Page 1

RMC-8357

User Manual

RMC-8357 User Manual

September 2017

377265A-01

Page 2

Support

Worldwide Technical Support and Product Information

ni.com

Worldwide Offices

Visit ni.com/niglobal to access the branch office websites, which provide up-to-date

contact information, support phone numbers, email addresses, and current events.

National Instruments Corporate Headquarters

11500 North Mopac Expressway Austin, Texas 78759-3504 USA Tel: 512 683 0100

For further support information, refer to the NI Services appendix. To comment on NI

documentation, refer to the NI website at ni.com/info and enter the Info Code feedback.

© 2017 National Instruments. All rights reserved.

Page 3

Legal Information

Limited Warranty

This document is provided ‘as is’ and is subject to being changed, without notice, in future editions. For the latest version,

ni.com/manuals. NI reviews this document carefully for technical accuracy; however, NI MAKES NO EXPRESS

refer to

OR IMPLIED WARRANTIES AS TO THE ACCURACY OF THE INFORMATION CONTAINED HEREIN AND

SHALL NOT BE LIABLE FOR ANY ERRORS.

NI warrants that its hardware products will be free of defects in materials and workmanship that cause the product to fail to

substantially conform to the applicable NI published specifications for one (1) year from the date of invoice.

For a period of ninety (90) days from the date of invoice, NI warrants that (i) its software products will perform substantially

in accordance with the applicable documentation provided with the software and (ii) the software media will be free from

defects in materials and workmanship.

If NI receives notice of a defect or non-conformance during the applicable warranty period, NI will, in its discretion: (i) repair

or replace the affected product, or (ii) refund the fees paid for the affected product. Repaired or replaced Hardware will be

warranted for the remainder of the original warranty period or ninety (90) days, whichever is longer. If NI elects to repair or

replace the product, NI may use new or refurbished parts or products that are equivalent to new in performance and reliability

and are at least functionally equivalent to the original part or product.

You must obtain an RMA number from NI before returning any product to NI. NI reserves the right to charge a fee for

examining and testing Hardware not covered by the Limited Warranty.

This Limited Warranty does not apply if the defect of the product resulted from improper or inadequate maintenance,

installation, repair, or calibration (performed by a party other than NI); unauthorized modification; improper environment;

use of an improper hardware or software key; improper use or operation outside of the specification for the product; improper

voltages; accident, abuse, or neglect; or a hazard such as lightning, flood, or other act of nature.

THE REMEDIES SET FORTH ABOVE ARE EXCLUSIVE AND THE CUSTOMER’S SOLE REMEDIES, AND SHALL

APPLY EVEN IF SUCH REMEDIES FAIL OF THEIR ESSENTIAL PURPOSE.

EXCEPT AS EXPRESSLY SET FORTH HEREI N, PRODUCTS ARE PROVIDED "AS IS" WITHOUT WARRANTY OF

ANY KIND AND NI DISCLAIMS ALL WARRANTIES, EXPRESSED OR IMPLIED, WITH RESPECT TO THE

PRODUCTS, INCLUDING ANY IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A

PARTICULAR PURPOSE, TITLE OR NON-INFRINGEMENT, AND ANY WARRANTIES THAT MAY ARISE FROM

USAGE OF TRADE OR COURSE OF DEALING. NI DOES NOT WARRANT, GUARANTEE, OR MAKE ANY

REPRESENTATIONS REGARDING THE USE OF OR THE RESULTS OF THE USE OF THE PRODUCTS IN TERMS

OF CORRECTNESS, ACCURACY, RELIABILITY, OR OTHERWISE. NI DOES NOT WARRANT THAT THE

OPERATION OF THE PRODUCTS WILL BE UNINTERRUPTED OR ERROR FREE.

In the event that you and NI have a separate signed written agreement with warranty terms covering the products, then the

warranty terms in the separate agreement shall control.

Copyright

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or mechanical,

including photocopying, recording, storing in an information retrieval system, or translating, in whole or in part, without the

prior written consent of National Instruments Corporation.

National Instruments respects the intellectual property of others, and we ask our users to do the same. NI software is protected

by copyright and other intellectual property laws. Where NI software may be used to reproduce software or other materials

belonging to others, you may use NI software only to reproduce materials that you may reproduce in accordance with the

terms of any applicable license or other legal restriction.

End-User License Agreements and Third-Party Legal Notices

You can find end-user license agreements (EULAs) and third-party legal notices in the following locations:

• Notices are located in the

directories.

• EULAs are located in the

•Review

<National Instruments>\_Legal Information.txt for information on including legal information in

installers built with NI products.

U.S. Government Restricted Rights

If you are an agency, department, or other entity of the United States Government (“Government”), the use, duplication,

reproduction, release, modification, disclosure or transfer of the technical data included in this manual is governed by the

Restricted Rights provisions under Federal Acquisition Regulation 52.227-14 for civilian agencies and Defense Federal

Acquisition Regulation Supplement Section 252.227-7014 and 252.227-7015 for military agencies.

Trademarks

Refer to the NI Trademarks and Logo Guidelines at ni.com/trademarks for more information on NI trademarks.

ARM, Keil, and µVision are trademarks or registered of ARM Ltd or its subsidiaries.

LEGO, the LEGO logo, WEDO, and MINDSTORMS are trademarks of the LEGO Group.

TETRIX by Pitsco is a trademark of Pitsco, Inc.

FIELDBUS FOUNDATION

®

EtherCAT

is a registered trademark of and licensed by Beckhoff Automation GmbH.

<National Instruments>\_Legal Information and <National Instruments>

<National Instruments>\Shared\MDF\Legal\license directory.

™

and FOUNDATION™ are trademarks of the Fieldbus Foundation.

Page 4

CANopen® is a registered Community Trademark of CAN in Automation e.V.

™

DeviceNet

Go!, SensorDAQ, and Vernier are registered trademarks of Vernier Software & Technol ogy. Vernier Software & Technology

and

and EtherNet/IP™ are trademarks of ODVA.

vernier.com are trademarks or trade dress.

Xilinx is the registered trademark of Xilinx, Inc.

Taptite and Trilobular are registered trademarks of Research Engineering & Manufacturing Inc.

®

is the registered trademark of Apple Inc.

FireWire

®

Linux

is the registered trademark of Linus Torvalds in the U.S. and other countries.

Handle Graphics

Simulink Coder

Tektronix

The Bluetooth

The ExpressCard

license.

The mark LabWindows is used under a license from Microsoft Corporation. Windows is a registered trademark of Microsoft

Corporation in the United States and other countries.

®

, MATLAB®, Simulink®, Stateflow®, and xPC TargetBox® are registered trademarks, and

™

, TargetBox™, and Target Language Compiler™ are trademarks of The MathWorks, Inc.

®

, Tek, and Tektronix, Enabling Technology are registered trademarks of Tektronix, Inc.

®

word mark is a registered trademark owned by the Bluetooth SIG, Inc.

™

word mark and logos are owned by PCMCIA and any use of such marks by National Instruments is under

Other product and company names mentioned herein are trademarks or trade names of their respective companies.

Members of the National Instruments Alliance Partner Program are business entities independent from NI and have no

agency, partnership, or joint-venture relationship with NI.

Patents

For patents covering NI products/technology, refer to the appropriate location: Help»Patents in your software,

the patents.txt file on your media, or the National Instruments Patent Notice at ni.com/patents.

Export Compliance Information

Refer to the Export Compliance Information at ni.com/legal/export-compliance for the NI global trade compliance

policy and how to obtain relevant HTS codes, ECCNs, and other import/export data.

WARNING REGARDING USE OF NATIONAL INSTRUMENTS PRODUCTS

YOU ARE ULTIMATELY RESPONSIBLE FOR VERIFYING AND VALIDATING THE SUITABILITY AND

RELIABILITY OF THE PRODUCTS WHENEVER THE PRODUCTS ARE INCORPORATED IN YOUR SYSTEM OR

APPLICATION, INCLUDING THE APPROPRIATE DESIGN, PROCESS, AND SAFETY LEVEL OF SUCH SYSTEM

OR APPLICATION.

PRODUCTS ARE NOT DESIGNED, MANUFACTURED, OR TESTED FOR USE IN LIFE OR SAFETY CRITICAL

SYSTEMS, HAZARDOUS ENVIRONMENTS OR ANY OTHER ENVIRONMENTS REQUIRING FAIL-SAFE

PERFORMANCE, INCLUDING IN THE OPERATION OF NUCLEAR FACILITIES; AIRCRAFT NAVIGATION; AIR

TRAFFIC CONTROL SYSTEMS; LIFE SAVING OR LIFE SUSTAINING SYSTEMS OR SUCH OTHER MEDICAL

DEVICES; OR ANY OTHER APPLICATION IN WHICH THE FAILURE OF THE PRODUCT OR SERVICE COULD

LEAD TO DEATH, PERSONAL INJURY, SEVERE PROPERTY DAMAGE OR ENVIRONMENTAL HARM

(COLLECTIVELY, “HIGH-RISK USES”). FURTHER, PRUDENT STEPS MUST BE TAKEN TO PROTECT AGAINST

FAILURES, INCLUDING PROVIDING BACK-UP AND SHUT-DOWN MECHANISMS. NI EXPRESSLY DISCLAIMS

ANY EXPRESS OR IMPLIED WARRANTY OF FITNESS OF THE PRODUCTS OR SERVICES FOR HIGH-RISK

USES.

Page 5

Contents

About This Manual

Related Documentation .................................................................................................... xiii

Chapter 1

Getting Started

Unpacking......................................................................................................................... 1-1

What You Need to Get Started ......................................................................................... 1-1

RMC-8357 Overview ....................................................................................................... 1-2

Key Features ..................................................................................................................... 1-2

Mainboard Features .................................................................................................. 1-2

CPU .................................................................................................................. 1-2

Memory ............................................................................................................ 1-2

Slots .................................................................................................................. 1-2

Video ................................................................................................................ 1-2

HDD.................................................................................................................. 1-2

Blu-ray .............................................................................................................. 1-3

Onboard LAN ................................................................................................... 1-3

Onboard I/O...................................................................................................... 1-3

Power Supply.................................................................................................... 1-3

Power Management Features............................................................................ 1-3

Front Panel LEDs ............................................................................................. 1-3

System Management......................................................................................... 1-3

RMC-8357 Description .................................................................................................... 1-4

Chapter 2

Installation and BIOS Setup

Safety Information ............................................................................................................ 2-1

Chassis Cooling Considerations ....................................................................................... 2-2

Providing Adequate Clearance ................................................................................. 2-2

Installation ........................................................................................................................ 2-2

Connecting Safety Ground ............................................................................................... 2-3

Connecting to Power Source ............................................................................................ 2-3

BIOS Setup ....................................................................................................................... 2-3

Starting the BIOS Setup Utility ................................................................................ 2-4

How to Change the Configuration Data ........................................................... 2-4

How to Start the Setup Utility .......................................................................... 2-4

Main Setup........................................................................................................................ 2-5

System Date/System Time................................................................................ 2-5

BIOS Version ................................................................................................... 2-5

Build Date......................................................................................................... 2-5

© National Instruments | v

Page 6

Contents

Memory Information.................................................................................................2-5

Total Memory ................................................................................................... 2-5

Memory Speed ..................................................................................................2-5

Advanced Setup Configurations ....................................................................................... 2-5

Boot Feature.............................................................................................................. 2-6

Quiet Boot......................................................................................................... 2-6

AddOn ROM Display Mode............................................................................. 2-6

Bootup NumLock State .................................................................................... 2-6

Wait For F1 If Error.......................................................................................... 2-6

INT19 (Interrupt 19) Trap Response ................................................................2-6

Re-try Boot ....................................................................................................... 2-6

Power Configuration................................................................................................. 2-6

DeepSx Power Policies ..................................................................................... 2-6

Watch Dog Function ......................................................................................... 2-7

Power Button Function ..................................................................................... 2-7

Restore on AC Power Loss............................................................................... 2-7

Chipset Configuration............................................................................................... 2-7

CPU Configuration ........................................................................................... 2-7

Clock Spread Spectrum .................................................................................... 2-8

Hyper-Threading............................................................................................... 2-8

Performance/Watt ............................................................................................. 2-8

Execute Disable Bit .......................................................................................... 2-8

PPIN Control..................................................................................................... 2-8

Hardware Prefetcher ........................................................................................ 2-8

Adjacent Cache Line Prefetch .......................................................................... 2-8

DCU Streamer Prefetcher ................................................................................. 2-9

DCU IP Prefetcher ............................................................................................ 2-9

DCU (Data Cache Unit) Mode ......................................................................... 2-9

Direct Cache Access (DCA) .............................................................................2-9

DCA Prefetch Delay ......................................................................................... 2-9

X2APIC (Extended Advanced Programmable Interrupt Controller) ............... 2-9

AES-NI ............................................................................................................. 2-9

Intel Virtualization Technology........................................................................ 2-10

Advanced Power Management Configuration.......................................................... 2-10

Power Technology ............................................................................................ 2-10

Config TDP...................................................................................................... 2-10

CPU P State Control .................................................................................................2-10

EIST (P-State)................................................................................................... 2-10

Turbo Mode ...................................................................................................... 2-10

P-state Coordination ......................................................................................... 2-10

CPU C State Control................................................................................................. 2-10

CPU C3 Report ................................................................................................. 2-11

CPU C6 Report ................................................................................................. 2-11

Enhanced Halt State (C1E) ............................................................................... 2-11

vi | ni.com

Page 7

RMC-8357 User Manual

CPU T State Control................................................................................................. 2-11

ACPI (Advanced Configuration Power Interface) T-States ............................. 2-11

Socket RAPL (Running Average Power Limit) Configuration................................ 2-11

FAST-RAPL-NSTRIKE-PL2-DUTY-CYCLE ................................................ 2-11

Turbo Power Limit Lock .................................................................................. 2-11

Long Power Limit Override ............................................................................. 2-11

Long Duration Power Limit ............................................................................. 2-11

Package Clamping Limit1 ................................................................................ 2-12

Short Duration Power Limit Enable ................................................................. 2-12

Short Duration Power Limit ............................................................................. 2-12

Package Clamping Limit2 ................................................................................ 2-12

Chipset Configuration....................................................................................................... 2-12

North Bridge ............................................................................................................. 2-12

IIO Configuration ..................................................................................................... 2-12

EV DFX (Device Function On-Hide) Feature.................................................. 2-12

IIO1 Configuration/IIO2 Configuration ........................................................... 2-12

IOAT Configuration ................................................................................................. 2-13

Enable I/OAT ................................................................................................... 2-13

No Snoop .......................................................................................................... 2-13

Relaxed Ordering.............................................................................................. 2-13

Intel VT for Directed I/O (VT-d) ............................................................................. 2-14

Interrupt Remapping......................................................................................... 2-14

Coherency Support (Non-Isoch)....................................................................... 2-14

Coherency Support (Isoch)............................................................................... 2-14

QPI (Quick Path Interconnect) Configuration.......................................................... 2-14

QPI Status ......................................................................................................... 2-14

Link Speed Mode.............................................................................................. 2-14

Link Frequency Select ...................................................................................... 2-14

Link L0p Enable ............................................................................................... 2-15

Link L1 Enable ................................................................................................. 2-15

Isoc Mode ......................................................................................................... 2-15

Memory Configuration ............................................................................................. 2-15

Enforce POR..................................................................................................... 2-15

Memory Frequency........................................................................................... 2-15

ECC Support..................................................................................................... 2-15

Data Scrambling ............................................................................................... 2-15

Enable ADR...................................................................................................... 2-15

DRAM RAPL (Running Average Power Limit) Baseline ............................... 2-15

Set Throttling Mode.......................................................................................... 2-16

Socket Interleave Below 4GB .......................................................................... 2-16

Channel Interleaving......................................................................................... 2-16

Rank Interleaving ............................................................................................. 2-16

A7 Mode ........................................................................................................... 2-16

DIMM Information................................................................................................... 2-16

© National Instruments | vii

Page 8

Contents

Memory RAS (Reliability_Availability_Serviceability) Configuration................... 2-16

RAS Mode ........................................................................................................ 2-16

Lockstep x4 DIMMs ......................................................................................... 2-17

Memory Rank Sparing...................................................................................... 2-17

Patrol Scrub....................................................................................................... 2-17

Patrol Scrub Interval ......................................................................................... 2-17

Demand Scrub................................................................................................... 2-17

Device Tagging................................................................................................. 2-17

South Bridge ............................................................................................................. 2-17

Legacy USB Support ........................................................................................2-17

XHCI Hand-Off ................................................................................................ 2-18

EHCI Hand-Off................................................................................................. 2-18

USB Mass Storage Driver Support................................................................... 2-18

Port 60/64 Emulation ........................................................................................ 2-18

USB 3.0 Support ...............................................................................................2-18

EHCI1 ............................................................................................................... 2-18

EHCI2 ............................................................................................................... 2-18

XHCI Pre-Boot Drive ....................................................................................... 2-18

XHCI Idle L1 .................................................................................................... 2-18

PCH DMI ASPM ..............................................................................................2-18

SATA Configuration.................................................................................................2-19

SATA Controller............................................................................................... 2-19

Configure SATA as .......................................................................................... 2-19

sSATA Configuration ............................................................................................... 2-21

sSATA Controller ............................................................................................. 2-21

Configure sSATA as......................................................................................... 2-21

Server ME (Management Engine) Configuration ..................................................... 2-23

PCIe/PCI/PnP Configuration ....................................................................................2-23

PCI AER (Advanced Error-Reporting) Support ............................................... 2-23

VGA Palette Snoop........................................................................................... 2-23

PERR# Generation Support..............................................................................2-23

SERR# Generation Support..............................................................................2-24

Above 4G Decoding .........................................................................................2-24

SR-IOV Support .............................................................................................. 2-24

Maximum Payload ............................................................................................2-24

Maximum Read Request...................................................................................2-24

ASPM Support..................................................................................................2-24

MMIOHBase .................................................................................................... 2-24

MMIO High Size .............................................................................................. 2-24

Onboard LAN OPROM .................................................................................... 2-25

VGA Priority..................................................................................................... 2-25

w

ork Stack...................................................................................................2-25

Net

Ipv6 PXE Support ............................................................................................ 2-25

viii | ni.com

Page 9

RMC-8357 User Manual

Super IO Configuration ............................................................................................ 2-25

Serial Port 1 Configuration/Serial Port 2 Configuration ................................. 2-25

Device Settings ................................................................................................. 2-25

Change Port 1 Settings/Change Port 2 Settings................................................ 2-25

Serial Port 2 Attribute....................................................................................... 2-26

Serial Port Console Redirection ............................................................................... 2-26

COM 1 Console Redirection ............................................................................ 2-26

COM1 Console Redirection ..................................................................................... 2-26

SOL/COM2 Console Redirection............................................................................. 2-28

SOL/COM2 Console Redirection Settings ............................................................... 2-28

EMS Console Redirection Settings .......................................................................... 2-30

Trusted Computing ................................................................................................... 2-30

Configuration.................................................................................................... 2-30

ACPI Settings ........................................................................................................... 2-31

WHEA Support................................................................................................. 2-31

Event Logs........................................................................................................................ 2-31

Change SMBIOS Event Log Settings ...................................................................... 2-31

Enabling/Disabling Options ............................................................................. 2-31

SMBIOS Event Log.......................................................................................... 2-31

Runtime Error Logging Support....................................................................... 2-31

Memory Corrected Error Enabling ................................................................... 2-32

PCI-Ex (PCI-Express) Error Enable................................................................. 2-32

Memory Correctable Error Threshold .............................................................. 2-32

Erasing Settings ................................................................................................ 2-32

SMBIOS Event Log Standard Settings ............................................................ 2-32

IPMI.................................................................................................................................. 2-33

IPMI Firmware Revision .................................................................................. 2-33

IPMI Status ....................................................................................................... 2-33

System Event Log..................................................................................................... 2-33

Enabling/Disabling Options ............................................................................. 2-33

Erasing Settings ................................................................................................ 2-33

BMC Network Configuration ................................................................................... 2-33

IPMI LAN Selection......................................................................................... 2-33

IPMI Network Link Status ............................................................................... 2-33

Update IPMI LAN Configuration..................................................................... 2-34

Configuration Address Source.......................................................................... 2-34

Security Settings ...............................................................................................................2-34

Password Check................................................................................................ 2-34

Administrator Password ................................................................................... 2-34

Secure Boot Menu ............................................................................................ 2-35

Boot Settings..................................................................................................................... 2-35

Setup Prompt Timeout...................................................................................... 2-35

Boot Mode Select ............................................................................................. 2-35

Fixed Boot Order Priorities .............................................................................. 2-35

Add New Boot Option ...................................................................................... 2-36

© National Instruments | ix

Page 10

Contents

Boot Option File Path ............................................................................................... 2-36

Create ................................................................................................................ 2-36

Delete Boot Option ........................................................................................... 2-36

Save & Exit ....................................................................................................................... 2-36

Discard Changes and Exit ................................................................................. 2-36

Save Changes and Reset ................................................................................... 2-36

Save Options .............................................................................................................2-36

Save Changes.................................................................................................... 2-36

Discard Changes ............................................................................................... 2-37

Restore Defaults................................................................................................ 2-37

Save As User Defaults ...................................................................................... 2-37

Restore User Defaults ....................................................................................... 2-37

Boot Override ................................................................................................... 2-37

BIOS Error Beep Codes.................................................................................................... 2-37

OS Reinstallation and Recovery ....................................................................................... 2-38

Cleaning ............................................................................................................................ 2-39

Exterior Cleaning ...................................................................................................... 2-39

Rack Mounting ................................................................................................................. 2-39

Installing the Inner Slides ......................................................................................... 2-39

Installing the Slide Mounting Brackets in the Rack .................................................2-41

Installing the Outer Slides in the Rack ..................................................................... 2-42

Installing the Chassis into the Rack .......................................................................... 2-43

Chapter 3

I/O Information

Front Panel Connectors.....................................................................................................3-1

Rear Panel Connectors...................................................................................................... 3-1

Universal Serial Bus ................................................................................................. 3-2

Serial ......................................................................................................................... 3-3

VGA.......................................................................................................................... 3-4

Ethernet ..................................................................................................................... 3-5

MXI-Express Connectors ................................................................................................. 3-5

Chapter 4

Common Configuration Questions

General Questions............................................................................................................. 4-1

Boot Options .....................................................................................................................4-2

Chassis Configuration.......................................................................................................4-2

Chapter 5

Troubleshooting

x | ni.com

Page 11

Appendix A

Specifications

Appendix B

Hardware Configuration

Appendix C

NI Services

Glossary

Index

RMC-8357 User Manual

© National Instruments | xi

Page 12

About This Manual

The RMC-8357 User Manual contains information about installing, configuring, using, and

maintaining the RMC-8357.

Related Documentation

The following documents contain information that you may find helpful as you read this manual:

• CompactPCI Specification PICMG 2.0 R 3.0

• PXI Hardware Specification, Revision 2.1

• PXI Software Specification, Revision 2.1

• ANSI/IEEE Standard 1014-1987, IEEE Standard for a Versatile Backplane Bus: VMEbus

• ANSI/VITA 1-1994, VME64

• NI-VISA User Manual

• NI-VISA Programmer Reference Manual

• Read Me First: Safety and Electromagnetic Compatibility, National Instruments

© National Instruments | xiii

Page 13

1

Getting Started

This chapter describes the key features of the RMC-8357 and lists the kit contents and optional

equipment you can order from National Instruments.

Unpacking

Carefully inspect the shipping container and the RMC-8357 for damage. Check for visible

damage to the metal work. Check to make sure all hardware and switches are undamaged. If

damage appears to have been caused during shipment, file a claim with the carrier. Retain the

packing material for possible inspection and/or reshipment.

What You Need to Get Started

The RMC-8357 kit contains the following items:

RMC-8357 rack mount controller

RMC-8357 Installation Guide

RMC-8357 User Manual (available at ni.com/support)

Windows recovery media (not included in diskless versions)

23-36 VDC 3-pin cable (ships with the DC option)

A power cable is not included with the RMC-8357 kit. Contact National Instruments if you need

help finding a power cable.

Table 1-1. AC Power Cables

Power Cable Reference Standards

Standard 120 V (USA) ANSI C73.11/NEMA 5-15-P/IEC83

Switzerland 220 V SEV

Australia 240 V AS C112

Universal Euro 230 V CEE (7), II, IV, VII IEC83

North America 240 V ANSI C73.20/NEMA 5-15-P/IEC83

© National Instruments | 1-1

Page 14

Chapter 1 Getting Started

Table 1-1. AC Power Cables (Continued)

Power Cable Reference Standards

United Kingdom 230 V BS 1363/IEC83

Japan 100 V ANSI C73.11/NEMA 5-15-P/IEC83

RMC-8357 Overview

The RMC-8357 is a rugged 1U PC-based controller for remote control of PXI chassis. The

controller provides leading-edge processing power with Intel Xeon E5-2620 v4 processors, high

disk bandwidth with software RAID support, high I/O bandwidth with two PCI Express 3.0 x16

slots, and up to 32 GB of memory.

Key Features

The RMC-8357 offers the performance of a high-end PC in a compact 1U rack-mountable form

factor for controlling a PXI or PXI Express system using a National Instruments remote

controller.

Mainboard Features

CPU

• Intel Xeon E5-2620 v4 Eight Core Processor, LGA 2011

Memory

• 32 GB DDR4 RAM

Slots

• One PCI Express 3.0 x16 slot, full height

• One PCI Express 3.0 x16 slot (requires a custom PCI Express bracket)

Note The x16 bottom slot requires a custom bracket and supports only half-height

cards.

Video

• PCIe video graphics card

HDD

• One 1 TB 2.5 in. SSD

• Supports up to four 2.5 in. drives

1-2 | ni.com

Page 15

Blu-ray

• Slim DVD-R/W Blu-ray drive

Onboard LAN

• Two Gigabit Ethernet ports

Onboard I/O

• Two Serial ports

• One DisplayPort

• One DVI port

• One VGA port (disabled by default)

• Two USB 2.0 ports (rear)

• Two USB 3.0 ports (front)

• Two USB 3.0 ports (rear)

Power Supply

• Supports redundant AC and DC power supplies

Power Management Features

• ACPI/ACPM power management

• Wake-On-LAN (WOL) header

• Power-on mode from AC power recovery

RMC-8357 User Manual

Front Panel LEDs

• Power indicator

• Power shuttle indicators

• LAN status indicators

• HDD indicator

• System temp (overheat) and fan (fail) warning indicator

System Management

• Monitoring for CPU and chassis environment

• CPU thermal trip support

• +5 V standby alert LED

• Fan speed control

© National Instruments | 1-3

Page 16

Chapter 1 Getting Started

Rugged Rackmount ControllerRugged Rackmount Controller

NI RMC-8357NI RMC-8357

4

4

32

12

9876

5 10

11

1

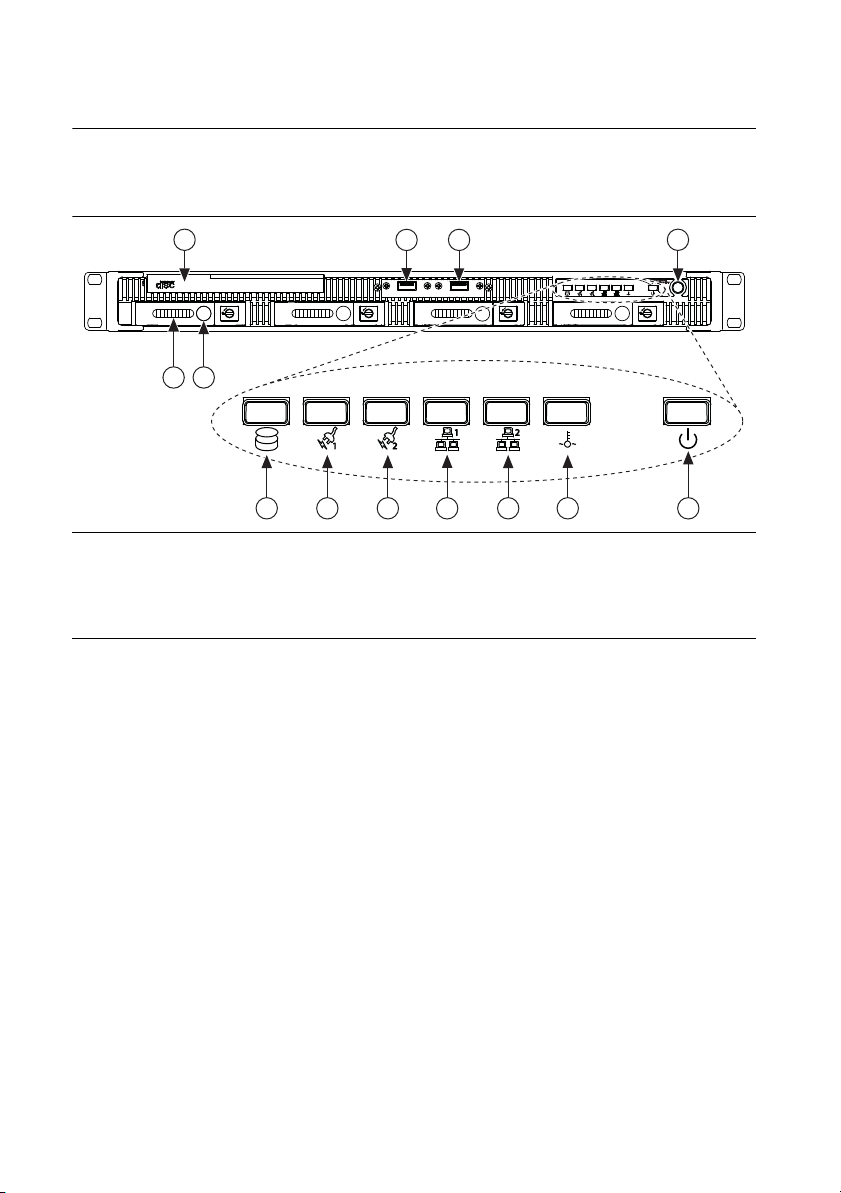

RMC-8357 Description

Figures 1-1 1-2 and shows the key features of the RMC-8357 front and rear panels. For detailed

information about the RMC-8357 front and rear panel, refer to Chapter 3, I/O Information.

Figure 1-1. Front View of the RMC-8357

1 DVD-R/W Blu-ray Drive

2 Hard Drives

3 Hard Drive Ejector Buttons

4USB Ports

5 Hard Drive Activity Indicator

6 Power Shuttle 1 Indicator

7 Power Shuttle 2 Indicator

8 LAN1 Status Indicator

9 LAN2 Status Indicator

10 System Temp and Fan Warning Indicator

11 Power Indicator

12 Power Button

The front panel includes the following LEDs:

• Hard drive activity indicator—Glows when there is hard drive activity.

• Power shuttle indicators—Glow when power shuttles are powered on.

• LAN status indicators—Flash when there is activity on LAN1 or LAN2.

• Overheat/fan fail indicator

– Off—Normal

– On—Overheat

– Flashing—Fan failure warning

• Power indicator—Glows when the RMC-8357 is powered on.

1-4 | ni.com

Page 17

RMC-8357 User Manual

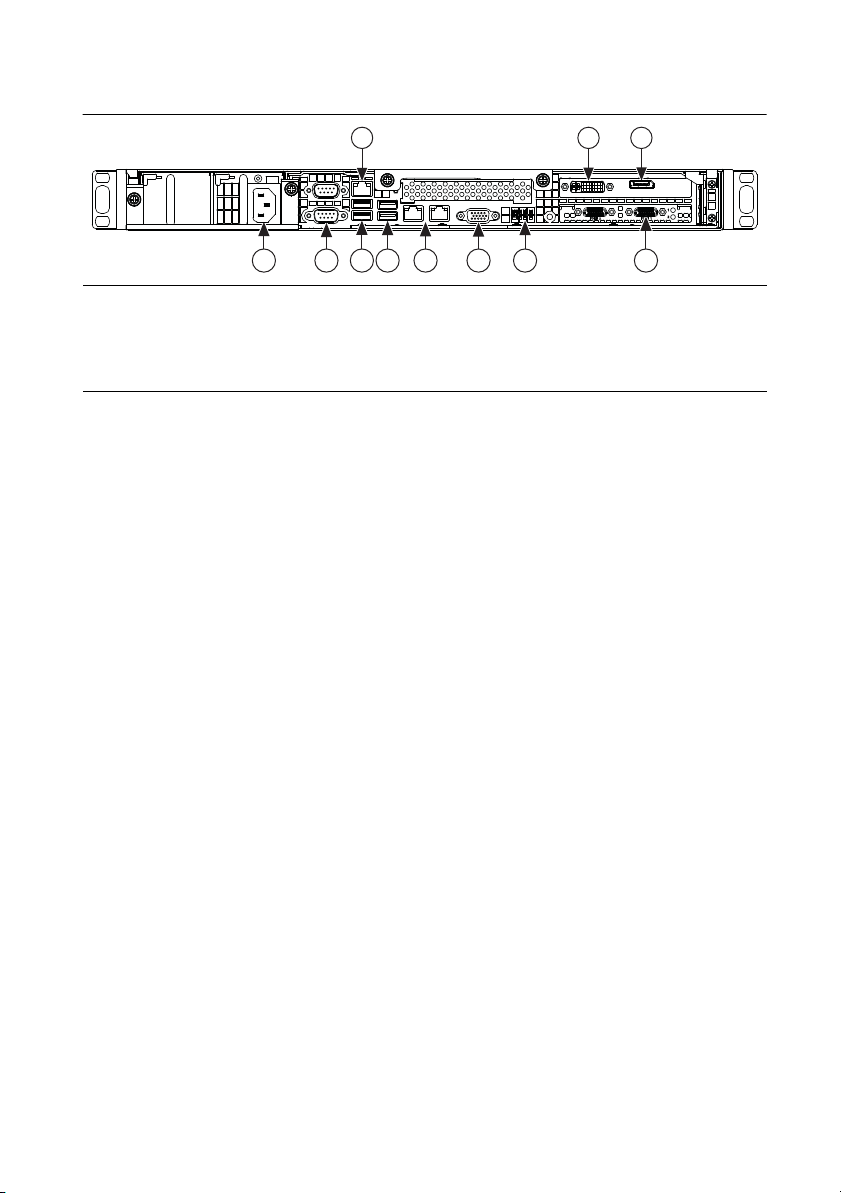

Figure 1-2. Rear View of the RMC-8357

1 2 3

11 10 9 8 7 6 5 4

1 IPMI Management Port

2DVI Port

3DisplayPort

4 MXI x1 Ports

5 UID Switch

6 VGA Port (Disabled By Default)

7 LAN Ports

8 USB 3.0 Ports

9 USB 2.0 Ports

10 Serial Ports

11 Power Connector

© National Instruments | 1-5

Page 18

2

Installation and BIOS Setup

This chapter describes how to install, configure, and use the RMC-8357. Read this chapter

before connecting the RMC-8357 to a power source.

Safety Information

Caution Before undertaking any troubleshooting, maintenance, or exploratory

procedure, carefully read the following caution notices.

Caution Product functionality can be disrupted if the knurled thumbscrews on the

back of the top cover are subjected to Electrostatic Discharge (ESD). To prevent

damage, you must employ industry-standard ESD prevention measures during

installation, maintenance, and operation.

Caution Overloading the circuits may damage supply wiring. Do not exceed the

ratings on the equipment nameplate when connecting equipment to the supply circuit.

Note Tighten the thumbscrew for the top panel cover with a tool after both initial

installation and subsequent access.

Caution To avoid risk of explosion, do not replace the battery (JBAT1) with an

incorrect battery type. Dispose of used batteries according to the battery instructions.

This equipment contains voltage hazardous to human life and safety, and is capable of inflicting

personal injury.

• Chassis Grounding—The RMC-8357 requires a connection from the premise wire safety

ground to the RMC-8357 chassis ground. The earth safety ground must be connected during

use of this equipment to minimize shock hazards. Refer to the Connecting Safety Ground

section for instructions on connecting safety ground.

• Mechanical Loading—To avoid a hazardous load condition, be sure the mechanical load

is even when rack mounting the equipment.

• Live Circuits—Operating personnel and service personnel must not remove protective

covers when operating or servicing the RMC-8357. Adjustments and service to internal

components must be undertaken by qualified service technicians. During service of

this product, the mains connector to the premise wiring must be disconnected. Dangerous

voltages may be present under certain conditions; use extreme caution.

© National Instruments | 2-1

Page 19

Chapter 2 Installation and BIOS Setup

• Explosive Atmosphere—Do not operate the chassis in conditions where flammable gases

are present. Under such conditions, this equipment is unsafe and may ignite the gases or gas

fumes.

• Parts Replacement—Service this equipment only with parts that are exact replacements,

both electrically and mechanically. Contact National Instruments for replacement part

information. Installation of parts with those that are not direct replacements may cause

harm to personnel operating the chassis. Furthermore, damage or fire may occur if

replacement parts are unsuitable.

• Modification—Do not modify any part of the RMC-8357 from its original condition.

Unsuitable modifications may result in safety hazards.

Chassis Cooling Considerations

The RMC-8357 is designed to operate on a bench or in an instrument rack. Determine how you

want to use the RMC-8357 and follow the appropriate installation instructions.

Caution If installed in a closed or multiunit rack assembly, the rack environment

operating ambient temperature may be greater than room ambient temperature.

Therefore, install the equipment in an environment compatible with the maximum

ambient operating temperature (Tma) specified in Appendix A, Specifications.

Providing Adequate Clearance

Apertures in the front and rear of the chassis facilitate power supply and motherboard cooling.

Air enters through the front of the chassis and exits through the fans on the rear of the chassis.

Place the RMC-8357 on a bench top or in an instrument rack so that the fans (air outlets) and the

air inlet apertures in the front and rear of the chassis have adequate ventilation. Keep other

equipment a minimum of 76.2 mm (3 in.) away from the air outlets on the rear of the chassis.

Installation

Follow these steps to connect devices to the RMC-8357:

1. Connect a keyboard and mouse to the appropriate connectors on the RMC-8357 rear panel.

2. Connect the DVI or DisplayPort monitor video cable to the DVI or DisplayPort connector

on the rear panel.

3. Connect the USB and serial devices as necessary to the RMC-8357 front and rear panel

ports.

Caution To minimize shock hazard, make sure the electrical power outlet you use

to power the RMC-8357 has an appropriate earth safety ground. Refer to the

Connecting Safety Ground section for more information.

Caution Use the DC power cable provided with DC power supplies for VDC input.

2-2 | ni.com

Page 20

RMC-8357 User Manual

4. Connect the AC power cable to the AC inlet on the rear panel and to an AC power outlet.

For more information, refer to the Connecting to Power Source section.

5. For the DC option, connect the DC positronic connector to the DC inlet on the rear panel

and wire to a DC power source.

6. Power on the RMC-8357.

7. Verify that the RMC-8357 boots. If it does not boot, refer to the What if the RMC-8357 does

not boot? section of Chapter 5, Troubleshooting.

Connecting Safety Ground

The RMC-8357 is designed with a three-position IEC C14 style plug that connects the ground

line to the chassis ground. To minimize shock hazard, make sure the electrical power outlet you

use to power the chassis has an appropriate earth safety ground.

Note The RMC-8357 also includes a grounding screw (8-32 thread size nut) on the

back of the chassis. (The nut is not supplied with the RMC-8357.)

Connecting to Power Source

Attach input power through the rear AC/DC inlet using the appropriate AC/DC power cable

supplied.

Caution Overloading the circuits may damage supply wiring. Do not exceed the

ratings on the equipment nameplate when connecting equipment to the supply circuit.

Caution To completely remove power, you must disconnect the AC/DC power cable.

Caution For a DC power supply, provide a 30 A or higher overcurrent protection

device external to the equipment.

The power switch allows you to power on the chassis or place it in standby mode. Push the power

switch to the On position (if not already on). Observe that all fans become operational and the

power indicator is lit.

BIOS Setup

This section describes the AMI BIOS™ Setup utility for the RMC-8357 motherboard. The ROM

BIOS is stored in a Flash EEPROM and can be easily updated.

Note Due to periodic changes to the BIOS, some settings may have been added

or deleted and might not yet be recorded in this manual. Refer to

downloads

for any changes to BIOS that may not be reflected in this manual.

© National Instruments | 2-3

ni.com/

Page 21

Chapter 2 Installation and BIOS Setup

Starting the BIOS Setup Utility

To enter the BIOS Setup Utility, press the <Delete> key while the system is booting-up.

Note In

screen. There are a few cases when other keys are used, such as <F1>, <F2>, etc...

Each main BIOS menu option is described in this manual. The AMI BIOS setup menu screen

has two main frames. The left frame displays all the options that can be configured. grayed-out

options cannot be configured. Options in blue can be configured by the user. The right frame

displays the key legend. Above the key legend is an area reserved for a text message. When

an option is selected in the left frame, it is highlighted in white. Often a text message will

accompany it.Highlighting a submenu and pressing the <Enter> key will open the list of

settings within that submenu.

Note The AMI BIOS has default text messages built in.

The BIOS setup utility uses a key-based navigation system called hot keys. Most of these hot

keys (<F1>, <F10>, <Enter>, <ESC>, <Arrow> keys, etc.) can be used at any time during the

setup navigation process.

Note Options in Bold are default settings.

most cases, the <Delete> key is used to invoke the A M I BIOS setup

How to Change the Configuration Data

The configuration data that determines the system parameters may be changed by entering the

AMI BIOS setup utility. This setup utility can be accessed by pressing <Del> at the appropriate

time during system boot.

How to Start the Setup Utility

Normally, the only visible Power-On Self-Test (POST) routine is the memory test. As the

memory is being tested, press the <Delete> key to enter the main menu of the AMI BIOS setup

utility. From the main menu, you can access the other setup screens. An AMI BIOS

identification string is displayed at the left bottom corner of the screen, below the copyright

message.

2-4 | ni.com

Caution Do not upgrade the BIOS unless your system has a BIOS-related issue.

Flashing the wrong BIOS can cause irreparable damage to the system. In no event

shall National Instruments be liable for direct, indirect, special, incidental, or

consequential damages arising from a BIOS update.

Page 22

RMC-8357 User Manual

Main Setup

When you first enter the AMI BIOS setup utility, you will enter the Main setup screen. You can

always return to the Main setup screen by selecting the Main tab on the top of the screen.

The following Main menu items will be displayed:

System Date/System Time

Use this option to change the system date and time. Highlight System Date or System Time using

the arrow keys. Enter new values using the keyboard. Press the <Tab> key or the arrow keys to

move between fields. The date must be entered in Day MM/DD/YYYY format. The time is

entered in HH:MM:SS format.

Note The time is in the 24-hour format. For example, 5:30 P.M. appears as

17:30:00. The date's default value is 01/01/2015 after RTC reset.

BIOS Version

This item displays the version of the BIOS ROM used in the system.

Build Date

This item displays the date when the version of the BIOS ROM used in the system was built.

Memory Information

Total Memory

This item displays the total size of memory available in the system.

Memory Speed

This item displays the de faul speed of the memory modules installed in the system.

Advanced Setup Configurations

Use the arrow keys to select Advanced Setup and press <Enter> to access the submenu items.

Caution Take caution when changing the Advanced settings. An incorrect value,

a very high DRAM frequency, or an incorrect BIOS timing setting may cause the

system to malfunction. When this occurs, restore the sett ing t o the default setting.

© National Instruments | 2-5

Page 23

Chapter 2 Installation and BIOS Setup

Boot Feature

Quiet Boot

Use this feature to select the screen display between the POST messages or the OEM logo at

bootup. Select Disabled to display the POST messages. Select Enabled to display the OEM

logo instead of the normal POST messages. The options are Enabled and Disabled.

AddOn ROM Display Mode

Use this item to set the display mode for the Option ROM. Select Keep Current to display the

current AddOn ROM display setting. Select Force BIOS to use the Option ROM display set

by the system BIOS. The options are Force BIOS and Keep Current.

Bootup NumLock State

Use this feature to set the Power-on state for the <Numlock> key. The options are Off and On.

Wait For F1 If Error

Use this feature to force the system to wait until the <F1> key is pressed if an error occurs.

The options are Disabled and Enabled.

INT19 (Interrupt 19) Trap Response

Interrupt 19 is the software interrupt that handles the boot disk function. When this item is

set to Immediate, the ROM BIOS of the host adapters will capture Interrupt 19 at bootup

immediately and allow the drives that are attached to these host adapters to function as

bootable disks. If this item is set to Postponed, the ROM BIOS of the host adapters will not

capture Interrupt 19 immediately and allow the drives attached to these adapters to function as

bootable devices at bootup. The options are Immediate and Postponed.

Re-try Boot

When EFI Boot is selected, the system BIOS will automatically reboot the system from an

EFI boot device after its initial boot failure. Select Legacy Boot, to allow the BIOS to

automatically reboot the system from a Legacy boot device after its initial boot

fa ilu re. The options are Disabled, Legacy Boot, and EFI Boot.

Power Configuration

DeepSx Power Policies

Use this item to configure the Advanced Configuration and Power Interface (ACPI) settings for

the system. Enable S3 to use Standby Mode (Suspend-to-RAM) and maintain power supply to

the system RAM when the system is in the sleep mode. Enable S4 to use Hibernation mode

(Suspend to Disk) so that all data stored in of the main memory can be saved in a non-volatile

memory area such as in a hard drive and then power down the system. Enable S5 to power off

the whole system except the power supply unit (PSU) and keep the power button alive so that

2-6 | ni.com

Page 24

RMC-8357 User Manual

the user can wake-up the system by using an USB keyboard or mouse. The options are Disabled,

Enabled in S5, Enabled in S4-S5, and Enabled in S3-S4-S5.

Watch Dog Function

Select Enabled to allow the Watch Dog Timer to reboot the system when it is inactive for

more than 5 minutes. The options are Enabled and Disabled.

Power Button Function

This feature controls how the system shuts down when the power button is pressed. Select

4_Seconds_Override for the user to power off the system after pressing and holding the power

button for 4 seconds or longer. Select Instant Off to instantly power off the system as soon

as the user presses the power button. The options are 4 Seconds Override and Instant Off.

Restore on AC Power Loss

Use this feature to set the power state after a power outage. Select Stay-Off for the system

power to remain off after a power loss. Select Power-On for the system power to be

turned on after a power loss. Select Last State to allow the system

state before a power loss. The options are Power-On, Stay-Off and Last State.

to resume its last power

Chipset Configuration

Caution Setting the wrong values in the following sections may cause the system

to malfunction.

CPU Configuration

The following CPU information will display:

• Processor Socket

• Processor ID

• Processor Frequency

• Max (Maximum) CPU Speed

• Min (Minimum) CPU Speed

• Processor Max Ratio

• Processor Min Ratio

• Microcode Revision

• L1 Cache RAM

• L2 Cache RAM

• L3 Cache RAM

• CPU1 Version

© National Instruments | 2-7

Page 25

Chapter 2 Installation and BIOS Setup

Clock Spread Spectrum

Select Enable for Clock Spectrum support, which will allow the BIOS to monitor and attempt

to reduce the level of Electromagnetic Interference caused by the components whenever needed.

Select Disabled to enhance system stability. The options are Disabled and Enabled.

Hyper-Threading

Select Enable to use Intel Hyper-Threading Technology to enhance CPU performance.

The options are Enable and Disable.

Performance/Watt

Select Power Optimized to use Intel Turbo Boost Technology to maximize system performance

(with maximum cooling) when performance state P0 lasts more than two seconds. If Traditional

is selected, Intel Turbo Boost Technology will be activated even when performance state P0 lasts

less than two seconds. The options are Traditional and Power Optimized.

Execute Disable Bit

Set to Enabled for Execute Disable Bit support which will allow the processor to designate areas

in the system memory where an application code can execute and where it cannot, thus

preventing a worm or a virus from looding illegal codes to overwhelm the processor or damaging

the system during a virus attack. The options are Enable and Disable. (Refer to Intel and

Microsoft websites for more information.)

Note Available when supported by the CPU.

PPIN Control

Select Unlock/Enable to use the Protected-Processor Inventory Number (PPIN) in the system.

The options are Unlock/Enable and Unlock/Disable.

Hardware Prefetcher

If this item is set to Enable, the hardware prefetcher will prefetch streams of data and

instructions from the main memory to the Level 2 (L2) cache to improve CPU performance. The

options are Disable and Enable.

Note Available when supported by the CPU.

Adjacent Cache Line Prefetch

Select Enable for the CPU to prefetch both cache lines for 128 bytes as comprised.

Select Disable for the CPU to prefetch both cache lines for 64 bytes. The options are Disable

and Enable.

Note Available when supported by the CPU.

2-8 | ni.com

Page 26

RMC-8357 User Manual

Note If there is any change to this setting, you will need to power off and reboot

the system for the change to take effect. Please refer to Intel’s web site for detailed

information.

DCU Streamer Prefetcher

If this item is set to Enable, the DCU (Data Cache Unit) streamer prefetcher will prefetch data

streams from the cache memory to the DCU (Data Cache Unit) to speed up data accessing and

processing for CPU performance enhancement. The options are Disable and Enable.

Note Available when supported by the CPU.

DCU IP Prefetcher

If this item is set to Enable, the IP prefetcher in the DCU (Data Cache Unit) will prefetch IP

addresses to improve network connectivity and system performance. The options are Enable

and Disable.

DCU (Data Cache Unit) Mode

Use this item to set the DCU data-prefecting mode. The options are 32KB 8Way Without ECC

and 16KB 4Way With ECC.

Direct Cache Access (DCA)

Select Enable to use Intel DCA (Direct Cache Access) Technology to maximize efficiency in

memory data transferring and accessing. The options are Auto, Enable and Disable.

DCA Prefetch Delay

A DCA prefetcher is used with a TOE (TCP/IP Ofload Engine) adapter to prefetch data to

shorten execution cycles and to maximize data processing efficiency. Prefetching data too

frequently can saturate the cache directory and delay necessary cache access. This feature

reduces or increases the frequency of system data prefetching activities. The options are Disable,

[8], [16], [32], [40], [48], [56], [64], [72], [80], [88], [96], [104], and [112].

X2APIC (Extended Advanced Programmable Interrupt Controller)

Based on the Intel Hyper-Threading technology, each logical processor (thread) is assigned

256 APIC IDs (APIDs) in 8-bit bandwidth. When this item is set to Enable, the APIC ID will

be expanded from 8 bits to 16 bits to provide 512 APIDs to each thread to enhance CPU

performance. The options are Disable and Enable.

AES-NI

Select Enable to use the Intel Advanced Encryption Standard (AES) New Instructions (NI) to

ensure data security. The options are Enable and Disable.

© National Instruments | 2-9

Page 27

Chapter 2 Installation and BIOS Setup

Intel Virtualization Technology

Select Enable to use Intel Virtualization Technology so that I/O device assignments will be

reported directly to the VMM (Virtual Memory Management) through the DMAR ACPI Tables.

This feature offers fully-protected I/O resource-sharing across the Intel platforms, providing the

user with greater reliability, security and availability in networking and data-sharing.

The settings are Enable and Disable.

Advanced Power Management Configuration

Power Technology

Select Energy Efficient to support power-saving mode. Select Custom to customize system

power settings. Select Disabled to disable power-saving settings. The options are Disable,

Energy Efficient, and Custom.

Config TDP

Select Enable to allow the user to configure the Thermal Design Power (TDP) settings for

the system. The TDP refers to the maximum amount of power allowed for running “real

applications” without triggering an overheating event. The options are Disable and Enable.

CPU P State Control

EIST (P-State)

EIST (Enhanced Intel SpeedStep Technology) allows the system to automatically adjust

processor voltage and core frequency in an effort to reduce power consumption and heat

dissipation. Please refer to Intel’s website for detailed information. The options are Disable

and Enable.

Turbo Mode

Select Enable for processor cores to run faster than the frequency specified by the manufacturer.

The options are Disable and Enable.

P-state Coordination

Use this item to configure the processor's P-State coordination settings. During a P-State, the

voltage and frequency of the processor will be reduced when it is in operation. This makes the

processor more energy efficient, resulting in further energy gains. The options are HW_ALL,

SW_ALL and SW-ANY.

CPU C State Control

Package C State limit

Use this item to set the limit on the C-State package register. The options are C0/1 state, C2

state, C6 (non-Retention) state, and C6 (Retention) state.

2-10 | ni.com

Page 28

RMC-8357 User Manual

CPU C3 Report

Select Enable to allow the BIOS to report the CPU C3 State (ACPI C2) to the operating system.

During the CPU C3 State, the CPU clock generator is turned off. The options are Enable and

Disable.

CPU C6 Report

Select Enable to allow the BIOS to report the CPU C6 state (ACPI C3) to the operating system.

During the CPU C6 state, power to all caches is turned off. The options are Enable and Disable.

Note Available when Power Technology is set to Custom.

Enhanced Halt State (C1E)

Select Enabled to enable "Enhanced Halt State" support, which will significantly reduce the

CPU's power consumption by minimizing CPU's clock cycles and voltage use during a "Halt

State." The options are Disable and Enable.

CPU T State Control

ACPI (Advanced Configuration Power Interface) T-States

If this item is set to Enable, CPU throttling will be supported by the operating system to reduce

power consumption. The options are Enable and Disable.

Socket RAPL (Running Average Power Limit) Configuration

FAST-RAPL-NSTRIKE-PL2-DUTY-CYCLE

This feature displays the value of the item above within the range between 25 (10%) and

64 (25%).

Turbo Power Limit Lock

Select Enable to set the power use limit for the machine when it is running in the turbo mode.

The options are Enable and Disable.

Long Power Limit Override

Select Enable to support long-term power limit override. If this feature is disabled, BIOS will

set the default value. The options are Enable and Disable.

Long Duration Power Limit

This item displays the power limit set by the user during which long duration power is

maintained. The default setting is 0.

© National Instruments | 2-11

Page 29

Chapter 2 Installation and BIOS Setup

Package Clamping Limit1

Use this item to set the limit on power performance states for the run-time processor, with P0

being the state with the highest frequency (clock speed) and power (consumption), and P1, a step

lower in performance than P0, with its frequency and voltage scaled back a notch. The options

are Between P1/P0 and Below P1.

Short Duration Power Limit Enable

Select Enable to support Short Duration Power Limit (Power Limit 2). The options are Enable

and Disable.

Short Duration Power Limit

This item displays the time period during which short duration power is maintained. The default

setting is 0.

Package Clamping Limit2

Use this item to set the limit on power performance states for the processor operating in turbo

mode, with P0 being the state with the highest frequency (clock speed) and power

(consumption), and P1, a step lower in performance than P0, with its frequency and voltage

scaled back a notch. The options are Between P1/P0 and Below P1.

Chipset Configuration

North Bridge

This feature allows the user to configure the settings for the Intel North Bridge.

IIO Configuration

EV DFX (Device Function On-Hide) Feature

When this feature is set to Enable, the EV_DFX Lock Bits that are located on a processor will

always remain clear during electric tuning. The options are Disable and Enable.

IIO1 Configuration/IIO2 Configuration

IOU2 (II0 PCIe Port 1)

This item configures the PCI-E port Bifuraction setting for a PCI-E port specified by the user.

The options are x4x4, X8, and Auto.

PORT 1A Link Speed

This item configures the link speed of a PCI-E port specified by the user. The options are

Gen 1 (Generation 1) (2.5 GT/s), Gen 2 (Generation 2) (5 GT/s) and Gen 3 (Generation 3)

(8 GT/s).

2-12 | ni.com

Page 30

RMC-8357 User Manual

IOU0 (II0 PCIe Port 2)

This item configures the PCI-E port Bifuraction setting for a PCI-E port specified by the user.

The options are x4x4x4x4, x4x4x8, x8x4x4, x8x8, x16, and Auto.

PORT 2A Link Speed

Use this item to configure the link speed of a PCI-E port specified by the user. The options

are Gen 1 (Generation 1) (2.5 GT/s), Gen 2 (Generation 2) (5 GT/s) and

Gen 3 (Generation 3) (8 GT/s).

IOU1 (II0 PCIE Port 3)

Use this item to configure the PCI-E port Bifuraction setting for a PCI-E port specified by the

user. The options are x4x4x4x4, x4x4x8, x8x4x4, x8x8, x16, and Auto.

PORT 3A Link Speed

Use this item to configure the link speed of a PCI-E port specified by the user. The options are

Gen 1 (Generation 1) (2.5 GT/s), Gen 2 (Generation 2) (5 GT/s) and Gen 3 (Generation 3)

(8 GT/s).

PCI-E Completion Timeout

Select Enable for PCI-E Completion Timeout support for electric tuning. The options are

Enable and Disable.

PCI-E Completion Timeout Value

Use this item to set the PCI-E Completion Time-out value for electric tuning. Enter a value

between 260 ms to 900 ms.

IOAT Configuration

Enable I/OAT

Select Enable to enable Intel I/OAT (I/O Acceleration Technology), which significantly reduces

CPU overhead by leveraging CPU architectural improvements and freeing the system resource

for other tasks. The options are Enable and Disable.

No Snoop

Select Enable to support no-snoop mode for each CB device. The options are Disable and

Enable.

Relaxed Ordering

Select Enable to enable Relaxed Ordering support which will allow certain transactions to

violate the strict-ordering rules of PCI and to be completed prior to other transactions that have

already been enqueued. The options are Disable and Enable.

© National Instruments | 2-13

Page 31

Chapter 2 Installation and BIOS Setup

Intel VT for Directed I/O (VT-d)

Select Enable to use Intel Virtualization Technology support for Direct I/O VT-d support by

reporting the I/O device assignments to the VMM (Virtual Machine Monitor) through the

DMAR ACPI Tables. This feature offers fully-protected I/O resource sharing across Intel

platforms, providing greater reliability, security and availability in networking and data-sharing.

The options are Enable and Disable.

Interrupt Remapping

Select Enable for Interrupt Remapping support to enhance system performance. The options are

Enable and Disable.

Coherency Support (Non-Isoch)

Select Enable for the Non-Iscoh VT-d engine to pass through DMA (Direct Memory Access) to

enhance system performance. The options are Enable and Disable.

Coherency Support (Isoch)

Select Enable for the Iscoh VT-d engine to pass through ATS to enhance system performance.

The options are Enable and Disable.

QPI (Quick Path Interconnect) Configuration

QPI Status

The following information will display:

• Number of CPU

• Number of IIO

• Current QPI Link Speed

• Current QPI Link Frequency

• QPI Global MMIO Low Base/Limit

• QPI Global MMIO High Base/Limit

• QPI PCIe Configuration Base/Size

Link Speed Mode

Use this item to select the data transfer speed for QPI Link connections. The options are Fast

and Slow.

Link Frequency Select

Use this item to select the desired frequency for QPI Link connections. The options are 6.4 GB/s,

8.0 GB/s, 9.6 GB/s, Auto, and Auto Limited.

2-14 | ni.com

Page 32

RMC-8357 User Manual

Link L0p Enable

Select Enable for Link L0p support. The options are Enable, Auto, and Disable.

Link L1 Enable

Select Enable for Link L1 support. The options are Enable, Auto, and Disable.

Isoc Mode

Select Enabled for Isochronous support to meet QoS (Quality of Service) requirements.

This feature is especially important for Virtualization Technology. The options are Enable

and Disable.

Memory Configuration

Enforce POR

Select Enable to enforce POR restrictions for DDR4 frequency and voltage programming.

The options are Enabled and Disabled.

Memory Frequency

Use this feature to set the maximum memory frequency for onboard memory modules.

The options are Auto, 1333, 1400, 1600, 1800, 1867, 2000, 2133, 2200, 2400, 2600, 2667,

and Reserved (Do not select Reserved).

ECC Support

Select Enable to enable Error Checking & Correction (ECC) support for onboard memory

modules. The options are Auto, Enable and Disable.

Data Scrambling

Select Enabled to enable data scrambling to enhance system performance and data integrity.

The options are Auto, Disabled and Enabled.

Enable ADR

Select Enabled for ADR (Automatic Diagnostic Repository) support to enhance memory

performance. The options are Enabled and Disabled.

DRAM RAPL (Running Average Power Limit) Baseline

Use this feature to set the run-time power-limit baseline for DRAM modules. The options are

Disable, DRAM RAPL Mode 0, and DRAM RAPL Mode 1.

© National Instruments | 2-15

Page 33

Chapter 2 Installation and BIOS Setup

Set Throttling Mode

Throttling improves reliability and reduces power consumption in the processor via automatic

voltage control during processor idle states. The options are Disabled and CLTT (Closed Loop

Thermal Throttling).

Socket Interleave Below 4GB

Select Enabled for the memory above the 4G Address space to be split between two sockets.

The options are Enable and Disable.

Channel Interleaving

Use this item to set DIMM channel interleaving mood. The options are Auto, 1 Way Interleave,

2 Way Interleave, 3, Way Interleave, and 4 Way Interleave.

Rank Interleaving

Use this item to select a rank memory interleaving method. The options are Auto, 1 Way, 2

Way, 4 Way, and 8 Way.

A7 Mode

Select Enabled to support A7 (Addressing) Mode to improve memory performance. The options

are Enable and Disable.

DIMM Information

This item displays the status of a DIMM module specified.

• DIMMA1

• DIMMA2

• DIMMB1

• DIMMB2

• DIMMC1

• DIMMC2

• DIMMD1

• DIMMD2

Memory RAS (Reliability_Availability_Serviceability) Configuration

Use this submenu to configure the following Memory RAS settings.

RAS Mode

Select Enable to enable RAS support to enhance reliability, availability and serviceability of

onboard memory modules. The options are Enable and Disable.

2-16 | ni.com

Page 34

RMC-8357 User Manual

Lockstep x4 DIMMs

Select Enable to enable Lockstep Technology support for x4 DIMM modules. The options are

Auto, Disabled, and Enabled.

Memory Rank Sparing

This item indicates if memory rank sparing is supported by the motherboard. Memory rank

sparing enhances system memory performance. The options are Enabled and Disabled.

Patrol Scrub