Page 1

TM

SCXI

SCXI-1520 User Manual

SCXI-1520 User Manual

May 2009

372583E-01

Page 2

Support

Worldwide Technical Support and Product Information

ni.com

National Instruments Corporate Headquarters

11500 North Mopac Expressway Austin, Texas 78759-3504 USA Tel: 512 683 0100

Worldwide Offices

Australia 1800 300 800, Austria 43 662 457990-0, Belgium 32 (0) 2 757 0020, Brazil 55 11 3262 3599,

Canada 800 433 3488, China 86 21 5050 9800, Czech Republic 420 224 235 774, Denmark 45 45 76 26 00,

Finland 358 (0) 9 725 72511, France 01 57 66 24 24, Germany 49 89 7413130, India 91 80 41190000,

Israel 972 3 6393737, Italy 39 02 41309277, Japan 0120-527196, Korea 82 02 3451 3400,

Lebanon 961 (0) 1 33 28 28, Malaysia 1800 887710, Mexico 01 800 010 0793, Netherlands 31 (0) 348 433 466,

New Zealand 0800 553 322, Norway 47 (0) 66 90 76 60, Poland 48 22 328 90 10, Portugal 351 210 311 210,

Russia 7 495 783 6851, Singapore 1800 226 5886, Slovenia 386 3 425 42 00, South Africa 27 0 11 805 8197,

Spain 34 91 640 0085, Sweden 46 (0) 8 587 895 00, Switzerland 41 56 2005151, Taiwan 886 02 2377 2222,

Thailand 662 278 6777, Turkey 90 212 279 3031, United Kingdom 44 (0) 1635 523545

For further support information, refer to the Technical Support Information Document. To comment on National

Instruments documentation, refer to the National Instruments Web site at

feedback.

ni.com/info and enter the info code

© 2001–2009 National Instruments Corporation. All rights reserved.

Page 3

Important Information

Warranty

The SCXI-1520 is warranted against defects in materials and workmanship for a period of one year from the date of shipment, as evidenced

by receipts or other documentation. National Instruments will, at its option, repair or replace equipment that proves to be defective during the

warranty period. This warranty includes parts and labor.

The media on which you receive National Instruments software are warranted not to fail to execute programming instructions, due to defects in

materials and workmanship, for a period of 90 days from date of shipment, as evidenced by receipts or other documentation. National Instruments

will, at its option, repair or replace software media that do not execute programming instruc tions if National Instruments receives notice of such defects

during the warranty period. National Instruments does not warrant that the operation of the software shall be uninterrupted or error free.

A Return Material Authorization (RMA) number must be obtained from the factory and clearly marked on the outside of the package before any

equipment will be accepted for warranty work. National Instruments will pay the shipping costs of returning to the owner parts which are covered by

warranty.

National Instruments believes that the information in this document is accurate. The document has been carefully reviewed for technical accuracy. In

the event that technical or typographical errors exist, National Instruments reserves the right to make changes to subsequent editions of this document

without prior notice to holders of this edition. The reader should consult National Instruments if errors are suspected. In no event shall National

Instruments be liable for any damages arising out of or related to this document or the information contained in it.

XCEPT AS SPECIFIED HEREIN, NATIONAL INSTRUMENTS MAKES NO WARRANTIES, EXPRESS OR IMPLIED, AND SPECIFICALLY DISCLAIMS ANY WARRANTY OF

E

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. CUSTOMER’S RIGHT TO RECOVER DAMAGES CAUSED BY FAULT OR NEGLIGENCE ON THE PART OF NATIONAL

NSTRUMENTS SHALL BE LIMITED TO THE AMOUNT THERETOFORE PAID BY THE CUSTOMER. NATIONAL INSTRUMENTS WILL NOT BE LIABLE FOR DAMAGES RESULTING FROM

I

LOSS OF DATA, PROFITS, USE OF PRODUCTS, OR INCIDENTAL OR CONSEQUENTIAL DAMAGES, EVEN IF ADVISED OF THE POSSIBILITY THEREOF. This limitation of the

liability of National Instruments will apply regardless of the form of action, whether in contract or tort, including negligence. Any action against

National Instruments must be brought within one year after the cause of action accrues. National Instruments shall not be liable for any delay in

performance due to causes beyond its reasonable control. The warranty provided herein does not cover damages, defects, malfunctions, or service

failures caused by owner’s failure to follow the National Instruments installation, operation, or maintenance instructions; owner’s modification of the

product; owner’s abuse, misuse, or negligent acts; and power failure or surges, fire, flood, accident, actions of third parties, or other events outside

reasonable control.

Copyright

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or mechanical, including photocopying,

recording, storing in an information retrieval system, or translating, in whole or in part, without the prior written consent of National

Instruments Corporation.

National Instruments respects the intellectual property of others, and we ask our users to do the same. NI software is protected by copyright and other

intellectual property laws. Where NI software may be used to reproduce software or other materials belonging to others, you may use NI software only

to reproduce materials that you may reproduce in accordance with the terms of any applicable license or other legal restriction.

Trademarks

National Instruments, NI, ni.com, and LabVIEW are trademarks of National Instruments Corporation. Refer to the Terms of Use section

ni.com/legal for more information about National Instruments trademarks.

on

Other product and company names mentioned herein are trademarks or trade names of their respective companies.

Members of the National Instruments Alliance Partner Program are business entities independent from National Instruments and have no agency,

partnership, or joint-venture relationship with National Instruments.

Patents

For patents covering National Instruments products/technology, refer to the appropriate location: Help»Patents in your software,

the patents.txt file on your media, or the National Instruments Patent Notice at ni.com/patents.

WARNING REGARDING USE OF NATIONAL INSTRUMENTS PRODUCTS

(1) NATIONAL INSTRUMENTS PRODUCTS ARE NOT DESIGNED WITH COMPONENTS AND TESTING FOR A LEVEL OF

RELIABILITY SUITABLE FOR USE IN OR IN CONNECTION WITH SURGICAL IMPLANTS OR AS CRITICAL COMPONENTS IN

ANY LIFE SUPPORT SYSTEMS WHOSE FAILURE TO PERFORM CAN REASONABLY BE EXPECTED TO CAUSE SIGNIFICANT

INJURY TO A HUMAN.

(2) IN ANY APPLICATION, INCLUDING THE ABOVE, RELIABILITY OF OPERATION OF THE SOFTWARE PRODUCTS CAN BE

IMPAIRED BY ADVERSE FACTORS, INCLUDING BUT NOT LIMITED TO FLUCTUATIONS IN ELECTRICAL POWER SUPPLY,

COMPUTER HARDWARE MALFUNCTIONS, COMPUTER OPERATING SYSTEM SOFTWARE FITNESS, FITNESS OF COMPILERS

AND DEVELOPMENT SOFTWARE USED TO DEVELOP AN APPLICATION, INSTALLATION ERRORS, SOFTWARE AND HARDWARE

COMPATIBILITY PROBLEMS, MALFUNCTIONS OR FAILURES OF ELECTRONIC MONITORING OR CONTROL DEVICES,

TRANSIENT FAILURES OF ELECTRONIC SYSTEMS (HARDWARE AND/OR SOFTWARE), UNANTICIPATED USES OR MISUSES, OR

ERRORS ON THE PART OF THE USER OR APPLICATIONS DESIGNER (ADVERSE FACTORS SUCH AS THESE ARE HEREAFTER

COLLECTIVELY TERMED “SYSTEM FAILURES”). ANY APPLICATION WHERE A SYSTEM FAILURE WOULD CREATE A RISK OF

HARM TO PROPERTY OR PERSONS (INCLUDING THE RISK OF BODILY INJURY AND DEATH) SHOULD NOT BE RELIANT SOLELY

UPON ONE FORM OF ELECTRONIC SYSTEM DUE TO THE RISK OF SYSTEM FAILURE. TO AVOID DAMAGE, INJURY, OR DEATH,

THE USER OR APPLICATION DESIGNER MUST TAKE REASONABLY PRUDENT STEPS TO PROTECT AGAINST SYSTEM FAILURES,

INCLUDING BUT NOT LIMITED TO BACK-UP OR SHUT DOWN MECHANISMS. BECAUSE EACH END-USER SYSTEM IS

CUSTOMIZED AND DIFFERS FROM NATIONAL INSTRUMENTS' TESTING PLATFORMS AND BECAUSE A USER OR APPLICATION

DESIGNER MAY USE NATIONAL INSTRUMENTS PRODUCTS IN COMBINATION WITH OTHER PRODUCTS IN A MANNER NOT

EVALUATED OR CONTEMPLATED BY NATIONAL INSTRUMENTS, THE USER OR APPLICATION DESIGNER IS ULTIMATELY

RESPONSIBLE FOR VERIFYING AND VALIDATING THE SUITABILITY OF NATIONAL INSTRUMENTS PRODUCTS WHENEVER

NATIONAL INSTRUMENTS PRODUCTS ARE INCORPORATED IN A SYSTEM OR APPLICATION, INCLUDING, WITHOUT

LIMITATION, THE APPROPRIATE DESIGN, PROCESS AND SAFETY LEVEL OF SUCH SYSTEM OR APPLICATION.

Page 4

Conventions

The following conventions are used in this manual:

<> Angle brackets that contain numbers separated by an ellipsis represent a

range of values associated with a bit or signal name—for example,

AO <3. .0>.

» The » symbol leads you through nested menu items and dialog box options

to a final action. The sequence File»Page Setup»Options directs you to

pull down the File menu, select the Page Setup item, and select Options

from the last dialog box.

This icon denotes a note, which alerts you to important information.

This icon denotes a caution, which advises you of precautions to take to

avoid injury, data loss, or a system crash. When this symbol is marked on a

product, refer to the Read Me First: Safety and Radio-Frequency

Interference for information about precautions to take.

bold Bold text denotes items that you must select or click in the software, such

as menu items and dialog box options. Bold text also denotes parameter

names.

italic Italic text denotes variables, emphasis, a cross-reference, or an introduction

to a key concept. Italic text also denotes text that is a placeholder for a word

or value that you must supply.

monospace Text in this font denotes text or characters that you should enter from the

keyboard, sections of code, programming examples, and syntax examples.

This font is also used for the proper names of disk drives, paths, directories,

programs, subprograms, subroutines, device names, functions, operations,

variables, filenames, and extensions.

monospace bold Bold text in this font denotes the messages and responses that the computer

automatically prints to the screen. This font also emphasizes lines of code

that are different from the other examples.

monospace italic

Italic text in this font denotes text that is a placeholder for a word or value

that you must supply.

Page 5

Contents

Chapter 1

About the SCXI-1520

What You Need to Get Started ......................................................................................1-1

National Instruments Documentation ............................................................................1-3

Installing Application Software, NI-DAQ, and the E/M Series DAQ Device .............. 1-5

Installing the SCXI-1520 Module into the SCXI Chassis...............................1-5

Connecting the SCXI-1520 in an SCXI Chassis to an E/M Series

DAQ Device for Multiplexed Scanning .......................................................1-5

Connecting the SCXI-1520 in a PXI/SCXI Combination Chassis to an

E/M Series DAQ Device for Multiplexed Scanning ....................................1-5

Verifying the SCXI-1520 Installation in Software ........................................................1-6

Installing SCXI Using NI-DAQmx in Software .............................................1-6

Manually Adding Modules in NI-DAQmx .....................................................1-6

Installing SCXI Using Traditional NI-DAQ (Legacy) in Software ................ 1-6

Manually Adding Modules in Traditional NI-DAQ (Legacy) ........................1-6

Verifying and Self-Testing the Installation .....................................................1-6

Troubleshooting the Self-Test Verification ...................................................................1-7

Troubleshooting in NI-DAQmx ......................................................................1-7

Troubleshooting in Traditional NI-DAQ (Legacy) ......................................... 1-8

Chapter 2

Connecting Signals

Connecting Bridge Sensor Signals ................................................................................ 2-1

Quarter-Bridge Type I .....................................................................................2-1

Quarter-Bridge Type II....................................................................................2-2

Half-Bridge Type I ..........................................................................................2-4

Half-Bridge Type II.........................................................................................2-5

Full-Bridge Type I...........................................................................................2-6

Full-Bridge Type II.......................................................................................... 2-7

Full-Bridge Type III ........................................................................................2-8

Remote Sense ..................................................................................................2-9

Pin Assignments ............................................................................................................2-10

© National Instruments Corporation v SCXI-1520 User Manual

Page 6

Contents

Chapter 3

Configuring and Testing

SCXI-1520 Software-Configurable Settings .................................................................3-1

Common Software-Configurable Settings ...................................................... 3-1

Bridge Configuration........................................................................ 3-1

Excitation Level................................................................................ 3-2

Filter Bandwidth ............................................................................... 3-2

Gain/Input Range.............................................................................. 3-3

Null Potentiometers .......................................................................... 3-4

Shunt Calibration Switches .............................................................. 3-4

Modes of Operation .......................................................................... 3-5

Simultaneous Sample and Hold........................................................ 3-5

Configurable Settings in MAX...................................................................................... 3-5

NI-DAQmx ..................................................................................................... 3-6

Creating a Strain Global Channel or Task........................................ 3-7

Creating a Custom Voltage with Excitation Global Channel

or Task ........................................................................................... 3-8

Traditional NI-DAQ (Legacy) ........................................................................ 3-9

Configuring Module Property Pages in Traditional NI-DAQ

(Legacy)......................................................................................... 3-10

Creating a Strain Virtual Channel .................................................... 3-11

Calibrating a Strain Virtual Channel ................................................ 3-11

Verifying the Signal ...................................................................................................... 3-12

Verifying the Signal in NI-DAQmx Using a Task or Global Channel........... 3-12

Verifying the Signal in Traditional NI-DAQ (Legacy) .................................. 3-13

Verifying the Signal Using Channel Strings .................................... 3-13

Verifying the Signal Using Strain Virtual Channel .......................... 3-14

Using the Strain Calibration Wizard in NI-DAQmx..................................................... 3-14

Chapter 4

Theory of Operation

Strain-Gauge Theory ..................................................................................................... 4-1

Wheatstone Bridges ........................................................................................ 4-1

Strain Gauges .................................................................................................. 4-2

Acronyms, Formulas, and Variable Definitions ............................................. 4-3

Software Scaling and Equations ..................................................................... 4-4

Quarter-Bridge Type I..................................................................................... 4-4

Quarter-Bridge Type II ................................................................................... 4-6

Half-Bridge Type I.......................................................................................... 4-9

Half-Bridge Type II ........................................................................................ 4-11

Full-Bridge Type I .......................................................................................... 4-13

SCXI-1520 User Manual vi ni.com

Page 7

Full-Bridge Type II.......................................................................................... 4-14

Full-Bridge Type III ........................................................................................4-16

SCXI-1520 Theory of Operation ...................................................................................4-18

Bridge Configuration and Completion ............................................................4-21

Excitation.........................................................................................................4-22

Remote Sense....................................................................................4-23

Gain ................................................................................................................. 4-24

Filter Bandwidth and Cutoff Frequency..........................................................4-25

Offset Null Compensation...............................................................................4-25

Shunt Calibration.............................................................................................4-27

Simultaneous Sample and Hold.......................................................................4-28

Maximum Simultaneous Sample and Hold Sample Rate Using

Maximum Simultaneous Sample and Hold Using Traditional

Modes of Operation......................................................................................... 4-34

Theory of Multiplexed Mode Operation ...........................................4-34

Theory of Parallel Mode Operation ..................................................4-35

Chapter 5

Using the SCXI-1520

Developing Your Application in NI-DAQmx ...............................................................5-1

Typical Program Flowchart.............................................................................5-2

General Discussion of Typical Flowchart .......................................................5-4

Creating a Task Using DAQ Assistant or Programmatically ...........5-4

Adjusting Timing and Triggering ..................................................... 5-4

Configuring Channel Properties........................................................5-5

Performing Offset Null Compensation .............................................5-7

Performing Shunt Calibration ...........................................................5-8

Acquiring, Analyzing, and Presenting ..............................................5-8

Completing the Application .............................................................. 5-9

Developing an Application Using LabVIEW..................................................5-9

Using a DAQmx Channel Property Node in LabVIEW ...................5-11

Specifying Channel Strings in NI-DAQmx.....................................................5-12

Text Based ADEs..............................................................................5-14

Measurement Studio (Visual Basic, .NET, and C#)........................................5-14

Programmable NI-DAQmx Properties..............................................5-16

Developing Your Application in Traditional NI-DAQ (Legacy) ..................................5-18

Traditional NI-DAQ (Legacy) in LabVIEW................................................... 5-19

Typical Program Flow ......................................................................5-20

Configuring the SCXI-1520 Settings Using Traditional NI-DAQ

(Legacy) in LabVIEW ..................................................................................5-22

Contents

NI-DAQmx ....................................................................................4-30

NI-DAQ (Legacy) ..........................................................................4-32

© National Instruments Corporation vii SCXI-1520 User Manual

Page 8

Contents

Performing Offset Null Compensation Using Traditional NI-DAQ

(Legacy) in LabVIEW.................................................................................. 5-24

Performing Shunt Calibration Using Traditional NI-DAQ (Legacy)

in LabVIEW ................................................................................................. 5-26

Configure, Start Acquisition, and Take Readings Using Traditional

NI-DAQ (Legacy) in LabVIEW .................................................................. 5-27

Converting Scaling Using Traditional NI-DAQ (Legacy) in LabVIEW ........ 5-27

Analyze and Display Using Traditional NI-DAQ (Legacy) in LabVIEW ..... 5-28

Traditional NI-DAQ (Legacy) in Text-Based ADEs ...................................... 5-28

Low-Level DAQ Functions ............................................................................ 5-29

Configuring System Settings Using Traditional NI-DAQ (Legacy) C API ... 5-31

Configuring Module Settings Using Traditional NI-DAQ (Legacy) C API... 5-32

Performing Offset Null Compensation Using Traditional NI-DAQ

(Legacy) C API ............................................................................................ 5-34

Performing Shunt Calibration Using Traditional NI-DAQ

(Legacy) C API ............................................................................................ 5-34

Performing Acquisition Using Traditional NI-DAQ (Legacy) C API............ 5-35

Performing Scaling, Analysis, and Display .................................................... 5-35

Other Application Documentation and Material ........................................................... 5-36

Traditional NI-DAQ (Legacy) CVI Examples................................................ 5-36

Traditional NI-DAQ (Legacy) Measurement Studio Examples ..................... 5-36

Calibrating the Strain System........................................................................................ 5-37

Calibrating the SCXI-1520 ............................................................................. 5-37

Internal Calibration Procedure.......................................................... 5-37

Internal Calibration Using LabVIEW............................................... 5-37

Internal Calibration Using a C-Based ADE ..................................... 5-38

External Calibration.......................................................................... 5-38

Calibrating the System .................................................................................... 5-39

Offset Null Compensation ................................................................ 5-39

Shunt Calibration.............................................................................. 5-39

Appendix A

Specifications

Appendix B

Using SCXI Channel Strings with Traditional NI-DAQ (Legacy) 7.0

or Later

Appendix C

Removing the SCXI-1520

SCXI-1520 User Manual viii ni.com

Page 9

Appendix D

Common Questions

Glossary

Index

Figures

Figure 2-1. Quarter-Bridge I Circuit Diagram .........................................................2-2

Figure 2-2. Quarter-Bridge II Circuit Diagram........................................................2-3

Figure 2-3. Half-Bridge Type I Circuit Diagram .....................................................2-4

Figure 2-4. Half-Bridge Type II Circuit Diagram....................................................2-5

Figure 2-5. Full-Bridge Type I Circuit Diagram......................................................2-6

Figure 2-6. Full-Bridge Type II Circuit Diagram ....................................................2-7

Figure 2-7. Full-Bridge Type III Circuit Diagram ...................................................2-8

Figure 2-8. Remote-Sense Circuit Diagram.............................................................2-9

Figure 4-1. Basic Wheatstone Bridge Circuit Diagram ...........................................4-1

Figure 4-2. Quarter-Bridge Type I Measuring Axial and Bending Strain ...............4-4

Figure 4-3. Quarter-Bridge I Circuit Diagram .........................................................4-5

Figure 4-4. Quarter-Bridge Type II Measuring Axial and Bending Strain..............4-7

Figure 4-5. Quarter-Bridge II Circuit Diagram........................................................4-7

Figure 4-6. Half-Bridge Type I Measuring Axial and Bending Strain ....................4-9

Figure 4-7. Half-Bridge Type I Circuit Diagram .....................................................4-9

Figure 4-8. Half-Bridge Type II Rejecting Axial and

Measuring Bending Strain.....................................................................4-11

Figure 4-9. Half-Bridge Type II Circuit Diagram....................................................4-11

Figure 4-10. Full-Bridge Type I Rejecting Axial and Measuring Bending Strain..... 4-13

Figure 4-11. Full-Bridge Type I Circuit Diagram......................................................4-13

Figure 4-12. Full-Bridge Type II Rejecting Axial and Measuring Bending Strain ...4-15

Figure 4-13. Full-Bridge Type II Circuit Diagram ....................................................4-15

Figure 4-14. Full-Bridge Type III Measuring Axial and

Rejecting Bending Strain.......................................................................4-17

Figure 4-15. Full-Bridge Type III Circuit Diagram ...................................................4-17

Figure 4-16. Block Diagram of SCXI-1314/SCXI-1520 Combination .....................4-19

Figure 4-17. Signal During Simultaneous Sample-and-Hold Sampling ....................4-29

Contents

Figure 5-1. Typical Program Flowchart...................................................................5-3

Figure 5-2. LabVIEW Channel Property Node with Filtering Enabled

at 10 kHz and SS/H Disabled................................................................5-12

Figure 5-3. Typical SCXI-1520 Program Flow with

Traditional NI-DAQ (Legacy)...............................................................5-21

© National Instruments Corporation ix SCXI-1520 User Manual

Page 10

Contents

Tables

Figure 5-4. Using the AI Parameter VI to Set Up the SCXI-1520 .......................... 5-24

Figure 5-5. Offset Null and Shunt Calibration Flowchart ....................................... 5-30

Figure C-1. Removing the SCXI-1520..................................................................... C-2

Table 1-1. Accessories Available for the SCXI-1520............................................ 1-2

Table 2-1. Front Signal Pin Assignments ..............................................................2-11

Table 2-2. Rear Signal Pin Assignments................................................................ 2-13

Table 2-3. SCXI-1520 Communication Signals..................................................... 2-14

Table 3-1. Excitation Voltage for Configuration and Gauge Resistances ............. 3-2

Table 4-1. Strain-Gauge Configurations ................................................................4-2

Table 4-2. Control Codes for Coarse and Fine Offset Null Potentiometers........... 4-26

Table 4-3. NI-DAQmx Values Used to Determine Maximum Sample Rate

in Multiplexed Mode............................................................................. 4-31

Table 4-4. NI-DAQmx Values Used to Determine Maximum Sample Rate

in Parallel Mode.................................................................................... 4-32

Table 4-5. Traditional NI-DAQ (Legacy) Values Used to Determine

Maximum Sample Rate in Multiplexed Mode...................................... 4-33

Table 5-1. NI-DAQmx Properties .......................................................................... 5-5

Table 5-2. Programming a Task in LabVIEW ....................................................... 5-9

Table 5-3. NI-DAQmx Properties .......................................................................... 5-16

Table 5-4. Settings for Configuring the SCXI-1520 Through the AI Parameter ...5-22

Table 5-5. Configuration Functions ....................................................................... 5-31

Table 5-6. NI-DAQ Functions Used to Configure SCXI-1520.............................. 5-33

Table D-1. Digital Signals on the SCXI-1520 ....................................................... D-2

SCXI-1520 User Manual x ni.com

Page 11

About the SCXI-1520

The SCXI-1520 module is an eight-channel module for interfacing to

strain-gauge bridges and other Wheatstone-bridge based sensors.

Note Descriptions in this chapter explicitly refer to the first channel (channel 0); however,

the same descriptions are applicable to channels <1..7>.

You can configure all settings on a per channel basis in software.

The SCXI-1520 is configured using Measurement & Automation Explorer

(MAX) or through NI-DAQmx property nodes.

With the SCXI-1520 and the accessory SCXI-1314 terminal block, you can

do the following:

• Connect sensors of all bridge configurations, including quarter-, half-,

and full-bridge

• Set the DC voltage excitation between 0 and 10 V (increments

dependent upon the driver software)

• Programmatically offset null bridge circuits connected to the

SCXI-1520

• Set the analog input lowpass filter cut-off frequency to 10 Hz, 100 Hz,

1 kHz, 10 kHz, or bypass

• Set the analog input gain between 1 and 1000 at any one of 49 settings

• Implement shunt calibration using two independent circuits

• Connect the bridge for remote-sense voltage excitation

1

What You Need to Get Started

To set up and use the SCXI-1520, you need the following:

❑ Hardware

– SCXI-1520 module

– One of the following terminal blocks:

• SCXI-1314 terminal block

• SCXI-1314T terminal block

© National Instruments Corporation 1-1 SCXI-1520 User Manual

Page 12

Chapter 1 About the SCXI-1520

– SCXI or PXI/SCXI combo chassis

– E/M Series DAQ device

– Computer, if using an SCXI chassis

– Cabling, cable adapter, and sensors as required for your

application

❑ Software

– NI-DAQ 7.0 or later

– Application software, such as LabVIEW, LabWindows

Measurement Studio, or other programming environments

❑ Documentation

– Read Me First: Safety and Radio-Frequency Interference

– DAQ Getting Started Guide

– SCXI Quick Start Guide

– SCXI-1520 User Manual

– Documentation for your hardware

– Documentation for your software

™

/CVI™,

The optional accessories listed in Table 1-1 are available for the

SCXI-1520.

Table 1-1. Accessories Available for the SCXI-1520

Accessory Description

SCXI-1314

†

Screw terminal block—Mounts on the front of the SCXI-1520 module.

It includes connections and sockets for two shunt calibration resistors and

a quarter-bridge completion resistor per channel.

SCXI-1314T

††

RJ-50 terminal block—Mounts on the front of the SCXI-1520 module.

It features eight RJ-50 10-position/10-conductor (10p10c) modular plugs

for connection to hardware TEDS smart sensors.

SCXI-1520 User Manual 1-2 ni.com

Page 13

Chapter 1 About the SCXI-1520

Table 1-1. Accessories Available for the SCXI-1520 (Continued)

Accessory Description

SCXI-1310

‡

Connector and shell assembly—The SCXI-1310 provides 96 eyelet-type

terminals for easy hook-and-solder signal connection and custom

mass termination connectivity.

TBX-96

‡

DIN-rail mounted terminal block with 96 generic screw terminals.

One of the following cables is required to connect the TBX-96 to an

SCXI module:

• SH96-96 shielded cable, 1 m

• R96-96 unshielded ribbon cable, 1 m

†

You must wire a shunt resistor between the pins that correspond to the SCA on the SCXI-1314 and the appropriate legs of

the bridge sensor. Refer to Chapter 4, Theory of Operation, for more information.

††

The SCXI-1314T only supports SCA. It does not support SCB. There are no quarter-bridge completion resistors in the

SCXI-1314T. If you are connecting a quarter-bridge sensor to an SCXI-1520 using an SCXI-1314T, you must place an

external resistor between the pins that correspond to PX– and SX+ on the terminals. Refer to Chapter 2, Connecting Signals,

for more information.

‡

There are no quarter-bridge completion resistors in the SCXI-1310 or TBX-96. If you are connecting a quarter-bridge

sensor to an SCXI-1520 using an SCXI-1310 or TBX-96, you must place an external resistor between the pins that

correspond to PX– and SX+ on the terminals. Refer to Chapter 2, Connecting Signals, for more information.

National Instruments Documentation

The SCXI-1520 User Manual is one piece of the documentation set for data

acquisition (DAQ) systems. You could have any of several types of

manuals depending on the hardware and software in the system. Use the

manuals you have as follows:

• Getting Started with SCXI—This is the first manual you should read.

It gives an overview of the SCXI system and contains the most

commonly needed information for the modules, chassis, and software.

• SCXI or PXI/SCXI chassis manual—Read this manual for

maintenance information on the chassis and for installation

instructions.

• The DAQ Getting Started Guide—This document has information on

installing NI-DAQ and the E/M Series DAQ device. Install these

before you install the SCXI module.

• The SCXI Quick Start Guide—This document contains a quick

overview for setting up an SCXI chassis, installing SCXI modules and

terminal blocks, and attaching sensors. It also describes setting up the

SCXI system in MAX.

© National Instruments Corporation 1-3 SCXI-1520 User Manual

Page 14

Chapter 1 About the SCXI-1520

• The SCXI hardware user manuals—Read these manuals for detailed

information about signal connections and module configuration. They

also explain, in greater detail, how the module works and contain

application hints.

• Accessory installation guides or manuals—Read the terminal block

and cable assembly installation guides. They explain how to physically

connect the relevant pieces of the system. Consult these guides when

you are making the connections.

• The E/M Series DAQ device documentation—This documentation has

detailed information about the DAQ device that plugs into or is

connected to the computer. Use this documentation for hardware

installation and configuration instructions, specification information

about the DAQ device, and application hints.

• Software documentation—You may have both application software

and NI-DAQ software documentation. National Instruments (NI)

application software includes LabVIEW, LabWindows/CVI, and

Measurement Studio. After you set up the hardware system, use either

your application software documentation or the NI-DAQ

documentation to help you write your application. If you have a large,

complex system, it is worthwhile to look through the software

documentation before you configure the hardware.

• One or more of the following help files for software information:

– Start»Programs»National Instruments»NI-DAQ»

NI-DAQmx Help

– Start»Programs»National Instruments»NI-DAQ»

Traditional NI-DAQ User Manual

– Start»Programs»National Instruments»NI-DAQ»

Traditional NI-DAQ Function Reference Help

• NI strain-gauge application notes or tutorials—NI has additional

material about strain gauges and strain measurements available at

ni.com/support.

You can download NI documents from

the latest version of NI-DAQ, click Download Software at

SCXI-1520 User Manual 1-4 ni.com

ni.com/manuals. To download

ni.com.

Page 15

Chapter 1 About the SCXI-1520

Installing Application Software, NI-DAQ, and the E/M Series DAQ Device

Refer to the DAQ Getting Started Guide packaged with the NI-DAQ

software to install your application software, NI-DAQ driver software, and

the DAQ device to which you will connect the SCXI-1520. NI-DAQ 7.0 or

later is required to configure and program the SCXI-1520 module. If you

do not have NI-DAQ 7.0 or later, you can either contact a NI sales

representative to request it on a CD or download the latest NI-DAQ version

ni.com.

from

Note Refer to the Read Me First: Radio-Frequency Interference document before

removing equipment covers or connecting or disconnecting any signal wires.

Installing the SCXI-1520 Module into the SCXI Chassis

Refer to the SCXI Quick Start Guide to install your SCXI-1520 module.

Connecting the SCXI-1520 in an SCXI Chassis to an E/M Series DAQ Device for Multiplexed Scanning

Refer to the SCXI Quick Start Guide to install the cable adapter and connect

the SCXI modules to the DAQ device.

If you have already installed the appropriate software, refer to Chapter 3,

Configuring and Testing, to configure the SCXI-1520 module(s).

Connecting the SCXI-1520 in a PXI/SCXI Combination Chassis to an E/M Series DAQ Device for Multiplexed Scanning

Refer to the SCXI Quick Start Guide to connect the SCXI modules to the

DAQ device.

If you have already installed the appropriate software, refer to Chapter 3,

Configuring and Testing, to configure the SCXI-1520 module(s).

© National Instruments Corporation 1-5 SCXI-1520 User Manual

Page 16

Chapter 1 About the SCXI-1520

Verifying the SCXI-1520 Installation in Software

Refer to the SCXI Quick Start Guide for information on verifying the SCXI

installation.

Installing SCXI Using NI-DAQmx in Software

Refer to the SCXI Quick Start Guide for information on installing modules

using NI-DAQmx in software.

Manually Adding Modules in NI-DAQmx

If you did not auto-detect the SCXI modules, you must manually add each

of the modules. Refer to the SCXI Quick Start Guide to manually add

modules.

Note NI recommends auto-detecting modules for the first time configuration of the

chassis.

Installing SCXI Using Traditional NI-DAQ (Legacy) in Software

Refer to the SCXI Quick Start Guide for information on installing modules

using Traditional NI-DAQ (Legacy) in software.

Manually Adding Modules in Traditional NI-DAQ (Legacy)

If you did not auto-detect the SCXI modules, you must manually add each

of the modules. Refer to the SCXI Quick Start Guide to manually add

modules.

Note NI recommends auto-detecting modules for the first time configuration of the

chassis.

Verifying and Self-Testing the Installation

The verification procedure for the SCXI chassis is the same for both

NI-DAQmx and Traditional NI-DAQ (Legacy). To test the successful

installation for the SCXI chassis, refer to the SCXI Quick Start Guide.

Verify that the chassis is powered on and correctly connected to an

E/M Series DAQ device.

SCXI-1520 User Manual 1-6 ni.com

Page 17

Chapter 1 About the SCXI-1520

After verifying and self-testing the installation, the SCXI system should

operate properly with your ADE software. If the test did not complete

successfully, refer to Chapter 3, Configuring and Testing, for

troubleshooting steps.

Troubleshooting the Self-Test Verification

If the Self-Test Verification did not verify the chassis configuration,

complete the steps in this section to troubleshoot the SCXI configuration.

Troubleshooting in NI-DAQmx

• If you get a Verify SCXI Chassis message box showing the SCXI

chassis model number, Chassis ID: x, and one or more messages

stating Slot Number: x Configuration has module: SCXI-XXXX

or 1520, hardware in chassis is: Empty, take the following

troubleshooting actions:

– Make sure the SCXI chassis is powered on.

– Make sure all SCXI modules are properly installed in the chassis.

Refer to the SCXI Quick Start Guide for proper installation

instructions.

– Make sure the cable between the SCXI chassis and E/M Series

DAQ device is properly connected.

– Inspect the cable connectors for bent pins.

– Make sure you are using the correct NI cable assembly.

– Test the DAQ device to verify it is working properly. Refer to the

DAQ device help file for more information.

• If you get a Verify SCXI Chassis message box showing the SCXI

chassis model number,

Number:

hardware in chassis is: SCXI-

complete the following troubleshooting steps to correct the error.

1. Expand the list of NI-DAQmx devices by clicking the + next to

2. Right-click the SCXI chassis and click Properties to load the

3. Under the Modules tab, ensure that the cabled module is listed in

x

Configuration has module: SCXI-

NI-DAQmx Devices.

chassis configurator.

the correct slot.

Chassis ID:

x

, and the message Slot

YYYY

XXXX

or 1520,

, 1520, or Empty,

© National Instruments Corporation 1-7 SCXI-1520 User Manual

Page 18

Chapter 1 About the SCXI-1520

4. If the cabled module is not listed in the correct slot, complete the

following troubleshooting steps:

a. If the cabled module is not listed in the correct slot and the

slot is empty, click the drop-down listbox next to the correct

slot and select the cabled module. Configure the cabled

module following the steps listed in the SCXI Quick Start

Guide. Click OK.

b. If another module appears where the cabled module should

be, click the drop-down listbox next to the correct slot and

select the cabled module. A message box appears asking you

to confirm the module replacement. Click OK. Configure the

cabled module following the steps listed in the SCXI Quick

Start Guide. Click OK.

• Ensure that you have the highest priority SCXI module cabled to the

E/M Series DAQ device. Refer to the SCXI Quick Start Guide to find

out which SCXI module in the chassis should be cabled to the DAQ

device.

• After checking the preceding items, return to the Troubleshooting the

Self-Test Verification section and retest the SCXI chassis.

If these measures do not successfully configure the SCXI system, contact

NI. Refer to the Technical Support Information document for contact

information.

Troubleshooting in Traditional NI-DAQ (Legacy)

• If you get the message Unable to test chassis at this time,

you have not designated at least one module as connected to a E Series

DAQ device. Refer to the Traditional NI-DAQ (Legacy) section of

Chapter 3, Configuring and Testing,

the cabled module in the system from Connected to: None to

Connected to: Device x.

• If you get the message

codes and the message

Failed to find followed by the module

Unable to communicate with chassis,

take the following troubleshooting actions:

– Make sure the SCXI chassis is powered on.

– Make sure the cable between the SCXI chassis and E Series DAQ

device is properly connected.

– Inspect the cable connectors for bent pins.

– Make sure you are using the correct NI cable assembly.

– Test the DAQ device to verify it is working properly. Refer to the

DAQ device help file for more information.

SCXI-1520 User Manual 1-8 ni.com

and change the configuration of

Page 19

Chapter 1 About the SCXI-1520

• If you get the message Failed to find, followed by module codes

and the message

Instead found: module with ID 0Xxx, refer

to the Traditional NI-DAQ (Legacy) section of Chapter 3, Configuring

and Testing, and make sure the correct module is in the specified slot.

Delete the incorrect module as described in Appendix C, Removing the

SCXI-1520, and add the correct module as described in the Traditional

NI-DAQ (Legacy) section of Chapter 3, Configuring and Testing.

• If you get the message

and the message

Failed to find, followed by a module code

Slot x is empty, make sure the configured module

is installed in the specified slot. If not, install the module by following

the instructions in the Installing the SCXI-1520 Module into the SCXI

Chassis section. If the module is installed in the correct slot, power off

the chassis, remove the module as specified in Appendix C, Removing

the SCXI-1520, and verify that no connector pins are bent on the rear

signal connector. Reinstall the module as described in the Installing the

SCXI-1520 Module into the SCXI Chassis section, ensuring

the module is fully inserted and properly aligned in the slot.

• After checking the preceding items, return to the Troubleshooting the

Self-Test Verification section and retest the SCXI chassis.

If these measures do not successfully configure the SCXI system, contact

NI. Refer to the Technical Support Information document for contact

information.

© National Instruments Corporation 1-9 SCXI-1520 User Manual

Page 20

Connecting Signals

This chapter describes how to connect Wheatstone bridge sensors to the

SCXI-1520 in quarter-, half-, and full-bridge configurations and for remote

sensing. It also provides the front and rear signal pin assignments of the

module.

Connecting Bridge Sensor Signals

This section discusses how to connect the signals of supported strain-gauge

configuration types as well as full-bridge sensors such as load, force,

torque, and pressure sensors. It also discusses connecting leads for remote

sensing and shunt calibration. Refer to Chapter 4, Theory of Operation, for

a discussion of strain-gauge concepts. Refer to the SCXI-1314 Installation

Guide for more signal connection information.

Notes The circuits in this section illustrate circuits using the SCXI-1314 terminal block.

If you are using the SCXI-1314T terminal block, refer to the SCXI-1314T TEDS Bridge

Sensor Terminal Block Installation Guide for the permitted circuit configuration diagrams.

2

Refer to Figure 2-5 and use its wiring diagram for full-bridge sensors such as load, force,

torque, and pressure sensors.

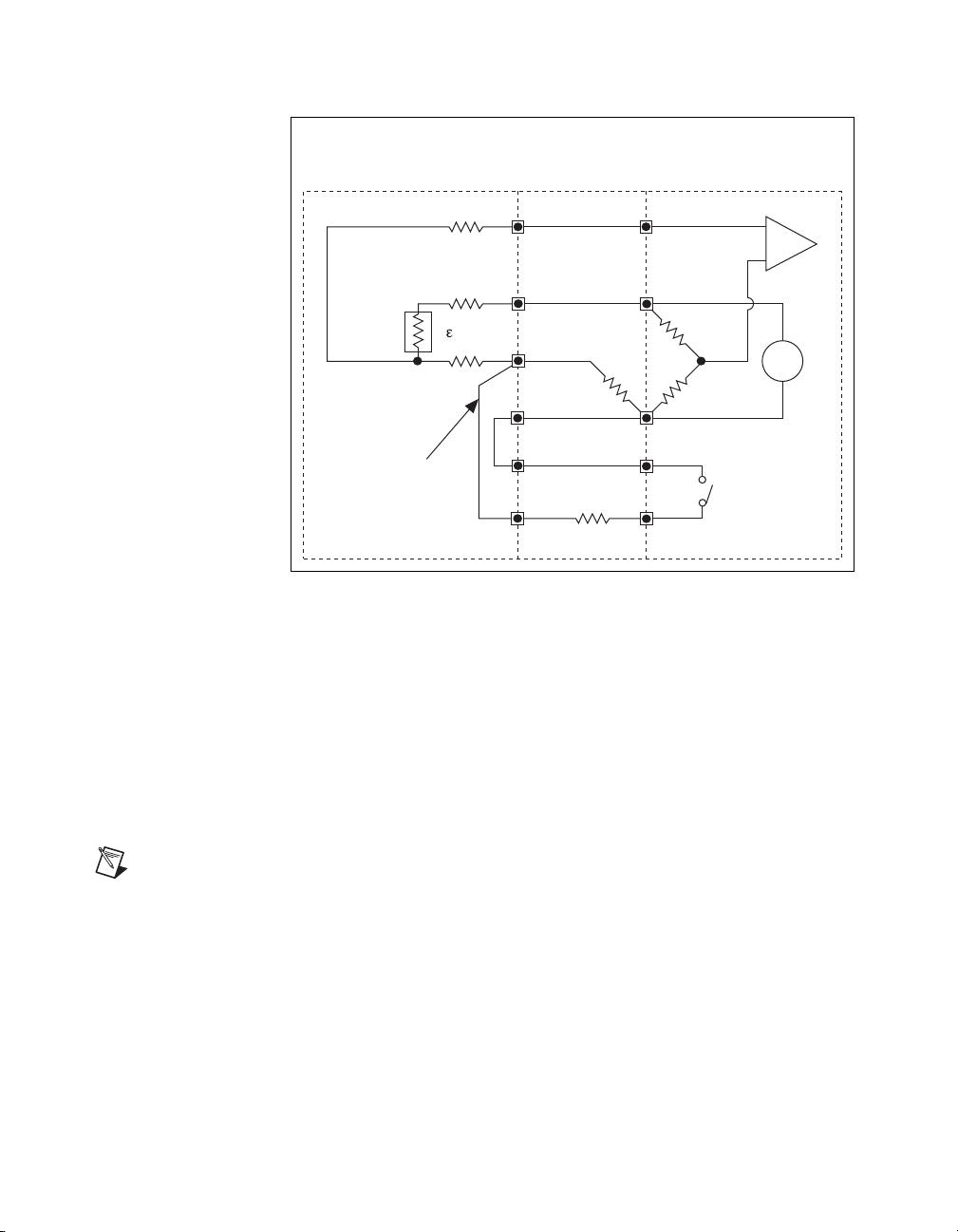

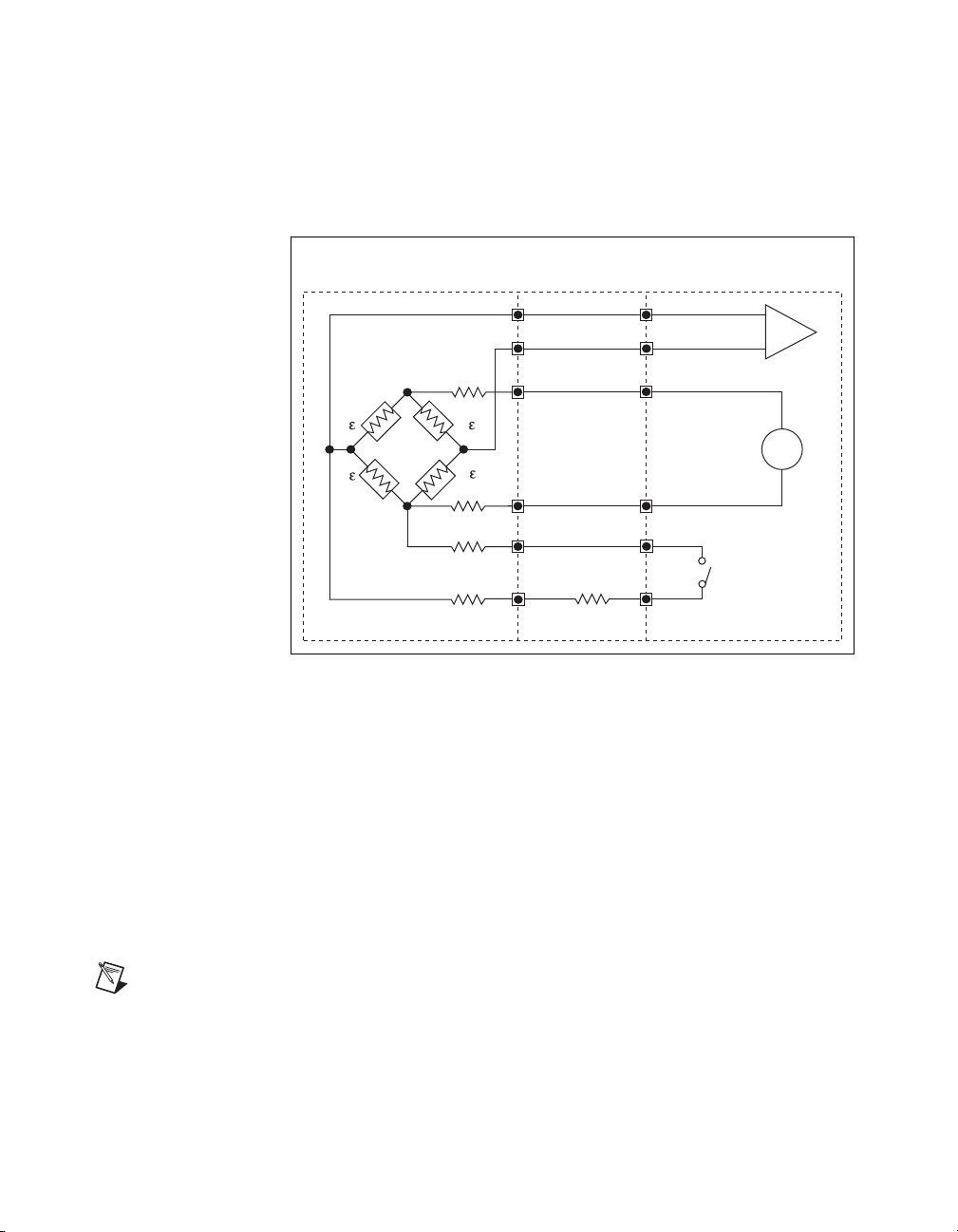

Quarter-Bridge Type I

This section provides information for connecting the quarter-bridge

strain-gauge configuration type I. Figure 2-1 shows the quarter-bridge

type I circuit wiring diagram.

Note S– is left unwired.

© National Instruments Corporation 2-1 SCXI-1520 User Manual

Page 21

Chapter 2 Connecting Signals

SCXI-1520 Set Bridge

Configuration to

Quarter Bridge

+

–

+

–

V

CH

S+

P+

R

L

R

L

R

L

QTR

SCA

SCA

Shunt

Cal A

P

SCXI-1314

R

1

R

2

R

S

R

3

R

4

(gauge)

V

EX

+

You must connect

the shunt calibration

wires externally using

the terminal block

screw connections.

Transducer

Figure 2-1. Quarter-Bridge I Circuit Diagram

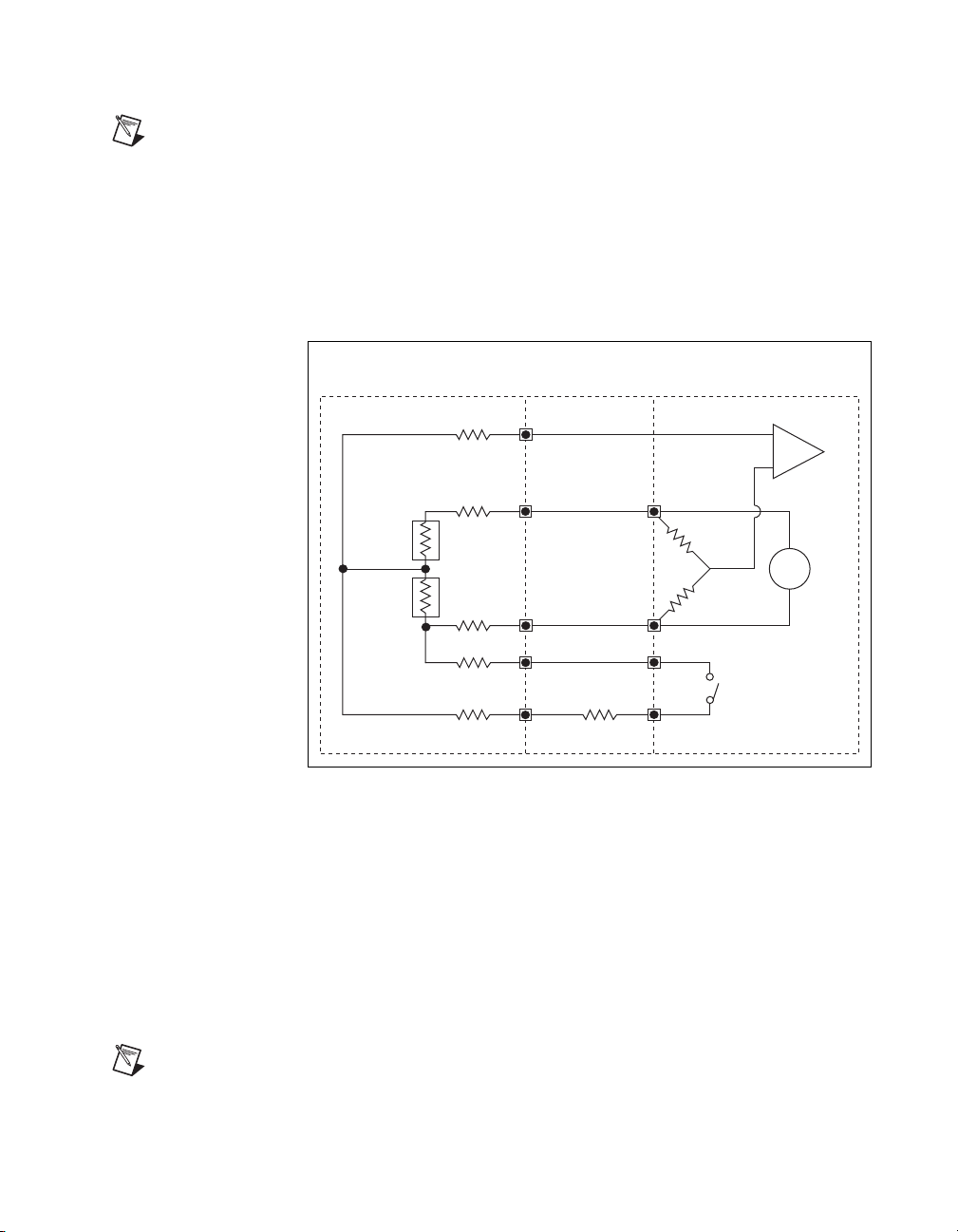

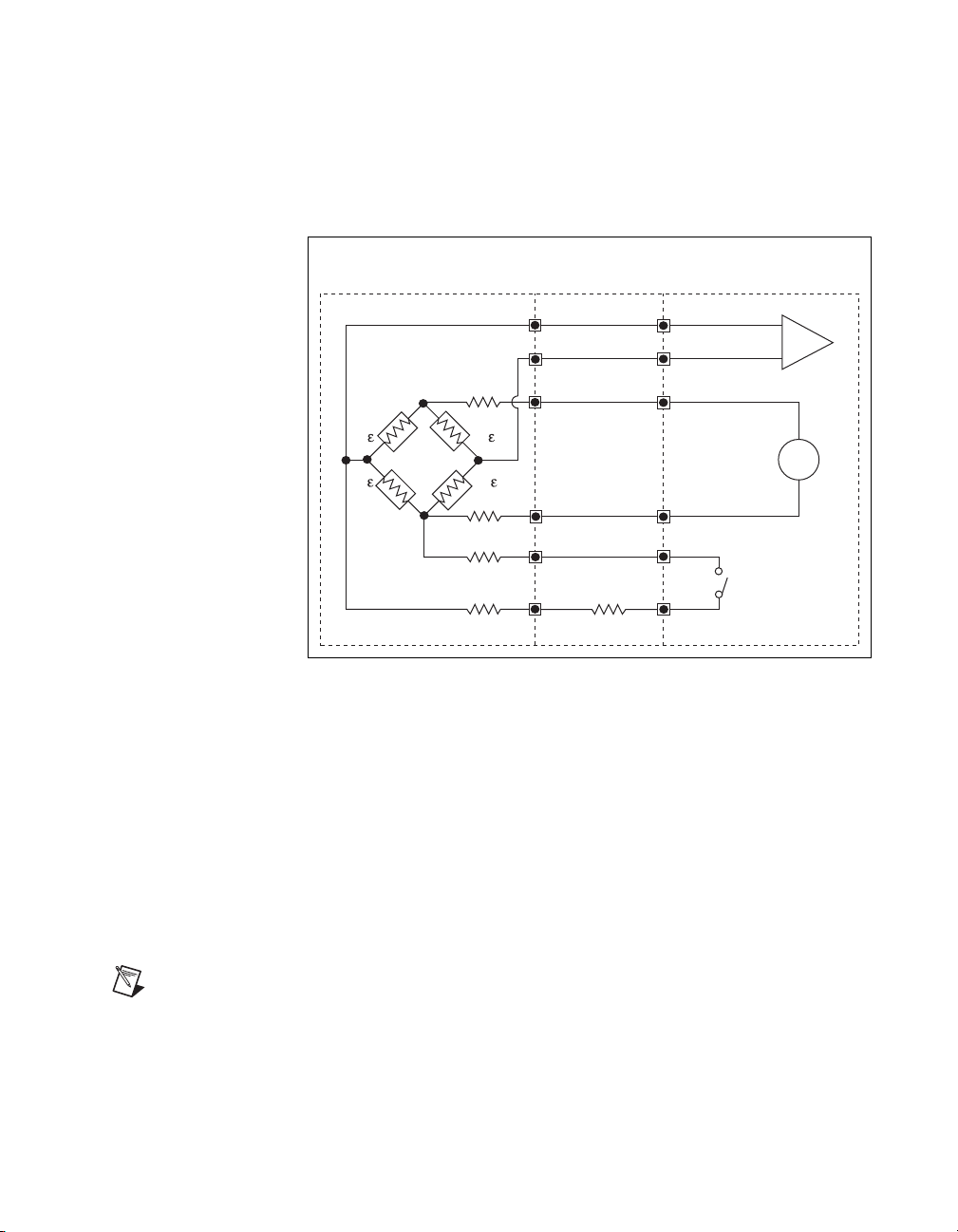

Quarter-Bridge Type II

SCXI-1520 User Manual 2-2 ni.com

The following symbols apply to the circuit diagram and equations:

•R

and R2 are half-bridge completion resistors.

1

•R

is the quarter-bridge completion resistor.

3

•R

is the active element measuring tensile strain (+ε).

4

• V

• R

• V

Note The value of the quarter-bridge completion resistor, R

resistance of the strain gauge. NI recommends using a 0.1% precision resistor.

This section provides information for connecting the quarter-bridge

strain-gauge configuration type II. Figure 2-2 shows the quarter-bridge

type II circuit wiring diagram.

is the excitation voltage.

EX

is the lead resistance.

L

is the measured voltage.

CH

, must equal the nominal

3

Page 22

Chapter 2 Connecting Signals

+

–

+

–

S+

P+

P

R

L

R

L

R

L

SCA

SCA

Shunt

Cal A

SCXI-1314Transducer

V

CH

R

1

R

2

R

S

R

4

(gauge)

V

EX

R

3

(dummy)

R

L

R

L

SCXI-1520 Set Bridge

Configuration to Quarter Bridge

Note The quarter-bridge type II configuration is often confused with the more commonly

used half-bridge type I configuration. In the half-bridge type I configuration, the R

3

element is active and bonded to the strain specimen to measure Poisson's ratio, while in the

quarter-bridge type II configuration, the R

element does not actively measure strain, but

3

is in close thermal contact with the strain specimen. In quarter-bridge type II configuration,

element is not bonded to the specimen. Typically it is either physically close to the

the R

3

specimen or mounted on the same type material at the same temperature, but is not under

strain.

Figure 2-2. Quarter-Bridge II Circuit Diagram

The following symbols apply to the circuit diagram and equations:

© National Instruments Corporation 2-3 SCXI-1520 User Manual

Note S– and QTR are left unwired.

•R

and R2 are half-bridge completion resistors.

1

•R

is the quarter-bridge temperature-sensing element (dummy gauge).

3

•R

is the active element measuring tensile strain (+ε).

4

• V

• R

• V

is the excitation voltage.

EX

is the lead resistance.

L

is the measured voltage.

CH

Page 23

Chapter 2 Connecting Signals

+

–

+

–

S+

P+

P

R

L

R

L

R

L

SCA

SCA

Shunt

Cal A

+

v

SCXI-1520 Set Bridge

Configuration to Half Bridge

SCXI-1314

Transducer

V

CH

R

1

R

2

R

S

R

4

(gauge)

V

EX

R

3

(gauge)

R

L

R

L

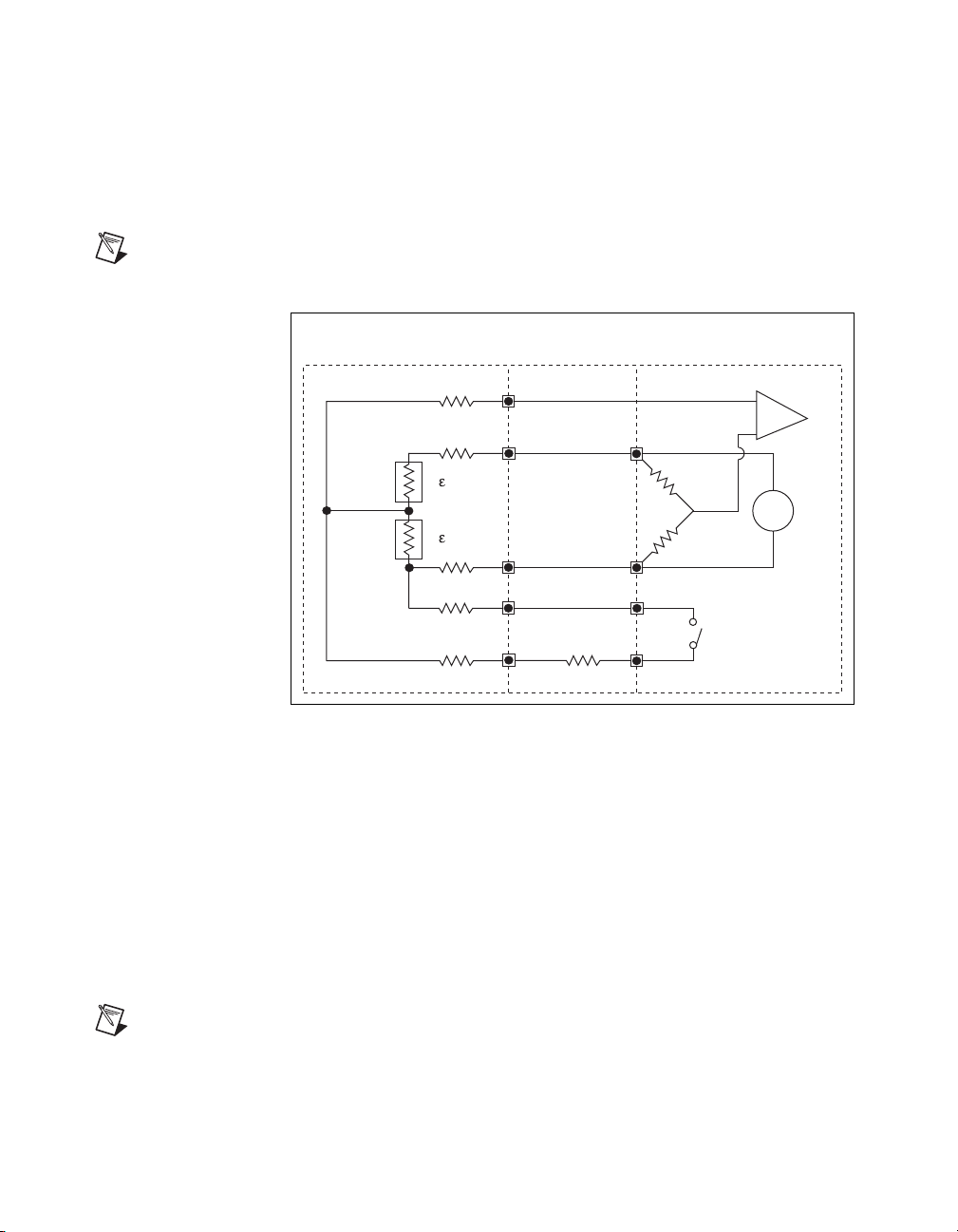

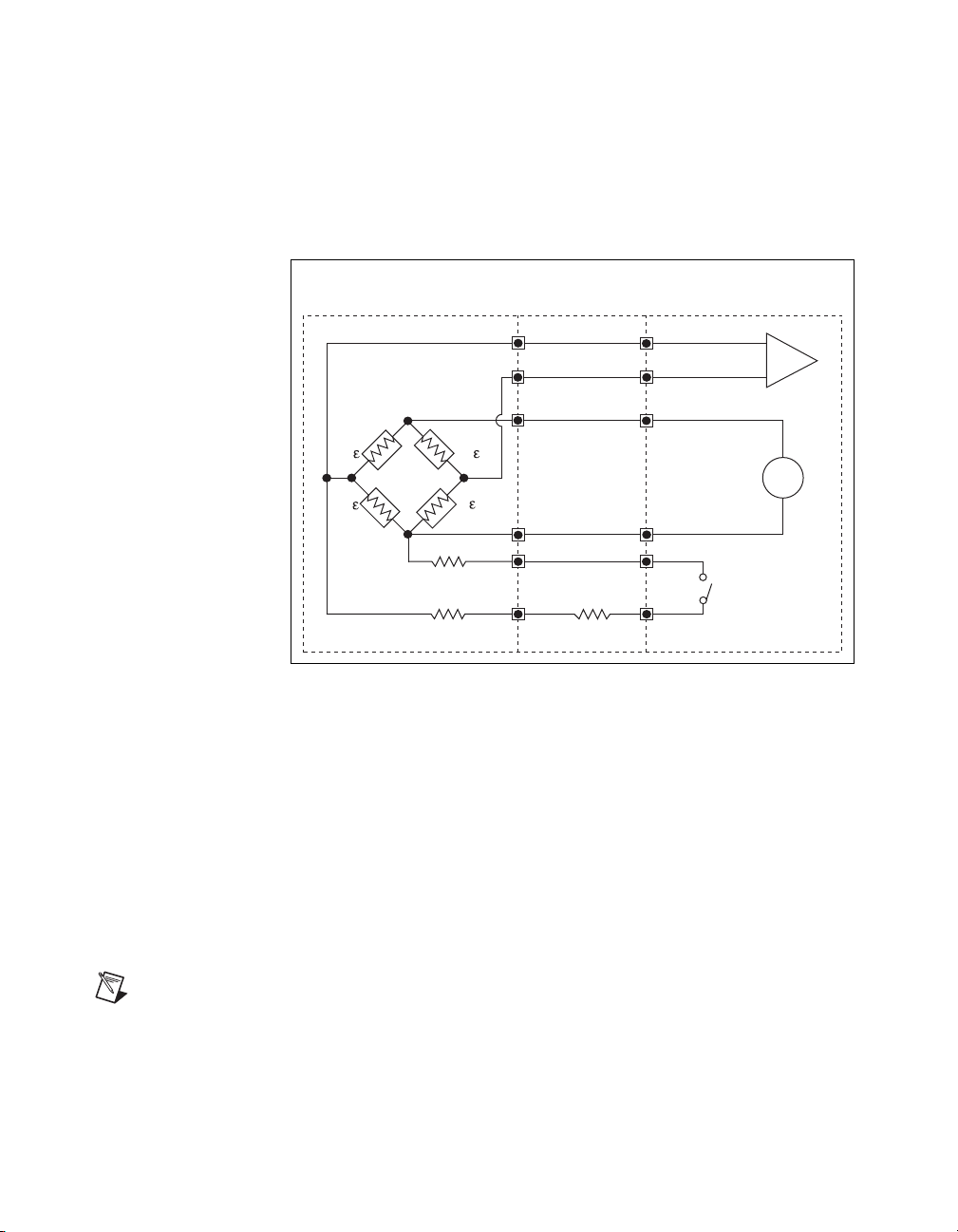

Half-Bridge Type I

Note S– is left unwired.

This section provides information for connecting the half-bridge

strain-gauge configuration type I. Figure 2-3 shows the half-bridge type I

circuit wiring diagram.

Figure 2-3. Half-Bridge Type I Circuit Diagram

The following symbols apply to the circuit diagram and equations:

•R

and R2 are half-bridge completion resistors.

1

•R

is the active element measuring compression from Poisson

3

effect (–νε).

Note As shown in Figure 2-4, for greatest calibration accuracy, use separate wires

•R

• V

• R

• V

between the bridge and the SCA terminals. Do not directly connect S+ or P– to the

SCXI-1520 User Manual 2-4 ni.com

SCA terminals inside the SCXI-1314 terminal block unless the strain-gauge cable

length is very short.

is the active element measuring tensile strain (+ε).

4

is the excitation voltage.

EX

is the lead resistance.

L

is the measured voltage.

CH

Page 24

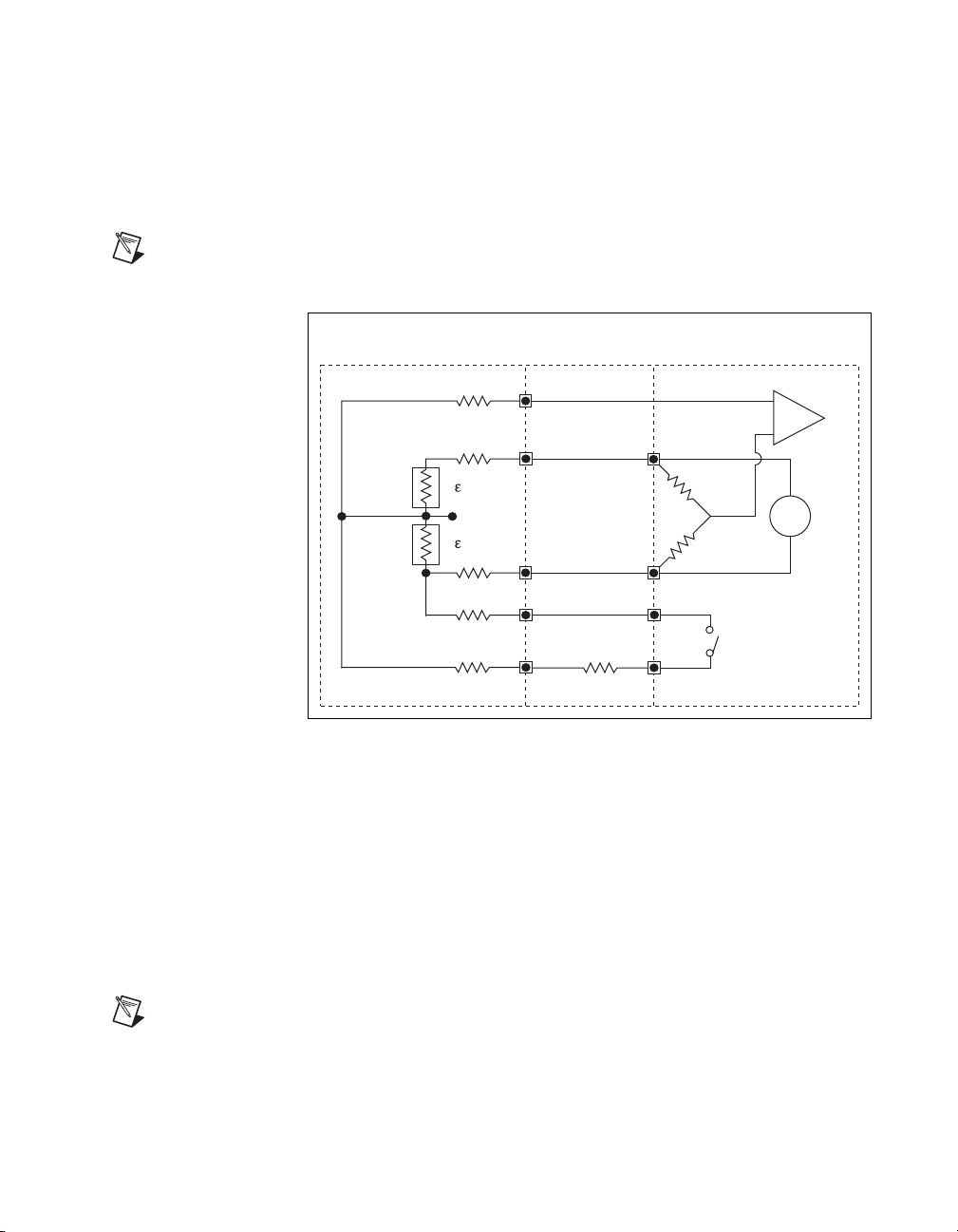

Half-Bridge Type II

+

–

+

–

S+

P+

P

R

L

R

L

R

L

SCA

SCA

Shunt

Cal A

+

–

SCXI-1314Transducer

V

CH

R

1

R

2

R

S

R

4

(gauge)

V

EX

R

3

(gauge)

R

L

R

L

V

out

+

V

out

SCXI-1520 Set Bridge

Configuration to Half Bridge

Note S– is left unwired.

Chapter 2 Connecting Signals

This section provides information for connecting the half-bridge

strain-gauge configuration type II. Figure 2-4 shows the half-bridge type II

circuit wiring diagram.

Figure 2-4. Half-Bridge Type II Circuit Diagram

The following symbols apply to the circuit diagram and equations:

•R

and R2 are half-bridge completion resistors.

1

•R

is the active element measuring compressive strain (–ε).

3

•R

© National Instruments Corporation 2-5 SCXI-1520 User Manual

Note As shown in Figure 2-3, for greatest calibration accuracy, use separate wires

between the bridge and the SCA terminals. Do not directly connect S+ or P– to the

SCA terminals inside the SCXI-1314 terminal block unless the strain-gauge cable

length is very short.

is the active element measuring tensile strain (+ε).

4

• V

• R

• V

is the excitation voltage.

EX

is the lead resistance.

L

is the measured voltage.

CH

Page 25

Chapter 2 Connecting Signals

+

–

V

EX

+

V

EX

+

–

S+

S

P+

P

R

1

R

2

R

4

R

3

SCA

SCA

Shunt

Cal A

+

–

+

–

R

L

R

L

SCXI-1520 Set Bridge

Configuration to Full BridgeSCXI-1314

Transducer

V

CH

R

S

CH+

CH

R

L

R

L

Full-Bridge Type I

This section provides information for connecting the full-bridge

strain-gauge configuration type I. Figure 2-5 shows the full-bridge type I

circuit wiring diagram.

Figure 2-5. Full-Bridge Type I Circuit Diagram

The following symbols apply to the circuit diagram and equations:

•R

is an active element measuring compressive strain (–ε).

1

•R

is an active element measuring tensile strain (+ε).

2

•R

is an active element measuring compressive strain (–ε).

3

•R

is an active element measuring tensile strain (+ε).

4

SCXI-1520 User Manual 2-6 ni.com

Note As shown in Figure 2-5, for greatest calibration accuracy, use separate wires

between the bridge and the SCA terminals. Do not directly connect S+ or P– to the

SCA terminals inside the SCXI-1314 terminal block unless the strain-gauge cable

length is very short.

• V

• R

• V

is the excitation voltage.

EX

is the lead resistance.

L

is the measured voltage.

CH

Page 26

Full-Bridge Type II

+

–

+

–

S+

S

P+

P

SCA

SCA

Shunt

Cal A

+

–

–v

+v

R

L

R

L

SCXI-1520 Set Bridge

Configuration to Full BridgeSCXI-1314

Transducer

R

1

R

2

R

4

R

3

V

CH

R

S

V

EX

+

V

EX–

R

L

R

L

Chapter 2 Connecting Signals

This section provides information for connecting the full-bridge

strain-gauge configuration type II. Figure 2-6 shows the full-bridge type II

circuit wiring diagram.

Figure 2-6. Full-Bridge Type II Circuit Diagram

The following symbols apply to the circuit diagram and equations:

•R

is an active element measuring compressive Poisson effect (–νε).

1

•R

is an active element measuring tensile Poisson effect (+νε).

2

•R

is an active element measuring compressive strain (–ε).

3

© National Instruments Corporation 2-7 SCXI-1520 User Manual

Note As shown in Figure 2-6, for greatest calibration accuracy, use separate wires

between the bridge and the SCA terminals. Do not directly connect S+ or P– to the

SCA terminals inside the SCXI-1314 terminal block unless the strain-gauge cable

length is very short.

• V

• R

• V

•R

is an active element measuring tensile strain (+ε).

4

is the excitation voltage.

EX

is the lead resistance.

L

is the measured voltage.

CH

Page 27

Chapter 2 Connecting Signals

+

–

+

–

S+

S

P+

P

SCA

SCA

Shunt

Cal A

+

–v

–v

+

SCXI-1520 Set Bridge

Configuration to Full BridgeSCXI-1314

Transducer

R

1

R

2

R

4

R

3

V

CH

R

S

V

EX

+

V

EX–

R

L

R

L

Full-Bridge Type III

This section provides information for connecting the full-bridge

strain-gauge configuration type I. The full-bridge type III only measures

axial strain. Figure 2-7 shows the full-bridge type III circuit wiring

diagram.

Figure 2-7. Full-Bridge Type III Circuit Diagram

The following symbols apply to the circuit diagram and equations:

•R

is an active element measuring compressive Poisson effect (–νε).

1

•R

is an active element measuring tensile strain (+ε).

2

•R

is an active element measuring compressive Poisson effect (–νε).

3

•R

is an active element measuring the tensile strain (+ε).

4

is the excitation voltage.

EX

is the lead resistance.

L

is the measured voltage.

CH

Note As shown in Figure 2-7, for greatest calibration accuracy, use separate wires

between the bridge and the SCA terminals. Do not directly connect S+ or P– to the

SCA terminals inside the SCXI-1314 terminal block unless the strain-gauge cable

• V

• R

• V

length is very short.

SCXI-1520 User Manual 2-8 ni.com

Page 28

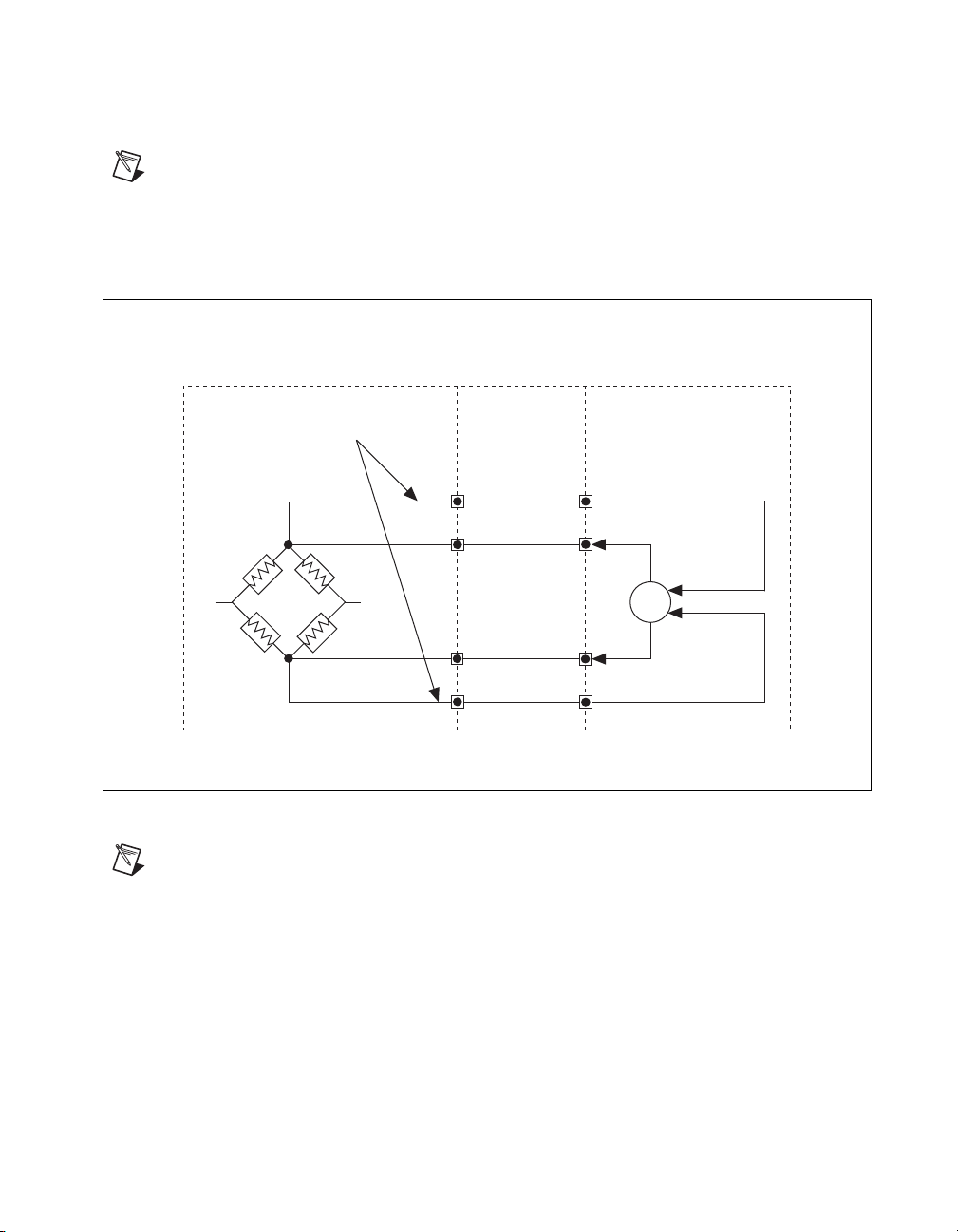

Remote Sense

Note NI recommends using remote sense if your application requires the improved

accuracy. Refer to Chapter 4, Theory of Operation, for more information about using

remote sense.

Run Separate Wires

Between Remote-Sense

Terminals and Bridge

R

1

Chapter 2 Connecting Signals

Wire the SCXI-1520 for remote sense as shown in Figure 2-8.

SCXI-1520SCXI-1314Transducer

RS+

V

EX

+

R

4

P+

+

–

Feedback

R

2

V

EX–

R

3

P

RS

Figure 2-8. Remote-Sense Circuit Diagram

Note

If you use remote sense, set RL to zero in the equations for measured strain (ε).

© National Instruments Corporation 2-9 SCXI-1520 User Manual

Page 29

Chapter 2 Connecting Signals

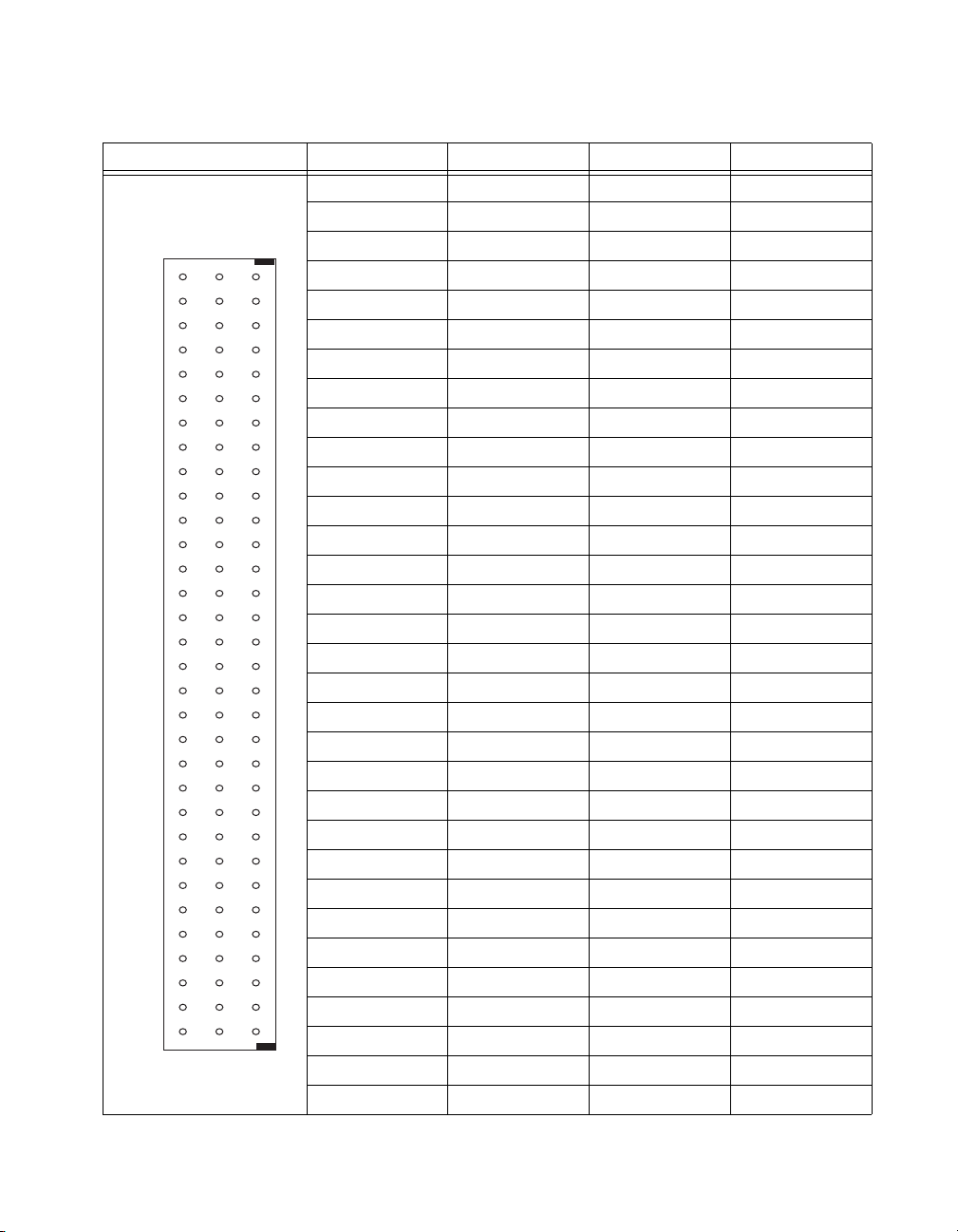

Pin Assignments

The pin assignments for the SCXI-1520 front signal connector are shown

in Table 2-1. The front signal connector is a special 96-pin DIN C male

connector through which you make all signal connections. The terminal

assignments are as follows:

•SX+ and SX– are for analog input

•RSX+ and RSX– are for remote sense

•PX+ and PX– are for excitation output

•SCAX are for shunt calibration circuit A

•SCBX are for shunt calibration circuit B

where X is the channel number.

The negative terminals are listed in Column B and the positive terminals are

listed in Column C. The pins labeled RSVD are reserved. Do not make any

connections to the RSVD pins.

SCXI-1520 User Manual 2-10 ni.com

Page 30

Column

A B C

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

© National Instruments Corporation 2-11 SCXI-1520 User Manual

Chapter 2 Connecting Signals

Table 2-1. Front Signal Pin Assignments

Front Connector Diagram Pin Number Column A Column B Column C

32 SCB0 S0– S0+

31 SCB0 RS0– RS0+

30 SCB1 P0– P0+

29 SCB1 SCA0 SCA0

28 RSVD S1– S1+

27 RSVD RS1– RS1+

26 RSVD P1– P1+

25 RSVD SCA1 SCA1

24 SCB2 S2– S2+

23 SCB2 RS2– RS2+

22 SCB3 P2– P2+

21 SCB3 SCA2 SCA2

20 RSVD S3– S3+

19 RSVD RS3– RS3+

18 RSVD P3– P3+

17 RSVD SCA3 SCA3

16 SCB4 S4– S4+

15 SCB4 RS4– RS4+

14 SCB5 P4– P4+

13 SCB5 SCA4 SCA4

12 RSVD S5– S5+

11 RSVD RS5– RS5+

10 RSVD P5– P5+

9 RSVD SCA5 SCA5

8 SCB6 S6– S6+

7 SCB6 RS6– RS6+

6 SCB7 P6– P6+

5 SCB7 SCA6 SCA6

4 RSVD S7– S7+

3 RSVD RS7– RS7+

2 RSVD P7– P7+

1 RSVD SCA7 SCA7

Page 31

Chapter 2 Connecting Signals

The rear signal connector is a 50-pin male cable connector used for analog

signal connectivity and communication between the SCXI-1520 and the

connected E/M Series DAQ device. The rear signal connector is shown in

Table 2-2. The rear signal connector allows the DAQ device to access all

eight differential analog output signals from the SCXI-1520. The positive

terminal of each analog output is named CHX+ and the negative terminal

CHX–.

SCXI-1520 User Manual 2-12 ni.com

Page 32

Rear Connector

Diagram

12

3 4

56

7 8

910

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25 26

27 28

29 30

31 32

33 34

35 36

37 38

3940

41 42

43 44

45 46

47 48

49 50

Chapter 2 Connecting Signals

Table 2-2. Rear Signal Pin Assignments

Signal Name Pin Number Pin Number Signal Name

— 1 2 —

CH 0 + 3 4 CH 0 –

CH 1 + 5 6 CH 1 –

CH 2 + 7 8 CH 2 –

CH 3 + 9 10 CH 3 –

CH 4 + 11 12 CH 4 –

CH 5 + 13 14 CH 5 –

CH 6 + 15 16 CH 6 –

CH 7 + 17 18 CH 7 –

— 19 20 —

— 21 22 —

— 23 24 DIG GND

SER DAT IN 25 26 SER DAT OUT

DAQ D*/A 27 28 —

SLOT 0 SEL* 29 30 —

— 31 32 —

DIG GND 33 34 —

— 35 36 AI HOLD COMP, AI HOLD

SER CLK 37 38 —

— 39 40 —

— 41 42 —

— 43 44 —

— 45 46 SYNC

— 47 48 —

— 49 50 —

In parallel output mode, channel 0 is selected at the output multiplexer and

is connected to CH 0. The seven other channels are directly connected to

CH 1 through CH 7, respectively, on the rear connector.

© National Instruments Corporation 2-13 SCXI-1520 User Manual

Page 33

Chapter 2 Connecting Signals

In multiplexed mode, the CH 0 signal pair is used for sending all eight

channels of the SCXI-1520, and analog signals from other modules, to the

connected E/M Series DAQ device. If the module is cabled directly to the

DAQ device, the other analog channels of the DAQ device are unavailable

for general-purpose analog input because they are connected to the

SCXI-1520 amplifier outputs. This means that connecting an SCXI-1180

module to the 50-pin breakout connector of the SCXI-1349, or other cable

adapter assembly, may cause interference and incorrect measurements

when the DAQ device is cabled to the SCXI-1520.

The communication signals between the DAQ device and the SCXI system

are listed in Table 2-3. If the DAQ device is connected to the SCXI-1520,

these digital lines are unavailable for general-purpose digital I/O.

Table 2-3. SCXI-1520 Communication Signals

NI-DAQmx

SCXI

Pin

24, 33 DIG GND D GND DGND — Digital ground—these

25 SER DAT IN P0.0 DIO0 Input Serial data in—this

26 SER DAT OUT P0.4 DIO4 Output Serial data out—this

27 DAQ D*/A P0.1 DIO1 Input Board data/address

Signal Name

Device Signal

Name

Traditional NI-DAQ

(Legacy) Device

Signal Name

Direction Description

pins supply the

reference for

E/M Series DAQ device

digital signals and are

connected to the

module digital ground.

signal taps into the

SCXIbus MOSI line to

send serial input data to

a module or Slot 0.

signal taps into the

SCXIbus MISO line to

accept serial output data

from a module.

line—this signal taps

into the SCXIbus D*/A

line to indicate to the

module whether the

incoming serial stream

is data or address

information.

SCXI-1520 User Manual 2-14 ni.com

Page 34

Chapter 2 Connecting Signals

Table 2-3. SCXI-1520 Communication Signals (Continued)

NI-DAQmx

SCXI

Pin

29 SLOT0SEL* P0.2 DIO2 Input Slot 0 select—this

36 SCANCLK AI HOLD COMP,

37 SER CLK EXTSTROBE* EXTSTROBE* Input Serial clock—this

46 HOLD TRIG PFI 7/

Signal Name

Device Signal

Name

AI HOLD

AI SAMP CLK,

AI SAMP

Traditional NI-DAQ

(Legacy) Device

Signal Name

SCANCLK Input Scan clock—a rising

PFI7/

START SCAN

Direction Description

signal taps into the

SCXIbus INTR* line to

indicate whether the

information on MOSI is

being sent to a module

or Slot 0.

edge indicates to the

scanned SCXI module

that the E/M Series

DAQ device has taken a

sample and causes the

module to advance

channels.

signal taps into the

SCXIbus SPICLK line

to clock the data on the

MOSI and MISO lines.

Input Hold trigger—this

signal is used by the

MIO to set the

track-and-hold state of

the module.

© National Instruments Corporation 2-15 SCXI-1520 User Manual

Page 35

Configuring and Testing

This chapter discusses configuring the SCXI-1520 in MAX for use with

either NI-DAQmx or Traditional NI-DAQ (Legacy), creating and testing a

virtual channel, global channel, and/or task.

SCXI-1520 Software-Configurable Settings

This section describes how to set the bridge configuration, voltage

excitation level, filter bandwidth, and gain/input signal range, as well as

how to use configuration utilities in MAX to programmatically perform

offset null compensation and shunt calibration. It also describes how to

perform configuration of these settings for the SCXI-1520 in NI-DAQmx

and Traditional NI-DAQ (Legacy). For more information on the

relationship between the settings and the measurements, and how to

configure settings in your application, refer to Chapter 4, Theory of

Operation.

Common Software-Configurable Settings

This section describes the most frequently used software-configurable

settings for the SCXI-1520. Refer to Chapter 4, Theory of Operation,

for a complete list of software-configurable settings.

3

Bridge Configuration

Bridge configuration is a software-configurable setting that allows you to

connect quarter-, half-, or full-bridge configuration Wheatstone bridge

sensors easily. When quarter- or half-bridge configuration is selected,

Terminal SX– (where X is a particular channel) is disconnected from the

front signal connector and internally connected to a half-bridge completion

network. Implementing quarter-bridge completion also involves making

field wiring connections to the quarter-bridge completion resistor (QTR) in

the terminal block.

© National Instruments Corporation 3-1 SCXI-1520 User Manual

Page 36

Chapter 3 Configuring and Testing

Excitation Level

Excitation level is a software-configurable setting that allows you to set the

voltage excitation level available on PX+ and PX– (where X is a particular

channel). You can choose voltage excitation settings between 0 and 10 V.

To prevent the module from overheating, do not set the excitation voltage

greater than

Note You need not include the loading effect of the internal half-bridge completion

resistors in the above calculation. When using internal quarter-bridge completion you must

include the nominal gauge resistance as well as the quarter-bridge completion resistance

+ R4).

(R

3

Table 3-1 shows the maximum allowable excitation voltages for standard

bridge configurations and resistances.

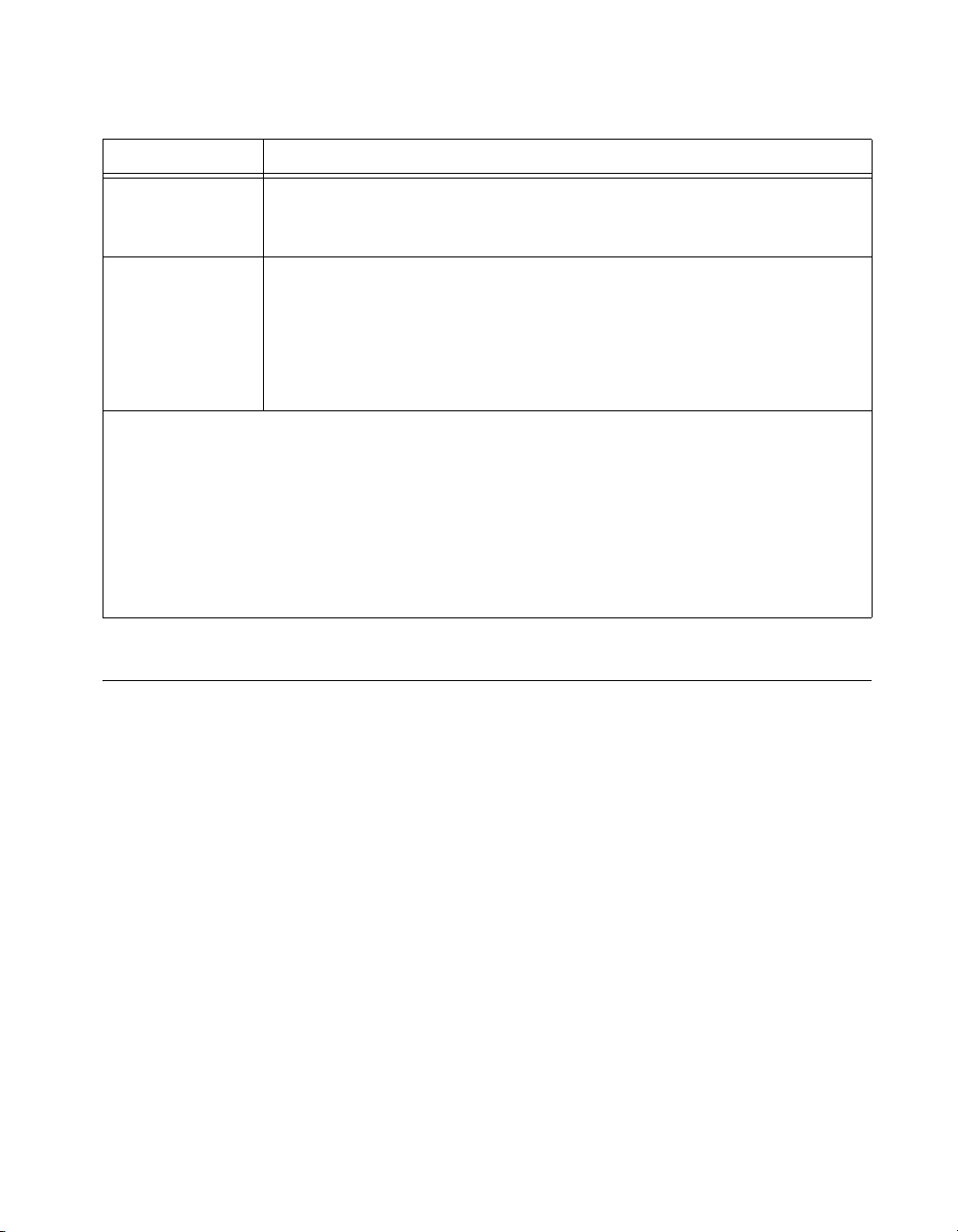

Table 3-1. Excitation Voltage for Configuration and Gauge Resistances

Configuration/

Sensor

Resistance

(resistance connected between the excitation terminals) × (29.0 mA)

Traditional NI-DAQ

NI-DAQmx Excitation

Vol ta g e R an g e

(Legacy) Excitation

Voltage Range

Quarter- or

Half-Bridge

120 Ω ≤6.96 V 0 to 6.875 V

350 Ω 0 to 10 V 0 to 10 V

1000 Ω 0 to 10 V 0 to 10 V

Full-Bridge or

Full-Bridge Sensor

120 Ω ≤3.48 V 0 to 3.125 V

350 Ω 0 to 10 V 0 to 10 V

1000 Ω 0 to 10 V 0 to 10 V

Filter Bandwidth

Filter bandwidth is a software-configurable setting that allows you to select

a lowpass filter cutoff frequency. You can choose 10 Hz, 100 Hz, 1 kHz,

10 kHz, or filter-bypass mode. If your application requires other cutoff

frequencies, refer to Chapter 4, Theory of Operation.

SCXI-1520 User Manual 3-2 ni.com

Page 37

Chapter 3 Configuring and Testing

quarter bridge (max strain) (excitation voltage)× (0.5 ×μV/V/με)=

half bridge (max strain) (excitation voltage)× (1.0 ×μV/V/με)=

full bridge (max strain) (excitation voltage)× (2.0 ×μV/V/με)=

gain

SCXI-1520 output voltage range()10 V()×

input signal voltage()

----------------------------------------------------------------------------------------------------------

≤

(max input signal voltage)

(sensor sensitivity) (excitation voltage)× (maximum input)×

(sensor full-scale input)

-------------------------------------------------------------------------------------------------------------------------------------------------=

12 mV

3.0 mV/V()10 V()200 psi()××

500 psi()

--------------------------------------------------------------------------------=

Gain/Input Range

Gain/input range is a software-configurable setting that allows you to

choose the appropriate amplification to fully utilize the range of the

E/M Series DAQ device. In most applications NI-DAQ chooses and sets

the gain for you determined by the input range. This feature is described in

Chapter 4, Theory of Operation. Otherwise, you should determine the

appropriate gain using the input signal voltage range and the full-scale

limits of the SCXI-1520 output signal. For common strain-gauge

configurations where the Gauge Factor is 2.0, the maximum input signal

(in microvolts) is:

When you have determined the input signal voltage you can use the

following equation to determine the appropriate gain:

© National Instruments Corporation 3-3 SCXI-1520 User Manual

If you are using a bridge-based sensor, use the manufacturer-specified

sensitivity (usually expressed in the units of millivolts per volt) to

determine the maximum input signal. The maximum input signal is:

For example, if you have a 0 to 500 psi pressure sensor with 3.0 mV/V

sensitivity, an excitation voltage of 10 V, and a maximum pressure of

200 psi, the maximum signal is:

Page 38

Chapter 3 Configuring and Testing

833

10 V

12 mV

----------------=

If you are using a DAQ device that has a maximum analog input range of

±10 V and you have a maximum input to the SCXI-1520 of +12 mV, set the

gain to the setting closest to

but less than 833. A larger gain setting saturates the DAQ device input for

a 12 mV signal. In this example, the closest lesser gain setting for the

SCXI-1520 is 750.

Null Potentiometers

Coarse and fine null potentiometers are software-configurable settings that

allow you to remove unwanted offset voltage. In most cases, you do not

explicitly set the null potentiometers, but instead allow driver software to

automatically adjust them for you. However, if you want to explicitly set

the null potentiometers, you can write an application program that adjusts

the null potentiometers settings. Refer to Chapter 4, Theory of Operation,

for more information.

Shunt Calibration Switches

Shunt calibration switches A and B are software control settings that allow

you to engage or disengage the shunt calibration resistors in order to

perform gain calibration. In most cases, you do not explicitly control

the shunt calibration switches, but instead allow driver software to

automatically adjust them for you during the automated shunt calibration

procedure. However, if you want to explicitly control the calibration

switches, you can write an application program that controls the shunt

calibration switches. Refer to Chapter 4, Theory of Operation, for more

information.

Note The gain adjustment is done for you automatically if you have performed shunt

calibration using the NI-DAQ driver. Refer to the Traditional NI-DAQ (Legacy) section

and the NI-DAQmx section for more information about how to perform shunt calibration

using the driver.

SCXI-1520 User Manual 3-4 ni.com

Page 39

Chapter 3 Configuring and Testing

Modes of Operation

The SCXI-1520 can operate in multiplexed mode or parallel mode. Using

NI-DAQmx, you can operate the SCXI-1520 in either multiplexed or

parallel mode. In Traditional NI-DAQ (Legacy), only multiplexed mode is

supported. Refer to the Strain-Gauge Theory section of Chapter 4, Theory

of Operation, for more information on multiplexed and parallel mode

operation.

Simultaneous Sample and Hold

When it is critical to measure two or more signals at the same instant

in time, simultaneous sample and hold (SS/H) is required. Typical

applications that might require SS/H include vibration measurements

and phase difference measurements. In NI-DAQmx, you can disable this

setting through your application if you require scan rates beyond the

maximum allowable with SS/H engaged. NI recommends leaving SS/H

engaged.

Note You cannot change the simultaneous sampling mode in MAX. You must use an ADE

such as LabVIEW or LabWindows/CVI to configure the setting using NI-DAQmx Channel

Property Node. Refer to your ADE help file for more information.

Configurable Settings in MAX

Note If you are not using an NI ADE, using an NI ADE prior to version 7.0, or are using

an unlicensed copy of an NI ADE, additional dialog boxes from the NI License Manager

appear allowing you to create a task or global channel in unlicensed mode. These messages

continue to appear until you install version 7.0 or later of an NI ADE.

This section describes where you can access each software-configurable

setting for modification in MAX. The location of the settings varies

depending on the version of NI-DAQ you use. Refer to either the

NI-DAQmx section or the Traditional NI-DAQ (Legacy) section. You also

can refer to the DAQ Getting Started Guide and the SCXI Quick Start Guide