Page 1

RMX

RMX Programmable Power Supplies User Manual

RMX-4120

RMX-4121

RMX-4122

RMX-4123

RMX-4124

RMX-4125

RMX-4126

RMX-4127

RMX Programmable Power Supplies User Manual

February 2017

375744C-01

Page 2

About the RMX User Manual

This manual is intended for users of the Regulated DC Power Supply and their instructors.

It is assumed that the reader has knowledge about electrical safety standards and the electrical

aspects of regulated DC power supplies.

Safety Guidelines

Indicates general danger, warning, or caution. When this symbol is marked on the

product, see the relevant section in the operation manual.

Indicates a location whose surface can become hot.

Protective conductor terminal.

Chassis (frame) terminal.

On (supply).

Off (supply).

Support

Worldwide Technical Support and Product Information

ni.com

Worldwide Offices

Visit ni.com/niglobal to access the branch office Web sites, which provide up-to-date

contact information, support phone numbers, email addresses, and current events.

National Instruments Corporate Headquarters

11500 North Mopac Expressway Austin, Texas 78759-3504 USA Tel: 512 683 0100

For further support information, refer to the NI Services appendix. To comment on National

Instruments documentation, refer to the National Instruments website at

enter the Info Code feedback.

© 2016-2017 National Instruments. All rights reserved.

ni.com/info and

Page 3

Legal Information

Limited Warranty

This document is provided ‘as is’ and is subject to being changed, without notice, in future editions. For the latest version,

refer to

ni.com/manuals. NI reviews this document carefully for technical accuracy; however, NI MAKES NO EXPRESS

OR IMPLIED WARRANTIES AS TO THE ACCURACY OF THE INFORMATION CONTAINED HEREIN AND

SHALL NOT BE LIABLE FOR ANY ERRORS.

NI warrants that its hardware products will be free of defects in materials and workmanship that cause the product to fail to

substantially conform to the applicable NI published specifications for one (1) year from the date of invoice.

For a period of ninety (90) days from the date of invoice, NI warrants that (i) its software products will perform substantially

in accordance with the applicable documentation provided with the software and (ii) the software media will be free from

defects in materials and workmanship.

If NI receives notice of a defect or non-conformance during the applicable warranty period, NI will, in its discretion: (i) repair

or replace the affected product, or (ii) refund the fees paid for the affected product. Repaired or replaced Hardware will be

warranted for the remainder of the original warranty period or ninety (90) days, whichever is longer. If NI elects to repair or

replace the product, NI may use new or refurbished parts or products that are equivalent to new in performance and reliability

and are at least functionally equivalent to the original part or product.

You must obtain an RMA number from NI before returning any product to NI. NI reserves the right to charge a fee for

examining and testing Hardware not covered by the Limited Warranty.

This Limited Warranty does not apply if the defect of the product resulted from improper or inadequate maintenance,

installation, repair, or calibration (performed by a party other than NI); unauthorized modification; improper environment;

use of an improper hardware or software key; improper use or operation outside of the specification for the product; improper

voltages; accident, abuse, or neglect; or a hazard such as lightning, flood, or other act of nature.

THE REMEDIES SET FORTH ABOVE ARE EXCLUSIVE AND THE CUSTOMER’S SOLE REMEDIES, AND SHALL

APPLY EVEN IF SUCH REMEDIES FAIL OF THEIR ESSENTIAL PURPOSE.

EXCEPT AS EXPRESSLY SET FORTH HEREI N, PRODUCTS ARE PROVIDED "AS IS" WITHOUT WARRANTY OF

ANY KIND AND NI DISCLAIMS ALL WARRANTIES, EXPRESSED OR IMPLIED, WITH RESPECT TO THE

PRODUCTS, INCLUDING ANY IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A

PARTICULAR PURPOSE, TITLE OR NON-INFRINGEMENT, AND ANY WARRANTIES THAT MAY ARISE FROM

USAGE OF TRADE OR COURSE OF DEALING. NI DOES NOT WARRANT, GUARANTEE, OR MAKE ANY

REPRESENTATIONS REGARDING THE USE OF OR THE RESULTS OF THE USE OF THE PRODUCTS IN TERMS

OF CORRECTNESS, ACCURACY, RELIABILITY, OR OTHERWISE. NI DOES NOT WARRANT THAT THE

OPERATION OF THE PRODUCTS WILL BE UNINTERRUPTED OR ERROR FREE.

In the event that you and NI have a separate signed written agreement with warranty terms covering the products, then the

warranty terms in the separate agreement shall control.

Copyright

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or mechanical,

including photocopying, recording, storing in an information retrieval system, or translating, in whole or in part, without the

prior written consent of National Instruments Corporation.

National Instruments respects the intellectual property of others, and we ask our users to do the same. NI software is protected

by copyright and other intellectual property laws. Where NI software may be used to reproduce software or other materials

belonging to others, you may use NI software only to reproduce materials that you may reproduce in accordance with the

terms of any applicable license or other legal restriction.

End-User License Agreements and Third-Party Legal Notices

You can find end-user license agreements (EULAs) and third-party legal notices in the following locations:

• Notices are located in the

directories.

• EULAs are located in the

•Review

<National Instruments>\_Legal Information.txt for information on including legal information in

installers built with NI products.

U.S. Government Restricted Rights

If you are an agency, department, or other entity of the United States Government (“Government”), the use, duplication,

reproduction, release, modification, disclosure or transfer of the technical data included in this manual is governed by the

Restricted Rights provisions under Federal Acquisition Regulation 52.227-14 for civilian agencies and Defense Federal

Acquisition Regulation Supplement Section 252.227-7014 and 252.227-7015 for military agencies.

Trademarks

Refer to the NI Trademarks and Logo Guidelines at ni.com/trademarks for more information on National Instruments

trademarks.

ARM, Keil, and µVision are trademarks or registered of ARM Ltd or its subsidiaries.

LEGO, the LEGO logo, WEDO, and MINDSTORMS are trademarks of the LEGO Group.

TETRIX by Pitsco is a trademark of Pitsco, Inc.

FIELDBUS FOUNDATION

<National Instruments>\_Legal Information and <National Instruments>

<National Instruments>\Shared\MDF\Legal\license directory.

™

and FOUNDATION™ are trademarks of the Fieldbus Foundation.

Page 4

EtherCAT® is a registered trademark of and licensed by Beckhoff Automation GmbH.

®

CANopen

DeviceNet

Go!, SensorDAQ, and Vernier are registered trademarks of Vernier Software & Technol ogy. Vernier Software & Technology

and

is a registered Community Trademark of CAN in Automation e.V.

™

and EtherNet/IP™ are trademarks of ODVA.

vernier.com are trademarks or trade dress.

Xilinx is the registered trademark of Xilinx, Inc.

Taptite and Trilobular are registered trademarks of Research Engineering & Manufacturing Inc.

®

is the registered trademark of Apple Inc.

FireWire

®

Linux

is the registered trademark of Linus Torvalds in the U.S. and other countries.

®

Handle Graphics

trademarks, and TargetBox

Tektronix

The Bluetooth

The ExpressCard

license.

The mark LabWindows is used under a license from Microsoft Corporation. Windows is a registered trademark of Microsoft

Corporation in the United States and other countries.

, MATLAB®, Real-Time Workshop®, Simulink®, Stateflow®, and xPC TargetBox® are registered

™

®

, Tek, and Tektronix, Enabling Technology are registered trademarks of Tektronix, Inc.

®

word mark is a registered trademark owned by the Bluetooth SIG, Inc.

™

and Target Language Compiler™ are trademarks of The MathWorks, Inc.

word mark and logos are owned by PCMCIA and any use of such marks by National Instruments is under

Other product and company names mentioned herein are trademarks or trade names of their respective companies.

Members of the National Instruments Alliance Partner Program are business entities independent from National Instruments

and have no agency, partnership, or joint-venture relationship with National Instruments.

Patents

For patents covering National Instruments products/technology, refer to the appropriate location: Help»Patents in your

software, the

patents.txt file on your media, or the National Instruments Patent Notice at ni.com/patents.

Export Compliance Information

Refer to the Export Compliance Information at ni.com/legal/export-compliance for the National Instruments global

trade compliance policy and how to obtain relevant HTS codes, ECCNs, and other import/export data.

WARNING REGARDING USE OF NATIONAL INSTRUMENTS PRODUCTS

YOU ARE ULTIMATELY RESPONSIBLE FOR VERIFYING AND VALIDATING THE SUITABILITY AND

RELIABILITY OF THE PRODUCTS WHENEVER THE PRODUCTS ARE INCORPORATED IN YOUR SYSTEM OR

APPLICATION, INCLUDING THE APPROPRIATE DESIGN, PROCESS, AND SAFETY LEVEL OF SUCH SYSTEM

OR APPLICATION.

PRODUCTS ARE NOT DESIGNED, MANUFACTURED, OR TESTED FOR USE IN LIFE OR SAFETY CRITICAL

SYSTEMS, HAZARDOUS ENVIRONMENTS OR ANY OTHER ENVIRONMENTS REQUIRING FAIL-SAFE

PERFORMANCE, INCLUDING IN THE OPERATION OF NUCLEAR FACILITIES; AIRCRAFT NAVIGATION; AIR

TRAFFIC CONTROL SYSTEMS; LIFE SAVING OR LIFE SUSTAINING SYSTEMS OR SUCH OTHER MEDICAL

DEVICES; OR ANY OTHER APPLICATION IN WHICH THE FAILURE OF THE PRODUCT OR SERVICE COULD

LEAD TO DEATH, PERSONAL INJURY, SEVERE PROPERTY DAMAGE OR ENVIRONMENTAL HARM

(COLLECTIVELY, “HIGH-RISK USES”). FURTHER, PRUDENT STEPS MUST BE TAKEN TO PROTECT AGAINST

FAILURES, INCLUDING PROVIDING BACK-UP AND SHUT-DOWN MECHANISMS. NI EXPRESSLY DISCLAIMS

ANY EXPRESS OR IMPLIED WARRANTY OF FITNESS OF THE PRODUCTS OR SERVICES FOR HIGH-RISK

USES.

Page 5

Contents

Chapter 1

Installation and Preparation

Attaching the Connector Cover ........................................................................................ 1-1

Connecting the Power Cord.............................................................................................. 1-1

RMX-4120/4121/4122/4123 (750 W Models)......................................................... 1-2

Necessary Cable ............................................................................................... 1-2

RMX-4124/4125/4126/4127 (1500 W Models)....................................................... 1-2

Necessary Cable ............................................................................................... 1-3

Switchboard Breaker Requirements ................................................................. 1-3

Connection Procedure............................................................................................... 1-4

Turning the Power On ...................................................................................................... 1-6

Turning the POWER Switch On .............................................................................. 1-6

Inrush Current................................................................................................... 1-7

Turning the POWER Switch Off .............................................................................. 1-7

Rack Mounting ................................................................................................................. 1-8

Load Considerations ......................................................................................................... 1-8

Loads with Peak Current or Pulse-Shaped Current.................................................. 1-8

Loads that Generate Reverse Current to the Power Supply ..................................... 1-9

Loads with Accumulated Energy ............................................................................. 1-9

Load Cables ...................................................................................................................... 1-10

Protecting Against Noise .......................................................................................... 1-11

Cabling Considerations When Using Remote Sensing ............................................ 1-11

Connecting to the Output Terminals ................................................................................ 1-12

Attaching the Output Terminal Cover ...................................................................... 1-15

Sensing.............................................................................................................................. 1-17

Local Sensing ........................................................................................................... 1-19

Remote Sensing ........................................................................................................ 1-19

Connecting an Electrolytic Capacitor Across the Load.................................... 1-22

Inserting a Mechanical Switch Between the RMX Programmable

Power Supply and the Load.............................................................................. 1-22

Accessories ....................................................................................................................... 1-23

Parallel Operation Signal Cable ............................................................................... 1-23

Chapter 2

Basic Functions

Measured Value Display and Setting Display .................................................................. 2-1

Measured Value Display .......................................................................................... 2-1

Power Display................................................................................................... 2-1

Setting Display ......................................................................................................... 2-2

Overvoltage Protection and Overcurrent Protection Setting Display....................... 2-2

System Configuration Setting Display ..................................................................... 2-2

Panel Operations............................................................................................................... 2-3

© National Instruments | v

Page 6

Contents

Measured Value Display, Setting Display, and Set OVP/OCP Display...................2-3

Fine Adjustment................................................................................................ 2-3

Output Operations............................................................................................................. 2-3

Output State at Power-up .......................................................................................... 2-4

Operation Overview.......................................................................................................... 2-4

CV Power Supply and CC Power Supply.........................................................................2-7

Crossover Point................................................................................................. 2-8

CV Mode and CC Mode Operation Examples .........................................................2-8

Example 1 .........................................................................................................2-8

Example 2 .........................................................................................................2-8

Using the RMX Programmable Power Supplies as a CV or CC Power Supply ..............2-9

Protection Functions and Alarms......................................................................................2-11

Alarm Occurrence and Clearing Alarms ..................................................................2-12

Alarm Occurrence............................................................................................. 2-12

Clearing Alarms................................................................................................2-13

Alarm Signal ..................................................................................................... 2-13

Protection Function Activation ................................................................................. 2-14

Setting limitation functions...............................................................................2-14

CONFIG Settings.............................................................................................................. 2-20

Specifying CF01 to CF36, CF 41 to CF52 CONFIG Settings.......................... 2-24

Specifying CF00/CF40 CONFIG Settings ....................................................... 2-25

CONFIG Parameter Details .............................................................................. 2-25

Preset Memory Function................................................................................................... 2-39

Saving Settings to Preset Memory............................................................................2-39

Recalling Preset Memory Entries ............................................................................. 2-40

Locking Panel Operations (Key Lock) .............................................................................2-41

Bleeder On/Off Feature .................................................................................................... 2-41

Fall Time................................................................................................................... 2-44

Switching from Remote Mode to Local Mode ................................................................. 2-44

Factory Default Settings (Initialization) ........................................................................... 2-45

Chapter 3

External Control

Overview........................................................................................................................... 3-1

About the J1 Connector ....................................................................................................3-1

Attaching the J1 Cable Core ..................................................................................... 3-2

About the J2 Connector ....................................................................................................3-5

Output Terminal Insulation............................................................................................... 3-7

When the Output Terminal is Not Grounded (Floating)........................................... 3-7

When the Output Terminal is Grounded................................................................... 3-9

Cautions When Controlling the Output with an External Voltage (Vext)................ 3-11

Controlling the Output Voltage ........................................................................................ 3-12

Control Using an External Voltage (Vext) ............................................................... 3-12

External Voltage (Vext) Connection ................................................................ 3-13

Control Using an External Resistance (Rext) ........................................................... 3-13

vi | ni.com

Page 7

RMX Programmable Power Supplies User Manual

External Resistance (Rext) Connection............................................................ 3-14

Controlling the Output Current......................................................................................... 3-14

Control Using an External Voltage (Vext) ............................................................... 3-15

Control Using an External Resistance (Rext) ........................................................... 3-16

External Resistance (Rext) Connection............................................................ 3-16

Controlling the Output On and Off States ........................................................................ 3-17

External Contact Connection.................................................................................... 3-18

Long-Distance Wiring ...................................................................................... 3-18

Controlling Output Shutdown .......................................................................................... 3-19

Output Shutdown Connection .................................................................................. 3-19

Long-Distance Wiring ...................................................................................... 3-20

Controlling the Clearing of Alarms .................................................................................. 3-20

Alarm Clear Connection ........................................................................................... 3-21

Long-Distance Wiring ...................................................................................... 3-22

External Monitoring ......................................................................................................... 3-22

Monitor Output Rating ............................................................................................. 3-22

External Monitoring of the Operation Status ................................................... 3-23

Chapter 4

Parallel/Series Operation

Master-Slave Parallel Operation....................................................................................... 4-1

Features of the RMX Programmable Power Supplies During

Master-Slave Parallel Operation............................................................................... 4-1

Voltage Display and Current Display............................................................... 4-1

Connection (Master-Slave Parallel Operation)......................................................... 4-3

Connecting the Signal Cables (Parallel Operation).......................................... 4-3

Connecting the Load (Parallel Operation) ........................................................ 4-4

Settings (Master-Slave Parallel Operation) .............................................................. 4-6

Setting the Master Unit, the Slave Units, and the Number of Units in

Parallel Operation (Including the Master Unit) ................................................ 4-6

Setting the Voltage and Current ....................................................................... 4-6

Setting the Overvoltage Protection (OVP) and Overcurrent Protection (OCP)

of the Master Unit............................................................................................. 4-6

Starting Master-Slave Parallel Operation ................................................................. 4-7

Turning Power On ............................................................................................ 4-7

Turning Power Off............................................................................................ 4-7

Series Operation ............................................................................................................... 4-8

Features of the RMX Programmable Power Supplies During Series Operation...... 4-8

Voltage Display and Current Display............................................................... 4-8

External Control ............................................................................................... 4-8

External Monitoring ......................................................................................... 4-8

Remote Sensing ................................................................................................ 4-9

Alarm ................................................................................................................ 4-10

Connection (Series Operation) ................................................................................. 4-10

Connecting the Load (Series Operation) .......................................................... 4-10

© National Instruments | vii

Page 8

Contents

Settings (Series Operation) ....................................................................................... 4-11

Setting the Voltage and Current........................................................................ 4-11

Setting the Overvoltage Protection (OVP) and Overcurrent Protection (OCP).. 4-11

Starting (Series Operation) .......................................................................................4-11

Turning the Power On and Off ......................................................................... 4-11

Turning the Output On and Off ........................................................................ 4-11

Chapter 5

Maintenance

Calibration Overview........................................................................................................ 5-1

Calibration Procedure ....................................................................................................... 5-1

Installation ................................................................................................................ 5-1

Launch ...................................................................................................................... 5-1

Calibration Items....................................................................................................... 5-2

Basic Instructions...................................................................................................... 5-3

Save Calibration........................................................................................................ 5-3

Backup Calibration Data to a XML File...........................................................5-3

Send Calibration Data from a XML File .......................................................... 5-3

Revision History ............................................................................................... 5-3

System Requirements ....................................................................................... 5-4

Hardware Requirements ...................................................................................5-4

Environment......................................................................................................5-4

Cleaning ............................................................................................................ 5-4

Connection ................................................................................................................5-5

Appendix A

Specifications

Appendix B

Troubleshooting

Appendix C

NI Services

Index

viii | ni.com

Page 9

1

Installation and Preparation

This chapter describes how to turn on an RMX programmable power supply, what kind of load

cables to use, and how to connect cables to the output connectors.

Note Protection provided by this equipment may be impaired if it is used in a

manner not described in the manual.

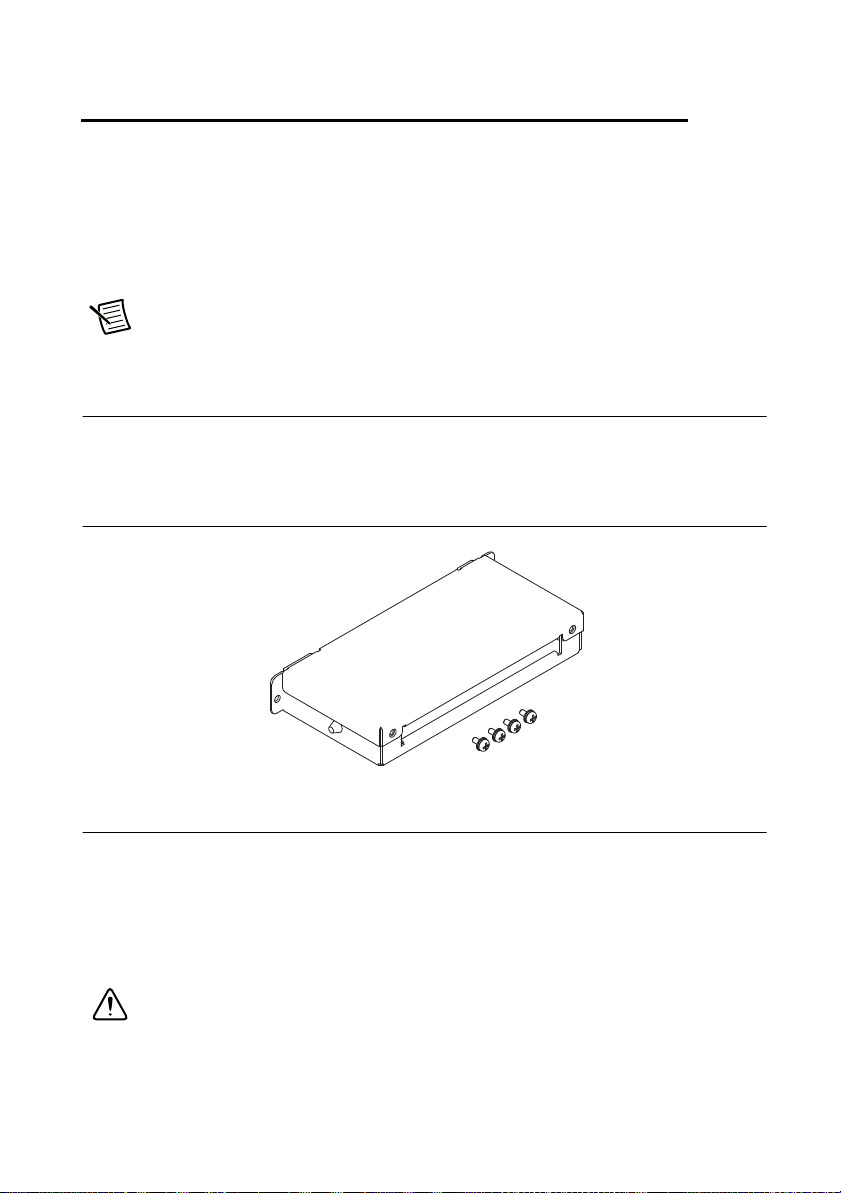

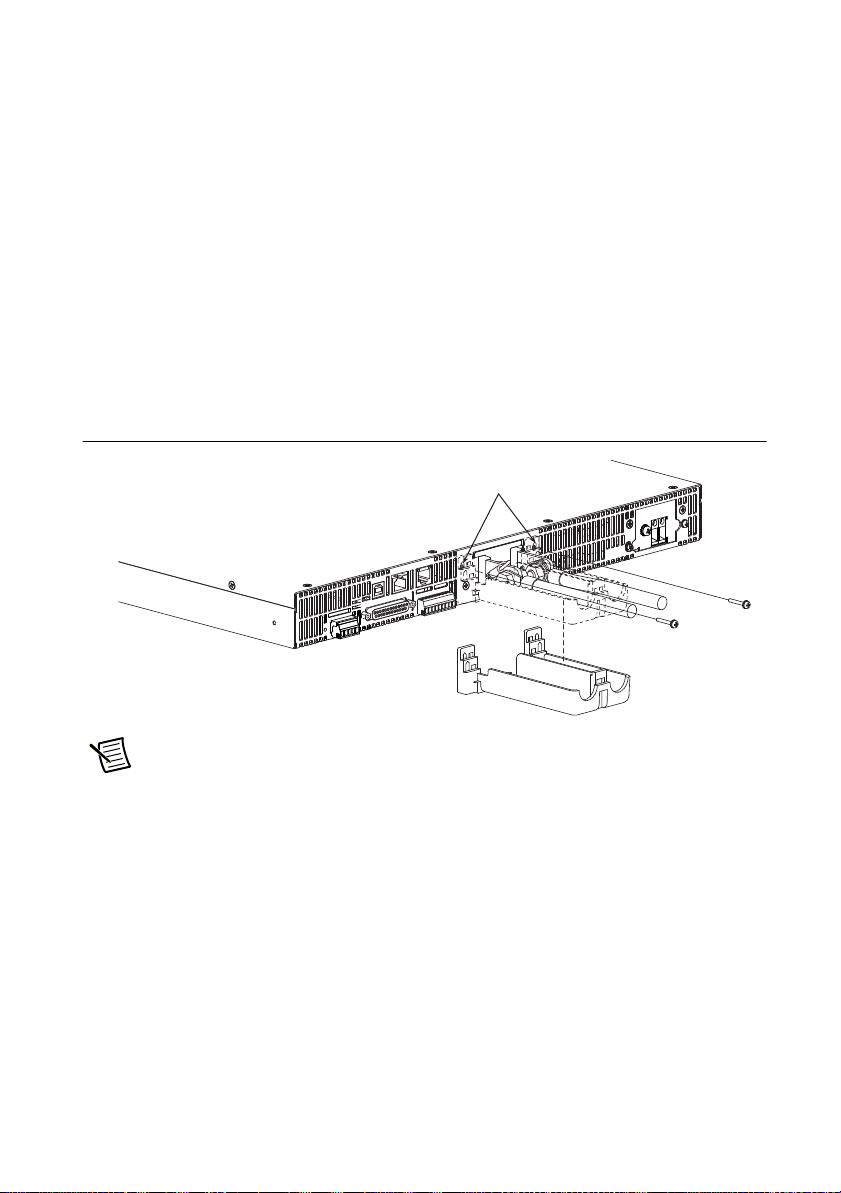

Attaching the Connector Cover

RMX programmable power supplies are supplied with a connector cover that fits over the entire

sensing, J1, and J2 connectors. For safety reasons, be sure to attach the connector cover when

you use the RMX programmable power supply.

Figure 1-1. Connector Cover

Connecting the Power Cord

This product is a piece of equipment that conforms to IEC Overvoltage Category II (equipment

that consumes energy supplied from a fixed installation).

A power cord is not included with the RMX-4124/4125/4126/4127. Use a power cord that

conforms to this product’s rated AC input voltage, input current, and configured for the

plug type. Refer to your product specifications for details.

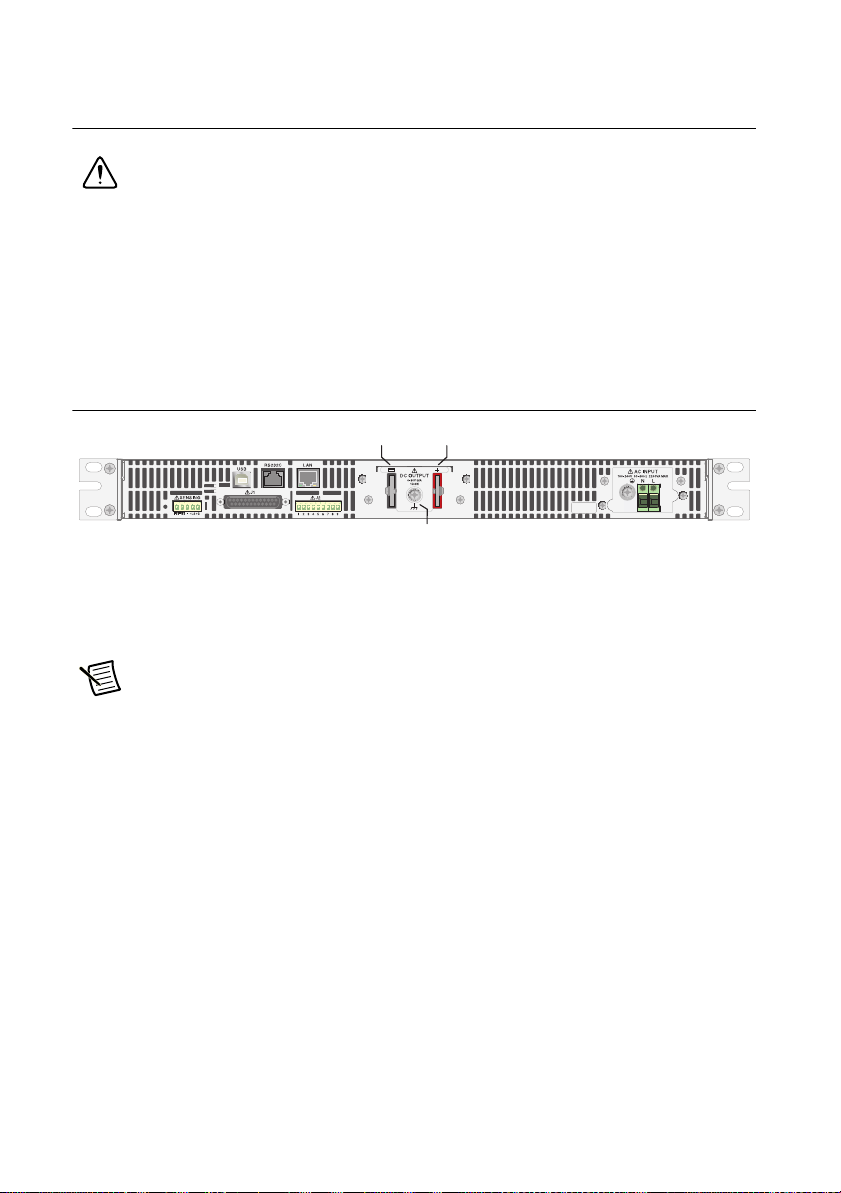

Caution Risk of electric shock. This product is a piece of equipment that conforms

to IEC Safety Class I (equipment that has a protective conductor terminal). Be sure

to earth ground the product to prevent electric shock. The product is grounded

through the power cord ground wire. Connect the protective conductor terminal to

earth ground.

© National Instruments | 1-1

Page 10

Chapter 1 Installation and Preparation

RMX-4120/4121/4122/4123 (750 W Models)

Necessary Cable

• North America—Extra Hard Usage Cord, min. 300 V, 60 C, 14 AWG, 3 Conductor cord,

3 m or less, with a NEMA 5-15P to C14.

• Europe—HAR Marked, min. 300 V, 60 C, 2.5mm2, 3 Conductor cord, 3 m or less, with a

plug configured for the country of use to C14.

• International—Certified for country of use, min. 300 V, 60 C, 2.5mm

3 m or less, with a plug configured for the country of use to C14.

The power cord can be used to disconnect the RMX programmable power supply from the

AC power line in an emergency. Connect the plug to an easily accessible power outlet so that the

plug can be removed from the outlet at any time. Be sure to provide adequate clearance around

the power outlet.

1. Check that the AC power line meets the nominal input rating of the product. The product

can receive a nominal line voltage in the range of 100 VAC to 240 VAC at 50 Hz or 60 Hz.

2. Check that the POWER switch is turned off.

3. Connect the power cord to the AC inlet on the rear panel.

4. Insert the power plug into a grounded outlet.

2

, 3 Conductor cord,

RMX-4124/4125/4126/4127 (1500 W Models)

Caution Risk of electric shock. Before you connect the power cord, turn off the

switchboard breaker (a switch that cuts off the power supply from the switchboard).

Risk of fire. Connection to the switchboard must be performed by a person who has

knowledge about electrical safety standards and the electrical aspects of regulated

DC power supplies. The switchboard breaker must meet the requirements shown

below.

Caution Inside the product, protective circuits are connected to match the polarity

of the input terminal. Be sure to connect the L, N, and (GND) terminals of the product

to the matching terminals on the switchboard.

In an emergency, turn off the switchboard breaker to disconnect the product from the AC power line.

1-2 | ni.com

Page 11

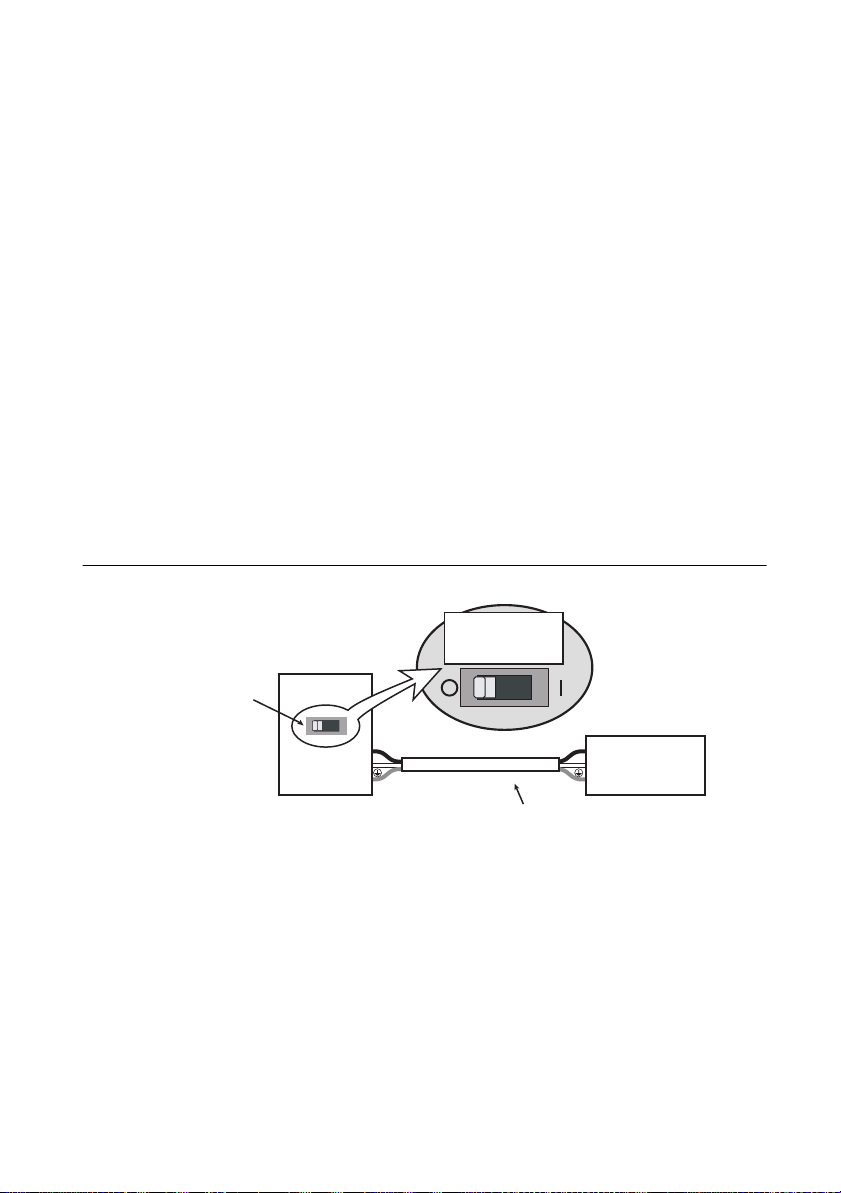

RMX Programmable Power Supplies User Manual

RMX-4125

Switchboard

N

L

N

L

Breaker indication example

For the

RMX-4125 only

30 A

Power cord

RMX-4125

dedicated breaker

Necessary Cable

• Vinyl cabtire cable (VCTF): Nominal cross-sectional area 5.5 mm2, 3 core

• Finished diameter: 10.5 to 14.4 mm in diameter

• Rated voltage: 250 V or higher

• Input terminal end: 14 mm of insulation stripped from conductor for the L and N wires.

Crimping terminal: (round, M4) that fixes the cable insulation in place

for the GND wire

• Length: 3 m or less

Switchboard Breaker Requirements

• Installation must be done in accordance with national wiring rules, such as NFPA 70 "NEC"

and CSA C22.1 "CEC".

• Rated current: 30 A (for safety, breakers whose rated current exceeds 30 A cannot be used)

• Do not power any other equipment from the switchboard breaker.

• Keep the breaker readily accessible at all times.

• Indicate that the breaker is dedicated for use with this product and that it is used to

disconnect the product from the AC power line.

Figure 1-2. Switchboard Diagram

© National Instruments | 1-3

Page 12

Chapter 1 Installation and Preparation

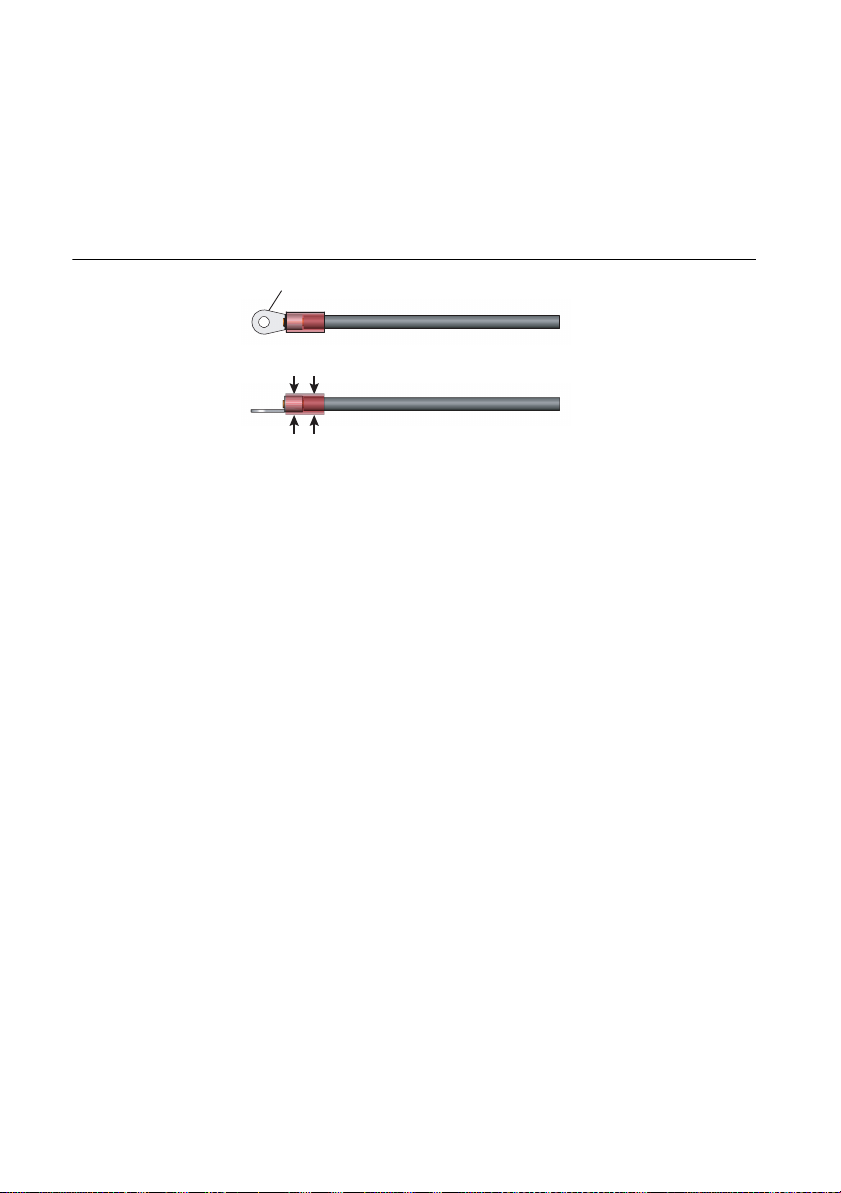

Crimping terminal (round, M4)

When crimping the core wire, use a

crimping terminal and tool that can

also grip the insulation.

Connection Procedure

1. Check that the AC power line meets the nominal input rating of the product. The product

can receive a nominal line voltage in the range of 100 VAC to 240 VAC at 50 Hz or 60 Hz.

2. Check that the POWER switch is turned off.

3. Attach a crimping terminal to the GND wire.

Figure 1-3. Attaching the Crimping Terminal

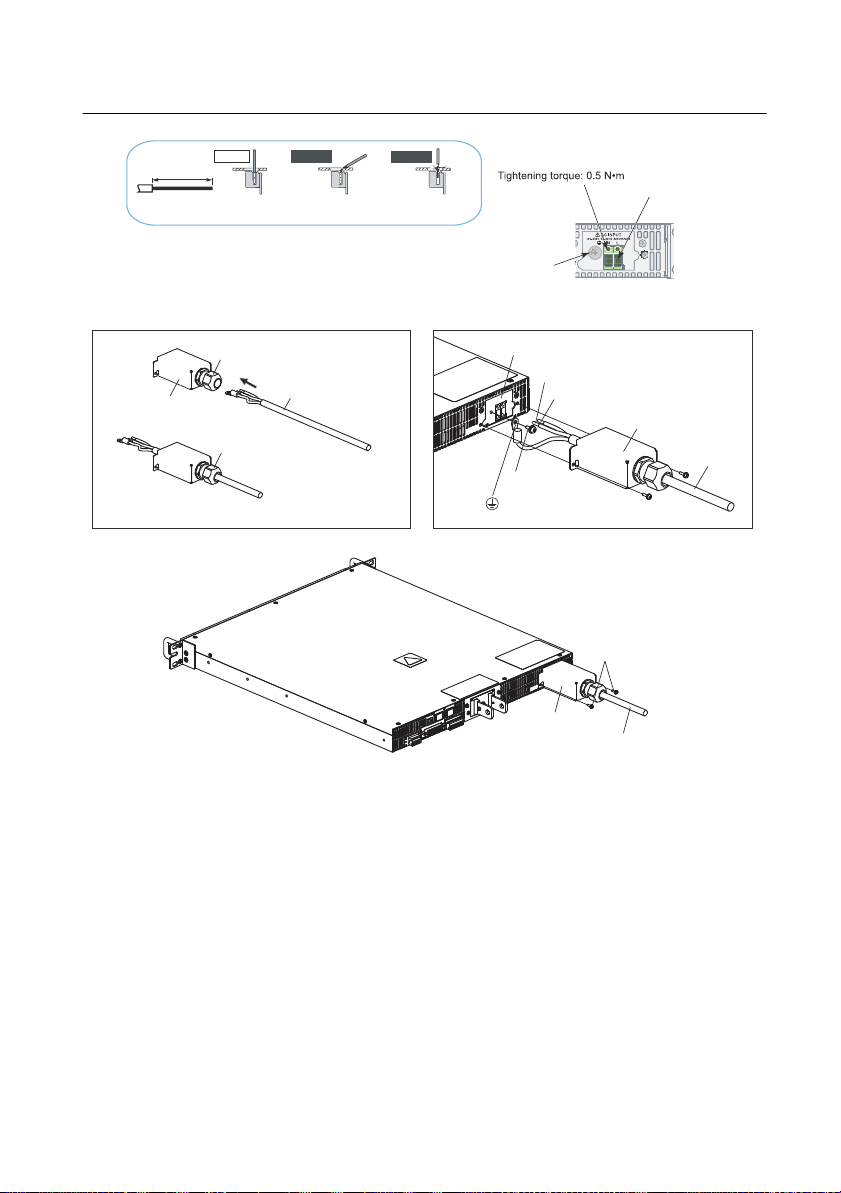

4. Connect the power cord and the included INPUT terminal cover to the AC INPUT terminal

on the rear panel. Be sure to connect the AC INPUT L, N, and (GND) terminals correctly.

Pass the power cord through the INPUT terminal cover, and fix the cord in place using the

cable gland.

1-4 | ni.com

Page 13

RMX Programmable Power Supplies User Manual

STRIP-GAUGE

14 mm

Correct

Incorrect

Incorrect

The stripped wire is

touching the chassis.

The wire strands are

touching the chassis.

INPUT terminal cover

INPUT terminal cover

INPUT terminal cover

AC INPUT terminal

L: Black or brown

N: White or blue

(GND)

Screw

: Green or green and yellow

Power cord

Power cord

Power cord

Screw

Use this screw to fix the

wire in place.

Screw M4

Remove the first

14 mm of the wire’s

covering, and then

insert the wire here.

AC INPUT terminal

Cable gland:

Turn left to unlock

Cable gland:

Turn right to lock

Cable gland: Supports wires from 10.5 to 14.4 mm in diameter

Figure 1-4. Connecting the Power Cord

5. Attach an appropriate crimping terminal to the switchboard end of the power cord.

6. Turn off the switchboard breaker.

7. Connect the L, N, and (GND) wires of the power cord to the matching terminals on the

switchboard.

© National Instruments | 1-5

Page 14

Chapter 1 Installation and Preparation

Turning the Power On

Turning the POWER Switch On

Caution Risk of electric shock. Regardless of whether load cables are connected to

the output terminals, be sure to attach the OUTPUT terminal cover before turning the

POWER switch on.

You can use the CONFIG settings to set how the RMX programmable power supplies

start when you turn the POWER switch on. Depending on the setting, the output may

be turned on automatically when the POWER switch is turned on. If you connect a

load without setting OVP and OCP to appropriate values, the load may be damaged

if the output is programmed to automatically turn on when the power is switched on.

When you turn the POWER switch on for the first time after purchase, the RMX programmable

power supply will be programmed with its factory default settings. Refer to Chapter 2, Factory

Default Settings (Initialization), for more information about these settings. Each subsequent

time you turn the power supply on, it starts with the panel settings (excluding the output on/off

setting) that were in use immediately before the POWER switch was turned off.

You can use the CONFIG setting CF02 to select how the RMX programmable power supply

starts when the POWER switch is turned on. Refer to Chapter 2, CF02 Power-on Status

Parameter, for more information about this setting.

1. Check that the power cord is connected correctly.

2. Check that the OUTPUT terminal cover is attached. Refer to the Attaching the Output

Terminal Cover section for more information about attaching the terminal cover. When the

product is shipped from the factory, the OUTPUT terminal cover is not attached.

3. Turn the POWER switch on. All the LEDs light, and then the voltmeter and the ammeter

display the following sequence of information: the rated voltage and rated current, the

firmware version number, the build number, and then the selected interface. Each item is

displayed for approximately 1 second. After a few seconds, the RMX programmable power

supply enters the operation standby state during which the output value is displayed.

1-6 | ni.com

Page 15

RMX Programmable Power Supplies User Manual

Figure 1-5. Power On Information Display

Inrush Current

When the POWER switch is turned on, an inrush current of up to 70 A can momentarily flow

into the rear AC input of the programmable power supply. Check that sufficient current capacity

is available in the AC power line or the switchboard, particularly if you are using multiple RMX

programmable power supplies and turning on their POWER switches simultaneously.

Turning the POWER Switch Off

Flip the POWER switch to the side to turn RMX programmable power supplies off. The RMX

programmable power supplies save the panel settings (except the output on/off setting) that were

in use immediately before the POWER switch was turned off.

You can use CONFIG settings CF02 to select how the RMX programmable power supply starts

when the POWER switch is turned on. Refer to Chapter 2, CF02 Power-on Status Parameter,

for more information about this setting.

If the POWER switch is turned off immediately after the settings have been changed, the last

settings may not be stored.

Caution After you turn the POWER switch off, wait at least 10 seconds after the

panel display turns off before you turn the POWER switch back on. Repeatedly

turning the POWER switch on and off at short intervals can cause damage to the

inrush current limiter. Furthermore, this will shorten the service life of the POWER

switch and the internal input fuse.

© National Instruments | 1-7

Page 16

Chapter 1 Installation and Preparation

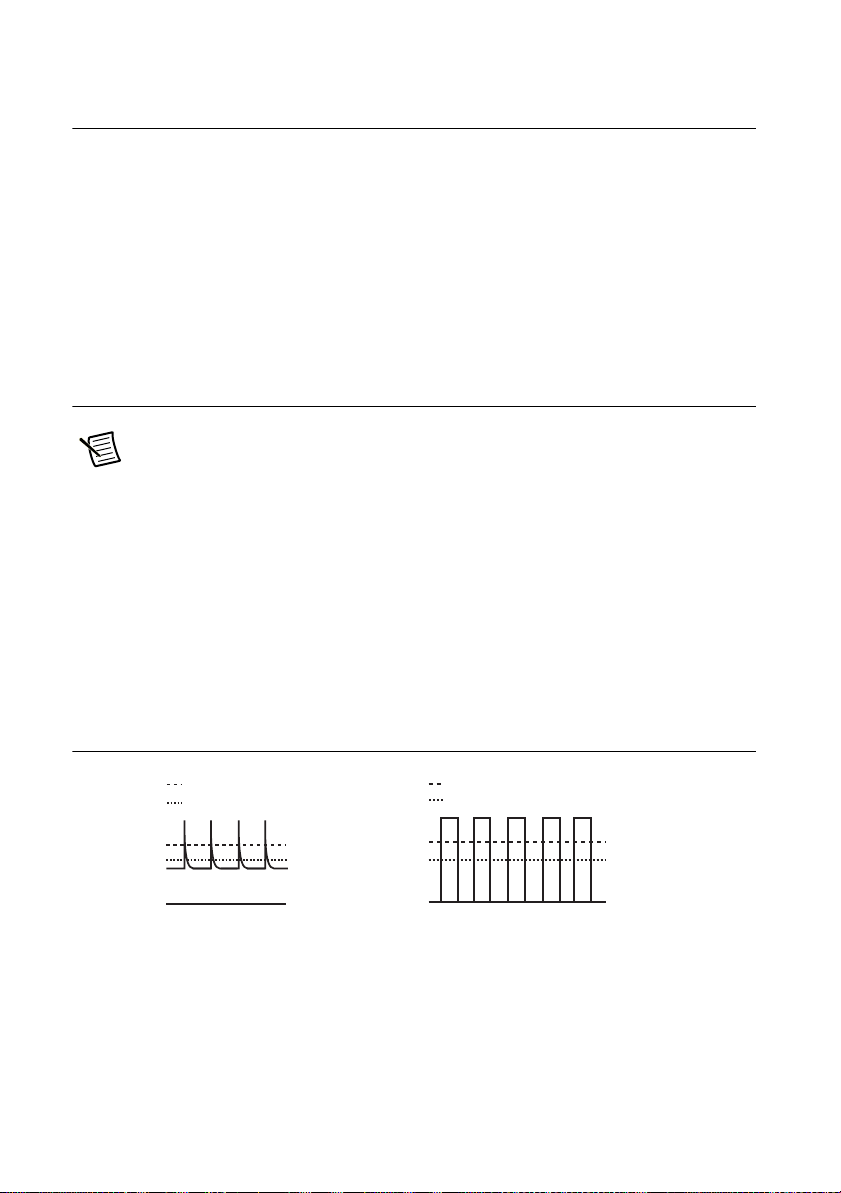

Load current with peaks Pulse-shaped load current

Set constant current

Ammeter reading (mean value)

Set constant current

Ammeter reading (mean value)

Rack Mounting

You can use brackets or slide rails to mount the RMX programmable power supply to a rack.

When you mount an RMX programmable power supply to a rack, install the optional support

angles (NI P/N) to support the device.

NI recommends that you keep all pieces that you remove from a RMX programmable power

supply during installation. You will need these pieces if you remove the device from a rack.

When using several RMX programmable power supplies together for master-slave parallel or

series operation, mount them to a rack before use.

Load Considerations

Note The output can become unstable if the following types of loads are connected.

Loads with Peak Current or Pulse-Shaped Current

The front panel of the RMX power supply only displays averaged voltage and current values.

If the supply is connected to a load that draws current in spikes or pulses it is possible that the

front panel will display a current reading lower than the programmed current setpoint. In reality,

the spikes or pulses in the load current are exceeding the programmed current setpoint causing

the supply to switch instantaneously into constant-current mode and causing the output voltage

to drop.

For these types of loads, you must increase the set constant current or increase the current

capacity.

Figure 1-6. Loads with Peak Current or Pulse-Shaped Current

1-8 | ni.com

Page 17

RMX Programmable Power Supplies User Manual

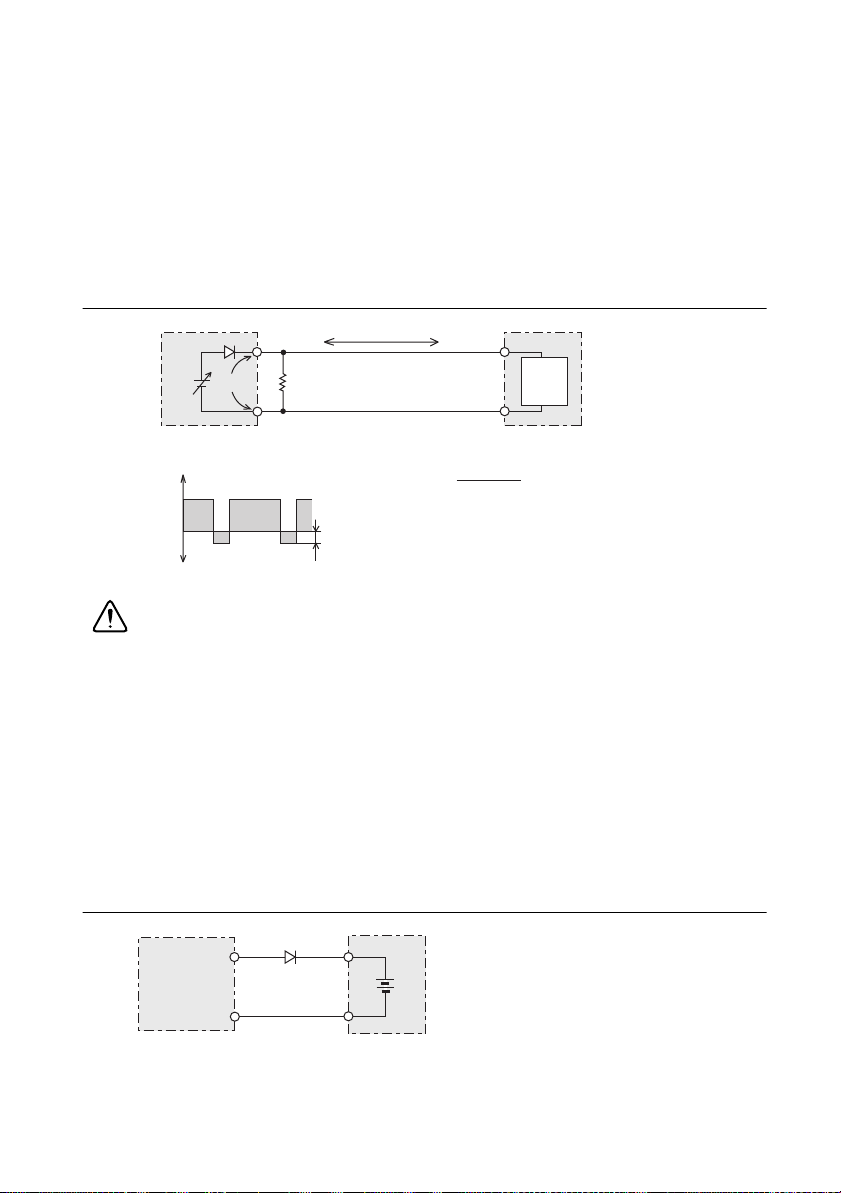

IO

RD

EO

Equivalent circuit of the RMX-4122

Regenerative load

+

0

Reverse current

-IO

+IO

Irp

RD (in Ω) ≤

RD: Reverse current bypass dummy load

E

O: Output voltage

Irp: Maximum reverse current

EO (in V)

Irp (in A)

Load

Output current

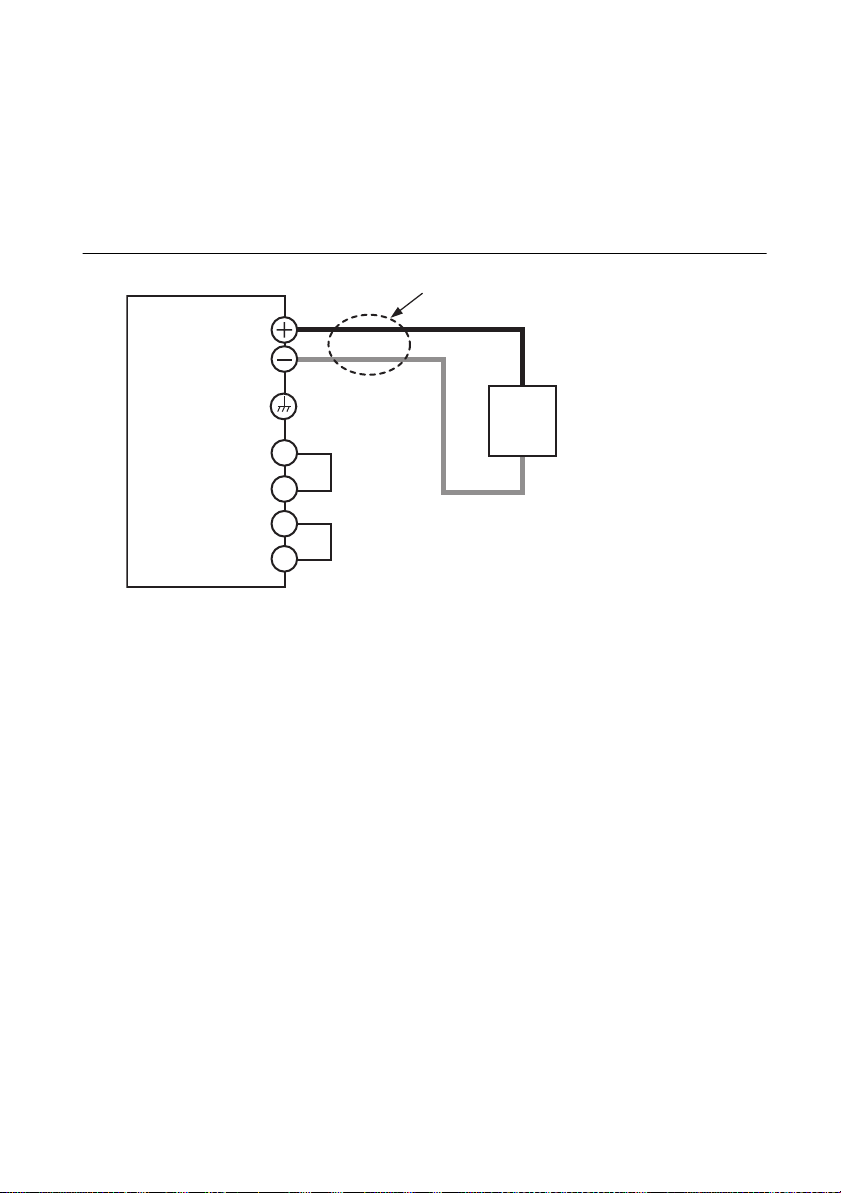

Loads that Generate Reverse Current to the Power Supply

RMX programmable power supplies cannot sink reverse current from the load. Therefore, if a

regenerative load (such as an inverter, converter, or transformer) is connected and tries to sink

power into the terminals of the power supply, the output voltage will increase and can become

unstable. This can cause a malfunction.

For these types of loads, connect a resistor (R

) as shown in the following figure to bypass the

D

reverse current. However, the amount of current to the load decreases by Irp.

Figure 1-7. Loads with Accumulated Energy

Caution Use a resistor with sufficient rated power for R

. If a resistor with

D

insufficient rated power for the circuit is used, the resistor will burn out.

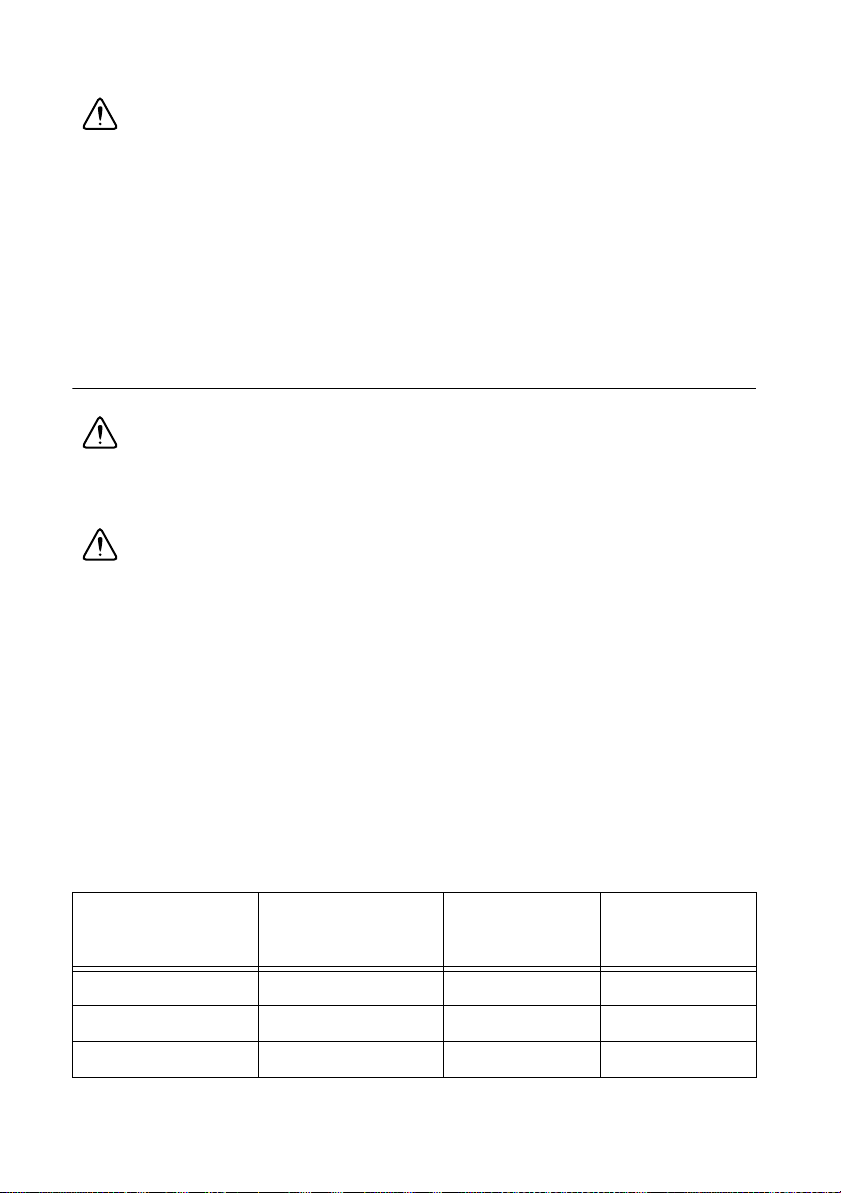

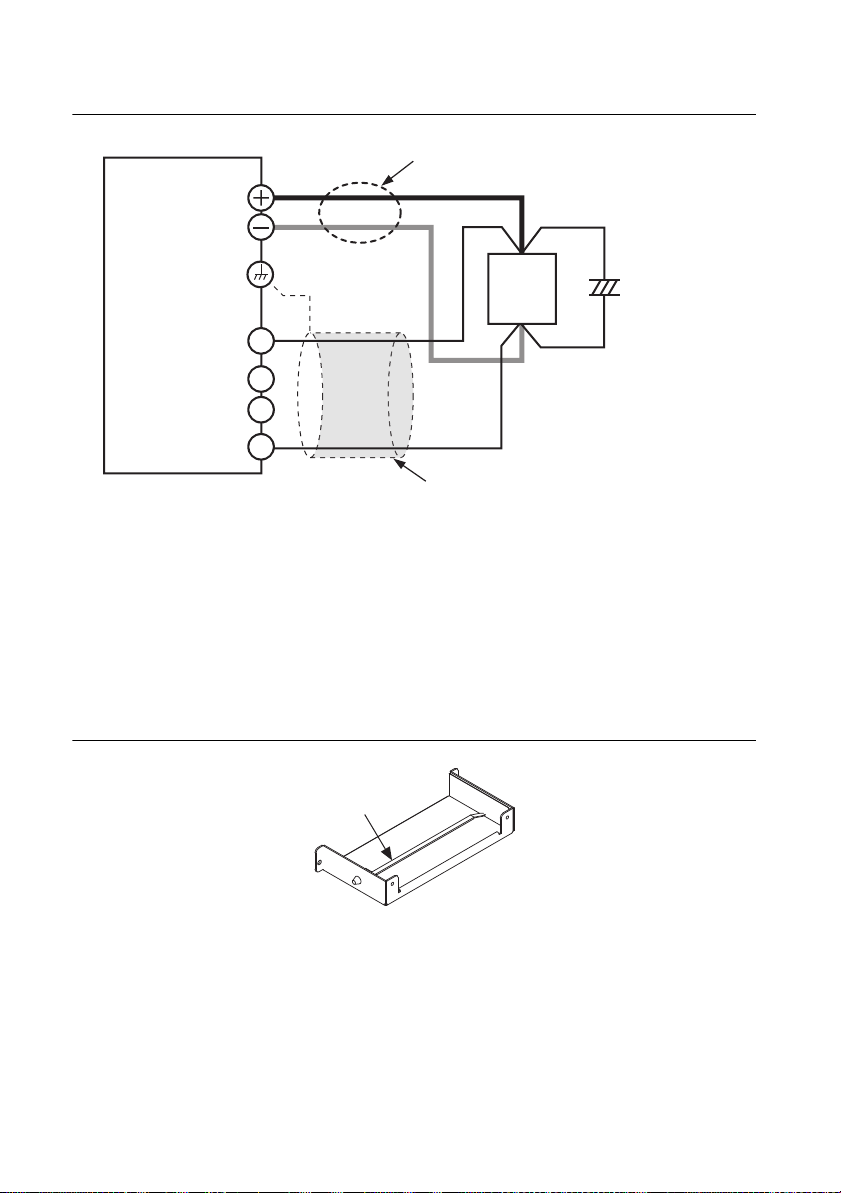

Loads with Accumulated Energy

Connecting a load with accumulated energy, such as a battery, to an RMX programmable power

supply may cause current to flow from the load to the internal circuit. This current may cause

damage or reduce the life of the load.

For this type of load, connect a reverse-current-prevention diode (D

programmable power supply and the load in series as shown in the following figure.

) between the RMX

RP

This cannot be used in conjunction with remote sensing.

RMX-4122

Figure 1-8. Loads with Accumulated Energy

D

RP

Load with accumulated energy

DRP: Reverse-current-protection diode

© National Instruments | 1-9

Page 18

Chapter 1 Installation and Preparation

Caution To protect the load and the RMX programmable power supplies, use a D

RP

that conforms to the following specifications.

• Reverse voltage withstand capacity–At least twice the rated output voltage of the RMX

programmable power supply.

• Forward current capacity–Three to ten times the rated output current of the RMX

programmable power supply.

• A diode with small loss.

• Be sure to take into account the heat generated by D

. DRP will burn out with inadequate

RP

heat dissipation.

Load Cables

Caution Risk of fire. Use load cables whose capacity is adequate for the

RMX programmable power supply’s rated output current. The output connector and

its surrounding area become hot. Use cables whose covers have heat resistance at

85 °C and higher.

Caution Risk of electric shock. Use the cable which has higher withstanding

voltage than the specified insulation voltage of the product to secure the double

insulation or reinforced insulation.

The current capacity of a load cable is dependent on the maximum allowable temperature of the

cable's insulation.

A cable’s temperature is determined by the resistive loss based on the current, the ambient

temperature, and the cable’s external thermal resistance. The following table shows the current

capacity of heat-resistant vinyl wires that have a maximum allowable temperature of 60 °C,

assuming that a wire is stretched out horizontally in air in an ambient temperature of 30 °C.

The current capacity must be reduced under certain conditions, such as when vinyl cables that

have a low heat resistance are used, when the ambient temperature is 30 °C or greater, or when

cables are bundled together and little heat is radiated.

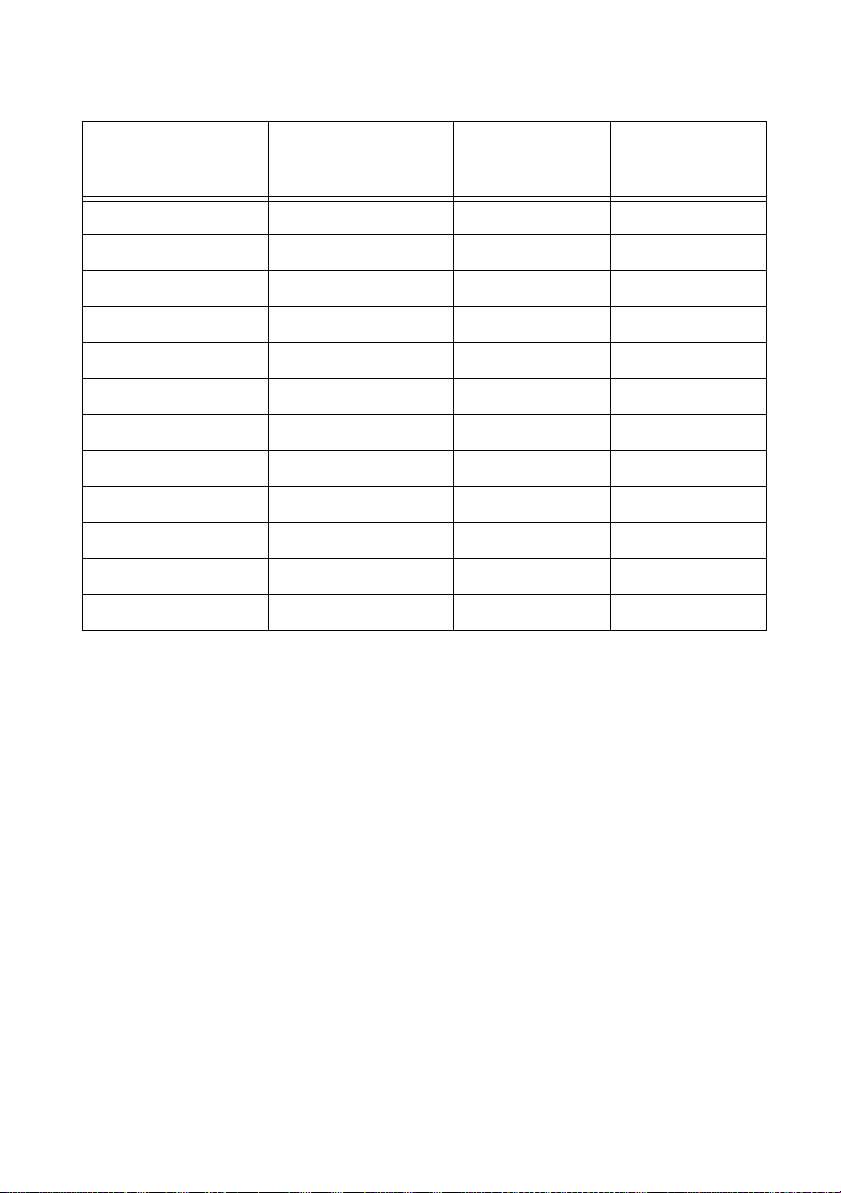

Table 1-1. Current Capacity of Heat-resistant Vinyl Wires

Nominal

Cross-sectional

Area

2 mm

3.5 mm

5.5 mm

1-10 | ni.com

2

2

2

AWG (Reference

Cross-sectional

Area)

Allowable

Current

(Ta = 30 °C)

Recommended

Current

14 (2.08 mm2) 27 A 10 A

12 (3.31 mm2) 37 A —

10 (5.26 mm2) 49 A 20 A

Page 19

RMX Programmable Power Supplies User Manual

Table 1-1. Current Capacity of Heat-resistant Vinyl Wires (Continued)

Nominal

Cross-sectional

Area

2

8 mm

2

14 mm

2

22 mm

2

30 mm

2

38 mm

2

50 mm

2

60 mm

2

80 mm

2

100 mm

2

125 mm

2

150 mm

2

200 mm

AWG (Reference

Cross-sectional

Area)

Allowable

Current

(Ta = 30 °C)

Recommended

Current

8 (8.37mm2) 61 A 30 A

6 (13.3 mm2) 88 A 50 A

4 (21.15 mm2) 115 A 80 A

2 (33.62 mm2) 139 A —

1 (42.41 mm2) 162 A 100 A

1/0 (53.49 mm2) 190 A —

2/0 (67.43 mm2) 217 A —

3/0 (85.01 mm2) 257 A 200 A

4/0 (107.2 mm2) 298 A —

— 344 A —

— 395 A 300 A

— 469 A —

Protecting Against Noise

When connecting wires that have the same heat resistance, separating the wires as much as

possible to increase heat radiation enables a greater amount of current to flow. However, wiring

the + (positive) and - (negative) output wires of the load cable side by side or bundling them

together will minimize unwanted noise on the output. The currents shown in Table 1-1 are

allowable currents that have been reduced in consideration of the potential bundling of load

cables. Use these values as a guideline when connecting load cables.

Cabling Considerations When Using Remote Sensing

As you increase the current setpoint or increase the resistance of your load cabling, the voltage

drop between the RMX power supply and your load will increase. This results in the voltage at

your load being smaller than the programmed voltage setpoint. Refer to Appendix A,

Specifications, to see the maximum voltage drop each RMX power supply's remote sense

terminals can compensate for. If the voltage drop exceeds this level, use shorter load cables or

cables with a greater cross-sectional area.

© National Instruments | 1-11

Page 20

Chapter 1 Installation and Preparation

- (negative) terminal + (positive) terminal

Chassis terminal

Connecting to the Output Terminals

Caution Risk of electric shock. Turn the POWER switch off before you touch the

OUTPUT terminals. Even if you turn the output off or turn the POWER switch off,

if the bleeder on/off setting (CF11) is set to “OFF,” the voltage that was present when

the output was on will remain at the output terminals. Turn the bleeder circuit on

before you touch the output terminals. Regardless of whether load cables are

connected to the output terminals, be sure to attach the OUTPUT terminal cover

before turning the POWER switch on. Confirm that the voltage between any output

terminal and ground is lower than the isolation voltage of the RMX programmable

power supply.

Figure 1-9. RMX-4125 Output Terminal

1. Turn the POWER switch off. Check that there is no voltage across the output terminals.

2. Connect one end of the included chassis connection wire to the chassis terminal, and then

connect the other end of the wire to the negative or positive output terminal.

Note For safety reasons, connect one of the output terminals to the chassis terminal

unless your application requires the output terminals to be floating.

Use the screw on the RMX to connect the wire to the chassis terminal. Use the screw on the

output terminal to connect the wire to the output terminal.

1-12 | ni.com

Page 21

RMX Programmable Power Supplies User Manual

Chassis

connection wire

Screw (M3)

Screw (M4)

Chassis

connection wire

Screw (M3)

Screw (M4)

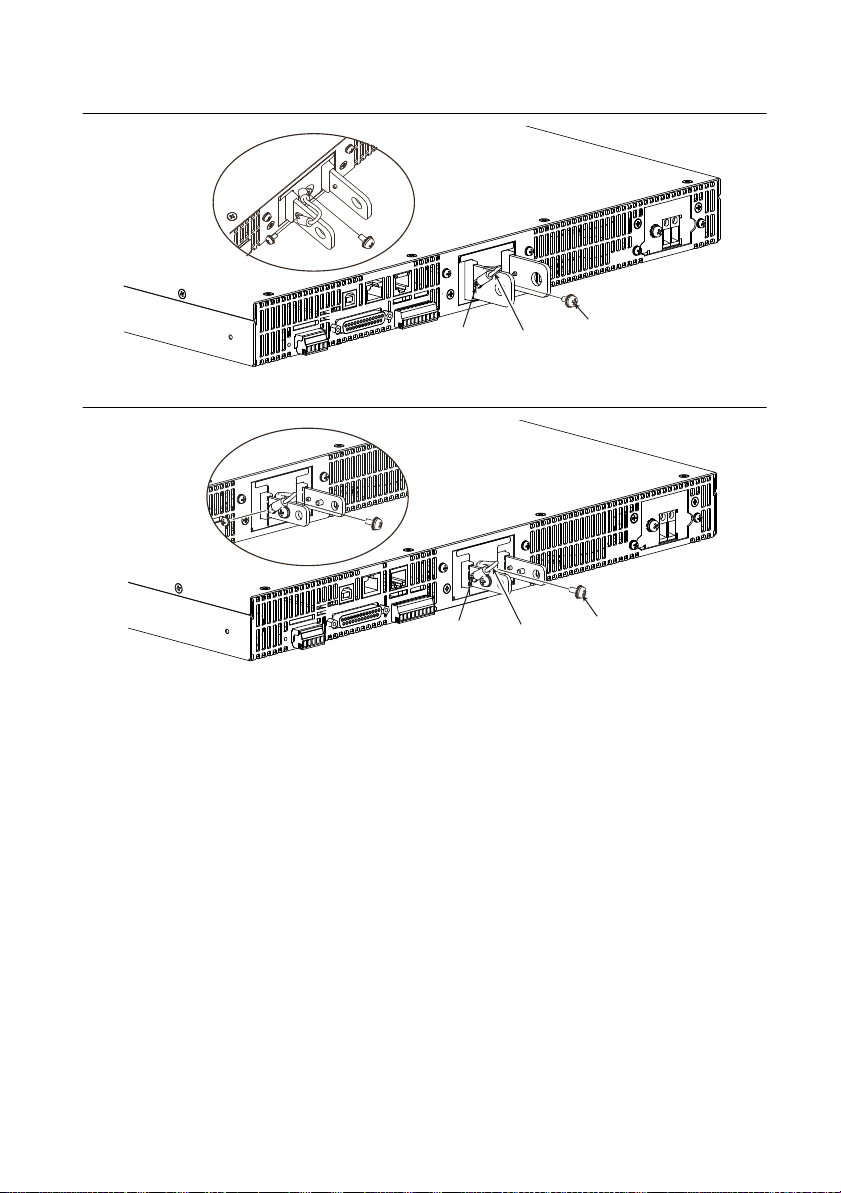

Figure 1-10. RMX-4120/4121/4124/4125

Figure 1-11. RMX-4122/4123/4126/4127

3. Attach crimping terminals to the load cables.

The output terminals have holes for connecting the load cables. Use crimping terminals that

are appropriate for the bolts that you are using.

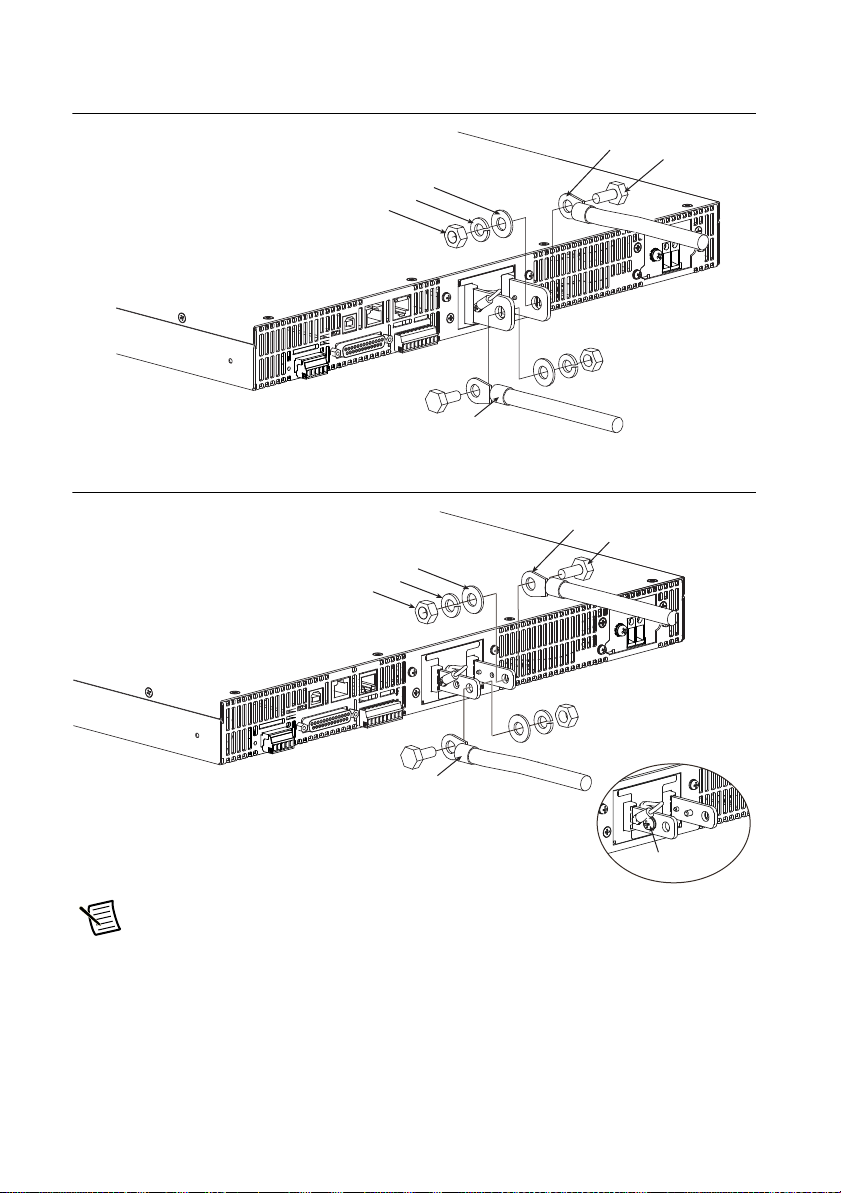

4. Use the included bolt set to connect the load cables to the output terminals.

Connect the positive cable to the positive output terminal and the negative cable to the

negative output terminal. The orientation of the crimping terminals will vary depending on

the wire diameter of the load cables used.

© National Instruments | 1-13

Page 22

Chapter 1 Installation and Preparation

Spring washer

Washer

Nut

Bolt (M8)

Crimping terminal

Attach the cable to the inner side

of the crimping terminal.

Attach the cable to the outer side

of the crimping terminal.

Spring washer

Washer

Nut

Bolt (M5)

Screw (M4)

Figure 1-12. Connection Using M8 Bolt Set for RMX-4120/4121/4124/4125

Figure 1-13. Connection Using M5 Bolt Set for RMX-4122/4123/4126/4127

Crimping terminal

Note If you do not connect load cables in the correct orientation, you will not be

able to attach the OUTPUT terminal cover.

1-14 | ni.com

Page 23

RMX Programmable Power Supplies User Manual

R

line up the half of the cover.

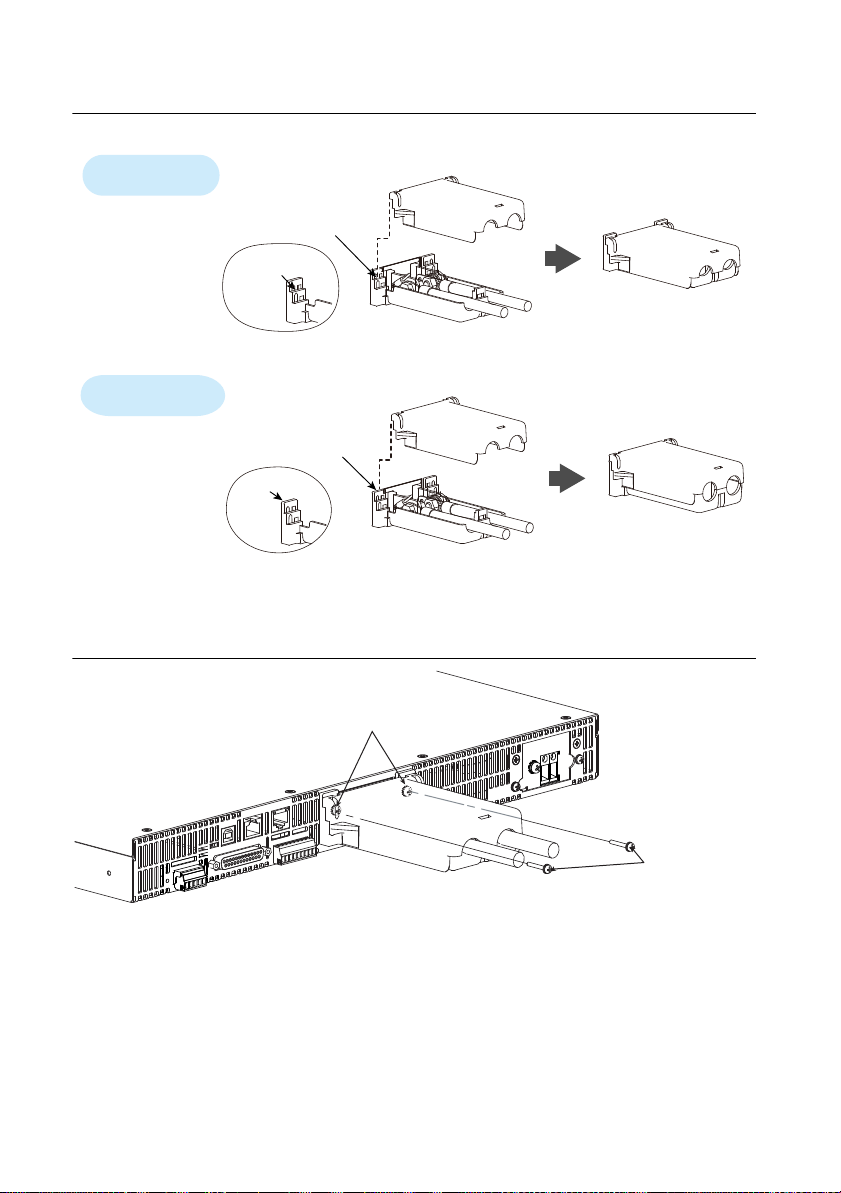

Attaching the Output Terminal Cover

You can adjust the diameter of the holes that the load cables pass through by changing the

positions in which the top and bottom halves of the OUTPUT terminal cover are put together.

There are two available positions. Use the appropriate position for the load cables that you are using.

• For cables that are up to 10 mm in diameter: Put the top and bottom halves of the OUTPUT

terminal cover together so that the hole diameter is small.

• For cables that are between 10 mm and 18 mm in diameter: Put the top and bottom halves

of the OUTPUT terminal cover together so that the hole diameter is large.

1. Remove the screw that is attached next to the output terminals on the RMX. Use this screw

to attach the OUTPUT terminal cover.

2. Place the bottom half of the OUTPUT terminal cover underneath the load cables connected

to the output terminals.

Figure 1-14. Attaching Bottom Half of the OUTPUT Terminal Cover

emove the screws, and then

Note The top and bottom halves of the OUTPUT terminal cover have different

shapes.

3. Align the tabs of the top half of the OUTPUT terminal cover with those of the bottom half.

Align the tabs of the OUTPUT terminal cover according to the load cable diameter.

© National Instruments | 1-15

Page 24

Chapter 1 Installation and Preparation

Top half of the cove

Align the protrusion of

the top half of the cover

with the top section

of the protrusion of the

bottom half.

Bottom half of the cover

For thick load cables

Cover hole diameter:

10 mm to 18 mm

Cover hole diameter:

Up to 10 mm

For thin load cables

Top half of the cover

Align the protrusion of

the top half of the cover

with the middle section

of the protrusion of the

bottom half of the cover.

Bottom half of the cover

Middle

section

Top section

After you have lined up the top and bottom halves

of the cover, use the screws to fix the cover in place.

Screws (M3)

Figure 1-15. Aligning Both Halves of the OUTPUT Terminal Cover

4. Push the OUTPUT terminal cover against the rear panel, and then use the RMX screws to

fix the cover in place. Ensure that the screws are securely fastened.

Figure 1-16. Attaching the OUTPUT Terminal Cover

1-16 | ni.com

Page 25

RMX Programmable Power Supplies User Manual

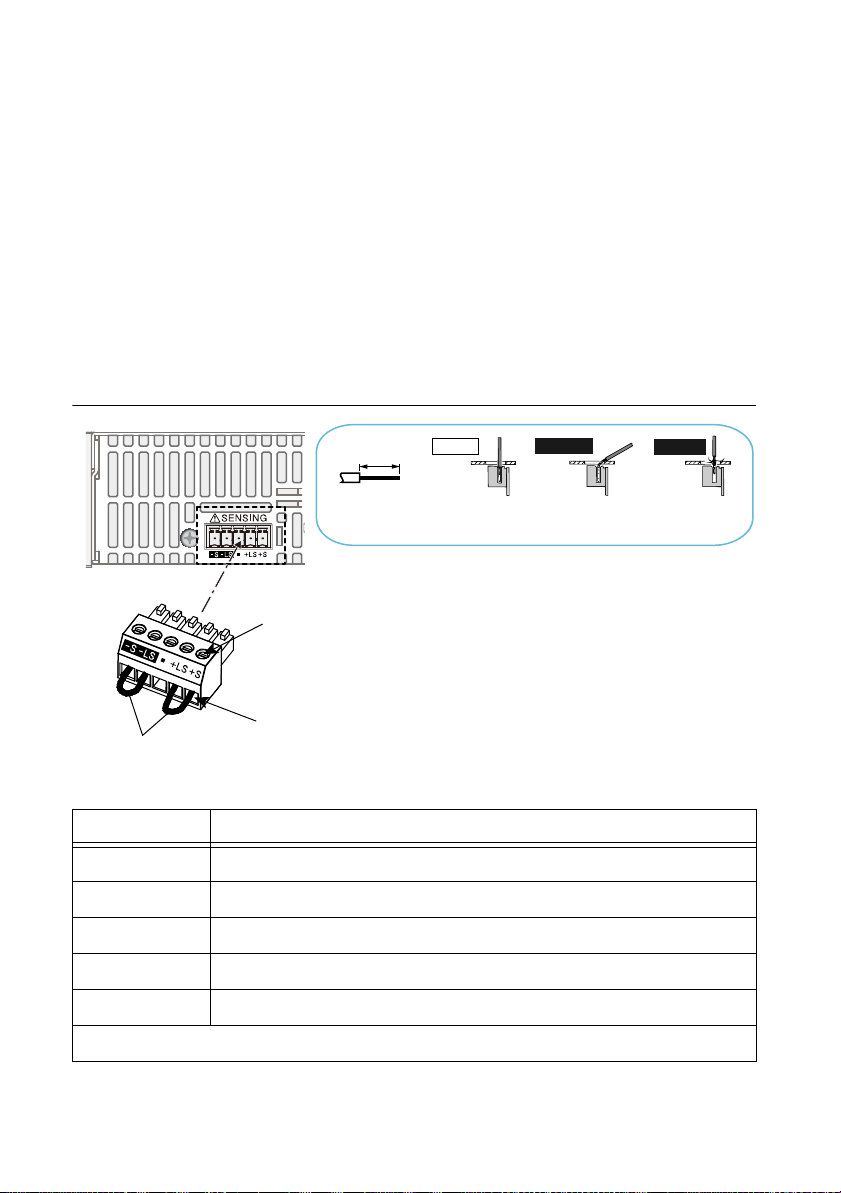

Sensing

When RMX programmable power supplies are shipped from the factory, the connector is

attached to the sensing terminals. RMX programmable power supplies are supplied with a

connector cover that fits over the entire sensing, J1, and J2 connectors. For safety reasons,

be sure to attach the connector cover when you use the RMX programmable power supply.

If they are damaged or lost, contact National Instruments.

Figure 1-17. Connector Cover

Figure 1-18. Terminal Connector

Caution Risk of electric shock and damage to internal circuits.

Never wire the sensing terminals while the POWER switch is turned on.

Use sensing cables that provide reinforced or double insulation with a capacity

greater than or equal to the isolation voltage of the RMX programmable power

supply. For uncovered sections of the shielded cables, use insulation tubes to secure

reinforced or double insulation with a capacity greater than or equal to the isolation

voltage of the RMX programmable power supply.

The sensing terminals are at approximately the same electric potential as the negative

output terminal. Insert the cables so that the wire strands do not touch the chassis

when they stick out of the sensing terminal. Also, insert the cables so that the stripped

wires do not stick out of the terminal.

© National Instruments | 1-17

Page 26

Chapter 1 Installation and Preparation

Strip 7 mm (0.28 inches) of the

cable covering, and then insert

the cable here.

Incorrect

Incorrect

Correct

The wire itself is

in contact with

the chassis.

Wire scraps are

in contact with

the chassis.

Strip gauge

7 mm (0.28 inches)

Use this screw to fix the cables

cables in place so that they do

not come loose.

Local sensing jumpers

Even if you turn the output off or turn the POWER switch off, if the bleeder on/off

setting (CF11) is set to oFF, the voltage that was present when the output was on will

remain at the output terminals. Set the bleeder on/off setting to on before you touch

the sensing terminals.

Regardless of whether local sensing or remote sensing is used, be sure to attach the

sensing terminal cover before turning the POWER switch on.

If the sensing cables come loose, the output voltage across the load may become unstable, and

an excessive voltage may be applied to the load. If an appropriate OVP trip point is set, the OVP

will trip before an excessive voltage is generated.

When you are finished with remote sensing, return to local sensing mode.

Figure 1-19. Sensing Cable Connections

Terminal Function

-S Negative remote sensing terminal.

-LS Negative local sensing terminal connected to the negative output terminal

— Not connected.

+LS Positive local sensing terminal connected to the positive output terminal.

+S Positive remote sensing terminal.

Sensing cable: AWG28 to AWG16

1-18 | ni.com

Table 1-2. Sensing Terminals and Functions

Page 27

RMX Programmable Power Supplies User Manual

+

–

+LS

+S

-LS

-S

Output terminal

Chassis terminal

Sensing terminal

RMX

Load

Use twisted-pair wires for the load cables.

Make the cables as short as possible.

Local Sensing

By factory default, RMX programmable power supplies are set to local sensing (the rear panel

sensing connector is hard wired). The sensing point during local sensing is the output terminal.

This method does not compensate for the voltage drop across the load cable, so use this method

when the load current is small or when you do not need to consider the load effect voltage.

Figure 1-20. Local Sensing

Remote Sensing

Remote sensing is a feature that reduces the effect of voltage drops across load cabling

resulting in a more accurate voltage being applied at the terminals of the load.

Refer to Appendix A, Specifications for the maximum voltage drop each RMX power supply's

remote sense terminals can compensate for. Select a load cable that has sufficient current

capacity to prevent the voltage drop in the load cable from exceeding the compensation voltage.

Refer to the Load Cables section for more information about the cables.

When using remote sensing, the output terminals compensate for the voltage drop across the load

cabling by increasing the output voltage above the programmed setpoint until the sense leads

detect the programmed setpoint at the load itself. This requires the output terminals to generate

a voltage that is greater than the programmed voltage level. If you are performing remote sensing

with the voltage close to the maximum output voltage of the power supply, the total output is

still limited by the maximum output voltage at the terminals of the power supply (105% of the

rated output voltage). If the signal doesn’t seem to be stable, an electrolytic capacitor may be

required at the sensing point (across the load).

To minimize noise on the output signal, use twisted-pair wires or 2-core shielded wires. Connect

the ground of your shielded wire to the ground of the RMX programmable power supply or the

load.

© National Instruments | 1-19

Page 28

Chapter 1 Installation and Preparation

Band

Figure 1-21. Remote Sensing

RMX

Output terminal

Chassis terminal

Sensing terminal

+S

+LS

-LS

-S

Use twisted-pair wires for the load cables.

Make the cables as short as possible.

+

+

Load

–

For the sensing cables, use twisted-pair

wires or shielded wires.

C

–

Connect an

electrolytic

capacitor

across the load

as necessary.

1. Turn the POWER switch off.

2. Remove the sensing connector from the rear panel sensing terminals.

3. Remove the local sensing jumpers from the sensing connector.

4. Remove 7 mm of the wire covering. Connect the negative sensing cable to -S and the

positive sensing cable to +S.

Use cable screws to securely fix the cables in place so that they do not come loose.

5. Pinch the tip of the band, and remove the band from the connector cover.

Figure 1-22. Bottom Cover with Band

6. As shown in the figure, create a ring 40 mm away from the connector, and fasten with the band.

Make the ring as small as possible, and fasten the band as tight as possible. The band can

be reused. Do not cut the extraneous portion of the band.

1-20 | ni.com

Page 29

RMX Programmable Power Supplies User Manual

through the hole by holding this area with

a pair of tweezers.

Figure 1-23. Sensing Wire Assembly

40 mm

You can pull out the band that you passed

7. Firmly attach the sensing connector to the sensing terminals.

8. Fasten the lower side of the connector cover to the panel with the included screws, and then

insert the tip of the band into the hole of the cover. Finally, bring the top and bottom sides

of the connector cover together, and fasten with the included screws.

Figure 1-24. Connector Cover Assembly

9. Turn the power switch on.

© National Instruments | 1-21

Page 30

Chapter 1 Installation and Preparation

Load

S

+

–

C

+

–

+S

–S

+

–

Connecting an Electrolytic Capacitor Across the Load

If the cabling is largely inductive, it may be necessary to connect an electrolytic capacitor across

the load. If you run into this problem, the following symptoms may appear:

• The output of the power supply is oscillating. If very long wires are used to connect the

load, the inductive and capacitive components of the cable can cause phase shifting that

results in oscillation at the output. You can reduce this effect by shortening the load cables.

However, if this does not rectify the problem, connect and electrolytic capacitor across the

load.

• If the load current is changing rapidly in a pulse-shaped pattern, the output voltage may

fluctuate due to inductance in the cabling. You can reduce the inductance component by

twisting the load cables, which stabilizes the voltage. However, if this does not rectify the

problem, connect an electrolytic capacitor across the load.

Table 1-3. Electrolytic Capacitor with RMX Programmable Power Supplies

RMX-4120

RMX-4124

RMX-4121/

RMX-4125

RMX-4122/

RMX-4126

RMX-4123/

RMX-4127

36 V or more 96 V or more 276 V or more 780 V or more

Capacitance: 0.1 μF to a few hundred μF.

Withstand voltage: At least 120% of the rated output voltage of the RMX programmable

power supply.

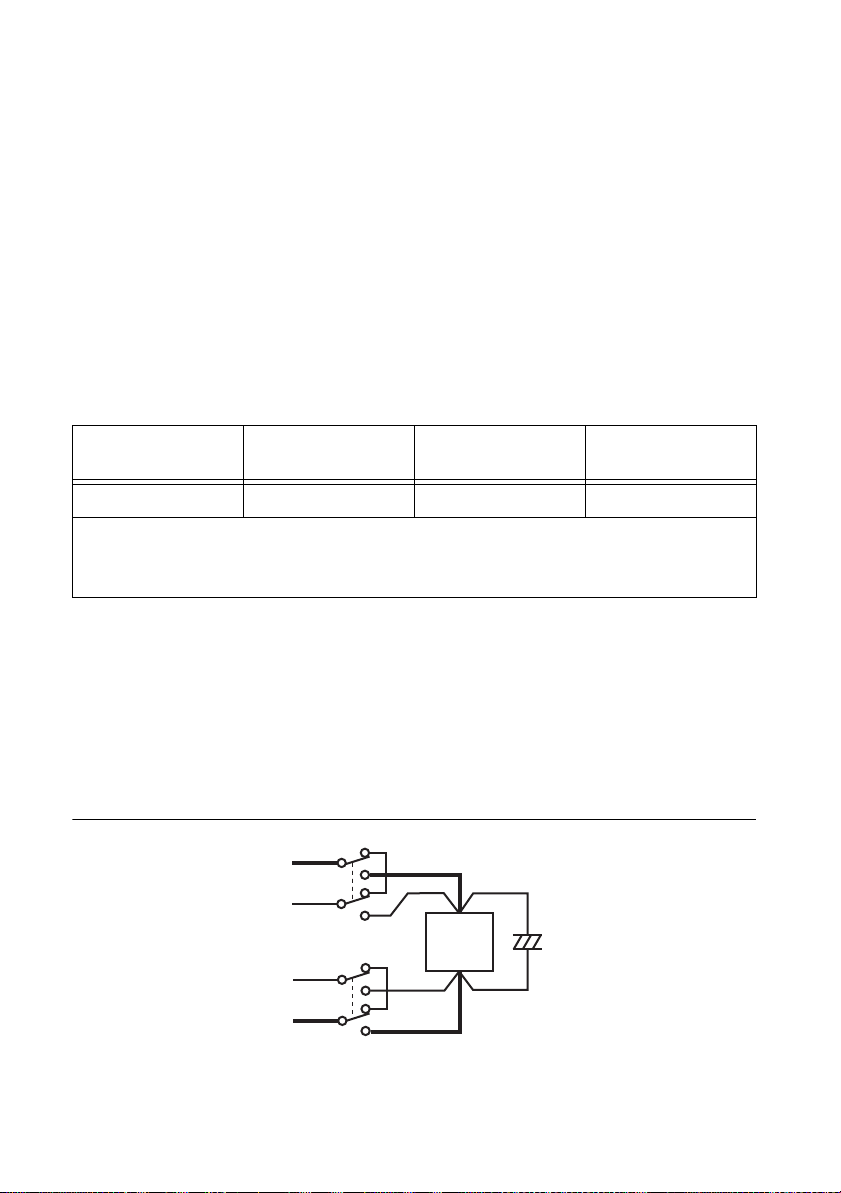

Inserting a Mechanical Switch Between the RMX Programmable Power Supply and the Load

If you want to connect and disconnect the load using a mechanical switch that is inserted

between the RMX programmable power supply and the load, be sure to include switches in the

sensing cables as shown in the following figure. Also make sure to turn on and off the load cable

and sensing cables simultaneously. Before you turn the mechanical switch on or off, be sure to

turn the output or the POWER switch off.

Figure 1-25. Mechanical Switch in a Sensing Cable

1-22 | ni.com

Page 31

RMX Programmable Power Supplies User Manual

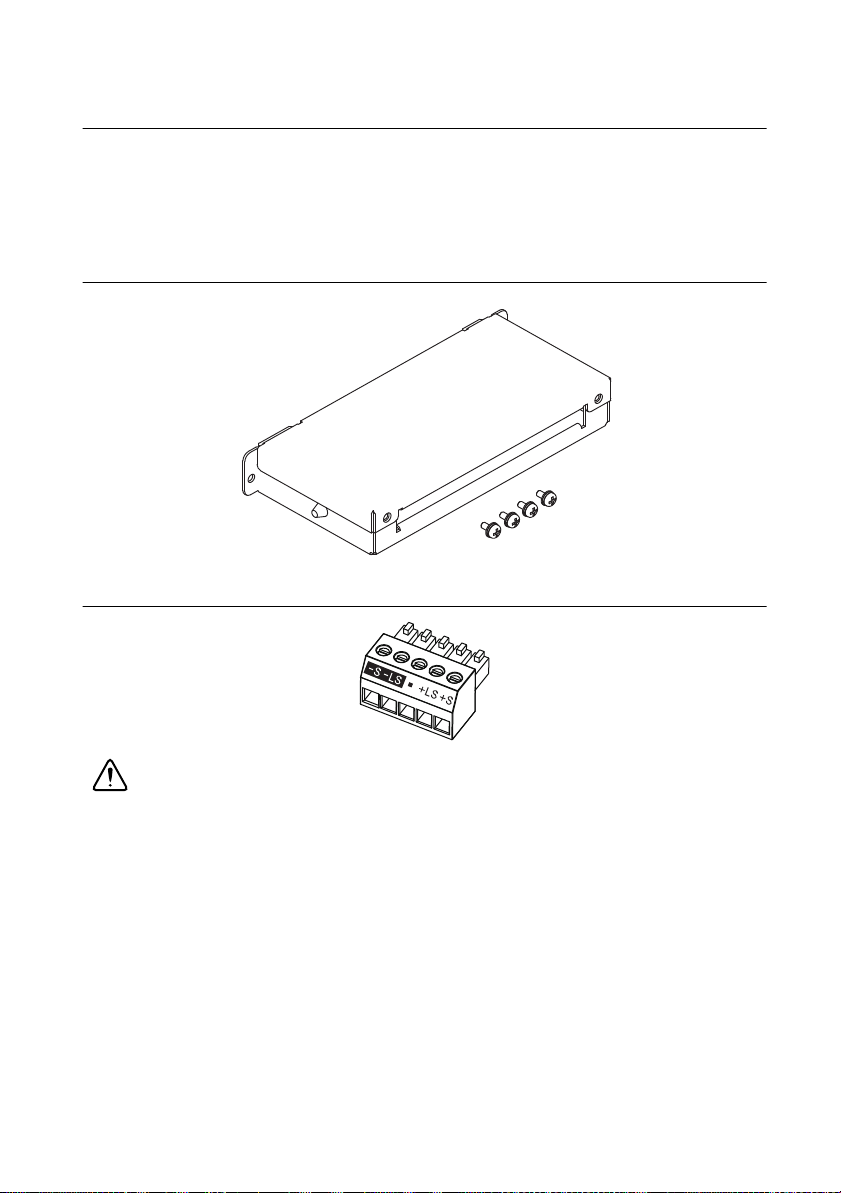

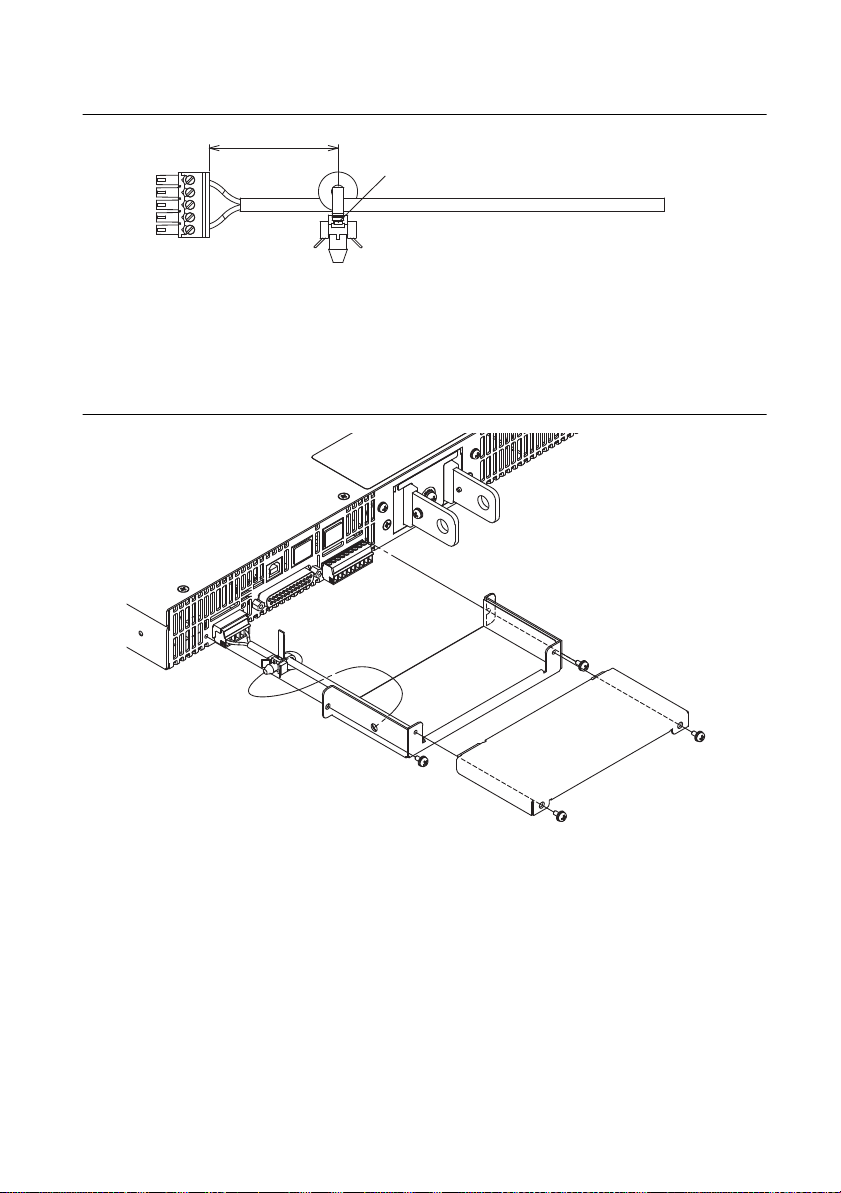

Accessories

RMX programmable power supplies have the following available accessories. For more

information about accessories contact National Instruments.

Parallel Operation Signal Cable

This cable is used when you perform parallel operations. The following three types are available:

Part Number Description

784821-01 Cable Assembly, RMX-412x Parallel Operation (2 units)

784822-01 Cable Assembly, RMX-412x Parallel Operation (3 units)

784823-01 Cable Assembly, RMX-412x Parallel Operation (4 units)

Figure 1-26. Parallel Operation Signal Cable

© National Instruments | 1-23

Page 32

2

Lit

Basic Functions

This chapter describes how to turn the output on and off and the basic operations that you can

perform from the front panel.

Measured Value Display and Setting Display

The voltage and current displays have the following two states:

• Measured value display

• Setting display

Measured Value Display

When the SET key LED is off, the front panel will display the measured value of the voltage and

current at the output terminals. You can still change the output voltage and current settings while

in this state, but the front panel will continue to display the values measured at the output. Refer

to the Using the RMX Programmable Power Supplies as a CV or CC Power Supply section for

more information about these functions.

Figure 2-1. Measured Value Display

Power Display

While in the measured value display, press PWR DSPL to display the output power on the

ammeter.

The output power is calculated from the measured output voltage and the measured output current.

When displaying the output power, the PWR DSPL key LED will light up. Press PWR DSPL

again to return to measured value display.

Figure 2-2. Power Display

© National Instruments | 2-1

Page 33

Chapter 2 Basic Functions

Lit

Lit

Setting Display

Press SET to display the present output voltage and output current settings, which will cause the

SET key LED to illuminate. Press SET again to return to the measured value display.

Figure 2-3. Setting Display

When you recall a preset memory entry, the values stored in the preset memory entry are

displayed on the panel.

Overvoltage Protection and Overcurrent Protection Setting Display

Press OCP•OVP to light its LED and display the present overcurrent protection and overvoltage

protection settings.

Figure 2-4. OCP and OVP Display

System Configuration Setting Display

Press CONFIG to light its LED and display the present system configuration settings. Refer to

the CONFIG Settings section for detailed information about these settings.

Figure 2-5. System Configuration Setting Display

Lit

2-2 | ni.com

Page 34

RMX Programmable Power Supplies User Manual

Decrease IncreaseIncrease Decrease

Panel Operations

Measured Value Display, Setting Display, and Set OVP/OCP Display

Turn the VOLTAGE knob to change the voltage. Turn the CURRENT knob to change the

current.

Figure 2-6. Panel Operations

While in setting display mode (the SET key LED is illuminated), turning the VOLTAGE and

CURRENT knobs will update the output voltage and current settings.

You cannot set the output voltage to a value that is 95% of the OVP trip point or higher. You

cannot set the output current to a value that is 95% of the OCP trip point or higher.

The displayed current or voltage may not change when you turn the CURRENT or VOLTAGE

knob. This is because the values are being changed at a finer resolution than the front panel can

display. The display will update when the amount that you change the value by reaches the

smallest display digit of the set voltage or current.

Fine Adjustment

Holding down the SHIFT key while turning the VOLTAGE or CURRENT knobs allows for

finer adjustment of the programmed voltage and current values.

Note When you set a value, it is convenient to first use normal resolution to set the

value roughly and then switch to fine resolution to set it precisely.

Output Operations

The toggles each time you press OUTPUT. When output is on, the OUTPUT LED in the display

area lights. When the output is off, the OUTPUT LED in the display area turns off.

When the OUTPUT key LED is on, the power supply will drive its output terminals to a level

determined by the voltage and current settings. If you change the settings while the output is on,

the changes are applied immediately to the output. If you change the settings while the output is

off, the device will switch to setting display mode (the SET key LED will light up). Pressing

OUTPUT will apply and drive the output terminals using the new settings.

© National Instruments | 2-3

Page 35

Chapter 2 Basic Functions

Lit

You can use external control to toggle the output as well. Refer to Chapter 3, External Control,

for additional information. CONFIG setting CF12 can be used to program the device to prioritize

CC or CV mode at startup.

Figure 2-7. Output Operations

Output State at Power-up

In the factory default settings, the output is off when the RMX programmable power supply

turns on. Using CONFIG parameter CF02, you can set the RMX programmable power supply

so that output is turned on at power on.

If you set the RMX programmable power supply so that output is turned on at power on, be sure

to check that the OVP trip point is set appropriately before you turn the RMX programmable

power supply off.

Caution If you change the load, it may be damaged if the RMX programmable

power supply OVP and OCP settings are not correct.

Operation Overview

The RMX programmable power supply is a constant voltage (CV)/constant current (CC)

regulated DC power supply that can output a wide range of voltage and current within rated

output power.

If you configure the settings so that output voltage × output current is less than or equal to the

rated output power, the RMX programmable power supply operates as a traditional

constant-voltage (CV)/constant-current (CC) power supply.

If you configure the settings so that “output voltage × output current” is greater than the rated

output power, the actual output is limited by the power limit (approximately 105% of the rated

output power), and the output voltage and output current change depending on the load value.

2-4 | ni.com

Page 36

RMX Programmable Power Supplies User Manual

35

30

25

20

15

10

5

0

0 20 40 60 80 100 120 140 150 160

Rated output voltage: 30 V

Rated output power

Rated output current

Output voltage (V)

Output current (A)

RMX-4120: 750 W

RMX-4124: 1500 W

Rated output power

01020304050 80

RMX-4120

60 70 75

RMX-4124

90

80

70

60

50

40

30

20

10

0

Output voltage (V)

Rated output voltage: 80 V

Rated output power

Rated output current

RMX-4121: 750 W

RMX-4125: 1500 W

Rated output power

0 5 10 15 20 25 30

0 102030405060

RMX-4121

RMX-4125

Output current (A)

56

28

Figure 2-8. RMX-4120/4124 Output Power

Figure 2-9. RMX-4121/4125 Output Power

© National Instruments | 2-5

Page 37

Chapter 2 Basic Functions

300

250

200

50

150

100

0

024681012

0 4 8 12162024

RMX-4122: 750 W

RMX-4126: 1500 W

Rated output voltage: 230 V

Rated output power

Rated output power

Rated output current

RMX-4122

RMX-4126

Output voltage (V)

Output current (A)

700

600

500

400

300

200

100

0

012345 786

Rated output voltage: 650 V

Rated output power

Rated output current

Output voltage (V)

Output current (A)

RMX-4123: 750 W

RMX-4127: 1500 W

Rated output power

0 0.5 1 1.5 2 2.5 3.5 43

RMX-4123

RMX-4127

Figure 2-10. RMX-4122/4126 Output Power

Figure 2-11. RMX-4123/4127 Output Power

2-6 | ni.com

Page 38

RMX Programmable Power Supplies User Manual

CV Power Supply and CC Power Supply

The RMX programmable power supply can operate in constant-voltage (CV) or constant-current

(CC) mode. The operation mode is determined by the following three values.

• The set output voltage (VS)

• The set output current (I

• The load resistance (RL)

The operation modes are described below.

Figure 2-12. RMX Programmable Power Supplies Operation Modes

)

S

V

ma x

V

S

out

p

A

Output voltage V

0

Output current I

RL > R

B

out

C

q

I

SImax

RL = R

RL < R

C

Crossover point

C

A = CV mode area

B

= CC mode area

= Set voltage

V

S

I

= Set current

S

R

= Vs/Is (Ohm’s Law)

C

= Load resistance

R

L

V

= Maximum settable voltage

max

= Maximum settable current

I

max

The above figure shows the operation modes of an RMX programmable power supply. The load

resistance is denoted as RL. The compliance resistance RC is calculated from the set voltage and

current (RC=VS/IS). The power supply is designed so that it operates in CV mode in area A and

CC mode in area B. The boundary between the two operation modes is the line defined by R

=

L

RC. This line represents the load at which the output voltage equals the set voltage and the output

current equals the set current. If load resistance RL is greater than the compliance resistance RC,

the operating point falls in area A, and the RMX programmable power supply will operate in CV

mode (point p). In this case, the set current I

operates as a current limit.

S

When operating in CV mode, the output voltage is maintained at the programmed voltage

setpoint. The output current I is determined by the equation I = V

and is less than current

S/RL

limit IS. The actual current that flows is determined by the voltage setpoint and the load

resistance and will not necessarily be equal to the programmed value.

For loads which may cause transient current spikes, current I

must be set so that the peak value

S

does not reach the current limit.

Conversely, if load resistance R

is less than the compliance resistance RC, the operating point

L

falls in area B, and the RMX programmable power supply operates in CC mode (point q). In this

case, set voltage V

operates as a voltage limit.

S

© National Instruments | 2-7

Page 39

Chapter 2 Basic Functions

When operating in CC mode, the output current is maintained at the programmed current

setpoint. The output voltage V is determined by the equation V = I

× RL and is less than voltage

S

limit VS. The actual voltage that flows is determined by the current setpoint and the load

resistance and will not necessarily be equal to the programmed value.

For loads that generate transient voltage spikes, V

must be set so that the surge voltage does not

S

reach the voltage limit.

Crossover Point

The RMX programmable power supply switches automatically between CV mode and CC mode

according to the changes in the load. A crossover point is the point at which the mode switches.

For example, when operating in CV mode, if the load changes and the output current reaches the

current limit, the RMX programmable power supply automatically switches to CC mode to

protect the load. Likewise, when operating in CC mode, if the output voltage reaches the voltage

limit, the RMX programmable power supply switches to CV mode.

CV Mode and CC Mode Operation Examples

This section uses a power supply with a rated output voltage of 100 V and a rated output current

of 10 A as an example.

Example 1

A load resistance (RL) of 8 Ω is connected to the output terminals of the power supply. The

output voltage and output current are set to 30 V and 5 A, respectively. In this case,

= 30 V/5 A = 6 Ω. Because 8 Ω is greater than 6 Ω (RL > RC), the power supply operates in

R

C

CV mode. When you want to increase the voltage in CV mode, you can increase the voltage up

to the voltage defined by the following equation: Vs = Is × R

Vs = 5 A × 8 Ω = 40 V. If you try to increase the voltage above this point, the crossover point is

reached, and the power supply automatically switches to CC mode. To maintain operations in

CV mode, increase the current limit.

. Substituting the values, obtains

L

Example 2

Next, a load resistance (RL) of 5 Ω is connected to the output terminals of the power supply.

The output voltage and output current are set to 30 V and 5 A, respectively. In this case,

= 30 V/5 A = 6 Ω. Because 5 Ω is less than 6 Ω (RL < RC), the power supply operates in

R

C

CC mode. When you want to increase the current in CC mode, you can increase the current up

to the current defined by the following equation: I

IS = 30 V/5 Ω = 6 A. If you try to increase the current above this point, the crossover point is

reached, and the power supply automatically switches to CV mode. To maintain operations in

CC mode, increase the voltage limit.

2-8 | ni.com

= VS/RL. Substituting the values, obtains

S

Page 40

RMX Programmable Power Supplies User Manual

Using the RMX Programmable Power Supplies as a CV or CC Power Supply

When using the RMX programmable power supply as a constant-voltage power supply, the set

current is the limit to the current that can flow through the load.

When using a RMX programmable power supply as a constant-current power supply, the set

voltage is the limit to the voltage that can be applied to the load.

If the specified limit is reached, the RMX programmable power supply automatically switches

its operation mode. When the RMX programmable power supply switches its operation mode,

the lit LED in the display area (CV LED or CC LED) changes to indicate the switch.

1. Turn the POWER switch off.

2. Connect the load to the output terminals.

3. Turn the POWER switch on. If the OUTPUT LED in the display area is lit, press OUTPUT

to turn the output off.

4. Press SET to change to the setting display. The SET key lights.

5. Turn the VOLTAGE knob to set the voltage.

Voltage Range: 0 to 105% of the Rated Output Voltage

RMX-4120 0 to 31.5 V

RMX-4121 0 to 84 V

RMX-4122 0 to 241.5 V

RMX-4123 0 to 682.5 V

RMX-4124 0 to 31.5 V

RMX-4125 0 to 84 V

RMX-4126 0 to 241.5 V

RMX-4127 0 to 682.5 V

© National Instruments | 2-9

Page 41

Chapter 2 Basic Functions

6. Turn the CURRENT knob to set the current.

Current Range: 0 to 105% of the Rated Output Voltage

RMX-4120 0 to 78.75 A

RMX-4121 0 to 29.4 A

RMX-4122 0 to 10.5 A

RMX-4123 0 to 3.675 A

RMX-4124 0 to 157.5 A

RMX-4125 0 to 58.8 A

RMX-4126 0 to 21 A

RMX-4127 0 to 7.35 A

7. Press OUTPUT to turn output on.

The SET LED turns off, and the OUTPUT LED in the display area lights. The voltage and

current are generated from the output terminals. When the device is operating as a

constant-voltage power supply, the CV LED in the display area lights. When the device is