Page 1

CALIBRATION PROCEDURE

™

SCXI -1141/1142/1143

This document contains the information and instructions needed to

calibrate the SCXI-1141/1142/1143 using Traditional NI-DAQ (Legacy).

Calibrate the SCXI-1141/1142/1143 at a regular interval as defined by the

measurement accuracy requirements of your application. NI recommends

performing a complete calibration at least once every year. Based on your

measurement accuracy needs, you can shorten this interval to 90 days or

six months.

Conventions

The following conventions apply to this document:

» The » symbol leads you through nested menu items and dialog box options

to a final action. The sequence File»Page Setup»Options directs you to

pull down the File menu, select the Page Setup item, and select Options

from the last dialog box.

This icon denotes a tip, which alerts you to advisory information.

This icon denotes a note, which alerts you to important information.

When this symbol is marked on a product, refer to the Read Me First: Safety

and Radio-Frequency Interference for information about precautions to

take.

When symbol is marked on a product, it denotes a warning advising you to

take precautions to avoid electrical shock.

When symbol is marked on a product, it denotes a component that may be

hot. Touching this component may result in bodily injury.

bold Bold text denotes items that you must select or click in the software, such

as menu items and dialog box options. Bold text also denotes parameter

names.

Page 2

italic Italic text denotes variables, emphasis, a cross-reference, or an introduction

to a key concept. Italic text also denotes text that is a placeholder for a word

or value that you must supply.

monospace Text in this font denotes text or characters that you should enter from the

keyboard, sections of code, programming examples, and syntax examples.

This font is also used for the proper names of disk drives, paths, directories,

programs, subprograms, subroutines, device names, functions, operations,

variables, filenames, and extensions.

Software

Calibration requires the latest version of Traditional NI-DAQ (Legacy),

which includes high-level function calls to simplify the task of writing

software to calibrate devices. Traditional NI-DAQ (Legacy) supports many

programming languages, including LabVIEW, LabWindows

Microsoft Visual C++, Microsoft Visual Basic, and Borland C++.

If the SCXI-1141/1142/1143 is revision F or later, this procedure requires

using a calibration software library. The library contains a function that is

needed to adjust calibration circuitry on the module. If you do not have the

software library files, you can download them from

info code

exgpxj.

ni.com/info, using

The calibration software library consists of these files:

•

SCXIdpCal.dll

• SCXIdpCal.h

™

/CVI™,

Determine the revision of the SCXI-1141/1142/1143 by checking the part number

Note

of the module, which is located on the outside of the module case. For example, part

number 182628C-01 is revision C.

SCXI-1141/1142/1143 Calibration Procedure 2 ni.com

Page 3

Documentation

Test Equipment

The following documents are the primary references for writing your

calibration utility:

• The Traditional NI-DAQ Function Reference Help includes

information about the functions in Traditional NI-DAQ (Legacy).

• The DAQ Getting Started Guide provides instructions for installing

and configuring NI-DAQ devices.

• The SCXI Quick Start Guide includes information for installing and

configuring the SCXI chassis.

• The Traditional NI-DAQ User Manual includes information about

creating applications that use Traditional NI-DAQ (Legacy).

You can add these help files when you install Traditional NI-DAQ

(Legacy). After adding these help files, you can access them by selecting

Start»Programs»National Instruments NI-DAQ»Online-DAQ

Support. The documents provide instructions about installing and

configuring DAQ devices. The documents also include detailed

information about creating applications that use Traditional NI-DAQ

(Legacy). For more information about the SCXI-1141/1142/1143, refer

to the SCXI-1141/1142/1143 User Manual.

NI recommends using the equipment in Table 1 to verify and calibrate the

SCXI-1141/1142/1143. If these instruments are not available, use the

accuracy requirements listed to select a suitable substitute.

Table 1. Test Equipment

Recommended

Equipment

Calibrator Fluke 5700A 50 ppm

DMM NI 4060 5 1/2 digit, 15 ppm

DAQ Device NI 6030E 16-bit minimum

Terminal Block SCXI-1304 N/A

© National Instruments Corporation 3 SCXI-1141/1142/1143 Calibration Procedure

Model

Accuracy

Page 4

Test Conditions

Follow these guidelines to optimize the connections and the environment

during calibration:

• Keep connections to the SCXI terminal block and the rear connector of

the SCXI module short. Long cables and wires act as antennae, picking

up extra noise and thermal offsets that can affect measurements.

• Use shielded copper wire for all cable connections to the

SCXI-1141/1142/1143. Use twisted-pair wire to reduce noise.

• Maintain the temperature between 18 and 28 °C.

• Keep relative humidity below 80%.

• Allow a warm-up time of at least 15 minutes for the SCXI module and

30 minutes for the DAQ device to ensure the measurement circuitry is

at a stable operating temperature.

Calibration Procedure

This section provides step-by-step instructions for calling the appropriate

calibration functions.

The steps used in the calibration procedure are as follows:

1. Setting up the SCXI-1141/1142/1143 for testing.

2. Verifying the existing operation of the SCXI-1141/1142/1143 to

determine whether it is operating within its test limits.

3. Adjusting the offset and gain errors using a known external voltage

source.

4. Verifying that the SCXI-1141/1142/1143 is operating within its test

limits after adjustments.

Setting up the SCXI-1141/1142/1143 for Calibration

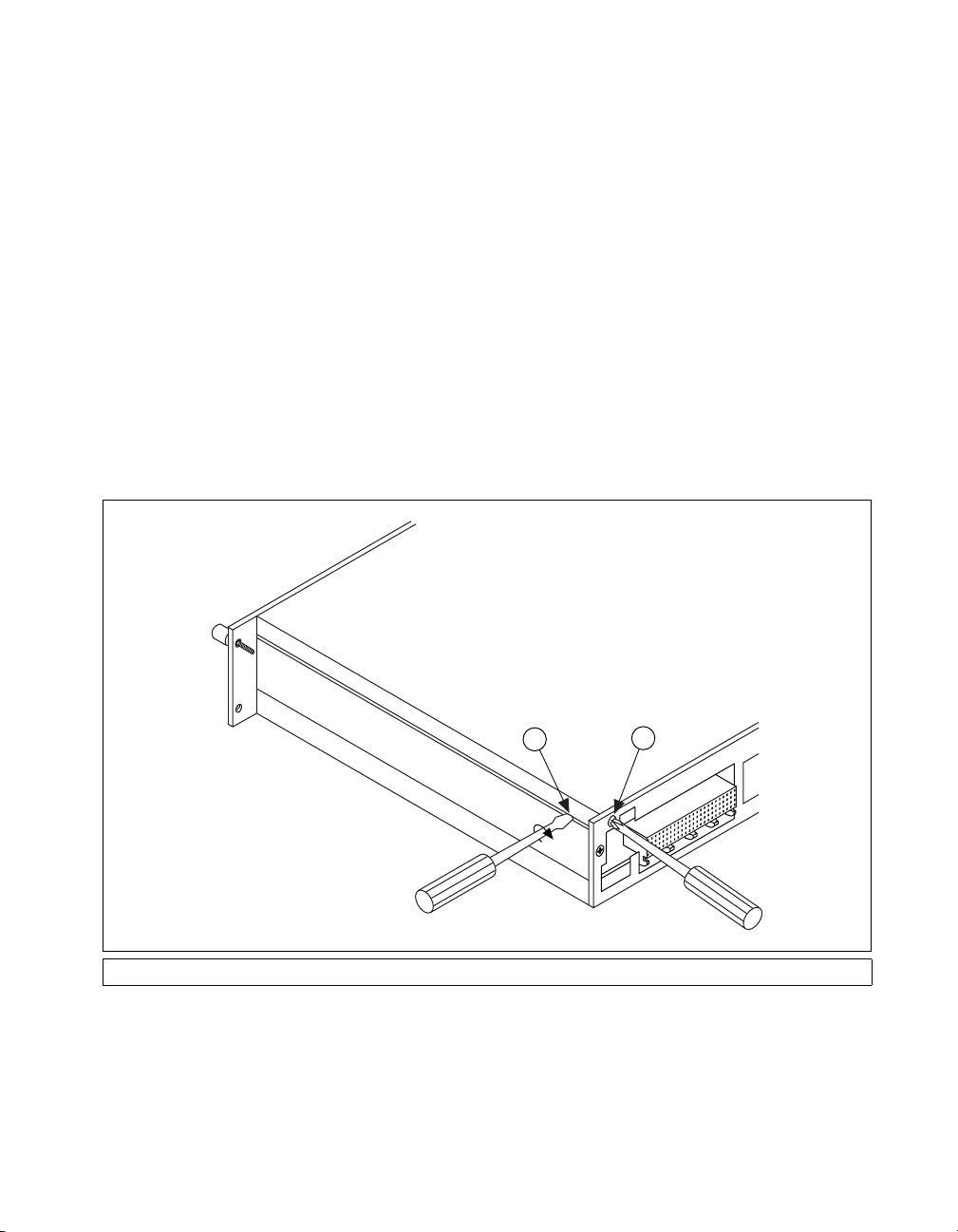

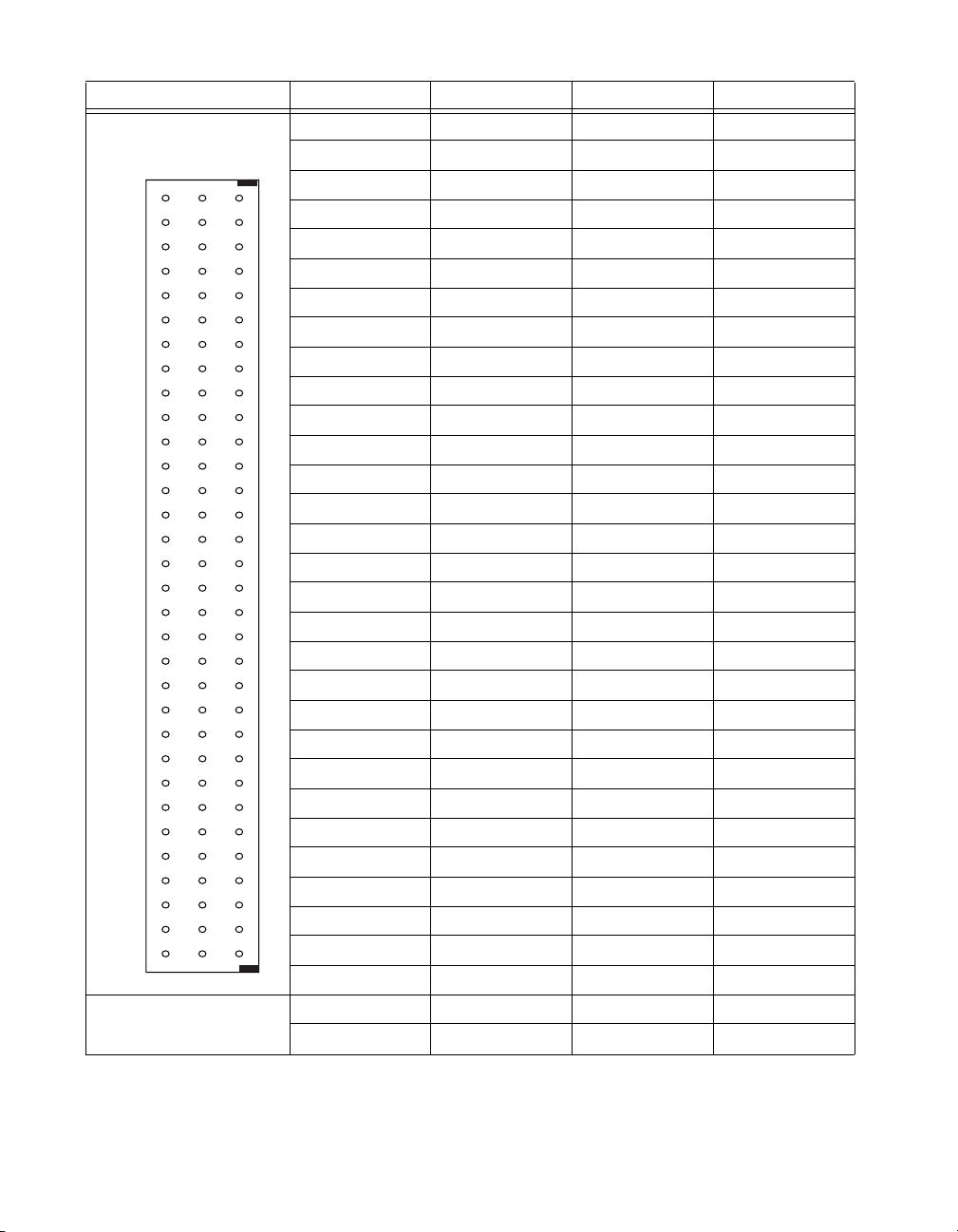

Complete the following steps, while referring to Figure 1 to set up the

SCXI-1141/1142/1143 for calibration.

1. Make sure all components involved in the calibration procedure are

powered-off.

2. Assemble the SCXI-1141/1142/1143, chassis, terminal block, and

DAQ device as shown in Figure 1. The SCXI module you are

calibrating must be connected directly to the DAQ device.

3. Power on the SCXI chassis and the external computer.

4. Make sure that all the appropriate driver and application software is

installed.

SCXI-1141/1142/1143 Calibration Procedure 4 ni.com

Page 5

5. You must configure the hardware properly with Measurement &

Automation Explorer (MAX) under Traditional NI-DAQ (Legacy).

Refer to the SCXI Quick Start Guide for details about configuring the

SCXI chassis.

5

4

3

6

2

1

S

C

X

I

1

1

0

0

®

5

4

3

2

1

ADDRESS

S

C

X

M

A

I

I

N

F

R

A

M

E

7

50

48

46

44

42

40

38

49

36

47

34

32

4345

30

41

28

39

26

37

24

35

20

33

20

31

29

1618

27

14

25

12

10

2123

8

19

6

17

24

15

91113

7

3 5

1

8

9

10

1 SCXI-1304 Terminal Block

2 SCXI-1141/1142/1143 Module

3 SCXI Chassis

4 SCXI-1349 Cable Adapter

5 Shielded 68-Pin Cable

6 NB1 Cable (50-Pin Ribbon Cable)

7 TBX 50-Pin Terminal Block

8 Cable to DMM

9 Cable to Calibrator

10 Calibrator

11 DMM

12 DAQ Device

Figure 1. Typical SCXI-1141/1142/1143 Setup for Calibration

Verifying the Operation of the SCXI-1141/1142/1143

The verification procedure determines how well the SCXI-1141/1142/1143

is meeting its specifications. You can use this information to select the

appropriate calibration interval for your application.

12

11

© National Instruments Corporation 5 SCXI-1141/1142/1143 Calibration Procedure

Page 6

Verifying Analog Input Measurements

Complete the following steps to verify the analog input offsets of the

SCXI-1141/1142/1143:

1. Read the Test Conditions section in this document.

2. Refer to Table 9 for the specifications to test. Table 9 shows all

acceptable settings for the module. NI recommends that you verify all

ranges and gains. However, you can save time by checking only the

ranges that your application uses.

3. Ensure that the E Series DAQ device is connected to the SCXI module.

4. Call

5. Call

6. Call

7. Call

8. Call

Calibrate_E_Series to minimize any uncertainty associated

with the E Series DAQ device. Set the following parameters:

• device—The Traditional NI-DAQ (Legacy) device number

assigned by MAX

• calOp—

ND_SELF_CALIBRATE

• setOfCalConst—ND_USER_EEPROM_AREA

• calRefVolts—0.0

MIO_Config to enable dithering on the E Series DAQ device

measurements. Set the following parameters:

• DAQdeviceNumber—The Traditional NI-DAQ (Legacy) device

number assigned by MAX

• dither—1

• useAMUX—0

SCXI_Single_Chan_Setup to configure the module for

single-channel measurements. Set the following parameters:

• SCXIchassisID—The chassis ID value obtained from MAX

• moduleSlot—1

• moduleChan—0

• DAQdeviceNumber—The cabled device number assigned by

MAX to the E Series DAQ device

SCXI_Set_Gain to configure the module to the gain value you

want to test. Set the following parameters:

• SCXIchassisID—The value obtained from MAX

• moduleSlot—1

• moduleChan—0

• gain—The gain value from Table 9 that you want to test

SCXI_Configure_Filter to disable the filter.

Set the following parameters:

• SCXIchassisID—The value obtained from MAX

SCXI-1141/1142/1143 Calibration Procedure 6 ni.com

Page 7

• moduleSlot—1

• channel—0

• filterMode—0

• freq—0 kHz

• cutoffDivDown—0

• outClkDivDown—2

9. Input the test voltage listed in Table 9 to channel 0 of the SCXI

module.

10. Call

DAQ_Op. Set the following parameters:

• DAQdeviceNumber—The device number for the DAQ device

• channel—0

• gain—1 for a 16-bit E Series DAQ device

• count—100

• sampleRate—100

11. Call

SCXI_Scale to convert the readings from binary to voltage.

Set the following parameters:

• SCXIChassisID—The device number assigned by MAX

• moduleSlot—1

• channel—0

• SCXIgain—The gain you are testing

• TBgain—1

• DAQboard—The device number for the DAQ device

• DAQChannel—0

• DAQgain—1

• numPoints—100

• binArray—The array returned from

DAQ_Op

The result is a set of scaled voltages read from the SCXI module.

12. Average the results returned by

SCXI_Scale. Compare the averaged

result to the upper and lower limits listed in Table 9.

13. Repeat steps 6 through 12 for each remaining test point.

14. Repeat steps 6 through 13 for each remaining channel, changing the

moduleChan variable to the channel number you are testing.

You have finished verifying the operation of the SCXI-1141/1142/1143.

© National Instruments Corporation 7 SCXI-1141/1142/1143 Calibration Procedure

Page 8

Verifying Filter Parameters

Complete the following steps to set up the SCXI-1141/1142/1143 for this

verification process:

1. Read the Test Conditions section in this document.

2. Ensure that the E Series DAQ device is connected to the

SCXI-1141/1142/1143.

3. Call

4. Call

5. Connect the calibrator to analog input channel 0. Refer to Table 7 to

6. Connect the DMM to the output of channel 0. Refer to Table 8 to

SCXI_Configure_Filter to enable the cutoff filter.

Set the following parameters:

• SCXIchassisID—The value obtained from MAX

• moduleSlot—1

• channel—0

• filterMode—1

• freq—10 kHz

• cutoffDivDown—0

• outClkDivDown—2

SCXI_Set_Gain to configure the module to a gain of 1.

Set the following parameters:

• SCXIchassisID—The value obtained from MAX

• moduleSlot—1

• moduleChan—0

• gain—1

determine which pins on the 96-pin front connector correspond to the

positive and negative inputs of the specified channel. If you are using

an SCXI-1304 connected to the SCXI-1141/1142/1143, connect the

calibrator to the AI 0 + and AI 0 – inputs.

determine which pins on the 50-pin rear connector correspond to the

positive and negative outputs for the specified channel. For example,

the positive output for channel 0 is pin 3, which is AI 0 +. The negative

output for channel 0 is pin 4, which is AI 0 –.

Verifying Stopband Attenuation

Verify the stopband attenuation by performing the following steps:

1. Set the calibrator to output a 10 kHz, 1 V

2. With a DMM, ensure that you read a 1 V

3. Increase the input signal frequency generated by the calibrator until the

level read by the DMM is 10 mV

SCXI-1141/1142/1143 Calibration Procedure 8 ni.com

rms

.

sine wave.

rms

signal.

rms

Page 9

4. Verify that the frequency is within the limits shown in Table 2.

Table 2. Input Frequency

Module Lower Limit (kHz) Upper Limit (kHz)

SCXI-1141 12.5 13.5

SCXI-1142 31.0 33.0

SCXI-1143 17.5 19.0

Verifying Corner Frequency

Verify the corner frequency by performing the following steps:

1. Set the calibrator to output a 10 kHz, 1 V

2. Verify that the DMM output is within the values shown in Table 3.

Table 3. SCXI-1141/1142/1143 Output

sine wave.

rms

Module Lower Limit (V

) Upper Limit (V

rms

SCXI-1141 0.9825 1.0201

SCXI-1142 0.6837 0.7331

SCXI-1143 0.6916 0.7765

Verifying Passband

Verify the passband by performing the following steps:

1. Set the calibrator output to a 1 V

specified in Tables 4, 5, or 6.

2. Verify that the DMM output is within the bounds specified by

Tables 4, 5, or 6.

3. Repeat steps 1 and 2 until all test points are verified.

Table 4. Passband Test Points for the SCXI-1141

Frequency (kHz) Lower Limit (V

5.94 0.9803 1.0143

9.39 0.9803 1.0143

sine wave at the frequency

rms

) Upper Limit (V

rms

rms

)

rms

)

© National Instruments Corporation 9 SCXI-1141/1142/1143 Calibration Procedure

Page 10

Table 5. Passband Test Points for the SCXI-1142

Frequency (kHz) Lower Limit (V

2.5 0.9596 0.9889

5.0 0.8909 0.9336

Table 6. Passband Test Point for the SCXI-1143

Frequency (kHz) Lower Limit (V

5.0 0.9882 1.0119

Adjusting the SCXI-1141/1142/1143

This section contains three adjustment procedures: one for measuring gain

error, one for adjusting calibration gain constants, and one for adjusting

filter AC gain.

Measuring Gain Errors

Complete the following steps to measure the gain errors in the

SCXI-1141/1142/1143:

1. Read the Test Conditions section in this document.

2. Refer to Table 9 for the specifications to be tested. Table 9 shows all

acceptable settings for the module.

3. Ensure that the E Series DAQ device is connected to the

SCXI-1141/1142/1143.

4. Call

5. Call

SCXI_Single_Chan_Setup to configure the module for

single-channel measurements. Set the following parameters:

• SCXIchassisID—The value obtained from MAX

• moduleSlot—1

• moduleChan—0

• DAQdeviceNumber—The device number assigned by MAX

for the E Series DAQ device

SCXI_Set_Gain to configure the module to the gain value you

want to adjust. Set the following parameters:

• SCXIchassisID—The value obtained from MAX

• moduleSlot—1

• moduleChan—0

• gain—The gain value from Table 9 that you are currently testing

) Upper Limit (V

rms

) Per Limit (V

rms

rms

rms

)

)

SCXI-1141/1142/1143 Calibration Procedure 10 ni.com

Page 11

6. Connect the calibrator to the appropriate analog input channel, starting

with channel 0. Refer to Table 7 to determine the pins on the 96-pin

front connector that correspond to the positive and negative inputs of

the specified channel. If you are using an SCXI-1304 connected to the

SCXI-1141/1142/1143, connect the calibrator to the AI 0 + and AI 0 –

inputs and verify that the SCXI-1304 is set to DC coupling.

7. Connect the DMM to the positive output on pin 3 (AI 0 +) and the

negative output on pin 4 (AI 0 –) on the rear panel connector,

illustrated in Table 8.

Tip For easy access to individual pins, use a TBX 50-pin connector block connected as

shown in Figure 1.

8. Set the calibrator voltage to the positive test-point value in Table 9.

9. Read the voltage from the DMM. Record the DMM reading as

output1, and the calibrator output voltage as volt1, for later use.

10. Set the calibrator to the negative test-point value for the same gain.

Skip any input limits that are specified as 0.0 V. You need only upper

and lower limits for adjustment.

11. Read the voltage from the DMM. Record the DMM reading as

output2, and the calibrator output voltage as volt2. You now have two

pairs of data points, (volt1, output1) and (volt2, output2), where volt1

and volt2 are calibrator readings, and output1 and output2 are DMM

readings.

12. Convert the DMM voltage readings (output1 and output2) to binary

readings (binary1 and binary2) using the following equation:

output

⎛⎞

binary reading for 16-bit E Series products (binary)

Note In both of the above equations, output is either output1 or output2.

-----------------

⎝⎠

20

216×=

For example, using a 16-bit product such as a NI 6030E and obtaining

a DMM reading of –9.90000 V, you get the following results:

9.90000–

⎛⎞

binary

----------------------

⎝⎠

20

216× 32440.32–==

13. Record binary1 with volt1, and binary2 with volt2, for later use.

14. Repeat steps 5 through 13 for the remaining gain values you want to

measure on this channel.

15. Repeat steps 4 through 14 for the remaining channels you want to

measure.

© National Instruments Corporation 11 SCXI-1141/1142/1143 Calibration Procedure

Page 12

You have finished measuring the gain on the SCXI-1141/1142/1143.

Adjusting Calibration Constants

Complete the following steps to adjust the calibration constants on the

SCXI-1141/1142/1143 to compensate for the gain error measured in the

Measuring Gain Errors section:

1. Reconnect the E Series DAQ device to the SCXI-1141/1142/1143.

2. Call

3. Repeat step 2, changing calibrationArea to 1.

4. Repeat step 2, changing calibrationArea to 3.

5. Repeat steps 2 through 4 for the next channel.

6. Repeat steps 2 through 5 for the next gain setting.

SCXI_Cal_Constants to create and store the new calibration

constants in the SCXI-1141/1142/1143 memory. Use the following

parameters:

• SCXIchassisID—The ID assigned by MAX

• moduleSlot—1, unless you installed the module in a different slot

• channel—The channel you want to adjust

• opCode—2

• calibrationArea—0

• rangeCode—0 (not used for the SCXI-1141/1142/1143)

• SCXIgain—The gain setting you want to adjust

• DAQboard—The device number assigned by MAX

• DAQChan—0

• DAQGain—1 for 16-bit devices

• Tbgain—1.0

• volt1 and volt2—The first and second voltage readings for the

gain values that you are saving on the SCXI-1141/1142/1143

• binary1 and binary2—The first and second binary readings for

the gain values that you are saving on the SCXI-1141/1142/1143

• calConst1 and calConst2—The return values

You have finished adjusting the calibration constants on the

SCXI-1141/1142/1143.

SCXI-1141/1142/1143 Calibration Procedure 12 ni.com

Page 13

Adjusting Filter AC Gain

The AC gain of the filter is independent of the gain of the amplifier, so you

can do this procedure with any amplifier gain. Ideally, you set the amplifier

gain (G

You can set V

due to ripple in the passband, the frequency of the sine wave must be lower

than 1/50th of the cutoff frequency. For this procedure, in sections

SCXI-1141/1142/1143 Before Revision F or SCXI-1141/1142/1143

Revision F or Later you will set the filters to a cutoff frequency of 25 kHz

and use a sine wave of less than 500 Hz.

SCXI-1141/1142/1143 Before Revision F

Complete the following steps to set up the SCXI-1141/1142/1143 for

adjustment and to adjust the AC gain filter, referring to Figures 2 and 3

as needed:

1. Remove the grounding screw from the module.

2. Remove the cover on the module to access the potentiometers.

) and the amplitude of the sine wave (Vs) so that Vs=3.4V

s

to a lower amplitude, but not a higher one. To prevent errors

s

rms/Gs

.

2

1 Grounding Screw 2 Module Cover

Figure 2. Grounding Screw and Cover Removal

© National Instruments Corporation 13 SCXI-1141/1142/1143 Calibration Procedure

1

Page 14

3. Remove the side plate of the SCXI chassis.

4. Install the module into slot 4 of the SCXI chassis.

®

S

C

X

I

M

A

I

N

F

R

A

M

E

NATIONAL

INSTRUMENTS

2

1

1 Thumbscrews 2Slot 4 3 Side Plate

Figure 3. Side Plate Removal and Module Installation

5. Read the Test Conditions section in this document.

6. Ensure that the E Series DAQ device is connected to the

SCXI-1141/1142/1143.

7. Call

SCXI_Set_Gain to configure the module to a gain value of 1.

Set the following parameters:

• SCXIchassisID—The device number assigned by MAX

• moduleSlot—4

• moduleChan—0

• gain—1

8. Call

SCXI_Configure_Filter to enable the filter bypass. Set the

following parameters:

• SCXIchassisID—The value configured in MAX

• moduleSlot—40

• channel—0

3

SCXI-1141/1142/1143 Calibration Procedure 14 ni.com

Page 15

• filterMode—0

• freq—0 kHz

• cutoffDivDown—0

• outClkDivDown—0

9. Connect the calibrator to analog input channel 0. Refer to Table 7

to determine the pins on the 96-pin front connector that correspond to

the positive and negative inputs of the specified channel. If you are

using an SCXI-1304 connected to the SCXI-1141/1142/1143, connect

the calibrator to the AI 0 + and AI 0 – inputs.

10. Connect the DMM to the output of channel 0. Refer to Table 8 to

determine the pins on the 50-pin rear connector that correspond to the

positive and negative outputs for the specified channel. For example,

the positive output for channel 0 is pin 3, which is AI 0 +. The negative

input for channel 0 is pin 4, which is AI 0 –.

11. Set the calibrator voltage to 3.4 V

, 400 Hz.

rms

12. Measure and record the amplitude of the sine wave with the DMM.

13. Call

SCXI_Configure_Filter to disable the filter bypass. Set the

following parameters:

• SCXIchassisID—The value configured in MAX

• moduleSlot—4

• channel—0

• filterMode—1

• freq—25 kHz

• cutoffDivDown—0

• outClkDivDown—2

14. Measure the amplitude of the sine wave at the output and adjust the

potentiometer until the amplitude is at the same level as it was with the

filter in bypass mode.

15. Repeat steps 8 through 14 for the remaining channels.

You have finished adjusting the filter AC gain of the

SCXI-1141/1142/1143.

SCXI-1141/1142/1143 Revision F or Later

Complete the following steps to adjust the AC gain of the filter on an

SCXI-1141/1142/1143 revision F or later:

1. Read the Test Conditions section in this document.

2. Ensure that the E Series DAQ device is connected to the

SCXI-1141/1142/1143.

© National Instruments Corporation 15 SCXI-1141/1142/1143 Calibration Procedure

Page 16

3. Call SCXI_Set_Gain to configure the module to a gain value of 1.

Set the following parameters:

• SCXIchassisID—The value obtained from MAX

• moduleSlot—4

• moduleChan—0

• gain—1

4. Call

SCXI_Configure_Filter to enable the filter bypass.

Set the following parameters:

• SCXIchassisID—The value obtained from MAX

• moduleSlot—4

• channel—0

• filterMode—0

• freq—0 kHz

• cutoffDivDown—0

• outClkDivDown—0

5. Connect the calibrator to analog input channel 0. Refer to Table 7 to

determine the pins on the 96-pin front connector that correspond to the

positive and negative inputs of the specified channel. If you are using

an SCXI-1304 that is connected to the SCXI-1141/1142/1143, connect

the calibrator to the AI 0 + and AI 0 – inputs.

6. Connect the DMM to the output of channel 0. Refer to Table 8 to

determine the pins on the 50-pin rear connector that correspond to the

positive and negative outputs for the specified channel. For example,

the positive output for channel 0 is pin 3, which is AI 0 +. The negative

input for channel 0 is pin 4, which is AI 0 –.

7. Set the calibrator voltage to 3.4 V

, 400 Hz.

rms

8. Measure and record the amplitude of the sine wave with the DMM.

9. Call

SCXI_Configure_Filter to enable the cutoff filter. Set the

following parameters:

• SCXIchassisID—The value obtained from MAX

• moduleSlot—4

• channel—0

• filterMode—1

• freq—25 kHz

• cutoffDivDown—0

• outClkDivDown—2

SCXI-1141/1142/1143 Calibration Procedure 16 ni.com

Page 17

10. Call the SCXI_SetDP function in SCXIdpCal.dll to set the digital

potentiometer to a neutral position, set the following short integer

parameters:

• SCXIchassisID—The value obtained from MAX

• moduleSlot—4

• channel—0

• value—127

11. Measure the amplitude of the sine wave at the output of the module.

12. If the measured value is less than the value measured with the filter

bypassed, increase the value to which the digital potentiometer is set.

If it is greater, decrease the value. You can set the digital potentiometer

from 0 to 255.

13. Call

14. Repeat steps 11 through 13 until the measured amplitude is as close as

15. Repeat steps 4 through 14 for the remaining channels.

SCXI_SetDP to set the digital potentiometer to the new value:

• SCXIchassisID—The value obtained from MAX

• moduleSlot—4

• channel—0

• value—The new value decided upon in step 12

possible to the level it was with the filter in bypass mode.

You have finished adjusting the filter AC gain of the

SCXI-1141/1142/1143.

Verifying Adjusted Values

After you complete the adjustment procedure, it is important that you verify

the accuracy of the adjusted values by repeating the procedure in the

Verifying the Operation of the SCXI-1141/1142/1143 section. Verifying

the adjusted values ensures that the SCXI-1141/1142/1143 is operating

within its specifications after adjustments.

Note If the module fails verification after adjustment, return it to NI for repair or

replacement.

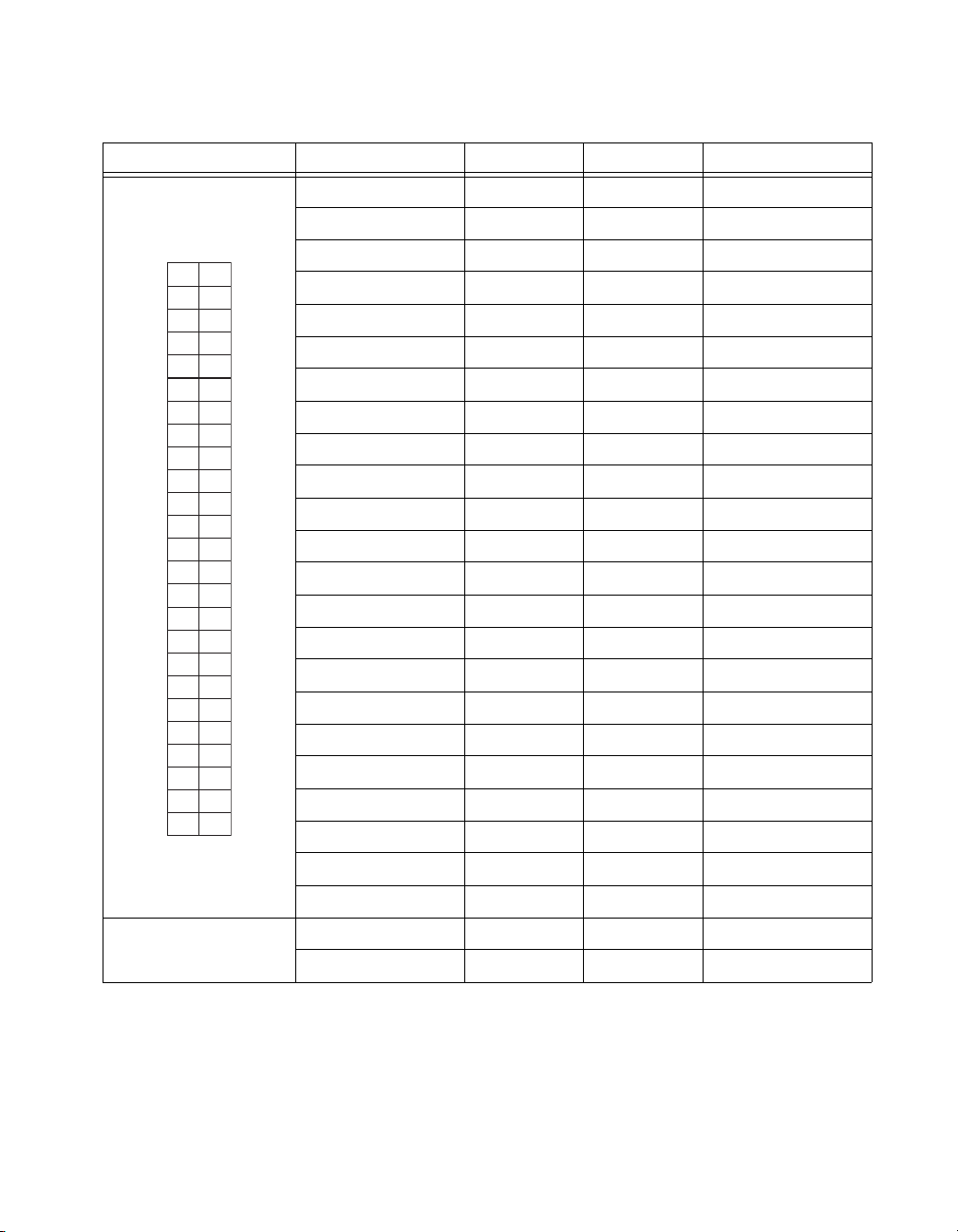

Front and Rear Panel Pin Assignments

Table 7 shows the pin assignments for the SCXI-1141/1142/1143 front

panel connector.

© National Instruments Corporation 17 SCXI-1141/1142/1143 Calibration Procedure

Page 18

Table 7. Front Signal Pin Assignments

Front Connector Diagram Pin Number Column A Column B Column C

32 AI 0 + NC AI 0 –

Column

A B C

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

NC means no connection.

RSVD means reserved.

31 NC NC NC

30 AI 1 + NC AI 1 –

29 NC NC NC

28 A GND NC A GND

27 NC NC NC

26 AI 2 + NC AI 2 –

25 NC NC NC

24 AI 3 + NC AI 3 –

23 NC NC NC

22 A GND NC A GND

21 NC NC NC

20 AI 4 + NC AI 4 –

19 NC NC NC

18 AI 5 + NC AI 5 –

17 NC NC NC

16 A GND NC A GND

15 NC NC NC

14 AI 6 + NC AI 6 –

13 NC NC NC

12 AI 7 + NC AI 7 –

11 NC NC NC

10 NC NC NC

9 NC NC NC

8 RSVD NC RSVD

7 NC NC NC

6 RSVD NC RSVD

5 NC NC NC

4 RSVD NC EXT CLK

3 NC NC NC

2 D GND NC OUT CLK

1 NC NC NC

SCXI-1141/1142/1143 Calibration Procedure 18 ni.com

Page 19

Table 8 shows the pin assignments for the SCXI-1141/1142/1143 rear

panel connector.

Table 8. Rear Signal Pin Assignments

Rear Connector Diagram Signal Name Pin Number Pin Number Signal Name

NC 1 2 NC

AI 0 + 3 4 AI 0 –

12

34

56

78

910

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25 26

27 28

29 30

31 32

33 34

35 36

37 38

39 40

41 42

43 44

45 46

47 48

49 50

AI 1 + 5 6 A GND

AI 2 + 7 8 A GND

AI 3 + 9 10 A GND

AI 4 + 11 12 A GND

AI 5 + 13 14 A GND

AI 6 + 15 16 A GND

AI 7 + 17 18 A GND

NC 19 20 NC

NC 21 22 NC

NC 23 24 DIG GND

SER DAT IN 25 26 SER DAT OUT

DAQ D*/A 27 28 NC

SLOT 0 SEL* 29 30 NC

NC 31 32 NC

DIG GND 33 34 NC

NC 35 36 SCAN CLK

SER CLK 37 38 NC

NC 39 40 NC

NC 41 42 NC

RSVD 43 44 NC

NC 45 46 NC

NC means no connection.

RSVD means reserved.

© National Instruments Corporation 19 SCXI-1141/1142/1143 Calibration Procedure

NC 47 48 NC

NC 49 50 NC

Page 20

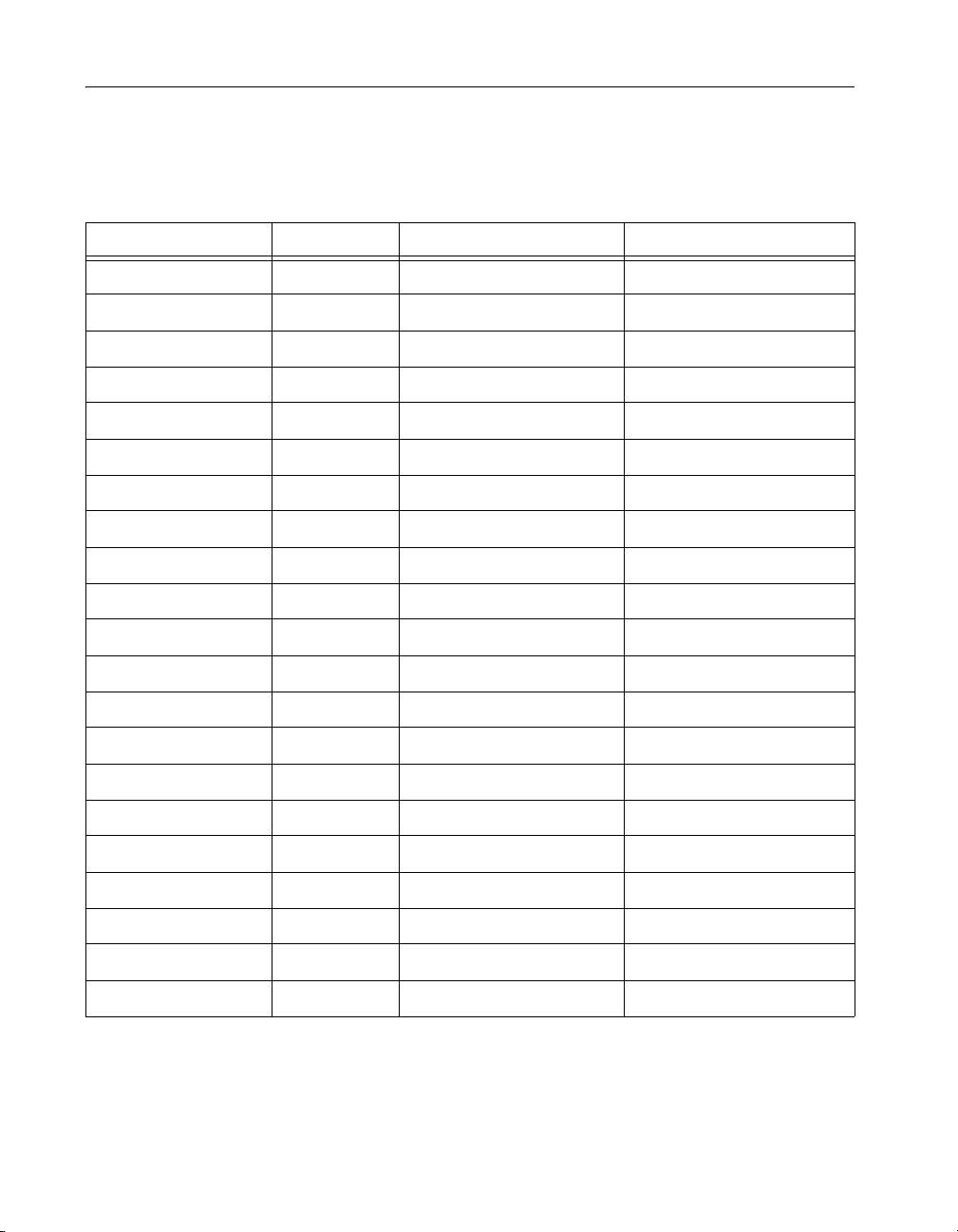

Specifications

Table 9 contains test specifications for the SCXI-1141/1142/1143. If the

module has been calibrated within the last year, the Test Point (V) value

should fall between the Upper Limit (V) and Lower Limit (V) values.

Table 9. SCXI-1141/1142/1143 Specifications

Test Point (V) Gain Upper Limit (V) Lower Limit (V)

4.7500 1 4.771715 4.728285

0.0000 1 0.020480 –0.020480

–4.7500 1 –4.728285 –4.771715

2.3750 2 2.390948 2.359052

0.0000 2 0.015330 –0.015330

–2.3750 2 –2.359052 –2.390948

0.9500 5 0.962487 0.937513

0.0000 5 0.012240 –0.012240

–0.9500 5 –0.937513 –0.962487

0.4750 10 0.486334 0.463666

0.0000 10 0.011210 –0.011210

–0.4750 10 –0.463666 –0.486334

0.2375 20 0.248258 0.226742

0.0000 20 0.010696 –0.010696

–0.2375 20 –0.226742 –0.248258

0.0750 50 0.085408 0.064592

0.0000 50 0.010388 –0.010388

–0.0750 50 –0.064592 –0.085408

0.0375 100 0.047796 0.027204

0.0000 100 0.010286 –0.010286

–0.0375 100 –0.027204 –0.047796

National Instruments, NI, ni.com, and LabVIEW are trademarks of National Instruments Corporation.

Refer to the Terms of Use section on ni.com/legal for more information about National

Instruments trademarks. Other product and company names mentioned herein are trademarks or trad e

names of their respective companies. For patents covering National Instruments products, refer to the

appropriate location: Help»Patents in your software, the patents.txt file on your CD, or

ni.com/patents.

© 2000–2007 National Instruments Corporation. All rights reserved.

370156C-01 Mar07

Loading...

Loading...