National Instruments sbRIO-9611, sbRIO-9612, sbRIO-9632, sbRIO-9632XT, sbRIO-9612XT User Manual

...Page 1

USER GUIDE

NI sbRIO-961x/963x/964x and

NI sbRIO-9612XT/9632XT/9642XT

Single-Board RIO OEM Devices

This document provides dimensions, pinouts, connectivity information,

and specifications for the National Instruments sbRIO-9611, sbRIO-9612,

sbRIO-9612XT, sbRIO-9631, sbRIO-9632, sbRIO-9632XT, sbRIO-9641,

sbRIO-9642, and sbRIO-9642XT. The devices are referred to inclusively in

this document as the NI sbRIO-961x/9612XT/963x/9632XT/964x/

9642XT.

Caution The NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT must be installed

inside a suitable enclosure prior to use. Hazardous voltages may be present.

Caution National Instruments makes no product safety, electromagnetic compatibility

(EMC), or CE marking compliance claims for NI sbRIO devices. The end-product supplier

is responsible for conformity to any and all compliance requirements.

Caution Exercise caution when placing the NI sbRIO devices inside an enclosure.

Auxiliary cooling may be necessary to keep the device under the maximum ambient

temperature rating for the NI sbRIO device. Refer to Specifications section for more

information about the maximum ambient temperature rating.

Page 2

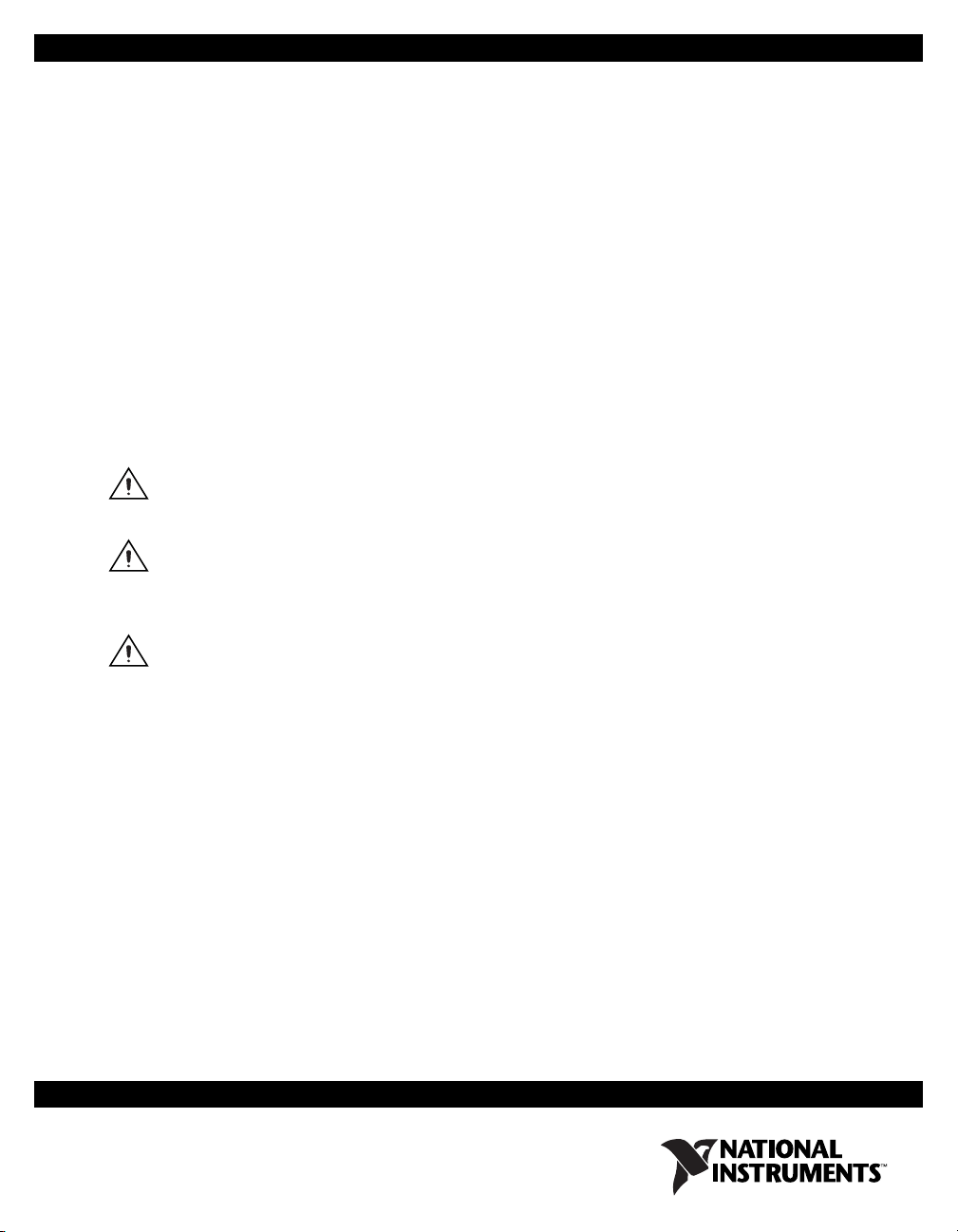

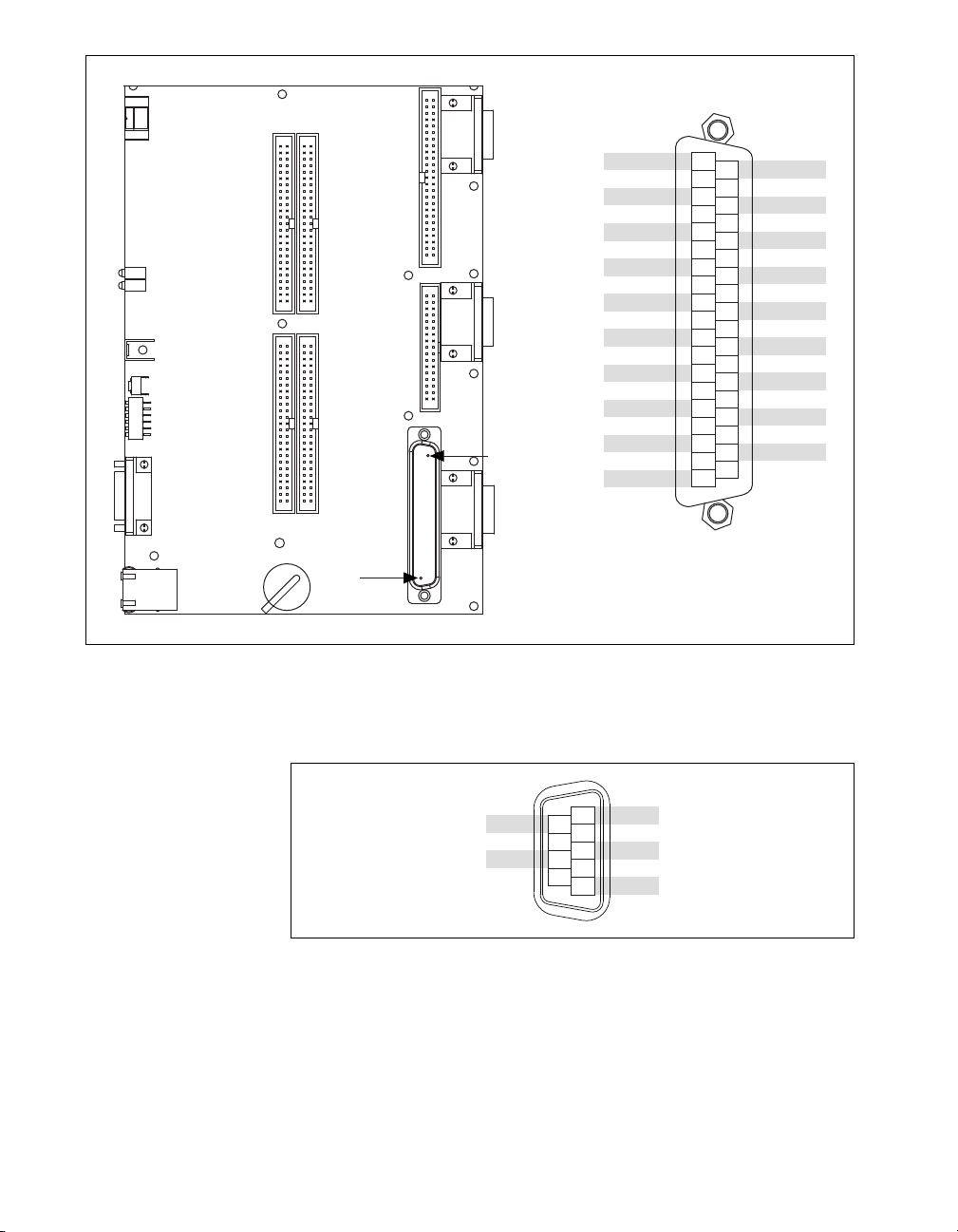

Figure 1 shows the NI sbRIO-961x/9612XT/963x/9632XT and the

NI sbRIO-964x/9642XT.

NI sbRIO-961x/9612XT/963x/9632XT NI sbRIO-964x/9642XT

Figure 1. NI sbRIO-961x/9612XT/963x/9632XT and NI sbRIO-964x/9642XT

What You Need to Get Started

This section lists the software and hardware you need to start programming

the NI sbRIO device.

Software Requirements

You need a development computer with the following software installed

on it. Go to

for information about software version compatibility.

ni.com/info and enter the Info Code rdsoftwareversion

❑ LabVIEW

❑ LabVIEW Real-Time Module

❑ LabVIEW FPGA Module

❑ NI-RIO

Hardware Requirements

You need the following hardware to use the NI sbRIO device.

❑ NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT

❑ 19–30 VDC power supply

❑ Ethernet cable

NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT 2 ni.com

Page 3

Dimensions

Note The plated mounting holes are all connected to P1, the ground lug. Connect P1 or

one of the plated mounting holes securely to earth ground. Refer to the Understanding

Ground Connections section for cautions about current loops through the grounding lug.

This section contains dimensional drawings of the NI sbRIO devices. For

three-dimensional models, refer to the Resources tab of the NI sbRIO

product page at

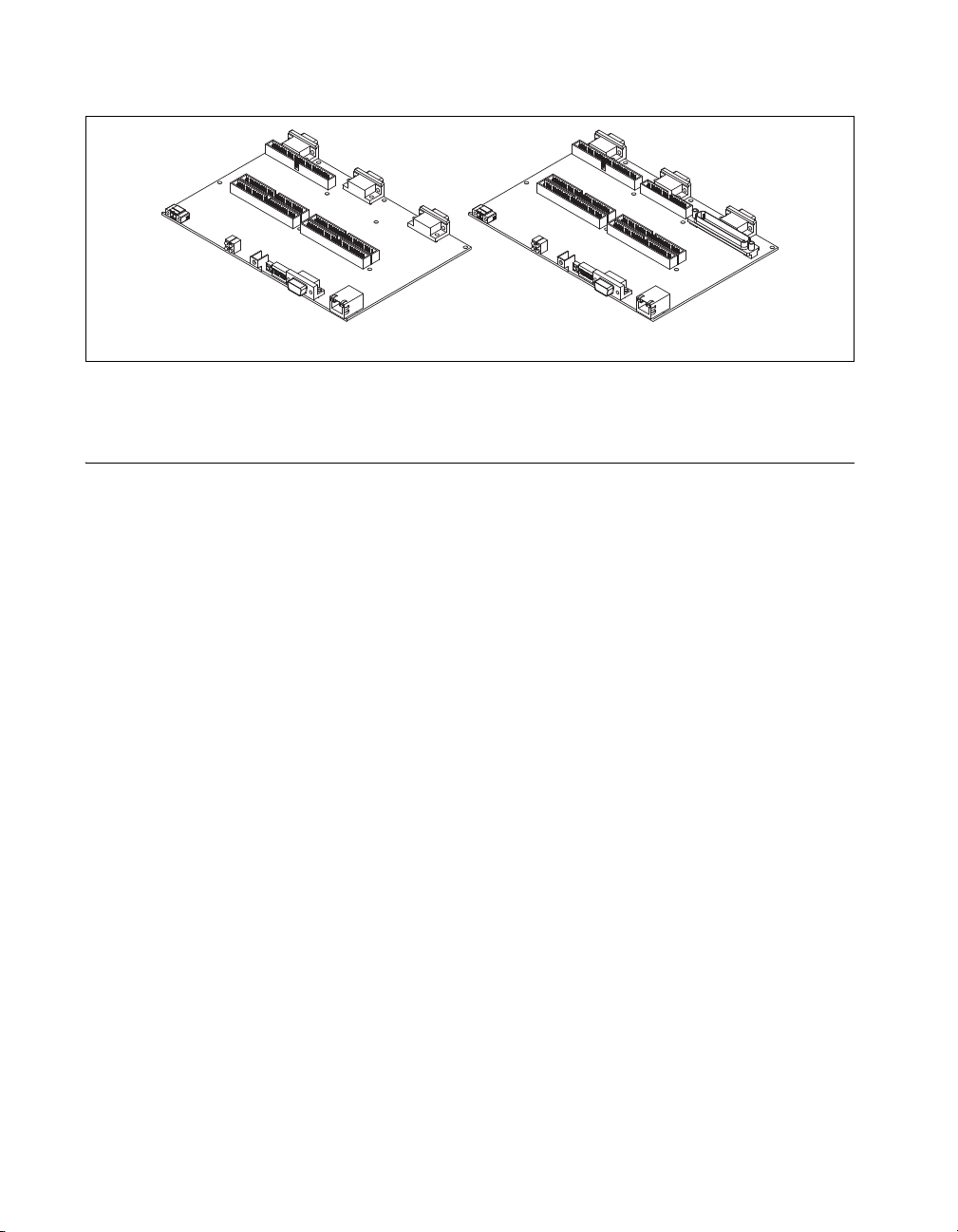

Figure 2 shows the dimensions of the NI sbRIO-961x/9612XT/963x/

9632XT/964x/9642XT.

ni.com.

© National Instruments Corporation 3 NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT

Page 4

0.166 (4.22)

0.000 (0)

0.847 (21.52)

5.492 (139.5)

5.633 (143.07)

6.617 (168.06)

2.905 (73.79)

3.100 (78.74)

6- 32 Threads

4- 40 Threads

Ø 0.112 (2.84)

Ø 0.138 (3.50)

0.080 (2.03)

0.000 (0)

0.220 (5.59)

0.180 (4.57)

0.380 (9.65)

0.365 (9.28)

0.242 (6.16)

0.327 (8.31)

0.469 (11.91)

0.625 (15.88)

1.107 (28.12)

0.000 (0)

2.091 (53.11)

4.017 (102.03)

5.001 (127.03)

6.927 (175.95)

7.911 (200.94)

0.574 (14.58)

–0.110 (2.79)

Minimum Clearance

Needed Below Board

2 mm Clearance

Required Above

This Capacitor

0.651 (16.54)

0.327 (8.31)

0.000 (0)

2.440 (61.98)

4.100 (104.14)

0.000 (0)

0.000 (0.00)

0.125 (3.18)

0.275 (6.99)

2 mm Clearance

Required Above

This Capacitor

4.400 (111.76)

5.415 (137.54)

5.550 (140.97)

0.450 (11.43)

0.131 (3.33)

3.691 (93.75)

6.796 (172.62)

7.295 (185.29)

8.200 (208.28)

8.076 (205.13)

5.826 (147.98)

4.466 (113.44)

2.916 (74.07)

1.556 (39.52)

5.121 (130.07)

12×Ø 0.134 (3.40)

Figure 2. NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT

Dimensions in Inches (Millimeters)

NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT 4 ni.com

Page 5

8.460 (214.88)

You can install up to three board-only C Series I/O modules on the

NI sbRIO device. The following figure shows the dimensions of the

NI sbRIO device with three board-only C Series I/O modules installed.

2.889 (73.38)

2.910 (73.91)

5.799 (147.29)

5.820 (147.83)

8.709 (221.21)

7.410 (188.21)

6.160 (156.46)

5.860 (148.84)

5.550 (140.97)

4.785 (121.55)

4.685 (119.00)

4.591 (116.60)

2.885 (73.28)

2.514 (63.86)

2 mm Clearance Required

Above This Capacitor

0.747 (18.97)

0.000 (0)

8×Ø 0.125 (3.18)

Ø 0.512 (13.00)

0.000 (0)

0.226 (5.74)

0.285 (7.24)

3.340 (84.84)

4.859 (123.42)

6.442 (163.63)

8.200 (208.28)

7.641 (194.08)

Figure 3. NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT with C Series Modules,

Dimensions in Inches (Millimeters)

Note

To maintain isolation clearances on the C Series modules, do not use mounting

hardware larger than 0.240 in. (6.1 mm) in diameter and maintain an air gap of at least

0.200 in. (5.0 mm) from the modules to anything else.

© National Instruments Corporation 5 NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT

Page 6

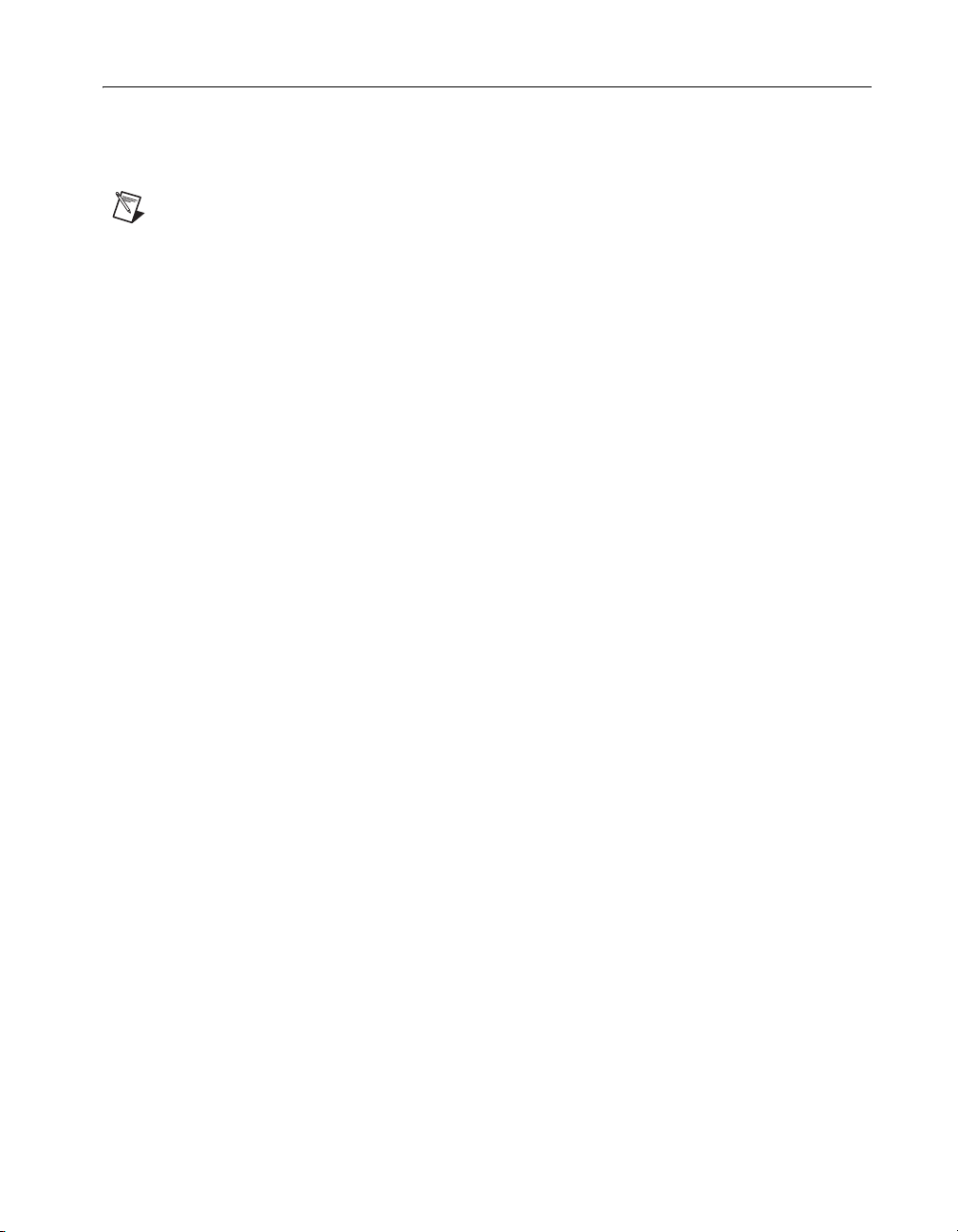

I/O and Other Connectors on the NI sbRIO Device

17

16

11

10

13

1415

9

19

6

8

12

4

1

3 722 2 2 2

2

2

2

2

2

2

2

18

5

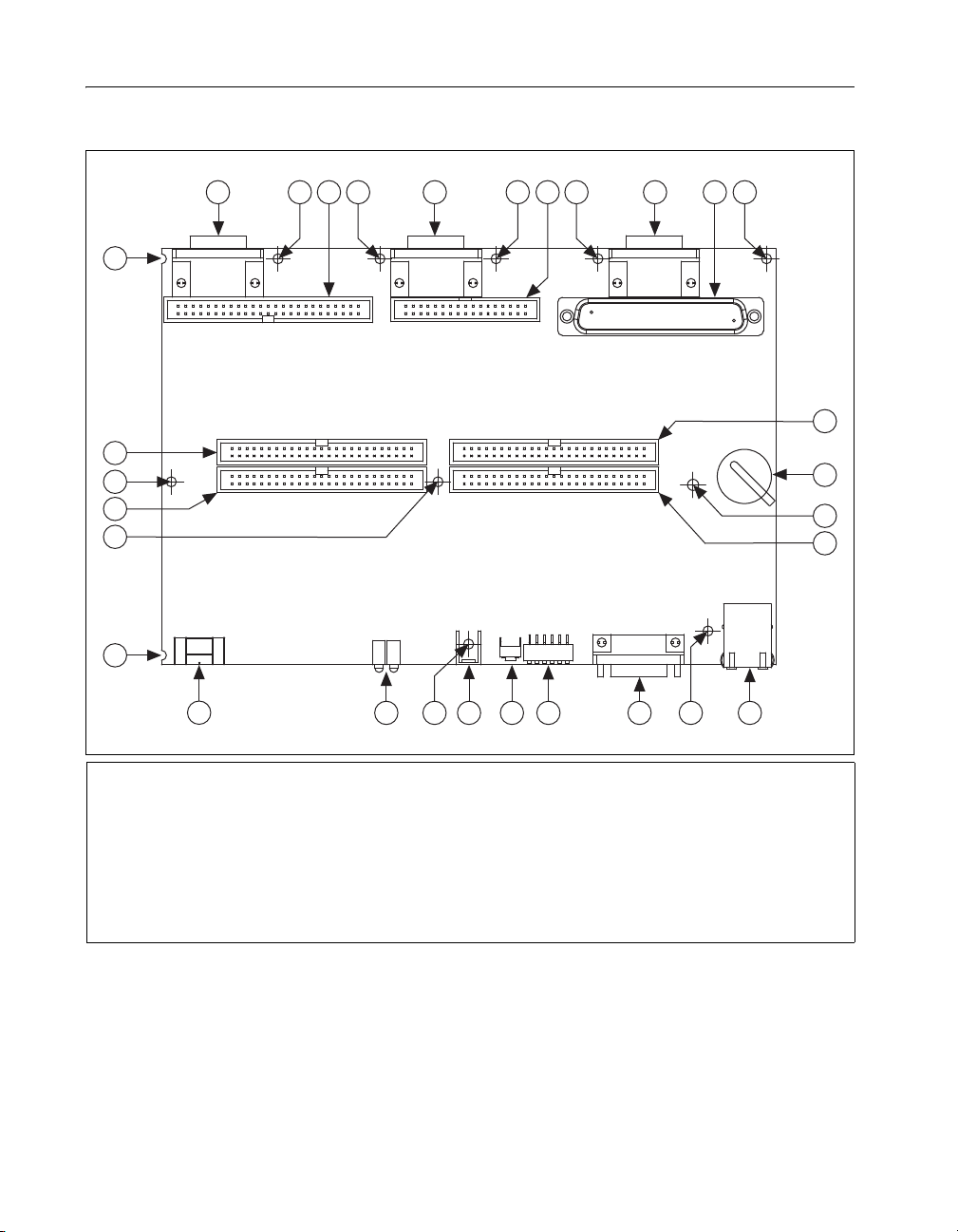

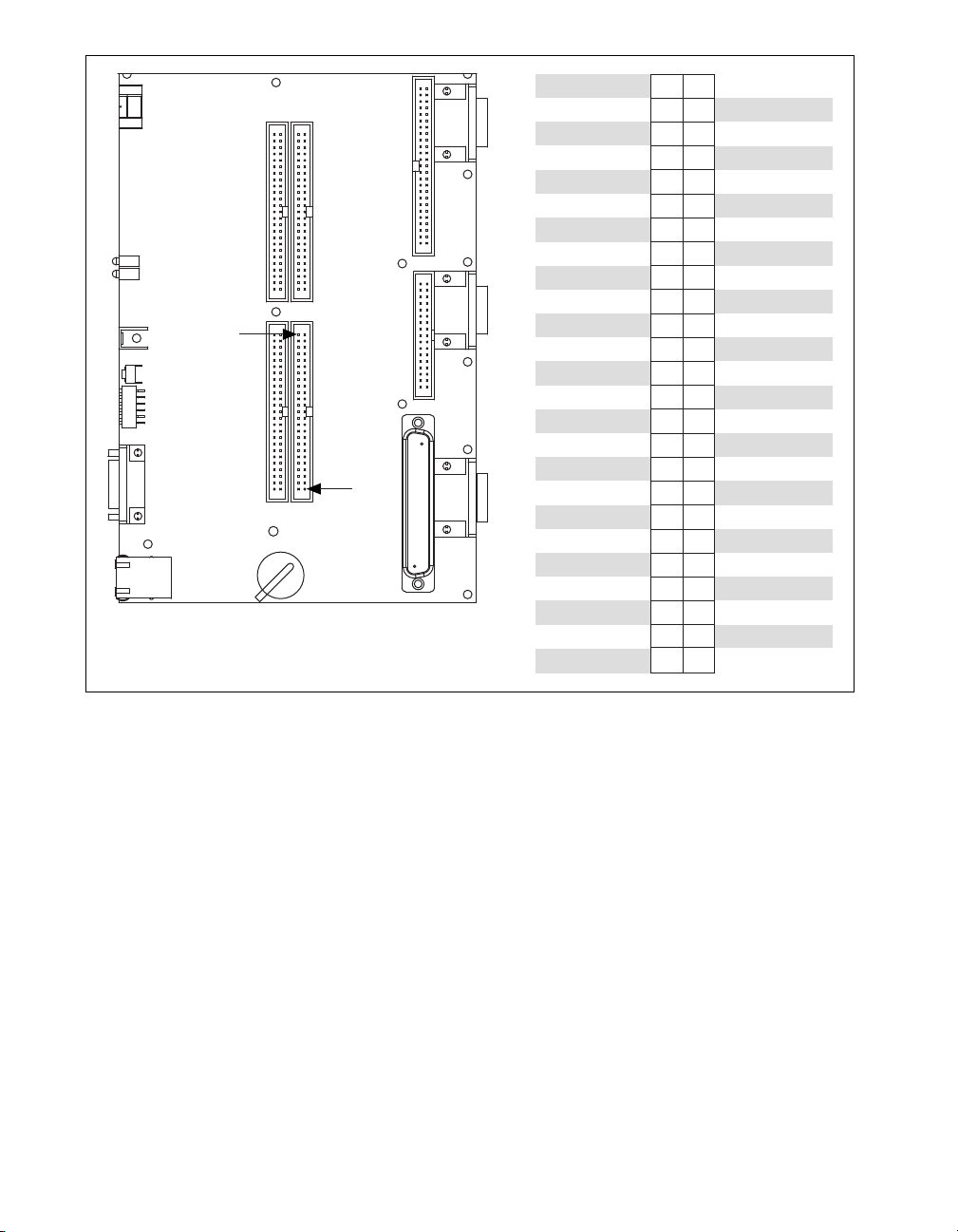

Figure 4 shows the locations of parts on the NI sbRIO device.

1 J10, Connector for C Series Module 3

2Plated Mounting Holes

3 J7, Analog I/O Connector

4 J9, Connector for C Series Module 2

5 J6, 24 V Digital Input (sbRIO-964x/9642XT Only)

6J8, Connector for C Series Module 1

7 J5, 24 V Digital Output (sbRIO-964x/9642XT Only)

8 P4, 3.3 V Digital I/O

9Backup Battery

10 P2, 3.3 V Digital I/O

11 J2, RJ-45 Ethernet Port

12 J1, RS-232 Serial Port

13 DIP Switches

14 Reset Button

15 P1, Ground Lug

16 LEDs

17 J3, Power Connector

18 P3, 3.3 V Digital I/O

19 P5, 3.3 V Digital I/O

Figure 4. NI sbRIO Device Parts Locator Diagram

NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT 6 ni.com

Page 7

Table 1 lists and describes the connectors on NI sbRIO devices and lists the

part number and manufacturer of each connector. Refer to the manufacturer

for information about using and matching these connectors.

Table 1. NI sbRIO Connector Descriptions

Connector Description

J3, Power 2-position MINI-COMBICON

header and plug,

0.285 in. (7.24 mm) high

J1, RS-232

Serial Port

9-pin DSUB plug,

0.318 in. (8.08 mm) high,

Manufacturer and

Part Number

Phoenix Contact,

1727566

Tyco Electronics,

5747840-6

Recommended

Mating Connector

Sauro,

CTF02BV8-BN

(included)

—

with 4-40 jacksockets

P2, P3, P4,

P5, J7

50-pin polarized header plug,

0.100 × 0.100 in.

3M, N2550-6002RB 3M, 8550-4500PL

(2.54 × 2.54 mm)

J5 37-pin DSUB plug

with 4-40 jacksockets

J6 34-pin polarized header plug,

D37P24B6GV00LF

3M, N2534-6002RB 3M, 8534-4500PL

FCI,

FCI, D37S24B6GV00

0.100 × 0.100 in.

(2.54 × 2.54 mm)

*

(NI sbRIO-964x/9642XT Only) Use Samtec connector ESW-125-33-S-D if you are connecting one board to P2/P3/P4/P5/J7 and

J5 to accommodate for the height of the J5 connector.

†

(NI sbRIO-964x/9642XT Only) Use Samtec connector ESW-117-33-S-D if you are connecting one board to J6 and J5 to

accommodate for the height of the J5 connector.

*

†

© National Instruments Corporation 7 NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT

Page 8

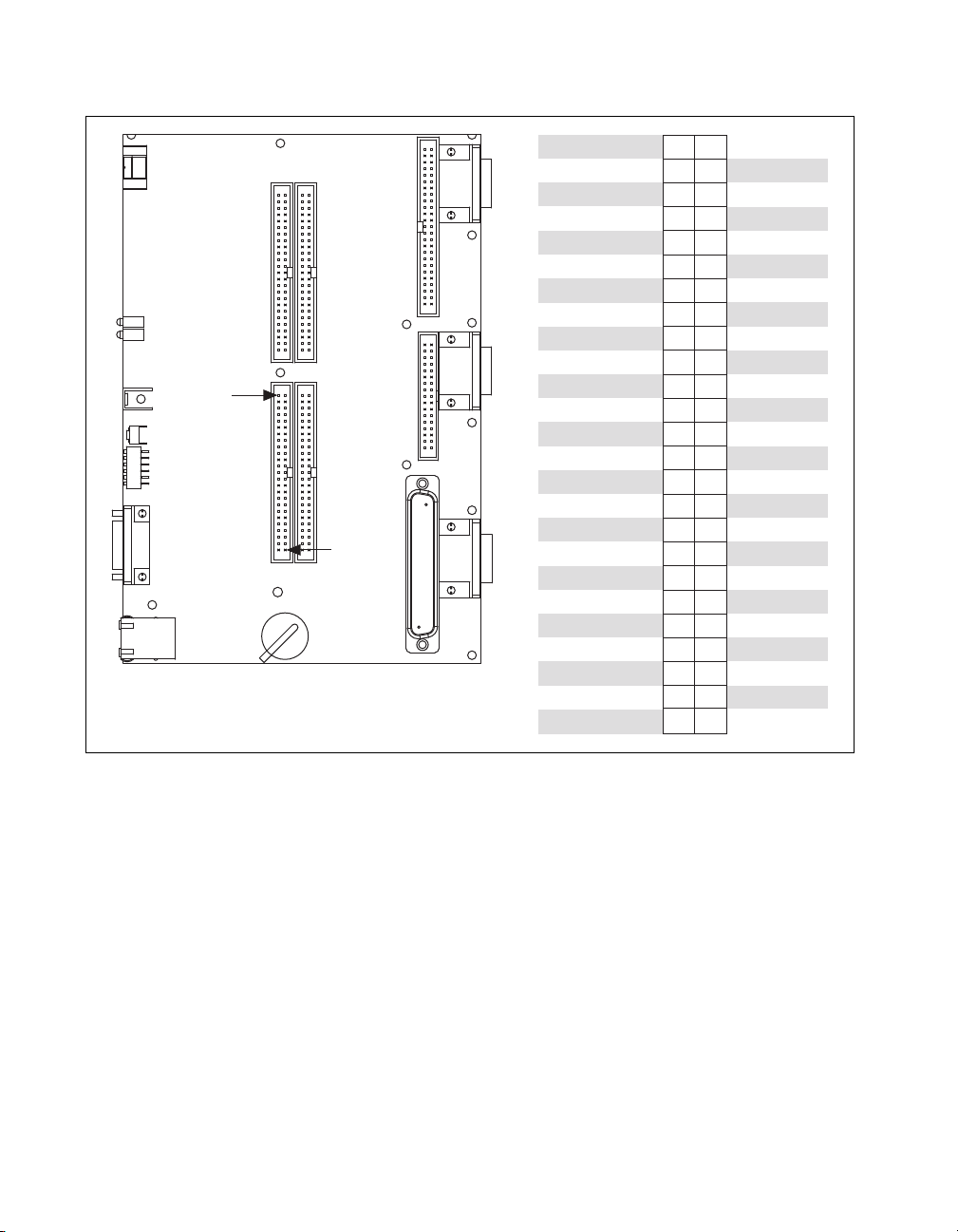

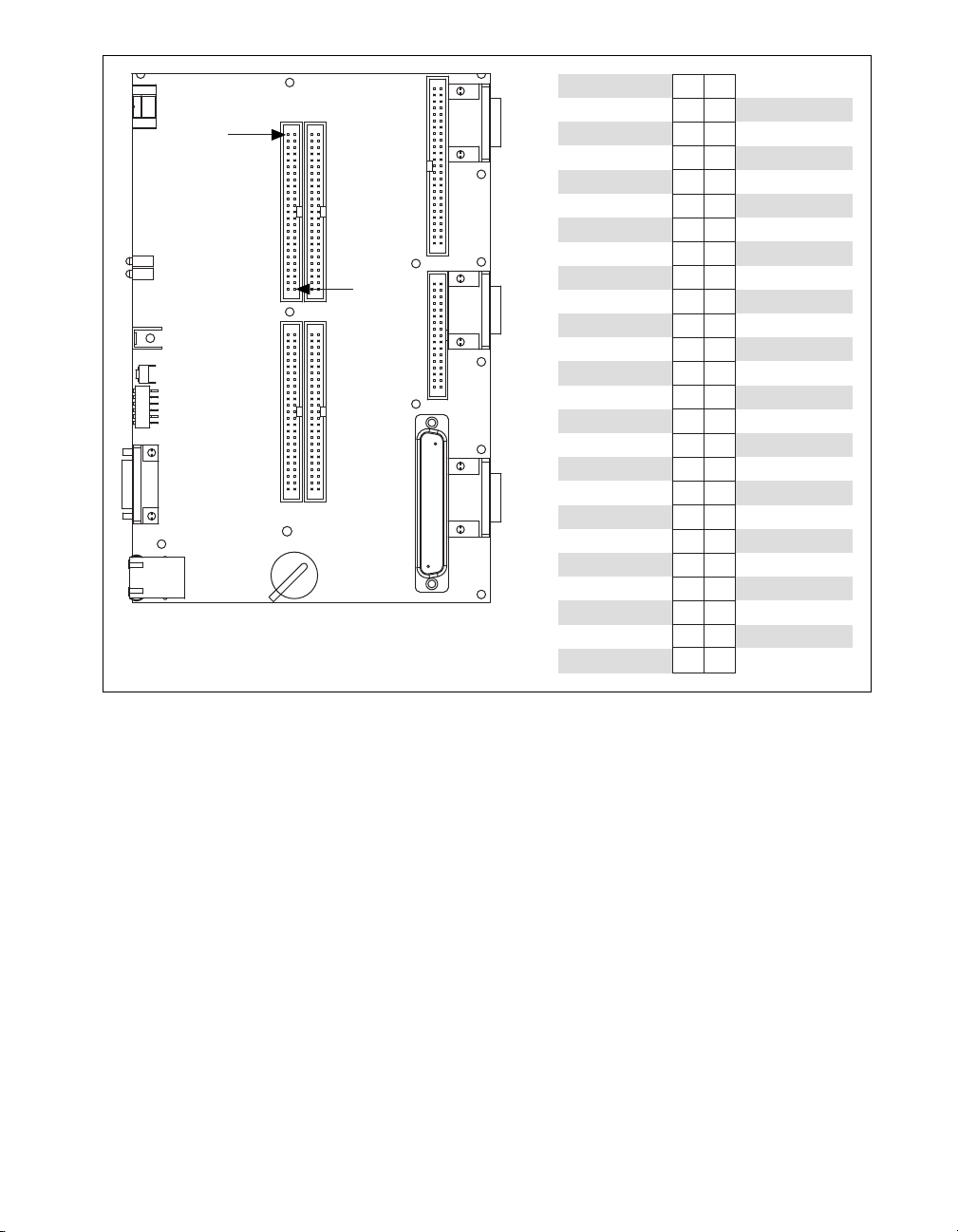

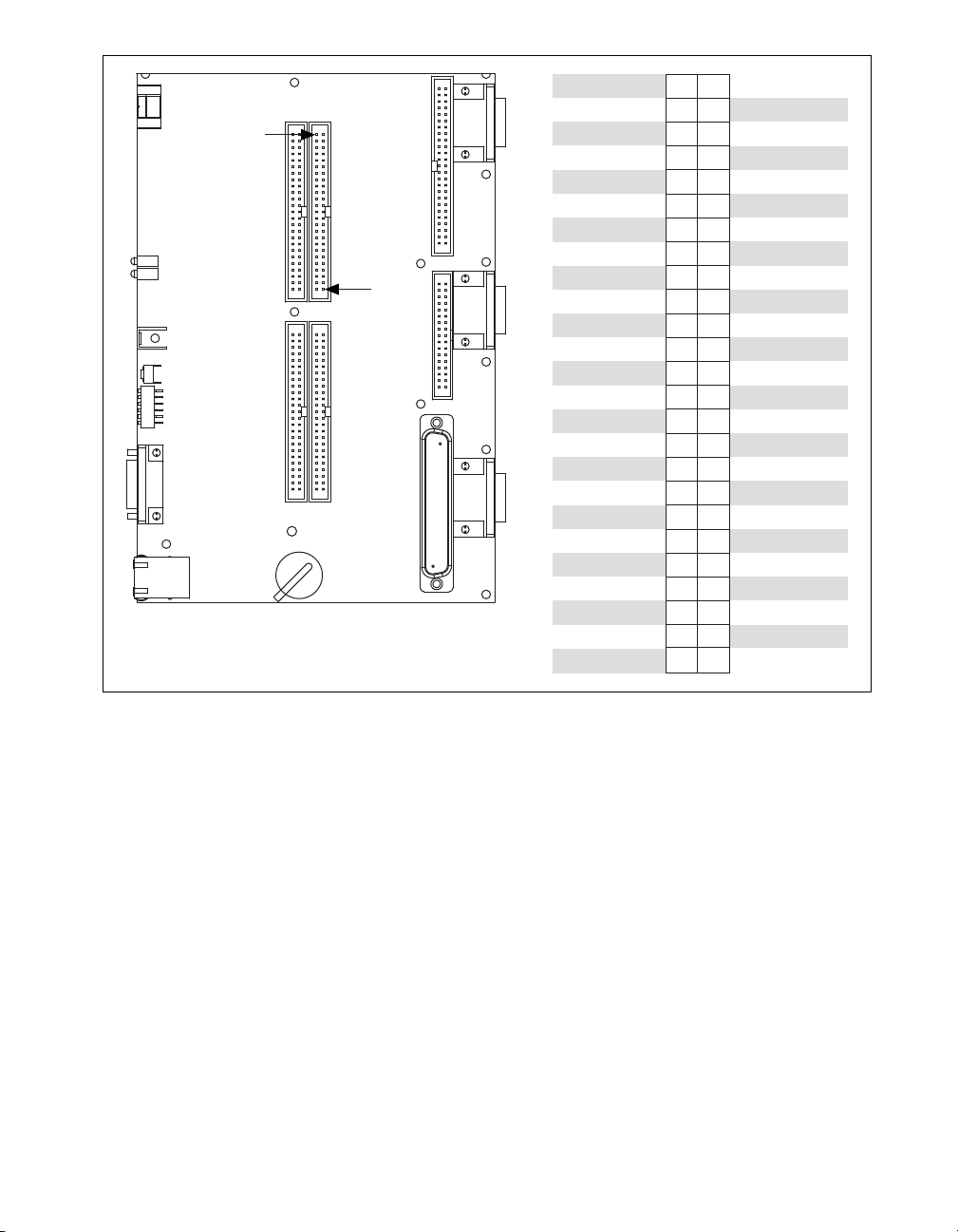

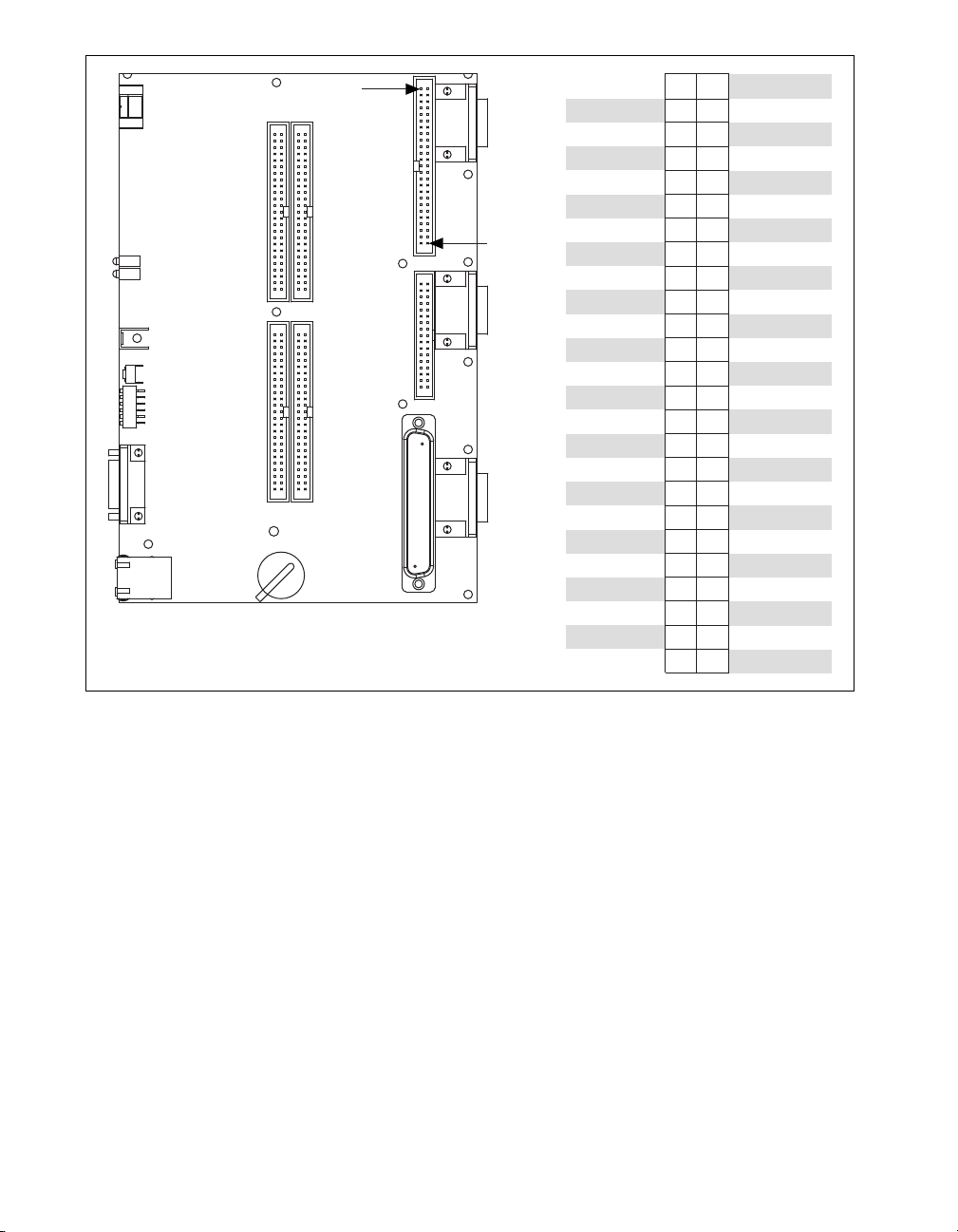

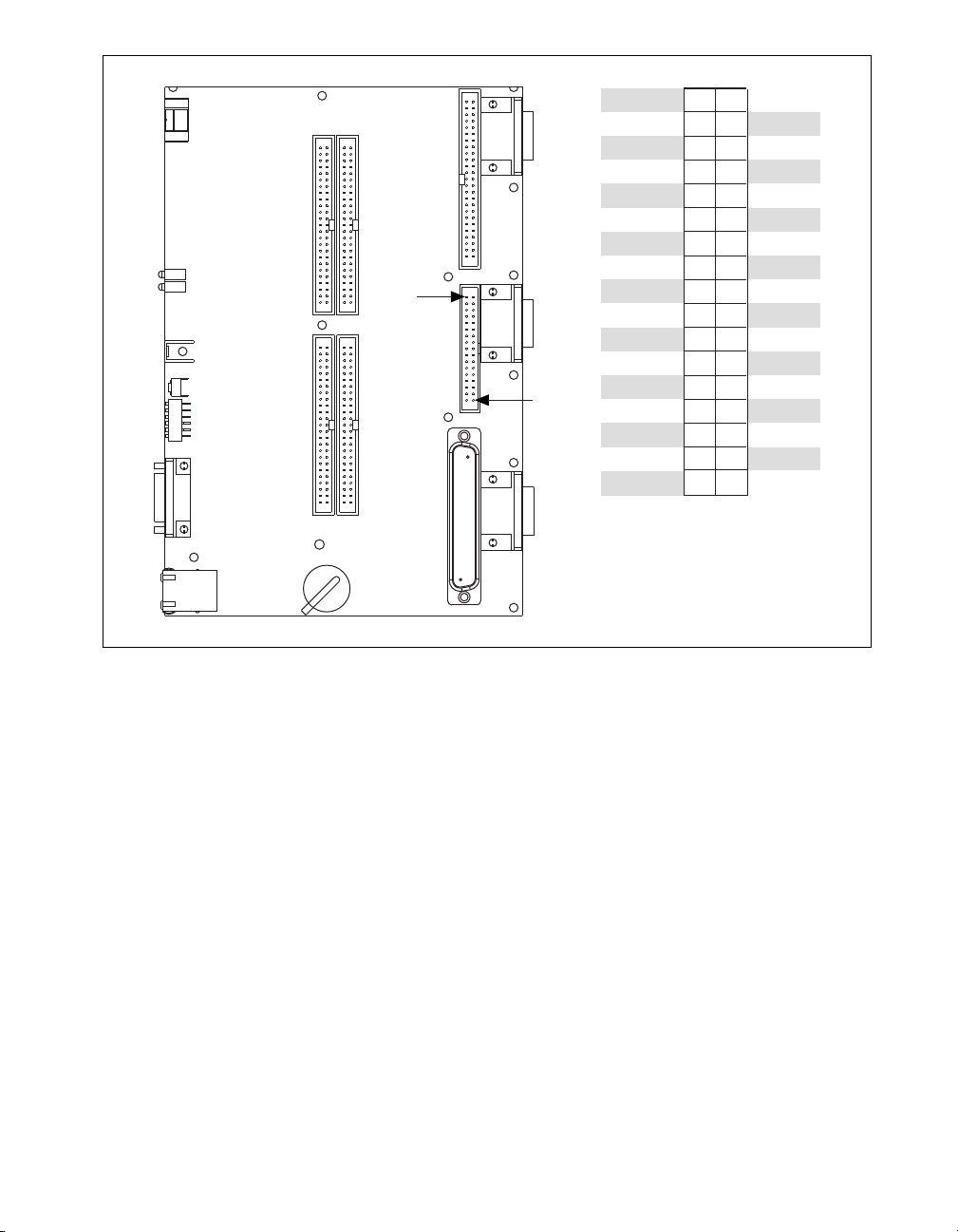

The following figures show the pinouts of the I/O connectors on the

Port5/DIOCTL

Port5/DIO9

5 V

D GND

5 V

D GND

D GND

D GND

D GND

D GND

Port6/DIOCTL

D GND

D GND

D GND

D GND

D GND

D GND

D GND

D GND

D GND

D GND

D GND

D GND

D GND

D GND

D GND

Port5/DIO1

Port5/DIO2

Port5/DIO4

Port5/DIO5

Port5/DIO6

Port5/DIO7

Port5/DIO0

Port5/DIO3

Port5/DIO8

Port6/DIO9

Port6/DIO0

Port6/DIO1

Port6/DIO2

Port6/DIO3

Port6/DIO4

Port6/DIO5

Port6/DIO6

Port6/DIO7

Port6/DIO8

Port2/DIO4

Port2/DIO5

Port2/DIO6

Port2/DIO7

Port2/DIO8

50 49

48 47

46 45

44 43

42 41

40 39

38 37

36 35

34 33

32 31

30 29

28 27

26 25

24 23

22 21

20 19

18 17

16 15

14 13

12 11

10 9

87

65

43

21

Pin 1

Pin 50

NI sbRIO devices.

Figure 5. Pinout of I/O Connector P2, 3.3 V Digital I/O

NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT 8 ni.com

Page 9

Pin 50

Pin 1

D GND

5 V

D GND

5 V

D GND

D GND

D GND

D GND

D GND

Port9/DIOCTL

D GND

D GND

D GND

D GND

D GND

D GND

D GND

D GND

D GND

Port8/DIOCTL

D GND

D GND

D GND

D GND

Port7/DIO4

50 49

48 47

46 45

44 43

42 41

40 39

38 37

36 35

34 33

32 31

30 29

28 27

26 25

24 23

22 21

20 19

18 17

16 15

14 13

12 11

10 9

8 7

6 5

4 3

2 1

Port9/DIO8

Port9/DIO7

Port9/DIO6

Port9/DIO5

Port9/DIO4

Port9/DIO3

Port9/DIO2

Port9/DIO1

Port9/DIO0

Port9/DIO9

Port8/DIO8

Port8/DIO7

Port8/DIO6

Port8/DIO5

Port8/DIO4

Port8/DIO3

Port8/DIO2

Port8/DIO1

Port8/DIO0

Port8/DIO9

Port7/DIO8

Port7/DIO7

Port7/DIO6

Port7/DIO5

D GND

Figure 6. Pinout of I/O Connector P3, 3.3 V Digital I/O

© National Instruments Corporation 9 NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT

Page 10

Port0/DIOCTL

Port0/DIO9

5 V

D GND

5 V

D GND

D GND

D GND

D GND

D GND

Port1/DIOCTL

D GND

D GND

D GND

D GND

D GND

D GND

D GND

D GND

D GND

Port2/DIOCTL

D GND

D GND

D GND

D GND

D GND

Port0/DIO1

Port0/DIO2

Port0/DIO4

Port0/DIO5

Port0/DIO6

Port0/DIO7

Port0/DIO0

Port0/DIO3

Port0/DIO8

Port1/DIO9

Port1/DIO0

Port1/DIO1

Port1/DIO2

Port1/DIO3

Port1/DIO4

Port1/DIO5

Port1/DIO6

Port1/DIO7

Port1/DIO8

Port2/DIO9

Port2/DIO0

Port2/DIO1

Port2/DIO2

Port2/DIO3

50 49

48 47

46 45

44 43

42 41

40 39

38 37

36 35

34 33

32 31

30 29

28 27

26 25

24 23

22 21

20 19

18 17

16 15

14 13

12 11

10 9

8 7

6 5

4 3

2 1

Pin 1

Pin 50

Figure 7. Pinout of I/O Connector P4, 3.3 V Digital I/O

NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT 10 ni.com

Page 11

Pin 50

Pin 1

D GND

5 V

D GND

5 V

D GND

D GND

D GND

D GND

D GND

Port4/DIOCTL

D GND

D GND

D GND

D GND

D GND

D GND

D GND

D GND

D GND

Port3/DIOCTL

D GND

D GND

D GND

Port7/DIO9

Port7/DIOCTL

50 49

48 47

46 45

44 43

42 41

40 39

38 37

36 35

34 33

32 31

30 29

28 27

26 25

24 23

22 21

20 19

18 17

16 15

14 13

12 11

10 9

87

65

43

21

Port4/DIO8

Port4/DIO7

Port4/DIO6

Port4/DIO5

Port4/DIO4

Port4/DIO3

Port4/DIO2

Port4/DIO1

Port4/DIO0

Port4/DIO9

Port3/DIO8

Port3/DIO7

Port3/DIO6

Port3/DIO5

Port3/DIO4

Port3/DIO3

Port3/DIO2

Port3/DIO1

Port3/DIO0

Port3/DIO9

Port7/DIO3

Port7/DIO2

Port7/DIO1

Port7/DIO0

D GND

Figure 8. Pinout of I/O Connector P5, 3.3 V Digital I/O

© National Instruments Corporation 11 NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT

Page 12

Pin 1

Pin 50

AI GND

AI8

AI1

AI2

AI11

AI GND

AI12

AI5

AI6

AI15

AI GND

AI24

AI17

AI18

AI27

AI GND

AI28

AI21

AI22

AI31

AI SENSE

AO3

AO2

AO1

AO0

21

43

65

87

109

1211

1413

1615

1817

2019

2221

2423

2625

2827

3029

3231

3433

3635

3837

4039

4241

4443

4645

4847

5049

AI0

AI9

AI GND

AI10

AI3

AI4

AI13

AI GND

AI14

AI7

AI16

AI25

AI GND

AI26

AI19

AI20

AI29

AI GND

AI30

AI23

AO GND

AO GND

AO GND

AO GND

AI GND

Figure 9. Pinout of I/O Connector J7, Analog I/O

NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT 12 ni.com

Page 13

Figure 10. Pinout of I/O Connector J6, 24 V Digital Input

DI0

DI2

DI4

DI6

DI8

DI10

DI12

DI14

DI16

DI18

DI20

DI22

DI24

DI26

DI28

DI30

D GND

D GND

DI3

DI5

DI9

DIa11

DI13

DI15

DI1

DI7

DI17

DI19

DI21

DI23

DI25

DI27

DI29

DI31

34 33

32 31

30 29

28 27

26 25

24 23

22 21

20 19

18 17

16 15

14 13

12 11

10 9

87

65

43

21

Pin 1

Pin 34

(NI sbRIO-964x/9642XT Only)

© National Instruments Corporation 13 NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT

Page 14

Figure 11. Pinout of I/O Connector J5, 24 V Digital Output

Pin 1

Pin 37

DO31

DO30

DO29

DO28

DO27

DO26

DO25

DO24

V

sup

V

sup

DO23

DO22

DO21

DO20

DO19

DO18

DO17

DO16

D GND

DO15

DO14

DO13

DO12

DO11

DO10

DO9

DO8

V

sup

V

sup

DO7

DO6

DO5

DO4

DO3

DO2

DO1

DO0

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

DSR

RTS

CTS

RI

DCD

RXD

TXD

DTR

GND

1

2

3

4

5

6

7

8

9

(NI sbRIO-964x/9642XT Only)

Figure 12 shows the signals on J1, the RS-232 serial port.

Figure 12. J1, RS-232 Serial Port

NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT 14 ni.com

Page 15

Understanding Ground Connections

All of the grounds (D GND, AI GND, AO GND, ground lug P1, and the

plated mounting holes) are connected together internally on the NI sbRIO

device. The ESD protection diodes are connected to the plated mounting

holes with a lower inductive path than the path to D GND, so the best ESD

protection is provided by connecting the plated mounting holes and ground

lug P1 to a low inductive earth ground.

Care must be taken to not connect the grounds in such a way that stray

power supply currents traverse through the board. For example, when using

the NI sbRIO-964x/9642XT, the D GND connections on the 24 V DIO

connectors J5 and J6 should not be carrying more than a few tens of

milliamps of current. Ideally, only the return current for the 24 V inputs

should return through D GND on J5, and D GND on J6 should have no

current flow. For the remaining connectors, a good rule of thumb is current

flowing out of the connector should match current flowing in.

To verify correct grounding of the NI sbRIO device, make sure current

flowing into the power connector J3 equals the current flowing out of power

connector J3. These currents should be measured with a current probe after

final assembly of the end product and any current differences investigated

and removed.

All external power supplies should have their connected to a system ground

external to the NI sbRIO device. Do not use the NI sbRIO device as the

common system grounding point. Significant currents traversing through

the NI sbRIO grounds can result in digital component failures. If more than

3 A flows through the common (–) pin on the J3 power connector,

components start to fuse open.

Connecting the NI sbRIO Device to a Network

Use a standard Category 5 (CAT-5) or better Ethernet cable to connect the

RJ-45 Ethernet port to an Ethernet network.

Caution To prevent data loss and to maintain the integrity of your Ethernet installation,

do not use a cable longer than 100 m.

If you need to build your own cable, refer to the Cabling section for more

information about Ethernet cable wiring connections.

© National Instruments Corporation 15 NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT

Page 16

The host computer communicates with the device over a standard Ethernet

connection. If the host computer is on a network, you must configure

the device on the same subnet as the host computer. If neither the host

computer nor the device is connected to a network, you can connect the

two directly using a crossover cable.

If you want to use the device on a subnet other than the one the host

computer is on, first connect the device on the same subnet as the host

computer. Use DHCP to assign an IP address or reassign a static IP address

for the subnet where you want it to be and physically move it to the other

subnet. Refer to the Measurement & Automation Explorer Help for more

information about configuring the device in Measurement & Automation

Explorer (MAX).

Powering the NI sbRIO Device

The NI sbRIO device requires a power supply connected to J3.

The supply voltage and current must meet the specifications in the Power

Requirements section of this document, but the actual power requirement

depends on how the device is physically configured, programmed, and

used. To determine the power requirement of your application, you must

measure the power consumption during execution, and add 20% to your

estimates to account for transient and startup conditions.

Note Select a high-quality power supply with less than 20 mV ripple. The NI sbRIO

device has some internal power-supply filtering on the positive side, but a low-quality

power supply can inject noise into the ground path, which is unfiltered.

Four elements of the NI sbRIO device can require power: NI sbRIO internal

operation, including integrated analog and digital I/O; 3.3 V DIO; 5 V

output; and board-only C Series modules installed on the device. Refer to

the Power Requirements section for formulas and examples for calculating

power requirements for different configurations and application types.

Complete the following steps to connect a power supply to the device.

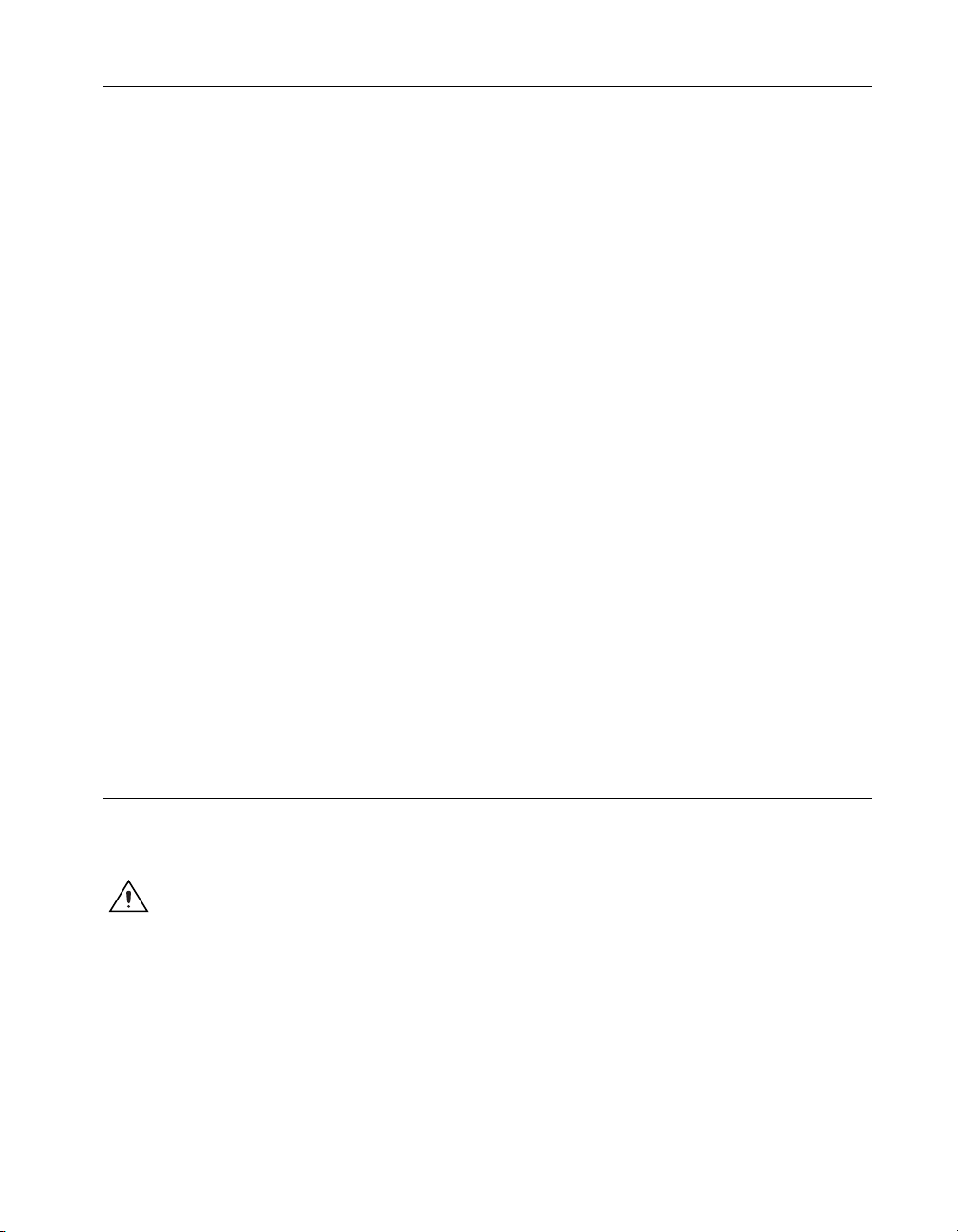

Refer to Figure 13 for an illustration of the power supply connection.

NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT 16 ni.com

Page 17

1. Remove the MINI-COMBICON plug from connector J3 of the

V

C

Common

(–)

Voltage

(+)

NI sbRIO device. Refer to Figure 4 for the location of J3.

2. Connect the positive lead of the power supply to the V terminal of the

MINI-COMBICON plug.

3. Connect the negative lead of the power supply to the C terminal of the

MINI-COMBICON plug.

4. Re-install the MINI-COMBICON connector in connector J3.

Note The 24 V digital output of the NI sbRIO-964x/9642XT requires a separate,

additional power supply. Refer to the Integrated 24 V Digital Output

(NI sbRIO-964x/9642XT Only) and Specifications sections for more information about

powering digital output channels.

Powering On the NI sbRIO Device

When you apply power to the NI sbRIO device, the device runs a power-on

self test (POST). During the POST, the Power and Status LEDs turn on.

When the Status LED turns off, the POST is complete. If the LEDs do not

behave in this way when the system powers on, refer to the Understanding

LED Indications section.

You can configure the device to launch an embedded stand-alone

LabVIEW RT application each time it is booted. Refer to the Running a

Stand-Alone Real-Time Application (RT Module) topic of the LabVIEW

Help for more information.

Figure 13. Connecting a Power Supply

© National Instruments Corporation 17 NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT

Page 18

Boot Options

Table 2 lists the reset options available on NI sbRIO devices. These options

determine how the FPGA behaves when the device is reset in various

conditions. Use the RIO Device Setup utility to select reset options. Access

the RIO Device Setup utility by selecting Start»All Programs»National

Instruments»NI-RIO»RIO Device Setup.

Table 2. NI sbRIO Reset Options

Reset Option Behavior

Do not autoload VI Does not load the FPGA bit stream from flash memory.

Autoload VI on device powerup Loads the FPGA bit stream from flash memory to the FPGA

when the device powers on.

Autoload VI on device reboot Loads the FPGA bit stream from flash to the FPGA when you

reboot the device either with or without cycling power.

Note If you want a VI to run when loaded to the FPGA, complete the following steps.

1. Right-click the FPGA Target item in the Project Explorer window in

LabVIEW.

2. Select Properties.

3. In the General category of the FPGA Target Properties dialog box,

place a check in the Run when loaded to FPGA checkbox.

4. Compile the FPGA VI.

Connecting Serial Devices to the NI sbRIO Device

The NI sbRIO device has an RS-232 serial port to which you can connect

devices such as displays or input devices. Use the Serial VIs to read from

and write to the serial port from a LabVIEW RT application. For more

information about using the Serial VIs, refer to the Serial VIs and

Functions topic of the LabVIEW Help.

Using the Internal Real-Time Clock

The system clock of the NI sbRIO device gets the date and time from the

internal real-time clock at startup. This synchronization provides

timestamp data to the device.

NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT 18 ni.com

Page 19

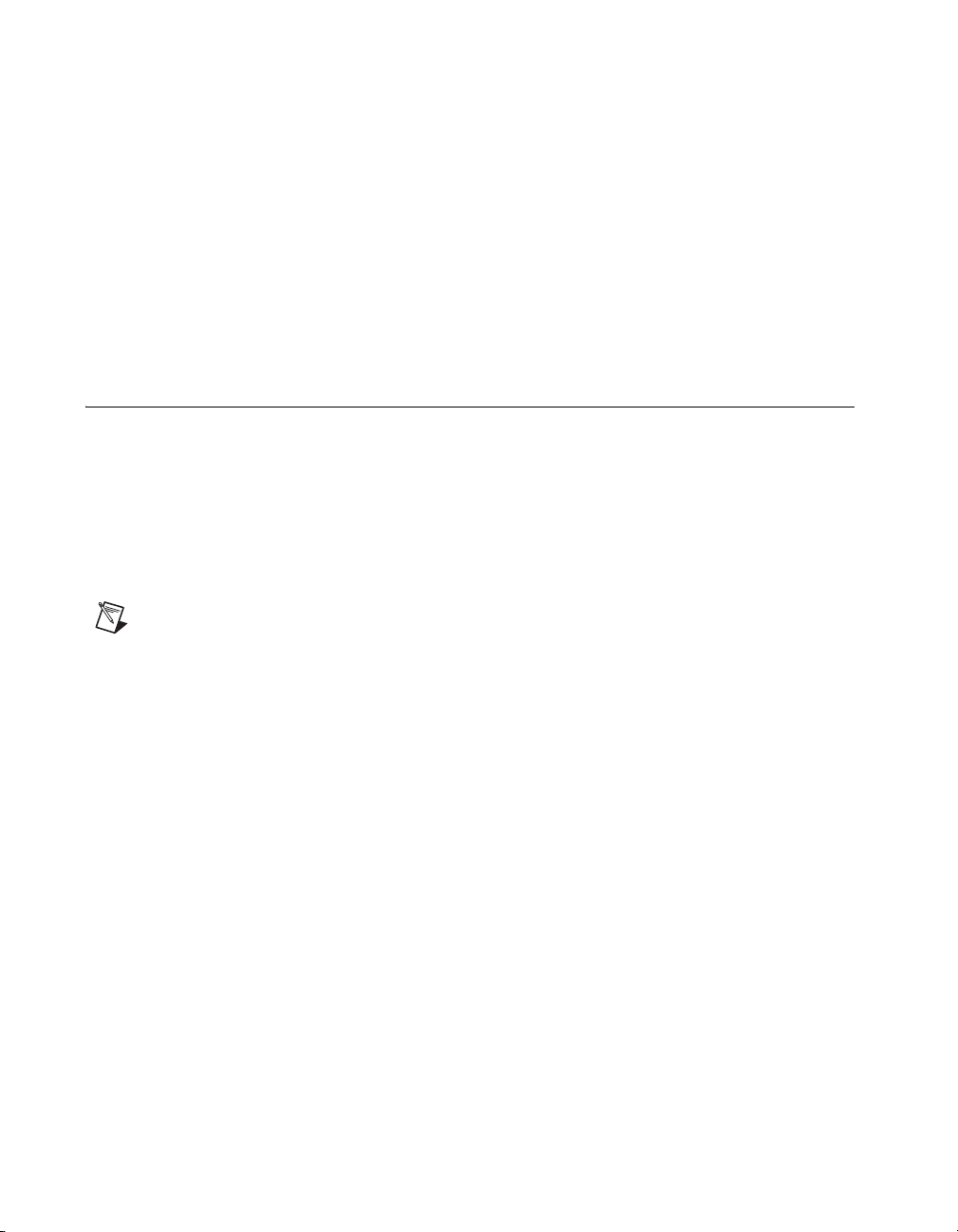

Configuring DIP Switches

AMP 0650

1-5435802-7

OFF

SAFE MODE Switch

1 SAFE MODE

2CONSOLE OUT

3 IP RESET

4NO APP

Figure 14. DIP Switches

5 USER1

6 NO FPGA

All of the DIP switches are in the OFF (up) position when the NI sbRIO

device is shipped from National Instruments.

The position of the SAFE MODE switch determines whether the embedded

LabVIEW Real-Time engine launches at startup. If the switch is in the OFF

position, the LabVIEW Real-Time engine launches. Keep this switch in the

OFF position during normal operation. If the switch is in the ON position

at startup, the NI sbRIO device launches only the essential services

required for updating its configuration and installing software. The

LabVIEW Real-Time engine does not launch.

Push the SAFE MODE switch to the ON position if the software on the

NI sbRIO device is corrupted. Even if the switch is not in the ON position,

if there is no software installed on the device, the device automatically

boots into safe mode. The SAFE MODE switch must be in the ON position

to reformat the drive on the device. Refer to the Measurement &

Automation Explorer Help for more about installing software and

reformatting the drive.

© National Instruments Corporation 19 NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT

Page 20

CONSOLE OUT Switch

With a serial-port terminal program, you can use the serial port to read the

IP address and firmware version of the NI sbRIO device. Use a null-modem

cable to connect the serial port on the device to a computer. Push the

CONSOLE OUT switch to the ON position. Make sure that the serial-port

terminal program is configured to the following settings:

• 9,600 bits per second

• Eight data bits

• No parity

• One stop bit

• No flow control

Keep this switch in the OFF position during normal operation. If

CONSOLE OUT is enabled, LabVIEW RT cannot communicate with the

serial port.

IP RESET Switch

Push the IP RESET switch to the ON position and reboot the NI sbRIO

device to reset the IP address to

subnet and the IP RESET switch is in the ON position, the device appears

in MAX with IP address

the device in MAX. Refer to the Resetting the Network Configuration of the

NI sbRIO Device section for more information about resetting the IP

address.

0.0.0.0. If the device is on your local

0.0.0.0. You can configure a new IP address for

NO APP Switch

Push the NO APP switch to the ON position to prevent a LabVIEW RT

startup application from running at startup. If you want to permanently

disable a LabVIEW RT application from running at startup, you must

disable it in LabVIEW. To run an application at startup, push the NO APP

switch to the OFF position, create an application using the LabVIEW

Application Builder, and configure the application in LabVIEW to launch

at startup. For more information about automatically launching VIs at

startup and disabling VIs from launching at startup, refer to the Running a

Stand-Alone Real-Time Application (RT Module) topic of the LabVIEW

Help.

USER1 Switch

You can define the USER1 switch for your application. To define the

purpose of this switch in your embedded application, use the RT Read

Switch VI in your LabVIEW RT embedded VI. For more information

about the RT Read Switch VI, refer to the LabVIEW Help.

NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT 20 ni.com

Page 21

NO FPGA Switch

1

2

3

4

Push the NO FPGA switch to the ON position to prevent a LabVIEW

FPGA application from loading at startup. The NO FPGA switch overrides

the options described in the Boot Options section. After startup you can

download bit files to flash memory from a LabVIEW project regardless of

switch position. If you already have an application configured to launch at

startup and you push the NO FPGA switch from ON to OFF, the startup

application is automatically enabled.

Using the Reset Button

Pressing the Reset button reboots the processor. The FPGA continues to

run unless you select the Autoload VI on device reboot boot option. Refer

to the Boot Options section for more information.

Understanding LED Indications

1FPGA 2 USER 3 POWER 4STATUS

Figure 15. NI sbRIO Device LEDs

FPGA LED

You can use the FPGA LED to help debug your application or easily

retrieve application status. Use the LabVIEW FPGA Module and NI-RIO

software to define the FPGA LED to meet the needs of your application.

Refer to LabVIEW Help for information about programming this LED.

USER LED

You can define the USER LED to meet the needs of your application. To

define the LED, use the RT LEDs VI in LabVIEW. For more information

about the RT LEDs VI, refer to the LabVIEW Help.

© National Instruments Corporation 21 NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT

Page 22

POWER LED

STATUS LED

The POWER LED is lit while the NI sbRIO device is powered on. This

LED indicates that the 5 V and 3.3 V rails are stable.

The STATUS LED is off during normal operation. The NI sbRIO device

indicates specific error conditions by flashing the STATUS LED a certain

number of times as shown in Table 3.

Table 3. Status LED Indications

Number of

Flashes

Indication

1

(one flash every

couple seconds)

2 The device has detected an error in its software. This

3 The device is in safe mode because the SAFE MODE

4 The device software has crashed twice without

Continuous

flashing or solid

The device is unconfigured. Use MAX to configure

the device. Refer to the Measurement & Automation

Explorer Help for information about configuring the

device.

usually occurs when an attempt to upgrade the

software is interrupted. Reinstall software on the

device. Refer to the Measurement & Automation

Explorer Help for information about installing

software on the device.

DIP switch is in the ON position. Refer to the

Configuring DIP Switches section for information

about the SAFE MODE DIP switch.

rebooting or cycling power between crashes. This

usually occurs when the device runs out of memory.

Review your RT VI and check the device memory

usage. Modify the VI as necessary to solve the

memory usage issue.

The device has detected an unrecoverable error.

Format the hard drive on the device. If the problem

persists, contact National Instruments.

NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT 22 ni.com

Page 23

Resetting the Network Configuration of the NI sbRIO Device

If the NI sbRIO device is not able to communicate with the network, you

can use the IP RESET switch to manually restore the device to the factory

network settings. When you restore the device to the factory network

settings, the IP address, subnet mask, DNS address, gateway, and Time

Server IP are set to

VIs are unaffected.

Complete the following steps to restore the device to the factory network

settings.

1. Move the IP RESET DIP switch to the ON position.

2. Press the Reset button.

3. Move the IP RESET switch to the OFF position.

The network settings are restored. You can reconfigure the settings in MAX

from a computer on the same subnet. Refer to the Measurement &

Automation Explorer Help for more information about configuring the

device.

Note If the device is restored to the factory network settings, the LabVIEW run-time

engine does not load. You must reconfigure the network settings and reboot the device for

the LabVIEW run-time engine to load.

0.0.0.0. Power-on defaults, watchdog settings, and

© National Instruments Corporation 23 NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT

Page 24

Integrated 3.3 V Digital I/O

User

Connection

Xilinx Spartan-3 FPGA

U1

+5 V

D2

D1

R1

The four 50-pin IDC headers, P2–P5, provide connections for

110 low-voltage DIO channels, 82 D GND, and eight +5 V voltage outputs.

Figure 16 represents a single DIO channel.

U1: 5 V to 3.3 V Level Shifter, SN74CBTD3384CDGV from Texas Instruments

D1 and D2: ESD-Rated Protection Diodes, NUP4302MR6T1G from ON Semiconductor

R1: Current-Limiting Posistor, PRG18BB330MS1RB from Murata

Figure 16. Circuitry of One 3.3 V DIO Channel

I/O Protection

Drive Strength

NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT 24 ni.com

The 33 Ω current-limiting posistor, R1, and the protection diodes, D1 and

D2, protect each DIO channel against externally applied voltages and ESD

events. The combination of R1 and D1 protects against overvoltage,

and the combination of R1 and D2 protects against undervoltage. The

resistance of R1 increases rapidly with temperature. During overvoltage

conditions, high current flows through R1 and into the protection diodes.

High current causes internal heating in the posistor, which increases the

resistance and limits the current. Refer to the Specifications section for

current-limiting and resistance values.

The NI sbRIO devices are tested with all 110 DIO channels driving 3 mA

DC loads, for a total of 330 mA sourcing from the FPGA. The FPGA uses

minimum 8 mA drivers, but the devices are not characterized for loads

higher than 3 mA.

Page 25

Signal Integrity

NI sbRIO boards have a 60 Ω characteristic trace impedance. The

characteristic impedance of most IDC ribbon cables is 110 Ω, which is

grossly mismatched from the board. However, headers P2–P5 were

designed such that the signals are interwoven with ground

(signal/ground/signal/ground, etc.), which greatly improves the signal

integrity. This is sufficient for most applications

For the best possible signal integrity, use a 3M 3353 series ribbon cable,

which has a characteristic impedance of 65 Ω. This cable has a ground

plane that connects to the ground plane of the board at pin 1 and pin 50. The

internal ground plane of this cable also reduces noise and radiated

emissions.

Using +5 V Power from 3.3 V DIO Headers P2–P5

Each of the four DIO headers has two pins to provide +5 V power for

external applications. These +5 V outputs are referenced to D GND on the

headers and are connected directly to the internal 5 V power plane of the

NI sbRIO device. The +5 V source has current limiting and overvoltage

clamps. Nevertheless, sudden current steps and noisy loads can inject

high-frequency transients into the power planes of the device. Such

transients can cause intermittent failures in the digital timing and lead to

unexpected behavior. Add filters and/or additional current limiting

between the external load and the +5 V output if the external load is not a

quiet, slowly ramping DC load. An LC filter of 6.8 μH and 100 μF per

200 mA load should be sufficient, but the OEM user is responsible for final

requirements and testing.

The NI sbRIO power supply has a total of 2 A external load at 5 V. This

total includes 200 mA per installed C Series module. For example, if three

C Series modules are installed, only 2 A – (3 × 0.2) = 1.4 A is available for

use on headers P2–P5. Each pin on the headers is rated for 2 A, but a typical

28 AWG ribbon cable is rated for only 225 mA per conductor. The OEM

user is responsible for determining cabling requirements and ensuring that

current limits are not exceeded.

© National Instruments Corporation 25 NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT

Page 26

Integrated Analog Input

Connector J7 provides connections for 32 single-ended analog input

channels or 16 differential analog input channels. Connector J7 also

provides one connection for AI SENSE and nine connections for AI GND.

Refer to the I/O and Other Connectors on the NI sbRIO Device section for

a pinout of connector J7.

The integrated analog input of the NI sbRIO device is similar to that of the

NI 9205, but there is no isolation or digital I/O. Figure 17 shows the input

circuitry for one channel.

The remainder of this section provides a brief discussion of possible analog

input configurations. For a more in-depth discussion and examples, refer to

the Analog Input chapter of the M Series User Manual on

Tr i g

PGIA

Trigger

ADC

16-bit

ADC

AI+

AI–

AISENSE

AI GND

Figure 17. Input Circuitry for One Analog Channel

MUX

Filtered

Differential

Amplifier

ni.com.

Differential Measurement Configurations

You can use a differential measurement configuration to attain more

accurate measurements and less noise. A differential measurement

configuration requires two inputs for each measurement, thus reducing the

number of available channels to 16. Table 4 shows the signal pairs that are

valid for differential connection configurations.

NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT 26 ni.com

Page 27

Table 4. Differential Pairs

+

–

+

–

AI+

AI–

AI GND

Grounded

Signal Source

+

–

+

–

AI+

AI–

AI GND

Floating

Signal Source

R

b

R

b

R

b

= 100 kΩ –1 MΩ

Channel Signal+ Signal– Channel Signal+ Signal–

0 AI0 AI8 16 AI16 AI24

1 AI1 AI9 17 AI17 AI25

2 AI2 AI10 18 AI18 AI26

3 AI3 AI11 19 AI19 AI27

4 AI4 AI12 20 AI20 AI28

5 AI5 AI13 21 AI21 AI29

6 AI6 AI14 22 AI22 AI30

7 AI7 AI15 23 AI23 AI31

Figure 18 shows how to make a differential connection for a floating signal

and for a ground-referenced signal.

Figure 18. Differential Analog Input Connection

© National Instruments Corporation 27 NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT

Page 28

Referenced Single-Ended (RSE) Measurements

+

–

+

–

AI

AI GND

Floating

Signal Source

Ground-loop potential (VA – VB) is added

to measured signal.

NOT RECOMMENDED

+

–

+

–

AI

AI GND

V

B

V

A

Grounded

Signal Source

You can use an RSE measurement configuration to take measurements on

32 channels when all channels share a common ground. Figure 19 shows

how to make an RSE analog input connection for a floating signal. National

Instruments does not recommend making an RSE connection for a

ground-referenced signal.

Figure 19. RSE Analog Input Connection

In an RSE connection configuration, the NI sbRIO device measures each

input channel with respect to AI GND.

Non-Referenced, Single-Ended (NRSE) Measurements

You can use an NRSE measurement configuration to take measurements on

all 32 channels while reducing noise more effectively than with an RSE

connection configuration. This configuration provides remote sense for the

negative (–) input of the programmable gain instrumentation amplifier

(PGIA) that is shared by all channels configured for NRSE mode. The

behavior of this configuration is similar to the behavior of RSE

connections, but it provides improved noise rejection. Figure 20 shows

how to make an NRSE analog input connection for a floating signal and for

a ground-referenced signal.

Floating

Signal Source

+

–

R

NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT 28 ni.com

b

Rb = 100 kΩ –1 MΩ

AI

+

AI SENSE

AI GND

Figure 20. NRSE Analog Input Connection

–

Grounded

Signal Source

+

–

AI SENSE

AI GND

AI

+

–

Page 29

Note The analog input and analog output of the NI sbRIO-963x/9632XT/964x/9642XT

share an internal power supply. Putting the analog input into Sleep Mode turns off analog

output as well. However, putting analog output into Sleep Mode does not turn off analog

input.

Integrated Analog Output (NI sbRIO-963x/9632XT/964x/9642XT Only)

Connector J7 of the NI sbRIO-963x/9632XT/964x/9642XT provides

connections for four analog output channels. Refer to the I/O and Other

Connectors on the NI sbRIO Device section for a pinout of connector J7.

The integrated analog output of the NI sbRIO device is similar to that of the

NI 9263, but there is no isolation. Each channel has a digital-to-analog

converter that produces a voltage signal. Each channel also has overvoltage

and short-circuit protection. Refer to the Specifications section for

information about the overvoltage and short-circuit protection.

Figure 21 shows the analog output circuitry for one channel.

DAC

Amplifier

Figure 21. Analog Output Circuitry for One Channel

Overvoltage/

Short-Circuit

Protection

AO

AO GND

When you apply power to the NI sbRIO device, analog output channels are

unpowered until data is written to them. When the channels receive the first

data, they turn on and drive the output voltage configured in software. This

behavior is similar to that of the NI 9263. Refer to the Specifications section

for more information about power-on voltage. Refer to the software help

for information about configuring startup output states in software.

© National Instruments Corporation 29 NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT

Page 30

Connect the positive lead of the load to the AO terminal. Connect the

ground of the load to an AO GND terminal. Figure 22 shows a load

connected to one analog input channel.

Figure 22. Load Connected to One Analog Input Channel

Integrated 24 V Digital Input (NI sbRIO-964x/9642XT Only)

Connector J6 of the NI sbRIO-964x/9642XT provides connections for

32 simultaneously sampled digital input channels. Each channel has

one pin, DI, to which you can connect a digital input signal. The remaining

two pins of J6 are the ground reference pins, D GND. Refer to the I/O and

Other Connectors on the NI sbRIO Device section for a pinout of

connector J6.

AO

Load

AO GND

The integrated digital input of the NI sbRIO device is similar to that of the

NI 9425, but there is no isolation. The 24 V digital input channels are

sinking inputs, meaning that when the device drives a current or applies a

voltage to the DI pin, the pin provides a path to D GND. D GND is the

current return path for sourcing digital input devices. The NI sbRIO-964x/

9642XT internally limits current signals connected to DI. For more

information about input current protection, refer to the Specifications

section.

You can connect 2-, 3-, and 4-wire sourcing-output devices to the

NI sbRIO-964x/9642XT. A sourcing-output device drives current or

applies voltage to the DI pin. An example of a sourcing-output device is an

open collector PNP.

NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT 30 ni.com

Page 31

Connect the sourcing-output device to the DI pin on the NI sbRIO-9642/

+

_

D GND

DI

Sourcing-Output

Device

External

Powe r

Supply

9642XT. Connect the common of the external device to the D GND pin.

Refer to Figure 23 for an illustration of connecting a device to the

NI sbRIO-9642/9642XT.

Figure 23. Device Connected to One Digital Input Channel

The digital input channel registers as ON when the sourcing-output device

applies a voltage or drives a current to the DI pin that is in the input ON

range. The channel registers as OFF when the device applies a voltage or

drives a current to the DI pin that is in the input OFF range. If no device is

connected to the DI pin, the channel registers as OFF. Refer to the

Specifications section for more information about ON and OFF states.

Integrated 24 V Digital Output (NI sbRIO-964x/9642XT Only)

Connector J5 of the NI sbRIO-964x/9642XT provides connections for

32 current-sourcing digital output channels. Refer to the I/O and Other

Connectors on the NI sbRIO Device section for a pinout of connector J5.

The DO pin of the channel drives current or applies voltage to a connected

device. You can directly connect the NI sbRIO-964x/9642XT to a variety

of industrial devices such as motors, actuators, relays, and lamps. Make

sure the devices you connect to the NI sbRIO-964x/9642XT are compatible

with the output specifications. Refer to the Specifications section for the

output specifications.

The 24 V digital outputs of the NI sbRIO-964x/9642XT require a

6–35 VDC power supply separate from the power supply connected to J3.

© National Instruments Corporation 31 NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT

Page 32

Connect the device to DO and D GND, and connect the external power

supply to V

Increasing Current Drive

If you do not modify the NI sbRIO device, each channel has a continuous

output current of 250 mA. If you want to increase the output current to a

device, you can connect any number of channels together in parallel. For

example, if you want to drive 1 A of current, connect DO<0..3> in parallel

as shown in Figure 25. You must turn all parallel channels on and off

simultaneously so that the current on any single channel cannot exceed the

250 mA rating. You must also select heavier cabling for the connection

between the negative terminal of the device and the negative terminal of the

power supply for the device. Refer to Figure 25 and use heavier cabling

where indicated by heavier traces.

and D GND, as shown in Figure 24.

sup

V

sup

6– 35 VDC

DO

Device

D GND

+

–

External

Powe r

Supply

Figure 24. Device Connected to One Digital Output Channel

V

sup

250 mA

DO0

250 mA

DO1

250 mA

DO2

250 mA

DO3

D GND

1 A

+

Device

–

6– 35 VDC

+

External

Powe r

–

Supply

Figure 25. Increasing the Current to a Device

Note

Refer to the Understanding Ground Connections section for cautions about D GND.

NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT 32 ni.com

Page 33

If you add heat sinks to the output transistors U49–U56 and U110–U117,

such that the measured case temperature of the transistors remains below

65 °C at ambient temperature of 55 °C, each channel can drive up to 1.5 A.

However, the total current through all channels must not exceed 20 A.

1

Use

a heat sink that dissipates 0.5 W for each transistor driving up to 1.5 A. For

example, for four transistors, each driving 1.5 A, use a 2 W heat sink.

Table 5 shows the channels associated with the output transistors.

Table 5. Transistors Associated with DO Channels

DO Channels Transistor

0, 1 U49

2, 3 U50

4, 5 U51

6, 7 U52

8, 9 U53

10, 11 U54

12, 13 U55

14, 15 U56

16, 17 U117

18, 19 U116

20, 21 U115

22, 23 U114

24, 25 U113

26, 27 U112

28, 29 U111

30, 31 U110

1

The 20 A total-current limit is based on the maximum current rating of the DSUB connector pins, 5 A, multiplied by 4, the

number of V

© National Instruments Corporation 33 NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT

sup

pins.

Page 34

Protecting the NI sbRIO Device from Flyback Voltages

If a digital output channel is switching an inductive or energy-storing

device such as a motor, solenoid, or relay, and the device does not have

flyback protection, install a flyback diode as shown in Figure 26.

V

sup

DO

Flyback

D GND

Diode

Figure 26. Connecting a Flyback Diode to the NI sbRIO 964x/9642XT

Inductive

Device

I/O Protection

The NI sbRIO-964x/9642XT is protected against overcurrent, inrush, and

short-circuit conditions in accordance with IEC 1131-2.

Each digital output channel on the NI sbRIO-964x/9642XT has circuitry

that protects it from voltage and current surges resulting from short circuits.

6– 35 VDC

+

External

Powe r

–

Supply

Caution The NI sbRIO-964x/9642XT can be damaged under overvoltage and reverse bias

voltage conditions. Check the voltage specifications for all devices that you connect to the

NI sbRIO-964x/9642XT.

Excessive current through a DO pin causes the channel to go into an

overcurrent state. In an overcurrent state, the channel cycles off and on until

the short circuit is removed or the current returns to an acceptably low level.

Refer the Specifications section for typical trip currents.

Each channel has a status line that indicates in software whether the

channel is in an overcurrent state. Refer to the software help for information

about the status line.

NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT 34 ni.com

Page 35

Specifications

Unless otherwise noted, the following specifications are typical for the

range –40 to 85 °C for the NI sbRIO-96x2XT, and for the range –20 to

55 °C for the NI sbRIO-961x/963x/964x.

Network

Network interface................................... 10BaseT and 100BaseTX

Compatibility ......................................... IEEE 802.3

Communication rates ............................. 10 Mbps, 100 Mbps,

Maximum cabling distance .................... 100 m/segment

RS-232 DTE Serial Port

Baud rate support ................................... Arbitrary

Maximum baud rate ...............................115,200 bps

Data bits ................................................. 5, 6, 7, 8

Ethernet

auto-negotiated

Stop bits.................................................. 1, 2

Parity ......................................................Odd, Even, Mark, Space, None

Flow control ........................................... RTS/CTS, XON/XOFF,

DTR/DSR, None

Processor Speed

NI sbRIO-9611/9631/9641 .................... 266 MHz

NI sbRIO-9612/9632/9642 and

NI sbRIO-96x2XT.................................. 400 MHz

© National Instruments Corporation 35 NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT

Page 36

Memory

Nonvolatile memory

NI sbRIO-9611/9631/9641..............128 MB minimum

NI sbRIO-9612/9632/9642 and

NI sbRIO-96x2XT ...........................256 MB minimum

System memory

NI sbRIO-9611/9631/9641..............64 MB minimum

NI sbRIO-9612/9632/9642 and

NI sbRIO-96x2XT ...........................128 MB minimum

For information about the life span of the nonvolatile memory and about

best practices for using nonvolatile memory, go to

the Info Code

SSDBP.

Xilinx Spartan-3 Reconfigurable FPGA

Number of logic cells

NI sbRIO-9611/9631/9641..............17,280

NI sbRIO-9612/9632/9642 and

NI sbRIO-96x2XT ...........................46,080

Available embedded RAM

NI sbRIO-9611/9631/9641..............432 kbits

NI sbRIO-9612/9632/9642 and

NI sbRIO-96x2XT ...........................720 kbits

ni.com/info and enter

3.3 V Digital I/O

Number of DIO channels........................110

Maximum tested current per channel .....3 mA

Maximum total current, all lines.............330 mA

Maximum tested DIO frequency ............10 MHz

Input logic levels

Input high voltage, V

Input low voltage, V

NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT 36 ni.com

....................2.0 V min; 5.25 V max

IH

......................0 V min; 0.8 V max

IL

Page 37

Output logic levels

Output high voltage, V

OH

,

sourcing 3 mA................................. 2.7 V min; 3.3 V max

Output low voltage, V

OL

,

sinking 3 mA................................... 0.07 V min; 0.54 V max

Overvoltage protection (maximum 2 pins in overvoltage)

NI sbRIO-961x/963x/964x

at –20 to 55 °C......................... ±20 V

NI sbRIO-96x2XT

at –20 to 85 °C......................... ±20 V

at –40 to –20 °C....................... ±7 V

Posistor (PRG18BB330MS1RB from Murata)

Maximum peak

abnormal-condition current............. 760 mA

Maximum hold current at 25 °C .....36 mA

Maximum hold current at 70 °C .....20 mA

Maximum hold current at 85 °C

(NI sbRIO-96x2XT only)................ 3 mA

Trip current at 25 °C ....................... 71 mA

Resistance at 25 °C .........................33 Ω ±20%

© National Instruments Corporation 37 NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT

Page 38

Resistance-temperature characteristics, typical curve

Resistance-Temperature Characteristics

1000

100

10

Resistance Change (R/R25)

1

Typical Curve

0.1

–40 –20 0 20 40 60 80 100 120 140 160

Temperature (°C)

NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT 38 ni.com

Page 39

Analog Input

All voltages are relative to AI GND unless otherwise noted.

Number of channels ............................... 32 single-ended or

16 differential analog input

channels

ADC resolution ...................................... 16 bits

Differential nonlinearity......................... No missing codes guaranteed

Integrated nonlinearity ........................... Refer to the AI Absolute Accuracy

Tables and Formulas

Conversion time ..................................... 4.00 μs (250 kS/s)

Input coupling ........................................ DC

Nominal input ranges ............................. ±10 V, ±5 V, ±1 V, ±0.2 V

Minimum overrange

(for 10 V range)......................................4%

Maximum working voltage for analog inputs

(signal + common mode) ....................... Each channel must remain within

±10.4 V of common

Input impedance (AI-to-AI GND)

Powered on ..................................... >10 GΩ in parallel with 100 pF

Powered off/overload...................... 1.2 kΩ min

Input bias current ................................... ±100 pA

Crosstalk (at 100 kHz)

Adjacent channels ........................... –65 dB

Non-adjacent channels.................... –70 dB

Small-signal bandwidth.......................... 700 kHz

Overvoltage protection

AI channel (0 to 31) ........................ ±24 V (one channel only)

AISENSE ........................................ ±24 V

CMRR (DC to 60 Hz) ............................ 92 dB

© National Instruments Corporation 39 NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT

Page 40

Typical performance graphs

0.2 V Range

10 V Range

5 V Range

1 V Range

AI <0..31> CMRR

0

20

40

60

80

100

120

10 100 1 k 10 k 100 k

Frequency (Hz)

CMRR (dB)

Settling Error Versus Time for Different Source Impedances

10 k

1 k

5 kΩ

10 kΩ

100

10

2 kΩ

1 kΩ

≤100 Ω

Error (ppm of Step Size)

1

1

10 100

Time (μs)

AI <0..31> Small Signal Bandwidth

2

0

–2

–4

–6

–8

–10

–12

–14

Normalized Signal Amplitude (dB)

1 k 10 k 100 k 1000 k 10000 k

Frequency (Hz)

NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT 40 ni.com

Page 41

Settling time for multichannel measurements, accuracy, all ranges

±120 ppm of full-scale step

(±8 LSB) ......................................... 4 μs convert interval,

5.5 μs (from 50 to 85 °C)

±30 ppm of full-scale step

(±2 LSB) ......................................... 8 μs convert interval

Analog triggers

Number of triggers.......................... 1

Resolution ....................................... 10 bits, 1 in 1,024

Bandwidth (–3 dB).......................... 700 kHz

Accuracy ......................................... ±1% of full scale

Scaling coefficients

Typical Scaling

Nominal Range (V)

Coefficient (μV/LSB)

±10 324.5

±5 162.2

±1 32.45

±0.2 6.49

AI Absolute Accuracy Tables and Formulas

The values in the following tables are based on calibrated scaling

coefficients, which are stored in an onboard EEPROM. Values are valid for

a two-year period between external calibrations.

Accuracy summary

Absolute Accuracy at

Nominal

Range

(V)

±10 7,820 36.6 52.0 244 97.6

±5 3,990 18.6 26.4 122 48.8

±1 870 4.27 6.07 30 12.0

±0.2 244 1.37 1.96 16 5.2

*

Sensitivity is the smallest voltage change that can be detected. It is a function of noise.

© National Instruments Corporation 41 NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT

Full Scale, within 5 °C

of Last Internal

Calibration (μV)

Absolute Accuracy

at Full Scale,

–20 to 55 °C (mV)

(XT Devices Only)

Absolute Accuracy

at Full Scale,

–40 to 85 °C (mV)

Random

Noise,

σ (μVrms)

Sensitivity

(μV)

*

Page 42

Accuracy details

100

Residual

Gain

Error

Nominal

Range (V)

±10 94 23 5 20 49 76

±5 104 23 5 20 50 76

±1 114 23 5 25 62 76

±0.2 154 23 5 40 118 76

(ppm of

Reading)

Gain

Tempco

(ppm/°C)

Reference

Tempco

Residual

Offset Error

(ppm of

Range)

Offset

Tempco

(ppm of

Range/°C)

Absolute accuracy formulas

AbsoluteAccuracy = Reading · GainError + Range · OffsetError +

NoiseUncertainty

GainError = ResidualGainError + GainTempco ·

TempChangeFromLastInternalCal + ReferenceTempco ·

TempChangeFromLastExternalCal

OffsetError = ResidualOffsetError + OffsetTempco ·

TempChangeFromLastInternalCal + INL_Error

NoiseUncertainty = (RandomNoise · 3) / for a coverage factor of 3σ

and averaging 100 points.

INL Error

(ppm of

Range)

Absolute accuracy at full scale on the analog input channels is determined

using the following assumptions:

TempChangeFromLastExternalCal = 45 °C

TempChangeFromLastInternalCal = 5°C

NumberOfReadings = 100

CoverageFactor = 3 σ

For example, on the 10 V range, the absolute accuracy at full scale is as

follows:

GainError = 94 ppm + 23 ppm · 5 + 5 ppm · 45

GainError = 434 ppm

OffsetError = 20 ppm + 49 ppm · 5 + 76 ppm

OffsetError = 341 ppm

NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT 42 ni.com

Page 43

NoiseUncertainty = (244 μV · 3) /

100

Noise Uncertainty = 73.2 μV

AbsoluteAccuracy = 10 V · 434 ppm + 10 V · 341 ppm + 73.2 μV

AbsoluteAccuracy = 7,823 μV (rounds to 7,820 μV)

To determine the absolute accuracy over the full operating temperature

range, let:

TempChangeFromLastInternalCal = 45 °C

Analog Output (NI sbRIO-963x/9632XT and NI sbRIO-964x/9642XT Only)

Number of channels ............................... 4 analog output channels

DAC resolution ...................................... 16 bits

Type of DAC.......................................... String

Output range........................................... ±10 V

Operating voltage

Nominal .......................................... ±10.7 V

Minimum ........................................ ±10.3 V

Maximum........................................ ±11 V

Current drive .......................................... ±3 mA per channel

Output impedance .................................. 0.1 Ω

Accuracy

Percent of Reading

Measurement Conditions

Calibrated, max (–40 to 85 °C) 0.35% 0.75%

Calibrated, typ (25 °C, ±5 °C) 0.01% 0.1%

Uncalibrated, max (–40 to 85 °C) 2.2% 1.7%

Uncalibrated, typ (25 °C, ±5 °C) 0.3% 0.25%

* Range equals ±10.7 V

(Gain Error)

Percent of Range*

(Offset Error)

Stability

Offset drift.......................................80 μV/°C

Gain drift......................................... 6 ppm/°C

© National Instruments Corporation 43 NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT

Page 44

Protection

Overvoltage .....................................±25 V at 25 °C

Short-circuit.....................................Indefinitely

Power-on voltage....................................0 V

Note All analog outputs are unpowered until a value is written to an analog output.

Update time

One channel in use...........................3 μs

Two channels in use ........................5 μs

Three channels in use ......................7.5 μs

Four channels in use ........................9.5 μs

Noise

Updating at 100 kS/s .......................600 μV

Not updating ....................................260 μV

rms

rms

Slew rate .................................................4 V/μs

Crosstalk .................................................76 dB

Settling time (100 pF load, to 1 LSB)

FS step .............................................20 μs

3 V step............................................10 μs

0.1 V step.........................................8 μs

Glitch energy

(256 steps, worst case)............................2 mV for 2 μs

Capacitive drive ......................................1,500 pF min

Monotonicity ..........................................16 bits

Differential nonlinearity .........................–1 to 2 LSBs max

Integrated nonlinearity (endpoint) ..........16 LSBs max

NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT 44 ni.com

Page 45

24 V Digital Input (NI sbRIO-964x/9642XT Only)

Number of channels ............................... 32 digital input channels

Input type ............................................... Sinking

Digital logic levels

OFF state

Input voltage ............................ ≤ 5V

Input current ............................≤ 150 μA

ON state

Input voltage ............................ ≥10 V

Input current ............................≥330 μA

Hysteresis

Input voltage ............................ 2 V min

Input current ............................60 μA min

Input impedance..................................... 30 kΩ ±5%

Input protection

8 channels ....................................... 60 VDC max

32 channels ..................................... 30 VDC max

Setup time

Transfer time

1

............................................. 1 μs max

2

......................................... 7 μs max

24 V Digital Output (NI sbRIO-964x/9642XT Only)

Number of channels ............................... 32 digital output channels

Output type............................................. Sourcing

Output voltage (V

Input voltage from

external power supply ............................ 6–35 VDC

Continuous output current (I

No heat sinks................................... 250 mA max

With external heat sinks added

1

Setup time is the amount of time input signals must be stable before you can read from the module.

2

Transfer time is the maximum time FPGA Device I/O functions take to read data from the module.

3

Refer to the Increasing Current Drive section for information about installing heat sinks.

) ................................ V

0

) on each channel

0

3

...... 1.5 A max

– (I0R0)

sup

© National Instruments Corporation 45 NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT

Page 46

Maximum total output current

on all channels ........................................20 A

Power Limits

Output impedance (R

) ...........................0.3 Ω max

0

Continuous overvoltage

protection range (V

)............................40 V

sup

Reversed-voltage protection ...................None

Current limiting ......................................None

Short-circuit protection...........................Indefinitely protected when a

channel is shorted to D GND or

to a voltage up to V

sup

Trip current for one channel

With all other channels

at 250 mA current............................3 A typ

With all other channels off ..............5 A typ

V

quiescent current consumption .......28 mA max

sup

Maximum update rate.............................40 µs max

Propagation delay ...................................500 μs max

Caution Exceeding the power limits may cause unpredictable behavior by the device.

5 V pins (P2, P3, P4, P5) ........................+5 V ±5%,

2 A max (shared with C Series

modules)

Power Requirements

The NI sbRIO device requires a power supply connected to connector J3.

Refer to Figure 4 for the location of J3. Refer to the Powering the NI sbRIO

Device section for information about connecting the power supply.

Power supply voltage range....................19–30 VDC

Power supply current limit .....................1.8 A

1

The NI sbRIO device is 1–2% more efficient with a 19 V supply than with a 30 V supply.

NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT 46 ni.com

1

Page 47

Power connector internal fuse................ 2 A non-replaceable

Total power requirement = P

where P

is the consumption by sbRIO internal operation, including

int

int

+ P

+ P5V + P

DIO

CSer

integrated I/O

P

is the consumption by the 3.3 V DIO

DIO

P

is the consumption by the 5 V voltage output

5V

P

is the consumption by installed board-only C Series

CSer

modules

Note You must add 20% to the calculated or measured total power requirement to account

for transient and startup conditions.

Maximum P

int

NI sbRIO-961x/9612XT ................. 7.50 W

NI sbRIO-963x/9632XT ................. 7.75 W

NI sbRIO-964x/9642XT ................. 8.00 W

Maximum P

....................................... 1.28 W

DIO

P

= Total DIO Current × 3.3 V/ 0.85

DIO

Maximum P

Maximum P

........................................ 11.1 W

5V

P

= Total 5 V Output Current × 5 V/0.9

5V

...................................... 3.3 W; each installed C Series

CSer

module consumes up to 1.1 W.

© National Instruments Corporation 47 NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT

Page 48

Example power requirement calculations:

• For an NI sbRIO-9642/9642XT with three installed board-only C

Series modules, 20 mA total current through the 3.3 V DIO pins, and

1 A of current through the 5 V output, calculate the total power

requirement as follows:

P

= 8.00 W

int

P

= 3.30 W

CSer

P

= 0.08 W

DIO

P

= 5.55 W

5V

Adding 20% for transient conditions, 16.93 W × 1.2 = 20.32 W

Total power requirement = 20.32 W

• For an sbRIO-9612/9612XT with one installed board-only C Series

module, 330 mA total current through the 3.3 V DIO pins, and no 5 V

output used, calculate the total power requirement as follows:

P

= 7.50 W

int

P

= 1.10 W

CSer

P

= 1.28 W

DIO

P

= 0.00 W

5V

Adding 20% for transient conditions, 9.88 W × 1.2 = 11.86 W

Total power requirement = 11.86 W

Backup battery........................................3 V lithium coin cell,

BR2032 (–40 to 85 °C)

Safety Voltages

Connect only voltages that are within this limit.

V terminal to C terminal.........................35 VDC max,

Measurement Category I

Measurement Category I is for measurements performed on circuits not

directly connected to the electrical distribution system referred to as

MAINS voltage. MAINS is a hazardous live electrical supply system that

powers equipment. This category is for measurements of voltages from

specially protected secondary circuits. Such voltage measurements include

signal levels, special equipment, limited-energy parts of equipment,

circuits powered by regulated low-voltage sources, and electronics.

NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT 48 ni.com

Page 49

Caution Do not connect the system to signals or use for measurements within

Cd/Hg/Pb

⬉ᄤֵᙃѻક∵ᶧࠊㅵ⧚ࡲ⊩ ˄Ё

RoHS

˅

Ёᅶ᠋

National Instruments

ヺড়Ё⬉ᄤֵᙃѻકЁ䰤ࠊՓ⫼ᶤѯ᳝ᆇ⠽䋼ᣛҸ

(RoHS)

DŽ

݇Ѣ

National Instruments

Ё

RoHS

ড়㾘ᗻֵᙃˈ䇋ⱏᔩ

ni.com/environment/rohs_china

DŽ

(For information about China RoHS compliance, go to

ni.com/environment/rohs_china

.)

Measurement Categories II, III, or IV.

Environmental Management

National Instruments is committed to designing and manufacturing

products in an environmentally responsible manner. NI recognizes that

eliminating certain hazardous substances from our products is beneficial to

the environment and to NI customers.

For additional environmental information, refer to the NI and the

Environment Web page at

environmental regulations and directives with which NI complies, as well

as other environmental information not included in this document.

Waste Electrical and Electronic Equipment (WEEE)

EU Customers At the end of the product life cycle, all products must be sent to a WEEE

recycling center. For more information about WEEE recycling centers, National

Instruments WEEE initiatives, and compliance with WEEE Directive 2002/96/EC on

Waste and Electronic Equipment, visit

Battery Replacement and Disposal

Battery Directive This device contains a long-life coin cell battery. If you need to replace

it, use the Return Material Authorization (RMA) process or contact an authorized National

Instruments service representative. For more information about compliance with the

EU Battery Directive 2006/66/EC about Batteries and Accumulators and Waste Batteries

and Accumulators, visit

ni.com/environment/batterydirective.

ni.com/environment. This page contains the

ni.com/environment/weee.

© National Instruments Corporation 49 NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT

Page 50

Environmental

The NI sbRIO-96xx/96x2XT is intended for indoor use only.

Ambient temperature in enclosure

(IEC 60068-2-1, IEC 60068-2-2)

NI sbRIO-961x/963x/964x...............–20 to 55 °C

NI sbRIO-96x2XT ...........................–40 to 85 °C

Storage temperature

(IEC 60068-2-1, IEC 60068-2-2) ...........–40 to 85 °C

Operating humidity

(IEC 60068-2-56) ...................................10 to 90% RH, noncondensing

Storage humidity (IEC 60068-2-56) .......5 to 95% RH, noncondensing

Maximum altitude...................................2,000 m

Pollution Degree (IEC 60664) ................2

Indoor use only

Physical Characteristics

Torque for screw terminals on J3 ...........0.5 to 0.6 N · m

(4.4 to 5.3 lb · in.)

Weight

NI sbRIO-961x/9612XT..................266.5 g (9.4 oz)

NI sbRIO-963x/9632XT..................269.3 g (9.5 oz)

NI sbRIO-964x/9642XT..................292.0 g (10.3 oz)

NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT 50 ni.com

Page 51

Cabling

C

C

Table 6 shows the standard Ethernet cable wiring connections for both

normal and crossover cables.

Table 6. Ethernet Cable Wiring Connections

Pin 1

onnector 1

Pin Connector 1

Connector 2

(Normal)

Connector 2

(Crossover)

1 white/orange white/orange white/green

2 orange orange green

3 white/green white/green white/orange

4 blue blue blue

5 white/blue white/blue white/blue

6 green green orange

7 white/brown white/brown white/brown

8 brown brown brown

onnector 2

Pin 1 Pin 8Pin 8

© National Instruments Corporation 51 NI sbRIO-961x/9612XT/963x/9632XT/964x/9642XT

Figure 27. Ethernet Connector Pinout

Page 52

Where to Go for Support

The National Instruments Web site is your complete resource for technical

support. At

troubleshooting and application development self-help resources to email

and phone assistance from NI Application Engineers.

National Instruments corporate headquarters is located at

11500 North Mopac Expressway, Austin, Texas, 78759-3504.

National Instruments also has offices located around the world to help

address your support needs. For telephone support in the United States,

create your service request at

instructions or dial 512 795 8248. For telephone support outside the United

States, contact your local branch office:

Australia 1800 300 800, Austria 43 662 457990-0,

Belgium 32 (0) 2 757 0020, Brazil 55 11 3262 3599,

Canada 800 433 3488, China 86 21 5050 9800,

Czech Republic 420 224 235 774, Denmark 45 45 76 26 00,

Finland 358 (0) 9 725 72511, France 01 57 66 24 24,

Germany 49 89 7413130, India 91 80 41190000, Israel 972 3 6393737,

Italy 39 02 41309277, Japan 0120-527196, Korea 82 02 3451 3400,

Lebanon 961 (0) 1 33 28 28, Malaysia 1800 887710,

Mexico 01 800 010 0793, Netherlands 31 (0) 348 433 466,

New Zealand 0800 553 322, Norway 47 (0) 66 90 76 60,

Poland 48 22 328 90 10, Portugal 351 210 311 210,

Russia 7 495 783 6851, Singapore 1800 226 5886,

Slovenia 386 3 425 42 00, South Africa 27 0 11 805 8197,

Spain 34 91 640 0085, Sweden 46 (0) 8 587 895 00,

Switzerland 41 56 2005151, Taiwan 886 02 2377 2222,

Thailand 662 278 6777, Turkey 90 212 279 3031,

United Kingdom 44 (0) 1635 523545

ni.com/support you have access to everything from

ni.com/support and follow the calling

LabVIEW, National Instruments, NI, ni.com, the National Instruments corporate logo, and the Eagle

logo are trademarks of National Instruments Corporation. Refer to the Trademark Information at

ni.com/trademarks for other National Instruments trademarks. Other product and company

names mentioned herein are trademarks or trade names of their respective companies. For patents

covering National Instruments products/technology, refer to the appropriate location: Help»Patents in

your software, the patents.txt file on your media, or the National Instruments Patent Notice at

ni.com/patents.

© 2008–2010 National Instruments Corporation. All rights reserved.

375052C-01 Jun10

Loading...

Loading...