Page 1

™

SCXI

SCXI-1121 User Manual

Four-Channel Isolated Universal Transducer Module

for Signal Conditioning

SCXI-1121 User Manual

September 1999 Edition

Part Number 320426C-01

Page 2

Worldwide Technical Support and Product Information

www.natinst.com

National Instruments Corporate Headquarters

11500 North Mopac Expressway Austin, Texas 78759-3504 USA Tel: 512 794 0100

Worldwide Offices

Australia 03 9879 5166, Austria 0662 45 79 90 0, Belgium 02 757 00 20, Brazil 011 284 5011,

Canada (Calgary) 403 274 9391, Canada (Ontario) 905 785 0085, Canada (Québec) 514 694 8521,

China 0755 3904939, Denmark 45 76 26 00, Finland 09 725 725 11, France 01 48 14 24 24,

Germany 089 741 31 30, Greece 30 1 42 96 427, Hong Kong 2645 3186, India 91805275406,

Israel 03 6120092, Italy 02 413091, Japan 03 5472 2970, Korea 02 596 7456, Mexico (D.F.) 5 280 7625,

Mexico (Monterrey) 8 357 7695, Netherlands 0348 433466, Norway 32 27 73 00, Singapore 2265886,

Spain (Barcelona) 93 582 0251, Spain (Madrid) 91 640 0085, Sweden 08 587 895 00,

Switzerland 056 200 51 51, Taiwan 02 2377 1200, United Kingdom 01635 523545

For further support information, see the Technical Support Resources appendix. To comment on the

documentation, send e-mail to techpubs@natinst.com.

© Copyright 1992, 1999 National Instruments Corporation. All rights reserved.

Page 3

Important Information

Warranty

The SCXI-1121 is warranted against defects in materials and workmanship f or a period of one year from the date of shipment,

as evidenced by receipts or other documentation. National Instruments will, at its option, repair or replace equipment that

proves to be defective during the warranty period. T his w arran ty i ncludes part s and l abo r.

A Return Material Authorization (RMA) number must be obtained from the factory and clearly marked on the outside of

the package before any equipment will be accepted for warranty work. National Instruments will pay the shipping costs of

returning to the owner parts which are covered by warrant y.

National Instruments believes that the information in this document is accurate. The document has been carefully reviewed

for technical accuracy. In the event that technical or typographical errors exist, National Instruments reserves the right to

make changes to subsequent editions of this document without prior notice to holders of this edition. The reader should consult

National Instruments if errors are suspected. In no even t shall Nati on al Inst rum ents be l iable fo r any dama ges aris in g o ut of

or related to this document or the information contained in it.

XCEPT AS SPECIFIED HEREIN

E

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE

OR NEGLIGENCE ON THE PART OF NATIONAL INSTRUMENTS SHALL BE LIMITED TO THE AMOUNT THERETOFORE PAID BY THE CUSTOMER

ATIONAL INSTRUMENTS WILL NOT BE LIABLE FOR DAMAGES RESULTING FROM LOSS OF DATA, PROFITS, USE OF PRODUCTS, OR INCIDENTAL

N

OR CONSEQUENTIAL DAMAGES, EVEN IF ADVISED OF THE POSSIBILITY THEREOF

will apply regardless of the form of action, whether in contract or tort, including negligence. Any action against National

Instruments must be brought within one year after the cause of action accrues. National Instruments shall not be liable for

any delay in performance due to causes beyond its reasonable control. The warranty provided herein does not cover damages,

defects, malfunctions, or service failures caused by owner’s failure to follow the National Instruments installation, operation,

or maintenance instructions; owner’s modification of the product; owner’s abuse, misuse, or negligent acts; and power failure

or surges, fire, flood, accident, actions of third part ies, o r other eve nts o ut side reasonab le co ntrol .

ATIONAL INSTRUMENTS MAKES NO WARRANTIES, EXPRESS OR IMPLIED, AND SPECIFICALLY DISCLAIMS ANY

, N

Copyright

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or mechanical,

including photocopying, recording, sto rin g in an i nform atio n ret rieval s ystem , o r t ranslati ng , i n w hole o r in part, w it ho ut

the prior written consent of National Instruments Corporation.

Trademarks

LabVIEW™, natinst.com™, National Instruments™, NI-DAQ™, RTSI™, and SCXI™ are trademarks of

National Instruments Corporation.

Product and company names mentioned herein are trademarks or trade names of their respective companies.

USTOMER’S RIGHT TO RECOVER DAMAGES CAUSED BY FAULT

. C

. This limitation of the liability of National Instruments

.

WARNING REGARDING USE OF NATIONAL INSTRUMENTS PRODUCTS

(1) NATIONAL INSTRUMENTS PRODUCTS ARE NOT DESIGNED WITH COMPONENTS AND TESTING

FOR A LEVEL OF RELIABILITY SUITABLE FOR USE IN OR IN CONNECTION WITH SURGICAL IMPLANT S

OR AS CRITICAL COMPONENTS IN ANY LIFE SUPPORT SYSTEMS WHOSE FAILURE TO PERFORM CAN

REASONABLY BE EXPECTED TO CAUSE SIGNIFICANT INJURY TO A HUMAN.

(2) IN ANY APPLICATION, INCLUDING THE ABOVE, RELIABILITY OF OPERATION O F THE SOFTWARE

PRODUCTS CAN BE IMPAIRED BY ADVERSE FACTORS, INCLUDING BUT NOT LIMITED TO FLUCTUATIONS

IN ELECTRICAL POWER SUPPLY, COMPUTER HARDWARE MALFUNCTIONS, COMPUTER OPERATING

SYSTEM SOFTWARE FITNESS, FITNESS OF COMPILERS AND DEVELOPMENT SOFTWARE USED TO DEVELOP

AN APPLICATION, INSTALLATION ERRORS, SOFTWARE AND HARDWARE COMPATIBILITY PROBLEMS,

MALFUNCTIONS OR FAILURES OF ELECTRONIC MONITORING OR CONTROL DEVICES, TRANSIENT

FAILURES OF ELECTRONIC SYSTEMS (HARDWARE AND/OR SOFTWARE), UNANTICIPATED USES OR

MISUSES, OR ERRORS ON THE PART OF THE USER OR APPLICATIONS DESIGNER (ADVERSE FACTORS SUCH

AS THESE ARE HEREAFTER COLLECTIVELY TERMED “SYSTEM FAILURES”). AN Y A PPLICATION WHE RE A

SYSTEM FAILURE WOULD CREATE A RISK OF HARM TO PROPERTY OR PERSONS (INCLUDING THE RISK OF

BODILY INJURY AND DEATH) SHOULD NOT BE RELIANT SOLELY UPON ONE FORM OF ELECTRONIC SYSTEM

DUE TO THE RISK OF SYSTEM FAILURE. TO AVOID DAMAGE, INJURY, OR DEATH , TH E U SER OR

APPLICATION DESIGNER MUST TAKE REASONABLY PRUDENT STEPS TO PROTECT AGAINST SYSTEM

FAILURES, INCLUDING BUT NOT LIMITED TO BACK-UP OR SHUT DOWN MECHANISMS. BECAUSE EACH

END-USER SYSTEM IS CUSTOMIZED AND DIFFERS FROM NATIONAL INSTRUMENTS' TESTING PLATFORMS

AND BECAUSE A USER OR APPLICATION DESIGNER MAY USE NATIONAL INSTRUMENTS PRODUCTS IN

COMBINATION WITH OTHER PRODUCTS IN A MANNER NOT EVALUATED OR CONTEMPLATED BY

NATIONAL INSTRUMENTS, THE USER OR APPLICATION DESIGNER IS ULTIMATELY RESPONSIBL E FOR

VERIFYING AND VALIDATING THE SUITABILITY OF NATIONAL INSTRUMENT S PRODUCTS WHENEVE R

NATIONAL INSTRUMENTS PRODUCTS ARE INCORPORATED IN A SYSTEM OR A PPLICATION, INCL UDING ,

WITHOUT LIMITATION, THE APPROPRIATE DESIGN, PROCESS AND SAFETY LEVEL OF SUCH SYSTEM OR

APPLICATION.

Page 4

Contents

About This Manual

Conventions ...................................................................................................................xi

Related Documentation........................................... .......................................................xii

Chapter 1

Introduction

What Your Kit Should Contain .....................................................................................1-2

Optional Software.............................................................. ............................................1-2

Optional Equipment.......................................................................................................1-4

Custom Cables.................................................................................................1-5

Unpacking......................................................................................................................1-6

Chapter 2

Configuration and Installation

Module Configuration....................................................................................................2-1

Digital Signal Connections..............................................................................2-3

Jumper W44......................................................................................2-3

Jumper W38......................................................................................2-4

Jumper W32......................................................................................2-4

Using Jumpers W32 and W38 ..........................................................2-4

Analog Configuration......................................................................................2-6

Grounding, Shielding, and Reference Mode Selection.....................2-6

Input Channel Jumpers......................................................................2-8

Excitation Jumpers......................................... ...................................2-9

Hardware Installation.....................................................................................................2-14

Signal Connections .................................................... ....................................................2-15

Front Connector...............................................................................................2-16

Front Connector Signal Descriptions ..............................................................2-18

Analog Input Channels......................................................................2-20

Excitation Channels ........................................................ ..................2-22

Temperature Sensor Connection.......................................................2-22

Connector-and-Shell Assembly ........................................................2-22

SCXI-1320, SCXI-1328, and SCXI-1321 Terminal Blocks.............2-24

Rear Signal Connector.....................................................................................2-37

Rear Signal Connector Signal Descriptions ...................................................2-38

Analog Output Signal Connections................................................... 2-39

Digital I/O Signal Connections.........................................................2-40

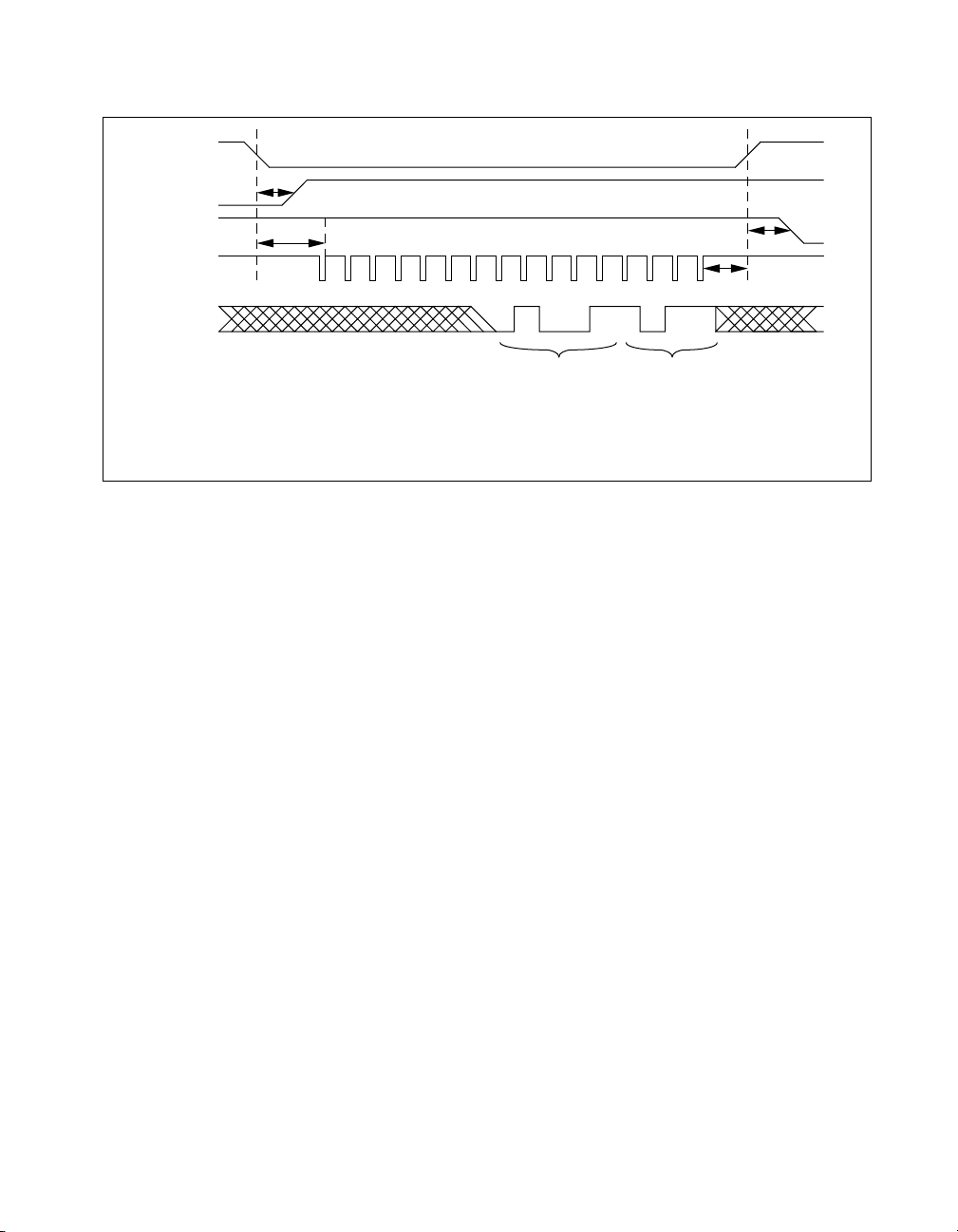

Timing Requirements and Communication Protocol........................2-42

Communication Signals....................................................................2-42

© National Instruments Corporation v SCXI-1121 User Manual

Page 5

Contents

Chapter 3

Theory of Operation

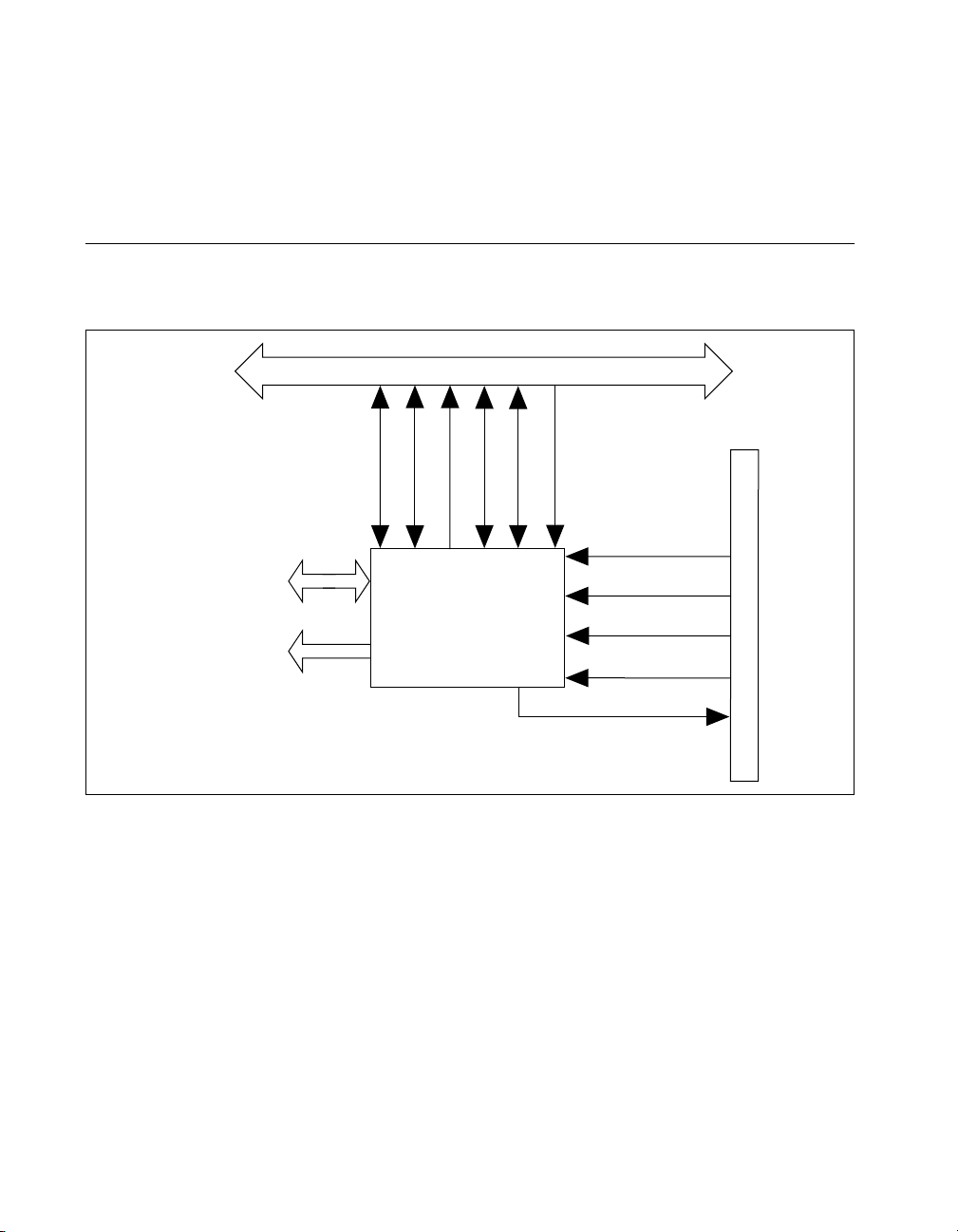

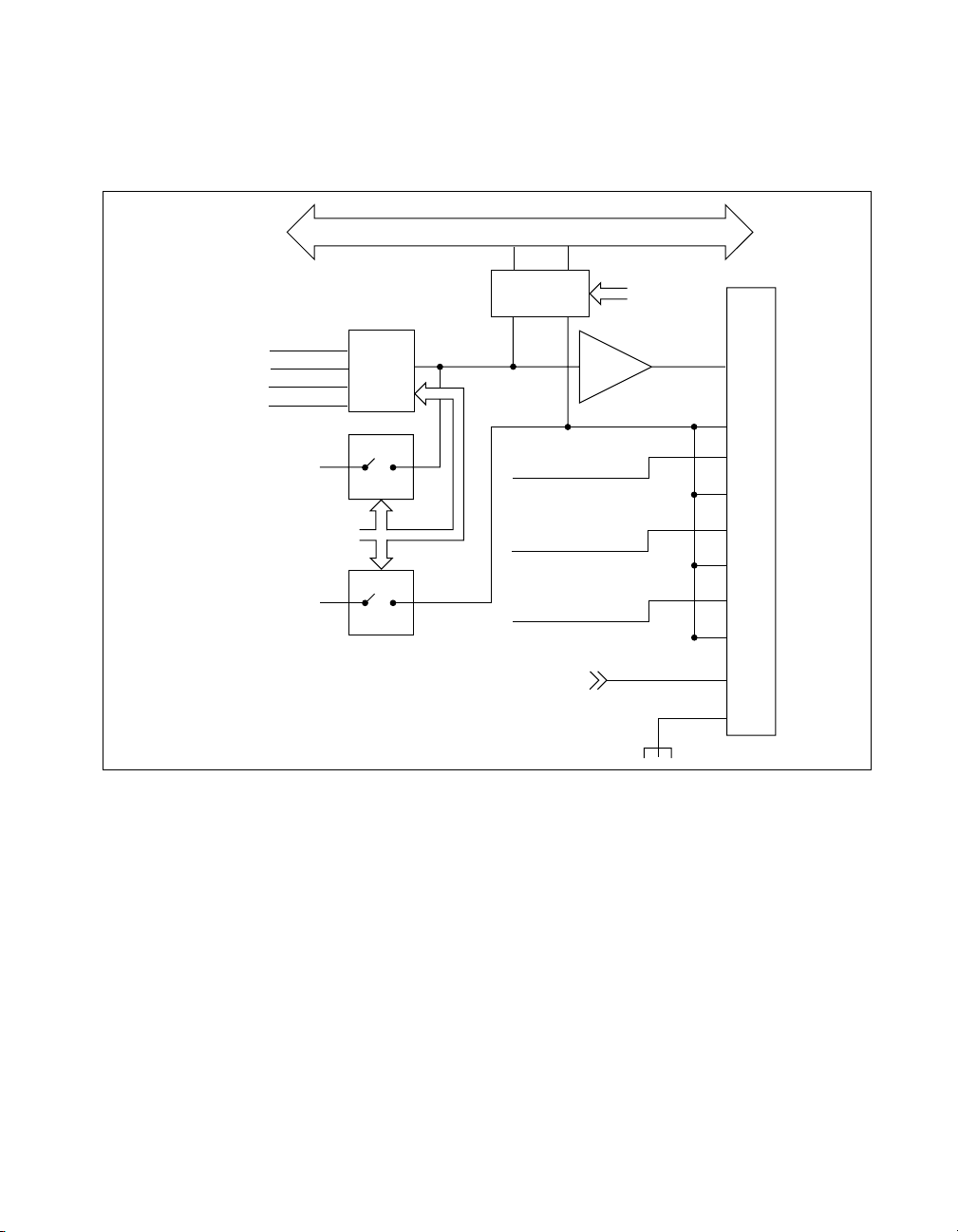

Functional Overview.....................................................................................................3-1

SCXIbus Connector ........................................................................................3-3

SCXIbus Connector Signal Descriptions........................................................3-4

Digital Interface............................................................. ................................................3-6

Digital Control Circuitry ...............................................................................................3-7

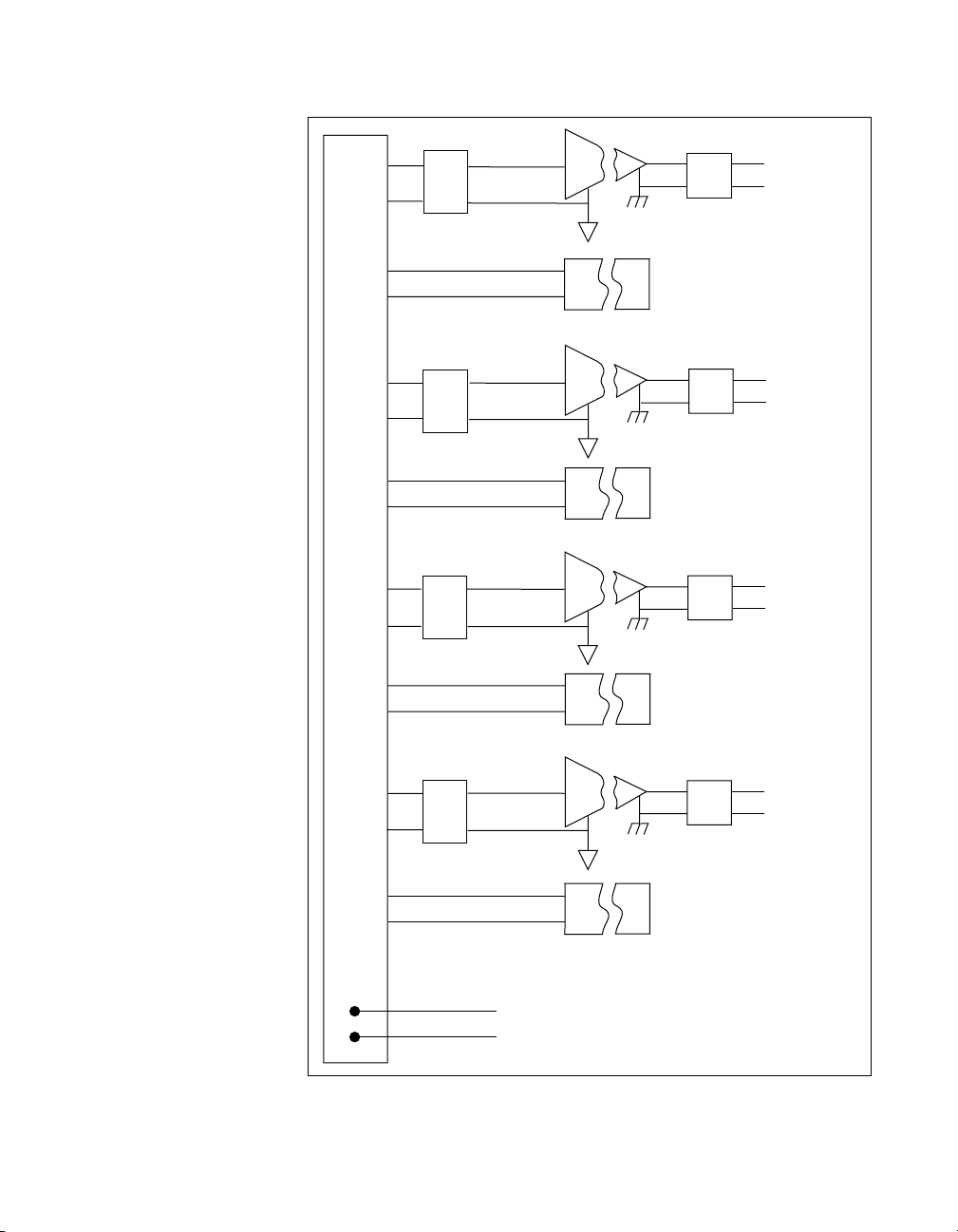

Analog and Timing Circuitry ........................................................................................3-8

Analog Input Channels....................................................................................3-8

Excitation Output Channels............................................................................3-11

Calibration.......................................................................................................3-11

Analog Output Circuitry .................................................................................3-15

Scanning Modes .............................................................. ..............................................3-17

Single-Module Parallel Scanning....................................................................3-17

Multiplexed Scanning.....................................................................................3-17

Calibration Equipment Requirements ..............................................3-11

Offset Null Adjust ............................................................................3-12

Excitation Adjust..............................................................................3-13

Single-Module Multiplexed Scanning..............................................3-18

Multiple-Module Multiplexed Scanning ..........................................3-19

Multiple-Chassis Scanning...............................................................3-20

Chapter 4

Register Descriptions

Register Description......................................................................................................4-1

Register Description Format...........................................................................4-1

SCXI-1121 Registers ......................................................................................4-1

Slot 0 Register Descriptions............................................................................4-5

Chapter 5

Programming

Programming Considerations........................................................................................5-1

Notation...........................................................................................................5-1

Register Writes................................................................................................5-2

Register Selection and Write Procedure...........................................5-2

Initialization......................................................................................5-3

Single-Channel Measurements .......................................................................5-4

Direct Measurements........................................................................5-4

Indirect Measurements .....................................................................5-5

Scanning Measurements ...................................... ...........................................5-7

1. Data Acquisition Board Setup Programming............................... 5-7

SCXI-1121 User Manual vi www.natinst.com

Page 6

2. Module Programming ...................................................................5-10

3. Programming the Slot 0 Hardscan Circuitry.................................5-13

4. Acquisition Enable, Triggering, and Servicing.............................5-14

Scanning Examples................................... ... ..................................................................5-15

Example 1........................................................................................................5-15

Example 2........................................................................................................5-15

Example 3........................................................................................................5-16

Appendix A

Specifications

Appendix B

Rear Signal Connector

Appendix C

SCXIbus Connector

Appendix D

SCXI-1121 Front Connector

Contents

Appendix E

SCXI-1121 Cabling

Appendix F

Revision A and B Photo and Parts Locator Diagrams

Appendix G

Technical Support Resources

Glossary

Index

© National Instruments Corporation vii SCXI-1121 User Manual

Page 7

Contents

Figures

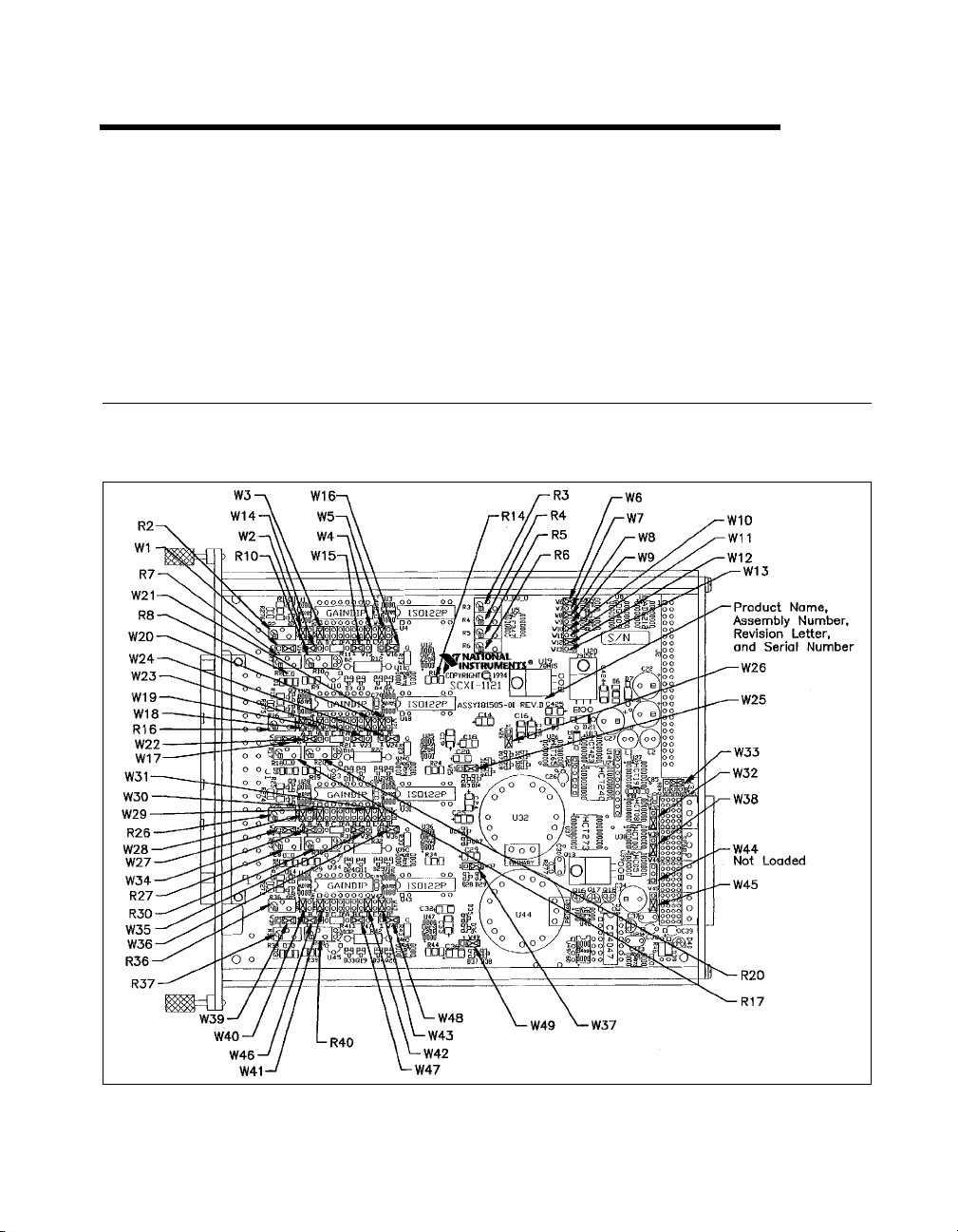

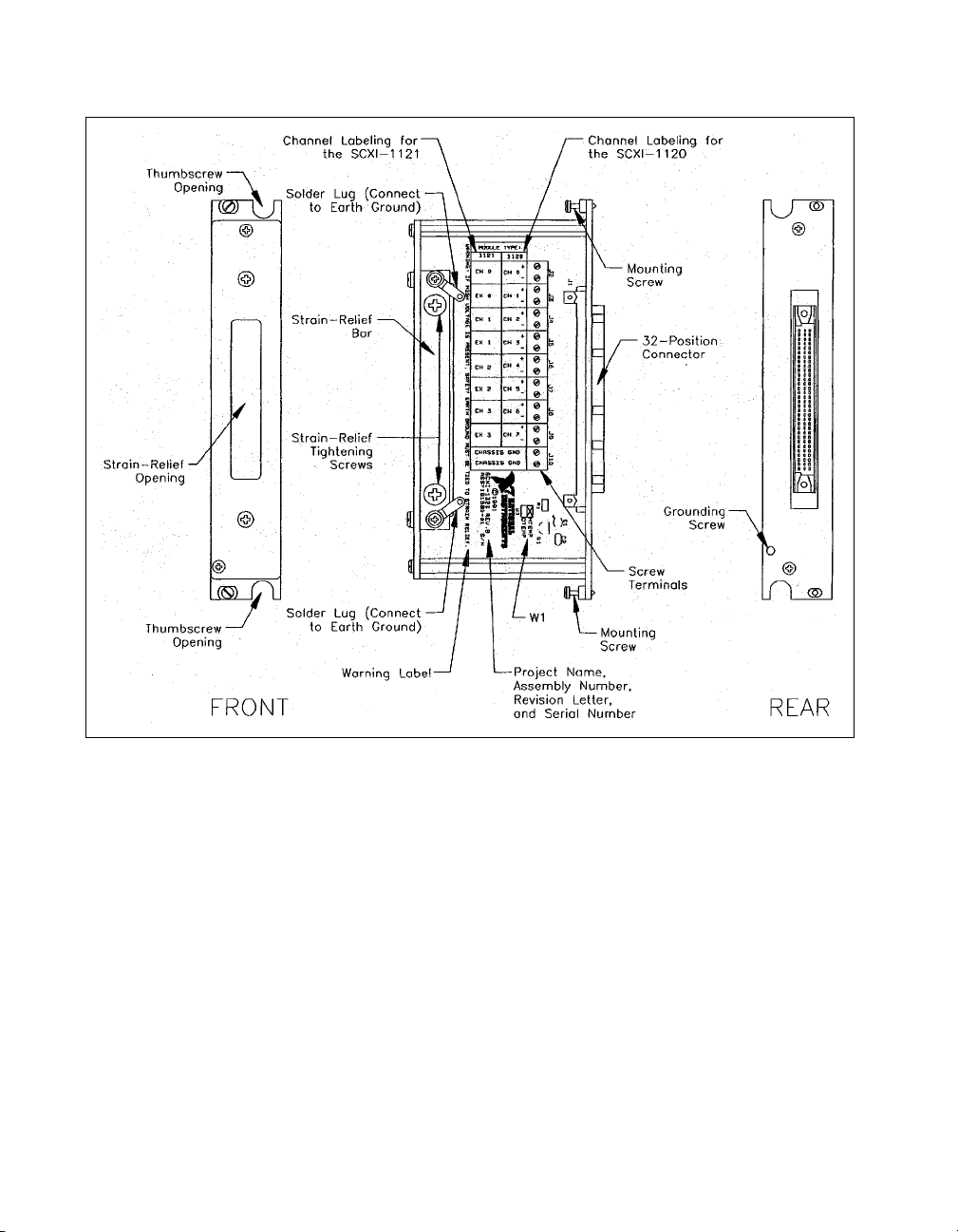

Figure 2-1. SCXI-1121 General Parts Locator Diagram.........................................2-2

Figure 2-2. SCXI-1121 Detailed Parts Locator Diagram........................................2-3

Figure 2-3. SCXI-1121 Front Connector Pin Assignment ......................................2-18

Figure 2-4. Ground-Referenced Signal Connection with

High Common-Mode Voltage ..............................................................2-21

Figure 2-5. Floating Signal Connection Referenced to Chassis Ground for

Better Signal-to-Noise Ratio.................................................................2-21

Figure 2-6. Floating AC-Coupled Signal Connection.............................................2-22

Figure 2-7. AC-Coupled Signal Connection with High Common-Mode Voltage.. 2-22

Figure 2-8. Assembling and Mounting the SCXI-1330

Connector-and-Shell Assembly ............................................................2-25

Figure 2-9. Nulling Circuit ......................................................................................2-29

Figure 2-10. Shunt Circuit.........................................................................................2-30

Figure 2-11. SCXI-1320 Parts Locator Diagram.......................................................2-36

Figure 2-12. SCXI-1328 Parts Locator Diagram.......................................................2-37

Figure 2-13. SCXI-1321 Parts Locator Diagram.......................................................2-38

Figure 2-14. SCXI-1121 Rear Signal Connector Pin Assignment ............................ 2-39

Figure 2-15. SCANCLK Timing Requirements........................................................2-43

Figure 2-16. Slot-Select Timing Diagram.................................................................2-44

Figure 2-17. Serial Data Timing Diagram.................................................................2-45

Figure 2-18. Configuration Register Write Timing Diagram....................................2-46

Figure 2-19. SCXI-1121 Module ID Register Timing Diagram ...............................2-47

Figure 3-1. SCXI-1121 Block Diagram...................................................................3-1

Figure 3-2. SCXIbus Connector Pin Assignment....................................................3-3

Figure 3-3. Digital Interface Circuitry Block Diagram ........................................... 3-6

Figure 3-4. SCXI-1121 Digital Control...................................................................3-7

Figure 3-5. Analog Input Block Diagram................................................................3-9

Figure 3-6. Analog Output Circuitry.......................................................................3-15

Figure 3-7. Single-Module Parallel Scanning .........................................................3-17

Figure 3-8. Single-Module Multiplexed Scanning (Direct) ....................................3-18

Figure 3-9. Single-Module Multiplexed Scanning (Indirect)..................................3-19

Figure 3-10. Multiple-Module Multiplexed Scanning...............................................3-19

Figure 3-11. Multiple-Chassis Scanning ...................................................................3-20

Figure B-1. SCXI-1121 Rear Signal Connector Pin Assignment ............................ B-1

Figure C-1. SCXIbus Connector Pin Assignment....................................................C-2

Figure D-1. SCXI-1121 Front Connector Pin Assignment......................................D-2

Figure E-1. SCXI-1340 Installation .........................................................................E-4

SCXI-1121 User Manual viii www.natinst.com

Page 8

Tables

Contents

Figure E-2. SCXI-1180 Rear Connections...............................................................E-9

Figure E-3. SCXI-1180 Front Panel Installation......................................................E-10

Figure E-4. Cover Removal......................................................................................E-11

Figure F-1. Revision A and B SCXI-1121 Signal Conditioning Module................F-1

Figure F-2. Revision A and B SCXI-1121 General Parts Locator Diagram............F-2

Figure F-3. Revision A and B SCXI-1121 Detailed Parts Locator Diagram...........F-3

Table 2-1. Digital Signal Connections, Jumper Settings........................................2-6

Table 2-2. Jumper W33 Settings.............................................................................2-8

Table 2-3. Gain Jumper Allocation.........................................................................2-9

Table 2-4. Gain Jumper Positions...........................................................................2-9

Table 2-5. Filter Jumper Allocation........................................................................2-10

Table 2-6. Voltage and Current Mode Excitation Jumper Setup............................2-11

Table 2-7. Maximum Load per Excitation Channel...............................................2-12

Table 2-8. Excitation Level Jumper Selection........................................................2-12

Table 2-9. Completion Network Jumpers............................................................... 2-14

Table 2-10. Trimmer Potentiometer and Corresponding Channel ...........................2-27

Table 2-11. Nulling Resistors and Corresponding Channel.....................................2-27

Table 2-12. Jumper Settings of the Nulling Circuits................................................2-29

Table 2-13. Jumper Settings on the SCXI-1320 Terminal Block.............................2-33

Table 2-14. Jumper Settings on the SCXI-1328 Terminal Block.............................2-34

Table 2-15. Jumper Settings on the SCXI-1321 Terminal Block.............................2-34

Table 2-16. SCXIbus to SCXI-1121 Rear Signal Connector to

Data Acquisition Board Pin Equivalences ............................................2-42

Table 3-1. SCXIbus Equivalents for the Rear Signal Connector ...........................3-5

Table 3-2. Calibration Potentiometer Reference Designators................................3-14

Table 5-1. SCXI-1121 Rear Signal Connector Pin Equivalences ..........................5-2

Table E-1. SCXI-1121 and MIO-16 Pinout Equivalences......................................E-2

Table E-2. SCXI-1341 and SCXI-1344 Pin Translations.......................................E-5

Table E-3. SCXI-1342 Pin Translations .................................................................E-7

Table E-4. SCXI-1343 Pin Connections.................................................................E-14

© National Instruments Corporation ix SCXI-1121 User Manual

Page 9

About This Manual

This manual describes the electrical and mechanical aspects of the

SCXI-1121 and contains information concerning its operation and

programming. The SCXI-1121 is a member of the National Instruments

Signal Conditioning eXtensions for Instrumentation (SCXI) Series for the

National Instruments data acquisition plug-in boards. This board is

designed for signal conditioning of strain gauges, RTDs, thermistors,

thermocouples, volt and millivolt sources, and 4 to 20 mA sources or 0 to

20 mA process-current sources where high common-mode voltages exist.

The SCXI-1121 operates as four isolated input channels and four isolated

excitation channels. Each channel is isolated and independently

configurable via jumpers.

This manual describes the installation, basic programming considerations,

and theory of operation for the SCXI-1121.

Conventions

The following conventions appear in this manual:

<> Angle brackets that contain numbers separated by an ellipsis represent a

range of values associated with a bit or signal name—for example,

DBIO<3..0>.

This icon denotes a note, which alerts you to important information.

This icon denotes a caution, which advises you of precautions to take to

avoid injury, data loss, or a system crash.

This icon denotes a warning, which advises you of precautions to take to

avoid being electrically shocked.

bold Bold text denotes items that you must select or click on in the software,

such as menu items and dialog box options. Bold text also denotes

parameter names.

italic Italic text denotes variables, emphasis, a cross reference, or an introduction

to a key concept. This font also denotes text that is a placeholder for a word

or value that you must supply.

© National Instruments Corporation xi SCXI-1121 User Manual

Page 10

About This Manual

monospace Text in this font denotes text or characters that you should enter from the

keyboard, sections of code, programming examples, and syntax examples.

This font is also used for the proper names of disk drives, paths, directories,

programs, subprograms, subroutines, device names, functions, operations,

variables, filenames and extensions, and code excerpts.

monospace italic

Italic text in this font denotes text that is a placeholder for a word or value

that you must supply.

Related Documentation

The following documents contain information that you may find helpful as

you read this manual:

• AT-MIO-16 User Manual (part number 320476-01)

• AT-MIO-16D User Manual (part number 320489-01)

• AT-MIO-16F-5 User Manual (part number 320266-01)

• AT-MIO-16X User Manual (part number 320488-01)

• AT-MIO-64F-5 User Manual (part number 320487-01)

• Lab-LC User Manual (part number 320380-01)

• Lab-NB User Manual (part number 320174-01)

• Lab-PC User Manual (part number 320205-01)

• Lab-PC+ User Manual (part number 320502-01)

• MC-MIO-16 User Manual, Revisions A to C (part number 320130-01)

• MC-MIO-16 User Manual, Revision D (part number 320560-01)

• NB-MIO-16 User Manual (part number 320295-01)

• NB-MIO-16X User Manual (part number 320157-01)

• PC-LPM-16 User Manual (part number 320287-01)

• SCXI-1000/1001 User Manual (part number 320423-01)

SCXI-1121 User Manual xii www.natinst.com

Page 11

Introduction

This chapter describes the SCXI-1121; lists the contents of your

SCXI-1121 kit; describes the optional software, optional equipment, and

custom cables; and explains how to unpack the SCXI-1121 kit.

The SCXI-1121 consists of four isolated input channels and four isolated

excitation channels. The SCXI-1121 is a module for signal conditioning of

strain gauges, RTDs, thermistors, thermocouples, volt and millivolt

sources, 4 to 20 mA current sources, and 0 to 20 mA process-current

sources. The SCXI-1121 can operate in two output modes—the

Parallel-Output mode with all four input channels connected in parallel to

four data acquisition board channels, or the Multiplexed-Output mode with

all four channels multiplexed into a single data acquisition board channel.

The SCXI-1121 operates with full functionality with National Instruments

MIO-16 boards. The SCXI-1121 operates with full functionality with the

Lab-PC+ board in single-chassis SCXI systems. However, the Lab-PC+

cannot control multiple-chassis SCXI systems. You can use the Lab-NB,

the Lab-PC, the Lab-LC, and the PC-LPM-16 boards with the SCXI-1121,

but these boards can control only single-chassis SCXI systems and cannot

scan the module when it is configured in the Multiplexed-Output mode.

These boards can perform only single-channel reads in this mode. You can

also use the SCXI-1121 with other systems that comply with the

specifications give n in Chapter 2, Configuration and Installation. You can

multiplex several SCXI-1121s into a single channel, thus greatly increasing

the number of analog input signals that can be digitized.

1

The addition of a shielded terminal block provides screw terminals for easy

signal attachment to the SCXI-1121. In addition, a temperature sensor for

cold-junction compensation of thermocouples is included on the terminal

block. This cold-junction reference (CJR) is either multiplexed along with

the four input channels or connected by jumpers to a different channel of

the data acquisition board.

With the SCXI-1121, the SCXI chassis can serv e as a fast-scanning signal

conditioner for laboratory testing, production testing, and industrial

process monitoring.

© National Instruments Corporation 1-1 SCXI-1121 User Manual

Page 12

Chapter 1 Introduction

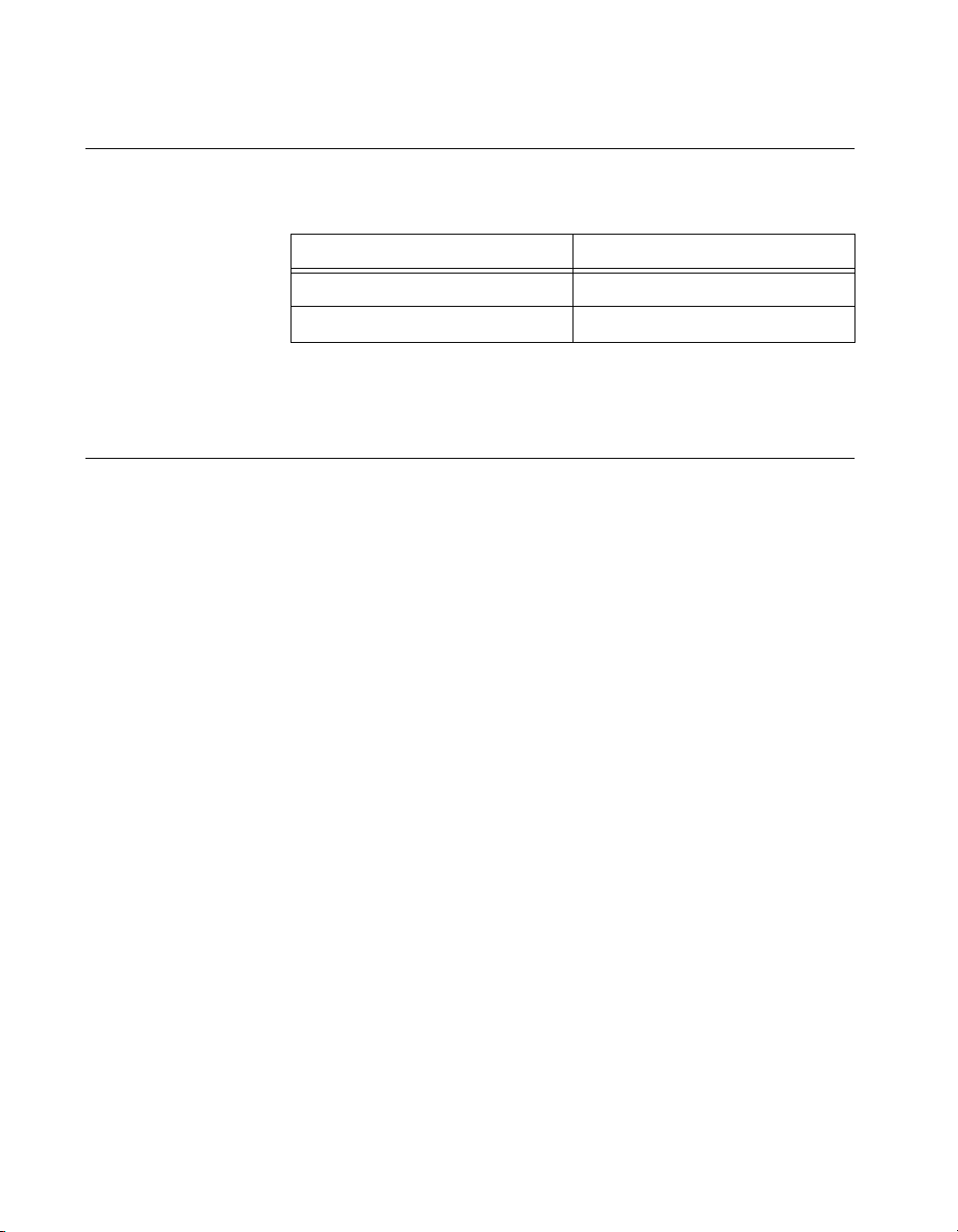

What Your Kit Should Contain

The contents of the SCXI-1121 kit (part number 776572-21) are listed as

follows:

Kit Component Part Number

SCXI-1121 module 181700-01

SCXI-1121 User Manual 320426-01

If your kit is missing any of the components, contact Nati onal Instruments .

Optional Software

This manual contains complete instructions for directly programming the

SCXI-1121. You can order separate software packages for controlling the

SCXI-1121 from National Instruments.

When you combine the PC, AT, and MC data acquisition boards with the

SCXI-1121, you can use LabVIEW for Windows or LabW indows for DOS.

LabVIEW and LabWindows are inno vativ e program development software

packages for data acquisition and control applications. LabVIEW uses

graphical programming, whereas LabWindows enhances Microsoft C and

QuickBASIC. Both packages include extensive libraries for data

acquisition, instrument control, data analysis, and graphical data

presentation.

Your National Instruments data acquisition board is shipped with the

NI-DA Q software. NI-DA Q has a library of functions that you can call from

your application programming environment. These functions include

routines for analog input (A/D conversion), buffered data acquisition

(high-speed A/D conversion), analog output (D/A conversion), waveform

generation, digital I/O, counter/timer, SCXI, RTSI, and self-calibration.

NI-DAQ maintains a consistent software interface among its different

versions so you can switch between platforms with minimal modifications

to your code.

You can also use the SCXI-1121, together with the PC, AT, and MC data

acquisition boards, with NI-DAQ software for DOS/Windows/

LabWindows/CVI. NI-DAQ software for DOS/Windows/

LabWindows/CVI comes with language interfaces for Professional

BASIC, T urbo Pascal, T urbo C, T urbo C++, Borland C++, and Microsoft C

SCXI-1121 User Manual 1-2 www.natinst.com

Page 13

Chapter 1 Introduction

for DOS and Visual Basic, Turbo Pascal, Microsoft C with SDK,

and Borland C++ for Windows. NI-DAQ software for

DOS/Windows/LabWindows is on high-density 5.25 in. and 3.5 in.

diskettes.

You can use the SCXI-1121, together with the Lab-LC or NB Series data

acquisition boards, with LabVIEW for Macintosh, a software system that

features interactive graphics, a state-of-the-art user interface, and a

powerful graphical programming language. The LabVIEW Data

Acquisition VI Library, a series of VIs for using LabVIEW with National

Instruments boards, is included with LabVIEW. The LabVIEW Data

Acquisition VI Library is functionally equivalent to the NI-DAQ software

for Macintosh.

You can also use the SCXI-1121, combined with the NB Series data

acquisition boards, with NI-DAQ software for Macintosh. NI-DAQ

software for Macintosh, which is shipped with all National Instruments

Macintosh data acquisition boards, comes with language interfaces for

MPW C, THINK C, Pascal, and Microsoft QuickBASIC. Any language

that uses Device Manager Toolbox calls can access NI-DAQ software for

Macintosh.

© National Instruments Corporation 1-3 SCXI-1121 User Manual

Page 14

Chapter 1 Introduction

Optional Equipment

NB6 cable

0.5 m 181305-01

1.0 m 181305-10

SCXI-1320 front terminal block 776573-20

SCXI-1321 offset-null and shunt-calibration terminal block 776573-21

SCXI-1328 high-accuracy isothermal terminal block 776573-28

SCXI-1330 32-pin connector-and-shell assembly 776573-30

SCXI-1340 cable assembly 776574-40

SCXI-1341 Lab-NB/Lab-PC/Lab-PC+ cable assembly 776574-41

SCXI-1342 PC-LPM-16 cable assembly 776574-42

SCXI-1343 rear screw terminal adapter 776574-43

SCXI-1344 Lab-LC cable assembly 776574-44

SCXI-1346 shielded multichassis cable adapter 776574-46

Equipment Part Number

SCXI-1347 SCXI shielded cable assembly

with 1 m cable 776574-471

with 2 m cable 776574-472

with 5 m cable 776574-475

with 10 m cable 776574-470

SCXI-1349 SCXI shielded cable assembly

with 1 m cable 776574-491

with 2 m cable 776574-492

with 5 m cable 776574-495

with 10 m cable 776574-490

SCXI-1350 multichassis adapter 776575-50

SCXI process-current resistor kit 776582-01

Standard ribbon cable

0.5 m 180524-05

1.0 m 180524-10

SCXI-1121 User Manual 1-4 www.natinst.com

Page 15

Custom Cables

Chapter 1 Introduction

Refer to the Signal Connections section in Chapter 2, Configuration and

Installation, and to Appendix E, SCXI-1121 Cabling, for additional

information on cabling, connectors, and adapters.

The SCXI-1121 rear signal connector is a 50-pin male ribbon-cable header.

The manufacturer part number used by National Instruments for this header

is as follows:

• AMP Inc. (part number 1-103310-0)

The mating connector for the SCXI-1121 rear signal connector is a

50-position polarized ribbon-socket connector with strain relief. National

Instruments uses a polarized or keyed connector to prevent inadvertent

upside-down connection to the SCXI-1121. Recommended manufacturer

part numbers for this mating connector are as follows:

• Electronic Products Division/3M (part number 3425-7650)

• T&B/Ansley Corporation (part number 609-5041CE)

Standard 50-conductor, 28 AWG, stranded ribbon cables that can be used

with these connectors are as follows:

• Electronic Products Division/3M (part number 3365/50)

• T&B/Ansle y Corporation (part number 171-50)

The SCXI-1121 front connector is a 32-pin DIN C male connector with

column A and column C even pins only. The manufacturer part number

used by National Instruments for this connector is as follows:

• Panduit Corporation (part number 100-932-023)

The mating connector for the SCXI-1121 front connector is a 32-pin DIN C

female connector. National Instruments uses a polarized connector to

prevent inadvertent upside-down connection to the SCXI-1121.

Recommended manufacturer part numbers for this mating connector are as

follows:

• Panduit Corporation (part number 100-932-434 straight-solder

eyelet pins)

• Panduit Corporation (part number 100-932-633; right-angle pins)

National Instruments selected these connectors to meet UL 1950 and

UL 1244 for 1,500 V

© National Instruments Corporation 1-5 SCXI-1121 User Manual

isolation.

rms

Page 16

Chapter 1 Introduction

Unpacking

Your SCXI-1121 module is shipped in an antistatic package to prevent

electrostatic damage to the module. Several components on the module can

be damaged by electrostatic discharge. To avoid such damage in handling

the module, take the following precautions.

• Touch the antistatic package to a metal part of your SCXI chassis

before removing the module from the package.

• Remo ve the module from the package and inspect the module for loose

components or any other sign of damage. Notify National Instruments

if the module appears damaged in any way. Do not install a damaged

module into your SCXI chassis.

SCXI-1121 User Manual 1-6 www.natinst.com

Page 17

Configuration and Installation

This chapter describes the SCXI-1121 jumper configurations, installation

of the SCXI-1121 into the SCXI chassis, signal connections to the

SCXI-1121, and cable wiring.

Module Configuration

The SCXI-1121 contains 49 jumpers that are shown in the parts locator

diagrams in Figures 2-1 and 2-2.

2

Figure 2-1.

© National Instruments Corporation 2-1 SCXI-1121 User Manual

SCXI-1121 General Parts Locator Diagram

Page 18

Chapter 2 Configuration and Installation

Figure 2-2. SCXI-1121 Detailed Parts Locator Diagram

The jumpers are used as follows:

• Fixed jumpers

– On Revision A and B modules, jumper W32 is unused and should

not be connected.

– Jumper W45 is reserved and should not be reconfigured.

– On Revision A and B modules, jumper W44 carries the

SLOT0SEL* signal from the rear signal connector, after

buffering, to the SCXIbus INTR* line and should be left in the

factory-set position (position 1). On Revision C or later modules,

jumper W44 does not exist.

• User-configurable jumpers

– Jumper W38 carries the SCXIbus MISO line, after buffering, to

the SERDATOUT signal on the rear signal connector.

– On Revision C or later modules, jumper W32 connects a pullup

resistor to the SERDATOUT signal on the rear signal connector.

– Jumper W33 configures the guard, the analog output ground, and

enables the Pseudodifferential Reference mode.

SCXI-1121 User Manual 2-2 www.natinst.com

Page 19

Chapter 2 Configuration and Installation

– Jumpers W3, W19, W29, and W41 configure the first-stage gain

of input channels 0 through 3, respectively.

– Jumpers W4, W20, W30, and W42 configure the second-stage

gain of input channels 0 through 3, resp ectively.

– Jumpers W5, W21, W31, and W43 configure the first-stage

filtering of input channels 0 through 3, respectively.

– Jumpers W6 and W7, W8 and W9, W10 and W11, and W12 and

W13 configure the second-stage filtering of input channels 0

through 3, respectively.

– Jumpers W14 and W15, W22 and W23, W34 and W35, and W46

and W47 configure the voltage or current mode of operation for

excitation channels 0 through 3, respectively.

– Jumpers W16 and W26, W24 and W25, W36 and W37, and W48

and W49 configure the level of excitation for excitation channels

0 through 3, respectively.

– Jumpers W1 and W2, W17 and W18, W27 and W28, and W39

and W40 configure the half-bridge completion network for

channels 0 through 3, respectively.

Further configuration of the board is software controlled and will be

discussed later in this chapter.

Digital Signal Connections

The SCXI-1121 has three jumpers dedicated for communication between

the data acquisition board and the SCXIbus. These jumpers are W32, W38,

and W44.

Jumper W44

Position 1 on Revision A and B modules connects, after buffering,

SLOT0SEL* to the SCXIbus INTR* line. This is the factory-default setting

and should not be changed. In this setting, the data acquisition board

controls the SCXIbus INTR* line. See the Timing Requirements and

Communication Protocol section later in this chapter, and Chapter 5,

Programming, for information on the use of the INTR* line. See

Appendix E, SCXI-1121 Cabling, for the pin equivalences of the

SCXI-1121 rear signal connector and the data acquisition board

I/O connector.

Position 3 is reserved and should not be used. This position is not explicitly

marked on the module.

© National Instruments Corporation 2-3 SCXI-1121 User Manual

Page 20

Chapter 2 Configuration and Installation

On Revision C or later modules, jumper W44 does not exist. SLOT0SEL*

is always buffered to the INTR* line.

Jumper W38

Position 1 connects, after buffering, the SCXIbus MISO line to the

SERDATOUT pin of the rear signal connector. In this setting, along with

the proper setting of W32, the data acquisition board can read the Module

ID Register of the SCXI-1121. See the Timing Requirements and

Communication Protocol section later in this chapter, and Chapter 4,

Register Descriptions, for information on reading the Module ID Register.

See Appendix E, SCXI-1121 Cabling, for the pin equivalences of the

SCXI-1121 rear signal connector and the data acquisition board I/O

connector. This is the factory-default setting.

Position 3 disconnects SERDATOUT from the SCXIbus MISO line.

Jumper W32

On Revision A and B modules, jumper W32 should not be connected. On

Revision C or later modules, Position 1 connects a 2.2 kΩ pullup resistor

to the SERDATOUT line (factory-default setting), and Position 3 does not

connect the pullup resistor to the SERDATOUT line.

Using Jumpers W32 and W38

Set jumpers W32 and W38 as follows:

If the SCXI-1121 is not cabled to a data acquisition board, the positions of

these jumpers do not matter, so leav e them in their factory default positions

(both in position 1).

If the SCXI-1121 is cabled to a data acquisition board, and the SCXI

chassis that the SCXI-1121 is in, is the only SCXI chassis cabled to that

data acquisition board, leave the jumpers in their factory default positions

(both in position 1).

If the SCXI-1121 is cabled to a data acquisition board, and there are

multiple SCXI chassis cabled to that data acquisition board with shielded

cables (you are using SCXI-1346 shielded cable multi-chassis adapters),

leave the jumpers in their factory default positions (both in position 1).

If the SCXI-1121 is cabled to a data acquisition board, and there are

multiple SCXI chassis cabled to that data acquisition board with ribbon

cables (you are using SCXI-1350 multi-chassis adapters), leave jumper

SCXI-1121 User Manual 2-4 www.natinst.com

Page 21

Chapter 2 Configuration and Installation

W38 in its factory default position (position 1). On all but one of the

SCXI-1121s that are cabled to the data acquisition board, move jumper

W32 to position 3. It does not matter which of the SCXI-1121 modules that

are cabled to the data acquisition board has jumper W32 set to position 1.

If you have different types of modules cabled to the data acquisition board,

those different modules will have jumpers similar to W38 and W32 of the

SCXI-1121. Set those jumpers on the different modules using the same

method described here for the SCXI-1121.

On Revision A and B SCXI-1121s, jumper W32 is not used. Y ou set jumper

W38 as explained in the cases above, except in the case of a multiple

chassis ribbon cable system. In a multichassis ribbon cable system with

Revision A and B SCXI-1121s cabled to the data acquisition board, you can

access the MISO line in only one chassis. Pick one of the chassis and set

jumper W38 to position 1 on the SCXI-1121 in that chassis that is cabled

to the data acquisition board. On the SCXI-1121s that are in the other

chassis and cabled to the data acquisition board, set jumper W38 to

position 3. Notice that you will only be able to access digital information

from the chassis that has the SCXI-1121 with jumper W38 set to position 1.

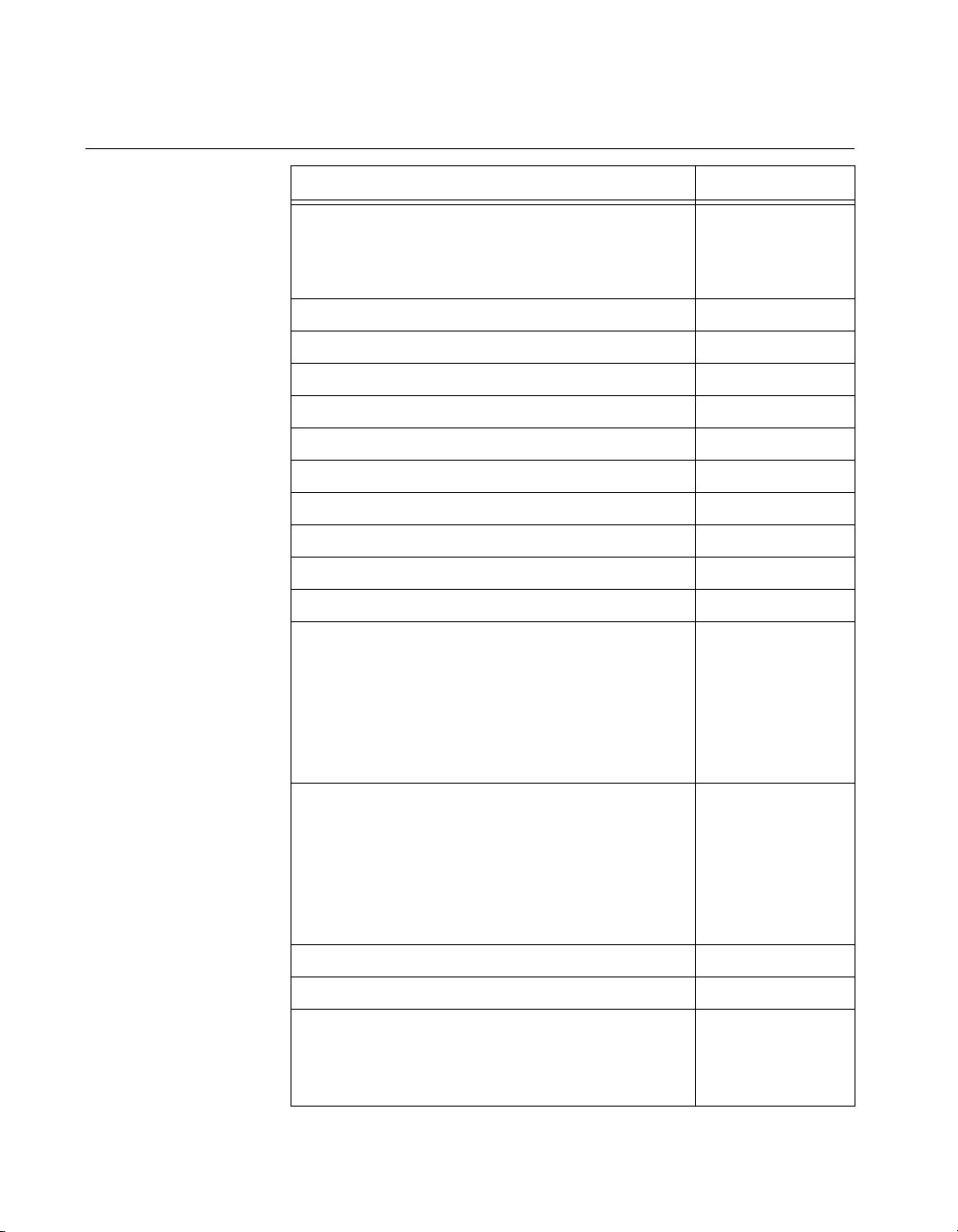

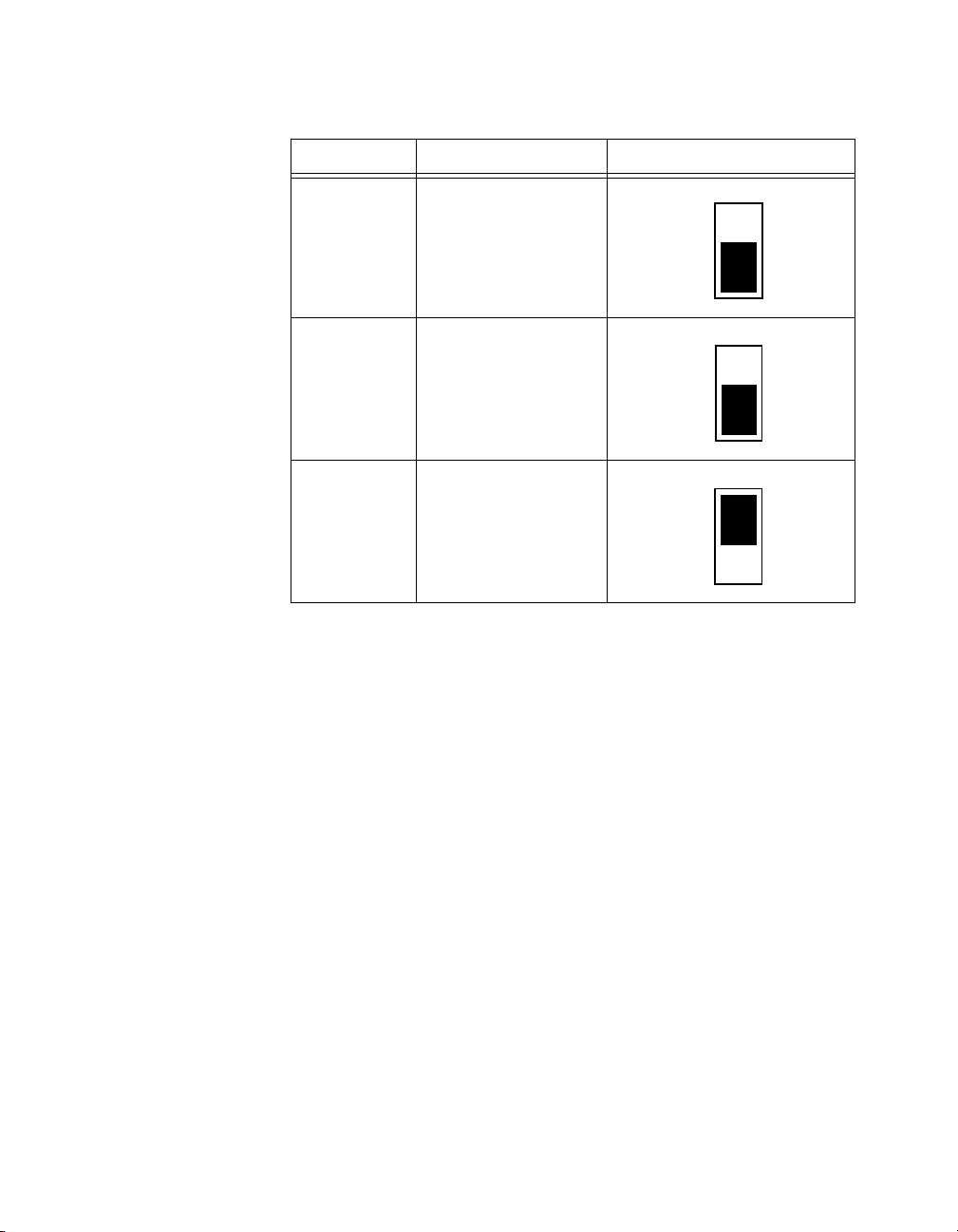

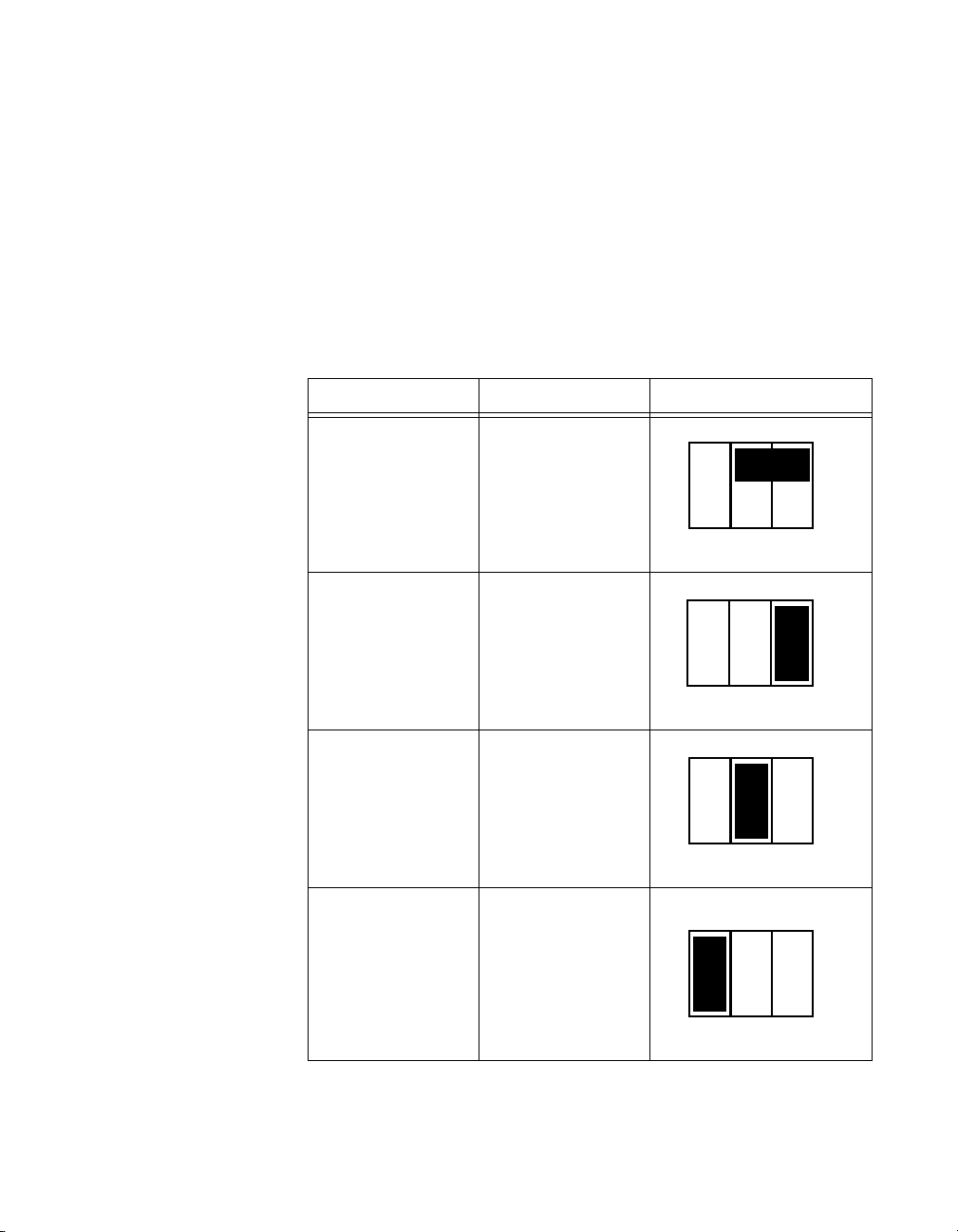

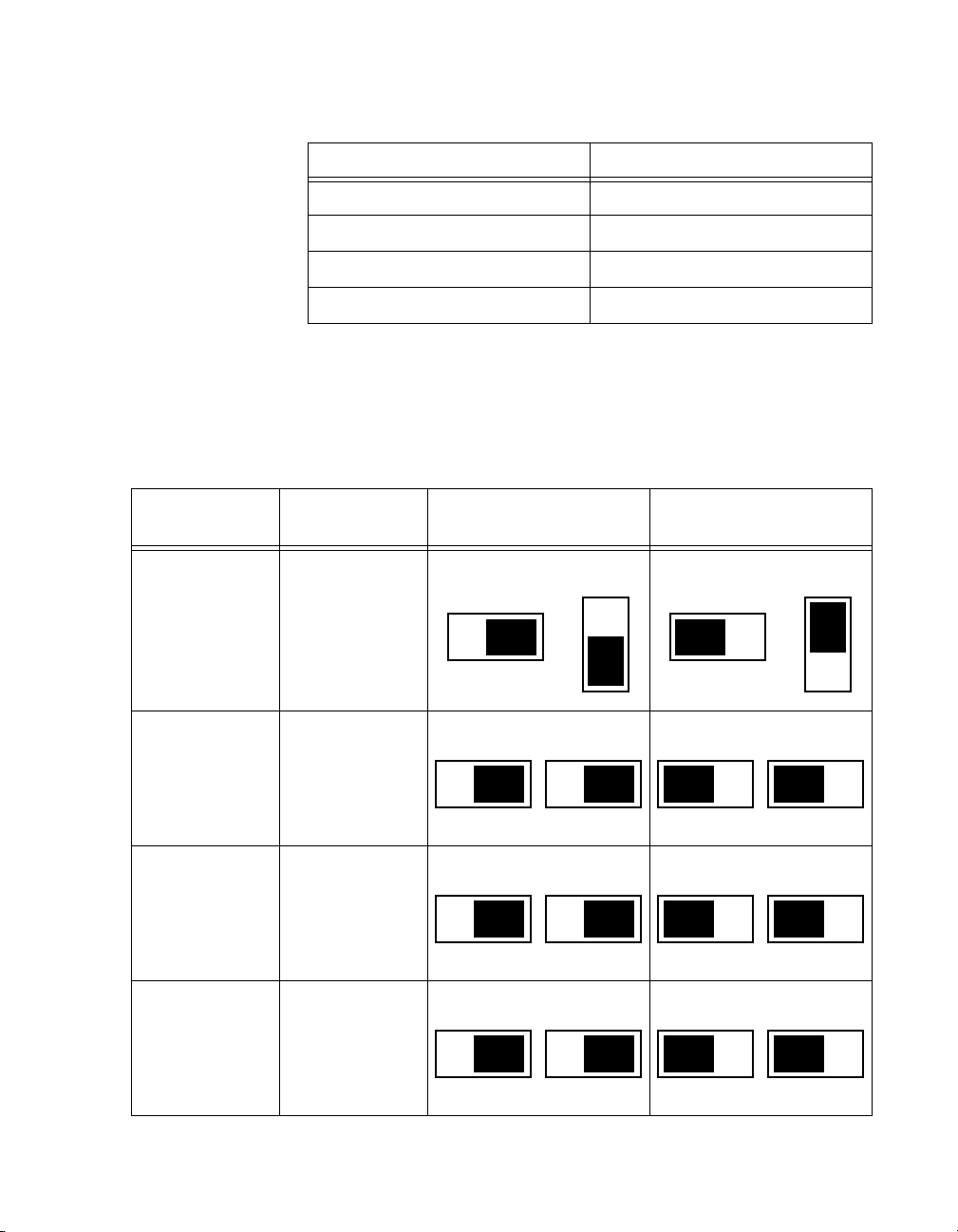

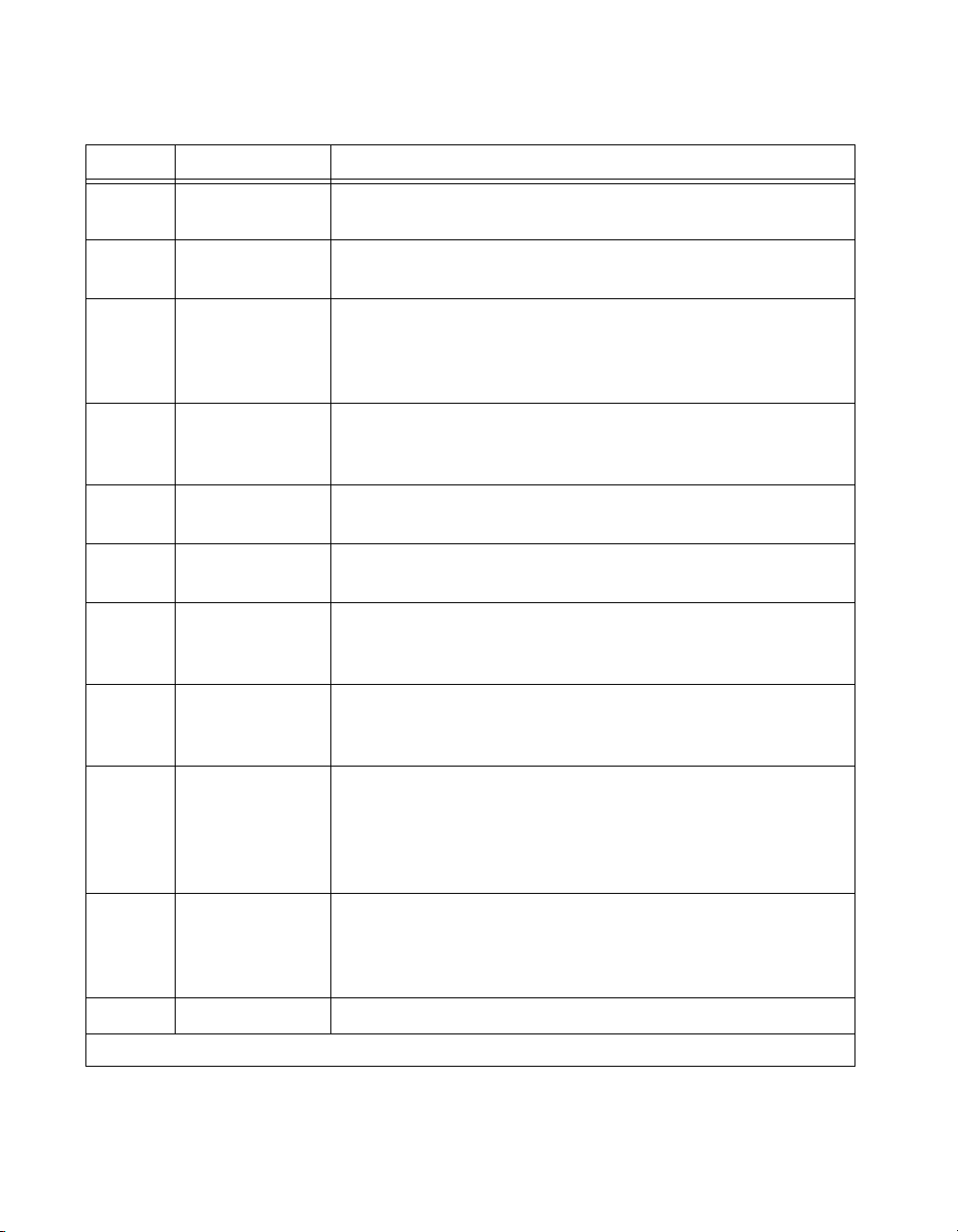

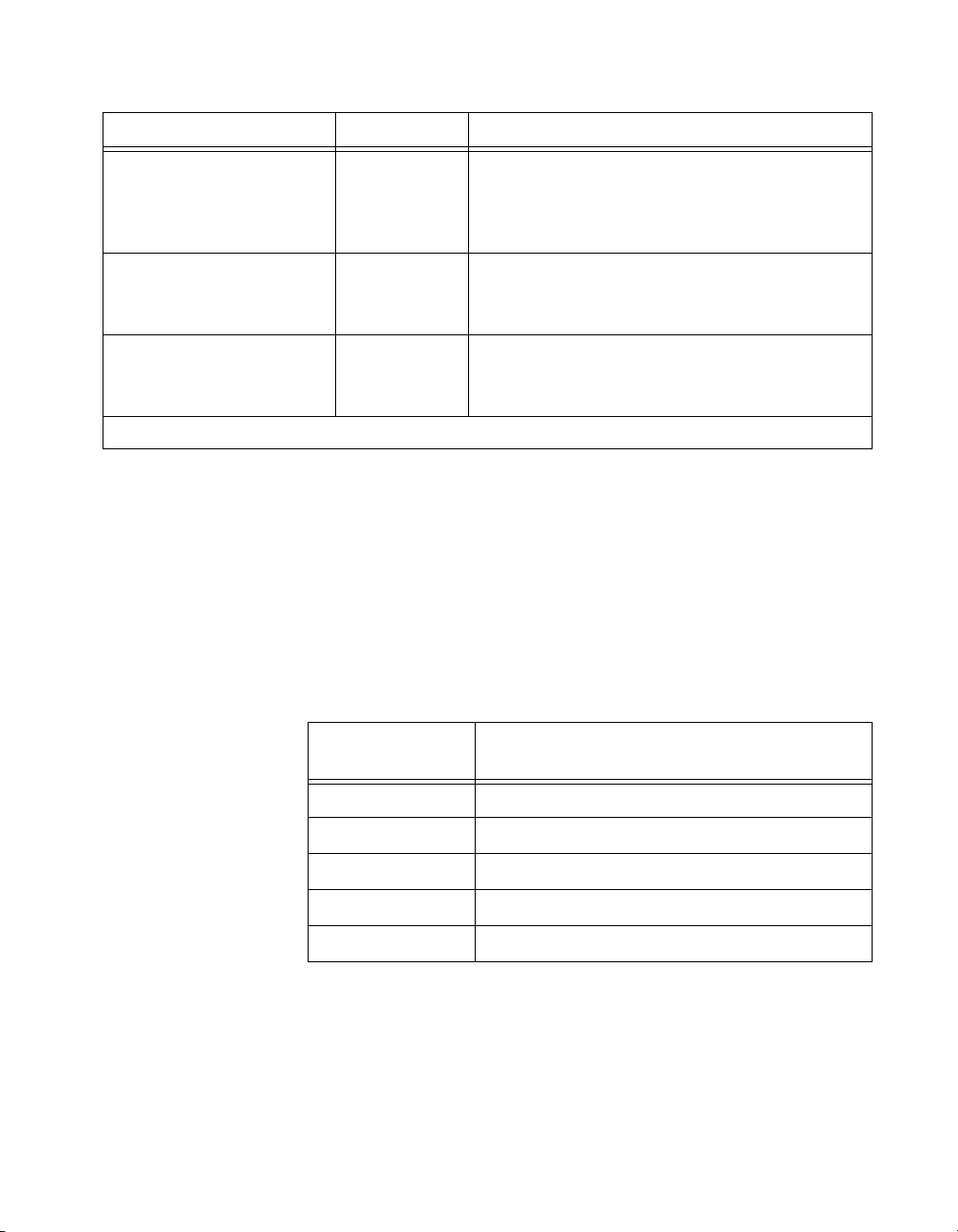

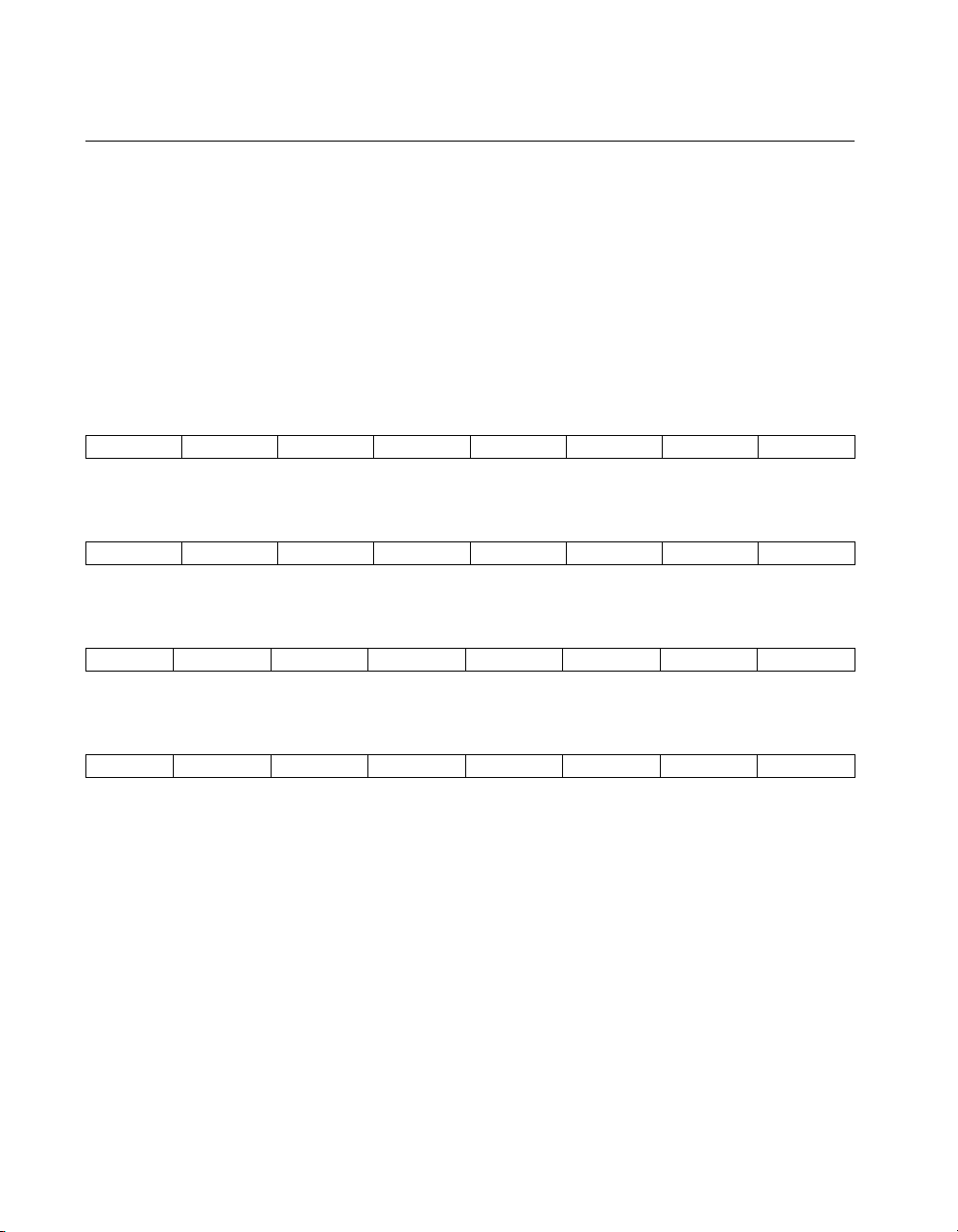

Table 2-1. Digital Signal Connections, Jumper Settings

Jumper Description Configuration

W38 Factory setting;

connects MISO to

SERDATOUT

3

•

2

•

1

•

W38 Parking position

3

•

2

•

1

•

W45 Factory setting

3

•

2

•

1

•

© National Instruments Corporation 2-5 SCXI-1121 User Manual

Page 22

Chapter 2 Configuration and Installation

Analog Configuration

The SCXI-1121 has 45 analog configuration jumpers.

Table 2-1.

Jumper Description Configuration

W44 Factory setting

W32 Fatory-default setting;

W32 Parking position (not

Digital Signal Connections, Jumper Settings (Continued)

(Revision A and B

modules only)

connects pullup to

SERDATOUT

(Revision C and later)

connected on

Revision A or B

modules)

3

•

2

•

1

•

3

•

2

•

1

•

3

•

2

•

1

•

Before starting, notice that the jumper configurations for each input

channel and each excitation channel are similar only the jumper numbers

differ . Therefore, when you learn ho w to set up one channel pair (input and

excitation), you can set up the other channel pairs as well.

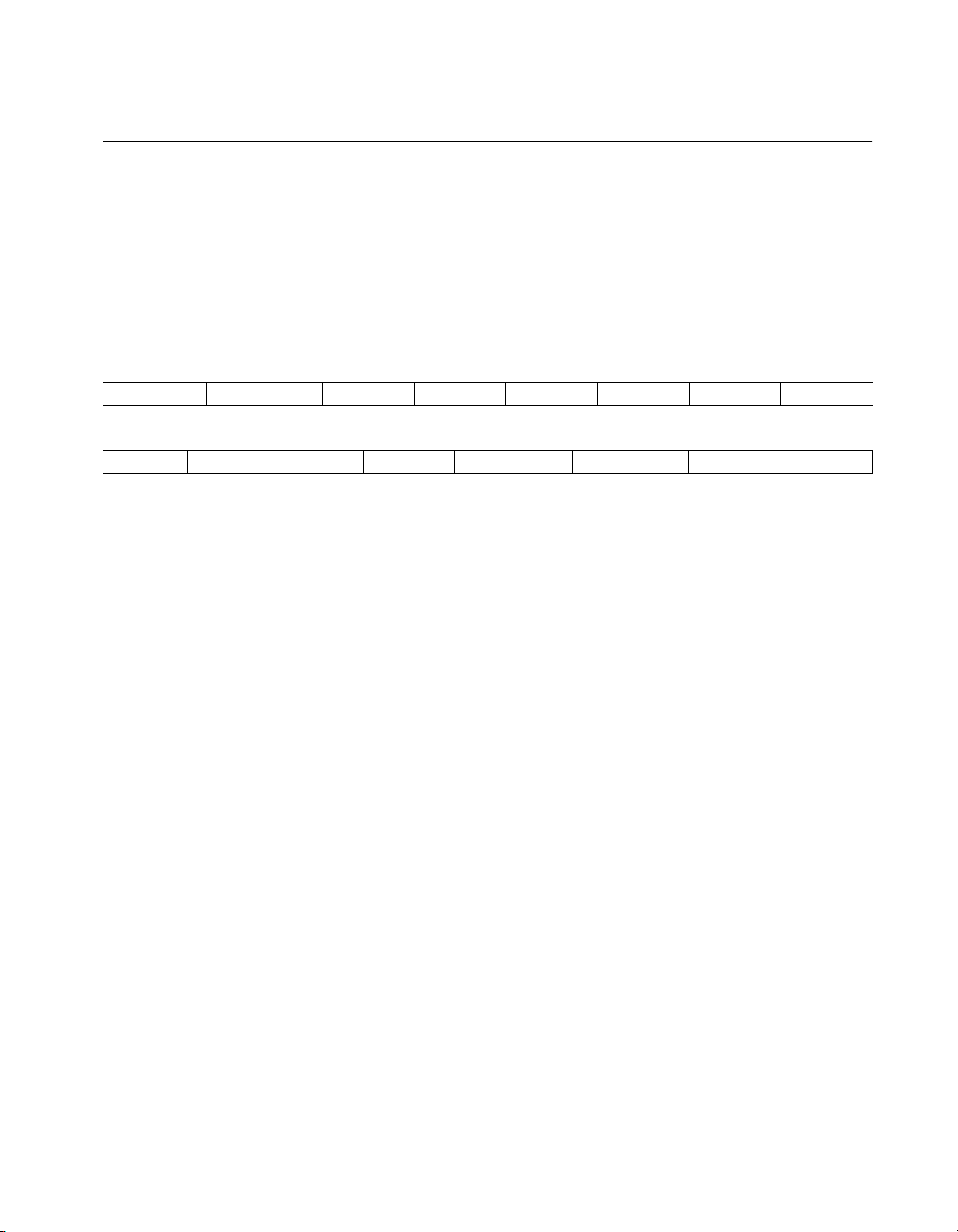

Grounding, Shielding, and Reference Mode Selection

Jumper W33

Position AB-R0 connects the analog reference to the analog output ground

(pins 1 and 2 on the rear signal connector). Select this configuration if you

are using an RSE data acquisition board. It is not recommended to use a

differential input data acquisition board when jumper W33 is in the AB-R0

position.

SCXI-1121 User Manual 2-6 www.natinst.com

Page 23

Chapter 2 Configuration and Installation

•••••

•

A

B

R2 R 1 R 0

•••••

•

A

B

R2 R 1 R 0

•••••

•

A

B

R2 R 1 R 0

•••••

•

A

B

R2 R 1 R 0

Position AB-R1 connects the analog reference to the SCXIbus guard.

Position A-R0R1 is the parking position and the factory setting.

Position AB-R2 enables the Pseudodifferential Reference mode and

connects the analog reference to the OUTREF pin on the rear signal

connector. Select this mode when the SCXI-1121 has to operate with data

acquisition boards that have a nonreferenced single-ended (NRSE) input. It

is not recommended to use differential-input data acquisition boards when

jumper W33 is in the AB-R2 position.

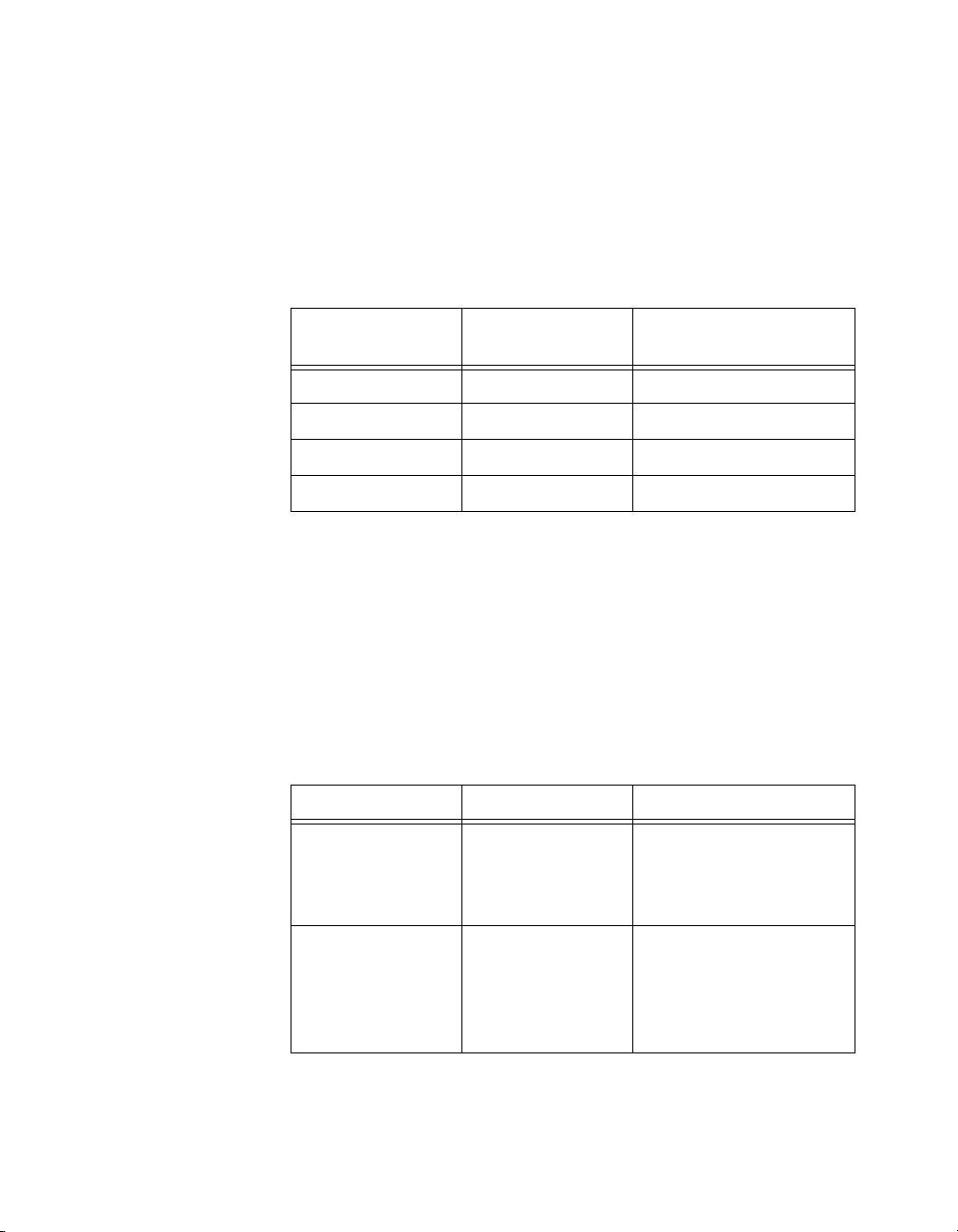

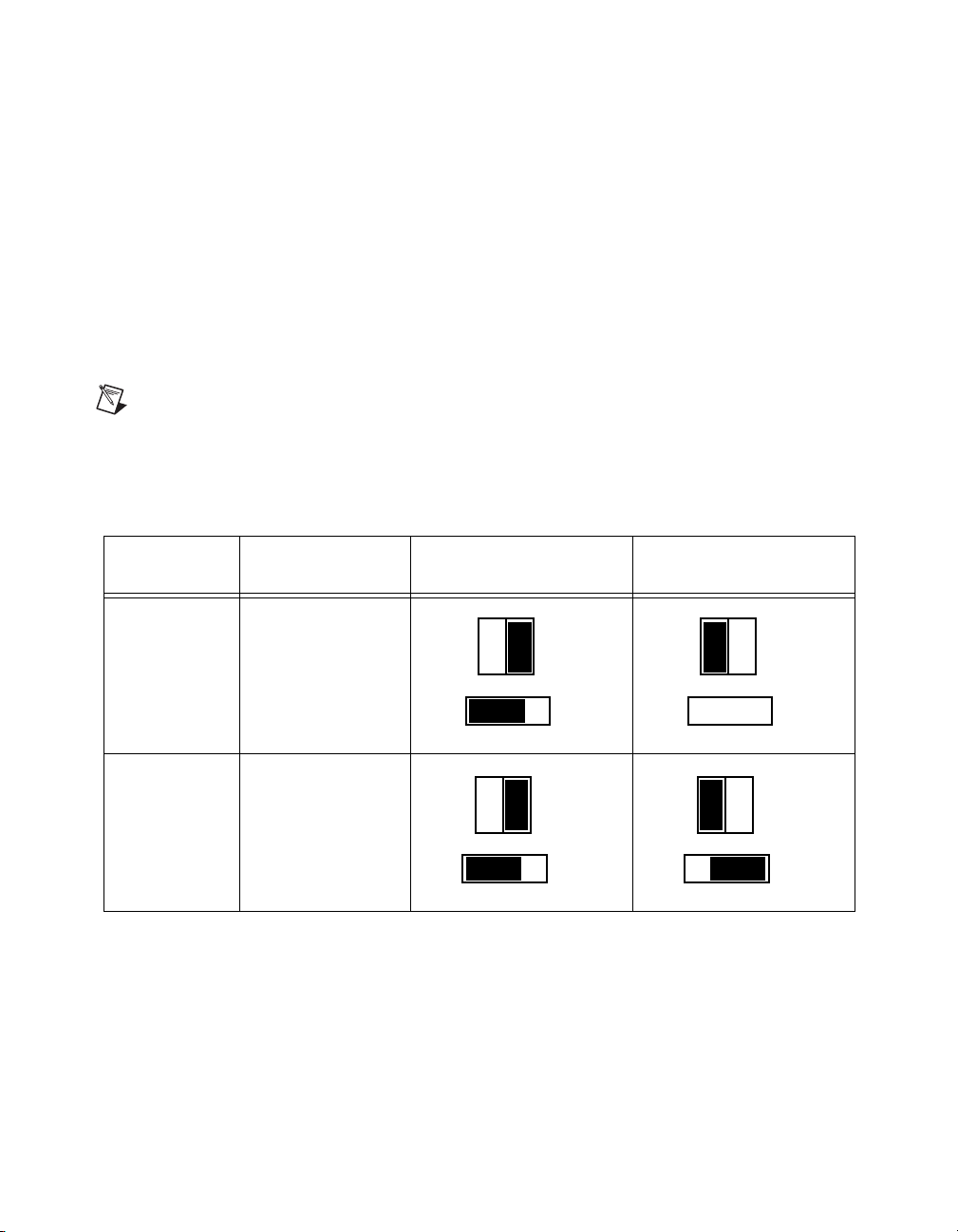

Table 2-2. Jumper W33 Settings

Jumper Description Configuration

W33 Factory setting in

parking position

W33 Connects the

analog reference to

AOGND (pins 1

and 2 of the rear

signal connector)

W33 Connects SCXIbus

guard to the analog

reference

W33 Enables the

Pseudodifferential

Reference mode

(pin 19 of the rear

signal connector is

connected to the

analog reference)

© National Instruments Corporation 2-7 SCXI-1121 User Manual

Page 24

Chapter 2 Configuration and Installation

Input Channel Jumpers

Gain Jumpers

Each input channel has two gain stages. The first gain stage provides gains

of 1, 10, 50, and 100 and the second stage provides gains of 1, 2, 5, 10, and

20. Tables 2-3 and 2-4 show how to set up the gain for each channel.

Table 2-3.

Input Channel

Number

Gain Jumper Allocation

First Gain

Jumper

Second Gain

Jumper

0 W3 W4

1 W19 W20

2 W29 W30

3 W41 W42

The board is shipped to you with the first-stage gain set to 100 (position A)

and a second-stage gain set to 10 (position D). To change the gain of your

module, move the appropriate jumper on your module to the position

indicated in T able 2-4. Refer to Figure 2-2 for the jumper locations on your

module.

T o determine the o verall g ain of a giv en channel use the follo wing formula:

Overall gain = First-stage gain × second-stage gain

Table 2-4.

Gain Jumper Positions

Gain Setting Jumper Position

First-stage 1

10

50

100

A (factory setting)

Second-stage 1

2

5

10

D (factory setting)

20

SCXI-1121 User Manual 2-8 www.natinst.com

D

C

B

A

B

C

E

Page 25

Chapter 2 Configuration and Installation

Filter Jumpers

Two-stage filtering is also available on your SCXI-1121 module. The first

stage is located in the isolated section of the input channel, whereas the

second stage is located in the nonisolated section of the input channel. This

permits a higher signal-to-noise ratio by eliminating the noise generated by

the isolation amplifier. Furthermore, two filter bandwidths are

available—10 kHz and 4 Hz.

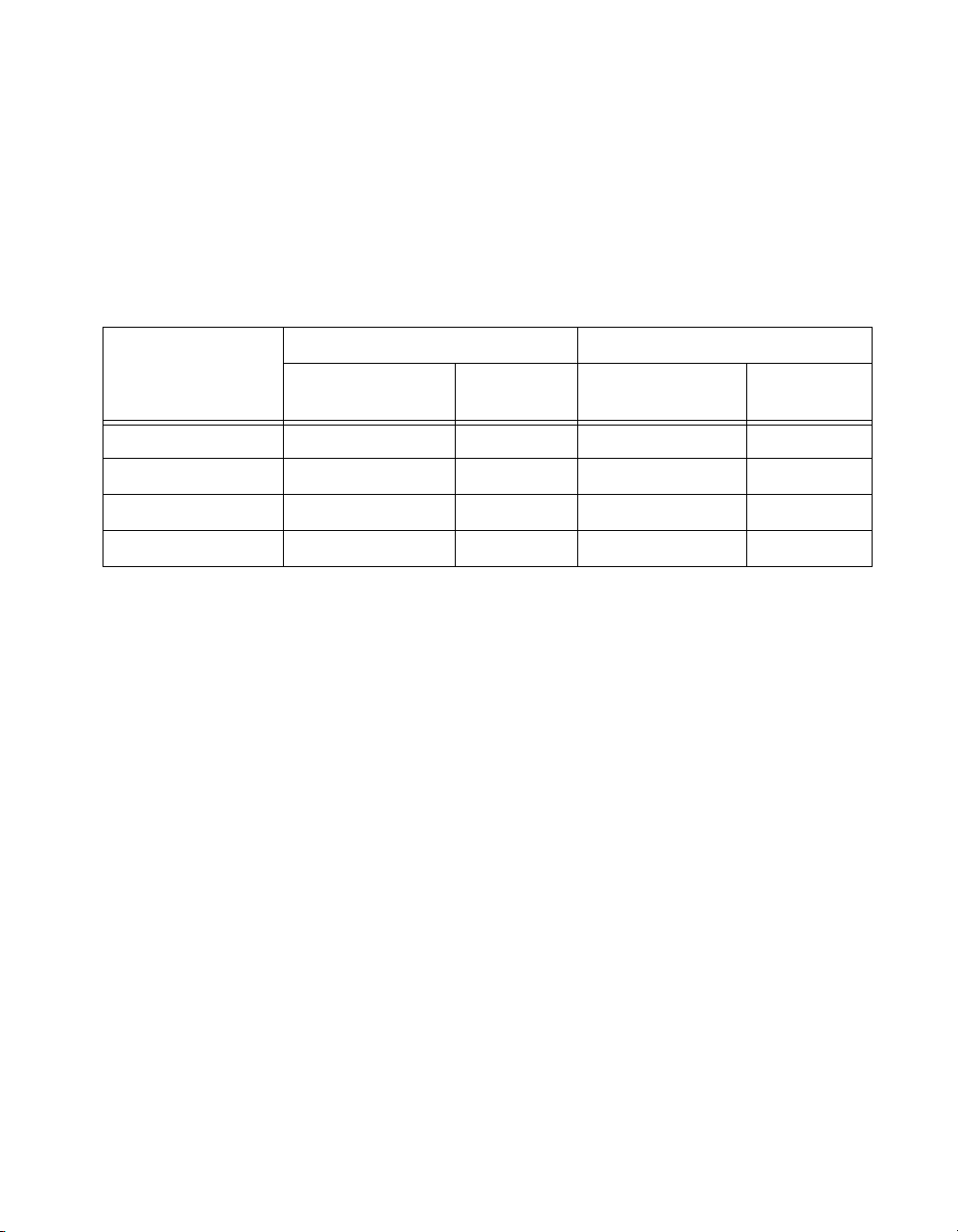

Table 2-5.

First Filter Jumper Second Filter Jumper

Input Channel

Number

0 W5-A W5-B W6 W7

1 W21-A W21-B W8 W9

2 W31-A W31-B W10 W11

3 W43-A W43-B W12 W13

4 Hz

(Factory Setting)

Your SCXI-1121 is shipped in the 4 Hz configuration. Always make sure

to set both stages to the same bandwidth. This will ensure that the required

bandwidth is achieved.

Filter Jumper Allocation

10 kHz

4 Hz

(Factory Setting)

Excitation Jumpers

Current and Voltage Excitation Jumpers

You can configure each excitation channel of your SCXI-1121 to either a

Voltage or Current excitation mode. Each channel has two jumpers for this

purpose. Set both jumpers in the same mode for correct operation of the

excitation channel. Refer to Table 2-6 for setting up your module in the

mode you want. Your SCXI-1121 is shipped to you in the Voltage mode.

10kHz

© National Instruments Corporation 2-9 SCXI-1121 User Manual

Page 26

Chapter 2 Configuration and Installation

•

•

•

W14

1 2 3

•

•

•

W15

1 2 3

•

•

•

W22

1 2 3

•

•

•

W23

1 2 3

•

•

•

W34

1 2 3

•

•

•

W35

1 2 3

•

•

•

W46

1 2 3

•

•

•

W47

1 2 3

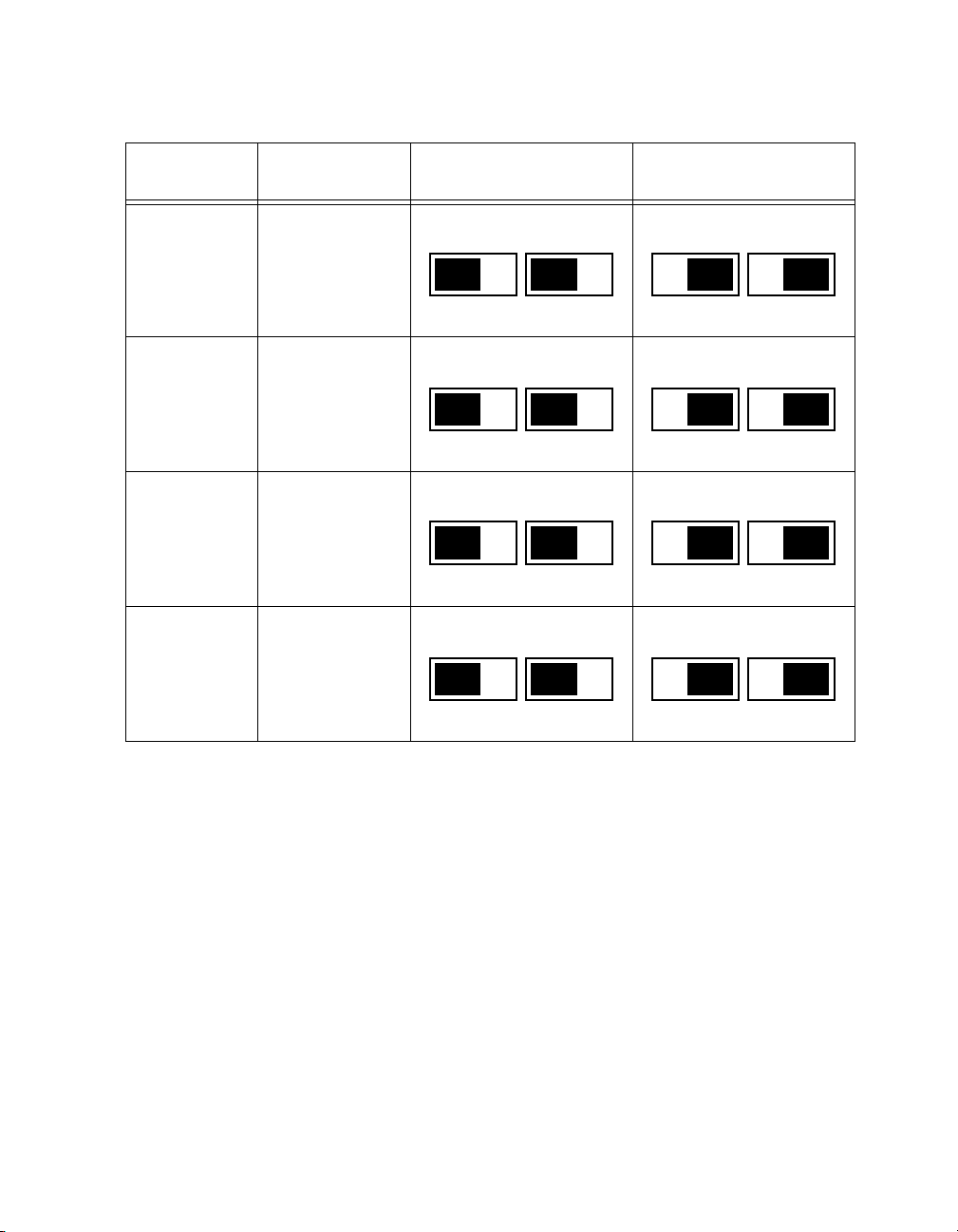

Table 2-6.

Excitation

Channel

Jumpers

0 W14 and W15

1 W22 and W23

2 W34 and W35

3 W46 and W47

Voltage and Current Mode Excitation Jumper Setup

Voltage Mode

(Factory Setting)

W14

•

•

•

1 2 3

W22

•

•

1 2 3

W34

•

•

1 2 3

W46

•

•

•

•

•

•

1 2 3

•

1 2 3

•

1 2 3

•

W15

•

W23

•

W35

•

W47

•

•

•

•

•

Current Mode

1 2 3

1 2 3

Excitation Level

Each excitation channel of your SCXI-1121 has two different current or

voltage levels. You can set a given channel to one of the following level

modes:

• In the Current mode 0.150 or 0.450 mA

• In the Voltage mode 3.333 or 10 V

It is important to notice that you should select the level of excitation

according to the load you are using. Table 2-7 lists the maximum load that

can be driven per channel at each level of excitation for both volt and

current excitation.

SCXI-1121 User Manual 2-10 www.natinst.com

Page 27

Chapter 2 Configuration and Installation

•

•

•

W16

1 2 3

•

•

•

W26

1

2

3

•

•

•

W24

1 2 3

•

•

•

W25

1 2 3

•

•

•

W36

1 2 3

•

•

•

W37

1 2 3

•

•

•

W48

1 2 3

•

•

•

W49

1 2 3

Table 2-7. Maximum Load per Excitation Channel

Excitation Level Maximum Load

3.333 V 28 mA

10 V 14 mA

0.150 mA 10 kΩ

0.450 mA 10 kΩ

After selecting the excitation mode of operation desired—Voltage or

Current—as described in the previous section, use Table 2-8 to set your

SCXI-1121 for the level of operation. Your SCXI-1121 is shipped with the

Voltage mode set to 3.333 V.

Table 2-8. Excitation Level Jumper Selection

Excitation

Channel

0 W16 and W26

1 W24 and W25

2 W36 and W37

3 W48 and W49

Jumpers

3.333 V or 0.150 mA

(Factory Setting)

W16

•

•

1 2 3

W24

•

•

1 2 3

W36

•

•

1 2 3

W48

•

•

•

•

•

1

•

2

3

W25

•

1 2 3

W37

•

1 2 3

W49

•

W26

•

•

•

10 V or 0.450 mA

•

•

•

•

•

•

1 2 3

© National Instruments Corporation 2-11 SCXI-1121 User Manual

1 2 3

Page 28

Chapter 2 Configuration and Installation

A B

W18

W17

1 2 3

•••

•

•

•

•

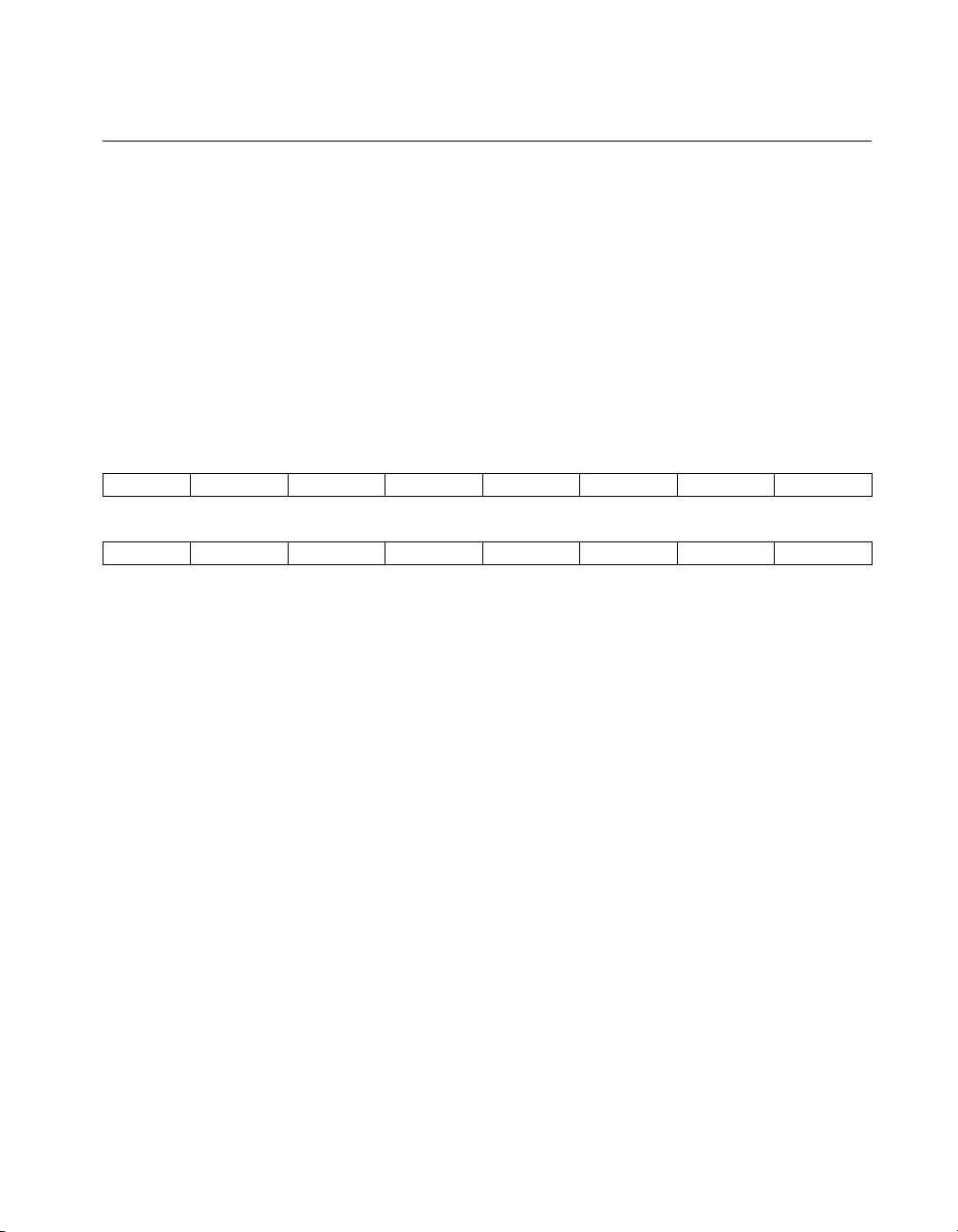

Using the Internal Half-Bridge Completion

Your SCXI-1121 includes half-bridge completion for half-bridge and

quarter-bridge setups. The completion network consists of two

4.5 kΩ ± 0.05% ratio tolerance resistors with a temperature coefficient of

5 ppm/°C. These resistors are connected in series. To enable the network,

you must set two jumpers for each input/excitation channel pair.

When the completion network is enabled, you cannot access the negative

input of the amplifier, which preserves the overvoltage protection of the

channel. Table 2-9 shows how to enable and disable the completion

network.

Note

When using the half-bridge completion network with a quarter-bridge setup, you

must use an extra resistor to complete the bridge. Place this resistor on the terminal block

between the positive input channel and the negative excitation output.

Table 2-9.

Completion Network Jumpers

Channel Jumpers Enable Completion

0 W1 and W2

•••

W2

•

A B

•

•

•

W1

1 2 3

1 W17 and W18

•••

W18

•

A B

•

•

•

W17

1 2 3

Disable Network

(Factory Setting)

•••

W2

•

A B

•

•

•

W1

1 2 3

SCXI-1121 User Manual 2-12 www.natinst.com

Page 29

Table 2-9. Completion Network Jumpers (Continued)

A B

W28

W27

1 2 3

•••

•

•

•

•

A B

W40

W39

1 2 3

•••

•

•

•

•

Channel Jumpers Enable Completion

Chapter 2 Configuration and Installation

Disable Network

(Factory Setting)

2 W27 and W28

3 W39 and W40

•••

•

A B

•

•

1 2 3

•••

•

A B

•

•

1 2 3

W28

•

W40

•

W27

W39

© National Instruments Corporation 2-13 SCXI-1121 User Manual

Page 30

Chapter 2 Configuration and Installation

Hardware Installation

You can install the SCXI-1121 in any available SCXI chassis. After you

have made any necessary changes and have verified and recorded the

jumper settings on the form in AppendixG, Technical Support Resources,

you are ready to install the SCXI-1121. The following are general

installation instructions consult the user manual or technical reference

manual of your SCXI chassis for specific instructions and warnings.

1. Turn off the computer that contains the data acquisition board or

disconnect it from your SCXI chassis.

2. Turn off the SCXI chassis. Do not insert the SCXI-1121 into a chassis

that is turned on.

3. Insert the SCXI-1121 into the board guides. Gently guide the module

into the back of the slot until the connectors make good contact. If a

cable assembly has already been installed in the rear of the chassis, the

module and cable assembly must be firmly engaged; however, do not

force the module into place.

4. Screw the front mounting panel of the SCXI-1121 to the top and

bottom threaded strips of your SCXI chassis.

5. If this module is to be connected to an MIO-16 data acquisition board,

attach the connector at the metal end of the SCXI-1340 cable assembly

to the rear signal connector on the SCXI-1121 module. Screw the rear

panel to the rear threaded strip. Attach the loose end of the cable to the

MIO-16 board.

Note

For installation procedures with other SCXI accessories and data acquisition boards,

consult Appendix E, SCXI-1121 Cabling.

6. Check the installation.

7. Turn on the SCXI chassis.

8. Turn on the computer or reconnect it to your chassis.

The SCXI-1121 module is installed and ready for operation.

SCXI-1121 User Manual 2-14 www.natinst.com

Page 31

Signal Connections

This section describes the input and output signal connections to the

SCXI-1121 board via the SCXI-1121 front connector and rear signal

connector, and includes specifications and connection instructions for the

signals given on the SCXI-1121 connectors.

Chapter 2 Configuration and Installation

Cautions

flammable gasses or fumes.

Keep away from live circuits. Do not remove equipment covers or shields unless you are

trained to do so. If signal wires are connected to the device, hazardous voltages may exist

even when the equipment is turned off. To avoid a shock hazard, do not perform procedures

involving co ver or shield remo v al unless you are qualified to do so and disconnect all field

power prior to removing covers or shields.

Equipment described in this document must be used in an Installation Category II

environment per IEC 60664. This category requires local level supply mains-connected

installation.

Do not operate damaged equipment. The safety protection features built into this device

can become impaired if the device becomes damaged in any way . If the device is damaged,

turn the device off and do not use until service-trained personnel can check its safety. If

necessary , return the device to National Instruments for service and repair to ensure that its

safety is not compromised.

Do not operate this equipment in a manner that contradicts the information specif ied in this

document. Misuse of this equipment could result in a shock hazard.

Terminals are for use only with equipment that has no accessible live parts.

Do not substitute parts or modify equipment. Because of the danger of introducing

additional hazards, do not install unauthorized parts or modify the device. Return the

device to National Instruments for service and repair to ensure that its safety features are

not compromised.

Do not operate the device in an explosive atmosphere or where there may be

When using the device with high common-mode voltages, you must insulate your signal

wires for the highest input voltage. National Instruments is not liable for any damages or

injuries resulting from inadequate signal wire insulation. Use only 26-14 AWG wire with

a voltage rating of 300 V and 60 °C for measuring 250 V. Prepare your signal wire by

stripping the insulation no more than 7 mm.

© National Instruments Corporation 2-15 SCXI-1121 User Manual

Page 32

Chapter 2 Configuration and Installation

When connecting or disconnecting signal lines to the SCXI terminal block screw terminals,

make sure the lines are powered off. Potential differences between the lines and the SCXI

ground create a shock hazard while you connect the lines.

Connect the signal wires to the screw terminals by inserting the stripped end of the wire

fully into the terminals. Tighten the terminals to a torque of 5 to 7 in.-lb.

Connections, including power signals to ground and vice versa, that exceed any of the

maximum signal ratings on the SCXI device can create a shock or fi re hazard or can

damage any or all of the boards connected to the SCXI chassis, the host computer, and the

SCXI device. National Instruments is not liable for any damages or injuries resulting from

incorrect signal connections.

If high voltages (≥30 Vrms and 42.4 V peak or 60 VDC) are present, you must connect a

safety earth ground wire to the terminal block safety ground solder lug. This complies with

safety agency requirements and protects against electric shock when the terminal block is

not connected to the chassis. T o connect the safety earth ground to the safety ground solder

lug, run an earth ground wire in the cable from the signal source to the terminal block.

National Instruments is not liable for any damages or injuries resulting from inadequate

safety earth ground connections.

Do not loosen or re-orient the safety ground solder lug hardware when connecting the

safety ground wire. To do so reduces the safety isolation between the high voltage and

safety ground.

Clean devices and terminal blocks by brushing off light dust with a soft, nonmetallic brush.

Remove other contaminants with deionized water and a stiff nonmetallic brush. The unit

must be completely dry and free from contaminants before returning to service.

Use only National Instruments TBX Series cable assemblies with high-voltage TBX Series

terminal blocks.

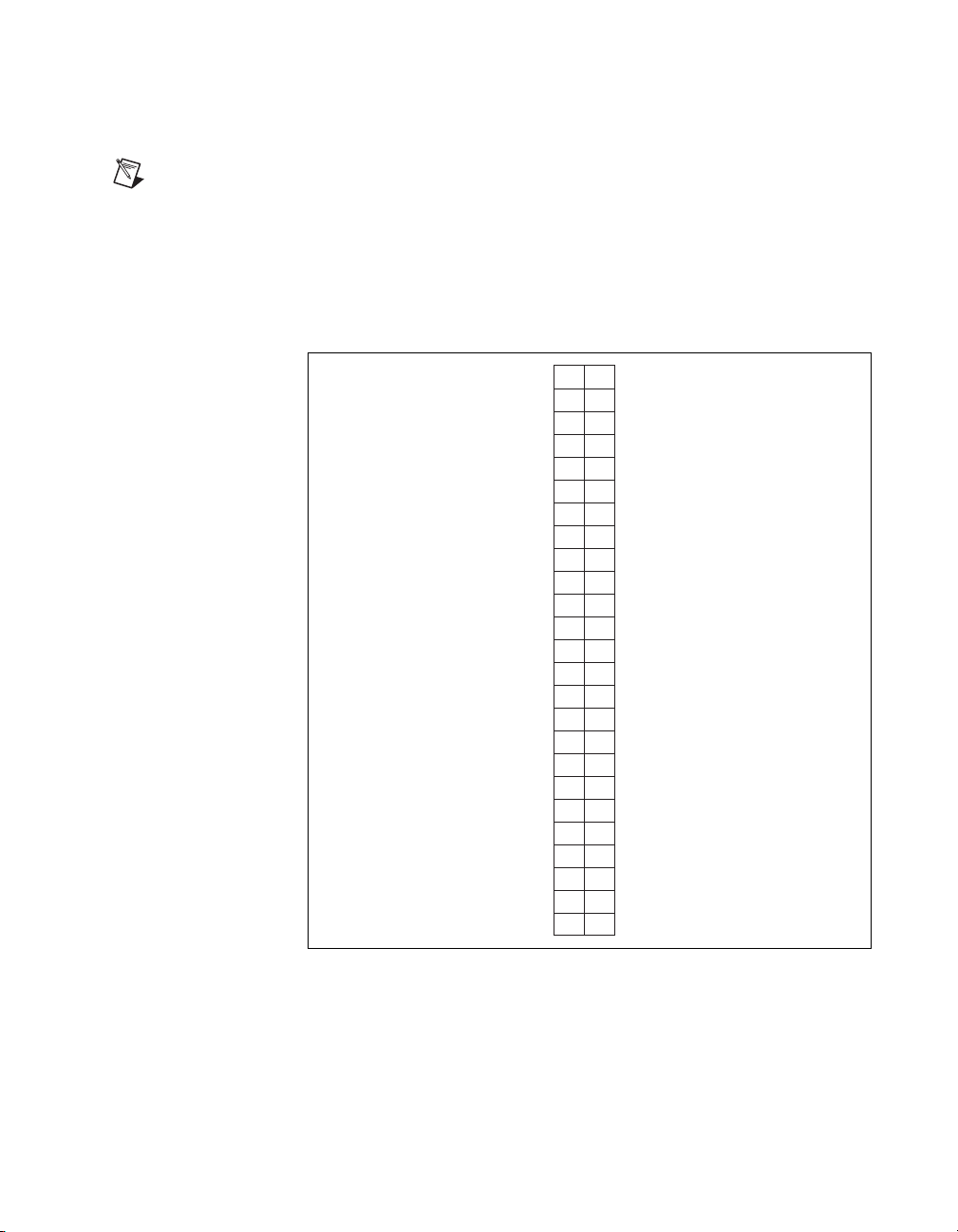

Front Connector

Figure 2-3 shows the pin assignments for the SCXI-1121 front connector.

SCXI-1121 User Manual 2-16 www.natinst.com

Page 33

Chapter 2 Configuration and Installation

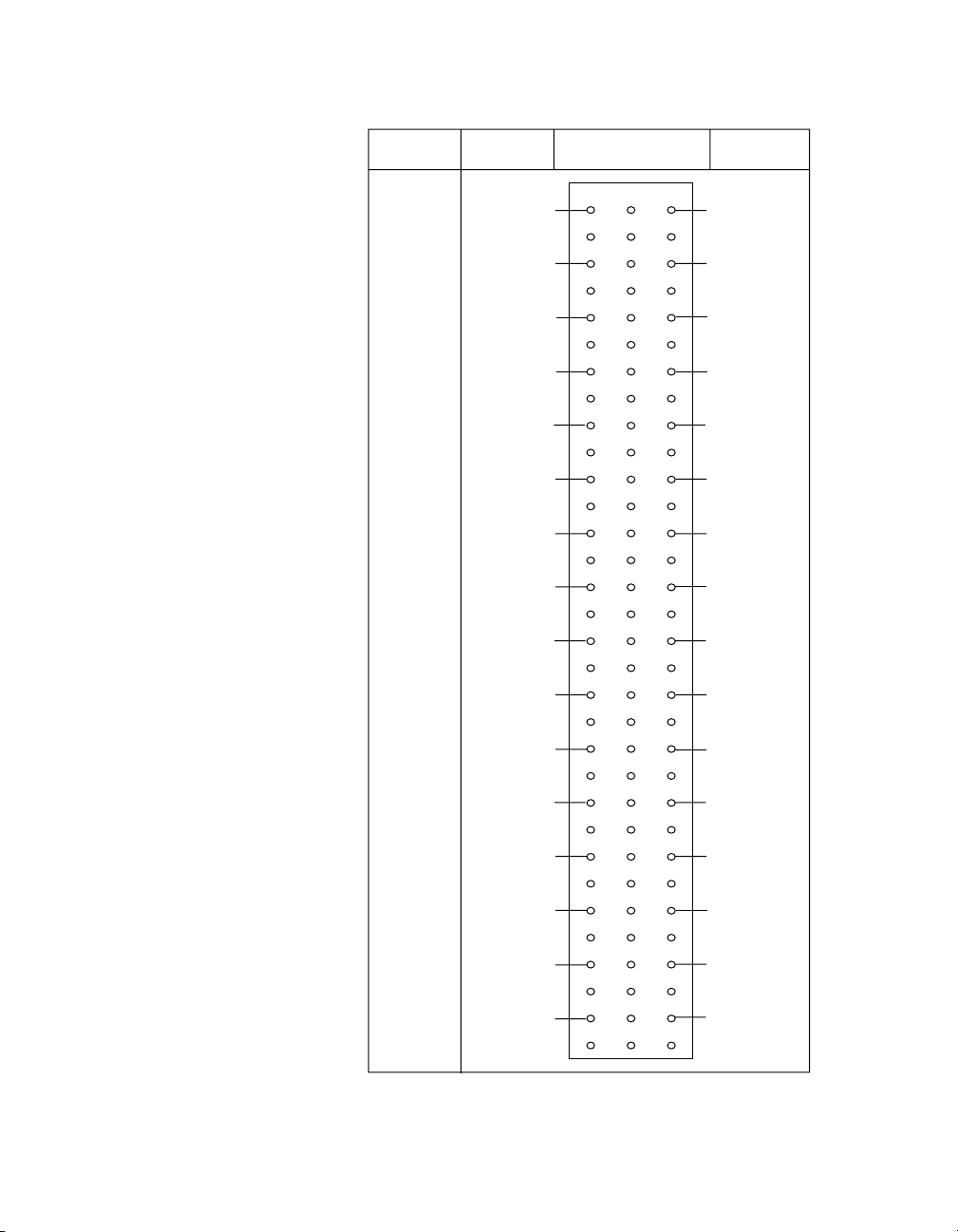

Pin

Number

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

Signal

Name

CH0+

EX0+

EGND0

CH1+

EX1+

EGND1

CH2+

EX2+

EGND2

CH3+

EX3+

EGND3

SCAL

+5 V

CGND

Column

A B C

Signal

Name

CH0–

EX0+

CH1–

EX1–

CH2–

EX2–

CH3–

EX3–

RSVD

RSVD

MTEMP

DTEMP

Figure 2-3. SCXI-1121 Front Connector Pin Assignment

© National Instruments Corporation 2-17 SCXI-1121 User Manual

Page 34

Chapter 2 Configuration and Installation

Front Connector Signal Descriptions

Pin Signal Name Description

A2 CGND Chassis Ground—This pin is tied to the SCXI chassis.

C2 DTEMP Direct Temperature Sensor—This pin connects the

temperature sensor to the MCH4+ when the terminal block

is configured for direct temperature connection.

A4 +5 V +5 VDC Source—This pin is used to power the

temperature sensor on the terminal block. 0.2 mA of source

not protected.

C4 MTEMP Multiplexed Temperature Sensor—This pin connects the

temperature sensor to the output multiplexer.

A6 SCAL Shunt Calibration—This pin is tied to the SCAL bit and is

used to control the SCXI-1321 shunt calibration switch.

CMOS/TTL output not protected.

C6, C8 RSVD Reserved—These pins are reserved. Do not connect any

signal to these pins.

A8, C10, C16,

C22, C28

A10 EGND3 Excitation Ground 3—This pin connects to the excitation

A12 EX3+ Positiv e Excitation Output 3—This pin is connected to the

C12 EX3– Negative Excitation Output 3—This pin is connected to the

A14 CH3+ Positive Input Channel 3—This pin is connected to the

C14 CH3– Negative Input Channel 3—This pin is connected to the

A16 EGND2 Excitation Ground 2—This pin connects to the excitation

A18 EX2+ Positiv e Excitation Output 2—This pin is connected to the

C18 EX2– Negative Excitation Output 2—This pin is connected to the

No Connect Do not connect any signal to these pins.

ground 3 via a 51 kΩ resistor.

excitation channel 3 positive output.

excitation channel 3 negative output.

input channel 3 positive input.

input channel 3 negative input.

ground 2 via a 51 kΩ resistor.

excitation channel 2 positive output.

excitation channel 2 negative output.

SCXI-1121 User Manual 2-18 www.natinst.com

Page 35

Chapter 2 Configuration and Installation

Pin Signal Name Description

A20 CH2+ Positive Input Channel 2—This pin is connected to the

input channel 2 positive input.

C20 CH2– Negative Input Channel 2—This pin is connected to the

input channel 2 negative input.

A22 EGND1 Excitation Ground 1—This pin connects to the excitation

ground 1 via a 51 kΩ resistor.

A24 EX1+ Positi v e Excitation Output 1—This pin is connected to the

excitation channel 1 positive output.

C24 EX1– Negative Excitation Output 1—This pin is connected to the

excitation channel 1 negative output.

A26 CH1+ Positive Input Channel 1—This pin is connected to the

input channel 1 positive input.

C26 CH1– Negative Input Channel 1—This pin is connected to the

input channel 1 negative input.

A28 EGND0 Excitation Ground 0—This pin connects to the excitation

ground 0 via a 51 kΩ resistor.

A30 EX0+ Positi v e Excitation Output 0—This pin is connected to the

excitation channel 0 positive output.

C30 EX0– Negative Excitation Output 0—This pin is connected to the

excitation channel 0 negative output.

A32 CH0+ Positive Input Channel 0—This pin is connected to the

input channel 0 positive input.

C32 CH0– Negative Input Channel 0—This pin is connected to the

input channel 0 negative input.

The signals on the front connector are all analog except pins A6, C6, and

C8, which are digital controls. These analog signals can be divided into

three groups—the analog input channels, the excitation channels, and the

temperature sensor.

© National Instruments Corporation 2-19 SCXI-1121 User Manual

Page 36

Chapter 2 Configuration and Installation

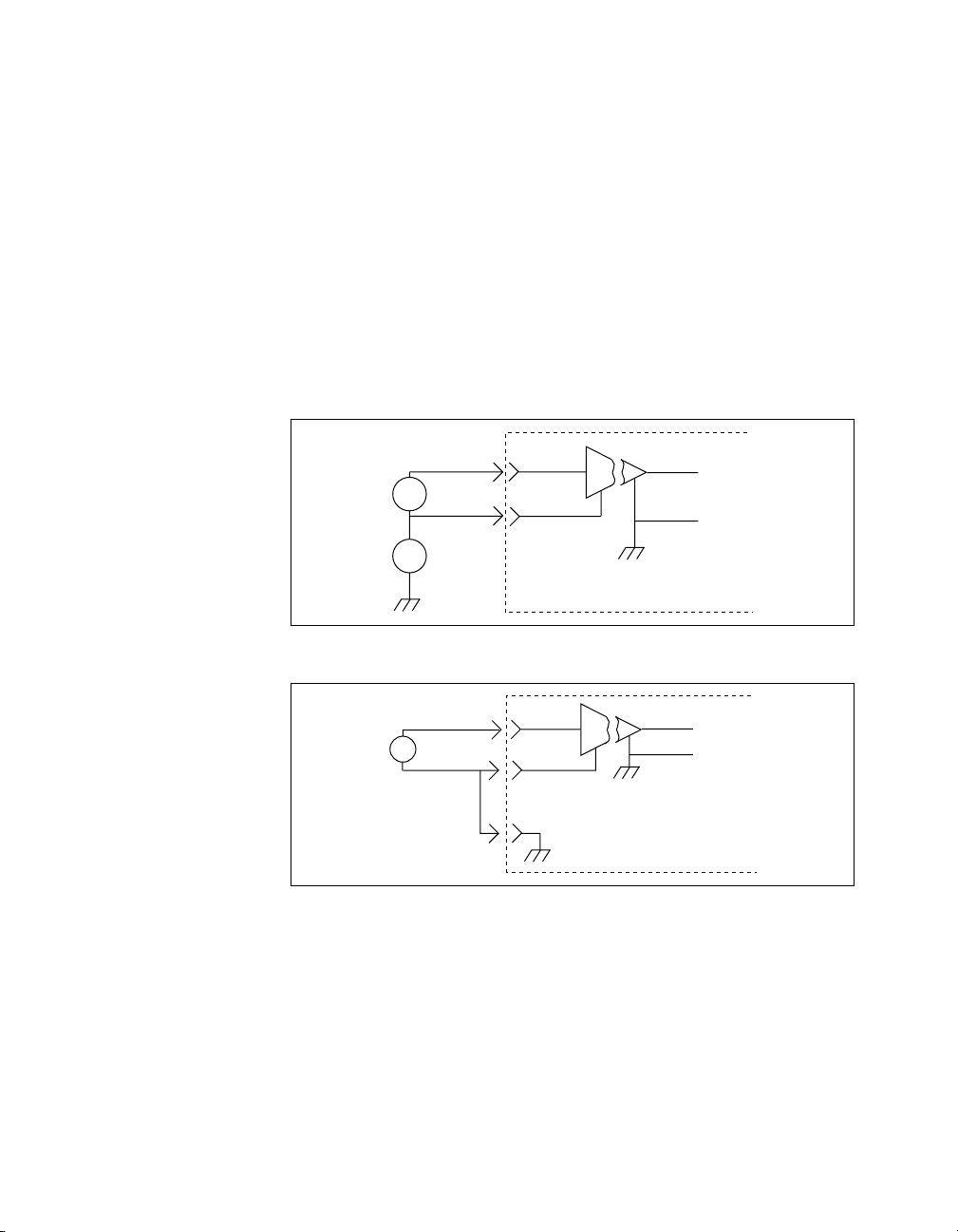

Analog Input Channels

The positive input channels are located in column A. Their corresponding

negative input channels are located in column C. Each input corresponds to

a separate amplifier and is fully isolated from the other channels and from

earth ground. The inputs are designed in a floating single-ended

configuration, hence the measured signal can be referenced to a ground

level with common-mode voltage up to 250 V

immunity, connect the negative input channel to the signal reference. If the

measured signals are floating, connect the negative input channel to chassis

ground on the terminal block. Figure 2-4 shows how to connect a

ground-referenced signal. Figure 2-5 shows how to connect a floating

signal. Figures 2-6 and 2-7 show how to connect AC-coupled signals.

. For better noise

rms

Figure 2-4.

Figure 2-5.

+

V

s

–

+

High

V

cm

CMV

–

+

Module

+

V

out

–

Ground-Referenced Signal Connection with High Common-Mode Voltage

+

V

s

–

+

Module

+

V

out

–

Floating Signal Connection Referenced to Chassis Ground for Better

Signal-to-Noise Ratio

SCXI-1121 User Manual 2-20 www.natinst.com

Page 37

Chapter 2 Configuration and Installation

+

V

R

s

bias

–

+

Module

+

V

out

–

Figure 2-6. Floating AC-Coupled Signal Connection

+

R

V

s

–

+

V

cm

–

bias

High

CMV

+

Module

+

V

out

–

Figure 2-7. AC-Coupled Signal Connection with High Common-Mode Voltage

For AC-coupled signals, you should connect an external resistor from the

positive input channel to the signal reference. This is needed to provide the

DC path for the positive input bias current. Typical resistor values range

from 100 kΩ to 1 MΩ. This solution, although necessary in this case, lowers

the input impedance of the input channel amplifier and introduces an

additional offset voltage proportional to the input bias current and to the

resistor value used. The typical input bias current of the amplif ier consists

of ±80 pA and a negligible offset drift current. When a 100 kΩ resistor is

used, this will result into ±8 µV of offset, which is insignificant in most

applications. However, if larger resistors are used, significant input offset

may result. To determine the maximum offset introduced by the biasing

resistor, use the following equation:

V

ofsbiasIbiasRbias

The input signal range of an SCXI-1121 input channel is ±5 V/ G

referenced to its negative input, where G

×=

is equal to the product of the

total

total

first-stage and second-stage gains. In addition, the input channels are

overvoltage protected to 250 V

4.5 m

© National Instruments Corporation 2-21 SCXI-1121 User Manual

sink or source.

Arms

with power on or off at a maximum of

rms

Page 38

Chapter 2 Configuration and Installation

Warning Exceeding the input signal range and the common-mode input range results in

distorted signals. Exceeding the maximum input voltage rating (250 V

and negative terminals and between any terminal and earth ground) can damage the

SCXI-1121, the SCXIbus, and the DAQ board. National Instruments is not liable for any

damages or injuries resulting from such signal connections.

Excitation Channels

Four fully isolated excitation channels are available. Each excitation

channel corresponds to an input channel. A 250 V

between two corresponding channels (for example, between input

channel 0 and excitation channel 0). In addition, the excitation outputs are

overvoltage protected to 250 V

Warning Exceeding the overvoltage protection or isolation rating on the excitation output

can damage the SCXI-1121, the SCXIbus, and the DA Q board. National Instruments is not

liable for any damages or injuries resulting from such signal connections.

Temperature Sensor Connection

Pins C2 and C4 are dedicated for connecting the temperature sensor to the

SCXI-1121. The temperature sensor is not isolated and is referenced to

chassis ground. The connection is overvoltage-protected to ±25 VDC with

power on and ±15 VDC with power off.

rms

with current foldback.

rms

between positive

rms

isolation barrier exists

Warning Exceeding the overv oltage protection on the temperature connections can

damage the SCXI-1121, the SCXIbus, and the DAQ board. National Instruments is not

liable for any damages resulting from such signal connections.

Connector-and-Shell Assembly

Two types of signal connectors are available to connect the transducers to

the SCXI-1121 inputs. The first, the SCXI-1330 32-pin DIN C female

connector-and-shell assembly, is available in a kit listed in the Optional

Equipment section in Chapter 1, Introduction. The connector has eyelet

ends for easy hook-and-solder wire connection. With this kit, you can build

your own signal cable to connect to the SCXI-1121 inputs. After you have

built the cable, the shell covers and protects the connector. Perform the

following steps to assemble and mount the connector-and-shell assembly

to your SCXI module:

1. Refer to Figure 2-8, Assembling and Mounting the SCXI-1330

Connector-and-Shell Assembly, and the diagram included with your

SCXI-1330 kit to build the connector-and-shell assembly.

2. Turn of f the computer that contains your DA Q board or disconnect the

board from your SCXI chassis.

SCXI-1121 User Manual 2-22 www.natinst.com

Page 39

Chapter 2 Configuration and Installation

3. Turn off your SCXI chassis.

4. Slide the selected module out of the SCXI chassis.

5. Remove the module cover.

6. Place one jack screw on the SCXI-1121 as indicated in Figure 2-8.

7. While holding the jack screw in place, insert the lock washe r and then

the nut. Notice that you might need long-nose pliers to insert the

washer and nut.

8. Tighten the nut by holding it firmly and rotating the jack screw.

9. Repeat steps 6 through 8 for the second jack screw.

10. Replace the module cover and tighten the grounding screw.

11. Slide the module back in place.

12. Connect the SCXI-1330 to your module connector and secure it by

tightening both mounting screws.

Shell Assembly

Mounting Screw

Connector

Mounting Screw

Jack

Screws

Shell Assembly

Lock Washers

Nut

SCXI-1121 Module

Nut

Grounding Screw

Figure 2-8. Assembling and Mounting the SCXI-1330 Connector-and-Shell Assembly

© National Instruments Corporation 2-23 SCXI-1121 User Manual

Page 40

Chapter 2 Configuration and Installation

SCXI-1320, SCXI-1328, and SCXI-1321

Terminal Blocks

The second type of connector available to connect the transducers to the

SCXI-1121 inputs is a terminal block with an onboard temperature sensor

and screw terminals for easy connection. One terminal block, the

SCXI-1328 isothermal terminal block, has a high-accuracy onboard

temperature sensor. The terminal block kits are listed in the Optional

Equipment section in Chapter 1, Introduction.

The terminal blocks consist of a shielded board with supports for

connection to the SCXI-1121 input connector. The terminal blocks have

18 screw terminals for easy connection. Four pairs of screw terminals are

for signal connection to the four inputs of the SCXI-1121, four pairs are for

the excitation channels, and one pair of screw terminals connects to the

chassis ground.

The following warnings contain important safety information concerning

hazardous voltages and terminal blocks.

Warnings

insulate your signal wires appropriately. National Instruments is not liabl e for any damages

or injuries resulting from inadequate signal wire insulation.

If high voltages (≥42 V

strain-relief tab. This complies with UL 1244 and protects ag ainst electric shock when the

terminal block is not connected to the chassis. To connect the safety earth ground to the

strain-relief tab, run an earth ground wire in the cable from the signal source to the terminal

block. National Instruments is not liable for any damages or injuries resulting from

inadequate safety earth ground connections.

When using the terminal block with high common-mode voltages, you must

) are present, you must connect the safety earth ground to the

rms

SCXI-1320 and SCXI-1328 Terminal Blocks

When connecting your signals to the SCXI-1320 terminal block for use

with the SCXI-1121, follow the labeling on the SCXI-1320 indicated under

the module type column for the SCXI-1121 as indicated in Figure 2-11.

When connecting your signals to the SCXI-1328 high-accuracy isothermal

terminal block for use with the SCXI-1121, follow the labeling on the

SCXI-1328 indicated along the module type row for the SCXI-1121 as

indicated in Figure 2-12.

SCXI-1121 User Manual 2-24 www.natinst.com

Page 41

Chapter 2 Configuration and Installation

SCXI-1321 Offset-Null and Shunt-Calibration Terminal Block

The SCXI-1321 terminal block operates only with Revision C and later

SCXI-1121 modules.

In addition to the 18 screw terminals, the SCXI-1321 has circuitry for

offset-null adjust of Wheatstone bridges as well as a shunt resistor for

strain-gauge shunt calibration. This terminal block works especially well

with bridge-type transducers such as strain gauges. The SCXI-1321 can

also easily accommodate thermocouples, RTDs, thermistors, millivolt

sources, volt sources, and current-loop receivers.

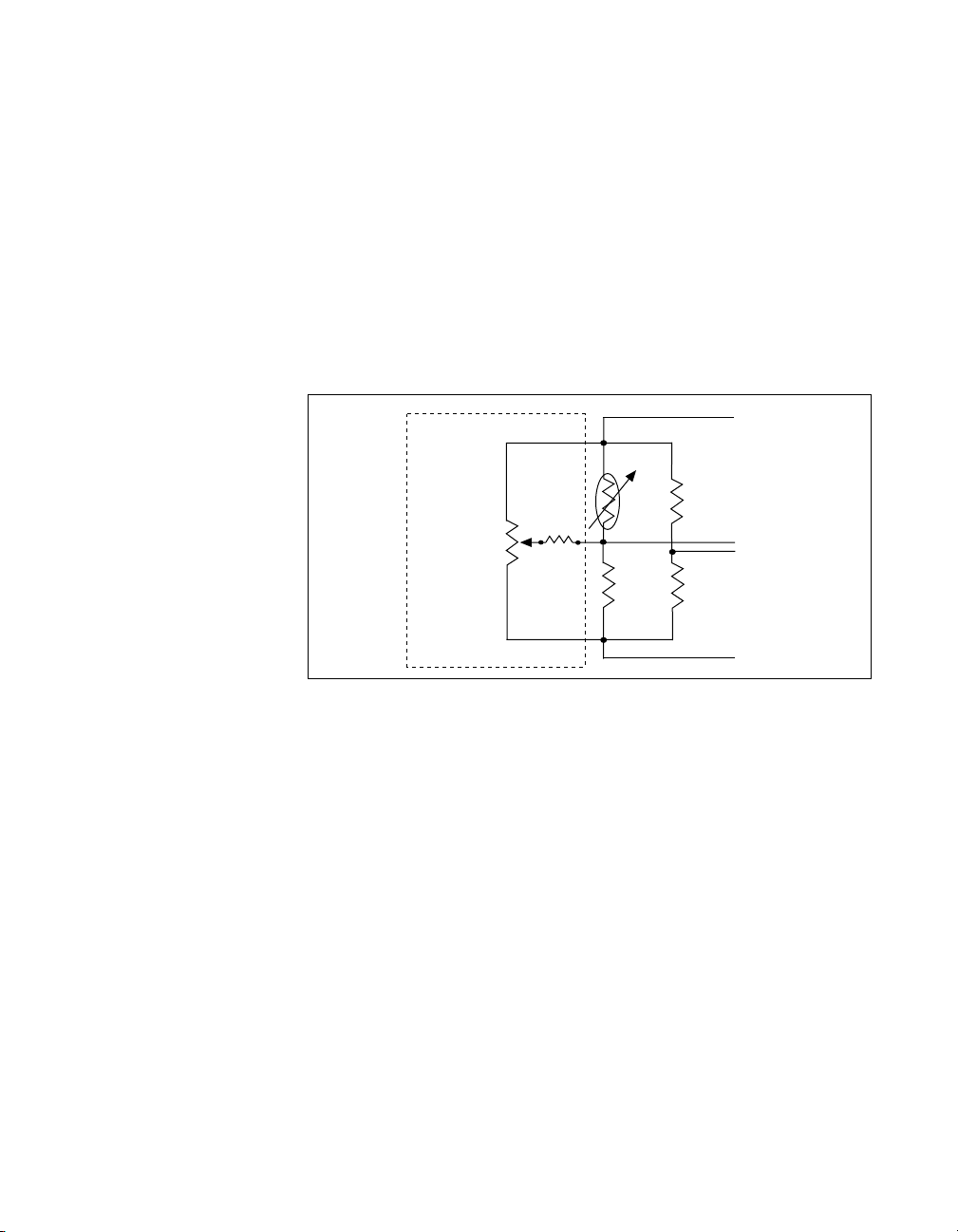

SCXI-1321 Nulling Circuitry

The nulling circuitry operates with full-bridge, half-bridge, quarter-bridge,

and strain-gauge configurations. Each channel has its own nulling circuitry

and its own trimming potentiometer as listed in Table 2-10.

Table 2-10.

Trimmer Potentiometer and Corresponding Channel

Channel Number Trimmer Potentiometer

0 R1

1 R2

2 R14

3 R15

To null the static offset voltage of the bridge, use the following procedure:

1. Configure your bridge to the selected channel.

2. Select and read the channel output.

3. While monitoring the output, rotate the trimmer wiper with a flathead

screwdriver until you reach 0 V.

You have nulled your bridge and are ready for a measurement.

The nulling range for your terminal block is ±2.5 mV, assuming that you

have a 120 Ω strain gauge and 3.333 V excitation voltage. You can change

this range by replacing the nulling resistor with a resistor of another value.

Each channel has an independent nulling resistor. You can therefore mix

your ranges to accommodate each channel requirement. T able 2-11 lists the

nulling resistors and their corresponding channels.

© National Instruments Corporation 2-25 SCXI-1121 User Manual

Page 42