Page 1

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

Instra

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

REMOTE INSPECTION

View

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Page 2

USER GUIDE

SCC-68

I/O Connector Block with 4 SCC Signal Conditioning Slots for DAQ Devices

The SCC-68 is an I/O connector block for easy signal connection to a

National Instruments M Series or E Series DAQ device. The SCC-68

features screw terminals and a general breadboard area for I/O signal

connection, and bus terminals for external power and grounding. The

SCC-68 has four SCC slots for use in integrating thermocouple, strain

gauge, RTD input, frequency input, current input, voltage attenuator,

lowpass filter, load cell input, accelerometer, feedthrough, SPDT relay,

isolated digital I/O, and isolated voltage input SCC modules into the

measurement system.

Contents

Conventions ............................................................................................ 3

Using the SCC-68 Enclosure .................................................................. 4

Opening the Enclosure..................................................................... 4

Closing the Enclosure ...................................................................... 5

Stacking and Wall Mounting ........................................................... 6

Installing Rubber Feet...................................................................... 7

Connecting to the DAQ Device ..............................................................8

Using the SCC-68 with 16 AI Channel M Series Devices .............. 8

Using the SCC-68 with 32 AI Channel M Series Devices .............. 8

Using the SCC-68 with a 68-Pin E Series Device ........................... 9

Using the SCC-68 with the NI 6025E, NI 6033E, or NI 6071E...... 10

SCC-68 Features .....................................................................................11

Screw Terminals .............................................................................. 12

Device Pinouts.......................................................................... 12

Wiring to Screw Terminals....................................................... 12

Integrated Strain Relief....................................................................12

SCC Modules................................................................................... 13

Breadboard Area ..............................................................................13

Using the Temperature Sensor for Cold-Junction

Compensation (CJC)..................................................................... 14

Cold Junction Temperature Measurement Accuracy ............... 15

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 3

Bus Terminals...................................................................................15

Power Supply....................................................................................16

Using SCC Modules with the SCC-68 ....................................................16

Supported SCC Modules ..................................................................17

Connecting Signals to SCC Modules in the SCC-68 .......................17

Power Supply Considerations...........................................................19

LED ...........................................................................................20

Installing the SCC Modules in the SCC-68......................................21

SCC Connector Pinouts.............................................................21

Direct Access to SCC signals....................................................23

Analog Input Measurement Considerations ............................................23

Differential .......................................................................................24

Single-Ended ....................................................................................24

Non-Referenced Single Ended (NRSE) ...........................................25

Grounded Signal Sources ..........................................................25

Floating Signal Sources.............................................................26

Ground-Referenced Single Ended (RSE).........................................26

Grounded Signal Sources ..........................................................26

Floating Signal Sources.............................................................26

Taking Measurements with NI-DAQmx .................................................27

Configuring the SCC-68...................................................................28

Configuring the SCC-68 as an SCC Carrier..............................28

Configuring the SCC-68 as a Screw Terminal Accessory ........28

Configuring Channels and Tasks......................................................29

Configure a Task .......................................................................29

Configure Global Virtual Channels...........................................31

Using Your Task in an Application..................................................32

Specifications...........................................................................................33

Quick Reference Guides..........................................................................38

SCC-68 User Guide 2 ni.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 4

Conventions

The following conventions are used in this manual:

<> Angle brackets that contain numbers separated by an ellipsis represent

a range of values associated with a bit or signal name—for example,

AO <3..0>.

» The » symbol leads you through nested menu items and dialog box options

to a final action. The sequence File»Page Setup»Options directs you to

pull down the File menu, select the Page Setup item, and select Options

from the last dialog box.

This icon denotes a note, which alerts you to important information.

This icon denotes a caution, which advises you of precautions to take to

avoid injury, data loss, or a system crash. When this symbol is marked on

the product, refer to the Read Me First: Safety and Radio-Frequency

Interference document, shipped with the product, for precautions to take.

When symbol is marked on a product, it denotes a warning advising you to

take precautions to avoid electrical shock.

When symbol is marked on a product, it denotes a component that may be

hot. Touching this component may result in bodily injury.

bold Bold text denotes items that you must select or click in the software, such

as menu items and dialog box options. Bold text also denotes parameter

names.

italic Italic text denotes variables, emphasis, a cross-reference, or an introduction

to a key concept. Italic text also denotes text that is a placeholder for a word

or value that you must supply.

monospace Text in this font denotes text or characters that you should enter from the

keyboard, sections of code, programming examples, and syntax examples.

This font is also used for the proper names of disk drives, paths, directories,

programs, subprograms, subroutines, device names, functions, operations,

variables, filenames, and extensions.

SCC-XX This name refers to any SCC module.

© National Instruments Corporation 3 SCC-68 User Guide

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 5

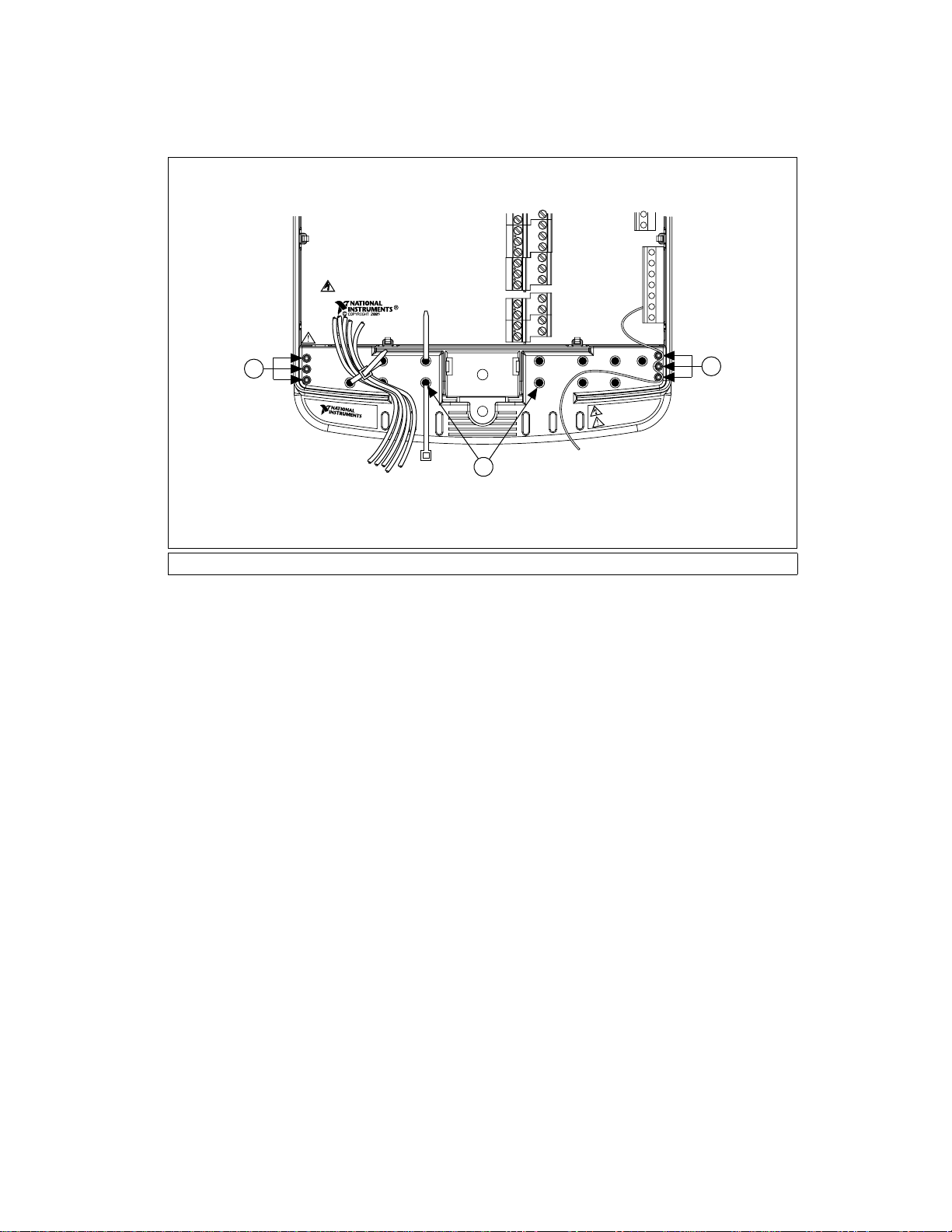

Using the SCC-68 Enclosure

Caution Refer to the Read Me First: Safety and Radio-Frequency Interference document

before removing equipment covers or connecting/disconnecting any signal wires.

4

3

2

1

9

1SCC Slots

2 Screw Terminals

3 68-Pin I/O Connector

4Enclosure Cover

5 Quick Reference Guide

Figure 1. SCC-68 Parts Locator Diagram

5

6

7

8

2

6 Enclosure Base

7 External Power Screw Terminal

8 External Power Switch

9 Strain Relief Wire Entry

Opening the Enclosure

To open the SCC-68, use a flathead screwdriver to loosen the captive screw

at the front of the device. After the screw is loosened, pull up on the front

of the enclosure cover to open. The top half of the SCC-68 enclosure can

be removed completely.

SCC-68 User Guide 4 ni.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 6

Closing the Enclosure

To close the SCC-68, align the two back tabs into the corresponding holes

at the back of the base, as shown in the detail in Figure 2. With the cover

and base of the enclosure aligned, snap the SCC-68 closed. To secure the

SCC-68 enclosure, use a flathead screwdriver to push the screw down

against the spring resistance and tighten the screw.

Caution The captive screw must be used to secure the enclosure when connecting

hazardous voltage (>30 V

Note For safest operation of the SCC-68, NI recommends always using the captive screw

to keep the SCC-68 in a closed position.

/42.4 Vpk/60 VDC) signals to an SCC-RLY01 module.

rms

1

5

1 Strain Relief Posts

2 Snapping Latches

3 Captive Screw

2

3

4

4 Hinge Tabs

5 Strain-Relief Holes for Cable Ties

Figure 2. SCC-68 Enclosure Features

© National Instruments Corporation 5 SCC-68 User Guide

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 7

Stacking and Wall Mounting

The SCC-68 has grooves on the bottom of the enclosure that allow the

device to be stacked on top of other SCC-68 connector blocks.

Note The SCC-68 cannot be securely stacked onto another SCC-68 if the rear rubber feet

are attached.

The SCC-68 also has mounting holes on the bottom of the device for secure

wall-mounting. The third mounting hole allows you to mount the SCC-68

onto a wall sideways or inverted. Refer to Figures 3 and 4 for more

information about the location and use of these enclosure features.

3

17.78 cm

(7.00 in.)

12.70 cm

(5.00 in.)

12.70 cm

(2.50 in.)

2.54 cm

(1.00 in.)

3.51 cm

(1.38 in.)

1

24.46 cm

(9.63 in.)

17.78 cm

(7.00 in.)

2

1 Mounting Holes

2 Directional Mounting Hole

3 I/O Connector Cable

Figure 3. SCC-68 Mounting Dimensions

SCC-68 User Guide 6 ni.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 8

Installing Rubber Feet

Rubber non-skid feet are shipped with the device that can be attached for

secure desktop use. To install the rubber feet, remove adhesive backing and

affix to the SCC-68 where indicated in Figure 4.

3

2

1

1 Rubber Feet

2 Wall-Mounting Holes

Figure 4. SCC-68 Mounting Features

1

3 Stacking Grooves

2

1

© National Instruments Corporation 7 SCC-68 User Guide

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 9

Connecting to the DAQ Device

The following sections describe how to connect the SCC-68 to the DAQ

device. The SCC-68 is designed to be used with M Series and E Series

DAQ devices only. Other 68-pin devices may not function properly with

the SCC-68.

Using the SCC-68 with 16 AI Channel M Series Devices

To use the SCC-68 with a 16 AI channel M Series device, complete the

following steps:

1. Attach the quick reference guide, shown in Figures 21 and 22, to the

top of the SCC-68 enclosure as shown in Figure 1. The quick reference

guide for Connector 0 (included in the SCC-68 kit) shows the pin

assignments of the SCC-68 and other useful information.

2. Attach the SCC-68 to the DAQ device using one of the following

cables:

• SHC68-68-EPM

• SHC68-68

• RC68-68

3. Proceed to the Taking Measurements with NI-DAQmx section for

information about using the SCC-68 in measurement applications.

Note Some M Series devices are available with a 37-pin connector. The SCC-68 cannot

be used with these devices.

Using the SCC-68 with 32 AI Channel M Series Devices

The 32 AI channel M Series DAQ device has two connectors.

• Connector 0 (AI 0-15)

• Connector 1 (AI 16-31)

The SCC-68 can be used with Connector 0 or Connector 1.

To use the SCC-68 with a 32 AI channel M Series device using

Connector 0, complete the following steps:

1. Attach the quick reference guide, shown in Figures 21 and 22, to the

top of the SCC-68 enclosure as shown in Figure 1. The quick reference

guide for Connector 0 (included in the SCC-68 kit) shows the pin

assignments of the SCC-68 and other useful information.

SCC-68 User Guide 8 ni.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 10

2. Attach the SCC-68 to Connector 0 of the DAQ device using one of the

following cables:

• SHC68-68-EPM

• SHC68-68

• RC68-68

3. Proceed to the Taking Measurements with NI-DAQmx section for

information about using the SCC-68 in measurement applications.

To use the SCC-68 with a 32 AI channel M Series device using

Connector 1, complete the following steps:

1. Attach the SCC-68 to Connector 1 of the DAQ device using one of the

following cables:

• SHC68-68-EPM

• SHC68-68

• RC68-68

2. Refer to Figure 22 in the Quick Reference Guides section for the quick

reference guide for the SCC-68 connected to Connector 1 of the DAQ

device. The guide shows the pin assignments of the SCC-68 and other

useful information. Attach a copy of this guide to the top of the

SCC-68 enclosure as shown in Figure 1.

Using the SCC-68 with a 68-Pin E Series Device

To use the SCC-68 with a 68-pin E Series device, complete the following

steps:

1. Attach the SCC-68 to the DAQ device using one of the following

cables:

• SH68-68-EP

• R68-68

2. Refer to Figure 23 in the Quick Reference Guides section for the quick

reference guide for the SCC-68 connected to the E Series DAQ device.

The guide shows the pin assignments of the SCC-68 and other useful

information. Attach a copy of this guide to the top of the SCC-68

enclosure as shown in Figure 1.

© National Instruments Corporation 9 SCC-68 User Guide

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 11

Using the SCC-68 with the NI 6025E, NI 6033E, or NI 6071E

To use the SCC-68 with the NI 6025E, NI 6033E, or NI 6071E, complete

the following steps:

1. Attach the SCC-68 to the DAQ device using an SH1006868 cable. This

cable has two 68-pin connectors labeled MIO 16 and Extended I/O.

Connect the MIO 16 connector to the SCC-68. Refer to Figure 5.

SCC-68

SCB-68 or

Other

Terminal

Block

MIO Connector

Extended

I/O Connector

SH1006868 Cable

Figure 5. Connecting a 100-Pin DAQ Device to an SCC-68 Connector Block and

Another Terminal Block

E Series

100-Pin Device

You cannot use the Extended I/O connector with an SCC-68. Use

another terminal block such as the SCB-68 or CB-68LPR with the

Extended I/O connector.

2. Refer to Figure 23 in the Quick Reference Guides section for the quick

reference guide for the SCC-68 connected to the E Series DAQ device.

The guide shows the pin assignments of the SCC-68 and other useful

information. Attach a copy of this pinout to the top of the SCC-68

enclosure as shown in Figure 1.

SCC-68 User Guide 10 ni.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 12

SCC-68 Features

The following sections describe the hardware features of the SCC-68.

4

3

2

1

FOR PATENTS: NI.COM/PATENTS

68

33

34

66

24

27

4

7

52

17

SCC

SCC

Mod 1

Mod 2

USE SCC CONNECTOR BACKSHELL FOR HAZARDOUS

LIVE SIGNALS (>42.4Vpk / 60VDC)

SCC Mod 1 SCC Mod 2

ROUTE SCC SIGNALWIRE S

ONTHIS SIDE

SCC

Mod 3

SCC Mod 3

65

31

29

9

49

SCC-68

30

63

32

12

47

SCC

Mod 4

SCC Mod 4

SW1

FRONT

SELF POWER

(DEFAULT)

EXTERNAL

POWER

+5V

GND

4.75-5.25V

2A MAX

13

39

15

1

18

40

35

2

36

46

44

45

8

50

53

69

72

73

76

77

78

79

70

71

3

37

38

5

6

41

42

43

10

11

48

16

51

19

74

75

80

81

82

83

57

23

56

25

58

59

60

26

64

28

61

62

67

20

22

54

21

55

5

6

7

8

9

NI SCC-68

10

1SCC Slots

2 SCC Screw Terminals

3 68-Pin I/O Connector

4 External Power Switch

5 External Power Screw Terminals

6 DIO Screw Terminals

7AI Screw Terminals

8 Bus Screw Terminals

9 AO Screw Terminals

10 Strain-Relief Wire Entry

Figure 6. SCC-68 Features

© National Instruments Corporation 11 SCC-68 User Guide

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 13

Screw Terminals

The SCC-68 provides screw terminals for easy I/O connectivity.

Device Pinouts

For a list of pins and their corresponding signal assignments, refer to the

quick reference guide for the device, which can be found in the Quick

Reference Guides section of this document. Refer to the DAQ device

documentation for additional details about the DAQ device signals.

Wiring to Screw Terminals

To connect signals to the SCC-68, complete the following steps while

referring to Figure 1.

1. Disconnect the 68-pin cable from the SCC-68.

2. Remove the top cover as directed in the Opening the Enclosure section.

3. Slide the signal wires through the wire entry strain-relief opening. For

more information about using strain relief with the SCC-68, refer to

the Integrated Strain Relief section.

4. Connect the wires to the screw terminals by stripping off 7 mm

(0.28 in.) of the insulation, inserting the conductors into the terminals,

and tightening the screws.

5. Close the top cover.

You can now connect the SCC-68 to the 68-pin I/O connector.

Integrated Strain Relief

Strain relief for the I/O connector wires is provided through a

labyrinth-style wire entry at the front of the SCC-68 device. For larger

gauge connector wires and jacketed cables, bundle the wires together and

secure the wires to the holes in the wire entry opening using the provided

cable ties.

For smaller gauge connector wires (26 AWG–30 AWG), thread the wires

through the strain-relief posts located on the side opposite the wire entry.

By lacing the connector wires through these posts, movement is limited.

Note Route all SCC signals through the left wire-entry side of the SCC-68. Route all other

signals through the right wire-entry side.

SCC-68 User Guide 12 ni.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 14

USE SCC CONNECTOR BACKSHELL FOR HAZARDOUS

LIVE SIGNALS (>42.4Vpk / 60VDC)

SCC Mod 1 SCC Mod 2

ROUTE SCC SIGNALWIRE S

ONTHIS SIDE

SCC Mod 3

SCC-68

SCC Mod 4

45

8

50

53

69

72

73

76

77

78

79

11

48

16

51

19

74

75

80

81

82

83

28

61

62

67

20

22

54

21

55

1

NI SCC-68

2

Right Wire EntryLeft Wire Entry

1 Small Gauge Strain Relief Posts 2 Larger Gauge Cable Tie Holes

Figure 7. SCC-68 Strain Relief

SCC Modules

The SCC-68 can accept SCC modules for integrating signal conditioning

into your application. Refer to the Using SCC Modules with the SCC-68

section for more information.

Breadboard Area

The SCC-68 features a general breadboard area for custom circuitry such

as filtering or attenuation. For soldering components to the underside of the

breadboard, remove the printed circuit board by carefully snapping it loose

from the SCC-68 enclosure. To desolder on the SCC-68, vacuum-type tools

work best.

1

© National Instruments Corporation 13 SCC-68 User Guide

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 15

Using the Temperature Sensor for Cold-Junction Compensation (CJC)

The SCC-68 has a temperature sensor connected to screw terminals 70 and

71 as shown in Figure 8. Refer to the Specifications section for the formula

for converting the measured voltage on CJC+ to temperature.

+5V

R

4,870 Ω

1

R

5 kΩ at 25 ˚C

T

AI GND

Figure 8. SCC-68 Temperature Sensor Connection

To use the temperature sensor for cold-junction compensation of

thermocouple measurements, connect CJC+ (terminal 70) to AI channel 7

of the SCC-68. Figure 9 shows the temperature sensor connected to AI 7.

CJC+

70

71

CJC+

AI GND

70

71

3

37

38

5

6

41

42

43

10

57

23

56

25

58

59

60

26

AI 7

AI 15

AI GND

Figure 9. Connecting the CJC Sensor to Channel AI 7

You must also ensure that the temperature sensor is powered by one of the

following:

• The DAQ device. Move the power switch to SELF POWER (shown in

item 4 of Figure 6).

• An external power supply. Refer to the Power Supply Considerations

section for more information.

SCC-68 User Guide 14 ni.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 16

To remove power from the temperature sensor, complete the following

steps:

1. Move the power switch to EXTERNAL POWER, shown in item 4 of

Figure 6.

2. Leave the external power screw terminals, shown in item 5 of Figure 6,

unconnected.

Cold Junction Temperature Measurement Accuracy

Note For the most accurate thermocouple measurements, NI recommends using an

SCC-TC series module. For more information, refer to

Temperature differences between the cold-junction temperature sensor and

the actual cold junction formed by a thermocouple connected to the screw

terminals will directly contribute to thermocouple measurement errors.

With minimal loading on the SCC-68 ±15V power supply, the temperature

difference between the screw terminals of the SCC-68 is typically less than

1 °C. Variations in the ambient temperature, SCC module heat dissipation,

and heat conducted along thermocouple wire can all contribute to

isothermal errors across the screw terminals.

For more information on thermocouple theory and use, refer to the Taking

Thermocouple Temperature Measurements tutorial at

ni.com/products.

ni.com/zone.

Bus Terminals

The bus terminals provide an easy interface for supplying external power,

extra ground terminals, or grounding to any sensors or custom circuits used

in the SCC-68. There are two buses—Bus A and Bus B—where all four

screw terminals on each side are connected together internally. To use these

terminals, you may connect the power supply from an external source, and

then use the remaining three terminals to connect sensors or circuits inside

the SCC-68.

76

Bus B

Bus A and Bus B are not connected to

© National Instruments Corporation 15 SCC-68 User Guide

77

78

79

any other signals on the SCC-68.

Figure 10. Bus Terminals

80

81

82

83

Bus A

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 17

The bus terminals do not provide external power to the SCC modules

installed in the SCC-68 or to the +5V terminal. Refer to the Power Supply

Considerations section for information about providing power to SCC

modules in your application.

Power Supply

In most situations, the SCC-68 is powered by the DAQ device, eliminating

the need for an external power supply. The +5V power provided by the

DAQ device is distributed to all components in the SCC-68, including the

+5V screw terminal (pin 8). The +5V power on the DAQ device is current

limited. For more information about the power supply and possible

limitations, refer to the Power Supply Considerations section.

Using SCC Modules with the SCC-68

The SCC-68 has four SCC slots for integrating signal conditioning into

your applications. Each SCC slot can be used with any analog input or

digital I/O SCC modules. The SCC-68 is not compatible with analog output

or counter SCC modules.

Note If you use analog input SCC modules with the SCC-68, you must connect

AI SENSE to AI GND, as shown in Figure 11.

62

AI SENSE

67

AI GND

20

22

54

21

55

Figure 11. Connecting AI SENSE to AI GND

SCC-68 User Guide 16 ni.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 18

Supported SCC Modules

The SCC-68 supports all analog input and digital I/O SCC modules.

Table 1 shows all SCC modules that are compatible with the SCC-68.

SCC-AI0x Isolated Voltage Input

SCC-TC0x Thermocouple Input

SCC-LP0x Lowpass Filters

SCC-SG0x Strain Gauge Input

SCC-SG24 Load Cell Input

SCC-ACC01 Accelerometer Input

SCC-FT01 Feedthrough

SCC-RTD01 RTD Input

SCC-FV01 Frequency Input

SCC-CI20 Current Input

SCC-A10 Voltage Attenuation

Table 1. SCC-68-Compatible SCC Modules

SCC Module Type

SCC-DI01/DO01 Isolated Digital I/O

SCC-RLY01 SPDT Relay

Connecting Signals to SCC Modules in the SCC-68

Caution Always refer to the specifications in the SCC-XX module user guide before

connecting signals. Exceeding specified module ratings can create a shock or fire hazard

and can damage any or all of the devices connected to the module.

Caution The captive screw must be used to secure the enclosure when connecting

hazardous voltage (>30 V

Disconnect the 68-pin cable for the DAQ device before installing or removing any

SCC modules.

© National Instruments Corporation 17 SCC-68 User Guide

/42.4 Vpk/60 VDC) signals to an SCC-RLY01 module.

rms

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 19

Caution You must use an SCC connector backshell when connecting hazardous voltage

(>30 V

/42.4 Vpk/60 VDC) signals to an SCC-RLY01 module. Refer to Figure 12.

rms

Figure 12. SCC Connector Backshell

Refer to the SCC-XX user documentation for additional safety information.

To connect an SCC module to the SCC-68, complete the following steps:

1. Remove power from the signal lines.

2. Strip insulation from the ends of the signal wires. Refer to the SCC-XX

user documentation for the exact strip length for the module.

3. Insert the conductors into the screw terminals. The SCC-XX module

has a fixed screw-terminal receptacle and a removable screw-terminal

block, as shown in Figure 13.

1

4

3

2

1

SCC-

XXXX

2

1 SCC Screw-Terminal Receptacle 2 Removable Screw-Terminal Block

Figure 13. SCC-XX Two -Part Sc re w-Termin al System

4. Tighten the screws to 0.5 to 0.6 N · m (4.4 to 5.3 lb · in.) of torque.

SCC-68 User Guide 18 ni.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 20

Power Supply Considerations

The +5V power provided by the DAQ device is distributed to all

components in the SCC-68 and is also used to generate ±15V power for

SCC modules. Figure 14 shows the power distribution of the SCC-68.

If your application exceeds the current limitation of the DAQ device, you

will need to connect an external power supply—such as the External Power

Supply for the SCC-68 Accessory (Part Number 779641-01)—to the

SCC-68. To use an external power supply with the SCC-68, connect the

power supply to the screw terminals shown in item 5 of Figure 6 and move

the power switch (shown in item 4 of Figure 6) to EXTERNAL POWER.

You may need an external power supply if you have SCC modules installed

and any of the following conditions apply to your application:

• More than two SCC-AI0x or SCC-SG24 modules are installed in the

SCC-68

• The cable connecting the DAQ device to the SCC-68 is longer

than2m

• You measure less than 4.50 V between terminals 8 and 50 when the

SCC-68 is under full load

• You are using a PCMCIA device such as the NI DAQCard-6024E

• You are using +5V to power custom circuitry on the breadboard area

1

1

If the +5V power from the DAQ device drops below about 4.5 V, SCC modules installed in the SCC-68 will not operate

properly. The LED in the SCC-68 will flash seven times per second to indicate this condition. There is no error or notification

in software.

© National Instruments Corporation 19 SCC-68 User Guide

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 21

Figure 14 shows the power supply path and power distribution of the

SCC-68.

External

Power Supply

GND

+5V

GND

PC or PXI

Chassis

Powe r

Supply

Current

Limiter

DAQ Device

+5V (Filtered)

Voltage

Monitor

Switching

Power Supply

LED

GND

SCC-68

+15V

–15V

SCC

Mod 1

SCC

Mod 2

SCC

Mod 3

SCC

Mod 4

+5V

SW1

Filter

+5V Screw

Terminal

(Pin 8)

Figure 14. SCC-68 Power Distribution Block Diagram

LED

The LED in the SCC-68 shows the status of the power supply. The SCC-68

monitors the voltage of the +5V signal from the DAQ device, as shown in

Figure 14. Table 2 shows the correlation between power levels in the

SCC-68 and the LED status.

Table 2. SCC-68 Power Levels

Voltage on +5V Signal LED Status Meaning

*

≥4.5 V

≥2 V and <4.5 V

*

On Power on

Blinking Power insufficient

†

<2 V Off Power is off or power

insufficient

*

Due to component variations, the threshold for the LED can vary between 4.25 V

and 4.5 V.

†

Refer to the Power Supply Considerations section for more information about supported

SCC module configurations and other SCC-68 power supply issues.

SCC-68 User Guide 20 ni.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 22

Installing the SCC Modules in the SCC-68

To install the SCC modules on the SCC slots of the SCC-68, plug the SCC

modules onto the appropriate connector block sockets. When properly

oriented, SCC modules plug easily onto the connector block socket. Never

force an SCC module onto the socket.

SCC Connector Pinouts

This section contains descriptions of all the signals carried by the 20-pin

sockets on the SCC-68 carrier. You can also access these signals by using

an SCC feedthrough module, such as the SCC-FT01. For more information

about the SCC-68 carrier connector locations, refer to the SCC Quick Start

Guide at

the SCC sockets.

ni.com/manuals. Refer to Figure 15 for the pin assignments of

© National Instruments Corporation 21 SCC-68 User Guide

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 23

AI 3

AI 11

AI GND

D GND

P0.3

3063321247

AI 2

AI 10

AI GND

D GND

P0.2

653129949

AI 1

AI 9

AI GND

D GND

P0.1

336627717

AI 3

AI SENSENCP0.3

13579

246

NC

AI 2

13579

246

NC

AI 1

13579

246

8

AI 11

AI GNDNCD GND

AI SENSENCP0.2

8

AI 10

AI GNDNCD GND

AI SENSENCP0.1

8

+5V (Filtered)

AI GND

+15V

NCNCNC

11

13

15

10

12

14

16

–15V

5V RefNCNC

+5V (Filtered)

AI GND

+15V

NCNCNC

11

13

15

14

10

+5V (Filtered)

10

16

12

–15V

5V RefNCNC

AI GND

+15V

NCNCNC

15

11

13

12

14

16

171819

20

SCC Module 4

NC

171819

20

SCC Module 3

NC

Figure 15. SCC Module 20-Pin Connector Orientation and Pinout

171819

20

SCC Module 2

NC

AI 9

AI 0

AI 8

AI GND

D GND

P0.0

683424452

AI GNDNCD GND

AI 0

AI SENSENCP0.0

13579

246

NC

8

AI 8

AI GNDNCD GND

–15V

5V RefNCNC

+5V (Filtered)

AI GND

+15V

NCNCNC

15

11

13

10

12

14

16

–15V

5V RefNCNC

NC

171819

20

SCC Module 1

NC

SCC-68 User Guide 22 ni.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 24

Direct Access to SCC signals

When no SCC module is installed in a socket, you can access the AI and

DIO signals on that SCC socket with screw terminals. The screw terminals

are located behind each SCC socket, as shown in Figure 6.

Caution When an SCC module is installed, do not connect signals to the

five corresponding screw terminals behind the module. Doing so can result in

unpredictable behavior in your application.

Analog Input Measurement Considerations

You can measure analog input signals with the SCC-68 the following ways:

• Connect AI signals to SCC modules

• Connect AI signals to SCC-68 screw terminals which get routed to the

DAQ device

If you are not using SCC modules in the system, refer to the M Series User

Manual or the E Series Help for information about connecting analog input

signals.

If you are using SCC modules for some of the AI signals, you can also

measure other AI signals using the AI screw terminals in the SCC-68. Refer

to Figure 6 for the location of the AI screw terminals.

This section describes some considerations for connecting these AI signals

to the SCC-68. When using SCC analog input modules you should connect

AI SENSE to AI GND as shown in Figure 11. This section only addresses

measurement considerations for signal sources that are connected to analog

input channels not used by installed SCC modules

© National Instruments Corporation 23 SCC-68 User Guide

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 25

Table 3 summarizes the recommended input configurations for floating

signal and ground-referenced signal sources.

Table 3. Recommended AI Ground Reference Setting when SCC Modules are Installed

*

Signal Source Type

AI Ground

Reference Setting

Floating Signal Sources

(Not Connected to Building Ground)

Ground-Referenced

Signal Sources

Differential (DIFF) Best Best

Referenced

Not Recommended Not Recommended

Single-Ended (RSE)

Non-Referenced

Good Not Recommended

Single-Ended

(NRSE)

*

This section assumes that when SCC modules are installed, AI SENSE and AI GND on the DAQ device are connected

together. If you are not using SCC modules in the system, refer to the M Series User Manual or the E Series Help for

information about connecting analog input signals.

Refer to the NI Developer Zone document, Field Wiring and Noise

Considerations for Analog Signals, for more information. To access this

document, go to

ni.com/info and enter the info code rdfwin.

Differential

A differential (DIFF) connection is a connection in which the AI signal has

its own reference signal return path as described in the M Series User

Manual or the E Series Help.

Use differential input connections for any channel that meets any of the

following conditions:

• The input signal is low-level (less than 1 V).

• The leads connecting the signal to the device are greater than

3m(10ft).

• The input signal requires a separate ground-reference point or return

signal.

• The signal leads travel through noisy environments.

Single-Ended

A single-ended connection is a connection in which the device AI signal

is referenced to a ground that it can share with other input signals.

National Instruments M Series and E Series devices provide two

single-ended connection configurations.

SCC-68 User Guide 24 ni.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 26

Use single-ended input connections if the input signal meets the following

conditions.

• The input signal is high-level (greater than 1 V).

• The leads connecting the signal to the device are less than 3 m (10 ft).

• The input signal can share a common reference point with other

signals.

Differential input connections are recommended for greater signal integrity

for any input signal that does not meet the preceding conditions.

Non-Referenced Single Ended (NRSE)

Refer to the NRSE connection considerations described in the MSeries

User Manual or the E Series Help. If you have SCC modules installed in

the SCC-68, the following cases should also be noted.

Grounded Signal Sources

If you have SCC modules installed in the SCC-68, differential

measurements are recommended over NRSE measurements. When you

have SCC modules installed, connect AI GND to AI SENSE. If you

connect the ground of the signal source to AI SENSE, you are also shorting

it to AI GND. Connecting the ground of the signal source to AI GND

introduces a ground loop and ground-loop-induced errors. Figure 16 shows

this measurement error.

SCC-68 DAQ Device

Ground-Referenced

Signal

Figure 16. Ground-Referenced Signal Connected in NRSE Mode

© National Instruments Corporation 25 SCC-68 User Guide

AI

+

–

AI SENSE (Pin 62)

AI GND (Pin 67)

Not Recommended

+

–

NRSE Mode

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 27

The difference in potential between the ground of the signal source and

AI GND causes an error when measuring the signal. The amount of this

error depends on several factors including the length of the cable

connecting the DAQ device to the SCC-68 and the amount of current being

drawn by the SCC-68 from the DAQ device +5V power supply.

Floating Signal Sources

Floating signals can be measured in NRSE mode with AI SENSE and

AI GND connected together with certain limitations. This configuration

can have implications depending on the bias resistor requirements of the

signal source. Refer to the M Series User Manual or the ESeries Help for

more information regarding floating source bias requirements.

SCC-68 DAQ Device

Floating

Signal

AI

+

–

AI SENSE (Pin 62)

AI GND (Pin 67)

+

–

NRSE Mode

Figure 17. Floating Signal Connected in NRSE Mode

Ground-Referenced Single Ended (RSE)

Refer to the RSE connection considerations described in the M Series User

Manual or the E Series Help. The following cases should also be noted.

Grounded Signal Sources

This configuration is not recommended as described in the M Series User

Manual or the E Series Help.

Floating Signal Sources

Connecting a floating signal source in RSE mode is not recommended.

When measuring floating signals with the SCC-68 configured for SCC

modules, use the NRSE measurement configuration.

SCC-68 User Guide 26 ni.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 28

If RSE is used to measure floating signals, there will be a measurement

error due to the current being drawn by the SCC-68 from the DAQ device

+5V power supply.

This potential will vary depending on the length of the cable connecting the

DAQ device to the SCC-68 and the amount of current being drawn from the

+5V power supply by the SCC-68. Figure 18 shows this measurement

error.

SCC-68 DAQ Device

Power Switch

+5V

+

Power for

SCC Modules and

CJC Sensor

–

GND

AI

+

AI GND

–

Floating

Signal

(Pin 67)

I

+–

Figure 18. Floating Signal Connected in RSE Mode

Taking Measurements with NI-DAQmx

Before beginning any signal conditioning applications with the SCC-68,

make sure you have the following software and documentation materials:

❑ NI-DAQmx 8.1 or later software and documentation

❑ One of the following software packages for development:

–LabVIEW

– LabWindows

– Visual C++

– Visual Basic

™

/CVI™ version 7.0 or later

Not Recommended

V

L

R

L

+

–

RSE Mode

+5V

+

–

To install NI-DAQmx, refer to the DAQ Getting Started Guide.

© National Instruments Corporation 27 SCC-68 User Guide

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 29

Configuring the SCC-68

The SCC-68 can be configured as an SCC carrier and as a screw terminal

accessory. To configure the SCC-68 as both an SCC carrier and a screw

terminal accessory, you need to follow the configuration instructions in the

Configuring the SCC-68 as an SCC Carrier section and the Configuring

the SCC-68 as a Screw Terminal Accessory section.

Configuring the SCC-68 as an SCC Carrier

To configure the SCC-68 as an SCC carrier accessory for a DAQ device

using Measurement & Automation Explorer (MAX), complete the

following steps:

1. Navigate to MAX by selecting Start»All Programs»National

2. In the left pane of MAX, expand Devices and Interfaces.

3. Right-click NI-DAQmx Devices and select Create New NI-DAQmx

4. Select the DAQ device that the SCC-68 is connected to from the DAQ

5. For each SCC module physically installed in the SCC-68 carrier, add

6. If the module name does not appear in the list, either the module is not

7. Click OK after completing all SCC entries to finish the configuration

Instruments»Measurement & Automation.

Device»NI-DAQmx SCC Connector Block»SCC-68.

Device menu. For devices with multiple connectors, select the

connector that is cabled to the DAQ device.

a corresponding entry in the SCC-68 configuration window. To add the

SCC, click the Socket drop-down list and select the correct module.

allowed in that location or you do not have the current version of

NI-DAQ. If you do not have the current version of NI-DAQ, download

it from

process.

ni.com/downloads.

Configuring the SCC-68 as a Screw Terminal

Accessory

To configure the SCC-68 as a screw terminal accessory for a DAQ device

using Measurement & Automation Explorer (MAX), complete the

following steps:

1. Right-click the DAQ device that the SCC-68 is connected to from the

DAQ Device menu and choose Properties.

2. Click the Accessory tab and select SCC-68.

SCC-68 User Guide 28 ni.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 30

Configuring Channels and Tasks

This section applies only if you are programming the device using

NI-DAQmx or NI application software.

A physical channel is a terminal or pin at which you can measure or

generate an analog or digital signal. A virtual channel is a collection or

settings such as a name, a physical channel, input terminal connections, the

type of measurement or generation, and can include scaling information.

In NI-DAQmx, virtual channels are integral to every measurement. In

NI-DAQmx, use the DAQ Assistant, accessible from MAX or NI

application software, to configure virtual channels and measurement tasks.

Refer to the DAQ Assistant Help and the Measurement & Automation

Explorer Help for NI-DAQmx. You also can configure virtual channels with

the NI-DAQmx API in your application program.

A task, an important concept for NI-DAQmx, is a collection of one or more

virtual channels with timing, triggering, and other properties. Conceptually,

a task represents a measurement or generation you want to perform. You

can set up and save all of the configuration information in a task and use the

task in an application.

In NI-DAQmx, you can configure virtual channels as part of a task or

separate from a task. Virtual channels created inside a task are local virtual

channels. Virtual channels defined outside a task are global virtual

channels. You can create global virtual channels in MAX or in your

application software and then save them in MAX. You can use global

virtual channels in any application or add them to a number of different

tasks. If you modify a global virtual channel, the change affects all tasks in

which you reference that global virtual channel.

Configure a Task

When using NI-DAQmx, configure tasks with the DAQ Assistant. To

create tasks using the SCC-68, you must have NI-DAQmx version 8.1

or later.

• To launch the DAQ Assistant in MAX, right-click Data

Neighborhood and select Create New. In the Create New window,

select NI-DAQmx Task and click Next. If you are using a remote RT

target, expand your target, then right-click Data Neighborhood and

select Create New.

• You also can open the DAQ Assistant directly within NI application

software. Refer to the help of your software package for more details.

© National Instruments Corporation 29 SCC-68 User Guide

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 31

The DAQ Assistant prompts you to create a new task.

1. Select an I/O type, such as analog input. For thermocouple

measurements, you must first ensure the hardware is configured

correctly and that the SCC-68 has been configured in MAX. For more

information, refer to the Configuring the SCC-68 section.

2. Select the measurement or generation to perform based on the

hardware functionality of the module. Table 1 lists the measurement

types in NI-DAQmx and how they correspond to the SCC modules. For

additional information about SCC-XX module-specific channel/task

settings, refer to the SCC Quick Start Guide and the SCC-XX module

user guide for the SCC device.

3. Select the sensor to use, if applicable for that measurement.

4. Select the physical channel(s) from which to create local virtual

channels in the task. Alternatively, you can add existing global virtual

channels to the task or copy information from an existing global virtual

channel to the local virtual channel. Click Next.

5. If you launched the DAQ Assistant from MAX, type the new task

name. Click Finish.

6. Set any timing and triggering information for the task.

Figure 19. A Task in the DAQ Assistant

SCC-68 User Guide 30 ni.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 32

Configure Global Virtual Channels

If you want to use virtual channels in multiple NI-DAQmx tasks or

applications, configure global virtual channels with the DAQ Assistant.

You can launch the DAQ Assistant to create a global virtual channel in

MAX or in LabVIEW.

• To open the DAQ Assistant in MAX, right-click Data Neighborhood

and select Create New. In the Create New window, select NI-DAQmx

Global Virtual Channel and click Next.

• To open the DAQ Assistant directly in LabVIEW to create a global

virtual channel, drop a DAQmx Global Channel control on the front

panel, right-click it, and select New DAQmx Channel.

The DAQ Assistant prompts you to create a new global virtual channel by

selecting an I/O type, such as analog input, the measurement or generation

to perform, the sensor applicable for that measurement, and the physical

channel from which to create a global virtual channel.

The DAQ Assistant prompts you to create a new global virtual channel.

1. Select an I/O type, such as analog input.

2. Select the measurement or generation to perform.

3. Choose the sensor to use, if applicable for that measurement. A dialog

box opens for the task you have specified.

4. Select the physical channel from which to create a global virtual

channel. Alternatively, you can copy information from an existing

global virtual channel. Click Next.

5. Type the new global virtual channel name. Click Finish.

6. Configure the onboard CJC sensor, if necessary.

To use the onboard CJC sensor for thermocouple measurements,

ensure that the CJC sensor is wired to AI 7, then select Built-In for the

CJC source. If this option is not available, check your configuration.

For more information, refer to the Configuring the SCC-68 section. For

CJC sensor wiring instructions, refer to the Using the Temperature

Sensor for Cold-Junction Compensation (CJC) section.

7. Select the terminal configuration. Refer to the Analog Input

Measurement Considerations section for more information about this

setting.

8. Save your configuration.

9. Click Test. Verify your data in the window that opens. If the data is

incorrect, verify the settings in the DAQ Assistant window.

© National Instruments Corporation 31 SCC-68 User Guide

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 33

You now can use the global virtual channel in an application or add the

global channel to a task. Refer to the DAQ Assistant Help for more

information about creating tasks and virtual channels and using them in an

application.

In LabWindows/CVI and Measurement Studio, you cannot directly create

a global virtual channel; you must create them in MAX as previously

described.

Using Your Task in an Application

Complete the following steps to use a measurement task in your

application. Refer to the DAQ Assistant Help for more information about

using a task or generating code.

To run examples without hardware installed, you can use NI-DAQmx

simulated devices. In MAX, refer to the Measurement & Automation

Explorer Help for NI-DAQmx by selecting Help»Help Topics»

NI-DAQmx for instructions about creating NI-DAQmx simulated devices

and importing NI-DAQmx simulated device configurations to physical

devices.

LabVIEW

1. Open a blank VI in LabVIEW.

2. Place the following constant on the block diagram from the functions

palette: NI Measurement»DAQmx-Data Acquisition»DAQmx

Task Name Constant.

3. Select the task from the pull-down menu.

4. Right-click the VI and select Generate Code»Example to generate

the code to run the task.

5. Run the program from the front panel.

LabWindows/CVI

Refer to ni.com/info and enter the information code rddq73 for

step-by-step instructions for using a task in LabWindows/CVI.

Measurement Studio

Refer to ni.com/info and enter the information code rddqms for

step-by-step instruction for using a task in Measurement Studio.

SCC-68 User Guide 32 ni.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 34

Specifications

This appendix lists the SCC-68 specifications. These ratings are typical at

25 °C unless otherwise stated.

Power Requirement

Power consumption (at +5 VDC, ±5%)

Typical ............................................1 mA with no signal

Note The maximum power consumption of the SCC-68 is a function of the SCC modules

installed and any circuits constructed on the general-purpose breadboard area. Refer to the

Power Supply Considerations section for more information.

External Power Supply Requirements

Using an external power supply is optional. Any external power supply

used with the SCC-68 must meet the following requirements.

Voltage output........................................ 4.75 V min,

Current output ........................................ 2 A max;

conditioning installed

5.25 V max

minimum current requirement

is load dependent.

External Power Supply Protection

The SCC-68 external power supply screw terminal is protected against

overcurrent, overvoltage, and reverse voltage.

Overcurrent ............................................ Fused at 2 ADC

Overvoltage and reverse voltage............ ±20 VDC max

±15V Power Supply

The ±15V power supply is only accessible by SCC modules. You may

access it using an SCC-FT01 module. Refer to Figure 14 and Figure 15.

Tolerance................................................ ±5%

Max load current .................................... 50 mA

© National Instruments Corporation 33 SCC-68 User Guide

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 35

Temperature Sensor

Temperature sensor

Accuracy..........................................±0.3 °C over a 0 to 55 °C range

Type.................................................Thermistor

Convert the voltage to temperature using the following Steinhart-Hart

equation:

T

--------------------------------------------------------------------- 273.15–=

ABln R

++

where A = 1.2873851 × 10

B = 2.3575235 × 10

C = 9.4978060 × 10

R1V

R

T

T

--------------------=

5 VT–()

1

()()C ln RT()()

T

–3

–4

–8

3

where R1=4,870Ω

V

is the CJC voltage measurement

T

For more information about the temperature sensor, refer to the Using the

Temperature Sensor for Cold-Junction Compensation (CJC) section.

SCC-68 User Guide 34 ni.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 36

Physical

5.30 cm

(2.09 in.)

17.78 cm

(7.00 in.)

NI SCC

24.46 cm

(9.63 in.)

-68

Figure 20. SCC-68 I/O Connector Block Dimensions

Weight.................................................... 623.7 g (1 lb 6 oz)

I/O connectors ........................................ One 68-pin male SCSI connector

SCC sockets

Number of sockets .......................... 4

SCC types supported....................... Analog input,

digital input/output, feedthrough

Screw terminals...................................... 84 (54 AI, AO, DIO; 20 SCC;

8 bus; 2 external power)

Wire gauge .............................................14–26 AWG

(0.14 mm

© National Instruments Corporation 35 SCC-68 User Guide

2

–1.5 mm2)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 37

Tightening torque ...................................0.5 to 0.6 N · m

Strip length .............................................7 mm (0.27 in.)

Maximum Working Voltage

Caution Refer to the DAQ device documentation for the voltage specifications for the

DAQ device.

Caution Ensure that signals connected to SCC modules are used within the voltage ratings

of the modules to which they are connected. Refer to the SCC-XX user manual for the

voltage specifications for the SCC module.

Maximum working voltage refers to the signal voltage plus the

common-mode voltage.

Channel-to-earth .....................................11 VDC,

Caution Do not use the SCC-68 for connections to signals or for measurements within

Categories II, III, or IV.

Environmental

Operating temperature ............................0 to 55 °C

(4.4 to 5.3 lb · in.)

Measurement Category I

Storage temperature ................................–20 to 70 °C

Humidity.................................................5 to 90% RH, noncondensing

Maximum altitude...................................2,000 meters

Pollution Degree (indoor use only) ........2

Shock and Vibration

Operational shock ...................................30 g peak, half-sine, 11 ms pulse

(Tested in accordance with

IEC-60068-2-27. Test profile

developed in accordance with

MIL-PRF-28800F.)

Random vibration

Operating .........................................5 to 500 Hz, 0.3 g

Nonoperating ...................................5 to 500 Hz, 2.4 g

(Tested in accordance with

IEC-60068-2-64.)

SCC-68 User Guide 36 ni.com

rms

rms

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 38

Note Nonoperating random vibration profiles for the SCC-68 exceeds the requirements of

MIL-PRF-28800F, Class 3.

Safety

This product is designed to meet the requirements of the following

standards of safety for electrical equipment for measurement, control,

and laboratory use:

• IEC 61010-1, EN-61010-1

• UL 61010-1, CAN/CSA-C22.2 No. 61010-1

Note For UL and other safety certifications, refer to the product label or visit

ni.com/certification, search by model number or product line, and click the

appropriate link in the Certification column.

Electromagnetic Compatibility

This product is designed to meet the requirements of the following

standards of EMC for electrical equipment for measurement, control,

and laboratory use:

• EN 61326 EMC requirements; Minimum Immunity

• EN 55011 Emissions; Group 1, Class A

• CE, C-Tick, ICES, and FCC Part 15 Emissions; Class A

Note For EMC compliance, operate this device according to product documentation.

CE Compliance

This product meets the essential requirements of applicable European

Directives, as amended for CE marking, as follows:

• 73/23/EEC; Low-Voltage Directive (safety)

• 89/336/EEC; Electromagnetic Compatibility Directive (EMC)

Note Refer to the Declaration of Conformity (DoC) for this product for any additional

regulatory compliance information. To obtain the DoC for this product, visit

ni.com/certification, search by model number or product line, and click the

appropriate link in the Certification column.

Waste Electrical and Electronic Equipment (WEEE)

EU Customers At the end of their life cycle, all products must be sent to a WEEE recycling

center. For more information about WEEE recycling centers and National Instruments

WEEE initiatives, visit

© National Instruments Corporation 37 SCC-68 User Guide

ni.com/environment/weee.htm.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 39

Quick Reference Guides

This section provides the quick reference guides for use with Connector 0

and Connector 1 of 68-pin M Series devices, and E Series devices. The

quick reference guides provide information about pin placements, their

corresponding signal assignments, and wire-stripping length for signal

connections.

SCC-68 User Guide 38 ni.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 40

AI 7

.27 in.(7 mm)

57

AI 15

23

AI GND

AI 6

25

56

AI 14

58

AI 5

AI GND

59

60

AI 13

26

AI GND

AI 4

28

64

AI 12

61

FOR SCC ANALOG

MODULES CONNECT

AI SENSE TO AI GND

AI SENSE

AI GND

67

62

APFI 0

AO 0

22

20

AO GND

54

AO GND

AO 1

Strip Gauge

55

21

SCC-68 Reference Label

CJC+

AI GND

71

M Series Connector 0 Devices

70

39

13

D GND

PFI 15/P2.7

AI 3

AI GND

D GND

AI 11

30

63

32

12

AI 2

AI GND

D GND

AI 10

31

AI 9

66

9

29

AI GND

D GND

7

27

65

AI 1

33

PFI 9/P2.1

PFI 7/P1.7

PFI 8/P2.0

38

37

3

1

15

D GND

PFI 14/P2.6

P0.3

47

P0.2

49

P0.1

17

SCC Mod 2 SCC Mod 3 SCC Mod 4

PFI 6/P1.6

5

40

18

D GND

PFI 13/P2.5

PFI 5/P1.5

PFI 4/P1.4

6

41

2

35

D GND

PFI 12/P2.4

PFI 3/P1.3

PFI 2/P1.2

43

42

36

46

D GND

PFI 11/P2.3

PFI 1/P1.1

PFI 0/P1.0

11

10

44

45

D GND

PFI 10/P2.2

P0.7

48

8

+5V

P0.6

16

P0.5

51

53

50

D GND

D GND

P0.4

SHIELD

74

19

697273

D GND

SHIELD

75

SHIELD

SHIELD

BUS A

BUS B

.27 in.(7 mm)

P/N 193574C-01

Figure 21. Quick Reference Guide for M Series 68-Pin Connector 0 DAQ Device

AI 0

AI GND

D GND

AI 8

34

68

P0.0

4

24

52

SCC Mod 1

© National Instruments Corporation 39 SCC-68 User Guide

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 41

AI 23

.27 in.(7 mm)

57

AI 31

23

AI GND

AI 22

25

56

AI 30

58

AI 21

AI GND

59

60

AI 29

26

AI GND

AI 20

28

64

AI 28

61

FOR SCC ANALOG

MODULES CONNECT

AI SENSE TO AI GND

AI SENSE 2

APFI 1

AI GND

67

20

62

AO 2*

AO GND

AO GND

AO 3*

54

22

21

Strip Gauge

55

* NC on some devices

SCC-68 Reference Label

CJC+

AI GND

M Series Connector 1 Devices

AI 19

30

AI 18

65

AI 17

33

AI 27

63

AI 26

31

AI 25

66

71

70

13

D GND

AI GND

D GND

32

12

AI GND

D GND

9

29

AI GND

D GND

7

27

P0.25

3

39

P0.31

P0.11

47

P0.10

49

P0.9

17

P0.24

37

15

D GND

P0.23

P0.21

P0.22

6

5

38

1

P0.30

40

18

P0.29

D GND

35

D GND

SCC Mod 2 SCC Mod 3 SCC Mod 4

P0.20

41

2

P0.28

P0.19

42

36

D GND

P0.18

43

46

P0.27

P0.17

10

44

D GND

P0.16

11

45

P0.26

P0.15

48

8

+5V

P0.14

16

50

D GND

P0.13

51

53

D GND

P0.12

SHIELD

74

19

697273

D GND

SHIELD

75

SHIELD

SHIELD

BUS A

BUS B

.27 in.(7 mm)

Figure 22. Quick Reference Guide for M Series 68-Pin Connector 1 DAQ Device

AI 16

AI GND

D GND

AI 24

34

68

P0.8

4

24

52

SCC Mod 1

SCC-68 User Guide 40 ni.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 42

AI 7

.27 in.(7 mm)

57

E Series Devices

AI 15

23

AI 6

AI GND

56

25

AI 14

58

AI 5

AI GND

59

60

AI 13

26

AI 4

AI GND

64

28

AI 12

61

FOR SCC ANALOG

AI GND

AI SENSE

62

67

MODULES CONNECT

AI SENSE TO AI GND

EXT REF*

AO 0*

AO

20

22

AO GND

54

AO GND

AO 1*

21

55

* NC on some devices

Strip Gauge

SCC-68 Reference Label

CJC+

AI GND

70

71

39

13

D GND

D GND

AI 3

AI GND

D GND

AI 11

30

63

32

12

AI 2

AI GND

D GND

AI 10

31

AI 9

66

9

29

AI GND

D GND

7

27

65

AI 1

33

PFI 9/CTR 0 GATE

PFI 7/AI SAMP CLK

PFI 8/CTR 0 SRC

38

37

3

1

15

D GND

FREQ OUT

P0.3

47

P0.2

49

P0.1

17

SCC Mod 2 SCC Mod 3 SCC Mod 4

PFI 6/AO START TRIG

40

18

D GND

CTR 1 OUT

PFI 5/AO SAMP CLK

PFI 3/CTR 1 SRC

PFI 4/CTR 1 GATE

6415

42

35

D GND

CTR 0 OUT

PFI 1/AI REF TRIG

PFI 2/AI CONV CLK

36

D GND

P0.7

PFI 0/AI START TRIG

101143

48

46245

44

D GND

EXT STROBE

AI HOLD COMP

P0.5

P0.4

P0.6

511916

8

5053697273

+5V

D GND

D GND

SHIELD

74

D GND

SHIELD

75

SHIELD

SHIELD

BUS A

BUS B

.27 in.(7 mm)

Figure 23. Quick Reference Guide for E Series DAQ Device

AI 0

AI 8

AI GND

D GND

P0.0

4

34

68

24

52

SCC Mod 1

© National Instruments Corporation 41 SCC-68 User Guide

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 43

National Instruments, NI, ni.com, and LabVIEW are trademarks of National Instruments Corporation.

Refer to the Terms of Use section on ni.com/legal for more information about National

Instruments trademarks. Other product and company names mentioned herein are trademarks or trad e

names of their respective companies. For patents covering National Instruments products, refer to the

appropriate location: Help»Patents in your software, the patents.txt file on your CD, or

ni.com/patents.

© 2006 National Instruments Corporation. All rights reserved.

374748A-01 Aug06

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 44

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

Instra

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

REMOTE INSPECTION

View

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Loading...

Loading...