Page 1

USER GUIDE AND TERMINAL BLOCK

SPECIFICATIONS

NI PXIe-4302/4303 and

TB-4302/4302C

32 Ch, 24-bit, 5 kS/s or 51.2 kS/s Simultaneous Filtered Data

Acquisition Module

This document explains how to install, configure, and set up the NI PXIe-4302 and

NI PXIe-4303 (NI PXIe-4302/4303) simultaneous filtered modules with the TB-4302 and

TB-4302C terminal blocks. Driver support for the NI PXIe-4302/4303 was first available in

NI-DAQmx 15.1. For the list of devices supported by a specific release, refer to the NI-DAQmx

Readme, available on the version-specific download page or installation media.

Note The keying of these terminal blocks prevents them from connecting to other

modules that could be damaged by the voltage present on the terminal block.

However, you should only use these terminal blocks with their supported modules.

Contents

Electromagnetic Compatibility Guidelines .............................................................................. 2

What You Need to Get Started ................................................................................................. 3

Installation ................................................................................................................................ 3

Install the Software ........................................................................................................... 3

Unpack and Install the Module......................................................................................... 4

Connect the Signals .......................................................................................................... 5

Install the Terminal Block ................................................................................................ 8

Confirm NI PXIe-4302/4303 Module Recognition.......................................................... 10

Run Test Panels ................................................................................................................ 11

Take an NI-DAQmx Measurement .................................................................................. 11

NI-DAQmx Channels and Tasks.............................................................................. 11

Configure a Task Using the DAQ Assistant in MAX .............................................. 11

Use Your NI PXIe-4302/4303 Module in an Application................................................ 12

Programming Examples ........................................................................................... 12

Terminal Block Removal..........................................................................................................13

Module Removal ...................................................................................................................... 14

Create a Simulated Device .......................................................................................................15

Page 2

Cold-Junction Compensation (TB-4302 Only)......................................................................... 15

Minimizing Thermal Gradients ................................................................................................15

More Information...................................................................................................................... 16

Troubleshooting ................................................................................................................ 16

Specifications (TB-4302/4302C)..............................................................................................16

Calibration Interval ...................................................................................................................17

Electrical ................................................................................................................................... 17

TB-4302 ............................................................................................................................ 17

TB-4302C ......................................................................................................................... 17

Mechanical........................................................................................................................ 17

Physical .............................................................................................................................18

Environmental Specifications ........................................................................................... 18

Operating Environment.............................................................................................18

Storage Environment ........................................................................................................ 19

Shock and Vibration ......................................................................................................... 19

Safety ................................................................................................................................ 19

Safety Standards ............................................................................................................... 19

Electromagnetic Compatibility ......................................................................................... 20

CE Compliance ................................................................................................................. 20

Online Product Certification.............................................................................................20

Environmental Management............................................................................................. 21

World Wide Support and Services............................................................................................ 21

Electromagnetic Compatibility Guidelines

This product was tested and complies with the regulatory requirements and limits for

electromagnetic compatibility (EMC) stated in the product specifications. These requirements

and limits provide reasonable protection against harmful interference when the product is

operated in the intended operational electromagnetic environment.

This product is intended for use in industrial locations. However, harmful interference may

occur in some installations, when the product is connected to a peripheral device or test object,

or if the product is used in residential or commercial areas. To minimize interference with radio

and television reception and prevent unacceptable performance degradation, install and use this

product in strict accordance with the instructions in the product documentation.

Furthermore, any modifications to the product not expressly approved by National Instruments

could void your authority to operate it under your local regulatory rules.

Caution To ensure the specified EMC performance, operate this product only with

shielded, twisted pair cables and shielded accessories.

Caution To ensure the specified EMC performance, the length of all I/O cables

must be no longer than 30 m (100 ft).

2 | ni.com | NI PXIe-4302/4303 and TB-4302/4302C

Page 3

What You Need to Get Started

To set up and use a NI PXIe-4302/4303 module with a TB-4302/4302C terminal block, you need

the following items:

Hardware

– NI PXIe-4302/4303 module

– TB-4302/4302C terminal block

– NI PXI Express chassis

– Cabling and sensors as required for your application

Tools

– Number 1 and 2 Phillips-head screwdrivers

– 1/8 in. flathead screwdriver

– Long-nose pliers

– Wire cutter

– Wire insulation stripper

Documentation

– Read Me First: Safety and Electromagnetic Compatibility

– NI PXIe-4302/4303 and TB-4302/4302C User Guide and Terminal Block

Specifications

– NI PXIe-4302/4303 User Manual

– NI PXI Express chassis user manual

You can download needed documents from

ni.com/manuals.

Installation

Install the Software

Note You must be an administrator to install NI software and devices on your

computer.

Ensure that the following software is installed before installing the NI PXIe-4302/4303 and

TB-4302/4302C hardware:

1. Your application software, such as LabVIEW, LabWindows

2. NI-DAQmx—NI PXIe-4302/4303 modules were first supported in NI-DAQmx 15.1.

Note For detailed NI software version support, refer to the NI-DAQmx Readme.

Back up any applications before upgrading software or modifying the application.

NI PXIe-4302/4303 and TB-4302/4302C | © National Instruments | 3

™

CVI™ or .NET.

Page 4

Unpack and Install the Module

Remove the packaging and inspect the module. Contact NI if the module is damaged. Do not

install a damaged module.

Caution The module is static sensitive. Always properly ground yourself and the

equipment when handling or connecting to the module.

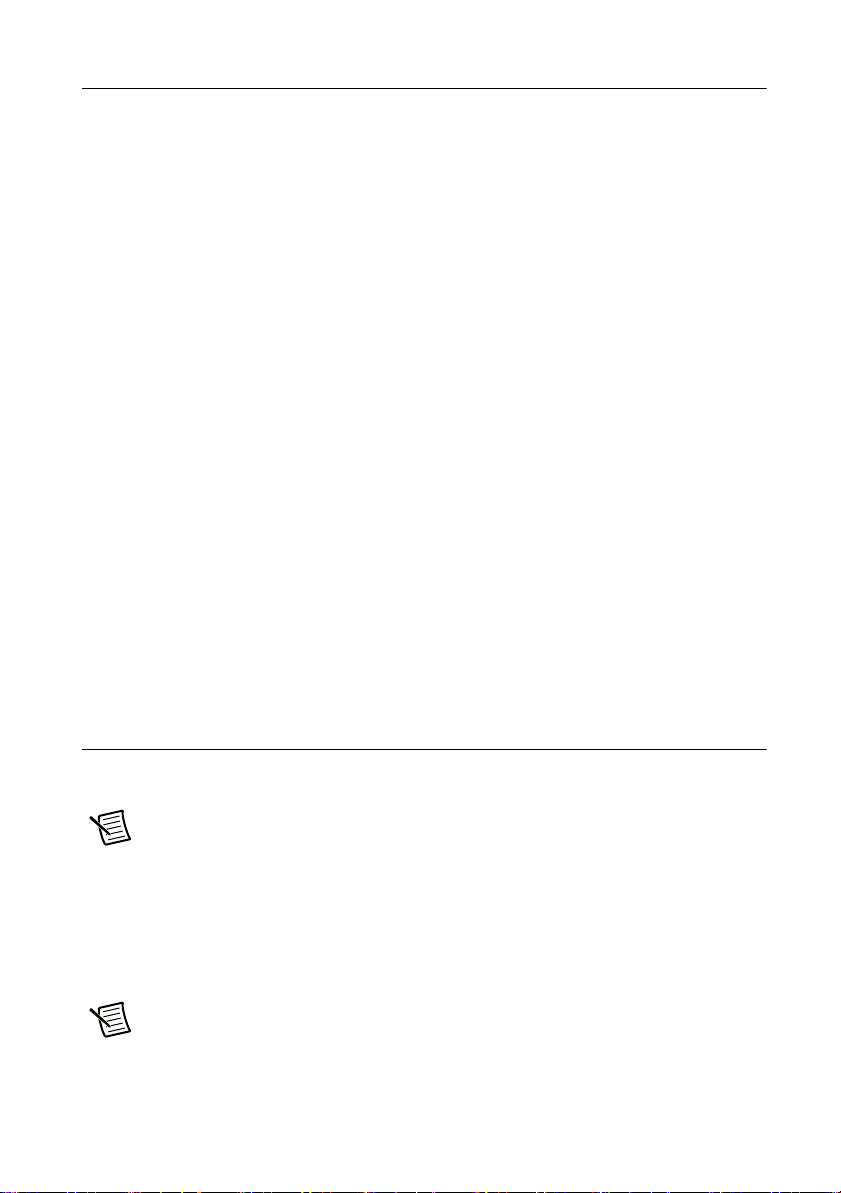

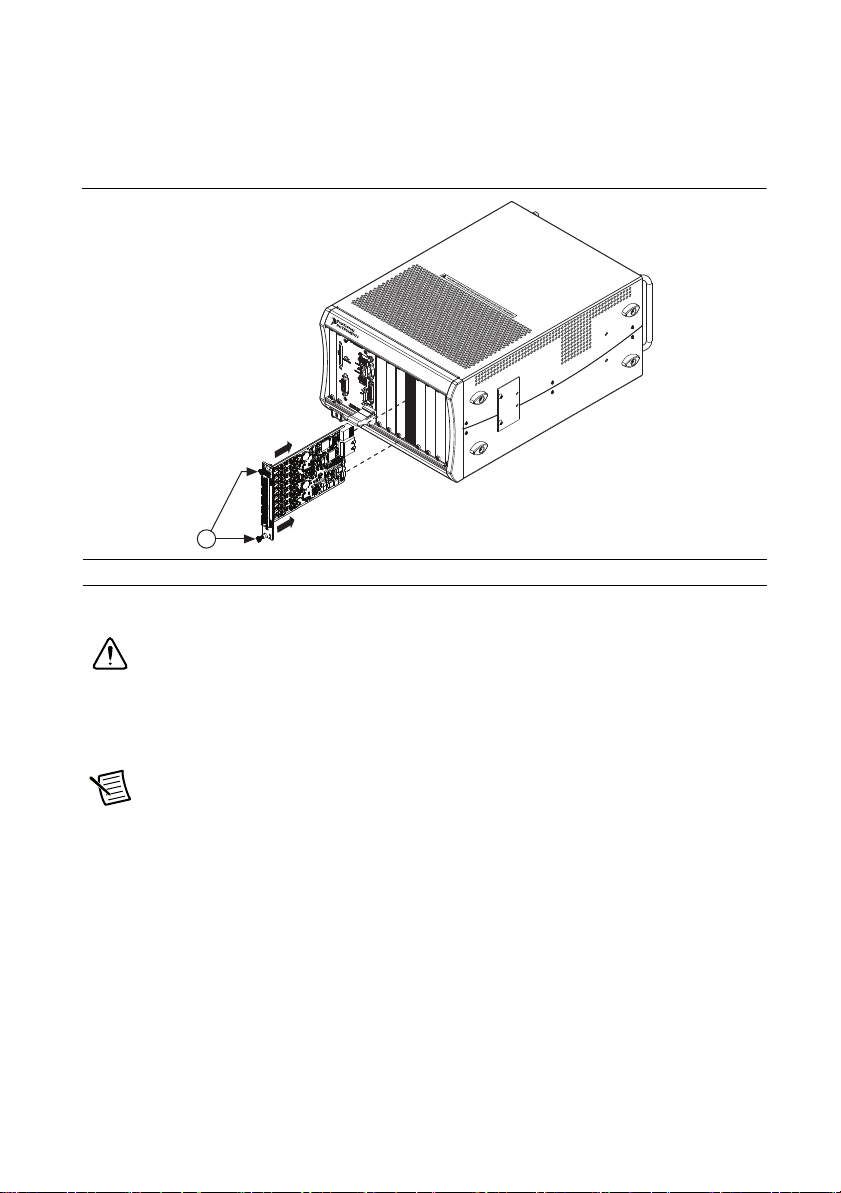

Complete the following steps to install the NI PXIe-4302/4303 module while referring to

Figures 1 and 2:

Note To maintain forced air cooling in the PXIe system, refer to the Maintain

Forced-Air Cooling Note to Users.

1. Plug in your chassis before installing the NI PXIe-4302/4303. The power cord grounds the

chassis and protects it from electrical damage while you install the module.

2. Make sure the chassis is powered off.

Caution To protect yourself, the chassis, and the NI PXIe-4302/4303 from

electrical hazards, leave the chassis powered off until you finish installing the

NI PXIe-4302/4303 module.

3. Touch a metal part on the chassis to discharge any accumulated static electricity.

4. Identify a supported PXI Express slot in the chassis. NI PXIe-4302/4303 modules can be

placed only in PXI Express Peripheral slots, PXI Express Hybrid Peripheral slots, and PXI

Express System Timing slots. Refer to the chassis documentation for details.

Figure 1. Symbols for PXI Express/ PXI Express Hybrid/ PXI Slots

NI PXIe-1062Q

1 PXI Express System Controller Slot

2 PXI Peripheral Slot

1 2 3 4

3 PXI Express Hybrid Peripheral Slot

4 PXI Express System Timing Slot

5. Remove the filler panel, and touch any metal part of the chassis to discharge static

electricity.

6. Place the module edges into the module guides at the top and bottom of the slot.

Caution When installing the module, make sure both edges are positioned inside

the guides and that the module components do not come into contact with adjacent

modules.

4 | ni.com | NI PXIe-4302/4303 and TB-4302/4302C

Page 5

7. Slide the module along the guides until it reaches the rear connector then seat the module

by pushing the front panel until it is flush with the front panel of the chassis.

8. Secure the module to the chassis using the front-panel captive screws, shown in Figure 2.

Tighten the screws to 0.31 N · m (2.7 lb · in.).

Figure 2. Installing NI PXIe-4302/4303 Modules

CO

O

L

I

NG

CL

E

A

RA

NCE

A

ND

F

A

N

F

I

L

T

E

R

MA

I

NTE

NA

NCE

RE

Q

U

I

RE

D

.

S

E

E

MA

NU

A

L

.

NI

PX

I

e

-1062Q

1

1Captive Screws

Connect the Signals

Caution For EMC compliance, operate this product with shielded cables and

accessories.

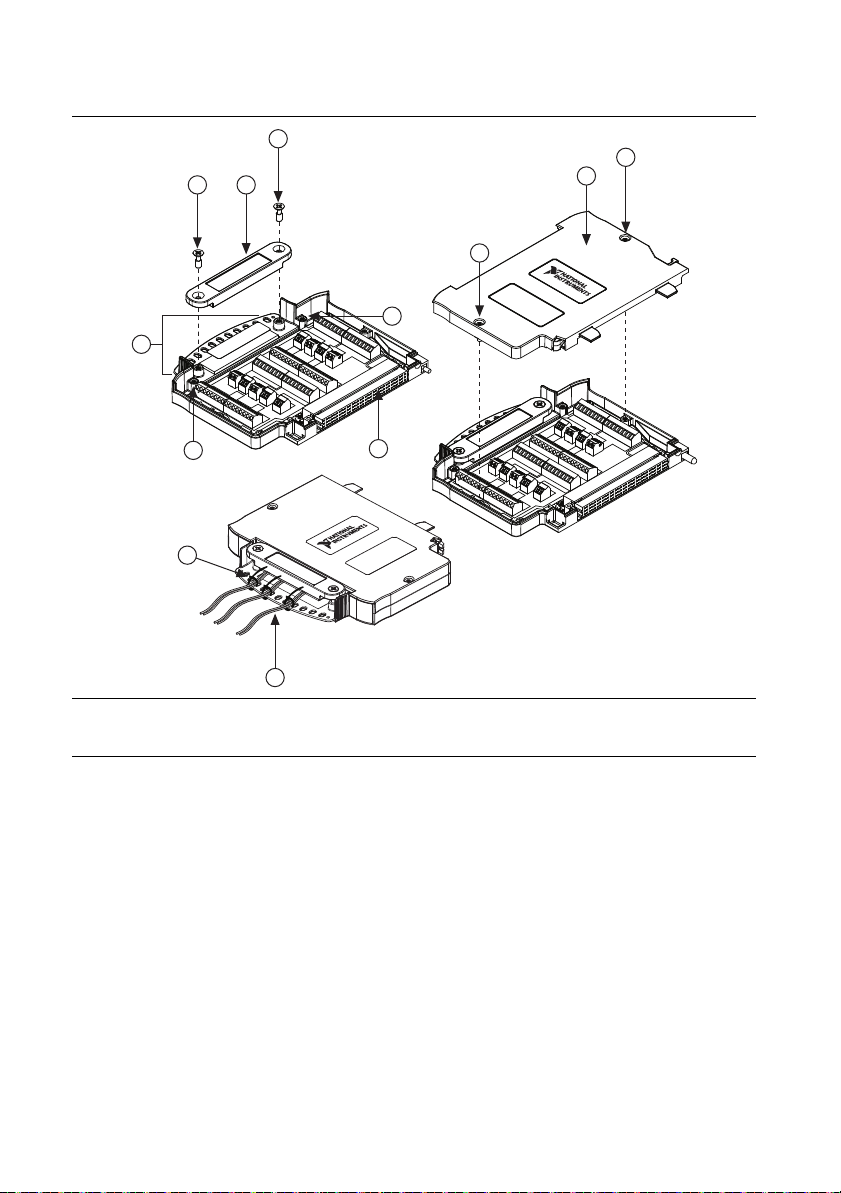

To connect signals to the terminal block, refer to Figures 3 and, 4 or 5 while completing the

following steps:

Note You can find the pinout names and locations in Measurement & Automation

Explorer (MAX) at any time by right-clicking the device name under Devices and

Interfaces and selecting Device Pinouts.

1. Loosen the captive top cover screws and remove the top cover.

2. Loosen the strain-relief screws and remove the strain-relief bar.

3. Prepare the shielded signal wire by stripping the insulation no more than 7 mm (0.28 in.).

NI PXIe-4302/4303 and TB-4302/4302C | © National Instruments | 5

Page 6

4. Run the shielded signal wires through the strain-relief opening.

Figure 3. TB-4302/4302C Parts Locator Diagram

1 2

3

4

8

1 Strain-Relief Screws

2 Strain-Relief Bar

3 Tie Wrap Holes

1

6

4

5

9

4 Ground Lugs

5 Terminal Block to Module Connector

6 Captive Top Cover Screws

6

7

7 Top Cover

8 Tie Wraps

9 Shielded Signal Wires

5. Insert the stripped end of the shielded signal wires fully into the appropriate terminal. Refer

to the label next to each screw terminal to determine the function of the terminal. The

NI PXIe-4302/4303 User Manual provides more detailed wiring information. Make sure no

exposed wire extends past the screw terminal. Exposed wire increases the risk of a short

circuit that can cause circuit failure.

6 | ni.com | NI PXIe-4302/4303 and TB-4302/4302C

Page 7

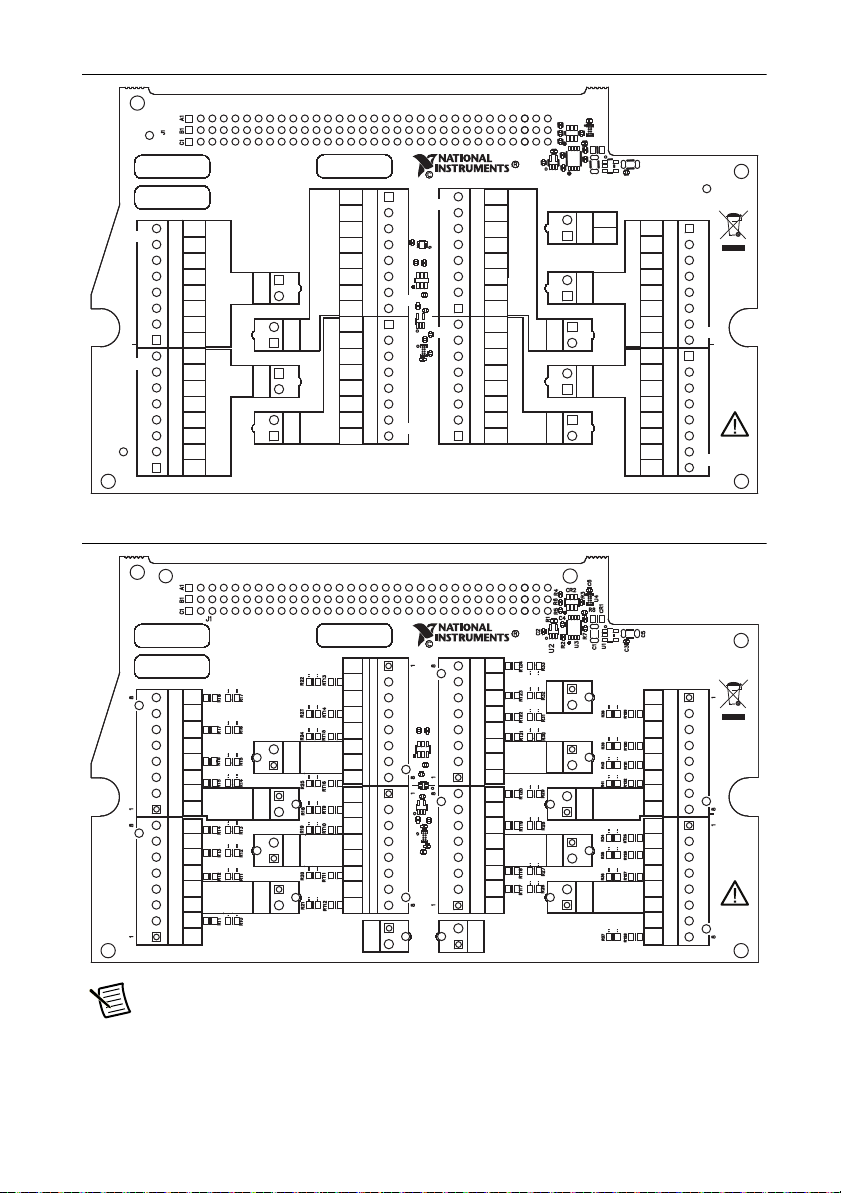

Figure 4. TB-4302 Circuit Board Parts Locator Diagram

U7

AI3-

AI3+

AI2+

AI4+

AI4-

AI5-

AI7-

AI7+

AI6-

AI6+

AI5+

AI0+

AI0-

AI1-

AI2+

AI1+

AI9+

AI9-

AI10+

AI13+

AI13-

AI14+

AI15+

AI15-

AI14-

AI12+

AI11+

AI10-

AI8+

AI11-

AI8-

AI12-

AI7+

AI7-

AI18+

AI21+

AI21-

AI22+

AI23+

AI23-

AI22-

AI20+

AI19+

AI18-

AI6+

AI19-

AI6-

AI20-

AI5+

AI5-

AI16+

AI29+

AI29-

AI30+

AI31+

AI31-

AI30-

AI28+

AI17+

AI16-

AI4+

AI17-

AI4-

AI28-

FOR PATENTS: NI.COM/PATENTS

NI TB-4302

S/N

158016B-01L

COPYRIGHT 2015

UL94V-0

AIGND AIGND

AIGND AIGND

J21J4188

J5

J3

J6 J8

J9

J7

J10 J121818

8181

U6

U5

CR3

AIGND AIGND

AIGND AIGND

J15

J17

J11 J13 J18

J16J14

8

1

8

1

U2

R2

U3

C1

U1

C3

C5

C2

R1

R5 R6 R4

R7

R8

R3

CR1

U4

C6

CR2

C4

PFI0

DGND

Figure 5. TB-4302C Circuit Board Parts Locator Diagram

S/N

158141A-01L

AI7

VSUP

J4

AI6

VSUP

AI5

VSUP

AI4

VSUP

AI3

VSUP

AI2

VSUP

AI1

VSUP

AI0

J2

VSUP

6. Tighten the terminal screws to a torque of 0.2 to 0.25 N · m (1.77 to 2.21 lb · in.).

Note Refer to the NI PXIe-4302/4303 User Manual for wiring diagrams showing

how to connect sensors to the TB-4302/4302C.

J9

J5

AISENSE

AISENSE

J7

J3

AISENSE

AISENSE

NI TB-4302C

VSUP

AI15

VSUP

AI4

VSUP

AI3

AISENSE

VSUP

AISENSE

AI2

VSUP

AI1

VSUP

AI0

AISENSE

VSUP

AISENSE

A9

VSUP

AI8

AISENSE

AIGND

NI PXIe-4302/4303 and TB-4302/4302C | © National Instruments | 7

J8

CR3

J6

J21

COPYRIGHT 2014

J12

U10

U11

U9

J10

J19

AI23

VSUP

AI22

VSUP

AI21

VSUP

AISENSE

AI20

AISENSE

VSUP

AI19

VSUP

AI18

AISENSE

VSUP

AISENSE

AI17

VSUP

AI16

VSUP

AISENSE

VSUP

FOR PATENTS: NI.COM/PATENTS

PFI0

GND

J13 J18

J17

AISENSE

AISENSE

J11

J15

AISENSE

AISENSE

VSUP

AI31

VSUP

AI30

VSUP

AI29

VSUP

AI28

VSUP

AI27

VSUP

AI26

VSUP

A25

VSUP

AI24

J16

J14

Page 8

Caution Any wires connected to the ground must be sufficiently insulated from

NI PXIe-1062Q

2

1

3

6

4

5

C

O

O

LI

N

G

C

LE

AR

A

N

C

E

AN

D

FA

N

FIL

TE

R

M

AIN

T

EN

AN

C

E

R

EQ

U

I

R

ED

.

S

EE M

AN

UAL.

C

O

O

L

IN

G

C

L

E

A

R

A

NC

E

A

N

D

F

A

N

F

I

LT

ER

M

A

I

NT

E

N

A

N

CE

R

E

Q

U

IRE

D.

S

E

E

M

A

N

UA

L.

high voltage.

7. Use the ground lugs to attach a shield wire to the ground.

Note Refer to the NI PXIe-4302/4303 User Manual for details about shielding the

signals.

8. Reinstall the strain-relief bar and tighten the strain-relief screws.

9. Use tie wraps to connect the shielded signal wires to the tie-wrap holes for additional strain

relief when necessary.

10. Reinstall the top cover and tighten the captive top cover screws.

Note For information about sensors, go to ni.com/sensors.

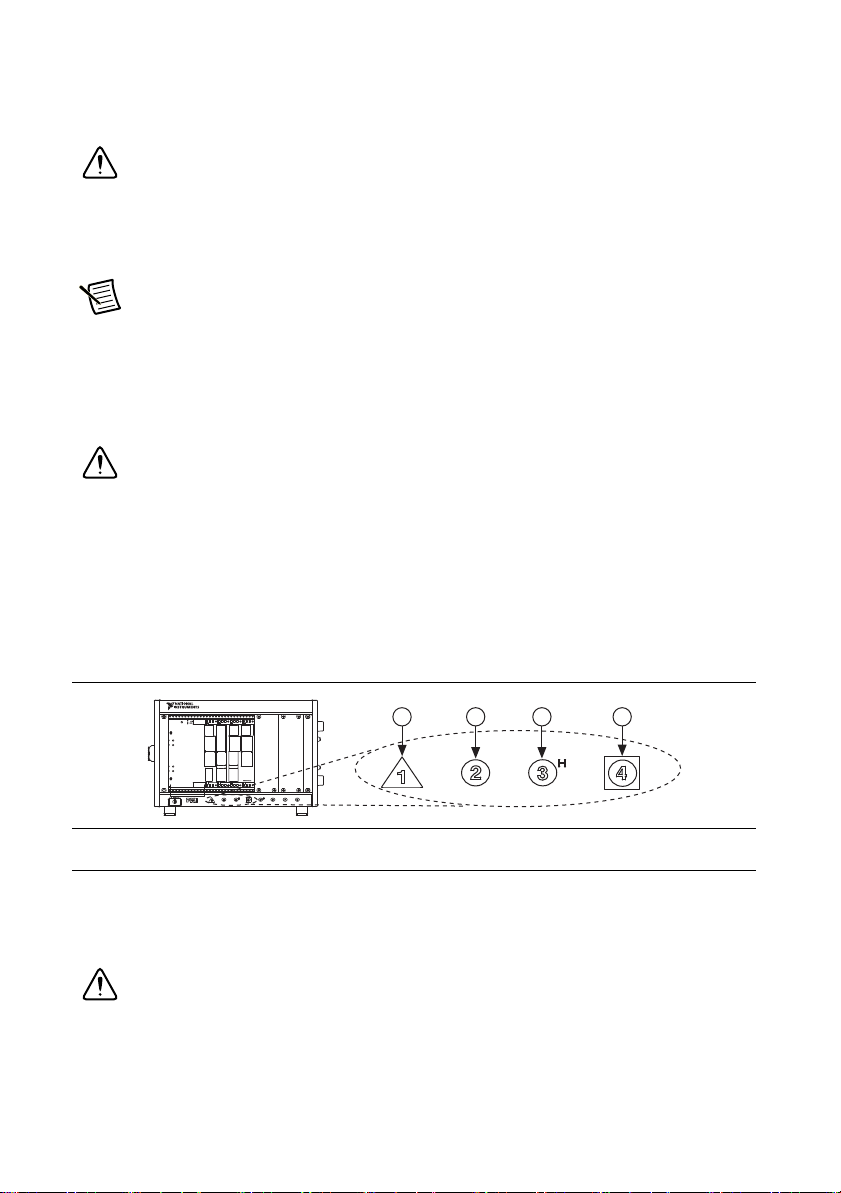

Install the Terminal Block

Refer to Figure 6 to install the terminal block on the module while completing the following

steps:

1. Move the TB-4302/4302C into position in front of the NI PXIe-4302/4303 and engage the

alignment feature with the guide on the associated module.

Figure 6. Installing the TB-4302/4302C on the NI PXIe-4302/4303 Module

1 PXIe Controller

2 PXIe Chassis

8 | ni.com | NI PXIe-4302/4303 and TB-4302/4302C

3 Mounting Screw

4 TB-4302/4302C Terminal Block

5 NI PXIe-4302/4303 Module

6 Alignment Feature

Page 9

2. Attach the TB-4302/4302C to the NI PXIe-4302/4303 module by pushing the terminal

NI PXIe-1

0

6

2

Q

1

COOL

I

N

G

CL

E

A

RA

NC

E

A

ND FA

N

F

I

L

T

ER

MA

I

NT

EN

A

N

CE

R

E

Q

UIRE

D

.

S

EE

MA

NU

A

L

.

COOL

I

NG

CL

E

A

RA

NC

E

A

ND F

A

N

FIL

TE

R

M

AI

NTE

N

A

N

C

E

REQU

IR

ED

.

S

EE

MA

N

UA

L

.

2

block straight into the module. A spring mechanism will lock in the bottom of the terminal

block.

3. Tighten the mounting screw at the top of the TB-4302/4302C to attach it to the

NI PXIe-4302/4303 module.

Note For safety purposes and to prevent damage to equipment when high voltages

are present, all NI PXIe-4302/4303 modules and TB-4302/4302C terminal blocks are

keyed to prevent connection between incompatible terminal blocks, modules, and/or

cables.

4. Power on the chassis.

Figure 7 shows an example NI PXIe-4302/4303 system setup.

Figure 7. Sample NI PXIe-4302/4303 System

1 Terminal Block 2 Signal Input

NI PXIe-4302/4303 and TB-4302/4302C | © National Instruments | 9

Page 10

Confirm NI PXIe-4302/4303 Module Recognition

To confirm module recognition, complete the following steps:

Note Software support for the NI PXIe-4302/4303 is provided by NI-DAQmx. The

DAQ Getting Started Guide, which you can download at

step-by-step NI-DAQmx instructions for installing software and hardware,

configuring channels and tasks, and getting started developing an application. For

detailed NI software version support, refer to the NI-DAQmx Readme.

1. Launch MAX.

2. Expand Devices and Interfaces, and expand the chassis in which the module is located to

confirm that MAX detects the module and terminal block. The terminal block should

appear beneath its associated module. If your module or terminal block is not listed, press

<F5> to refresh MAX. If the module is still not recognized, go to

.

daqmx

ni.com/manuals, offers

ni.com/support/

Tip Using an NI-DAQmx simulated device, you can test NI-DAQmx applications

without installing hardware. Refer to the Create a Simulated Device section for

instructions for creating NI-DAQmx simulated devices.

3. Right-click the module name and select Self-Test. When the self-test completes, a

verification message appears. If an error occurs, refer to

For information about sensors, go to

10 | ni.com | NI PXIe-4302/4303 and TB-4302/4302C

ni.com/sensors.

ni.com/support/daqmx.

Page 11

Run Test Panels

1. In MAX, expand Devices and Interfaces select the chassis in which the module is located.

2. Right-click the device, and select Test Panels.

3. Click Start to test device functions, or Help for operating instructions.

To troubleshoot errors, refer to the NI-DAQmx Help, or go to

ni.com/support.

Take an NI-DAQmx Measurement

NI-DAQmx Channels and Tasks

Refer to the NI-DAQmx Help for complete information about channels and tasks.

Use the DAQ Assistant to configure virtual channels and tasks in MAX or in your application.

Configure a Task Using the DAQ Assistant in MAX

Complete the following steps to create a task using the DAQ Assistant in MAX:

1. In MAX, right-click Data Neighborhood and select Create New to open the DAQ

Assistant.

2. Select NI-DAQmx Task and click Next.

3. Select Acquire Signals.

4. Select the analog input, and the measurement type, such as voltage.

5. Select the physical channel(s) to use and click Next.

NI PXIe-4302/4303 and TB-4302/4302C | © National Instruments | 11

Page 12

6. Name the task and click Finish.

7. Configure the individual channel settings. Each physical channel you assign to a task

receives a virtual channel name. To modify the input range or other settings, select the

channel. Click Details for physical channel information. Configure the timing and

triggering for your task. Click Run.

Use Your NI PXIe-4302/4303 Module in an Application

For NI software version compatibility, refer to the NI-DAQmx Readme, available from Start»

All Programs»National Instruments»NI-DAQmx.

To get started with data acquisition in your application software, refer to the tutorials listed in

Table 1.

Table 1. DAQ Assistant Tutorial Locations

Application Tutorial Location

LabVIEW Go to ni.com and search for Taking an NI-DAQmx Measurement in

LabVIEW.

LabWindows/CVI Go to Help»Contents. Next, go to Using LabWindows/CVI»Data Acquisition»

Taking an NI-DAQmx Measurement in LabWindows/CVI.

Measurement

Studio

NI SignalExpress*Go to Help»Taking an NI-DAQmx Measurement in SignalExpress.

*

NI SignalExpress, an easy-to-use configuration-based tool for data logging applications, is at Start»All

Programs»National Instruments»NI SignalExpress.

Go to NI Measurement Studio Help»Getting Started with the Measurement

Studio Class Libraries»Measurement Studio Walkthroughs»Walkthrough:

Creating a Measurement Studio NI-DAQmx Application.

Programming Examples

NI-DAQmx includes example programs to help you get started developing an application.

LabVIEW and CVI examples are located at Help»Find Examples in your application software.

Text-based code examples are located at All Programs»National Instruments»NI-DAQmx»

Text-Based Code Support. Modify example code and save it in an application, or use examples

to develop a new application or add example code to an existing application.

For other examples, go to

12 | ni.com | NI PXIe-4302/4303 and TB-4302/4302C

ni.com/info and enter the Info Code daqmxexp.

Page 13

Terminal Block Removal

CO

O

L

I

N

G CL

E

A

R

A

N

CE

A

ND

FA

N

F

ILT

E

R MA

IN

TE

N

A

NC

E

R

E

QU

I

R

E

D

. S

E

E

M

A

N

U

A

L

.

To remove the terminal block, refer to Figure 8 while completing the following steps:

Note The chassis can be powered on or off when removing the terminal block.

1. Loosen the terminal block mounting screw located at the top of the terminal block.

2. To remove the terminal block:

a. Raise the latch release using a flathead screwdriver to disengage the latch.

b. With the latch release raised, grasp the terminal block and pull it away from the

module.

Figure 8. Removing the TB-4302/4302C from the NI PXIe-4302/4303 Module

4

1

2

3

COO

LING CLEA

RA

NCE

A

ND FAN FIL

NI

PXI

e-1

062Q

5

1 Mounting Screw

2 Latch Release

3. Store the terminal block in an antistatic protective bag.

3 PXIe Controller

4 PXIe Chassis

TE

R M

A

INTE

N

A

NCE RE

Q

UIRED

. S

E

E

M

A

NUAL.

5 TB-4302/4302C Terminal Block

NI PXIe-4302/4303 and TB-4302/4302C | © National Instruments | 13

Page 14

Module Removal

NI P

X

Ie-

10

62Q

CO

O

L

I

NG

CL

E

A

RA

NC

E

A

ND

F

A

N

FI

L

TE

R

MA

I

NTENA

NC

E

RE

Q

UI

RE

D

.

S

E

E

MA

N

U

A

L

.

21

Caution Do not remove a module with the power on. Doing so can damage the

module.

To remove the module, refer to Figure 9 while completing the following steps:

Note To maintain forced air cooling in the PXIe system, refer to the Maintain

Forced-Air Cooling Note to Users.

1. Make sure that the chassis is powered off before removing the module.

2. Loosen the captive screws on the top and bottom of the module.

Caution Do not pull the front panel to remove the module. Doing so may cause

module components to come into contact with adjacent modules, causing damage to

the modules.

3. Pull the captive screws to unseat the module and slowly slide the module along the guides.

4. Replace the filler panel in the empty slot.

5. Store the module in an antistatic protective bag.

Figure 9. Removing NI PXIe-4302/4303 Modules

1 Captive Screws (Use to remove modules.) 2 Front Panel (Do not use to remove modules.)

14 | ni.com | NI PXIe-4302/4303 and TB-4302/4302C

Page 15

Create a Simulated Device

To run examples without the hardware installed, use an NI-DAQmx simulated device. To create

a simulated device in MAX:

1. Launch MAX.

2. Right click Devices and Interfaces»Create New.

3. From the dialog, select Simulated NI-DAQmx Device or Modular Instrument.

4. Type

5. Select the device from the list provided.

6. Click OK.

4302 or 4303 in the text box at the top of the window.

Cold-Junction Compensation (TB-4302 Only)

The TB-4302 contains a temperature sensor that is used to measure the temperature of the

terminal block for cold-junction compensation, which is performed when computing the

thermocouple temperature measurement.

Cold-junction compensation is the process of measuring the temperature of the screw terminal

junction for the thermocouple and applying a representative compensating temperature to the

temperature measured by the thermocouple channel. The accuracy of the cold-junction

temperature measurement contributes to the accuracy of the overall thermocouple temperature

measurement. The TB-4302 is designed to ensure high-accuracy cold-junction temperature

measurements under a variety of conditions; however, care must be taken to ensure the best

possible accuracy. Refer to the Minimizing Thermal Gradients section for guidelines to

minimize thermal gradients that can impact the CJC accuracy. Refer to the TB-4302 section for

the CJC accuracy specifications.

Minimizing Thermal Gradients

Thermal gradients can be caused by changes in the ambient air temperature near the terminal

block, heat sources from other devices near the terminal block, or by the thermocouple wire if it

conducts heat to or away from the terminal junctions. For optimal CJC accuracy performance,

ensure that changes in ambient temperature and temperature gradients near the terminal block

are kept to a minimum.

Follow these guidelines to minimize thermal gradients that can impact the CJC accuracy:

• Use the smallest gauge thermocouple wire suitable for the application. Smaller wire

transfers less heat to or from the terminal junction.

• Run thermocouple wiring together near the terminal block to keep the wires at the same

temperature.

• Avoid running thermocouple wires near hot or cold objects.

• If you connect any extension wires to thermocouple wires, use wires made of the same

conductive material as the thermocouple wires.

• Minimize adjacent heat sources and air flow across the terminal block.

NI PXIe-4302/4303 and TB-4302/4302C | © National Instruments | 15

Page 16

• Keep the ambient temperature as stable as possible.

• Keep the terminal block, module, and chassis in a stable and consistent orientation.

• Install the PXIe filler panels in any unused slots.

• When stacking the system, avoid stacking the chassis above a heat source as heat rises and

can introduce error.

• Allow the thermal gradients to settle after a change in system power or in ambient

temperature. A change in system power can occur when the system powers on. Refer to the

warm-up time in the NI PXIe-4302/4303 Specifications for more information.

• If your PXIe chassis has fan filters, clean or replace them regularly to ensure proper system

cooling. Refer to the PXI/PXI Express Chassis Fan Filter Kit document for more

information.

Note Refer to the Maintain Forced-Air Cooling Note to Users for more

information about maintaining optimal forced-air cooling for PXI/PXI Express

devices.

More Information

After you install NI-DAQmx, the NI-DAQmx documentation is available from Start»All

Programs»National Instruments»NI-DAQmx. Additional resources are online at

gettingstarted

You can access online device documentation by right-clicking your module in MAX and

selecting Help»Online Device Documentation. A browser window opens to

manuals

documents for supported modules are included on the NI-DAQmx disc.

with the results of a search for relevant documents. If you do not have Web access,

.

ni.com/

ni.com/

Troubleshooting

• Go to ni.com/support/install or ni.com/kb.

• If you need to return your National Instruments hardware for repair or device calibration,

go to

ni.com/info and enter rdsenn to start the Return Merchandise Authorization

(RMA) process.

Specifications (TB-4302/4302C)

Note NI PXIe-4302/4303 module specifications are located in the

NI PXIe-4302/4303 Specifications document.

All performance specifications are typical unless otherwise noted. These specifications are valid

within the full operating temperature range.

16 | ni.com | NI PXIe-4302/4303 and TB-4302/4302C

Page 17

Calibration Interval

TB-4302............................................................ No calibration

TB-4302C ......................................................... 1 year interval (verification only)

Electrical

TB-4302

Input range........................................................ Refer to NI PXIe-4302/4303 Specifications

CJC accuracy .................................................... 1.5 °C

TB-4302C

Input range

Nominal .................................................... ±20 mA

Minimum .................................................. ±20.38 mA

Typical ...................................................... ±20.68 mA

Current shunt

Value ......................................................... 5 Ω

Accuracy ................................................... 0.5% max

Temperature stability ................................ 25 ppm/°C

Input impedance

between AI to AISENSE .................................. 47 Ω

Max voltage of AISENSE ................................ ±8.4 V

pins

V

sup

Current ...................................................... 2 A max

Voltage ...................................................... 30 V max

Overvoltage protection

between AI, AISENSE, and AIGND................ ±30 V for up to two AI pins

1, 2

Mechanical

Screw terminal wire gauge ............................... 1.5 mm2 (16 AWG), max

1

Combines CJC sensor accuracy and temperature difference between the CJC sensor and each screw

terminal.

2

Represents performance for wire gauge of 24 AWG.

NI PXIe-4302/4303 and TB-4302/4302C | © National Instruments | 17

Page 18

Physical

12.95 cm

(5.10 in.)

15.28 cm

(6.02 in.)

Figure 10. TB-4302/4302C Dimensions

Weight

TB-4302 ....................................................556 g (20 oz)

TB-4302C .................................................632 g (22 oz)

Caution Clean the hardware with a soft, nonmetallic brush. Make sure that the

hardware is completely dry and free from contaminants before returning it to service.

Environmental Specifications

Maximum altitude............................................. 2,000 m (800 mbar), at 25 °C ambient

temperature

Pollution Degree ...............................................2

Indoor use only

Operating Environment

Ambient temperature range ..............................0 °C to 55 °C

(Tested in accordance with IEC 60068-2-1 and

Relative humidity range....................................10% to 90%, noncondensing

18 | ni.com | NI PXIe-4302/4303 and TB-4302/4302C

IEC 60068-2-2. Meets MIL-PRF-28800F

Class 3 low temperature limit and

MIL-PRF-28800F Class 2 high temperature

limit.)

(Tested in accordance with IEC 60068-2-56.)

Page 19

Storage Environment

Ambient temperature range .............................. -40 °C to 71 °C

(Tested in accordance with IEC 60068-2-1 and

IEC 60068-2-2. Meets MIL-PRF-28800F

Class 3 limits.)

Relative humidity range.................................... 5% to 95%, noncondensing

(Tested in accordance with IEC 60068-2-56.)

Shock and Vibration

Operating shock ................................................ 30 g peak, half-sine, 11 ms pulse

(Tested in accordance with IEC 60068-2-27.

Meets MIL-PRF-28800F Class 2 limits.)

Random vibration

Operating ..................................................5 Hz to 500 Hz, 0.3 g

Non-operating........................................... 5 Hz to 500 Hz, 2.4 g

(Tested in accordance with IEC 60068-2-64.

Non-operating test profile exceeds the

requirements of MIL-PRF-28800F, Class 3.)

rms

rms

Safety

Measurement Category..................................... I

Caution Do not connect the TB-4302/4302C to signals or use for measurements

within Measurement Categories II, III or IV.

1

Caution The protection provided by the TB-4302/4302C can be impaired if it is

used in a manner not described in this document.

Safety Standards

This product meets the requirements of the following standards of safety for electrical equipment

for measurement, control, and laboratory use:

• IEC 61010-1, EN 61010-1

• UL 61010-1, CSA 61010-1

Note For UL and other safety certifications, refer to the product label or the Online

Product Certification section.

1

Measurement Categories CAT I and CAT O are equivalent. These test and measurement circuits are not

intended for direct connection to the MAINS building installations of Measurement Categories CAT II,

CAT III, or CAT IV.

NI PXIe-4302/4303 and TB-4302/4302C | © National Instruments | 19

Page 20

Electromagnetic Compatibility

This product meets the requirements of the following EMC standards for electrical equipment

for measurement, control, and laboratory use:

• EN 61326-1 (IEC 61326-1): Class A emissions; Basic immunity

• EN 55011 (CISPR 11): Group 1, Class A emissions

• EN 55022 (CISPR 22): Class A emissions

• EN 55024 (CISPR 24): Immunity

• AS/NZS CISPR 11: Group 1, Class A emissions

• AS/NZS CISPR 22: Class A emissions

• FCC 47 CFR Part 15B: Class A emissions

• ICES-001: Class A emissions

Note In the United States (per FCC 47 CFR), Class A equipment is intended for use

in commercial, light-industrial, and heavy-industrial locations. In Europe, Canada,

Australia and New Zealand (per CISPR 11) Class A equipment is intended for use

only in heavy-industrial locations.

Note Group 1 equipment (per CISPR 11) is any industrial, scientific, or medical

equipment that does not intentionally generate radio frequency energy for the

treatment of material or inspection/analysis purposes.

Note For the standards applied to assess the EMC of this product, refer to the

Online Product Certification section.

CE Compliance

This product meets the essential requirements of applicable European Directives as follows:

• 2014/35/EU; Low-Voltage Directive (safety)

• 2014/30/EU; Electromagnetic Compatibility Directive (EMC)

Online Product Certification

Refer to the product Declaration of Conformity (DoC) for additional regulatory compliance

information. To obtain product certifications and the DoC for this product, visit

certification

Certification column.

20 | ni.com | NI PXIe-4302/4303 and TB-4302/4302C

, search by model number or product line, and click the appropriate link in the

ni.com/

Page 21

Environmental Management

⬉ᄤֵᙃѻક∵ᶧࠊㅵ⧚ࡲ⊩ ˄Ё

RoHS

˅

Ёᅶ᠋

National Instruments

ヺড়Ё⬉ᄤֵᙃѻકЁ䰤ࠊՓ⫼ᶤѯ᳝ᆇ⠽䋼ᣛҸ

(RoHS)

DŽ݇Ѣ

National InstrumentsЁRoHS

ড়㾘ᗻֵᙃˈ䇋ⱏᔩ

ni.com/

environment/rohs_china

DŽ

(For information about China RoHS compliance,

go to

ni.com/environment/rohs_china

.)

NI is committed to designing and manufacturing products in an environmentally responsible

manner. NI recognizes that eliminating certain hazardous substances from our products is

beneficial to the environment and to NI customers.

For additional environmental information, refer to the Minimize our Environmental Impact Web

ni.com/environment. This page contains the environmental regulations and

page at

directives with which NI complies, as well as other environmental information not included in

this document.

Waste Electrical and Electronic Equipment (WEEE)

EU Customers At the end of the product life cycle, all products must be sent to a

WEEE recycling center. For more information about WEEE recycling centers,

National Instruments WEEE initiatives, and compliance with WEEE Directive

2002/96/EC on Waste and Electronic Equipment, visit

.

weee

ni.com/environment/

World Wide Support and Services

The National Instruments website is your complete resource for technical support. At ni.com/

support

self-help resources to email and phone assistance from NI Application Engineers.

Vis it

other services.

Vis it

facilitates technical support and ensures that you receive important information updates from NI.

National Instruments corporate headquarters is located at 11500 North Mopac Expressway,

Austin, Texas, 78759-3504. National Instruments also has offices located around the world. For

telephone support in the United States, create your service request at

1 866 ASK MYNI (275 6964). For telephone support outside the United States, visit the

Worldwide Offices section of

provide up-to-date contact information, support phone numbers, email addresses, and current

events.

you have access to everything from troubleshooting and application development

ni.com/services for NI Factory Installation Services, repairs, extended warranty, and

ni.com/register to register your National Instruments product. Product registration

ni.com/niglobal to access the branch office websites, which

NI PXIe-4302/4303 and TB-4302/4302C | © National Instruments | 21

ni.com/support or dial

Page 22

Refer to the NI Trademarks and Logo Guidelines at ni.com/trademarks for more information on National Instruments trademarks. Other

product and company names mentioned herein are trademarks or trade names of their respective companies. For patents covering National

Instruments products/technology, refer to the appropriate location: Help»Patents in your software, the patents.txt file on your media, or the

National Instruments Patents Notice at ni.com/patents. You can find information about end-user license agreements (EULAs) and third-party

legal notices in the readme file for your NI product. Refer to the Export Compliance Information at ni.com/legal/export-compliance

for the National Instruments global trade compliance policy and how to obtain re levant HTS codes, ECCNs, and other import/export data. NI MAKES

NO EXPRESS OR IMPLIED WARRANTIES AS TO THE ACCURACY OF THE INFORMATION CONTAINED HEREIN AND SHALL NOT BE LIABLE FOR

ANY ERRORS. U.S. Government Customers: The data contained in this manual was developed at private expense and is subject to the applicable

limited rights and restricted data rights as set forth in FAR 52.227-14, DFAR 252.227-7014, and DFAR 252.227-7015.

© 2015 National Instruments. All rights reserved.

77008A-01 Jul15

3

Loading...

Loading...