Page 1

TM

SCXI

SCXI-1125 User Manual

SCXI-1125 User Manual

April 2008

372425B-01

Page 2

Support

Worldwide Technical Support and Product Information

ni.com

National Instruments Corporate Headquarters

11500 North Mopac Expressway Austin, Texas 78759-3504 USA Tel: 512 683 0100

Worldwide Offices

Australia 1800 300 800, Austria 43 662 457990-0, Belgium 32 (0) 2 757 0020, Brazil 55 11 3262 3599,

Canada 800 433 3488, China 86 21 5050 9800, Czech Republic 420 224 235 774, Denmark 45 45 76 26 00,

Finland 358 (0) 9 725 72511, France 01 57 66 24 24, Germany 49 89 7413130, India 91 80 41190000,

Israel 972 3 6393737, Italy 39 02 41309277, Japan 0120-527196, Korea 82 02 3451 3400,

Lebanon 961 (0) 1 33 28 28, Malaysia 1800 887710, Mexico 01 800 010 0793, Netherlands 31 (0) 348 433 466,

New Zealand 0800 553 322, Norway 47 (0) 66 90 76 60, Poland 48 22 3390150, Portugal 351 210 311 210,

Russia 7 495 783 6851, Singapore 1800 226 5886, Slovenia 386 3 425 42 00, South Africa 27 0 11 805 8197,

Spain 34 91 640 0085, Sweden 46 (0) 8 587 895 00, Switzerland 41 56 2005151, Taiwan 886 02 2377 2222,

Thailand 662 278 6777, Turkey 90 212 279 3031, United Kingdom 44 (0) 1635 523545

For further support information, refer to the Signal Conditioning Technical Support Information document.

To comment on National Instruments documentation, refer to the National Instruments Web site at

ni.com/info and enter the info code feedback.

© 1999–2008 National Instruments Corporation. All rights reserved.

Page 3

Important Information

Warranty

The SCXI-1125 is warranted against defects in materials and workmanship for a period of one year from the date of shipment, as evidenced

by receipts or other documentation. National Instruments will, at its option, repair or replace equipment that proves to be defective during the

warranty period. This warranty includes parts and labor.

The media on which you receive National Instruments software are warranted not to fail to execute programming instructions, due to defects in

materials and workmanship, for a period of 90 days from date of shipment, as evidenced by receipts or other documentation. National Instruments

will, at its option, repair or replace software media that do not execute programming instruc tions if National Instruments receives notice of such defects

during the warranty period. National Instruments does not warrant that the operation of the software shall be uninterrupted or error free.

A Return Material Authorization (RMA) number must be obtained from the factory and clearly marked on the outside of the package before any

equipment will be accepted for warranty work. National Instruments will pay the shipping costs of returning to the owner parts which are covered by

warranty.

National Instruments believes that the information in this document is accurate. The document has been carefully reviewed for technical accuracy. In

the event that technical or typographical errors exist, National Instruments reserves the right to make changes to subsequent editions of this document

without prior notice to holders of this edition. The reader should consult National Instruments if errors are suspected. In no event shall National

Instruments be liable for any damages arising out of or related to this document or the information contained in it.

E

XCEPT AS SPECIFIED HEREIN, NATIONAL INSTRUMENTS MAKES NO WARRANTIES, EXPRESS OR IMPLIED, AND SPECIFICALLY DISCLAIMS ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. CUSTOMER’S RIGHT TO RECOVER DAMAGES CAUSED BY FAULT OR NEGLIGENCE ON THE PART OF NATIONAL

I

NSTRUMENTS SHALL BE LIMITED TO THE AMOUNT THERETOFORE PAID BY THE CUSTOMER. NATIONAL INSTRUMENTS WILL NOT BE LIABLE FOR DAMAGES RESULTING

FROM LOSS OF DATA, PROFITS, USE OF PRODUCTS, OR INCIDENTAL OR CONSEQUENTIAL DAMAGES, EVEN IF ADVISED OF THE POSSIBILITY THEREOF. This limitation of

the liability of National Instruments will apply regardless of the form of action, whether in contract or tort, including negligence. Any action against

National Instruments must be brought within one year after the cause of action accrues. National Instruments shall not be liable for any delay in

performance due to causes beyond its reasonable control. The warranty provided herein does not cover damages, defects, malfunctions, or service

failures caused by owner’s failure to follow the National Instruments installation, operation, or maintenance instructions; owner’s modification of the

product; owner’s abuse, misuse, or negligent acts; and power failure or surges, fire, flood, accident, actions of third parties, or other events outside

reasonable control.

Copyright

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or mechanical, including photocopying,

recording, storing in an information retrieval system, or translating, in whole or in part, without the prior written consent of National

Instruments Corporation.

National Instruments respects the intellectual property of others, and we ask our users to do the same. NI software is protected by copyright and other

intellectual property laws. Where NI software may be used to reproduce software or other materials belonging to others, you may use NI software only

to reproduce materials that you may reproduce in accordance with the terms of any applicable license or other legal restriction.

Trademarks

National Instruments, NI, ni.com, and LabVIEW are trademarks of National Instruments Corporation. Refer to the Terms of Use section

on

ni.com/legal for more information about National Instruments trademarks.

Other product and company names mentioned herein are trademarks or trade names of their respective companies.

Members of the National Instruments Alliance Partner Program are business entities independent from National Instruments and have no

agency, partnership, or joint-venture relationship with National Instruments.

Patents

For patents covering National Instruments products, refer to the appropriate location: Help»Patents in your software, the patents.txt file

on your media, or

ni.com/patents.

WARNING REGARDING USE OF NATIONAL INSTRUMENTS PRODUCTS

(1) NATIONAL INSTRUMENTS PRODUCTS ARE NOT DESIGNED WITH COMPONENTS AND TESTING FOR A LEVEL OF

RELIABILITY SUITABLE FOR USE IN OR IN CONNECTION WITH SURGICAL IMPLANTS OR AS CRITICAL COMPONENTS IN

ANY LIFE SUPPORT SYSTEMS WHOSE FAILURE TO PERFORM CAN REASONABLY BE EXPECTED TO CAUSE SIGNIFICANT

INJURY TO A HUMAN.

(2) IN ANY APPLICATION, INCLUDING THE ABOVE, RELIABILITY OF OPERATION OF THE SOFTWARE PRODUCTS CAN BE

IMPAIRED BY ADVERSE FACTORS, INCLUDING BUT NOT LIMITED TO FLUCTUATIONS IN ELECTRICAL POWER SUPPLY,

COMPUTER HARDWARE MALFUNCTIONS, COMPUTER OPERATING SYSTEM SOFTWARE FITNESS, FITNESS OF COMPILERS

AND DEVELOPMENT SOFTWARE USED TO DEVELOP AN APPLICATION, INSTALLATION ERRORS, SOFTWARE AND HARDWARE

COMPATIBILITY PROBLEMS, MALFUNCTIONS OR FAILURES OF ELECTRONIC MONITORING OR CONTROL DEVICES,

TRANSIENT FAILURES OF ELECTRONIC SYSTEMS (HARDWARE AND/OR SOFTWARE), UNANTICIPATED USES OR MISUSES, OR

ERRORS ON THE PART OF THE USER OR APPLICATIONS DESIGNER (ADVERSE FACTORS SUCH AS THESE ARE HEREAFTER

COLLECTIVELY TERMED “SYSTEM FAILURES”). ANY APPLICATION WHERE A SYSTEM FAILURE WOULD CREATE A RISK OF

HARM TO PROPERTY OR PERSONS (INCLUDING THE RISK OF BODILY INJURY AND DEATH) SHOULD NOT BE RELIANT SOLELY

UPON ONE FORM OF ELECTRONIC SYSTEM DUE TO THE RISK OF SYSTEM FAILURE. TO AVOID DAMAGE, INJURY, OR DEATH,

THE USER OR APPLICATION DESIGNER MUST TAKE REASONABLY PRUDENT STEPS TO PROTECT AGAINST SYSTEM FAILURES,

INCLUDING BUT NOT LIMITED TO BACK-UP OR SHUT DOWN MECHANISMS. BECAUSE EACH END-USER SYSTEM IS

CUSTOMIZED AND DIFFERS FROM NATIONAL INSTRUMENTS' TESTING PLATFORMS AND BECAUSE A USER OR APPLICATION

DESIGNER MAY USE NATIONAL INSTRUMENTS PRODUCTS IN COMBINATION WITH OTHER PRODUCTS IN A MANNER NOT

EVALUATED OR CONTEMPLATED BY NATIONAL INSTRUMENTS, THE USER OR APPLICATION DESIGNER IS ULTIMATELY

RESPONSIBLE FOR VERIFYING AND VALIDATING THE SUITABILITY OF NATIONAL INSTRUMENTS PRODUCTS WHENEVER

NATIONAL INSTRUMENTS PRODUCTS ARE INCORPORATED IN A SYSTEM OR APPLICATION, INCLUDING, WITHOUT

LIMITATION, THE APPROPRIATE DESIGN, PROCESS AND SAFETY LEVEL OF SUCH SYSTEM OR APPLICATION.

Page 4

Conventions

The following conventions are used in this manual:

< > Angle brackets that contain numbers separated by an ellipsis represent a

range of values associated with a bit or signal name—for example,

P0.<3..0>.

» The » symbol leads you through nested menu items and dialog box options

to a final action. The sequence File»Page Setup»Options directs you to

pull down the File menu, select the Page Setup item, and select Options

from the last dialog box.

This icon denotes a note, which alerts you to important information.

This icon denotes a caution, which advises you of precautions to take to

avoid injury, data loss, or a system crash. When this symbol is marked on a

product, refer to the Read Me First: Safety and Radio-Frequency

Interference for information about precautions to take.

When symbol is marked on a product, it denotes a warning advising you to

take precautions to avoid electrical shock.

When symbol is marked on a product it, denotes a component that may be

hot. Touching this component may result in bodily injury.

bold Bold text denotes items that you must select or click in the software, such

as menu items and dialog box options. Bold text also denotes parameter

names.

italic Italic text denotes variables, emphasis, a cross-reference, or an introduction

to a key concept. Italic text also denotes text that is a placeholder for a word

or value that you must supply.

monospace Text in this font denotes text or characters that you should enter from the

keyboard, sections of code, programming examples, and syntax examples.

This font is also used for the proper names of disk drives, paths, directories,

programs, subprograms, subroutines, device names, functions, operations,

variables, filenames, and extensions.

monospace bold Bold text in this font denotes the messages and responses that the computer

automatically prints to the screen. This font also emphasizes lines of code

that are different from the other examples.

monospace italic

Italic text in this font denotes text that is a placeholder for a word or value

that you must supply.

Page 5

Contents

Chapter 1

About the SCXI-1125

What You Need to Get Started ......................................................................................1-1

National Instruments Documentation ............................................................................1-2

Installing Application Software, NI-DAQ, and the DAQ Device .................................1-4

Installing the SCXI-1125 Module into the SCXI Chassis...............................1-4

Connecting the SCXI-1125 in an SCXI Chassis

to an E/M Series DAQ Device for Multiplexed Scanning ...........................1-4

Connecting the SCXI-1125 in a PXI/SCXI Combination Chassis

to an E/M Series DAQ Device for Multiplexed Scanning ...........................1-4

Connecting the SCXI-1125 to a n E/M Series DAQ Device

for Parallel Scanning ....................................................................................1-5

Verifying the SCXI-1125 Installation in Software ........................................................1-5

Installing SCXI Using NI-DAQmx in Software .............................................1-5

Manually Adding Modules in NI-DAQmx .....................................................1-6

Installing SCXI Using Traditional NI-DAQ (Legacy) in Software ................1-6

Manually Adding Modules in Traditional NI-DAQ (Legacy) ........................1-6

Verifying and Self-Testing the Installation .....................................................1-6

Troubleshooting the Self-Test Verification ...................................................................1-7

Troubleshooting in NI-DAQmx ......................................................................1-7

Chapter 2

Connecting Signals

AC and DC Voltage Connections..................................................................................2-1

Ground-Referenced Signal ..............................................................................2-2

Floating Signal.................................................................................................2-3

AC-Coupling ...................................................................................................2-4

Pin Assignments ............................................................................................................2-5

Temperature Sensor Connection .....................................................................2-7

Rear Signal Connector.....................................................................................2-7

© National Instruments Corporation v SCXI-1125 User Manual

Page 6

Contents

Chapter 3

Configuring and Testing

SCXI-1125 Software-Configurable Settings .................................................................3-1

Common Software-Configurable Settings ...................................................... 3-1

Filter Bandwidth ............................................................................... 3-1

Gain/Input Range.............................................................................. 3-1

Connecting the SCXI-1125 in an SCXI Chassis

to an E/M Series DAQ Device for Multiplexed Scanning........................... 3-2

Connecting the SCXI-1125 in a PXI/SCXI Combination Chassis

to an E/M Series DAQ Device for Multiplexed Scanning........................... 3-2

Configurable Settings in MAX...................................................................................... 3-2

NI-DAQmx ..................................................................................................... 3-3

Creating a Voltage Global Channel or Task..................................... 3-3

Traditional NI-DAQ (Legacy) ........................................................................ 3-4

Configuring Module Property Pages

in Traditional NI-DAQ (Legacy)................................................... 3-5

Creating a Virtual Channel ............................................................... 3-6

Verifying the Signal ...................................................................................................... 3-6

Verifying the Signal in NI-DAQmx Using a Task or Global Channel........... 3-6

Verifying the Signal in Traditional NI-DAQ (Legacy) .................................. 3-7

Verifying the Signal Using Channel Strings .................................... 3-7

Verifying the Signal Using Virtual Channel .................................... 3-8

Chapter 4

Theory of Operation

Gain ............................................................................................................................... 4-1

Filter Bandwidth and Cutoff Frequency ........................................................................ 4-2

Operating in Multiplexed Mode .................................................................................... 4-2

Multiplexed Hardware Operation Theory....................................................... 4-3

Operating in Parallel Mode ........................................................................................... 4-3

Theory of Parallel Hardware Operation.......................................................... 4-4

Chapter 5

Using the SCXI-1125

Temperature Measurements Using Thermocouples...................................................... 5-1

Making High-Voltage Measurements ........................................................................... 5-4

Developing Your Application in NI-DAQmx............................................................... 5-5

Typical Program Flowchart ............................................................................ 5-5

General Discussion of Typical Flowchart....................................................... 5-7

Creating a Task Using DAQ Assistant or Programmatically ........... 5-7

Adjusting Timing and Triggering..................................................... 5-7

SCXI-1125 User Manual vi ni.com

Page 7

Contents

Configuring Channel Properties........................................................5-8

Acquiring, Analyzing, and Presenting ..............................................5-9

Completing the Application ..............................................................5-9

Developing an Application Using LabVIEW..................................................5-9

Using a DAQmx Channel Property Node in LabVIEW ...................5-11

Specifying Channel Strings in NI-DAQmx.....................................................5-12

Text Based ADEs..............................................................................5-14

Measurement Studio (Visual Basic, .NET, and C#)........................................5-14

Programmable NI-DAQmx Properties..............................................5-14

Developing Your Application in Traditional NI-DAQ (Legacy) ..................................5-15

Traditional NI-DAQ (Legacy) in LabVIEW...................................................5-16

Typical Program Flow ......................................................................5-17

Configure the SCXI-1125 Settings Using Traditional NI-DAQ

(Legacy) in LabVIEW ..................................................................................5-18

Configure, Start Acquisition, and Take Readings Using Traditional

NI-DAQ (Legacy) in LabVIEW...................................................................5-19

Convert Scaling Using Traditional NI-DAQ (Legacy) in LabVIEW .............5-20

Analyze and Display Using Traditional NI-DAQ (Legacy) in LabVIEW ...... 5-20

Traditional NI-DAQ (Legacy) in Text-Based ADEs ......................................5-21

Configuring System Settings Using Traditional NI-DAQ (Legacy) C API....5-21

Configure Module Settings Using Traditional NI-DAQ (Legacy) C API ...... 5-22

Perform Offset Null Compensation

Using Traditional NI-DAQ (Legacy) C API ................................................5-23

Perform Acquisition Using Traditional NI-DAQ (Legacy) C API .................5-23

Perform Scaling, Analysis, and Display..........................................................5-24

Using Software for Multiplexed Scanning ......................................................5-24

LabVIEW and the SCXI Channel String ..........................................5-25

LabVIEW and the Virtual Channel String ........................................5-26

Performing a Multiplexed Scan.......................................................................5-27

C and Low-Level DAQ Functions .................................................... 5-28

Using Software for Parallel Scanning .............................................................5-28

LabVIEW and Parallel Mode............................................................5-28

C and Parallel Mode..........................................................................5-29

Other Application Documentation and Material ...........................................................5-29

Traditional NI-DAQ (Legacy) CVI Examples ................................................5-29

Traditional NI-DAQ (Legacy) Measurement Studio Examples......................5-29

Calibration .....................................................................................................................5-30

Calibration Procedures ....................................................................................5-30

One-Point Offset Calibration ............................................................5-31

Two-Point Gain and Offset Calibration ............................................5-32

© National Instruments Corporation vii SCXI-1125 User Manual

Page 8

Contents

Appendix A

Specifications

Appendix B

Using SCXI Channel Strings with Traditional NI-DAQ (Legacy) 7.0

or Later

Appendix C

Removing the SCXI-1125

Appendix D

Common Questions

Glossary

Index

Figures

Figure 2-1. Connecting a Ground-Referenced Signal ............................................. 2-2

Figure 2-2. Connecting a Floating Signal................................................................ 2-3

Figure 2-3. Connecting a Floating AC-Coupled Signal ..........................................2-4

Figure 2-4. Connecting a Ground-Referenced AC-Coupled Signal ........................ 2-4

Figure 4-1. SCXI-1125 Block Diagram................................................................... 4-1

Figure 5-1. Typical Program Flowchart .................................................................. 5-6

Figure 5-2. LabVIEW Channel Property Node with Lowpass Frequency

Set at 10 kHz on Channel SC1Mod1/ai0 .............................................. 5-12

Figure 5-3. Typical SCXI-1125 Program Flow

with Traditional NI-DAQ (Legacy) ...................................................... 5-17

Figure 5-4. Using the AI Parameter VI to Set Up the SCXI-1125 .......................... 5-19

Figure A-1. SCXI-1125 Dimensions ........................................................................ A-7

Figure C-1. Removing the SCXI-1125.....................................................................C-2

SCXI-1125 User Manual viii ni.com

Page 9

Tables

Contents

Table 2-1. Front Signal Pin Assignments ..............................................................2-6

Table 2-2. Rear Signal Pin Assignments ................................................................2-8

Table 5-1. Extended Gain and Range Using the SCXI-1327 or SCXI-1313A....... 5-4

Table 5-2. Extended Gain and Range Using the TBX-1316 ..................................5-5

Table 5-3. NI-DAQmx Properties ..........................................................................5-8

Table 5-4. Programming a Task in LabVIEW........................................................5-10

Table 5-5. NI-DAQmx Properties ..........................................................................5-15

Table 5-6. Settings for Configuring the SCXI-1125

Through the AI Parameter.....................................................................5-18

Table 5-7. Configuration Functions........................................................................5-22

Table 5-8. NI-DAQ Functions Used to Configure SCXI-1125 ..............................5-23

Table 5-9. Gain Values and Input Limits ..............................................................5-31

Table A-1. Input Signal Range Versus Gain ...........................................................A-1

Table A-2. Terminal Block Maximum Voltages.....................................................A-8

Table D-1. Comparison of the SCXI-1125 with the SCXI-1120 ............................D-1

Table D-2. Digital Signals on the SCXI-1125.........................................................D-3

© National Instruments Corporation ix SCXI-1125 User Manual

Page 10

About the SCXI-1125

This chapter introduces the SCXI-1125 module and explains how to install

the software and hardware.

The SCXI-1125 is an eight-channel isolated analog input conditioning

module with programmable gain and filter settings on each channel and

is jumperless. Each channel has 12 programmable gain settings from

1 to 2000 and two programmable filter settings of either 4 Hz or 10 kHz.

Each channel has an external circuit for grounding the inputs that you can

use for offset calibration. An onboard EEPROM provides nonvolatile

storage of software correction constants for both gain and offset.

1

The SCXI-1125 provides up to 300 V

has an input range of up to 1000 VDC when using an appropriate attenuator

terminal block. The SCXI-1125 supports both multiplexed and parallel

output modes and includes a cold-junction compensation (CJC) channel

that you can scan in multiplexed mode.

What You Need to Get Started

To set up and use the SCXI-1125 module, you need the following:

❑ Hardware

– SCXI-1125 module

– One of the following terminal blocks:

• SCXI-1305

• SCXI-1313A

• SCXI-1320

• SCXI-1327

• SCXI-1328

• SCXI-1338

• TBX-1316

• TBX-1328

• TBX-1329

working isolation per channel and

rms

© National Instruments Corporation 1-1 SCXI-1125 User Manual

Page 11

Chapter 1 About the SCXI-1125

Note For maximum allowable voltage for a particular terminal block refer to Table A-2,

Terminal Block Maximum Voltages.

– SCXI or PXI/SCXI combination chassis

– One of the following:

• E/M Series DAQ device

• SCXI-1600 module

– A computer if using an SCXI chassis

– Cabling, cable adapter, and sensors as required for your

application

❑ Software

– NI-DAQ 7.0 or later

– One of the following software packages:

•LabVIEW

™

• LabWindows

• Measurement Studio

/CVI

™

❑ Documentation

– Read Me First: Safety and Radio-Frequency Interference

– DAQ Getting Started Guide

– SCXI Quick Start Guide

– SCXI-1125 User Manual

– Documentation for your hardware

– Documentation for your software

National Instruments Documentation

The SCXI-1125 User Manual is one piece of the documentation set for data

acquisition (DAQ) systems. You could have any of several types of

manuals depending on the hardware and software in the system. Use the

manuals you have as follows:

• SCXI or PXI chassis manual—Read this manual for maintenance

information on the chassis and for installation instructions.

• The DAQ Getting Started Guide—This document has information on

installing NI-DAQ and the E/M Series DAQ device. Install these

before you install the SCXI module.

SCXI-1125 User Manual 1-2 ni.com

Page 12

Chapter 1 About the SCXI-1125

• The SCXI Quick Start Guide—This document contains a quick

overview for setting up an SCXI chassis, installing SCXI modules and

terminal blocks, and attaching sensors. It also describes setting up the

SCXI system in MAX.

• The SCXI hardware user manuals—Read these manuals next

for detailed information about signal connections and module

configuration. They also explain, in greater detail, how the module

works and contain application hints.

• Accessory installation guides or manuals—If you are using accessory

products, read the terminal block and cable assembly installation

guides. They explain how to physically connect the relevant pieces

of the system. Consult these guides when you are making the

connections.

• The E/M Series DAQ device documentation—This documentation has

detailed information about the E/M Series DAQ device that plugs into

or is connected to the computer. Use this documentation for hardware

installation and configuration instructions, specification information

about the E/M Series DAQ device, and application hints.

• Software documentation—You may have both application software

and NI-DAQ software documentation. National Instruments (NI)

application software includes LabVIEW, LabWindows/CVI, and

Measurement Studio. After you set up the hardware system, use either

your application software documentation or the NI-DAQ

documentation to help you write your application. If you have a large,

complex system, it is worthwhile to look through the software

documentation before you configure the hardware.

• One or more of the following help files for software information:

– Start»Programs»National Instruments»NI-DAQ»

NI-DAQmx Help

– Start»Programs»National Instruments»NI-DAQ»

Traditional NI-DAQ User Manual

– Start»Programs»National Instruments»NI-DAQ»

Traditional NI-DAQ Function Reference Help

• NI application notes or tutorials—NI has additional material on

measurements available at

ni.com/support.

You can download NI documents from

the latest version of NI-DAQ, click Drivers and Updates at

© National Instruments Corporation 1-3 SCXI-1125 User Manual

ni.com/manuals. To download

ni.com.

Page 13

Chapter 1 About the SCXI-1125

Installing Application Software, NI-DAQ, and the DAQ Device

Refer to the DAQ Getting Started Guide packaged with the NI-DAQ

software to install your application software, NI-DAQ driver software, and

the DAQ device to which you will connect the SCXI-1125. NI-DAQ 7.0 or

later is required to configure and program the SCXI-1125 module. If you

do not have NI-DAQ 7.0 or later, you can either contact a NI sales

representative to request it on a CD or download the latest NI-DAQ version

from

ni.com.

Note Refer to the Read Me First: Safety and Radio-Frequency Interference document

before removing equipment covers or connecting or disconnecting any signal wires.

Installing the SCXI-1125 Module into the SCXI Chassis

Refer to the SCXI Quick Start Guide to install your SCXI-1125 module.

Connecting the SCXI-1125 in an SCXI Chassis to an E/M Series DAQ Device for Multiplexed Scanning

Refer to the SCXI Quick Start Guide to install the cable adapter and connect

the SCXI modules to the DAQ device.

If you have already installed the appropriate software, refer to Chapter 3,

Configuring and Testing, to configure the SCXI-1125 module(s).

Connecting the SCXI-1125 in a PXI/SCXI Combination Chassis to an E/M Series DAQ Device for Multiplexed Scanning

Refer to the SCXI Quick Start Guide to connect the SCXI modules to the

DAQ device.

If you have already installed the appropriate software, refer to Chapter 3,

Configuring and Testing, to configure the SCXI-1125 module(s).

SCXI-1125 User Manual 1-4 ni.com

Page 14

Chapter 1 About the SCXI-1125

Connecting the SCXI-1125 to a n E/M Series DAQ Device for Parallel Scanning

This configuration allows you to route all eight channels of the SCXI-1125

in parallel to eight input channels of the E/M Series DAQ device to which

it is connected. In this mode, you cannot directly access the CJC channel.

Use this mode if you require a higher scanning rate than an SCXI system in

multiplexed mode allows.

If you have not already installed all the modules, refer to the Installing the

SCXI-1125 Module into the SCXI Chassis section, then complete the

following steps:

1. Power off the SCXI chassis and the computer that contains the

E/M Series DAQ device.

2. Insert the cable adapter into the rear of the SCXI-1125 module that is

to be accessed in parallel mode by the E/M Series DAQ device. Refer

to the installation guide for the cable assembly for more information.

3. Connect the cable to the back of the cable adapter ensuring that the

cable fits securely.

4. Connect the other end of the cable to the E/M Series DAQ device that

you want to use to access the SCXI-1125 in parallel mode.

5. Connect additional SCXI-1125 modules intended for parallel mode

operation by repeating steps 2 through 4.

6. Check the installation, making sure the cable is securely fastened at

both ends.

7. Power on the SCXI chassis.

8. Power on the computer.

If you have already installed the appropriate software, you are ready to

configure the SCXI-1125 module(s) you installed for parallel mode

operation.

Verifying the SCXI-1125 Installation in Software

Refer to the SCXI Quick Start Guide for information on verifying the SCXI

installation.

Installing SCXI Using NI-DAQmx in Software

Refer to the SCXI Quick Start Guide for information on installing modules

using NI-DAQmx in software.

© National Instruments Corporation 1-5 SCXI-1125 User Manual

Page 15

Chapter 1 About the SCXI-1125

Manually Adding Modules in NI-DAQmx

If you did not auto-detect the SCXI modules, you must manually add each

of the modules. Refer to the SCXI Quick Start Guide to manually add

modules.

Note NI recommends auto-detecting modules for the first time configuration of the

chassis.

Installing SCXI Using Traditional NI-DAQ (Legacy) in Software

Refer to the SCXI Quick Start Guide for information on installing modules

using Traditional NI-DAQ (Legacy) in software.

Manually Adding Modules in Traditional NI-DAQ (Legacy)

If you did not auto-detect the SCXI modules, you must manually add each

of the modules. Refer to the SCXI Quick Start Guide to manually add

modules.

Note NI recommends auto-detecting modules for the first time configuration of the

chassis.

Verifying and Self-Testing the Installation

The verification procedure for the SCXI chassis is the same for both

NI-DAQmx and Traditional NI-DAQ (Legacy). To test the successful

installation for the SCXI chassis, refer to the SCXI Quick Start Guide.

Verify that the chassis is powered on and correctly connected to an

E/M Series DAQ device.

After verifying and self-testing the installation, the SCXI system should

operate properly with your ADE software. If the test did not complete

successfully, refer to Chapter 3, Configuring and Testing, for

troubleshooting steps.

SCXI-1125 User Manual 1-6 ni.com

Page 16

Chapter 1 About the SCXI-1125

Troubleshooting the Self-Test Verification

If the Self-Test Verification did not verify the chassis configuration,

complete the steps in this section to troubleshoot the SCXI configuration.

Troubleshooting in NI-DAQmx

• If you get a Verify SCXI Chassis message box showing the SCXI

chassis model number, Chassis ID: x, and one or more messages

stating Slot Number: x Configuration has module: SCXI-XXXX

or 1125, hardware in chassis is: Empty, take the following

troubleshooting actions:

– Make sure the SCXI chassis is powered on.

– Make sure all SCXI modules are properly installed in the chassis.

Refer to the SCXI Quick Start Guide for proper installation

instructions.

– Make sure the cable between the SCXI chassis and E/M Series

DAQ device is properly connected.

– Inspect the cable connectors for bent pins.

– Make sure you are using the correct NI cable assembly.

– Test the E/M Series DAQ device to verify it is working properly.

Refer to the E/M Series DAQ device help file for more

information.

• If you get a Verify SCXI Chassis message box showing the SCXI

chassis model number, Chassis ID: x, and the message Slot

Number: x Configuration has module: SCXI-XXXX or 1125,

hardware in chassis is: SCXI-YYYY, 1125, or Empty, complete the

following troubleshooting steps to correct the error.

1. Expand the list of NI-DAQmx devices by clicking the + next to

NI-DAQmx Devices.

2. Right-click the SCXI chassis and click Properties to load the

chassis configurator.

3. Under the Modules tab, ensure that the cabled module is listed in

the correct slot.

4. If the cabled module is not listed in the correct slot, complete the

following troubleshooting steps:

a. If the cabled module is not listed in the correct slot and the

slot is empty, click the drop-down listbox next to the correct

slot and select the cabled module. Configure the cabled

© National Instruments Corporation 1-7 SCXI-1125 User Manual

Page 17

Chapter 1 About the SCXI-1125

module following the steps listed in the SCXI Quick Start

Guide. Click OK.

b. If another module appears where the cabled module should

be, click the drop-down listbox next to the correct slot and

select the cabled module. A message box appears asking you

to confirm the module replacement. Click OK. Configure the

cabled module following the steps listed in the SCXI Quick

Start Guide. Click OK.

• Ensure that you have the highest priority SCXI module cabled to the

E/M Series DAQ device. Refer to the SCXI Quick Start Guide to find

out which SCXI module in the chassis should be cabled to the

E/M Series DAQ device.

• After checking the preceding items, return to the Troubleshooting the

Self-Test Verification section and retest the SCXI chassis.

If these measures do not successfully configure the SCXI system, contact

NI. Refer to the Signal Conditioning Technical Support Information

document for contact information.

SCXI-1125 User Manual 1-8 ni.com

Page 18

Connecting Signals

This chapter describes the input and output signals connections to the

SCXI-1125 module with the module front connector and the rear signal

connector. This chapter also includes specifications and connection

instructions for the signals on the SCXI-1125 module connectors.

Notes Refer to the Read Me First: Safety and Radio-Frequency Interference document

before removing equipment covers or connecting or disconnecting any signal wires.

For EMC compliance, operate this device with shielded cabling.

The isolated channels of the SCXI-1125 allow you to make precision

high-voltage measurements or low-voltage measurement of signals riding

on high common-mode voltages while protecting sensitive computer parts

and equipment connected to the module. The isolated amplifiers fulfill

two purposes on the SCXI-1125 module. First, they can convert a small

signal riding on a high common-mode voltage into a single-ended signal

with respect to the SCXI-1125 chassis ground. With this conversion, you

can extract the analog input signal from a high common-mode voltage

before sampling by the E/M Series DAQ device. Second, the isolation

amplifier amplifies and filters an input signal resulting in increased

measurement resolution and accuracy. The following sections explain how

to make signal connections to maximize the effectiveness of the

SCXI-1125 for conditioning analog signals.

2

AC and DC Voltage Connections

You can make input signal connections to the SCXI-1125 through the front

signal connector or through accessory terminal blocks. Chapter 1, About

the SCXI-1125, contains a list of SCXI-1125-compatible terminal blocks.

Terminal blocks have features such as screw-terminal connectivity, BNC

connectivity, cold-junction temperature measurement, and attenuation.

The pin assignment for the SCXI-1125 front signal connector is shown in

Table 2-1. The positive input terminal for each channel is in Column A and

the negative input terminal for each channel is in Column C. Input

connections to each channel are fully floating with respect to ground and

© National Instruments Corporation 2-1 SCXI-1125 User Manual

Page 19

Chapter 2 Connecting Signals

completely isolated from other channels. You can operate with

common-mode voltage levels up to 300 V

Figures 2-1 through 2-4 show signal connection methods that give the

highest noise immunity.

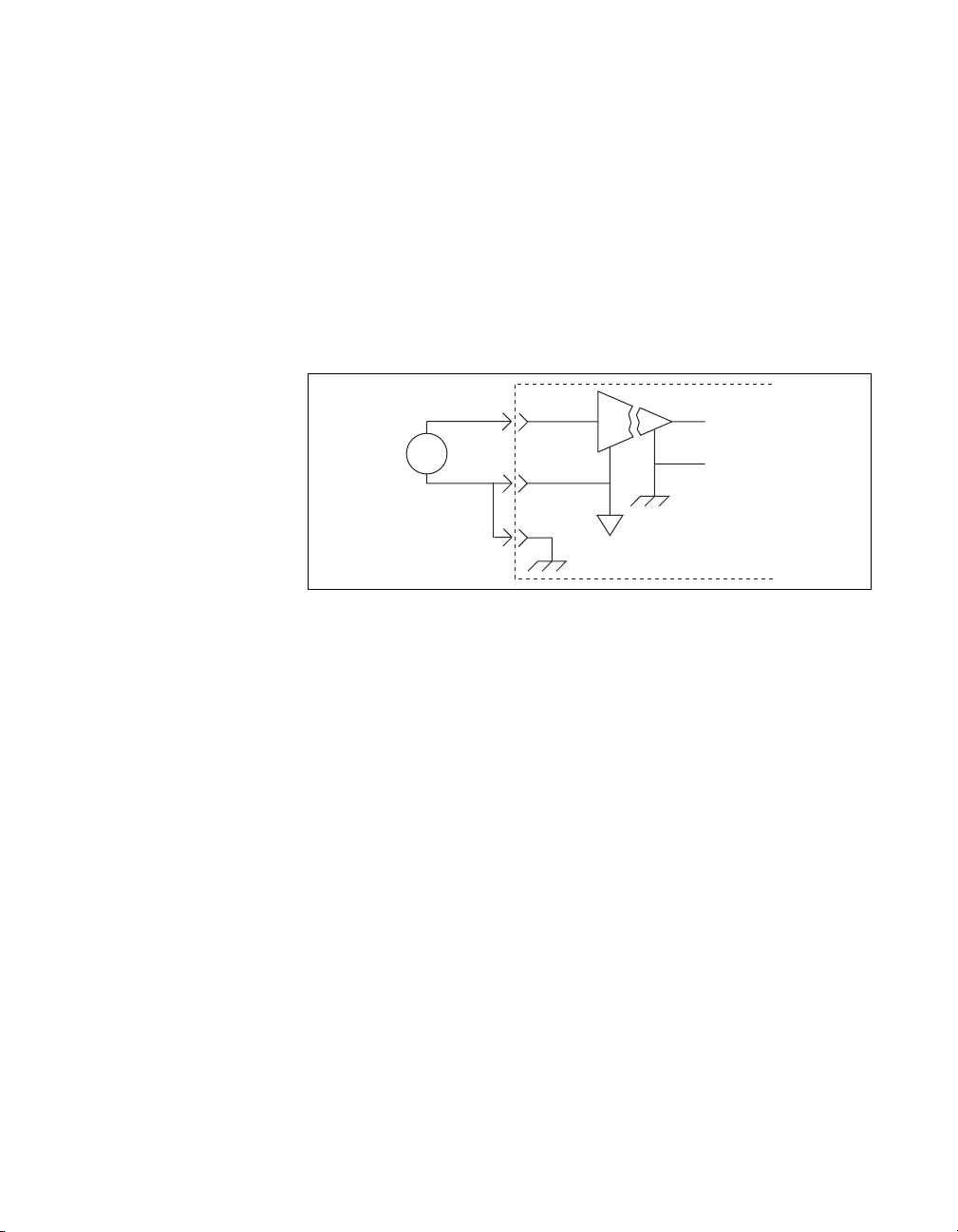

Ground-Referenced Signal

When the negative input signal line is connected either directly or

indirectly to earth ground (usually at the transducer end), connect this line

to the negative input terminal, as shown in Figure 2-1. No ground

connection is made at the SCXI-1125. This situation includes cases where

a floating source can be riding on a high common-mode voltage that is

ground referenced.

rms

.

+

V

s

–

+

V

High

cm

CMV

–

+

I

Module

+

V

out

–

Figure 2-1. Connecting a Ground-Referenced Signal

SCXI-1125 User Manual 2-2 ni.com

Page 20

Floating Signal

Chapter 2 Connecting Signals

In cases where both signal lines at the transducer end are floating and no

common-mode voltage exists, establish an earth connection at the

SCXI-1125 by connecting the negative input line to chassis ground in the

terminal block, as shown in Figure 2-2. This eliminates noise that can ride

on the floating signal. If the floating signal is not configured like

Figure 2-2, the noise can couple to the chassis ground through the amplifier

and exhibit a differential mode signal that can be amplified by the

amplifier. Connecting the signal to chassis ground breaks the isolation

barrier.

+

V

s

–

+

I

Module

Figure 2-2. Connecting a Floating Signal

+

V

out

–

© National Instruments Corporation 2-3 SCXI-1125 User Manual

Page 21

Chapter 2 Connecting Signals

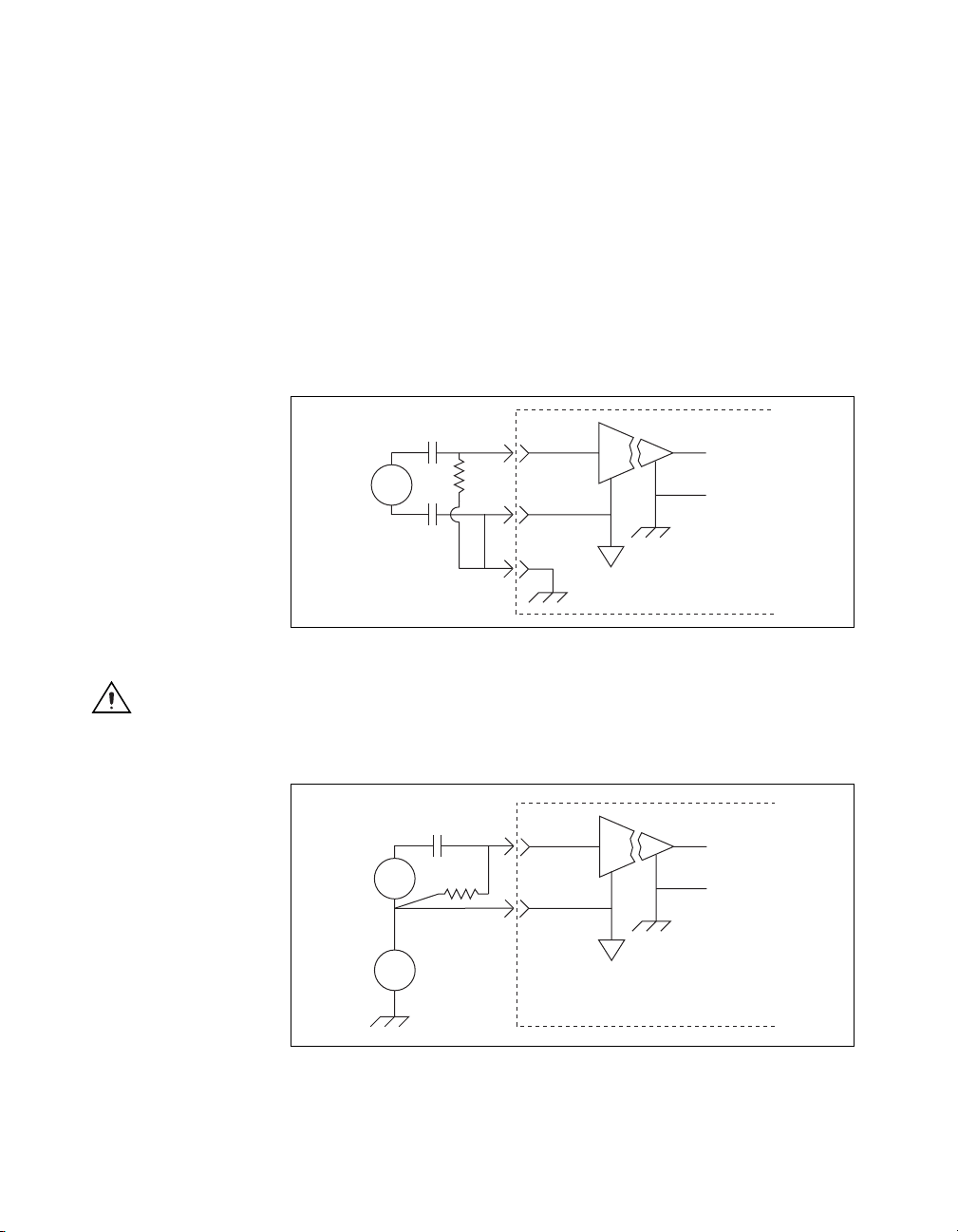

AC-Coupling

You can have an application where you wish to measure only AC voltages

and remove the DC component of a signal before amplification and

sampling. In such cases, you can connect a capacitor in series with one or

both input terminals of the SCXI-1125, as shown in Figures 2-3 and 2-4.

A resistor is connected across the input terminals of the channel to DC

reference the input stage of the SCXI-1125. You do not need to use a bias

resistor with any high-voltage terminal blocks, since the terminal blocks

already have a resistor between the input terminals, or with the SCXI-1305

BNC connectivity terminal block, since this terminal block already has an

AC-coupling option built in.

Caution

Connecting a signal source to chassis ground in Figures 2-2 and 2-3, breaks the

isolation barrier.

+

V

s

–

R

bias

+

I

Module

+

V

–

Figure 2-3. Connecting a Floating AC-Coupled Signal

+

R

–

+

–

bias

High

CMV

V

s

V

cm

+

I

Module

+

–

out

V

out

Figure 2-4. Connecting a Ground-Referenced AC-Coupled Signal

SCXI-1125 User Manual 2-4 ni.com

Page 22

The value of the bias resistor should be between 100 kΩ and 1 MΩ . An

added DC offset voltage results, due to input bias current flowing through

the bias resistor. For example, with a 1 MΩ bias resistor and the specified

maximum input bias current of 1 nA, you have a maximum added input

offset voltage of ±1 mV in addition to the initial offset voltage.

Since only the AC signal is of interest when AC-coupling, you can choose

to remove the DC offset in software by using a simple highpass filter.

Caution Pins A2, A4, A8, C2, C4, C6, and C8 on the front signal connector are not isolated

and do not have the same protection circuitry as the positive and negative analog input pairs

discussed in the Floating Signal section. Hooking up external signals to these pins can

damage the SCXI-1125 module.

Pin Assignments

The front signal connector is a special 32-pin DIN C male front connector

used for connecting analog input signals, including the CJC, to the analog

circuitry of the SCXI-1125. This connection allows access to the eight

differential analog input signals. The positive terminal is AIx + and the

negative terminal AIx –. A missing pin exists between two consecutive

input channels to meet the UL spacing requirements for high voltage

signals. CJ TEMP is the signal connection used by the cold-junction

channel on the SCXI-1125. The signals on pins A6, A8, C6, and C8 are

reserved for serial communication. The +5 V signal and CHS GND signals

are used as the power supply and ground signals for the CJC sensor and

other circuitry on the terminal block. The pin assignments for the

SCXI-1125 front signal connection are shown in Table 2-1.

Chapter 2 Connecting Signals

Caution Do not make signal connections to pins A2, A4, A6, A8, C2, C4, C6, or C8 on the

front signal connector. Connecting external signals to these pins can damage the

SCXI-1125 Module.

© National Instruments Corporation 2-5 SCXI-1125 User Manual

Page 23

Chapter 2 Connecting Signals

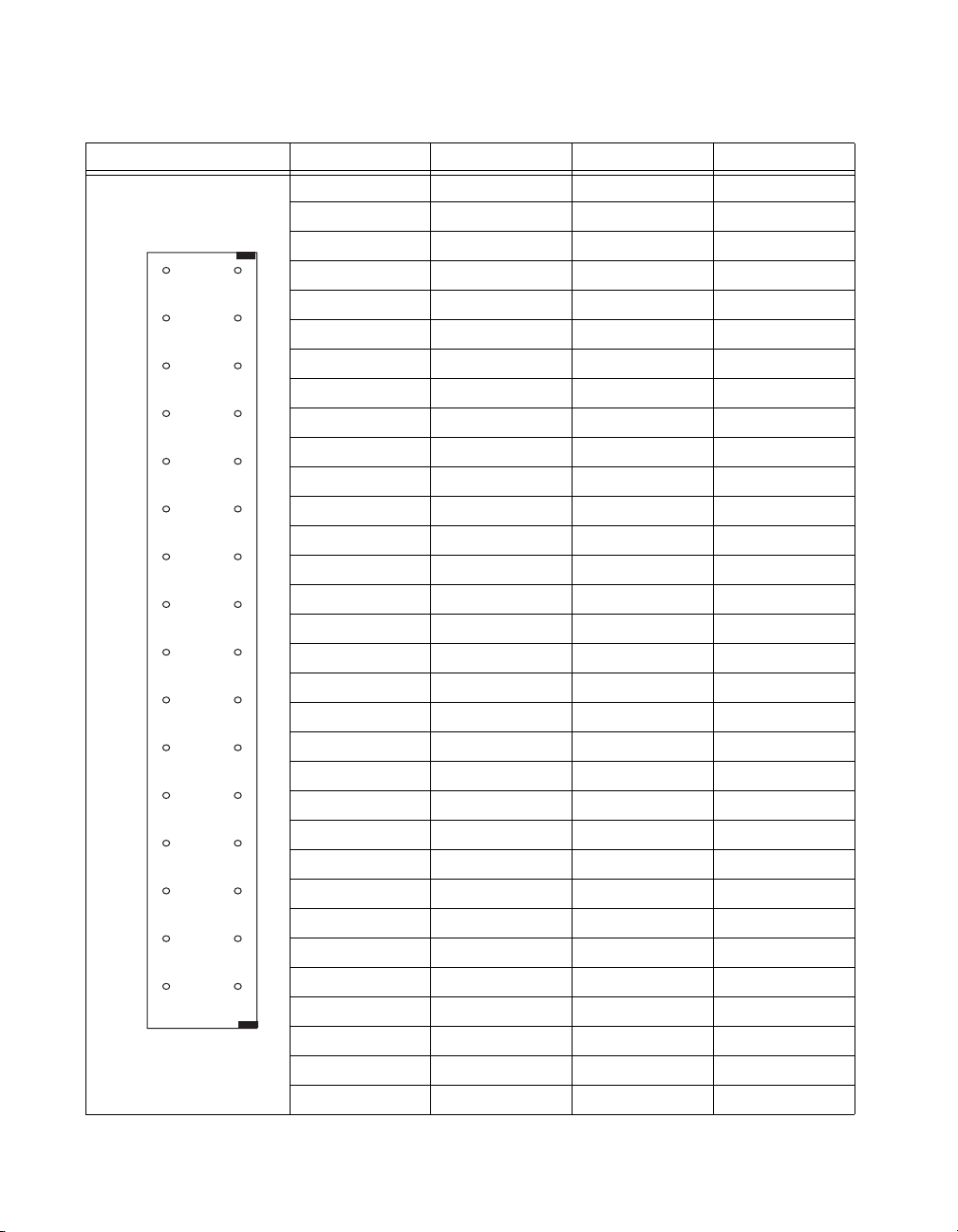

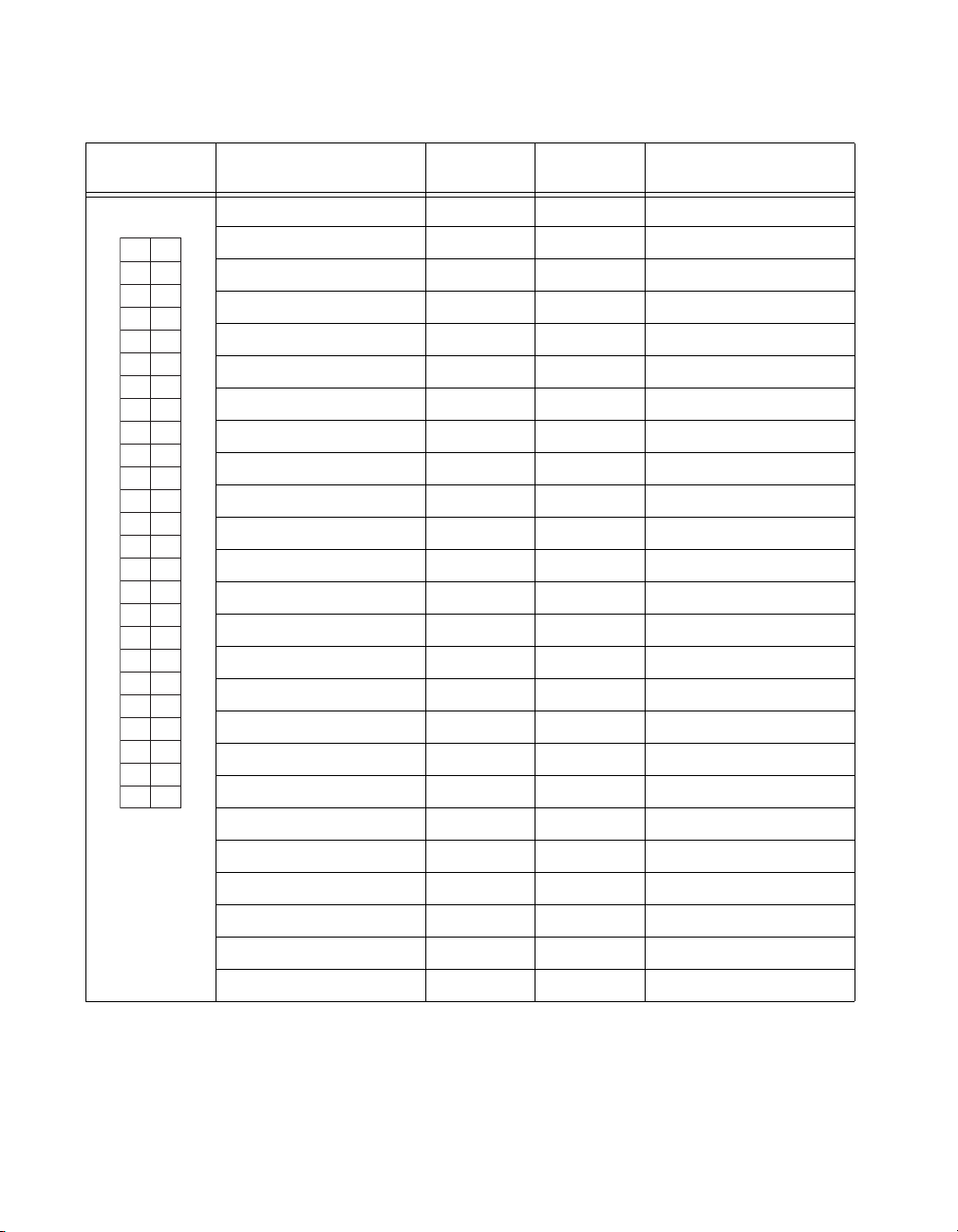

Table 2-1. Front Signal Pin Assignments

Front Connector Diagram Pin Number Column A Column B Column C

32 AI 0 + — AI 0 –

Column

A B C

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

NC means no connection

— means no pin

31 — — —

30 AI 1 + — AI 1 –

29 — — —

28 NC — NC

27 — — —

26 AI 2 + — AI 2 –

25 — — —

24 AI 3 + — AI 3 –

23 — — —

22 NC — NC

21 — — —

20 AI 4 + — AI 4 –

19 — — —

18 AI 5 + — AI 5 –

17 — — —

16 NC — NC

15 — — —

14 AI 6 + — AI 6 –

13 — — —

12 AI 7 + — AI 7 –

11 — — —

10 NC — NC

9 — — —

8 RSVD — RSVD

7 — — —

6 RSVD — RSVD

5 — — —

4 +5 V — CJ TEMP

3 — — —

2 CHS GND — RSVD

1 — — —

SCXI-1125 User Manual 2-6 ni.com

Page 24

Temperature Sensor Connection

Pin C4 on the front signal connector is used to connect to a terminal block

temperature sensor. The temperature sensor channel is not isolated and is

referenced to the chassis ground. The connection is overvoltage protected

to ±25 VDC with power on and ±15 VDC with power off.

Rear Signal Connector

The rear signal connector is a 50-pin male ribbon cable connector used for

analog signal connectivity and communication between the

SCXI-1125 and the connected DAQ device. The rear signal connector

allows the DAQ device to access all eight differential analog output signals

from the SCXI-1125. The positive terminal of each analog output is

CH x + and the negative terminal CH x –. Grounding signals, AI GND

and OUT REF, provide reference signals needed in the various analog

referencing modes on the E/M Series DAQ device. In multiplexed mode,

the CH 0 signal pair is used for sending all eight channels of the

SCXI-1125, and other analog signals from other modules, to the connected

E/M Series DAQ device. If the module is directly connected to the E/M

Series DAQ device, the other analog channels of the E/M Series DAQ

device are still unavailable for general-purpose analog input because they

are still connected to the amplifier outputs of the SCXI-1125 in multiplexed

mode.

Chapter 2 Connecting Signals

The communication signals between the DAQ device and the SCXI system

are SER DAT IN, SER DAT OUT, DAQ D*/A, SLOT 0 SEL*, SER CLK,

and AI HOLD COMP, AI HOLD. The digital ground, D GND on pins 24

and 33, provides a separate ground reference for the communication

signals. SER DAT IN, SER DAT OUT, DAQ D*/A, SLOT 0 SEL*, and

SER CLK are the communication lines for programming the SCXI-1125.

The AI HOLD COMP, AI HOLD and SYNC signals are the signals

necessary for multiplexed mode scanning. If the E/M Series DAQ device is

connected to the SCXI-1125, these digital lines are unavailable for

general-purpose digital I/O. The rear signal pin assignments are shown in

Table 2-2.

© National Instruments Corporation 2-7 SCXI-1125 User Manual

Page 25

Chapter 2 Connecting Signals

Rear Connector

Diagram

Table 2-2. Rear Signal Pin Assignments

Signal Name Pin Number Pin Number Signal Name

AI GND 1 2 AI GND

12

34

56

78

910

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25 26

27 28

29 30

31 32

33 34

35 36

37 38

39 40

41 42

43 44

45 46

47 48

49 50

NC means no

connection

CH 0 + 3 4 CH 0 –

CH 1 + 5 6 CH 1–

CH 2 + 7 8 CH 2 –

CH 3 + 9 10 CH 3 –

CH 4 + 11 12 CH 4 –

CH 5 + 13 14 CH 5 –

CH 6 + 15 16 CH 6 –

CH 7 + 17 18 CH 7 –

OUT REF 19 20 NC

NC 21 22 NC

NC 23 24 D GND

SER DAT IN 25 26 SER DAT OUT

DAQ D*/A 27 28 NC

SLOT 0 SEL* 29 30 NC

NC 31 32 NC

D GND 33 34 NC

NC 35 36 AI HOLD COMP, AI HOLD

SER CLK 37 38 NC

NC 39 40 NC

NC 41 42 NC

NC 43 44 NC

NC 45 46 SYNC

NC 47 48 NC

NC 49 50 NC

SCXI-1125 User Manual 2-8 ni.com

Page 26

Configuring and Testing

This chapter discusses configuring the SCXI-1125 in MAX for use with

either NI-DAQmx or Traditional NI-DAQ (Legacy), creating and testing a

virtual channel, global channel or task. For more information on the

relationship between the settings and the measurements and how to

configure settings in your application, refer to Chapter 4, Theory of

Operation.

SCXI-1125 Software-Configurable Settings

This section describes the common software configurable settings and how

to verify the signal using both NI-DAQmx and Traditional NI-DAQ

(Legacy).

Common Software-Configurable Settings

This section describes the most frequently used software-configurable

settings for the SCXI-1125. Refer to Chapter 4, Theory of Operation, for a

complete list of software-configurable settings.

3

Filter Bandwidth

Filter bandwidth is a software-configurable setting that allows you to select

a lowpass filter cutoff frequency. You can choose 4.0 Hz or 10 kHz.

Gain/Input Range

Gain/input range is a software-configurable setting that allows you to

choose the appropriate amplification to fully utilize the range of the

E/M Series DAQ device. In most applications NI-DAQ chooses and sets

the gain for you determined by the input range.

© National Instruments Corporation 3-1 SCXI-1125 User Manual

Page 27

Chapter 3 Configuring and Testing

Connecting the SCXI-1125 in an SCXI Chassis to an E/M Series DAQ Device for Multiplexed Scanning

Refer to the SCXI Quick Start Guide to install the cable adapter and connect

the SCXI modules to the DAQ device.

If you have already installed the appropriate software, refer to Chapter 3,

Configuring and Testing, to configure the SCXI-1125 module(s).

Connecting the SCXI-1125 in a PXI/SCXI Combination Chassis to an E/M Series DAQ Device for Multiplexed Scanning

Refer to the SCXI Quick Start Guide to connect the SCXI modules to the

DAQ device.

If you have already installed the appropriate software, refer to Chapter 3,

Configuring and Testing, to configure the SCXI-1125 module(s).

Configurable Settings in MAX

Note If you are not using an NI ADE, using an NI ADE prior to version 7.0, or are using

an unlicensed copy of an NI ADE, additional dialog boxes from the NI License Manager

appear allowing you to create a task or global channel in unlicensed mode. These messages

continue to appear until you install version 7.0 or later of an NI ADE.

This section describes where users can access each software-configurable

setting for modification in MAX. The location of the settings varies

depending on the version of NI-DAQ you use. Refer to either the

NI-DAQmx section or the Traditional NI-DAQ (Legacy) section. You also

can refer to the DAQ Getting Started Guide and the SCXI Quick Start Guide

for more information on installing and configuring your hardware. You also

can use the DAQ Assistant to graphically configure common measurement

tasks, channels, or scales.

SCXI-1125 User Manual 3-2 ni.com

Page 28

NI-DAQmx

Note All software-configurable settings are not configurable both ways. This section only

discusses settings in MAX. Refer to Chapter 4, Theory of Operation, for information on

using functions in your application.

Chapter 3 Configuring and Testing

In NI-DAQmx, you can configure software settings such as filter

bandwidth and gain/input signal range in the following ways:

• Task or global channel in MAX

• Functions in your application

These sections describe settings that you can change in MAX and where

they are located.

• Filter bandwidth—configure the Device tab using either NI-DAQmx

Task or NI-DAQmx Global Channel. You also can set the value

through your application.

• Input signal range—configure the input signal range using either

NI-DAQmx Task or NI-DAQmx Global Channel. When you set the

minimum and maximum range of NI-DAQmx Task or NI-DAQmx

Global Channel, the driver selects the best gain for the measurement.

You also can set it through your application.

• Modes of operation—configure only using chassis installation in

software. Refer to Chapter 1, About the SCXI-1125, for more

information on chassis installation. The default setting in NI-DAQmx

is multiplexed.

• Terminal block attenuation—for terminal blocks with manually

adjustable attenuation such as the SCXI-1327, you must configure the

attenuator in the chassis configurator. Refer to the SCXI Quick Start

Guide for more information.

Note Refer to Chapter 4, Theory of Operation, for information on configuring the settings

for your application using Traditional NI-DAQ (Legacy).

Creating a Voltage Global Channel or Task

To create a new NI-DAQmx global task or channel, complete the following

steps:

1. Double-click Measurement & Automation on the desktop.

2. Right-click Data Neighborhood and select Create New.

3. Select NI-DAQmx Task or NI-DAQmx Global Channel, and click

Next.

© National Instruments Corporation 3-3 SCXI-1125 User Manual

Page 29

Chapter 3 Configuring and Testing

4. Select Analog Input.

5. Select Voltage.

6. If you are creating a task, you can select a range of channels by holding

7. Name the task or channel and click Finish.

8. In the box labelled Channel List, select the channel(s) you want to

9. Enter the specific values for your application in the Settings tab.

10. Click the Device tab and select the autozero mode and lowpass filter

11. If you are creating a task and want to set timing or triggering controls,

down the <Shift> key while selecting the channels. You can select

multiple individual channels by holding down the <Ctrl> key while

selecting channels. If you are creating a channel, you can only select

one channel. Click Next.

configure. You can select a range of channels by holding down the

<Shift> key while selecting the channels. You can select multiple

individual channels by holding down the <Ctrl> key while selecting

channels.

Context help information for each setting is provided on the right side

of the screen. Refer to Chapter 3, Configuring and Testing, for more

information.

cutoff frequency.

enter the values in the Task Timing and Task Triggering tabs.

Traditional NI-DAQ (Legacy)

In Traditional NI-DAQ (Legacy), you can configure software settings, such

as configuration, voltage excitation level, filter bandwidth, gain/input

signal range, and calibration settings in the following three ways:

• module property pages in MAX

• virtual channels properties in MAX

• functions in your ADE

Note All software-configurable settings are not configurable in all three ways. This

section only discusses settings in MAX. Refer to Chapter 4, Theory of Operation, for

information on using functions in your application.

Most of these settings are available in module properties and/or using

virtual channels:

• Filter bandwidth—configure only using module properties. You also

can set bandwidth through your application. The default filter

bandwidth level for Traditional NI-DAQ (Legacy) is 4 Hz.

SCXI-1125 User Manual 3-4 ni.com

Page 30

Chapter 3 Configuring and Testing

• Gain/input signal range—configure gain using module properties.

When you set the minimum and maximum range of the virtual

channel, the driver selects the best gain. The default gain setting

for Traditional NI-DAQ (Legacy) is 1000.

• Terminal block gain—this setting is only configurable if you selected

a terminal block that supports adjustable attenuation.

• Modes of operation—configure only using module properties. The

default setting in Traditional NI-DAQ (Legacy) is multiplexed mode.

Note Refer to Chapter 4, Theory of Operation, for information on configuring the settings

for your application using Traditional NI-DAQ (Legacy).

Configuring Module Property Pages in Traditional NI-DAQ (Legacy)

1. Right-click the SCXI-1125 module you want to configure and select

Properties. Click General.

2. If the module you are configuring is connected to an E Series DAQ

device, select that device by using Connected to. If you want this

E Series DAQ device to control the chassis, confirm there is a check in

the This device will control the chassis checkbox. If the module you

are configuring is not connected to an E Series DAQ device, select

None.

3. Click the Channel tab. Select the appropriate gain and filter for each

channel. If you want to configure all the channels at the same time,

select the Channel drop-down menu, scroll to the bottom, and select

All Channels. Refer to the SCXI-1125 Software-Configurable Settings

section for a detailed description of each setting. Click Apply.

4. Click Accessory. Select the accessory you connected to the module. If

the accessory has a configurable gain, select the desired gain. When

configuration is complete, click OK.

The Traditional NI-DAQ (Legacy) chassis and SCXI-1125 should now be

configured properly. If you need to change the module configuration,

right-click the module and repeat steps 1 through 4. Test the system

following the steps in the Troubleshooting the Self-Test Verification

section of Chapter 1, About the SCXI-1125.

© National Instruments Corporation 3-5 SCXI-1125 User Manual

Page 31

Chapter 3 Configuring and Testing

Creating a Virtual Channel

To create a virtual channel, complete the following steps:

1. Right-click Data Neighborhood and select Create New.

2. Select Traditional NI-DAQ Virtual Channel and click Finish.

3. Click Add Channel.

4. Select Analog Input from the drop-down list and click Next.

5. Enter the Channel Name and Channel Description, and click Next.

6. Select Voltage from the drop-down list and click Next.

7. Enter the units and input range, and click Next.

8. Select the appropriate scaling option and click Next.

9. Enter the following information:

10. What DAQ hardware will be used? from the drop-down list.

11. Click Finish.

a. What channel on your DAQ hardware? from the drop-down list.

b. Which analog input mode will be used? from the drop-down list.

Verifying the Signal

This section describes how to take measurements using test panels in order

to verify signal, and configuring and installing a system in NI-DAQmx and

Traditional NI-DAQ (Legacy).

Verifying the Signal in NI-DAQmx Using a Task or Global Channel

You can verify the signals on the SCXI-1125 using NI-DAQmx by

completing the following steps:

1. Expand Data Neighborhood.

2. Expand NI-DAQmx Tasks.

3. Click the task.

4. Click the Add Channels or Remove Channels button to add/remove

channels.

5. In the window that appears, click the + next to the module of interest.

6. Select the channel(s) you want to verify. You can select a block of

channels by holding down the <Shift> key or multiple channels by

holding down the <Ctrl> key. Click OK.

7. Enter the appropriate information on the Settings tab.

SCXI-1125 User Manual 3-6 ni.com

Page 32

8. Click the Device tab.

9. Enter the appropriate information on the Device tab.

10. Click the Test button.

11. Click the Start button.

12. After you have completed verifying the channels, click the Stop

button.

You have now verified the SCXI-1125 configuration and signal connection.

Note For more information on how to further configure the SCXI-1125, or how to use

LabVIEW to configure the module and take measurements, refer to Chapter 4, Theory of

Operation.

Verifying the Signal in Traditional NI-DAQ (Legacy)

This section discusses how to verify the signal in Traditional NI-DAQ

(Legacy) using channel strings and virtual channels.

Verifying the Signal Using Channel Strings

The format of the channel string is as follows:

obx

! scy ! mdz ! channel

Chapter 3 Configuring and Testing

where

•obx is the onboard E Series DAQ device channel, with x representing

a particular channel where the multiplexed channels are sent. This

value is 0 for E Series DAQ device channel 0 in a single-chassis

system. In a multichassis or remote chassis system, the E Series DAQ

device channel x corresponds to chassis number n – 1, where E Series

DAQ device channel x is used for scanning the nth chassis in the

system.

•scy is the SCXI chassis ID, where y is the number you chose when

configuring the chassis.

•mdz is the slot position where the module is located, with z being the

particular slot number. The slots in a chassis are numbered from left to

right, starting with 1.

• channel is the channel that is sampled from module z.

Use the format

single input channel.

© National Instruments Corporation 3-7 SCXI-1125 User Manual

obx ! scy ! mdz ! n to verify the signal, where n is a

Page 33

Chapter 3 Configuring and Testing

Complete the following steps to use channel strings in verifying the signal:

1. Expand Devices and Interfaces.

2. Expand Traditional NI-DAQ Devices.

3. Right-click the appropriate E Series DAQ device.

4. Click Test Panels.

5. Enter the channel string.

6. Enter the input limits.

7. Select the Data Mode.

8. Select the Y Scale Mode.

Refer to the LabVIEW Measurements Manual for more information and for

proper formatting of channel strings for different uses.

Verifying the Signal Using Virtual Channel

If you have already created a virtual channel, complete the following steps

to verify the signal:

1. Right-click the virtual channel you want to verify and select Test.

2. In Channel Names, select the channel you want to verify.

3. When you have completed verifying the channel, click Close.

SCXI-1125 User Manual 3-8 ni.com

Page 34

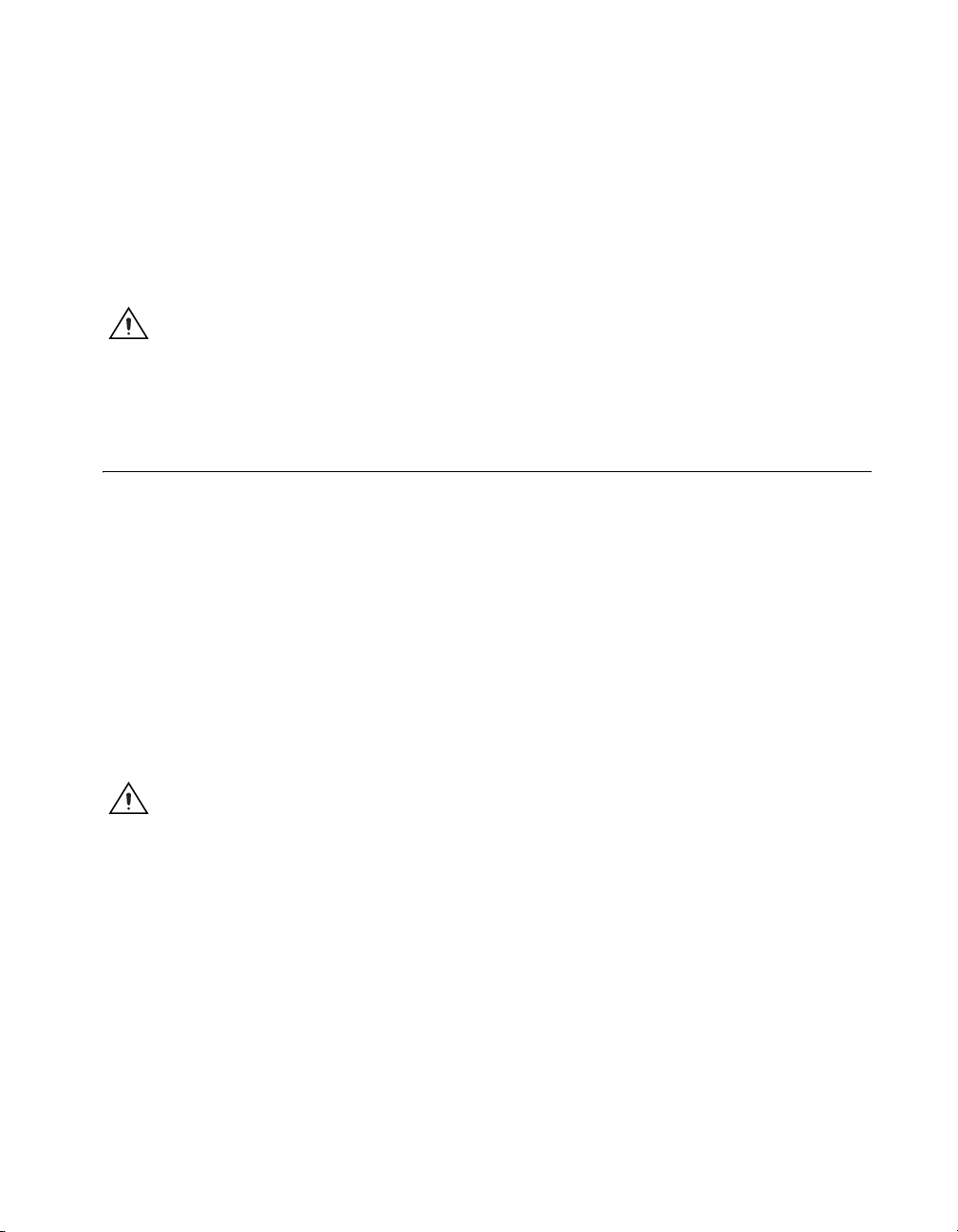

Theory of Operation

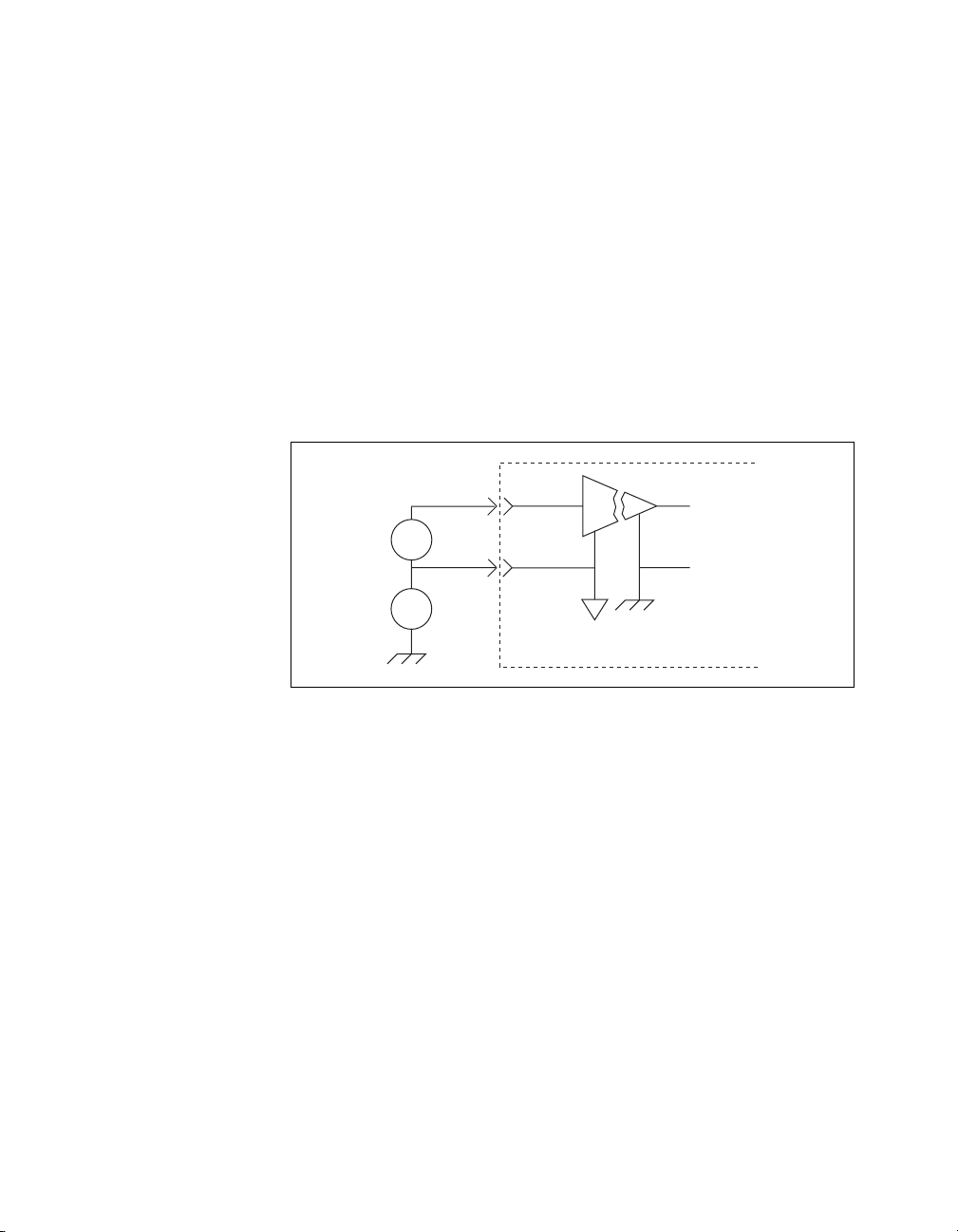

The section includes a brief overview and a detailed discussion of the

circuit features of the module. The two major modes of operation,

multiplexed and parallel mode, are discussed. Refer to Figure 4-1 while

reading this section.

Gain Select

4

AI 0

AI 7

Gain

Lowpass

+

Filter

–

Gain Select

Front Signal Connector

Lowpass

+

Filter

–

MTEMP

+

+

Lowpass

Filter

Lowpass

Filter

AI 0

Analog

Multiplexer

AI 7

Multiplexer

Control

Figure 4-1. SCXI-1125 Block Diagram

Buffer

Analog

Analog

Switch

Bus

Bus

Digital Interface

and Control

Scan

Clock

To

AI 0+

AI 0–

AI 7+

AI 7–

Rear Signal Connector

SCXIbus Connector

The SCXI-1125 has 12 different gain settings, from 1 to 2000, enabling

signal ranges ±5 V to ±2.5 mV. When the SCXI-1125 is used with a

terminal block that provides attenuation, the input range expands up to

1000 V. Refer to Appendix A, Specifications for a full list of input ranges.

© National Instruments Corporation 4-1 SCXI-1125 User Manual

Page 35

Chapter 4 Theory of Operation

Refer to the Configurable Settings in MAX section of Chapter 3,

Configuring and Testing, for more information about programmatically

setting gain using range settings in MAX. For more information about

programmatically setting gain using range settings in NI-DAQmx and

Traditional NI-DAQ (Legacy), refer to the Developing Your Application in

NI-DAQmx section or the Developing Your Application in Traditional

NI-DAQ (Legacy) section, respectively, of Chapter 5, Using the

SCXI-1125.

Filter Bandwidth and Cutoff Frequency

The SCXI-1125 provides two filtering stages with an overall response of a

four-pole Butterworth filter. You can control the cutoff frequency of the

filter through software. You can choose 4 Hz or 10 kHz. For additional

flexibility in cutoff frequency settings and for greater suppression, NI

recommends combining the hardware filtering provided by the SCXI-1125

with digital filtering. NI recommends using the Advanced Analysis

functions of LabVIEW, LabWindows/CVI, or Measurement Studio. By

combining hardware anti-aliasing with digital filtering, you can choose any

cutoff frequency.

The Advanced Analysis functions are only available in LabVIEW Full or

Professional Development Systems, and LabWindows/CVI Base or Full

Development Systems.

Refer to the Configurable Settings in MAX section of Chapter 3,

Configuring and Testing, for more information about programmatically

setting the cutoff frequency of the filter in MAX. For more information

about programmatically setting the cutoff frequency of the filter in

NI-DAQmx and Traditional NI-DAQ (Legacy), refer to the Developing

Your Application in NI-DAQmx section or the Developing Your

Application in Traditional NI-DAQ (Legacy) section, respectively, of

Chapter 5, Using the SCXI-1125.

Operating in Multiplexed Mode

You can configure the SCXI-1125 to operate in multiplexed mode as

described in Chapter 1, About the SCXI-1125. Using this mode of

operation, you can scan all input channels of the SCXI-1125 into one

output channel that is read by the National Instruments DAQ device. You

can also multiplex the CJC channel that connects to a sensor on the SCXI

terminal block for making temperature measurements.

SCXI-1125 User Manual 4-2 ni.com

Page 36

Multiplexed Hardware Operation Theory

When you configure a module for multiplexed mode operation, the routing

of multiplexed signals to the E/M Series DAQ device depends on which

module in the SCXI system is cabled to the E/M Series DAQ device. There

are several possible scenarios for routing signals from the multiplexed

modules to the E/M Series DAQ device. If the module being scanned is not

directly cabled to the E/M Series DAQ device, the module sends its signals

through the SCXIbus to the cabled module. The cabled module, whose

routing is controlled by the SCXI chassis, routes the SCXIbus signals to the

E/M Series DAQ device through the CH0 signal on the rear signal

connector. If the E/M Series DAQ device scans the cabled module, the

module routes its input signals through the CH0 signal on the rear signal

connector. The power of SCXI multiplexed scanning is its ability to route

many input channels to a single channel on the E/M Series DAQ device.

Note The SCXI-1125 parallel outputs continuously drive the rear signal connector output

pins even when you configure the module in multiplexed mode. If the module is cabled to

an E/M Series DAQ device in multiplexed mode, the differential inputs 1 through 7 on the

E/M Series DAQ device cannot be used for general-purpose analog input. Refer to

Appendix D, Common Questions, for more information on available pins on the rear signal

connector.

Chapter 4 Theory of Operation

Multiplexed mode is typically used for performing scanning operations

with the SCXI-1125. Immediately prior to a multiplexed scanning

operation, the SCXI chassis is programmed with a module scan list that

controls which module sends its output to the SCXIbus during a scan. You

can specify this list to scan the modules in the chassis in any order, with an

arbitrary number of channels for each module entry in the list. You can

randomly scan the channels on the SCXI-1125, meaning channels can be in

any order and occur multiple times in a single scan. When performing

multiple scans, the list pointer of the module automatically wraps around

and starts scanning with the first channel in the scan list.

Operating in Parallel Mode

You can configure the SCXI-1125 to operate in parallel mode as described

in Chapter 1, About the SCXI-1125. In parallel mode, all eight analog

output channels on the SCXI-1125 are connected to eight analog input

channels on the E/M Series DAQ device. The CJC channel is not

accessible. Every SCXI-1125 configured for parallel mode must have a

E/M Series DAQ device directly cabled to it.

© National Instruments Corporation 4-3 SCXI-1125 User Manual

Page 37

Chapter 4 Theory of Operation

Theory of Parallel Hardware Operation

In parallel mode, the CH0 signal on the rear signal connector is configured

as the output of the SCXI-1125 analog input channel 0. The rear signal

connector carries each of the analog outputs of the SCXI-1125 to the

connected DAQ device. You can use an SCXI-1180 feedthrough connector

to make each of the outputs available at the front of the chassis; which is

useful for cascading these signals to other modules for additional signal

conditioning purposes. Parallel mode allows you to bypass scanning and

you are not limited by the settling time required by the multiplexer of

SCXI-1125. You can scan the channels more accurately at a faster rate,

depending on which E/M Series DAQ device you connect to the module.

SCXI-1125 User Manual 4-4 ni.com

Page 38

5

Using the SCXI-1125

This chapter discusses typical applications for the SCXI-1125. While this

list is not comprehensive, it provides some guidance on how to improve

measurement accuracy for some of the most popular applications of the

SCXI-1125. Advanced operations such as calibration and using the CJC

channel are discussed as well.

Temperature Measurements Using Thermocouples

Making isolated temperature measurements from thermocouples is a

common use of the SCXI-1125. This section discusses how to use

thermocouples, CJC, and how to calculate the temperature accuracy of the

SCXI-1125.

NI recommends using the SCXI-1328 terminal block to make

thermocouple measurements with the SCXI-1125. Although you can use

many of the SCXI terminal blocks for thermocouple measurements, the

SCXI-1328 has an isothermal design that reduces temperature gradients

within the terminal block housing. This design reduces the CJC errors

which might reduce the accuracy of your temperature measurement. Most

SCXI terminal blocks available for the SCXI-1125 contain a cold-junction

temperature sensor, which is used for measuring ambient temperature. This

sensor connects to a special channel on the SCXI-1125 inside the terminal

block close to where the thermocouple connects to the screw terminals.

Note Place the SCXI chassis away from extreme temperature gradients to minimize the

temperature gradient inside the terminal block and maintain its isothermal nature for

accurate CJC.

A thermocouple relies on the principle that a small voltage that varies with

temperature is produced at the junction of two dissimilar metals. CJC is

necessary because the junction between the end of the thermocouple lead

wires and the screw terminals produces a small potential difference, adding

error to the thermocouple voltage. Knowing the temperature at the point

where the thermocouple is connected to the measurement instrument

allows you to determine the correct temperature reading at the

thermocouple junction. Due to the nonlinear relationship between

© National Instruments Corporation 5-1 SCXI-1125 User Manual

Page 39

Chapter 5 Using the SCXI-1125

thermocouple junction voltage and temperature, this voltage conversion

(linearization) is best done through software.

NI-DAQ has built-in scaling for most thermocouple types. In NI-DAQmx,

you can create a thermocouple task or global channel. In Traditional

NI-DAQ (Legacy), you can create a thermocouple virtual channel.

If you choose to not let the driver scale the voltage readings for you in

software, you must do several conversions by using conversion coefficients

that reflect the voltage-temperature relationship for the type of

thermocouple and CJC being used. Complete the following steps to

accurately determine thermocouple temperature:

1. Read the voltage from the CJC sensor and convert this voltage to a

temperature.

2. Convert this temperature to the corresponding voltage for the

thermocouple type in use.

3. Read the input voltage from the thermocouple.

4. Add the two voltages.

5. Translate the resultant voltage into the thermocouple temperature

reading.

You have completed the steps to get the true temperature reading from the

thermocouple junction.

National Instruments software ADEs have useful conversion functions for

CJC. In LabVIEW, virtual channels with the CJC channel invoked or the

Convert Thermocouple Reading VI are used. In C, use the NI-DAQ

function,

function

Thermocouple_Convert. In C, you might also need to use the

Thermistor_Convert, if your terminal block uses a thermistor

to perform CJC. For more information about CJC, refer to your software

ADE user documentation.

To calculate the temperature accuracy of your SCXI-1125, you must

consider several factors. First, the type of sensor and the temperature range

you expect directly affects which gain your SCXI-1125 module uses for

voltage readings, thereby directly affecting the resolution with which you

can read temperature. After determining the range necessary for your

application, you can apply the measurement accuracy specifications of the

SCXI-1125; such as offset error, gain error, and noise to determine how

these will affect your temperature measurement. Next, you must consider

the accuracy of your cold-junction sensor and incorporate this into the total

temperature error of your reading. Finally, the accuracy of the DAQ device

you use must be factored in to determine your overall system error.

SCXI-1125 User Manual 5-2 ni.com

Page 40

Chapter 5 Using the SCXI-1125

Complete the following steps to calculate the overall temperature error

using the SCXI-1125 with an E Series MIO DAQ device:

1. Based on the required temperature range and the type of sensor,

determine the gain to use. For example, using a K-type thermocouple

with a required temperature range of 0 to 100 °C, the corresponding

voltage range is –1.002 mV to 4.0962 mV (averaging 41.0 µV/°C in

this range). For this example, use a gain of 1000 for this temperature

range to get maximum temperature resolution.

2. Next, look up the analog accuracy specifications from Appendix A,

Specifications, for the gain and filter settings you have chosen. You

must consider how offset, gain, and system noise affect your

measurement. You might also consider common-mode rejection,

temperature drift, and other specifications based on the operating

environment. For example, using a gain of 1000, the offset error is

± 0.2 µV, the gain error is ± 0.03% which corresponds to ± 1.43 µV at

full-scale temperature, and the system noise is 100 V

noise which is about 3 times this, or 300 nV