Page 1

GETTING STARTED GUIDE AND SPECIFICATIONS

SLSC-12001 Chassis

12 Slot Switch Load Signal Conditioning Chassis for 4U SLSC Modules

This document describes how to get started with the National Instruments SLSC-12001 chassis.

The document contains chassis specifications, information about installing and mounting

hardware, and powering and connecting the chassis.

Contents

Electromagnetic Compatibility Guidelines .............................................................................. 2

Unpacking the Chassis.............................................................................................................. 3

What You Need to Get Started ................................................................................................. 3

Chassis Overview ..................................................................................................................... 4

SLSC-12001 Chassis Blo

SLSC-12001 Chassis

Installing the Chassis ................................................................................................................ 8

Installing Rear Transition Interfaces ........................................................................................ 9

Installing SLSC Modules.......................................................................................................... 9

Removing SLSC Modules ........................................................................................................ 10

Connecting the Chassis............................................................................................................. 11

Saf

ety Guidelines.............................................................................................................. 11

Grounding the Chassis.................

Wiring Power to the Chassis .

wering on the Chassis................................................................................................... 12

Po

C

onnecting the Chassis to a Host ..................................................................................... 13

Connecting to a Measurement

Maintenance.............................................................................................................................. 13

Cleanin

Cleaning and Replacing the Chassis Intake Filter ..

Fan

B

Troubleshooting........................................................................................................................ 21

Un

Network Communication Troubleshootin

Resetting the Chassis and Modules .................................................................................. 22

Fan Faults ......................................................................................................................... 22

Module Short

g the Chassis......................................................................................................... 13

Clean

ing the Filter .................................................................................................... 14

Removing the

Inser

ting the Filter .................................................................................................... 14

Maintenance............................................................................................................... 15

Fan Replacemen

attery Replacement......................................................................................................... 19

derstanding LED Indicators......................................................................................... 21

Circuit Behavior ........................................................................................ 22

ck Diagram............................................................................... 6

Rear Transition Interface............................................................... 7

..................................................................................... 11

........................................................................................... 11

System ............................................................................. 13

.......................................................... 14

Filter.................................................................................................. 14

t ...................................................................................................... 16

g...................................................................... 21

Page 2

Specifications............................................................................................................................ 23

C

hassis Power ...................................................................................................................23

Battery........................................................................

Network .

Physical

Chassis C

Environmental.

Shock and Vib

Safety .

Safety Standards .

...........................................................................................................................24

Characteristics ....................................................................................................25

ooling ................................................................................................................26

..................................................................................................................26

ration .........................................................................................................27

...............................................................................................................................27

..............................................................................................................27

Electromagnetic Compatibility ...........................

C

E Compliance .................................................................................................................28

Online Product Certification..........

Environmen

tal Management.............................................................................................28

...................................................................................28

.......................................................24

..............................................................27

Worldwide Support and Services ............................................................................................. 29

Electromagnetic Compatibility Guidelines

This product was tested and complies with the regulatory requirements and limits for

electromagnetic compatibility (EMC) stated in the product specifications. These requirements

and limits provide reasonable protection against harmful interference when the product is

operated in the intended operational electromagnetic environment.

This product is intended for use in industrial locations. However, harmful interference may

occur in some installations, when the product is connected to a peripheral device or test object,

or if the product is used in residential or commercial areas. To minimize interference with radio

and television reception and prevent unacceptable performance degradation, install and use this

product in strict accordance with the instructions in the product documentation.

Furthermore, any modifications to the product not expressly approved by National Instruments

could void your authority to operate it under your local regulatory rules.

Caution To ensure the specified EMC performance, operate this product only with

shielded cables and accessories.

Caution To ensure the specified EMC performance, the length of any cable

connected to a trigger port must be no longer than 3 m (10 ft).

Caution To ensure the specified EMC performance, all front and rear slots must be

covered. Front filler panels must be used in all slots not containing modules. Rear

filler panels must be used in all slots not using Rear Transition Interface (RTI)

adapters. These filler panels are available at

ni.com.

2 | ni.com | SLSC-12001 Chassis Getting Started Guide and Specifications

Page 3

Unpacking the Chassis

Carefully inspect the shipping container and the chassis for damage. Check for visible damage

to the exterior and interior of the chassis. If damage appears to have been caused during

shipment, file a claim with the carrier. Retain the packing material for possible inspection

and/or reshipment. If the chassis is damaged, do not install it and contact NI.

What You Need to Get Started

To set up and use the SLSC-12001 chassis you need the following items:

• Hardware

– SLSC-12001 chassis

– SLSC module(s)

– Front filler panels if not using modules in all slots

– Rear filler panels if not using RTIs in all slots

– Power supply, refer to the Chassis Power section

– Power cable

– Power input connector

– Ethernet cable

– Data Acquisition system (optional)

– Host System (may be Data Acquisition system)

– Grounding wire

– Grounding lug

• Software

– NI-SLSC driver, downloadable from

– Software as needed for your application

• Tools

– Screwdriver as needed for your application

– Wire stripper

• Documentation

– SLSC-12001 Chassis Getting Started Guide and Specifications

– Documents as required for your application

You can download needed documents from

ni.com

ni.com/manuals.

SLSC-12001 Chassis Getting Started Guide and Specifications | © National Instruments | 3

Page 4

Chassis Overview

4

NATIONAL

INSTRUMENTS

POWER

ACTIVITY

STATUS

SLSC-12001

SWITCH/LOAD/SIGNAL COND.

DO NOT INSERT OR REMOVE

MODULES WHILE POWERED

123456789

10 11 12

5

1

3

2

6

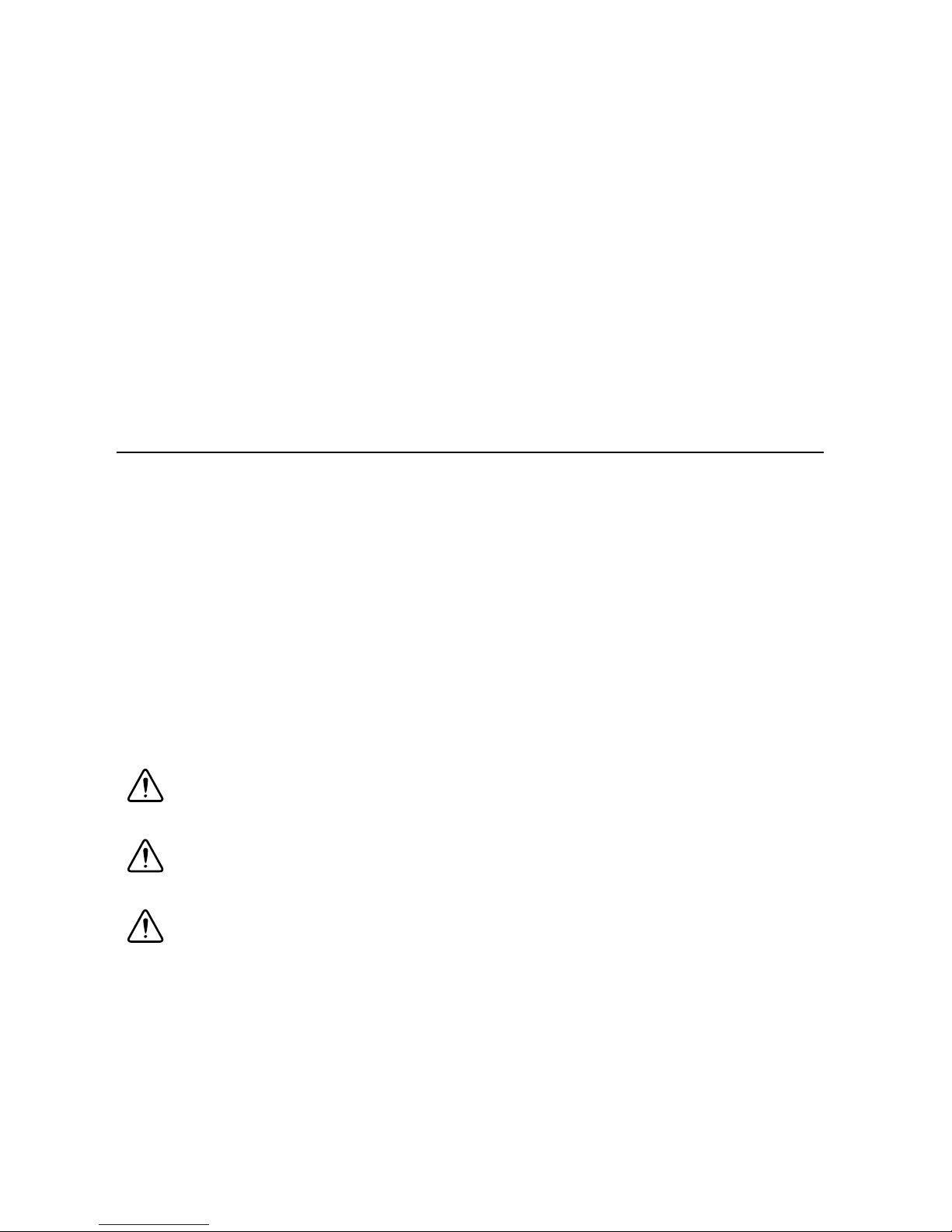

The SLSC-12001 chassis is designed for use with any SLSC module designed in accordance

with the SLSC Module Design Specification 1.0. The SLSC-12001 chassis must be powered

by an external power supply as described in the Chassis Power section of this document.

The chassis allows communication between a host system and the SLSC modules in order

to configure them. Additionally a Data Acquisition (DAQ) System, such as PXIe or cRIO,

can be connected to SLSC modules through an RTI.

Figure 1 shows the front features of the SLSC-12001 chassis.

Figure 1. SLSC-12001 Chassis Front View

1 POWER, STATUS, and ACTIVITY LEDs

2 Mounting Bracket (2)

3 Chassis Model Name

4 Chassis Feet (4)

5 Front Air Intake

6 SLSC Peripheral Slots (12)

4 | ni.com | SLSC-12001 Chassis Getting Started Guide and Specifications

Page 5

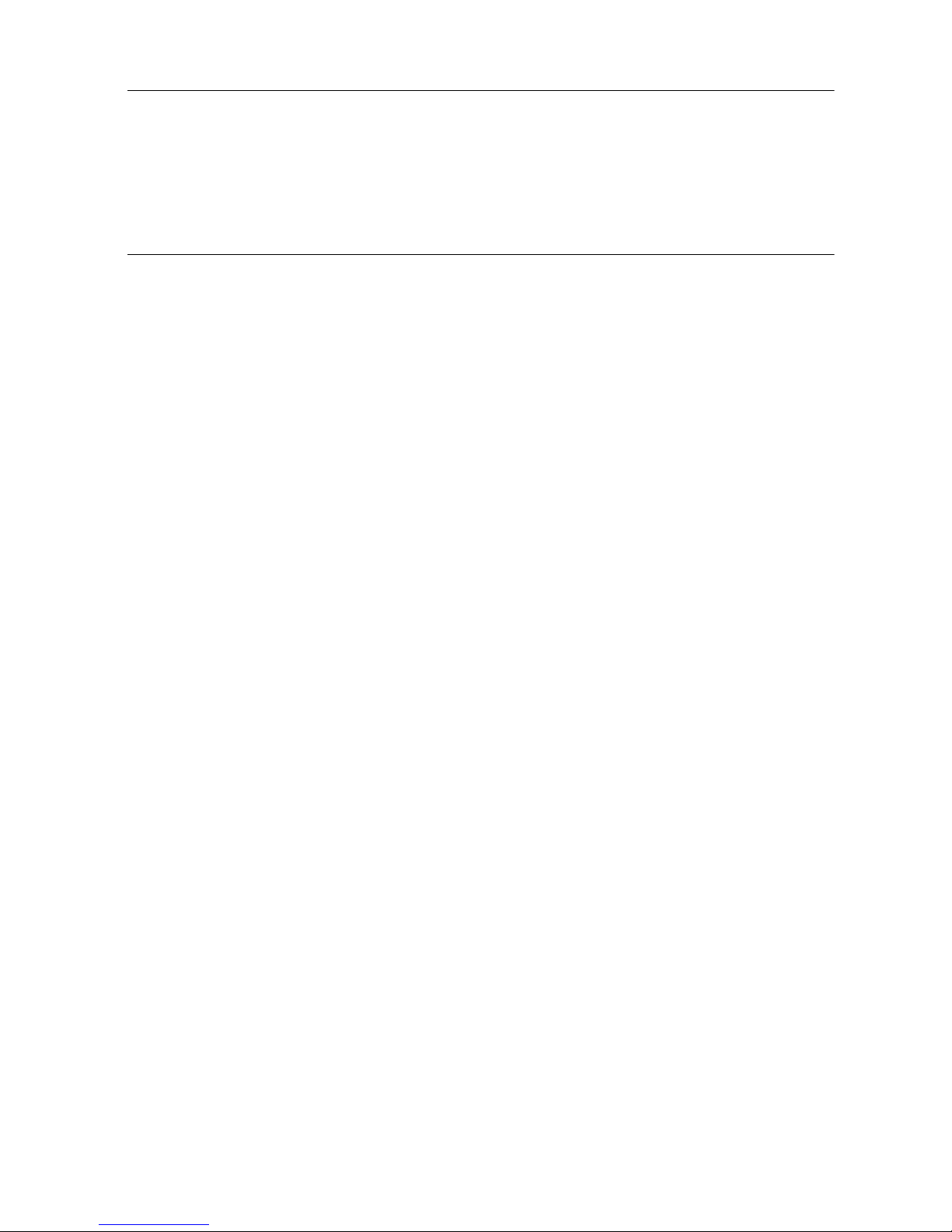

Figure 2 shows the rear features of the SLSC-12001 chassis.

DO NOT TOUCH CONTACTS OR

REMOVE I/O BOARDS OR CABLES

WHILE SYSTEM IS ENERGIZED.

TRIG 0 TRIG 1

RESET

ACT

SPD

720W MAX

+24V

+

4

1

2

5 56

7

8 109 11

12

3

Figure 2. SLSC-12001 Chassis Rear View

1 SLSC Peripheral Rear I/O Area

2 Rear Air Exhaust

3 Upper Rear Panel Screws (4)

4 Upper Rear Panel

5 Bumpers (2)

6 Trigger 0

7 Trigger 1

8Button

9 Ethernet Port

10 Chassis Ground Screw

11 DC Voltage Input

12 Backplane Panel

SLSC-12001 Chassis Getting Started Guide and Specifications | © National Instruments | 5

Page 6

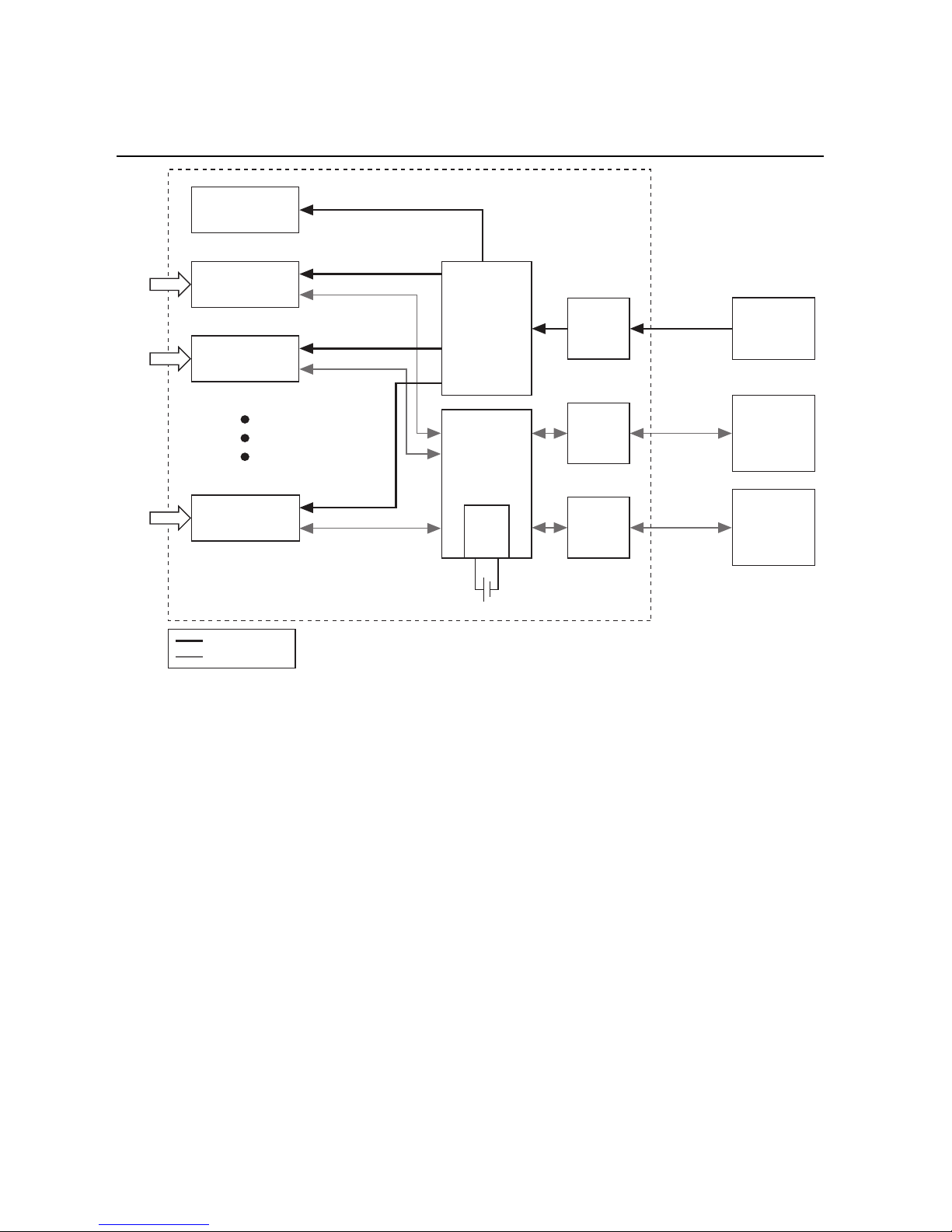

SLSC-12001 Chassis Block Diagram

Battery

Host

System

Host DAQ

or other

trigger

source

+24 V

Supply

+24 V

Power

Input

Triggers

GigE

24 V

0-5 V

Ethernet

Power

Distribution

and

Protection

SLSC

Chassis

Manager

Real

Time

Clock

SLSC Module

SLSC Module

SLSC Module

Fans

I/O

I/O

I/O

SLSC-12001 Chassis

SLSC Interface

+24 V and +3.3 V

Digital Signals

Powe r

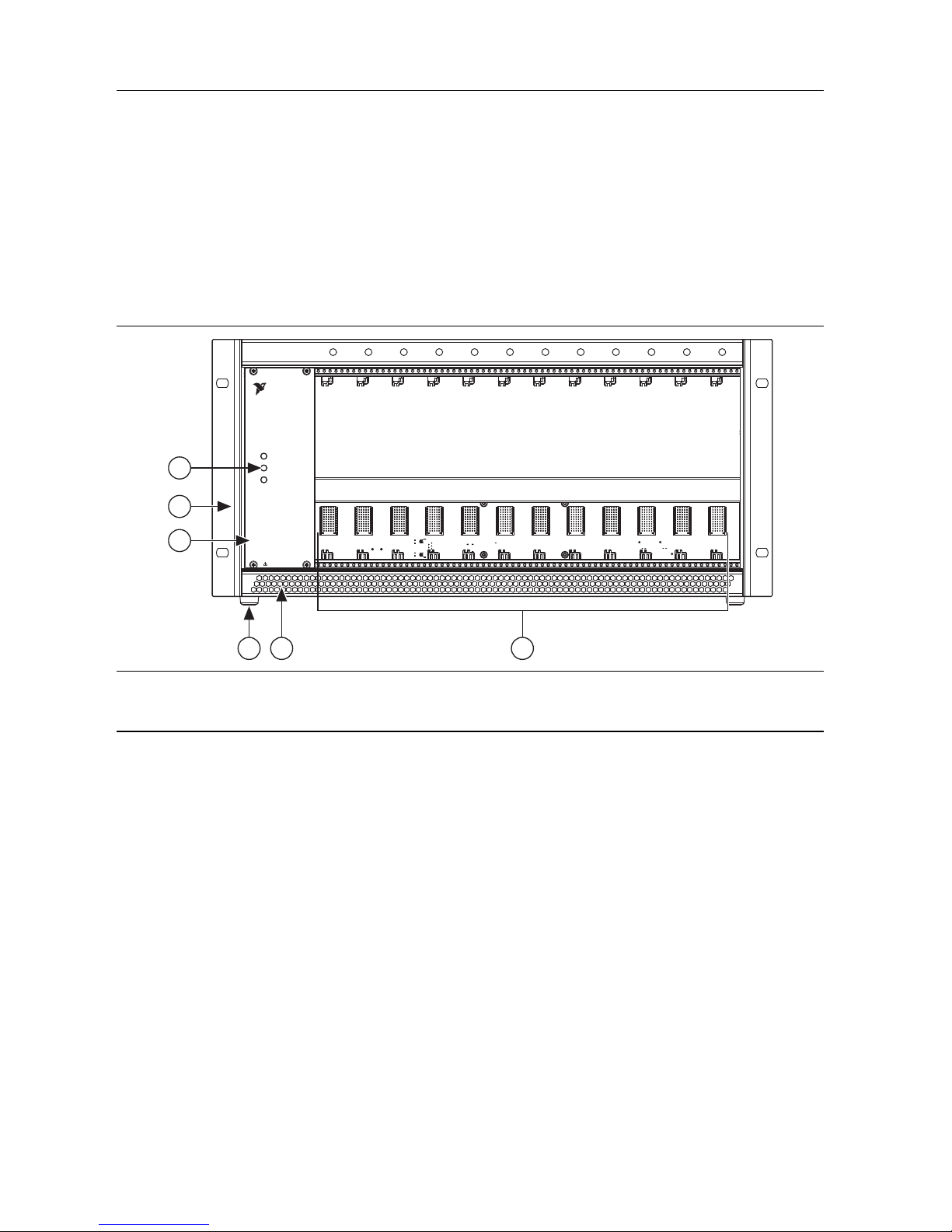

Figure 3 shows the SLSC-12001 chassis block diagram.

Figure 3. SLSC-12001 Chassis Block Diagram

The chassis power comes from an external +24 V supply and is distributed to each SLSC module

through an internal power bus. The +24 V bus has input overvoltage, reverse voltage, and short

circuit protection at each SLSC module output. The chassis does not have a power switch,

therefore power is energized as soon as the external power supply is connected to the chassis

and powered.

The SLSC-12001 chassis communicates with each module through the SLSC interface and

manages the Ethernet connectivity with a host computer.

The SLSC-12001 chassis also has built-in diagnosis functions, such as battery and fan

monitoring, that is accessible through the NI-SLSC driver. The chassis will shut down the

24 V rail supplied to the module unless all 5 fans are powered.

6 | ni.com | SLSC-12001 Chassis Getting Started Guide and Specifications

Page 7

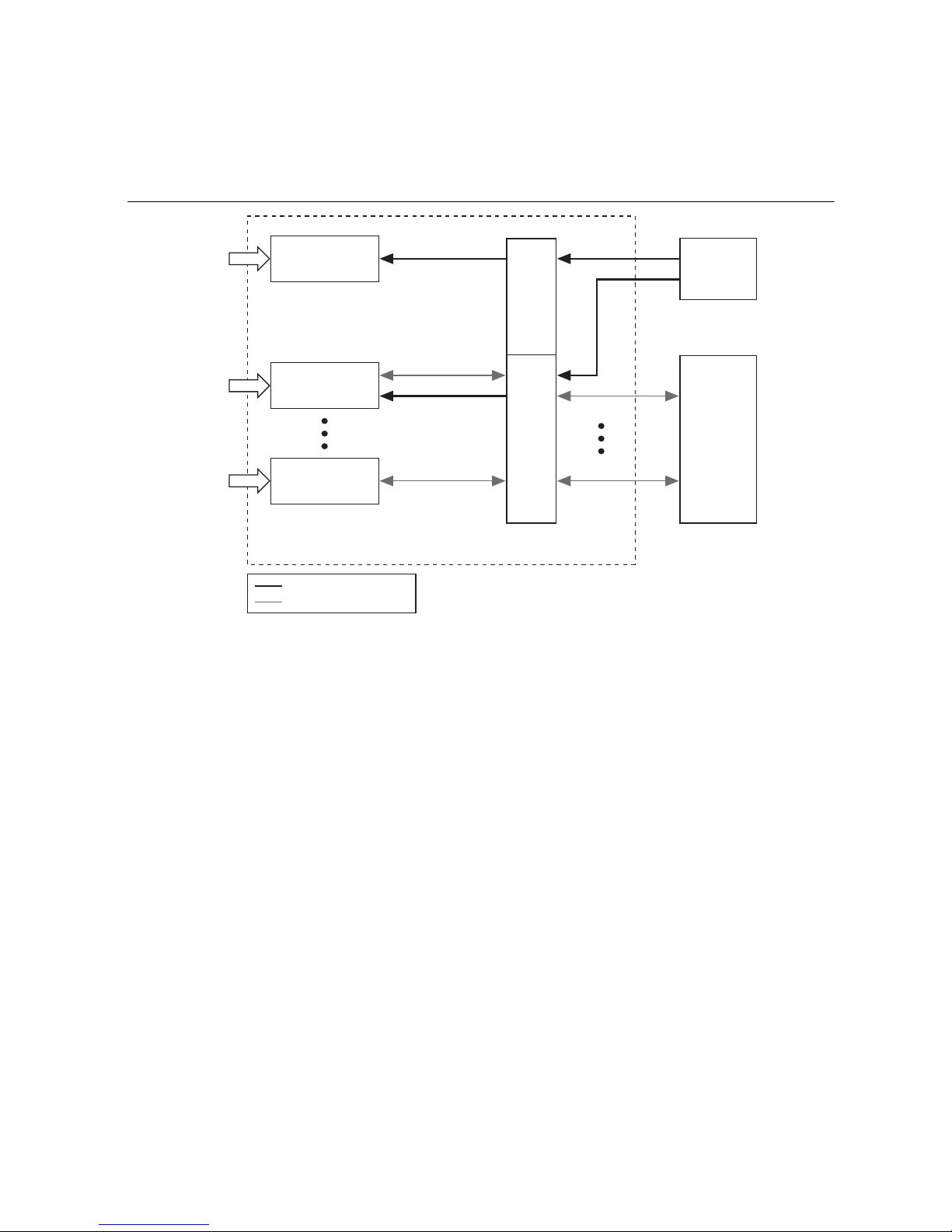

SLSC-12001 Chassis Rear Transition Interface

DAQ

System

Power

Rear Transition

Interface

Rear Transition

Interface

SLSC Module

SLSC Module

SLSC Module

I/O

I/O

I/O

SLSC-12001 Chassis

Conditioned

Signals

Digital/Analog Signals

Powe r

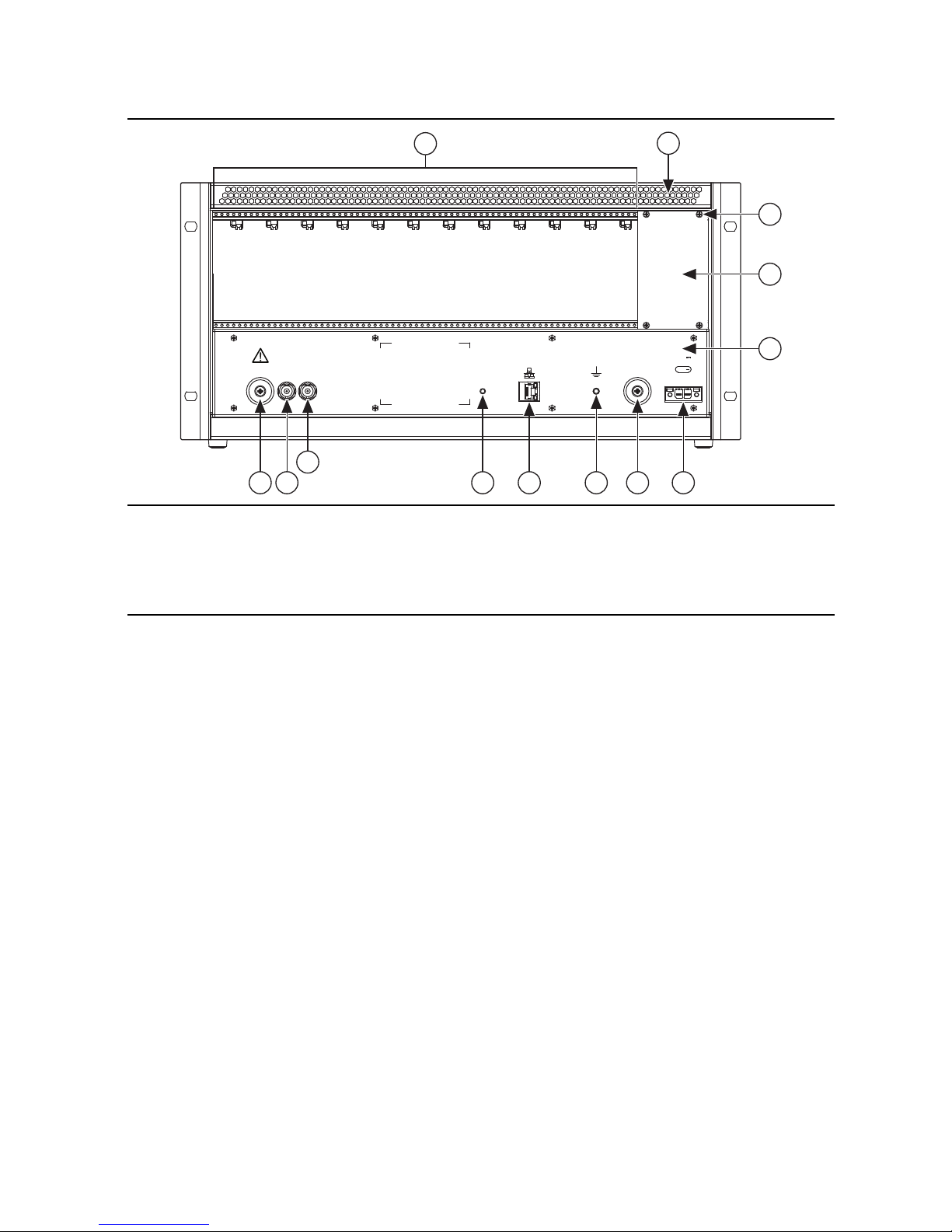

An optional secondary backplane, RTI, may be used with the SLSC-12001 chassis to route

conditioned I/O signals directly to the DAQ system. The RTI can be used to distribute additional

power to one or more modules as shown in Figure 4.

Figure 4. Rear Transition Interface

RTIs must be implemented as follows:

1. All slots must have the SLSC Peripheral Rear I/O Area covered by either an RTI or rear

2. RTI implementation is flexible and can be used as follows:

filler panel to meet EMC and airflow requirements.

• An RTI can be a single slot width therefore resulting in 12 RTIs.

• An RTI can be a single PCB 12 slots wide taking into account all slots.

• An RTI can cover any number of slots from 1 to 12.

SLSC-12001 Chassis Getting Started Guide and Specifications | © National Instruments | 7

Page 8

Installing the Chassis

2

1

101.60 mm

(4.00 in.)

101.60 mm

(4.00 in.)

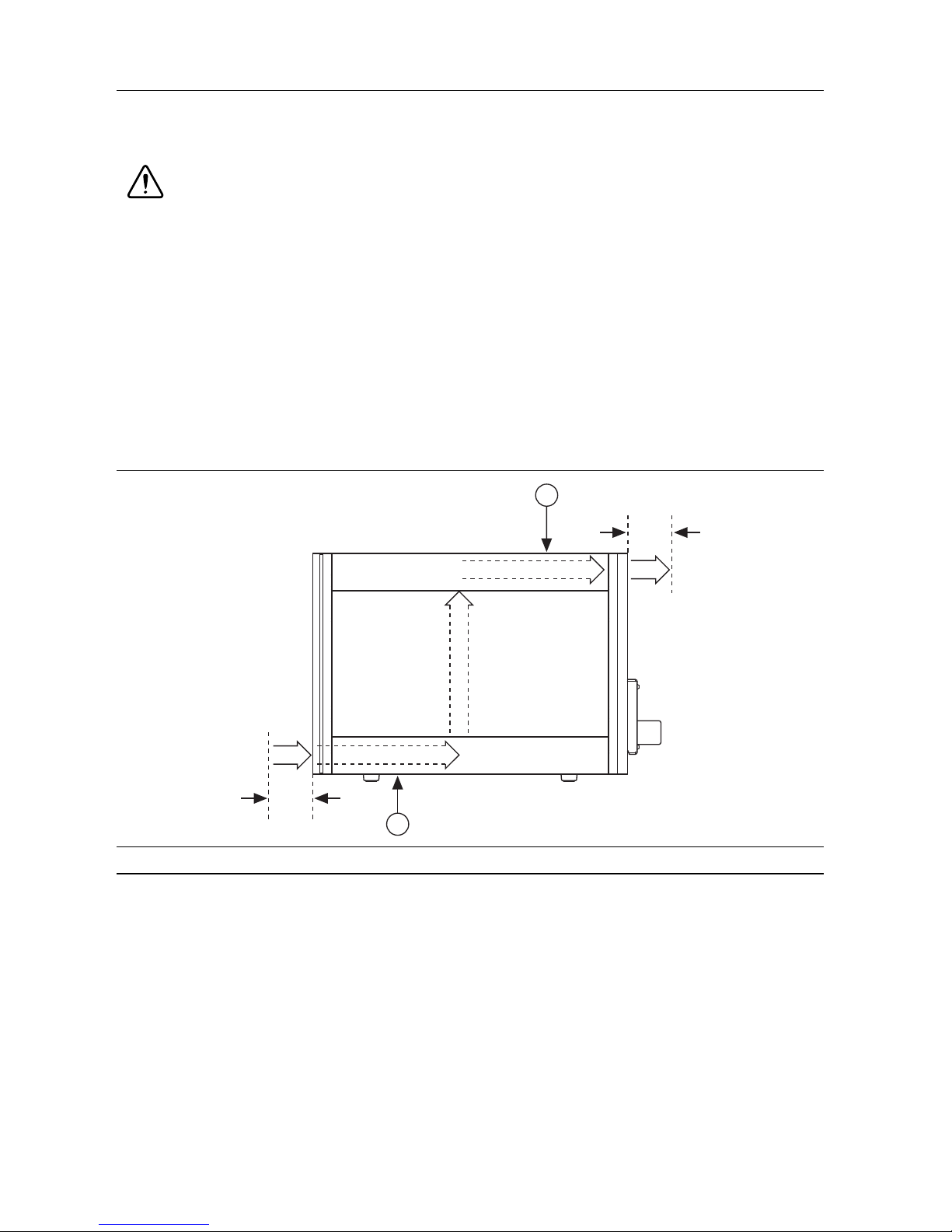

The SLSC-12001 chassis is designed to operate in an instrument rack with cooling clearances

to allow for proper airflow circulation.

Caution The SLSC-12001 chassis must be installed in a rack or similar enclosure

that ensures the rear of the chassis is not accessible (per IEC 61010-1) during normal

use. Access to the RTIs must require a tool. The front of the chassis may remain

accessible. Additionally, the rack or enclosure must meet the enclosure requirements

of IEC 61010-1 for containing the potential spread of fire from the RTIs.

The SLSC-12001 chassis cooling inlet air vents are located on the front lower side of the chassis

and the outlet air vents are on the back upper side of the chassis. Position the air inlet to pull

air from outside the instrument rack. For best performance the air vents must allow easy air

circulation without wiring or panels blocking the vents. Refer to Figure 5 for airflow and

clearance information.

Figure 5. SLSC-12001 Chassis Airflow

1 Airflow Out 2 Airflow In

In order to operate the chassis at the maximum allowable ambient temperature and maximum

power as specified in the Environmental section, you must mount the chassis horizontally in the

rack and allow for airflow at the intake and exhaust as shown in Figure 5. Filler panels, which

are available at

ni.com, must be inserted in any empty front module slots and in any empty rear

RTI slots.

8 | ni.com | SLSC-12001 Chassis Getting Started Guide and Specifications

Page 9

Installing Rear Transition Interfaces

Caution Do not touch or remove the I/O boards or cables while the system is

energized. I/O boards may have exposed hazardous live voltages. Access must be

prevented in normal operation

Note Refer to RTI manufacturer documentation for product-specific installation

instructions.

NI recommends installing all RTIs prior to the initial module installation. Complete the

following steps to install RTIs:

1. Power off the main DC power source or disconnect it from the chassis before installing

any RTI.

2. Ensure that the chassis is powered off. The POWER LED should be off. If it is not off,

do not proceed until the POWER LED is off.

3. Loosen the screws of the upper rear panel. Refer to Figure 2 for the upper rear panel screws

locations.

4. Position the RTI at the desired slot and insert the securing screws, but do not fully tighten

them.

5. Insert a corresponding module in the same slot providing additional resistance at the rear

of the RTI for the module to fully mate to the RTI.

6. Repeat steps 4 and 5 for all required RTIs.

7. Tighten the screws for all RTIs and the upper rear panel. This ensures proper alignment for

future connections between modules and these RTIs.

Installing SLSC Modules

Caution The SLSC-12001 chassis and the SLSC modules do not support hot

plug-in. The entire chassis must be powered down when a module is installed.

Complete the following steps to install an SLSC module in the chassis while referring to

Figure 6:

Caution Power off the main DC power source or disconnect it from the chassis

before installing the module. To completely remove power, you must disconnect

all power cables.

Note Refer to module and RTI documentation to ensure electrical compatibility for

rear I/O connections.

1. Ensure that the chassis is powered off. The POWER LED should be off. If it is not off,

do not proceed until the POWER LED is off.

SLSC-12001 Chassis Getting Started Guide and Specifications | © National Instruments | 9

Page 10

2. Ensure that any alternate power source(s) connected the RTI(s) or modules are powered off.

S

LS

C-120

0

1

S

W

I

T

C

H

/

L

O

AD

/

S

I

G

NA

L

C

ON

D.

D

O

N

O

T

I

N

S

E

R

T

O

R

R

E

MOV

E

MO

D

U

L

E

S

WH

I

L

E

P

O

WE

R

E

D

P

OW

E

R

ACT

I

V

I

T

Y

S

T

A

T

US

S

LS

C-120

0

1

S

W

I

T

C

H

/

L

O

AD

/

S

I

G

NA

L

C

ON

D.

D

O

N

O

T

I

N

S

E

R

T

O

R

R

E

MOV

E

MO

D

U

L

E

S

WH

I

L

E

P

O

WE

R

E

D

P

OW

E

R

ACT

I

V

I

T

Y

S

T

A

T

US

2

1

3. Inspect the slot pins on the chassis backplane for any bending or damage prior to installing

a module.

4. Install a module into a chassis slot by first placing the module PCB into the front of the PCB

guides at the top and bottom.

5. Slide the module into the chassis until you begin to feel resistance then push up the

injector/ejector handle to fully seat the module into the chassis frame.

6. Secure the module front panel to the chassis using the module front-panel mounting screws.

Figure 6. SLSC-12001 Module Installation

1 Module 2 Injector/Ejector Handle

Removing SLSC Modules

Caution The SLSC-12001 chassis and the SLSC modules do not support hot

plug-in. The entire chassis must be powered down when a module is removed.

Complete the following steps to remove an SLSC module from the chassis:

1. Power off the main DC power source or disconnect it from the chassis before removing the

module.

2. Ensure that the chassis is powered off. The POWER LED should be off. If it is not off,

do not proceed until the POWER LED is off.

3. Ensure that any alternate power source(s) connected the RTI(s) are powered off.

10 | ni.com | SLSC-12001 Chassis Getting Started Guide and Specifications

Page 11

4. Unsecure the module front panel from the chassis by loosening the module front-panel

mounting screws.

5. Push down on the injector/ejector handle to pull the module away from the backplane

connector(s).

6. Slide the module to the front of the chassis, making sure the module remains in the guide

rails as you slide it out of the chassis.

Connecting the Chassis

Safety Guidelines

Caution Before undertaking any troubleshooting, maintenance, or exploratory

procedure; carefully read the following cautionary notices.

• Chassis Grounding—The SLSC chassis grounding screw may be connected to facility

ground. Refer to the Grounding the Chassis section for instructions on connecting a

grounding conductor.

– Live Circuits—Operating personnel and service personnel must not remove

protective covers when operating or servicing the chassis. Adjustments and service

to internal components must be undertaken by qualified service technicians. During

service of this product, disconnect the external power supply from the SLSC chassis.

– Explosive Atmosphere—Do not operate the chassis in conditions where flammable

gases are present. Under such conditions, this equipment is unsafe and may ignite the

gases or gas fumes.

– Part Replacement—Only service this equipment with parts that are exact

replacements, both electrically and mechanically. Contact NI for replacement part

information. Installation of parts with those that are not direct replacements can cause

harm to personnel operating the chassis. Furthermore, damage or fire may occur if

replacement parts are unsuitable.

– Modification—Do not modify any part of the chassis from its original condition.

Unsuitable modifications can result in safety hazards.

Grounding the Chassis

Connect the grounding electrode system of the facility to the chassis using the chassis grounding

screw located on the back of the SLSC-12001 chassis. Refer to Figure 2 for the location of the

chassis ground screw. Use an AWG 8 wire with a lug as appropriate for your application.

Wiring Power to the Chassis

The SLSC-12001 chassis requires a +24 V, DC supply as power for the chassis and installed

modules. Refer to the Chassis Power section for the minimum specifications of the external

power supply. For best results ensure that the external power supply is mounted as required

by the manufacturer and has enough air circulation for proper cooling.

SLSC-12001 Chassis Getting Started Guide and Specifications | © National Instruments | 11

Page 12

The SLSC-12001 chassis can draw a significant current from the +24 V power input to support

module requirements. Refer to the Physical Characteristics section for wire gauge sizes

permitted by the SLSC-12001 chassis connector when wiring the power. Minimize the cable

length between the power supply and SLSC-12001 chassis. Avoid unnecessary intermediate

connections on the power lines. If possible, direct wiring between the power supply and chassis

is preferred.

Complete the following steps to connect the external power supply:

1. Ensure the +24 V external power supply is powered off.

2. Wire the power supply to the SLSC-12001 chassis power input connector, which is shipped

with the SLSC-12001 chassis. Refer to the Physical Characteristics section for wire gauge

information. Refer to Table 1 for signal connection information.

Table 1. Power Input Cable Connector

Connector Pin Description

- Negative power input

–

+

+ Positive power input

3. Install the power connector on the rear of the SLSC-12001 chassis and secure it with the

locking tabs.

Note If a source with remote sensing is used, connect the sensing wires as close

as possible to the chassis power input connector.

Powering on the Chassis

The SLSC-12001 chassis does not have an on/off switch since an external power supply

provides power to the SLSC-12001 chassis. Connecting an already powered on 24 V supply

to the SLSC-12001 is allowed, but higher transient currents may be involved.

When you apply power to the SLSC-12001, the chassis fans start and the POWER LED should

turn green immediately. When the POWER LED and the STATUS LED are both green, the

chassis is ready for host communication. Refer to the Understanding LED Indicators section

to identify other LED indications.

Note Ensure that SLSC modules are installed in the chassis prior to power-up.

12 | ni.com | SLSC-12001 Chassis Getting Started Guide and Specifications

Page 13

Note If an SLSC module requires auxiliary power supplies, refer to the module

datasheet to determine the power-up sequence.

Tip After the SLSC-12001 is powered on, check the voltage at the chassis power

connector to ensure that the power line does not drop below the minimum operational

voltage range specified in the Chassis Power section.

Connecting the Chassis to a Host

Use a shielded Category 5 Ethernet cable to connect the SLSC-12001 using one of the following

methods:

Note By default, the SLSC-12001 uses DHCP to acquire an IP address. If the

network to which it is connected does not have a DHCP server, the SLSC-12001

assigns itself a link-local IP address. To use a static IP address, you must use DHCP

or link-local to access the web-based configuration interface of the SLSC-12001 and

then reconfigure it to use a static IP address.

• Connect the SLSC-12001 to the network, typically through a router or switch shared with

the host using a standard Ethernet cable.

• Connect the SLSC-12001 to the Ethernet port on the host system using an Ethernet

crossover cable.

Connecting to a Measurement System

The SLSC-12001 direct signal connection to a measurement system is optimized to be

completed through RTI(s) as required by individual SLSC modules. Use signal cables as

required by individual SLSC modules and measurements system to route the signals.

Maintenance

Power off the chassis and any alternate power supplies connected to the modules or RTIs when

performing maintenance on the chassis. After maintenance is complete, ensure that the chassis

is completely dry and free from contaminants before returning it to service.

Caution Many components within the chassis are susceptible to static discharge

damage. Service the chassis only in a static-free environment. Observe standard

handling precautions for static-sensitive devices while servicing the chassis. Always

wear a grounded wrist strap or equivalent while servicing the chassis.

Cleaning the Chassis

Clean dust from the chassis exterior and interior as needed, based on the operating environment.

Periodic cleaning increases reliability.

Use a dry, low-velocity stream of air to clean the interior of the chassis. Use a soft-bristle brush

for cleaning around components.

SLSC-12001 Chassis Getting Started Guide and Specifications | © National Instruments | 13

Page 14

Clean the exterior surfaces of the chassis with a dry lint-free cloth or a soft-bristle brush. If any

dirt remains, wipe with a cloth moistened in a mild soap solution. Remove any soap residue by

wiping with a cloth moistened with clear water. Do not use abrasive compounds on any part of

the chassis.

Cleaning and Replacing the Chassis Intake Filter

Caution Operating the SLSC-12001 without the chassis intake filter installed

degrades the cooling performance of the chassis.

Cleaning the Filter

A dirty intake filter dramatically affects the cooling performance of an SLSC-12001 chassis.

Clean the intake filter whenever it becomes visibly dirty.

1. For minor dust buildup, you can vacuum the intake filter without removing it from the

chassis.

2. For significant dust buildup, NI recommends removing and cleaning the intake filter,

or replacing the intake filter.

• Clean the intake filter by:

1. Washing it in a mild soap solution.

2. Rinsing it with water.

3. Vacuuming or blowing air through it.

4. Allowing it to dry before reinstalling it in the chassis.

• You can replace the intake filter with a new one, which is available from

ni.com.

Removing the Filter

1. Remove the four screws from the front panel that contains the chassis LEDs and set them

aside.

2. Remove the front panel that contains the chassis LEDs and set it aside.

3. Reach into the bottom front of the chassis and pull out the intake filter.

Inserting the Filter

1. Remove modules as needed to place the intake filter in its original location flush against the

chassis intake across the entire front length of the chassis.

2. Ensure that the intake filter is oriented as shown in Figure 7.

3. Reinsert the front panel that contains the LEDs.

4. Install the four front panel screws.

14 | ni.com | SLSC-12001 Chassis Getting Started Guide and Specifications

Page 15

Figure 7. Intake Filter Orientation

S

LS

C-120

0

1

S

W

I

T

CH/

L

O

AD/

SI

G

N

A

L

CO

N

D

.

P

OW

E

R

ACT

I

V

I

T

Y

S

T

A

T

US

S

LS

C-120

0

1

S

W

I

T

CH/

L

O

AD/

SI

G

N

A

L

CO

N

D

.

D

O

N

O

T

I

N

S

E

RT

O

R

R

E

MOV

E

MO

D

U

L

E

S

WH

I

L

E

P

O

W

E

R

E

D

P

OW

E

R

ACT

I

V

I

T

Y

S

T

A

T

US

1

2 3

4035302520

60,000

20,000

10,000

0

Chassis Intake Temperature (°C)

Operating Duration (Hours)

30,000

40,000

50,000

70,000

80,000

50 W per Module Average

40 W per Module Average

30 W per Module Average

1Filter

3 Chassis Side Sectioned View

2 Filter Inserted in Correct Orientation

Fan Maintenance

Figure 8 shows estimated fan life based on empirical and manufacturer reliability information.

Actual fan operating life may vary based on individual module airflow and heat dissipation

characteristics. The information provided in Figure 8 allows you to maximize the performance

and operation of the SLSC-12001 chassis by allowing you to manage maintenance schedules.

Figure 8. Projected Fan Lifetime

SLSC-12001 Chassis Getting Started Guide and Specifications | © National Instruments | 15

Page 16

Fan Replacement

National Instruments provides a replacement kit containing five fans and two plastic cable ties.

The replacement kit is available at ni.com.

Fan Removal

1. Insert a small flathead screwdriver into the small notches shown in Figure 9 to remove the

side panels.

Figure 9. Removing Chassis Panels

2

3

1 1

N

A

T

IN

ION

S

T

AL

R

UM

EN

T

S

4

S

L

S

S

W

C-12001

I

T

C

H

/

L

O

A

D

/

S

I

G

N

A

L

C

O

N

D

.

N

ATIO

IN

ST

N

AL

R

UM

E

N

T

S

S

L

S

S

W

C-12001

I

T

C

H

/

L

O

A

D

/

S

I

G

N

A

L

C

O

N

D

.

4

3

1 Top Panel

2 Top Panel Retention Screw (2)

3 Side Panel (2)

4 Notches for Screwdriver Insertion

2. Remove the two top panel retention screws using a Phillips screwdriver.

Note Use care when reinstalling the top panel retention screws. These are

thread-forming screws and may cause cross-threading damage if inserted incorrectly.

3. Remove the top panel by holding its side edges and lifting it off the chassis.

4. Locate the fan terminal block, by referring to Figure 10.

5. Disconnect the wires associated with the fan(s) that you want to replace. Figure 12

illustrates the fan wire locations.

2

3

a. Insert a small flathead screwdriver into a spring clamp activation slot to open the

corresponding connector terminal as shown in Figure 11.

b. Pull the wire out of the connector terminal and remove the screwdriver.

c. Repeat step a and b for each fan you replace.

6. Cut the plastic cable ties shown in Figure 10.

7. Lift the fan(s) vertically from the standoffs.

16 | ni.com | SLSC-12001 Chassis Getting Started Guide and Specifications

Page 17

Figure 10. Chassis Fan Components

2

1

3

4

9

1Fan 1

2Fan 2

3 Standoff (15)

4Fan 3

5Fan 5

NATIONAL

8

INSTRUMENTS

S

LSC

SW

IT

C

H

/

LO

-1

A

2

D

/SIG

0

N

0

A

L

1

C

O

N

D

.

7

6 Fan Terminal Block

7 Plastic Cable Ties and Cable Tie Anchors

8 Fan 4

9 Fan Power Cable

Figure 11. Fan Terminal Block Wire Removal and Insertion

5

6

3+

F4+

F

F2+

F1+

F4–

F3–

F2–

F1–

1 2 3 4

1 Step 1 Insert the Screwdriver

2 Step 2 Remove the Fan Terminal Block Wire

SLSC-12001 Chassis Getting Started Guide and Specifications | © National Instruments | 17

4+

F

F3+

F2+

F1+

F4–

F3–

F2–

F1–

F4+

3+

2+

F

F

F1+

F4–

F3–

F2–

F1–

4+

F

F3+

F2+

F1+

F4–

F3–

F2–

F1–

3 Step 3 Replace the Fan Terminal Block Wire

4 Step 4 Remove the Screwdriver

Page 18

Figure 12. Fan Terminal Block Wiring

Fan 4 Red (+)

Fan 3 Red (+)

Fan 2 Red (+)

Fan 1 Red (+)

Fan 4 Black (–)

Fan 3 Black (–)

Fan 2 Black (–)

Fan 1 Black (–)

F4+

F3+

F2+

F1+

F4–

F3–

F2–

F1–

F5+

Fan 5 Red (+)

J+

J+

V+

Fan Pwr (+)

Fan 5 Black (–)

F5–

J–

J–

V–

Fan Pwr (–)

Fan Installation

1. Slide the fan(s) down onto the standoffs.

2. Connect the fan wires to the terminal block as shown in Figure 12 using the process shown

in Figure 11.

a. Insert the screwdriver into the spring clamp activation slot to open the corresponding

connector terminal.

b. Press the new fan wire into the open connector terminal.

c. Remove the screwdriver from the activation slot to clamp the wire into place.

d. Repeat step a through c for each fan you install.

3. Route the wires between the fans, not over them. For fan 3 in Figure 10, route the wire

beneath the fan tray and back through the two small grommets shown in Figure 13. Pull

the wire taut to prevent it from dangling loosely beneath the tray.

4. Coil up the wires and cable as needed to prevent the wires from being pinched when the

panel is reattached. Use the chassis sheet metal cable tie anchors shown in Figure 10, and

the plastic cable ties from the fan kit to hold the wires and cable tightly in place. Figure 14

illustrates the anchor and cable tie detail.

5. Replace the top panel with the vent holes toward the back.

6. Reinsert the two top panel retention screws using a Phillips screwdriver and tighten the

screws to a torque of 1.92 N · m (17 lb · in.).

7. Replace the side panels.

18 | ni.com | SLSC-12001 Chassis Getting Started Guide and Specifications

Page 19

1 Small Grommets

Figure 13. Fan 3 Wiring Detail

1

Figure 14. Tie Anchor Detail

2

1

3

1Wires

2 Plastic Cable Tie

3 Cable Tie Anchor

Battery Replacement

The SLSC-12001 contains a lithium cell battery that is required for storing the Real Time Clock

information when the chassis is powered off. There is only a slight drain on the battery when

power is applied to the SLSC-12001 power connector. The rate at which the battery drains when

power is disconnected depends on the ambient storage temperature. The battery is located on the

backplane. To replace the battery, complete the following steps while referring to Figure 15:

1. Power off the chassis and any power source(s) connected to module(s) and RTI(s).

2. Remove the chassis power, trigger, and Ethernet cables from the chassis.

3. Remove the washer and nut from around each BNC connector.

4. Remove the eight backplane panel fixing screws.

SLSC-12001 Chassis Getting Started Guide and Specifications | © National Instruments | 19

Page 20

5. Remove the backplane panel.

D

O

N

O

T

T

O

U

C

H

C

O

N

T

A

C

TS O

R

R

EMO

VE I/O

B

OA

R

D

S

O

R

C

A

B

LES

W

H

IL

E SYSTEM

IS EN

ER

G

IZED.

T

R

IG

0

TR

IG

1

5

6

4

3

2

1

6. Remove the battery.

Note Refer to the Battery Replacement and Disposal section for information about

proper disposal of the old battery.

7. Replace the battery with a new Tadiran TL-2450 or an equivalent battery.

8. Replace the backplane panel.

9. Secure the back panel with the eight fixing screws tightened to a torque of 0.56 N · m

(5 lb · in.).

10. Secure each BNC connector with a washer and nut.

11. Replace the chassis power connector.

Once the battery is replaced, the Real Time Clock will reset. Refer to NI-SLSC Help for

information about setting the clock.

Figure 15. SLSC-12001 Chassis Battery Replacement

1 Backplane Panel

2 Backplane Panel Affixing Screws (8)

3 BNC Connector Washer (2)

20 | ni.com | SLSC-12001 Chassis Getting Started Guide and Specifications

4 BNC Connector Nut (2)

5Battery

6 Chassis Power Connector

Page 21

Troubleshooting

Understanding LED Indicators

The SLSC-12001 has three LEDs on the front panel. The significance of the LEDs is described

in Table 2.

Table 2. Troubleshooting Using LED Indicators

LED Type LED Indicator Status

POWER Off No power or short circuit on +3.3 V rail causing failure to

power on.

Green Power is on.

ACTIVITY Blinking green Ethernet communication in progress.

Off No Ethernet communication.

STATUS Red Less than 3 seconds: chassis is starting to boot.

Reset button is pressed.

More than 3 seconds after boot start: chassis failed to

boot. This could be due to corrupt firmware, incorrect

power input, fan failure, or other hardware issues.

Amber Chassis is booting.

Green Normal operation.

Network Communication Troubleshooting

Multiple problems may result in network communication issues during setup.

Things to try:

• Ensure the chassis is connected to a working 24 VDC power source.

• If the STATUS LED is off, there may be a short circuit. Refer to the Module Short Circuit

Behavior section for more information.

• If the STATUS LED is green, but the ACTIVITY LED is off, try the following:

– Verify the Ethernet cable is connected properly.

– If communication is routed through a switch, verify that the switch is powered on and

functioning.

– Verify that your network has a DHCP server or that the chassis is connected to the host

system using a crossover cable.

– Verify that the host computer firewall is disabled.

– Verify that the host computer is not configured to use a proxy server.

SLSC-12001 Chassis Getting Started Guide and Specifications | © National Instruments | 21

Page 22

Resetting the Chassis and Modules

The SLSC-12001 chassis has a button, located on the rear of the chassis.

Pressing the reset button results in the following chassis responses:

• Reset—When pressed for less than five seconds, the chassis reboots with the current

configuration.

• Factory Reset—When pressed for five seconds or longer, then released, the chassis reboots

into factory default mode, which returns the chassis user configuration to the factory-set

defaults listed in Table 3. If the chassis was set to a static IP address, it takes two factory

resets to revert to DHCP or Link Local IP address.

Table 3. SLSC-12001 Factory Default Mode Settings

Attribute Value

Host Name/Chassis Name SLSC-12001-<8-digit serial number>

Module Name SLSC-12001-<8-digit serial number>-Mod<slot number>

IP DHCP or Link Local

Comment Empty

NI Auth User name = admin Password = no password required

User name = anonymous Password = no password required

Note: If the serial number is less than 8-digits, zeros will be added to the front of the serial number to

make it 8 digits long.

Fan Faults

The NI-SLSC software driver provides the ability to monitor the SLSC-12001 Fan Voltage

Sensor to determine whether a fan fault is detected. This feature allows you to determine when

a fan should be replaced. If fan faults are not resolved immediately, system performance is

impacted. Refer to the NI-SLSC Driver Help for more details on monitoring the fans. If the

SLSC-12001 detects that all fans have failed, the modules are sent a reset command and the

+24 V rail to each slot is turned off to prevent system damage.

Module Short Circuit Behavior

Each SLSC module is powered from the SLSC-12001 through +3.3 V and +24 V rails. If a

defective module is present, the SLSC-12001 may fail to start. If one SLSC module has a short

circuit condition on the +3.3 V rail, the SLSC-12001 chassis will not start, there will be no

Ethernet communication with the chassis, and all front panel LEDs will be off.

If one SLSC module has a short circuit condition on the +24 V rail, the +24 V rail is turned off

for all modules once the chassis starts and the POWER LED will be amber. In both cases, power

off the chassis and remove the defective module before attempting a restart.

22 | ni.com | SLSC-12001 Chassis Getting Started Guide and Specifications

Page 23

Specifications

The following specifications apply to an SLSC-12001 mounted in a rack with recommended

cooling clearances found in the Installing the Chassis section and using a power supply that

meets the specifications provided in this Specifications section. The specifications are valid

for the entire temperature range of the chassis unless otherwise specified.

Chassis Power

Nominal input voltage ...................................... 24 V

Maximum input voltage.................................... 27.6 V

Minimum input voltage .................................... 21 V

Maximum input voltage ripple

20 Hz to 20 MHz .............................................. 200 mV

Chassis power consumption (no modules) ....... 45 W

Maximum input current .................................... 35 A

Maximum power consumption with

modules............................................................. 720 W

Maximum power cable length .......................... 3 m

Note The external power supply must meet the DC input specifications at the

chassis input with a minimum power output of 720 W and must provide suitable

overvoltage and overcurrent protection as well as a suitable easily reached disconnect

switch or circuit breaker.

Note Depending on populated modules, the startup current could be significantly

higher than the steady DC current. The external power supply should sustain the

initial startup current without entering the overcurrent protection.

SLSC-12001 Chassis Getting Started Guide and Specifications | © National Instruments | 23

Page 24

Table 4. DC Output per Slot

Rail Minimum Volts Maximum Volts Maximum Current Comments

24 V 20.4 26.4 2 A Across two pins

3.3 V 3.135 3.465 400 mA —

Note Each slot has short circuit protection.

SLSC-12001 power dissipation

Maximum chassis power dissipation ........650 W

Maximum continuous

power dissipation per slot .........................50 W

Battery

Battery type....................................................... Tadiran TL-2450

Typical battery life with power applied

to power connector............................................ 8 years

Network

Network interface .............................................10BASE-T, 100BASE-T, 1000BASE-T

Ethernet compatibility....................................... IEEE 802.3

Communication rates ........................................10 Mbps, 100 Mbps, 1,000 Mbps

auto-negotiated

Maximum cabling distance...............................100 m/segment

24 | ni.com | SLSC-12001 Chassis Getting Started Guide and Specifications

Page 25

Physical Characteristics

Figure 16. SLSC-12001 Dimensions

36.5 mm

(1.44 in.)

315.56 mm

(12.42 in.)

325.26 mm

(12.81 in.)

23.83 mm

(0.95 in.)

448.9 mm

(17.67 in.)

482.6 mm

(19.00 in.)

POWER

228.65 mm

(9.00 in.)

POWER

ACTIVITY

ACTIVITY

STATUS

STATUS

SLSC-12001

SWITCH/LOAD/SIGNAL COND.

DO NOT INSERT OR REMOVE

DO NOT INSERT OR REMOVE

MODULES WHILE POWERED

MODULES WHILE POWERED

7.2 mm

(0.28 in.)

Power connector screw-terminal

wire gauge......................................................... 8.36 mm2 (8 AWG)

Power connector screw-terminal

wire type ........................................................... Copper conductor wire

SLSC-12001 Chassis Getting Started Guide and Specifications | © National Instruments | 25

Page 26

Power connector screw-terminal

wire strip length ................................................10 mm (0.394 in.) of insulation stripped

from the end

Power connector screw-terminal

screw torque ...................................................... 0.5 N · m (4.4 lb · in.)

Weight (chassis only)........................................6.2 kg (13.6 lb)

Chassis Cooling

Module cooling system

Slot airflow direction ................................ Bottom of module to top of module

Module cooling intake .............................. Bottom front of chassis

Module cooling exhaust............................Top rear of chassis

Environmental

Operating temperature at chassis air intake ......0 °C to 40 °C

1

(Tested in accordance with IEC 60068-2-1 and

IEC 60068-2-2.)

Storage temperature range ................................ -40 °C to 85 °C

(Tested in accordance with IEC 60068-2-1 and

IEC 60068-2-2.)

Relative humidity range, operating...................10% to 90%, noncondensing

(Tested in accordance with IEC 60068-2-56.)

Relative humidity range, storage ......................5% to 95%, noncondensing

(Tested in accordance with IEC 60068-2-56.)

Maximum altitude.............................................2,000 m (800 mbar) (at 25 °C ambient)

Pollution Degree ...............................................2

Indoor use only.

1

The chassis internal ambient temperature may reach 85 °C with all slots at the maximum allowed power

dissipation.

26 | ni.com | SLSC-12001 Chassis Getting Started Guide and Specifications

Page 27

Shock and Vibration

Operational shock ............................................. 30 g peak, half-sine, 11 ms pulse

(Tested in accordance with IEC 60068-2-27.

Meets MIL-PRF-28800F Class 2 limits.)

Operating vibration, random............................. 5 Hz to 500 Hz, 0.3 g

(Tested in accordance with IEC 60068-2-64.)

Non-operating vibration, random ..................... 5 Hz to 500 Hz, 2.4 g

(Tested in accordance with IEC 60068-2-64.

Non-operating test profile exceeds the

requirements of MIL-PRF-28800F, Class 3.)

rms

rms

Safety

Measurement Category1................................... I

Caution Do not connect the SLSC-12001 to signals or use for measurements

within Measurement Categories II, III or IV.

Caution The protection provided by the SLSC-12001 can be impaired if it is used

in a manner not described in this document.

Safety Standards

This product meets the requirements of the following standards of safety for electrical equipment

for measurement, control, and laboratory use:

• IEC 61010-1, EN 61010-1

• UL 61010-1, CSA C22.2 No. 61010-1

Note For UL and other safety certifications, refer to the product label or the Online

Product Certification section.

Electromagnetic Compatibility

This product meets the requirements of the following EMC standards for electrical equipment

for measurement, control, and laboratory use:

• EN 61326-1 (IEC 61326-1): Class A emissions; Basic immunity

• EN 55011 (CISPR 11): Group 1, Class A emissions

• EN 55022 (CISPR 22): Class A emissions

• EN 55024 (CISPR 24): Immunity

• AS/NZS CISPR 11: Group 1, Class A emissions

1

Measurement Categories CAT I and CAT O are equivalent. These test and measurement circuits are not

intended for direct connection to the MAINS building installations of Measurement Categories CAT II,

CAT III, or CAT IV.

SLSC-12001 Chassis Getting Started Guide and Specifications | © National Instruments | 27

Page 28

• AS/NZS CISPR 22: Class A emissions

• FCC 47 CFR Part 15B: Class A emissions

• ICES-001: Class A emissions

Note In the United States (per FCC 47 CFR), Class A equipment is intended for use

in commercial, light-industrial, and heavy-industrial locations. In Europe, Canada,

Australia and New Zealand (per CISPR 11) Class A equipment is intended for use

only in heavy-industrial locations.

Note Group 1 equipment (per CISPR 11) is any industrial, scientific, or medical

equipment that does not intentionally generate radio frequency energy for the

treatment of material or inspection/analysis purposes.

Note For the standards applied to assess the EMC of this product, refer to the

Online Product Certification section.

CE Compliance

This product meets the essential requirements of applicable European Directives as follows:

• 2014/35/EU; Low-Voltage Directive (safety)

• 2014/30/EU; Electromagnetic Compatibility Directive (EMC)

• 2011/65/EU; RoHS Directive

Online Product Certification

Refer to the product Declaration of Conformity (DoC) for additional regulatory compliance

information. To obtain product certifications and the DoC for this product, visit

certification

in the Certification column.

, search by model number or product line, and click the appropriate link

ni.com/

Environmental Management

NI is committed to designing and manufacturing products in an environmentally responsible

manner. NI recognizes that eliminating certain hazardous substances from our products is

beneficial to the environment and to NI customers.

For additional environmental information, refer to the Minimize our Environmental Impact

web page at

directives with which NI complies, as well as other environmental information not included in

this document.

ni.com/environment. This page contains the environmental regulations and

28 | ni.com | SLSC-12001 Chassis Getting Started Guide and Specifications

Page 29

Waste Electrical and Electronic Equipment (WEEE)

⬉ᄤֵᙃѻક∵ᶧࠊㅵ⧚ࡲ⊩ ˄Ё

RoHS

˅

Ёᅶ᠋

National Instruments

ヺড়Ё⬉ᄤֵᙃѻકЁ䰤ࠊՓ⫼ᶤѯ᳝ᆇ⠽䋼ᣛҸ

(RoHS)

DŽ݇Ѣ

National Instruments

Ё

RoHS

ড়㾘ᗻֵᙃˈ䇋ⱏᔩ

ni.com/

environment/rohs_china

DŽ

(For information about China RoHS compliance,

go to

ni.com/environment/rohs_china

.)

EU Customers At the end of the product life cycle, all products must be sent to

a WEEE recycling center. For more information about WEEE recycling centers,

National Instruments WEEE initiatives, and compliance with WEEE Directive

2002/96/EC on Waste and Electronic Equipment, visit

.

weee

ni.com/environment/

Battery Replacement and Disposal

Battery Directive This device contains a long-life coin cell battery. If you need

Cd/Hg/Pb

to replace it, use the Return Material Authorization (RMA) process or contact an

authorized National Instruments service representative. For more information

about compliance with the EU Battery Directive 2006/66/EC about Batteries

and Accumulators and Waste Batteries and Accumulators, visit

environment/batterydirective

.

ni.com/

Worldwide Support and Services

The NI website is your complete resource for technical support. At ni.com/support you have

access to everything from troubleshooting and application development self-help resources to

email and phone assistance from NI Application Engineers.

ni.com/services for NI Factory Installation Services, repairs, extended warranty, and

Visit

other services.

Visit ni.com/register to register your NI product. Product registration facilitates technical

support and ensures that you receive important information updates from NI.

NI corporate headquarters is located at 11500 North Mopac Expressway, Austin, Texas,

78759-3504. NI also has offices located around the world. For telephone support in the United

States, create your service request at

For telephone support outside the United States, visit the Worldwide Offices section of

ni.com/niglobal to access the branch office websites, which provide up-to-date contact

information, support phone numbers, email addresses, and current events.

ni.com/support or dial 1 866 ASK MYNI (275 6964).

SLSC-12001 Chassis Getting Started Guide and Specifications | © National Instruments | 29

Page 30

Refer to the NI Trademarks and Logo Guidelines at ni.com/trademarks for more information on National Instruments trademarks. Other

product and company names mentioned herein are trademarks or trade names of their respective companies. For patents covering National

Instruments products/technology, refer to the appropriate location: Help»Patents in your software, the patents.txt file on your media, or the

National Instruments Patents Notice at ni.com/patents. You can find information about end-user license agreements (EULAs) and third-party

legal notices in the readme file for your NI product. Refer to the Export Compliance Information at ni.com/legal/export-compliance

for the National Instruments global trade compliance policy and how to obtain relevant HTS codes, ECCNs, and other import/export data. NI MAKES

NO EXPRESS OR IMPLIED WARRANTIES AS TO THE ACCURACY OF THE INFORMATION CONTAINED HEREIN AND SHALL NOT BE LIABLE FOR

ANY ERRORS. U.S. Government Customers: The data contained in this manual was developed at private expense and is subject to the applicable

limited rights and restricted data rights as set forth in FAR 52.227-14, DFAR 252.227-7014, and DFAR 252.227-7015.

© 2016–2017 National Instruments. All rights reserved.

377023D-01 Oct17

Loading...

Loading...