Page 1

RT Series

DAQ Device User Manual

RT Series DAQ Device User Manual

April 2000 Edition

Part Number 322635A-01

Page 2

Worldwide Technical Support and Product Information

www.ni.com

National Instruments Corporate Headquarters

11500 North Mopac Expressway Austin, Texas 78759-3504 USA Tel: 512 794 0100

Worldwide Offices

Australia 03 9879 5166, Austria 0662 45 79 90 0, Belgium 02 757 00 20, Brazil 011 284 5011,

Canada (Calgary) 403 274 9391, Canada (Ontario) 905 785 0085, Canada (Québec) 514 694 8521,

China 0755 3904939, Denmark 45 76 26 00, Finland 09 725 725 11, France 01 48 14 24 24,

Germany 089 741 31 30, Greece 30 1 42 96 427, Hong Kong 2645 3186, India 91805275406,

Israel 03 6120092, Italy 02 413091, Japan 03 5472 2970, Korea 02 596 7456, Mexico (D.F.) 5 280 7625,

Mexico (Monterrey) 8 357 7695, Netherlands 0348 433466, New Zealand 09 914 0488, Norway 32 27 73 00,

Poland 0 22 528 94 06, Portugal 351 1 726 9011, Singapore 2265886, Spain 91 640 0085,

Sweden 08 587 895 00, Switzerland 056 200 51 51, Taiwan 02 2528 7227, United Kingdom 01635 523545

For further support information, see the Technical Support Resources appendix. To comment on the

documentation, send e-mail to techpubs@ni.com

© Copyright 1999, 2000 National Instruments Corporation. All rights reserved.

Page 3

Important Information

Warranty

The RT Series DAQ hardware is warranted against defects in materials and workmanship for a period of one year from the date

of shipment, as evidenced by receipts or other documentation. National Instruments will, at its option, repair or replace equip ment

that proves to be defective during the warranty period. Th is warrant y in cludes parts and labor.

The media on which you receive National Instruments software are warranted not to fail to execute programming instructions,

due to defects in materials and workmanship, for a period of 90 days from date of sh ipmen t, as evid enced b y receipt s o r other

documentation. National Instruments will, at its op ti on , repair or repl ace soft ware me dia th at do not ex ecu te pr ogram mi ng

instructions if National Instruments receives notice of such defects during the warranty period. National Instruments does not

warrant that the operation of the software shall be uni nterrup ted or error free.

A Return Material Authorization (RMA) number must be obtained from the factory and clearly marked on the outside of

the package before any equipment will be accepted for warranty work. National Instruments will pay the shipping costs of

returning to the owner parts which are covered by warrant y.

National Instruments believes that the information in this document is accurate. The document has been carefully reviewed

for technical accuracy. In the event that technical or typographical errors exist, National Instruments reserves the right to

make changes to subsequent editions of this document withou t p rio r no ti ce to hold ers o f thi s ed itio n. The read er sh ou ld consul t

National Instruments if errors are suspected. In no even t shall Nati on al Inst rum ents be l iable fo r any dama ges aris in g o ut of

or related to this document or the information contained in it.

XCEPT AS SPECIFIED HEREIN

E

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE

NEGLIGENCE ON THE PART OF NATIONAL INSTRUMENTS SHALL BE LIMITED TO THE AMOUNT THERETOFORE PAID BY THE CUSTOMER

NSTRUMENTS WILL NOT BE LIABLE FOR DAMAGES RESULTING FROM LOSS OF DATA, PROFITS, USE OF PRODUCTS, OR INCIDENTAL OR

I

CONSEQUENTIAL DAMAGES, EVEN IF ADVISED OF THE POSSIBILITY THEREOF

apply regardless of the form of action, whether in contract or tort, including negligence. Any action against National Instruments

must be brought within one year after the cause of action accrues. National Instruments shall not be liable for any delay in

performance due to causes beyond its reasonable control. The warranty provided herein does not co ver d amag es, defects,

malfunctions, or service failures caused by ow ner’s fai lu re t o foll ow th e Nation al Inst rum ent s in stal l ation, op erat i on, or

maintenance instructions; owner’s modification of the pro du ct; ow ner’s abus e, m isus e, or negligent acts; and po wer failure or

surges, fire, flood, accident, actions of third parties, or other events outside reasonable control.

ATIONAL INSTRUMENTS MAKES NO WARRANTIES, EXPRESS OR IMPLIED, AND SPECIFICALLY DISCLAIMS ANY

, N

Copyright

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or mechanical, including

photocopying, recording, storing in an informatio n retriev al s ystem, o r t ran sl ating , in who le or i n p art, wit ho ut t he prior written

consent of National Instruments Corporation.

USTOMER’S RIGHT TO RECOVER DAMAGES CAUSED BY FAULT OR

. C

. This limitation of the liability of National Instruments will

. N

ATIONAL

Trademarks

LabVIEW™, MITE™, National Instruments™, ni.com™, NI-DAQ™, PXI™, RTSI™, and SCXI™ are trademarks of

National Instruments Corporati on.

Product and company names mentioned herein are trad emarks o r trad e name s of thei r respect ive compan ies .

WARNING REGARDING USE OF NATIONAL INSTRUMENTS PRODUCTS

(1) NATIONAL INSTRUMENTS PRODUCTS ARE NOT DESIGNED WITH COMPONENTS AND TESTING FOR A LEVEL

OF RELIABILITY SUITABLE FOR USE IN OR IN CONNECTION WITH SURGICAL IMPLANTS OR AS CRITICAL

COMPONENTS IN ANY LIFE SUPPORT SYSTEMS WHOSE FAILURE TO PERFORM CAN REASONABLY BE

EXPECTED TO CAUSE SIGNIFICANT INJURY TO A HUMAN.

(2) IN ANY APPLICATION, I NCLUDING THE ABOVE , RELIABILITY OF OP ERATION OF THE SOFT WARE PRODUCTS

CAN BE IMPAIRED BY ADVERSE FACTORS, INCLUDING BUT NOT LIMITED TO FLUCTUATIONS IN ELECTRICAL

POWER SUPPLY, COMPUTER HARDWARE MALFUNCTIONS, COMPUTER OPERATING SYSTEM SOFTWARE

FITNESS, FITNESS OF COMPILERS AND DEVELOPMENT SOFTWARE USED TO DE VEL OP AN APPLICAT ION,

INSTALLATION ERRORS, SOFTWARE AND HARDWARE COMPATIBILITY PROBLEMS, MALFUNCTIONS OR

FAILURES OF ELECTRONIC MONITORING OR CONTROL DEVICES, TRANSIENT FAILURES OF ELECTRONIC

SYSTEMS (HARDWARE AND/OR SOFTWARE), UNANTICIPATED USES OR MISUSES, OR ERRORS ON THE PART OF

THE USER OR APPLICATIONS DESIGNER (ADVERSE FACTORS SUCH AS THESE ARE HEREAFTER

COLLECTIVELY TERMED “SYSTEM FAILURES”). ANY APPLICATION WHERE A SYSTEM FAILURE WOULD

CREATE A RISK OF HARM TO PROPERTY OR PERSONS (INCLUDING THE RISK OF BODILY INJURY AND DEATH)

SHOULD NOT BE RELIANT SOLELY UPON ONE FORM OF ELECTRON IC SYSTE M DUE TO THE RISK OF SYSTEM

FAILURE. TO AVOID DAMAGE, INJURY, OR DEATH, THE USER OR APPLICATION DESIGNE R MU ST T AKE

REASONABLY PRUDENT STEPS TO PROTECT AGAINST SYSTEM FAILURES, INCLUDING BUT NOT LIMITED TO

BACK-UP OR SHUT DOWN MECHANISMS. BECAUSE EACH END-USER SYSTEM IS CUSTOMIZED AND DIFFERS

FROM NATIONAL INSTRUMENTS' TESTING PLATFORMS AND BECAUSE A USER OR APPLICATION DESIGNER

MAY USE NATIONAL INSTRUMENTS PRODUCTS IN COMBINATION WITH OTHER PRODUCTS IN A MANNER NOT

EVALUATED OR CONTEMPLATED BY NATIONAL INSTRUMENTS, THE USER OR A PPLICATION DE SIGNER IS

ULTIMATELY RESPONSIBLE FOR VERIFYING AND VALIDATING THE SUITAB ILITY OF NA TIONAL

INSTRUMENTS PRODUCTS WHENEVER NATIONAL INSTRUMENTS PRODUCTS ARE INCORPORATED IN A

SYSTEM OR APPLICATION, INCLUDING, WITHOUT LIMITATION, THE APPROPRIATE DESIGN, PROCESS AND

SAFETY LEVEL OF SUCH SYSTEM OR APPLICATION.

Page 4

Compliance

FCC/Canada Radio Frequency Interference Compliance*

Determining FCC Class

The Federal Communications Commission (FCC) has rules to protect wireless communications from interference.

The FCC places digital electronics into two classes. These classes are known as Class A (for use in industrialcommercial locations only) or Class B (for use in residential or commercial locations). Depending on where it is

operated, this product could be subject to restrictions in the FCC rules. (In Canada, the Department of

Communications (DOC), of Industry Canada, regulates wireless interference in much the same way.)

Digital electronics emit weak signals during normal operation that can affect radio, television, or other wireless

products. By examining the product you purchased, you can determine the FCC Class and therefore which of the two

FCC/DOC Warnings apply in the following sections. (Some products may not be labelled at all for FCC, if so the

reader should then assume these are Class A devices.)

FCC Class A products only display a simple warning statement of one paragraph in length regarding interference and

undesired operation. Most of our products are FCC Class A. The FCC rules have restrictions regarding the locations

where FCC Class A products can be operated.

FCC Class B products display either a FCC ID code, starting with the letters EXN,

or the FCC Class B compliance mark that appears as shown here on the right.

The curious reader can consult the FCC web site

information.

FCC/DOC Warnings

This equipment generates and uses radio frequency energy and, if not installed and used in strict accordance with the

instructions in this manual and the CE Mark Declaration of Conformity**, may cause interference to radio and

television reception. Classification requirements are the same for the Federal Communications Commission (FCC)

and the Canadian Department of Communications (DOC).

Changes or modifications not expressly approved by National Instruments could void the user’s authority to operate

the equipment under the FCC Rules.

Class A

Federal Communications Commission

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15

of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to

radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in

which case the user will be required to correct the interference at his own expense.

http://www.fcc.gov for more

Canadian Department of Communications

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le matériel brouilleur du

Canada.

Class B

Federal Communications Commission

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15

of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio communications. However,

there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful

Page 5

interference to radio or television reception, which can be determined by turning the equipment off and on, the user

is encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Canadian Department of Communications

This Class B digital apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations.

Cet appareil numérique de la classe B respecte toutes les exigences du Règlement sur le matériel brouilleur du

Canada.

European Union - Compliance to EEC Directives

Readers in the EU/EEC/EEA must refer to the Manufacturer's Declaration of Conformity (DoC) for information**

pertaining to the CE Mark compliance scheme. The Manufacturer includes a DoC for most every hardware product

except for those bought for OEMs, if also available from an original manufacturer that also markets in the EU, or

where compliance is not required as for electrically benign apparatus or cables.

* Certain exemptions may apply in the USA, see FCC Rules §15.103 Exempted devices, and §15.105(c). Also

available in sections of CFR 47.

** The CE Mark Declaration of Conformity will contain important supplementary information and instructions for

the user or installer.

Page 6

Contents

About This Manual

Conventions ...................................................................................................................xi

Related Documentation........................................... .................................. .....................xii

Chapter 1

Introduction

About the RT Series.......................................................................................................1-1

What You Need to Get Started......................................................................................1-2

Unpacking......................................................................................................................1-2

Software Programming Choices....................................................................................1-3

Chapter 2

Installation and Configuration

Hardware Installation.....................................................................................................2-1

PCI Installation................................................................................................2-1

PXI Installation................................................................................................2-2

Board Configuration ......................................................................................................2-2

Chapter 3

Hardware Overview

Processor Board............................................................................................................. 3-2

DAQ Daughterboard......................................................................................................3-3

Host-to-RT Series DAQ Board Communication...........................................................3-4

RTSI...............................................................................................................................3-4

LEDs..............................................................................................................................3-4

Chapter 4

LabVIEW RT Programming

Targeting LabVIEW RT and Downloading VIs............................................................4-1

Resetting the RT Series DAQ Board...............................................................4-2

Creating Stand-Alone Executables................................................................................4-2

Embedded Applications...................................................................................4-2

Command-Line Arguments.............................................................................4-2

Programming LabVIEW RT..........................................................................................4-3

© National Instruments Corporation vii RT Series DAQ Device User Manual

Page 7

Contents

Real-Time Programming............................................................................................... 4-4

Running a VI at Time-Critical Priority

without the RT Development System..........................................................4-4

Use of Shared Memory...................................................................................4-4

Configuration Issues ................................. .................................. ....................4-4

RT Series DAQ Functions.............................................................................................4-6

RT Series DAQ VIs ........................................................................................4-6

RT Board Utilities VIs......................................................................4-7

RT Shared Memory Read Write VIs................................................ 4-8

RT Peek Poke with Error Cluster VIs ..............................................4-8

RT Low-Level Peek/Poke VIs..........................................................4-8

Appendix A

Specifications

Appendix B

Technical Support Resources

Glossary

Index

Figures

Figure 2-1. Measurement & Automation Explorer..................................................2-3

Figure 3-1. PCI RT Series Real-Time Data Acquisition Hardware ........................ 3-1

Figure 3-2. PXI RT Series Real-Time Data Acquisition Hardware ........................ 3-2

Figure 3-3. RT Series Processor Board Diagram .......................... ..........................3-3

Figure 4-1. Select Target Platform Dialog Box.......................................................4-1

Figure 4-2. RT Series DAQ Functions Palette ........................................................4-7

Tables

Table 1-1. RT Series DAQ Board and Corresponding DAQ Device Manual ......1-1

Activities

Activity 4-1. Communicating with an Embedded VI.................................................4-5

RT Series DAQ Device User Manual viii www.ni.com

Page 8

About This Manual

This manual contains information about the RT Series Data Acquisition

(DAQ) devices and working with LabVIEW RT. The RT Series DAQ

hardware consists of the following devices:

• PCI-7030/6040E

• PCI-7030/6030E

• PCI-7030/6533

• PXI-7030/6040E

• PXI-7030/6030E

• PXI-7030/6533

The R T Series DAQ family of boards are multifunction I/O boards with an

embedded processor. You can use LabVIEW RT and NI-DAQ to create

embedded, real-time applications that run on the RT Series DAQ board.

Conventions

The following conventions appear in this manual:

» The » symbol leads you through nested menu items and dialog box options

to a final action. The sequence File»Page Setup»Options directs you to

pull down the File menu, select the Page Setup item, and select Options

from the last dialog box.

This icon denotes the beginning of an activity.

This icon denotes the end of an activity.

This icon denotes a tip, which alerts you to advisory information.

This icon denotes a note, which alerts you to important information.

bold Bold text denotes items that you must select or click on in the software,

such as menu items and dialog box options. Bold text also denotes

parameter names.

© National Instruments Corporation ix RT Series DAQ Device User Manual

Page 9

About This Manual

italic Italic text denotes variables, emphasis, a cross reference, or an introduction

to a key concept. This font also denotes text that is a placeholder for a w ord

or value that you must supply.

monospace Text in this font denotes text or characters that you should enter from the

keyboard, sections of code, programming examples, and syntax examples.

This font is also used for the proper names of disk drives, paths, directories,

programs, subprograms, subroutines, device names, functions, operations,

variables, filenames and extensions, and code excerpts.

Related Documentation

The following documents contain information that you might find helpful

as you read this manual:

• LabVIEW RT User Manual

• LabVIEW RT Release Notes

• LabVIEW RT Help, available by selecting Help»LabVIEW RT Help

• LabVIEW QuickStart Guide

• LabVIEW User Manual

• G Programming Reference Manual

• LabVIEW Data Acquisition Basics Manual

• LabVIEW Online Reference, available by selecting

Help»Online Reference

Refer to the hardware user manual for the specific I/O board attached to

your RT Series board for more information about the I/O portion of your

hardware. For example, if you are using the PXI-7030/6040E, refer to the

PXI E Series User Manual for information on the 6040E daughterboard.

RT Series DAQ Device User Manual x www.ni.com

Page 10

Introduction

This chapter describes the RT Series DAQ boards, lists what you need

to get started, explains how to unpack your RT Series DAQ board, and

describes the software you need to use.

About the RT Series

The RT Series DAQ boards are multifunction DAQ boards with an

embedded processor. The RT Series DAQ board, along with LabVIEW RT

and NI-DAQ, provide an easy-to-use system for real-time applications.

Each RT Series D A Q board is made up of two parts—a processor board and

a DA Q daughterboard. The processor board contains a microprocessor that

runs real-time, embedded LabVIEW R T applications. The RT Series D AQ

board provides the same high-performance data acquisition as other

National Instruments DAQ boards. For example, the PXI-7030/6040E

contains a DAQ board that is equivalent to the PXI-6040E.

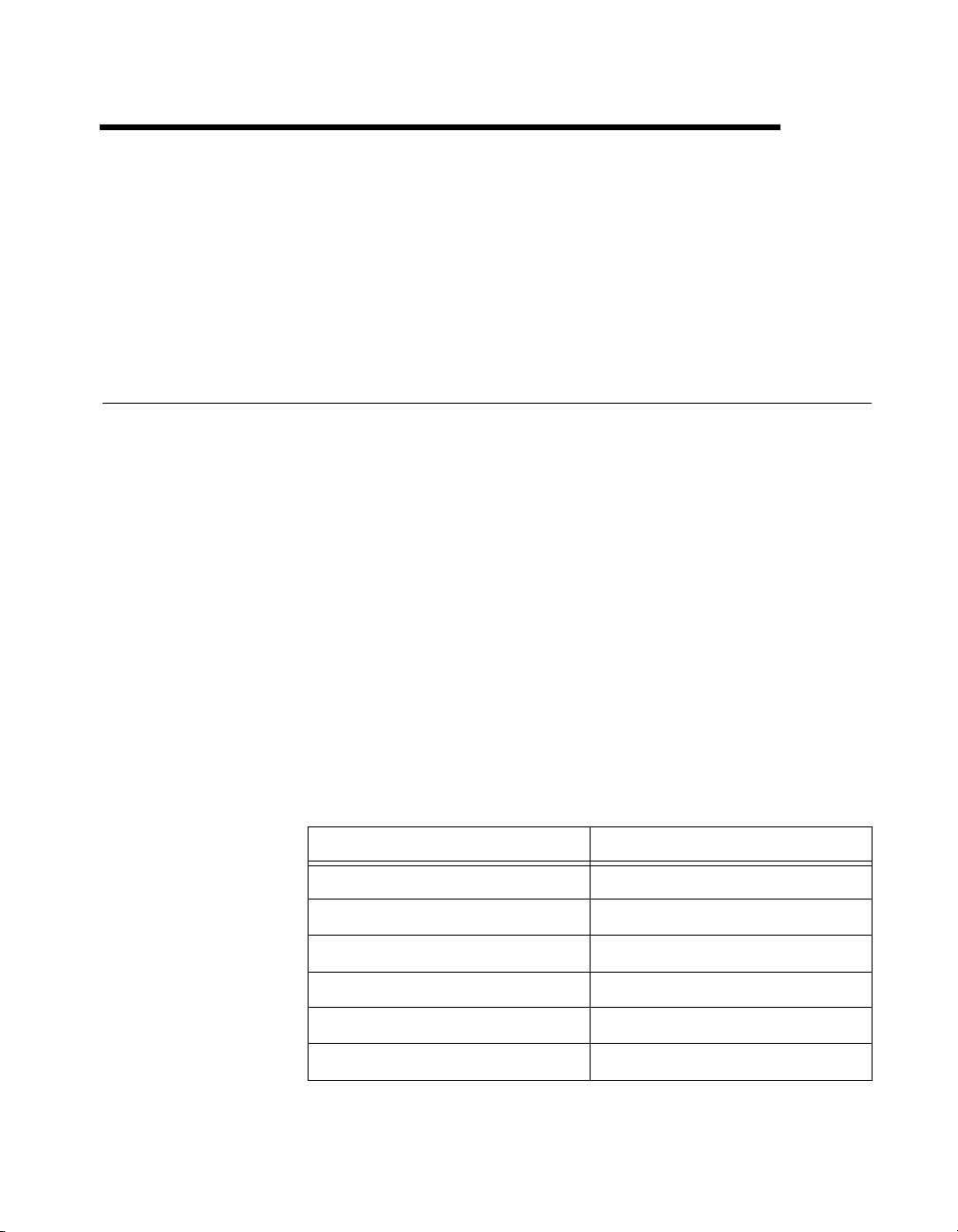

This manual does not contain detailed information about the DAQ

component of the RT Series DAQ boards. Refer to the appropriate DAQ

hardware user manual for more information, including optional equipment

and custom cabling for your DAQ device. Table 1-1 lists the appropriate

DAQ board user manual for each of the RT Series DAQ boards.

1

Table 1-1.

RT Series DAQ Board DAQ Manual

PXI-7030/6040E PXI E Series User Manual

PXI-7030/6030E PXI E Series User Manual

PXI-7030/6533 DIO 6533 User Manual

PCI-7030/6040E PCI E Series User Manual

PCI-7030/6030E PCI E Series User Manual

PCI-7030/6533 DIO 6533 User Manual

© National Instruments Corporation 1-1 RT Series DAQ Device User Manual

RT Series DAQ Board and Corresponding DAQ Device Manual

Page 11

Chapter 1 Introduction

What You Need to Get Started

To set up and use your RT Series DAQ board, you need the following:

❑ One of the following boards:

– PXI-7030/6XXX

– PCI-7030/6XXX

❑ This manual

❑ Hardware user manual for your DAQ daughterboard, shown

in Table 1-1

❑ LabVIEW RT

❑ LabVIEW RT User Manual

❑ LabVIEW RT Release Notes

❑ NI-DAQ and the NI-DAQ documentation installed with the software

❑ Your computer

Unpacking

Your RT Series DAQ board is shipped in an antistatic package to prevent

electrostatic damage to the board. Electrostatic discharge can damage

several components on the board. To avoid such damage in handling the

board, take the following precautions:

• Ground yourself by using a grounding strap or by holding a grounded

object.

• Touch the antistatic package to a metal part of your computer chassis

before removing the board from the package.

• Remove the board from the package and inspect the board for

loose components or any other sign of damage. Notify National

Instruments if the board appears damaged in any way. Do not install

a damaged board into your computer.

• Never touch the exposed pins of connectors.

RT Series DAQ Device User Manual 1-2 www.ni.com

Page 12

Software Programming Choices

You can use the RT Series DAQ boards with LabVIEW RT and NI-DAQ.

NI-DAQ is included with LabVIEW RT and you can install it during the

LabVIEW RT installation. For specific information on LabVIEW RT and

NI-DAQ version compatibility, refer to your LabVIEW RT Release Notes.

Refer to Chapter 2, Installation and Configuration, for more information

about installing your RT Series hardware.

Chapter 1 Introduction

© National Instruments Corporation 1-3 RT Series DAQ Device User Manual

Page 13

Installation and Configuration

This chapter explains how to install and configure your RT Series DAQ

hardware.

Hardware Installation

You can install the RT Series DAQ board in any available expansion slot

in your computer or PXI chassis. However, to reduce noise, leave as much

room as possible between the RT Series DAQ board and other boards and

hardware. The following are general installation instructions, so refer to

your computer user manual or technical reference manual for specific

instructions and warnings about installing hardware.

Note

Install LabVIEW RT and NI-D A Q before you install your R T Series D A Q hardware.

Refer to Chapter 2, Installation, of the LabVIEW RT User Manual for more information

about installing LabVIEW RT and NI-DAQ.

PCI Installation

Complete the following steps to install your RT Series PCI board:

1. Write down the RT Series DAQ board serial number for future

reference.

2. Power off and unplug your computer.

3. Remove the cover to your computer.

4. Remove the expansion slot cover on the back panel of the computer.

5. Insert the RT Series DAQ board into a 5 V PCI slot. Gently rock the

board to ease it into place. It may be a tight fit, but do not force the

board into place.

6. Screw the mounting bracket of the RT Series DAQ board to the back

panel rail of the computer.

7. Replace the cover.

8. Plug in and power on your computer.

2

Your RT Series DAQ device is installed. You are now ready to configure

your software.

© National Instruments Corporation 2-1 RT Series DAQ Device User Manual

Page 14

Chapter 2 Installation and Configuration

PXI Installation

Complete the following steps to install your RT Series PXI board:

1. Write down the PXI E Series board serial number for future reference.

2. Power off and unplug your computer.

3. Choose two adjacent unused PXI slots in your system.

4. Remove the filler panels for the slots you have chosen.

5. Insert the RT Series DAQ board into the 5 V PXI slots. Use the

injector/ejector handle to fully insert the board into the chassis.

6. Screw the front panel of the RT Series DAQ board to the front panel

mounting rail of the system.

7. Plug in and power on your computer.

Your RT Series DAQ device is installed. You are now ready to configure

your software.

Board Configuration

Because of the National Instruments standard architecture for data

acquisition and the PCI and PXI bus specifications, the RT Series DAQ

boards are completely software configurable.

The PCI RT Series DAQ boards are fully compatible with the industry

standard PCI Local Bus Specification Revision 2.0. The PXI RT Series

DAQ boards are fully compatible with the PXI Specification Revision 1.0.

This compatibility allows the PCI or PXI system to automatically perform

all bus-related configurations and requires no user interaction.

DAQ-related configuration includes such settings as analog inp ut polarity

and range, analog input mode, and others. You also can configure virtual

channels, SCXI, and DAQ accessories. You can modify these settings

through Measurement & Automation Explorer and through LabVIEW RT

and NI-DAQ.

After you complete the installation, double-click the Measurement &

Automation Explorer icon on your desktop. Measurement & Automation

Explorer finds the RT Series DAQ board and any other DAQ boards you

have in your system and assigns device numbers to them. The RT Series

DAQ device appears in Measurement & Automation Explorer as shown in

Figure 2-1.

RT Series DAQ Device User Manual 2-2 www.ni.com

Page 15

Chapter 2 Installation and Configuration

Figure 2-1. Measurement & Automation Explorer

Notice that Measurement & Automation Explorer assigns separate device

numbers to the PCI/PXI-7030 device and the DAQ daughterboard, as

shown in Figure 2-1. The DA Q daughterboard is shown as a separate de vice

under the 7030. However, the daughterboard has a device number that is

different from the 7030.

Remember the device numbers of your R T Series DA Q hardware. You need

them to download and run LabVIEW RT VIs to your RT Series DAQ

boards.Y ou can change de vice numbers and other configuration settings for

the devices using Measurement & Automation Explorer. Changes to these

settings do not take effect on the RT Series DAQ board until you reset the

board.

You can test the resources of the 7030 using Measurement & Automation

Explorer. Ho wever , you cannot test resources or run test panels for the DA Q

daughterboard because even though the daughterboard is configured using

the host PC, the daughterboard is actually located on the local PCI bus of

the of the RT Series daughterboard. Only LabVIEW RT applications

targeted to the 7030 can access the DA Q daughterboard. For this reason, the

resource configuration on the PCI bus cannot be tested from the host PC.

You do not need to test the resource configuration because National

Instruments configures it and it does not change. In addition, applications

run on the host PC cannot access the DAQ daughterboard directly, even

© National Instruments Corporation 2-3 RT Series DAQ Device User Manual

Page 16

Chapter 2 Installation and Configuration

though the DAQ daughterboard is configured as a separate device. Only

LabVIEW RT applications targeted to the RT Series DAQ device can

access the DAQ daughterboard.

Tip If you want to test whether the DA Q daughterboard is working, run any DA Q example

that ships with LabVIEW RT.

Save the configuration information by selecting File»Save. Then close

Measurement & Automation Explorer.

RT Series DAQ Device User Manual 2-4 www.ni.com

Page 17

Hardware Overview

This chapter describes the PCI and PXI RT Series DAQ hardware. You can

find most of the hardware information you need in the DAQ board manual.

Table 1-1, RT Series DAQ Board and Corresponding DAQ Device Manual,

lists the DAQ board manuals for the various RT Series DAQ boards.

As shown in Figure 3-1 and Figure 3-2, a DAQ daughterboard attaches to

the processor board, and together they form the RT Series DAQ hardware.

The following sections describe the components that make up the R T Series

DAQ hardware.

3

Processor Board

DAQ Daughterboard

Figure 3-1.

© National Instruments Corporation 3-1 RT Series DAQ Device User Manual

PCI RT Series Real-Time Data Acquisition Hardware

Page 18

Chapter 3 Hardware Overview

Processor Board

DAQ

Daughterboard

Figure 3-2. PXI RT Series Real-Time Data Acquisition Hardware

Processor Board

The 7030 processor board contains a microprocessor and support circuitry,

as shown in Figure 3-3. The support circuitry includes a chipset with PCI

controller and ISA bridge, main memory (DRAM), L2 cache (SRAM), and

BIOS. The LabVIEW RT software uses this embedded processor system

for its execution platform.

The DAQ daughterboard resides on the embedded PCI bus as shown in

Figure 3-3. This provides a high-performance system for communication

between the software running on the processor and the DAQ

daughterboard.

The processor board also holds the shared memory that communicates

between the host system and the embedded processor. Refer to the

Host-to-RT Series DAQ Board Communication section later in this chapter

and to Chapter 3, Software Overview, of the LabVIEW RT User Manual,

for more information about using shared memory for your applications.

RT Series DAQ Device User Manual 3-2 www.ni.com

Page 19

Processor Board

CPU

Embedded CPU Bus

Chapter 3 Hardware Overview

BIOS

Host PCI Bus

MITE

DAQ Daughterboard

ISA Bridge

Controller

Embedded ISA Bus

Shared Memory

Interface

Shared

Memory

I/O Daughter Board

Figure 3-3. RT Series Processor Board Diagram

SRAM/DRAM

BIOS

Extension

Cache Memory

PCI Controller

Embedded PCI Bus

The daughterboard in the RT Series system provides the DAQ

functionality. Each daughterboard is a National Instruments PXI DAQ

device with some mechanical modifications to allow it to connect to

the processor board. This means that you can expect the same high

performance and specifications from the daughterboard that you do from

the standard version of the device. For example, the PCI/PXI-7030/6040E

boards have the same DAQ characteristics as the PXI-6040E. For this

reason, you should refer to appropriate daughterboard manual for

© National Instruments Corporation 3-3 RT Series DAQ Device User Manual

Page 20

Chapter 3 Hardware Overview

specifications, cabling requirements, and accessory information. Table 1-1,

RT Series DAQ Board and Corresponding DAQ Device Manual, lists the

appropriate manual for each available daughterboard. Refer to the DAQ

section of the LabVIEW Online Reference, available by selecting

Help»Online Reference in LabVIEW, for more information abou t

hardware and software configuration.

Host-to-RT Series DAQ Board Communication

The computer into which the RT Series DAQ board is installed is called the

host computer. The RT Series DAQ board communicates to the host

computer in which it resides through shared memory on the 7030 processor

board. Both the host computer and the embedded processor have access to

the shared memory. The memory is allocated for various tasks. For

example, the LabVIEW RT Development System, on the host, uses part of

the shared memory for downloading software to the board. There is also

some memory space allocated to the user for passing data between the host

computer and the processor board.

RTSI

The real-time system integration bus (RTSI bus) directly connects DAQ

boards for precise synchronization of functions. The RT Series boards

provide all RTSI functionality. The RTSI bus allows you to connect

RT Series boards to any other DAQ board regardless of whether the other

board is an RT Series board or standard DAQ board.

The R TSI connections are made across the PXI trigger bus for the PXI RT

boards. For PCI R T Series boards, the connection is made with a connector

on the top edge of the board and a RTSI cable available from National

Instruments. Refer to your daughterboard user manual for information

on how to use the RTSI signals. Table 1-1, RT Series DAQ Board and

Corresponding DAQ Device Manual, lists the appropriate manual for

each available daughterboard.

LEDs

There are two LEDs on the RT Series processor board. You can use these

LEDs to indicate the state of your running application. On the PXI-7030,

the LEDs are visible on the front panel. On the PCI-7030, the LEDs are

located along the top edge of the board, and you must remove the cover

from the case of your computer to view them.

RT Series DAQ Device User Manual 3-4 www.ni.com

Page 21

Chapter 3 Hardware Overview

The red LED turns on during a portion of the reset of the RT Series DAQ

board. Also, the red LED turns on and remains lighted if the RT Engine

detects an internal error. You can control both the red LED and a second

green LED from LabVIEW RT applications to provide status information.

You can use the RT Board LEDs VI, located in the Functions»RT»RT

Series DAQ»RT Board Utilities palette, in your application to control

each LED independently . You can turn each LED on, off, or toggle its state.

Refer to the LabVIEW RT Online Reference for more information on the

RT Board LEDs VI.

© National Instruments Corporation 3-5 RT Series DAQ Device User Manual

Page 22

LabVIEW RT Programming

This chapter provides an overview of using LabVIEW RT and your

RT Series DAQ hardware.

Targeting LabVIEW RT and Downloading VIs

In the LabVIEW RT Development System, select Operate»Switch

Execution Target to access the Select Target Platform dialog box, shown

in Figure 4-1.

4

Figure 4-1.

Use the pull-down menu to select where you want to run VIs. When you

select a target platform, the RT Development System downloads any VI

you subsequently run to that target platform. Selecting Host PC

(LabVIEW for Windows) makes LabVIEW RT behave like LabVIEW

for Windows on the host PC.

Any RT Series DAQ board that you configured with Measurement &

Automation Explorer appears in the pull-down menu. The menu selection

for each device displays the de vice number , for example, DAQ::1, where 1

is the device number . Click the Reset device checkbox in the Select Target

Platform dialog box to reset the RT Series DAQ device. Any VIs you

previously downloaded to the RT Series DAQ device are aborted and

© National Instruments Corporation 4-1 RT Series DAQ Device User Manual

Select Target Platform Dialog Box

Page 23

Chapter 4 LabVIEW RT Programming

unloaded from memory. Click Configure in the Select Target Platform

dialog box to launch Measurement & Automation Explorer and configure

your RT Series DAQ devices.

Resetting the RT Series DAQ Board

Resetting the RT Series DAQ board is necessary only after you first turn on

the system or if communication with the RT Engine cannot be established

or has been lost. Also, reset the board when you change the DAQ

configuration information for the RT Series DAQ board.

Creating Stand-Alone Executables

Use the Application Builder, included in the LabVIEW RT Professional

Development System, to create stand-alone LabVIEW RT applications.

Refer to the LabVIEW RT User Manual and the LabVIEW Application

Builder Release Notes for more information about the Application Builder.

Note

If you have the LabVIEW RT Full Development System, you can purchase the

Application Builder upgrade.

Embedded Applications

Because the RT Series DAQ hardware has no media storage device (for

example, a hard drive), you cannot permanently embed applications on the

hardware. You must launch applications on the host and target them to the

RT Series DAQ device.

Command-Line Arguments

You can use command-line arguments to disable the Select Target

Platform dialog box and explicitly specify a target for the application. You

can use the parameters in a batch file, or shortcut, from your Windows

StartUp folder to automatically launch RT Engine VIs when your host PC

is booted. For example, create a Windows shortcut with the shortcut target:

c:\mybuiltapp.exe -target DAQ::1 -quithost

This command line automatically downloads and runs mybuiltapp on

device 1 and closes the RT Development System on the host PC.

RT Series DAQ Device User Manual 4-2 www.ni.com

Page 24

T o disable the Select T arget Platform dialog box, specify the target platform

in the command line argument of your built e xecutable using

example:

c:\mybuiltapp_rtengine.exe -target DAQ::3 (for device 3)

or to run the application on the host PC:

c:\mybuiltapp_host.exe -target host

You also can reset the specified board using -reset. For example:

c:\mybuiltapp_rtengine.exe -target DAQ::3 -reset

T o disconnect the host PC from the R T Engine after all VIs are downloaded

and leave the RT Engine VIs running, use

c:\mybuiltapp_rtengine.exe -target DAQ::3 -quithost

Programming LabVIEW RT

Because you run LabVIEW RT on hardware platforms that do not have all

the components of a computer, LabVIEW RT lacks some LabVIEW

features when targeted to the RT Engine. For example, there is no disk

drive on the RT Series DAQ device, therefore, LabVIEW RT does not

support file I/O when targeted to the RT Series DAQ device. LabVIEW RT

does not support the following LabVIEW functions on RT Series DAQ

hardware:

•ActiveX

• Datalogging

• Dialog boxes

• Ethernet

•File I/O

• Instrument I/O: VISA, 488, RS-232/Serial

• Printing

•Profiler

• Programmatic Menu Bar

Chapter 4 LabVIEW RT Programming

–target. For

-quithost. For example:

Note

If you attempt to download to and run on your target platform a VI that has any of

the unsupported functionality listed above, the VI still executes. Unsupported functions do

not work and return standard LabVIEW error codes.

© National Instruments Corporation 4-3 RT Series DAQ Device User Manual

Page 25

Chapter 4 LabVIEW RT Programming

Real-Time Programming

This section provides an overview of real-time programming using your

RT Series DAQ hardware.

Running a VI at Time-Critical Priority without the RT Development System

Instead of using TCP/IP or VI Server to communicate data to a host PC

application, you can maximize real-time VI performance on RT Series

DAQ devices by peeking and poking data to shared memory. Peeking, or

reading directly from shared memory, and poking, or writing directly to

shared memory, are common programming techniques and do not require

the VI to yield any processor time. You can create deterministic control

loops that run in excess of 1 kHz when you peek and poke data to shared

memory. Refer to Chapter 3, Software Overview, of the LabVIEW RT User

Manual for more information about TCP/IP and VI Server.

Note

Windo ws NT does not support peeking and poking to shared memory on the PC.

However, because the shared memory is located on the RT Series DAQ device, Windows

NT does support peeking and poking to this shared memory.

Use of Shared Memory

Using peek and poke VIs to write directly to shared memory offers the best

performance. Because you can access shared memory both from a host

LabVIEW application and from an embedded LabVIEW RT VI, you can

write a control loop program that does not have to slow down or yield to

communicate with the host system. Many such examples are in the

examples\RT\RTControl.llb library.

Configuration Issues

The LabVIEW RT Development System downloads the RT Engine to the

RT Series DAQ hardware and sends configuration information when you

reset the hardware. If you make any change to the board configuration

information from Measurement & Automation Explorer, you must reset the

RT Series DAQ hardware for the changes to take effect.

LabVIEW RT also supports virtual channels, SCXI, and DA Q accessories

on the RT Series DAQ hardware, but their descriptions download to the

board when the board is reset. If you add a new channel or change the

parameters of a channel using Measurement & Automation Explorer, you

must reset the RT Series DAQ hardware for these changes to take effect.

RT Series DAQ Device User Manual 4-4 www.ni.com

Page 26

However, unlike virtual channels, you can set board parameters or

accessory configuration information programmatically inside a VI

without running Measurement & Automation Explorer. Therefore, you

can programmatically change these parameters in your VI, without

resetting the hardware.

Refer to your NI-DAQ documentation and the DAQ section of the

LabVIEW Online Reference, available by selecting Help»Online

Reference, for more information about configuration.

Activity 4-1. Communicating

with an Embedded VI

Your objective is to communicate with an embedded VI using shared

memory.

1. Open LabVIEW RT and select Operate»Switch Execution Target to

access the Select Target Platform dialog box.

2. Select the appropriate RT Series DAQ board from the Select Target

Platform dialog box. Click OK.

3. Run the Peek Poke I32 - RT Engine VI, found in the

Examples\RT\RTComm.llb library.

4. Select Operate»Switch Execution Target to close the

RT Development System but not the embedded VI.

5. Select Host PC (LabVIEW for Windows) from the Select Target

Platform dialog box. Run the Peek Poke I32 - Host PC VI, found in

the

Examples\RT\RTComm.llb library.

Refer to Windows»Show VI Info of these VIs for more information.

Chapter 4 LabVIEW RT Programming

Tip

Although peek and poke VIs are the low level, f astest form of communication, using

several of these VIs in a control loop can slow down your application. If you need a loop

with communication to run at maximum rates, use the R T Incremental Single Write VI and

R T Incrementa l Single Read VI, found on the RT»RT Series DAQ»RT Board Utilities

palette.

The size of the shared memory is limited to 1 kB. If you need to

transfer several megabytes of data, you must separate the data into

smaller portions and then transfer them. In doing so, you must make

sure that you do not overwrite data in the shared memory before you

read it. TCP/IP VIs manage flow control and are more convenient for

bulk transfers.

© National Instruments Corporation 4-5 RT Series DAQ Device User Manual

Page 27

Chapter 4 LabVIEW RT Programming

6. Open and run the TCP - RT Engine VI on the RT Series DAQ device.

You can find the VI in the

7. Select Operate»Switch Execution Target to close the

RT Development System but not the embedded VI.

8. Open and run the TCP - Host PC VI on the host PC. You can find the

VI in the

9. Exit LabVIEW RT by selecting File»Exit. Do not save changes.

This closes LabVIEW RT and stops and closes the TCP - RT Engine

VI on the RT Series DAQ device.

Examples\RT\RTComm.llb library.

End of Activity 4-1.

RT Series DAQ Functions

This section contains information about the RT Series DAQ VIs. Refer to

the LabVIEW RT Online Help, available by selecting Help»LabVIEW RT

Help, for more information about the LabVIEW RT VIs.

Examples\RT\RTComm.llb library.

RT Series DAQ VIs

In addition to the RT Series DAQ VIs, LabVIEW RT includes the PID

Control T oolset, which includes functions for PID and Fuzzy Logic control.

The Fuzzy Controller VI requires information for a specific designed fuzzy

controller loaded from its corresponding data file (

LabVIEW RT does not support file I/O, you must save this information as

the default values of the front panel controls of the Fuzzy Controller VI

before attempting to use it on the RT Series DA Q de vice. Refer to the PID

Control for G Reference Manual for more information about the PID

Control and Fuzzy Logic VIs.

You can find VIs specific to RT Series DAQ on the Functions»RT»RT

Series DAQ palette, as shown in Figure 4-2.

*.fc). Because

RT Series DAQ Device User Manual 4-6 www.ni.com

Page 28

Chapter 4 LabVIEW RT Programming

Figure 4-2. RT Series DAQ Functions Palette

RT Board Utilities VIs

Use the RT Board Utilities VIs to check the shared memory size, toggle the

board LEDs, and facilitate high-level communication between the

RT Series DAQ device and the host PC.

© National Instruments Corporation 4-7 RT Series DAQ Device User Manual

Page 29

Chapter 4 LabVIEW RT Programming

RT Shared Memory Read Write VIs

Use the RT Read Write VIs to read and write data from the shared memory

of your PXI or PCI-7030 RT Series DAQ device. The read and write shared

memory VIs differ from the peek and poke shared memory VIs in that the

read and write shared memory VIs use a read/write flag to determine if data

has changed.

RT Peek Poke with Error Cluster VIs

Use the RT Peek Poke VIs to peek and poke data to and from the shared

memory on the RT Series DAQ board. The RT Peek Poke VIs differ from

the RT Low-Level Peek Poke VIs in that they include the standard error

cluster and provide the next byte offset indicator.

RT Low-Level Peek Poke VIs

Use the RT Low-Level Peek Poke VIs to peek and poke data to and from

the shared memory on the RT Series DAQ board. The RT Low-Level Peek

Poke VIs differ from the RT Peek Poke with Error Cluster VIs in that they

do not include the standard error cluster nor provide the next byte offset

indicator.

RT Series DAQ Device User Manual 4-8 www.ni.com

Page 30

Specifications

This appendix lists the specifications of the embedded processor system.

Processor

Processor................................................AMD 486 DX5

Processor clock speed ............................133 MHz

CPU bus speed.......................................33 MHz

Memory........................................... .......8 MB DRAM user-programmable

On-chip cache ........................................ 16 KB write-back

L2 cache.................................................256 KB write-back

Floating-point unit..................................Yes

A

32-bit architecture

60 ns, EDO, 5 V,

72-Pin SODIMM

Host-Embedded Communication

Shared Memory

Type .......................................................SRAM

Size.........................................................1 KB user available

Bus Interface

Type .......................................................PCI Slave

© National Instruments Corporation A-1 RT Series DAQ Device User Manual

Page 31

Appendix A Specifications

Power Requirement

Note

T o calculate the total power requirement, add the processor board requireme nt from

this section to the I/O board requirement given in the I/O board manual.

Physical

PCI-7030 only (without

daughterboard)........................................1.9 A at +5 VDC (±5%)

PXI-7030 only (without

daughterboard)........................................2.0 A at +5 VDC (±5%)

Dimensions (Not Including Connectors)

PCI-7030.................................................312.9 by 160.5 cm

(12.3 by 4.2 in.)

One PCI slot

PXI-7030 ................................................16 by 10 cm (6.3 by 3.9 in.)

Two PXI slots

Environment

Operating temperature............................0 to 55 °C

Storage temperature................................–20 to 70 °C

Relative humidity ...................................10% to 90% noncondensing

RTSI

Refer to the RTSI section of Chapter 3, Hardware Overview.

I/O Daughterboard Specifications

Refer to the appropriate I/O board manual, listed in Table 1-1, RT Series

DAQ Board and Corresponding DAQ Device Manual, for more

information about I/O daughterboard specifications.

RT Series DAQ Device User Manual A-2 www.ni.com

Page 32

Technical Support Resources

This appendix describes the comprehensive resources available to yo u in

the Technical Support section of the National Instruments Web site and

provides technical support telephone numbers for you to use if you have

trouble connecting to our Web site or if you do not have internet access.

NI Web Support

To provide you with immediate answers and solutions 24 hours a day,

365 days a year, National Instruments maintains extensi ve online technical

support resources. They are available to you at no cost, are updated daily,

and can be found in the Technical Support section of our Web site at

www.ni.com/support

Online Problem-Solving and Diagnostic Resources

• KnowledgeBase—A searchable database containing thousands of

frequently asked questions (F A Qs) and their corresponding answers or

solutions, including special sections devoted to our newest products.

The database is updated daily in response to new customer experiences

and feedback.

• Troubleshooting Wizards—Step-by-step guides lead you through

common problems and answer questions about our entire product line.

Wizards include screen shots that illustrate the steps being described

and provide detailed information ranging from simple getting started

instructions to advanced topics.

• Product Manuals—A comprehensive, searchable library of the latest

editions of National Instruments hardware and software product

manuals.

• Hardware Reference Database—A searchable database containing

brief hardware descriptions, mechanical drawings, and helpful images

of jumper settings and connector pinouts.

• Application Notes—A library with more than 100 short papers

addressing specific topics such as creating and calling DLLs,

developing your own instrument driver software, and porting

applications between platforms and operating systems.

B

© National Instruments Corporation B-1 RT Series DAQ Device User Manual

Page 33

Appendix B Technical Support Resources

Software-Related Resources

• Instrument Driver Network—A library with hundreds of instrument

drivers for control of standalone instruments via GPIB, VXI, or serial

interfaces. You also can submit a request for a particular instrument

driver if it does not already appear in the library.

• Example Programs Database—A database with numerous,

non-shipping example programs for National Instruments

programming environments. You can use them to complement the

example programs that are already included with National Instruments

products.

• Software Library—A library with updates and patches to application

software, links to the latest versions of driver software for National

Instruments hardware products, and utility routines.

Worldwide Support

National Instruments has offices located around the globe. Many branch

offices maintain a Web site to provide information on local services. You

can access these Web sites from

www.ni.com/worldwide

If you have trouble connecting to our Web site, please contact your local

National Instruments office or the source from which you purchased your

National Instruments product(s) to obtain support.

For telephone support in the United States, dial 512 795 8248. For

telephone support outside the United States, contact your local branch

office:

Australia 03 9879 5166, Austria 0662 45 79 90 0, Belgium 02 757 00 20,

Brazil 011 284 5011, Canada (Calgary) 403 274 9391,

Canada (Ontario) 905 785 0085, Canad a (Québec) 514 694 8521,

China 0755 3904939, Denmark 45 76 26 00, Finland 09 725 725 11,

France 01 48 14 24 24, Germany 089 741 31 30, Greece 30 1 42 96 427,

Hong Kong 2645 3186, India 91805275406, Israel 03 6120092,

Italy 02 41309 1, Japan 03 5472 2970, Korea 02 596 7456,

Mexico (D.F.) 5 280 7625, Mexico (Monterrey) 8 357 7695,

Netherlands 0348 433466, New Zealand 09 914 0488,

Norway 32 27 73 00, Poland 0 22 528 94 06, Portugal 351 1 726 9011,

Singapore 2265886, Spain 91 640 0085, Sweden 08 587 895 00,

Switzerland 056 200 51 51, Taiwan 02 2528 7227,

United Kingdom 01635 523545

RT Series DAQ Device User Manual B-2 www.ni.com

Page 34

Glossary

Prefix Meanings Value

m- milli- 10

k- kilo- 10

M- mega- 10

G- giga- 10

Numbers/Symbols

% percent

+ positive of, or plus

– negative of, or minus

°degree

–3

3

6

9

A

A amperes

address character code that identifies a specific location (or series of locations) in

memory

B

b bit—one binary digit, either 0 or 1

B byte—eight related bits of data, an eight-bit binary number. Also used to

denote the amount of memory required to store one byte of data.

BIOS basic input/output system—BIOS functions are the fundamental level of

any PC or compatible computer. BIOS functions embody the basic

operations needed for successful use of the computer’s hardw are resources.

© National Instruments Corporation G-1 RT Series DAQ Device User Manual

Page 35

Glossary

bus the group of conductors that interconnect individual circuitry in a computer.

Typically, a bus is the expansion vehicle to which I/O or other devices are

connected. Examples of PC buses are the ISA and PCI bus.

C

C Celsius

cache high-speed processor memory that buff ers commonly used instructions or

data to increase processing throughput

channel pin or wire lead to which you apply or from which you read the analog or

digital signal. Analog signals can be single-ended or differential. For digital

signals, you group channels to form ports. Ports usually consist of either

four or eight digital channels.

clock hardware component that controls timing for reading from or writing to

groups

CPU central processing unit

D

DAQ data acquisition—(1) collecting and measuring electrical signals from

sensors, transducers, and test probes or fixtures and inputting them to a

computer for processing; (2) collecting and measuring the same kinds of

electrical signals with A/D and/or DIO boards plugged into a computer , and

possibly generating control signals with D/A and/or DIO boards in the

same computer

device a plug-in data acquisition board, card, or pad that can contain multiple

channels and conversion devices. Plug-in boards, PCMCIA cards, and

devices such as the DAQPad-1200, which connects to your computer

parallel port, are all examples of DAQ devices. SCXI modules are distinct

from devices, with the exception of the SCXI-1200, which is a hybrid.

DIO digital input/output

DRAM dynamic RAM

RT Series DAQ Device User Manual G-2 www.ni.com

Page 36

Glossary

H

hardware the physical components of a computer system, such as the circuit boards,

plug-in boards, chassis, enclosures, peripherals, and cables

Hz hertz—the number of scans read or updates written per second

I

I/O input/output—the transfer of data to/from a computer system involving

communications channels, operator interface devices, and/or data

acquisition and control interfaces

ISA industry standard architecture

K

K kilo—the prefix for 1,024, or 210, used with B in quantifying data or

computer memory

L

LabVIEW laboratory virtual instrument engineering workbench

LED light-emitting diode

library a fi le containing compiled object modules, each comprised of one of more

functions, that can be linked to other object modules that make use of these

functions. NIDAQMSC.LIB is a library that contains NI-DAQ functions.

The NI-DAQ function set is broken down into object modules so that only

the object modules that are relevant to your application are linked in, while

those object modules that are not relevant are not linked.

M

M Me ga, the standard metric prefix for 1 million or 106, when used with units

of measure such as volts and hertz

MB megabytes of memory

© National Instruments Corporation G-3 RT Series DAQ Device User Manual

Page 37

Glossary

N

NI-DAQ Nationa l In struments driver software for DAQ hardware

O

operating system base-level software that controls a computer , runs programs, interacts with

users, and communicates with installed hardware or peripheral devices

P

PCI Peripheral Component Interconnect—a high-performance expansion bus

architecture originally developed by Intel to replace ISA and EISA. It is

achieving widespread acceptance as a standard for PCs and work-stations;

it offers a theoretical maximum transfer rate of 132 Mbytes/s.

PID control a three-term control mechanism combining proportional, integral, and

derivative control actions. Also see proportional control, integral control,

and derivative control.

R

RAM random-access memory

real time a property of an event or system in which data is processed as it is acquired

instead of being accumulated and processed at a later time

resource locking a technique whereby a device is signaled not to use its local memory while

the memory is in use from the bus

S

shared memory memory that can be sequentially accessed by more than one controller or

processor but not simultaneously accessed. Also known as dual-mode

memory.

soft reboot restarting a computer witho ut cycling the power, usually through the

operating system

RT Series DAQ Device User Manual G-4 www.ni.com

Page 38

T

TCP Transmission Control Protocol

trigger any event that causes or starts some form of data capture

V

V volts

VI virtual instrument—(1) a combination of hardware and/or software

elements, typically used with a PC, that has the functionality of a classic

stand-alone instrument; (2) a LabVIEW software module (VI), which

consists of a front panel user interface and a block diagram program

VISA virtual instrument software architecture—a new driv er software

architecture developed by National Instruments to unify

instrumentation software GPIB, DAQ, and VXI. It has been accepted as

a standard for VXI by the VXIplug&play Systems Alliance.

Glossary

© National Instruments Corporation G-5 RT Series DAQ Device User Manual

Page 39

Index

B

board configuration, 2-2 to 2-4

bus interface specifications, A-1

C

command-line arguments, 4-2 to 4-3

communication

communicating with embedded VI

(activity 4-1), 4-5 to 4-6

host-embedded communication shared

memory, A-1

host-to-RT Series DAQ board

communication, 3-4

configuration

board configuration, 2-2 to 2-4

real-time programming issues, 4-4 to 4-5

conventions used in manual, xi-xii

D

DAQ devices. See RT Series DAQ devices.

DAQ functions. See RT series DAQ functions.

daughterboard

hardware overview, 3-3 to 3-4

specifications, A-2

diagnostic resources, online, B-1

documentation

about this manual, xi

conventions used in manual, xi-xii

devices and corresponding manual

(table), 1-1

related documentation, xii

downloading VIs, 4-1 to 4-2

E

embedded applications, 4-2

embedded VI, communicating with

(activity4-1), 4-5to4-6

environment specifications, A-2

executables. See stand-alone executables,

creating.

F

functions. See RT series DAQ functions.

H

hardware overview, 3-1 to 3-5

daughterboard, 3-3 to 3-4

host-to-RT Series DAQ board

communication, 3-4

LEDs, 3-4 to 3-5

PCI RT Series RT DAQ hardware

(figure), 3-1

processor board, 3-2 to 3 -3

PXI RT Series RT DAQ hardware

(figure), 3-2

RTSI bus, 3-4

host-embedded communication shared

memory, A-1

host-to-RT Series DAQ board

communication, 3-4

I

installation, 2-1 to 2-2

PCI boards, 2-1

PXI boards, 2-1

unpacking RT Series DAQ devices, 1-2

© National Instruments Corporation I-1 RT Series DAQ Device User Manual

Page 40

Index

L

LabVIEW functions not supported on DAQ

hardware, 4-3

LabVIEW RT programming, 4-1 to 4-8

creating stand-alone executables,

4-2 to 4-3

downloading VIs, 4-1 to 4-2

LabVIEW functions not supported on

DAQ hardware, 4-3

real-time programming, 4-4 to 4-6

communicating with embedded VI

(activity 4-1), 4-5 to 4-6

configuration issues, 4-4 to 4-5

running VI at time-critical

priority, 4-4

shared memory, 4-4

resetting RT Series DAQ board, 4-2

RT series DAQ functions, 4-6 to 4-8

RT Board Utilities VIs, 4-7

RT Low-Level Peek/Poke VIs, 4-8

RT Peek Poke with Error

Cluster VIs, 4-8

RT Series DAQ VIs, 4-6 to 4-7

RT Shared Memory Read

Write VIs, 4-8

targeting LabVIEW RT, 4-1 to 4-2

LEDs, 3-4 to 3-5

M

manual. See documentation.

Measurement & Automation

Explorer, 2-2 to 2-4

N

National Instruments Web support, B-1 to B-2

O

online problem-solving and diagnostic

resources, B-1

P

PCI boards. See also hardware overview.

installation, 2-1

PCI RT Series RT DAQ hardware

(figure), 3-1

Peek Poke VIs

RT Low-Level Peek/Poke VIs, 4-8

RT Peek Poke with Error Cluster VIs, 4-8

physical specifications, A-2

power requirement specifications, A-2

problem-solving and diagnostic resources,

online, B-1

processor board, 3-2 to 3-3

board diagram, 3-3

description, 3-2

specifications, A-1

programming. See LabVIEW RT

programming.

PXI boards. See also hardware overview.

installation, 2-1

PXI RT Series RT DAQ hardware

(figure), 3-2

RT Series DAQ Device User Manual I-2 www.ni.com

Page 41

Index

R

real-time programming, 4-4 to 4-6

communicating with embedded VI

(activity 4-1), 4-5 to 4-6

configuration issues, 4-4 to 4-5

running VI at time-critical priority

without RT Development System, 4-4

shared memory, 4-4

requirements for getting started, 1-2

resetting RT Series DAQ board, 4-2

RT Series DAQ devices. See also hardware

overview.

configuration, 2-2 to 2-4

devices and corresponding manual

(table), 1-1

installation, 2-1 to 2-2

overview, 1-1

programming. See LabVIEW RT

programming.

requirements for getting started, 1-2

software programming choices, 1-3

specifications, A-1 to A-2

unpacking, 1-2

RT Series DAQ functions, 4-6 to 4-8

RT Board Utilities VIs, 4-7

RT Low-Level Peek/Poke VIs, 4-8

RT Peek Poke with Error Cluster VIs, 4-8

RT Series DAQ Functions palette

(figure), 4-7

RT Series DAQ VIs, 4-6 to 4-7

RT Shared Memory Read Write VIs, 4-8

RTSI bus, 3-4

S

shared memory

communicating with embedded VI

(activity 4-1), 4-5 to 4-6

host-embedded communication shared

memory, A-1

real-time programming, 4-4

RT Shared Memory Read Write VIs, 4-8

software programming choices, 1-3

software-related resources, B-2

specifications, A-1 to A-2

stand-alone executables, creating, 4-2 to 4-3

command-line arguments, 4-2 to 4-3

embedded applications, 4-2

T

targeting LabVIEW RT, 4-1 to 4-2

technical support resources, B-1 to B-2

U

unpacking RT Series DAQ devices, 1-2

V

VIs

communicating with embedded VI

(activity 4-1), 4-5 to 4-6

downloading VIs, 4-1 to 4-2

RT Board Utilities VIs, 4-7

RT Low-Level Peek/Poke VIs, 4-8

RT Peek Poke with Error Cluster VIs, 4-8

RT Series DAQ VIs, 4-6 to 4-7

RT Shared Memory Read Write VIs, 4-8

W

Web support from National Instruments,

B-1 to B-2

online problem-solving and diagnostic

resources, B-1

software-related resources, B-2

Worldwide technical support, B-2

© National Instruments Corporation I-3 RT Series DAQ Device User Manual

Loading...

Loading...