Page 1

Serial

Serial Hardware and Software for Windows User Manual

PCI, PXI , PCMCIA, and AT

Serial Hardware

Serial Hardware and Software for Windows

December 2000 Edition

Part Number 322983A-01

Page 2

Support

Worldwide Technical Support and Product Information

ni.com

National Instruments Corporate Headquarters

11500 North Mopac Expressway Austin, Texas 78759-3504 USA Tel: 512 794 0100

Worldwide Offices

Australia 03 9879 5166, Austria 0662 45 79 90 0, Belgium 02 757 00 20, Brazil 011 284 5011,

Canada (Calgary) 403 274 9391, Canada (Ottawa) 613 233 5949, Canada (Québec) 514 694 8521,

China (Shanghai) 021 6555 7838, China (ShenZhen) 0755 3904939, Denmark 45 76 26 00,

Finland 09 725 725 11, France 01 48 14 24 24, Germany 089 741 31 30, Greece 30 1 42 96 427,

Hong Kong 2645 3186, India 91805275406, Israel 03 6120092, Italy 02 413091, Japan 03 5472 2970,

Korea 02 596 7456, Mexico 5 280 7625, Netherlands 0348 433466, New Zealand 09 914 0488,

Norway 32 27 73 00, Poland 0 22 528 94 06, Portugal 351 1 726 9011, Singapore 2265886, Spain 91 640 0085,

Sweden 08 587 895 00, Switzerland 056 200 51 51, Taiwan 02 2528 7227, United Kingdom 01635 523545

For further support information, see the Technical Support Resources appendix. To comment on the

documentation, send e-mail to techpubs@ni.com

© Copyright 1997, 2000 National Instruments Corporation. All rights reserved.

Page 3

Important Information

Warranty

The serial hardware is warranted against defects in materials and workmanship for a period of one year from the date of shipment,

as evidenced by receipts or other documentation. National Instruments will, at its option, repair or replace equipment that proves

to be defective during the warranty period. This warranty includes parts and labor.

The media on which you receive National Instruments software are warranted not to fail to execute programming instructions,

due to defects in materials and workmanship, for a period of 90 days from date of shipment, as evidenced by receipts or other

documentation. National Instruments will, at its option, repair or replace software media that do not execute programming

instructions if National Instruments receives notice of such defects during the warranty period. National Instruments does not

warrant that the operation of the software shall be uninterrupted or error free.

A Return Material Authorization (RMA) number must be obtained from the factory and clearly marked on the outside of

the package before any equipment will be accepted for warranty work. National Instruments will pay the shipping costs of

returning to the owner parts which are covered by warranty.

National Instruments believes that the information in this document is accurate. The document has been carefully reviewed

for technical accuracy. In the event that technical or typographical errors exist, National Instruments reserves the right to

make changes to subsequent editions of this document without prior notice to holders of this edition. The reader should consult

National Instruments if errors are suspected. In no event shall National Instruments be liable for any damages arising out of

or related to this document or the information contained in it.

E

XCEPT AS SPECIFIED HEREIN,NATIONAL INSTRUMENTS MAKES NO WAR RANTIES, EXPRESS OR IMPLIED, AND SPECIFICALLY DISCLAIMS ANY

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE

NEGLIGENCE ON THE PART OF

INSTRUMENTS WILL NOT BE LIABLE FOR DAMAGES RESULTING F ROM LOSS OF DATA, PROFITS, USE OF PRODUCTS, OR INCIDENTAL OR

CONSEQUENTIAL DAMAGES

apply regardless of the form of action, whether in contract or tort, including negligence. Any action against National Instruments

must be brought within one year after the cause of action accrues. National Instruments shall not be liable for any delay in

performance due to causes beyond its reasonable control. The warranty provided herein does not cover damages, defects,

malfunctions, or service failures caused by owner’s failure to follow the National Instruments installation, operation, or

maintenance instructions; owner’s modification of the product; owner’s abuse, misuse, or negligent acts; and power failure or

surges, fire, flood, accident, actions of third parties, or other events outside reasonable control.

NATIONAL INSTRUMENTS SHALL BE LIMITED TO THE AMOUNT THERETOFORE PAID BY THE CUSTOMER.NATIONAL

, EVEN IF ADVISED OF THE POSSIBILITY THEREOF. This limitation of the liability of National Instruments will

.CUSTOMER’S RIGHT TO RECOVER DAMAGES CAUSED BY FAULT OR

Copyright

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or mechanical, including

photocopying, recording, storing in an information retrieval system, or translating, in whole or in part, without the prior written

consent of National Instruments Corporation.

Trademarks

CVI™,LabVIEW™, National Instruments™,ni.com™,andPXI™are trademarks of National Instruments Corporation.

Product and company names mentioned herein are trademarks or trade names of their respective companies.

WARNING REGARDING USE OF NATIONAL INSTRUMENTS PRODUCTS

(1) NATIONAL INSTRUMENTS PRODUCTS ARE NOT DESIGNED WITHCOMPONENTS AND TESTING FOR A LEVEL

OF RELIABILITY SUITABLE FOR USE IN OR IN CONNECTION WITH SURGICAL IMPLANTS OR AS CRITICAL

COMPONENTS IN ANY LIFE SUPPORT SYSTEMS WHOSE FAILURE TO PERFORM CAN REASONABLY BE

EXPECTED TO CAUSE SIGNIFICANT INJURY TO A HUMAN.

(2) IN ANY APPLICATION, INCLUDING THE ABOVE, RELIABILITYOF OPERATION OFTHE SOFTWARE PRODUCTS

CAN BE IMPAIRED BY ADVERSE FACTORS, INCLUDING BUT NOT LIMITED TO FLUCTUATIONS IN ELECTRICAL

POWER SUPPLY, COMPUTER HARDWARE MALFUNCTIONS, COMPUTER OPERATING SYSTEM SOFTWARE

FITNESS, FITNESS OF COMPILERS AND DEVELOPMENT SOFTWARE USED TO DEVELOP AN APPLICATION,

INSTALLATION ERRORS, SOFTWARE AND HARDWARE COMPATIBILITY PROBLEMS, MALFUNCTIONS OR

FAILURES OF ELECTRONIC MONITORING OR CONTROL DEVICES, TRANSIENT FAILURES OF ELECTRONIC

SYSTEMS (HARDWARE AND/OR SOFTWARE), UNANTICIPATED USES OR MISUSES, OR ERRORS ONTHE PART OF

THE USER OR APPLICATIONS DESIGNER (ADVERSE FACTORS SUCH AS THESE ARE HEREAFTER

COLLECTIVELY TERMED “SYSTEM FAILURES”). ANY APPLICATION WHERE A SYSTEM FAILURE WOULD

CREATE A RISK OF HARM TO PROPERTY OR PERSONS (INCLUDING THE RISK OF BODILY INJURY AND DEATH)

SHOULD NOT BE RELIANT SOLELY UPON ONE FORM OF ELECTRONIC SYSTEM DUE TO THE RISK OF SYSTEM

FAILURE. TO AVOID DAMAGE, INJURY, OR DEATH, THE USER OR APPLICATION DESIGNER MUST TAKE

REASONABLY PRUDENT STEPS TO PROTECT AGAINST SYSTEM FAILURES, INCLUDING BUT NOT LIMITED TO

BACK-UP OR SHUT DOWN MECHANISMS. BECAUSE EACH END-USER SYSTEM IS CUSTOMIZED AND DIFFERS

FROM NATIONAL INSTRUMENTS' TESTING PLATFORMS AND BECAUSE A USER OR APPLICATION DESIGNER

MAY USE NATIONAL INSTRUMENTS PRODUCTS IN COMBINATION WITH OTHER PRODUCTS IN A MANNER NOT

EVALUATED OR CONTEMPLATED BY NATIONAL INSTRUMENTS, THE USER OR APPLICATION DESIGNER IS

ULTIMATELY RESPONSIBLE FOR VERIFYING AND VALIDATING THE SUITABILITY OF NATIONAL

INSTRUMENTS PRODUCTS WHENEVER NATIONAL INSTRUMENTS PRODUCTS ARE INCORPORATED IN A

SYSTEM OR APPLICATION, INCLUDING, WITHOUT LIMITATION, THE APPROPRIATE DESIGN, PROCESS AND

SAFETY LEVEL OF SUCH SYSTEM OR APPLICATION.

Page 4

Compliance

FCC/Canada Radio Frequency Interference Compliance*

Determining FCC Class

The Federal Communications Commission (FCC) has rules to protect wireless communications from interference.

The FCC places digital electronics into two classes. These classes are known as Class A (for use in industrialcommercial locations only) or Class B (for use in residential or commercial locations). Depending on where it is

operated, this product could be subject to restrictions in the FCC rules. (In Canada, the Department of

Communications (DOC), of Industry Canada, regulates wireless interference in much the same way.)

Digital electronics emit weak signals during normal operation that can affect radio, television, or other wireless

products. By examining the product you purchased, you can determine the FCC Class and therefore which of the two

FCC/DOC Warnings apply in the following sections. (Some products may not be labeled at all for FCC; if so, the

reader should then assume these are Class A devices.)

FCC Class A products only display a simple warning statement of oneparagraph in length regarding interference and

undesired operation. Most of our products are FCC Class A. The FCC rules have restrictions regarding the locations

where FCC Class A products can be operated.

FCC Class B products display either a FCC ID code, starting with the letters EXN,

or the FCC Class B compliance mark that appears as shown here on the right.

Consult the FCC web site

http://www.fcc.gov

FCC/DOC Warnings

This equipment generates and uses radio frequency energy and, if not installed and used in strict accordance with the

instructions in this manual and the CE Mark Declaration of Conformity**, may cause interference to radio and

television reception. Classification requirements are the same for the Federal Communications Commission (FCC)

and the Canadian Department of Communications (DOC).

Changes or modifications not expressly approved by National Instruments could void the user’s authority to operate

the equipment under the FCC Rules.

Class A

Federal Communications Commission

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15

of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to

radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in

which case the user will be required to correct the interference at his own expense.

for more information.

Canadian Department of Communications

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le matériel brouilleur du

Canada.

Class B

Federal Communications Commission

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15

of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio communications. However,

there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the equipment off and on, the user

is encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

Page 5

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Canadian Department of Communications

This Class B digital apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations.

Cet appareil numérique de la classe B respecte toutes les exigences du Règlement sur le matériel brouilleur du

Canada.

European Union - Compliance to EEC Directives

Readers in the EU/EEC/EEA must refer to the Manufacturer's Declaration of Conformity (DoC) for information**

pertaining to the CE Mark compliance scheme. The Manufacturer includes a DoC for most every hardware product

except for those bought for OEMs, if also available from an original manufacturer that also markets in the EU, or

where compliance is not required as for electrically benign apparatus or cables.

* Certain exemptions may apply in the USA, see FCC Rules §15.103 Exempted devices,and§15.105(c).

Also available in sections of CFR 47.

** The CE Mark Declaration of Conformity will contain important supplementary information and instructions

for the user or installer.

Page 6

Contents

About This Manual

Conventions ...................................................................................................................xiii

Related Documentation..................................................................................................xiv

Chapter 1

Introduction

How to Use This Manual ............................................................................................... 1-1

What You Need to Get Started ......................................................................................1-2

Optional Equipment.......................................................................................................1-3

Serial Hardware Overview.............................................................................................1-3

PCI Kits ...........................................................................................................1-3

PXI Kits...........................................................................................................1-4

PCMCIA Kits ..................................................................................................1-6

AT Kits ............................................................................................................ 1-6

NI-Serial Software Overview ........................................................................................1-8

Time-Saving Development Tools..................................................................................1-8

Chapter 2

PCI Serial Hardware Installation, Verification, and Configuration

Windows 2000 ............................................................................................................... 2-1

Install the Software..........................................................................................2-1

Install the Hardware ........................................................................................2-2

Verify the Installation......................................................................................2-4

Configure Communication Port Settings.........................................................2-5

Windows Me/9x.............................................................................................................2-9

Install the Software..........................................................................................2-9

Install the Hardware ........................................................................................2-10

Verify the Installation......................................................................................2-12

Configure Communication Port Settings.........................................................2-14

Windows NT..................................................................................................................2-18

Install the Software..........................................................................................2-18

Install the Hardware ........................................................................................2-18

Verify the Installation......................................................................................2-20

Configure Communication Port Settings.........................................................2-21

© National Instruments Corporation vii Serial Hardware and Software for Windows

Page 7

Contents

Chapter 3

PXI Serial Hardware Installation, Verification, and Configuration

Windows 2000............................................................................................................... 3-1

Install the Software ......................................................................................... 3-1

Install the Hardware........................................................................................3-2

Verify the Installation ..................................................................................... 3-4

Configure Communication Port Settings ........................................................ 3-5

Windows Me/9x............................................................................................................. 3-9

Install the Software ......................................................................................... 3-9

Install the Hardware........................................................................................3-10

Verify the Installation ..................................................................................... 3-11

Configure Communication Port Settings ........................................................ 3-13

Windows NT ................................................................................................................. 3-17

Install the Software ......................................................................................... 3-17

Install the Hardware........................................................................................3-17

Verify the Installation ..................................................................................... 3-19

Configure Communication Port Settings ........................................................ 3-20

Chapter 4

PCMCIA Serial Hardware Installation, Verification, and Configuration

Windows 2000............................................................................................................... 4-1

Install the Software ......................................................................................... 4-1

Install the Hardware........................................................................................4-2

Verify the Installation ..................................................................................... 4-3

Configure Communication Port Settings ........................................................ 4-5

Windows Me/9x............................................................................................................. 4-8

Install the Software ......................................................................................... 4-8

Install the Hardware........................................................................................4-9

Verify the Installation ..................................................................................... 4-10

Configure Communication Port Settings ........................................................ 4-13

Windows NT ................................................................................................................. 4-16

Install the NI-Serial Software ......................................................................... 4-16

Install the PCMCIA Serial Hardware .............................................................4-17

Verify the Installation ..................................................................................... 4-18

Configure Communication Port Settings ........................................................ 4-19

Serial Hardware and Software for Windows viii ni.com

Page 8

Chapter 5

AT Serial Hardware Installation, Verification, and Configuration

Windows 2000 ............................................................................................................... 5-1

Install the Software..........................................................................................5-1

Install the Hardware ........................................................................................5-2

Verify the Installation......................................................................................5-4

Configure Communication Port Settings.........................................................5-5

Windows Me/9x.............................................................................................................5-9

Install the Software..........................................................................................5-9

Install the Hardware ........................................................................................5-10

Verify the Installation......................................................................................5-12

Configure Communication Port Settings.........................................................5-14

Windows NT..................................................................................................................5-18

Installing the Microsoft PnP ISA Enabler Driver............................................5-18

Install the NI-Serial Software.......................................................................... 5-19

Install the Serial Hardware ..............................................................................5-19

Verify the Installation......................................................................................5-21

Configure Communication Port Settings.........................................................5-22

Chapter 6

Contents

Using Your Serial Hardware

General Programming Requirements.............................................................................6-1

Advanced Transceiver Control for the PCI/PXI/PCMCIA/AT-485 Boards .................6-1

Four-Wire Mode..............................................................................................6-2

Two-Wire Mode: DTR

Two-Wire Mode: DTR

Two-Wire Mode: TXRDY

Setting the Transceiver Control Mode ............................................................6-3

Setting the Transceiver Mode with DeviceIoControl......................................6-4

with Echo...................................................................6-2

Controlled..................................................................6-2

Auto Control ........................................................6-3

Appendix A

Connector Descriptions

Appendix B

Serial Port Information

Appendix C

Uninstalling the Hardware and Software

© National Instruments Corporation ix Serial Hardware and Software for Windows

Page 9

Contents

Appendix D

Troubleshooting and Common Questions

Appendix E

Specifications

Appendix F

Technical Support Resources

Glossary

Index

Figures

Figure 2-1. PCI Serial Board Installation ................................................................ 2-3

Figure 2-2. Device Manager for PCI Serial Board Ports......................................... 2-4

Figure 2-3. Port Settings Tab................................................................................... 2-7

Figure 2-4. Advanced Settings Dialog Box............................................................. 2-8

Figure 2-5. PCI Serial Board Installation ................................................................ 2-11

Figure 2-6. Device Manager Tab for PCI Serial Board Ports.................................. 2-13

Figure 2-7. Port Settings Tab................................................................................... 2-16

Figure 2-8. Advanced Port Settings Dialog Box ..................................................... 2-17

Figure 2-9. Installing the PCI Serial Board .............................................................2-19

Figure 2-10. niports Configuration Utility................................................................. 2-21

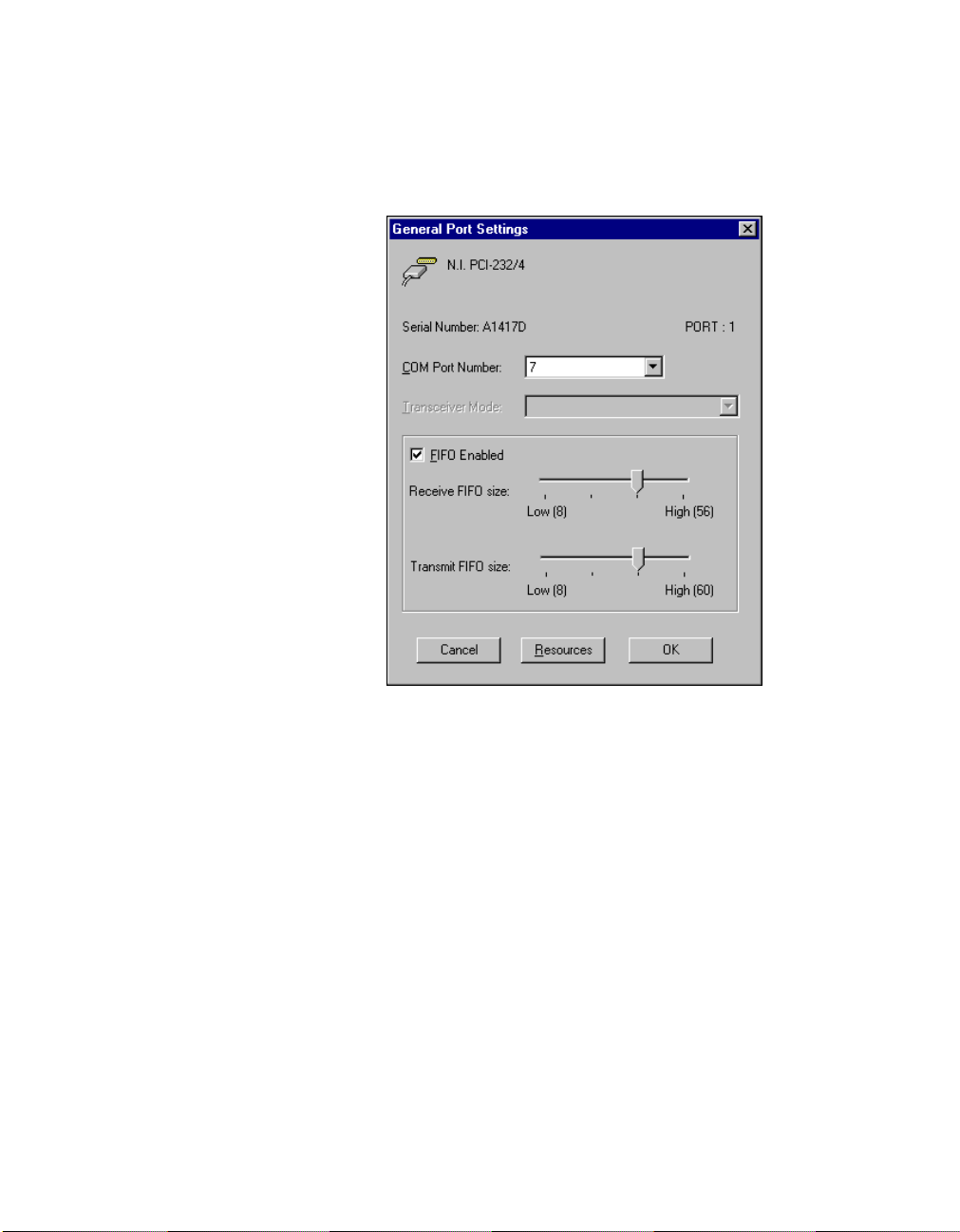

Figure 2-11. General Port Settings Dialog Box......................................................... 2-22

Figure 3-1. Installing the PXI Serial Board ............................................................. 3-3

Figure 3-2. Device Manager for PXI Serial Board Ports......................................... 3-4

Figure 3-3. Port Settings Tab................................................................................... 3-7

Figure 3-4. Advanced Settings Dialog Box............................................................. 3-8

Figure 3-5. Installing the PXI Serial Board ............................................................. 3-10

Figure 3-6. Device Manager for PXI Serial Board Ports......................................... 3-12

Figure 3-7. Port Settings Tab................................................................................... 3-15

Figure 3-8. Advanced Settings Dialog Box............................................................. 3-16

Figure 3-9. Installing the PXI Serial Board ............................................................. 3-18

Figure 3-10. niports Configuration Utility................................................................. 3-20

Figure 3-11. General Port Settings Dialog Box......................................................... 3-21

Figure 4-1. Inserting a PCMCIA Serial Card .......................................................... 4-3

Figure 4-2. Device Manager for PCMCIA Serial Card Ports.................................. 4-4

Serial Hardware and Software for Windows x ni.com

Page 10

Contents

Figure 4-3. Port Settings Tab ...................................................................................4-6

Figure 4-4. Advanced Settings Dialog Box .............................................................4-7

Figure 4-5. Inserting a PCMCIA Serial Card...........................................................4-10

Figure 4-6. Device Manager Ports List for PCMCIA Serial Card

Correctly Installed .................................................................................4-11

Figure 4-7. Port Settings Tab ...................................................................................4-14

Figure 4-8. Advanced Port Settings Dialog Box......................................................4-15

Figure 4-9. Inserting a PCMCIA Serial Card...........................................................4-17

Figure 4-10. niports Configuration Utility .................................................................4-19

Figure 4-11. General Port Settings Dialog Box .........................................................4-20

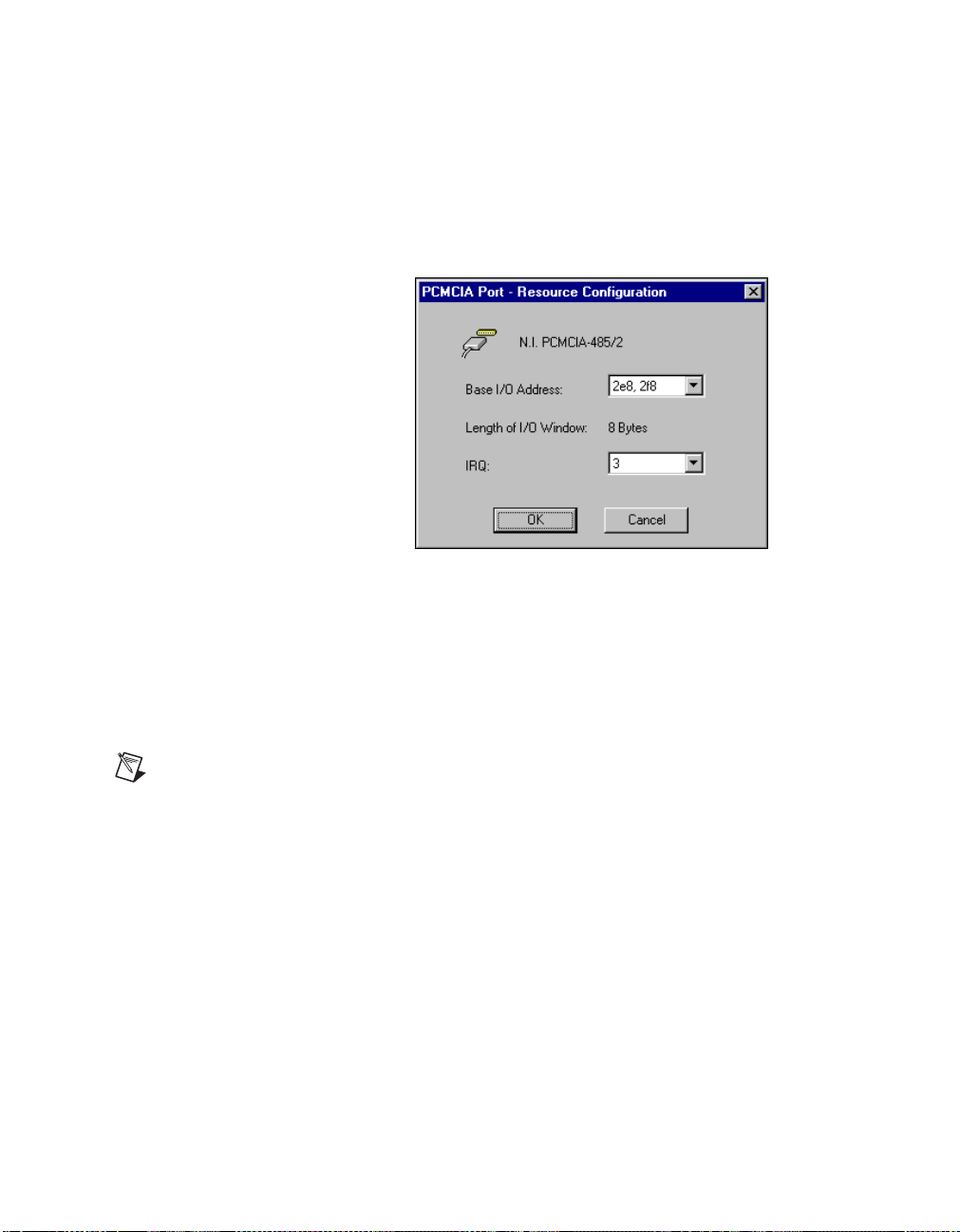

Figure 4-12. Resource Configuration Dialog Box for the PCMCIA-485 ..................4-22

Figure 4-13. Resource Configuration Dialog Box for the PCMCIA-485/2...............4-23

Figure 5-1. AT Serial Board Installation..................................................................5-3

Figure 5-2. Device Manager for AT Serial Board Ports ..........................................5-4

Figure 5-3. Port Settings Tab ...................................................................................5-7

Figure 5-4. Advanced Settings Dialog Box .............................................................5-8

Figure 5-5. AT Serial Board Installation..................................................................5-11

Figure 5-6. Device Manager Ports List for AT Serial Board

Correctly Installed .................................................................................5-13

Figure 5-7. Port Settings Tab ...................................................................................5-16

Figure 5-8. Advanced Port Settings Dialog Box......................................................5-17

Figure 5-9. AT Serial Board Installation..................................................................5-20

Figure 5-10. niports Configuration Utility .................................................................5-22

Figure 5-11. General Port Settings Dialog Box .........................................................5-23

Figure 5-12. PnP Port Configuration Dialog Box for the AT-232/4..........................5-25

Figure A-1. DB-9 Connector Pin Locations .............................................................A-2

Figure A-2. 10-Position Modular Jack Pin Locations...............................................A-3

Figure A-3. DB-25 Connector Pin Locations ...........................................................A-4

Figure A-4. Connecting the Cables to Your Four-Port PCI Serial Board................. A-5

Figure A-5. 68-Pin Connector Pin Locations............................................................A-6

Figure A-6. 100-Pin Connector Pin Locations..........................................................A-8

Figure B-1. Typical Full-Duplex System .................................................................B-4

Figure B-2. Typical Half-Duplex System .................................................................B-4

Figure B-3. Multidrop Network Using Terminating Resistors................................. B-5

Figure B-4. Transmission Line Using Bias Resistors...............................................B-6

Figure B-5. Straight-Through Cabling in a DTE-to-DCE Interface .........................B-7

Figure B-6. Null-Modem Cabling in a DTE-to-DTE Interface ................................B-7

Figure C-1. Selecting an Interface to Uninstall ........................................................C-2

Figure C-2. Selecting an Interface to Uninstall ........................................................C-4

Figure C-3. Selecting an Interface to Uninstall ........................................................C-5

© National Instruments Corporation xi Serial Hardware and Software for Windows

Page 11

Contents

Tables

Figure C-4. Selecting an Interface to Uninstall ........................................................ C-7

Figure C-5. Selecting an Interface to Uninstall ........................................................ C-9

Figure C-6. Selecting an Interface to Uninstall ........................................................ C-10

Figure C-7. Selecting an Interface to Uninstall ........................................................ C-12

Figure C-8. Selecting an Interface to Uninstall ........................................................ C-14

Figure C-9. Selecting an Interface to Uninstall ........................................................ C-16

Figure C-10. Selecting an Interface to Uninstall........................................................ C-17

Figure C-11. Selecting an Interface to Uninstall........................................................ C-19

Figure C-12. Selecting an Interface to Uninstall........................................................ C-21

Figure D-1. Selecting an Interface to Uninstall........................................................ D-2

Figure D-2. Ports List in Device Manager ............................................................... D-12

Figure D-3. Ports List in Device Manager ............................................................... D-14

Figure D-4. Multi-Function Adapter Class in the Device Manager ......................... D-17

Table 1-1. PXI Board Names and Descriptions .................................................... 1-5

Table 6-1. Transceiver Control Modes................................................................... 6-2

Table 6-2. Transceiver Mode Control Bytes .......................................................... 6-4

Table 6-3. DeviceIoControl Function Input Values .............................................. 6-5

Table A-1. DB-9 Pin Descriptions .......................................................................... A-2

Table A-2. 10-Position Modular Jack Pin Descriptions.......................................... A-3

Table A-3. DB-25 Pin Descriptions ........................................................................ A-4

Table A-4. 68-Pin Connector Pin Descriptions.......................................................A-7

Table A-5. 100-Pin Connector Pin Descriptions..................................................... A-9

Table B-1. RS-232, RS-422, and RS-485 Features................................................. B-1

Table D-1. Standard DOS-Based Addresses........................................................... D-15

Serial Hardware and Software for Windows xii ni.com

Page 12

About This Manual

This manual contains instructions to help you install and configure the

National Instruments serial hardware and the NI-Serial software for

Windows 2000/NT/Me/9x. This manual includes information about the

following serial hardware:

• PCI-232/2, PCI-232/4, PCI-232/8, PCI-232/16, PCI-485/2,

PCI-485/4, and PCI-485/8 boards in both isolated and nonisolated

versions

• PXI-8420 (two, four, eight, and 16 port), PXI-8421 (two, four, and

eight port), PXI-8422 (two and four port), and PXI-8423 (two and

four port)

• PCMCIA-232, PCMCIA-232/2, PCMCIA-232/4, PCMCIA-485, and

PCMCIA-485/2

• AT-232/2, AT-232/4, AT-485/2, and AT-485/4 boards in both isolated

and nonisolated versions

This manual assumes that you are already familiar with

Windows 2000/NT/Me/9x.

Conventions

The following conventions appear in this manual:

» The » symbol leads you through nested menu items and dialog box options

to a final action. The sequence File»Page Setup»Options directs you to

pull down the File menu, select the Page Setup item, and select Options

from the last dialog box.

♦ The ♦ symbol indicates that the following text applies only to a specific

product, a specific operating system, or a specific software version.

This icon denotes a note, which alerts you to important information.

This icon denotes a caution, which advises you of precautions to take to

avoid injury, data loss, or a system crash.

AT serial boards AT serial boards refers to all port versions of the AT serial boards.

© National Instruments Corporation xiii Serial Hardware and Software for Windows

Page 13

About This Manual

bold Bold text denotes items that you must select or click on in the software,

such as menu items and dialog box options. Bold text also denotes

parameter names.

DTR

italic Italic text denotes variables, emphasis, a cross reference, or an introduction

monospace

monospace bold

PCI serial boards PCI serial boards refers to all port versions of the PCI serial boards.

PCMCIA serial boards PCMCIA serial boards refers to all versions of the PCMCIA serial boards.

PXI serial boards PXI serial boards refers to all port versions of the PXI serial boards.

Signal names with an overscore, such as DTR, indicate that the signal is

active low.

to a key concept. This font also denotes text that is a placeholder for a word

or value that you must supply.

Text in this font denotes text or characters that you should enter from the

keyboard, sections of code, programming examples, and syntax examples.

This font is also used for the proper names of disk drives, paths, directories,

programs, subprograms, subroutines, device names, functions, operations,

variables, filenames and extensions, and code excerpts.

Bold text in this font denotes the messages and responses that the computer

automatically prints to the screen. This font also emphasizes lines of code

that are different from the other examples.

Related Documentation

The following documents contain information that you might find helpful

as you read this manual:

• ANSI/EIA-232-D Standard, Interface Between Data Terminal

Equipment and Data Circuit-Terminating Equipment Employing

Serial Binary Data Interchange

• EIA/RS-422-A Standard, Electrical Characteristics of Balanced

Voltage Digital Interface Circuits

• EIA-485 Standard, Standard for Electrical Characteristics of

Generators and Receivers for Use in Balanced Digital

Multipoint Systems

• Microsoft Win32 Software Developer Kit, Online Documentation for

Win32 Overviews, Win32 Reference, Microsoft Programmer’s Guide

to Windows 98/95,andMicrosoft Windows NT System Guide,

Microsoft Corporation

Serial Hardware and Software for Windows xiv ni.com

Page 14

About This Manual

• NS16550AF Universal Asynchronous Receiver/Transmitter with

FIFOs, National Semiconductor

• ST16C654 Asynchronous Receiver/Transmitter with FIFOs,

EXAR Corporation

© National Instruments Corporation xv Serial Hardware and Software for Windows

Page 15

Introduction

This chapter explains how to use this manual, lists what you need to get

started and optional equipment you can order, and briefly describes the

serial hardware and the NI-Serial software.

How to Use This Manual

1

Chapter 1

Chapters

2, 3, 4, and 5

Chapter 6

Gather What You Need

to Get Started

Install the NI Serial Software

Install the Serial Hardware

Verify the Installation

Passes?

Ye s

Configure the Serial Port

Learn About Transceiver

Control Modes

Review Programming

Requirements

Write Application Program

No

Troubleshooting

© National Instruments Corporation 1-1 Serial Hardware and Software for Windows

Page 16

Chapter 1 Introduction

What You Need to Get Started

Before you install your serial hardware and the NI-Serial software, make

sure you have all of the following items:

❑

Windows 2000/NT/Me/9x installed on your computer

❑

One of the following serial boards, which is included in your kit:

PCI Kits

– PCI-232 (two, four, eight, or 16 port)

– PCI-485 (two, four, or eight port)

– PCI-232 isolated (two or four port)

– PCI-485 isolated (two or four port)

PXI Kits

– PXI-8420 (two, four, eight, or 16 port)

– PXI-8421 (two, four, or eight port)

– PXI-8422 (two or four port)

– PXI-8423 (two or four port)

PCMCIA Kits

– PCMCIA-232 (one, two, or four port)

– PCMCIA-485 (one or two port)

AT Kits

– AT-232 (two or four port)

– AT-485 (two or four port)

– AT-232 (two or four port) isolated

– AT-485 (two or four port) isolated

❑

CD, NI-Serial Software for Windows 2000/NT/Me/9x,whichis

included in your kit

Serial Hardware and Software for Windows 1-2 ni.com

Page 17

Optional Equipment

For more information about ordering the following optional equipment,

contact National Instruments:

• DB-9 RS-485 termination connector (PCI-485, PCMCIA-485,

PXI-8421, PXI-8423, and AT-485 only)

• 10-position modular jack to DB-9 cable (PCI, PXI, and AT four-port

boards only)

• 10-position modular jack to DB-25 cable (PCI, PXI, and AT four-port

boards only)

• 68-pin to DB-9 adapter cable (PCI and PXI eight-port boards only)

• RS-232 9-pin to 9-pin null modem cable

• RS-232 9-pin to 25-pin null modem cable

• RS-485 9-pin to 9-pin null modem cable

• Breakout box (PCI/PXI-232 16-port board only)

Serial Hardware Overview

Chapter 1 Introduction

PCI Kits

The serial hardware gives you a variety of solutions for serial

communication. The PCI-232 boards work with the RS-232 protocols, and

the PCI-485 boards work with the RS-422 and RS-485 protocols. You can

use the PCI-232 boards for serial communication up to distances of 50 ft.

You can connect the PCI-485 boards to up to 31 devices using serial cable

lengths up to 4,000 ft.

Additionally, the PCI serial boards are available in a two-port version

(PCI-232/2 and PCI-485/2), a four-port version (PCI-232/4 and

PCI-485/4), an eight-port version (PCI-232/8 and PCI-485/8), and a

sixteen-port version (PCI-232/16). The two-port versions use DB-9

connectors. The four-port versions use 10-position modular jacks to

provide all four connections on a single back panel. Optional cable

accessories convert the 10-position modular jacks to either DB-9 or DB-25

connectors with standard pinouts. The eight-port versions use adapter

cables to convert the 68-pin connector on the board to eight DB-9

connectors. The 16-port version uses a breakout box to convert the 100-pin

connector on the board to sixteen DB-9 connectors. Throughout this

manual, PCI serial boards refers to all versions of the PCI serial boards.

© National Instruments Corporation 1-3 Serial Hardware and Software for Windows

Page 18

Chapter 1 Introduction

The isolated PCI-232 and PCI-485 boards are designed for applications in

harsh environments. Isolated ports provide reliable communication in

situations involving ground loops from different ground levels or high

common mode voltage induced on the lines in noisy environments.

Non-isolated ports may not provide reliable communication in those

situations. The isolation between each communication port and the host PC

ensures the safe operation of the PC and the devices connected to other

ports on the same board, in case of accidental high voltages on

communication lines.

The PCI-485 boards support four hardware transceiver control modes

for reliable communication with two- and four-wire devices. For more

information about transceiver control modes, refer to Chapter 6, Using

Your Serial Hardware.

All serial hardware uses standard 16550-compatible UARTs (Universal

Asynchronous Receiver/Transmitters) for complete compatibility

with standard PC COM ports. The serial hardware contains FIFOs

(First-In-First-Out) buffers to reduce susceptibility to interrupt latency

for faster transmission rates. Full Plug and Play compatibility allows

switchless configuration and installation. For more information about

the serial hardware specifications and operating conditions, refer to

Appendix E, Specifications.

PXI Kits

The serial hardware gives you a variety of solutions for serial

communication. The RS-232 boards (PXI-8420 and PXI-8422) work with

the RS-232 protocols. The RS-485 boards (PXI-8421 and PXI-8423) work

with the RS-422 and RS-485 protocols. You can use the RS-232 boards for

serial communication up to distances of 50 ft. You can connect the RS-485

boardstoupto31devicesusingserialcablelengthsupto4,000ft.

Additionally, the PXI serial boards are available in a two-port version, a

four-port version, an eight-port version (PXI-8420 and PXI-8421 only),

and a 16-port version (PXI-8420 only). The two-port versions use DB-9

connectors. The four-port versions use 10-position modular jacks to

provide all four connections on a single front panel. Optional cable

accessories convert the 10-position modular jacks to either DB-9 or DB-25

connectors with standard pinouts. The eight-port versions use two different

adapter cables to convert the 68-pin connector on the board to eight DB-9

connectors. The 16-port version uses a breakout box to convert the 100-pin

connector on the board to sixteen DB-9 connectors. Throughout this

manual, PXI serial boards refers to all versions of the PXI serial boards.

Serial Hardware and Software for Windows 1-4 ni.com

Page 19

Chapter 1 Introduction

The isolated PXI boards are designed for applications in harsh

environments. Isolated ports provide reliable communication in situations

involving ground loops from different ground levels or high common mode

voltage induced on the lines in noisy environments. Non-isolated ports may

not provide reliable communication in those situations. The isolation

between each communication port and the host PC ensures the safe

operation of the PC and the devices connected to other ports on the same

board, in case of accidental high voltages on communication lines.

The RS-485 boards (PXI-8421 and PXI-8423) support four hardware

transceiver control modes for reliable communication with two- and

four-wire devices. For more information about transceiver control modes,

refer to Chapter 6, Using Your Serial Hardware.

All serial hardware uses standard 16550-compatible UARTs (Universal

Asynchronous Receiver/Transmitters) for complete compatibility

with standard PC COM ports. The serial hardware contains FIFOs

(First-In-First-Out) buffers to reduce susceptibility to interrupt latency

for faster transmission rates. Full Plug and Play compatibility allows

switchless configuration and installation. For more information about

the serial hardware specifications and operating conditions, refer to

Appendix E, Specifications.

Table 1-1 lists the PXI serial board numbers and corresponding board

descriptions.

Table 1-1. PXI Board Names and Descriptions

PXI Board Name Description

PXI-8420 RS-232 two port

RS-232 four port

RS-232 eight port

RS-232 16 port

PXI-8421 RS-485 two port

RS-485 four port

RS-485 eight port

PXI-8422 RS-232 two port isolated

RS-232 four port isolated

PXI-8423 RS-485 two port isolated

RS-485 four port isolated

© National Instruments Corporation 1-5 Serial Hardware and Software for Windows

Page 20

Chapter 1 Introduction

PCMCIA Kits

The serial hardware gives you a variety of solutions for serial

communications. The PCMCIA-232 interfaces work with the RS-232

protocols, and the PCMCIA-485 interfaces work with the RS-422 and

RS-485 protocols. You can use the PCMCIA-232 hardware for serial

communication up to distances of 50 ft. You can connect the PCMCIA-485

hardware with up to 31 devices using serial cable lengths up to 4,000 ft.

The PCMCIA-232 is available with one, two, or four ports. The

PCMCIA-485 is available in a one-port version or two-port version.

All PCMCIA cards come with cables for each port that terminates in a

standard DB-9 D-Sub connector. Throughout this manual, references to

PCMCIA serial interfaces generally refer to all versions of the interfaces.

The PCMCIA-485 interfaces support four hardware transceiver control

modes for reliable communication with two-wire and four-wire devices.

Refer to Chapter 6, Using Your Serial Hardware, for more information

about transceiver control modes.

All of the serial hardware uses standard 16550-compatible UARTs

(Universal Asynchronous Receiver/Transmitters) for 100 percent

compatibility with standard PC COM ports. The serial hardware contains

FIFOs (First-In-First-Out buffers) for reduced susceptibility to interrupt

latency and faster transmission rates. Full Plug and Play compatibility gives

you the convenience of switchless configuration and installation. Refer to

Appendix E, Specifications,for more information about the serial hardware

specifications and operating conditions.

AT Kits

The serial hardware gives you a variety of solutions for serial

communications. The AT-232 boards work with the RS-232 protocols, and

the AT-485 boards work with the RS-422 and RS-485 protocols. You can

use the AT-232 hardware for serial communication up to distances of 50 ft.

You can connect the AT-485 hardware with up to 31 devices using serial

cable lengths up to 4,000 ft.

The AT boards are available in three different versions:

• Shared IRQ: All ports on the board share the same IRQ.

• Isolated: All ports on the board are isolated and share the same IRQ.

Serial Hardware and Software for Windows 1-6 ni.com

Page 21

Chapter 1 Introduction

Additionally, the AT serial boards are available in a two-port version

(AT-232/2 and AT-485/2) or a four-port version (AT-232/4 and AT-485/4).

The two-port versions use DB-9 connectors. The four-port versions use

10-position modular jacks to provide all four connections on a single back

panel. Optional cable accessories convert the 10-position modular jacks to

either DB-9 or DB-25 connectors with standard pinouts. Throughout this

manual, references to AT serial boards generally refer to all versions of the

boards.

The isolated AT-232 and AT-485 boards are designed for applications in

harsh environments. Isolated ports provide reliable communication in

situations involving ground loops from different ground levels or high

common mode voltage induced on the lines in noisy environments. The

non-isolated ports may not provide reliable communication in those

situations. The isolation between each communication port and the host PC

ensures safe operation of the PC and the devices connected to other ports

on the same board in case of accidental high voltages on communication

lines.

The AT-485 boards support four hardware transceiver control modes

for reliable communication with two- and four-wire devices. For more

information about transceiver control modes, refer to Chapter 6, Using

Your Serial Hardware.

All serial hardware uses standard 16550-compatible UARTs (Universal

Asynchronous Receiver/Transmitters) for complete compatibility

with standard PC COM ports. The serial hardware contains FIFOs

(First-In-First-Out) buffers to reduce susceptibility to interrupt latency

for faster transmission rates. Full Plug and Play compatibility allows

switchless configuration and installation. For more information about

the serial hardware specifications and operating conditions, refer to

Appendix E, Specifications.

© National Instruments Corporation 1-7 Serial Hardware and Software for Windows

Page 22

Chapter 1 Introduction

NI-Serial Software Overview

The NI-Serial software for Windows 2000/NT/Me/9x includes a native

Windows 2000/Me/9x device driver and Windows NT kernel driver that

provide full interrupt-driven, buffered I/O for multiple COM ports. You

can obtain a maximum baud rate of either 460.8 KBaud (PCI/PXI-485 kits)

or 115.2 KBaud (PCI/PXI/PCMCIA/AT-232 kits). You can also use up to

256 serial ports under Windows 2000 or up to 99 serial ports under

Windows NT/Me/9x. The NI-Serial software also includes a configuration

utility, which is fully integrated into the Windows 2000/Me/9x Device

Manager and Windows NT Control Panel. For more information about

software specifications, refer to Appendix E, Specifications.

The NI-Serial software includes the following components:

• Device driver

• Diagnostic utility

• Configuration utility

• Product manuals

Time-Saving Development Tools

Your kit includes the NI-Serial software for Windows 2000/NT/Me/9x.In

addition, you can order the Measurement Studio or LabVIEW software

from National Instruments to speed your application development time and

make it easier to communicate with your instruments.

LabVIEW is an easy-to-use, graphical programming environment you can

use to acquire data from thousands of different instruments, including

IEEE 488.2 devices, VXI devices, serial devices, PLCs, and plug-in data

acquisition boards. After you have acquired raw data, you can convert it

into meaningful results using the powerful data analysis routines in

LabVIEW. LabVIEW also comes with hundreds of instrument drivers,

which dramatically reduce software development time, because you do not

have to spend time programming the low-level control of each instrument.

Serial Hardware and Software for Windows 1-8 ni.com

Page 23

Chapter 1 Introduction

Measurement Studio bundles LabWindows/CVI for C programmers,

ComponentWorks for Microsoft Visual C++ programmers, and

ComponentWorks++ for Microsoft Visual C++ programmers.

Measurement Studio is designed for building measurement and automation

applications with the programming environment of your choice:

• LabWindows/CVI is an interactive ANSIC programming environment

designed for building virtual instrument applications.

LabWindows/CVI delivers a drag-and-drop editor for building user

interfaces, a complete ANSI C environment for building your test

program logic, and a collection of automated code generation tools, as

well as utilities for building automated test systems, monitoring

applications, or laboratory experiments.

• ComponentWorks for Visual Basic is a collection of ActiveX controls

designed for building virtual instrumentation systems. Based on

ActiveX technology, ComponentWorks controls are configured

through simple property pages. You can use the ComponentWorks

GPIB, Serial, and VISA I/O controls and property pages to set up

communication with your instruments.

• ComponentWorks++ for Visual C++ takes advantage of integrated

C++ libraries and ActiveX to help you build measurement and

automation applications. With the ComponentWorks++ instrument

classes, you can use the IEEE 488.2 library and VISA, an

industry-standard I/O library, to communicate with GPIB, VXI, or

Serial devices using the same set of components.

After you install your serial hardware and the NI-Serial software, you can

use standard serial I/O functions in LabVIEW and Measurement Studio

with your serial interface. If you already have one or more of these

applications and want to use them with your serial interface, refer to your

product documentation for information about serial I/O functions. For

ordering information, contact National Instruments.

© National Instruments Corporation 1-9 Serial Hardware and Software for Windows

Page 24

PCI Serial Hardware Installation,

Verification, and Configuration

This chapter describes how to install the NI-Serial software and PCI serial

hardware and how to verify the installation. It also describes how to

configure the communication port settings.

To begin your installation, see the section of this chapter containing

instructions for your operating system (Windows 2000, Windows Me/9x,or

Windows NT.)

Windows 2000

Install the Software

Before you install your serial hardware, complete the following steps to

install the NI-Serial software for Windows 2000:

1. Select Start»Settings»Control Panel.

2. Double-click on the Add/Remove Programs icon. The Add/Remove

Programs dialog box appears.

3. ClickontheAdd New Programs button and then the CD or Floppy

button.

4. When prompted, insert the NI-Serial Software for Windows

2000/NT/Me/9x CD and click on the Next button.

5. When prompted, click on the Finish button to install the program files

from the CD.

6. The setup wizard begins. The setup wizard guides you through the

necessary steps to install the NI-Serial software. To exit the setup

wizard at any time, click on the Cancel button.

7. If you need to install your hardware, or if this is your first time to install

the NI-Serial software for Windows 2000, skip to the next section,

Install the Hardware. Otherwise, continue to step 8.

8. If your hardware is already installed, restart Windows 2000.

2

© National Instruments Corporation 2-1 Serial Hardware and Software for Windows

Page 25

Chapter 2 PCI Serial Hardware Installation, Verification, and Configuration

9. Windows 2000 should automatically detect your hardware and display

the Found New Hardware Wizard. Complete the wizard by clicking

Next in each window and then Finish. When you complete the wizard,

continue to the Verify the Installation section.

If the Found New Hardware Wizard does not appear, refer to the

Forcing Windows to Detect Your Hardware section in Appendix D,

Troubleshooting and Common Questions.

Install the Hardware

Note

If you are installing a PCI-485, you might need to adjust the value of the bias

resistors, depending on your application. Bias resistors are not available on the eight-port

PCI-485. For more information, refer to Appendix B, Serial Port Information.

Caution

Before you remove your board from the package, touch the antistatic plastic

package to a metal part of your system chassis to discharge electrostatic energy, which can

damage several components on your serial board.

To install your PCI serial board, complete the following steps:

1. Turn off your computer. Keep the computer plugged in so that it

remains grounded while you install the PCI serial board.

2. Remove the top or side cover of the computer.

3. Find an unused PCI expansion slot in your computer.

4. Remove the corresponding expansion slot cover on the back panel of

the computer.

5. Touch a metal part on your chassis to discharge any static electricity.

6. Insert the PCI serial board into the slot with the serial connectors

toward the opening on the back panel. Make sure that you insert the

board all the way into the slot. The board might seem to click firmly

into place, even though it is only part of the way in. Figure 2-1 shows

how to install the PCI serial board into an expansion slot.

Serial Hardware and Software for Windows 2-2 ni.com

Page 26

Chapter 2 PCI Serial Hardware Installation, Verification, and Configuration

2

1

1PC 2 PCI Serial Board 3PCISlot

Figure 2-1. PCI Serial Board Installation

3

7. Screw the PCI serial board mounting bracket to the back panel

mounting rail of the computer.

8. Replace the cover.

9. Turn on your computer and start Windows 2000.

10. Windows 2000 should automatically detect your hardware and display

the Found New Hardware Wizard. Complete the wizard by clicking

Next in each window and then Finish.

If the Found New Hardware Wizard does not appear, refer to the

Forcing Windows to Detect Your Hardware section in Appendix D,

Troubleshooting and Common Questions.

The serial hardware installation is complete. Continue to the next section,

Verify the Installation.

© National Instruments Corporation 2-3 Serial Hardware and Software for Windows

Page 27

Chapter 2 PCI Serial Hardware Installation, Verification, and Configuration

Verify the Installation

To verify the hardware and software installation, complete the following

steps:

1. Select Start»Settings»Control Panel and double-click on the

System icon.

2. Click on the Hardware tabandclickontheDevice Manager button.

3. Double-click on the Ports (COM & LPT) icon to display all of

the ports.

4. Double-click on the Multi-function adapters icon.

The PCI serial boards are configured as devices belonging to the

multi-function adapters class. The multi-function parent device is

listed under the Multi-function adapters icon, and each child device

is listed as a port under the Ports (COM & LPT) icon.

Figure 2-2 shows the Device Manager tab for serial hardware that is

installed properly.

Figure 2-2. Device Manager for PCI Serial Board Ports

Serial Hardware and Software for Windows 2-4 ni.com

Page 28

Chapter 2 PCI Serial Hardware Installation, Verification, and Configuration

5. Verify the hardware resources, as follows:

a. In the Device Manager under Multi-function adapters,

double-click on a serial board.

b. ClickontheResources tab. If the resources were assigned

properly, the Resources tab shows which resources are assigned

to your serial ports.

c. Repeat steps 5a and 5b until you have verified the resources for

each board.

6. (Optional) To determine which physical port is associated with COMx,

note the Port 1, Port 2, etc. entries next to the COM numbers. For all

serial hardware, PORT1 refers to the top port, PORT2 refers to the next

port down, and so on.

7. Run the diagnostic utility, as follows: select Start»Programs»

National Instruments»NI-Serial»Diagnostics.

The diagnostic utility verifies that your serial driver is installed

properly, that the configuration of your hardware does not conflict with

anything else in your system, and that the serial driver can

communicate with your hardware correctly.

If the test is successful, your serial hardware and software are installed

properly. If the test fails, refer to Appendix D, Troubleshooting and

Common Questions, to troubleshoot the problem.

8. After you verify the hardware and software installation, connect the

cables. See Appendix A, Connector Descriptions, for information

about cable connections.

Configure Communication Port Settings

The serial configuration utility is fully integrated into the Windows 2000

Device Manager. You can use it to view or change the configuration of

your serial ports.

To configure a serial port, complete the following steps:

1. Select Start»Settings»Control Panel and double-click on the

System icon.

2. ClickontheHardware tabandclickontheDevice Manager button.

3. Double-click on the Ports (COM & LPT) icon.

© National Instruments Corporation 2-5 Serial Hardware and Software for Windows

Page 29

Chapter 2 PCI Serial Hardware Installation, Verification, and Configuration

4. Double-click on the port you want to configure and refer to the

following instructions:

• To view the hardware resources assigned to the serial port, click

on the Resources tab.

• To view or change the port settings, click on the Port Settings tab.

For more information about the settings, refer to the next section,

Port Settings Tab.

• To change the RS-485 transceiver mode, or to enable or disable

the FIFOs on the serial hardware, in the Port Settings tab, click

on the Advanced button. For more information about the settings,

refer to the next section, Port Settings Tab.

Note

Transceiver modes apply to RS-485 interfaces only. For more information about

transceiver modes, refer to Chapter 6, Using Your Serial Hardware.

5. To save your changes, click on the OK button. To exit without saving

the changes, click on the Cancel button.

Port Settings Tab

In the Port Settings tab, you can change any of the settings by clicking on

the arrow button to the right of a field. When you click on the arrow button,

a list of valid values for that field appears and you can select the desired

setting from the list. Figure 2-3 shows the Port Settings tab.

Serial Hardware and Software for Windows 2-6 ni.com

Page 30

Chapter 2 PCI Serial Hardware Installation, Verification, and Configuration

Figure 2-3.

© National Instruments Corporation 2-7 Serial Hardware and Software for Windows

Port Settings Tab

Page 31

Chapter 2 PCI Serial Hardware Installation, Verification, and Configuration

Advanced Settings

To view or change the advanced settings, click on the Advanced button.

Figure 2-4 shows the Advanced Settings dialog box.

Figure 2-4. Advanced Settings Dialog Box

The following sections describe the advanced settings options.

Transceiver Mode

This field shows the transceiver mode in use, and applies only to PCI-485

boards. For more information about transceiver modes, refer to Chapter 6,

Using Your Serial Hardware.

Serial Hardware and Software for Windows 2-8 ni.com

Page 32

Chapter 2 PCI Serial Hardware Installation, Verification, and Configuration

Use FIFO Buffers

FIFO buffers are present on the 16550-compatible UARTs—one for the

transmitter and one for the receiver. The Receive Buffer control sets the

number of characters received in the FIFO before the PC is interrupted to

read the data. The Transmit Buffer control sets the maximum number of

bytes written to the FIFO in a block when the PC is interrupted to write the

data. When you configure FIFO settings, consider the following points:

• You can select larger FIFO buffer sizes to reduce the number of

interrupts your PC receives and therefore minimize system overhead.

• If transfer rates are high, you can lower the Receive Buffer value to

prevent overrun errors due to interrupt latency.

• If your data transfer sizes are small and your Receive Buffer value is

above your data sizes, your system is less efficient. Therefore, set the

Receive Buffer value below your data sizes.

Restore Defaults

To reset the fields to their default values at any time, click on the Restore

Defaults button.

Windows Me/9x

Install the Software

Before you install your serial hardware, complete the following steps to

install the NI-Serial software for Windows Me/9x:

1. Select Start»Settings»Control Panel.

2. Double-click on the Add/Remove Programs icon. The Add/Remove

Programs dialog box appears.

3. ClickontheInstall button.

4. When prompted, insert the NI-Serial Software for Windows

2000/NT/Me/9x CD,andclickontheNext button.

5. When prompted, click on the Finish button to install the program files

from floppy disks or CD-ROM.

6. The setup wizard begins. The setup wizard guides you through the

necessary steps to install the NI-Serial software. To exit the setup

wizard at any time, click on the Cancel button.

7. If you need to install your hardware, or if this is your first time to install

the NI-Serial software for Windows Me/9x, skip to the next section,

Install the Hardware. Otherwise, continue to step 8.

© National Instruments Corporation 2-9 Serial Hardware and Software for Windows

Page 33

Chapter 2 PCI Serial Hardware Installation, Verification, and Configuration

8. If your hardware is already installed, restart Windows Me/9x.

9. Windows Me/9x should automatically detect your hardware and

display one or more New Hardware Found dialog boxes. Your

operating system (Windows Me/9x)mayshowtheWindows Default

Driver option. If so, make sure the Windows Default Driver is

selected and click on the OK button. If the Windows Default Driver

option is not shown, the installation continues automatically. When

you finish, continue to the Verify the Installation section.

If no New Hardware Found dialog box appears, refer to the Forcing

Windows to Detect Your Hardware sectioninAppendixD,

Troubleshooting and Common Questions.

Install the Hardware

Note

If you are installing a PCI-485, you might need to adjust the value of the bias

resistors, depending on your application. Bias resistors are not available on the eight-port

PCI-485. For more information, refer to Appendix B, Serial Port Information.

Caution

Before you remove your board from the package, touch the antistatic plastic

package to a metal part of your system chassis to discharge electrostatic energy, which can

damage several components on your serial board.

To install your PCI serial board, complete the following steps:

1. Turn off your computer. Keep the computer plugged in so that it

remains grounded while you install the PCI serial board.

2. Remove the top or side cover of the computer.

3. Find an unused PCI expansion slot in your computer.

4. Remove the corresponding expansion slot cover on the back panel of

the computer.

5. Touch a metal part on your chassis to discharge any static electricity.

6. Insert the PCI serial board into the slot with the serial connectors

toward the opening on the back panel. Make sure that you insert the

board all the way into the slot. The board might seem to click firmly

into place, even though it is only part of the way in. Figure 2-5 shows

how to install the PCI serial board into an expansion slot.

Serial Hardware and Software for Windows 2-10 ni.com

Page 34

Chapter 2 PCI Serial Hardware Installation, Verification, and Configuration

2

1

1PC 2 PCI Serial Board 3PCISlot

Figure 2-5. PCI Serial Board Installation

3

7. Screw the PCI serial board mounting bracket to the back panel

mounting rail of the computer.

8. Replace the cover.

9. Turn on your computer and start Windows Me/9x.

10. Windows Me/9x should automatically detect your hardware and

display one or more New Hardware Found dialog boxes. Your

operating system (Windows Me/9x)mayshowtheWindows Default

Driver option. If so, make sure the Windows Default Driver is

selected and click on the OK button. If the Windows Default Driver

option is not shown, the installation continues automatically.

If no New Hardware Found dialog box appears, refer to the Forcing

Windows to Detect Your Hardware sectioninAppendixD,

Troubleshooting and Common Questions.

The serial hardware installation is complete. Continue to the next section,

Verify the Installation.

© National Instruments Corporation 2-11 Serial Hardware and Software for Windows

Page 35

Chapter 2 PCI Serial Hardware Installation, Verification, and Configuration

Verify the Installation

Before you verify the installation, keep in mind that the serial ports

built into your computer are typically named from COM1 to COM4.

Windows Me/9x typically issues port names to the ports on NI serial

hardware starting with COM5, COM6, and so on. If not enough resources

are available to assign to all the NI serial ports, the port with the higher

COMx name is not configured.

To verify the hardware and software installation, complete the following

steps:

1. Select Start»Settings»Control Panel and double-click on the

System icon.

2. Click on the Device Manager tabandclickontheView devices by

type button.

3. Double-click on the Ports (COM & LPT) icon to display all of

the ports.

4. Double-click on the Multi-function adapters icon.

The PCI serial boards are configured as devices belonging to the

multi-function adapters class. The multi-function parent device is

listed under the Multi-function adapters icon, and each child device

is listed as a port under the Ports (COM & LPT) icon.

Serial Hardware and Software for Windows 2-12 ni.com

Page 36

Chapter 2 PCI Serial Hardware Installation, Verification, and Configuration

Figure 2-6 shows the Device Manager tab for serial hardware that is

installed properly.

Figure 2-6.

Device Manager Tab for PCI Serial Board Ports

5. Verify the hardware resources, as follows:

a. In the Device Manager tab, under Multi-function adapters,

double-click on a serial board.

b. ClickontheResources tab. If the resources were assigned

properly, the Resources tab shows which resources are assigned

to your serial ports.

c. Repeat steps 5a and 5b until you have verified the resources for

each board.

© National Instruments Corporation 2-13 Serial Hardware and Software for Windows

Page 37

Chapter 2 PCI Serial Hardware Installation, Verification, and Configuration

6. (Optional) To determine which physical port is associated with COMx,

complete the following steps:

a. In the Device Manager tab, under Ports (COM & LPT),

double-click on the serial port (COMx).

b. Click on the Port Settings tab to display the serial number of the

serial hardware and the physical port number starting at 1. For all

serial hardware, PORT1 refers to the top port, PORT2 refers to the

next port down, and so on.

7. Run the diagnostic utility, as follows: select Start»Programs»

National Instruments Serial»Diagnostics.

The diagnostic utility verifies that your serial driver is installed

properly, that the configuration of your hardware does not conflict

with anything else in your system, and that the serial driver can

communicate with your hardware correctly.

If the test is successful, your serial hardware and software are installed

properly. If the test fails, refer to Appendix D, Troubleshooting and

Common Questions, to troubleshoot the problem.

8. After you verify the hardware and software installation, connect the

cables. See Appendix A, Connector Descriptions, for information

about cable connections.

Configure Communication Port Settings

The serial configuration utility is fully integrated into the Windows Me/9x

Device Manager. You can use it to view or change the configuration of

your serial ports.

To configure a serial port, complete the following steps:

1. Select Start»Settings»Control Panel and double-click on the

System icon.

2. Click on the Device Manager tabandclickontheView devices by

type button.

3. Double-click on the Ports (COM & LPT) icon.

Note

If you want your serial ports to use the names COM1, COM2, COM3, or COM4,

refer to the Common Questions section of Appendix D, Troubleshooting and

Common Questions.

Serial Hardware and Software for Windows 2-14 ni.com

Page 38

Chapter 2 PCI Serial Hardware Installation, Verification, and Configuration

4. Double-click on the port you want to configure and refer to the

following instructions:

• To view the hardware resources assigned to the serial port, click

on the Resources tab.

• To view or change the port settings, click on the Port Settings tab.

For more information about the settings, refer to the next section,

Port Settings Tab.

• To change the RS-485 transceiver mode, or to enable or disable

the FIFOs on the serial hardware, in the Port Settings tab, click

on the Advanced button. For more information about the settings,

refer to the next section, Port Settings Tab.

Note

Transceiver modes apply to RS-485 interfaces only. For more information about

transceiver modes, refer to Chapter 6, Using Your Serial Hardware.

5. To save your changes, click on the OK button. To exit without saving

the changes, click on the Cancel button.

© National Instruments Corporation 2-15 Serial Hardware and Software for Windows

Page 39

Chapter 2 PCI Serial Hardware Installation, Verification, and Configuration

Port Settings Tab

In the Port Settings tab, you can change any of the settings by clicking on

the arrow button to the right of a field. When you click on the arrow button,

a list of valid values for that field appears and you can select the desired

setting from the list. Figure 2-7 shows the Port Settings tab.

Figure 2-7. Port Settings Tab

Serial Hardware and Software for Windows 2-16 ni.com

Page 40

Chapter 2 PCI Serial Hardware Installation, Verification, and Configuration

Advanced Port Settings

To view or change the advanced port settings, click on the Advanced

button. Figure 2-8 shows the Advanced Port Settings dialog box.

Figure 2-8.

The following sections describe the advanced port setting options.

Advanced Port Settings Dialog Box

Transceiver Mode

This field shows the transceiver mode in use, and applies only to PCI-485

boards. For more information about transceiver modes, refer to Chapter 6,

Using Your Serial Hardware.

Use FIFO Buffers

FIFO buffers are present on the 16550-compatible UARTs—one for the

transmitter and one for the receiver. The Receive Buffer control sets the

number of characters received in the FIFO before the PC is interrupted to

read the data. The Transmit Buffer control sets the maximum number of

bytes written to the FIFO in a block when the PC is interrupted to write the

data. When you configure FIFO settings, consider the following points:

• You can select larger FIFO buffer sizes to reduce the number of

interrupts your PC receives and therefore minimize system overhead.

• If transfer rates are high, you can lower the Receive Buffer value to

prevent overrun errors due to interrupt latency.

• If your data transfer sizes are small and your Receive Buffer value is

above your data sizes, your system is less efficient. Therefore, set the

Receive Buffer value below your data sizes.

© National Instruments Corporation 2-17 Serial Hardware and Software for Windows

Page 41

Chapter 2 PCI Serial Hardware Installation, Verification, and Configuration

Restore Defaults