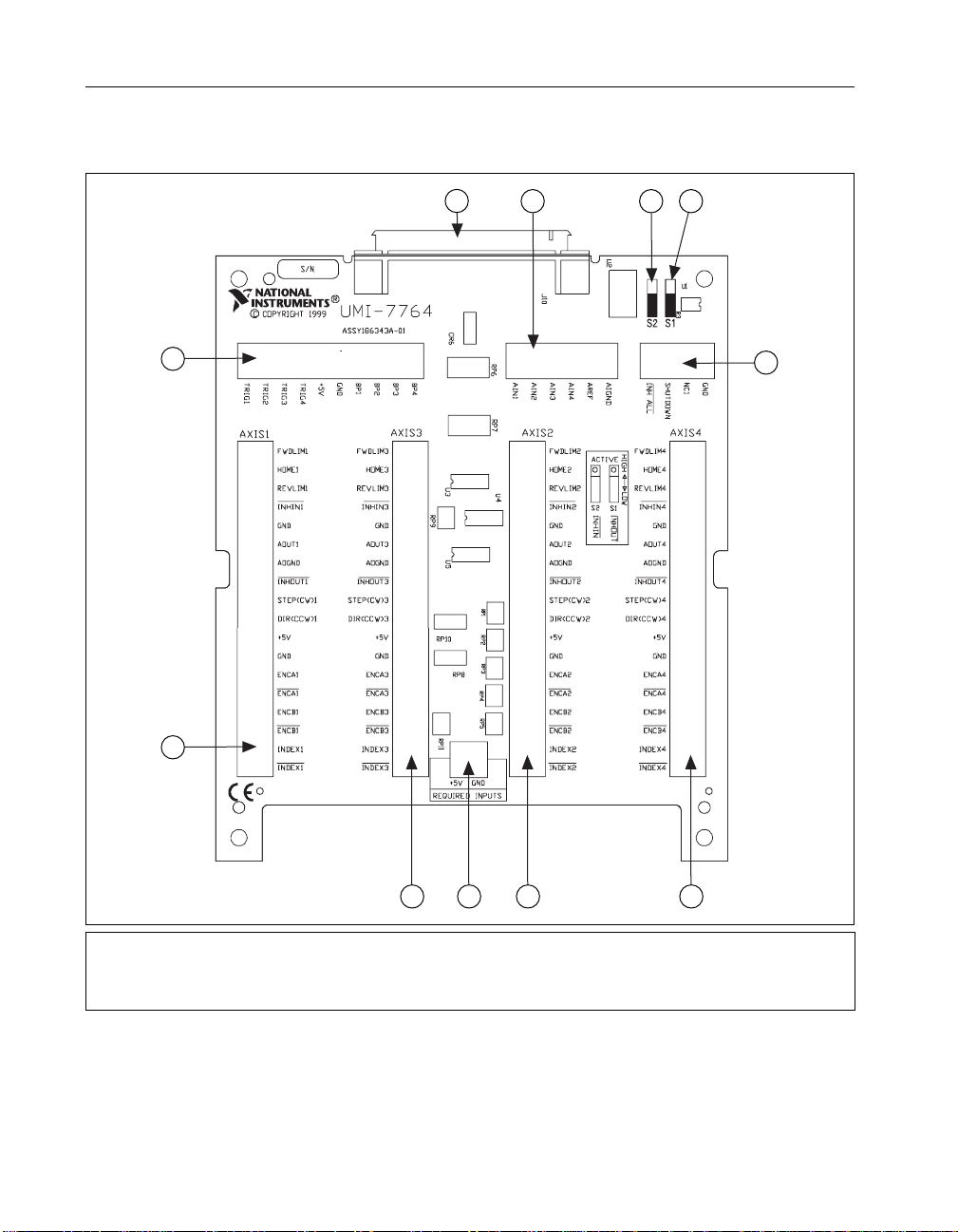

UMI-7764

This section describes the UMI-7764 terminal block. Refer to Figure 1 to

help you locate the different parts of the UMI-7764 accessory.

11

10

1

9 8 7

6

2 3 45

1 Axis 1 Motion I/O Terminal Block

2 Axis 3 Motion I/O Terminal Block

3 Axis 2 Motion I/O Terminal Block

4 Axis 4 Motion I/O Terminal Block

UMI Accessory User Guide — UMI-7764 4 www.natinst.com

5 Power Input Terminal Block

6 Shutdown/Inhibit All Terminal Block

7 Inhibit Output Polarity Switch (S1)

8 Inhibit Input Polarity Switch (S2)

Figure 1.

UMI-7764 Parts Locator Diagram

9 Analog Input Terminal Block

10 68-Pin Motion I/O Connector

11 Breakpoint/Trigger Terminal

Block

Page 5

Motion I/O Terminal Block

Each axis connected to the UMI-7764 has a motion I/O terminal block to

which the following signals are wired:

• Amplifier/driv er connections

• Encoder connections

• Limit switch connections

• Distributed power connections

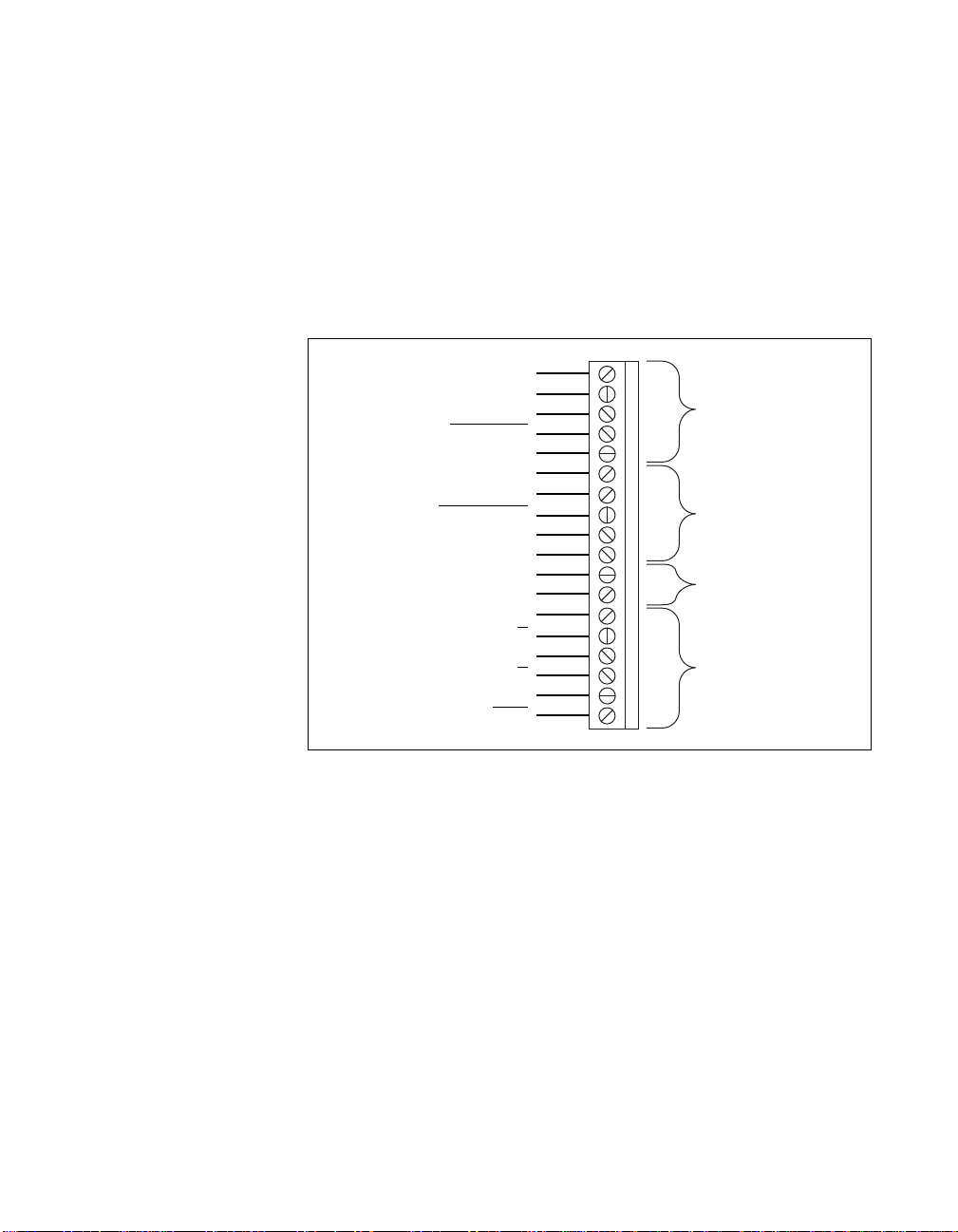

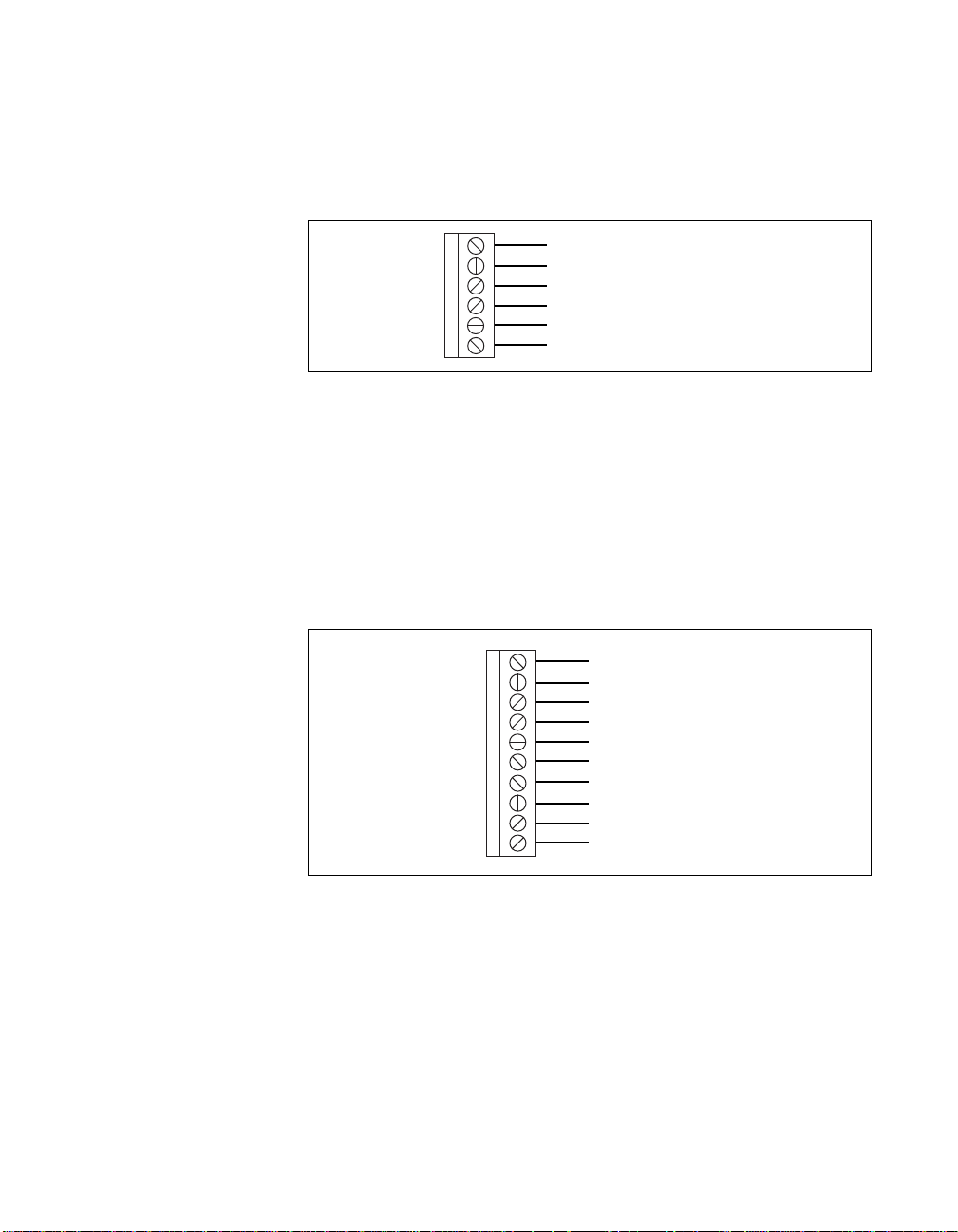

Figure 2 shows which portions of the terminal block are used for different

functionality.

Forward Limit

Home Input

Reverse Limit

Inhibit Input

Digital Ground

Analog Output

Analog Output Ground

Inhibit Output

Step (CW)

Dir (CCW)

+5 V (Output)

Digital Ground

Encoder Phase A

Encoder Phase A

Encoder Phase B

Encoder Phase B

Encoder Index

Encoder Index

Limit Switch

Terminals

Amplifier/Driver

Terminals

Distributed

Power

Encoder

Terminals

Figure 2.

UMI-7764 Motion I/O Terminal Block

Amplifier/Driver Terminal Block

Each UMI-7764 axis motion I/O terminal block has five terminals for

amplifier/driver connections. Refer to Figures 1 and 2 to locate the

amplifier/driver terminals on your UMI-7764 accessory. Figure 3 shows

the UMI-7764 amplifier/driver terminal block pin assignment for the

servo/stepper axes.

© National Instruments Corporation 5 UMI Accessory User Guide — UMI-7764

Page 6

Analog Output

Analog Output Ground

Inhibit Output

Step (CW)

Dir (CCW)

Figure 3. UMI-7764 Axes Amplifier/Driver Terminal Block Pin Assignments

The Analog Output signals are used as command outputs to a servo

amplifier or as general-purpose voltage outputs. The Step and Dir signals

are used as command outputs to a stepper driver.

The Inhibit Output signals are used to disable the amplifier/driver for that

axis. The UMI combines the host bus interlock circuit, the Inhibit All

signal, the per axis Inhibit Input signals, and the per axis controller Inhibit

Output to create the per axis Inhibit Output signal. The host bus interlock

monitors the +5 V pin from the motion controller to verify that the

controller is powered and properly connected to the UMI. If the host bus

interlock detects a problem, if the Inhibit All signal is asserted, or if the

Inhibit Input signal or the controller Inhibit Output signal for that axis is

asserted, the Inhibit Output from the UMI-7764 for that axis is asserted.

You can configure the axis Inhibit Out signal as active-low or active-high

output using switch S1. Setting S1 to the bottom configures the signal as

active-low; setting S1 to the top configures the signal as active-high.

Note You must configure the controller’s Inhibit Output signals as active-low for proper

operation of the inhibit circuitry.

Encoder Terminal Block

Each UMI-7764 axis motion I/O terminal block has six terminals for

incremental encoder connections. The UMI-7764 accepts either

single-ended TTL or differential line driver inputs. You can connect

open-collector encoders to the UMI-7764 accessory by installing a 2.2 kΩ

pull-up resistor to +5 V.

Note Encoders with line driver outputs are recommended for all applications and must be

used if the encoder cable length is greater than 10 feet.

UMI Accessory User Guide — UMI-7764 6 www.natinst.com

Page 7

Power for the encoders is internally routed from the power input terminal

block and is available on the +5 V terminal on each axis motion I/O

terminal block. You must supply a +5 V source to the power input terminal

block for proper operation. Refer to Figures 1 and 2 to help you locate the

encoder terminals on your UMI-7764 accessory. Figure 4 shows the wiring

for a differential encoder.

Note The dotted loop indicates a shielded cable.

Phase A

Phase A

Phase B

Phase B

Index

Index

1

Connect to Digital Ground

Figure 4. Differential Encoder Wiring

Figure 5 shows the wiring for the single-ended encoder.

Shield

1

1

Shield

Phase A

Phase B

Index

1

Connect to Digital Ground

Figure 5. Single-Ended Encoder Wiring

The UMI-7764 accessory allows for differential inputs for Phase A,

Phase B, and Index signals. You can easily accommodate encoders with

phase relationships different from Figure 6 by swapping the signals as

required by the specific application. The Inde x pulse must occur when both

Phase A and Phase B signals are logic low as shown in Figure 6. Servo and

closed-loop stepper applications require encoder feedback and consistent

directional polarity between the motor and encoder for stable operation.

The UMI-7764 uses the following standards for motor direction:

• Positive = forward = Clockwise (CW) facing motor shaft

• Negativ e = reverse = Counter-clockwise (CCW) facing motor shaft

© National Instruments Corporation 7 UMI Accessory User Guide — UMI-7764

Page 8

The encoder inputs are filtered by both analog and digital noise filters. You

must use cables with twisted pairs and an overall shield for improved noise

immunity . When connecting the encoder to the UMI-7764, you should use

at least 24-AWG wire.

Caution Using an unshielded cable allows noise to corrupt the encoder signals, which

results in lost counts, reduced accuracy, and other erroneous encoder and controller

operations.

Limit Switch Terminal Block

Each UMI-7764 axis motion I/O terminal block has five terminals for

Forward and Reverse Limit and Home Input switch connections. Refer to

Figures 1 and 2 to help you locate the limit switch terminals on your

UMI-7764 accessory. See Figure 7 for the UMI-7764 limit switch terminal

block pinout.

Phase A

Phase B

Index

Figure 6. Encoder Signal Phasing—CW Rotation

Forward Limit

Home Input

Reverse Limit

Inhibit Input

Digital Ground

Figure 7. UMI-7764 Limit Switch Terminal Block Pin Assignment

Y ou can conf igure the axis Inhibit Input signals as active-lo w or active-high

inputs using switch S2. Setting S2 to the bottom configures the signal as

active-low; setting S2 to the top configures the signal as active-high. The

Inhibit Input signals include a 3.3 kΩ pull-up resistor on their inputs.

UMI Accessory User Guide — UMI-7764 8 www.natinst.com

Page 9

Analog Input Terminal Block

For analog input wiring, the UMI-7764 has a 6-position terminal block,

which provides access to the four analog input channels on your motion

controller. Refer to Figure 1 to help you locate the analog input terminal

block on your UMI-7764 accessory. See Figure 8 for analog input terminal

block pinout information.

Analog Input Ground

Analog Reference (Output)

Analog Input 4

Analog Input 3

Analog Input 2

Analog Input 1

Figure 8.

UMI-7764 Analog Input Terminal Block Pin Assignments

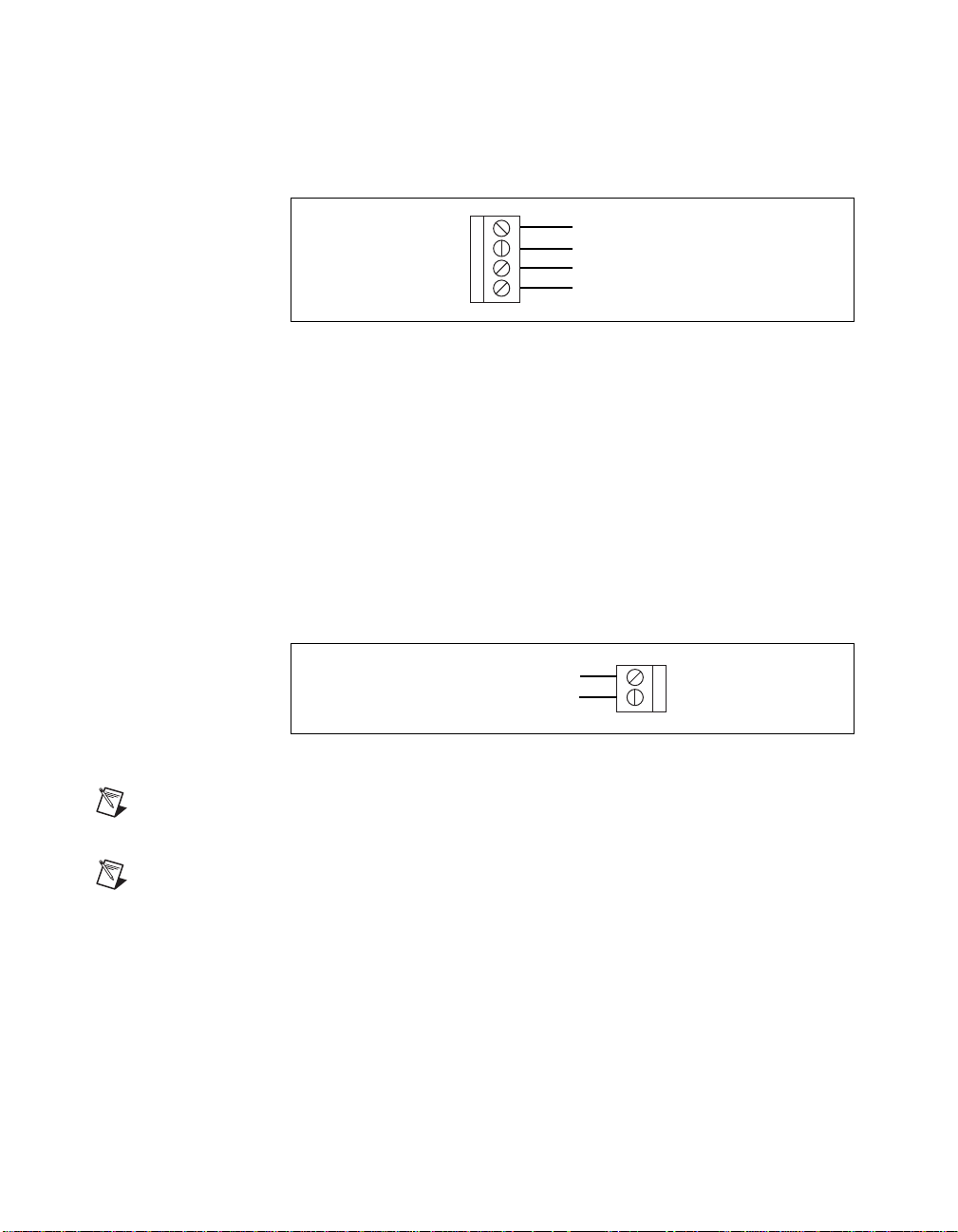

Breakpoint Output/Trigger Input Terminal Block

For breakpoint output and trigger input wiring, the UMI-7764 has a

10-position terminal block. This terminal block provides access to the four

breakpoint outputs and the four trigger inputs. Refer to Figure 1 to help you

locate the breakpoint output/trigger input terminal block on your

UMI-7764 accessory. See Figure 9 for more information on breakpoint

output and trigger input wiring.

Figure 9.

UMI-7764 Breakpoint/Trigger Terminal Block Pin Assignments

Breakpoint 4

Breakpoint 3

Breakpoint 2

Breakpoint 1

Digital Ground

+5 V (Output)

Trigger 4

Trigger 3

Trigger 2

Trigger 1

© National Instruments Corporation 9 UMI Accessory User Guide — UMI-7764

Page 10

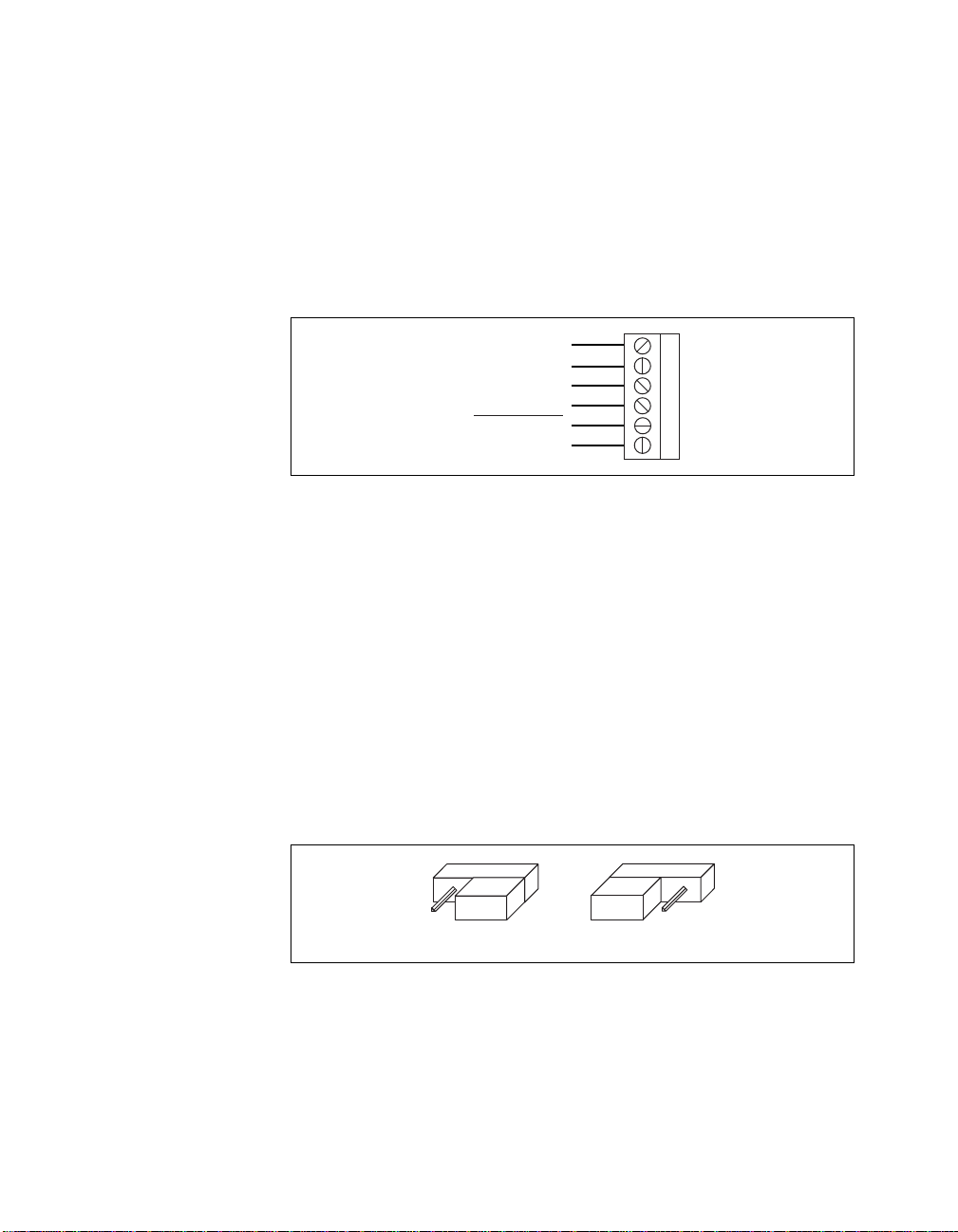

Shutdown/Inhibit All Terminal Block

The UMI accessory has a 4-position terminal block for shutdown and

inhibit all wiring. Refer to Figure 1 to help you locate the shutdown/inhibit

all terminal block on your UMI-7764 accessory. See Figure 10 for more

information on shutdown/inhibit all wiring.

Digital Ground

NC

Shutdown

Inhibit All

Figure 10.

The Inhibit All signal acts as a global inhibit, and, when asserted, activ ates

the Inhibit Outputs. The Inhibit All signal includes a 3.3 kΩ pull-up resistor

on its input. The Shutdown signal is passed through to the motion controller

and is typically used to disable the controller.

Power Input Terminal Block

The UMI-7764 has a 2-position terminal block for wiring power to the unit.

Refer to Figure 1 to help you locate the power input terminal block on your

UMI-7764 accessory. Figure 11 shows the 2-position terminal block

pinout.

Figure 11.

Note

To properly operate your UMI-7764 accessory, you must supply a +5 V source to

the power input terminal block.

Note

The +5 V power is redistributed to other terminal blocks as an output power source.

Shutdown/Inhibit All Terminal Block Pin Assignments

+5 V

Digital Ground

2-Position Power Input Terminal Block Pin Assignment

UMI Accessory User Guide — UMI-7764 10 www.natinst.com

Page 11

UMI-7764 Specifications

The following specifications apply only to the UMI-7764 accessory. To

obtain a system specification, you must account for your motion controller.

Please refer to your controller specifications to determine overall system

specifications.

Some signals have compatibility defined as signal pass-through. This

means the UMI-7764 may have passive filtering on these signals but will

not affect the voltage range or current handling capability. Consult your

motion controller specifications to determine the allowable voltage range

and logic level compatibility of the signal.

These specifications are typical at 25 °C unless otherwise specified. Refer

to your motion controller user manual for detailed specifications on

encoder inputs, limit and home switch inputs, breakpoint outputs, trigger

inputs, and analog inputs.

Encoder Interface (Each Axis)

Inputs......................................................Quadrature, incremental

Differential input threshold....................±0.3 V (typical)

Single-ended input threshold .................TTL/CMOS

Voltage range.........................................0 to 5 VDC

Noise filter (RC time constant)..............100 ns

Max quadrature frequency .....................1 MHz

Limit and Home Switch Inputs (Each Axis)

Noise filter (RC time constant)..............10 µs

Compatibility .........................................Signal pass-through

Trigger Inputs

Noise filter (RC time constant)..............100 ns

Compatibility .........................................Signal pass-through

© National Instruments Corporation 11 UMI Accessory User Guide — UMI-7764 Specifications

Page 12

Inhibit and Inhibit All Inputs

Voltage range..........................................0 to 12 VDC

Input voltage threshold...........................TTL/CMOS

Input pull-up resistor ..............................3.3 kΩ

Compatibility.................................... .. ....Signal pass-through

Analog Inputs

Noise filter (RC time constant)...............10 µs

Compatibility.................................... .. ....Signal pass-through

Axis Inhibit Out

Voltage range..........................................0 to 5 VDC

Output low voltage .................................0.5 V at 16 mA

Output high voltage ................................2.4 V at 3.2 mA

Operating Environment

Temperature............................................0 to 55 °C

Storage temperature................................–20 to 70 °C

Relative humidity ...................................10 to 90% (noncondensing)

Power Requirements

+5 VDC...................................................0.2 amps + user-defined encoder

and limit power

Host Bus Voltage Interlock

Voltage....................................................5 VDC ± 5%

Physical

Dimensions.............................................19.5 by 15.2 by 4.5 cm

(7.7 by 6.0 by 1.8 in.)

UMI Accessory User Guide — UMI-7764 Specifications 12 www.natinst.com

Page 13

UMI-4A

This section describes the UMI-4A terminal block. Refer to Figure 12 to

help you locate the different parts of the UMI-4A accessory.

14

17

Amplifier

Connectors

1 Axis 1 (J13)

2 Axis 2 (J14)

3 Axis 3 (J15)

4 Axis 4 (J16)

15

20 9 19 10 18 11

Encoder

Connectors

5 Axis 1 (J2)

6 Axis 2 (J4)

7 Axis 3 (J6)

8 Axis 4 (J8)

1 2 36

Limits

Connectors

9 Axis 1 (J3)

10 Axis 2 (J5)

11 Axis 3 (J7)

12 Axis 4 (J9)

5

Other

Connectors

13 I/O Bits 1–4 (J10)

I/O Bits 5–8 (J11)

14 Opto 22 Compatible (J19)

15 Power (J18)

Figure 12.

7

12 1613

Miscellaneous

16 ValueMotion Controller (J1)

17 Jumpers (Axes 1–4)

18 Assembly Number

19 Serial Number

20 Reserved—Do not remove

UMI-4A Parts Locator Diagram

48

Amplifier/Driver Terminal Block

For amplifier/driver wiring, each UMI-4A axis has a separate 6-position

terminal block. Refer to Figure 12 to help you locate the amplifier/driver

terminal block on your UMI-4A accessory. Figure 13 shows the terminal

block pin assignment for the UMI-4A amplifier/driver used with a servo

board.

Analog Output

Analog Output Ground

+5 V (Output)

Digital Ground

System Inhibit

I/O Bit (Axis #)

Figure 13.

© National Instruments Corporation 13 UMI Accessory User Guide — UMI-4A

UMI-4A Amplifier/Driver with Servo Terminal Block Pin Assignment

1

2

3

4

5

6

Page 14

The analog output signals are used as command outputs to a servo

amplifier. The System Inhibit output signals are used to disable all of the

amplifiers. The UMI accessory combines the host bus interlock circuit and

the Enable Input signals to create the global System Inhibit signals. The

host bus interlock monitors the +5 V pin from the motion controller to

verify that the controller is powered and properly connected to the UMI. If

the host bus interlock detects a problem, or if both Enable Input signals are

deasserted, the System Inhibit signals are asserted.

Figure 14 shows the UMI-4A amplifier/driver terminal block pin

assignment used with a stepper board.

Step (CW)

Dir (CCW)

+5 V (Output)

Digital Ground

Inhibit Output

I/O Bit (Axis #)

Figure 14. UMI-4A Amplifier/Driver with Stepper Terminal Block Pin Assignment

1

2

3

4

5

6

The Step and Dir signals are used as command outputs to a stepper driver.

The Inhibit Output signals are used to disable the driver for that axis. The

UMI accessory combines the host bus interlock circuit, the Enable Input

signals, and the per axis controller Inhibit Output to create the per axis

Inhibit Output signal. If the voltage drops to the host bus interlock circuit,

if both Enable Inputs are deasserted, or if the controller Inhibit Output for

that axis is asserted, the Inhibit Output signal for that axis is asserted.

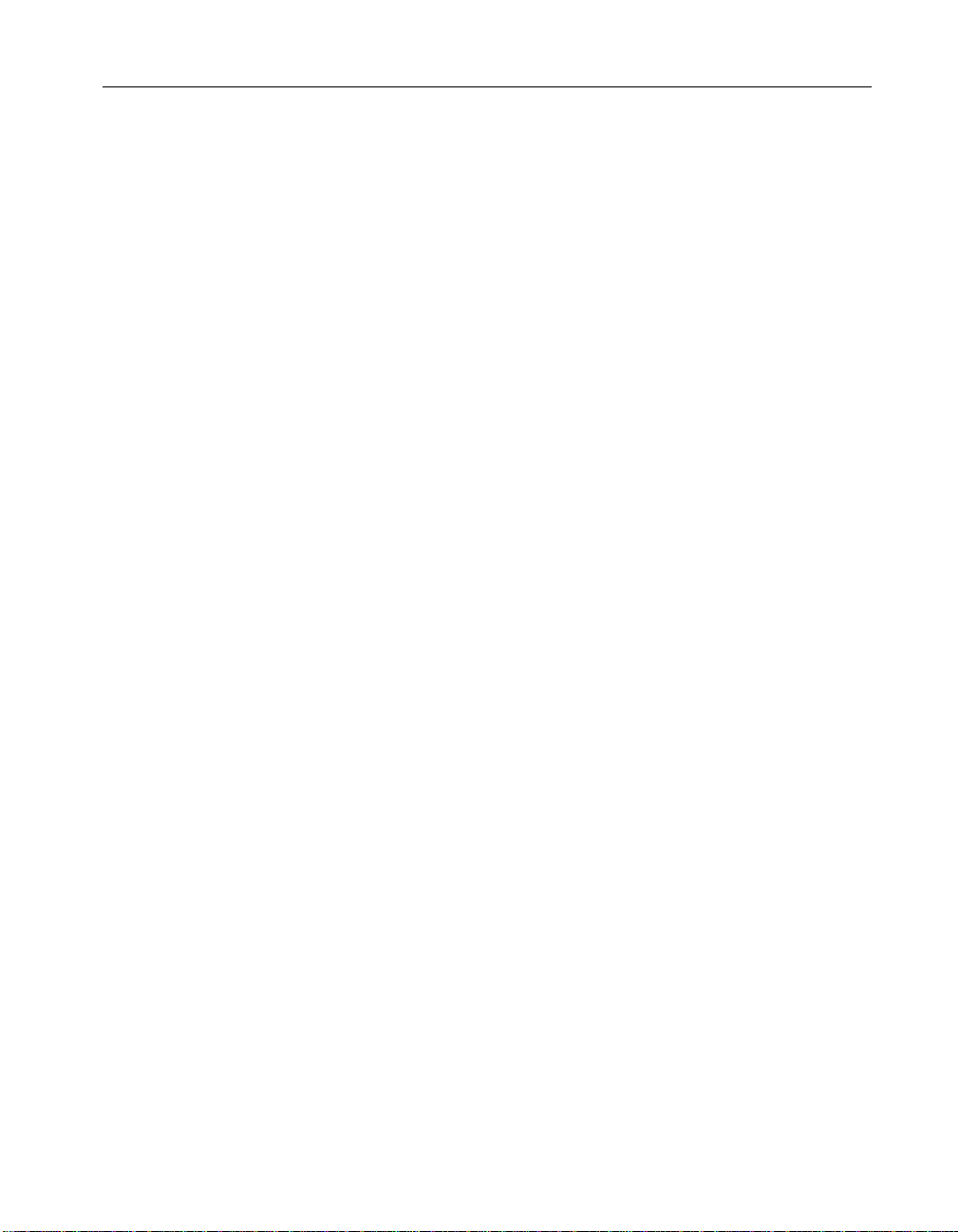

To configure your UMI-4A accessory for servo, move all four jumpers to

the right. T o conf igure your accessory for stepper , mo ve all four jumpers to

the left. See Figure 15 for more information on configuring your UMI-4A

jumpers. Refer to Figure 12 to help you locate the jumpers on your

UMI-4A accessory.

Servo Stepper

Figure 15. UMI-4A Jumper Configuration

UMI Accessory User Guide — UMI-4A 14 www.natinst.com

Page 15

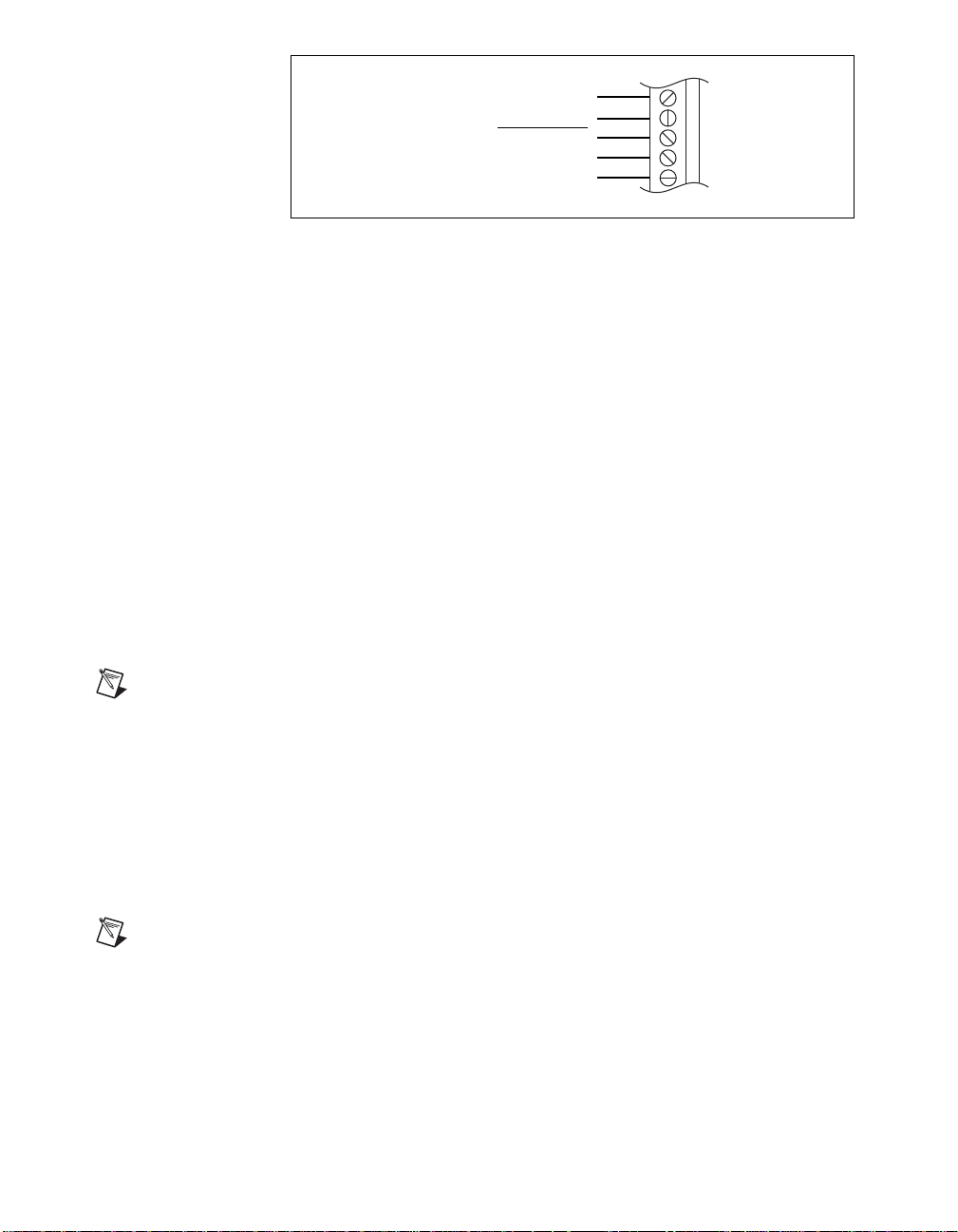

Encoder Terminal Block

For incremental encoder connections, each UMI-4A axis has a separate

8-position terminal block. UMI-4A accepts either single-ended TTL or

differential line driver inputs. You can connect open-collector encoders to

the UMI-4A accessory by installing a 2.2 kΩ pull-up resistor to +5 V.

Note

Encoders with line driver outputs are recommended for all applications and must be

used if the encoder cable length is greater than 10 feet.

Power for the encoders is internally routed from the power input terminal

block and is available on pin 7 (+5 V). You must supply a +5 V source to

the power input terminal block for proper operation. Refer to Figure 12 to

help you locate the encoder terminal blocks on your UMI-4A accessory.

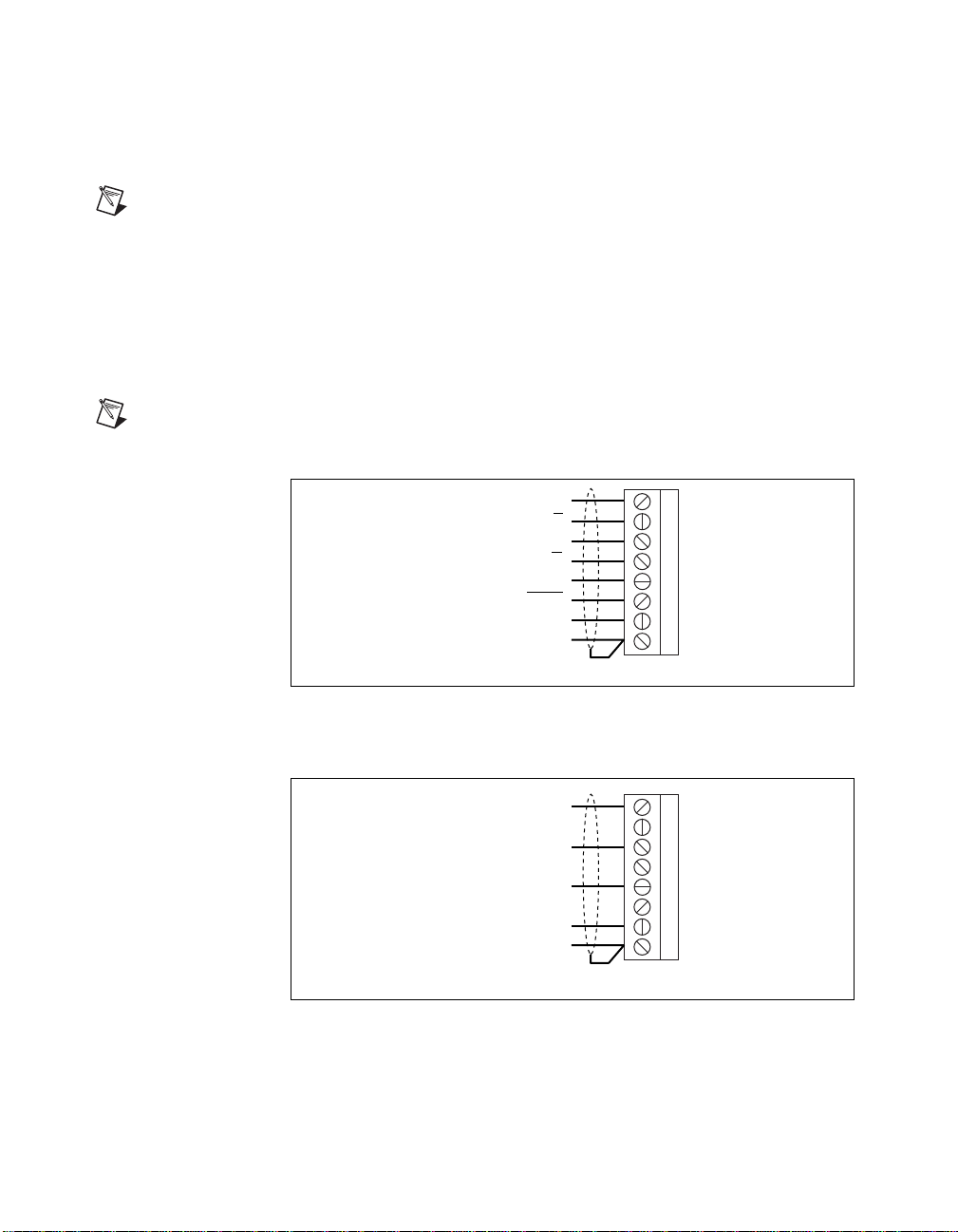

Figure 16 shows the wiring for the differential encoder.

Note

The dotted loop indicates a shielded cable.

Phase A

Phase A

Phase B

Phase B

+5 V (Output)

Digital Ground

Figure 16.

Index

Index

Shield

Differential Encoder Wiring

1

2

3

4

5

6

7

8

Figure 17 shows the wiring for the single-ended encoder.

+5 V (Output)

Digital Ground

Figure 17.

Phase A

Phase B

Index

Shield

Single-Ended Encoder Wiring

1

2

3

4

5

6

7

8

© National Instruments Corporation 15 UMI Accessory User Guide — UMI-4A

Page 16

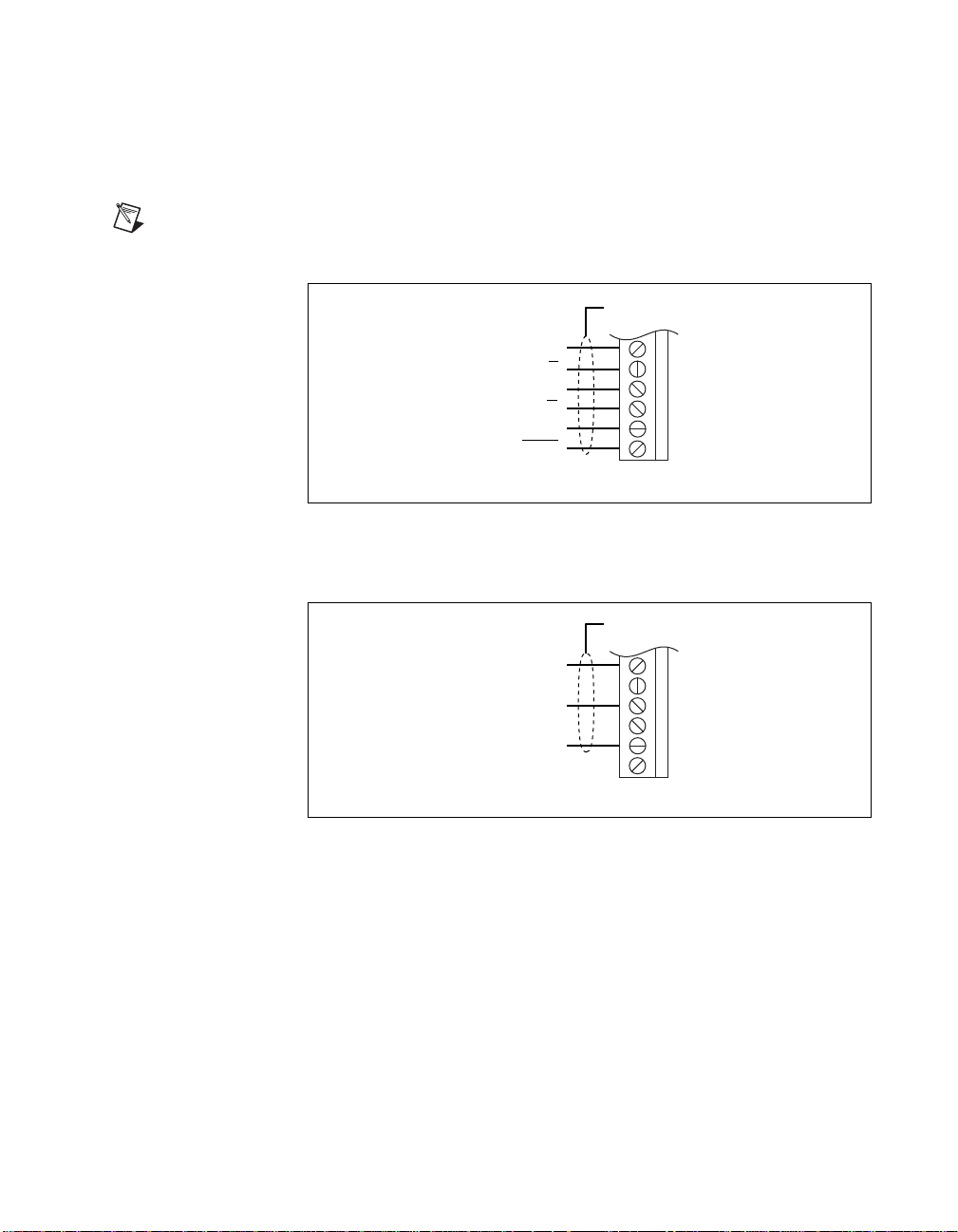

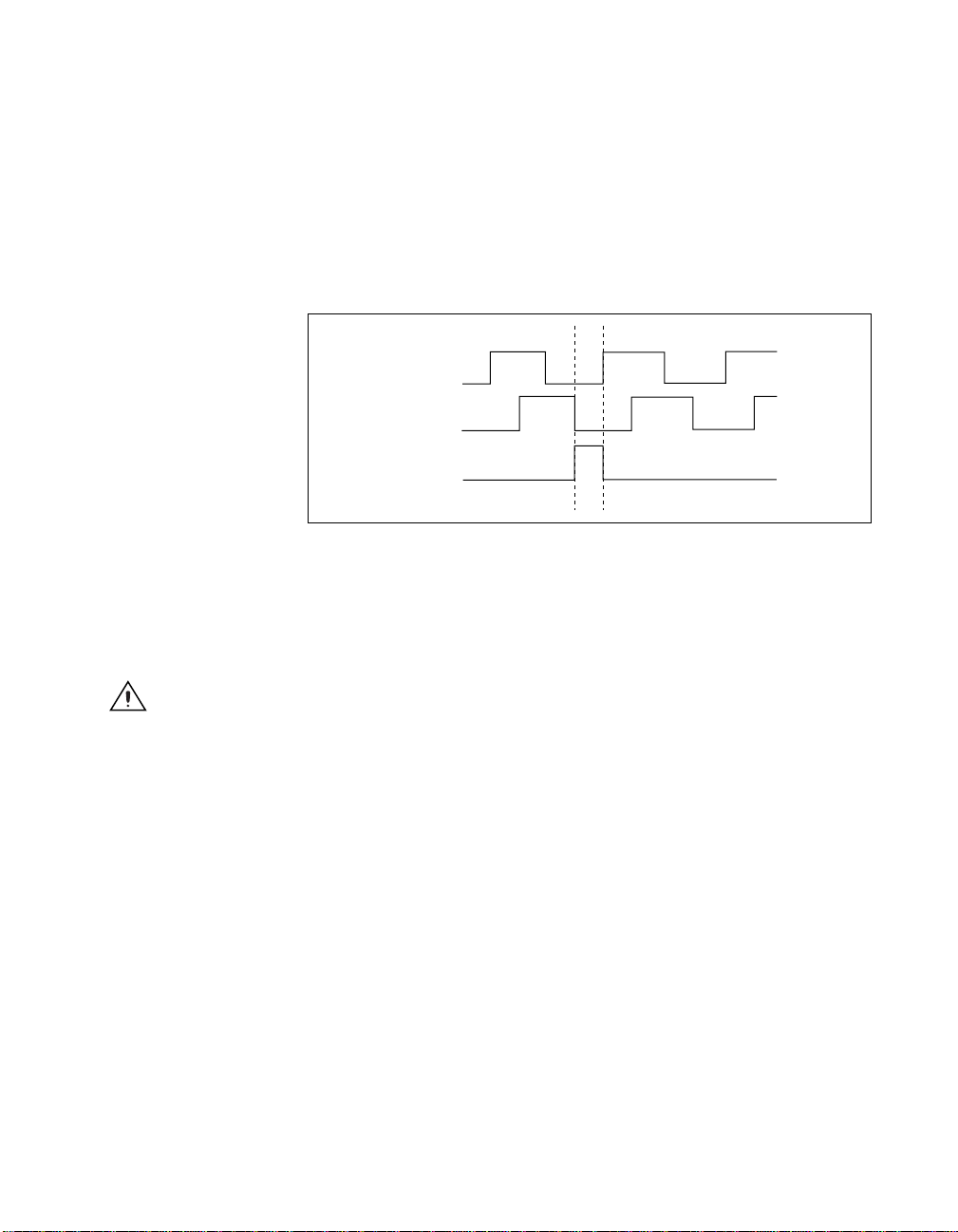

The UMI-4A accessory allows for diff erential inputs for Phase A, Phase B,

and Index signals. You can easily accommodate encoders with phase

relationships different from Figure 18 by swapping the signals as required

by the specific application. The Index pulse must occur when both Phase A

and Phase B signals are logic low as shown in Figure 7. Servo and

closed-loop stepper applications require encoder feedback and consistent

directional polarity between the motor and encoder for stable operation.

The UMI-4A uses the following standards for motor direction:

• Positive = forward = Clockwise (CW) facing motor shaft

• Negativ e = reverse = Counter-clockwise (CCW) facing motor shaft

Phase A

Phase B

Index

Figure 18. Encoder Signal Phasing—CW Rotation

The encoder inputs are filtered by both analog and digital noise filters. You

must use cables with twisted pairs and an overall shield for improved noise

immunity . When connecting the encoder to the UMI-4A, you should use at

least 24-AWG wire.

Caution Using an unshielded cable allows noise to corrupt the encoder signals, which

results in lost counts, reduced accuracy, and other erroneous encoder and controller

operations.

Limit Switch Terminal Block

For forward and reverse limit and home switch connections, each UMI-4A

has a separate 6-position terminal block per axis. All limit and home switch

inputs are filtered on the UMI-4A to enhance noise immunity.

The UMI-4A supports active and passive limit switches. You can use

auxiliary VDC on pin 4 to power active, open-collector limit switches. To

use the auxiliary VDC you must supply a voltage to the auxiliary VDC

input (pin 2 of the power input terminal block). Refer to Figure 12 to help

you locate the limit switch terminal block on your UMI-4A accessory.

Figure 19 shows an example of a passive limit switch terminal block

pinout.

UMI Accessory User Guide — UMI-4A 16 www.natinst.com

Page 17

Figure 19. UMI-4A Limit Switch Terminal Block Pin Assignment

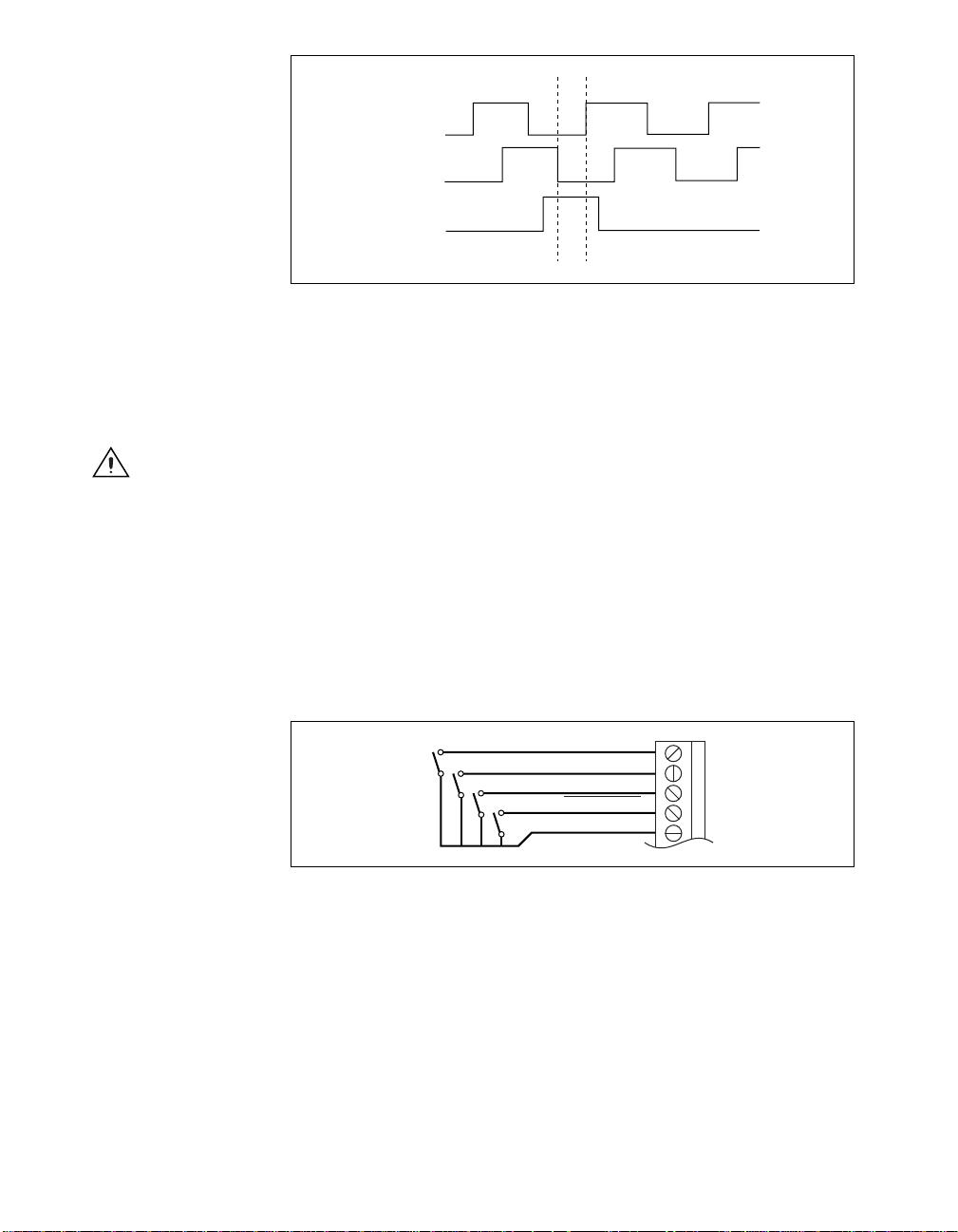

Digital I/O Terminal Blocks

The UMI-4A has two I/O connectors: a 34-pin male box header (J19),

which is compatible with standard Opto 22 I/O racks, and two 6-pin

removable screw terminal blocks (J10 and J11) for all other I/O

configurations. You can use both I/O configurations separately or in

parallel.

Pin 5 of each terminal block (J10 and J11) is an Enable Input connection.

This connection controls a system enable–system inhibit function. If your

configuration uses the inhibit output signal available on each per-axis

driver/amplifier terminal block, the enable input on J10 or J11 must be

connected to the common (ground) signal to enable the driver/amplifier.

Note You do not need to duplicate the switch on both J10 and J11; use only one or the

other for the Enable Input.

Forward Limit

Home Switch

Reverse Limit

Aux. VDC

+5 V (Output)

Digital Ground

1

2

3

4

5

6

(Passive Limit Switch Connection Example)

J10 J11

I/O 1

I/O 2

I/O 3

I/O 4

Enable Input

Digital Ground

1

Reserved when used with a stepper board. Do not connect anything to these pins.

1

2

3

4

5

6

or

Enable Input

Digital Ground

I/O 5

I/O 6

I/O 7

I/O 8

1

1

1

1

1

2

3

4

5

6

Figure 20. Using Available Pins On J10 and J11

Caution

If you connect the enable input to the common signal and bypass the

enable/disable function, you need to provide enable/disable control of the

drivers/amplifiers elsewhere in the system.

© National Instruments Corporation 17 UMI Accessory User Guide — UMI-4A

Page 18

Figure 21 shows the 34-pin Opto 22 compatible connector.

Figure 21. 34-Pin Opto 22 Compatible Connector Pin Assignment

Power Input Terminal Block

The UMI-4A has a 4-position terminal block for wiring power to the unit.

Refer to Figure 12 to help you locate the power input terminal block on

your UMI-4A accessory. Figure 11 shows the 4-position terminal block

pinout.

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

I/O Bit 8

I/O Bit 7

I/O Bit 6

I/O Bit 5

I/O Bit 4

I/O Bit 3

I/O Bit 2

I/O Bit 1

N/C

12

34

56

78

910

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25 26

27 28

29 30

31 32

33 34

Digital Ground

Digital Ground

Digital Ground

Digital Ground

Digital Ground

Digital Ground

Digital Ground

Digital Ground

Digital Ground

Digital Ground

Digital Ground

Digital Ground

Digital Ground

Digital Ground

Digital Ground

Digital Ground

Digital Ground

+5 V

Aux. VDC

NC

Digital Ground

1

2

3

4

Figure 22. 4-Position Power Input Terminal Block Pin Assignment

Note

To properly operate your UMI-4A accessory, you must supply a +5 V source to the

power input terminal block.

Note The auxiliary VDC input on the power input terminal block is optional and is

redistributed to other terminal blocks as an output power source.

UMI Accessory User Guide — UMI-4A 18 www.natinst.com

Page 19

UMI-4A Specifications

The following specifications apply only to the UMI-4A accessory. To

obtain a system specification, you must account for your motion controller.

Please refer to your controller specifications to determine overall system

specifications.

Some signals have compatibility defined as signal pass-through. This

means the UMI-4A may have passive f iltering on these signals but will not

affect the voltage range or current handling capability . Consult your motion

controller specifications to determine the allowable voltage range and logic

level compatibility of the signal.

These specifications are typical at 25 °C unless otherwise specified. Refer

to your motion controller user manual for detailed specifications on

encoder inputs, limit and home switch inputs, breakpoint outputs, trigger

inputs, and analog inputs.

Encoder Interface (Each Axis)

Inputs......................................................Quadrature, incremental

Differential input threshold....................±0.3 V (typical)

Single-ended input threshold .................TTL/CMOS

Voltage range.........................................0 to 5 VDC

Noise filter (RC time constant)..............100 ns

Max quadrature frequency .....................1 MHz

Limit and Home Switch Inputs (Each Axis)

Noise filter (RC time constant)..............10 µs

Compatibility .........................................Signal pass-through

Configurable I/O

Compatibility .........................................Signal pass-through

Opto 22 compatible................................via J19 connector

© National Instruments Corporation 19 UMI Accessory User Guide — UMI-4A Specifications

Page 20

Operating Environment

Temperature ............................................0 to 55 °C

Storage temperature................................–20 to 70 °C

Relative humidity ...................................10 to 90% (noncondensing)

Power Requirements

+5 VDC...................................................0.2 A + user-defined encoder

Aux. VDC...............................................User-defined limit switch power

Host Bus Voltage Interlock

Voltage....................................................5 VDC ± 5%

Physical

Dimensions.............................................23.62 by 10.03 cm

power

(9.3 by 3.95 in.)

Universal DIN-rail base

(supplied)

UMI Accessory User Guide — UMI-4A Specifications 20 www.natinst.com

Page 21

UMI-Flex6

This section describes the UMI-Flex6 terminal block. Refer to Figure 23 to

help you locate the different parts of the UMI-Flex6 accessory.

23

*

25

Amplifier

Connectors

1 Axis 1 (J18)

2 Axis 2 (J19)

3 Axis 3 (J20)

4 Axis 4 (J21)

5 Axis 5 (J22)

6 Axis 6 (J23)

18 1617

Encoder

Connectors

7 Axis 1 (J2)

8 Axis 2 (J4)

9 Axis 3 (J6)

10 Axis 4 (J8)

11 Axis 5 (J10)

12 Axis 6 (J12)

5

Limits

Connectors

13 Axis 1 (J3)

14 Axis 2 (J5)

15 Axis 3 (J7)

16 Axis 4 (J9)

17 Axis 5 (J11)

18 Axis 6 (J13)

46

Figure 23.

14

2

7911

1

19

24

1315

Miscellaneous

21 Breakpoint Connector (J15)

22 Power Connector (J26)

23 FlexMotion Controller (J1)

24 Switches

25 Assembly and serial

number (bottom)

3

81012

Analog Input

Connectors

19 1-4 (J14)

20 5-8 (J16)

UMI-Flex6 Parts Locator Diagram

20

21

22

Amplifier/Driver Terminal Block

For amplifier/driver wiring, each UMI-Flex6 axis has a separate 5- or

7-position terminal block. Refer to Figure 23 to help you locate the

amplifier/driver terminal blocks on your UMI-Flex6 accessory. Figure 24

shows the UMI-Flex6 amplifier/driver terminal block pin assignment for

the servo and combined servo/stepper axes. The 5-position UMI-Flex6

terminal block supports the servo axes, and the 7-position terminal block

adds stepper support.

© National Instruments Corporation 21 UMI Accessory User Guide — UMI-Flex6

Page 22

Analog Output

Analog Output Ground

+5 V (Output)

Digital Ground

Inhibit Output

Axes 1–4 Axes 5–6

Figure 24. UMI-Flex6 Axes Amplifier/Driver Terminal Block Pin Assignments

The Analog Output signals are used as command outputs to a servo

amplifier or as general-purpose voltage outputs. The Step and Dir signals

are used as command outputs to a stepper driver.

The Inhibit Output signals are used to disable the amplifier/driver for that

axis. The UMI combines the host bus interlock circuit, the Inhibit Input

signals, and the per axis controller Inhibit Output to create the per axis

Inhibit Output signal. The host bus interlock monitors the +5 V pin from

the motion controller to verify that the controller is powered and properly

connected to the UMI. If the host bus interlock detects a problem, or if any

Inhibit Input signal is asserted, or the controller Inhibit Output signal for

that axis is asserted, the Inhibit Output for that axis is asserted.

You can configure the Axis Inhibit Out signal as active-low or active-high

outputs using switch SW2. Setting SW2 to the right configures the signal

as active-low; setting SW2 to the left configures the signal as active-high.

Analog Output Ground

1

2

3

4

5

Analog Output

+5 V (Output)

Digital Ground

Inhibit Output

Step (CW)

Dir (CCW)

1

2

3

4

5

6

7

Note You must configure the controller’s Inhibit Output signals as active low for proper

operation of the inhibit circuitry.

Encoder Terminal Block

For incremental encoder connections, each UMI-Flex6 axis has a separate

8-position terminal block. UMI-Flex6 accepts either single-ended TTL or

differential line driver inputs. You can connect open-collector encoders to

the UMI-Flex6 accessory by installing a 2.2 kΩ pull-up resistor to +5 V.

Note Encoders with line driver outputs are recommended for all applications and must be

used if the encoder cable length is greater than 10 feet.

UMI Accessory User Guide — UMI-Flex6 22 www.natinst.com

Page 23

Power for the encoders is internally routed from the power input terminal

block and is available on pin 7 (+5 V). You must supply a +5 V source to

the power input terminal block for proper operation. Refer to Figure 23 to

help you locate the encoder terminal blocks on your UMI-Flex6 accessory .

Figure 25 shows the wiring for the differential encoder.

Note The dotted loop indicates a shielded cable.

Phase A

Phase A

Phase B

Phase B

Index

Index

+5 V (Output)

Digital Ground

Shield

1

2

3

4

5

6

7

8

Figure 25. Differential Encoder Wiring

Figure 26 shows the wiring for the single-ended encoder.

Phase A

Phase B

Index

+5 V (Output)

Digital Ground

Shield

Figure 26. Single-Ended Encoder Wiring

1

2

3

4

5

6

7

8

The UMI-Flex6 accessory allows for differential inputs for Phase A,

Phase B, and Index signals. You can easily accommodate encoders with

phase relationships different from Figure 27 by swapping the signals as

required by the specific application. The Inde x pulse must occur when both

Phase A and Phase B signals are logic low as sho wn in Figure 27. Servo and

closed-loop stepper applications require encoder feedback and consistent

directional polarity between the motor and encoder for stable operation.

The UMI-Flex6 uses the following standards for motor direction:

• Positive = forward = Clockwise (CW) facing motor shaft

• Negativ e = reverse = Counter-clockwise (CCW) facing motor shaft

© National Instruments Corporation 23 UMI Accessory User Guide — UMI-Flex6

Page 24

The encoder inputs are filtered by both analog and digital noise filters. You

must use cables with twisted pairs and an overall shield for improved noise

immunity . When connecting the encoder to the UMI-Flex6, you should use

at least 24-AWG wire.

Caution Using an unshielded cable allows noise to corrupt the encoder signals, which

results in lost counts, reduced accuracy, and other erroneous encoder and controller

operations.

Limit Switch Terminal Block

For Forward and Reverse Limit and Home Input switch connections, each

UMI-Flex6 axis has a separate 6-position terminal block. All limit and

home switch inputs are connected to the Opto-coupled inputs on the

FlexMotion board. Refer to Figure 23 to help you locate the limit switch

terminal block on your UMI-Flex6 accessory. See Figure 28 for the

UMI-Flex6 limit switch terminal block pinout.

Phase A

Phase B

Index

Figure 27. Encoder Signal Phasing—CW Rotation

Forward Limit

Home Input

Reverse Limit

Trigger Input

Inhibit Input

ISO Common

1

NC on Axis 5 and 6

1

1

2

3

4

5

6

Figure 28. UMI-Flex6 Limit Switch Terminal Block Pin Assignment

UMI Accessory User Guide — UMI-Flex6 24 www.natinst.com

Page 25

You can configure the functionality of the Inhibit Inputs using switches

SW1 and SW3. These inputs can be configured as a group as active low

global inhibits or as active high global E-Stops. When configured as global

inhibits, an active low signal applied to any input asserts the inhibit output

lines on the UMI. When configured as global E-Stops, an active high signal

applied to any input asserts the inhibit output lines on the UMI and asserts

the E-Stop signal back to the FlexMotion controller . See Table 1 for switch

SW1 and SW3 settings.

SW1 SW3 Inhibit Input Configuration

Right Right Enable active low global inhibits

Left Left Enable active high global E-Stops

Left Right Disable active high global E-Stops

Right Left Reserved, do not select.

*

This grounds the input signal on the board. Do not connect a source to the input pin that

cannot tolerate a short to ground.

Analog Input Terminal Blocks

For analog input wiring, the UMI-Flex6 has two, 6-position terminal

blocks. Each connector provides access to four of the eight analog input

channels on the FlexMotion boards. Refer to Figure 23 to help you locate

the analog input terminal blocks on your UMI-Flex6 accessory. See

Figures 29 and 30 for analog input terminal block pinout information.

Table 1.

Analog Reference (Output)

Inhibit Input Configuration

Analog Input 1

Analog Input 2

Analog Input 3

Analog Input 4

Analog Input Ground

*

1

2

3

4

5

6

Figure 29.

Figure 30.

© National Instruments Corporation 25 UMI Accessory User Guide — UMI-Flex6

UMI-Flex6 Analog Input Channels 1 through 4

Analog Input Channel 5

Analog Input Channel 6

Analog Input Channel 7

Analog Input Channel 8

Analog Reference (Output)

Analog Input Ground

UMI-Flex6 Analog Input Channels 5 through 8

1

2

3

4

5

6

Page 26

Breakpoint Output Terminal Block

For breakpoint output wiring, the UMI-Flex6 has a 6-position terminal

block. This terminal block also provides access to the four breakpoint

outputs as well as the isolated voltage input. See Figure 31 for more

information on breakpoint output and isolated voltage input wiring.

Figure 31.

The opto-couplers on the FlexMotion board can be powered either from an

external source or from the FlexMotion board itself. If you want to use an

external source for the isolated voltage, you must configure the Fle xMotion

board for this setting prior to connecting the external source.

Caution

Failure to configure the board properly for an external power source may damage

your UMI and FlexMotion board.

Power Input Terminal Block

The UMI-Flex6 has a 4-position terminal block for wiring power to the

unit. Refer to Figure 23 to help you locate the power input terminal block

on your UMI-Flex6 accessory. Figure 32 shows the 4-position terminal

block pinout.

Breakpoint 1

Breakpoint 2

Breakpoint 3

Breakpoint 4

Isolated Voltage (Input)

Isolated Common

UMI-Flex6 Breakpoint Output Channels 1 through 4

1

2

3

4

5

6

+5 V

NC

NC

Digital Ground

Figure 32.

Note

To properly operate your UMI-Flex6 accessory, you must supply a +5 V source to

4-Position Power Input Terminal Block Pin Assignment

1

2

3

4

the power input terminal block.

Note

The +5 V power is redistributed to other terminal blocks as an output power source.

UMI Accessory User Guide — UMI-Flex6 26 www.natinst.com

Page 27

UMI-Flex6 Specifications

The following specifications apply only to the UMI-Flex6 accessory. To

obtain a system specification, you must account for your motion controller.

Please refer to your controller specifications to determine overall system

specifications.

These specifications are typical at 25 °C unless otherwise specified. Refer

to your motion controller user manual for detailed specifications on

encoder inputs, limit and home switch inputs, high speed inputs, breakpoint

outputs, and analog inputs.

Axis Inhibit Out

Voltage range.........................................0 to 5 VDC

Output current........................................16 mA sink max.

Operating Environment

Temperature...........................................0 to 55 °C

Storage temperature . ..............................–20 to 70 °C

Relative humidity...................................10 to 90% (noncondensing)

Power Requirements

+5 VDC..................................................0.2 A + user-defined encoder and

limit power

+ISO

Voltage...................................................5 to 24 VDC

Current ...................................................User-defined isolated signals

Host Bus Voltage Interlock

Voltage...................................................5 VDC ± 5%

Physical

Dimensions.............................................26.67 by 11.18 cm

(10.5 by 4.4 in)

© National Instruments Corporation 27 UMI Accessory User Guide — UMI-Flex6 Specifications

Page 28

UMI-Flex4

This section describes the UMI-Flex4 terminal block. Refer to Figure 33 to

help you locate the different parts of the UMI-Flex4 accessory.

17

Amplifier

Connectors

1 Axis 1 (J13)

2 Axis 2 (J14)

3 Axis 3 (J15)

4 Axis 4 (J16)

4

19

Encoder

Connectors

5 Axis 1 (J2)

6 Axis 2 (J4)

7 Axis 3 (J6)

8 Axis 4 (J8)

8

12

Limits

Connectors

9 Axis 1 (J3)

10 Axis 2 (J5)

11 Axis 3 (J7)

12 Axis 4 (J9)

18

7

3

11

2

6

5

10

Other

Connectors

13 Analog Input (J10)

14 Breakpoint Output

(J11)

15 Power (J18)

9

1

13

14 20

Miscellaneous

16 FlexMotion Controller (J1)

17 Jumpers

18 Assembly Number

19 Serial Number

20 Reserved—Do not remove

1516

Figure 33.

UMI-Flex4 Parts Locator Diagram

Amplifier/Driver Terminal Block

For amplifier/driver wiring, the UMI-Flex4 has four separate 6-position

terminal blocks. Figure 34 shows a UMI-Flex4 terminal block pin

assignment. The first two terminal blocks (items 1 and 2 in Figure 33) are

dedicated to servo axes 1 and 2. The third terminal block (item 3 in

Figure 33) is jumper configurable to support servo axes 3 and 5 and stepper

axis 5. The fourth terminal block (item 4 in Figure 33) is jumper

configurable to support servo axes 4 and 6 and stepper axis 6. See Figure 35

for more information on configuring these jumpers.

UMI Accessory User Guide — UMI-Flex4 28 www.natinst.com

Page 29

Analog Output or Step

Analog Output Ground or Dir

+5 V (Output)

Digital Ground

Inhibit Output

NC

1

2

3

4

5

6

Figure 34. UMI-Flex4 Axes Amplifier/Driver Terminal Block Pin Assignment

The Analog Output signals are used as command outputs to a servo

amplifier or as general-purpose voltage outputs. The Step and Dir signals

are used as command outputs to a stepper driver.

The Inhibit Output signals are used to disable the amplifier/driver for that

axis. The UMI combines the host bus interlock circuit, the per axis Inhibit

Input signals, and the per axis controller Inhibit Output to create the per

axis Inhibit Output signal. The host bus interlock monitors the +5 V pin

from the motion controller to verify that the controller is powered and

properly connected to the UMI. If the host bus interlock detects a problem,

or if the Inhibit Input signal or the controller Inhibit Output signal for that

axis is asserted, the Inhibit Output for that axis is asserted.

Note You must configure the controller’s Inhibit Output signals as active-low for proper

operation of the inhibit circuitry.

Axis 3

Analog Output

Analog Output Ground

JP2 Jumper Configuration for J15

Axis 4

Analog Output

Analog Output Ground

JP3 Jumper Configuration for J16

Axis 5

Analog Output

Analog Output Ground

Axis 6

Analog Output

Analog Output Ground

Axis 5

Step

Dir

Axis 6

Step

Dir

Figure 35. UMI-Flex4 Jumper Configuration

© National Instruments Corporation 29 UMI Accessory User Guide — UMI-Flex4

Page 30

Encoder Terminal Block

For incremental encoder connections, each UMI-Flex4 axis has a separate

8-position terminal block. UMI-Flex4 accepts either single-ended TTL or

differential line driver inputs. You can connect open-collector encoders to

the UMI-Flex4 accessory by installing a 2.2 kΩ pull-up resistor to +5 V.

Note

Encoders with line driver outputs are recommended for all applications and must be

used if the encoder cable length is greater than 10 feet.

Power for the encoders is internally routed from the power input terminal

block and is available on pin 7 (+5 V). You must supply a +5 V source to

the power input terminal block for proper operation. Refer to Figure 33 to

help you locate the encoder terminal blocks on your UMI-Flex4 accessory .

Figure 36 shows the wiring for the differential encoder.

Note

The dotted loop indicates a shielded cable.

Phase A

Phase A

Phase B

Phase B

+5 V (Output)

Digital Ground

Figure 36.

Index

Index

Shield

Differential Encoder Wiring

1

2

3

4

5

6

7

8

Figure 37 shows the wiring for the single-ended encoder.

+5 V (Output)

Digital Ground

Figure 37.

Phase A

Phase B

Index

Shield

Single-Ended Encoder Wiring

1

2

3

4

5

6

7

8

UMI Accessory User Guide — UMI-Flex4 30 www.natinst.com

Page 31

The UMI-Flex4 accessory allows for differential inputs for Phase A,

Phase B, and Index signals. You can easily accommodate encoders with

phase relationships different from Figure 38 by swapping the signals as

required by the specific application. The Inde x pulse must occur when both

Phase A and Phase B signals are logic low as sho wn in Figure 38. Servo and

closed-loop stepper applications require encoder feedback and consistent

directional polarity between the motor and encoder for stable operation.

The UMI-Flex4 uses the following standards for motor direction:

• Positive = forward = Clockwise (CW) facing motor shaft

• Negativ e = reverse = Counter-clockwise (CCW) facing motor shaft

Phase A

Phase B

Index

Figure 38. Encoder Signal Phasing—CW Rotation

The encoder inputs are filtered by both analog and digital noise filters. You

must use cables with twisted pairs and an overall shield for improved noise

immunity . When connecting the encoder to the UMI-Flex4, you should use

at least 24-AWG wire.

Caution Using an unshielded cable allows noise to corrupt the encoder signals, which

results in lost counts, reduced accuracy, and other erroneous encoder and controller

operations.

© National Instruments Corporation 31 UMI Accessory User Guide — UMI-Flex4

Page 32

Limit Switch Terminal Block

For Forward and Reverse Limit and Home Input switch connections, the

UMI-Flex4 accessory has a separate 6-position terminal block per axis. All

limit and home switch inputs are connected to the opto-coupled inputs on

the FlexMotion board. Refer to Figure 33 to help you locate the limit switch

terminal block on your UMI-Flex4 accessory. See Figure 39 for the

UMI-Flex4 limit switch terminal block pinout.

Figure 39.

Analog Input Terminal Block

For analog input wiring, the UMI-Flex4 has one, 6-position terminal block.

The connector provides access to four of the eight analog input channels on

the FlexMotion boards. Refer to Figure 33 to help you locate the analog

input terminal blocks on your UMI-Flex4 accessory. See Figure 40 for

analog input terminal block pinout information.

Forward Limit

Home Input

Reverse Limit

Trigger Input

Inhibit Input

ISO Common

1

2

3

4

5

6

UMI-Flex4 Limit Switch Terminal Block Pin Assignment

Analog Input 1

Analog Input 2

Analog Input 3

Analog Input 4

Analog Reference (Output)

Analog Input Ground

Figure 40.

UMI-Flex4 Analog Input Channels 1 through 4

1

2

3

4

5

6

UMI Accessory User Guide — UMI-Flex4 32 www.natinst.com

Page 33

Breakpoint Output Terminal Block

For breakpoint output wiring, the UMI-Flex4 has a 6-position terminal

block. This terminal block also provides access to the four breakpoint

outputs as well as the isolated voltage input. See Figure 41 for more

information on breakpoint output and isolated voltage input wiring.

Figure 41.

The opto-couplers on the FlexMotion board can be powered either from an

external source or from the FlexMotion board itself. If you want to use an

external source for the isolated voltage, you must configure the Fle xMotion

board for this setting prior to connecting the external source.

Caution

Failure to configure the board properly for an external po wer source may damage

your UMI and FlexMotion board.

Power Input Terminal Block

The UMI-Flex4 has a 4-position terminal block for wiring power to the

unit. Refer to Figure 33 to help you locate the power input terminal block

on your UMI-Flex4 accessory. Figure 42 shows the 4-position terminal

block pinout.

Breakpoint 1

Breakpoint 2

Breakpoint 3

Breakpoint 4

Isolated Voltage (Input)

Isolated Common

UMI-Flex4 Breakpoint Output Channels 1 through 4

1

2

3

4

5

6

+5 V

NC

NC

Digital Ground

Figure 42.

Note

To properly operate your UMI-Flex4 accessory, you must supply a +5 V source to

4-Position Power Input Terminal Block Pin Assignment

1

2

3

4

the power input terminal block.

Note

The +5 V power is redistributed to other terminal blocks as an output power source.

© National Instruments Corporation 33 UMI Accessory User Guide — UMI-Flex4

Page 34

UMI-Flex4 Specifications

The following specifications apply only to the UMI-Flex4 accessory. To

obtain a system specification, you must account for your motion controller.

Please refer to your controller specifications to determine overall system

specifications.

These specifications are typical at 25 °C unless otherwise specified. Refer

to your motion controller user manual for detailed specifications on

encoder inputs, limit and home switch inputs, high speed inputs, breakpoint

outputs, and analog inputs.

Axis Inhibit Out

Voltage range..........................................0 to 5 VDC

Output current.........................................16 mA sink max.

Operating Environment

Temperature ............................................0 to 55 °C

Storage temperature................................–20 to 70 °C

Relative humidity ...................................10 to 90% (noncondensing)

Power Requirements

+5 VDC...................................................0.2 A + user-defined encoder

power

+ISO

Voltage....................................................5 to 24 VDC

Current....................................................User-defined isolated signals

Host Bus Voltage Interlock

Voltage....................................................5 VDC ± 5%

Physical

Dimensions.............................................23.62 by 10.03 cm

(9.3 by 3.95 in.)

Universal DIN-rail base

(supplied)

UMI Accessory User Guide — UMI-Flex4 Specifications 34 www.natinst.com

Page 35

Loading...

Loading...