Page 1

SC-2040

User Manual

Eight-Channel Simultaneous Sample-and-Hold Accessory

September 1994 Edition

Part Number 371191A-01

© Copyright 1994 National Instruments Corporation.

All Rights Reserved.

Page 2

National Instruments Corporate Headquarters

6504 Bridge Point Parkway

Austin, TX 78730-5039

(512) 794-0100

Technical support fax: (800) 328-2203

(512) 794-5678

Branch Offices:

Australia (03) 879 9422, Austria (0662) 435986, Belgium 02/757.00.20, Canada (Ontario) (519) 622-9310,

Canada (Québec) (514) 694-8521, Denmark 45 76 26 00, Finland (90) 527 2321, France (1) 48 14 24 24,

Germany 089/741 31 30, Italy 02/48301892, Japan (03) 3788-1921, Netherlands 03480-33466, Norway 32-848400,

Spain (91) 640 0085, Sweden 08-730 49 70, Switzerland 056/20 51 51, U.K. 0635 523545

Page 3

Limited Warranty

The SC-2040 is warranted against defects in materials and workmanship for a period of one year from the date of

shipment, as evidenced by receipts or other documentation. National Instruments will, at its option, repair or replace

equipment that proves to be defective during the warranty period. This warranty includes parts and labor.

A Return Material Authorization (RMA) number must be obtained from the factory and clearly marked on the

outside of the package before any equipment will be accepted for warranty work. National Instruments will pay the

shipping costs of returning to the owner parts which are covered by warranty.

National Instruments believes that the information in this manual is accurate. The document has been carefully

reviewed for technical accuracy. In the event that technical or typographical errors exist, National Instruments

reserves the right to make changes to subsequent editions of this document without prior notice to holders of this

edition. The reader should consult National Instruments if errors are suspected. In no event shall National

Instruments be liable for any damages arising out of or related to this document or the information contained in it.

EXCEPT AS SPECIFIED HEREIN, NATIONAL INSTRUMENTS MAKES NO WARRANTIES, EXPRESS OR IMPLIED,

AND SPECIFICALLY DISCLAIMS ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE

OF

NATIONAL INSTRUMENTS WILL NOT BE LIABLE FOR DAMAGES RESULTING FROM LOSS OF DATA, PROFITS,

USE OF PRODUCTS, OR INCIDENTAL OR CONSEQUENTIAL DAMAGES, EVEN IF ADVISED OF THE POSSIBILITY

THEREOF

whether in contract or tort, including negligence. Any action against National Instruments must be brought within

one year after the cause of action accrues. National Instruments shall not be liable for any delay in performance due

to causes beyond its reasonable control. The warranty provided herein does not cover damages, defects,

malfunctions, or service failures caused by owner's failure to follow the National Instruments installation, operation,

or maintenance instructions; owner's modification of the product; owner's abuse, misuse, or negligent acts; and

power failure or surges, fire, flood, accident, actions of third parties, or other events outside reasonable control.

. CUSTOMER'S RIGHT TO RECOVER DAMAGES CAUSED BY FAULT OR NEGLIGENCE ON THE PART

NATIONAL INSTRUMENTS SHALL BE LIMITED TO THE AMOUNT THERETOFORE PAID BY THE CUSTOMER.

. This limitation of the liability of National Instruments will apply regardless of the form of action,

Copyright

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or

mechanical, including photocopying, recording, storing in an information retrieval system, or translating, in whole

or in part, without the prior written consent of National Instruments Corporation.

Trademarks

LabVIEW®, NI-DAQ®, and RTSI® are trademarks of National Instruments Corporation.

Product names and company names listed are trademarks or trade names of their respective companies.

Page 4

Warning Regarding Medical and Clinical Use

of National Instruments Products

National Instruments products are not designed with components and testing intended to ensure a level of reliability

suitable for use in treatment and diagnosis of humans. Applications of National Instruments products involving

medical or clinical treatment can create a potential for accidental injury caused by product failure, or by errors on

the part of the user or application designer. Any use or application of National Instruments products for or involving

medical or clinical treatment must be performed by properly trained and qualified medical personnel, and all

traditional medical safeguards, equipment, and procedures that are appropriate in the particular situation to prevent

serious injury or death should always continue to be used when National Instruments products are being used.

National Instruments products are NOT intended to be a substitute for any form of established process, procedure, or

equipment used to monitor or safeguard human health and safety in medical or clinical treatment.

Page 5

Contents

About This Manual................................................................................................................ix

Organization of This Manual............................................................................................ix

Conventions Used in This Manual....................................................................................x

The National Instruments Documentation Set..................................................................x

Related Documentation ....................................................................................................xi

Customer Communication................................................................................................xi

Chapter 1

Introduction

About the SC-2040.........................................................................................................1-1

What You Need to Get Started ......................................................................................1-1

Software Programming Choices....................................................................................1-2

Optional Equipment.......................................................................................................1-4

Unpacking......................................................................................................................1-4

Chapter 2

Configuration and Installation

Board Configuration ......................................................................................................2-1

Installation......................................................................................................................2-8

Power On Sequence.......................................................................................................2-8

..........................................................................................................................1-1

LabVIEW and LabWindows Application Software..........................................1-2

NI-DAQ Driver Software...................................................................................1-2

Register-Level Programming.............................................................................1-4

.......................................................................................2-1

Supplementary Configuration Information........................................................2-6

Power Supply Selection.........................................................................2-6

Shield Selection......................................................................................2-6

DAQ Board Ground Isolation Selection................................................2-6

Gain Selection....................................................................................................2-6

Input Mode Selection.........................................................................................2-7

Chapter 3

Signal Connections

I/O Connector Pin Description.......................................................................................3-1

Signal Connection Description..........................................................................3-4

Analog Signal Input...........................................................................................3-7

Digital Signal Input............................................................................................3-11

Monitoring Signal Outputs.................................................................................3-11

Other Connection Considerations..................................................................................3-11

© National Instruments Corporation v SC-2040 User Manual

.............................................................................................................3-1

DC-Coupled Inputs................................................................................3-7

AC-Coupled Signals ..............................................................................3-8

Analog Input Ranges..................................................................3-10

Page 6

Contents

Chapter 4

Theory of Operation

Functional Overview......................................................................................................4-1

Analog Circuitry ............................................................................................................4-3

Input Protection..................................................................................................4-3

Amplification.....................................................................................................4-3

Track-and-Hold (T/H) Circuitry........................................................................4-3

..........................................................................................................4-1

Triggering from the DAQ Board ...........................................................4-4

External Triggering................................................................................4-5

Output Connection.................................................................................4-6

Power Supply.........................................................................................4-6

Chapter 5

Calibration Procedures

Software Calibration......................................................................................................5-1

Offset Adjustment..............................................................................................5-1

Gain Adjustment................................................................................................5-2

Linearity Adjustment.........................................................................................5-2

Hardware Calibration.....................................................................................................5-2

.....................................................................................................5-1

Appendix A

Specifications

........................................................................................................................A-1

Appendix B

Customer Communication

...............................................................................................B-1

Glossary........................................................................................................................Glossary-1

Index..................................................................................................................................Index-1

SC-2040 User Manual vi © National Instruments Corporation

Page 7

Contents

Figures

Figure 1-1. The Relationship between the Programming Environment,

NI-DAQ, and Your Hardware............................................................................. 1-3

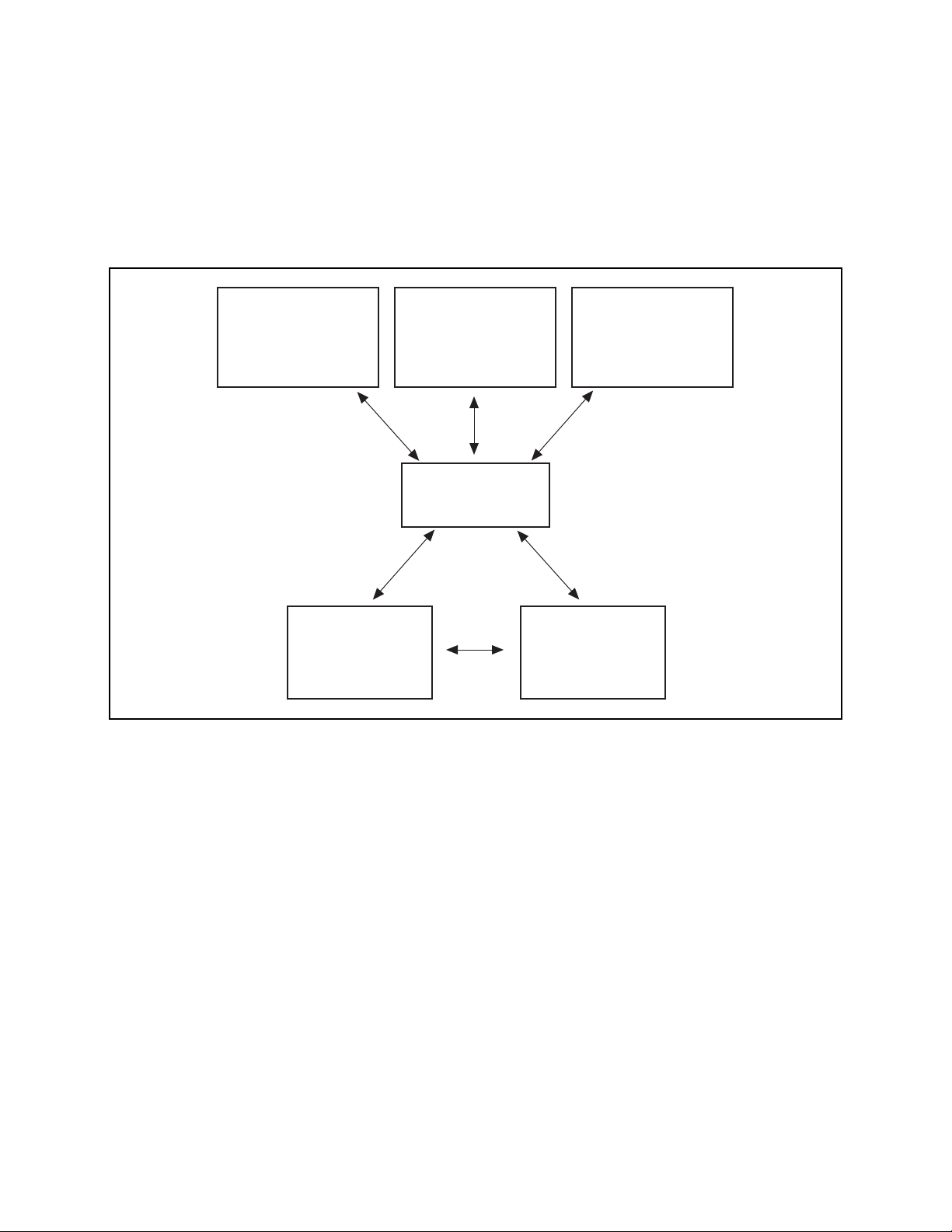

Figure 2-1. SC-2040 Parts Locator Diagram..........................................................................2-2

Figure 3-1. SC-2040 I/O Connectors J11 and J12..................................................................3-2

Figure 3-2. SC-2040 Signal Routing......................................................................................3-6

Figure 3-3. Ground-Referenced Signal Connection...............................................................3-7

Figure 3-4. Floating Signal Connection.................................................................................3-8

Figure 3-5. Ground-Referenced AC-Coupled Signal Connection .........................................3-9

Figure 3-6. Ground-Offset AC-Coupled Signal Connection..................................................3-9

Figure 3-7. Floating AC-Coupled Signal Connection............................................................3-10

Figure 4-1. SC-2040 Block Diagram......................................................................................4-2

Figure 4-2. T/H Amplifier Hold Settling Time and Track Acquisition Time........................4-4

Figure 4-3. MIO-16E Controlled Triggering..........................................................................4-5

Figure 4-4. External Triggering..............................................................................................4-6

Tables

Table 2-1. Power Supply Selection.......................................................................................2-3

Table 2-2. Shield Selection...................................................................................................2-4

Table 2-3. DAQ Board Ground Isolation Selection..............................................................2-4

Table 2-4. Channel Gain Selection.......................................................................................2-5

Table 2-5. Channel Input Mode............................................................................................2-5

Table 2-6. Gain Switches for Each Channel.........................................................................2-6

Table 2-7. Switch Settings for Gain Selection......................................................................2-7

Table 2-8. Input Mode Selection Jumpers............................................................................2-7

Table 3-1. Pin Assignments for Connectors J11 and J12......................................................3-3

Table 3-2. Input Connectors Signal Summary......................................................................3-4

Table 3-3. Output Connectors (J11 and J12) Signal Summary.............................................3-4

Table 5-1. Calibration Component Identification.................................................................5-3

© National Instruments Corporation vii SC-2040 User Manual

Page 8

About This Manual

This manual describes the electrical and mechanical aspects of the SC-2040 and contains

information concerning its configuration and operation. The SC-2040 is an eight-channel

simultaneously sampling differential amplifier for the National Instruments MIO-16E Series

DAQ boards. The SC-2040 samples all eight channels at the same time, preserving interchannel

phase relationships for the MIO-16E.

Organization of This Manual

The SC-2040 User Manual is organized as follows:

• Chapter 1, Introduction, describes the SC-2040, lists what you need to get started with your

SC-2040, describes the optional software and optional equipment, and explains how to

unpack your SC-2040.

• Chapter 2, Configuration and Installation, describes the configuration and installation of

your SC-2040. The topics discussed are switch and jumper configuration, connection of the

SC-2040 to the MIO-16E, and the power-on sequence for your SC-2040 configuration.

• Chapter 3, Signal Connections, describes the signal connections to the SC-2040 board, and

cable wiring.

• Chapter 4, Theory of Operation, contains a functional overview of the SC-2040 board and

explains the operation of each functional unit making up the SC-2040.

• Chapter 5, Calibration Procedures, discusses the calibration procedures for the SC-2040

board.

• Appendix A, Specifications, lists the specifications for the SC-2040.

• Appendix B, Customer Communication, contains forms you can use to request help from

National Instruments or to comment on our products.

• The Glossary contains an alphabetical list and description of terms used in this manual,

including abbreviations, acronyms, metric prefixes, mnemonics, and symbols.

• The Index contains an alphabetical list of key terms and topics used in this manual, including

the page where you can find each one.

© National Instruments Corporation ix SC-2040 User Manual

Page 9

About This Manual

Conventions Used in This Manual

The following conventions are used in this manual:

bold italic Bold, italic text denotes a note, caution, or warning.

italic Italic text denotes emphasis, a cross reference, or an introduction to a key

concept.

MIO-16E MIO-16E refers to the National Instruments E-Series of MIO-16 DAQ

boards unless otherwise noted.

monospace Lowercase text in this font denotes text or characters that are to be literally

input from the keyboard, sections of code, programming examples, and

syntax examples. This font is also used for the proper names of disk

drives, paths, directories, programs, subprograms, subroutines, device

names, functions, variables, filenames, and extensions, and for statements

and comments taken from program code.

Abbreviations, acronyms, metric prefixes, mnemonics, symbols, and terms are listed in the

Glossary.

The National Instruments Documentation Set

The SC-2040 User Manual is one piece of the documentation set for your system. You could

have any of several types of manuals, depending on the hardware and software in your system.

Use the manuals you have as follows:

• Your DAQ hardware user manuals–These manuals have detailed information about the DAQ

hardware that plugs into or is connected to your computer. Use these manuals for hardware

installation and configuration instructions, specification information about your DAQ

hardware, and application hints.

• Software manuals–Examples of software manuals you might have are the LabVIEW and

LabWindows

system, use either the application software (LabVIEW or LabWindows) manuals or the

NI-DAQ manuals to help you write your application. If you have a large and complicated

system, it is worthwhile to look through the software manuals before you configure your

hardware.

• Accessory manuals–If you are using accessory products, read the terminal block and cable

assembly installation guides or accessory board user manuals. They explain how to

physically connect the relevant pieces of the system together. Consult these guides when you

are making your connections.

®

manual sets and the NI-DAQ manuals. After you set up your hardware

SC-2040 User Manual x © National Instruments Corporation

Page 10

About This Manual

Related Documentation

The following document contains information that you may find helpful as you read this manual:

• Your DAQ hardware user manual

Customer Communication

National Instruments wants to receive your comments on our products and manuals. We are

interested in the applications you develop with our products, and we want to help if you have

problems with them. To make it easy for you to contact us, this manual contains comment and

configuration forms for you to complete. These forms are in Appendix B, Customer

Communication, at the end of this manual.

© National Instruments Corporation xi SC-2040 User Manual

Page 11

Chapter 1 Introduction

This chapter describes the SC-2040, lists what you need to get started with your SC-2040,

describes the optional software and optional equipment, and explains how to unpack your

SC-2040.

About the SC-2040

The SC-2040 is an eight-channel simultaneously sampling differential amplifier for the National

Instruments MIO-16E Series DAQ boards. Each channel provides DIP-switch-selectable gain

followed by a track-and-hold amplifier. The track-and-hold amplifiers sample all the inputs at

the same time, which is useful for preserving interchannel phase relationships. The MIO-16E

can trigger the track-and-hold amplifiers, or you can supply an external trigger source.

Note: When a board is referred to without an AT prefix (that is, MIO-16E), the reference

applies to the AT versions of that board.

The SC-2040 is a circuitboard assembly that is placed on a workbench or mounted in a 19-in.

rack. You can configure the SC-2040 to draw power from the MIO-16E board or from an

external +5 V supply. A red LED indicates when the board is powered on. Input signal leads are

attached at screw terminals.

What You Need to Get Started

To set up and use your SC-2040, you will need the following components:

• SC-2040 board

• SC-2040 User Manual

• 1.0, 2.0, 5.0, or 10.0 m SH6868 or R6868 cable

Detailed specifications of the SC-2040 are in Appendix A, Specifications.

© National Instruments Corporation 1-1 SC-2040 User Manual

Page 12

Introduction Chapter 1

Software Programming Choices

Your SC-2040 kit does not include software. There are four options to choose from when

programming your National Instruments DAQ and SCXI hardware. You can use LabVIEW,

LabWindows, NI-DAQ, or register-level programming software.

The SC-2040 works with LabVIEW for Windows, LabVIEW for Macintosh, LabWindows for

DOS, LabWindows/CVI for Windows, NI-DAQ software for PC compatibles, and NI-DAQ

software for Macintosh.

LabVIEW and LabWindows Application Software

LabVIEW and LabWindows are innovative program development software packages for data

acquisition and control applications. LabVIEW uses graphical programming, whereas

LabWindows enhances traditional programming languages. Both packages include extensive

libraries for data acquisition, instrument control, data analysis, and graphical data presentation.

LabVIEW currently runs on three different platforms–AT/MC/EISA computers running

Microsoft Windows, the Macintosh platform, and the Sun SPARCstation platform. LabVIEW

features interactive graphics, a state-of-the-art user interface, and a powerful graphical

programming language. The LabVIEW Data Acquisition VI Library, a series of VIs for using

LabVIEW with National Instruments DAQ hardware, is included with LabVIEW. The

LabVIEW Data Acquisition VI Libraries are functionally equivalent to the NI-DAQ software,

except that the SCXI functions are not included in the LabVIEW software for Sun.

LabWindows has two versions–LabWindows for DOS is for use on PCs running DOS, and

LabWindows/CVI is for use on PCs running Windows and for Sun SPARCstations.

LabWindows/CVI features interactive graphics, a state-of-the-art user interface, and uses the

ANSI standard C programming language. The LabWindows Data Acquisition Library, a series

of functions for using LabWindows with National Instruments DAQ hardware, is included with

the NI-DAQ software kit. The LabWindows Data Acquisition libraries are functionally

equivalent to the NI-DAQ software, except that the SCXI functions are not included in the

LabWindows/CVI software for Sun.

Using LabVIEW or LabWindows software will greatly reduce the development time for your

data acquisition and control application.

NI-DAQ Driver Software

The NI-DAQ driver software is included at no charge with all National Instruments DAQ

hardware. NI-DAQ is not packaged with SCXI or accessory products. NI-DAQ has an

extensive library of functions that you can call from your application programming environment.

These functions include routines for analog input (A/D conversion), buffered data acquisition

(high-speed A/D conversion), analog output (D/A conversion), waveform generation, digital I/O,

counter/timer operations, SCXI, RTSI, self-calibration, messaging, and acquiring data to

extended memory.

SC-2040 User Manual 1-2 © National Instruments Corporation

Page 13

Chapter 1 Introduction

NI-DAQ also internally addresses many of the complex issues between the computer and the

DAQ hardware such as programming interrupts and DMA controllers. NI-DAQ maintains a

consistent software interface among its different versions so that you can change platforms with

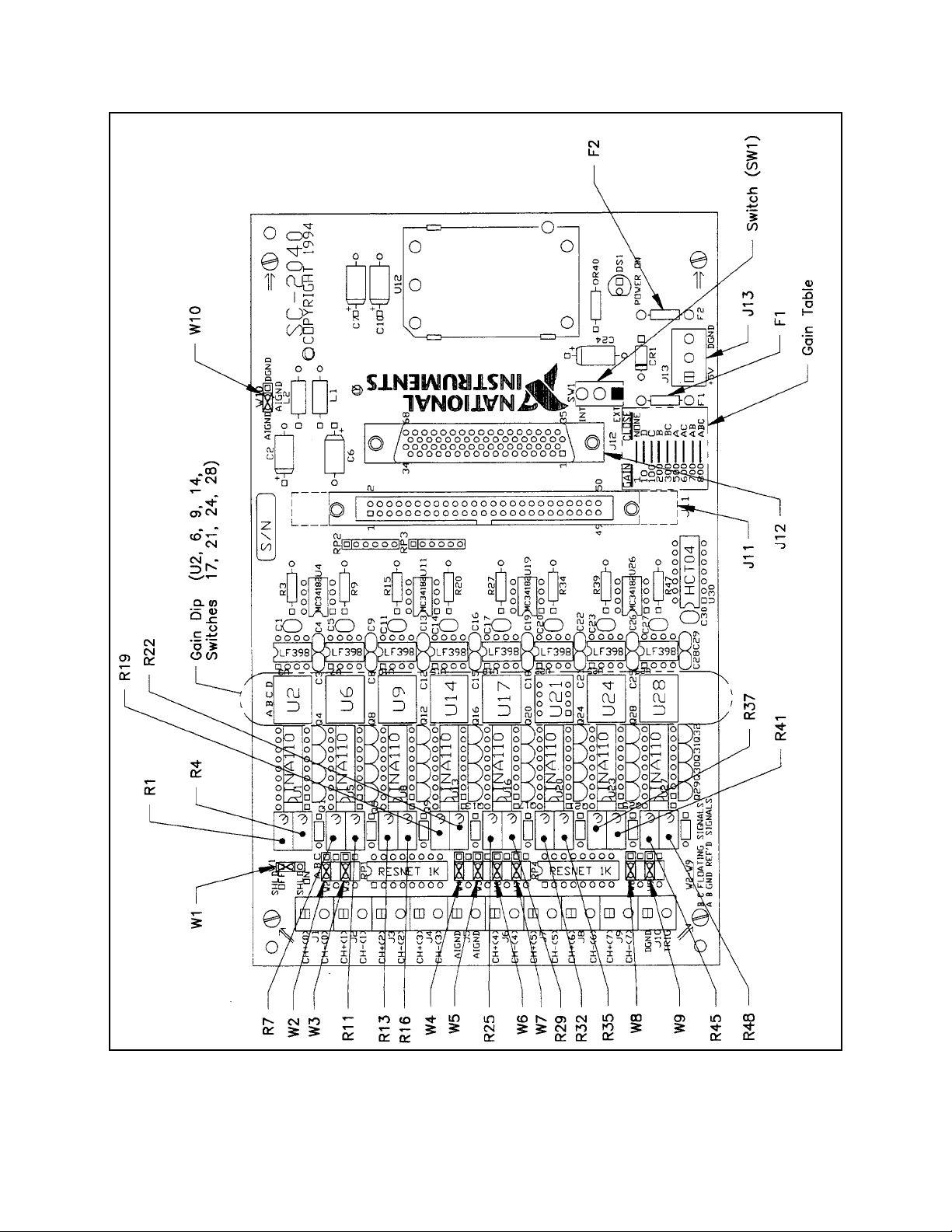

minimal modifications to your code. Figure 1-1 illustrates the relationship between NI-DAQ and

LabVIEW and LabWindows. You can see that the data acquisition parts of LabVIEW and

LabWindows are functionally equivalent to the NI-DAQ software.

Conventional

Programming

Environment

(PC, Macintosh, or

Sun SPARCstation)

LabVIEW

(PC, Macintosh, or

Sun SPARCstation)

NI-DAQ

Driver Software

LabWindows

(PC or

Sun SPARCstation)

DAQ or

SCXI Hardware

Personal

Computer

or

Workstation

Figure 1-1. The Relationship between the Programming Environment,

NI-DAQ, and Your Hardware

The National Instruments PC, AT, MC, EISA, DAQCard, and DAQPad Series DAQ hardware is

packaged with NI-DAQ software for PC compatibles. NI-DAQ software for PC compatibles

comes with language interfaces for Professional BASIC, Turbo Pascal, Turbo C, Turbo C++,

Borland C++, and Microsoft C for DOS; and Visual Basic, Turbo Pascal, Microsoft C with SDK,

and Borland C++ for Windows. You can use your AT-MIO-16, together with other PC, AT,

MC, EISA, DAQCard, and DAQPad Series DAQ and SCXI hardware, with NI-DAQ software

for PC compatibles.

The National Instruments NB Series DAQ boards are packaged with NI-DAQ software for

Macintosh. NI-DAQ software for Macintosh comes with language interfaces for MPW C,

THINK C, Pascal, and Microsoft QuickBASIC. Any language that uses Device Manager

Toolbox calls can access NI-DAQ software for Macintosh. You can use NB Series DAQ boards

and SCXI hardware with NI-DAQ software for Macintosh.

The National Instruments SB Series DAQ boards are packaged with NI-DAQ software for Sun,

which comes with a language interface for ANSI C.

© National Instruments Corporation 1-3 SC-2040 User Manual

Page 14

Introduction Chapter 1

Register-Level Programming

There are no register-level programming concerns for the SC-2040. When using the SC-2040,

only the MIO-16E Series board needs to be programmed. Refer to your MIO-16E board manual

for further information on register-level programming.

Optional Equipment

Contact National Instruments to order the following optional equipment:

• CB-50 I/O connector (50-screw terminals) with 0.5 or 1.0 m cable

• Single or double height rack-mount kit with acrylic plastic cover

• Single or double height rack-mount kit with metal wraparound cover

Unpacking

Your SC-2040 board is shipped in an antistatic package to prevent electrostatic damage to the

board. Electrostatic discharge can damage several components on the board. To avoid such

damage in handling the board, take the following precautions:

• Ground yourself via a grounding strap or by holding a grounded chassis such as a computer

chassis.

• Touch the antistatic package to a metal part of your computer chassis before removing the

board from the package.

• Remove the board from the package and inspect the board for loose components or any other

sign of damage. Notify National Instruments if the board appears damaged in any way.

Do not install a damaged board into your computer.

• Never touch the exposed pins of connectors.

SC-2040 User Manual 1-4 © National Instruments Corporation

Page 15

Chapter 2 Configuration and Installation

This chapter describes the configuration and installation of your SC-2040. The topics discussed

are switch and jumper configuration, connection of the SC-2040 to the MIO-16E, and the poweron sequence for your SC-2040 configuration.

Board Configuration

The SC-2040 has 10 jumpers, eight DIP switches, and one slide switch that you use to configure

the board. These switches and jumpers are shown in Figure 2-1.

© National Instruments Corporation 2-1 SC-2040 User Manual

Page 16

Configuration and Installation Chapter 2

Figure 2-1. SC-2040 Parts Locator Diagram

SC-2040 User Manual 2-2 © National Instruments Corporation

Page 17

Chapter 2 Configuration and Installation

The SC-2040 has one switch that controls whether the board is powered from an external supply

or from the MIO-16E board. Furthermore, two jumpers control how the board is shielded and

grounded. Additionally, there are eight sets of switches and jumpers that configure the gain

settings and input modes of the eight SC-2040 channels.

Table 2-1. Power Supply Selection

Switch Description Configuration

INT position—Use this setting

to configure the SC-2040 to

SW1

INT

draw power through the

EXT

A. Internal

Power

SW1

INT

SW1

MIO-16E board. (factory

setting)

J13

EXT position—Use this

setting to draw +5 V power

from an external supply

connected to connector J13.

EXT

B. External

Power

© National Instruments Corporation 2-3 SC-2040 User Manual

Page 18

Configuration and Installation Chapter 2

Table 2-2. Shield Selection

Jumper Description Configuration

W1

SHLD OFF position—Place

the jumper in this position to

keep the SC-2040 analog

SHLD OFF

W1

ground isolated from the metal

standoffs in the corners of the

board (factory setting).

SHLD ON position—Place

the jumper in this position to

SHLD ON

W1

SHLD OFF

connect the SC-2040 analog

ground to the metal standoffs

or to a rack-mount kit, which

SHLD ON

may provide shielding for the

SC-2040.

Table 2-3. DAQ Board Ground Isolation Selection

Jumper Description Configuration

W10

AIGND-AIGND position—

Use this setting if you are

using a MIO-16E DAQ board.

W10

AIGND

Place the jumper in this

position to keep the SC-2040

AIGND

digital ground and analog

grounds isolated (factory

setting).

DGND

AIGND-DGND position—

Place the jumper in this

position to connect the

SC-2040 analog ground to

W10

DGNDAIGND

AIGND

digital ground.

SC-2040 User Manual 2-4 © National Instruments Corporation

Page 19

Chapter 2 Configuration and Installation

Table 2-4. Channel Gain Selection

Switch Description Configuration

U2

U6

U9

U14

U17

U21

U24

U28

Unity gain position—For

unity gain (gain = 1), open all

the switches by pushing down

the OFF end of the switches.

(factory setting)

The unity gain position has

Gain Table

A B C D

1234

OFF

the number side up.

Other gains—Refer to

Supplementary Configuration

Information, later in the

chapter, and the gain table on

the board itself.

Table 2-5. Channel Input Mode

Switch Description Configuration

W2

W3

W4

W5

W6

W7

W8

W9

A-B position—Use this

setting for connecting groundreferenced signals to the

SC-2040 (factory setting).

B-C position—Use this setting

for connecting floating (nonground referenced) sources.

A 100 kΩ resistor is

connected from the negative

channel input to the SC-2040

analog ground.

A B C

W2

A B C

W2

The W3–W9 jumper

positions are the same

as on W2.

© National Instruments Corporation 2-5 SC-2040 User Manual

Page 20

Configuration and Installation Chapter 2

Supplementary Configuration Information

Power Supply Selection

Set switch SW1 to the INT position to connect the SC-2040 power converter to the +5 V lines on

the MIO-16E board. Set switch SW1 to the EXT position to draw power from an external +5 V

power supply connected to J13.

The MIO-16E is fused to provide 5 W of power (at +5 V and 1 A). The SC-2040 consumes

nearly all of this available power. Therefore, if you have other DAQ accessories that you would

like to power from the MIO, you should switch the SC-2040 to external power and provide an

external +5 V power source. In external power mode, the SC-2040 is fuse limited to 1 A at

+5 V.

Shield Selection

If you are using a rack-mount kit, shield the SC-2040 from unwanted noise by connecting the

analog ground on the board to the metal chassis of the rack using jumper W1. When you set W1

to the SHLD ON position, the jumper connects the analog ground to the metal standoffs used to

mount the board in a rack. In the SHLD OFF position, the SC-2040 analog ground is isolated

from the metal standoffs.

DAQ Board Ground Isolation Selection

You can use jumper W10 to connect the SC-2040 digital and analog grounds. If you are using a

MIO-16E board, you must isolate the grounds by leaving the jumper in its default position.

Gain Selection

The gain selection switches can select gains of 1, 10, 100, 200, 300, 500, 600, 700, and 800 for

each channel, as shown in Table 2-6.

Table 2-6. Gain Switches for Each Channel

Channel Close Switches

0U2

1U6

2U9

3 U14

4 U17

5 U21

6 U24

7 U28

SC-2040 User Manual 2-6 © National Instruments Corporation

Page 21

Chapter 2 Configuration and Installation

To close a switch, push down the number side. Closing switch A selects a gain of 500. Closing

switch B selects a gain of 200. Closing switch C selects a gain of 100. Closing switch D selects

a gain of 10. Opening all the switches selects a gain of 1. You can select other gains by closing

more than one switch, as shown in Table 2-7.

Table 2-7. Switch Settings for Gain Selection

Desired Gain Close Switches

1 None

10 D

100 C

200 B

300 B and C

500 A

600 A and C

700 A and B

800 A, B, and C

Input Mode Selection

Jumpers W2 through W9 select the input mode for each channel on the SC-2040. Position A-B

leaves the negative input of the instrumentation amplifier connected only to the front connector.

This is the factory-default setting. Position B-C connects the negative input of the

instrumentation amplifier to the board analog ground through a 100 kΩ resistor. This setting is

useful for keeping floating, or nonground-referenced, sources from saturating the instrumentation

amplifier. Table 2-8 shows the input mode jumper and channel selections.

Table 2-8. Input Mode Selection Jumpers

Channel Use Jumper

0W2

1W3

2W4

3W5

4W6

5W7

6W8

7W9

© National Instruments Corporation 2-7 SC-2040 User Manual

Page 22

Configuration and Installation Chapter 2

Installation

Note: You must turn off power to the PC, and to the SC-2040 board if the board is externally

powered, before installing the board or making any connections to it.

To install the SC-2040, connect the 68-pin ribbon from the MIO-16E I/O connector to connector

J12 on the SC-2040. The SC-2040 can be mounted in a rack-mount chassis using the mounting

holes (indicated with an arrow on the board) in the four corners of the SC-2040 board.

The SC-2040 is installed. You are now ready to install and configure your software.

If you are using NI-DAQ, refer to your NI-DAQ manual. The software installation and

configuration instructions are in Chapter 1, Introduction to NI-DAQ. Find the installation and

system configuration section for your operating system and follow the instructions given there.

If you are using LabVIEW, the software installation instructions are in your LabVIEW release

notes. After you have installed LabVIEW, refer to the Configuring LabVIEW section of

Chapter 1 of your LabVIEW user manual for software configuration instructions.

If you are using LabWindows, the software installation instructions are in Part 1, Introduction to

LabWindows, of the Getting Started with LabWindows manual. After you have installed

LabWindows, refer to Chapter 1, Configuring LabWindows, of the LabWindows User Manual

for software configuration instructions.

Power-on Sequence

If the SC-2040 is powered by an external power source, you must turn on power to the SC-2040

before turning on the computer. Similarly, you must turn off power to the SC-2040 after turning

off the computer. The red LED labeled DS1 indicates when power is applied to the board.

SC-2040 User Manual 2-8 © National Instruments Corporation

Page 23

Chapter 3 Signal Connections

This chapter describes the signal connections to the SC-2040 board, and cable wiring.

I/O Connector Pin Description

Warning: Connections that exceed any of the maximum ratings of input or output signals on

the MIO-16 can result in damage to the MIO-16 board and to the personal

computer. This includes connecting any power signals to ground and vice versa.

National Instruments is not liable for any damages resulting from any such signal

connections.

Corresponding signals on connectors J11 and J12 are connected together through the SC-2040.

Connector J12 carries the signals to and from the MIO-16E board. Use connector J11 to access

these signals. You can use this connector to monitor these signals, using a National Instruments

CB-50, for example, or you can use this connector to connect to other DAQ accessories.

Figure 3-1 shows these connectors.

© National Instruments Corporation 3-1 SC-2040 User Manual

Page 24

Signal Connections Chapter 3

2

11

13

15

17

19

21

23

25

27

29

31

33

35

37

39

41

43

45

47

49

1

4

3

6

5

8

7

10

9

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

50

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

A. Breakout Connector J11

B. I/O Connector J12

Figure 3-1. SC-2040 I/O Connectors J11 and J12

Table 3-1 lists the pin assignments for the breakout connector J11 and the I/O connector J12 on

the SC-2040 and the corresponding and MIO-16E Series signal names.

SC-2040 User Manual 3-2 © National Instruments Corporation

Page 25

Chapter 3 Signal Connections

Table 3-1. Pin Assignments for Connectors J11 and J12

Breakout Connector J11

Pin Numbers

1, 2 AIGND AIGND 24, 27, 29, 32, 56, 59, 64, 67

3 ACH0 ACH0 68

4 AIGND ACH8 34

5 ACH1 ACH1 33

6 AIGND ACH9 66

7 ACH2 ACH2 65

8 AIGND ACH10 31

9 ACH3 ACH3 30

10 AIGND ACH11 63

11 ACH4 ACH4 28

12 AIGND ACH12 61

13 ACH5 ACH5 60

14 AIGND ACH13 26

15 ACH6 ACH6 25

16 AIGND ACH14 58

17 ACH7 ACH7 57

18 AIGND ACH15 23

19 NC AISENSE 62

20 NC DAC0OUT 22

21 NC DAC1OUT 21

22 NC EXTREF 20

23 NC AOGND 54, 55

24, 33 DGND DGND 4, 7, 9, 12, 13, 15, 18, 35, 36, 39,

25 NC DIO0 52

26 NC DIO4 19

27 NC DIO1 17

28 NC DIO5 51

29 NC DIO2 49

30 NC DIO6 16

31 NC DIO3 47

32 NC DIO7 48

34, 35 +5V +5V 8, 14

36 NC SCANCLK 46

37 NC EXTSTROBE* 45

38 NC PFI0/TRIG1 11

39 NC PFI1/TRIG2 10

40 TRIG PFI2/CONVERT* 43

41 NC PFI3/GPCTR1_SOURCE 42

42 NC PFI4/GPCTR1_GATE 41

43 NC GPCTR1_OUT 40

44 NC PFI5/UPDATE* 6

45 NC PFI6/WFTRIG 5

46 TRACK*/HOLD PFI7/STARTSCAN 38

47 NC PFI8/GPCTR0_SOURCE 37

48 NC PFI9/GPCTR0_GATE 3

49 NC GPCTR0_OUT 2

50 NC FREQ_OUT 1

SC-2040

Signal Names

MIO-16E Series

1

Signal Names

I/O Connector J12

Pin Numbers

44, 50, 53

1

All signals labeled NC are unused by the SC-2040.

© National Instruments Corporation 3-3 SC-2040 User Manual

Page 26

Signal Connections Chapter 3

Signal Connection Description

Table 3-2. Input Connectors Signal Summary

Connector Signal Name Description

J5 AIGND Analog Input Ground—These inputs provide a bias current return point

for AC-coupled signals.

J1, J2, J3, J4,

J6, J7, J8, J9

J1, J2, J3, J4,

J6, J7, J8, J9

J10, J13 DGND Digital Ground—These inputs provide the reference for all digital signals

J10 TRIG Trigger—This input, which is connected directly to the PFI2 pin on

J13 +5 V +5 VDC Source—When external power is selected, this input provides

CH+<0..7> Positive Inputs—These inputs are the positive signal inputs for

channels 0 through 7.

CH-<0..7> Negative Inputs—These inputs are the negative signal inputs for

channels 0 through 7.

and the reference for the +5 V power source.

connectors J11 and J12, is a trigger input for the MIO-16E. A low-tohigh transition on TRIG alerts the MIO-16E to place the SC-2040 into

hold mode and start acquiring data.

DC power for the SC-2040 from an external +5 V. The SC-2040 fuses

the input to 1 A of the +5 V supply.

Table 3-3. Output Connectors (J11 and J12) Signal Summary

J11 Pin

(50-pin)

1, 2, 4, 6, 8,

10, 12, 14, 16,

18

3, 5, 7, 9, 11,

13, 15, 17

24, 33 4, 7, 9, 12, 13,

34, 35 8, 14 +5 V +5 VDC Source—When internal power is selected,

40 43 TRIG (PFI2) Trigger—This pin, which is connected directly to the

J12 Pin

(68-pin)

23, 24, 26, 27,

29, 31, 32, 34,

56, 58, 59, 61,

63, 64, 66, 67

68, 33, 65, 30,

28, 60, 25, 57

15, 18, 35, 36,

39, 44, 50, 53

Signal Name Description

AIGND Analog Input Ground—These pins establish the

reference point for the SC-2040 outputs (ACH<0..7>).

They are also connected directly to the AIGND input

connector J5 for use with AC-coupled signals.

ACH<0..7> Analog Channels 0 through 7—These pins carry the

outputs of the SC-2040 eight channels to the DAQ

board. They are referenced to AIGND.

DGND Digital Ground—These pins are the reference for the

+5 V power source and for the digital signals used by

the SC-2040: TRIG (PFI2) and TRACK*/HOLD

(PFI7/STARTSCAN).

these pins provide DC power for the SC-2040 from

the MIO-16E board. The MIO-16E pins are fused to

1 A of +5 V supply.

TRIG input on screw terminal connector J10, is a

trigger input to the MIO-16E PFI2 line. A low-tohigh transition on PFI2 alerts the MIO-16E to place

the SC-2040 into hold mode and start acquiring data.

(continues)

SC-2040 User Manual 3-4 © National Instruments Corporation

Page 27

Chapter 3 Signal Connections

Table 3-3. Output Connectors (J11 and J12) Signal Summary (Continued)

J11 Pin

(50-pin)

46 38 TRACK*/HOLD

others others compatibility The remaining pins provide 50 pin compatibility with

J12 Pin

(68-pin)

Signal Name Description

Track-or-hold—This pin, used as an output from the

(PFI7/STARTSCAN)

MIO-16E, controls whether the SC-2040 is in hold

mode or track mode. A high level output from the

DAQ board places the SC-2040 into hold mode, while

a low level returns the SC-2040 into track mode. With

an MIO-16E attached, pin 46 on J11 should be used

for monitoring purposes only.

the 68 pin MIO-16E. They can be monitored from

connector J11. Refer to Figure 3-1 for pin locations

and to Chapter 3, Signal Connections, in your MIO16E manual for pin descriptions.

The signals from the SC-2040 screw terminal connectors are connected to the MIO-16E via J12

as shown in Figure 3-2. Observe that the PFI7/STARTSCAN signal returns from the MIO-16E

as a level-sensitive track-and-hold signal to the SC-2040. Notice also that AISENSE is

disconnected.

© National Instruments Corporation 3-5 SC-2040 User Manual

Page 28

Signal Connections Chapter 3

J5

J1

J2

J9

SC-2040

Input Signals

AIGND

CH0+

CH0-

CH1+

CH1-

.

.

.

.

.

.

CH7

CH7

T/H

T/H

T/H

Signals Sent

to MIO-16

AIGND

AISENSE

ACH0

ACH1

.

.

.

.

.

.

.

.

ACH7

J10

TRIG

DGND

SC-2040

Screw Terminals

Track*/Hold

Figure 3-2. SC-2040 Signal Routing

PFI2/

STARTSCAN

PFI7

DGND

J11 and J12

Connectors on SC-2040

SC-2040 User Manual 3-6 © National Instruments Corporation

Page 29

Chapter 3 Signal Connections

Analog Signal Inputs

Connect the differential signals to be measured to the screw terminal connectors J1 through J4

and J5 through J9.

DC-Coupled Inputs

Note: If all your inputs are DC-coupled, leave connector J5 disconnected.

All eight channels have fully differential inputs, so the signals you are measuring should be

ground referenced. If they are not, set jumpers W2 through W9 of the nonreferenced channels to

position B-C to create a DC path for the input bias currents. If you do not do this, the bias

currents of the instrumentation amplifiers of the nonreferenced channels produce stray

capacitances, resulting in uncontrollable drift and possible saturation.

Figure 3-3 illustrates how to connect a ground-referenced signal.

CH+

IN+

Vin

CH-

A B C

100 kΩ

A

IN-

SC-2040

Figure 3-3. Ground-Referenced Signal Connection

© National Instruments Corporation 3-7 SC-2040 User Manual

Page 30

Signal Connections Chapter 3

Figure 3-4 illustrates how to connect a floating signal.

CH+

IN+

Vin

CH-

A B C

100 kΩ

A

IN-

SC-2040

Figure 3-4. Floating Signal Connection

AC-Coupled Signals

Note: For AC-coupled signals, you must reference the analog ground of your

instrumentation to the DAQ board. The SC-2040 connector J5 provides the analog

reference, connecting directly to the MIO-16E board as shown in Figure 3-2.

For AC-coupled signals, set jumpers W2 through W9 to position B-C with an external resistor

from the positive input channel connected to its negative ground. Doing this creates the DC path

for the positive input bias current. Typical resistor values range from 100 kΩ to 10 MΩ. This

solution, although necessary in this case, lowers the input impedance of the channel and

introduces an additional offset voltage proportional to the product of the input bias current and

the resistor value used. The inputs of the SC-2040 have a typical bias current of about ±100 pA.

When you use a 1 MΩ resistor, the result is ±100 µV of offset, which is insignificant in most

applications. However, if you use larger valued bias resistors, significant input offset may result.

Lower valued bias resistors will increase loading of the source, possibly resulting in gain error.

SC-2040 User Manual 3-8 © National Instruments Corporation

Page 31

Chapter 3 Signal Connections

Figures 3-5 through 3-7 illustrate how to connect AC-coupled signals.

CH+

IN+

Vin

CH-

A B C

100 kΩ

A

IN-

SC-2040

Figure 3-5. Ground-Referenced AC-Coupled Signal Connection

CH+

IN+

Vin

CH-

A B C

IN-

Analog

GND

100 kΩ

A

SC-2040

A

Figure 3-6. Ground-Offset AC-Coupled Signal Connection

© National Instruments Corporation 3-9 SC-2040 User Manual

Page 32

Signal Connections Chapter 3

CH+

IN+

Vin

CH-

A B C

100 kΩ

IN-

SC-2040

A

Figure 3-7. Floating AC-Coupled Signal Connection

Analog Input Ranges

Warning: Exceeding the differential and common-mode input ranges results in distorted

input signals. Exceeding the maximum input voltage rating can result in damage

to the SC-2040 board, and the DAQ board. National Instruments is

NOT liable for

any damages resulting from such signal connections.

The SC-2040 instrumentation amplifiers can reject any voltage within their common-mode input

range caused by ground-potential differences between the signal source and the board. In

addition, the amplifiers can reject common-mode noise pickup in the leads connecting the signal

sources to the SC-2040 board. However, you should be careful to minimize noise pickup. The

common-mode rejection of the instrumentation amplifiers decreases significantly at high

frequencies. The amplifiers do not reject normal-mode noise.

The common-mode input range of the SC-2040 instrumentation amplifiers is defined as the

magnitude of the greatest common-mode signal that can be rejected. Thus the common-mode

input range for the SC-2040 depends on the gain and size of the differential input signal:

(V

diff

= V

+

in

- V

-

).

in

The exact formula for the permissible common-mode input range is as follows:

diff

V

cm-allowed

= ± (12 V -

Thus, with a differential voltage of 10 V and a gain of G

G V

).

2

= 1, the maximum possible common-

mode voltage would be ±7 V. The same range would apply for a differential input of 100 mV

and a gain of 100. The range increases to ±12 V for zero differential input voltage. The actual

common-mode voltage available at the input is measured with respect to the SC-2040 ground,

and can be calculated by the following formula:

+

V

V

cm-actual

SC-2040 User Manual 3-10 © National Instruments Corporation

()

=

−

in

−V

in

2

.

Page 33

Chapter 3 Signal Connections

where V

+

is the signal at the positive input (IN0+ through IN7+), and V

n

i

corresponding negative input (IN0- through IN7-). Both V

+

i

and V

n

-

is the signal at the

n

i

-

are measured with respect

n

i

to the SC-2040 chassis ground.

Digital Signal Inputs

If you are using an external trigger, connect the trigger source and the digital reference to screw

connector J9. This signal should be in the range 0 to +5 V, with switching occurring around

1.5 V.

Note: All digital signals on the SC-2040 are referenced to the +5 V power supply. If the

MIO-16E supplies power, it provides this reference. If an external supply provides

power, it provides this reference through connector J13.

A rising edge on the trigger will place the SC-2040 into hold mode, and the SC-2040 will return

to track mode when the MIO-16E indicates that the data acquisition is complete.

Although the TRIG signal is a digital signal, it is still susceptible to noise, particularly at its

transitions. This noise can cause the SC-2040 to enter hold mode on the wrong edge. Two

possible sources of noise are interference and reflection. The best way to reduce noise

corruption is to minimize the distance that the signal must travel. Furthermore, you can

minimize interference by properly shielding the incoming trigger signal. You can minimize

reflection by ensuring that the impedance of the source of the trigger signal matches the

impedance of the cable used to transmit the signal; inserting a small resistor (about 50 Ω) in

series with the signal source will minimize reflection.

Monitoring Signal Outputs

You can use connector J11 to monitor the signals being sent to and from the MIO-16E board.

Figure 4-3 shows a sampled analog signal as the SC-2040 channel output.

You can also monitor the state of the SC-2040 through line PFI7/STARTSCAN. A high level on

PFI7/STARTSCAN indicates the SC-2040 is in hold mode, while a low level indicates that the

SC-2040 is in track mode.

Other Connection Considerations

Refer to the sections titled Analog Input Signal Connections and Cabling and Field Wiring in

Chapter 3 of your MIO-16E board user manual for additional signal connection information.

© National Instruments Corporation 3-11 SC-2040 User Manual

Page 34

Chapter 4 Theory of Operation

This chapter contains a functional overview of the SC-2040 board and explains the operation of

each functional unit making up the SC-2040.

Functional Overview

The SC-2040 consists of eight channels, each one comprising an instrumentation amplifier with

DIP switch-programmable gains of 1, 10, 100, 200, 300, 500, 600, 700, or 800, and a track-andhold amplifier. The analog inputs are overvoltage protected. The DAQ board or a user-supplied

external trigger switches the SC-2040 between hold mode and track mode as desired. All eight

channels are simultaneously placed in hold mode.

The block diagram in Figure 4-1 illustrates the key functional components of the SC-2040.

© National Instruments Corporation 4-1 SC-2040 User Manual

Page 35

Theory of Operation Chapter 4

68-Pin I/O Connector

50-Pin Breakout Connector

PFI7

ACH0

ACH7

PFI2

(Track/Hold Signal)

+5 V

Power-On

LED

External

+5 V

T/H

Inst.

Amp

+

Input

Protection

CH0+

• • • • •

• • •

Gains

-

• • •

A

• • •

CH0-

T/H

Inst.

Amp

+

Input

Protection

CH7+

-

CH7-

Gains

Power

Converter

+15 V

-15 V

(External Trigger)

A

External

Track/Hold

Trigger

Figure 4-1. SC-2040 Block Diagram

SC-2040 User Manual 4-2 © National Instruments Corporation

Page 36

Chapter 4 Theory of Operation

Analog Circuitry

The analog input circuitry consists of eight channels with DIP-switch-programmable

instrumentation amplifiers followed by buffered track-and-hold amplifiers. In addition, you can

include the voltage-regulation circuitry and input protection in the analog section. Each block is

described in the following paragraphs.

Input Protection

The first block an incoming analog signal encounters is the input protection. Each input terminal

is protected against input voltages up to ±15 V powered off and ±30 V powered on. The input

protection consists of a 1 kΩ resistor in series with each input line followed by low-leakage

diodes to the supply rails (±15 V).

Amplification

Next in the signal path are the instrumentation amplifiers, which fulfill two purposes on the

SC-2040 board. First, the instrumentation amplifiers convert differential input signals into

single-ended signals referred to the SC-2040 analog ground for input common-mode signal

rejection. With this conversion, the SC-2040 can extract the analog input signals from commonmode noise voltages before the DAQ board samples and converts the signals. Second, the

instrumentation amplifiers amplify input signals, resulting in an increase in measurement

resolution and accuracy. Furthermore, the amplifiers exhibit low bias currents and good

bandwidth, even at high gains.

You can select gains for each channel independently with separate DIP switches. Gains are 1,

10, 100, 200, and 500, although gains of 300, 600, 700, and 800 are available with reduced

accuracy. See Appendix A, Specifications, for details on the performance of the instrumentation

amplifiers.

Track-and-Hold (T/H) Circuitry

The track-and-hold amplifiers operate as simple buffers when in track mode, but freeze their

outputs when placed into hold mode. Because all of the track-and-hold amplifiers in each

SC-2040 board enter hold mode at the same time, they implement simultaneous sampling of all

channels. Simultaneous sampling is useful for preserving phase relationships between channels.

The track-and-hold amplifiers are subject to various imperfections, which are listed in

Appendix A, Specifications. The most relevant of these performance specifications are the trackmode acquisition time and the hold-mode settling time, as these parameters affect how the DAQ

board acquires the data, most noticeably through the sampling rate.

The hold-mode settling time refers to how long it takes the T/H amplifiers to settle a stable value.

Thus, the hold-mode settling time affects how long the DAQ board must wait before attempting

to acquire data. The track-mode acquisition time refers to how long it takes the T/H amplifiers to

© National Instruments Corporation 4-3 SC-2040 User Manual

Page 37

Theory of Operation Chapter 4

find the inputs again after having been in hold mode. Therefore, this delay indicates how long

the SC-2040 must remain in track mode before it is ready to re-enter hold mode. Returning the

SC-2040 to hold mode before the track-mode acquisition delay has elapsed will cause the

SC-2040 to "hold" erroneously. Figure 4-2 illustrates these timing concerns. Typical hold mode

settling times and track acquisition times for 12-bit and 16-bit accuracies are given in

Appendix A, Specifications.

differential channel

input

T/H output

hold setting time

hold

track*/hold signal

(PF17)

track

hold setting

time

hold

track acquisition

time

track

Figure 4-2. T/H Amplifier Hold Settling Time and Track Acquisition Time

Triggering from the DAQ Board

This section applies to you only if you are triggering the SC-2040 from the MIO-16E board.

Note: No signal should be connected to connector J10 for MIO-16E triggering.

You can place the SC-2040 into hold mode on command using the MIO-16E DAQ board. You

must either program the MIO-16E board for this purpose or use the NI-DAQ software included

with your MIO board. After placing the SC-2040 into hold mode, the MIO-16E board performs

data acquisition and conversion. Once this process is complete, the MIO-16E board releases the

SC-2040 into track mode.

The MIO-16E board uses line PFI7/STARTSCAN to indicate to the SC-2040 whether it should

track the input signals or hold them at a constant level. A logic zero (low level) on

PFI7/STARTSCAN indicates track mode, while a logic one (high level) indicates hold mode, as

indicated in Figure 4-3.

SC-2040 User Manual 4-4 © National Instruments Corporation

Page 38

Chapter 4 Theory of Operation

Differential Channel Input

. . . . . . . . .

PFI7 (track*/hold)

. . . . . .

SC-2040 Channel Output

. . . . . .

hold hold track

. . . . . .

. . . . . .

. . . . . . . .

. . . . . .

. . . . . . . . . . .

t

DAQ Conversion

(DAQ board is scanning)

t

DAQ Conversion

Figure 4-3. MIO-16E Controlled Triggering

External Triggering

This section applies to you only if you are triggering the board from an external signal

connected to J10.

You can connect an external trigger to place the SC-2040 into hold mode on command. A rising

edge on the external trigger signal places the SC-2040 into hold mode and alerts the MIO-16E

board to start scanning the SC-2040 outputs. After the MIO-16E board has acquired data from

all of the channels, it returns the SC-2040 to track mode. The external trigger signal is a digital

input and must conform to digital logic levels.

Because the SC-2040 track-and-hold circuitry must re-acquire the input signals at the conclusion

of each hold mode operation, the external trigger source should not return the SC-2040 to hold

mode until after the SC-2040 has had time to re-acquire the signals. The acquisition times for

the SC-2040 at various accuracies are given in Appendix A, Specifications.

The external trigger is connected directly to signal PFI2 on the DAQ board. A rising edge alerts

the DAQ board to place the SC-2040 into hold mode. The DAQ board then begins scanning the

channels. After the scanning process is complete, the board returns the SC-2040 to track mode

using PFI7/STARTSCAN. Notice that additional rising edges from the external trigger are

ignored while the MIO-16E is scanning. Figure 4-4 illustrates the external triggering process.

© National Instruments Corporation 4-5 SC-2040 User Manual

Page 39

Theory of Operation Chapter 4

Differential Channel Input

. . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

PFI2 (external trigger)

. . . . .

. . . . . . . . . . . .

. . . .

PFI7 (track*/hold)

SC-2040 Channel Output

hold hold

track

. . . . . .

track

. . . . .

. . . . . . . .

t

DAQ Conversion

(DAQ board is scanning)

t

DAQ Conversion

Figure 4-4. External Triggering

Output Connection

The output of every channel is connected to the 68-pin rear signal connector and the 50-pin

supplemental I/O connector. The 68-pin connector carries signals to and from the DAQ board,

and also provides +5 V power if selected by the power switch. The corresponding pins of the

50-pin connector are tied to those of the 68-pin connector so that you can monitor these signals

on the 50-pin connector. The pin connections of these connectors are given in Chapter 3, Signal

Connections.

Power Supply

The SC-2040 contains an onboard power switch to either power the SC-2040 from the MIO-16E

board or to draw power from an external +5 V supply. From the +5 V power, an onboard

DC-to-DC converter generates a ±15 V source, which is used to power the analog circuitry. A

red LED indicates that the board is receiving power.

SC-2040 User Manual 4-6 © National Instruments Corporation

Page 40

Chapter 5 Calibration Procedures

This chapter discusses the calibration procedures for the SC-2040 board.

Note: In many applications, the SC-2040 factory-hardware calibration is sufficient to meet

accuracy requirements, and no further calibration, either hardware or software, is

needed.

Although hardware calibration is discussed in greater detail than software calibration, software

calibration is the preferred choice for the following reasons:

• The calibration adjustments on the SC-2040 are inaccessible under most normal operating

circumstances.

• With software calibration, the board is calibrated in the exact environment in which it will be

operating. Software calibration compensates for system-introduced, in addition to boardintroduced, errors. You can perform software calibration fairly frequently, which helps

reduce drift effects.

Because board-introduced errors are minimal with the SC-2040, the use of software rather than

hardware calibration does not significantly reduce dynamic range. The main drawback of

software calibration is reduced throughput due to the increased processing time.

Software Calibration

Software calibration is very simple. Depending on your accuracy requirements, you may want to

perform only offset adjustment; offset and gain adjustments; or offset, gain, and linearity

adjustments.

Offset Adjustment

Offset adjustment requires you to apply an input signal of zero to the channel to be calibrated.

Zero input can mean shorting the board inputs to zero, or it can mean applying zero excitation to

the transducer being used. In the former case, you can remove only board and DAQ board

offset; in the latter case, transducer offset is removed as well. In either case, measurements are

taken with the zero input signal. Average these measurements to reduce uncertainty. This

average represents the offset. Next, subtract the offset from all subsequent measurements.

Notice that offset changes with gain; thus, during calibration, set the channel to the gain at which

the subsequent measurements will be taken.

© National Instruments Corporation 5-1 SC-2040 User Manual

Page 41

Calibration Procedures Chapter 5

Gain Adjustment

Gain adjustment requires you to apply two different input signals. One of the two points is

typically zero, because zero is easy to generate with a high degree of accuracy. The other should

be near full scale, either a DC-voltage from a precision calibrator or a voltage generated by

applying a known excitation to the transducer being used. Of course, you should generate both

signals—zero and full scale—from the same source.

Take measurements on both signals and compute separate averages. Then combine the averages

with the known input signals to generate linear correction factors for all subsequent

measurements. Specifically, if the input X yields measurement x, and the input Y yields

measurement y, then you should process measurement z as shown in the following equation to

yield the corrected measurement Z:

Z = X +

(Y − X)(z− x)

(y − x)

.

Linearity Adjustment

The SC-2040 seldom needs linearity adjustment because its linearity is quite good, especially at

low gains. Linearity error is often caused by the nonlinearity of the DAQ board you use. If

necessary, the method described previously for correcting gain and offset error may be extended

to include linearity by taking more points along the transfer function and processing the

subsequently acquired data according to a polynomial fit of the calibration points.

Alternatively, and preferably for DAQ boards with no more than 12 bits of resolution, you can

determine the nonlinearity of the system on a code-by-code basis, and you can subtract the error

of each code from any measurement that returns that value. This method has the advantage of

correcting differential as well as integral linearity errors. However, this method may be timeconsuming. If time permits, you may determine the nonlinearity of your system on a code-bycode basis with even higher resolution DAQ boards. Describing methods of measuring system

nonlinearity is beyond the scope of this manual. If linearity correction becomes necessary, refer

to your DAQ board user manual.

Hardware Calibration

There are two potentiometers (pots) to adjust for each channel. These are set at the factory and

should not need to be readjusted for most applications. The pots adjust input offset voltage and

output offset voltage for each of the eight channels. Gain error and linearity are not adjustable.

For detailed specifications of offset, gain, and linearity error, see Appendix A, Specifications.

Input offset is any error voltage that appears to be added to the input signal; that is, its effect is

multiplied by the gain of the instrumentation amplifier. Output offset is any error voltage that

appears to be added to the output signal; that is, its effect is independent of the gain of the

instrumentation amplifier. At a fixed gain, these errors are indistinguishable; thus, it is necessary

to switch between gains to properly calibrate the SC-2040.

SC-2040 User Manual 5-2 © National Instruments Corporation

Page 42

Chapter 5 Calibration Procedures

Your accuracy needs determine how carefully the offsets need to be calibrated. A typical

requirement might be for total offset referred to output to be less than half of an LSB of the DAQ

board being used. For example, a 12-bit, 20 V system has a resolution of 20 V/212 = 4.88 mV.

Calibration to under 2 mV would thus be sufficient for most applications. The SC-2040 is

factory calibrated to have total offset referred to output of less than 2 mV at low gains.

Table 5-1 shows which pots to adjust for each type of offset for each channel and which DIP

switch selects the gain for each channel. Refer to the parts locator diagram in Chapter 2,

Configuration and Installation, to determine the location of each component.

Table 5-1. Calibration Component Identification

Channel Output Offset Adjust Input Offset Adjust Gain DIP Switch

0R1 R4 U2

1 R7 R11 U6

2 R13 R16 U9

3 R18 R22 U14

4 R25 R29 U17

5 R32 R35 U21

6 R37 R41 U24

7 R45 R48 U28

A complicating factor in the calibration of the board is that the output offset is not the same in

track mode as in hold mode. This difference is because of a phenomenon known as hold step, in

which a small amount of charge is transferred to the track-and-hold amplifier hold capacitor

during the transition from track mode to hold mode. This charge transfer slightly changes the

voltage at the output of the track-and-hold amplifier.

The magnitude of the hold step on the SC-2040 is approximately 5 mV, enough to make it

necessary to calibrate output offset in hold mode rather than track mode. You may calibrate

input offset without switching the board to hold mode.

To calibrate the SC-2040 board, the following steps are required:

1. If you are using a rack-mount kit, remove the cover to expose the DIO switches and jumpers.

Connect the board so that the pots and DIP switches are readily accessible.

2. Short each input of the board to ground.

At low gains, more alternatives exist to serve as a short circuit, but at a gain of 500, 1 mV

referred to the output is only 2 µV referred to the input. Thermoelectric effects make it

difficult to keep a short circuit from generating such voltages. The best solution is to use

short lengths of heavy copper wire, and to keep the short away from heat sources.

3. Program the DAQ board to take data in the differential input mode.

The SC-2040 should switch between track mode and hold mode, with the DAQ board

sampling occurring while the board is in hold mode.

© National Instruments Corporation 5-3 SC-2040 User Manual

Page 43

Calibration Procedures Chapter 5

4. Set the DAQ board to a high gain and measure its offset by shorting its input.

You must subtract this measured offset from all subsequent board measurements to ensure

accuracy.

For the offset of the DAQ board not to affect the calibration, you must subtract the offset

from all board offset measurements. Thus, you must first measure the offset to an accuracy

better than that to which the board is to be calibrated. Furthermore, setting the DAQ board to

a high gain (100, for example) makes it possible to resolve offset changes that would be

indiscernible at lower gains. Because the DAQ board offset will not be independent of gain,

you should set the gain first, and then measure the offset. To measure the offset, disconnect

the board from the DAQ board, short circuit the board inputs to ground, and take some data.

The measured value is the offset. For a reliable value, use software to average a few hundred

readings. After you have measured and recorded the offset, remove the short circuits and

reconnect the board.

5. Measure the output of the first channel with its gain set to one and adjust its output offset pot

until the output is close to zero.

At this gain, most of the board offset is due to output offset. The input offset adjustment has

minimal effect. Set the DAQ board to read the channel. Acquire the data, averaging as in

step 4. Adjust the output offset pot until the difference between the measured offset and the

DAQ board offset is close to zero. There is no need to adjust it perfectly because the input

offset adjustment in the next step might make a slight change in the measured gain-of-one

offset.

6. Measure the output of the same channel with its gain set to 500 and adjust its input offset pot

until the output is close to zero.

At this gain, the input offset adjustment has the dominant effect. Acquire the data and

average as before. Adjust the input offset pot until the difference between the measured

offset and the DAQ board offset is close to zero. Again, it is not necessary to adjust the input

offset perfectly because there will be a slight interdependence between the two offsets.

7. Repeat step 5, adjusting the offset as carefully as desired. Then repeat step 6, adjusting the

offset as carefully as desired. Switch back to a gain of one to ensure that the low-gain offset

is still calibrated. If necessary, repeat steps 5 and 6 until the offset is calibrated at both gains.

8. Repeat steps 5 through 7 for the additional channels you want to calibrate. There is no

calibration interdependence among the channels.

9. Replace the rack-mount chassis cover, if used.

SC-2040 User Manual 5-4 © National Instruments Corporation

Page 44

Appendix A Specifications

This appendix lists the specifications for the SC-2040. These are typical at 25° C unless otherwise stated. The

operating temperature range is 0° to 50° C.

Analog Input

Input Characteristics

Number of channels 8 differential

Input signal ranges Board Gain

(Hardware

Selectable)

1 ±10 V

10 ±1 V

100 ±100 mV

200 ±50 mV

300 ±33.3 mV

500 ±20 mV

600 ±16.67 mV

700 ±14.29 mV

800 ±12.5 mV

Input coupling DC

Max working voltage

(signal + common mode) Average of 2 inputs should remain within ±7 V of ground

Overvoltage protection ±30 V powered on, ±15 V powered off

Inputs protected ACH<0..7>

Board Range

Max Output Range ±10 V

Transfer Characteristics

Offset error

Pregain error after calibration ±100 µV max

Postgain error after calibration ±2 mV max

Gain error and nonlinearity Gain

(DIP-switch-

selectable)

1 ±0.05% ±25 ppm/°C ±0.01%

10 ±0.1% ±25 ppm/°C ±0.01%

100 ±0.2% ±45 ppm/°C ±0.02%

200 ±0.4% ±60 ppm/°C ±0.02%

300 -0.3%, ±0.6% ±80 ppm/°C ±0.03%

500 ±1.0% ±100 ppm/°C ±0.04%

600 -0.2%, ±1.5% ±120 ppm/°C ±0.05%

700 -0.1%, ±2.0% ±150 ppm/°C ±0.06%

800 -0.3%, ±3.0% ±200 ppm/°C ±0.07%

Max

Gain Error

Max

Gain Tempco

Max

Nonlinearity

© National Instruments Corporation A-1 SC-2040 User Manual

Page 45

Specifications Appendix A

Amplifier Characteristics

Input impedance

Normal powered on 100 GΩ in parallel with 20 pF

Input bias current ±100 pA, ±10 mA max

Input offset current ±10 pA

CMRR Gain dB (min and typ)

Gain = 1 70 dB min, 90 dB typ

Gain = 10 87 dB min, 104 dB typ

Gain ≥ 100 100 dB min, 110 dB typ

Output range ±10 V

Dynamic Characteristics

Bandwidth Gain -3 dB

Bandwidth

1

10 800 kHz

100 500 kHz

200 300 kHz

300 180 kHz

500 120 kHz

600 100 kHz

700 80 kHz

800 70 kHz

2 MHz

System noise Gain Filter

1 175 µVrms

10 50 µVrms

100 45 µVrms

200 40 µVrms

300 35 µVrms

500 33 µVrms

600 30 µVrms

700 29 µVrms

800 27 µVrms

Noise spectral density