Page 1

USER GUIDE

SLSC-12101

Prototyping Module

RADIAL

SELECTOR

CONNECTOR J1

CONNECTOR J2

SLSC -12101

POWER

READY

PROTOTYPING MODULE

Overview

The SLSC-12101 is a prototyping module intended to help SLSC module developers quickly

prototype designs. The module is Level-2 compatible, but can be Level-1 compatible if you

configure the rear I/O signals properly.

The SLSC-12101 features a MAX V CPLD as a module controller, which is pre-programmed

to provide basic access to the board peripherals. The MAX V CPLD is divided into four banks,

and the I/O for each is routed to its own region in the prototyping area. Each bank may have

Page 2

independent voltage settings to allow the use of different digital standards supported by the

CPLD. Custom circuitry in the prototyping area has access to 24 V and 3.3 V rails from the

backplane, 5 V from the auxiliary power supply and corresponding bank power supply. Two of

the regions of the prototyping area, Bank 1 and Bank 2, include connections to two 44-pin

DSUB connectors in the front panel. A fifth region in the prototyping area, labeled RTI,

provides additional space to access the upper rear I/O connectors.

The peripherals designed into the SLSC-12101 board include two front panel LEDs (which

follow the recommendations of the SLSC Design Guidelines), a 16-position rotary switch, four

temperature sensors, and 17 ports 8-bit wide routed to their corresponding banks in the

prototyping area.

Additionally, to ease debugging and prototyping, a JTAG header compatible with Altera's USB

Blaster pinout is populated on the board which allows you to program the CPLD with a

custom design. A MICTOR connector exists between the CPLD and the SLSC connector to

allow monitoring of the SLSC interface signals using a logic analyzer such as the one on NI

VirtualBench.

Note All modifications to this module must comply with the Switch Load and

Signal Conditioning Module Design Specifications. It is the user's responsibility to

make sure that the product is modified and used in a way that complies with local

rules, regulations, and best practices.

Note All specifications and certifications in the manual apply only to the unaltered

product as provided by National Instruments. Any changes to the product invalidate

these specifications and certifications.

Related Documentation

This user guide assumes you have access to the documentation of the SLSC Module

Development Kit (MDK) and that you are familiar with the following documents:

• Switch Load and Signal Conditioning Module Design Specifications—Specifications

SLSC modules must abide in order to be compatible with SLSC systems.

• SLSC Design Guidelines—Describes best practices recommended for SLSC modules.

• SLSC-12101 Schematic—Schematic of the SLSC-12101 prototyping module.

• SLSC-12101 Specifications—Specifications of the unaltered SLSC MDK.

Other Files Available for the SLSC-12101 Module

These files are included in the SLSC Example Modules Files .zip file of the SLSC MDK.

• Module Controller VHDL code—Slsc12101Top.vhd, PkgEdBlock.vhd,

PkgRevision.vhd, PkgSlsc12101Registers.vhd, PkgSlscProtocol.vhd,

EdBlock.vhd, Interrupt.vhd, IoPort.vhd, Leds.vhd,

SpiChannelSelect.vhd, Control.vhd, CrcGen.vhd, ShiftRegister.vhd,

Spi.vhd

• Module Controller Quartus project files—SlscCpldTop.qpf, SlscCpldTop.qsf,

SlscCpldTop.sdc, SlscCpldTop.pof

• SLSC-12101 Capabilities files—SLSC-12101.bin, SLSC-12101.json

2 | ni.com | SLSC-12101 User Guide

Page 3

• 2D Mechanical Drawings and 3D Models

• SLSC-12101 PCB Drawing

Required Software

• NI LabVIEW 2015 or newer

• NI-SLSC driver

• To customize the CPLD: Quartus Design software, found on Quartus Software's website

1

• To customize the Flash: createNvmemImage.py, included in the SLSC MDK files

Other Files

• SLSC-12101.vi—Example VI to access the SLSC-12101 properties.

Getting Started with the SLSC-12101

The SLSC-12101 can be inserted into an SLSC chassis and used the way it is shipped.

Note The SLSC chassis and SLSC modules do not support hot plug-in. The entire

chassis must be powered down when a module is installed or removed.

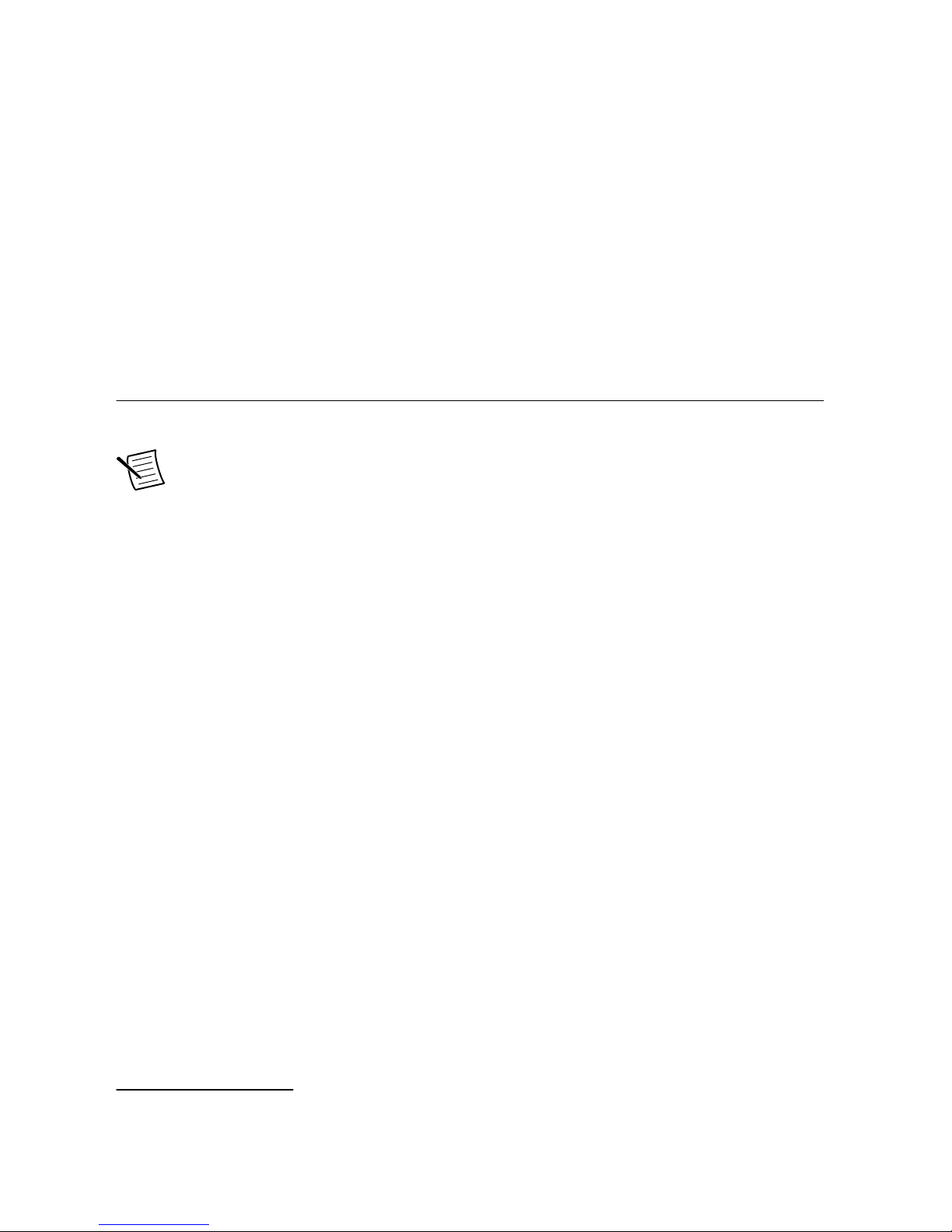

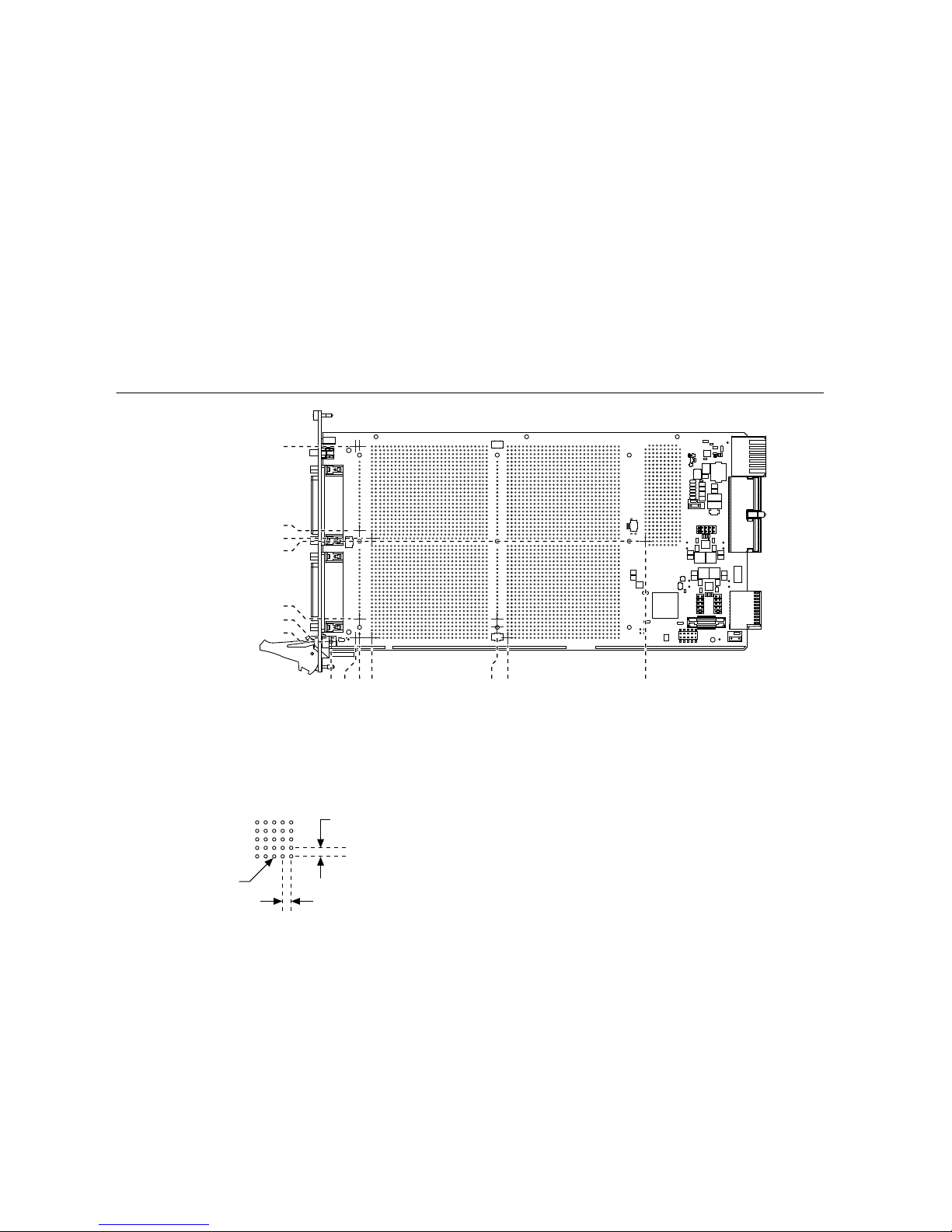

1. Ensure the CPLD power supplies are properly set.

After taking the module out of its packaging, check that three jumpers are inserted

between pins 5 and 10 of headers W2, W3, and W4. This ensures that the voltage is set to

3.3 V for the CPLD I/O banks 2, 3, and 4.

1

Quartus Design Software is offered in a variety of editions with different features and price ranges.

Refer to the Quartus Software website for more information.

SLSC-12101 User Guide | © National Instruments | 3

Page 4

Figure 1. Jumper Configuration

2. Install the module in the SLSC chassis.

Power off the SLSC chassis and then insert the module into an available slot. If you are

using the JTAG connector to program the CPLD or MICTOR cable to a logic analyzer,

leave one empty slot to the right of the module for cable routing. Connect the cable(s)

before inserting the module in the chassis.

3. Power up the chassis.

As soon as the chassis is powered up, the power LED of the front panel of the

SLSC-12101 should be lit green. The chassis will boot-up and start querying the slots for

module presence. Once the module is detected, the Ready LED should be lit green.

4. Access the module's properties and physical channels.

Use a host computer with LabVIEW and the NI-SLSC driver installed, and connected to

the same network as the SLSC chassis. Open SLSC-12101.vi. This VI gives you

access to the properties and physical channels that control the peripherals of the module.

You can control the LEDs, read the value dialed in the rotary switch, and access all the

DIO going to the prototyping area.

Description of the SLSC-12101

Mechanical Features

Unless otherwise noted, mechanical attributes and restrictions such as maximum component

height are defined in the Switch Load and Signal Conditioning Module Design Specifications.

4 | ni.com | SLSC-12101 User Guide

Page 5

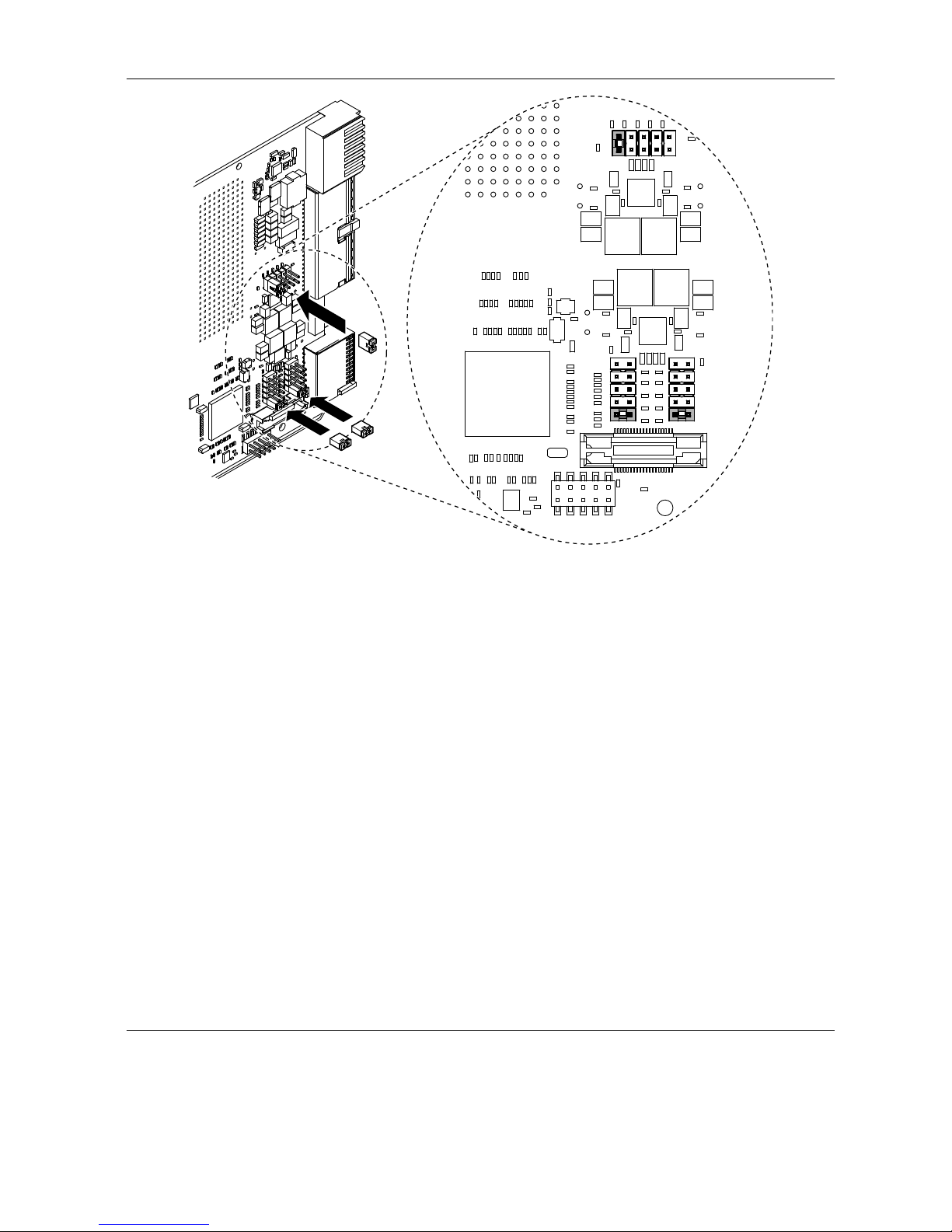

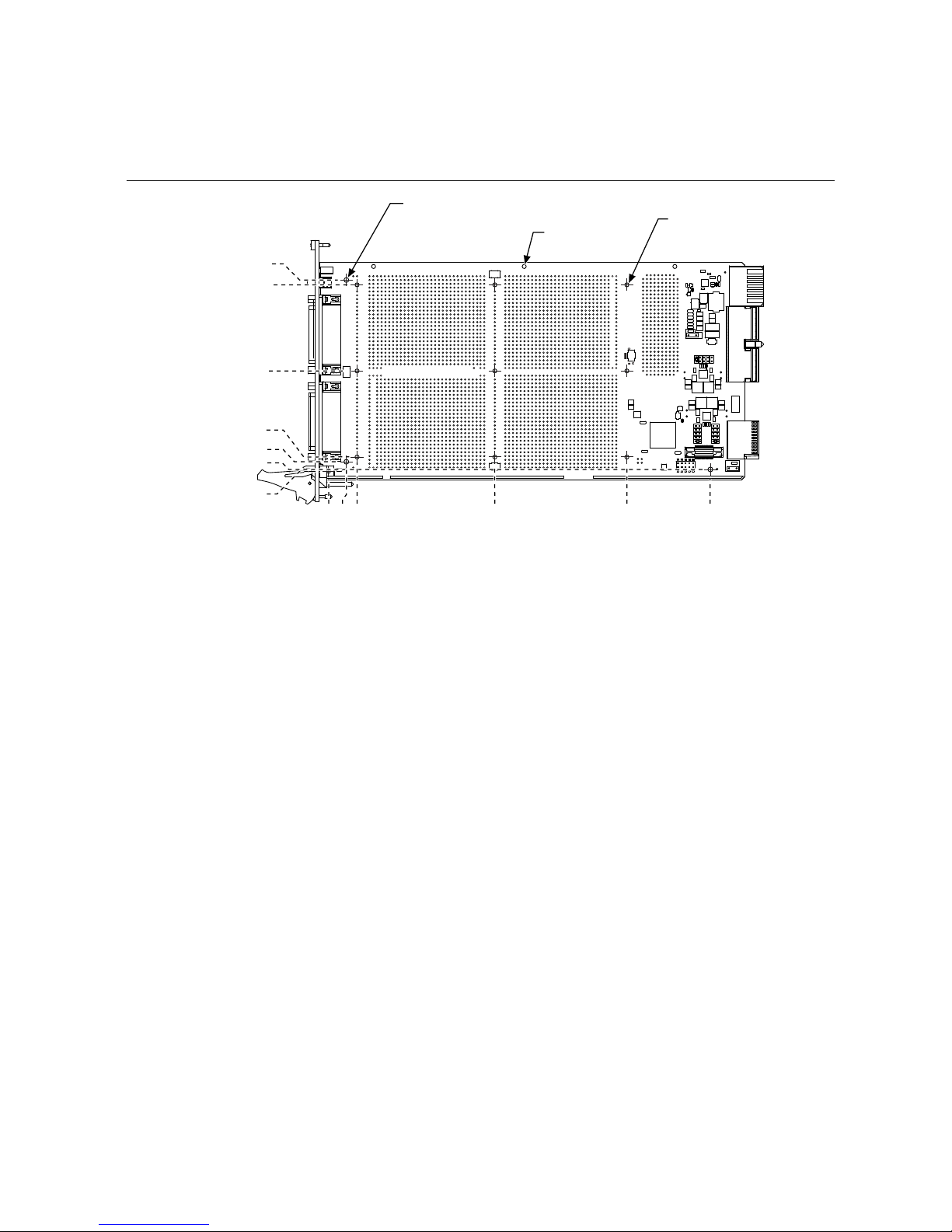

Top View and Main Components

The following figure shows the top view of the SLSC-12101 module and highlights its most

relevant components.

Figure 2. SLSC-12101 Top View

1 1 1 2

BANK 1

BANK 2

BANK 3

RTI

BANK 4

1

6

5

4

3

1. Temperature Sensor (4x)

2. Voltage Configuration Header - Bank 2

3. Voltage Configuration Header - Bank 4

4. Voltage Configuration Header - Bank 3

5. MICTOR Connector (for NI VirtualBench)

6. JTAG Header (CPLD Programming)

• Prototyping area—The biggest area of the board is used for prototyping and is divided

into five areas filled with thru-hole grids. These grids can be used with standard 0.10"

headers, or may have wires or thru-hole components soldered to them. The prototyping

area provides access to the majority of the CPLD I/O, the front and rear connectors,

power supplies, and ground.

• Module controller—Implemented in a MAX V CPLD, handles the communication with

the SLSC chassis and controls the peripherals.

• Variable power supplies for CPLD Banks 2, 3, and 4—These power supplies can be set

by the developer by placing the jumper of the corresponding header in the correct

position.

Note The jumpers must be set before powering the module and should not be

changed once the system is powered.

• Front and rear connectors—The connectors on the front panel and those facing the RTI

area are the same as those recommended in the Switch Load and Signal Conditioning

Module Design Specifications and in the SLSC Design Guidelines.

• Rotary switch—The position of the rotary switch can be accessed by standard SLSC

properties.

• Front panel LEDs—The LEDs can be controlled through standard SLSC properties.

• Temperature sensors—4x ADT7310 are connected to the CPLD.

SLSC-12101 User Guide | © National Instruments | 5

Page 6

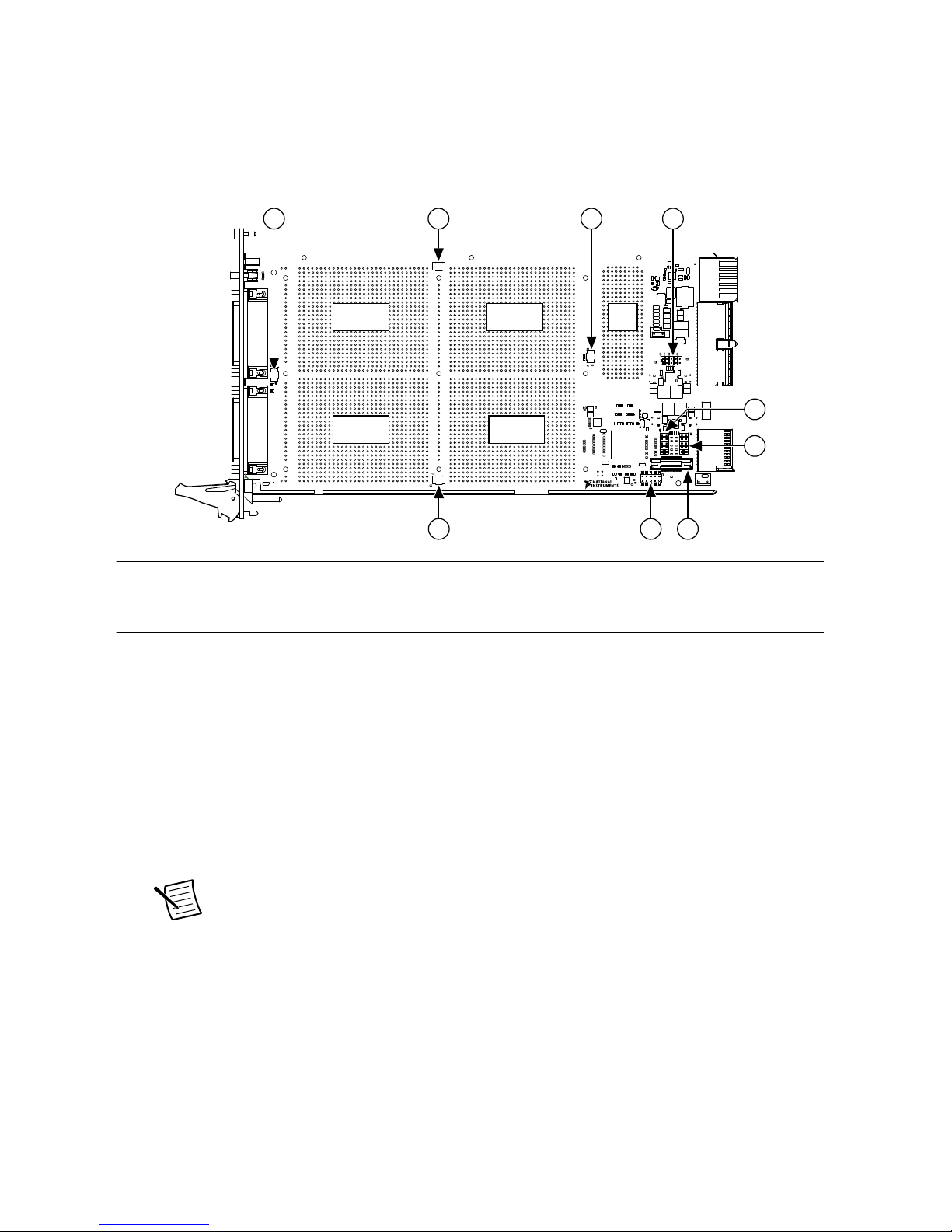

Front Panel

The following figure shows the front view of the module and highlights its features.

Figure 3. Front Panel

CONNECTOR J1 CONNECTOR J2

SLSC -12 101

PROTOTYPING MODULE

POWER

READY

RADIAL

SELECTOR

5

6

7

8

9

3

2

1

4

1. SLSC Interface Compatibility Glyph—This

indicates chassis compatibility type.

2. SLSC Rear I/O Compatibility Glyph—This

indicates RTI compatibility type, which is left blank

for customization. See the Switch Load and Signal

Conditioning Module Design Specifications for

more information.

3. Top Module Mounting Screw

4. LEDs—See Front Panel LEDs section for more

details.

5. Rotary Switch

6. Connector J1 (high-density 44-position DSUB)

7. Connector J2 (high-density 44-position DSUB)

8. Injector/Ejector Handle

9. Bottom Module Mounting Screw

6 | ni.com | SLSC-12101 User Guide

Page 7

Connectors

The SLSC-12101 is designed with the front and rear connectors recommended in the Switch

Load and Signal Conditioning Module Design Specifications and SLSC Design Guidelines.

The module has the proper connectors for meeting Level-1 compatibility, but you must

properly configure signals to and from these connectors in the RTI prototyping area. Refer to

the Switch Load and Signal Conditioning Module Design Specifications for compatibility

requirements.

Prototyping Area Hole Arrays

The following figure provides information about the arrays of holes found in the prototyping

areas. These holes may be used for direct soldering of components and wires, or for attaching

standard headers to connect to jumpers or secondary PCBs.

Figure 4. Prototyping Area Hole Array Details

2.54 mm

(0.100 in.)

2.54 mm

(0.100 in.)

Ø 1.02 mm

(0.040 in.)

plated

Prototyping Area

Hole Array Detail

129.54 mm (5.100 in.)

71.12 mm (2.800 in.)

68.58 mm (2.700 in.)

66.68 mm (2.625 in.)

15.24 mm (0.600 in.)

2.54 mm (0.100 in.)

0.0 mm (0.0 in.)

0.0 mm (0.0 in.)

16.51 mm (0.650 in.)

19.05 mm (0.750 in.)

27.31 mm (1.075 in.)

117.48 mm (4.625 in.)

208.92 mm (8.225 in.)

110.49 mm (4.350 in.)

Mounting Holes

The following figure provides information about the location and size of mounting holes. The

three holes across the top of the PCB are reserved for future extension hardware. See the

Switch Load and Signal Conditioning Module Design Specifications for information about

placement restrictions around these holes.

SLSC-12101 User Guide | © National Instruments | 7

Page 8

Twelve other mounting holes are provided: three larger holes in the corners of the board, and

nine smaller holes forming a grid in the center of the board in the prototyping area. These may

be used at the discretion of the module developer to provide mechanical fixturing as needed,

including shields, brackets, or mounting standoffs for custom secondary PCBs.

Figure 5. Mounting Hole Sizes and Locations

127.00 mm

(5.000 in.)

3X 66.68 mm

(2.625 in.)

3X 9.53 mm

(0.375 in.)

6.35 mm (0.250 in.)

0.0 mm (0.0 in.)

1.27 mm (0.50 in.)

253.54 mm (9.982 in.)

3X Ø 3.18 mm (0.125 in.)

Non-plated Thru Holes

3X Holes Reserved

for Extension HW

9X Ø 2.69 mm (0.106 in.)

Non-plated Thru Holes

3X 110.49 mm (4.350 in.)

3x 198.12 mm (7.800 in.)

0.0 mm (0.0 in.)

2X 11.94 mm (0.470 in.)

3X 19.05 mm (0.750 in.)

3X 123.83 mm

(4.875 in.)

Electrical Features

The Input Rails and Fuse

The module takes its power from the 24 V and 3.3 V provided by the chassis. 3.3 V is only

used for the VCCO of Bank 1 and other support circuitry such as the 40 MHz oscillator, flash

memory, and thermal sensors. The rest of the banks and the core power used by the CPLD

come from cascaded switcher regulators powered from an auxiliary 5 V supply connected to

the 24 V rail. Banks 2-4 can be set to different values to allow you to use different digital

standards available in the CPLD.

All the 24 V, 5 V, and Banks 1-4 VCCOs are available in the prototyping area to be used by

the support circuitry required by your design. You should make sure your design does not

exceed the power limitations of these rails.

As required by the Switch Load and Signal Conditioning Module Design Specifications, the

24 V power supply is protected by a 3.5 mA fuse. See the SLSC-12101 Bill of Materials for

more information.

8 | ni.com | SLSC-12101 User Guide

Page 9

Auxiliary 5 V Power Supply

The programmable power supplies and the CPLD core power supply of 1.8 V are all powered

by an auxiliary 5 V power supply which is powered from the 24 V provided by the SLSC

chassis. This 5 V power supply is also available in the prototyping area. The power supply can

support a maximum of 6 A.

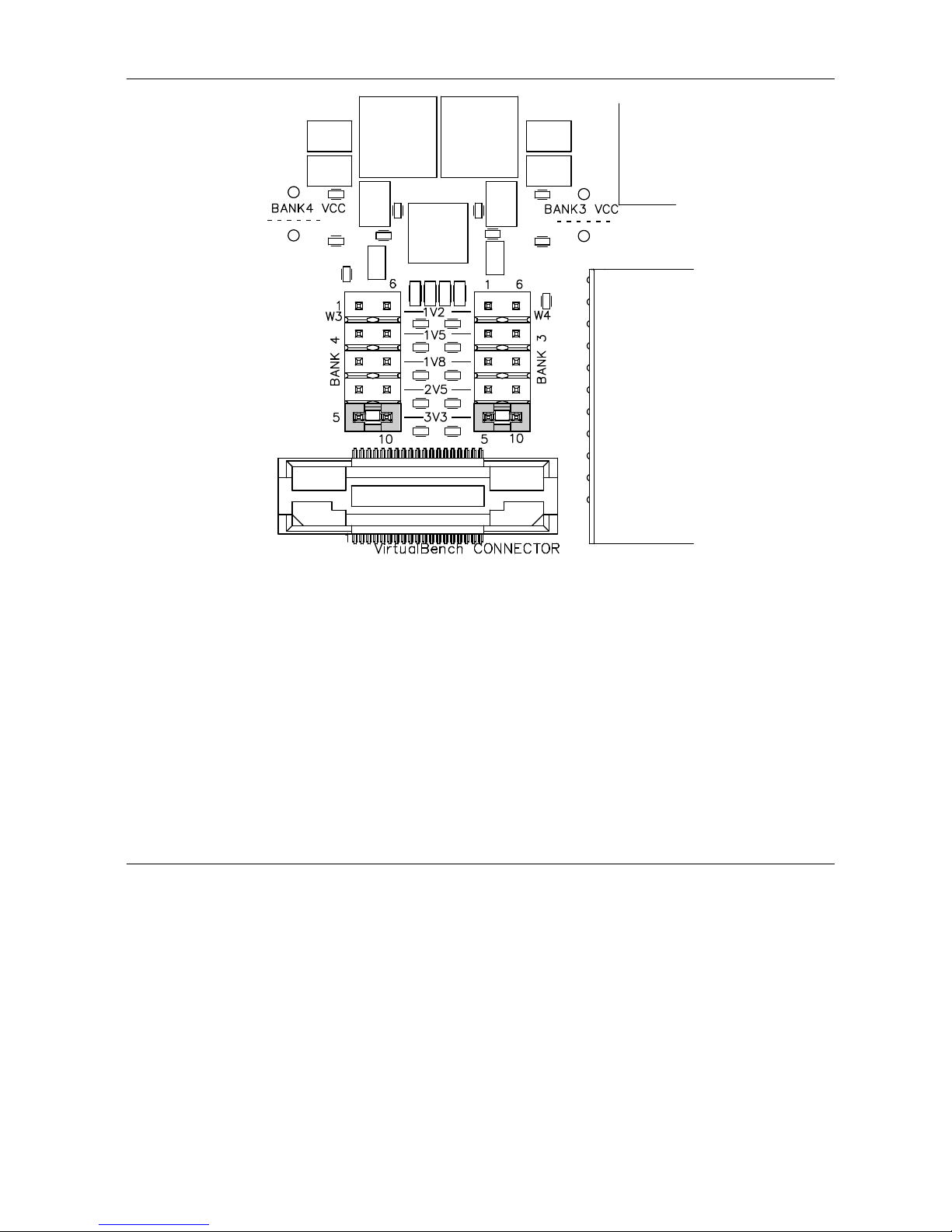

Variable Voltage Power Supplies

The MAX V supports VCCIO of 1.2 V, 1.5 V, 1.8 V, 2.5 V, and 3.3 V in order to use several

I/O standards. The SLSC-12101 has user-configurable power supplies for three of the four

CPLD banks. The voltages are set by placing a jumper in the corresponding header connecting

the pair labeled with the desired voltage. The jumper should be placed on the board before the

module is inserted in the SLSC chassis.

Once a voltage is set for a bank, all the signals on that bank need to use an I/O standard

supported by that voltage. For more information about the supported I/O standards and rules to

interconnect I/O standards with the MAX V CPLD, refer to Altera's MAX V Device Handbook.

The voltages of all the banks are also routed to the prototyping area to allow the circuits built

there to use it. The maximum current that can be withdrawn from each bank depends on the

maximum current the source can provide, as well as the estimated current used by the CPLD.

Bank 1 is powered directly from the SLSC chassis and, by SLSC Specification 1.0, the module

shall not withdraw more than 400 mA. Banks 2-4 take their power from 24 V on-board power

supplies and can provide up to 2 A. In addition to the limitations imposed by the current limits

on the different rails on the module, you should also consider the power dissipation limitations

as defined in the Switch Load and Signal Conditioning Module Design Specifications.

Table 1. Bank Rail Available Voltages and Current Limits

Bank Available Voltages Maximum Current

1 3.3 V fixed, provided by the SLSC backplane 400 mA

2 1.2 V, 1.5 V, 1.8 V, 2.5 V, 3.3 V 2 A

3 1.2 V, 1.5 V, 1.8 V, 2.5 V, 3.3 V 2 A

4 1.2 V, 1.5 V, 1.8 V, 2.5 V, 3.3 V 2 A

Module Controller

The SLSC-12101 Module Controller is implemented using Altera's MAX V

5M1270ZF256I5N. The CPLD is shipped pre-programmed with the compiled version of the

Slsc12101Top.vhd design also included in the SLSC Module Development Kit. The

controller's default image already implements the EdBlock.vhd design to handle SLSC

Frames and the required compliance registers as described in Chapter 8 of the Switch Load

and Signal Conditioning Design Specifications. Through the ED Mode, the controller can

access the peripherals present on the board, such as the front panel LEDs, the front panel

rotary switch, and 17 8-bit I/O ports routed from the CPLD to the prototyping area.

SLSC-12101 User Guide | © National Instruments | 9

Page 10

CPLD Programming

The SLSC-12101 has a header that directly connects to Altera's USB Blaster to quickly

program the CPLD with a custom design. You can use the SLSC12101Top.vhd file provided

in the SLSC Module Development Kit as a starting point for development.

Front Panel LEDs

The SLSC-12101 has Power and Ready LEDs as recommended in section 3.6 of the Switch

Load and Signal Conditioning Design Specifications. The LEDs can be lit red, yellow, and

green—continuously or blinking—so you can implement the information in Table 3-1 of that

specification. The default module controller behavior implements the Power Solid Green and

the Ready Solid Green as recommended in Table 3-1.

The Leds.vhd component provided with the SLSC Module Development Kit implements an

easy interface to control the LEDs through the NI.ReadyLedColor, NI.ReadyLedMode,

NI.PowerLedColor, and NI.PowerLedMode properties described in the capabilities file

included as part of the kit.

Rotary Switch

The 16-position, 4-bit rotary switch on the front panel is accessible from the CPLD. The value

can be accessed through the SLSC API using the NI.RotarySwitch property.

SI5356A Clock Generator

The module has pads for you to add an SI5356A clock generator should you need more clocks

in your design. This clock generator can provide up tp four different frequencies on eight pins.

Each output clock has two pins. In the SLSC-12101, one pin is routed to a global clock pin of

the CPLD, and another pin is routed to the prototyping area. For more information on the

routing of these clocks to the prototyping area, refer to the pinout sections and the

SLSC-12101 Schematic.

Design Development, Characterization, and

Debugging

The SLSC-12101 was designed to provide an easy way to prototype SLSC modules in

development. Use the resources provided by the SLSC chassis, the module controller, and the

connectors to help you implement your design, to characterize some aspects such as power

consumption and dissipation, as well as for increased visibility for diagnostics.

Prototyping Area

Most of the board consists of the prototyping areas, which are filled with hole arrays of

2.54 mm (0.100 in.) pitch. These are all plated holes to ease soldering. There are five main

grid areas for prototyping: Bank 1, Bank 2, Bank 3, Bank 4, and RTI. Each bank gives access

to signals of the corresponding bank on the CPLD as well as to the corresponding bank

VCCO. Banks 1 and 2 also provide access to the front panel connectors.

10 | ni.com | SLSC-12101 User Guide

Page 11

The RTI grid contains holes connected to the rear I/O connectors, XJ02 and XJ03, along with

several grounds, access to the 24 V supply from the backplane, and two pairs of holes

connected to each of the bank rails.

Each of the five grids has its own coordinate system. Rows are numbered from top to bottom,

and columns are marked with letters from left to right. Hole A1 is always at the top-left corner.

These coordinates are referenced in this document.

For a detailed assignment of the hole arrays, refer to the SLSC-12101 pinout sections of this

manual.

Power Consumption Validation

To ease the validation of power consumption in the module, you can monitor the power rails.

The 24 V and 3.3 V rails provided by the backplane go through bridge resistors that can be

removed so that current measurements can be performed. Resistor R 16 connects the

backplane 24 V rail to the module, and W1 provides two holes to connect a bypass cable for

current measurement or an external power supply. The 3.3 V rail uses resistor R168 as the

bridge and W6 as the bypass holes.

Figure 6. 24 V Bridge Resistor and Bypass Holes

The power supplies for banks 2-4 do not have a bridge resistor. Instead they are routed in such

a way that they have a thick trace on the primary side of the board so it can be cut. Holes exist

for bypass cables. A dotted line with a label of the bank it supplies power to indicates where

the trace should be cut. See the following figures.

Figure 7. Bank 2 Voltage Setting Header and Dotted Lines for Power Trace Cutting

SLSC-12101 User Guide | © National Instruments | 11

Page 12

Figure 8. Bank 3 and Bank 4 Voltage Setting Header

Logic Analyzer Connector

A 43-pin MICTOR Connector is placed between the CPLD and SLSC Interface connector for

direct monitoring of the signals using a logic analyzer. In addition to the SLSC signals, 17

debug lines are connected directly from the CPLD to the connector. In the shipping CPLD

image, two of these lines are controlled by DIO ports, one line is a copy of the internal 40

MHz clock, and 14 lines are only driven to GND. You can use all 17 lines to monitor internal

signals of your design. See pinout sections for more information on the signal routing to this

connector.

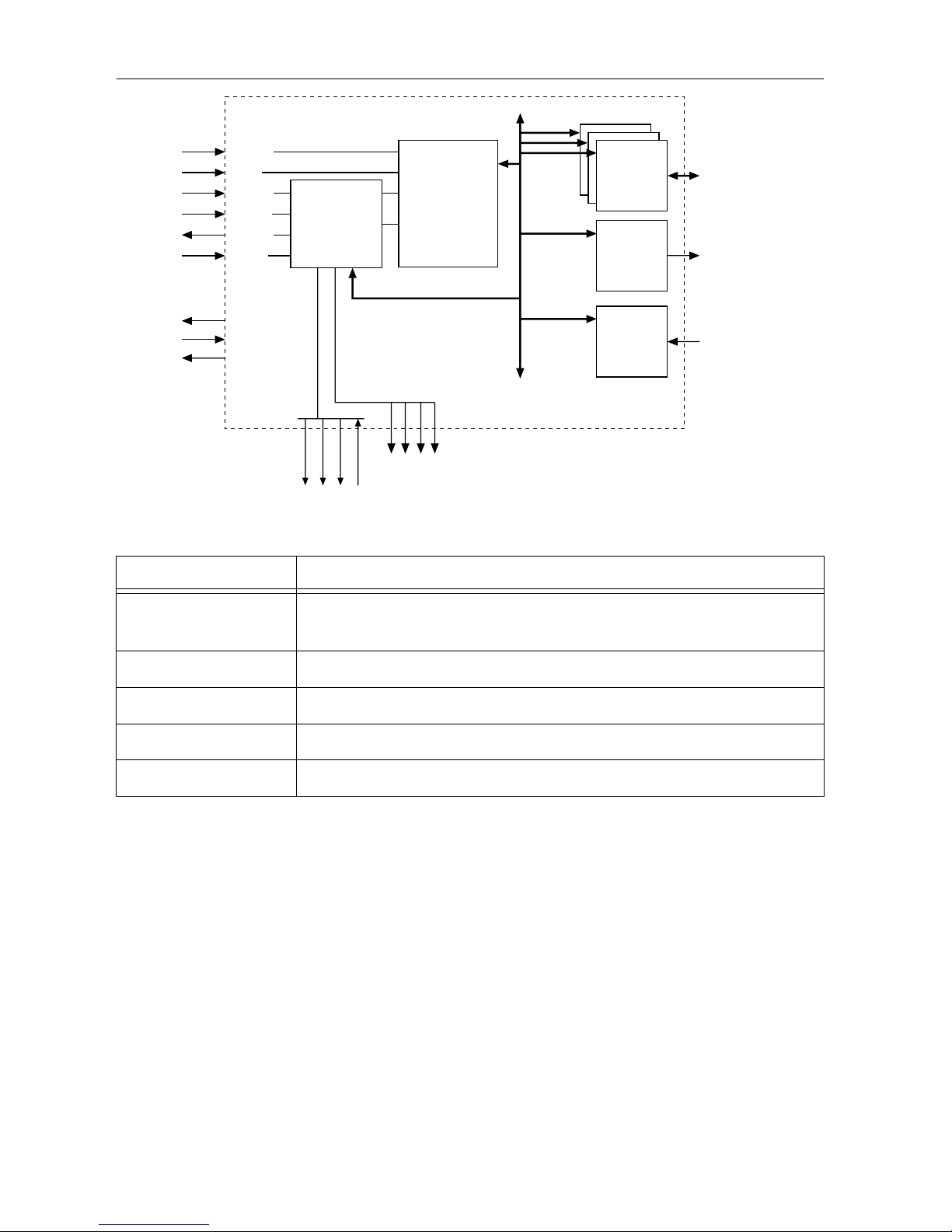

Description of the Module Controller HDL

General Architecture

The SLSC-12101 Module Controller instantiated in the MAX V CPLD is implemented in

VHDL. The top-level file is Slsc12101Top.vhd. The design uses an instance of EdBlock

(EdBlock.vhd) to handle the communication between the SLSC chassis and the Module

Controller. The design features an SPI Channel selector which can be used for future SPI

channel expansion in the SLSC architecture. This channel expansion can be used in this

module to access temperature sensors in the prototyping area.

12 | ni.com | SLSC-12101 User Guide

Page 13

Figure 9. SLSC-12101 Block Diagram

Prototyping

Area Banks

Front Panel

LEDs

Temperature

Sensors

Alarms

Other Internal

Registers

4x Temp Sensor

Channels

Rdy/Rst#

SLSC-12101 Controller

(5M1270ZF25615N)

SpiClk

SpiMOSI

ED_SS#

ID_SS#

Int#

TTM

TFM

Id SPI Channel

MISO

ID_SS

SpiClk

SpiMosi

SpiMISO

RegInterface Bus

IoPort.vhd

Interrupt.vhd

Interrupt

LEDs

17x I/O

Ports

EdBlock

SPI

Channel

Select

SpiChannelSelect.vhd

EdBlock RegInterface

(cRegPortOut, cRegPortIn)

EdBlock.vhd

Spi.vhd

Control.vhd

CrcGen.vhd

SlscCpldTop.vhd

Table 2. Main Files Included in the Module Development Kit (Without Dependencies)

File Name Notes

Slsc12101Top.vhd Top-level file which can be compiled to generate a programming

bitfile for the CPLD

SlscCpldTop.qpf Quartus II project file

SlscCpldTop.qsf Quartus II settings file

SlscCpldTop.sdc Constraints file

SlscCpldTop.pof Programming bitfile

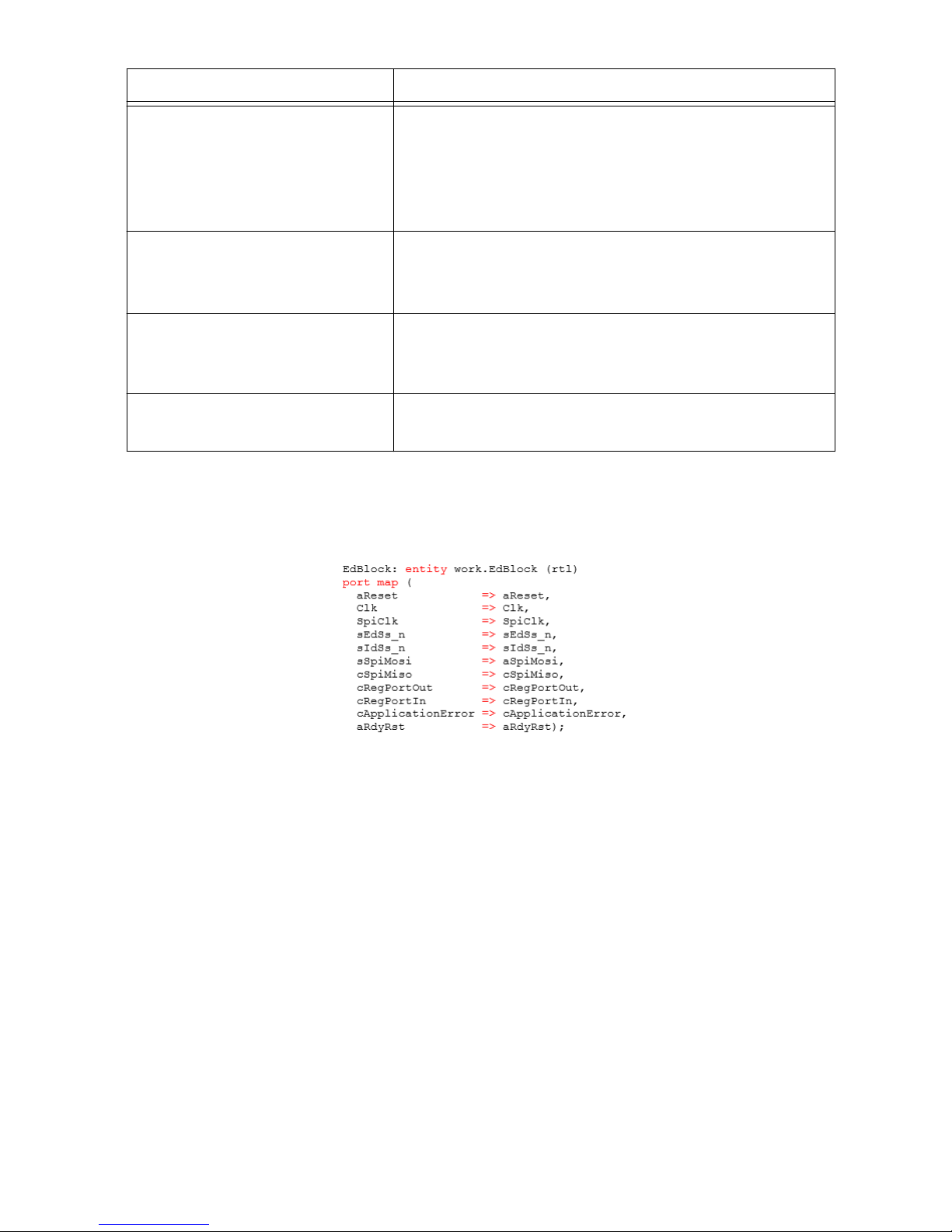

EdBlock Implementation

The EdBlock abstracts out the frames received through the SPI lines of the SLSC interface

into a register port. You can use it to easily implement registers in your design by calling the

RegisterRead and RegisterWrite functions declared in the PkgEdBlock.vhd file. You will

only need to focus on implementing a digital circuit that converts these register accesses into

useful control and monitor signals in your design.

The Error Detection block is implemented in VHDL and consists of the following files:

SLSC-12101 User Guide | © National Instruments | 13

Page 14

File Name Notes

EdBlock.vhd Top-level file of the component which can be instantiated

in a CPLD top-level design. It handles incoming SLSC

frames, handles errors when detected, and executes the

corresponding register access when valid frames are

received.

Spi.vhd, Control.vhd,

CrcGen.vhd,

ShiftRegister.vhd

Sub-components of the EdBlock.

PkgEdBlock.vhd Contains the RegisterRead and RegisterWrite functions

and records to easily implement registers in a top-level

design.

PkgSlscProtocol.vhd Contains constants relevant to the SLSC Specifications

1.0.

Error Detection Block Instantiation

You can instantiate the Error Detection block in your design as follows:

Variable Voltage Power Supplies

The MAX V supports VCCIO of 1.2 V, 1.5 V, 1.8 V, 2.5 V, and 3.3 V in order to use several

I/O standards. The SLSC-12101 has user-configurable power supplies for three of the four

CPLD banks. The voltages are set by placing a jumper in the corresponding header connecting

the pair labeled with the desired voltage. The jumper should be placed on the board before the

module is inserted in the SLSC chassis.

Once a voltage is set for a bank, all the signals on that bank need to use an I/O standard

supported by that voltage. For more information about the supported I/O standards and rules to

interconnect I/O standards with the MAX V CPLD, refer to Altera's MAX V Device Handbook.

The voltages of all the banks are also routed to the prototyping area to allow the circuits built

there to use it. The maximum current that can be withdrawn from each bank depends on the

maximum current the source can provide, as well as the estimated current used by the CPLD.

Bank 1 is powered directly from the SLSC chassis and, by SLSC Specification 1.0, the module

shall not withdraw more than 400 mA. Banks 2-4 take their power from 24 V on-board power

14 | ni.com | SLSC-12101 User Guide

Page 15

supplies and can provide up to 2 A. In addition to the limitations imposed by the current limits

on the different rails on the module, you should also consider the power dissipation limitations

as defined in the Switch Load and Signal Conditioning Module Design Specifications.

Table 3. Bank Rail Available Voltages and Current Limits

Bank Available Voltages Maximum Current

1 3.3 V fixed, provided by the SLSC backplane 400 mA

2 1.2 V, 1.5 V, 1.8 V, 2.5 V, 3.3 V 2 A

3 1.2 V, 1.5 V, 1.8 V, 2.5 V, 3.3 V 2 A

4 1.2 V, 1.5 V, 1.8 V, 2.5 V, 3.3 V 2 A

Peripheral Implementations

Along with EdBlock, the Module Development Kit provides a few examples of useful

instances that can be used directly with EdBlock to implement common functionality to

interact with a wide range of devices that can be placed in the prototyping area or with

peripherals already present on the board.

File Name Notes

Interrupt.vhd Customizable entity that implements interrupts which follow

the Switch Load and Signal Conditioning Design Specifications

and are compatible with the EdBlock register map.

IoPort.vhd Customizable entity that implements digital I/O compatible

with the EdBlock register map.

Leds.vhd LED controller compatible with the EdBlock register map that

allows the control of bi-color LEDs for the SLSC-12101.

SpiChannelSelect.vhd Customizable entity that allows switching SPI channels for all

the slaves in the SLSC-12101.

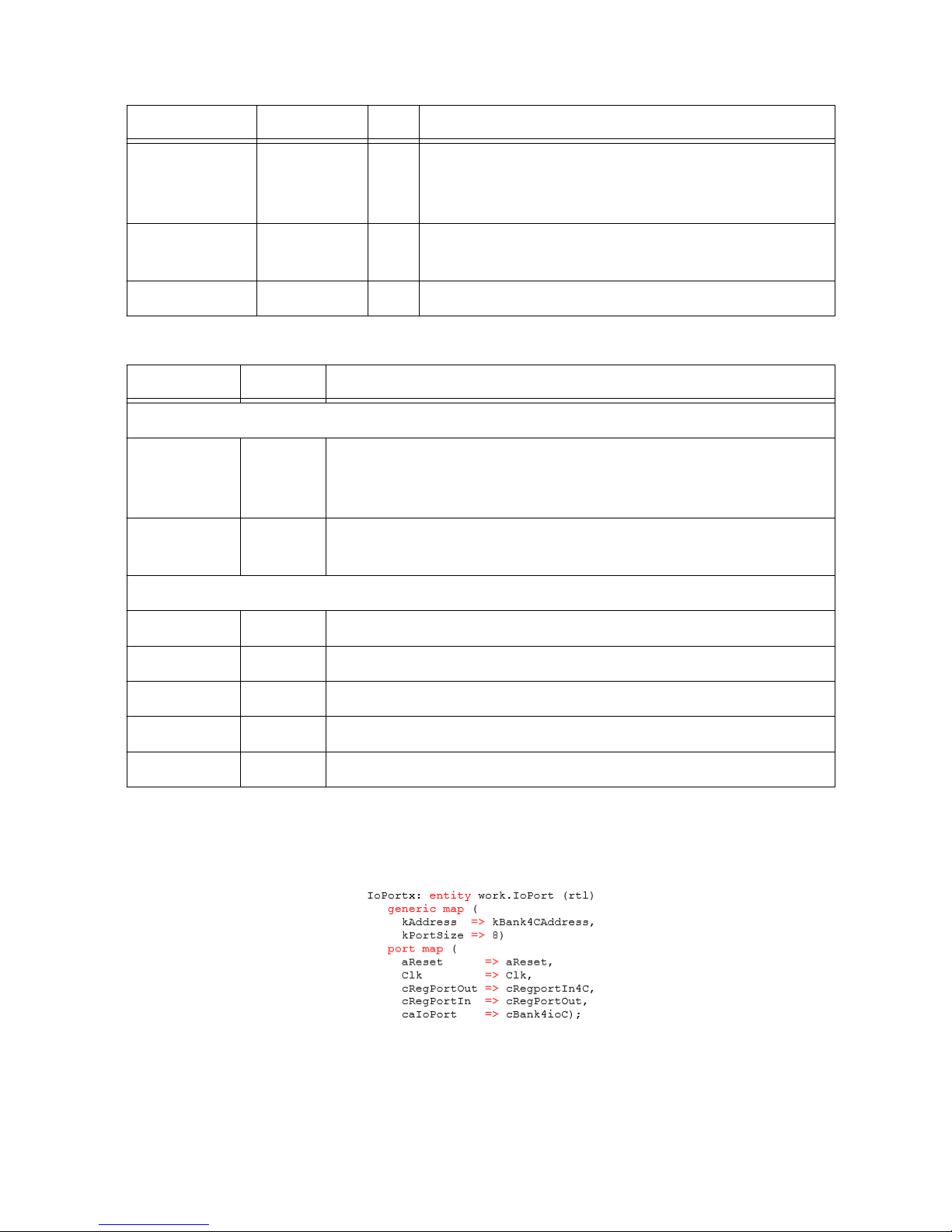

Digital Input and Output

The IoPort.vhd file allows the implementation of bi-directional signals on the CPLD. The

entity is configurable via generics to set its address base and its port size. Each instantiated

block will add three registers of the same size that are defined by the generic kPortSize.

Because of this, if the entity is instantiated, you should avoid adding other registers in the

range kAddress to kAddress + 2 where kAddress is the address generic of the entity.

The maximum length of kPortSize is 64.

SLSC-12101 User Guide | © National Instruments | 15

Page 16

Table 4. Register Descriptions

Register Name Address Type Explanation

Output kAddress R/W The value of this register defines the output state

when the corresponding direction bit is set as output

(1).

Direction kAddress + 1 R/W For each pin of the port, 1 configures the pin as an

output and 0 configures the pin an input.

Input kAddress + 2 R Mirrors the state of the external pin for read.

Table 5. Signal Descriptions

Signal Name Direction Explanation

Generics

kAddress N/A Defines the base address of the block. This address will also

correspond to the Output register. The next two consecutive

addresses are assigned to Direction and Input.

kPortSize N/A Determines the number of I/O implemented. Acceptable values go

from 1 to 64.

Signals

aReset In Board Reset Signal

Clk In Stable clock provided by the CPLD.

caIoPort In/Out Digital input/output.

cRegPortOut Out Signals to the EdBlock Register Port.

cRegPortIn In Signals from the EdBlock Register Port.

I/O Port Instantiation

You can instantiate the I/O Port block in your design as follows:

16 | ni.com | SLSC-12101 User Guide

Page 17

SLSC Interrupt

This entity implements an interrupt block that complies with Section 8.1 of the Switch Load

and Signal Conditioning Design Specifications. It is configurable through generic constants. It

can handle edge-sensitive and level-sensitive signals. The configuration on the sensitivity is

controlled through kSensitivity. The incoming interrupts should be synchronous to Clk.

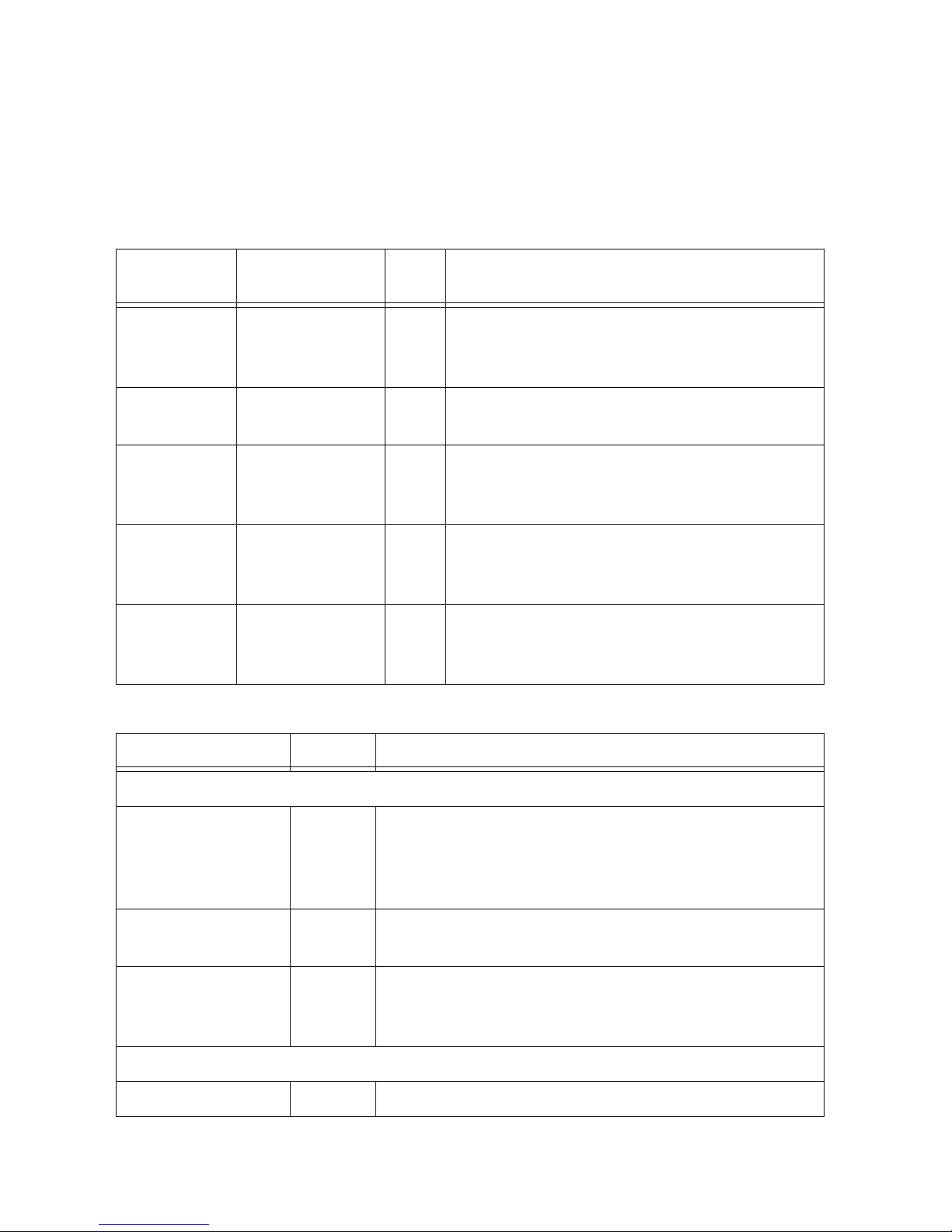

Table 6. Register Descriptions for the Interrupt Block

Register

Name

Address Type Explanation

Status kRegisterBase R A 1 indicates that an interrupt has occurred. The

interrupt is propagated to IntIn# only if the

corresponding bit has been enabled.

Mask kRegisterBase + 1 R A 1 indicates that the corresponding interrupt is

enabled.

Enable kRegisterBase + 2 Strobe Writing a 1 enables the corresponding interrupt

and turns the corresponding bit in the Mask

Register into 1. Writing a 0 has no effect.

Disable kRegisterBase + 3 Strobe Writing a 1 disables the corresponding interrupt

and turns the corresponding bit in the Mask

Register into a 0. Writing a 0 has no effect.

Ack kRegisterBase + 4 Strobe Writing a 1 to the corresponding bit removes the

interrupt condition. This bit is self-clearing.

Writing a 0 has no effect.

Table 7. Signal Descriptions of the Interrupt Component

Signal Name Direction Explanation

Generics

kRegisterBase N/A Defines the base address of the block. This address will

also correspond to the Status register. The next four

consecutive addresses are assigned to Mask,

InterruptEnable, InterruptDisable, and Ack.

kNumberOfInterrupts N/A Determines the number of interrupts implemented.

Acceptable values range from 1 to 64.

kSensitivity N/A Determines the sensitivity of the corresponding line of

cInterruptsIn. A 0 defines a level sensitive interrupts,

while a 1 defines an edge sensitive.

Signals

aReset In Board reset signal.

SLSC-12101 User Guide | © National Instruments | 17

Page 18

Table 7. Signal Descriptions of the Interrupt Component (Continued)

Signal Name Direction Explanation

Clk In Stable clock provided by the CPLD.

cRdyRst In Ready/Rst signal. The Block follows the reset

requirements defined in Chapter 6 of the Switch Load and

Signal Conditioning Design Specifications. Additionally,

this implementation disables and clears all interrupts

when the module goes to Reset.

cRegPortOut Out Signals to the EdBlock Register Port.

cRegPortIn In Signals from the EdBlock Register Port.

cInterrupt_n Out Interrupt signal of the SLSC interface.

cInterruptsIn In Drive 1 to these signals to generate an interrupt. The

sensitivity of each of these signals is configured by

kSensitivity.

Instantiation of the Interrupt Block

You can instantiate the interrupt block in your design as follows.

LED Implementation

This entity provides an LED controller for 2-pin bicolor LEDs. In this case, the entity has two

green/red dual LEDs. The block allows control of the LEDs and illuminates them green, red,

and yellow either in a solid or blinking pattern. The yellow color is achieved by alternating

between red and green at approximately 300 Hz.

This component has a single register; the address is defined by the kAddress generic.

18 | ni.com | SLSC-12101 User Guide

Page 19

Table 8. Relative Addresses of the Interrupt Block Registers

Register Name Address Type Explanation

LedControl kAddress R/W This register contains two groups of 3 fields. Each group

uses a 4-bit nibble of a byte and each controls each of the

LEDs in the front panel.

Table 9. Bitfield Descriptions of the LedControl Register

Field Name Bit Range Field Size

(bits)

Explanation

ReadyColor 0-1 2 Determines whether the LED is lit and in which

color:

• b'00: Off

• b'01: Red

• b'10: Green

• b'11: Yellow

ReadyMode 2 1 Determines how the LED lights:

• b'0: solid

• b'1: toggles

PowerColor 3-5 2 Determines whether the LED is lit and in which

color:

• b'00: Off

• b'01: Red

• b'02: Green

• b'11: Yellow

PowerMode 6 1 Determines how the LED lights:

• b'0: solid

• b'1: toggles

Table 10. Signal Description of the LED Component

Signal Name Direction Explanation

Generics

kAddress N/A Defines the base address of the block. This address corresponds to

the LedControl register.

Signals

aReset In Board reset signal.

SLSC-12101 User Guide | © National Instruments | 19

Page 20

Table 10. Signal Description of the LED Component (Continued)

Signal Name Direction Explanation

Clk In Stable clock provided by the CPLD. It expects a 40 MHz clock.

cRdyRst In Ready/Rst signal. If RdyRst is low, the state of the LED is Power

solid green and Ready off.

cRegPortOut Out Signals to the EdBlock register port.

cRegPortIn In Signals from the EdBlock register port.

cReadyRed Out Connects to the Ready red anode.

cReadyGreen Out Connects to the Ready green anode,

cPowerRed Out Connects to the Power red anode.

cPowerGreen Out Connects to the Power green anode.

Instantiating the LEDs Component

You can instantiate the LEDs component as follows:

Creating Registers

Read and write registers can easily be implemented using the EdBlock register interface by

invoking the RegisterRead and RegisterWrite functions defined in the PkgEdBlock.vhd file.

These two functions have the following signatures:

Function

Signature

RegisterWrite RegisterWrite(<Register Address (natural)>,

cRegPortOut)

RegisterRead RegisterRead(<Register Address (natural)>,

cRegPortOut)

Both functions will return a Boolean value. This value is true if the command in the incoming

master packet matches the function and if the address in the master packet matches the address

20 | ni.com | SLSC-12101 User Guide

Page 21

of the first argument. The following example shows the implementation of a 64-bit read and

write register on address 0x20.

Instantiating a Readable Register with the RegisterRead

Function

Instantiating a Write Register with the RegisterWrite Function

Other Auxiliary Files

These files contain constants used in the shipping version of the CPLD. You can change these

values or create your own files to better fit your design.

File Name

Notes

PkgRevision.vhd Code version.

PkgSlsc12101Registers.vhd Registers constants.

Programming the CPLD

The J18 header is compatible with Altera's 10-pin plug.

SLSC-12101 User Guide | © National Instruments | 21

Page 22

Figure 10. JTAG Header for CPLD Programming

Table 11. CPLD JTAG Pinout Descriptions

J18 Connector Pin Schematic Name CPLD Bank CPLD Pin Pin Name

1 CPLD_TCK 1 P3 #TCK

2 GND

3 CPLD_TDO 1 M5 #TDO

4 3.3 V

5 CPLD_TMS 1 N4 #TMS

6 NC

7 NC

8 NC

9 CPLD_TDI 1 L6 #TDI

10 GND

Pinouts

Front I/O Connector Pinout

See the following image for the front I/O connector pinout.

22 | ni.com | SLSC-12101 User Guide

Page 23

Figure 11. Front Connector Pinout

PIN 31

PIN 44

PIN 30

PIN 15

PIN 1

PIN 16

Prototyping Area

The front connectors J10 and J11 (labeled J1 and J2 on the front panel) are routed directly to

the prototyping area without any series resistors. The traces have 50 Ω characteristic

impedance and support a maximum of 400 mA.

All signals from the CPLD to the prototyping area are routed with 50 Ω characteristic

impedance traces and have a 33.2 Ω series resistor places near the CPLD.

All connections between XJ2 and the RTI prototyping area are routed with 50 Ω characteristic

impedance without any series resistors.

The connections between XJ3 and the RTI prototyping area with high current traces are

capable of carrying 8 A each. For more information, refer to the SLSC-12101 Specifications,

which can be found on ni.com/manuals.

Hole Marking Codes

Holes in the prototyping area are marked according to their purpose, as shown below.

SLSC-12101 User Guide | © National Instruments | 23

Page 24

Table 12. Marking Codes to Identify the Holes in the Prototyping Area

Unconnected Ground Signal Power

Unconnected holes

do not have any

silkscreen marking.

These holes can be

used for any

connections. An

example of this kind

of hole is M8 of

Bank 1.

Holes connected

to ground are

marked with a

solid white square

(represented in

black in this

document). An

example of this

type of hole is

AD4 of Bank 2.

Holes connected to a trace

have a box around them. The

box can be a rectangle around

adjacent holes connected to

traces. An example of this

type of hole is C18 of Bank 3.

An example of a rectangle

enclosing adjacent holes are

holes AB7 to AB9 of Bank 3.

The rectangles have labels

attached providing an

indication of which signals

these are. For example, C18

of Bank 3 is labeled

CPLD(133) and holes AB7 to

AB9 are labeled

CPLD(134:136).

Holes connected

to power rails

have a circle

around them. An

example of this

hole is A23 of

Bank 4, which is

a hole connected

to the 5 V rail.

These may also

have boxes

around them to

help with

labeling.

24 | ni.com | SLSC-12101 User Guide

Page 25

Bank 1 Prototyping Area

Figure 12. Bank 1 Prototyping Area

Table 13. CPLD Connectivity to Bank 1 Prototyping Area

Bank 1 Lattice

Lattice

Location

Schematic

Name

2

CPLD

Bank

CPLD

Pin

HDL Name Physical Channel

Name

C14 Bank1_IO(19) 1 G3 cBank1ioA(0) Bank1_PortA_DIO0

E13 Bank1_IO(20) 1 G4 cBank1ioA(1) Bank1_PortA_DIO1

E14 Bank1_IO(22) 1 H1 cBank1ioA(2) Bank1_PortA_DIO2

AC13 Bank1_IO(23) 1 H2 cBank1ioA(3) Bank1_PortA_DIO3

AC14 Bank1_IO(24) 1 H3 cBank1ioA(4) Bank1_PortA_DIO4

AE14 Bank1_IO(25) 1 H4 cBank1ioA(5) Bank1_PortA_DIO5

AE13 Bank1_IO(27) 1 J1 cBank1ioA(6) Bank1_PortA_DIO6

2

In the silkscreen, these signals are marked CPLD(Pin Number) for space reasons.

SLSC-12101 User Guide | © National Instruments | 25

Page 26

Table 14. Connector 1 Connectivity to Bank 1 Prototyping Area

Connector J1

J1 Pin Schematic Name

3

Lattice

Coordinate

(Bank 1)

J1 Pin Schematic Name

4

Lattice

Coordinate

(Bank 1)

1 Front1_IO(1) A24 23 Front1_IO(23) D24

2 Front1_IO(2) A23 24 Front1_IO(24) D23

3 Front1_IO(3) A22 25 Front1_IO(25) D22

4 Front1_IO(4) A21 26 Front1_IO(26) D21

5 Front1_IO(5) A20 27 Front1_IO(27) D20

6 Front1_IO(6) A19 28 Front1_IO(28) D19

7 Front1_IO(7) A18 29 GND GND

8 Front1_IO(8) A17 30 Front1_IO(30) D17

9 Front1_IO(9) A16 31 Front1_IO(31) D16

10 Front1_IO(10) A15 32 Front1_IO(32) D15

11 Front1_IO(11) A14 33 Front1_IO(33) D14

12 Front1_IO(12) A13 34 Front1_IO(34) D13

13 Front1_IO(13) A12 35 Front1_IO(35) D12

14 Front1_IO(14) A11 36 Front1_IO(36) D11

15 Front1_IO(15) A10 37 Front1_IO(37) D10

16 Front1_IO(16) A9 38 Front1_IO(38) D9

17 GND GND 39 Front1_IO(39) D8

18 Front1_IO(18) A7 40 Front1_IO(40) D7

19 Front1_IO(19) A6 41 Front1_IO(41) D6

20 Front1_IO(20) A5 42 Front1_IO(42) D5

3

In the silkscreen, these signals are marked IO1(Pin Number) for space reasons.

4

In the silkscreen, these signals are marked IO1(Pin Number) for space reasons.

26 | ni.com | SLSC-12101 User Guide

Page 27

Table 14. Connector 1 Connectivity to Bank 1 Prototyping Area (Continued)

Connector J1

J1 Pin Schematic Name

3

Lattice

Coordinate

(Bank 1)

J1 Pin Schematic Name

4

Lattice

Coordinate

(Bank 1)

21 Front1_IO(21) A4 43 Front1_IO(43) D4

22 Front1_IO(22) A3 44 Front1_IO(44) D3

Table 15. Miscellaneous Signals In Bank 1 Prototyping Area

Miscellaneous Signals

Coordinate Signal Coordinate Signal

A1-D1 3.3 V B2-B24 GND

A25-D15 3.3 V E25-AC25 GND

AD1 3.3 V AD2-AD24 GND

AE1 3.3 V C24 GND

AD25 3.3 V C23 VCC (5 V)

AE25 3.3 V AE16 LAT_CLK2

E1-AC1 GND AE17 LAT_CLK1

3

In the silkscreen, these signals are marked IO1(Pin Number) for space reasons.

4

In the silkscreen, these signals are marked IO1(Pin Number) for space reasons.

SLSC-12101 User Guide | © National Instruments | 27

Page 28

Bank 2 Prototyping Area

Figure 13. Bank 2 Prototyping Area

Table 16. CPLD Connectivity to Bank 2 Prototyping Area

Bank 2 Lattice

Lattice

Location

Schematic Name CPLD

Bank

CPLD

Pin

HDL Name Physical Channel

Name

C19 Bank2_IO(51) 2 A10 cBank2ioA(0) Bank2_PortA_DIO0

C18 Bank2_IO(52) 2 A11 cBank2ioA(1) Bank2_PortA_DIO1

C17 Bank2_IO(53) 2 A12 cBank2ioA(2) Bank2_PortA_DIO2

C16 Bank2_IO(54) 2 A13 cBank2ioA(3) Bank2_PortA_DIO3

C15 Bank2_IO(55) 2 A15 cBank2ioA(4) Bank2_PortA_DIO4

C14 Bank2_IO(56) 2 A2 cBank2ioA(5) Bank2_PortA_DIO5

C13 Bank2_IO(57) 2 A4 cBank2ioA(6) Bank2_PortA_DIO6

C12 Bank2_IO(58) 2 A5 cBank2ioA(7) Bank2_PortA_DIO7

C11 Bank2_IO(59) 2 A6 cBank2ioB(0) Bank2_PortB_DIO0

C10 Bank2_IO(60) 2 A7 cBank2ioB(1) Bank2_PortB_DIO1

C9 Bank2_IO(61) 2 A8 cBank2ioB(2) Bank2_PortB_DIO2

28 | ni.com | SLSC-12101 User Guide

Page 29

Table 16. CPLD Connectivity to Bank 2 Prototyping Area (Continued)

Bank 2 Lattice

Lattice

Location

Schematic Name CPLD

Bank

CPLD

Pin

HDL Name Physical Channel

Name

C8 Bank2_IO(62) 2 A9 cBank2ioB(3) Bank2_PortB_DIO3

E8 Bank2_IO(64) 2 B10 cBank2ioB(4) Bank2_PortB_DIO4

E9 Bank2_IO(65) 2 B11 cBank2ioB(5) Bank2_PortB_DIO5

E10 Bank2_IO(66) 2 B12 cBank2ioB(6) Bank2_PortB_DIO6

E11 Bank2_IO(67) 2 B13 cBank2ioB(7) Bank2_PortB_DIO7

E12 Bank2_IO(68) 2 B14 cBank2ioC(0) Bank2_PortC_DIO0

E13 Bank2_IO(69) 2 B16 cBank2ioC(1) Bank2_PortC_DIO1

E14 Bank2_IO(70) 2 B3 cBank2ioC(2) Bank2_PortC_DIO2

E15 Bank2_IO(71) 2 B4 cBank2ioC(3) Bank2_PortC_DIO3

E16 Bank2_IO(72) 2 B5 cBank2ioC(4) Bank2_PortC_DIO4

E17 Bank2_IO(73) 2 B6 cBank2ioC(5) Bank2_PortC_DIO5

E18 Bank2_IO(74) 2 B7 cBank2ioC(6) Bank2_PortC_DIO6

E19 Bank2_IO(75) 2 B8 cBank2ioC(7) Bank2_PortC_DIO7

AC8 Bank2_IO(78) 2 C11 cBank2ioD(0) Bank2_PortD_DIO0

AC9 Bank2_IO(79) 2 C12 cBank2ioD(1) Bank2_PortD_DIO1

AC10 Bank2_IO(80) 2 C13 cBank2ioD(2) Bank2_PortD_DIO2

AC11 Bank2_IO(81) 2 C4 cBank2ioD(3) Bank2_PortD_DIO3

AC12 Bank2_IO(82) 2 C5 cBank2ioD(4) Bank2_PortD_DIO4

AC13 Bank2_IO(83) 2 C6 cBank2ioD(5) Bank2_PortD_DIO5

AC14 Bank2_IO(84) 2 C7 cBank2ioD(6) Bank2_PortD_DIO6

AC15 Bank2_IO(85) 2 C8 cBank2ioD(7) Bank2_PortD_DIO7

AC16 Bank2_IO(86) 2 C9 cBank2ioE(0) Bank2_PortE_DIO0

AC17 Bank2_IO(87) 2 D10 cBank2ioE(1) Bank2_PortE_DIO1

AC18 Bank2_IO(88) 2 D11 cBank2ioE(2) Bank2_PortE_DIO2

AC19 Bank2_IO(89) 2 D12 cBank2ioE(3) Bank2_PortE_DIO3

AE19 Bank2_IO(90) 2 D4 cBank2ioE(4) Bank2_PortE_DIO4

SLSC-12101 User Guide | © National Instruments | 29

Page 30

Table 16. CPLD Connectivity to Bank 2 Prototyping Area (Continued)

Bank 2 Lattice

Lattice

Location

Schematic Name CPLD

Bank

CPLD

Pin

HDL Name Physical Channel

Name

AE18 Bank2_IO(91) 2 D5 cBank2ioE(5) Bank2_PortE_DIO5

AE17 Bank2_IO(92) 2 D6 cBank2ioE(6) Bank2_PortE_DIO6

AE16 Bank2_IO(93) 2 D7 cBank2ioE(7) Bank2_PortE_DIO7

AE15 Bank2_IO(94) 2 D8 cBank2ioF(0) Bank2_PortF_DIO0

AE14 Bank2_IO(95) 2 D9 cBank2ioE(1) Bank2_PortF_DIO0

AE13 Bank2_IO(96) 2 E10 cBank2ioE(2) Bank2_PortF_DIO0

AE12 Bank2_IO(97) 2 E11 cBank2ioE(3) Bank2_PortF_DIO0

AE11 Bank2_IO(98) 2 E6 cBank2ioE(4) Bank2_PortF_DIO0

AE10 Bank2_IO(99) 2 E7 cBank2ioE(5) Bank2_PortF_DIO0

AE9 Bank2_IO(100) 2 E8 cBank2ioE(6) Bank2_PortF_DIO0

AE8 Bank2_IO(101) 2 E9 cBank2ioE(7) Bank2_PortF_DIO0

Table 17. Connector 2 Connectivity to Bank 2 Prototyping Area

Connector J2

J2 Pin Schematic Name

5

Lattice

Coordinate

(Bank 2)

J2 Pin Schematic Name

6

Lattice

Coordinate

(Bank 2)

1 Front2_IO(1) A24 23 Front2_IO(23) D24

2 Front2_IO(2) A23 24 Front2_IO(24) D23

3 Front2_IO(3) A22 25 Front2_IO(25) D22

4 Front2_IO(4) A21 26 Front2_IO(26) D21

5 Front2_IO(5) A20 27 Front2_IO(27) D20

6 Front2_IO(6) A19 28 Front2_IO(28) D19

7 Front2_IO(7) A18 29 GND GND

8 Front2_IO(8) A17 30 Front2_IO(30) D17

5

In the silkscreen, these signals are marked IO2(Pin Number) for space reasons

6

In the silkscreen, these signals are marked IO2(Pin Number) for space reasons

30 | ni.com | SLSC-12101 User Guide

Page 31

Table 17. Connector 2 Connectivity to Bank 2 Prototyping Area (Continued)

Connector J2

J2 Pin Schematic Name

5

Lattice

Coordinate

(Bank 2)

J2 Pin Schematic Name

6

Lattice

Coordinate

(Bank 2)

9 Front2_IO(9) A16 31 Front2_IO(31) D16

10 Front2_IO(10) A15 32 Front2_IO(32) D15

11 Front2_IO(11) A14 33 Front2_IO(33) D14

12 Front2_IO(12) A13 34 Front2_IO(34) D13

13 Front2_IO(13) A12 35 Front2_IO(35) D12

14 Front2_IO(14) A11 36 Front2_IO(36) D11

15 Front2_IO(15) A10 37 Front2_IO(37) D10

16 Front2_IO(16) A9 38 Front2_IO(38) D9

17 GND GND 39 Front2_IO(39) D8

18 Front2_IO(18) A7 40 Front2_IO(40) D7

19 Front2_IO(19) A6 41 Front2_IO(41) D6

20 Front2_IO(20) A5 42 Front2_IO(42) D5

21 Front2_IO(21) A4 43 Front2_IO(43) D4

22 Front2_IO(22) A3 44 Front2_IO(44) D3

Table 18. Miscellaneous Signals in Bank 2 Prototyping Area

Miscellaneous Signals

Coordinate Signal Coordinate Signal

A1-D1 BANK2_VCC E1-AC1 GND

A25-D15 BANK2_VCC B2-B24 GND

AD1 BANK2_VCC E25-AC25 GND

AE1 BANK2_VCC AD2-AD24 GND

AD25 BANK2_VCC C24 GND

AE25 BANK2_VCC C23 VCC (5 V)

5

In the silkscreen, these signals are marked IO2(Pin Number) for space reasons

6

In the silkscreen, these signals are marked IO2(Pin Number) for space reasons

SLSC-12101 User Guide | © National Instruments | 31

Page 32

Bank 3 Prototyping Area

Figure 14. Bank 3 Prototyping Area

Table 19. CPLD Connectivity to Bank 3 Prototyping Area

Bank 3 Lattice

Lattice

Location

Schematic

Name

7

CPLD

Bank

CPLD

Pin

HDL Name Physical Channel

Name

A18 Bank3_IO(104) 3 C14 cBank3ioA(0) Bank3_PortA_DIO0

A17 Bank3_IO(105) 3 C15 cBank3ioA(1) Bank3_PortA_DIO1

A16 Bank3_IO(106) 3 D13 cBank3ioA(2) Bank3_PortA_DIO2

A15 Bank3_IO(107) 3 D14 cBank3ioA(3) Bank3_PortA_DIO3

A14 Bank3_IO(108) 3 D15 cBank3ioA(4) Bank3_PortA_DIO4

A13 Bank3_IO(109) 3 D16 cBank3ioA(5) Bank3_PortA_DIO5

A12 Bank3_IO(110) 3 E12 cBank3ioA(6) Bank3_PortA_DIO6

A11 Bank3_IO(111) 3 E13 cBank3ioA(7) Bank3_PortA_DIO7

A10 Bank3_IO(112) 3 E14 cBank3ioB(0) Bank3_PortB_DIO0

A9 Bank3_IO(113) 3 E15 cBank3ioB(1) Bank3_PortB_DIO1

7

In the silkscreen, these signals are marked as CPLD(Pin Number) for space reasons.

32 | ni.com | SLSC-12101 User Guide

Page 33

Table 19. CPLD Connectivity to Bank 3 Prototyping Area (Continued)

Bank 3 Lattice

Lattice

Location

Schematic

Name

7

CPLD

Bank

CPLD

Pin

HDL Name Physical Channel

Name

A8 Bank3_IO(114) 3 E16 cBank3ioB(2) Bank3_PortB_DIO2

C7 Bank3_IO(115) 3 F11 cBank3ioB(3) Bank3_PortB_DIO3

C8 Bank3_IO(116) 3 F12 cBank3ioB(4) Bank3_PortB_DIO4

C9 Bank3_IO(117) 3 F13 cBank3ioB(5) Bank3_PortB_DIO5

C10 Bank3_IO(118) 3 F14 cBank3ioB(6) Bank3_PortB_DIO6

C11 Bank3_IO(119) 3 F15 cBank3ioB(7) Bank3_PortB_DIO7

C12 Bank3_IO(120) 3 F16 cBank3ioC(0) Bank3_PortC_DIO0

C13 Bank3_IO(122) 3 G12 cBank3ioC(1) Bank3_PortC_DIO1

C14 Bank3_IO(123) 3 G13 cBank3ioC(2) Bank3_PortC_DIO2

C15 Bank3_IO(124) 3 G14 cBank3ioC(3) Bank3_PortC_DIO3

C16 Bank3_IO(125) 3 G15 cBank3ioC(4) Bank3_PortC_DIO4

C17 Bank3_IO(126) 3 G16 cBank3ioC(5) Bank3_PortC_DIO5

C18 Bank3_IO(133) 3 J13 cBank3ioC(6) Bank3_PortC_DIO6

AB7 Bank3_IO(134) 3 J14 cBank3ioD(0) Bank3_PortD_DIO0

AB8 Bank3_IO(135) 3 J15 cBank3ioD(1) Bank3_PortD_DIO1

AB9 Bank3_IO(136) 3 J16 cBank3ioD(2) Bank3_PortD_DIO2

AB10 Bank3_IO(138) 3 K12 cBank3ioD(3) Bank3_PortD_DIO3

AB11 Bank3_IO(139) 3 K13 cBank3ioD(4) Bank3_PortD_DIO4

AB12 Bank3_IO(140) 3 K14 cBank3ioD(5) Bank3_PortD_DIO5

AB13 Bank3_IO(141) 3 K15 cBank3ioD(6) Bank3_PortD_DIO6

AB14 Bank3_IO(142) 3 K16 cBank3ioD(7) Bank3_PortD_DIO7

AB15 Bank3_IO(143) 3 L11 cBank3ioE(0) Bank3_PortE_DIO0

AB16 Bank3_IO(144) 3 L12 cBank3ioE(1) Bank3_PortE_DIO1

AB17 Bank3_IO(145) 3 L13 cBank3ioE(2) Bank3_PortE_DIO2

AB18 Bank3_IO(146) 3 L14 cBank3ioE(3) Bank3_PortE_DIO3

7

In the silkscreen, these signals are marked as CPLD(Pin Number) for space reasons.

SLSC-12101 User Guide | © National Instruments | 33

Page 34

Table 19. CPLD Connectivity to Bank 3 Prototyping Area (Continued)

Bank 3 Lattice

Lattice

Location

Schematic

Name

7

CPLD

Bank

CPLD

Pin

HDL Name Physical Channel

Name

AD19 Bank3_IO(147) 3 L15 cBank3ioE(4) Bank3_PortE_DIO4

AD18 Bank3_IO(148) 3 L16 cBank3ioE(5) Bank3_PortE_DIO5

AD17 Bank3_IO(149) 3 M13 cBank3ioE(6) Bank3_PortE_DIO6

AD16 Bank3_IO(150) 3 M14 cBank3ioE(7) Bank3_PortE_DIO7

AD15 Bank3_IO(151) 3 M15 cBank3ioF(0) Bank3_PortF_DIO0

AD14 Bank3_IO(152) 3 M16 cBank3ioF(1) Bank3_PortF_DIO1

AD13 Bank3_IO(153) 3 N13 cBank3ioF(2) Bank3_PortF_DIO2

AD12 Bank3_IO(154) 3 N14 cBank3ioF(3) Bank3_PortF_DIO3

AD11 Bank3_IO(155) 3 N15 cBank3ioF(4) Bank3_PortF_DIO4

AD10 Bank3_IO(156) 3 N16 cBank3ioF(5) Bank3_PortF_DIO5

AD9 Bank3_IO(157 3 P14 cBank3ioF(6) Bank3_PortF_DIO6

AD8 Bank3_IO(158) 3 P15 cBank3ioF(7) Bank3_PortF_DIO7

Table 20. Miscellaneous Signals in Bank 3 Prototyping Area

Miscellaneous Signals

Coordinate Signal Coordinate Signal

A1 BANK3_VCC C1-AB1 GND

B1 BANK3_VCC B2-B24 GND

A25 BANK3_VCC C25-AB25 GND

B25 BANK3_VCC AC2-AC24 GND

AC1 BANK3_VCC A24 GND

AD1 BANK3_VCC A23 VCC (5 V)

AC25 BANK3_VCC AD21 LAT_CLK4

AD25 BANK3_VCC AD22 LAT_CLK3

7

In the silkscreen, these signals are marked as CPLD(Pin Number) for space reasons.

34 | ni.com | SLSC-12101 User Guide

Page 35

Bank 4 Prototyping Area

Figure 15. Bank 4 Prototyping Area

Table 21. CPLD Connectivity to Bank 4 Prototyping Area

Bank 4 Lattice

Lattice

Location

Schematic

Name

8

CPLD

Bank

CPLD

Pin

HDL Name Physical Channel

Name

A17 Bank4_IO(161) 4 M10 cBank4ioA(0) Bank4_PortA_DIO0

A16 Bank4_IO(162) 4 M11 cBank4ioA(1) Bank4_PortA_DIO1

A15 Bank4_IO(163) 4 M12 cBank4ioA(2) Bank4_PortA_DIO2

A14 Bank4_IO(164) 4 M6 cBank4ioA(3) Bank4_PortA_DIO3

A13 Bank4_IO(165) 4 M7 cBank4ioA(4) Bank4_PortA_DIO4

A12 Bank4_IO(168) 4 N10 cBank4ioA(5) Bank4_PortA_DIO5

A11 Bank4_IO(169) 4 N11 cBank4ioA(6) Bank4_PortA_DIO6

A10 Bank4_IO(170) 4 N12 cBank4ioA(7) Bank4_PortA_DIO7

C10 Bank4_IO(171) 4 N5 cBank4ioB(0) Bank4_PortB_DIO0

C11 Bank4_IO(188) 4 R11 cBank4ioB(1) Bank4_PortB_DIO1

8

In the silkscreen, these signals are marked as CPLD(Pin Number) for space reasons.

SLSC-12101 User Guide | © National Instruments | 35

Page 36

Table 21. CPLD Connectivity to Bank 4 Prototyping Area (Continued)

Bank 4 Lattice

Lattice

Location

Schematic

Name

8

CPLD

Bank

CPLD

Pin

HDL Name Physical Channel

Name

C12 Bank4_IO(189) 4 R12 cBank4ioB(2) Bank4_PortB_DIO2

C13 Bank4_IO(190) 4 R13 cBank4ioB(3) Bank4_PortB_DIO3

C14 Bank4_IO(191) 4 R14 cBank4ioB(4) Bank4_PortB_DIO4

C15 Bank4_IO(192) 4 R16 cBank4ioB(5) Bank4_PortB_DIO5

C16 Bank4_IO(193) 4 R3 cBank4ioB(6) Bank4_PortB_DIO6

C17 Bank4_IO(194) 4 R4 cBank4ioB(7) Bank4_PortB_DIO7

AB10 Bank4_IO(195) 4 R5 cBank4ioC(0) Bank4_PortC_DIO0

AB11 Bank4_IO(196) 4 R6 cBank4ioC(1) Bank4_PortC_DIO1

AB12 Bank4_IO(197) 4 R7 cBank4ioC(2) Bank4_PortC_DIO2

AB13 Bank4_IO(198) 4 R8 cBank4ioC(3) Bank4_PortC_DIO3

AB14 Bank4_IO(199) 4 R9 cBank4ioC(4) Bank4_PortC_DIO4

AB15 Bank4_IO(200) 4 T10 cBank4ioC(5) Bank4_PortC_DIO5

AB16 Bank4_IO(201) 4 T11 cBank4ioC(6) Bank4_PortC_DIO6

AB17 Bank4_IO(202) 4 T12 cBank4ioC(7) Bank4_PortC_DIO7

AD17 Bank4_IO(203) 4 T13 cBank4ioD(0) Bank4_PortD_DIO0

AD16 Bank4_IO(204) 4 T15 cBank4ioD(1) Bank4_PortD_DIO1

AD15 Bank4_IO(205) 4 T2 cBank4ioD(2) Bank4_PortD_DIO2

AD14 Bank4_IO(206) 4 T4 cBank4ioD(3) Bank4_PortD_DIO3

AD13 Bank4_IO(207) 4 T5 cBank4ioD(4) Bank4_PortD_DIO4

AD12 Bank4_IO(209) 4 T7 cBank4ioD(5) Bank4_PortD_DIO5

AD11 Bank4_IO(210) 4 T8 cBank4ioD(6) Bank4_PortD_DIO6

AD10 Bank4_IO(211) 4 T9 cBank4ioD(7) Bank4_PortD_DIO7

8

In the silkscreen, these signals are marked as CPLD(Pin Number) for space reasons.

36 | ni.com | SLSC-12101 User Guide

Page 37

Table 22. Miscellaneous Signals in Bank 4 Prototyping Area

Miscellaneous Signals

Coordinate Signal Coordinate Signal

A1 BANK4_VCC AD25 BANK4_VCC

B1 BANK4_VCC C1-AB1 GND

A25 BANK4_VCC B2-B24 GND

B25 BANK4_VCC C25-AB25 GND

AC1 BANK4_VCC AC2-AC24 GND

AD1 BANK4_VCC A24 GND

AC25 BANK4_VCC A23 VCC (5 V)

RTI Prototyping Area

Figure 16. RTI Prototyping Area

SLSC-12101 User Guide | © National Instruments | 37

Page 38

Table 23. Connectivity of XJ2 Connector to RTI Prototyping Area

Connector XJ2

XJ2

pin

Lattice

Coordinate

(RTI)

XJ2

pin

Lattice

Coordinate

(RTI)

XJ2

pin

Lattice

Coordinate

(RTI)

XJ2

pin

Lattice

Coordinate

(RTI)

XJ2

pin

Lattice

Coordinate

(RTI)

A1 I10 B1 G10 C1 E10 D1 C10 E1 B10

A2 I11 B2 G11 C2 E11 D2 C11 E2 B11

A3 GND B3 GND C3 GND D3 GND E3 GND

A4 I12 B4 G12 C4 E12 D4 C12 E4 B12

A5 I13 B5 G13 C5 E13 D5 C13 E5 B13

A6 GND B6 GND C6 GND D6 GND E6 GND

A7 I14 B7 G14 C7 E14 D7 C14 E7 B14

A8 I15 B8 G15 C8 E15 D8 C15 E8 B15

A9 GND B9 GND C9 GND D9 GND E9 GND

A10 I16 B10 G16 C10 E16 D10 C16 E10 B16

A11 I17 B11 G17 C11 E17 D11 C17 E11 B17

A15 I18 B15 G18 C15 E18 D15 C18 E15 B18

A16 I19 B16 G19 C16 E19 D16 C19 E16 B19

A17 GND B17 GND C17 GND D17 GND E17 GND

A18 I20 B18 G20 C18 E20 D18 C20 E18 B20

A19 I21 B19 G21 C19 E21 D19 C21 E19 B21

A20 GND B20 GND C20 GND D20 GND E20 GND

A21 I22 B21 G22 C21 E22 D21 C22 E21 B22

A22 I23 B22 G23 C22 E23 D22 C23 E22 B23

A23 GND B23 GND C23 GND D23 GND E23 GND

A24 I24 B24 G24 C24 E24 D24 C24 E24 B24

A25 I25 B25 G25 C25 E25 D25 C25 E25 B25

38 | ni.com | SLSC-12101 User Guide

Page 39

Table 24. Connectivity of XJ3 Connector to RTI Prototyping Area

Connector XJ3

XJ3 Pin Lattice Coordinates (RTI)

A I(3-6)

B H(3-6)

C G(3-6)

D F(3-6)

E E(3-6)

F D(3-6)

G C(3-6)

H B(3-6)

Table 25. RTI Miscellaneous Signals

Miscellaneous Signals

Coordinate Signal Coordinate Signal

B1-I1 GND J3-J6 24 V

A2 GND A7-A26 GND

B2-C2 3.3 V J7-J26 GND

D2-E2 Bank 2 VCC D26-E26 Bank 2 VCC

F2-G2 Bank 3 VCC F26-G26 Bank 3 VCC

H2-I2 Bank 4 VCC H26-I26 Bank 4 VCC

A3-A6 24 V B27-I27 GND

SLSC-12101 User Guide | © National Instruments | 39

Page 40

CPLD Pins

Table 26. Miscellaneous Connections to the CPLD

Miscellaneous Pins

Schematic Name CPLD Bank CPLD Pin Pin Name Notes

Bank2_IO(77) 2 C10 aTFM_Lattice

Bank2_IO(76) 2 B9 aTTM_Lattice

Bank2_IO(63) 2 B1 unused

CPLD_CLK1 1 H5 Clk System clock for the design.

LED_Red_0 1 L1 cPowerGreen LED signal.

LED_Green_0 1 L3 cPowerRed LED signal.

LED_Red_1 1 L2 cReadyGreen LED signal.

LED_Green_1 1 L4 cReadyRed LED signal.

CPLDESET# 1 K4 aReset_n Module Reset.

Table 27. Rotary Switch Connectivity to the CPLD

Rotary Switch

SW1 pin Schematic Name CPLD Bank CPLD Pin HDL Name Physical Channel

Name

1 Switch(0) 3 H16 aSwitch(0) NI.RotarySwitch

2 Switch(1) 3 H15 aSwitch(1) NI.RotarySwitch

4 Switch(2) 3 H14 aSwitch(2) NI.RotarySwitch

8 Switch(3) 3 H13 aSwitch(3) NI.RotarySwitch

C Bank3_VCC

Table 28. SI 5356 Clock Generator Connectivity to the CPLD

SI5356 Clock Generator Interface

SI5356 pin Schematic Name CPLD Bank CPLD Pin HDL Name

8 CLK_INT 1 F5 unused

18 CPLD_CLK2 1 J5 unused

14 CPLD_CLK3 3 H12 unused

40 | ni.com | SLSC-12101 User Guide

Page 41

Table 28. SI 5356 Clock Generator Connectivity to the CPLD (Continued)

SI5356 Clock Generator Interface

SI5356 pin Schematic Name CPLD Bank CPLD Pin HDL Name

10 CPLD_CLK4 3 J12 unused

12 SCL_HDR 1 F6 unused

19 SDA_HDR 1 G1 unused

5 SSC_DIS 1 K5 unused

Table 29. Temperature Sensors Connectivity to the CPLD

Temperature Sensors

Pin Number on Sensor

Sensor1Sensor2Sensor3Sensor

4

Schematic

Name

CPLD

Bank

CPLD

Pin

HDL Name

1 1 SPI0_CLK 1 C2 aSpi0Clk

2 2 SPI0_MISO 1 C3 aSpi0Miso

3 3 SPI0_MOSI 1 D1 aSpi0Mosi

4 SPI0_CS#(0) 1 D2 aSpi0Ss(0)

4 SPI0_CS#(1) 1 D3 aSpi0Ss(1)

6 6 L0_CT 1 F1 aL0Ct

5 5 L0_INT 1 F2 aL0Int

1 1 SPI1_CLK 1 E1 aSpi1Clk

2 2 SPI1_MISO 1 E2 aSpi1Miso

3 3 SPI1_MOSI 1 E3 aSpi1Mosi

4 SPI1_CS#(0) 1 E4 aSpi1Ss(0)

4 SPI1_CS#(1) 1 E5 aSpi1Ss(1)

6 6 L1_CT 1 F3 aL1Ct

5 5 L1_INT 1 F4 aL1Int

Deploying the SLSC-12101 as a Final Product

If you decide to use a modified SLSC-12101 as a final product, it is your responsibility to

make sure that the product is modified and used in such a way that complies with local rules,

SLSC-12101 User Guide | © National Instruments | 41

Page 42

regulations, and best practices. Additionally, the modules must comply with the requirements

specified in this section.

Module Design Specification Compliance

Use, design, and distribution of this module must comply with the Switch Load and Signal

Conditioning Module Design Specifications, as well as the license agreement included in the

SLSC Module Development Kit.

Regulatory Compliance and Markings

All compliance testing and certifications for the SLSC-12101 apply only to the unmodified

module. Any modification to the module requires the removal of regulatory markings.

Cosmetic Alterations

The module should not be deployed as a final product without cosmetic modification. Be sure

to make the following changes:

• Remove the National Instruments label on the ejector handle. This may be replaced with

another label, such as one with the corporate logo of the module developer.

• On the front panel, cover or remove the model name and description ("SLSC-12101

Prototyping Module").

• Customize LED and connector labeling as needed.

• Add the new model name and pertinent information. A custom overlay may be used for

this purpose. See the Switch Load and Signal Conditioning Module Design Specifications

for more details.

• Update the blank SLSC Rear I/O Compatibility Glyph on the SLSC-12101 front panel

with the proper alphanumeric code to reflect the final module rear I/O implementation.

See the Switch Load and Signal Conditioning Module Design Specifications for more

details.

SLSC-12101 Bill of Materials

Table 30. Bill of Materials for the SLSC-12101

Reference

Designator

Description Qty Manufacturer Part Number

06 JUMPER, 2 X 1,

0.100 IN (2.54 MM)

PITCH, BLUE,

GOLD-PLATED

3 SAMTEC SNT-100-BL-G

C001 CAP, SM, 75 PF, 50

V, 1%, COG, CER,

0402, H= .022 IN

1 KEMET C0402C750F5GACTU

42 | ni.com | SLSC-12101 User Guide

Page 43

Table 30. Bill of Materials for the SLSC-12101 (Continued)

Reference

Designator

Description Qty Manufacturer Part Number

C002, C005, C008 CAP, SM, 820 PF,

50 V, 5%, COG,

0402, H= .029 IN

3 MURATA GRM1555C1H821JA01D

C003, C004, C006,

C009

CAP, SM, 1 UF, 16

V, 10%, X7R, 0603,

H= .035 IN

4 KEMET C0603C105K4RACTU

C007 CAP, SM, 220 PF,

50 V, 5%, COG,

CER, 0603, H= .033

IN

1 MURATA GRM1885C1H221JA01D

C011 CAP, SM, 0.1 UF,

50 V, 10%, X7R,

CER, 0603, H= .039

IN

1 VENKEL C0603X7R500-104KNP

C014, C015, C020,

C023

CAP, SM, 10 UF, 50

V, 20%, X7S, 1210,

H= .106 IN

4 TAIYO YUDEN UMK325C7106MM-T

C016, C021 CAP, SM, 10 UF, 25

V, 10%, X7R, 1210,

H= .083 IN

2 MURATA GRM32DR71E106KA12L

C017, C026, C031,

C033, C035, C036,

C038, C042, C043,

C048, C050, C051,

C053

CAP, SM, 0.1 UF,

16 V, 10%, X7R,

CER, 0402, H= .025

IN

13 AVX 0402YC104KAT2A

C024 CAP, SM, 330 UF,

6.3 V, 20%,

POLYMER

TANTALUM,

A_RMS =3.2 AMP

@20 C, 7343, H= .

122 IN

1 VENKEL TA6R3PCJ337MDR0015

C027, C030, C056,

C059

CAP, SM, 0.01 UF,

16 V, 5%,

CERAMIC, COG,

0805, H= .055 IN

4 VENKEL C0805C0G500-103JNP

SLSC-12101 User Guide | © National Instruments | 43

Page 44

Table 30. Bill of Materials for the SLSC-12101 (Continued)

Reference

Designator

Description Qty Manufacturer Part Number

C028, C029, C057,

C058

CAP, SM, 2700 PF,

50V, 5%, COG,

CER, 0603, H =.039

IN

4 MURATA GRM1885C1H272JA01D

C032, C039, C040,

C041, C044, C045,

C047, C054

CAP, SM, 100 UF,

6.3 V, 20%, CER,

X5R, 1210, H= .106

IN

8 VENKEL C1210X5R6R3-107MNU

C034, C037, C049,

C052

CAP, SM, 22 UF, 16

V, 10%, CER, X5R,

1210, H= .125 IN

4 MURATA GRM32ER61C226KE20L

C062, C064, C066,

C067, C072, C073,

C074, C081, C082,

C083, C084, C085,

C086, C087, C088,

C089, C091, C094,

C095, C096, C097,

C098, C099, C100,

C101, C102, C103,

C104, C105

CAP, SM, 0.1 UF,

16 V, 10%, X7R,

CER, 0402, H= .025

IN

29 AVX 0402YC104KAT2A

C065 CAP, SM, 820 PF,

50 V, 5%, COG,

0402, H= .029 IN

1 MURATA GRM1555C1H821JA01D

C068, C069, C070,

C071

CAP, SM, 680 PF,

5%, 50 V, COG,

0603, H= .034 IN

4 AVX 06035A681JAT2A

CR001, CR002 DIODE, SM,

SCHOTTKY,

MSS1P6, 60 V, 2PIN MICROSMP,

H= .029 IN

2 VISHAY MSS1P6-M3/89A

CR003, CR004 DIODE, SM,

BAT54,

SCHOTTKY,

DUAL, SOT-323,

H= .039 IN

2 NXP BAT54SW,115

44 | ni.com | SLSC-12101 User Guide

Page 45

Table 30. Bill of Materials for the SLSC-12101 (Continued)

Reference

Designator

Description Qty Manufacturer Part Number

CR005 DIODE,SM,

ZENER, 3W, 6.2 V,

403 A

1 ON

SEMICONDUCTOR

1SMB5920BT3G

DS001 LED, TH, DUAL-

LEVEL,

INDICATOR RED/

GREEN, H= .395 IN

1 DIALIGHT 5530711F

F001 FUSE, SM,

NANO2, 3.5 A, 125

V, W/OMNI-BLOK

FUSEHOLDER,

FAST, H= .150 IN

1 LITTELFUSE 015403.5DRT

J010, J011 CONN, RCPT, HDR

D SUB, 44 POS,

PWB MT

2 TE

CONNECTIVITY

5748482-5

J017 CONN, MICTOR

38, RCPT, SM W /

THRU HOLE

GROUND BUS,

VERT, KEYED,

H= .242 IN

1 TE

CONNECTIVITY

5767171-1

J018 CONN, SM, HDR,

2X5.100, POST

H= .380 IN

1 SAMTEC TSM-105-01-TM-DV-P-

TR

L001 INDUCTOR, SM,

10 UH, 20%, 7.5 A,

H=.158 IN

1 VISHAY-DALE IHLP4040DZER100M11

L002, L003, L004,

L005

INDUCTOR, SM,

LOW PROFILE

HIGH CURRENT,

3.3 UH, 20%, 6 A,

H= .118 IN

4 VISHAY-DALE IHLP2525CZER3R3M01

Q001 TRANSISTOR, SM,

FDG6335N, DUAL

N-CHANNEL FET,

SC-70-6, H= .043

IN

1 FAIRCHILD FDG6335N

SLSC-12101 User Guide | © National Instruments | 45

Page 46

Table 30. Bill of Materials for the SLSC-12101 (Continued)

Reference

Designator

Description Qty Manufacturer Part Number

Q002, Q003 TRANSISTOR, SM,

MOSFET,

BSC097N06NS, NCHANNEL 60 V

OPTIMOS,

POWER, PGTDSON-8, H= .043

IN

2 INFINEON BSC097N06NSATMA1

R001, R006, R007,

R008, R049, R061,

R062, R167, R171,

R172, R173

RES, SM, 10K, 1/16

W, .5%,

THINFILM, 25

PPM, 0402, H= .016

IN

11 VENKEL TFCR0402-16W-

E-1002DT

R002 RES, SM, 45.3 K,

1/16 W, 0.5%, +/-25

PPM, THIN FILM,

0402, H= .016 IN

1 THIN FILM

TECHNOLOGY

RR0510P4532D-C

R003, R010 RES, SM, 10.7 K,

1/16 W, 0.5%, 25

PPM, THIN FILM,

0402, H= .016 IN

2 IRC PCF-W0402LF-03-1072-

D-P-LT

R004, R013 RES, SM, 1 K, 1/16

W, 50 V, 1%,

THICK FILM, 0402,

H= .014 IN

2 VISHAY-DALE CRCW04021K00FKED

R005 RES, SM, 3.32, 1/4

W, 1%, 200 PPM,

THICK FILM, 1206,

H= .028 IN

1 VENKEL CR1206-4W-3R32FT

R009 RES, SM, 75 K,

1/16 W, 50 V, 1%,

THICK FILM, 0402,

H= .016 IN

1 VISHAY-DALE CRCW040275K0FKED

R011 RES, SM, 0, 1/10 W,

5%, 200 PPM,

THICK FILM, 0603,

H= .0217 IN

1 VENKEL CR0603-10W-000SNT

46 | ni.com | SLSC-12101 User Guide

Page 47

Table 30. Bill of Materials for the SLSC-12101 (Continued)

Reference

Designator

Description Qty Manufacturer Part Number

R012, R014 RES, SM, 10, 1/10

W, 50 V, 1%,

THICK FILM, 0603,

H= .020 IN

2 VENKEL CR0603-10W-10R0FT

R015 RES, SM, 0.015, 1

W, 1%, THIN

FILM, 0815, H= .

022 IN

1 THIN FILM

TECHNOLOGY

RL3720WTR015F-C

R016, R168 RES, SM, 0, 1/4 W,

5%, THICK FILM,

1206

2 YAGEO /

PHYCOMP

RC1206JR-070RL

SLSC-12101 User Guide | © National Instruments | 47

Page 48

Table 30. Bill of Materials for the SLSC-12101 (Continued)

Reference

Designator

Description Qty Manufacturer Part Number

R018, R019, R026,

R028, R037, R039,

R041, R042, R043,

R044, R045, R046,

R047, R048, R051,

R052, R053, R054,

R055, R056, R057,

R058, R059, R060,

R067, R068, R069,

R070, R071, R072,

R073, R074, R075,

R076, R077, R078,

R084, R085, R089,

R090, R091, R092,

R093, R094, R095,

R096, R097, R098,

R099, R100, R101,

R102, R103, R104,

R105, R106, R111,

R112, R113, R114,

R115, R116, R117,

R118, R119, R120,

R121, R122, R123,

R124, R125, R126,

R127, R128, R129,

R130, R131, R132,

R137, R138, R139,

R140, R141, R142,

R143, R144, R147,

R148, R149, R150,

R151, R152, R153,

R154, R156, R157,

R158, R159, R160,

R161, R162, R164,

R165, R170, R174

RES, SM, 33.2 ,1/16

W, 50 V, 1%,

THICK FILM, 0402,

H= .016 IN

105 VISHAY-DALE CRCW040233R2FKEDC

R020, R145, R146 RES, SM, 47 K,

1/16 W, 0.5%, 25

PPM, THIN FILM,

0402, H= .014 IN

3 VENKEL TFCR0402-16W-

E-4702DT

48 | ni.com | SLSC-12101 User Guide

Page 49

Table 30. Bill of Materials for the SLSC-12101 (Continued)

Reference

Designator

Description Qty Manufacturer Part Number

R021, R134, R136 RES, SM, 27 K

OHM, 1/16 W, 1%,

THICK FILM, 0402,

H= .016 IN

3 VISHAY-DALE CRCW040227K0FKED

R022, R133, R135 RES, SM, 15 K,

1/16 W, .5%, THIN

FILM, 25 PPM,

0402, H= .016 IN

3 VENKEL TFCR0402-16W-

E-1502DT

R023, R108, R110 RES, SM .8.2 K

OHM, 1/16 W, 1%,

50 V, 100 PPM,

THICK FILM, 0402,

H= .016 IN

3 VISHAY-DALE CRCW04028K20FKED

R024, R107, R109 RES, SM, 4.7 K

OHM, 1/16 W, 1%,

THICK FILM, 0402,

H= .016 IN

3 KOA RK73H1ETTP4701F

R025, R029, R166 RES, SM, 1 K, 1/16

W, .5%, THIN

FILM, 25 PPM,

0402 ,H= .016 IN

3 THINFILM RR0510P102D-C

R030, R033, R034,

R035, R036, R038,

R040, R079, R081,

R082

RES, SM, 10 K,

1/16 W, 50 V, 1%,

THICK FILM, 0402,

H= .014 IN

10 VISHAY-DALE CRCW040210K0FKEDC

R031, R087, R088 RES, SM, 22.1 K,

1/16 W, 50 V, 1%,

THICK FILM, 0603,

H= .024 IN

3 VISHAY-DALE CRCW060322K1FKEA

R032 RES, SM, 33 K,

1/10 W, 1%, THICK

FILM, 0603, H= .

022 IN

1 VISHAY-DALE CRCW060333K0FKEA

R155 RES, SM, 0 OHM, 1

W, THICK FILM,

0402, H= .016 IN

1 KOA RK73Z1ETTP

SLSC-12101 User Guide | © National Instruments | 49

Page 50

Table 30. Bill of Materials for the SLSC-12101 (Continued)

Reference

Designator

Description Qty Manufacturer Part Number

R163 RES, SM, 124, 1/16

W, 0.1%, 25 PPM,

THIN FILM, 0402,

H= .016 IN

1 VENKEL TFCR0402-16W-

E-1240BT

R169 RES, SM, 10 M, 1/8

W, 5%, THICK

FILM,1206

1 VENKEL CR1206-8W-106JSNT

R175, R285 RES, SM, 1 K, 1/16

W, .5%, THIN

FILM, 25 PPM,

0402, H= .016 IN

2 THINFILM RR0510P102D-C

R176, R182, R187,

R277, R278

RES, SM, 10 K,

1/16 W, 50 V, 1%,

THICK FILM, 0402,

H= .014 IN

5 VISHAY-DALE CRCW040210K0FKEDC

R177, R186, R188,

R201, R202, R203,

R204, R205, R206,

R207, R208, R209,

R219, R220, R221,

R222, R223, R224,

R225, R226, R227,

R228, R229, R233,

R235, R239, R240,

R241, R242, R243,

R244, R245, R246,

R247, R248, R249,

R250, R251, R252,

R253, R254, R255,

R256, R257, R258,

R259, R260, R261,

R262, R263, R264,

R265, R266, R267,

R268, R269, R272,

R273, R275, R276,

R279, R281, R282,

R283, R284, R289

RES, SM, 33.2, 1/16

W, 50 V, 1%,

THICK FILM, 0402,

H= .016 IN

66 VISHAY-DALE CRCW040233R2FKEDC

50 | ni.com | SLSC-12101 User Guide

Page 51

Table 30. Bill of Materials for the SLSC-12101 (Continued)

Reference

Designator

Description Qty Manufacturer Part Number

R178 RES, SM, 13.3 K,

1/16 W, 0.5%, THIN

FILM, 0402, H= .

016 IN

1 VENKEL TFCR0402-16W-

E-1332DT

R179, R183, R190,

R195, R214, R232

RES, SM, 0 OHM,

JUMPER, THICK

FILM, 0402, H= .

014 IN

6 KOA RK73Z1ETTP

R180 RES, SM, 6.98 K,

1/16 W, 0.5%, +/-25

PPM, THIN FILM,

0402, H= .016 IN

1 VENKEL TFCR0402-16W-

E-6981DT

R181 RES, SM, 2 K, 1/16

W, .5%, THIN

FILM, 25 PPM,

0402, H= .016 IN

1 THINFILM RR0510P202D-C

R184 RES, SM, 10.7 K,

1/16 W, 0.5%, 25

PPM, THIN FILM,

0402, H= .016 IN

1 IRC PCF-W0402LF-03-1072-

D-P-LT

R185 RES, SM, 49.9 ,1/16

W, .5%, THIN

FILM, 100 PPM,

0402, H= .016 IN

1 THINFILM RR0510R49R9D-C

R189 RES, SM, 75 K,

1/16 W, 50 V, 1%,

THICK FILM, 0402,

H= .016 IN

1 VISHAY-DALE CRCW040275K0FKED

R192, R217 RES, SM, 8.25 K,

1/16 W, 50 V, 1%,

THICK FILM, 0402,

H= .014 IN

2 VENKEL CR0402-16W-8251FT

R193, R216 RES, SM, 4.75 K,

1/16 W, 50 V, 1%,

THICK FILM, 0402,

H= .016 IN

2 VISHAY-DALE CRCW04024K75FKED

SLSC-12101 User Guide | © National Instruments | 51

Page 52

Table 30. Bill of Materials for the SLSC-12101 (Continued)

Reference

Designator

Description Qty Manufacturer Part Number

R196 RES, SM, 15 K,

1/16 W, .5%, THIN

FILM, 25 PPM,

0402, H= .016 IN

1 VENKEL TFCR0402-16W-

E-1502DT

R197, R198, R199,

R200

RES, SM, 2.21

OHM, 1/10 W, 1%,

THICK FILM, 0603,

H= .022 IN

4 VENKEL CR0603-10W-2R21FSNT

R270 RES, SM, 0 OHM, 1

W, THICK FILM,

0402, H= .016 IN

1 KOA RK73Z1ETTP

R274, R287, R288 RES, SM, 10 K,

1/16 W, .5%, THIN

FILM, 25 PPM,

0402, H= .016 IN

3 VENKEL TFCR0402-16W-

E-1002DT

R280 RES, SM, 124, 1/16

W, 0.1%, 25 PPM,

THIN FILM, 0402,

H= .016 IN

1 VENKEL TFCR0402-16W-

E-1240BT

R290 RES, SM, 10 M, 1/8

W, 5%, THICK

FILM, 1206

1 VENKEL CR1206-8W-106JSNT

SW001 SWITCH, THRU-

HOLE, RA,

ROTARY, 16 POS,

FLUSH,

SCREWDRIVER

SLOT, HEX

OUTPUT, 30 V, 0.1

A, H= .299 IN

1 C&K RTE1600V44

U001, U003,

U004, U011

IC, SM, ADT7310,

TEMP SENSOR,

16-BIT DIGITAL,

±0.5 C, SOIC-8,

H= .069 IN

4 ANALOG

DEVICES

ADT7310TRZ-REEL7

52 | ni.com | SLSC-12101 User Guide

Page 53

Table 30. Bill of Materials for the SLSC-12101 (Continued)

Reference

Designator

Description Qty Manufacturer Part Number

U002 IC, SM,

LM25117PSQ,

WIDE INPUT

RANGE

SYNCHRONOUS

BUCK

CONTROLLER, 24

PIN - LLP (4MM X

4MM), H= .043 IN

1 TI LM25117PSQ NOPB

U005, U009 IC, SM,

ADP2114ACPZ,

STEP-DOWN

SWITCHING

REGULATOR,

LFCSP, H= .039 IN

2 ANALOG

DEVICES

ADP2114ACPZ-R7

U006 OSC, SM, 40.000

MHZ, 3.3 V, LOW

CURRENT

CONSUMPTION

CRYSTAL

OSCILLATOR, 4

PIN, H= .047 IN

1 EPSON SG-310SCF40.000M-M0

U007 IC, SM, TPS3808,

1.8 V

SUPERVISORY

CIRCUIT,

PROGRAMMABLE

DELAY, SOT-23,

H= .057 IN

1 TI TPS3808G18DBVR

U010 BGA IC, SM,

5M1270ZF256I5N,

CPLD, BLANK,

256FBGA, H= .061

IN

1 INTEL 5M1270ZF256I5N

SLSC-12101 User Guide | © National Instruments | 53

Page 54

Table 30. Bill of Materials for the SLSC-12101 (Continued)

Reference

Designator

Description Qty Manufacturer Part Number

U012 IC, SM, M25P80-

VMC6TG, SERIAL

FLASH

EMBEDDED

MEMORY, 8 MBIT,

4X3MM,

UFDFPN8, H= .024

IN

1 MICRON M25P80-VMC6TG

W002, W003,

W004

CONN, HDR, 2X5,

0.1CT, 0.230 H,

30UGOLD/

200UTIN

3 SAMTEC TSW-105-07-S-D

XJ001 CONN, HARD-

METRIC,

FEMALE, RA,

TYPE C,

PRESSFIT, H= .319

IN

1 ERNI 374047

XJ002 CONN, HARD-

METRIC,

FEMALE, RA,

TYPE A,

PRESSFIT, H= .319

IN

1 ERNI 354142

XJ003 CONN, HDR, RA,

UNIV PWR

MODULE, 8 POS,

PRESSFIT, H= .385

IN

1 TE

CONNECTIVITY

120958-1

Worldwide Support and Services

NI corporate headquarters is located at 11500 North Mopac Expressway, Austin, Texas,

78759-3504. NI also has offices located around the world. For support in the United States,