Page 1

National Instruments TBX-1328 Manual

Get Pricing & Availability at

ApexWaves.com

Call Today: 1-800-915-6216

Email: sales@apexwaves.com

https://www.apexwaves.com/test-measurement-misc/national-instruments/terminal-blocks/TBX-1328

Page 2

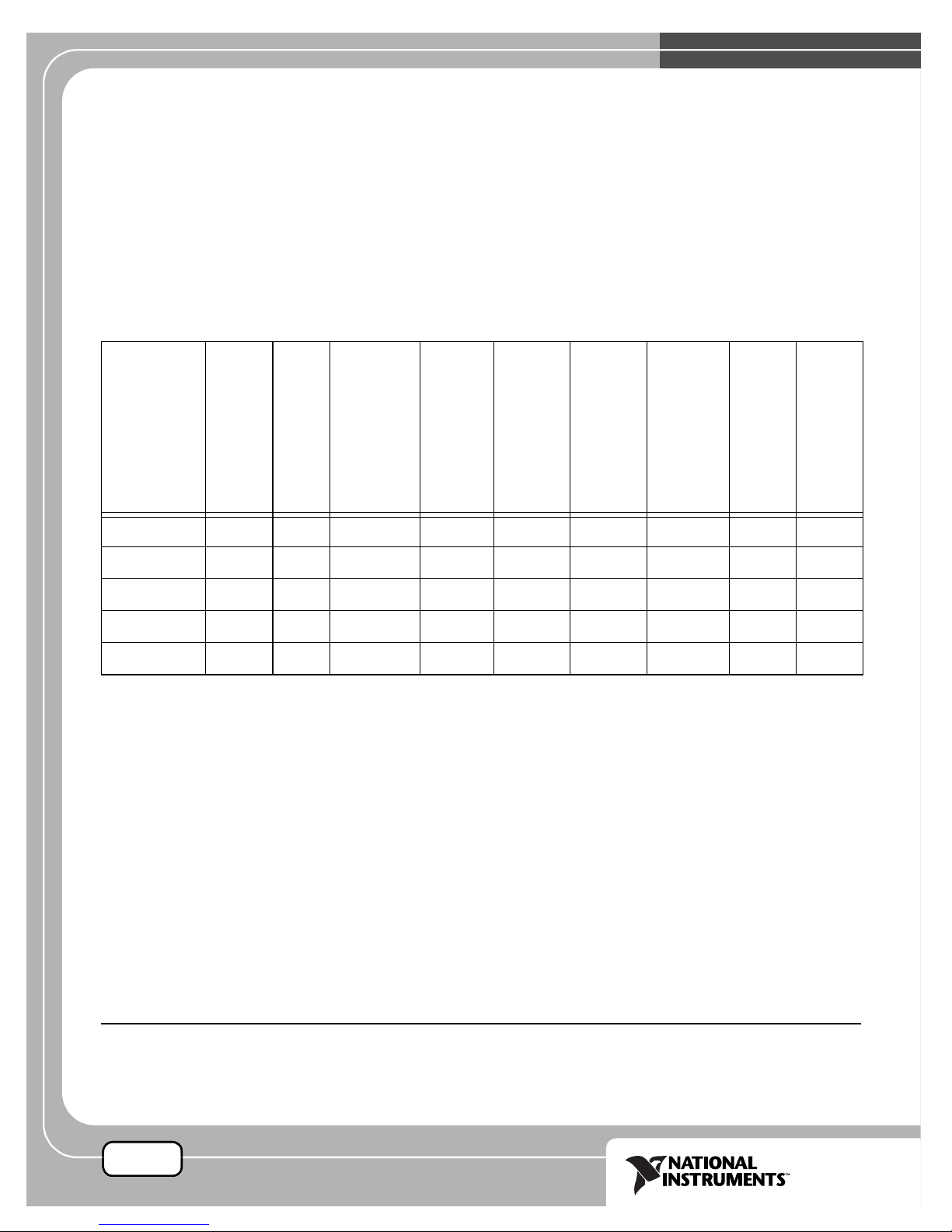

TBX-1328 High-Accuracy Isothermal

Terminal Block Installation Guide

This guide describes how to install and use the TBX-1328 high-accuracy

isothermal terminal block with the SCXI-1120/D, SCXI-1121, SCXI-1125,

or SCXI-1126 modules. Table 1 shows the signals you can use with each

module.

Table 1. SCXI Module and Signal Compatibility

Module

SCXI-1120 Ye s Ye s Ye s Ye s No Ye s No No No

SCXI-1120D Ye s Ye s Ye s Ye s No No No No No

SCXI-1121 Ye s Ye s Ye s Ye s No Ye s Ye s Ye s Yes

SCXI-1125 Ye s Ye s Ye s Ye s No Ye s No No No

SCXI-1126 Ye s Ye s Ye s Ye s Ye s No No No No

Millivolts/Volts

Medium Voltage (60 V)

High Voltage

(250 V/1,000 V)

Current (4 to 20 mA)

Frequency to Voltage

Thermocouple

RTD/Thermisto r

Strain Gauge

The TBX-1328 high-accuracy isothermal terminal block is a DIN-rail

mountable, shielded terminal block with screw terminals to connect to the

SCXI-1120/D, SCXI-1121, SCXI-1125, or SCXI-1126 front connector.

The TBX-1328 has a high-precision thermistor for precise cold-junction

compensation and isothermal copper planes that minimize the temperature

gradients across the screw terminals when you take thermocouple

measurements. The TBX-1328 mounts on most European standard

DIN EN mounting rails.

The terminal block has 24 screw terminals for easy signal connection. Eight

screw terminals connect to the SCXI chassis ground through the shield of

the SH32-32-A cable. With the SCXI-1120/D, SCXI-1125, or SCXI-1126,

the remaining eight pairs of screw terminals connect signals to the eight

Force, Load, Torque

LabVIEW™, Measurement Studio™, National Instruments™, NI™, ni.com™, NI-DAQ™, and SCXI™ are trademarks of

National Instruments Corporation. Product and company names mentioned herein are trademarks or trade names of

their respective companies. For patents covering National Instruments products, refer to the appropriate location:

Help»Patents in your software, the patents.txt file on your CD, or ni.com/patents.

ni.com

© 1996–2003 National Instruments Corp. All rights reserved.

February 2003

371207A-01

Page 3

SCXI module input channels. With the SCXI-1121, four pairs of screw

terminals connect signals to the four SCXI module input channels and four

pairs connect to the SCXI module excitation channels. There are eight

resistor sockets, R<0..7>, for use with the 4 to 20 mA current input.

Conventions

The following conventions are used in this guide:

<> Angle brackets that contain numbers separated by an ellipsis represent

a range of values associated with a bit or signal name—for example,

DIO<3..0>.

» The » symbol leads you through nested menu items and dialog box options

to a final action. The sequence File»Page Setup»Options directs you to

pull down the File menu, select the Page Setup item, and select Options

from the last dialog box.

This icon denotes a note, which alerts you to important information.

bold Bold text denotes items that you must select or click on in the software,

such as menu items and dialog box options. Bold text also denotes

parameter names.

italic Italic text denotes variables, emphasis, a cross reference, or an introduction

to a key concept. This font also denotes text that is a placeholder for a word

or value that you must supply.

monospace Text in this font denotes text or characters that you should enter from the

keyboard, sections of code, programming examples, and syntax examples.

This font is also used for the proper names of disk drives, paths, directories,

programs, subprograms, subroutines, device names, functions, operations,

variables, filenames and extensions, and code excerpts.

monospace italic Italic text in this font denotes text that is a placeholder for a word or value

that you must supply.

What You Need to Get Started

To set up and use the TBX-1328, you need the following items:

❑ TBX-1328 high-accuracy isothermal terminal block

❑ TBX-1328 High-Accuracy Isothermal Terminal Block Installation

❑ Read Me First: Safety and Radio-Frequency Interference

TBX-1328 Installation Guide 2 ni.com

Guide

Page 4

❑ SCXI chassis and documentation

❑ One of the following modules and its documentation:

– SCXI-1120/D

– SCXI-1121

– SCXI-1125

– SCXI-1126

❑ SH32-32-A shielded cable assembly that includes the TBX cable

adapter

❑ 3/16 in. wrench

❑ Numbers 1 and 2 Phillips screwdrivers

❑ 1/8 in. flathead screwdriver

❑ Long-nose pliers

❑ Wire cutter

❑ Wire insulation stripper

Note You can download any NI document from ni.com/manuals.

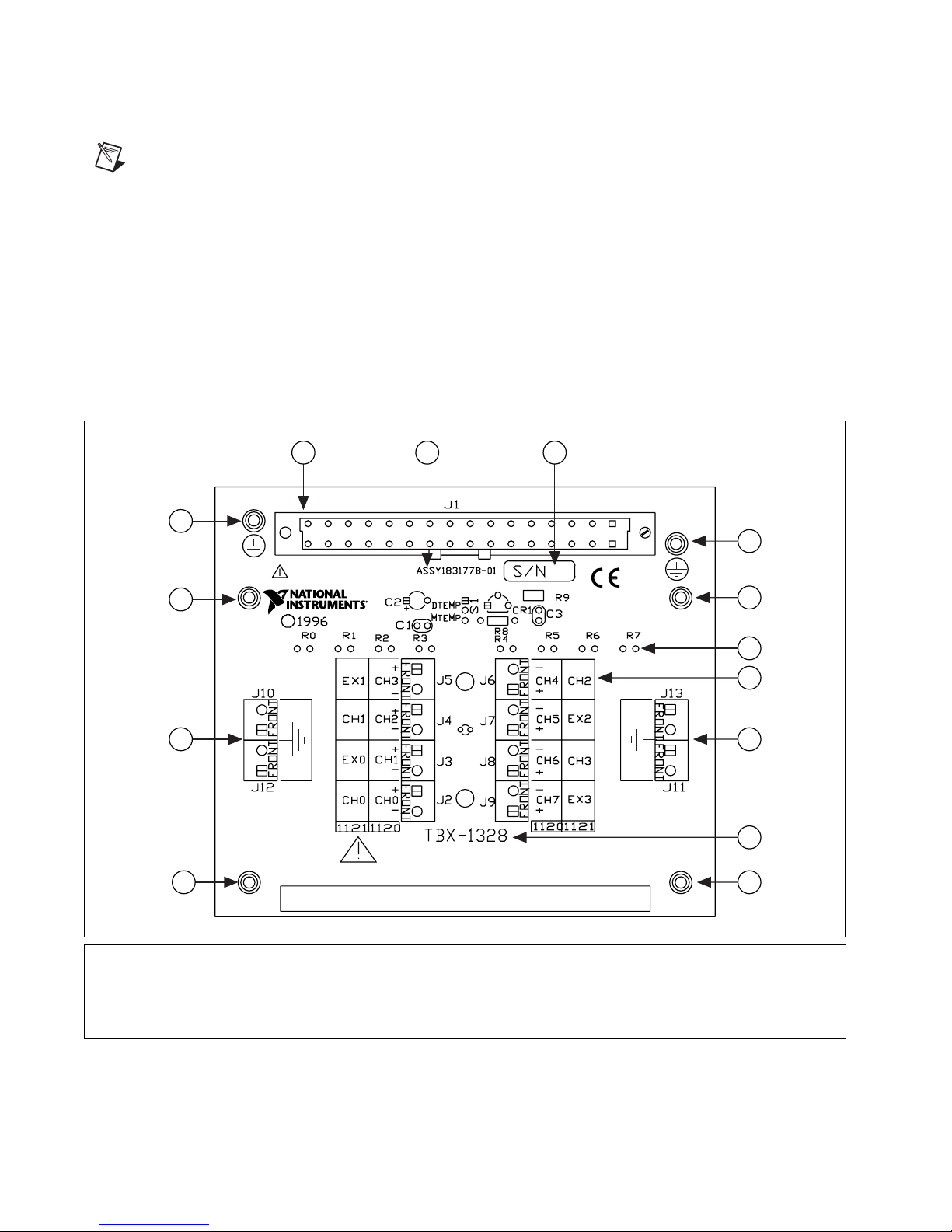

Connecting the Signals

Note Refer to the Read Me First: Safety and Radio-Frequency Interference document

before removing equipment covers or connecting or disconnecting any signal wires.

To connect the field signals to the TBX-1328 for use with the SCXI-1120

or SCXI-1121, follow the labeling on the TBX-1328 indicated along with

the appropriate SCXI module type column as shown in Figure 1. For the

SCXI-1120D, SCXI-1125, and SCXI-1126 modules, use the SCXI-1120

label.

To connect the signals, complete the following steps, referring to Figures 1

through 3 as necessary:

1. Remove the TBX-1328 terminal block cover by unscrewing the four

captive cover screws in the cover corners. These screws stay attached

to the cover without falling out.

2. Connect the signal wires to the screw terminals. Refer to the SCXI

© National Instruments Corporation 3 TBX-1328 Installation Guide

module user manual for examples of how to connect to field signals

and loads. The chassis ground terminals are connected to the SCXI

Page 5

chassis through the cable shield. This connection is not shown in the

SCXI module user manual. Allow the signal wires to exit through the

TBX-1328 cover opening.

Notes When using the SCXI-1121 module to measure current, you must populate

R<0...7>, which corresponds to CH<0...7>. Since the SCXI-1121 can measure a maximum

current of 20 mA, the minimum usable resistor value is R = 10 V ÷ 20 mA = 500 Ω.

This terminal block does not provide strain relief for field signal wires. Add strain relief,

insulation, and padding for the wires, if necessary.

3. Replace the TBX-1328 terminal block cover and tighten the captive

cover screws.

The signal connection is now complete.

4 5 6

3

HIGH VOLTAGE

1

C

2

1

1 Cover Mounting Nut

2 Chassis Ground Screw Terminals

3 Backshell Mounting Kit

4 Cable Connector

5 Assembly Number

250 V CAT II MAX CHANNEL-TO-CHANNEL

250 V CAT II MAX CHANNEL-TO-EARTH

6 Serial Number

7 Current–Receiver Resistor Sockets

R<0..7> = Channel<0..7>

8 Signal Wire Screw Terminals

9 Product Name

3

1

7

8

2

9

1

TBX-1328 Installation Guide 4 ni.com

Figure 1. TBX-1328 Terminal Block Parts Locator Diagram

Page 6

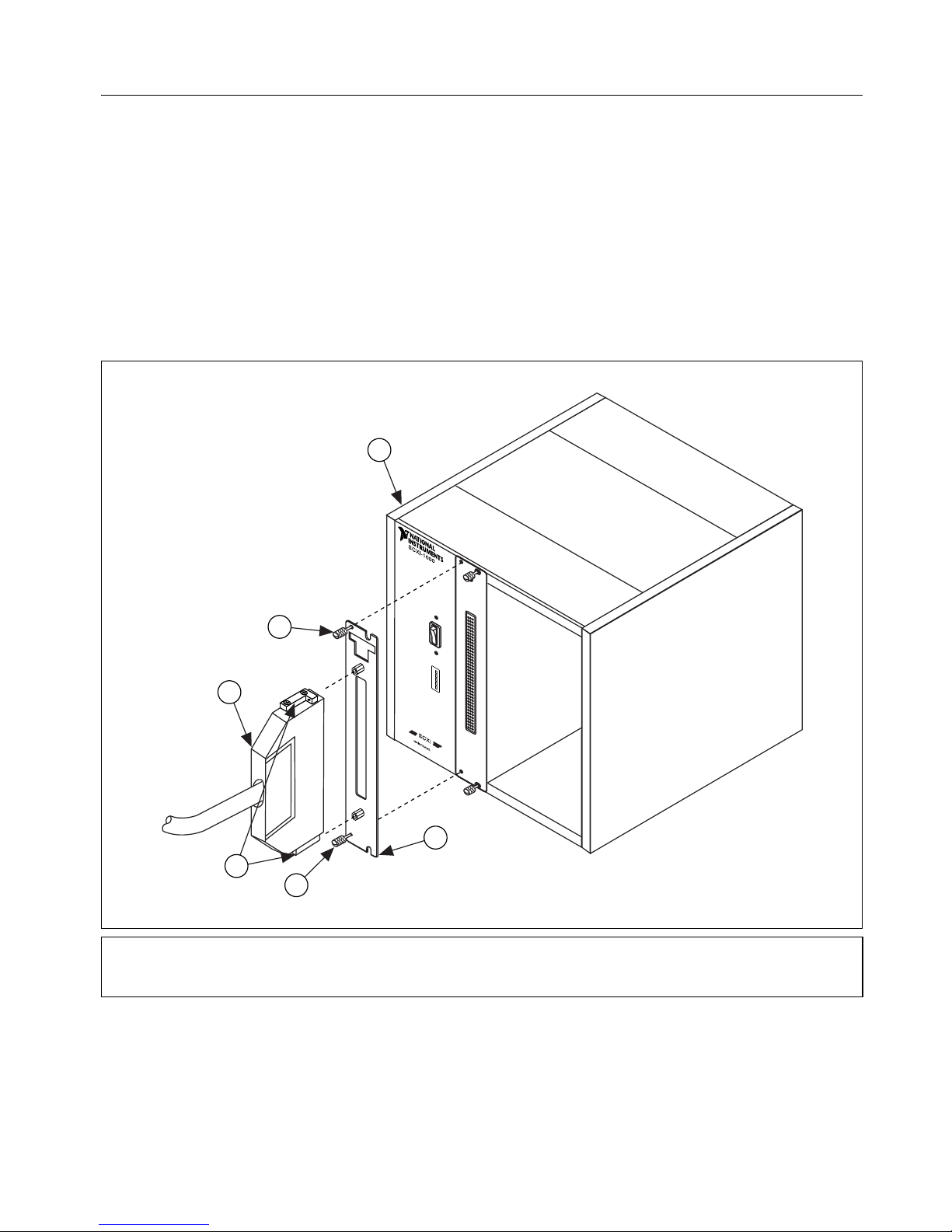

Installing the Terminal Block and Cable Assembly

After completing the Connecting the Signals section, you can install the

terminal block. Complete the following steps to mount the SH32-32-A

cable assembly and connect the TBX-1328 to the SCXI module while

referring to Figures 2 through 4 as needed.

1. Power off the SCXI chassis.

2. Power off the computer that contains the E Series data acquisition

(DAQ) device or disconnect the device from the SCXI chassis.

3. Connect the TBX cable adapter to the appropriate SCXI module and

secure it by tightening both thumb screws.

4

3

2

1

1 M 2.5 Mounting Screws

2 Cable Assembly

3 Thumb Screws

5

4

3

2

1

ADDRESS

5

3

4 SCXI Chassis

5 TBX Cable Adapter

Figure 2. Connecting the SH32-32-A Cable to the SCXI Module

© National Instruments Corporation 5 TBX-1328 Installation Guide

Page 7

4. Verify that the four backshell mounting ears on the cable assembly are

in the position shown in Figure 3. If not, remove the backshell

mounting ears and install them in the position shown.

3

5

3

1 Backshell Mounting Screws and Ears

2 Safety Ground Lugs

3 Captive Cover Screws

Figure 3. Connecting the SH32-32-A Cable to the TBX-1328 Terminal Block

5. Connect one end of the cable assembly to the SCXI module front

connector and secure the SH32-32-A cable by tightening both

backshell mounting screws.

4

1

2

1

4 Terminal Block Connector

5 Signal Wire Entry

6. Connect the other end of the cable assembly to the TBX-1328 terminal

7. Reconnect the E Series DAQ device to the SCXI chassis.

TBX-1328 Installation Guide 6 ni.com

block connector and secure the SH32-32-A cable by tightening both

backshell mounting screws.

Page 8

Rack Mounting

5

4

3

2

1

ADDRESS

Figure 4. The Completed Installation

When you have completed the Installing the Terminal Block and Cable

Assembly section, you can mount the TBX assembly in the rack. If you are

using the National Instruments TBX Rack-Mount Assembly, refer to the

TBX Rack-Mount Installation Guide for instructions.

If you are not using this rack-mount assembly, complete the following steps

to mount the TBX assembly directly onto the DIN rail:

1. Snap the TBX terminal block onto the DIN rail with a firm push.

2. Install the SCXI chassis using the appropriate chassis rack-mount kit.

Note To remove the TBX terminal block from the DIN rail, place a flathead screwdriver

into the slot above the terminal block base and pry it from the rail.

© National Instruments Corporation 7 TBX-1328 Installation Guide

Page 9

Specifications

Electrical

All specifications are typical at 25 °C unless otherwise specified.

Compatible modules

SCXI-1120/D...................................8 input channels

SCXI-1121.......................................4 input channels,

4 excitation output channels

SCXI-1125.......................................8 input channels

SCXI-1126.......................................8 input channels

Cold-junction temperature-sensor circuitry

Sensor type ......................................Thermistor

Output range ....................................1.91 to 0.65 VDC from 0 to 50 °C

Accuracy

1

........................................±0.5 °C from 15 to 35 °C

±0.9 °C from 0 to 15 °C

and 35 to 50 °C

Repeatability....................................±0.2 °C from 15 to 35 °C

Coupling .................................................DC

2

Current-receiver resistors........................Resistors not included

Resistor sockets are provided

for each channel

Field-wiring connectors

Signal screw terminals.....................16 screw terminals (8 pairs)

Functional earth ground...................8 screw terminals

Terminal spacing .............................0.5 cm (0.2 in.)

center-to-center

Maximum wire gauge......................16 AWG

Strain relief ......................................none

Dimensions of front entrance .................1.2 by 7.3 cm

(0.47 by 2.87 in.)

1

This specification includes the accuracy of the temperature-sensor circuitry itself and the temperature difference between the

thermistor and any screw terminal. The temperature-sensor circuitry accuracy includes manufacturing tolerances in all

component values, effects caused by component-value temperature drift, voltage-divider loading, and thermistor self-heating.

2

In instrumentation terminology, DC coupling means that both DC and AC signals are passed.

TBX-1328 Installation Guide 8 ni.com

Page 10

Mechanical

Dimensions............................................. 12.7 by 7.62 by 11.16 cm

Weight.................................................... 100 g (3.5 oz)

Compatible DIN rails............................. DIN EN 50 022

Isothermal construction (with cover attached)

Maximum Working Voltage

Maximum working voltage refers to the signal voltage plus the

common-mode voltage.

Channel-to-earth..................................... Each channel must remain within

Channel-to-channel ................................ Each channel must remain within

(5.0 by 3.0 by 4.4 in.)

DIN EN 50 035

250 V

Installation Category II

250 V

voltage applied to any other

channel, Installation Category II

or ±250 VDC of ground,

rms

or ±250 VDC of the

rms

Environmental

Safety

Operating temperature............................ 0 to 50 °C

Storage temperature ............................... –20 to 70 °C

Humidity ................................................ 10 to 90% RH, noncondensing

Maximum altitude.................................. 2,000 m

Pollution Degree (indoor use only)........ 2

The TBX-1328 is designed to meet the requirements of the following

standards of safety for electrical equipment for measurement, control and

laboratory use:

• IEC 61010-1, EN 61010-1

• UL 3111-1, UL61010B-1

• CAN/CSA C22.2 No. 1010.1

Note For UL and other safety certifications refer to the product label or to ni.com.

© National Instruments Corporation 9 TBX-1328 Installation Guide

Page 11

Electromagnetic Compatibility

Emissions................................................EN 55011 Class A at 10 m

Immunity ................................................EN 61326:1997 + A2:2001,

EMC/EMI ...............................................CE, C-Tick and FCC Part 15

Note For EMC compliance, operate this device with shielded cabling.

CE Compliance

The TBX-1328 meets the essential requirements of applicable European

Directives, as amended for CE marking, as follows:

Low-Voltage Directive (safety)..............73/23/EEC

Electromagnetic Compatibility

Directive (EMC) .....................................89/336/EEC

FCC Part 15A above 1 GHz

Table 1

(Class A) Compliant

Note Refer to the Declaration of Conformity (DoC) for this product for any additional

regulatory compliance information. To obtain the DoC for this product, click Declarations

of Conformity Information at

ni.com/hardref.nsf/.

Temperature Measurement Considerations

The TBX-1328 provides high-accuracy temperature measurements for

isolation modules such as the SCXI-1120/D, SCXI-1121, and SCXI-1125.

The TBX-1328 provides connectivity to thermocouples, thermistors,

and RTDs.

The TBX-1328 provides high-accuracy thermocouple measurements using

an onboard cold-junction compensation (CJC) sensor. To find out how to

read the CJC, refer to the documentation for the module in use.

Temperature measurements with thermistors and RTDs require excitation.

The TBX-1328 provides excitation connectivity when used with an

SCXI-1121. Refer to the SCXI-1121 User Manual for more information on

connecting thermistors and RTDs to the excitation channels.

Switch S1 switches the temperature sensor output between MTEMP

(multiplexed mode) and DTEMP (parallel mode) modes. In either mode, if

there are temperature variations, the measurements can be less accurate. In

MTEMP mode, you must scan the temperature independently of the other

TBX-1328 Installation Guide 10 ni.com

Page 12

channels on the SCXI-1120/D, SCXI-1121, and SCXI-1126. You can read

a temperature at the beginning of the test and use that value with the data

that follows. Using this method assumes that there are no temperature

variations during the measurement period. If there are temperature

variations, the measurements can be less accurate. When using the

SCXI-1125 MTEMP can be scanned from any location in the scan list.

Notes Do not place switch S1 in DTEMP mode. DTEMP mode is not supported.

When using SCXI-112X modules, the TBX-1328 does not provide open thermocouple

detection. To provide open thermocouple detection, you must provide a resistor to +5 V

and another resistor to GND, which defeats the isolation boundary and changes the

specifications.

Temperature Sensor Output and Accuracy

The TBX-1328 temperature sensor outputs 1.91 to 0.65 V from 0 to 50 °C.

LabVIEW, Measurement Studio, and NI-DAQ can convert a thermistor

voltage to the thermistor temperature for the circuit diagram shown in

Figure 5.

Note The circuit diagram in Figure 5 is optional information you can use if you want

more details about the TBX-1328 temperature sensor.

+5 V

4.7 kΩ

1%

2.5 V

2

5 kΩ

LM 4040

2.5 V

0.1%

0.1 µF

–t°

0.1%

R

(5 kΩ

T

at 25° C)

+

1

10 µF

16 V

2

1

0.1 µF

2

V

TEMPOUT

© National Instruments Corporation 11 TBX-1328 Installation Guide

Figure 5. Temperature Sensor Circuit Diagram

Page 13

In LabVIEW, you can use the Convert Thermistor Reading VI in the

Data Acquisition»Signal Conditioning palette. If you are using

Measurement Studio or NI-DAQ, use the

Thermistor_Convert

function. The VI takes the output voltage of the temperature sensor, the

reference voltage, and the precision resistance and returns the thermistor

temperature.

Alternatively, you can use the following formulas:

where T

is the temperature in degrees kelvin

K

a = 1.295361 × 10

b = 2.343159 × 10

c = 1.018703 × 10

–3

–4

–7

T(°C) = T

T

K

--------------------------------------------------------------=

ab R

++[]

– 273.15

K

ln()cR

T

RT = resistance of the thermistor in ohms

V

--------------------------------------

2.5 V

–

T °C()[]9

----------------------- 32+=

V

TEMPOUT

=

R

5,000

T

= output voltage of the temperature sensor

T °F()

5

1

ln()

TEMPOUT

TEMPOUT

3

T

where T(°F) and T(°C) are the temperature readings in degrees Fahrenheit

and degrees Celsius, respectively.

Note Use the average of a large number of samples to obtain the most accurate reading.

For example, sample for 1 second and average all the samples. Noisy environments require

more samples for greater accuracy.

TBX-1328 Installation Guide 12 ni.com

Page 14

Reading the Temperature Sensor in LabVIEW

Notes This section does not apply to the SCXI-1126.

When using virtual channels, select Built-in as the source of the CJC and NI-DAQ will

perform compensation automatically for that thermocouple channel. You do not need to

use

mtemp.

In LabVIEW, the channel string used to read V

module is connected to the TBX-1328. For more information about

channel-string arrays and the SCXI channel-addressing syntax, refer to the

LabVIEW Measurements Manual, which you can download at

ni.com/manuals.

• With the SCXI-1120/D, or SCXI-1121, use the address string:

obx ! scy ! mdz ! mtemp

Yo u cannot put this channel-address string in the same channel-string

array as other channels on the module that you are addressing.

• With the SCXI-1125, use the address string:

obx ! scy ! mdz ! cjtemp

You can put this channel-address string in the same channel-string

array as other channels on the same SCXI-1125 module, but it must be

the first channel scanned on the SCXI-1125.

Reading the Temperature Sensor in NI-DAQ

Refer to the NI-DAQ Function Reference Manual for the description for

reading the temperature sensor using the

SCXI_Change_Chan, and SCXI_SCAN_Setup functions.

TEMPOUT

SCXI_Single_Chan_Setup,

depends on which

Note The method for scanning the temperature sensor on the SCXI-1125 with other

channels on the same module using the

SCXI-1102.

Strain Measurement Considerations

When you use the SCXI-1121 with the TBX-1328 to measure strain, a

small amount of voltage drop develops across the excitation wires in the

SH32-32-A cable. This voltage drop is due to the wire resistance and the

current flow in these leads when a strain gauge is connected at the

TBX-1328 across the excitation outputs provided on the SCXI-1121.

To reduce errors in the output voltage, first calculate the voltage drop across

the SH32-32-A cable. This voltage drop results in a measurement error that

© National Instruments Corporation 13 TBX-1328 Installation Guide

SCXI_SCAN_Setup is the same as that of the

Page 15

depends on the cable length, and on the strain-gauge value and

configuration. The SH32-32-A cable has a resistance (R

) of 0.21 Ω/m.

L

Figure 6 shows a typical full-bridge strain-gauge circuit.

To determine the amount of error introduced by the cable, complete the

following steps:

1. Calculate the total resistance (R

) of the cable, based on the cable

TL

length.

Note Remember to include the lead resistance of both V

2. Determine the bridge resistance of the strain gauge (R

the TBX-1328.

+ and Vex–.

ex

) connected at

SG

TBX-1328 Installation Guide 14 ni.com

Page 16

TBX-1328

HIGH VOLTAGE

C

5

4

3

2

1

R

L

ADDRESS

SCXI-1121

EX+

FRONTFRONTFRONTFRONT

–

+

–

R

4

+

–

+

FRONTFRONT

R

3

–

+

EX–

R

L

R

L

FRONTFRONT

+

–

+

–

+

–

FRONTFRONTFRONTFRONT

+

–

250 V CAT II MAX CHANNEL-TO-CHANNEL

250 V CAT II MAX CHANNEL-TO-EARTH

Note: Each sensor lead (RL) has an added lead resistance of RL = 0.21 Ω/m

Figure 6. Full-Bridge Strain-Gauge Circuit Diagram

R

1

CH–CH+

R

2

R

L

R

L

© National Instruments Corporation 15 TBX-1328 Installation Guide

Page 17

3. Use the following formula to determine the total voltage drop (V

drop

)

in the SH32-32-A cable excitation leads:

R

TL

V

drop

------------------------

R

TL

RSG+

×=

V

ex

For example, if you have a 1 m SH32-32-A cable, 120 Ω full-bridge strain

gauge, and V

1. R

= 2 × 0.21 Ω/m × 1 m = 0.42 Ω; multiply the cable length by two

TL

to take into consideration both the V

2. R

3. V

= 120 Ω is the total equivalent bridge resistance as seen from the

SG

V

+/– terminals of the TBX-1328.

ex

drop

= 3.333 V, then the calculations from steps 1 through 3 are:

ex

+ and Vex– lead resistances.

ex

= 11.6 mV, which is 0.3% of the 3.333 V excitation.

Now calculate the voltage drop across the field signal wires you are

connecting to the TBX-1328. Perform similar calculations for the field

wires as you did for the cable. Resistance can vary depending on the cable

and field wires. Add this error amount to the voltage drop across the

SH32-32-A cable to get a total voltage drop.

You can compensate for this error along with any additional cable lead

resistance introduced by the strain-gauge connection wires. One simple

way of compensation is to calculate the lead resistance, then input it along

with the other strain-gauge parameters into the conversion formula

provided in your software applications, such as LabVIEW and

Measurement Studio. To minimize resistive compensation, move the load

closer to the SCXI module by using shorter cable lengths, or use

heavy-gauge wire to connect to the TBX-1328.

Loading...

Loading...