National Instruments TPC-2206, TPC-2212, TPC-2215 User Manual

TPC-2206/TPC-2212/

TPC-2215

User Manual

TPC-2206/TPC-2212/TPC-2215 User Manual

October 2011

373297B-01

Support

Worldwide Technical Support and Product Information

ni.com

Worldwide Offices

Visit ni.com/niglobal to access the branch office Web sites, which provide up-to-date contact information,

support phone numbers, email addresses, and current events.

National Instruments Corporate Headquarters

11500 North Mopac Expressway Austin, Texas 78759-3504 USA Tel: 512 683 0100

For further support information, refer to the Technical Support and Professional Services appendix. To comment

on National Instruments documentation, refer to the National Instruments Web site at

the Info Code

feedback.

© 2010–2011 National Instruments Corporation. All rights reserved.

ni.com/info and enter

Important Information

Warranty

The TPC-2206, TPC-2212, and TPC-2215 are warranted against defects in materials and workmanship for a period of one year from the date

of shipment, as evidenced by receipts or other documentation. National Instruments will, at its option, repair or replace equipment that proves

to be defective during the warranty period. This warranty includes parts and labor.

The media on which you receive National Instruments software are warranted not to fail to execute programming instructions, due to defects in

materials and workmanship, for a period of 90 days from date of shipment, as evidenced by receipts or other documentation. National Instruments

will, at its option, repair or replace software media that do not execute programming instructions if National Instruments receives notice of such defects

during the warranty period. National Instruments does not warrant that the operation of the software shall be uninterrupted or error free.

A Return Material Authorization (RMA) number must be obtained from the factory and clearly marked on the outside of the package before any

equipment will be accepted for warranty work. National Instruments will pay the shipping costs of returning to the owner parts which are covered by

warranty.

National Instruments believes that the information in this document is accurate. The document has been carefully reviewed for technical accuracy. In

the event that technical or typographical errors exist, National Instruments reserves the right to make changes to subsequent editions of this document

without prior notice to holders of this edition. The reader should consult National Instruments if errors are suspected. In no event shall National

Instruments be liable for any damages arising out of or related to this document or the information contained in it.

XCEPT AS SPECIFIED HEREIN, NATIONAL INSTRUMENTS MAKES NO WARRANTIES, EXPRESS OR IMPLIED, AND SPECIFICALLY DISCLAIMS ANY WARRANTY OF

E

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. CUSTOMER’S RIGHT TO RECOVER DAMAGES CAUSED BY FAULT OR NEGLIGENCE ON THE PART OF NATIONAL

NSTRUMENTS SHALL BE LIMITED TO THE AMOUNT THERETOFORE PAID BY THE CUSTOMER. NATIONAL INSTRUMENTS WILL NOT BE LIABLE FOR DAMAGES RESULTING

I

FROM LOSS OF DATA, PROFITS, USE OF PRODUCTS, OR INCIDENTAL OR CONSEQUENTIAL DAMAGES, EVEN IF ADVISED OF THE POSSIBILITY THEREOF. This limitation of

the liability of National Instruments will apply regardless of the form of action, whether in contract or tort, including negligence. Any action against

National Instruments must be brought within one year after the cause of action accrues. National Instruments shall not be liable for any delay in

performance due to causes beyond its reasonable control. The warranty provided herein does not cover damages, defects, malfunctions, or service

failures caused by owner’s failure to follow the National Instruments installation, operation, or maintenance instructions; owner’s modification of the

product; owner’s abuse, misuse, or negligent acts; and power failure or surges, fire, flood, accident, actions of third parties, or other events outside

reasonable control.

Copyright

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or mechanical, including photocopying,

recording, storing in an information retrieval system, or translating, in whole or in part, without the prior written consent of National

Instruments Corporation.

National Instruments respects the intellectual property of others, and we ask our users to do the same. NI software is protected by copyright and other

intellectual property laws. Where NI software may be used to reproduce software or other materials belonging to others, you may use NI software only

to reproduce materials that you may reproduce in accordance with the terms of any applicable license or other legal restriction.

Trademarks

LabVIEW, National Instruments, NI, ni.com, the National Instruments corporate logo, and the Eagle logo are trademarks of National

Instruments Corporation. Refer to the Trademark Information at

Other product and company names mentioned herein are trademarks or trade names of their respective companies.

Members of the National Instruments Alliance Partner Program are business entities independent from National Instruments and have no agency,

partnership, or joint-venture relationship with National Instruments.

ni.com/trademarks for other National Instruments trademarks.

Patents

For patents covering National Instruments products/technology, refer to the appropriate location: Help»Patents in your software,

the patents.txt file on your media, or the National Instruments Patent Notice at ni.com/patents.

Export Compliance Information

Refer to the Export Compliance Information at ni.com/legal/export-compliance for the National Instruments global trade compliance

policy and how to obtain relevant HTS codes, ECCNs, and other import/export data.

WARNING REGARDING USE OF NATIONAL INSTRUMENTS PRODUCTS

(1) NATIONAL INSTRUMENTS PRODUCTS ARE NOT DESIGNED WITH COMPONENTS AND TESTING FOR A LEVEL OF

RELIABILITY SUITABLE FOR USE IN OR IN CONNECTION WITH SURGICAL IMPLANTS OR AS CRITICAL COMPONENTS IN

ANY LIFE SUPPORT SYSTEMS WHOSE FAILURE TO PERFORM CAN REASONABLY BE EXPECTED TO CAUSE SIGNIFICANT

INJURY TO A HUMAN.

(2) IN ANY APPLICATION, INCLUDING THE ABOVE, RELIABILITY OF OPERATION OF THE SOFTWARE PRODUCTS CAN BE

IMPAIRED BY ADVERSE FACTORS, INCLUDING BUT NOT LIMITED TO FLUCTUATIONS IN ELECTRICAL POWER SUPPLY,

COMPUTER HARDWARE MALFUNCTIONS, COMPUTER OPERATING SYSTEM SOFTWARE FITNESS, FITNESS OF COMPILERS

AND DEVELOPMENT SOFTWARE USED TO DEVELOP AN APPLICATION, INSTALLATION ERRORS, SOFTWARE AND HARDWARE

COMPATIBILITY PROBLEMS, MALFUNCTIONS OR FAILURES OF ELECTRONIC MONITORING OR CONTROL DEVICES,

TRANSIENT FAILURES OF ELECTRONIC SYSTEMS (HARDWARE AND/OR SOFTWARE), UNANTICIPATED USES OR MISUSES, OR

ERRORS ON THE PART OF THE USER OR APPLICATIONS DESIGNER (ADVERSE FACTORS SUCH AS THESE ARE HEREAFTER

COLLECTIVELY TERMED “SYSTEM FAILURES”). ANY APPLICATION WHERE A SYSTEM FAILURE WOULD CREATE A RISK OF

HARM TO PROPERTY OR PERSONS (INCLUDING THE RISK OF BODILY INJURY AND DEATH) SHOULD NOT BE RELIANT SOLELY

UPON ONE FORM OF ELECTRONIC SYSTEM DUE TO THE RISK OF SYSTEM FAILURE. TO AVOID DAMAGE, INJURY, OR DEATH,

THE USER OR APPLICATION DESIGNER MUST TAKE REASONABLY PRUDENT STEPS TO PROTECT AGAINST SYSTEM FAILURES,

INCLUDING BUT NOT LIMITED TO BACK-UP OR SHUT DOWN MECHANISMS. BECAUSE EACH END-USER SYSTEM IS

CUSTOMIZED AND DIFFERS FROM NATIONAL INSTRUMENTS' TESTING PLATFORMS AND BECAUSE A USER OR APPLICATION

DESIGNER MAY USE NATIONAL INSTRUMENTS PRODUCTS IN COMBINATION WITH OTHER PRODUCTS IN A MANNER NOT

EVALUATED OR CONTEMPLATED BY NATIONAL INSTRUMENTS, THE USER OR APPLICATION DESIGNER IS ULTIMATELY

RESPONSIBLE FOR VERIFYING AND VALIDATING THE SUITABILITY OF NATIONAL INSTRUMENTS PRODUCTS WHENEVER

NATIONAL INSTRUMENTS PRODUCTS ARE INCORPORATED IN A SYSTEM OR APPLICATION, INCLUDING, WITHOUT

LIMITATION, THE APPROPRIATE DESIGN, PROCESS AND SAFETY LEVEL OF SUCH SYSTEM OR APPLICATION.

Compliance

Electromagnetic Compatibility Information

This hardware has been tested and found to comply with the applicable regulatory requirements and limits for electromagnetic

compatibility (EMC) as indicated in the hardware’s Declaration of Conformity (DoC)

designed to provide reasonable protection against harmful interference when the hardware is operated in the intended

electromagnetic environment. In special cases, for example when either highly sensitive or noisy hardware is being used in close

proximity, additional mitigation measures may have to be employed to minimize the potential for electromagnetic interference.

While this hardware is compliant with the applicable regulatory EMC requirements, there is no guarantee that interference will

not occur in a particular installation. To minimize the potential for the hardware to cause interference to radio and television

reception or to experience unacceptable performance degradation, install and use this hardware in strict accordance with the

instructions in the hardware documentation and the DoC

If this hardware does cause interference with licensed radio communications services or other nearby electronics, which can be

determined by turning the hardware off and on, you are encouraged to try to correct the interference by one or more of the

following measures:

• Reorient the antenna of the receiver (the device suffering interference).

• Relocate the transmitter (the device generating interference) with respect to the receiver.

• Plug the transmitter into a different outlet so that the transmitter and the receiver are on different branch circuits.

Some hardware may require the use of a metal, shielded enclosure (windowless version) to meet the EMC requirements for

special EMC environments such as, for marine use or in heavy industrial areas. Refer to the hardware’s user documentation and

the DoC

When the hardware is connected to a test object or to test leads, the system may become more sensitive to disturbances or may

cause interference in the local electromagnetic environment.

Operation of this hardware in a residential area is likely to cause harmful interference. Users are required to correct the

interference at their own expense or cease operation of the hardware.

Changes or modifications not expressly approved by National Instruments could void the user’s right to operate the hardware

under the local regulatory rules.

1

for product installation requirements.

1

.

1

. These requirements and limits are

1

The Declaration of Conformity (DoC) contains important EMC compliance information and instructions for the user or

installer. To obtain the DoC for this product, visit

and click the appropriate link in the Certification column.

ni.com/certification, search by model number or product line,

Conventions

The following conventions are used in this manual:

» The » symbol leads you through nested menu items and dialog box options

to a final action. The sequence Options»Settings»General directs you to

pull down the Options menu, select the Settings item, and select General

from the last dialog box.

This icon denotes a note, which alerts you to important information.

This icon denotes a caution, which advises you of precautions to take to

avoid injury, data loss, or a system crash. When this symbol is marked on a

product, refer to the Safety section of Appendix A, Specifications, for

information about precautions to take.

When this symbol is marked on a product, it denotes a warning advising

you to take precautions to avoid electrical shock.

bold Bold text denotes items that you must select or click in the software, such

as menu items and dialog box options. Bold text also denotes parameter

names.

italic Italic text denotes variables, emphasis, a cross-reference, or an introduction

to a key concept. Italic text also denotes text that is a placeholder for a word

or value that you must supply.

monospace Text in this font denotes text or characters that you should enter from the

keyboard, sections of code, programming examples, and syntax examples.

This font is also used for the proper names of disk drives, paths, directories,

programs, subprograms, subroutines, device names, functions, operations,

variables, filenames, and extensions.

TPC-22xx Wherever this reference appears, the information applies to all three

versions of the TPC-22xx Human Machine Interface (HMI): the TPC-2206,

TPC-2212, and TPC-2215.

Contents

Chapter 1

General Information

Introduction....................................................................................................................1-1

I/O Ports.........................................................................................................................1-1

Chapter 2

System Setup

Important Safety Information ........................................................................................2-1

Setup ..............................................................................................................................2-2

Touchscreen Calibration..................................................................................2-3

Panel Mounting..............................................................................................................2-4

Chapter 3

Jumpers and Connectors

Jumper and Connector Functions ..................................................................................3-1

Jumper and Connector Locations ..................................................................................3-3

Appendix A

Specifications

Appendix B

Serial Port Settings

Appendix C

Features in Windows XP Embedded and Windows Embedded Standard 7

Appendix D

Touchscreen Configuration

Appendix E

Technical Support and Professional Services

Index

© National Instruments Corporation vii TPC-2206/TPC-2212/TPC-2215 User Manual

General Information

This chapter includes general information about the TPC-22xx Human

Machine Interface (HMI).

Introduction

The TPC-22xx touch panel computer, an HMI based on an x86 platform,

includes these key features:

• Powerful processing—The TPC-22xx uses the Intel Atom processor,

specifically designed for embedded, industrial applications.

• Fanless—By using an advanced but low-power Intel Atom processor,

the TPC-22xx does not require a fan for cooling.

• Robust communication—The TPC-22xx is a powerful I/O interface

for easy communication with other devices. The I/O interface includes

serial ports, gigabit Ethernet, and USB 2.0 support.

1

I/O Ports

• Wide operating temperature and isolation protection—The

TPC-22xx provides a –20 to 60 °C operating temperature range and

complete isolation protection for the serial ports.

• Windows Embedded support—The TPC-22xx supports the latest

embedded Windows operating systems from Microsoft, including

Windows XP Embedded (XPe) and Windows Embedded Standard 7

(WES7).

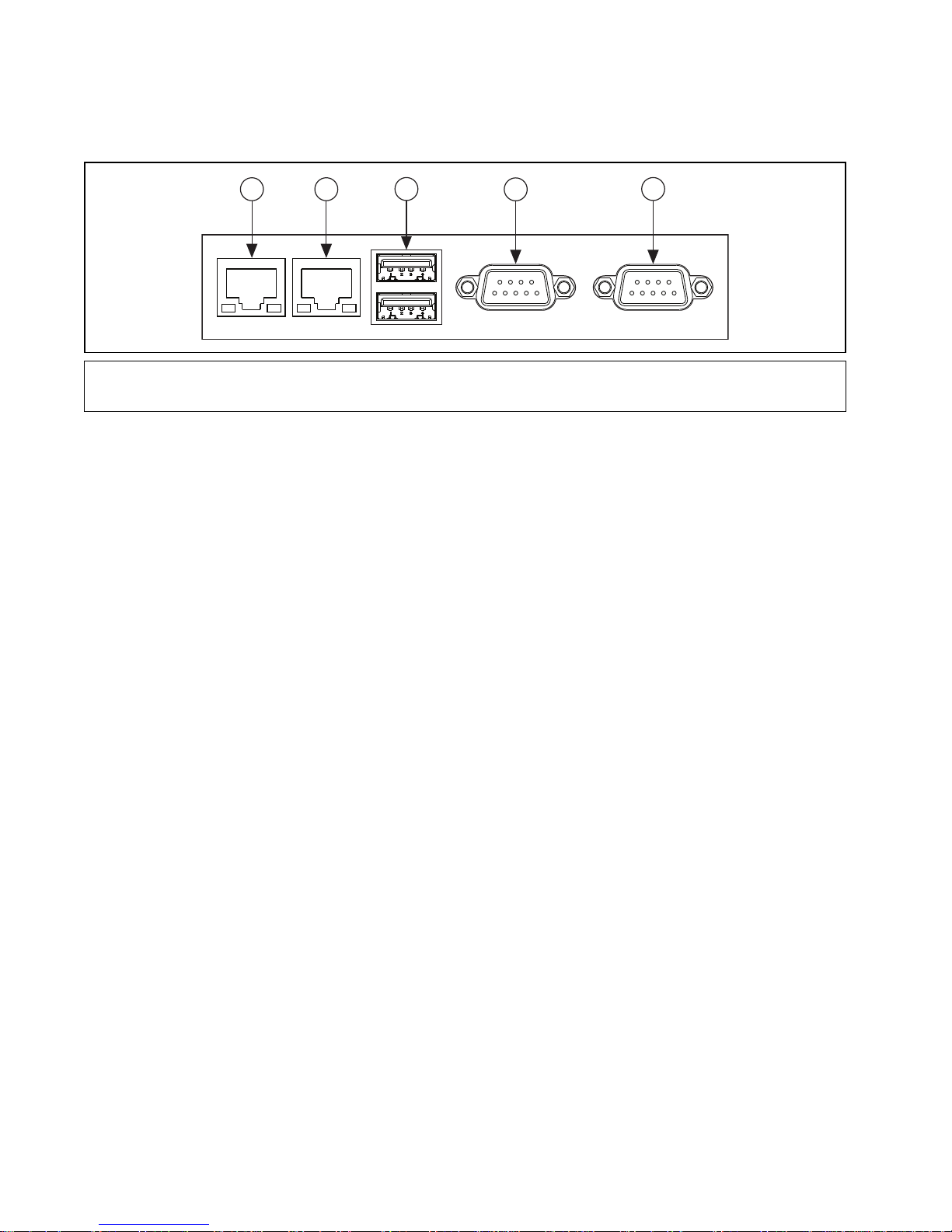

The TPC-22xx includes the following ports:

• Two serial ports: RS232 (COM1) and RS422/485 (COM2)

• Two USB 2.0 ports compliant with USB 1.0 and 1.1

• Two RJ-45 Gigabit Ethernet ports

© National Instruments Corporation 1-1 TPC-2206/TPC-2212/TPC-2215 User Manual

Chapter 1 General Information

Figure 1-1 shows the I/O port arrangement.

1LAN 1

2LAN 2

1 2

3USB

4 COM2 (RS422/485)

3

4

5 COM1 (RS232)

5

Figure 1-1. I/O Port Arrangement

For more TPC-22xx specifications, refer to Appendix A, Specifications.

TPC-2206/TPC-2212/TPC-2215 User Manual 1-2 ni.com

System Setup

This chapter includes setup information for the TPC-22xx.

Important Safety Information

Before setting up the TPC-22xx, read these safety instructions carefully.

Disconnect this equipment from any AC outlet before cleaning. Use a damp

cloth. Do not use liquid or spray detergents for cleaning.

For plug-in equipment, the power outlet socket must be located near the

equipment and must be easily accessible.

Keep this equipment away from excessive humidity.

2

Place this equipment on a reliable surface during installation. Dropping it

or letting it fall may cause damage.

The openings on the enclosure are for air convection and protect the

equipment from overheating. Do not cover the openings.

Make sure the power source voltage is correct before connecting the

equipment to the power outlet.

Position the power cord so that it cannot be stepped on. Do not place

anything over the power cord.

All cautions and warnings on the equipment should be noted.

If the equipment is not used for a long time, disconnect it from the power

source to avoid damage by transient overvoltage.

Never pour any liquid into an opening. This may cause fire or electrical

shock.

Never open the equipment. For safety reasons, only qualified service

personnel should open the equipment.

© National Instruments Corporation 2-1 TPC-2206/TPC-2212/TPC-2215 User Manual

Chapter 2 System Setup

Caution There is a danger of explosion if the battery is incorrectly replaced. Replace the

battery only with the same or equivalent type recommended by the manufacturer. Discard

used batteries according to the manufacturer’s instructions.

If one of the following situations arises, have service personnel check the

equipment:

• The power cord or plug is damaged.

• Liquid has penetrated into the equipment.

• The equipment has been exposed to moisture.

• The equipment does not work well, or you cannot get it to work

according to the user manual.

• The equipment has been dropped and damaged.

• The equipment has obvious signs of breakage.

Do not leave this equipment in an environment where the storage

temperature may go below –30 °C (–22 °F) or above 80 °C (176 °F). Doing

so could damage the equipment. The equipment should be in a controlled

environment.

Setup

The sound pressure level at the operator’s position according to

IEC 704-1:1982 is no more than 70 dB (A).

Caution The protection this equipment provides may be impaired if it is used in a manner

not described in this manual.

Follow these steps to set up the TPC-22xx:

1. Unpack the TPC-22xx. Be sure your kit includes the following items:

• The TPC-22xx HMI

• Six panel mounting clamps (TPC-2206)

• Six panel mounting screws (TPC-2206)

• Eight panel mounting clamps (TPC-2212 and TPC-2215)

• Eight panel mounting screws (TPC-2212 and TPC-2215)

• One 3-pin power connector

• One HMI Resource CD

TPC-2206/TPC-2212/TPC-2215 User Manual 2-2 ni.com

• One earth ground cable

If any items are missing or damaged, contact National Instruments.

Chapter 2 System Setup

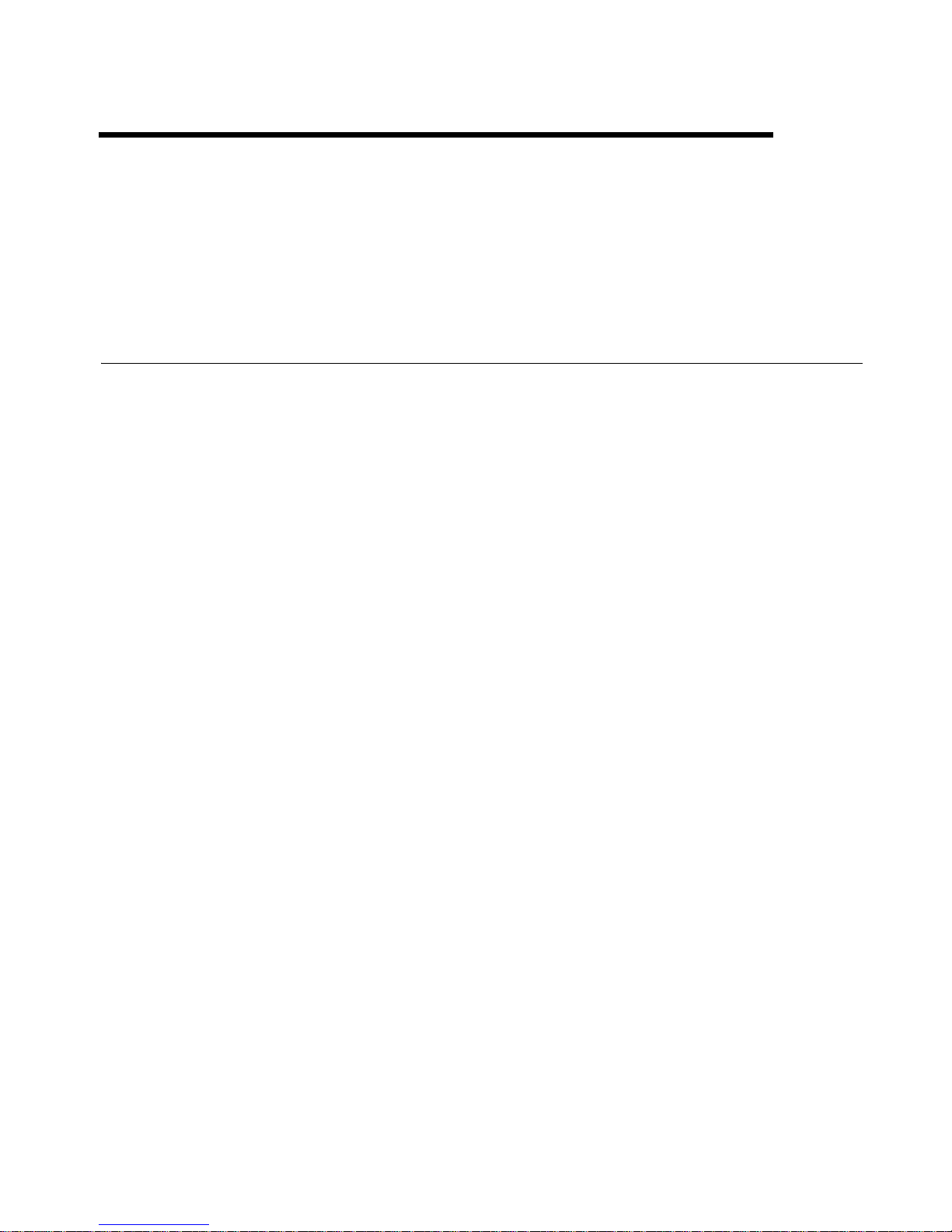

+

–

GND

GND

–

+

Caution Be sure system power is off before plugging in or pulling out the CompactFlash

card.

2. Verify that the CompactFlash card containing Windows Embedded or

another operating system is installed in the unit.

3. Connect the power connector to an 18–32 VDC power line. Be sure to

connect the positive, negative, and ground lines as shown in

Figure 2-1. The power lines can be from either a power adapter or

in-house power source.

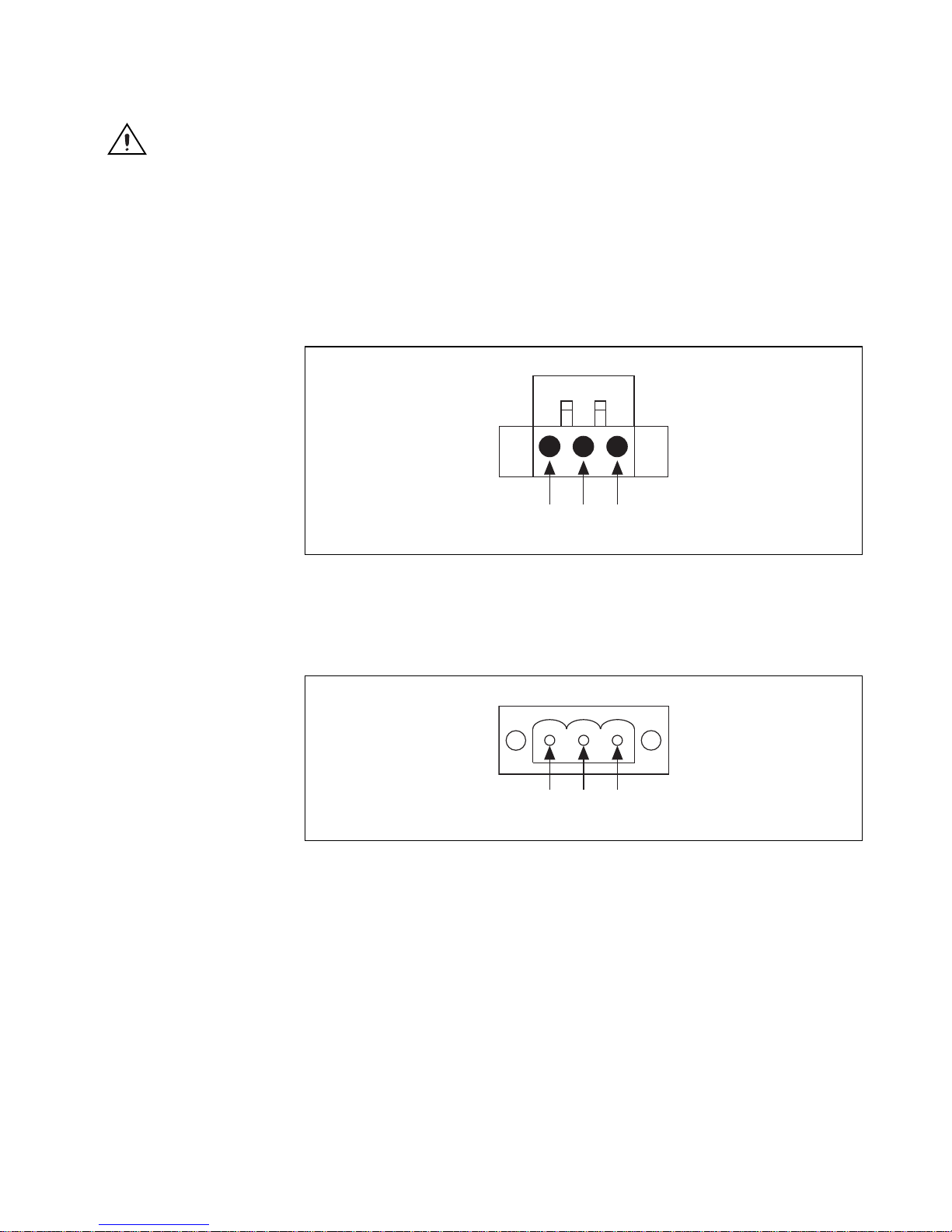

4. Connect the power connector to the power receptor on the TPC-22xx.

The power receptor pin assignment is shown in Figure 2-2.

5. The system turns on immediately after you apply power.

Touchscreen Calibration

The TPC-22xx touchscreen should be correctly calibrated and ready to use

when you power on the system. However, if the calibration is not correct or

you want to choose custom calibration options, refer to Appendix D,

Touchscreen Configuration.

Figure 2-1. Power Connector

Figure 2-2. Power Receptor and Pin Assignment

© National Instruments Corporation 2-3 TPC-2206/TPC-2212/TPC-2215 User Manual

Loading...

Loading...