Page 1

INSTALLATION GUIDE

TBX-1316 High-Voltage

Attenuator Terminal Block

This guide describes how to install and use the TBX-1316 high-voltage

attenuator terminal block with the following modules:

• SCXI-1125 (recommended)

• SCXI-1126

• SCXI-1120/D

The TBX-1316 is a shielded metal enclosure with a built-in high-voltage

attenuator. You can use it to measure high-voltage signals of up to 1000 V

Category I and 600 V Category II.

Caution Do not use the TBX-1316 to connect to signals above 600 V Category II. Do not

use the TBX-1316 in Category III or IV applications. Do not connect to MAINS supply

circuits above 600 VAC.

The TBX-1316 has eight differential high-voltage input channels. Each

high-voltage input channel has three screw terminals—one each for input

plus, input minus, and chassis ground. For maximum safety, all the

chassis-ground terminals and the enclosure are connected. You can use

6 to 20 AWG signal wire in the screw terminals. Use an SH3232 shielded

cable to connect the TBX-1316 to the module.

Note Refer to the Read Me First: Safety and Radio-Interference document for definitions

of Categories and other safety information.

Caution Do not use uninsulated input signal wires. All input signal wires must be

separated from each other and must have a minimum voltage rating of 1000 V for

Category I or 600 V for Category II and have a temperature rating of 90 °C.

Each input channel is formed by a pair of 200:1 fixed-attenuation-ratio

high-voltage resistor networks. The nominal inaccuracy of the attenuation

factor is < 1%, and the attenuation-ratio drift temperature coefficient is

< 20 ppm/°C.

Page 2

Caution Install an application appropriate UL-Listed external breaker (disconnect) for

each input line.

A calibration EEPROM is built into the TBX-1316. When the TBX-1316

is used in conjunction with an SCXI-1125, the EEPROM stores calibration

constants. These constants provide software correction values that the

application development software uses to correct measurements for gain

error in the attenuation circuitry. The EEPROM is shipped with nominal

values. Refer to the Calibrating the TBX-1316 section for calibration

information.

Conventions

The following conventions are used in this guide:

» The » symbol leads you through nested menu items and dialog box options

to a final action. The sequence File»Page Setup»Options directs you to

pull down the File menu, select the Page Setup item, and select Options

from the last dialog box.

This icon denotes a note, which alerts you to important information.

This icon denotes a caution, which advises you of precautions to take to

avoid injury, data loss, or a system crash. When this icon is marked on the

product, refer to the Read Me First: Safety and Radio-Frequency

Interference document, shipped with the product, for precautions to take.

When symbol is marked on a product it denotes a warning advising you to

take precautions to avoid electrical shock.

When symbol is marked on a product it denotes a component that may be

hot. Touching this component may result in bodily injury.

bold Bold text denotes items that you must select or click in the software, such

as menu items and dialog box options. Bold text also denotes parameter

names.

italic Italic text denotes variables, emphasis, a cross reference, or an introduction

to a key concept. This font also denotes text that is a placeholder for a word

or value that you must supply.

monospace Text in this font denotes text or characters that you should enter from the

keyboard, sections of code, programming examples, and syntax examples.

This font is also used for the proper names of disk drives, paths, directories,

programs, subprograms, subroutines, device names, functions, operations,

variables, filenames, and extensions.

TBX-1316 High-Voltage Attenuator Terminal Block 2 ni.com

Page 3

What You Need to Get Started

To install and use the TBX-1316, you need the following items:

❑ Hardware

– TBX-1316 terminal block

– One of the following modules:

• SCXI-1125 (recommended)

• SCXI-1126

• SCXI-1120/D

– One of the following chassis:

•SCXI

• PXI/SCXI combination

– One of the following:

• E/M Series DAQ PCI device

• E/M Series DAQ PXI module

– SH3232 shielded cable and cable adapter as required for your

application

❑ Documentation

– Read Me First: Safety and Radio-Frequency Interference

– DAQ Quick Start Guide

– SCXI Quick Start Guide

– TBX-1316 High-Voltage Attenuator Terminal Block Installation

Guide

– One of the following user manuals (application-dependent):

• SCXI-1125 User Manual

• SCXI-1126 User Manual

• SCXI-1120/D User Manual

– SCXI or PXI/SCXI combination chassis user manual

❑ Tools

– Number 1 and 2 Phillips screwdriver

– 1/8 and 3/8 in. flathead screwdriver

– Long nose pliers

© National Instruments Corporation 3 TBX-1316 High-Voltage Attenuator Terminal Block

– Wire cutter

Page 4

– Wire insulation stripper

– Miscellaneous tools to permanently mount the enclosure

Installing the TBX-1316 Enclosure

Note Refer to the Read Me First: Safety and Radio-Frequency Interference document

before removing equipment covers or connecting or disconnecting any signal wires.

To install the TBX-1316 enclosure, complete the following steps:

1. Install an application appropriate UL-Listed external breaker

(disconnect) for each input line as follows:

a. Install the disconnect device(s) within close proximity of the

TBX-1316 and within easy reach of the operator.

b. Mark this enclosure as a disconnect device.

Note The TBX-1316 is intended for mounting in a permanent location. NI recommends

installing the enclosure in a permanent location whenever possible.

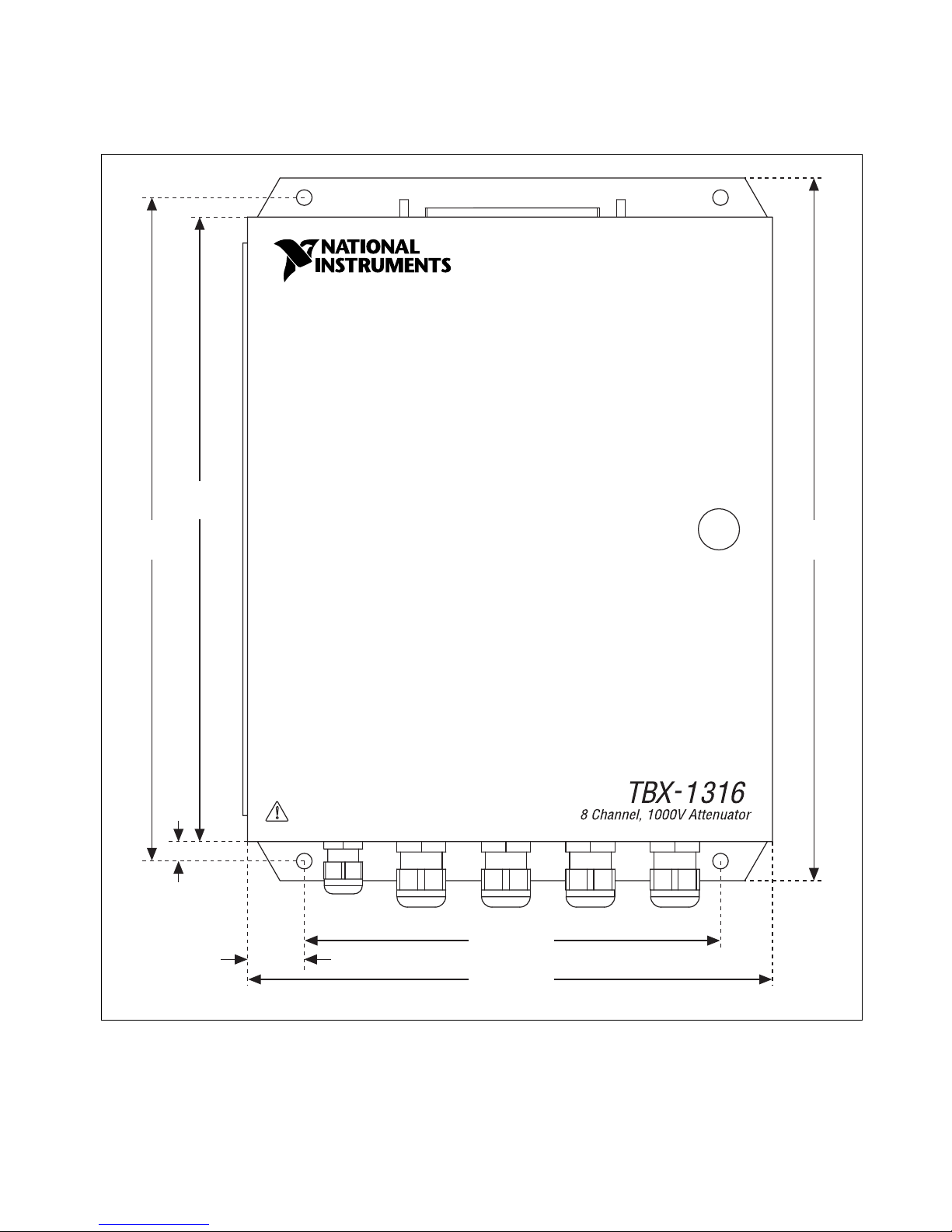

2. Securely mount the enclosure to the building per the local safety codes.

If the enclosure is mounted on plaster board (drywall), mount the

enclosure using four #14

four, 7.6 mm (0.3 in.) clearance mounting holes. Position the enclosure

so that all four screws are driven into wooden studs. Figure 1 shows the

clearance holes.

3. While referring to Figure 2, unlock and open the enclosure door using

a 3/8 in. flathead screwdriver.

4. While referring to Figure 3, complete the following steps to install the

protective earth (PE) ground wire.

Note The PE ground wire must comply with your local codes and be the same or larger

size AWG as the input signal wires.

a. Insert the PE ground wire through the PE ground strain-relief

collar.

b. Install a UL-Listed uninsulated closed-ring terminal, suitable to

your application, on the end of the PE ground wire.

c. Place the lock-washer over the ground-screw followed by the

PE ground terminal.

× 1 1/2 in. wood screws installed through the

TBX-1316 High-Voltage Attenuator Terminal Block 4 ni.com

d. Place the provided lock washer over the end of the ground screw.

The screw should now have a ring terminal between two lock

washers.

Page 5

304.80 mm

[12.000 in]

323.85 mm

[12.750 in]

e. Install the ground-screw/lock-washer into the enclosure, and

tighten it with a number 2 Phillips screwdriver.

f. Tighten the PE ground strain-relief collar.

342.90 mm

[13.500 in]

1000 V CAT I

600 V CAT II

50 µA MAX per channel

9.53 mm

[0.375 in]

25.4 mm

[1.000 in]

© National Instruments Corporation 5 TBX-1316 High-Voltage Attenuator Terminal Block

203.20 mm

[8.000 in]

254.00 mm

[10.000 in]

Figure 1. TBX-1316 Enclosure Mounting Hole Spacing

Page 6

Connecting the Signals

Note Be certain that the signal wires are of the appropriate AWG and voltage for your

application, and are rated for 90 °C.

To connect a signal to the TBX-1316, perform the following steps while

referring to Figures 2 and 3:

1. Unlock and open the enclosure door using a 3/8 in. flathead

screwdriver.

2. Loosen the signal strain-relief collar.

3. Run the signal wires through the strain-relief opening.

4. Prepare the signal wire by stripping the insulation no more than

Note When connecting the signals to the TBX-1316, follow the labeling on the

TBX-1316.

TBX-1316 High-Voltage Attenuator Terminal Block 6 ni.com

Figure 2. Opening the TBX-1316

10 mm (0.39 in.).

Page 7

5. Connect chassis ground to the chassis-ground terminal strip.

6. Connect the signal wires to the signal wire screw terminals by inserting

the stripped end of the wire fully into the terminal.

Caution No bare wire should extend past the screw terminal. Exposed wire increases the

risk of short circuits and failures.

7. Tighten the terminal screws to a torque of 1.2 to 1.5 N · m

(10.62 to 13.28 in. · lb).

8. Tighten the signal strain-relief collar.

9. Repeat steps 2 through 8 for each signal wire.

10. Close and lock the enclosure door.

11. Connect the TBX-1316 to the SCXI module front connector as

explained in the Connecting the Module section.

© National Instruments Corporation 7 TBX-1316 High-Voltage Attenuator Terminal Block

Page 8

8

6

5

1 Protective Earth Ground

Strain-Relief Collar

2 Protective Earth Ground

3 Signal Cable Insulation

4 Signal Wire Insulation

7

4

3

2

1

5 Enclosure Door Lock

6 Enclosure Door

7 Enclosure Door Ground

8 SH3232 Shielded Cable

Connector

9

10

11

12

13

9 Protective Cover

10 Signal Wire Terminal Strip

11 Chassis Ground Terminal Strip

12 Enclosure

13 Signal Strain-Relief Collar

Connecting the Module

This section describes how to connect the TBX-1316 to an SCXI and

PXI/SCXI combination chassis.

Note The illustrations show the SCXI chassis only.

TBX-1316 High-Voltage Attenuator Terminal Block 8 ni.com

Figure 3. TBX-1316 Parts Locator Diagram

Page 9

To connect the TBX-1316 to an SCXI module front connector, perform the

following steps:

1. If you have not already installed the E/M Series DAQ device, refer to

the DAQ Quick Start Guide for installation instructions.

2. If you have not already installed the SCXI module, refer to the

SCXI Quick Start Guide for installation instructions.

3. Power off the SCXI chassis.

4. Do one of the following:

• Power off the computer that contains the E/M Series DAQ device,

and disconnect the device from the chassis.

• Power off the PXI portion of the PXI/SCXI combination chassis,

and if used, remove the cable connecting the SCXI portion of the

chassis to E/M Series device.

5. Connect the TBX cable adapter to the appropriate SCXI module, and

secure it by tightening both thumbscrews, as shown in Figure 4.

4

3

5

4

3

2

2

1

ADDRESS

5

1

3

1 Mounting Screws and Ears

2 Cable

© National Instruments Corporation 9 TBX-1316 High-Voltage Attenuator Terminal Block

3 Thumbscrews

5 TBX Cable Adapter

4 SCXI Chassis

Figure 4. Connecting the Cable to the SCXI Module

Page 10

6. Connect one end of the cable assembly to the SH3232 shielded cable

connector on the TBX-1316, and secure the cable by tightening both

mounting screws, as shown in Figure 5.

1

2

1

1 Mounting Screws 2 Cable Assembly

Figure 5. Connecting the Cable to the TBX-1316

TBX-1316 High-Voltage Attenuator Terminal Block 10 ni.com

Page 11

7. Connect the other end of the cable assembly to the SCXI module front

connector, and secure the cable by tightening the mounting screws.

Figure 6 shows the completed installation.

8. If necessary, reconnect the E/M Series DAQ device to the chassis.

9. Refer to the SCXI Quick Start Guide to power on the SCXI chassis and

configure the system in software.

Calibrating the TBX-1316

NI recommends you perform an external calibration once a year.

You can download all available external calibration documents from

ni.com/calibration by clicking Manual Calibration Procedures.

5

4

3

2

1

ADDRESS

Figure 6. Completed Installation

© National Instruments Corporation 11 TBX-1316 High-Voltage Attenuator Terminal Block

Page 12

Specifications

All specifications are typical at 25 °C unless otherwise specified.

Input Voltage Range

AC/DC ....................................................1000 V Category I

AC/DC ....................................................600 V Category II

Max input current per channel................50 µA

Impulse overvoltage ...............................4000 V

Bandwidth (3 dB)

Attenuation ratio .....................................200:1 (fixed)

Attenuation-ratio accuracy

SCXI-1125.......................................400 Hz

SCXI-1120.......................................400 Hz

Physical

Uncalibrated ....................................1% max

Attenuation-ratio temperature drift.........20 ppm/°C max

Differential input resistance....................44 MΩ typ

NI recommends that the TBX-1316 be permanently connected equipment

with an appropriate UL Listed external breaker for each line.

Enclosure protective earth (PE) ground must be installed.

Dimensions .............................................30.48

(12

Weight ....................................................5.8 kg

(12.8 lb)

Strain-relief cable diameter.....................6 to 12 mm signals

(0.24 to 0.47 in.)

4 to 8 mm PE ground

(0.157 to 0.314 in.)

× 25.40 × 15.24 cm

× 10 × 6 in.)

TBX-1316 High-Voltage Attenuator Terminal Block 12 ni.com

Page 13

Note If your application cable diameter is smaller than what is listed above, replace the

supplied strain reliefs with the following strain reliefs or their equivalents. These strain

reliefs are not supplied with the TBX-1316.

Strain-relief cable diameter.................... 5 to 9 mm signals

(0.197 to 0.354 in.)

SKINTOP # S2213

2 to 6 mm PE ground

(0.079 to 0.236 in.)

SKINTOP # S2209

Strain reliefs available............................ 8 signals

1 PE ground

Field wire

Diameter.......................................... 6 to 20 AWG

Temperature rating.......................... 90 °C

Connector type ....................................... Screw terminal

Environmental

Safety

Operating temperature............................ 0 to 55 °C

Storage temperature ............................... –20 to 70 °C

Humidity ................................................ 10 to 90% RH, noncondensing

Maximum altitude .................................. 2,000 m

Pollution Degree

(indoor use only) .................................... 2

The TBX-1316 is designed to meet the requirements of the following

standards of safety for electrical equipment for measurement, control,

and laboratory use:

• IEC 61010-1, EN 61010-1

• UL 61010-1

• CAN/CSA-C22.2 No. 61010-1

Note For UL and other safety certifications, refer to the product label, or visit

ni.com/certification, search by model number or product line, and click the

appropriate link in the Certification column.

© National Instruments Corporation 13 TBX-1316 High-Voltage Attenuator Terminal Block

Page 14

Electromagnetic Compatibility

Emissions................................................EN 55011 Class A at 10 m

Immunity ................................................EN 61326:1997 + A2:2001,

EMC/EMI ...............................................CE, C-Tick, and FCC Part 15

Note For EMC compliance, operate this device with shielded cabling.

CE Compliance

The TBX-1316 meets the essential requirements of applicable European

Directives, as amended for CE marking, as follows:

Low-Voltage Directive (safety)..............73/23/EEC

Electromagnetic Compatibility

Directive (EMC) .....................................89/336/EEC

FCC Part 15A above 1 GHz

Table 1

(Class A) Compliant

Note Refer to the Declaration of Conformity (DoC) for this product for any additional

regulatory compliance information. To obtain the DoC for this product, visit

ni.com/certification, search by model number or product line, and click the

appropriate link in the Certification column.

TBX-1316 High-Voltage Attenuator Terminal Block 14 ni.com

Page 15

National Instruments, NI, ni.com, and LabVIEW are trademarks of National Instruments Corporation.

Refer to the Terms of Use section on ni.com/legal for more information about National

Instruments trademarks. Other product and company names mentioned herein are trademarks or trade

names of their respective companies. For patents covering National Instruments products, refer to the

appropriate location: Help»Patents in your software, the patents.txt file on your CD, or

ni.com/patents.

© 2004–2005 National Instruments Corporation. All rights reserved.

374061C-01 Apr05

Loading...

Loading...