Page 1

NI RMC-8355

User Manual

NI RMC-8355 User Manual

August 2012

373693A-01

Page 2

Support

Worldwide Technical Support and Product Information

ni.com

Worldwide Offices

Visit ni.com/niglobal to access the branch office Web sites, which provide up-to-date contact information,

support phone numbers, email addresses, and current events.

National Instruments Corporate Headquarters

11500 North Mopac Expressway Austin, Texas 78759-3504 USA Tel: 512 683 0100

For further support information, refer to the Technical Support and Professional Services appendix. To comment

on National Instruments documentation, refer to the National Instruments Web site at

the Info Code

feedback.

ni.com/info and enter

© 2012 National Instruments. All rights reserved.

Page 3

Important Information

Warranty

The NI RMC-8355 is warranted against defects in materials and workmanship for a period of one year from the date of shipment, as evidenced

by receipts or other documentation. National Instruments will, at its option, repair or replace equipment that proves to be defective during the

warranty period. This warranty includes parts and labor.

The media on which you receive National Instruments software are warranted not to fail to execute programming instructions, due to defects in

materials and workmanship, for a period of 90 days from date of shipment, as evidenced by receipts or other documentation. National Instruments

will, at its option, repair or replace software media that do not execute programming instruc tions if National Instruments receives notice of such defects

during the warranty period. National Instruments does not warrant that the operation of the software shall be uninterrupted or error free.

A Return Material Authorization (RMA) number must be obtained from the factory and clearly marked on the outside of the package before any

equipment will be accepted for warranty work. National Instruments will pay the shipping costs of returning to the owner parts which are covered by

warranty.

National Instruments believes that the information in this document is accurate. The document has been carefully reviewed for technical accuracy. In

the event that technical or typographical errors exist, National Instruments reserves the right to make changes to subsequent editions of this document

without prior notice to holders of this edition. The reader should consult National Instruments if errors are suspected. In no event shall National

Instruments be liable for any damages arising out of or related to this document or the information contained in it.

XCEPT AS SPECIFIED HEREIN, NATIONAL INSTRUMENTS MAKES NO WARRANTIES, EXPRESS OR IMPLIED, AND SPECIFICALLY DISCLAIMS ANY WARRANTY OF

E

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. CUSTOMER’S RIGHT TO RECOVER DAMAGES CAUSED BY FAULT OR NEGLIGENCE ON THE PART OF NATIONAL

NSTRUMENTS SHALL BE LIMITED TO THE AMOUNT THERETOFORE PAID BY THE CUSTOMER. NATIONAL INSTRUMENTS WILL NOT BE LIABLE FOR DAMAGES RESULTING

I

FROM LOSS OF DATA, PROFITS, USE OF PRODUCTS, OR INCIDENTAL OR CONSEQUENTIAL DAMAGES, EVEN IF ADVISED OF THE POSSIBILITY THEREOF. This limitation of

the liability of National Instruments will apply regardless of the form of action, whether in contract or tort, including negligence. Any action against

National Instruments must be brought within one year after the cause of action accrues. National Instruments shall not be liable for any delay in

performance due to causes beyond its reasonable control. The warranty provided herein does not cover damages, defects, malfunctions, or service

failures caused by owner’s failure to follow the National Instruments installation, operation, or maintenance instructions; owner’s modification of the

product; owner’s abuse, misuse, or negligent acts; and power failure or surges, fire, flood, accident, actions of third parties, or other events outside

reasonable control.

Copyright

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or mechanical, including photocopying,

recording, storing in an information retrieval system, or translating, in whole or in part, without the prior written consent of National

Instruments Corporation.

National Instruments respects the intellectual property of others, and we ask our users to do the same. NI software is protected by copyright and other

intellectual property laws. Where NI software may be used to reproduce software or other materials belonging to others, you may use NI software only

to reproduce materials that you may reproduce in accordance with the terms of any applicable license or other legal restriction.

End-User License Agreements and Third-Party Legal Notices

You can find end-user license agreements (EULAs) and third-party legal notices in the following locations:

• Notices are located in the

• EULAs are located in the

•Review

Trademarks

CVI, LabVIEW, National Instruments, NI, ni.com, the National Instruments corporate logo, and the Eagle logo are trademarks of National

Instruments Corporation. Refer to the Trademark Information at

The mark LabWindows is used under a license from Microsoft Corporation. Windows is a registered trademark of Microsoft Corporation in the United

States and other countries. Other product and company names mentioned herein are trademarks or trade names of their respective companies.

Members of the National Instruments Alliance Partner Program are business entities independent from National Instruments and have no agency,

partnership, or joint-venture relationship with National Instruments.

Patents

For patents covering National Instruments products/technology, refer to the appropriate location: Help»Patents in your software,

the

Export Compliance Information

Refer to the Export Compliance Information at ni.com/legal/export-compliance for the National Instruments global trade compliance

policy and how to obtain relevant HTS codes, ECCNs, and other import/export data.

WARNING REGARDING USE OF NATIONAL INSTRUMENTS PRODUCTS

(1) NATIONAL INSTRUMENTS PRODUCTS ARE NOT DESIGNED WITH COMPONENTS AND TESTING FOR A LEVEL OF

RELIABILITY SUITABLE FOR USE IN OR IN CONNECTION WITH SURGICAL IMPLANTS OR AS CRITICAL COMPONENTS IN

ANY LIFE SUPPORT SYSTEMS WHOSE FAILURE TO PERFORM CAN REASONABLY BE EXPECTED TO CAUSE SIGNIFICANT

INJURY TO A HUMAN.

(2) IN ANY APPLICATION, INCLUDING THE ABOVE, RELIABILITY OF OPERATION OF THE SOFTWARE PRODUCTS CAN BE

IMPAIRED BY ADVERSE FACTORS, INCLUDING BUT NOT LIMITED TO FLUCTUATIONS IN ELECTRICAL POWER SUPPLY,

COMPUTER HARDWARE MALFUNCTIONS, COMPUTER OPERATING SYSTEM SOFTWARE FITNESS, FITNESS OF COMPILERS

AND DEVELOPMENT SOFTWARE USED TO DEVELOP AN APPLICATION, INSTALLATION ERRORS, SOFTWARE AND HARDWARE

COMPATIBILITY PROBLEMS, MALFUNCTIONS OR FAILURES OF ELECTRONIC MONITORING OR CONTROL DEVICES,

TRANSIENT FAILURES OF ELECTRONIC SYSTEMS (HARDWARE AND/OR SOFTWARE), UNANTICIPATED USES OR MISUSES, OR

ERRORS ON THE PART OF THE USER OR APPLICATIONS DESIGNER (ADVERSE FACTORS SUCH AS THESE ARE HEREAFTER

COLLECTIVELY TERMED “SYSTEM FAILURES”). ANY APPLICATION WHERE A SYSTEM FAILURE WOULD CREATE A RISK OF

HARM TO PROPERTY OR PERSONS (INCLUDING THE RISK OF BODILY INJURY AND DEATH) SHOULD NOT BE RELIANT SOLELY

UPON ONE FORM OF ELECTRONIC SYSTEM DUE TO THE RISK OF SYSTEM FAILURE. TO AVOID DAMAGE, INJURY, OR DEATH,

<National Instruments>\_Legal Information.txt for more information on including legal information in installers built with

NI products.

patents.txt file on your media, or the National Instruments Patent Notice at ni.com/patents.

<National Instruments>\_Legal Information and <National Instruments> directories.

<National Instruments>\Shared\MDF\Legal\license directory.

ni.com/trademarks for other National Instruments trademarks.

Page 4

THE USER OR APPLICATION DESIGNER MUST TAKE REASONABLY PRUDENT STEPS TO PROTECT AGAINST SYSTEM FAILURES,

INCLUDING BUT NOT LIMITED TO BACK-UP OR SHUT DOWN MECHANISMS. BECAUSE EACH END-USER SYSTEM IS

CUSTOMIZED AND DIFFERS FROM NATIONAL INSTRUMENTS' TESTING PLATFORMS AND BECAUSE A USER OR APPLICATION

DESIGNER MAY USE NATIONAL INSTRUMENTS PRODUCTS IN COMBINATION WITH OTHER PRODUCTS IN A MANNER NOT

EVALUATED OR CONTEMPLATED BY NATIONAL INSTRUMENTS, THE USER OR APPLICATION DESIGNER IS ULTIMATELY

RESPONSIBLE FOR VERIFYING AND VALIDATING THE SUITABILITY OF NATIONAL INSTRUMENTS PRODUCTS WHENEVER

NATIONAL INSTRUMENTS PRODUCTS ARE INCORPORATED IN A SYSTEM OR APPLICATION, INCLUDING, WITHOUT

LIMITATION, THE APPROPRIATE DESIGN, PROCESS AND SAFETY LEVEL OF SUCH SYSTEM OR APPLICATION.

Page 5

Compliance

Electromagnetic Compatibility Information

This hardware has been tested and found to comply with the applicable regulatory requirements and limits for electromagnetic

compatibility (EMC) as indicated in the hardware’s Declaration of Conformity (DoC)

designed to provide reasonable protection against harmful interference when the hardware is operated in the intended

electromagnetic environment. In special cases, for example when either highly sensitive or noisy hardware is being used in close

proximity, additional mitigation measures may have to be employed to minimize the potential for electromagnetic interference.

While this hardware is compliant with the applicable regulatory EMC requirements, there is no guarantee that interference will

not occur in a particular installation. To minimize the potential for the hardware to cause interference to radio and television

reception or to experience unacceptable performance degradation, install and use this hardware in strict accordance with the

instructions in the hardware documentation and the DoC

If this hardware does cause interference with licensed radio communications services or other nearby electronics, which can be

determined by turning the hardware off and on, you are encouraged to try to correct the interference by one or more of the

following measures:

• Reorient the antenna of the receiver (the device suffering interference).

• Relocate the transmitter (the device generating interference) with respect to the receiver.

• Plug the transmitter into a different outlet so that the transmitter and the receiver are on different branch circuits.

Some hardware may require the use of a metal, shielded enclosure (windowless version) to meet the EMC requirements for

special EMC environments such as, for marine use or in heavy industrial areas. Refer to the hardware’s user documentation and

1

for product installation requirements.

the DoC

When the hardware is connected to a test object or to test leads, the system may become more sensitive to disturbances or may

cause interference in the local electromagnetic environment.

Operation of this hardware in a residential area is likely to cause harmful interference. Users are required to correct the

interference at their own expense or cease operation of the hardware.

Changes or modifications not expressly approved by National Instruments could void the user’s right to operate the hardware

under the local regulatory rules.

1

.

1

. These requirements and limits are

1

The Declaration of Conformity (DoC) contains important EMC compliance information and instructions for the user or

installer. To obtain the DoC for this product, visit

and click the appropriate link in the Certification column.

ni.com/certification, search by model number or product line,

Page 6

Contents

About This Manual

Conventions ...................................................................................................................xi

Related Documentation..................................................................................................xii

Chapter 1

Getting Started

Unpacking......................................................................................................................1-1

What You Need to Get Started ......................................................................................1-1

NI RMC-8355 Overview ...............................................................................................1-2

Key Features ..................................................................................................................1-2

Mainboard Features .........................................................................................1-2

NI RMC-8355 Description ............................................................................................1-5

Upgrade/Optional Equipment ........................................................................................1-6

Memory Upgrades...........................................................................................1-6

Upgrade Options..............................................................................................1-6

National Instruments Software ......................................................................................1-7

CPU...................................................................................................1-2

Chipset ..............................................................................................1-2

Memory.............................................................................................1-3

Slots...................................................................................................1-3

Video.................................................................................................1-3

HDD ..................................................................................................1-3

DVD-R/W .........................................................................................1-3

Onboard LAN ...................................................................................1-3

Onboard I/O ......................................................................................1-3

Power Supply ....................................................................................1-4

Fan.....................................................................................................1-4

Power Management Features ............................................................1-4

Front Panel LEDs..............................................................................1-4

System Management .........................................................................1-4

Chapter 2

Installation and BIOS Setup

Safety Information .........................................................................................................2-1

Chassis Cooling Considerations ....................................................................................2-2

Providing Adequate Clearance ........................................................................2-2

Installation .....................................................................................................................2-3

Cable Retention Bracket ................................................................................................2-4

© National Instruments vii NI RMC-8355 User Manual

Page 7

Contents

Connecting Safety Ground ............................................................................................ 2-4

Connecting to Power Source .........................................................................................2-5

BIOS Setup.................................................................................................................... 2-5

Main BIOS Setup Menu.................................................................................. 2-5

System Overview.............................................................................. 2-6

SuperMicro X8DTU ......................................................................... 2-6

Processor...........................................................................................2-6

System Memory................................................................................ 2-7

Advanced Setup Configurations ..................................................................... 2-7

Boot Features....................................................................................2-8

Power Configuration......................................................................... 2-9

Processor and Clock Options............................................................2-9

Advanced Chipset Control................................................................ 2-12

North Bridge Configuration.............................................................. 2-14

South Bridge Configuration.............................................................. 2-16

IDE/SATA Configuration................................................................. 2-17

PCI/PnP Configuration ..................................................................... 2-20

Super IO Device Configuration........................................................ 2-21

Remote Access Configuration .......................................................... 2-22

Hardware Health Event Monitoring ................................................. 2-23

ACPI Configuration.......................................................................... 2-25

IPMI Configuration (Not Supported) ............................................... 2-27

View BMC System Event Log ......................................................... 2-27

Set LAN Configuration .................................................................... 2-28

Event Log Configuration .................................................................. 2-29

Security Settings ............................................................................................. 2-30

Supervisor Password......................................................................... 2-30

Change Supervisor Password ........................................................... 2-30

User Access Level ............................................................................ 2-31

Change User Password ..................................................................... 2-31

Clear User Password......................................................................... 2-31

Password Check................................................................................ 2-31

Boot Sector Virus Protection............................................................ 2-31

Clear User Password......................................................................... 2-31

Password Check................................................................................ 2-31

Boot Configuration ......................................................................................... 2-32

Boot Device Priority......................................................................... 2-32

Removable Drives ............................................................................ 2-32

CD/DVD Drives ............................................................................... 2-32

USB Drives....................................................................................... 2-33

Network Drives................................................................................. 2-33

NI RMC-8355 User Manual viii ni.com

Page 8

Exit Options.....................................................................................................2-33

BIOS Error Beep Codes ..................................................................................2-34

OS Reinstallation and Recovery ....................................................................................2-35

Cleaning .........................................................................................................................2-36

Exterior Cleaning.............................................................................................2-36

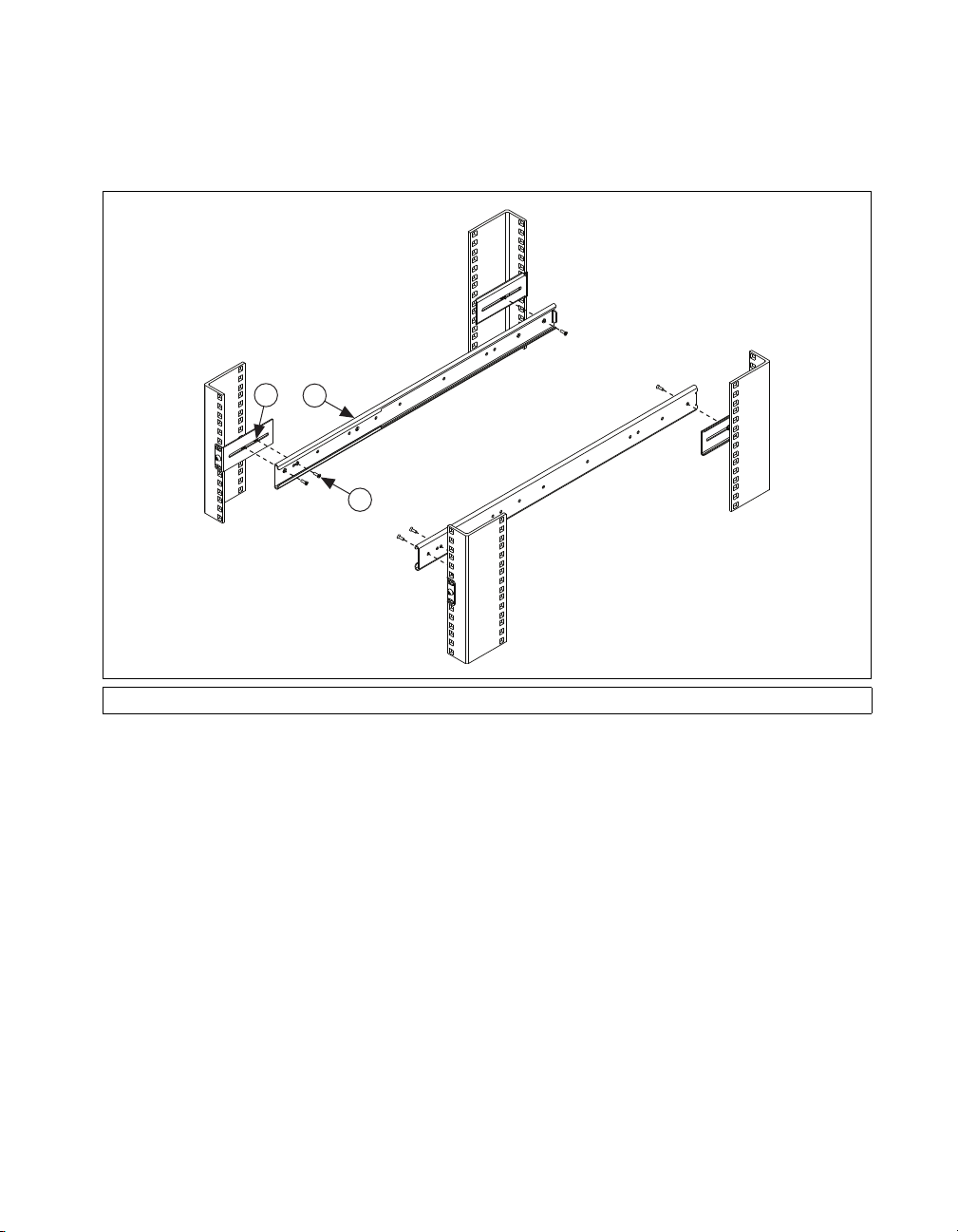

Rack Mounting ..............................................................................................................2-36

Installing the Inner Slides................................................................................2-37

Installing the Slide Mounting Brackets in the Rack ........................................2-38

Installing the Outer Slides in the Rack ............................................................2-39

Installing the Chassis into the Rack.................................................................2-40

Chapter 3

I/O Information

Rear Panel Connectors...................................................................................................3-1

PS/2..................................................................................................................3-2

Universal Serial Bus........................................................................................3-3

Serial................................................................................................................3-4

VGA ................................................................................................................3-5

Ethernet............................................................................................................3-7

MXI-Express Connectors ..............................................................................................3-8

Contents

Save Changes and Exit......................................................................2-33

Discard Changes and Exit .................................................................2-34

Discard Changes ...............................................................................2-34

Load Optimal Defaults......................................................................2-34

Load Fail-Safe Defaults ....................................................................2-34

Chapter 4

Common Configuration Questions

General Questions..........................................................................................................4-1

Boot Options ..................................................................................................................4-2

Chassis Configuration....................................................................................................4-2

Upgrade Information......................................................................................................4-3

Chapter 5

Troubleshooting

Appendix A

Specifications

© National Instruments ix NI RMC-8355 User Manual

Page 9

Contents

Appendix B

Hardware Configuration

Appendix C

Intel SATA RAID Utility for Intel ICH10R

Appendix D

Technical Support and Professional Services

Glossary

Index

NI RMC-8355 User Manual x ni.com

Page 10

About This Manual

The NI RMC-8355 User Manual contains information about installing,

configuring, using, and maintaining the NI RMC-8355.

Conventions

The following conventions appear in this manual:

» The » symbol leads you through nested menu items and dialog box options

to a final action. The sequence Options»Settings»General directs you to

pull down the Options menu, select the Settings item, and select General

from the last dialog box.

This icon denotes a note, which alerts you to important information.

This icon denotes a caution, which advises you of precautions to take to

avoid injury, data loss, or a system crash. When this symbol is marked on a

product, refer to the Read Me First: Safety and Electromagnetic

Compatibility for information about precautions to take.

bold Bold text denotes items that you must select or click in the software, such

as menu items and dialog box options. Bold text also denotes parameter

names.

italic Italic text denotes variables, emphasis, a cross-reference, or an introduction

to a key concept. Italic text also denotes text that is a placeholder for a word

or value that you must supply.

monospace Text in this font denotes text or characters that you should enter from the

keyboard, sections of code, programming examples, and syntax examples.

This font is also used for the proper names of disk drives, paths, directories,

programs, subprograms, subroutines, device names, functions, operations,

variables, filenames, and extensions.

monospace bold Bold text in this font denotes the messages and responses that the computer

automatically prints to the screen. This font also emphasizes lines of code

that are different from the other examples.

© National Instruments xi NI RMC-8355 User Manual

Page 11

About This Manual

Related Documentation

The following documents contain information that you may find helpful as

you read this manual:

• CompactPCI Specification PICMG 2.0 R 3.0

• PXI Hardware Specification, Revision 2.1

• PXI Software Specification, Revision 2.1

• ANSI/IEEE Standard 1014-1987, IEEE Standard for a Versatile

Backplane Bus: VMEbus

• ANSI/VITA 1-1994, VME64

• NI-VISA User Manual

• NI-VISA Programmer Reference Manual

• Read Me First: Safety and Electromagnetic Compatibility, National

Instruments

NI RMC-8355 User Manual xii ni.com

Page 12

Getting Started

This chapter describes the key features of the NI RMC-8355 and lists the

kit contents and optional equipment you can order from National

Instruments.

Unpacking

Carefully inspect the shipping container and the NI RMC-8355 for damage.

Check for visible damage to the metal work. Check to make sure all

hardware and switches are undamaged. If damage appears to have been

caused during shipment, file a claim with the carrier. Retain the packing

material for possible inspection and/or reshipment.

What You Need to Get Started

The NI RMC-8355 kit contains the following items:

❑ NI RMC-8355 rack mount controller

1

❑ NI RMC-8355 User Manual

❑ Windows recovery CD/DVD (not included in the RT version)

❑ Rack mount kit

❑ Bracket for rear cable retention

❑ AC power cable (refer to Table 1-1 for a list of AC power cables)

❑ 23–36 VDC 3-pin connector (ships with the DC option)

© National Instruments 1-1 NI RMC-8355 User Manual

Page 13

Chapter 1 Getting Started

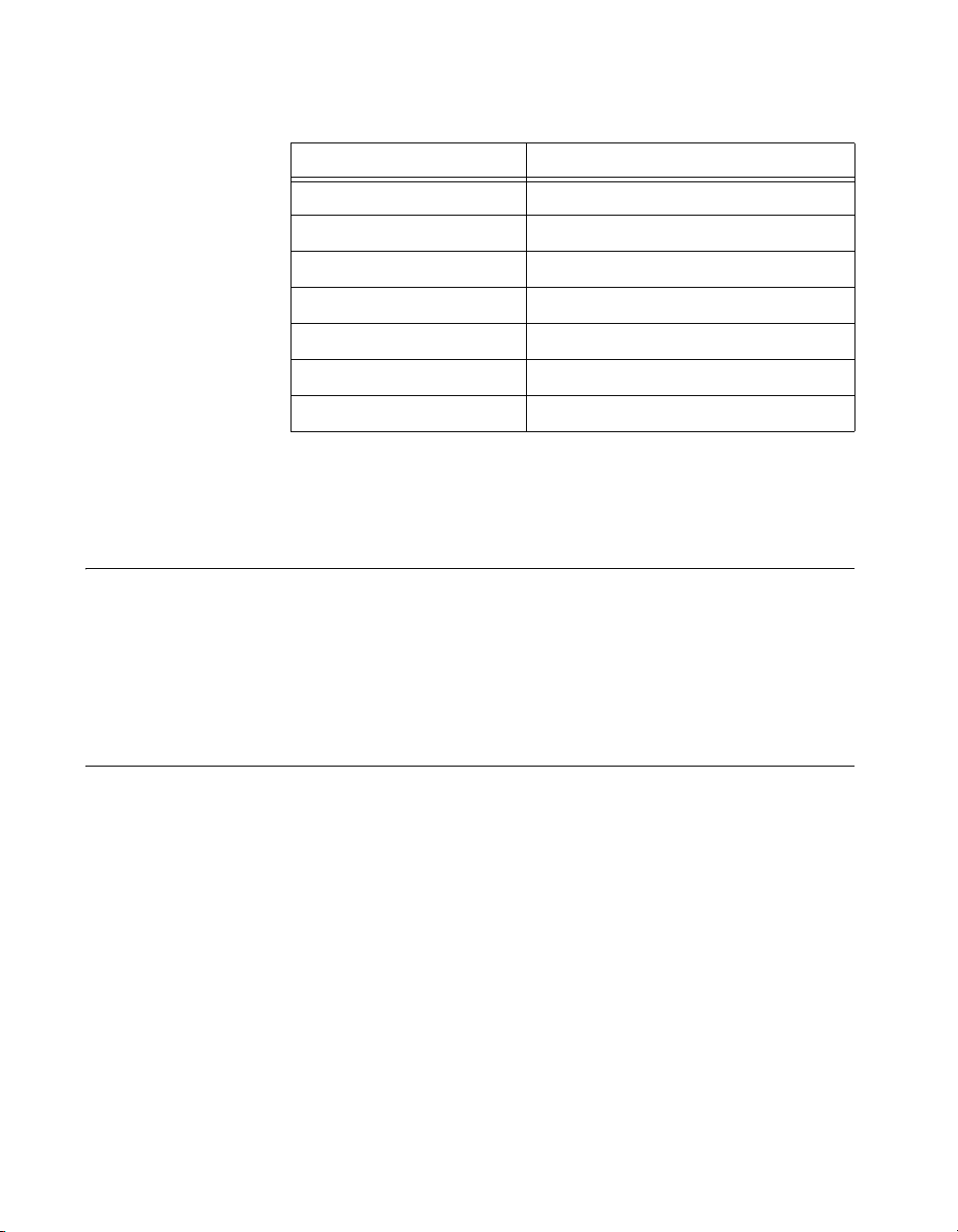

Power Cable Reference Standards

Standard 120 V (USA) ANSI C73.11/NEMA 5-15-P/IEC83

Switzerland 220 V SEV

Australia 240 V AS C112

Universal Euro 230 V CEE (7), II, IV, VII IEC83

North America 240 V ANSI C73.20/NEMA 5-15-P/IEC83

United Kingdom 230 V BS 1363/IEC83

Japan 100 V ANSI C73.11/NEMA 5-15-P/IEC83

The unit comes with the standard 120 V (USA) cable. If you have the

incorrect AC power cable, contact National Instruments.

NI RMC-8355 Overview

The NI RMC-8355 is a rugged 1U PC-based controller for remote control

of PXI chassis. The controller provides leading-edge processing power

with Intel Xeon 5620 processors, high disk bandwidth with hardware

RAID support, high I/O bandwidth with a PCI Express 2.0 x16 and x8 slot,

and up to 48 GB of RDIMM ECC memory per processor.

Table 1-1. AC Power Cables

Key Features

The NI RMC-8355 offers the performance of a high-end PC in a compact

1U rack-mountable form factor for controlling a PXI or PXI Express

system using a National Instruments remote controller.

Mainboard Features

CPU

• Dual Intel Xeon E5620 2.4 GHZ, 80 W, LGA1366 (second processor

optional upgrade)

Chipset

• Intel 5520 chipset, including the 5520 (North Bridge) and ICH10R

(South Bridge)

NI RMC-8355 User Manual 1-2 ni.com

Page 14

Chapter 1 Getting Started

Memory

• 3 GB RDIMM ECC DDR3 memory standard (3 × 1 GB)

• Maximum memory supported: 48 GB registered ECC

DDR3-800/1066 in 6 DIMM sockets (per processor)

Slots

• One PCI Express 2.0 x16 slot

• One PCI Express 2.0 x8 slot (requires a custom PCI Express bracket)

Note The x8 bottom slot requires a custom bracket and supports only half-height cards.

Video

• Matrox G200eW 16 MB DDR2 (max resolution 1280 × 1024)

HDD

•1 × 500 GB or 2 × 500 GB SATA (3 Gbps) hard drive JBOD/RAID0/1

• Upgrade option: 1 × 300 GB or 2 × 300 GB SATA (3 Gbps) SSD

JBOD/RAID0/1

DVD-R/W

• Front removable slim slot load DVD-R/W drive

Onboard LAN

•2 × Intel 82576 Gigabit Ethernet controller

Onboard I/O

• PS/2 keyboard port

• PS/2 mouse port

•Serial port

• VGA port

• Two USB 2.0 ports (rear)

• Two USB 2.0 ports (front)

• Two RJ-45 ports

© National Instruments 1-3 NI RMC-8355 User Manual

Page 15

Chapter 1 Getting Started

Power Supply

• Supports redundant AC and DC power supplies

Fan

• Accessible and hot swappable fans

Power Management Features

• ACPI/ACPM power management

• Main switch override mechanism

• Wake-On-LAN (WOL) header

• Wake up on keyboard/mouse from Soft-Off

• Power-on mode from AC power recovery

Front Panel LEDs

• Power indicator

• Power shuttle indicators

• LAN status indicators

• HDD indicator

• System temp (overheat) and fan (fail) warning indicator

System Management

• Monitoring for CPU and chassis environment

• CPU thermal trip support

• +5 V standby alert LED

• Fan speed control

NI RMC-8355 User Manual 1-4 ni.com

Page 16

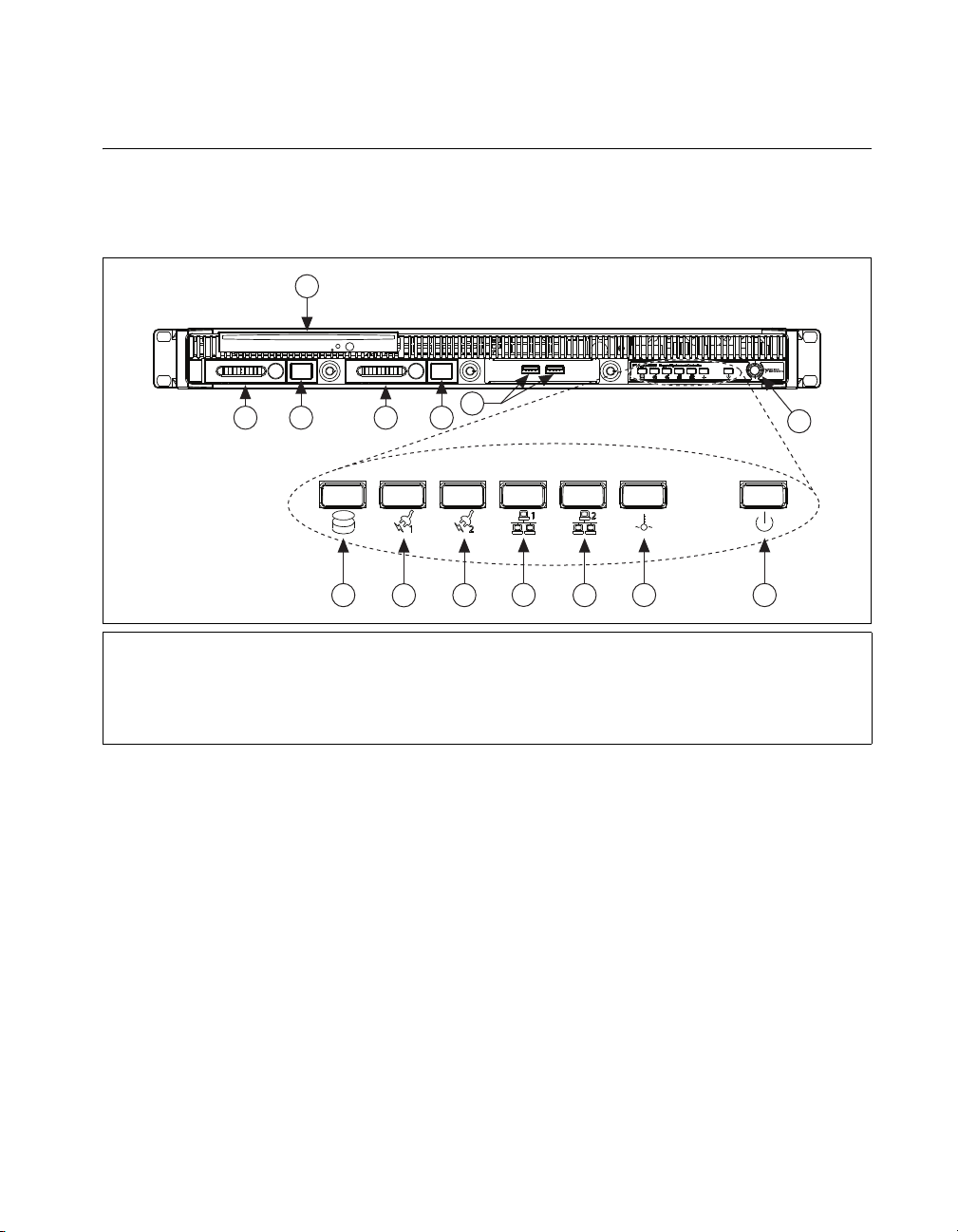

NI RMC-8355 Description

Figure 1-1 shows the key features of the NI RMC-8355 front panel. For

detailed information about the NI RMC-8355 rear panel, refer to Chapter 3,

I/O Information.

1

Chapter 1 Getting Started

3

2

1 DVD R/W Drive

2 Hard Drives

3 Hard Drive Ejector Buttons

4USB Ports

5 Hard Drive Activity Indicator

6 Power Shuttle 1 Indicator

2

5

6

7

8

7 Power Shuttle 2 Indicator

8 LAN1 Status Indicator

9 LAN2 Status Indicator

10 System Temp and Fan Warning Indicator

11 Power Indicator

12 Power Switch

10

9

12

11

4

3

Figure 1-1. Front View of the NI RMC-8355

The front panel includes the following LEDs:

• Hard drive activity indicator—glows when there is hard drive

activity.

• Power shuttle indicators—glow when power shuttles are

powered on.

• LAN status indicators—flash when there is activity on LAN1 or

LAN2.

• Overheat/fan fail indicator

– Off—Normal

– On—Overheat

– Flashing—Fan failure warning

• Power indicator—glows when the NI RMC-8355 is powered on.

© National Instruments 1-5 NI RMC-8355 User Manual

Page 17

Chapter 1 Getting Started

Upgrade/Optional Equipment

Memory Upgrades

You can upgrade the NI RMC-8355 memory to a maximum of 96 GB

(48 GB per processor).

Note A 32-bit operating system such as Windows XP Pro addresses a maximum of 4 GB.

The NI RMC-8355 supports tri-channel DDR-3 SDRAM registered

memory in four 240-pin RDIMM sockets. The NI RMC-8355 is

compatible with ECC memory.

Note Supported RDIMM sizes are 1 GB, 4 GB, and 8 GB.

Note National Instruments has tested and verified that the DDR-3 RDIMMs we offer

work with the NI RMC-8355. We recommend you purchase your DDR-3 RDIMM

modules from National Instruments. Other off-the-shelf DDR-3 RDIMM modules are not

guaranteed to work properly.

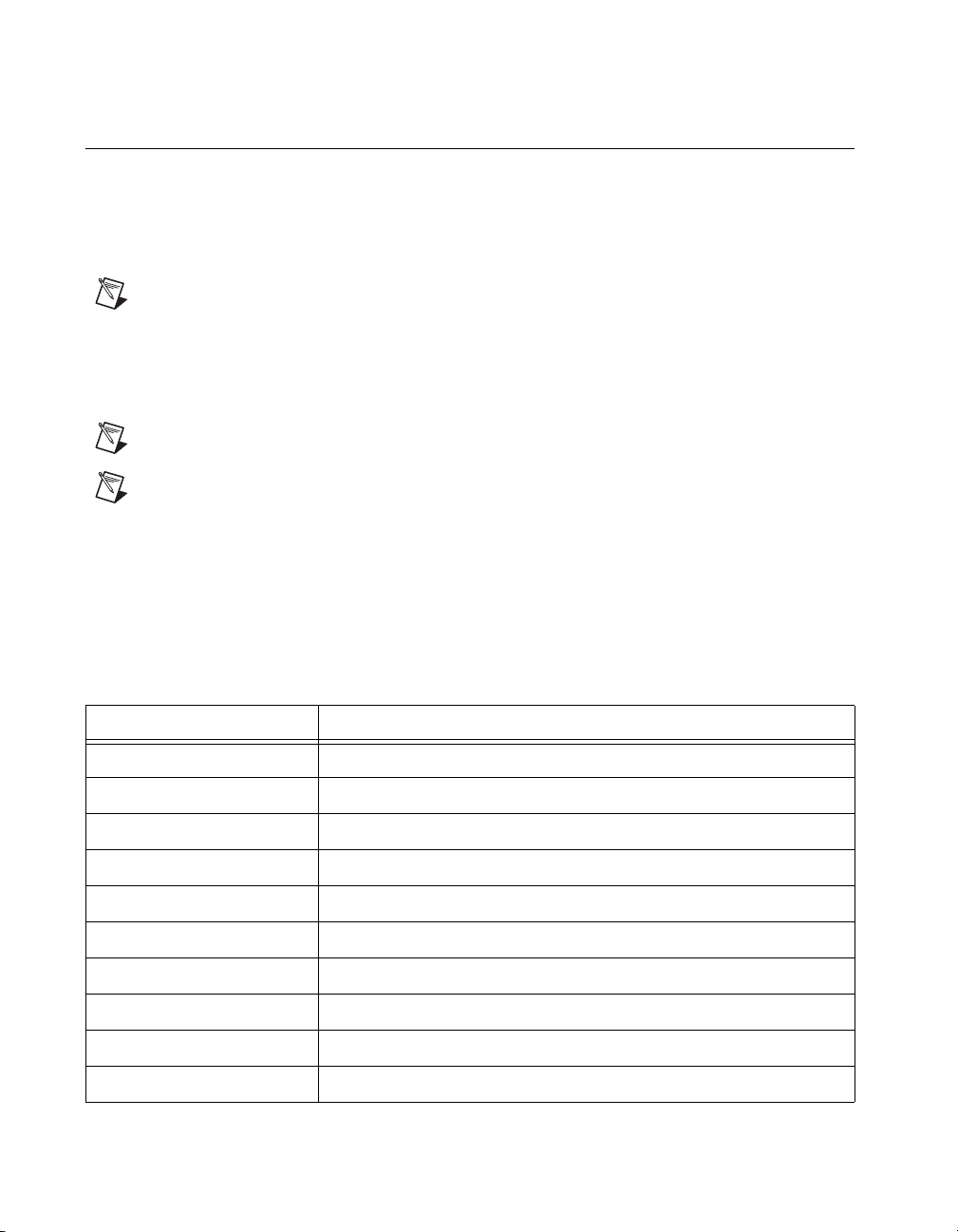

Upgrade Options

Table 1-2 lists upgrade options available for the NI RMC-8355.

Table 1-2. NI RMC-8355 Upgrade Options

Orderable P/N Description

782116-01 Spare optical drive for NI RMC-8355

782117-01 Spare 250 GB SSD and drive bay for NI RMC-8355

782314-01 Spare 500 GB HDD and drive bay for NI RMC-8355

782301-01 PCI Express plug-in video card with dual digital display outputs

782302-01 Rack mount rails for NI RMC-8355

782544-01 Spare/replacement AC power supply for NI RMC-8355

782545-01 Spare/replacement DC power supply for NI RMC-8355

782547-01 DC power cable for NI RMC-8355

782546-01 Spare/replacement fan for NI RMC-8355

782567-1024 1 GB RAM replacement/upgrade for NI RMC-8355

NI RMC-8355 User Manual 1-6 ni.com

Page 18

Table 1-2. NI RMC-8355 Upgrade Options (Continued)

Orderable P/N Description

782567-4096 4 GB RAM replacement/upgrade for NI RMC-8355

782567-8192 8 GB RAM replacement/upgrade for NI RMC-8355

782596-01 Dual CPU Upgrade, Intel Xeon E5620

National Instruments Software

National Instruments hardware and software work together to help you

make the most of your PXI Express system. The LabVIEW, Measurement

Studio, and LabWindows

combine with leading hardware drivers such as NI-DAQmx to provide

exceptional control of NI hardware. Instrument drivers are available at

ni.com/idnet to simplify communication with instruments over a

variety of buses.

LabVIEW is a powerful and easy-to-use graphical programming

environment you can use to acquire data from thousands of different

instruments including USB, IEEE 488.2, VXI, serial, PLCs, and plug-in

boards. LabVIEW helps you convert acquired data into meaningful results

using powerful data analysis routines. Add-on tools provide additional

specialized functionality. For more information, visit

ni.com/toolkits.

and

™

/CVI™ application development environments

Chapter 1 Getting Started

ni.com/labview

If you prefer to use Microsoft’s Visual Basic, Visual C++, and Visual

Studio .NET for the core of your application, Measurement Studio adds

tools for measurement and automation to each language. For more

information, visit

ni.com/mstudio.

LabWindows/CVI is an interactive ANSI C programming environment

designed for building virtual instrument applications. LabWindows/CVI

includes a drag-and-drop editor for building user interfaces, a complete

ANSI C environment for building your test program logic, and a collection

of automated code generation tools, as well as utilities for building

automated test systems, monitoring applications, or laboratory

experiments. For more information, visit

ni.com/lwcvi.

NI-DAQmx provides an extensive library of functions you can call from

your application development environment or interactive environment,

such as NI Signal Express. These functions provide an intuitive API for

National Instruments multifunction DAQ products. Features include analog

© National Instruments 1-7 NI RMC-8355 User Manual

Page 19

Chapter 1 Getting Started

input (A/D conversion), buffered data acquisition (high-speed A/D

conversion), analog output (D/A conversion), waveform generation, digital

I/O, counter/timer operations, SCXI signal conditioning, RTSI or PXI

synchronization, self-calibration, messaging, and acquiring data to

extended memory. For more information, visit

ni.com/daq.

National Instruments modular instruments use specialized drivers suited to

each product’s specialization. Express VIs provide customized, interactive

programming of instruments in a single interface, and soft front panels

provide an interface for testing the functionality of each instrument with

no programming required. NI switches, DMMs, high-speed DIO,

high-speed digitizers, and sources each have customized drivers for

high-end modular instrumentation systems. RF applications leverage

two drivers, NI-RFSG and NI-RFSA, and dynamic signal acquisition is

available through NI-DAQmx. For more information, visit

modularinstruments

.

ni.com/

You can expand the timing and triggering functionality of your PXI system

with PXI timing and synchronization products. These products provide

precision clock sources, custom routing of triggers for multichassis

synchronization, clock sharing, and more, and are programmed with

NI-Sync. For more information, visit

ni.com/pxi.

NI-VISA is the National Instruments implementation of the VISA

specification. VISA is a uniform API for communicating and controlling

USB, Serial, GPIB, PXI, VXI, and various other types of instruments. This

API aids in the creation of portable applications and instrument drivers. For

information about writing your own PXI instrument driver with NI-VISA,

refer to the NI-VISA Help and the

directory. For more information, visit

NI RMC-8355 User Manual 1-8 ni.com

readme.txt file in the NI-VISA

ni.com/visa.

Page 20

Installation and BIOS Setup

This chapter describes how to install, configure, and use the NI RMC-8355.

Before connecting the NI RMC-8355 to a power source, read this chapter

and the Read Me First: Safety and Electromagnetic Compatibility

document included with your NI RMC-8355.

Safety Information

Caution Before undertaking any troubleshooting, maintenance, or exploratory procedure,

carefully read the following caution notices.

Caution Product functionality can be disrupted if the knurled thumbscrews on the back of

the top cover are subjected to Electrostatic Discharge (ESD). To prevent damage, you must

employ industry-standard ESD prevention measures during installation, maintenance, and

operation.

Caution Overloading the circuits may damage supply wiring. Do not exceed the ratings on

the equipment nameplate when connecting equipment to the supply circuit.

2

Note Tighten the thumbscrew for the top panel cover with a tool after both initial

installation and subsequent access.

Caution To avoid risk of explosion, do not replace the battery (JBAT1) with an incorrect

battery type. Dispose of used batteries according to the battery instructions.

This equipment contains voltage hazardous to human life and safety, and is

capable of inflicting personal injury.

• Chassis Grounding—The NI RMC-8355 requires a connection from

the premise wire safety ground to the NI RMC-8355 chassis ground.

The earth safety ground must be connected during use of this

equipment to minimize shock hazards. Refer to the Connecting Safety

Ground section for instructions on connecting safety ground.

• Mechanical Loading—To avoid a hazardous load condition, be sure

the mechanical load is even when rack mounting the equipment.

© National Instruments 2-1 NI RMC-8355 User Manual

Page 21

Chapter 2 Installation and BIOS Setup

• Live Circuits—Operating personnel and service personnel must

• Explosive Atmosphere—Do not operate the chassis in conditions

• Parts Replacement—Service this equipment only with parts that

• Modification—Do not modify any part of the NI RMC-8355 from

not remove protective covers when operating or servicing the

NI RMC-8355. Adjustments and service to internal components must

be undertaken by qualified service technicians. During service of

this product, the mains connector to the premise wiring must be

disconnected. Dangerous voltages may be present under certain

conditions; use extreme caution.

where flammable gases are present. Under such conditions, this

equipment is unsafe and may ignite the gases or gas fumes.

are exact replacements, both electrically and mechanically. Contact

National Instruments for replacement part information. Installation of

parts with those that are not direct replacements may cause harm to

personnel operating the chassis. Furthermore, damage or fire may

occur if replacement parts are unsuitable.

its original condition. Unsuitable modifications may result in safety

hazards.

Chassis Cooling Considerations

The NI RMC-8355 is designed to operate on a bench or in an instrument

rack. Determine how you want to use the NI RMC-8355 and follow the

appropriate installation instructions.

Caution If installed in a closed or multiunit rack assembly, the rack environment operating

ambient temperature may be greater than room ambient temperature. Therefore, install the

equipment in an environment compatible with the maximum ambient operating

temperature (Tma) specified in Appendix A, Specifications.

Providing Adequate Clearance

Apertures in the front, top, rear, and along both sides of the chassis

facilitate power supply and motherboard cooling. Air enters through the

front and top inlets of the chassis and exits through the fans on the rear of

the chassis. Place the NI RMC-8355 on a bench top or in an instrument rack

so that the fans (air outlets) and the air inlet apertures along the top and

front of the chassis have adequate ventilation. Keep other equipment a

minimum of 76.2 mm (3 in.) away from the air outlets on the rear of the

chassis.

NI RMC-8355 User Manual 2-2 ni.com

Page 22

Installation

Caution To minimize shock hazard, make sure the electrical power outlet you use to power

the NI RMC-8355 has an appropriate earth safety ground. Refer to the Connecting Safety

Ground section for more information.

Caution Use the DC power cable provided with DC power supplies for VDC input.

Chapter 2 Installation and BIOS Setup

Follow these steps to connect devices to the NI RMC-8355:

1. Connect a keyboard and mouse to the appropriate connectors on the

NI RMC-8355 rear panel.

2. Connect the VGA monitor video cable to the VGA connector on the

rear panel.

3. (Optional) To boot into LabVIEW RT, connect the network cable to

LAN jack 1 on the rear panel. (Refer to Figure 3-1, NI RMC-8355 Rear

Panel Layout, for the location of LAN jack 1.)

4. Connect the USB and serial devices as necessary to the NI RMC-8355

front and rear panel ports.

5. Connect the AC power cable to the AC inlet on the rear panel and to an

AC power outlet. For more information, refer to the Connecting to

Power Source section.

6. For the DC option, connect the DC positronic connector to the DC inlet

on the rear panel and wire to a DC power source.

7. Power on the NI RMC-8355.

8. Verify that the NI RMC-8355 boots. If it does not boot, refer to the

What if the NI RMC-8355 does not boot? section of Chapter 5,

Troubleshooting.

© National Instruments 2-3 NI RMC-8355 User Manual

Page 23

Chapter 2 Installation and BIOS Setup

1

2

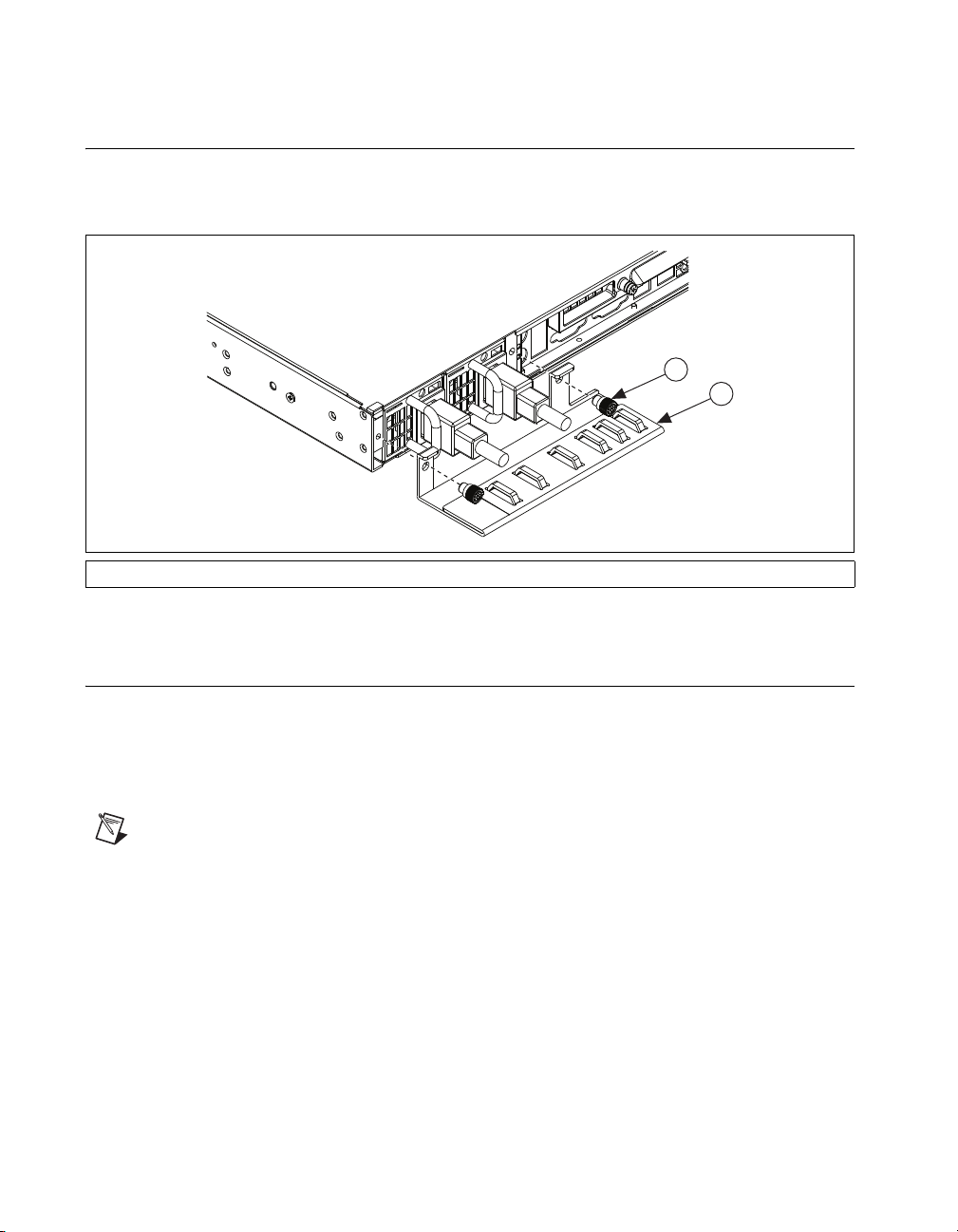

Cable Retention Bracket

The NI RMC-8355 includes a cable retention bracket. Install the bracket

with the retaining screws, as shown in Figure 2-1.

1 Retaining Screw (x2) 2 Cable Retention Bracket

Connecting Safety Ground

The NI RMC-8355 is designed with a three-position NEMA 5-15 style plug

for the U.S. that connects the ground line to the chassis ground. To

minimize shock hazard, make sure the electrical power outlet you use to

power the chassis has an appropriate earth safety ground.

Note The NI RMC-8355 also includes a grounding screw (8-32 thread size nut) on the

back of the chassis. (The nut is not supplied with the NI RMC-8355.)

Figure 2-1. Cable Retention Bracket

NI RMC-8355 User Manual 2-4 ni.com

Page 24

Connecting to Power Source

Attach input power through the rear AC/DC inlet using the appropriate

AC/DC power cable supplied.

Caution Overloading the circuits may damage supply wiring. Do not exceed the ratings on

the equipment nameplate when connecting equipment to the supply circuit.

Caution To completely remove power, you must disconnect the AC/DC power cable.

Caution For a DC power supply, provide a 20 A max overcurrent protection device

external to the equipment.

The power switch allows you to power on the chassis or place it in standby

mode. Push the power switch to the On position (if not already on). Observe

that all fans become operational and the power indicator is lit.

BIOS Setup

This section describes all main BIOS setup options.

Chapter 2 Installation and BIOS Setup

To enter the BIOS menu, press <Del>. Use the up and down arrow keys to

move among the different settings in each menu. Use the left and right

arrow keys to change the options for each setting.

Press <Esc> to exit the CMOS setup menu. The next section describes in

detail how to navigate through the menus.

To access submenus, highlight a menu item and press <Enter>.

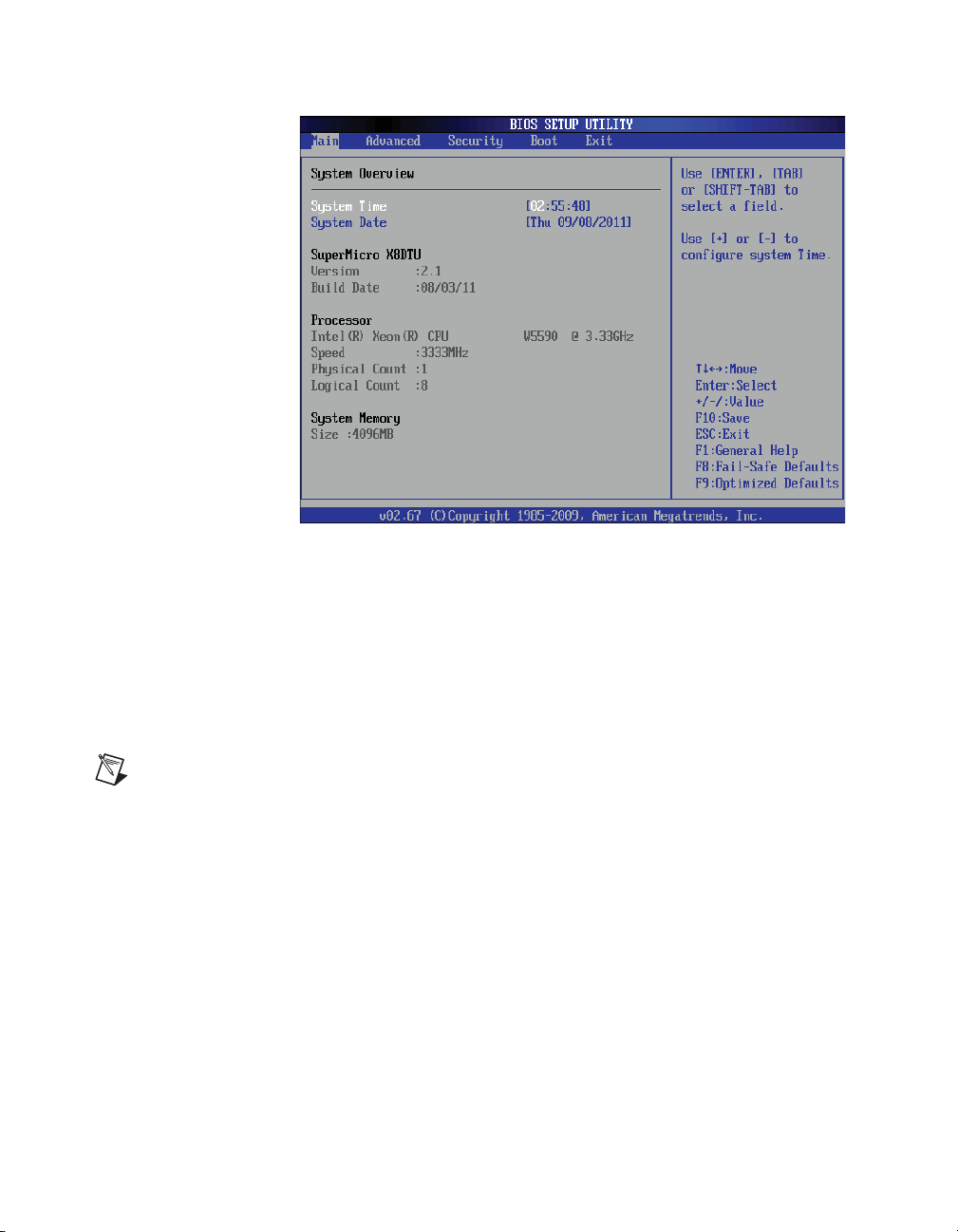

Main BIOS Setup Menu

When you first enter the AMI BIOS Setup Utility, you will enter the Main

BIOS setup screen. You always can return to the Main setup screen by

selecting the Main tab at the top of the screen. The Main BIOS setup screen

is shown below. (The processor and memory values in the image below

may not accurately reflect your system configuration.)

© National Instruments 2-5 NI RMC-8355 User Manual

Page 25

Chapter 2 Installation and BIOS Setup

System Overview

The following BIOS information displays on the System Overview screen.

System Time/System Date

These items display the system time and date. Highlight System Time or

System Date using the arrow keys. The date is displayed in MM/DD/YY

format. The time is displayed in HH:MM:SS format.

Note The time is in the 24-hour format. For example, 5:30 p.m. appears as 17:30:00.

SuperMicro X8DTU

Version

This item displays the BIOS revision used in your system.

Build Date

This item displays the date when this BIOS was completed.

Processor

The AMI BIOS automatically displays the status of the processor in your

system.

NI RMC-8355 User Manual 2-6 ni.com

Page 26

CPU Type

This item displays the type of processors used in the motherboard.

Speed

This item displays the speed of the processor(s) the BIOS detects.

Physical Count

This item displays the number of processors installed in your system, as the

BIOS detects.

Logical Count

This item displays the number of CPU cores installed in your system, as the

BIOS detects.

System Memory

This item displays the system’s available memory size.

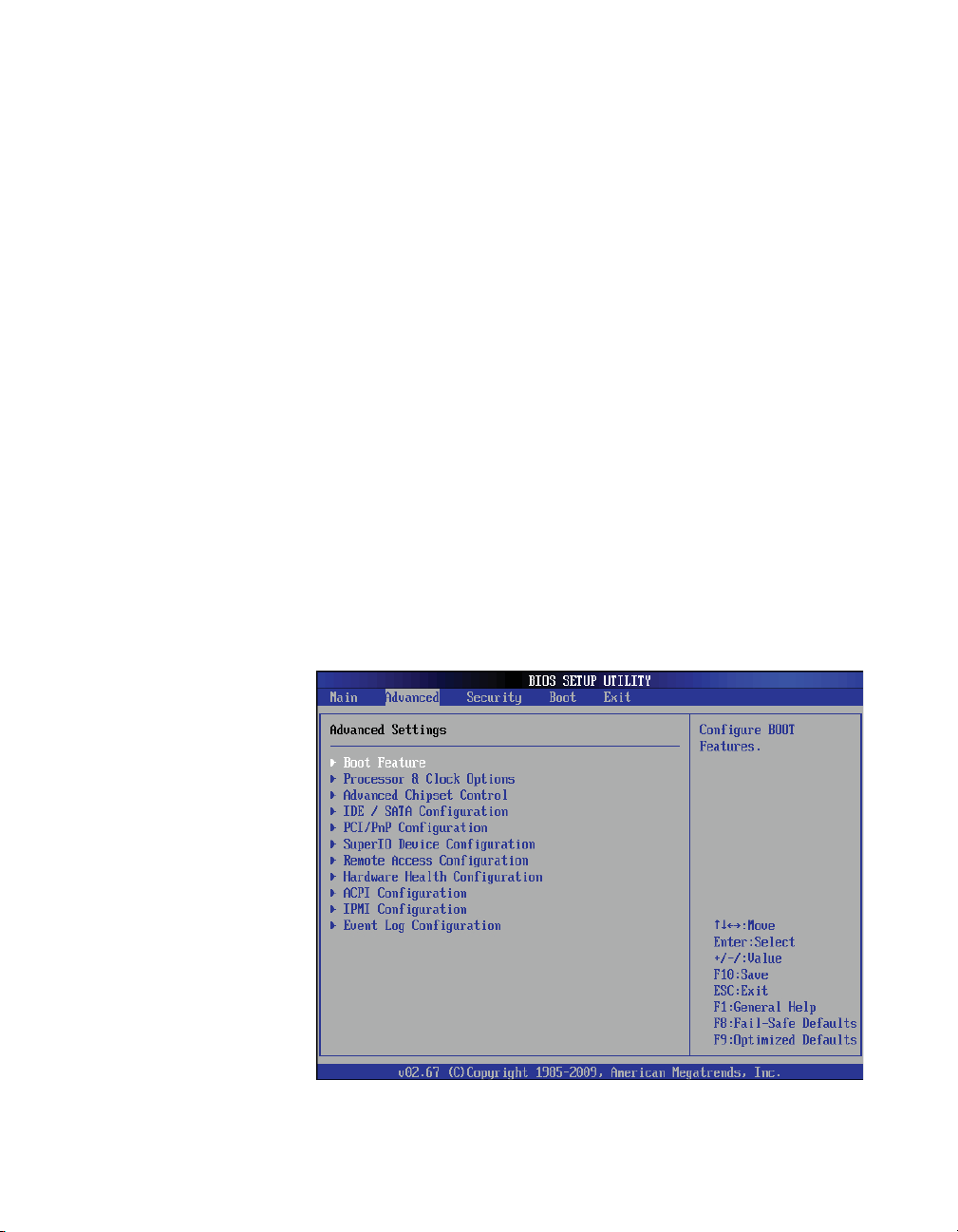

Advanced Setup Configurations

Use the arrow keys to select Boot Setup and press <Enter> to access the

submenu items. The Advanced BIOS setup screen is shown below.

Chapter 2 Installation and BIOS Setup

© National Instruments 2-7 NI RMC-8355 User Manual

Page 27

Chapter 2 Installation and BIOS Setup

Boot Features

Quick Boot

If enabled, this option skips certain tests during POST to reduce the time

needed for system boot. The options are Enabled and Disabled.

Quiet Boot

Use this option to choose the bootup screen display between POST

messages or the OEM logo. Select Disabled to display the POST messages.

Select Enabled to display the OEM logo instead of the normal POST

messages. The options are Enabled and Disabled.

Add On ROM Display Mode

This item sets the display mode for the Option ROM. The options are Force

BIOS and Keep Current.

Bootup Num Lock

Use this feature to select the power-on state for the Num Lock key. The

options are Off and On.

Wait for F1 If Error

This forces the system to wait until you press the <F1> key if an error

occurs. The options are Disabled and Enabled.

Hit Del Message Display

Select Enabled to display Press DEL to run Setup during POST. The

options are Enabled and Disabled.

Interrupt 19 Capture

Interrupt 19 is the software interrupt that handles the boot disk function.

When this item is set to Enabled, the ROM BIOS of the host adaptors

“captures” Interrupt 19 at bootup and allows the drives attached to these

host adaptors to function as bootable disks. If this item is set to Disabled,

the ROM BIOS of the host adaptors does not capture Interrupt 19, and the

drives attached to these adaptors do not function as bootable devices. The

options are Enabled and Disabled.

NI RMC-8355 User Manual 2-8 ni.com

Page 28

Chapter 2 Installation and BIOS Setup

Power Configuration

Watchdog Function

If enabled, the watchdog timer allows the system to reboot when it is

inactive for more than 5 minutes. The options are Enabled and Disabled.

Power Button Function

If set to Instant_Off, the system powers off immediately as soon as you

press the power button. If set to 4_Second_Override, the system powers

off when you press the power button for 4 seconds or longer. The options

are Instant_Off and 4_Second_Override.

Restore on AC Power Loss

Use this feature to set the power state after a power outage. Select

Power-Off for the system power to remain off after a power loss. Select

Power-On for the system power to be turned on after a power loss. Select

Last State to allow the system to resume its last state before a power loss.

The options are Power-On, Power-Off, and Last State.

Processor and Clock Options

Use this submenu to configure the processor and clock settings.

CPU Ratio

Select Manual to manually configure the ratio between the CPU core clock

and FSB frequency. Select Auto to allow the BIOS to configure the CPU

ratio automatically. The options are Auto and Manual.

Clock Spread Spectrum

Select Enable to enable Clock Spread Spectrum support, which allows the

BIOS to monitor and attempt to reduce, whenever needed, the level of

electromagnetic interference the components cause. The options are

Disabled and Enabled.

Hardware Prefetcher

If set to Enabled, the hardware prefetcher prefetches streams of data and

instructions from the main memory to the L2 cache forward or backward to

improve CPU performance. The options are Disabled and Enabled.

1

Available when the CPU supports this option.

1

© National Instruments 2-9 NI RMC-8355 User Manual

Page 29

Chapter 2 Installation and BIOS Setup

Adjacent Cache Line Prefetch

1

The CPU prefetches the cache line for 64 bytes if this option is set to

Disabled. The CPU fetches both cache lines for 128 bytes as comprised if

Enabled.

DCU Prefetcher

1

Select Enabled to activate Level 1 Data Prefetcher to enhance system

performance. For better performance of your DP server, refer to the

specifications for the applications installed on your server to enable or

disable this feature. The options are Enabled and Disabled.

Data Reuse Optimization

1

Select Enabled to maximize Data Reuse support to enhance system

performance for DP platforms. For better performance of your DP server,

refer to the specifications of your applications installed in your server to

enable or disable this feature. The options are Enabled and Disabled.

MPS and ACPI MADT Ordering

Use this feature to configure the multiprocessor specification (MPS) and

ACPI settings for your motherboard. Select Modern Ordering if using

Windows XP or later on the motherboard. Select Legacy Ordering if using

Windows 2000 or earlier. The options are Modern Ordering and Legacy

Ordering.

Intel Virtualization Technology

1

Select Enabled to use the Virtualization Technology feature to allow one

platform to run multiple operating systems and applications in independent

partitions, creating multiple “virtual” systems in one computer. The options

are Enabled and Disabled.

Note If you change this setting, you must power off and restart the system for the change

to take effect. Refer to the Intel Web site (

1

Available when the CPU supports this option.

NI RMC-8355 User Manual 2-10 ni.com

intel.com) for detailed information.

Page 30

Chapter 2 Installation and BIOS Setup

Execute-Disable Bit Capability

1

Set to Enabled to enable the Execute Disable Bit, which allows the

processor to designate areas in the system memory where an application

code can execute and where it cannot, thus preventing a worm or a virus

from flooding illegal codes to overwhelm the processor or damage the

system during an attack. The default is Enabled. (Refer to the Intel

intel.com) and Microsoft (microsoft.com) Web sites for more

(

information.)

Intel AES-NI

2

If this feature is set to Enabled, Intel AES-NI adds new encryption features

to help accelerate AES software application, providing code authorization

and signature verification to improve system performance. The default is

Disabled. (Refer to the Intel (

microsoft.com) Web sites for more information.)

(

Simultaneous Multithreading

intel.com) and Microsoft

1

Set to Enabled to use the simultaneous multithreading technology for

increased CPU performance. The options are Disabled and Enabled.

Active Processor Cores

Set to Enabled to use a processor’s second core and beyond. (Refer to the

Intel Web site (

2, 3, 4, and 5.

intel.com) for more information.) The options are All, 1,

Intel EIST Technology

Enhanced Intel SpeedStep Technology (EIST) allows the system to adjust

processor voltage and core frequency automatically to reduce power

consumption and heat dissipation. (Refer to the Intel Web site

intel.com) for more information.) The options are Disable (Disable

(

GV3) and Enable (Enable GV3).

Intel TurboMode Technology

Select Enabled to use the turbo mode to boost system performance. The

options are Enabled and Disabled.

1

Available when the OS and CPU support this option.

© National Instruments 2-11 NI RMC-8355 User Manual

Page 31

Chapter 2 Installation and BIOS Setup

C1E Support

Select Enabled to use the Enhanced Halt State feature. C1E significantly

reduces CPU power consumption by reducing CPU clock cycle and voltage

during a halt state. The options are Disabled and Enabled.

Intel C-State Tech

If this item is set to Enabled, the system automatically sets the C-State to

either C2, C3, or C4 state. The options are Disabled and Enabled.

C-State Package Limit Setting

If this item is set to Auto, the AMI BIOS automatically sets the limit on the

C-State package register. The options are Auto, C1, C3, C6, and C7.

C1 Auto Demotion

When this item is set to Enabled, the CPU conditionally demotes C3, C6,

or C7 requests to C1 based on un-core auto-demote information. The

options are Disabled and Enabled.

C3 Auto Demotion

When this item is set to Enabled, the CPU conditionally demotes C6 or C7

requests to C3 based on un-core auto-demote information. The options are

Disabled and Enabled.

ACPI T State

Select Enabled to report processor throttling in Advanced Configuration

and Power Interface (ACPI). The options are Disabled and Enabled.

Advanced Chipset Control

The items included in the Advanced Settings submenu are listed below:

CPU Bridge Configuration

CPU Revision

This item displays the CPU revision number.

Current QPI Frequency

This item displays current QPI frequency.

NI RMC-8355 User Manual 2-12 ni.com

Page 32

Chapter 2 Installation and BIOS Setup

Current Memory Frequency for CPU1/ CPU2

This item displays current CPU memory frequency for CPU1/CPU2.

Memory Reference Code Rev.

This item displays the memory reference code revision number.

QPI Reference Code Rev.

This item displays the revision number of the QPI reference code for the

motherboard.

Request Transaction ID

1

QuickPath Interconnect (QPI) is the connection between the CPUs and the

I/O hubs (IOHs). Processing a transaction in the QPI required a transaction

ID, which an agent (CPU1, CPU2, or the IOH) assigns. Each agent is

allocated a number of transaction IDs based on the QPI IO bandwidth and

the Request Transaction ID (RTID) setting (32–24–32 or 32–16–40). Once

transaction IDs are allocated to an agent, it assigns a transaction ID to an

event so it can be processed in the QPI. Select Balanced to allocate

transaction IDs to an agent based on the 32–24–32 setting. Select IO Bias

to allocate RTIDs based on the 32–16–40 setting. The options are

Balanced and IO Bias.

QPI Links Speed

Use this feature to select the data transfer speed for QPI. The options are

Slowmode and Full-Speed.

QPI Frequency

Use this feature to select the desired QPI frequency. The options are Auto,

4.800 GT, 5.866GT, and 6.400 GT.

QPI L0s and L1

Select Enabled to set QPI power to a lower state. The motherboard

automatically selects L0s and L1. The options are Disabled and Enabled.

1

Available for the Intel Xeon 5600 platform only.

© National Instruments 2-13 NI RMC-8355 User Manual

Page 33

Chapter 2 Installation and BIOS Setup

Memory Frequency

This feature forces a DDR3 frequency slower than what the system has

detected to desired setting. The available options are Auto, Force

DDR-800, Force DDR-1066, Force DDR-1333, and Force SPD (for

memory modules with Serial Presence Detect capability).

Memory Mode

Select Independent to make all DIMMs available to the operating system.

Select Channel Mirroring to maintain two identical copies of all data in

Channel 1 and Channel 2 memory modules for data security. Select

Lockstep for the motherboard to use two areas of memory to run the same

set of operations in parallel. Select Sparing for a preset threshold of

correctable errors to be used to trigger fail-over. The spare memory is put

online and used as active memory in place of the failed memory. This

option is supported by Intel 5600 Series processors only. The options are

Independent, Channel Mirroring, and Lockstep.

Demand Scrubbing

This option is a memory error correction scheme in which the processor

writes corrected data back into the memory block from where the processor

read it. The options are Enabled and Disabled.

Patrol Scrubbing

This option is the memory error correction scheme that works in the

background looking for and correcting resident errors. The options are

Enabled and Disabled.

Throttling—Closed Loop/Throttling—Open Loop

Throttling improves reliability and reduces power in the processor by

automatic voltage control during processor idle states. Available options

are Disabled and Enabled.

North Bridge Configuration

Use this feature to configure Intel IOH settings.

NB Revision

This item indicates the North Bridge chipset revision number.

NI RMC-8355 User Manual 2-14 ni.com

Page 34

Chapter 2 Installation and BIOS Setup

Intel I/OAT

The Intel I/O Acceleration Technology (I/OAT) significantly reduces CPU

overhead by leveraging CPU architectural improvements, freeing

resources for more other tasks. The options are Disabled and Enabled.

Direct Cache Access (DCA) Technology

This feature works in conjunction with the Intel I/O Acceleration

Technology (I/OAT) to accelerate the performance of the TOE device.

When this feature is set to Enabled, it enhances overall system

performance by providing direct cache access for data transferring. The

options are Enabled and Disabled.

DCA Prefetch Delay

A DCA Prefetcher is used with TOE components to prefetch data to shorten

execution cycles and maximize data processing efficiency. Prefetching too

frequently can saturate the cache directory and delay necessary cache

accesses. This feature reduces or increases the frequency the system

prefetches data. The options are [8], [16], [24], [32], [40], [48], [56], [64],

[72], [80], [88], [96], [104], [112], and [120].

Intel VT-d

Select Enabled to enable Intel Virtualization Technology support for

Direct I/O VT-d by reporting the I/O device assignments to VMM through

the DMAR ACPI tables. This feature offers fully protected I/O resource

sharing across the Intel platforms, providing greater reliability, security and

availability in networking and data sharing. The options are Enabled and

Disabled.

Active State Power Management

Select Enabled to use the power management for signal transactions

between the PCI Express L0 and L1 Links. Select Enabled to configure

PCI Express L0 and L1 Link power states. The options are Disabled and

Enabled.

IOH PCI Express Max Payload Size

Some add-on boards perform faster with coalesce, which limits the payload

size to 128 B. Other boards have a payload size of 256 B, which inhibits

coalesce support. Refer to your add-on board documentation for the desired

setting. The options are 256B and 128B.

© National Instruments 2-15 NI RMC-8355 User Manual

Page 35

Chapter 2 Installation and BIOS Setup

Slot SXB2/SXB3 Width

Use this feature to change the link width of a PCI slot as specified to

support a riser or add-on board installed in the slot. The options are x4x4,

x8, and Auto.

Slot SXB1 Width

Use this feature to change the link width of a PCI slot as specified to

support a riser or add-on board installed in the slot. The options are

x4x4x4x4, x4x4x8, x8x4x4, x8x8, x16, and Auto.

South Bridge Configuration

Use this feature to configure Intel ICH South Bridge settings.

USB Functions

Use this feature to enable or disable onboard USB support. The options are:

Disabled and Enabled.

Legacy USB Support

Select Enabled to use legacy USB devices. If this item is set to Auto,

legacy USB support is enabled automatically if a legacy USB device is

installed on the motherboard, and vise versa. The settings are Disabled,

Enabled, and Auto.

Port 60h/64h Emulation

Select Enabled to enable 60h/64h emulation for complete USB keyboard

support for operating systems that are not compatible with USB devices.

The options are Enabled and Disabled.

USB 2.0 Controller

This feature displays the current USB controller on the motherboard.

1

USB 2.0 Controller Mode

Use this setting to select the USB 2.0 controller mode. The options are

Hi-Speed (480 Mbps) and Full Speed (12 Mbps).

1

Available when the USB Functions item is disabled.

NI RMC-8355 User Manual 2-16 ni.com

Page 36

Chapter 2 Installation and BIOS Setup

BIOS EHCI Hand-Off

Select Enabled to support BIOS Enhanced Host Controller Interface to

provide a workaround solution for an operating system without EHCI

hand-off support. When enabled, the EHCI interface changes from BIOS

controlled to OS controlled. The options are Disabled and Enabled.

IDE/SATA Configuration

When you select this submenu, the AMI BIOS automatically detects the

presence of the IDE or floppy devices and displays the following items.

SATA#1 Configuration

If Compatible is selected, SATA#1 is set to a legacy compatibility mode.

Select Enhanced to set SATA#1 to the native SATA mode. The options

are Disabled, Compatible, and Enhanced.

Configure SATA#1 As

Use this feature to select the drive type for SATA#1. The options are IDE,

RAID, and AHCI. (When RAID is selected, ICH RAID Code Base

appears. When AHCI is selected, SATA AHCI is available.)

ICH RAID Code Base

1

Select Intel to enable the Intel SATA RAID firmware to configure the Intel

SATA RAID settings. Select Adaptec to enable Adaptec SATA RAID

firmware to configure Adaptec SATA RAID settings. The options are Intel

and Adaptec.

SATA AHCI

2

Select Enable to enable the Serial ATA Advanced Host Interface function.

(Be careful when using this option. This feature is for advanced

programmers only.)

SATA#2 Configuration

3

Selecting Enhanced sets SATA#2 to native SATA mode. The options are

Disabled and Enhanced.

1

Available when RAID is selected.

2

Available when AHCI is selected.

3

Available when IDE is selected.

© National Instruments 2-17 NI RMC-8355 User Manual

Page 37

Chapter 2 Installation and BIOS Setup

IDE Detect Timeout (Sec)

Use this feature to set the timeout value in seconds for the BIOS to detect

the ATA and ATAPI devices installed in the system. The options are 0, 5,

10, 15, 20, 25, 30, and 35.

Primary IDE Master/Slave, Secondary IDE Master/Slave,

Third IDE Master, and Fourth IDE Master

Use these settings to set the Primary IDE Master/Slave, Secondary IDE

Master/Slave, and Third and Fourth IDE Master slot parameter. Press

<Enter> to access the submenu screen for detailed options for these items.

Set the correct configurations accordingly. The submenu includes the

following items.

Type

Use this item to select the type of device connected to the system. The

options are Not Installed, Auto, CD/DVD, and ARMD.

LBA/Large Mode

Logical Block Addressing (LBA) is a method of addressing data on a disk

drive. In LBA mode, the maximum drive capacity is 137 GB. For drive

capacities over 137 GB, your system must be equipped with a 48-bit LBA

mode addressing support. If not, contact your manufacturer or install an

ATA/133 IDE controller card that supports 48-bit LBA mode. The options

are Disabled and Auto.

Block (Multisector Transfer)

Block Mode boosts the IDE drive performance by increasing the amount

of data transferred. When not in Block Mode, data transfer is limited to

512 bytes of data per interrupt. Block Mode allows transfers of up to 64 KB

per interrupt. Select Disabled to allow data to be transferred to and from

the device one sector at a time. Select Auto to allow data transfer to and

from the device occur multiple sectors at a time if the device supports it.

The options are Auto and Disabled.

PIO Mode

The IDE Programmable I/O (PIO) Mode programs timing cycles between

the IDE drive and programmable IDE controller. As the PIO mode

increases, the cycle time decreases. The options are Auto, 0, 1, 2, 3, and 4.

Select Auto to allow the AMI BIOS to detect the PIO mode automatically.

Use this value if you cannot determine the IDE disk drive support.

NI RMC-8355 User Manual 2-18 ni.com

Page 38

Chapter 2 Installation and BIOS Setup

Select 0–4 to allow the AMI BIOS to use PIO mode 0–4, for data transfer

rates of 3.3–16.6 Mbytes/s. Refer to Table 2-1 for PIO mode options.

Table 2-1. PIO Mode Options

Option PIO Mode Maximum Transfer Rate

0 PIO Mode 0 3.3 Mbytes/s

1 PIO Mode 1 5.2 Mbytes/s

2 PIO Mode 2 8.3 Mbytes/s

3 PIO Mode 3 11.1 Mbytes/s

4 PIO Mode 4 16.6 Mbytes/s

DMA Mode

Select Auto to allow the BIOS to detect IDE DMA mode automatically

when you cannot determine the IDE disk drive support. The options are

Auto, SWDMAn, MWDMAn, and UDMAn. Refer to Table 2-2 for DMA

mode options.

Table 2-2. DMA Mode Options

Maximum

Option DMA Mode

Transfer R ate

SWDMA 0 Single-word DMA 0 2.1 Mbytes/s

SWDMA 1 Single-word DMA 1 4.2 Mbytes/s

SWDMA 2 Single-word DMA 2 8.3 Mbytes/s

MWDMA 0 Multiword DMA 0 4.2 Mbytes/s

MWDMA 1 Multiword DMA 1 13.3 Mbytes/s

MWDMA 2 Multiword DMA 2 16.6 Mbytes/s

UDMA 0 Ultra DMA 0 16.6 Mbytes/s

UDMA 1 Ultra DMA 1 25 Mbytes/s

UDMA 2 Ultra DMA 2 33.3 Mbytes/s

UDMA 3 Ultra DMA 3 44.4 Mbytes/s

UDMA 4 Ultra DMA 4 66.6 Mbytes/s

© National Instruments 2-19 NI RMC-8355 User Manual

Page 39

Chapter 2 Installation and BIOS Setup

SMART for Hard Disk Drives

Self-Monitoring Analysis and Reporting Technology (SMART) can help

predict impending disk drive failures. Select Auto to allow the AMI BIOS

to detect hard disk drive support automatically. Select Disabled to prevent

the AMI BIOS from using SMART. Select Enabled to allow the AMI

BIOS to use SMART to support the hard disk drive. The options are

Disabled, Enabled, and Auto.

32-Bit Data Transfer

Select Enabled to enable 32-bit IDE data transfer. The options are

Enabled and Disabled.

PCI/PnP Configuration

Table 2-2. DMA Mode Options

Maximum

Option DMA Mode

UDMA 5 Ultra DMA 5 100 Mbytes/s

UDMA 6 Ultra DMA 6 133 Mbytes/s

Transfer R ate

Clear NVRAM

This feature clears the NVRAM during system boot. The options are No

and Yes.

Plug & Play OS

Selecting Yes allows the OS to configure Plug & Play devices. (This is not

required for system boot if your system OS supports Plug & Play.) Select

No to allow the AMI BIOS to configure all devices in the system.

PCI Latency Timer

This feature sets the latency timer of each PCI device installed on a PCI

bus. Select 64 to set the PCI latency to 64 PCI clock cycles. The options are

32, 64, 96, 128, 160, 192, 224, and 248.

PCI IDE Bus Master

When this feature is enabled, the BIOS uses PCI bus mastering for

reading/writing to IDE drives. The options are Disabled and Enabled.

NI RMC-8355 User Manual 2-20 ni.com

Page 40

Chapter 2 Installation and BIOS Setup

SR-IOV Supported

Select Enabled to enable Single Root I/O Virtualization (SR-IOV) support,

which works with the Intel Virtualization Technology to allow multiple

operating systems to run simultaneously within a single computer. These

systems run via natively shared PCI Express devices to enhance network

connectivity and performance. The options are Enabled and Disabled.

PCI Express Slot from SXB1/PCI Express Slot from SXB2/

PCI Express Slot from SXB3

Select Enabled to enable the PCI Express SXB1 slot, PCI Express SXB2

slot, or PCI Express SXB3 slot. This option also can enable option ROMs

to boot the computer using a network interface from these slots. (You can

configure SXB1, a x16 slot, into two x8 slots. You can configure SXB2, a

x8 slot, into two x4 slots.) The options are Enabled and Disabled.

Onboard LAN Option ROM Select

Select iSCSI to use iSCSI option ROMs to boot the computer using a

network device. Select PXE to use PXE option ROMs to boot the computer

using a network device. The options are iSCSI and PXE.

Load Onboard LAN1 Option ROM/Load Onboard LAN2

Option ROM

Select Enabled to enable the onboard LAN1 or LAN2 Option ROM, to

boot the computer using a network interface. The options for Load Onboard

LAN1 and Load Onboard LAN 2 are Enabled and Disabled.

Boot Graphics Adapter Priority

Use this feature to select the priority graphics adapter for system boot. The

options are Onboard VGA and Offboard VGA.

Super IO Device Configuration

Serial Port1 Address/Serial Port2 Address

This option specifies the serial port 1 and serial port 2 base I/O port address

and interrupt request address. Select Disabled to prevent the serial port

from accessing any system resources. When this option is set to Disabled,

the serial port physically becomes unavailable. Select 3F8/IRQ4 to allow

© National Instruments 2-21 NI RMC-8355 User Manual

Page 41

Chapter 2 Installation and BIOS Setup

the serial port to use 3F8 as its I/O port address and IRQ 4 as the interrupt

address. The options for Serial Port1 are Disabled, 3F8/IRQ4, 3E8/IRQ4,

2E8/IRQ3. The options for Serial Port2 are Disabled, 2F8/IRQ3,

3E8/IRQ4, and 2E8/IRQ3.

Serial Port 2 Attribute

Use this feature to set COM 2 as a normal serial port or virtual COM port

for Serial Over LAN (SOL). The options are SOL and COM.

Remote Access Configuration

Remote Access

Use this feature to enable the remote access feature. The options are

Disabled and Enabled. If remote access is set to Enabled, the following

items display.

Serial Port Number

Use this feature to select which serial port to use for console redirection.

The options are COM 1 and COM 2.

Serial Port Mode

Use this feature to set the serial port mode for console redirection. The

options are 115200 8, n, 1; 57600 8, n, 1; 38400 8, n, 1; 19200 8, n, 1; and

9600 8, n, 1.

Flow Control

Use this feature to set the flow control for console redirection. The options

are None, Hardware, and Software.

Redirection After BIOS POST

Select Disabled to turn off console redirection after Power-On Self-Test

(POST). Select Always to keep console redirection active all the time after

POST.

Note Some operating systems may not support this setting.

Select Boot Loader to keep console redirection active during POST and

when the Boot Loader is booting. The options are Disabled, Boot Loader,

and Always.

NI RMC-8355 User Manual 2-22 ni.com

Page 42

Chapter 2 Installation and BIOS Setup

Terminal Type

Use this feature to select the target terminal type for console redirection.

The options are ANSI, VT100, and VT-UTF8.

VT-UTF8 Combo Key Support

Select Enabled to enable a terminal keyboard to send commands from a

remote console. The options are Enabled and Disabled.

Sredir Memory Display Delay

This feature defines the length of time in seconds to display memory

information. The options are No Delay, Delay 1 Sec, Delay 2 Sec, and

Delay 4 Sec.

Hardware Health Event Monitoring

Use this feature to monitor system health and review the status of each item

as displayed.

CPU Overheat Alarm

Caution Any temperature that exceeds the CPU threshold temperature the CPU

manufacturer predefines may result in CPU overheating or system instability. When the

CPU temperature reaches this predefined threshold, the CPU and system cooling fans run

at full speed. To avoid possible system overheating, be sure to provide adequate airflow to

your system.

Use this option to select the CPU Overheat Alarm setting, which

determines when the CPU OH alarm is activated to warn of possible CPU

overheating.

The options are:

• Early Alarm—Select this setting for the CPU overheat alarm

(including the LED and the buzzer) to be triggered as soon as the CPU

temperature reaches the CPU overheat threshold, as the CPU

manufacturer predefines.

• Default Alarm—Select this setting for the CPU overheat alarm

(including the LED and the buzzer) to be triggered when the CPU

temperature reaches about 5 ºC above the threshold temperature, as the

CPU manufacturer predefines, to give the CPU and system fans

additional time needed for CPU and system cooling. For both alarms,

take immediate action as described below.

© National Instruments 2-23 NI RMC-8355 User Manual

Page 43

Chapter 2 Installation and BIOS Setup

CPU 1 Temperature/CPU 2 Temperature/System Temperature

This feature displays current CPU and system temperature readings. The

following items are displayed for your reference only.

CPU1 Temperature/CPU2 Temperature

Intel has upgraded the CPU thermal technology that reports absolute

temperatures (Celsius/Fahrenheit) to a more advanced feature in its newer

processors. The basic concept is that each CPU is embedded with unique

temperature information the motherboard can read. This temperature

threshold or temperature tolerance is assigned at the factory. It is the

baseline on which the motherboard takes action during different CPU

temperature conditions (that is, by increasing CPU fan speed, triggering the

overheat alarm, and so on). Because CPUs can have different temperature

tolerances, the installed CPU now can send information to the motherboard

regarding its temperature tolerance, and not the other way around. This

results in better CPU thermal management.

National Instruments has leveraged this feature by assigning a temperature

status to certain thermal conditions in the processor (low, medium, and