Page 1

USER MANUAL

sbRIO-9687

General Purpose Inverter Controller Universal Interface Board

This document describes the features of the sbRIO-9687 and contains information about

connecting, configuring, and operating the device.

Contents

Overview...................................................................................................................................2

Features..................................................................................................................................... 3

Connectors................................................................................................................................ 4

Switch and Resistor Configuration........................................................................................... 5

Power Considerations............................................................................................................... 6

System Power and Grounding Recommendations............................................................7

Power Input............................................................................................................................... 8

GPIC Signals.............................................................................................................................8

Inverter Signals......................................................................................................................... 9

Inverter CAN Bus Configuration....................................................................................12

Inverter Analog Output Configuration............................................................................13

Inverter Driving Signals..................................................................................................14

Analog Input........................................................................................................................... 14

Simultaneous Sampled Analog Input..............................................................................15

Scanned Analog Input.....................................................................................................24

Analog Output.........................................................................................................................27

Analog Output Configuration......................................................................................... 27

Over-Range Comparators........................................................................................................28

Over-Range Comparator Input Configuration................................................................ 28

Setting the Over-Range Threshold..................................................................................29

Sourcing Digital Input.............................................................................................................30

Sourcing Digital Input Connector................................................................................... 31

Sourcing Digital Input Configuration............................................................................. 32

Sinking Digital Output............................................................................................................ 33

Sinking DO Connector....................................................................................................34

Sinking Digital Output Configuration.............................................................................34

Inverter Digital Signals........................................................................................................... 35

Halt Signals..................................................................................................................... 36

GPIO Signals...................................................................................................................37

LVTTL Lines...........................................................................................................................38

Page 2

Expansion Board..................................................................................................................... 40

Expansion Board Connectors..........................................................................................40

Expansion Board Power..................................................................................................42

Expansion Board Dimensions.........................................................................................42

Feedback Input........................................................................................................................42

Feedback Connectors...................................................................................................... 42

RS485 Input Signals........................................................................................................44

Hall Sensor Input Signals................................................................................................44

+5 V Output.................................................................................................................... 44

Debug LEDs............................................................................................................................44

Thermistor...............................................................................................................................45

Thermistor Connector..................................................................................................... 45

Thermistor Reading.........................................................................................................46

Relative Humidity Sensor....................................................................................................... 46

Relay Connector......................................................................................................................47

Display Connector...................................................................................................................48

Inverter Connectors.................................................................................................................48

Worldwide Support and Services............................................................................................ 54

Overview

Overview of the sbRIO-9687 interface board.

The sbRIO-9687 interface board is an addition to the sbRIO-9683 or sbRIO-9684 General

Purpose Inverter Controller stacked with the sbRIO-9607 CompactRIO Single-Board

Controller. The sbRIO-9687 implements functionality required to control a variety of power

conversion cabinets based on Semikron insulated-gate bipolar transistor (IGBT) modules.

The interface board supports signal inputs from inverter connectors and external connectors,

and it can accommodate many configuration options for a wide spectrum of applications.

Aside from handling all inverter signals, the sbRIO-9687 interface board provides additional

functionality required for more complex systems implementation.

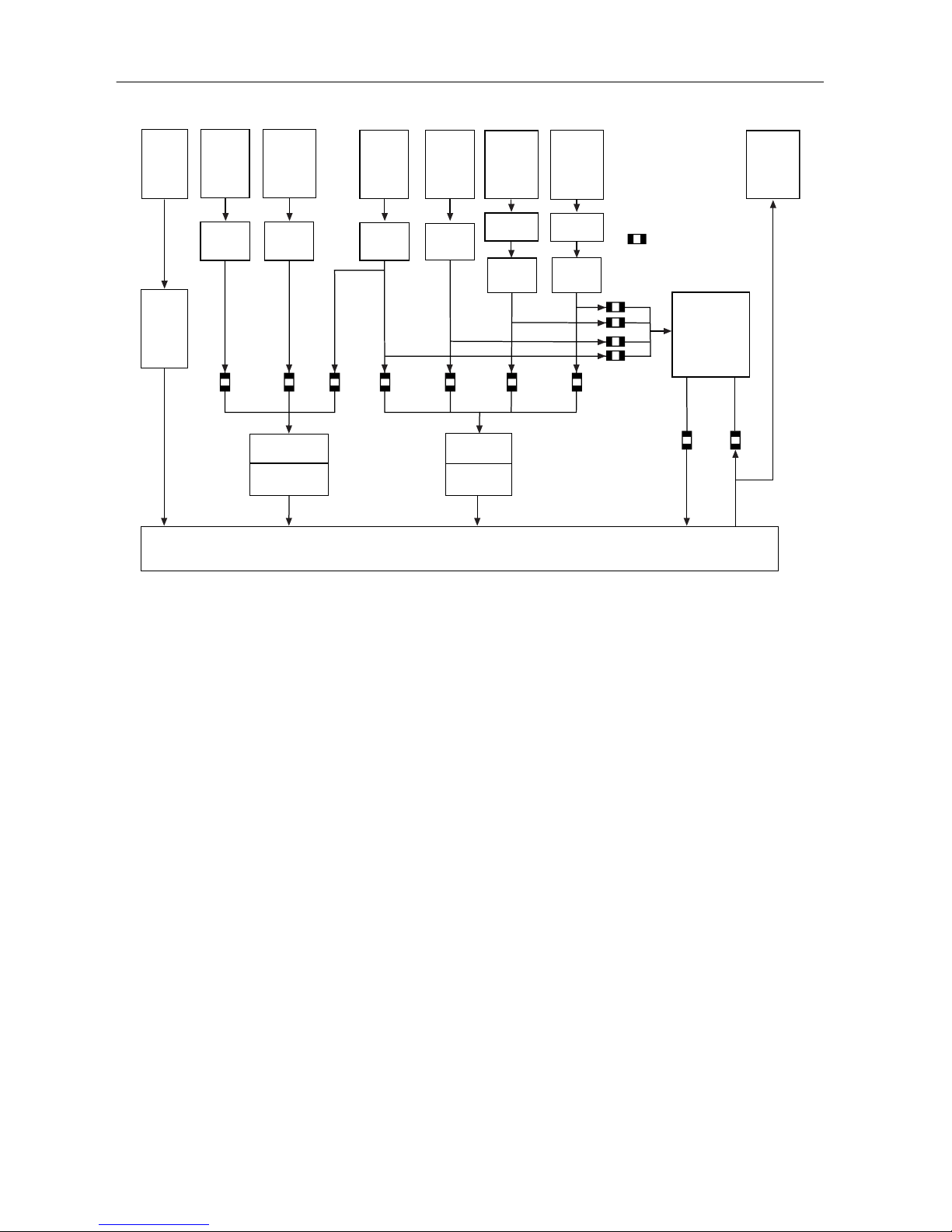

The following figure is a simplified block diagram of the sbRIO-9687 interface board.

Figure 1. sbRIO-9687 Block Diagram

Breakout Connectors

• Analog Input

• Feedback Input

• Analog Output

• Sinking DO

• Half Bridge DO

Power

Relay

Connectors

Inverter Connectors

• SKiiP 4 GB

• SKiiP 3 GB

• Semikube GB

• Semikube GD

• SKiiP 3 GD

Signal Conditioning

• Signal Routing

• Low Pass Filters

• Gain stages

• Over-Range Detection

GPIC

Connectors

Display

Connectors

Extension

Connectors

Sensors

• Temp

• RH

2 | ni.com | sbRIO-9687 User Manual

Page 3

Features

The sbRIO-9687 interface board provides a wide variety of input/output connectors, breakout

connectors for onboard signals, expansion connectors for add-in boards, debugging LEDs, and

options for configuration.

Inverter connectors

• 7 Semikron SKiiP 4 connectors

• 7 Semikron SKiiP 3 connectors

• 6 Semikron Semikube connectors

• 2 Semikron SKiiP 3 GD connectors

• 2 Semikron Semikube GD connectors

Analog inputs and outputs

• 16 simultaneous analog inputs

1

• 8 over-range detection circuits for simultaneous analog inputs or inverter inputs

• 7 scanned analog inputs

2

• 8 analog outputs

Thermal control inputs and outputs

• Onboard RH and temperature sensor

• 2 thermistor inputs

• 4 relay control switches

Serial connector

• RS232 connector

• +5 V connector for remote device

Breakout connectors for onboard signals

• 28 lines of high voltage digital inputs (DI)

• 24 lines of high voltage digital outputs (DO)

• 14 digital lines for inverter control (HB)

Expansion connectors for add-in boards

• 32 low voltage TTL lines (LVTTL)

• +3.3 V rail

• +5 V rail

1

Current-sensing resistors, low pass filters, and gain stage for each simultaneous analog input.

2

Bipolar/unipolar selection for each scanned analog input.

sbRIO-9687 User Manual | © National Instruments | 3

Page 4

Debugging LEDs

• 3 debugging LEDs

• 1 power LED

Configuration options

• Onboard DIP switches for configuration

• 0 Ω resistors for configuration

• Pads for current-sensing resistors on analog inputs

• Easy access for changing low pass filter components

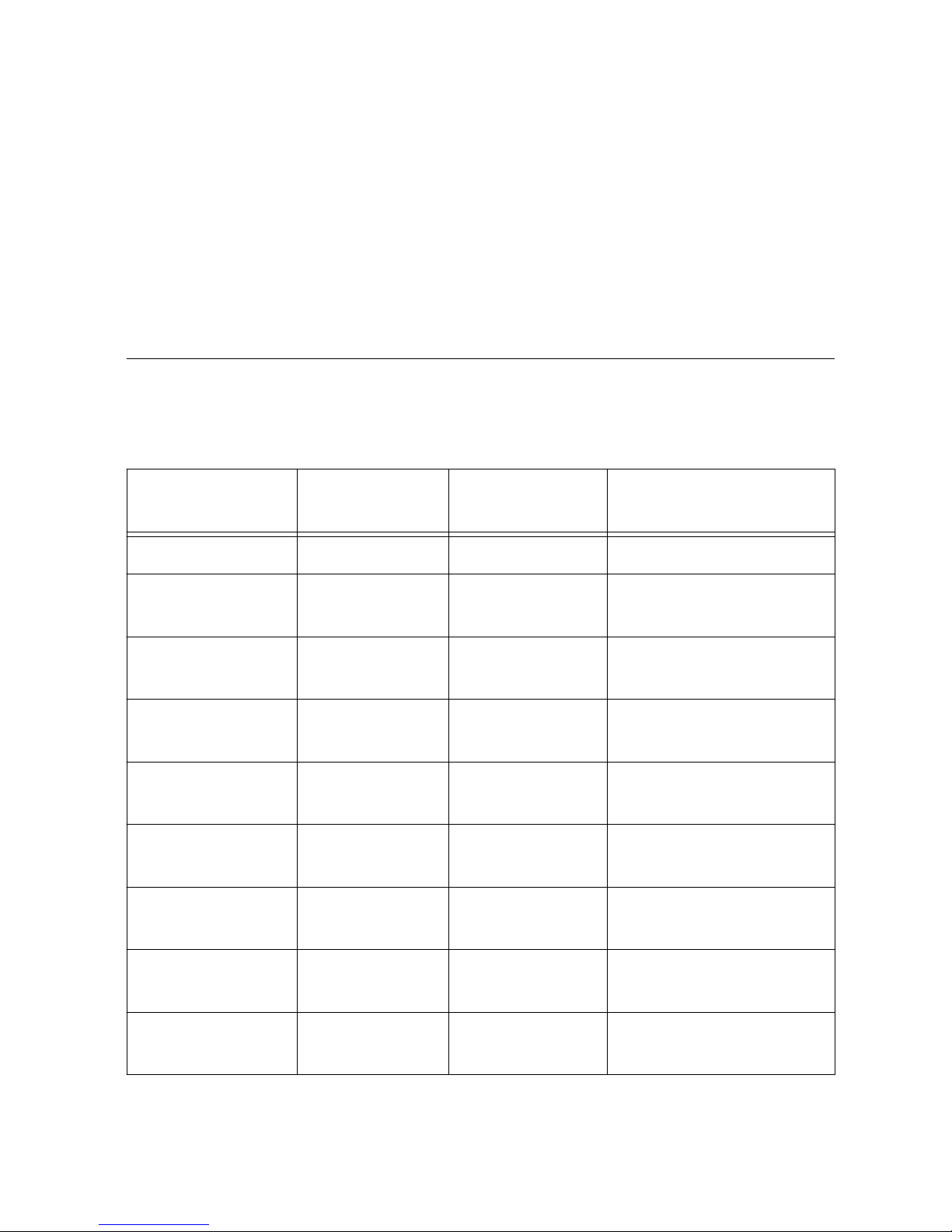

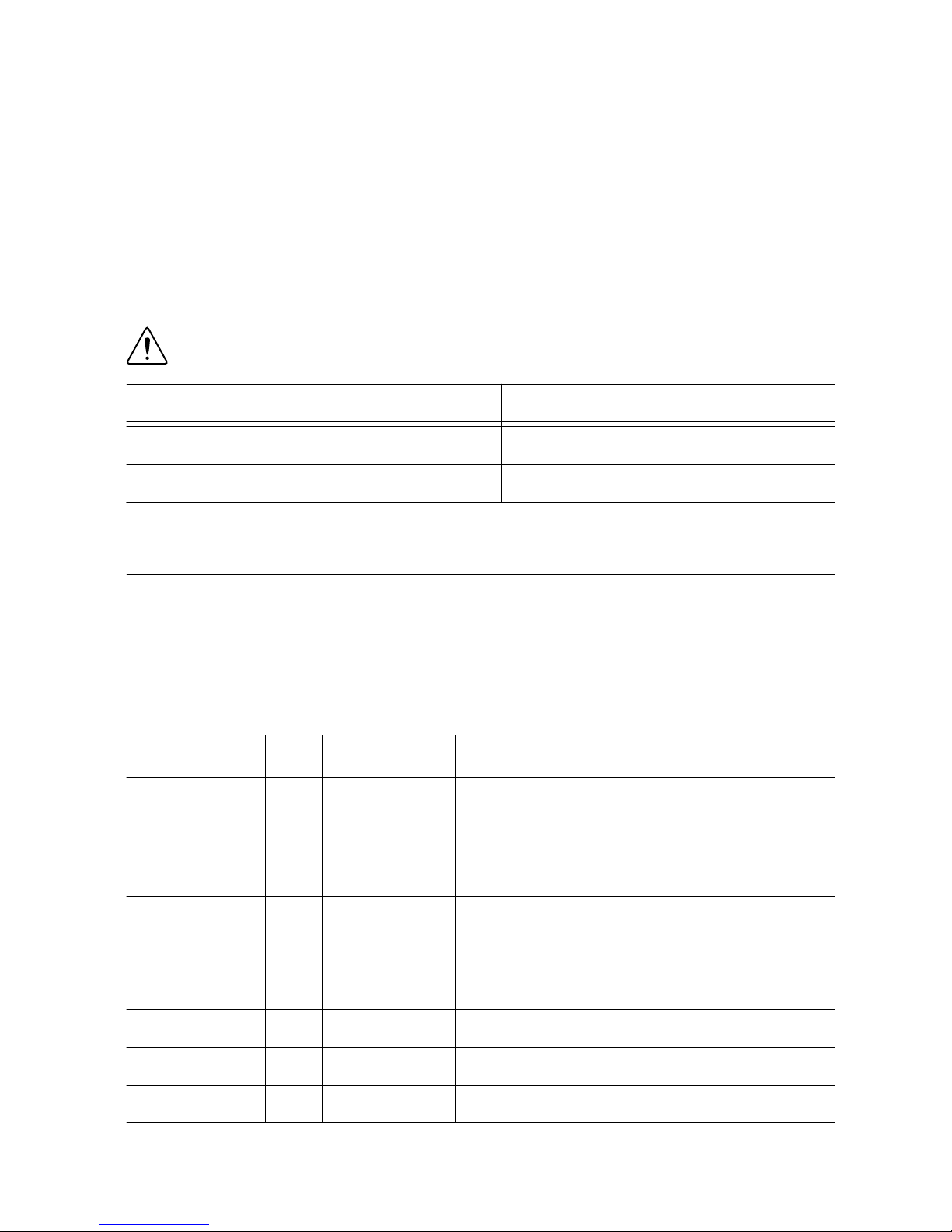

Connectors

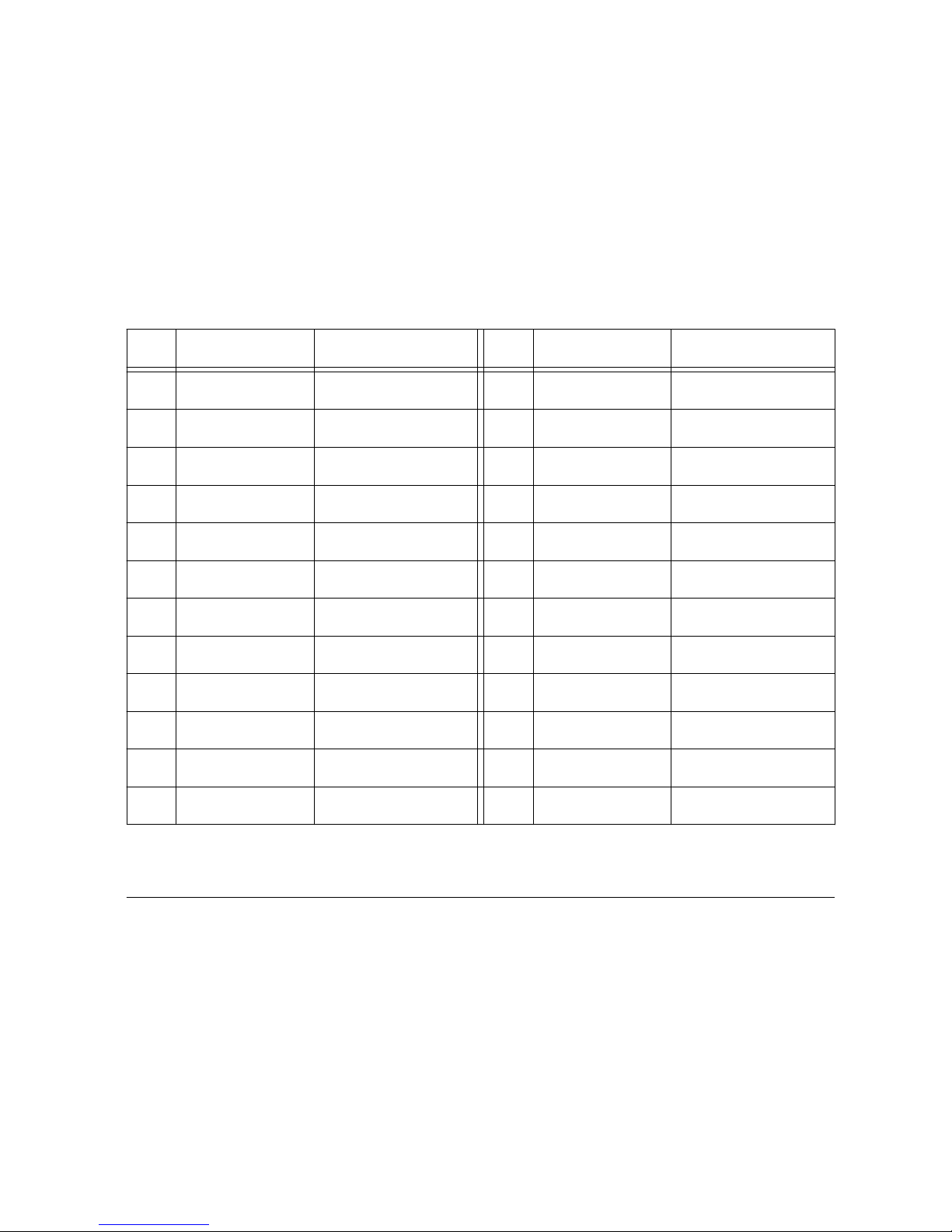

The following table lists the sbRIO-9687 connectors and recommended mating connectors.

Refer to the manufacturer for information about using and matching these connectors.

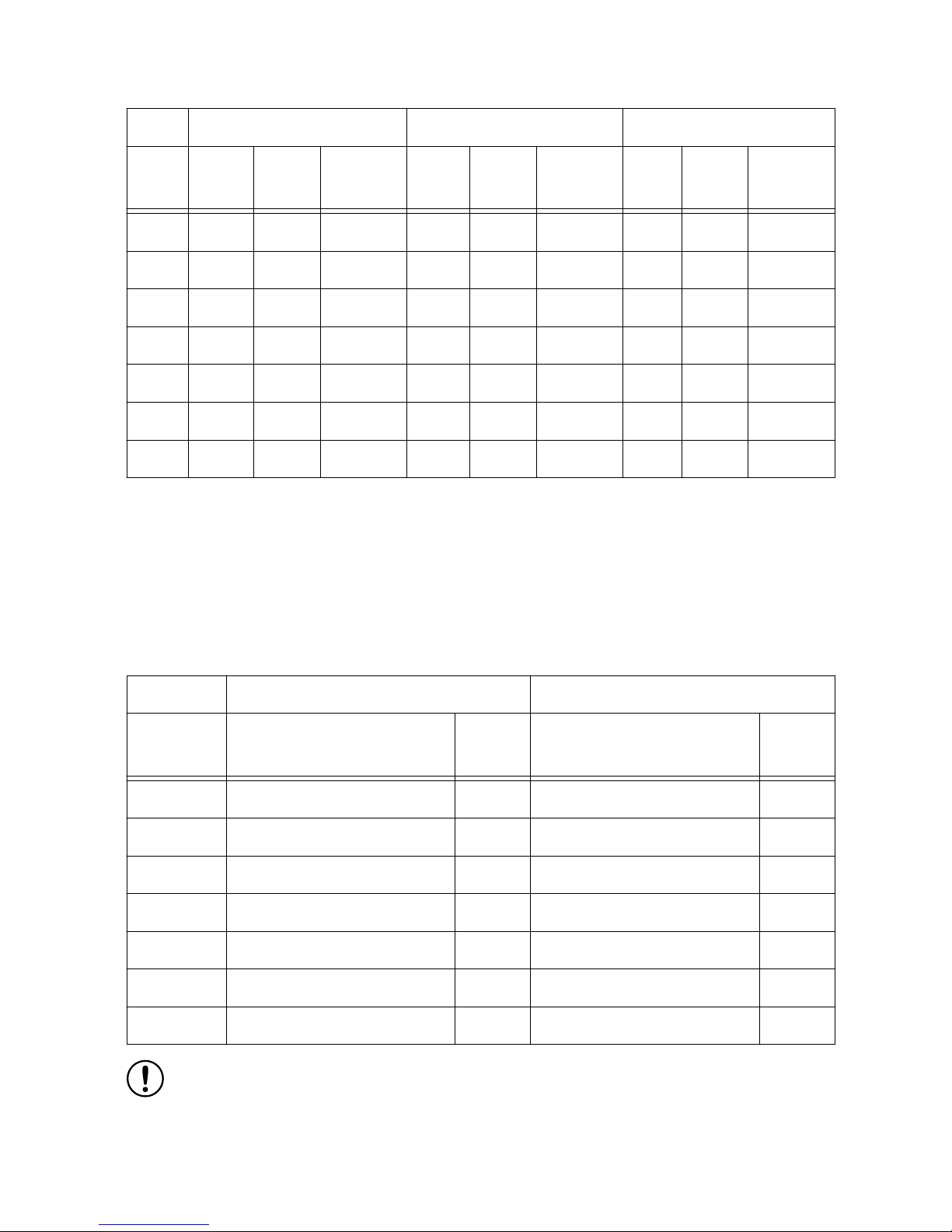

Table 1. sbRIO-9687 Connector Types

sbRIO-9687

Connector

Reference

Designator

Description Recommended Mating

Connector

24 V power J35 2-pin header Weidmuller (1930050000)

SKiiP 3 (x7) J36, J37, J38, J39,

J40, J41, J42

14-pin header On-Shore Technology, Inc.

(101-146)

SKiiP 4 (x7) J16, J17, J18, J19,

J20, J21, J22

25-pin Dsub header Kycon (K85X-BA-25S-30)

Semikube GB (x6) J29, J30, J31, J32,

J33, J34

20-pin header On-Shore Technology, Inc.

(101-206)

Semikube GD (x2) J24, J25 34-pin header On-Shore Technology, Inc.

(101-346)

SKiiP 3 GD (x2) J26, J27 26-pin header On-Shore Technology, Inc.

(101-266)

Simultaneous AI

(x2)

J5, J11 26-pin header Weidmuller (B2CF

3.50/26/180LH SN BK BX)

Feedback input (x2) J6, J10 24-pin header Weidmuller (B2CF

3.50/24/180LH SN BK BX)

Scanned AI, AO J14 26-pin header Weidmuller (B2CF

3.50/26/180LH SN BK BX)

4 | ni.com | sbRIO-9687 User Manual

Page 5

Table 1. sbRIO-9687 Connector Types (Continued)

sbRIO-9687

Connector

Reference

Designator

Description Recommended Mating

Connector

Thermistor J28 6-pin header Weidmuller (B2CF

3.50/6/180LH SN BK BX)

Relay output J4 12-pin header Weidmuller (B2CF

3.50/12/180LH SN BK BX)

Half-bridge DO J13 24-pin header Weidmuller (B2CF

3.50/24/180LH SN BK BX)

Sourcing DI J12 36-pin header Weidmuller (B2CF

3.50/36/180LH SN BK BX)

Sinking DO J9 36-pin header Weidmuller (B2CF

3.50/36/180LH SN BK BX)

LVTTL expansion

(x2)

J7, J8 26-pin header On-Shore Technology, Inc.

(SH2-26G-PT)

RS232 display

interface

J23 9-pin header Kycon (K85X-EA-9S-30)

Display power J15 2-pin header Sauro (CBF020D8)

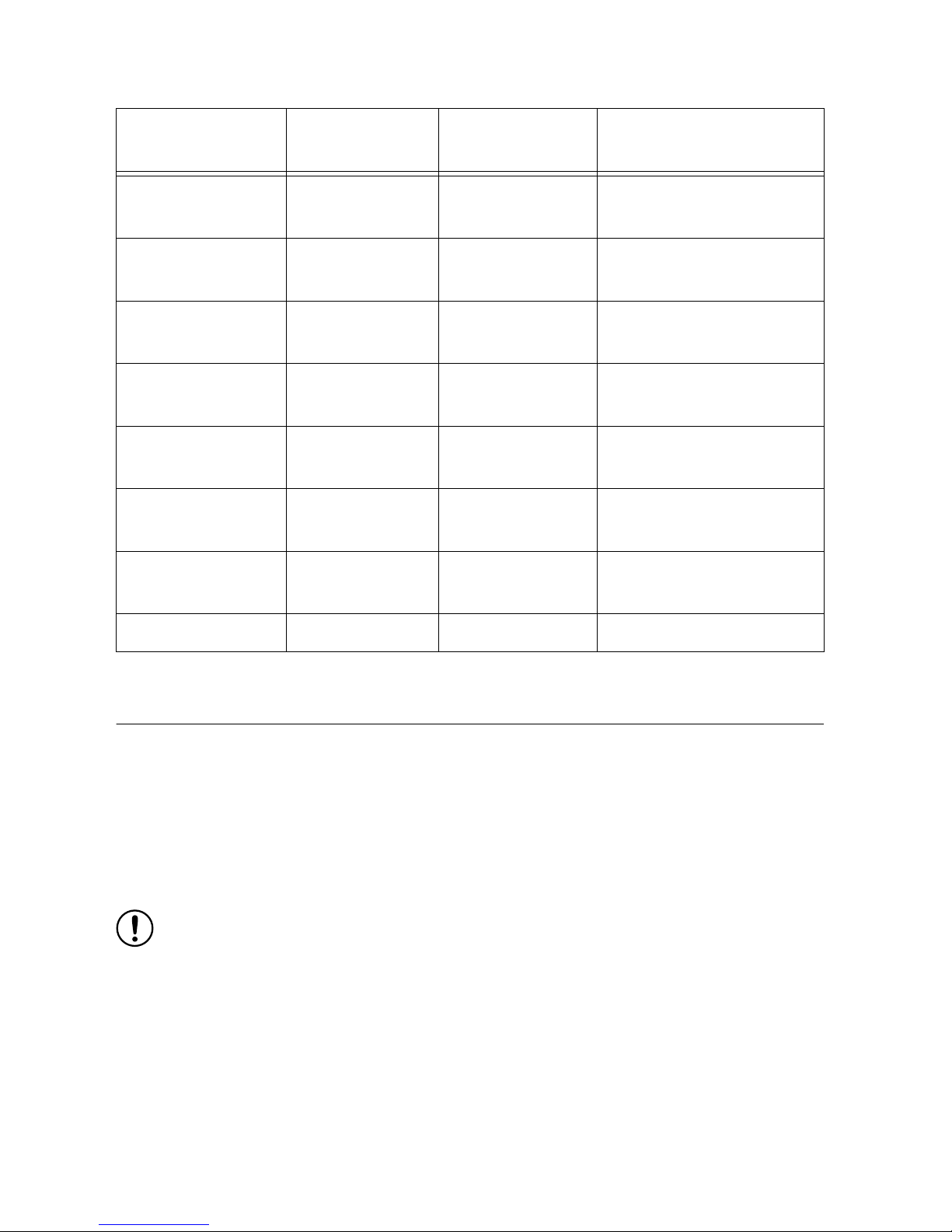

Switch and Resistor Configuration

The sbRIO-9687 utilizes a flexible design and can be configured to integrate with most

inverter-based applications and circuit topologies for power conversion, motor driving, and so

on.

The sbRIO-9687 must be configured before it can be used. The board configuration can be set

by toggling the onboard DIP switches. Alternatively, the spare resistors in parallel with the

switches can be populated with 0 Ω.

Notice On a new board, all switch contacts are open by default. The sbRIO-9687

will not work as expected until switch contacts are configured as described in this

manual.

When a DIP switch actuator is moved to the ON position, the switch contacts are closed (input

selected). All the DIP switches are oriented so that the closing position is to the right or down.

The following figure shows board and DIP switch orientation.

sbRIO-9687 User Manual | © National Instruments | 5

Page 6

Figure 2. Board and DIP Switch Orientation

Contacts OFF

(open circuit)

Contacts ON

(closed circuit)

1

2

ON

1

2

ON

1

2

3

4

ON

1

2

3

4

ON

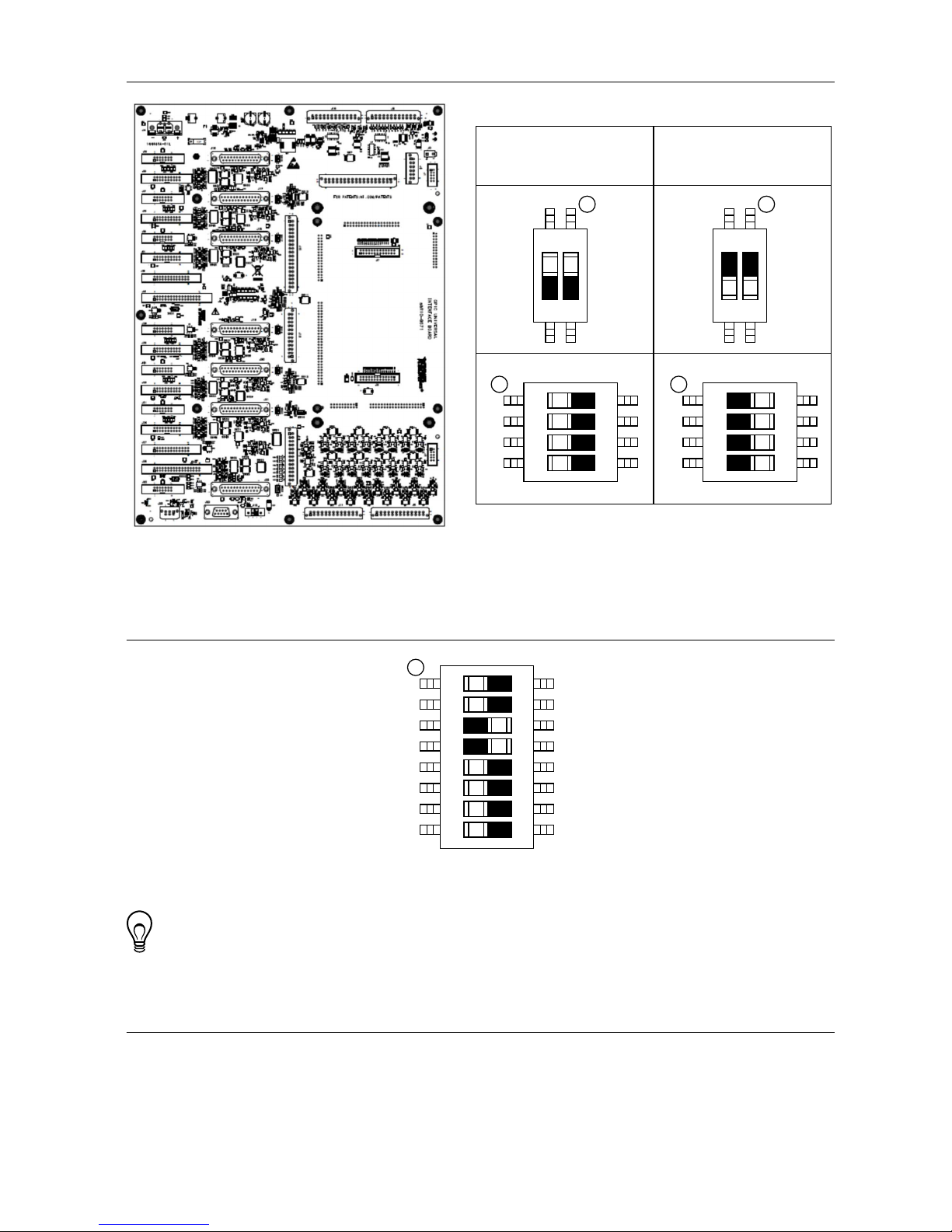

Contacts are referenced by the switch reference designator. As an example, the following

figure shows SW48 configured with contacts 3 and 4 closed.

Figure 3. Contact Configuration

1

2

3

4

ON

5

6

7

8

SW48

Tip Use a sharp tool to toggle the contacts.

Power Considerations

It is recommended that you perform all resistor changes and switch configurations before the

sbRIO-9687 is placed in its final location.

6 | ni.com | sbRIO-9687 User Manual

Page 7

Before you fix the sbRIO-9687 in the final position, ensure that the mounting plate is

grounded and that there is enough airflow around the board stack.

Note Exercise caution when placing the sbRIO-9687 inside an enclosure.

Auxiliary cooling may be necessary to keep the device under the maximum ambient

temperature rating for the sbRIO-9687. Refer to the sbRIO-9687 Specifications for

more information about the maximum ambient temperature rating. For information

and examples regarding factors that can affect thermal performance, visit ni.com/info

and enter the Info Code sbriocooling.

Before powering on the sbRIO-9687, make sure there are no wires or metal parts that could

touch the surface of the sbRIO-9687.

To power the sbRIO-9687, use a +24 V supply capable of delivering the current required by

the application. Inverter driver boards, the sbRIO-9607, and the GPIC are all powered through

the sbRIO-9607. The total power consumption should be considered when choosing an

external power supply. For information about sbRIO-9687 power consumption, refer to the

sbRIO-9687 Specifications.

For information about connector type, see the Connectors on page 4 section. For details about

wiring, see Power Input on page 8.

System Power and Grounding Recommendations

NI recommends making the following connections to power and ground your system. For the

main sbRIO-9687 Power +24 VDC Power connection, make sure that the following

recommendations are incorporated into the design.

• Connect the power supply to the sbRIO-9687 power connector with wires that can carry

the current for the sbRIO-9687 as well as all of the attached peripheral hardware.

• If more power is needed for the inverters, consider disconnecting them from the

sbRIO-9687 power and supplying them directly with +24 V from a separate power

supply.

• Connect the inverter power supply ground to the inverter driver board; do not connect it

to the sbRIO-9687 main power supply.

• If separate power supplies are used for sensors, connect the sensor supply ground with the

sbRIO-9687 ground at the analog input connector.

• Power the sbRIO-9687 before, or at the same time as, other power supplies in the system.

• For lower earth connection impedance, add a low-gauge wire between one of the standoff

fixing screws and the chassis. The sbRIO-9687 is connected to earth ground through the

standoffs.

• If shielded wires are used, ground them at the inverter connectors or at one of the standoff

fixing screws.

• Electrically isolate the thermistors from earth ground and from other rails in the system.

sbRIO-9687 User Manual | © National Instruments | 7

Page 8

Power Input

The sbRIO-9687 interface board must be powered with a +24 V DC supply. The power supply

should have a maximum output current higher than the current consumption of the interface

board and all attached inverters. Refer to the sbRIO-9687 Specifications for maximum current

consumption.

The sbRIO-9687 power input is protected against reverse polarity, and it uses a 10 A fuse to

provide protection for overcurrent. Littlefuse Series 314 is recommended, but any compatible

fuse can be used. Refer to the sbRIO-9687 Specifications for maximum fuse rating.

Caution Disconnect the main +24 V supply before replacing the fuse.

Connector Pin Signal Name

1 GND

2 +24 V

GPIC Signals

The main function of the sbRIO-9687 is to provide an interface between the GPIC controller

and different Semikron inverters. The GPIC controller utilizes the following signals. Refer to

the sbRIO-9683 or sbRIO-9684 documentation for connector pinouts and detailed signal

descriptions.

Table 2. GPIC Signals

Generic Name Lines Signal Name Description

Half-Bridge DO 14 DO<0…13> High voltage digital signals for inverter control.

Sourcing DI 28 DI_P0.<0…13>

DI_P1.<0…13>

High voltage digital input with pull-up resistors.

Sinking DO 24 DO_<0…22 > Open collector digital outputs.

Simultaneous AI 16×2 AI<0…15>± Simultaneous sampled differential analog inputs.

Scanned AI 8 AI_<0…7> Scanned analog inputs 0 V to 5 V.

Analog Output 8 AO<0…7> Analog outputs 0 V to 5 V.

LVTTL 32 DIO<0…31> Low voltage TTL lines.

Relay Control 4×2 DO<0…3>± Relay control lines.

8 | ni.com | sbRIO-9687 User Manual

Page 9

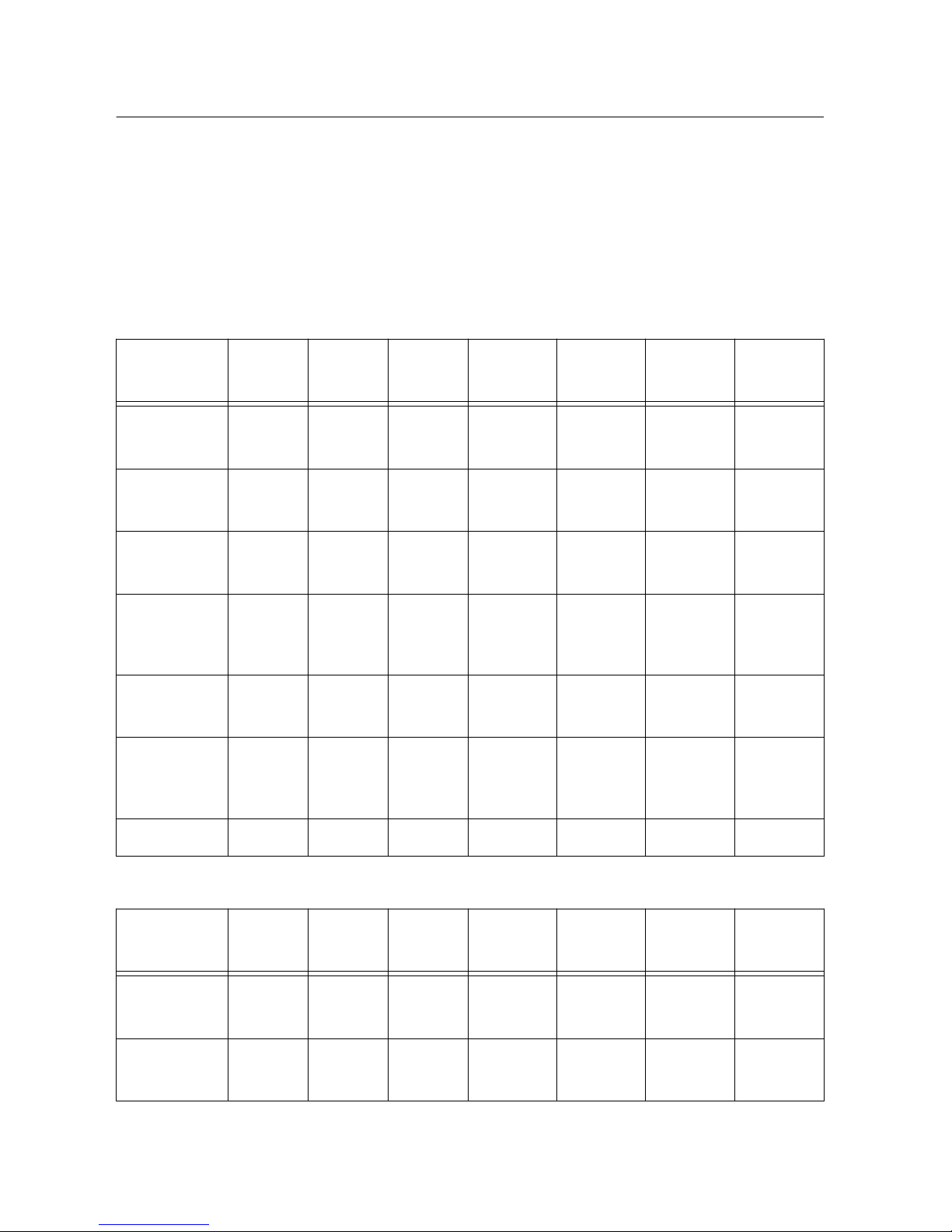

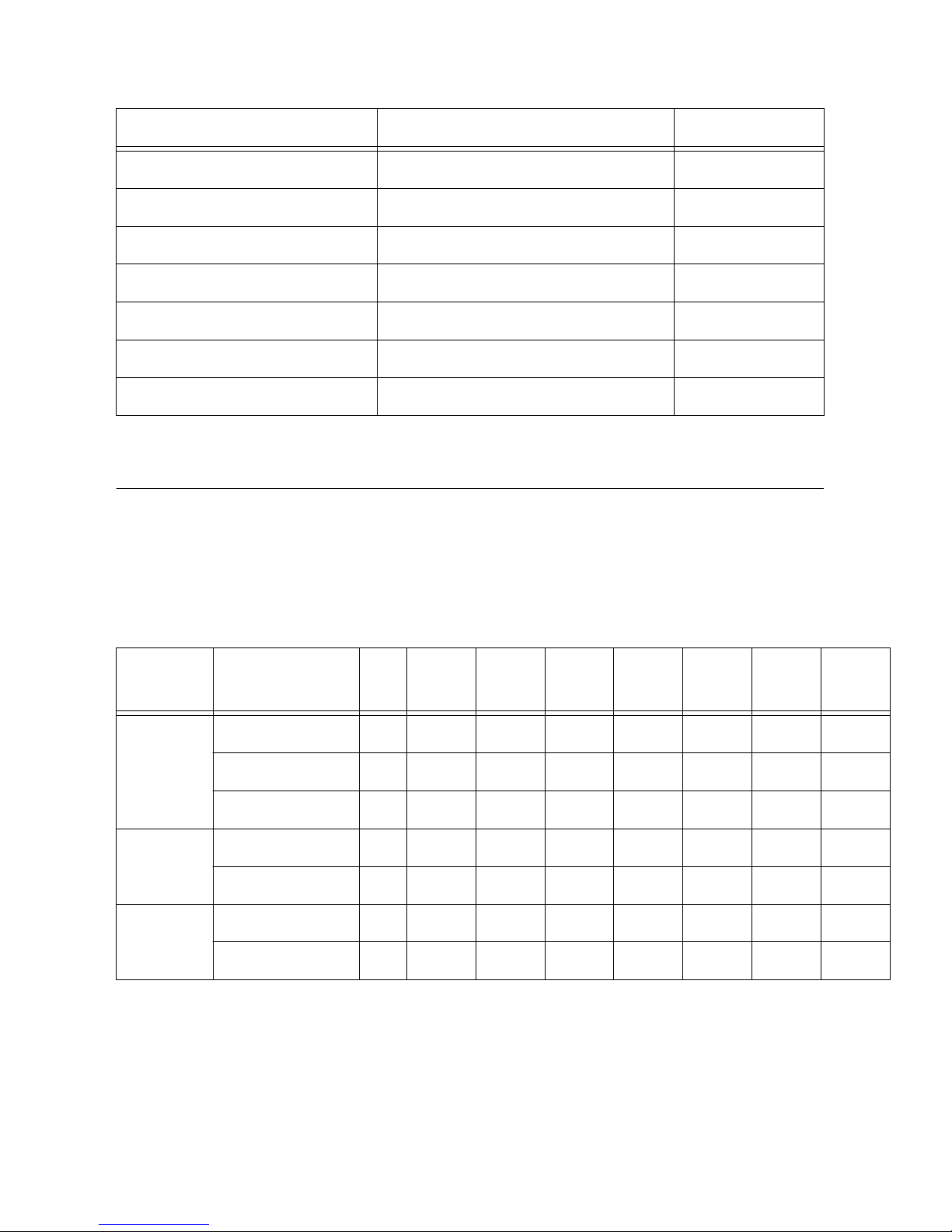

Inverter Signals

One of the main functions of the sbRIO-9687 is to provide an interface between the

sbRIO-9683 or sbRIO-9684 GPIC controller and up to seven single-phase Semikron inverters.

The following tables show the connections between inverter signals and the GPIC. Only one

connector from each column of the following tables can be used at a time. Using two

connectors from one column could result in unpredictable behavior or damage to the interface

board or inverters.

Table 3. Signal Assignments, GPIC to SKiiP 4 (Single-Phase Inverter)

Signal Inv. 0

(J16)

Inv. 1

(J17)

Inv. 2

(J18)

Inv. 3

(J19)

Inv. 4

(J20)

Inv. 5

(J21)

Inv. 6

(J22)

High Side

IGBT

DO1 DO3 DO5 DO7 DO9 DO11 DO13

Low Side

IGBT

DO0 DO2 DO4 DO6 DO8 DO10 DO12

Current

Sensor

AI0± AI1± AI2± AI3± AI4± AI5± AI6±

DC Link

Voltage

AI7±

or AI_0

AI8±

or AI_1

AI9±

or AI_2

AI10±

or AI_3

AI11±

or AI_4

AI12±

or AI_5

AI13±

or AI_6

Temperature

Sensor

AI_0 AI_1 AI_2 AI_3 AI_4 AI_5 AI_6

HALT DO_0,

DI_P0.0

DO_1,

DI_P0.1

DO_2,

DI_P0.2

DO_3,

DI_P0.3

DO_4,

DI_P0.4

DO_5,

DI_P0.5

DO_6,

DI_P0.6

GPIO DI_P0.7 DI_P0.8 DI_P0.9 DI_P0.10 DI_P0.11 DI_P0.12 DI_P0.13

Table 4. Signal Assignments, GPIC to SKiiP 3 GB (Single-Phase Inverter)

Signal Inv. 0

(J36)

Inv. 1

(J37)

Inv. 2

(J38)

Inv. 3

(J39)

Inv. 4

(J40)

Inv. 5

(J41)

Inv. 6

(J42)

High Side

IGBT

DO1 DO3 DO5 DO7 DO9 DO11 DO13

Low Side

IGBT

DO0 DO2 DO4 DO6 DO8 DO10 DO12

sbRIO-9687 User Manual | © National Instruments | 9

Page 10

Table 4. Signal Assignments, GPIC to SKiiP 3 GB (Single-Phase Inverter) (Continued)

Signal Inv. 0

(J36)

Inv. 1

(J37)

Inv. 2

(J38)

Inv. 3

(J39)

Inv. 4

(J40)

Inv. 5

(J41)

Inv. 6

(J42)

Current

Sensor

AI0± AI1± AI2± AI3± AI4± AI5± AI6±

DC Link

Voltage

AI7±

or AI_0

AI8±

or AI_1

AI9±

or AI_2

AI10±

or AI_3

AI11±

or AI_4

AI12±

or AI_5

AI13±

or AI_6

Temperature

Sensor

AI_0 AI_1 AI_2 AI_3 AI_4 AI_5 AI_6

HALT DO_0,

DI_P0.0

DO_1,

DI_P0.1

DO_2,

DI_P0.2

DO_3,

DI_P0.3

DO_4,

DI_P0.4

DO_5,

DI_P0.5

DO_6,

DI_P0.6

GPIO DI_P0.7 DI_P0.8 DI_P0.9 DI_P0.10 DI_P0.11 DI_P0.12 DI_P0.13

Table 5. Signal Assignments, GPIC to Semikube GB (Single-Phase Inverter)

Signal Inv. 0

(J29)

Inv. 1

(J30)

Inv. 2

(J31)

Inv. 3 (J32) Inv. 4 (J33) Inv. 5 (J34)

High Side

IGBT

DO1 DO3 DO5 DO7 DO9 DO11

Low Side

IGBT

DO0 DO2 DO4 DO6 DO8 DO10

Current Sensor AI0± AI1± AI2± AI3± AI4± AI5±

DC Link

Voltage

AI7±

or AI_0

AI8±

or AI_1

AI9±

or AI_2

AI10±

or AI_3

AI11±

or AI_4

AI12±

or AI_5

Temperature

Sensor

AI_0 AI_1 AI_2 AI_3 AI_4 AI_5

HALT DO_0,

DI_P0.0

DO_1,

DI_P0.1

DO_2,

DI_P0.2

DO_3,

DI_P0.3

DO_4,

DI_P0.4

DO_5,

DI_P0.5

GPIO DI_P0.7 DI_P0.8 DI_P0.9 DI_P0.10 DI_P0.11 DI_P0.12

10 | ni.com | sbRIO-9687 User Manual

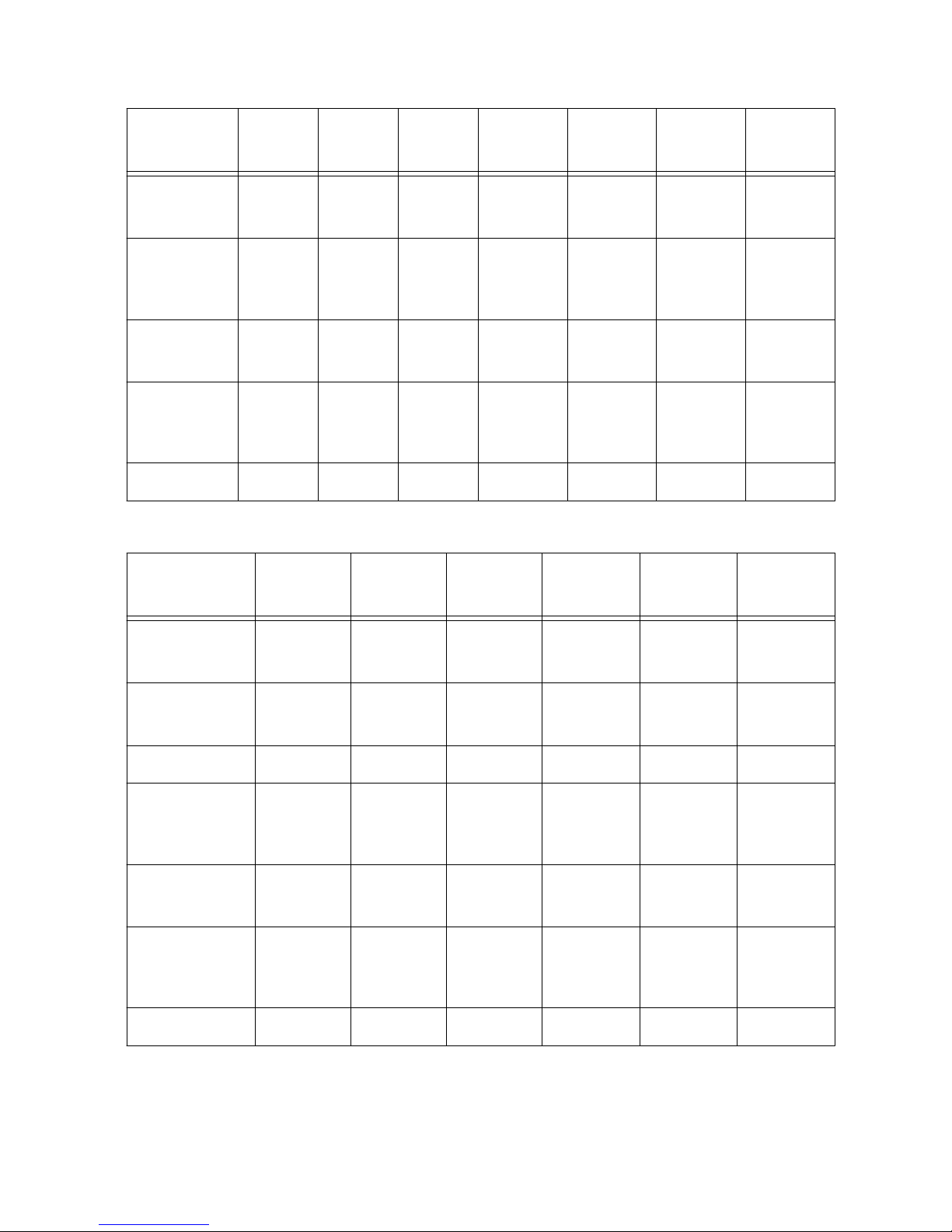

Page 11

Table 6. Signal Assignments, GPIC to SKiiP 3 GD (Three-Phase Inverter)

Signal Inv. 0 (J26) Inv. 1 (J27)

Phase 1 Phase 2 Phase 3 Phase 1 Phase 2 Phase 3

High Side IGBT DO1 DO3 DO5 DO7 DO9 DO11

Low Side IGBT DO0 DO2 DO4 DO6 DO8 DO10

Current Sensor AI0± AI1± AI2± AI3± AI4± AI5±

DC Link Voltage AI7±

or AI_0

— — — — AI12±

or AI_5

Temperature Sensor — AI_1 — — AI_4 —

HALT DO_0,

DI_P0.0

DO_1,

DI_P0.1

DO_2,

DI_P0.2

DO_3,

DI_P0.3

DO_4,

DI_P0.4

DO_5,

DI_P0.5

GPIO DI_P0.7 — — — — DI_P0.12

Table 7. Signal Assignments, GPIC to Semikube GD (Three-Phase Inverter)

Signal Inv. 0 (J24) Inv. 1 (J25)

Phase 1 Phase 2 Phase 3 Phase 1 Phase 2 Phase 3

High Side IGBT DO1 DO3 DO5 DO7 DO9 DO11

Low Side IGBT DO0 DO2 DO4 DO6 DO8 DO10

Current Sensor AI0± AI1± AI2± AI3± AI4± AI5±

DC Link Voltage AI7±

or AI_0

— — — — AI12±

or AI_5

Temperature Sensor — AI_1 — — AI_4 —

HALT DO_0,

DI_P0.0

— — — — DO_5,

DI_P0.5

GPIO DI_P0.7 — — — — DI_P0.12

The signals on connectors 0 to 6 for SKiiP 3 GB and SKiiP 4, and signals on connectors 1 and

2 of SKiiP 3 GD and Semikube GB are shared. The two full bridge connectors for SKiiP 3 GD

and Semikube GD are also in parallel. One full bridge connector reuses signals from three

half-bridge connectors.

sbRIO-9687 User Manual | © National Instruments | 11

Page 12

Each signal can only be used by one inverter at a time. For example, if SKiiP 3 GB half-bridge

inverter 0 is connected on J16, then connectors J36, J29, J26, and J24 cannot be used because

all of these connectors share several lines with J16.

The DC link voltage output can be connected to either simultaneous scanned analog input or

scanned analog input. Refer to the Simultaneous Sampled Analog Input on page 15 and

Scanned Analog Input on page 24 sections for details about signal routing.

Note By default, the inverter analog outputs are not connected to the GPIC analog

inputs. The onboard switches should be configured before using the sbRIO-9687

interface board.

Inverter CAN Bus Configuration

The SKiiP 4 inverters have a CAN port for easy diagnosis of the system. The inverters are

connected to CAN bus in order, with inverter 0 closest to the GPIC. If one of the SKiiP 4

inverters is not used, the corresponding switch should be closed for CAN bus continuity. The

switches should be open only when a SKiiP 4 inverter is connected to the corresponding

connector.

Figure 4. sbRIO-9687 CAN Bus Topology

GPIC

SKiiP 4

SKiiP 4

SKiiP 4

SKiiP 4

SKiiP 4

SKiiP 4

SKiiP 4

Semikube GD

Semikube GD

0 1

2

3 4

5

6

SW15 SW16 SW17 SW18 SW19 SW20 SW22

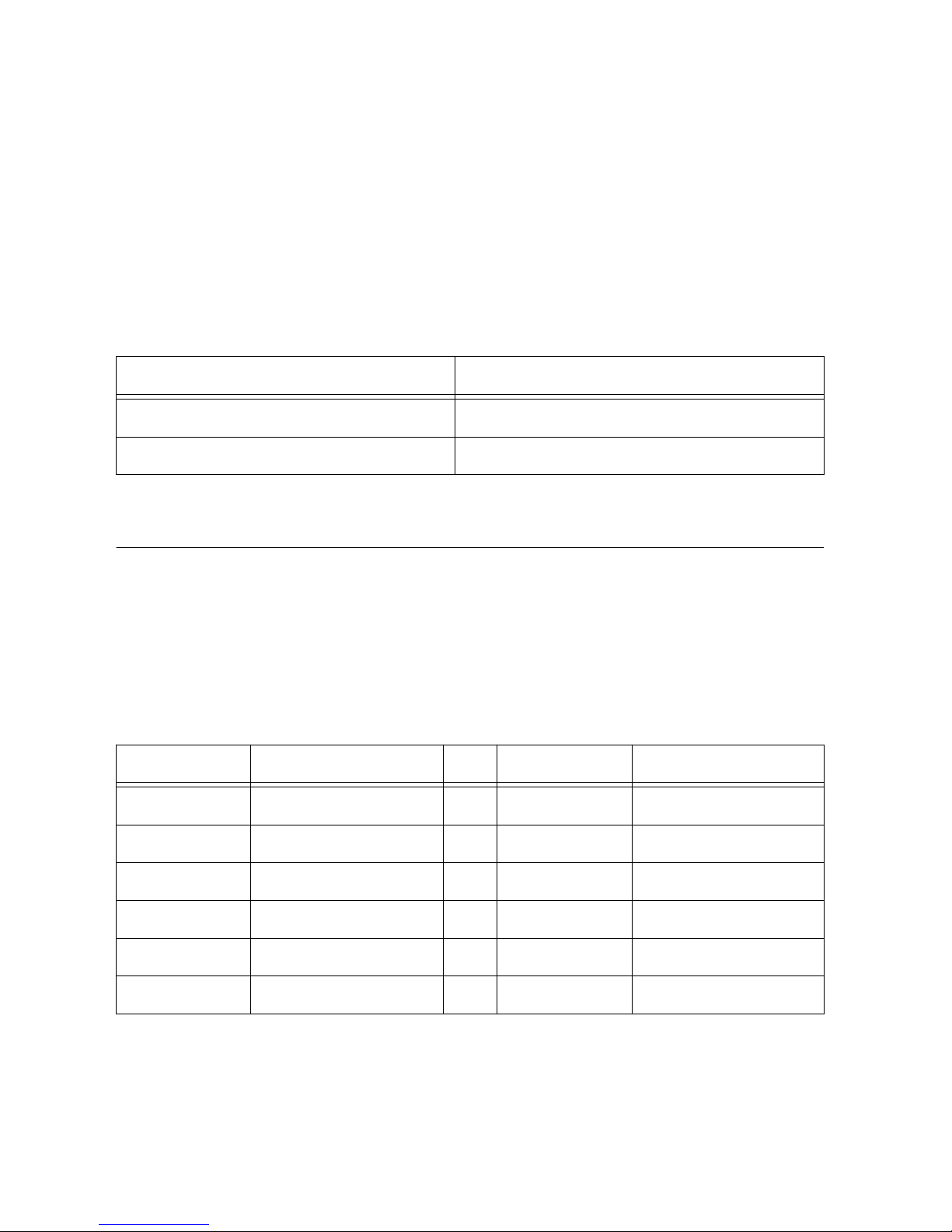

Table 8. SKiiP 4 Connector CAN Configuration

Inverter Inverter Connector CAN Switch Contacts

0 J16 SW15 1, 2

1 J17 SW16 1, 2

2 J18 SW17 1, 2

3 J19 SW18 1, 2

4 J20 SW19 1, 2

12 | ni.com | sbRIO-9687 User Manual

Page 13

Table 8. SKiiP 4 Connector CAN Configuration (Continued)

Inverter Inverter Connector CAN Switch Contacts

5 J21 SW20 1, 2

6 J22 SW22 1, 2

Inverter Analog Output Configuration

SKiiP 3 GB inverters come in two variants: one with temperature output, another with voltage

output on pin 12. The return for all analog signals is on pin 13. The interface board can be

configured so that the signals are routed to the correct GPIC analog inputs. You can configure

the signals by populating resistors on the sbRIO-9687. The options are listed below.

Table 9. SKiiP 3 Connector Output Type Selection

Inverter Inverter Connector Temperature Output

3

DC Link Voltage Output

0 J36 R865 R859

1 J37 R860 R852

2 J38 R861 R854

3 J39 R862 R855

4 J40 R863 R856

5 J41 R864 R858

6 J42 R818 R817

SKiiP 3 GD inverters do not have separate return paths for DC link voltage and temperature

analog outputs. For accurate measurements, the returns for the signal that is used in the system

should be connected to ground with the onboard switch. If both temperature and DC link

voltage are used, close both circuits on the corresponding switch. The options are listed below.

Table 10. SKiiP 3 GD Connector Signal Ground Connections

Inverter Inverter Connector Temperature Ground DC Link Voltage Ground

0 J26 SW51 contact 1 SW52 contact 1

1 J27 SW51 contact 2 SW52 contact 2

3

Temperature output is populated by default.

sbRIO-9687 User Manual | © National Instruments | 13

Page 14

Inverter Driving Signals

Fast, high voltage digital signals are used to turn the high side and low side IGBT modules on

and off. The connections between the inverter signals and the GPIC are described in Inverter

Signals on page 9. The digital signals for SKiiP 3 GD and SKiiP 3 GB connectors are 15 V

logic. For the other connectors, the signals are 24 V logic. All digital driving signals are

available at breakout connector J13 with 24 V logic levels.

The following table shows the pin assignments for the J13 breakout connector.

Table 11. J13 Pin Assignments (HB Signals Breakout Connector)

Pin GPIC Signal Inverter Signal Pin GPIC Signal Inverter Signal

1 GND — 13 GND —

2 DO0 HB0_BOT 14 DO1 HB0_TOP

3 DO2 HB1_BOT 15 DO3 HB1_TOP

4 GND — 16 GND —

5 DO4 HB2_BOT 17 DO5 HB2_TOP

6 DO6 HB3_BOT 18 DO7 HB3_TOP

7 GND — 19 GND —

8 DO8 HB4_BOT 20 DO9 HB4_TOP

9 DO10 HB5_BOT 21 DO11 HB5_TOP

10 GND — 22 GND —

11 DO12 HB6_BOT 23 DO13 HB6_TOP

12 GND — 24 GND —

Analog Input

The sbRIO-9687 interface board can accept inputs from analog input connectors or from

inverters. The analog input signals can be configured on the sbRIO-9687 in a variety of ways;

as a result, it is possible to use the sbRIO-9687 to control most of the power conversion

circuits without any additional wiring or circuitry.

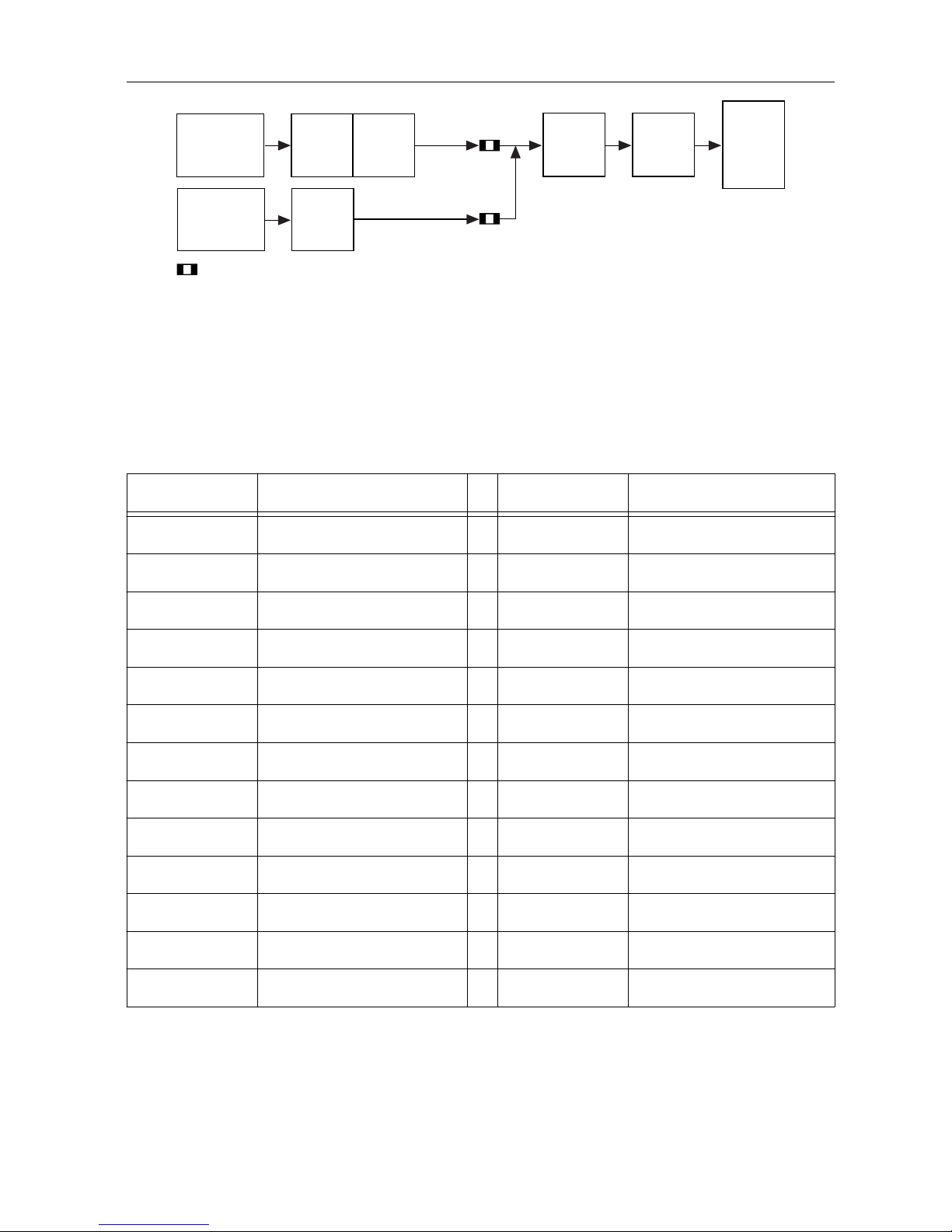

The following figure shows a block diagram of the sbRIO-9687 analog input subsystem.

14 | ni.com | sbRIO-9687 User Manual

Page 15

Figure 5. sbRIO-9687 Analog Input Subsystem

Over-Range

Comparators

DIO

Current-

Sensing

Resistor

DC Link Voltage

Phase Current

Differential

Amplifier

Bipolar to

Unipolar

CM

Filter

Simultaneous AI

Thermistor

Connector

Inverter

Connectors

Breakout

Connector

Scanned AI Scanned AI

Temp

Signals

External

Slow AI

UDC

Signals

I Phase

Signals

External

Fast AI

External

Fast AI

AO

Configurable Position

Low Pass

Filter

Gain

Stage

CurrentSensing

Resistor

CM

Filter

CM

Filter

CM

Filter

CM

Filter

CM

Filter

Inverter

Connectors

Inverter

Connectors

Breakout

Connector

Breakout

Connector

Breakout

Connector

Thermistor

Circuit

Temperature

Configuration

Resistors or Contacts

AO

GPIC

Simultaneous Sampled Analog Input

The General Purpose Inverter Controller (GPIC) has 16 simultaneous sampling analog inputs,

which acquire samples at a rate of 180 kS/s per channel. Phase difference between channels is

minimal due to the simultaneous sampling and high bandwidth of these signals. Each GPIC

input is differential with a software-range of ±10 V or ±5 V. These inputs should be used for

signals whose bandwidth and phase information is important for the control algorithm. Phase

current and DC link voltage from inverters can be connected to simultaneous sampled AI.

The sbRIO-9687 has 16 external analog inputs that can be connected to the GPIC

simultaneous sampling analog inputs. Other features of the analog input circuitry include:

• Pads for current-sensing resistor option on each input.

• Low pass filter and gain stage for each input.

• Eight configurable over-range comparators.

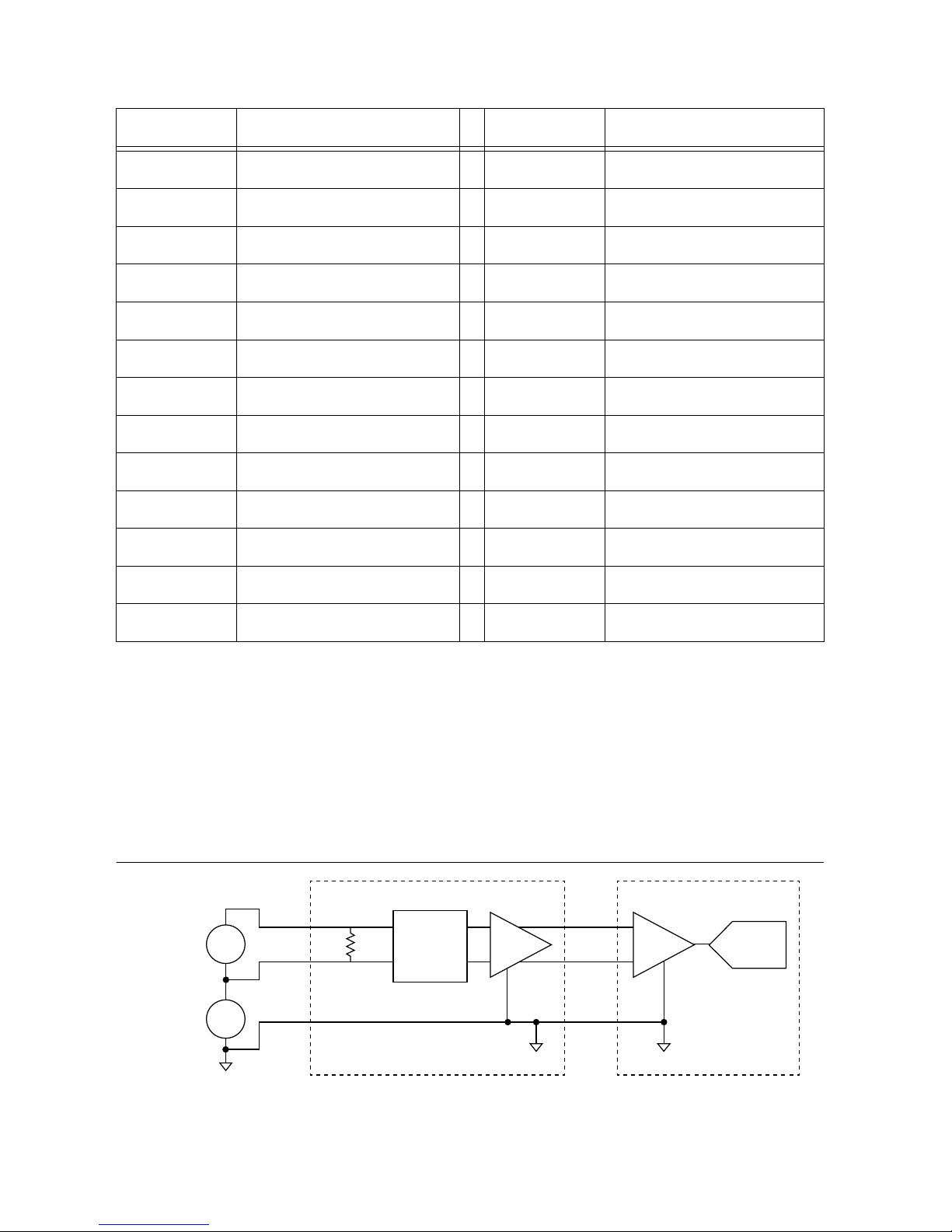

The following figure shows depicts a block diagram for simultaneous sampled analog input.

sbRIO-9687 User Manual | © National Instruments | 15

Page 16

Figure 6. Simultaneous Sampled Analog Input

GPIC

Input

Connector

Inverter

Connectors

CurrentSensing

Resistor

Low

Pass

Filter

Gain

Stage

CM

Filter

ssAI

Phase Current

DC Link Voltage

CM

Filter

Configurable position

Simultaneous Analog Input Connectors

The sbRIO-9687 interface board includes 16 external simultaneous sampling analog inputs at

two connectors, J5 and J11. The following tables provide pin assignment information for the

J5 and J11 simultaneous AI breakout connectors.

Table 12. J5 Pin Assignments

Pin Signal Pin Signal

1 GND 14 GND

2 ssAI0+ 15 ssAI0–

3 ssAI1+ 16 ssAI1–

4 GND 17 GND

5 ssAI2+ 18 ssAI2–

6 ssAI3+ 19 ssAI3–

7 GND 20 GND

8 ssAI4+ 21 ssAI4–

9 ssAI5+ 22 ssAI5–

10 GND 23 GND

11 ssAI6+ 24 ssAI6–

12 ssAI7+ 25 ssAI7–

13 GND 26 GND

16 | ni.com | sbRIO-9687 User Manual

Page 17

Table 13. J11 Pin Assignments

Pin Signal Pin Signal

1 GND 14 GND

2 ssAI8+ 15 ssAI8–

3 ssAI9+ 16 ssAI9–

4 GND 17 GND

5 ssAI10+ 18 ssAI10–

6 ssAI11+ 19 ssAI11–

7 GND 20 GND

8 ssAI12+ 21 ssAI12–

9 ssAI13+ 22 ssAI13–

10 GND 23 GND

11 ssAI14+ 24 ssAI14–

12 ssAI15+ 25 ssAI15–

13 GND 26 GND

Connecting Voltage Sources to Simultaneous Analog Input

All sixteen inputs share a common ground that is the same as the digital and analog ground of

the GPIC. The differential input signal and absolute voltage of each input should be within the

input range of each channel. Refer to the sbRIO-9687 Specifications for details.

The simultaneous sampling analog inputs are differential, so the input measures the voltage

between the positive and negative terminals.

Figure 7. Connecting a Differential Voltage Signal to Simultaneous AI

+

–

+

–

Voltage

Source

Common

Mode

Voltage

Source

ssAI+

ssAI–

GND

ADC

sbRIO-9687

Gain

sbRIO-9683/9684

Termination

Resistor

Differential

Amplifier

Lowpass

Filter

AI+

AI–

sbRIO-9687 User Manual | © National Instruments | 17

Page 18

If single-ended signals are measured, one end of the signal source and one input terminal

should be connected to ground, as in the following diagram.

Figure 8. Connecting a Single-Ended Voltage Signal to Simultaneous AI

+

–

Voltage

Source

ssAI+

ssAI–

GND

ADC

sbRIO-9687

Gain

sbRIO-9683/9684

Differential

Amplifier

Lowpass

Filter

AI+

AI–

The gain stage of each input channel can be set as x1, x2, x3, or x4. See Gain Stage on page

22 for details.

Connecting Current Output Sensors to Simultaneous Analog

Input

A large selection of current output sensors can be connected to the sbRIO-9687. For current

measurements, a current-sensing resistor converts input current into voltage. The burden

voltage of the resistor follows the same signal path as the voltage inputs.

Figure 9. Connecting a Current Output Sensor to Simultaneous AI

ADC

sbRIO-9687

Gain

sbRIO-9683/9684

ssAI+

ssAI–

Current Output

Sensor

Power

Supply

PS+

PS–

Termination

Resistor

Differential

Amplifier

Lowpass

Filter

AI+

AI–

If the sensor is powered, the sensor power supply ground should be connected to the ground

pin on the simultaneous AI connector. The common mode and differential input signal on the

burden resistor should stay within the limits listed in the Simultaneous Sampled Analog Input

section of the sbRIO-9687 Specifications.

Current-Sensing Resistor

By default, the current-sensing resistor is not populated. The current-sensing resistor pads

accommodate a resistor footprint of 2512, with a maximum dissipated power of 1 W. For

lower power applications, the sbRIO-9687 includes a 1206 footprint (0.25 W) in parallel with

the current-sensing resistor.

18 | ni.com | sbRIO-9687 User Manual

Page 19

Select the current-sensing resistor value so that the power dissipation is minimized while as

much of the GPIC input range as possible is used. The current-sensing resistor value should be

less than or equal to the lesser of the values obtained from the following equations:

R

CSR_max

≤

P

CSR

I

in

_

rms

2

R

CSR

_

max

≤

GPIC

range

AI

gain

× I

in

_

max

where

P

CSR

= Current-sensing resistor power (1 W for 2512 footprint, 0.25 W for 1206

footprint).

R

CSR_max

= Maximum resistance of the current-sensing resistor (in Ohms).

I

in_rms

= RMS value of the input current (in Amps).

I

in_max

= Maximum input current (DC or

pk − pk

2

) (in Amps).

GPIC

range

= Input range set for the GPIC (10 V or 5 V).

AI

gain

= Gain of the interface board amplifier (x1, x2, x3, x4).

Note Use the maximum gain for simultaneous sampled analog input to get a lower

power dissipation from the current-sensing resistor.

Table 14. Simultaneous Sampled AI Current-Sensing Resistors

Simultaneous AI 2 W Current-Sensing Resistor 0.25 W Current-Sensing Resistor

ssAI0± R141 R140

ssAI1± R121 R120

ssAI2± R91 R90

ssAI3± R60 R59

ssAI4± R46 R45

ssAI5± R30 R29

ssAI6± R17 R16

ssAI7± R5 R4

ssAI8± R304 R303

ssAI9± R266 R265

sbRIO-9687 User Manual | © National Instruments | 19

Page 20

Table 14. Simultaneous Sampled AI Current-Sensing Resistors (Continued)

Simultaneous AI 2 W Current-Sensing Resistor 0.25 W Current-Sensing Resistor

ssAI10± R243 R242

ssAI11± R232 R231

ssAI12± R213 R212

ssAI13± R198 R197

ssAI14± R186 R185

ssAI15± R161 R160

Common Mode Filters

The sbRIO-9687 uses a high frequency common mode filter for each analog input from

external connectors and from Semikron modules. The common mode filter attenuates the

inverters' high frequency switching noise, which can interfere with the input signal.

Simultaneous Analog Input Configuration

The signal source for each GPIC simultaneous analog input is selected with a series of DIP

switches. Because all input signals are differential, a pair of contacts should be closed to select

one signal source. Refer to the following table for information about selecting simultaneous

sampled analog input signal source.

Table 15. Simultaneous Sampled Analog Input Signal Source Selection

Input 1 (Inverters) Input 2 (AI Connector)

GPIC Input Name Switch Contact Pair Name Switch Contact Pair

AI0± I Phase 0 SW42 3, 4 ssAI0± SW42 1, 2

AI1± I Phase 1 SW34 3, 4 ssAI1± SW34 1, 2

AI2± I Phase 2 SW36 3, 4 ssAI2± SW36 1, 2

AI3± I Phase 3 SW38 3, 4 ssAI3± SW38 1, 2

AI4± I Phase 4 SW44 3, 4 ssAI4± SW44 1, 2

AI5± I Phase 5 SW40 3, 4 ssAI5± SW40 1, 2

AI6± I Phase 6 SW25 3, 4 ssAI6± SW25 1, 2

AI7± U DC 0 SW41 3, 4 ssAI7± SW41 1, 2

AI8± U DC 1 SW33 3, 4 ssAI8± SW33 1, 2

20 | ni.com | sbRIO-9687 User Manual

Page 21

Table 15. Simultaneous Sampled Analog Input Signal Source Selection (Continued)

Input 1 (Inverters) Input 2 (AI Connector)

GPIC Input Name Switch Contact Pair Name Switch Contact Pair

AI9± U DC 2 SW35 3, 4 ssAI9± SW35 1, 2

AI10± U DC 3 SW37 3, 4 ssAI10± SW37 1, 2

AI11± U DC 4 SW43 3, 4 ssAI11± SW43 1, 2

AI12± U DC 5 SW39 3, 4 ssAI12± SW39 1, 2

AI13± U DC 6 SW24 3, 4 ssAI13± SW24 1, 2

AI14± — — — ssAI14± connected —

AI15± — — — ssAI15± connected —

Notice Only one signal source should be connected to each GPIC analog input at

one time. Connecting two signal sources in parallel can produce unexpected results.

Analog inputs from inverters are shared between the half-bridge modules and the full-bridge

modules. For proper operation, each analog line should be driven by only one inverter. Refer

to Inverter Signals on page 9 for more information.

Low Pass Filters

The sbRIO-9687 provides a low pass filter for each analog input. The filter has two stages that

are populated by default with 10 kΩ resistors and 3.3 nF capacitors. Refer to the sbRIO-9687

Specifications for details about the filter characteristics.

Figure 10. Simultaneous Sampled AI Input Low Pass Filter

From Input

Selection

To Gain

Stage

C1 C2

R1 R2

R1 R2

The first two filter resistors (R1) have a second functionality on the board and have a value of

10 kΩ. Other filter elements can be changed to set filter characteristics as required by the

application. The R2 has a default value of 10 kΩ (0603 footprint), and C1 and C2 have a

default value of 3.3 nF (0805 footprint).

sbRIO-9687 User Manual | © National Instruments | 21

Page 22

Table 16. Filter Component Reference Designators

GPIC Input R2 C1 C2

AI0± R195, R207 C122 C121

AI1± R219, R227 C142 C141

AI2± R219, R226 C140 C139

AI3± R194, R206 C120 C119

AI4± R183, R170 C105 C104

AI5± R138, R153 C88 C87

AI6± R169, R182 C103 C102

AI7± R137, R152 C86 C85

AI8± R68, R75 C47 C46

AI9± R107, R118 C70 C69

AI10± R99, R116 C66 C65

AI11± R80, R66 C50 C49

AI12± R38, R50 C31 C30

AI13± R12, R24 C14 C13

AI14± R49, R37 C29 C28

AI15± R23, R11 C12 C11

Note For a different cut-off frequency, change only the filter capacitors while

keeping C1 and C2 of equal value.

Gain Stage

Each analog input channel has a gain stage immediately after the low pass filter. Gain can be

set as x1, x2, x3, and x4. The output of the gain stage will work correctly only if the input

voltage at the simultaneous AI connector is within the common mode and differential range

listed in the sbRIO-9687 Specifications for each selected gain.

The gain should be set to use as much of the GPIC input range as possible. When current

signals are converted to voltage with onboard current-sensing resistors, it is preferable to set

the gain to the maximum value so that power dissipation from resistors is minimized.

Refer to the following tables for information regarding simultaneous sampled AI gain

configuration and related DIP switch reference designators and contact assignments.

22 | ni.com | sbRIO-9687 User Manual

Page 23

Table 17. Simultaneous Sampled AI Gain Configuration

Gain_A Contact Gain_B Contact Gain Input Range

open open x1 ±10 V

closed open x2 ±5 V

open closed x3 ±3.33 V

closed closed x4 ±2.5 V

Table 18. DIP Switch Reference Designators and Contact Assignments

GPIC Input Switch Reference Designator Gain_A Contact Gain_B Contact

AI0± SW9 3 4

AI1± SW9 1 2

AI2± SW8 3 4

AI3± SW8 1 2

AI4± SW6 3 4

AI5± SW6 1 2

AI6± SW5 3 4

AI7± SW5 1 2

AI8± SW4 3 4

AI9± SW4 1 2

AI10± SW3 3 4

AI11± SW3 1 2

AI12± SW2 3 4

AI13± SW2 1 2

AI14± SW1 3 4

AI15± SW1 1 2

Note For analog inputs that are connected to inverter current or voltage outputs,

the gain should be set to x1.

sbRIO-9687 User Manual | © National Instruments | 23

Page 24

Scanned Analog Input

The sbRIO-9683 or sbRIO-9684 GPIC controller has eight scanned analog inputs with an

input range of 0 V to 5 V. These inputs have limited bandwidth, and each input is read at a

slightly different time as it is scanned. These inputs should be used for slow analog signals as

temperature or DC voltages.

The sbRIO-9687 interface board connects slow analog inputs from inverter and breakout

connectors to the GPIC scanned AI. The signals are conditioned. The input range on the

sbRIO-9687 is 0 V to 10 V or -5 V to 5 V.

Figure 11. Scanned AI Block Diagram

Differential/

Single-Ended

Amplifier

Breakout

Connector

Temperature

External AI

UDC Input

scAI

GPIC

Configurable position

CM

Filter

CM

Filter

CM

Filter

Inverter

Connectors

Scanned Analog Input Connectors

The sbRIO-9687 interface board has seven external scanned analog inputs that are available at

breakout connector J14. The following table provides pinout information for the breakout

connector.

Table 19. J14 Pin Assignments

Pin Signal Pin Signal

1 GND 14 GND

2 AO0 15 AO1

3 AO2 16 AO3

4 GND 17 GND

5 AO4 18 AO5

6 AO6 19 AO7

7 scAI0 20 scAI0 GND

24 | ni.com | sbRIO-9687 User Manual

Page 25

Table 19. J14 Pin Assignments (Continued)

Pin Signal Pin Signal

8 scAI1 GND 21 scAI1

9 scAI2 22 scAI2 GND

10 scAI3 GND 23 scAI3

11 scAI4 24 scAI4 GND

12 scAI5 GND 25 scAI5

13 scAI6 26 scAI6 GND

The sbRIO-9687 uses scanned analog input 7 for thermistor measurement; it is not available

on the breakout connector.

Connecting Voltage Sources to Scanned Analog Input

The scanned analog inputs are single ended. One of the input pins is always ground. It is

recommended to connect the signal source to the ground pin assigned to each analog input.

Figure 12. Connecting a Voltage Signal to Scanned AI

+

–

Voltage

Source

ssAI

scAI_GND

ADC

sbRIO-9687 sbRIO-9683/9684

Single Ended/Bipolar

Scanned Analog Input Configuration

The input source for scanned analog inputs 0 to 6 is selected with the onboard DIP switches.

The signal source can be inverter temperature, inverter DC link voltage, or external voltage

from the input breakout connector. Refer to the following table for information about selecting

scanned analog input signal source.

sbRIO-9687 User Manual | © National Instruments | 25

Page 26

Table 20. Scanned Analog Input Signal Source Selection

Input 1 Input 2 Input 3

GPIC

Input

Name Switch Contact

Pair

Name Switch Contact

Pair

Name Switch Contact

Pair

AI_0 UDC 0 SW30 1, 2 Temp0 SW30 3, 4 scAI0 SW30 5, 6

AI_1 UDC 1 SW26 1, 2 Temp1 SW26 3, 4 scAI1 SW26 5, 6

AI_2 UDC 2 SW27 1, 2 Temp2 SW27 3, 4 scAI2 SW27 5, 6

AI_3 UDC 3 SW28 1, 2 Temp3 SW28 3, 4 scAI3 SW28 5, 6

AI_4 UDC 4 SW29 1, 2 Temp4 SW29 3, 4 scAI4 SW29 5, 6

AI_5 UDC 5 SW31 1, 2 Temp5 SW31 3, 4 scAI5 SW31 5, 6

AI_6 UDC 6 SW23 1, 2 Temp6 SW23 3, 4 scAI6 SW23 5, 6

Unipolar/Bipolar Mode Configuration

Each scanned analog input can be configured to accept unipolar or bipolar input voltages.

Refer to the sbRIO-9687 Specifications for details about the input range and accuracy for each

setting. Refer to the following table for information about configuring unipolar and bipolar

input voltages.

Table 21. Scanned Analog Input Unipolar/Bipolar Configuration

Unipolar Input (0 V to 10 V) Bipolar Input (-5 V to 5 V)

GPIC Input Switch Reference

Designator

Contact Switch Reference

Designator

Contact

AI0 SW12 1 SW12 2

AI1 SW12 3 SW12 4

AI2 SW11 1 SW11 2

AI3 SW11 3 SW11 4

AI4 SW13 1 SW13 2

AI5 SW13 3 SW13 4

AI6 SW14 1 SW14 2

Notice Only one configuration should be selected for each scanned analog input.

Selecting both unipolar/bipolar configuration at the same time will produce

unexpected results.

26 | ni.com | sbRIO-9687 User Manual

Page 27

Note Scanned analog inputs connected to inverters should be set to unipolar mode.

Analog Output

The analog outputs of the GPIC are connected directly to the breakout connector. See Scanned

Analog Input Connectors on page 24 for details. The following figure shows a block diagram

for analog output subsystem.

Figure 13. Analog Output Block Diagram

GPIC

AO

Breakout

Connector

Onboard

Functionality

Configurable position

Analog output can be used on the sbRIO-9687 to set over-range thresholds. See Over-Range

Comparators on page 28 for details about onboard functionality.

The analog output lines have the same specifications as the AO lines of the GPIC. For more

information, refer to NI 9683 User Manual and Specifications and NI 9684 User Manual and

Specifications.

Analog Output Configuration

Analog outputs can be disconnected from the onboard functionality by changing the

corresponding DIP switch to the OFF position. Refer to the following table for information

about analog output configuration.

Table 22. Analog Output Configuration

GPIC Analog Output SW21 Contact

AO0 1

AO1 2

AO2 3

AO3 4

AO4 5

AO5 6

sbRIO-9687 User Manual | © National Instruments | 27

Page 28

Table 22. Analog Output Configuration (Continued)

GPIC Analog Output SW21 Contact

AO6 7

AO7 8

Note Analog outputs that are used outside the sbRIO-9687 should be disconnected

from onboard functionality.

Over-Range Comparators

The sbRIO-9687 interface board has eight over-range comparators that can be connected to

analog input signals. The over-range comparators are triggered if the absolute value of the

input is over the set voltage. For example, if the threshold is set at 7 V, then the over range is

triggered if the input is over 7 V or under -7 V.

The following figure is a block diagram for the over-range circuits.

Figure 14. Over-Range Circuit Block Diagram

Input

Connectors

Inverter

Connectors

Phase Current

DC Link Voltage

Over Range

Set Point

AO

DIO

GPIC

Configurable position

Over-Range

Comparators

CM

Filter

CM

Filter

Current-

Sensing

Resistor

CM

Filter

The eight over-range comparators can be connected to inverter phase current, inverter DC link

voltage, or to one of the 16 simultaneous sampled analog inputs. The over-range threshold can

be set using one of the GPIC analog outputs or by populating a resistor divider on the board.

The over-range output is an active low digital signal connected to the GPIC low voltage TTL

inputs.

Note If any of the DIO lines (DIO0 to DIO7) are to be used for the extension

board, they should be disconnected from the onboard functionality by depopulating

the corresponding 0 Ω resistor. See LVTTL Lines on page 38 for details.

Over-Range Comparator Input Configuration

Over-range comparators are connected to the input source with a series of DIP switches.

Because all input signals are differential, a pair of contacts should be closed to select one

28 | ni.com | sbRIO-9687 User Manual

Page 29

signal source. Refer to the following tables for information about selecting over-range

comparator input signal source.

Table 23. Over-Range Comparator Input Selection, Inputs 1 and 2

Circuit Input 1 Switch Contacts Input 2 Switch Contacts

O-Ra 0 I Phase Inv. 0 SW47 5, 6 UDC Inv. 0 SW47 1, 2

O-Ra 1 I Phase Inv. 1 SW45 5, 6 UDC Inv. 1 SW45 1, 2

O-Ra 2 I Phase Inv. 2 SW48 5, 6 UDC Inv. 2 SW48 1, 2

O-Ra 3 I Phase Inv. 3 SW49 5, 6 UDC Inv. 3 SW49 1, 2

O-Ra 4 I Phase Inv. 4 SW50 5, 6 UDC Inv. 4 SW50 1, 2

O-Ra 5 I Phase Inv. 5 SW46 5, 6 UDC Inv. 5 SW46 1, 2

O-Ra 6 I Phase Inv. 6 SW32 5, 6 UDC Inv. 6 SW32 1, 2

O-Ra 7 — — — — — —

Table 24. Over-Range Comparator Input Selection, Inputs 3 and 4

Circuit Input 3 Switch Contacts Input 4 Switch Contacts

O-Ra 0 ssAI0± SW47 7, 8 ssAI7± SW47 3, 4

O-Ra 1 ssAI1± SW45 7, 8 ssAI8± SW45 3, 4

O-Ra 2 ssAI2± SW48 7, 8 ssAI9± SW48 3, 4

O-Ra 3 ssAI3± SW49 7, 8 ssAI10± SW49 3, 4

O-Ra 4 ssAI4± SW50 7, 8 ssAI11± SW50 3, 4

O-Ra 5 ssAI5± SW46 7, 8 ssAI12± SW46 3, 4

O-Ra 6 ssAI6± SW32 7, 8 ssAI13± SW32 3, 4

O-Ra 7 ssAI14± SW10 3, 4 ssAI15± SW10 1, 2

Setting the Over-Range Threshold

Analog input signals are connected to the over-range comparators before the gain stage, so the

threshold should be set in accordance with the signal level at the sbRIO-9687 input, which is

the breakout connector or inverter connector. The over-range circuit has a gain of 0.5 that

should be considered when setting the threshold.

The over-range threshold can be set by using the GPIC analog outputs or by populating an

onboard resistive divider.

To use the GPIC analog output for the set point, configure AO for onboard use; see Analog

Output Configuration on page 27 for details. For each over-range comparator, set the

sbRIO-9687 User Manual | © National Instruments | 29

Page 30

corresponding AO channel to the appropriate DC value. The comparator threshold is twice the

set AO voltage and acts for both positive and negative input voltages.

VAO=

V

tℎresℎold

2

Note If GPIC analog outputs are used for the over-range comparator set point, the

corresponding contact on switch SW21 should be turned ON.

If using the onboard resistors to set the over-range threshold, the analog outputs should be

disconnected from the onboard functionality. See Analog Output Configuration on page 27 for

configuration information. The set point is established by populating the corresponding

resistor for each channel. To calculate the resistor value, use the following formula:

R

tℎresℎold

=

V

tℎresℎold

10V − V

tℎresℎold

× 100kΩ

The following table provides threshold settings for the sbRIO-9687 over-range comparators.

Table 25. Over-Range Comparator Threshold Setting

Circuit Set Point 1 Set Point 2 Over-Range OUT

O-Ra 0 AO0 R381 DIO0

O-Ra 1 AO1 R383 DIO1

O-Ra 2 AO2 R373 DIO2

O-Ra 3 AO3 R386 DIO3

O-Ra 4 AO4 R394 DIO4

O-Ra 5 AO5 R396 DIO5

O-Ra 6 AO6 R403 DIO6

O-Ra 7 AO7 R244 DIO7

Note If any of the lines DIO0 to DIO7 are to be used for the extension board, they

should be disconnected from the onboard functionality by depopulating the

corresponding 0 Ω resistor. See LVTTL Lines on page 38 for details.

Sourcing Digital Input

The GPIC has 28 sourcing digital inputs grouped in two ports. Each of the sourcing digital

inputs is connected to a breakout connector on the sbRIO-9687 interface board. The DI lines

30 | ni.com | sbRIO-9687 User Manual

Page 31

used onboard can be disconnected from the sbRIO-9687 circuitry by depopulating the 0 Ω

resistors.

The following figure shows a block diagram for the sourcing digital input circuitry.

Figure 15. Sourcing Digital Input Block Diagram

Breakout

Connector

Onboard

Functionality

GPIC

Configurable position

DI Port 0

DI Port 1

The sourcing DI lines have the same specifications as the sourcing DI lines of the GPIC. Port 1

should be powered at the VI_P1 pin for proper operation. The digital input operates in the low

range or high range based on the VI_P1 voltage.

Note If no device is connected to the sourcing digital input, the channel registers as

OFF. If the input is connected to ground, the channel registers as ON.

Sourcing Digital Input Connector

Sourcing digital inputs are available at breakout connector J12. Refer to the following table for

pinout information.

Table 26. J12 Sourcing Digital Input Connector Pinout

Pin Signal Pin Signal

1 GND 19 GND

2 DI_P0.0 20 DI_P0.1

3 DI_P0.2 21 DI_P0.3

4 DI_P0.4 22 DI_P0.5

5 DI_P0.6 23 DI_P0.7

6 DI_P0.8 24 DI_P0.9

7 DI_P0.10 25 DI_P0.11

8 DI_P0.12 26 DI_P0.13

9 +24 V 27 +24 V

10 GND 28 GND

sbRIO-9687 User Manual | © National Instruments | 31

Page 32

Table 26. J12 Sourcing Digital Input Connector Pinout (Continued)

Pin Signal Pin Signal

11 DI_P1.2 29 DI_P1.3

12 DI_P1.4 30 DI_P1.5

13 DI_P1.6 31 DI_P1.7

14 DI_P1.8 32 DI_P1.9

15 DI_P1.10 33 DI_P1.11

16 DI_P1.12 34 DI_P1.13

17 GND 35 VI_P1

18 Not Connected 36 Not Connected

Sourcing Digital Input Configuration

Port 0 of the sourcing digital input is powered at +24 V through the sbRIO-9687 interface

board. This power is available at the DI connector on pins 9 and 27. The +24 V can be used to

power external circuits or port 1.

Port 1 is not powered from sbRIO-9687 interface board; it should be powered externally at a

voltage that matches the voltage levels of the application. Power for port 1 is connected at pins

18 and 36 of J12 connector.

Port 0 DI lines are used on the sbRIO-9687 interface board. For details, refer to Halt Signals

on page 36 and GPIO Signals on page 37. If Port 0 DI lines are not used for the application,

they can be disconnected from onboard functionality by depopulating the corresponding

resistor.

Note If port 0 sinking DI lines are used outside the sbRIO-9687, they should be

disconnected from onboard functionality.

The following table provides information about the onboard function and corresponding

resistor for sourcing DI signals.

Table 27. Sourcing Digital Input Signals

GPIC DI Signal Onboard Function Disconnecting Resistor

DI_P0.0 HALT0 R550

DI_P0.1 HALT1 R570

DI_P0.2 HALT2 R554

32 | ni.com | sbRIO-9687 User Manual

Page 33

Table 27. Sourcing Digital Input Signals (Continued)

GPIC DI Signal Onboard Function Disconnecting Resistor

DI_P0.3 HALT3 R535

DI_P0.4 HALT4 R516

DI_P0.5 HALT5 R633

DI_P0.6 HALT6 R566

DI_P0.7 GPIO0 R500

DI_P0.8 GPIO1 R501

DI_P0.9 GPIO2 R497

DI_P0.10 GPIO3 R498

DI_P0.11 GPIO4 R572

DI_P0.12 GPIO5 R499

DI_P0.13 GPIO6 R573

Sinking Digital Output

The GPIC has 24 sinking digital outputs. Each sinking DO is connected to the breakout

connector. The sbRIO-9687 interface board uses some of the DO lines, which can be

disconnected from sbRIO-9687 circuitry by depopulating 0 Ω resistors.

The sinking DO lines have the same electrical specifications as the DO lines of the GPIC. For

more information, refer to the NI 9683 User Manual and Specifications or the NI 9684 User

Manual and Specifications. The GPIC has current sinking digital outputs, which means that

the output pin is driven to ground (GND) when the channel is ON.

The following figure is a block diagram of the sinking digital output.

Figure 16. Sinking Digital Output Block Diagram

Breakout

Connector

Onboard

Functionality

GPIC

Configurable position

DO

sbRIO-9687 User Manual | © National Instruments | 33

Page 34

Sinking DO Connector

Sinking digital outputs are available at breakout connector J9. The following table contains

pinout information for the sinking DO connector.

Table 28. J9 Sinking Digital Output Pinout

Pin Signal Pin Signal

1 GND 19 GND

2 DO_0 20 DO_1

3 DO_2 21 DO_3

4 DO_4 22 DO_5

5 DO_6 23 DO_7

6 DO_8 24 DO_9

7 DO_10 25 DO_11

8 DO_12 26 DO_13

9 — 27 —

10 GND 28 GND

11 DO_14 29 DO_15

12 DO_16 30 DO_17

13 DO_18 31 DO_19

14 DO_20 32 DO_21

15 DO_22 33 DO_23

16 GND 34 GND

17 GND 35 GND

18 — 36 —

Sinking Digital Output Configuration

The first seven digital output lines are used on the sbRIO-9687 interface board for inverter

signals. See Inverter Digital Signals on page 35 for more details. If sinking digital outputs

need to be used externally, they can be disconnected from onboard functionality by

depopulating the corresponding resistors. The following table provides information about the

onboard function and corresponding resistor for sinking DO signals.

34 | ni.com | sbRIO-9687 User Manual

Page 35

Table 29. Sinking Digital Output Signals

GPIC DO Signal Onboard Function Resistor

DO_0 HALT0 R524

DO_1 HALT1 R552

DO_2 HALT2 R508

DO_3 HALT3 R534

DO_4 HALT4 R517

DO_5 HALT5 R632

DO_6 HALT6 R567

Inverter Digital Signals

Semikron inverters have several digital signals that can be read by and in some case written by

the GPIC. The functionality of the digital signals depends on the inverter type and is described

in Semikron documentation. The following tables provide information about the Semikron

inverter digital signal connections.

Table 30. Semikron Inverter Digital Signal Connections (Single-Phase Inverters)

Inverter

Connector

Signal

(Semikron)

R/W Inv. 0 Inv. 1 Inv. 2 Inv. 3 Inv. 4 Inv. 5 Inv. 6

SKiiP 4 CMM_HALT R/W HALT0 HALT1 HALT2 HALT3 HALT4 HALT5 HALT6

CMM_GPIO R GPIO0 GPIO1 GPIO2 GPIO3 GPIO4 GPIO5 GPIO6

CMM_GPIO2 R — — — — — — —

SKiiP 3

GB

ERROR out R HALT0 HALT1 HALT2 HALT3 HALT4 HALT5 HALT6

Overtemp out R GPIO0 GPIO1 GPIO2 GPIO3 GPIO4 GPIO5 GPIO6

SemikubeGBIF_CMN_nHALT R/W HALT0 HALT1 HALT2 HALT3 HALT4 HALT5 HALT6

IF_CMN_GPIO R/W GPIO0 GPIO1 GPIO2 GPIO3 GPIO4 GPIO5 GPIO6

sbRIO-9687 User Manual | © National Instruments | 35

Page 36

Table 31. Semikron Inverter Digital Signal Connections (Three-Phase Inverters)

Inverter Connector Signal (Semikron) Read/Write Inv. 0 Inv. 1

SKiiP 3 GD ERROR HB1 out R HALT0 HALT3

ERROR HB2 out R HALT1 HALT4

ERROR HB3 out R HALT2 HALT5

Overtemp out R GPIO0 GPIO5

Semikube SL GD IF_CMN_nHALT R/W HALT0 HALT5

IF_CMN_GPIO R GPIO0 GPIO5

Semikube GD IF_CMN_nHALT R/W HALT0 HALT5

Reserved R/W GPIO0 GPIO5

Halt Signals

The sbRIO-9687 HALT signals are bidirectional. Both ends of the signal line use a pull-up

resistor and a transistor for pull-down functionality. Both the controller and the inverter can set

or read the status of the signal line. The following diagram shows the HALT signal schematic.

Figure 17. HALT Signal Schematic

Vp

Write

Read

Inverter

sbRIO-9687

Vp

DI

DO

To read the line status, set the corresponding sinking digital output to high; the logic level will

be read on the corresponding sourcing digital input. To write to the line, set the sinking digital

output to low or high.

The following table shows the mapping between inverter HALT signals and GPIC sourcing

DO and sinking DI.

36 | ni.com | sbRIO-9687 User Manual

Page 37

Table 32. Mapping for HALT, Sourcing DO, and Sinking DI Signals

HALT Lines GPIC DI Line GPIC DO Line

HALT0 DI_P0.0 DO_0

HALT1 DI_P0.1 DO_1

HALT2 DI_P0.2 DO_2

HALT3 DI_P0.3 DO_3

HALT4 DI_P0.4 DO_4

HALT5 DI_P0.5 DO_5

HALT6 DI_P0.6 DO_6

GPIO Signals

The sbRIO-9687 GPIO signals are unidirectional. The signals can only be read by the GPIC.

On the inverter side, the signal has a pull-up to 24 V for SKiiP 4, Semikube GB, Semikube

GD, Semikube SL GD inverters, and it is open collector for SKiiP 3 GB and SKiiP 3 GD

inverters. The following figure is a schematic diagram of the GPIO signals.

Figure 18. GPIO Signal Schematic

+24 V

Write

+24 V

DI

Inverter

SKiiP 3

InvertersbRIO-9687 sbRIO-9687

+24 V

DI

Write

The GPIO signals can be read on one of the sourcing digital input lines. The following table

shows the mapping between inverter GPIO signals and GPIC sinking digital input.

Table 33. Mapping Between GPIO Signals and Sinking Digital Input

GPIO Line (Inverters) DI Line (GPIC)

GPIO0 DI_P0.7

GPIO1 DI_P0.8

GPIO2 DI_P0.9

GPIO3 DI_P0.10

sbRIO-9687 User Manual | © National Instruments | 37

Page 38

Table 33. Mapping Between GPIO Signals and Sinking Digital Input (Continued)

GPIO Line (Inverters) DI Line (GPIC)

GPIO4 DI_P0.11

GPIO5 DI_P0.12

GPIO6 DI_P0.13

LVTTL Lines

The sbRIO-9683 or sbRIO-9684 GPIC has 32 LVTTL digital signals. These signals are high

speed bidirectional lines with 3.3 V logical levels. All LVTTL lines are used for onboard

functions on the sbRIO-9687. All LVTTL signals are available at the two expansion board

connectors. The LVTTL signals are connected directly to the expansion board connectors and

have 0 Ω resistors to onboard functions.

The following figure shows a block diagram for the LVTTL lines.

Figure 19. LVTTL Lines Block Diagram

GPIC

LVTTL

Extension

Connector

Onboard

Functionality

Connector

Configurable position

The following table provides information about the onboard function and corresponding

resistor for the LVTTL lines.

Note It is highly recommended to disconnect the LVTTL signals from sbRIO-9687

functionality when they are being used with an expansion board.

Table 34. LVTTL Lines

GPIC Signal Onboard Function Direction (to

GPIC)

Active State Disconnecting

Resistor

DIO0 Over Range 0 Input Low R165

DIO1 Over Range 1 Input Low R156

DIO2 Over Range 2 Input Low R155

38 | ni.com | sbRIO-9687 User Manual

Page 39

Table 34. LVTTL Lines (Continued)

GPIC Signal Onboard Function Direction (to

GPIC)

Active State Disconnecting

Resistor

DIO3 Over Range 3 Input Low R150

DIO4 Over Range 4 Input Low R142

DIO5 Over Range 5 Input Low R134

DIO6 Over Range 6 Input Low R133

DIO7 Over Range 7 Input Low R129

DIO8 Feedback_0.0 Input Low/High R123

DIO9 Feedback_0.1 Input Low/High R114

DIO10 Feedback_0.2 Input Low/High R113

DIO11 Feedback_0.3 Input Low/High R104

DIO12 Feedback_0.4 Input Low/High R96

DIO13 Feedback_0.5 Input Low/High R95

DIO14 Hall_0.0 Input Low R86

DIO15 Hall_0.1 Input Low R78

DIO16 Hall_0.2 Input Low R65

DIO17 Feedback_1.0 Input Low/High R72

DIO18 Feedback_1.1 Input Low/High R73

DIO19 Feedback_1.2 Input Low/High R79

DIO20 Feedback_1.3 Input Low/High R87

DIO21 Feedback_1.4 Input Low/High R97

DIO22 Feedback_1.5 Input Low/High R98

DIO23 Hall_1.0 Input Low R105

DIO24 Hall_1.1 Input Low R115

DIO25 Hall_1.2 Input Low R124

DIO26 SCL (I2C RH sensor) Input/Output — R125

DIO27 SDA (I2C RH sensor) Input/Output — R130

sbRIO-9687 User Manual | © National Instruments | 39

Page 40

Table 34. LVTTL Lines (Continued)

GPIC Signal Onboard Function Direction (to

GPIC)

Active State Disconnecting

Resistor

DIO28 MUX A0 (TC Input) Output Low/High R135

DIO29 DS3 (Green LED) Output Low R136

DIO30 DS2 (Green LED) Output Low R143

DIO31 DS1 (Red LED) Output Low R151

The sbRIO-9683 LVTTL DIO lines connect directly to the FPGA DIO on the

sbRIO-9505/9506/9507 and are unbuffered and unprotected.

Caution Operating the LVTTL DIO outside the rated specifications may result in

permanent damage to the FPGA on the sbRIO-9605/9606/9607.

If overshoot, undershoot, and signal integrity are concerns for your application, use a single

load per line that does not exceed 25 pF.

The LVTTL DIO channels on the sbRIO-9687 are routed with a 50 Ω impedance trace. It is

recommended to route all external circuitry with a similar impedance to ensure the best signal

quality.

Expansion Board

LVTTL lines are available at two expansion connectors that allow a custom expansion board

to be placed on top of the sbRIO-9687 interface board.

Expansion Board Connectors

Each expansion board connector (J7 and J8) consists of a 26-pin header. For information about

mating connectors, refer to the Connectors on page 4 section. The following tables provide

pinout information for the expansion board connectors.

Table 35. LVTTL Expansion Connector Pinout (J7)

Pin Signal Pin Signal

1 DIO0 2 DIO1

3 DIO2 4 GND

5 DIO3 6 DIO4

7 GND 8 DIO5

40 | ni.com | sbRIO-9687 User Manual

Page 41

Table 35. LVTTL Expansion Connector Pinout (J7) (Continued)

Pin Signal Pin Signal

9 DIO6 10 DIO7

11 DIO8 12 GND

13 DIO9 14 DIO10

15 GND 16 DIO11

17 DIO12 18 DIO13

19 DIO14 20 GND

21 GND 22 DIO15

23 +3.3 V 24 +3.3 V

25 +5 V 26 +5 V

Table 36. LVTTL Expansion Connector Pinout (J8)

Pin Signal Pin Signal

1 DIO16 2 DIO17

3 DIO18 4 GND

5 DIO19 6 DIO20

7 GND 8 DIO21

9 DIO22 10 DIO23

11 DIO24 12 GND

13 DIO25 14 DIO26

15 GND 16 DIO27

17 DIO28 18 DIO29

19 DIO30 20 GND

21 GND 22 DIO31

23 +3.3 V 24 +3.3 V

25 +5 V 26 +5 V

sbRIO-9687 User Manual | © National Instruments | 41

Page 42

Expansion Board Power

The expansion board connectors have pins for +3.3 V and a +5 V power.

The +3.3 V is supplied directly by the GPIC, and the power is provided at the same time as the

sbRIO-9607 FPGA power. The current on the +3.3 V rail should not exceed 330 mA. For

details, refer to the NI sbRIO-9607 Specifications.

The +5 V pin is connected to the sbRIO-9687 internal rail and can supply up to 1 A for both

connectors.

Note A short circuit on the +5 V rail could shut down the sbRIO-9687 and may

require cycling the +24 V input.

Expansion Board Dimensions

An expansion board must have two mating connectors on the secondary side, each with pin 1

located as shown in the following figure.

Figure 20. Expansion Board Dimensions

4.5 in (114.3 mm)

2x 4.3 in (109.22 mm)

Pin 1 Location

26 POS 0.1” Pin Receptacles

Placed Bottom Side

1.55 in (39.37 mm)

2x .0 in (0 mm)

.2 in (5.08 mm)

.2 in (5.08 mm)

2x .0 in (0 mm)

2x 6.68 in (169.67 mm)

6.88 in (174.75 mm)

1.14 in (28.85 mm)

5.54 in (140.82 mm)

2.75 in (69.85 mm)

Top Side Shown

Feedback Input

The sbRIO-9687 interface board includes two connectors for feedback signals. Each connector

has six RS485 digital inputs for quadrature encoders, named Feedback_x.x_x, and three

inputs for open collector Hall sensors, named Hall_x.x.

Feedback Connectors

The following tables provide pinout information for the J6 and J10 feedback connectors.

42 | ni.com | sbRIO-9687 User Manual

Page 43

Table 37. J6 Feedback Connector Pinout

Pin Signal Pin Signal

1 GND 13 GND

2 Feedback_0.0_A 14 Feedback_0.0_B

3 Feedback_0.1_A 15 Feedback_0.1_B

4 Feedback_0.2_A 16 Feedback_0.2_B

5 GND 17 GND

6 Feedback_0.3_A 18 Feedback_0.3_B

7 Feedback_0.4_A 19 Feedback_0.4_B

8 Feedback_0.5_A 20 Feedback_0.5_B

9 GND 21 GND

10 Hall_0.0 22 Hall_0.1

11 Hall_0.2 23 GND

12 +5 V 24 +5 V

Table 38. J10 Feedback Connector Pinout

Pin Signal Pin Signal

1 GND 13 GND

2 Feedback_1.0_A 14 Feedback_1.0_B

3 Feedback_1.1_A 15 Feedback_1.1_B

4 Feedback_1.2_A 16 Feedback_1.2_B

5 GND 17 GND

6 Feedback_1.3_A 18 Feedback_1.3_B

7 Feedback_1.4_A 19 Feedback_1.4_B

8 Feedback_1.5_A 20 Feedback_1.5_B

9 GND 21 GND

10 Hall_1.0 22 Hall_1.1

sbRIO-9687 User Manual | © National Instruments | 43

Page 44

Table 38. J10 Feedback Connector Pinout (Continued)

Pin Signal Pin Signal

11 Hall_1.2 23 GND

12 +5 V 24 +5 V

See the LVTTL Lines on page 38 section for more information on how feedback signals are

connected to the GPIC digital lines.

RS485 Input Signals

RS485 input signals are used for interfacing with a large selection of encoders. Differential

RS485 signals are connected between the Feedback_x.x_A and Feedback_x.x_B lines. Each

input line can support up to ±25 V fault voltage. In normal operating mode, the input voltage

should be kept within the RS485 specifications.

The outputs of the RS485 receivers are directed to the LVTTL lines. The name of the

corresponding LVTTL signal is Feedback_x.x. For details, refer to LVTTL Lines on page

38.

Hall Sensor Input Signals

Each of the six Hall sensor inputs are designed for open collector driving outputs. Each input

has a 10 kΩ pull-up resistor connected to +5 V. The inputs have a Schmitt trigger input circuit

that reduces the false transitions for a noisy input signal. The output of the Schmitt trigger

circuit is connected to the LVTTL signals. For details, refer to LVTTL Lines on page 38.

+5 V Output

The feedback connectors have an +5 V output that can be used for powering encoders. The

+5 V output is connected to the sbRIO-9687 internal rail and can supply up to 0.5 A for each

connector.

Note A short circuit on the +5 V rail could shut down the sbRIO-9687 and may

require cycling the +24 V input.

Debug LEDs

The sbRIO-9687 interface board provides four LEDs for debugging purposes. One LED is

powered by the 5 V rails, and the others are driven by the LVTTL lines. The LED turns ON

when the corresponding LVTTL line is low. The following table provides information for each

LED, including reference indicator, color and LVTTL command line.

44 | ni.com | sbRIO-9687 User Manual

Page 45

Table 39. LED Command Lines

LED Reference Indicator LED Color LVTTL Command Line

DS1 RED DIO31

DS2 GREEN DIO30

DS3 GREEN DIO29

DS4 GREEN Always On

Thermistor

The sbRIO-9687 has support for two 10 kΩ thermistors for temperature measurement. The

sensors are connected to a 2.5 V reference through a 10 kΩ precision resistor. The thermistor

voltage is amplified by a factor of 2 on a gain stage, and then directed to the GPIC scanned

analog inputs.

Figure 21. Thermistor Measurement Circuit

ADCx2

sbRIO-9687 sbRIO-9683/9684

GAIN

Differential

Amplifier

scAI

GNDGND

Therm

Thermistor

10kΩ

2.5V

Reference

The thermistors should be connected between the two available terminals, Therm and

Therm_GND.

Caution Do not electrically connect the thermistor body to the chassis ground or to

high voltage lines in the cabinet. Such a connection could permanently damage the

sbRIO-9687.

Thermistor Connector

The following table provides pinout information for the thermistor connector. If a shielded

cable is used for the thermistor, connect the shield to the CHASSIS GND pins.

sbRIO-9687 User Manual | © National Instruments | 45

Page 46

Table 40. J28 Thermistor Input

Pin Signal Pin Signal

1 Therm1 4 Therm0

2 Therm1_GND 5 Therm0_GND

3 CHASSIS GND 6 CHASSIS GND

Thermistor Reading

The two thermistor outputs are multiplexed into the GPIC scanned AI_7 with the help of one

LVTTL line. When the LVTTL line is 0, the Therm0 signal is connected to AI_7. When the

LVTTL line is 1, the Therm1 signal is connected to AI_7.

DIO29 AI_7 Input

0 Thermocouple 0 input (Therm0)

1 Thermocouple 1 input (Therm1)

The following formula describes how the thermistor value can be obtained from the scanned

AI voltage:

R

Tℎermistor

=

V

AI_7

5V − V

AI_7

× 10 kΩ

where

R

Thermistor

= Thermistor resistance.

V

AI_7

= Voltage reading at the GPIC scanned AI_7.

To obtain the temperature, the thermistor value must be converted into temperature units based

on the typical thermistor characteristics obtained from thermistor manufacturer.

Relative Humidity Sensor

For safety, a high voltage system should not be operated when condensation conditions are

present. The sbRIO-9687 interface board has a built-in environmental sensor that measures

temperature and relative humidity (RH) on the board.

Use the following formula to determine the RH on a different point of the cabinet:

RH

cabinet

= RH

board

× e

17.502 × T

board

240.97 + T

board

−

17.502 × T

cabinet

240.97 + T

cabinet

46 | ni.com | sbRIO-9687 User Manual

Page 47

where

RH

cabinet

= RH value at a given point inside the cabinet (%).

T

cabinet

= Temperature at the point where we want to determine the RH (˚C).

RH

board

= RH value read from the onboard RH sensor (%).

T

board

= Temperature read from the onboard RH sensor (˚C).

The RH sensor type is HDC1080 (Texas Instruments). It communicates with the GPIC through

an I2C bus connected to the LVTTL lines. The following table shows the signal assignments

for the RH sensor. Consult the Texas Instruments Web site for a full description of the RH

sensor communication protocol.

Table 41. RH Sensor I2C Lines

I2C Signal LVTTL Line

SCL DIO26

SDA DIO27

Relay Connector

The sbRIO-9687 provides connections for four relay control outputs. Each output has a relay

control DO+ and a current return pin, relay control DO-. The sbRIO-9683 and sbRIO-9684

have current sinking outputs, which means that the relay control DO+ is driven to relay control

DO- when the channel is ON.

The following table provides pinout information for the relay connector.

Table 42. J4 Relay Connector Pinout

Pin Signal Pin Signal

1 +24 V 7 +24 V

2 DO0– 8 DO0+

3 DO1– 9 DO1+

4 DO2– 10 DO2+

5 DO3– 11 DO3+

6 GND 12 GND

The relay control lines are directly connected to the GPIC relay control connector. For further

details regarding best practices for relay connections, refer to the NI 9683 User Manual and

Specifications and the NI 9684 User Manual and Specifications.

sbRIO-9687 User Manual | © National Instruments | 47

Page 48

Display Connector

The sbRIO-9687 interface board includes support to drive an Amulet Technologies display

4

that connects to sbRIO using an RS232 interface. The sbRIO-9687 provides power for the

display on a separate connector.