Page 1

Signal Conditioning

SC-2345/2350 Carrier User Manual

SC-2345/2350 Carrier User Manual

July 2007

371064F-01

Page 2

Support

Worldwide Technical Support and Product Information

ni.com

National Instruments Corporate Headquarters

11500 North Mopac Expressway Austin, Texas 78759-3504 USA Tel: 512 683 0100

Worldwide Offices

Australia 1800 300 800, Austria 43 662 457990-0, Belgium 32 (0) 2 757 0020, Brazil 55 11 3262 3599,

Canada 800 433 3488, China 86 21 5050 9800, Czech Republic 420 224 235 774, Denmark 45 45 76 26 00,

Finland 358 (0) 9 725 72511, France 01 57 66 24 24, Germany 49 89 7413130, India 91 80 41190000,

Israel 972 3 6393737, Italy 39 02 413091, Japan 81 3 5472 2970, Korea 82 02 3451 3400,

Lebanon 961 (0) 1 33 28 28, Malaysia 1800 887710, Mexico 01 800 010 0793, Netherlands 31 (0) 348 433 466,

New Zealand 0800 553 322, Norway 47 (0) 66 90 76 60, Poland 48 22 3390150, Portugal 351 210 311 210,

Russia 7 495 783 6851, Singapore 1800 226 5886, Slovenia 386 3 425 42 00, South Africa 27 0 11 805 8197,

Spain 34 91 640 0085, Sweden 46 (0) 8 587 895 00, Switzerland 41 56 2005151, Taiwan 886 02 2377 2222,

Thailand 662 278 6777, Turkey 90 212 279 3031, United Kingdom 44 (0) 1635 523545

For further support information, refer to the Technical Support Information document that shipped with the device.

To comment on National Instruments documentation, refer to the National Instruments Web site at

and enter the info code

feedback.

ni.com/info

© 1997–2007 National Instruments Corporation. All rights reserved.

Page 3

Important Information

Warranty

The SC-2345/2350 carrier is warranted against defects in materials and workmanship for a period of one year from the date of shipment, as

evidenced by receipts or other documentation. National Instruments will, at its option, repair or replace equipment that proves to be defective

during the warranty period. This warranty includes parts and labor.

The media on which you receive National Instruments software are warranted not to fail to execute programming instructions, due to defects

in materials and workmanship, for a period of 90 days from date of shipment, as evidenced by receipts or other documentation. National

Instruments will, at its option, repair or replace software media that do not execute programming instructions if National Instruments receives

notice of such defects during the warranty period. National Instruments does not warrant that the operation of the software shall be

uninterrupted or error free.

A Return Material Authorization (RMA) number must be obtained from the factory and clearly marked on the outside of the package before

any equipment will be accepted for warranty work. National Instruments will pay the shipping costs of returning to the owner parts which are

covered by warranty.

National Instruments believes that the information in this document is accurate. The document has been carefully reviewed for technical

accuracy. In the event that technical or typographical errors exist, National Instruments reserves the right to make changes to subsequent

editions of this document without prior notice to holders of this edition. The reader should consult National Instruments if errors are suspected.

In no event shall National Instruments be liable for any damages arising out of or related to this document or the information contained in it.

E

XCEPT AS SPECIFIED HEREIN, NATIONAL INSTRUMENTS MAKES NO WARRANTIES, EXPRESS OR IMPLIED, AND SPECIFICALLY DISCLAIMS ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PUR POSE. CUSTOMER’S RIGHT TO R ECOVER DAMAGES CAUSED BY FAULT OR NEGLIGENCE ON THE PART OF

NATIONAL INSTRUMENTS SHALL BE LIMITED TO THE AMOUNT THERETOFORE PAID BY THE CUSTOMER. NATIONAL INSTRUMENTS WILL NOT BE LIABLE FOR

DAMAGES RESULTING FROM LOSS OF DATA, PROFITS, USE OF PRODUCTS, OR INCIDENTAL OR CONSEQUENTIAL DAMAGES, EVEN IF ADVISED OF THE POSSIBILITY

THEREOF. This limitation of the liability of National Instruments will apply regardless of the form of action, whether in contract or tort, including

negligence. Any action against National Instruments must be brought within one year after the cause of action accrues. National Instruments

shall not be liable for any delay in performance due to causes beyond its reasonable control. The warranty provided herein does not cover

damages, defects, malfunctions, or service failures caused by owner’s failure to follow the National Instruments installation, operation, or

maintenance instructions; owner’s modification of the product; owner’s abuse, misuse, or negligent acts; and power failure or surges, fire,

flood, accident, actions of third parties, or other events outside reasonable control.

Copyright

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or mechanical, including photocopying,

recording, storing in an information retrieval system, or translating, in whole or in part, without the prior written consent of National

Instruments Corporation.

National Instruments respects the intellectual property of others, and we ask our users to do the same. NI software is protected by copyright and other

intellectual property laws. Where NI software may be used to reproduce software or other materials belonging to others, you may use NI software only

to reproduce materials that you may reproduce in accordance with the terms of any applicable license or other legal restriction.

Trademarks

National Instruments, NI, ni.com, and LabVIEW are trademarks of National Instruments Corporation. Refer to the Terms of Use section

on

ni.com/legal for more information about National Instruments trademarks.

Product and company names mentioned herein are trademarks or trade names of their respective companies.

Members of the National Instruments Alliance Partner Program are business entities independent from National Instruments and have no

agency, partnership, or joint-venture relationship with National Instruments.

Patents

For patents covering National Instruments products, refer to the appropriate location: Help»Patents in your software, the patents.txt file

on your CD, or

ni.com/patents.

WARNING REGARDING USE OF NATIONAL INSTRUMENTS PRODUCTS

(1) NATIONAL INSTRUMENTS PRODUCTS ARE NOT DESIGNED WITH COMPONENTS AND TESTING FOR A LEVEL OF

RELIABILITY SUITABLE FOR USE IN OR IN CONNECTION WITH SURGICAL IMPLANTS OR AS CRITICAL COMPONENTS IN

ANY LIFE SUPPORT SYSTEMS WHOSE FAILURE TO PERFORM CAN REASONABLY BE EXPECTED TO CAUSE SIGNIFICANT

INJURY TO A HUMAN.

(2) IN ANY APPLICATION, INCLUDING THE ABOVE, RELIABILITY OF OPERATION OF THE SOFTWARE PRODUCTS CAN BE

IMPAIRED BY ADVERSE FACTORS, INCLUDING BUT NOT LIMITED TO FLUCTUATIONS IN ELECTRICAL POWER SUPPLY,

COMPUTER HARDWARE MALFUNCTIONS, COMPUTER OPERATING SYSTEM SOFTWARE FITNESS, FITNESS OF COMPILERS

AND DEVELOPMENT SOFTWARE USED TO DEVELOP AN APPLICATION, INSTALLATION ERRORS, SOFTWARE AND

HARDWARE COMPATIBILITY PROBLEMS, MALFUNCTIONS OR FAILURES OF ELECTRONIC MONITORING OR CONTROL

DEVICES, TRANSIENT FAILURES OF ELECTRONIC SYSTEMS (HARDWARE AND/OR SOFTWARE), UNANTICIPATED USES OR

MISUSES, OR ERRORS ON THE PART OF THE USER OR APPLICATIONS DESIGNER (ADVERSE FACTORS SUCH AS THESE ARE

HEREAFTER COLLECTIVELY TERMED “SYSTEM FAILURES”). ANY APPLICATION WHERE A SYSTEM FAILURE WOULD

CREATE A RISK OF HARM TO PROPERTY OR PERSONS (INCLUDING THE RISK OF BODILY INJURY AND DEATH) SHOULD

NOT BE RELIANT SOLELY UPON ONE FORM OF ELECTRONIC SYSTEM DUE TO THE RISK OF SYSTEM FAILURE. TO AVOID

DAMAGE, INJURY, OR DEATH, THE USER OR APPLICATION DESIGNER MUST TAKE REASONABLY PRUDENT STEPS TO

PROTECT AGAINST SYSTEM FAILURES, INCLUDING BUT NOT LIMITED TO BACK-UP OR SHUT DOWN MECHANISMS.

BECAUSE EACH END-USER SYSTEM IS CUSTOMIZED AND DIFFERS FROM NATIONAL INSTRUMENTS' TESTING

PLATFORMS AND BECAUSE A USER OR APPLICATION DESIGNER MAY USE NATIONAL INSTRUMENTS PRODUCTS IN

COMBINATION WITH OTHER PRODUCTS IN A MANNER NOT EVALUATED OR CONTEMPLATED BY NATIONAL

Page 4

INSTRUMENTS, THE USER OR APPLICATION DESIGNER IS ULTIMATELY RESPONSIBLE FOR VERIFYING AND VALIDATING

THE SUITABILITY OF NATIONAL INSTRUMENTS PRODUCTS WHENEVER NATIONAL INSTRUMENTS PRODUCTS ARE

INCORPORATED IN A SYSTEM OR APPLICATION, INCLUDING, WITHOUT LIMITATION, THE APPROPRIATE DESIGN,

PROCESS AND SAFETY LEVEL OF SUCH SYSTEM OR APPLICATION.

Page 5

Conventions

The following conventions are used in this manual:

<> Angle brackets that contain numbers separated by an ellipsis represent

a range of values associated with a bit or signal name—for example,

AO <3..0>.

» The » symbol leads you through nested menu items and dialog box options

to a final action. The sequence File»Page Setup»Options directs you to

pull down the File menu, select the Page Setup item, and select Options

from the last dialog box.

This icon denotes a note, which alerts you to important information.

This icon denotes a caution, which advises you of precautions to take to

avoid injury, data loss, or a system crash. When this symbol is marked

on the product, refer to the Read Me First: Safety and Radio-Frequency

Interference document shipped with the product for precautions to take.

When symbol is marked on a product, it denotes a warning advising you to

take precautions to avoid electrical shock.

When symbol is marked on a product, it denotes a component that may be

hot. Touching this component may result in bodily injury.

bold Bold text denotes items that you must select or click in the software, such

as menu items and dialog box options. Bold text also denotes parameter

names.

italic Italic text denotes variables, emphasis, a cross-reference, or an introduction

to a key concept. Italic text also denotes text that is a placeholder for a word

or value that you must supply.

monospace Text in this font denotes text or characters that you should enter from the

keyboard, sections of code, programming examples, and syntax examples.

This font is also used for the proper names of disk drives, paths, directories,

programs, subprograms, subroutines, device names, functions, operations,

variables, filenames, and extensions.

monospace italic

Italic text in this font denotes text that is a placeholder for a word or value

that you must supply.

Page 6

Contents

Chapter 1

Setting up the SC-2345/2350 Carrier

About the SCC Hardware ..............................................................................................1-1

SC-2345 Carrier...............................................................................................1-1

SC-2350 Carrier...............................................................................................1-2

What You Need to Get Started ......................................................................................1-2

Installing the Driver Software........................................................................................1-3

Connecting the SC-2345/2350 Carrier to the DAQ Device ..........................................1-4

Configuring the SC-2345 Carrier as a DAQ Accessory ................................................1-4

Configuring the SC-2350 Carrier as a DAQ Accessory ................................................1-6

TEDS .............................................................................................................................1-9

Importing TEDS Information..........................................................................1-10

Importing Virtual TEDS Sensor Information..................................................1-12

Affixing the Quick Reference Label to the SC-2345 Carrier ........................................1-15

Connecting Power to the SC-2345/2350 Carrier ...........................................................1-15

SCC-PWR01....................................................................................................1-17

SCC-PWR02....................................................................................................1-18

SCC-PWR03....................................................................................................1-19

Installing SCC Modules in the SC-2345/2350 Carrier....................................1-19

Chapter 2

Connecting Signals to the Terminal Block of the SC-2345/2350 Carrier

Rack-Mounting and Stack-Mounting Options...............................................................2-2

Installing the Rack-Mount Kit.........................................................................2-2

Installing the Stack-Mount Kit ........................................................................2-3

Appendix A

Specifications

Appendix B

Carrier Socket Signal Assignments

Appendix C

SCC Power Requirements and Solutions

© National Instruments Corporation vii SC-2345/2350 Carrier User Manual

Page 7

Contents

Appendix D

Common Questions

Glossary

Index

SC-2345/2350 Carrier User Manual viii ni.com

Page 8

Setting up the SC-2345/2350

Carrier

This document assumes you have already installed, configured, and tested

the SC carrier, SCC modules, and the DAQ device to which they are

connected. If you have not done so, follow the instructions in the DAQ

Getting Started Guide and SCC Quick Start Guide, included with the

hardware, before continuing. The SCC Quick Start Guide and DAQ Getting

Started Guide are also available at

Start»Programs»National Instruments»NI-DAQ»Browse Device

Documentation after you install the DAQ documentation browser.

About the SCC Hardware

ni.com/manuals or accessible from

1

SC-2345 Carrier

The SC-2345/2350 carrier transfers signals to and from 68-pin E/M Series

data acquisition (DAQ) devices, referred to as the DAQ device in this

manual. When used with SCC Series modules and a shielded 68-pin cable,

the SC-2345/2350 carrier offers easy-to-use, rugged, low-noise signal

conditioning on a per-channel basis. The SC-2345/2350 carrier also has

42 screw terminals for direct connection to the DAQ device digital signals.

Some SC-2345 carrier enclosures are available with configurable

connectors to maximize I/O flexibility through the use of panelettes.

All SC-2345/2350 carriers are portable enclosures for laptop and desktop

applications.

Optional rack-mount and stack-mount accessories enable you to mount

the SC-2345/2350 carrier with configurable connectors to suit your

application. The rack-mount option is available for standard 19 in. racks.

The SC-2345 carrier supports analog I/O and digital I/O SCC modules. The

SC-2345 is available in the following forms:

• SC-2345 connector block—the SC-2345 connector block requires you

to pass input signal wires through a strain relief

© National Instruments Corporation 1-1 SC-2345/2350 Carrier User Manual

Page 9

Chapter 1 Setting up the SC-2345/2350 Carrier

• SC-2345 carrier with configurable connectors and a rear cable

connector

• SC-2345 carrier with configurable connectors and a side cable

connector

Note Refer to Figure 1-9 and the SCC Quick Start Guide for more information about all

these carrier forms.

SC-2350 Carrier

The SC-2350 carrier supports analog I/O SCC modules. The SC-2350

carrier supports reading from and writing to Transducer Electronic Data

Sheet (TEDS) Class II sensors for its analog input SCC modules. The

SC-2350 carrier is available with configurable connectors and a side cable

connector. Refer to Figure 1-9 and the SCC Quick Start Guide for more

information.

What You Need to Get Started

To set up and use the SC-2345/2350 carrier, you need the following items:

❑ Hardware

– SC-2345/2350 carrier with one of the following factory-installed

power modules:

• SCC-PWR01

• SCC-PWR02 and the PS01 power supply

• SCC-PWR03 (requires a 7 to 42 VDC power supply,

not included)

– 68-pin E/M Series DAQ device with a shielded 68-pin cable of

less than 2 m length

or

– 100-pin E Series DAQ device with an SH1006868 cable

(to connect 100-pin devices to two 68-pin connectors)

– One or more SCC modules

– Rack-mount or stack-mount kit (optional)

Note You cannot use the I/O panelettes on the SC-2345 carrier with connector block.

SC-2345/2350 Carrier User Manual 1-2 ni.com

– One or more I/O panelettes

Page 10

Chapter 1 Setting up the SC-2345/2350 Carrier

❑ Software

– NI-DAQ 7.4 or later for Windows 2000/NT/XP

Note Software scaling of measurements is not supported on the Macintosh operating

system.

❑ Documentation

– SCC Quick Start Guide

– 100-pin or 68-pin E/M Series DAQ device documentation

– DAQ Getting Started Guide

– Read Me First: Safety and Radio-Frequency Interference

– SC-2345 carrier Quick Reference Label, if you have an SC-2345

carrier

❑ Tools

– 1/8 in. flathead screwdriver

– Numbers 1 and 2 Phillips screwdrivers

– Wire insulation strippers

Installing the Driver Software

Install your application development environment (ADE) software and/or

NI application software, if you have not already done so, according to their

instructions.

Install NI-DAQ, which came with the DAQ device, if you have not already

done so. If you do not have version NI-DAQ 7.4 or later, you can either

download it from the National Instruments Web site at

downloads

Follow the software prompts to install NI-DAQ. If you do not see the Install

NI-DAQ screen when you insert the CD, go to the Windows Start»Run.

Type

x

installer detects the language of your operating system and the screens

appear in that language.

or contact a sales representative to request a CD.

:\setup.exe (

x

is the letter of your CD drive). The NI-DAQ

ni.com/

© National Instruments Corporation 1-3 SC-2345/2350 Carrier User Manual

Page 11

Chapter 1 Setting up the SC-2345/2350 Carrier

Connecting the SC-2345/2350 Carrier to the DAQ Device

Caution Refer to the Read Me First: Safety and Radio-Frequency Interference document

before removing equipment covers or connecting or disconnecting any signal wires.

Use a 68-pin shielded cable to connect the SC-2345/2350 carrier to the

E/M Series DAQ device. Use connector J24 on the SC-2345/2350 carrier.

The pin assignment of J24 is defined by the DAQ device MIO front

connector. Refer to Figure 1-9 for the location of connector J24.

The chassis ground terminal on the SC-2345 carrier and the

electromagnetic interference (EMI) gasket attached to the strain

relief of the SC-2345 carrier are for grounding a floating source

(1 mA maximum). Do not use these terminals as safety earth grounds.

Configuring the SC-2345 Carrier as a DAQ Accessory

Complete the following steps to run Measurement & Automation Explorer

(MAX) and configure the SCC system:

1. Open MAX.

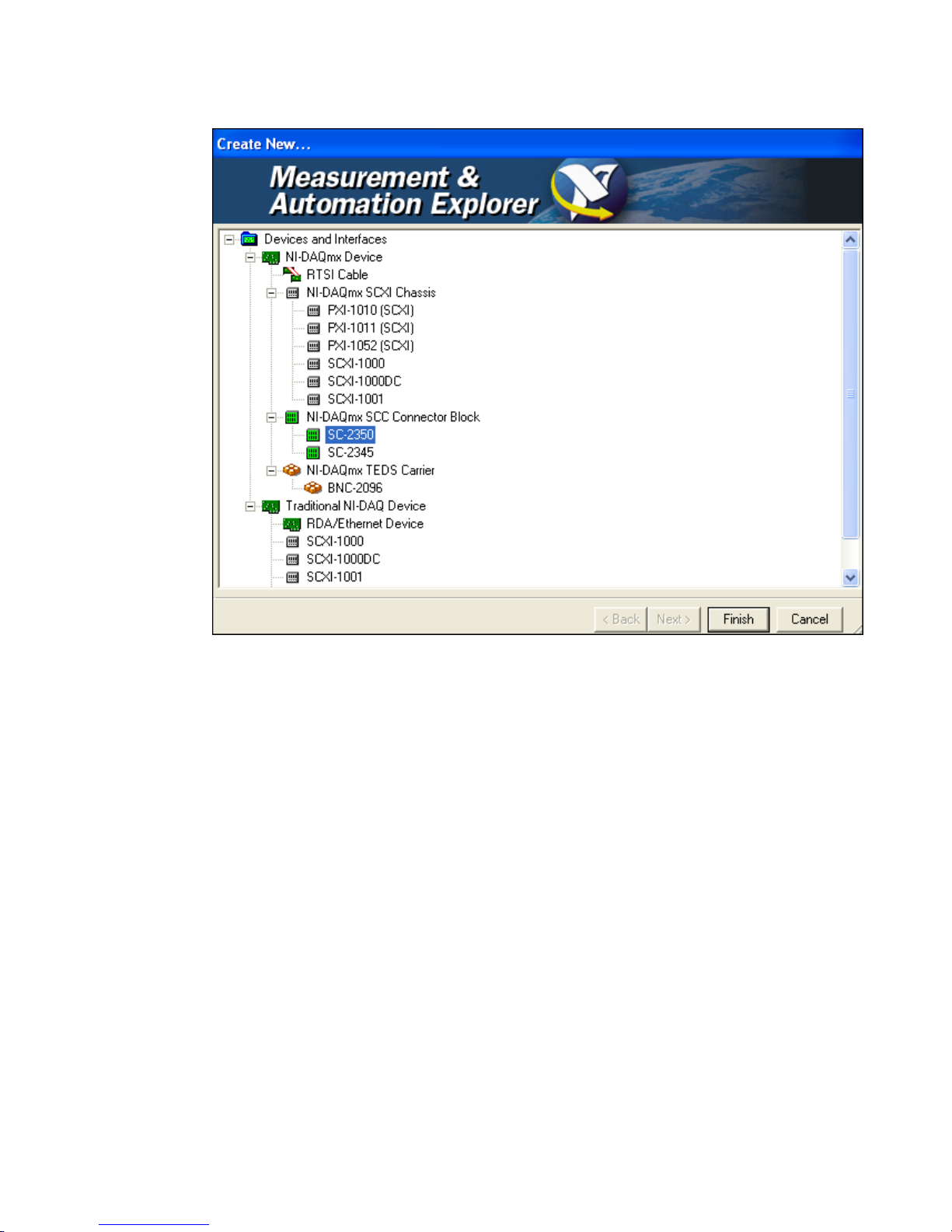

2. Right-click Devices and Interfaces and select Create New.

3. Under NI-DAQmx SCC Connector Block, select SC-2345. Click

Finish.

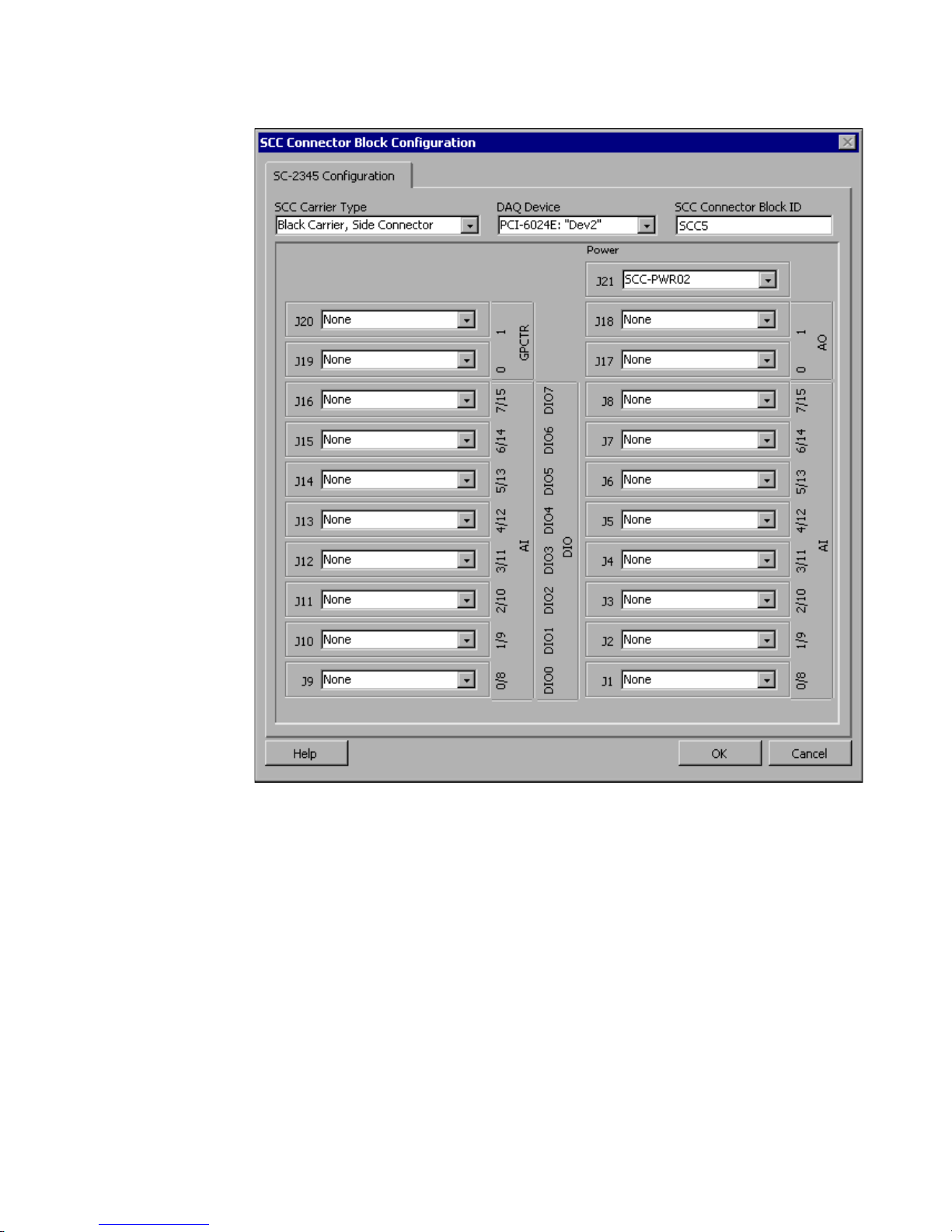

4. In the SCC Connector Block Configuration window, configure the

SCC system as follows.

SC-2345/2350 Carrier User Manual 1-4 ni.com

Page 12

Chapter 1 Setting up the SC-2345/2350 Carrier

© National Instruments Corporation 1-5 SC-2345/2350 Carrier User Manual

Figure 1-1. SCC Connector Block Configuration Window

a. Specify the SCC Carrier Type. The location of the SCC sockets

changes depending on the SCC carrier type.

b. In the drop-down listbox under DAQ Device, select the

E/M Series DAQ device that is connected to the SC-2345 carrier.

c. Type the SCC Connector Block ID. The default value is

SCC1.

d. In the J21 drop-down listbox next to Power, select the correct

SC-2345 power configuration. Refer to Connecting Power to the

SC-2345/2350 Carrier section for information about power

configurations.

Page 13

Chapter 1 Setting up the SC-2345/2350 Carrier

e. For each SCC module physically installed in the SC-2345 carrier,

add a corresponding entry in the SC-2345 Connector Block

Configuration window. Click the drop-down listbox and select the

correct module. If the module name does not appear in the list,

either the module is not allowed in that location or you do not have

NI-DAQ 7.4 or later. If you do not have the current version of

NI-DAQ, download it from

5. Click OK after completing all SCC module entries.

6. Click OK to complete the configuration process and close MAX.

You have completed the steps to configure the SC-2345 carrier as an

E/M Series DAQ device accessory.

Note Configuring the SCC system using MAX automatically sets the E/M Series DAQ

device analog input mode to NRSE. If you are configuring digital SCC modules, the

configuration automatically sets individual digital lines to the appropriate direction, input

or output.

ni.com/downloads.

Configuring the SC-2350 Carrier as a DAQ Accessory

Complete the following steps to run MAX and configure the SCC system:

1. Open MAX.

2. Right-click Devices and Interfaces and select Create New.

3. Under NI-DAQmx SCC Connector Block, select SC-2350.

SC-2345/2350 Carrier User Manual 1-6 ni.com

Page 14

Chapter 1 Setting up the SC-2345/2350 Carrier

Figure 1-2. MAX Window with the SC-2350 Carrier Selected

4. Click Finish. The SC-2350 Configuration window opens.

© National Instruments Corporation 1-7 SC-2345/2350 Carrier User Manual

Page 15

Chapter 1 Setting up the SC-2345/2350 Carrier

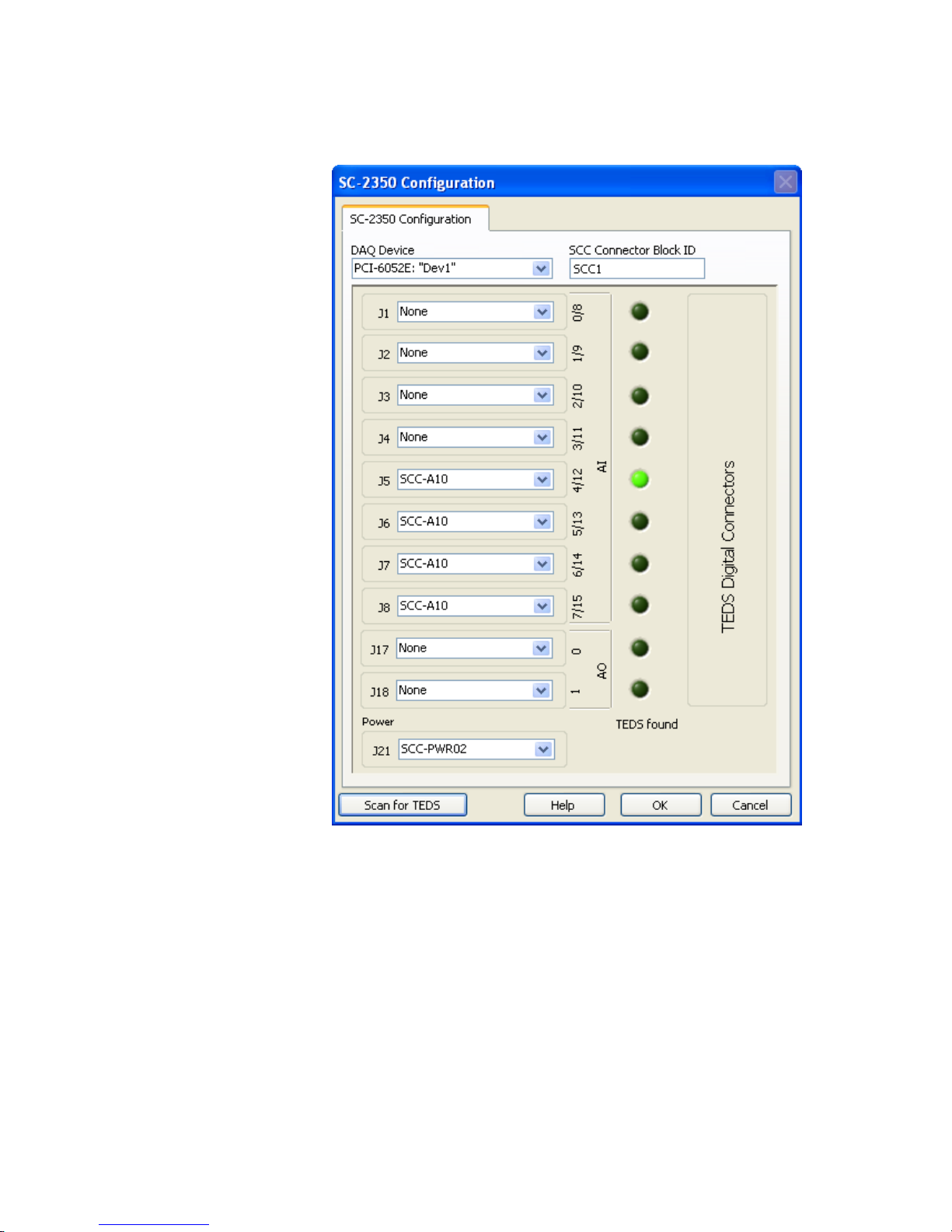

5. To configure the SCC system, complete the following steps:

SC-2345/2350 Carrier User Manual 1-8 ni.com

Figure 1-3. SC-2350 Configuration Window

a. In the drop-down listbox located under DAQ Device, select the

E/M Series DAQ device that is connected to the SC-2350 carrier.

b. Type the SCC Connector Block ID. The default value is

SCC1.

c. In the J21 drop-down listbox next to Power, select the correct

SC-2350 carrier power configuration. Refer to the Connecting

Power to the SC-2345/2350 Carrier section for information about

power configurations.

Page 16

Chapter 1 Setting up the SC-2345/2350 Carrier

d. For each SCC module physically installed in the SC-2350 carrier,

add a corresponding entry in the SC-2350 Configuration window.

Click the drop-down listbox and select the correct module. If the

module name does not appear in the list, either the module is not

allowed in that location or you do not have NI-DAQ 7.4 or later. If

you do not have the current version of NI-DAQ, download it from

ni.com/downloads.

e. MAX automatically scans the SCC modules you select for IEEE

P1451.4 sensors that are compatible with TEDS. If MAX finds a

TEDS, MAX scans and maps a TEDS icon and information under

the SCC module in MAX. For more information, refer to the

TEDS section.

6. Click OK after completing all SCC module entries.

7. Click OK to complete the configuration process and close MAX.

You have completed the steps to configure the SC-2350 carrier as an

E/M Series DAQ device accessory.

TEDS

Note Configuring the SCC system using MAX automatically sets the E/M Series DAQ

device analog input mode to NRSE.

This section describes TEDS.

IEEE P1451.4 specifies two classes of TEDS sensors:

• Class I—Uses the same two wires for both analog and digital signals

(such as accelerometers and microphones).

• Class II—Separates analog and digital signals on different wires. In

addition to the analog signal wires, uses two wires for digital signals.

The SC-2350 carrier uses Class II TEDS.

On IEEE P1451.4 TEDS-compatible sensors, the manufacturer places

an EEPROM on the sensor that stores a TEDS. The TEDS includes vendor

and calibration information, sensor constants, and user-defined data.

TEDS-compatible hardware, like the SC-2350 carrier, can read the TEDS

data. Software can use TEDS data to streamline measurement setup.

Advantages and disadvantages to using TEDS-compatible sensors include

the following:

• Smart, or hardware, TEDS—Provides easier connectivity. You can

© National Instruments Corporation 1-9 SC-2345/2350 Carrier User Manual

plug it in and automatically set up your measurement system.

Page 17

Chapter 1 Setting up the SC-2345/2350 Carrier

• Virtual, or software, TEDS (also part of the IEEE P1451.4

specification)—Obtains sensor information from a vendor Web site,

instead of an EEPROM. The information is free and does not require a

hardware upgrade. However, you must manually select the correct

channel and sensor.

The following resources provide additional information about

IEEE P1451.4 TEDS-compatible smart sensors:

• SCXI-1314T TEDS Bridge Sensor Terminal Block Installation Guide

• Refer to

–

rd2350

– rdsenr

– rdpnpy

– rdpnsn

– rdtntg

• ni.com/devzone

For information about how to configure channels and tasks with the

SC-2350 carrier, refer to the SCC Quick Start Guide.

Importing TEDS Information

To import smart hardware TEDS sensor information into MAX, first install

and configure the SCC modules. Refer to the SCC Quick Start Guide for

more information about how to install and configure the SCC modules.

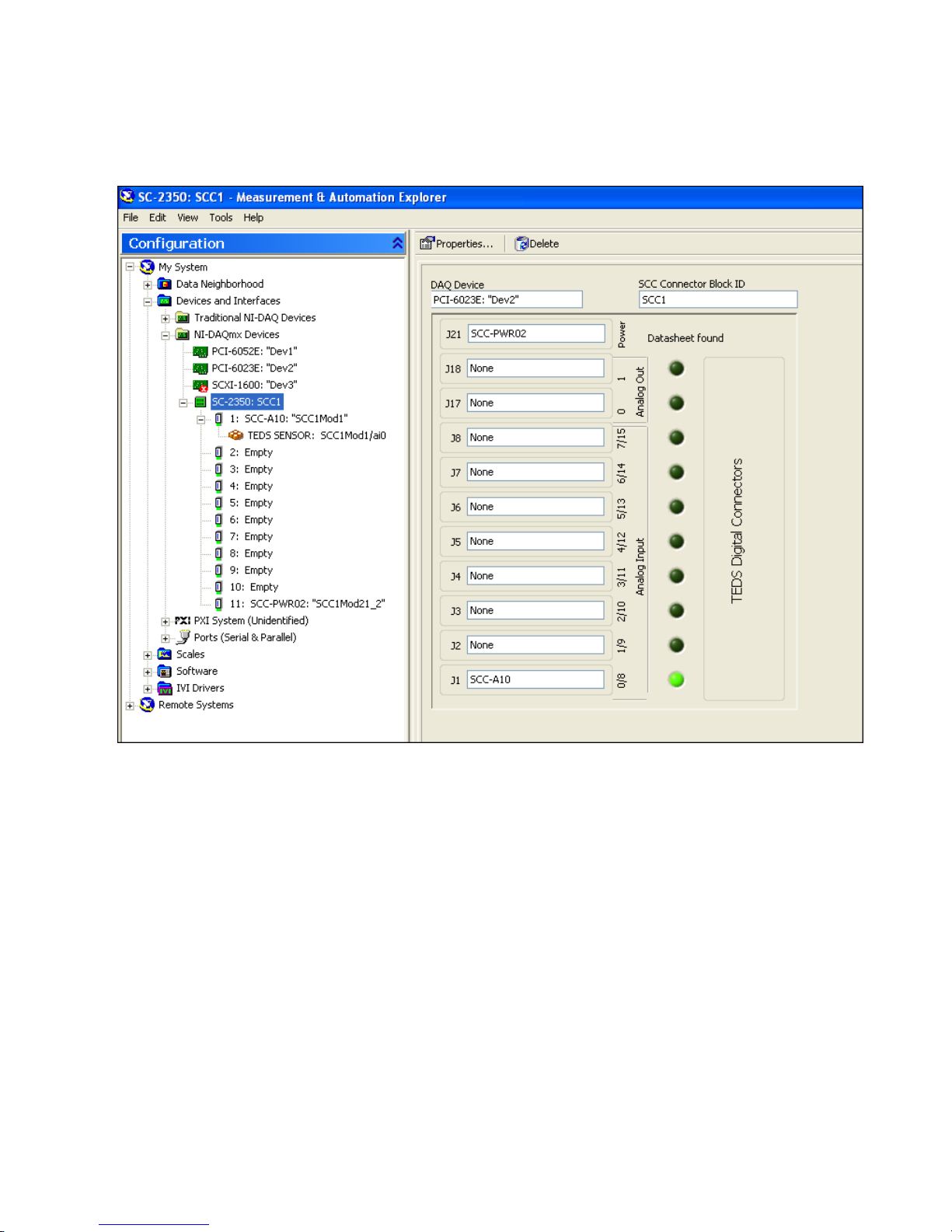

If your system has smart hardware TEDS, MAX automatically scans and

maps the TEDS sensor information into MAX. If MAX finds a TEDS

associated with the SCC module, the LED lights up as shown in Figure 1-4.

ni.com/info, and enter any of the following info codes:

If you later add SCC modules to your system that have TEDS-compatible

sensors physically wired to them, click Scan for TEDS to import the TEDS

sensor information into MAX and refresh the configuration tree.

SC-2345/2350 Carrier User Manual 1-10 ni.com

Page 18

Chapter 1 Setting up the SC-2345/2350 Carrier

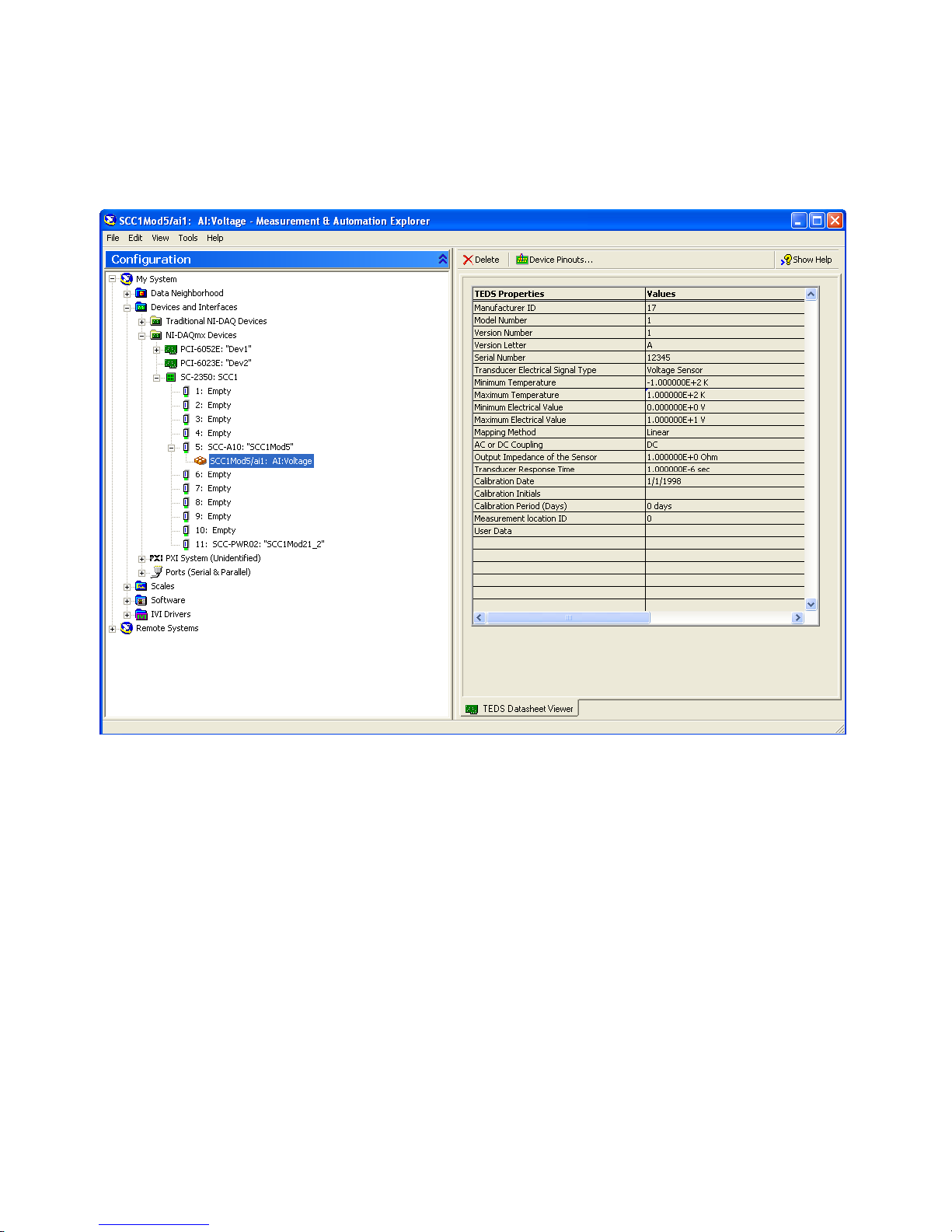

As shown in Figure 1-4, MAX scans and maps the TEDS information

under the SC-2350 carrier.

© National Instruments Corporation 1-11 SC-2345/2350 Carrier User Manual

Figure 1-4. TEDS Sensor Information Scanned and Mapped Into MAX

Page 19

Chapter 1 Setting up the SC-2345/2350 Carrier

To view the TEDS sensor data sheet, click the TEDS listing under the

SC-2350 in MAX. The TEDS sensor data sheet opens as shown in

Figure 1-5.

Figure 1-5. TEDS Sensor Data Sheet

Verify that the TEDS data is correctly imported. Next, create an

NI-DAQmx Global Channel or Task using the channel that has a TEDS

sensor associated to it. Refer to

ni.com/info and enter rd2350, for more

information about how to create an NI-DAQmx Global Channel or Task for

a TEDS sensor.

Importing Virtual TEDS Sensor Information

To import Virtual TEDS sensor information into MAX, first install and

configure the SCC modules. Refer to the SCC Quick Start Guide, for more

information about how to install and configure the SCC modules.

SC-2345/2350 Carrier User Manual 1-12 ni.com

Page 20

Chapter 1 Setting up the SC-2345/2350 Carrier

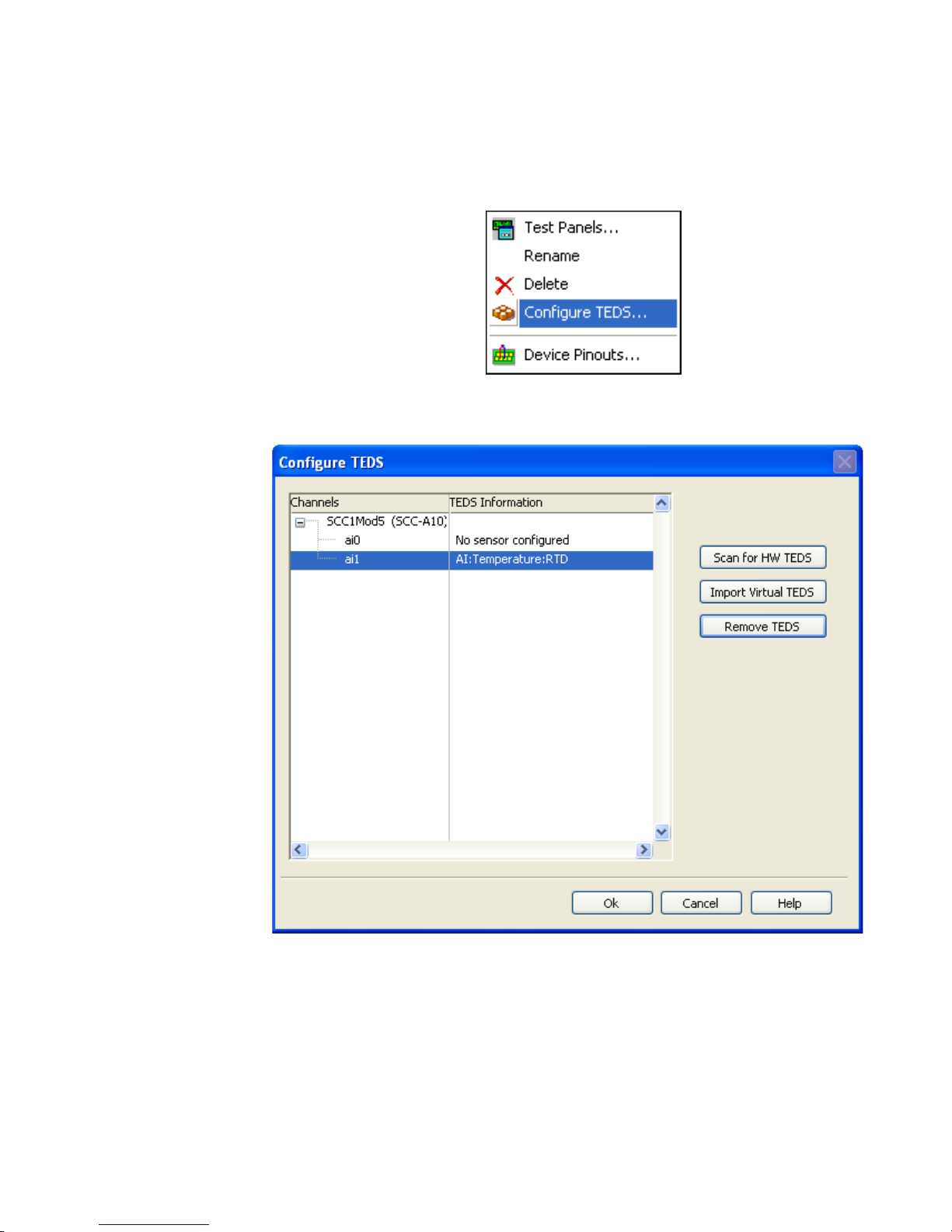

To import Virtual TEDS sensor information into MAX, right-click the SCC

module that you want a Virtual TEDS sensor associated to and select

Configure TEDS.

The Configure TEDS window opens as shown in Figure 1-6.

1. Click Import Virtual TEDS.

© National Instruments Corporation 1-13 SC-2345/2350 Carrier User Manual

Figure 1-6. Configure TEDS Window

Page 21

Chapter 1 Setting up the SC-2345/2350 Carrier

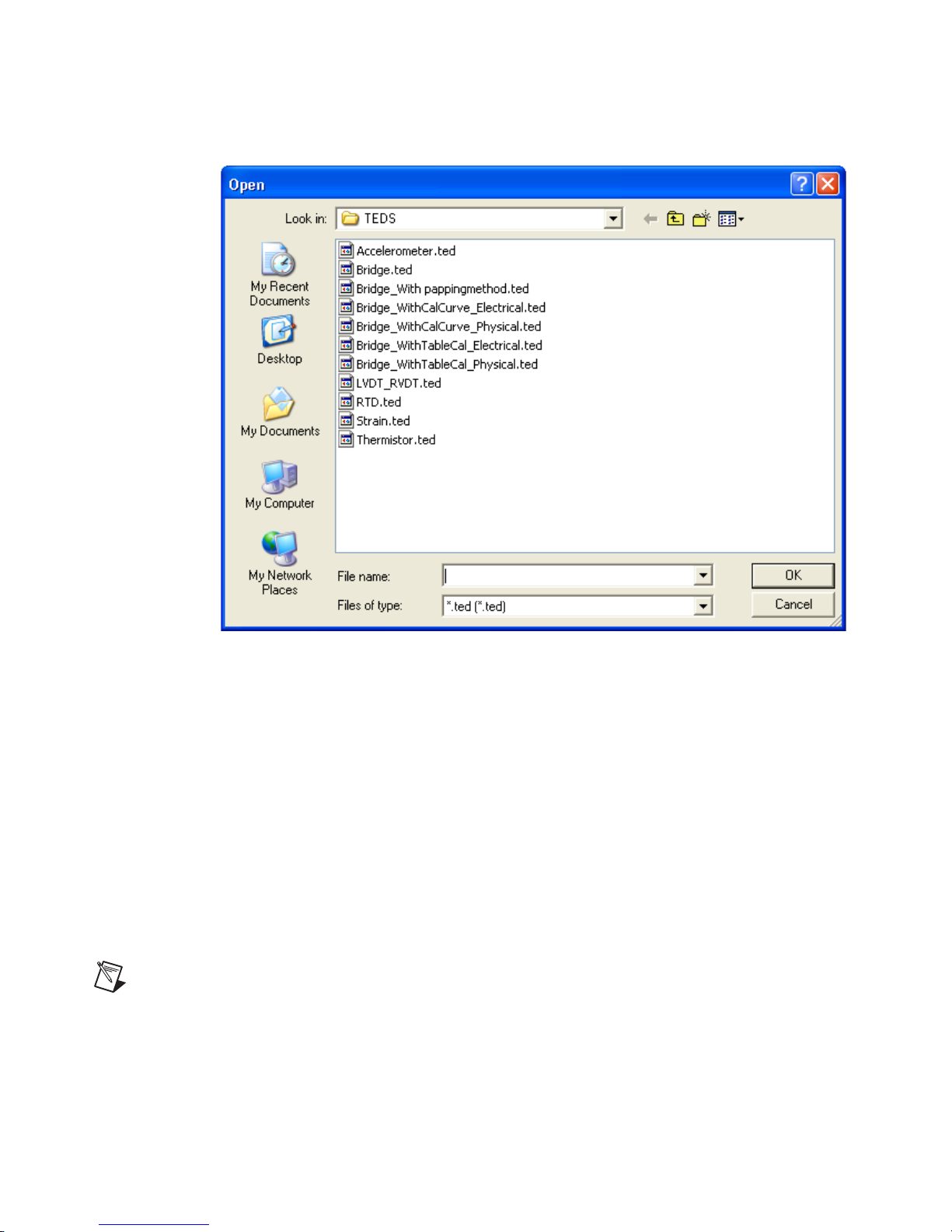

2. The virtual TEDS directory opens as shown in Figure 1-7.

Figure 1-7. Virtual TEDS Directory

3. Press <Ctrl> and select the virtual TEDS file you want to import into

MAX to associate with the SCC module.

4. Click OK.

MAX scans and maps the TEDS sensor information into MAX. The

LED turns green.

5. To verify that the TEDS sensor information imported correctly, click

the TEDS sensor icon in the configuration tree. The TEDS sensor data

sheet opens as shown in Figure 1-5.

6. Next, you need to create an NI-DAQmx Global Channel or Task

using the channel that has a TEDS sensor associated to it.

Note Refer to ni.com/info and enter rd2350, for more information about how to create

a NI-DAQmx Global Channel or Task for a TEDS sensor.

You have configured the SC-2350 carrier in MAX.

SC-2345/2350 Carrier User Manual 1-14 ni.com

Page 22

Chapter 1 Setting up the SC-2345/2350 Carrier

Affixing the Quick Reference Label to the SC-2345

Carrier

Note Only the SC-2345 carrier is shipped with a Quick Reference Label.

Affix the Quick Reference Label to the inside cover of the SC-2345 carrier.

You will refer to the Quick Reference Label when installing the SCC

modules.

Connecting Power to the SC-2345/2350 Carrier

The SC-2345/2350 shielded carrier has one of the following power

modules factory-installed in socket J21:

•SCC-PWR01

•SCC-PWR02

•SCC-PWR03

4

3

2

1

1 Negative or GND of External Supply

2J1

3 Positive of External +5 VDC Supply

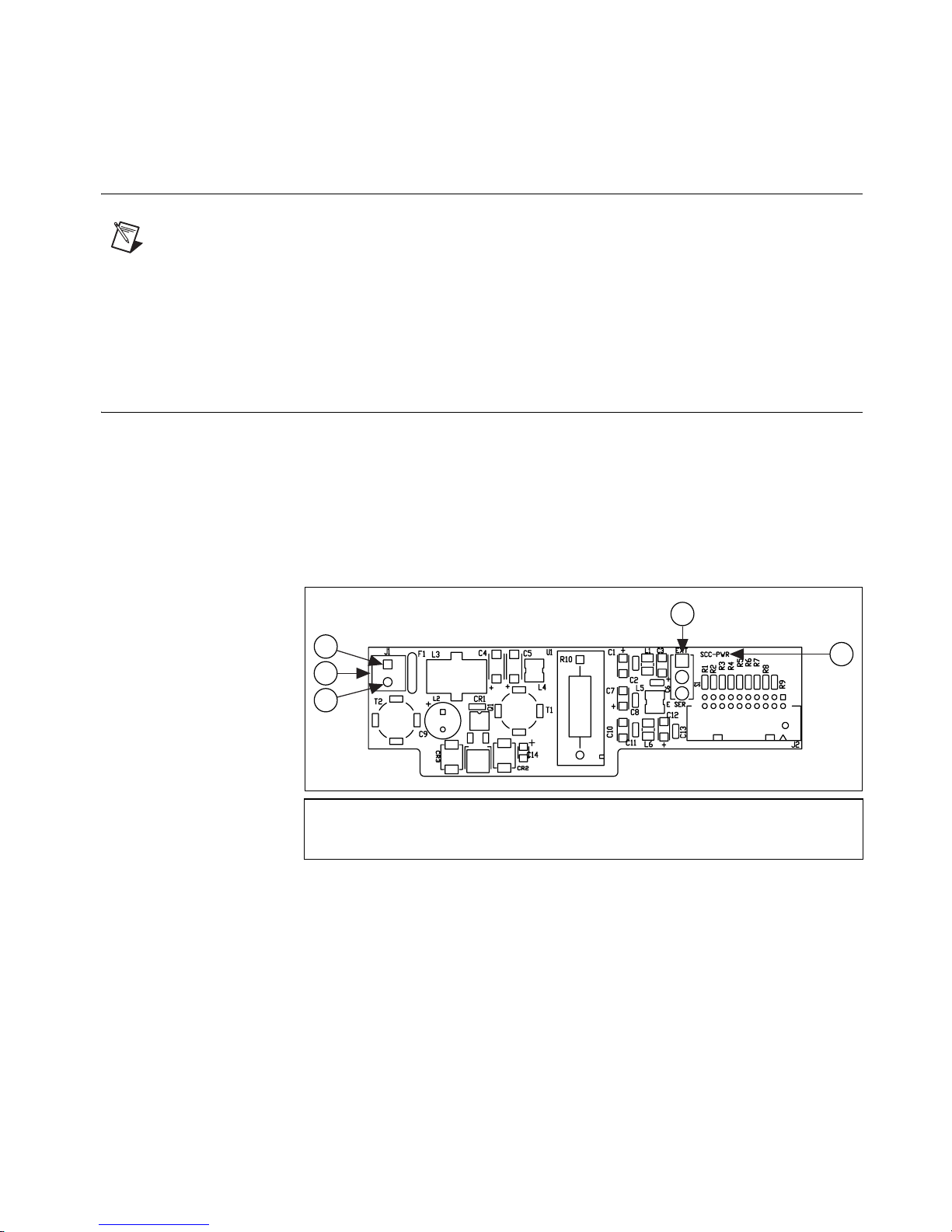

Figure 1-8. SCC-PWR0X Parts Locator Diagram

4S1

5 Product Name

5

Each power module supplies digital power (+5 V) for the SC-2345/2350

carrier only and analog power (±15 V) to SCC modules in the

SC-2345/2350 carrier. LEDs on the SC-2345/2350 indicate whether the

+5 V and ±15 V power supplies are functioning properly. If the LEDs do

not light when you connect power to the SC-2345/2350 carrier, refer to

Appendix C, SCC Power Requirements and Solutions. Figure 1-9 shows

the locations of sockets J24 and J25 on each of the three types of SC-2345

carrier enclosures and the SC-2350 carrier enclosure.

© National Instruments Corporation 1-15 SC-2345/2350 Carrier User Manual

Page 23

Chapter 1 Setting up the SC-2345/2350 Carrier

2

6

4

5

3

5

1

1 SC-2345 Carrier

2 SC-2345 Carrier with Configurable

Connectors, Side Cabled

3 SC-2350 Carrier with Configurable

Connectors, Side Cabled

4 SC-2345 Carrier with Configurable

Connectors,

Rear Cabled

6

5

6

6

5

5 Connector J24 (Connects to 68-Pin

E/M Series DAQ Device)

6 Connector J25 (Connects to PS01 Power Supply

for Use with SCC-PWR02 Power Module)

SC-2345/2350 Carrier User Manual 1-16 ni.com

Figure 1-9. SC-2345/2350 Enclosures

Page 24

SCC-PWR01

Chapter 1 Setting up the SC-2345/2350 Carrier

The SCC-PWR01 converts +5 V to ±15 V, which is the analog power

supply that SCC modules use. Set switch S1 on the SCC-PWR01 to select

the source of the +5 V as either ESER (E/M Series) or EXT (external). If

you select ESER, the SCC-PWR01 uses +5 V power from the E/M Series

DAQ device. If you select EXT, you must connect a +5 V supply (user

supplied) to the screw terminals of J1 on the SCC-PWR01. Wire the

positive lead to the screw terminal labeled

+

5V and wire the negative lead

to the screw terminal labeled GND. If you are using the SC-2345 carrier,

pass the leads through the strain relief on the front of the enclosure. If you

are using an SC-2345/2350 with configurable connectors, use a strain-relief

panelette for the leads.

1

1 SC-2345/2350 Carrier

2 5 VDC Power Supply (User-Supplied, Optional)

3DAQ Device

4J24

3

4

5

2

5 Positive Lead to +5 V Screw Terminal

on SCC-PWR01 Connector J1

6 Negative Lead to GND Screw Terminal

on SCC-PWR01 Connector J1

Figure 1-10. Using the SCC-PWR01

© National Instruments Corporation 1-17 SC-2345/2350 Carrier User Manual

Page 25

Chapter 1 Setting up the SC-2345/2350 Carrier

SCC-PWR02

The SCC-PWR02 is a two-part system that consists of a desktop power

supply (PS01) and a filtering component (SCC-PWR02 inside the carrier

enclosure). The PS01 is a 15 W switching supply powered by 90 to

264 VAC (50/60 Hz 1.0 A). To install the PS01, plug the 6-position

connector of the PS01 into connector J25 on the SC-2345/2350.

3

4

1 SC-2345/2350 Carrier

2 PS01 Power Supply

3 DAQ Device

5

2

1

4 To Connector J24

5 To Connector J25

Figure 1-11. Using the SCC-PWR02

SC-2345/2350 Carrier User Manual 1-18 ni.com

Page 26

SCC-PWR03

Chapter 1 Setting up the SC-2345/2350 Carrier

The SCC-PWR03 converts an external voltage of 7 to 42 VDC to +5 V and

±15 V and requires an external user-supplied DC power source. Attach the

voltage source to the screw terminals of J1 on the SCC‘-PWR03. Wire the

positive lead to the screw terminal labeled 7– 42 V and wire the negative

lead to the screw terminal labeled GND. If you are using the SC-2345

carrier, pass the leads through the strain relief on the front of the enclosure.

If you are using an SC-2345/2350 carrier with configurable connectors, use

a strain-relief panelette for the leads. You can power the SCC-PWR03 with

any appropriate 7 to 42 VDC source.

3

4

6

(–) (+)

5

1

1 SC-2345/2350 Carrier

2 7–42 VDC Source (User-Supplied)

3 DAQ Device

4 To Connector J24

5 Negative Lead to GND Screw Terminal

on SCC-PWR03 Connector J1

6 Positive Lead to +5 V Screw Terminal

on SCC-PWR03 Connector J1

Figure 1-12. Using the SCC-PWR03

Installing SCC Modules in the SC-2345/2350 Carrier

For instructions about how to install SCC modules in the SC-2345/2350

carrier and information about signal conditioning with SCC modules, refer

to the SCC Quick Start Guide.

2

© National Instruments Corporation 1-19 SC-2345/2350 Carrier User Manual

Page 27

Connecting Signals to the

Terminal Block of the

SC-2345/2350 Carrier

The SC-2345/2350 carrier has a 42-position, triple-row screw-terminal

block for connecting to E/M Series DAQ device digital signals. The

SC-2345 Quick Reference Label identifies the location of each signal on

the terminal rows A to C. The terminal label numbers correspond to the pin

number location of each signal on the 68-pin E/M Series connector. Refer

to the E Series Help or M Series Help for more information about this

connector. The E Series Help and the M Series Help are available for

download at

National Instruments»NI-DAQ»Browse Device Documentation after

you install the DAQ documentation browser.

ni.com/manuals or accessible from Start»Programs»

2

Figure 2-1 shows the locations of the digital signals on the SC-2345 and

SC-2350 terminal block when using an E Series or M Series connector 0.

Refer to the M Series Help, for specific pinout descriptions for M Series

devices when using connector 1.

© National Instruments Corporation 2-1 SC-2345/2350 Carrier User Manual

Page 28

Chapter 2 Connecting Signals to the Terminal Block of the SC-2345/2350 Carrier

Not Used

Not Used

PFI 14/FREQ OUT

PFI 12/CTR 0 OUT

PFI 8/CTR 0 SOURCE

PFI 6/AO START TRIG

PFI 4/CTR 1 GATE

PFI 2/AI CONV CLK

PFI 0/AI START TRIG

+ 5 V

P0.6

P0.4

P0.2

P0.0

A

1

2

37

5

41

43

11

14

16

19

49

52

Not Used

D GND

D GND

D GND

D GND

D GND

D GND

D GND

D GND

D GND

D GND

D GND

D GND

D GND

B

35

4

36

39

7

9

44

12

13

15

50

18

53

Not Used

AI SENSE

PFI 10/EXTSTROBE*

PFI 13/CTR 1 OUT

PFI 9/CTR 0 GATE

PFI 7/AI SAMP CLK

PFI 5/AO SAMPLE CLK

PFI 3/CTR 1 SOURCE

PFI 1/AI REF TRIG

PFI 11/AI HOLD COMP

P0.7

P0.5

P0.3

P0.1

C

62

45

40

3

38

6

42

10

46

48

51

47

17

Figure 2-1. Terminal Block I/O Connector Pin Assignments E Series

and M Series Connector 0

Rack-Mounting and Stack-Mounting Options

To use the SC-2345/2350 carrier with configurable connectors in a

standard 19 in. rack-mount configuration, install the optional CA-1000

rack-mount kit. To use the SC-2345/2350 carrier with configurable

connectors in a desktop stacking configuration, install the optional

CA-1000 stack-mount kit.

Installing the Rack-Mount Kit

Refer to Figure 2-2 and complete the following steps to install the CA-1000

rack-mount kit on the SC-2345/2350 carrier with configurable connectors:

1. Remove the rubber feet from the bottom of the SC-2345/2350 carrier

enclosure.

2. Attach a rack-mount bracket to both ends of the enclosure with

four 4-40 × 1/4 in. screws from the rack-mount kit.

SC-2345/2350 Carrier User Manual 2-2 ni.com

Page 29

Chapter 2 Connecting Signals to the Terminal Block of the SC-2345/2350 Carrier

1

2

1

14-40× 1/4 in. Screws 2 Rack-Mount Brackets

Figure 2-2. Rack-Mount Option

Installing the Stack-Mount Kit

Refer to Figure 2-3 and complete the following steps to install the CA-1000

stack-mount kit on the SC-2345/2350 carrier with configurable connectors:

1. Remove the rubber feet from all except the bottom enclosure.

2. Attach the stack-mount brackets to both ends of the lower

enclosure with the 4-40 × 1/4 in. flathead screws from the

stack-mount kit.

3. Place the upper enclosure on top of the lower enclosure.

4. Attach the stack-mount brackets to both ends of both enclosures with

the 4-40 × 1/4 in. flathead screws from the stack-mount kit.

2

© National Instruments Corporation 2-3 SC-2345/2350 Carrier User Manual

Page 30

Chapter 2 Connecting Signals to the Terminal Block of the SC-2345/2350 Carrier

1

2

1

3

1

3

1

14-40× 1/4 in. Screws 2 Stack-Mount Brackets 3 Handle Screws

Figure 2-3. Stack-Mount Option

You can stack additional enclosures by using additional stack-mount kits.

You can remove the stack-mount kit handles, if necessary, by removing the

four screws that attach the handles.

2

SC-2345/2350 Carrier User Manual 2-4 ni.com

Page 31

Specifications

These ratings are typical at 25 °C unless otherwise stated.

SC-2345 Carrier

Analog Input and Output

I/O connections ...................................... Sixteen, 20-pin connectors for

Digital Input and Output

A

analog-input SCC modules

(eight are shared with digital);

two 20-pin connectors for

analog-output SCC modules

I/O connections ...................................... Eight, 20-pin connectors for

Onboard Voltage Reference

Output voltage........................................ 5.000 V ±2.5 mV

Output voltage drift................................ 5 ppm/°C max (at 0 to 70 °C)

Long-term stability................................. ±15 ppm/1,000 h

Output noise (0.1 to 10 Hz).................... 4 μV

Load regulation

Sourcing 0 < I

Sinking –10 < I

Quiescent current ...................................2 mA

digital (shared with analog input)

42-position, triple-row terminal

block for digital and counter

< 10 mA............. 100 μV/mA

OUT

< 0 mA............. 400 μV/mA

OUT

p-p

Power consumption................................ 30 mW, 15 V

© National Instruments Corporation A-1 SC-2345/2350 Carrier User Manual

Page 32

Appendix A Specifications

LED Power Requirements

6.5 mA at 5 V .........................................32.5 mW

9 mA at 15 V ..........................................135 mW

9 mA at –15 V ........................................135 mW

Maximum Working Voltage

Cautions Refer to your DAQ device documentation for the voltage specifications for your

DAQ device.

Ensure that signals connected to SCC modules are used within the voltage ratings of the

modules to which they are connected. Refer to your SCC-XX user manual for the voltage

specifications for your SCC module.

Maximum working voltage refers to the signal voltage plus the

common-mode voltage.

Physical

Channel-to-earth .....................................11 VDC

Measurement Category I

Caution Do not use the SCC-2345 for connections to signals or for measurements within

Categories II, III, or IV.

Field-wiring diameter

(terminal block) ......................................26 to 16 AWG

SC-2345/2350 Carrier User Manual A-2 ni.com

Page 33

SC-2345 Connector Block

Appendix A Specifications

24.77 cm

(9.75 in.)

4.4 cm

(1.73 in.)

26.2 cm

(10.31 in.)

Figure A-1. SC-2345 Connector Block Dimensions

Weight.................................................... 1.66 kg (3 lb 10 oz)

I/O connectors ........................................ One 68-pin male SCSI connector;

one 6-pin male power connector

© National Instruments Corporation A-3 SC-2345/2350 Carrier User Manual

Page 34

Appendix A Specifications

SC-2345 with Configurable Connectors

(Rear and Side Cabled)

25.4 cm

(10.00 in.)

4.9 cm

(1.93 in.)

30.75 cm

(12.11 in.)

Figure A-2. SC-2345 With Configurable Connectors Dimensions

Weight ....................................................1.51 kg (3 lb 5 oz)

I/O connectors.........................................User-defined panelettes;

one 68-pin male SCSI connector;

one 6-pin male power connector

SC-2345/2350 Carrier User Manual A-4 ni.com

Page 35

Environmental

Safety

Appendix A Specifications

Operating temperature............................ 0 to 50 °C

Storage temperature ............................... –20 to 70 °C

Humidity ................................................ 10 to 90% RH, noncondensing

Maximum altitude .................................. 2,000 m

Pollution Degree (indoor use only) ........ 2

This product is designed to meet the requirements of the following

standards of safety for electrical equipment for measurement, control,

and laboratory use:

• IEC 61010-1, EN-61010-1

• UL 61010-1, CSA 61010-1

Note For UL and other safety certifications, refer to the product label or visit ni.com/

certification

in the Certification column.

, search by model number or product line, and click the appropriate link

Electromagnetic Compatibility

This product is designed to meet the requirements of the following

standards of EMC for electrical equipment for measurement, control,

and laboratory use:

• EN 61326 EMC requirements; Minimum Immunity

• EN 55011 Emissions; Group 1, Class A

• CE, C-Tick, ICES, and FCC Part 15 Emissions; Class A

Note For EMC compliance, operate this device according to product documentation.

© National Instruments Corporation A-5 SC-2345/2350 Carrier User Manual

Page 36

Appendix A Specifications

⬉ᄤֵᙃѻક∵ᶧࠊㅵ⧚ࡲ⊩ ˄Ё

˅

Ёᅶ᠋

CE Compliance

This product meets the essential requirements of applicable European

Directives, as amended for CE marking, as follows:

• 2006/95/EC; Low-Voltage Directive (safety)

• 2004/108/EEC; Electromagnetic Compatibility Directive (EMC)

Note Refer to the Declaration of Conformity (DoC) for this product for any additional

regulatory compliance information. To obtain the DoC for this product, visit

certification

, search by model number or product line, and click the appropriate link

in the Certification column.

Environmental Management

National Instruments is committed to designing and manufacturing

products in an environmentally responsible manner. NI recognizes that

eliminating certain hazardous substances from our products is beneficial

not only to the environment but also to NI customers.

ni.com/

For additional environmental information, refer to the NI and the

Environment Web page at

ni.com/environment. This page contains the

environmental regulations and directives with which NI complies, as well

as any other environmental information not included in this document.

Waste Electrical and Electronic Equipment (WEEE)

EU Customers At the end of their life cycle, all products must be sent to a WEEE recycling

center. For more information about WEEE recycling centers and National Instruments

WEEE initiatives, visit

ni.com/environment/weee.htm.

RoHS

National Instruments

݇Ѣ

National Instruments

(For information about China RoHS compliance, go to

Ё

ヺড়Ё⬉ᄤֵᙃѻકЁ䰤ࠊՓ⫼ᶤѯ᳝ᆇ⠽䋼ᣛҸ

ড়㾘ᗻֵᙃˈ䇋ⱏᔩ

RoHS

(RoHS)

ni.com/environment/rohs_china

ni.com/environment/rohs_china

DŽ

DŽ

.)

SC-2345/2350 Carrier User Manual A-6 ni.com

Page 37

SC-2350

Analog Input and Output

I/O connections ...................................... Eight, 20-pin connectors and

Typical maximum smart TEDS

sensor cable length ................................. 61 m (200 ft)

IEEE P1451.4 compliance ..................... Tier 2 (standard system

Appendix A Specifications

eight 2-channel TEDS screw

terminal blocks for analog-input

SCC modules;

two, 20-pin connectors for analog

output SCC modules

capability)

Note Future releases of NI-DAQmx might contain support for TEDS analog ouput

devices.

Onboard Voltage Reference

Output voltage........................................ 5.000 V ±2.5 mV

Output voltage drift................................ 5 ppm/°C max (at 0 to 70 °C)

Long-term stability................................. ±15 ppm/1,000 h

Output noise (0.1 to 10 Hz).................... 4 μV

Load regulation

Sourcing 0 < I

Sinking –10 < I

Quiescent current ...................................2 mA

Power consumption................................ 30 mW

< 10 mA............. 100 μV/mA

OUT

< 0 mA............. 400 μV/mA

OUT

p-p

LED Power Requirements

6.5 mA at 5 V......................................... 32.5 mW

9 mA at 15 V.......................................... 135 mW

9 mA at –15 V........................................ 135 mW

© National Instruments Corporation A-7 SC-2345/2350 Carrier User Manual

Page 38

Appendix A Specifications

Maximum Working Voltage

Cautions Refer to your DAQ device documentation for the voltage specifications for your

DAQ device.

Ensure that signals connected to SCC modules are used within the voltage ratings of the

modules to which they are connected. Refer to your SCC-XX user manual for the voltage

specifications for your SCC module.

Maximum working voltage refers to the signal voltage plus the

common-mode voltage.

Channel-to-earth .....................................11 VDC

Measurement Category I

Caution Do not use the SCC-2350 for connections to signals or for measurements within

Categories II, III, or IV.

SC-2345/2350 Carrier User Manual A-8 ni.com

Page 39

Physical

Appendix A Specifications

Field-wiring diameter

(terminal block)...................................... 26 to 16 AWG

SC-2350 with Configurable Connectors

(Side Cabled)

4.9 cm

(1.93 in.)

25.4 cm

(10.00 in.)

30.9 cm

(12.17 in.)

Figure A-3. SC-2350 Dimensions

Weight.................................................... 1.60 kg (3 lb 8.8 oz)

I/O connectors ........................................ User-defined panelettes;

one 68-pin male SCSI connector;

one 6-pin male power connector;

one 50-pin male test header

© National Instruments Corporation A-9 SC-2345/2350 Carrier User Manual

Page 40

Appendix A Specifications

Environmental

Safety

Operating temperature ............................0 to 50 °C

Storage temperature ................................–20 to 70 °C

Humidity.................................................10 to 90% RH, noncondensing

Maximum altitude...................................2,000 m

Pollution Degree (indoor use only) ........2

This product is designed to meet the requirements of the following

standards of safety for electrical equipment for measurement, control,

and laboratory use:

• IEC 61010-1, EN-61010-1

• UL 61010-1, CSA 61010-1

Note For UL and other safety certifications, refer to the product label or visit ni.com/

certification

in the Certification column.

, search by model number or product line, and click the appropriate link

Electromagnetic Compatibility

This product is designed to meet the requirements of the following

standards of EMC for electrical equipment for measurement, control,

and laboratory use:

• EN 61326 EMC requirements; Minimum Immunity

• EN 55011 Emissions; Group 1, Class A

• CE, C-Tick, ICES, and FCC Part 15 Emissions; Class A

Note For EMC compliance, operate this device according to product documentation.

SC-2345/2350 Carrier User Manual A-10 ni.com

Page 41

CE Compliance

⬉ᄤֵᙃѻક∵ᶧࠊㅵ⧚ࡲ⊩ ˄Ё

˅

Ёᅶ᠋

This product meets the essential requirements of applicable European

Directives, as amended for CE marking, as follows:

• 2006/95/EC; Low-Voltage Directive (safety)

• 2004/108/EEC; Electromagnetic Compatibility Directive (EMC)

Note Refer to the Declaration of Conformity (DoC) for this product for any additional

regulatory compliance information. To obtain the DoC for this product, visit

certification

, search by model number or product line, and click the appropriate link

in the Certification column.

Environmental Management

National Instruments is committed to designing and manufacturing

products in an environmentally responsible manner. NI recognizes that

eliminating certain hazardous substances from our products is beneficial

not only to the environment but also to NI customers.

Appendix A Specifications

ni.com/

For additional environmental information, refer to the NI and the

Environment Web page at

ni.com/environment. This page contains the

environmental regulations and directives with which NI complies, as well

as any other environmental information not included in this document.

Waste Electrical and Electronic Equipment (WEEE)

EU Customers At the end of their life cycle, all products must be sent to a WEEE recycling

center. For more information about WEEE recycling centers and National Instruments

WEEE initiatives, visit

ni.com/environment/weee.htm.

RoHS

National Instruments

݇Ѣ

National Instruments

(For information about China RoHS compliance, go to

Ё

ヺড়Ё⬉ᄤֵᙃѻકЁ䰤ࠊՓ⫼ᶤѯ᳝ᆇ⠽䋼ᣛҸ

ড়㾘ᗻֵᙃˈ䇋ⱏᔩ

RoHS

(RoHS)

ni.com/environment/rohs_china

ni.com/environment/rohs_china

DŽ

DŽ

.)

© National Instruments Corporation A-11 SC-2345/2350 Carrier User Manual

Page 42

Appendix A Specifications

SCC Power Modules

SCC-PWR01

Input

DC input voltage

From external power source ............+5 VDC ±5%

From E/M Series DAQ device ........+5 VDC ±5%

DC input power ......................................500 mW without SCC modules

Output

Maximum Power Output by Voltage Level

+5 VDC

(+4.17 to

Voltage Source

AT/PCI/PXI E/M Series

DAQ Device

1

DAQCard/DAQPad

E Series DAQ Device

2

External +5 VDC Supply 6.97 W

1

These power calculations apply to E/M Series DAQ devices that provide +5 VDC at 1 A at the I/O connector. Refer to the

specifications for the E/M Series DAQ device. Tests were performed using a 1 m cable. Longer cables yield a lower level of

power, but the difference is negligible for cables of 2 m or less in length.

2

These power calculations apply to E Series DAQ devices that provide +5 VDC at 250 mA at the I/O connector. Refer to the

specifications for the E Series DAQ device. Tests were performed using a 1 m cable. Longer cables yield a lower level of

power, but the difference is negligible for cables of 2 m or less in length.

*

Subtract 0.08 W for the SC-2350 carrier due to its TEDS circuitry.

+5.25 VDC)

4.18 W

0.80 W

*

*

*

Nominal

Voltage Level

Efficiency Line Regulation Load Regulation

+15 VDC

(+14.20 to

+15.25 VDC)

–15 VDC

(–14.20 to

–15.25 VDC)

0.87 W 0.87 W

0.24 W 0.24 W

0.87 W 0.87 W

Ripple and Noise

(DC to 10 MHz)

+5 VDC 100% System-dependent System-dependent System-dependent

+15 VDC 62% ±0.5% typ ±0.1% typ 15 mV

–15 VDC 62% ±0.5% typ ±0.1% typ 20 mV

SC-2345/2350 Carrier User Manual A-12 ni.com

rms

rms

typ

typ

Page 43

SCC-PWR02

Appendix A Specifications

Physical

Screw-terminal wiring diameter

(J1 connector)......................................... 24 to 16 AWG

PS01 Power Supply

AC input voltage .................................... 100 to 240 VAC

AC input frequency................................ 47 to 63 Hz

AC input current (steady state) .............. 1.0 A max

In-rush current (at cold start) ................. 30 A max

Max output ............................................. 45 W

Efficiency ............................................... 65% typ

Switching frequency .............................. 50 kHz nominal

Measurement Category .......................... II

Output (SCC-PWR02 Module)

Maximum

Power

Voltage Range

Available

+5 VDC (+4.64 to +5.25 VDC) 6.97 W

*

Line

Regulation

Load

Regulation

±1% ±9% 20 mV

+15 VDC (+14.45 to +15.25 VDC) 4.37 W ±5% ±10% 20 mV

–15 VDC (–14.45 to –15.25 VDC) 4.37 W ±5% ±10% 20 mV

*

Subtract 0.08 W for the SC-2350 carrier due to its TEDS circuitry.

Output Noise

(DC to

10 MHz)

Other Features (PS01)

rms

rms

rms

typ

typ

typ

Short-circuit protection .......................... Yes

Overvoltage protection........................... 343 VAC (130%)

Dimensions of the external supply......... 15.5 cm × 8.5 cm × 4.8 cm

© National Instruments Corporation A-13 SC-2345/2350 Carrier User Manual

(6.1 in. × 3.3 in. × 1.9 in.)

Page 44

Appendix A Specifications

SCC-PWR03

Environment for External Supply

Operating temperature ............................0 to 40 °C

Storage temperature ................................–20 to 80 °C

Relative humidity ...................................10 to 90%, noncondensing

Maximum altitude...................................2,000 m

Pollution Degree (indoor use only) ........2

Input

DC input voltage.....................................7 to 42 VDC

Reverse-voltage protection .....................–42 VDC max

Power ......................................................325 mA at 12 VDC

Output

Maximum

Power

Voltage Range

Available

+5 VDC (+4.36 to +5.25 VDC) 6.55 W

*

Line

Regulation

Load

Regulation

±1% ±12% 20 mV

+15 VDC (+14.25 to +15.75 VDC) 0.87 W ±5% ±10% 20 mV

–15 VDC (–14.45 to –15.75 VDC) 0.87 W ±5% ±10% 20 mV

* Subtract 0.08 W for the SC-2350 carrier due to its TEDS circuitry.

Output Noise

(DC to

10 MHz)

Physical

Screw-terminal wiring diameter

(J1 connector on module) .......................24 to 16 AWG

rms

rms

rms

typ

typ

typ

SC-2345/2350 Carrier User Manual A-14 ni.com

Page 45

Carrier Socket Signal

Assignments

This appendix contains descriptions of all the signals carried by the 20-pin

sockets on the SC-2345/2350 carrier. The pins are laid out on SCC modules

as shown in Figure B-1. For more information about the SC-2345/2350

carrier connector locations, refer to the SCC Quick Start Guide.

B

4 1

5

1Pin 1 2Pin 2 3PWB Key 4Pin 19 5Pin 20

Figure B-1. SCC Module Bottom View

3

2

© National Instruments Corporation B-1 SC-2345/2350 Carrier User Manual

Page 46

Appendix B Carrier Socket Signal Assignments

SC-2345 Carrier

Table B-1. SC-2345 Carrier—Sockets J1–J16

Pin Number

J9–J16: Digital I/O or

Single-Stage Analog Input

J1–J8: Single- or

Dual-Stage Analog Input

1 AI (X)+ to second stage AI (X) to DAQ device

2 AI (X)– to second stage —

3 AI SENSE AI SENSE

4 AI (X+8)+ to second stage AI (X+8) to DAQ device

5 AI SENSE —

6 AI GND AI GND

7 P0.(X) PFI 7/AI SAMP CLK

8 AI (X+8)– to second stage —

9 +5 V +5 V

10 GND GND

11 A GND A GND

12 REF 5 V REF 5 V

13 +15 V +15 V

14 –15 V –15 V

15 — AI SENSE

16 To second stage To firs t sta ge

17 — AI (X)– from first stage

18 — AI (X+8)+ from first stage

19 — AI (X)+ from first stage

20 — AI (X+8)– from first stage

SC-2345/2350 Carrier User Manual B-2 ni.com

Page 47

Appendix B Carrier Socket Signal Assignments

Table B-2. SC-2345 Carrier—Sockets J17–J18

Pin Number J17–J18: Analog Output DAC0 J17–J18: Analog Output DAC1

1 AO 0 AO 1

2 AO GND AO GND

3 AO 1 AO 0

4 AO GND AO GND

5 APFI 0/AO EXT REF APFI 0/AO EXT REF

6 PFI 5/AO SAMP CLK PFI 5/AO SAMP CLK

7 — —

8 PFI 6/AO START TRIG PFI 6/AO START TRIG

9 +5 V +5 V

10 GND GND

11 A GND A GND

12 REF 5 V REF 5 V

13 +15 V +15 V

14 –15 V –15 V

15 — —

16 — —

17 — —

18 — —

19 — —

20 — —

© National Instruments Corporation B-3 SC-2345/2350 Carrier User Manual

Page 48

Appendix B Carrier Socket Signal Assignments

Table B-3. SC-2345 Carrier—Sockets J19–J20

Pin Number J19–J20: GPCTR 0 J19–J20: GPCTR 1

1 PFI 12/CTR0 OUT PFI 13/CTR1 OUT

2 PFI 14/FREQ OUT PFI 14/FREQ OUT

3 PFI 9/CTR 0 GATE PFI 4/ CTR 1 GATE

4 P0.6 P0.7

5 PFI 8/CTR 0 SOURCE PFI 3/CTR 1 SOURCE

6 — —

7 — —

8 — —

9 +5 V +5 V

10 GND GND

11 A GND A GND

12 REF 5 V REF 5 V

13 +15 V +15 V

14 –15 V –15 V

15 — —

16 — —

17 — PFI 1/AI REF TRIG

18 PFI 5/AO SAMP CLK PFI 11/AI HOLD COMP

19 PFI 0/AI START TRIG PFI 0/AI START TRIG

20 PFI 6/AO START TRIG PFI 10/EXTSTROBE

SC-2345/2350 Carrier User Manual B-4 ni.com

Page 49

SC-2350

Appendix B Carrier Socket Signal Assignments

Table B-4. SC-2350—Socket J1–J8

Pin Number J1–J8: Analog Input

1 AI (X) to DAQ device

2 —

3 AI SENSE

4 AI (X+8) to DAQ device

5 —

6 AI GND

7 PFI 7/AI SAMP CLK

8 —

9 +5 V

10 GND

11 A GND

12 REF 5 V

13 +15 V

14 –15 V

15 1-Wire (X+8)

16 1-Wire (X)

17 —

18 —

19 —

20 —

© National Instruments Corporation B-5 SC-2345/2350 Carrier User Manual

Page 50

Appendix B Carrier Socket Signal Assignments

Table B-5. SC-2350—Sockets J17–J18

Pin Number J17: Analog Output DAC0 J18: Analog Output DAC1

1 AO 0 AO 1

2 AO GND AO GND

3 AO 1 AO 0

4 AO GND AO GND

5 APFI 0/AO EXT REF APFI 0/AO EXT REF

6 PFI 5/AO SAMP CLK PFI 5/AO SAMP CLK

7 — —

8 PFI 6/AO START TRIG PFI 6/AO START TRIG

9 +5 V +5 V

10 GND GND

11 A GND A GND

12 REF 5 V REF 5 V

13 +15 V +15 V

14 –15 V –15 V

15 1-Wire (AO 1) 1-Wire (AO 0)

16 1-Wire (AO 0) 1-Wire (AO 1)

17 — —

18 — —

19 — —

20 — —

SC-2345/2350 Carrier User Manual B-6 ni.com

Page 51

SC-2345/2350 Carrier

Appendix B Carrier Socket Signal Assignments

Table B-6. SC-2345/2350 Carrier—Socket J21

Pin Number Signal

1 A GND

2 A GND/AI GND

3 +15 V

4 –15 V

5 +5 V

6 —

7 External +5 VDC

8 External chassis GND

9 External +5 VDC

10 External chassis GND

11 External +15 VDC

12 External common

13 External –15 VDC

14 External common

15 DAQ device +5 VDC

16 DAQ device GND

17 DAQ device +5 VDC

18 DAQ device GND

19 DAQ device +5 VDC

20 DAQ device GND

© National Instruments Corporation B-7 SC-2345/2350 Carrier User Manual

Page 52

Appendix B Carrier Socket Signal Assignments

Table B-7. SC-2345/2350 Carrier—SCC-PWR0X Module Pin Signal Assignments (Socket J21)

Pin

Number

1 A GND A GND A GND Ground reference for

2 AI GND AI GND AI GND Signal ground from E/M Series

3 +15 V out +15 V out +15 V out +15 V supply to all SCC modules

4 –15 V out –15 V out –15 V out –15 V supply to all SCC modules

5 — External +5 V out — +5 V supply to all SCC modules

6 — — — —

7 — External +5 VDC — From external supply

8 — — — —

9 — External +5 VDC — From external supply

PWR01 Signal PWR02 Signal PWR03 Signal Signal Description

±15 V supply

DAQ device

10 — — — —

11 — External +15 VDC — From external supply

12 — External common DC — From external supply

13 — External –15 VDC — From external supply

14 — External common DC — From external supply

15 DAQ device +5 V — — From E/M Series DAQ device

16 DAQ device GND — — From E/M Series DAQ device

17 DAQ device +5 V — — From E/M Series DAQ device

18 DAQ device GND — — From E/M Series DAQ device

19 DAQ device +5 V — — From E/M Series DAQ device

20 DAQ device GND — — From E/M Series DAQ device

SC-2345/2350 Carrier User Manual B-8 ni.com

Page 53

Connector

Diagram

12

34

56

78

910

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25 26

27 28

29 30

31 32

33 34

35 36

37 38

39 40

41 42

43 44

45 46

47 48

49 50

Appendix B Carrier Socket Signal Assignments

Table B-8. SC-2350 TEDS Test Header Pin Signal Assignments (Socket J35)

Signal Name Pin Number Pin Number Signal Name

AI TEDS CHDATA (0) 1 2 AI TEDS CHRTN (0)

AI TEDS CHDATA (8) 3 4 AI TEDS CHRTN (8)

AI TEDS CHDATA (1) 5 6 AI TEDS CHRTN (1)

AI TEDS CHDATA (9) 7 8 AI TEDS CHRTN (9)

AI TEDS CHDATA (2) 9 10 AI TEDS CHRTN (2)

AI TEDS CHDATA (10) 11 12 AI TEDS CHRTN (10)

AI TEDS CHDATA (3) 13 14 AI TEDS CHRTN (3)

AI TEDS CHDATA (11) 15 16 AI TEDS CHRTN (11)

AI TEDS CHDATA (4) 17 18 AI TEDS CHRTN (4)

AI TEDS CHDATA (12) 19 20 AI TEDS CHRTN (12)

AI TEDS CHDATA (5) 21 22 AI TEDS CHRTN (5)

AI TEDS CHDATA (13) 23 24 AI TEDS CHRTN (13)

AI TEDS CHDATA (6) 25 26 AI TEDS CHRTN (6)

AI TEDS CHDATA (14) 27 28 AI TEDS CHRTN (14)

AI TEDS CHDATA (7) 29 30 AI TEDS CHRTN (7)

AI TEDS CHDATA (15) 31 32 AI TEDS CHRTN (15)

AO TEDS C HDATA (0) 33 34 AO TEDS CHRTN (0)

AO TEDS C HDATA (1) 35 36 AO TEDS CHRTN (1)

NC 37 38 NC

NC 39 40 NC

NC 41 42 NC

NC 43 44 NC

NC 45 46 NC

NC 47 48 NC

NC = No

Connect

© National Instruments Corporation B-9 SC-2345/2350 Carrier User Manual

NC 49 50 NC

Page 54

SCC Power Requirements

and Solutions

Installing new SCC modules in the SC-2345/2350 carrier increases the

power requirements of the SCC system. Depending on the number and

types of modules you are using, the power requirements of an SCC system

can eventually exceed the amount of power available from the SCC-PWR

module. Copy the following worksheets and use them to recalculate the

power requirements of the SCC system when you add new SCC modules.

To calculate the analog and digital power requirements for all the SCC

modules in each SC-2345/2350 carrier, complete the following steps:

1. Enter the number of modules of each type that you plan to use in

Tabl e C -1, Number of Modules per Carrier.

2. For each module type, multiply Number of Modules per Carrier by

Maximum Analog Power Required (mW) and enter the product in

Analog Power Required by Module Type.

C

3. For each module type, multiply Number of Modules per Carrier by

Maximum Digital Power Required (mW) and enter the product in

Digital Power Required by Module Type.

4. In Table C-2, total Analog Power Required by Module Type and enter

the sum as Total Analog Power Required per Carrier.

5. In Table C-2, total Digital Power Required by Module Type and enter

the sum as Total Digital Power Required per Carrier.

6. Use Table C-3 and the sections that follow to determine which power

option works for your system. The calculated power requirement must

be lower than the available power for each power type.

© National Instruments Corporation C-1 SC-2345/2350 Carrier User Manual

Page 55

Appendix C SCC Power Requirements and Solutions

Table C-1. Power Requirements of SCC Modules by Module Type

Maximum

Digital Power

Required

(mW)

SCC Module

Maximum Analog

Power Required

(mW)

SCC-A10 90 0

SCC-AIXX 375 525

SCC-AO10 180 1150

SCC-CI20 75 0

SCC-CO20 175 645

SCC-CTR01 0 140

SCC-DI01 0 61

SCC-DO01 0 70

SCC-FT01 — —

SCC-FV01 60 0

SCC-ACC01 80 330

SCC-LP01,

135 0

SCC-LP02

Number of

Modules per

Carrier

Analog Power

Required by

Module Type

Digital Power

Required by

Module Type

SCC-LP03,

475 0

SCC-LP04

SCC-RLY01 0 300

SCC-RTD01 135 153

SCC-SG0X 103 115

SCC-SG11 0 0.1

SCC-SG24 340 930

SCC-TCXX 60 0

Tota l =

SC-2345/2350 Carrier User Manual C-2 ni.com

Page 56

Appendix C SCC Power Requirements and Solutions

Table C-2. Total Power Requirements per Carrier

Total Analog Power

Required per Carrier

Total Digital Power

Required per Carrier

Table C-3. SC-2345/2350 Carrier: Power Available from SCC-PWR Modules

SCC-PWR Module

PWR01 with AT/PCI/PXI

1

PWR01 with DAQCard/DAQPad

PWR01 with External

+5 VDC Supply

3

Maximum

Analog Power

Available, P

2

AMax

1.74 W 4.18 W

0.49 W 0.80 W

1.74 W 6.97 W

Maximum

Digital Power

Available, P

PWR02 8.74 W 6.97 W

PWR03 with External

1.74 W 6.55 W

7–42 VDC Supply

Total Combined Power

Required per Carrier

Power Available

from Power

DMax

*

*

*

*

*

Supply, P

5.00 W

1.25 W

External

N/A

External

S

1

These power calculations apply to E/M Series DAQ devices that provide +5 VDC at 1 A at the I/O connector. Refer to the

specifications for the E/M Series DAQ device. Tests were performed using a 1 m cable. Longer cables yield a lower level of

power, but the difference is negligible for cables of 2 m or less in length.

2

These power calculations apply to E Series DAQ devices that provide +5 VDC at 250 mA at the I/O connector. Refer to the

specifications for the E Series DAQ device. Tests were performed using a 1 m cable. Longer cables yield a lower level of

power, but the difference is negligible for cables of 2 m or less in length.

3

Refer to the Calculating the Power Available from the SCC-PWR01 section.

* Subtract 0.08 W for the SC-2350 carrier due to its TEDS circuitry.

© National Instruments Corporation C-3 SC-2345/2350 Carrier User Manual

Page 57

Appendix C SCC Power Requirements and Solutions

Calculating the Power Available from the SCC-PWR01

To maximize the amount of power available from the SCC-PWR01, use

an external +5 VDC power supply with a minimum rating of 10.2 W.

Analog power available is limited by the 2 W DC–DC converter on the

SC-2345/2350 carrier and cannot exceed 1.74 W.

SC-2345 Carrier

For the SCC-PWR01 to supply enough power for your SCC configuration

in the SC-2345 carrier, the following three conditions must be true:

P

≤ P

A

AMax

and

P

≤ P

D

DMax

and

where

P

is the total analog power required by your SCC configuration,

A

in watts;

P

AMax

Tabl e C -3;

P

is the total digital power required by your SCC configuration,

D

in watts;

P

DMax

Tabl e C-3 ; a nd

P

is the rating of the power supply in watts.

S

P

/0.62 + PD + 0.45 W ≤ P

A

S

is the maximum analog power available in watts, from

is the maximum digital power available in watts, from

SC-2345/2350 Carrier User Manual C-4 ni.com

Page 58

SC-2350 Carrier

Appendix C SCC Power Requirements and Solutions

For the SCC-PWR01 to supply enough power for your SCC configuration

in the SC-2350 carrier, the following three conditions must be true:

P

≤ P

A

AMax

and

P

≤ P

D

DMax

and

P

/0.62 + PD + 0.53 W ≤ P

A

S

where

P

is the total analog power required by your SCC configuration,

A

in watts;

P

is the maximum analog power available in watts, from

AMax

Tabl e C -3;

P

is the total digital power required by your SCC configuration,

D

in watts;

P

is the maximum digital power available in watts, from

DMax

Tabl e C-3 ; a nd

P

is the rating of the power supply in watts.

S

Calculating the Power Available from the SCC-PWR02

The following section discusses the conditions which must be met for the

SCC-PWR02 to supply enough power for the SCC configuration on the

SC carriers.

© National Instruments Corporation C-5 SC-2345/2350 Carrier User Manual

Page 59

Appendix C SCC Power Requirements and Solutions

SC-2345/2350 Carrier

For the SCC-PWR02 to supply enough power for your SCC configuration

on the SC-2345/2350 carrier, the following two conditions must be true:

and

where

P

is the total analog power required by your SCC configuration,

A

in watts;

P

is the maximum analog power available in watts, from

AMax

Tabl e C -3;

P

is the total digital power required by your SCC configuration,

D

in watts; and

P

is the maximum digital power available in watts, from

DMax

Tabl e C -3.

P

≤ P

A

AMax

P

≤ P

D

DMax

Calculating the Power Available from the SCC-PWR03

The following section discusses the conditions which must be met for the

SCC-PWR03 to supply power to the SCC configuration on the SC carriers.

SC-2345 Carrier

For the SCC-PWR03 to supply enough power for your SCC configuration

in the SC-2345 carrier, the following three conditions must be true:

P

≤ P

A

AMax

and

P

/0.62 + PD ≤ P

and

where

A

P

/0.62 + PD + 0.45 W ≤ 0.75P

A

P

is the total analog power required by your SCC configuration,

A

in watts;

DMax

S

SC-2345/2350 Carrier User Manual C-6 ni.com

P

is the maximum analog power available in watts, from

AMax

Tabl e C -3;

Page 60

SC-2350 Carrier

Appendix C SCC Power Requirements and Solutions

PD is the total digital power required by your SCC configuration,

in watts;

P

is the maximum digital power available in watts, from

DMax

Tabl e C-3 ; a nd

P

is the rating of the power supply in watts.

S

For the SCC-PWR03 to supply enough power for your SCC configuration

in the SC-2350 carrier, the following three conditions must be true:

P

≤ P

A

AMax

and

P

/0.62 + PD ≤ P

A

DMax

and

P

/0.62 + PD + 0.53 W ≤ 0.75P

A

S

where

P

is the total analog power required by your SCC configuration,

A

in watts;

P

is the maximum analog power available in watts, from

AMax

Tabl e C -3;

P

is the total digital power required by your SCC configuration,

D

in watts;

P

is the maximum digital power available in watts, from

DMax

Tabl e C-3 ; a nd

P

is the rating of the power supply in watts.

S

© National Instruments Corporation C-7 SC-2345/2350 Carrier User Manual

Page 61

Common Questions

Which power option should I use for my application?

Refer to Appendix C, SCC Power Requirements and Solutions, to

determine which option to use.

I am sampling a very-low-voltage, noisy signal. How should I condition

the signal?

If the signal is within the ±50 mV range, use an SCC-AI07 isolated analog

input module. If the signal is of higher amplitude, but still within the

±100 mV range, use an SCC-AI06. Each of these modules has a 10 kHz

lowpass filter. The SCC-AI07 applies a gain of 200, and the SCC-AI06

applies a gain of 100.

Why should I amplify a noisy, low-amplitude analog signal using an

SCC module? Can’t I just amplify it using my E/M Series DAQ device?

D

One reason to amplify low-level signals close to the signal source instead

of at the E/M Series DAQ device is to increase the signal-to-noise ratio. If

you use the E/M Series DAQ device to amplify the signal, the E/M Series

DAQ device also measures and digitizes any noise that enters the lead wires

along the signal path. However, if you amplify the signal closer to the signal

source, the ratio of signal voltage to noise voltage that enters the lead wires

is larger. Therefore, the noise has a less destructive effect on the signal.

I need to sample a 24 V signal. Which SCC module(s) should I use?

Use an SCC-AI01 isolated analog input module. The SCC-AI01 has an

input range of ±42 V and applies a gain of 0.2, yielding a signal of ±8.4 V.

This produces a signal within the input range of the E/M Series DAQ

device.

© National Instruments Corporation D-1 SC-2345/2350 Carrier User Manual

Page 62

Appendix D Common Questions

I am taking measurements from a strain gage mounted on a motor, and

I am concerned that voltages from the motor might damage my

E/M Series DAQ device. What can I use for isolation?

In this case, to make an isolated-strain measurement, use two SCC

modules.

• Use an isolated analog output module to provide excitation.

• If remote sense is desired, use a third module such as an SCC-AIXX

• To measure the return voltage from the strain gage, use the appropriate

module. Use an isolated analog input module with appropriate range

to monitor the excitation voltage (remote sense the voltage). For

example, use the SCC-AI03 to perform remote sense if you are using

10 V

. If you are using 5 VEX, use the SCC-AI04 to perform remote

EX

sense. Use the remote sense voltage measurements to scale the strain