Page 1

Computer-Based

Instruments

NI 5401 User Manual

™

PXI /PCI Arbitrary Function Generator

NI 5401 User Manual

March 1999 Edition

Part Number 322419A-01

Page 2

Worldwide Technical Support and Product Information

www.natinst.com

National Instruments Corporate Headquarters

11500 North Mopac Expressway Austin, Texas 78759-3504 USA Tel: 512 794 0100

Worldwide Offices

Australia 03 9879 5166, Austria 0662 45 79 90 0, Belgium 02 757 00 20, Brazil 011 284 5011,

Canada (Ontario) 905 785 0085, Canada (Québec) 514 694 8521, China 0755 3904939, Denmark 45 76 26 00,

Finland 09 725 725 11, France 01 48 14 24 24, Germany 089 741 31 30, Hong Kong 2645 3186,

India 91805275406, Israel 03 6120092, Italy 02 413091, Japan 03 5472 2970, Korea 02 596 7456,

Mexico (D.F.) 5 280 7625, Mexico (Monterrey) 8 357 7695, Netherlands 0348 433466, Norway 32 27 73 00,

Singapore 2265886, Spain (Madrid) 91 640 0085, Spain (Barcelona) 93 582 0251, Sweden 08 587 895 00,

Switzerland 056 200 51 51, Taiwan 02 2377 1200, United Kingdom 01635 523545

For further support information, see the Technical Support Resources appendix. To comment on the

documentation, send e-mail to techpubs@natinst.com.

© Copyright 1999 National Instruments Corporation. All rights reserved.

Page 3

Important Information

Warranty

The NI 5401 is warranted against defects in materials and workmanship for a period of one year from the date of shipment,

as evidenced by receipts or other documentation. National Instruments will, at its opt ion, repair or replace equipment that

proves to be defective during the warranty period . T his w arran ty i ncludes part s and l abo r.

The media on which you receive National Instruments software are warranted not to fail to execute programming

instructions, due to defects in materials and work man ship, for a peri od of 90 d ays from da te o f sh ipm ent, as evi denced

by receipts or other documentation. National Instruments will, at its option, repair or replace software media that do not

execute programming instructions if National Instruments receives noti ce of su ch defect s d uring th e warranty perio d.

National Instruments does not warrant that the op eration of t he soft ware shall b e uni nterrup ted or erro r free.

A Return Material Authorization (RMA) number must b e ob tain ed fro m th e facto ry an d clearl y mark ed on t he outsi de

of the package before any equipment wil l be accepted for warranty work. National Instruments will pay the shippi ng costs

of returning to the owner parts which are covered by warran ty.

National Instruments believes that the information in this document is accurate. The document has been carefully

reviewed for technical accuracy. In the event that technical or typographical errors exist, National Instruments reserves

the right to make changes to subsequent editions of this document without prior notice to holders of this edition. The

reader should consult National Instruments if errors are suspected. In no event shall National Instruments be liable for

any damages arising out of or related to th is d ocum ent o r th e in form ation con tained in i t.

XCEPT AS SPECIFIED HEREIN

E

ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE

BY FAULT OR NEGLIGENCE ON THE PART OF NATIONAL INSTRUMENTS SHALL BE LIMITED TO THE AMOUNT THERETOFORE PAID BY THE

CUSTOMER

OR INCIDENTAL OR CONSEQUENTIAL DAMAGES, EVEN IF ADVISED OF THE POSSIBILITY THEREOF

National Instruments will apply regardless of the form of action, wh ether in con tract or tort , incl udin g n egli gen ce.

Any action against National Instruments must be brought within one year after the cause of action accrues. National

Instruments shall not be liable for any delay in performance due to causes beyond its reasonable control. The warranty

provided herein does not cover damages, defects, malfuncti ons, or s ervice failur es caused by own er’s fai lure to fol low

the National Instruments installation, operation, or maintenance instructions; owner’s modification of the product;

owner’s abuse, misuse, or negligent acts; and power failure or surges, fire, flood, accident, actions of third parties,

or other events outside reasonable control.

ATIONAL INSTRUMENTS WILL NOT BE LIABLE FOR DAMAGES RESULTING FROM LOSS OF DATA, PROFITS, USE OF PRODUCTS

. N

ATIONAL INSTRUMENTS MAKES NO WARRANTIES, EXPRESS OR IMPLIED, AND SPECIFICALLY DISCLAIMS

, N

Copyright

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or mechanical,

including photocopying, recording, storing in an information retrieval system, or translating, in whole or in part, without

the prior written consent of National Instruments Corporation.

USTOMER’S RIGHT TO RECOVER DAMAGES CAUSED

. C

. This limitation of the liability of

,

Trademarks

ComponentWorks™, CVI™, LabVIEW™, natinst.com™, PXI™, RTSI™, and VirtualBench™ are trademarks of

National Instruments Corporation.

Product and company names mentioned herein are trademarks or trade names of their respective companies.

WARNING REGARDING MEDICAL AND CLINICAL USE OF NATIONAL INSTRUMENTS PRODUCTS

National Instruments products are not designed with com ponent s and tes ting for a level o f reli ability suit abl e for use in

or in connection with surgical implants o r as cri tical co m ponent s i n any li fe su pp ort sy stem s wh ose fail ure t o pe rform

can reasonably be expected to cause s ignifi cant in ju ry to a hu m an. A ppli cations of Nation al In st rument s prod ucts

involving medical or clinical treatment can create a pot enti al for d eath or bod ily i njury caused b y p rodu ct fail ure, o r by

errors on the part of the user or application designer. Because each end-user system is customized and differs from

National Instruments testing platforms and because a user or application designer may use National Instruments products

in combination with other products in a m ann er no t ev alu ated or co ntem p lated b y N ati onal Ins trum ents , the user or

application designer is ultimately responsible for verifying and validating the suitability of National Instruments products

whenever National Instruments products are incorporated in a system or application, including, without limitation,

the appropriate design , pr ocess and safet y level of such syst em or ap plicat io n.

Page 4

Conventions

The following conventions are used in this manual:

» The » symbol leads you through nested menu items and dialog box options

to a final action. The sequence File»Page Setup»Options directs you to

pull down the File menu, select the Page Setup item, and select Options

from the last dialog box.

♦ The ♦ symbol indicates that the following text applies only to a specific

product, a specific operating system, or a specific software version.

This icon denotes a note, which alerts you to important information.

This icon denotes a caution, which advises you of precautions to take to

avoid injury, data loss, or a system crash.

This icon denotes a warning, which advises you of precautions to take to

avoid being electrically shocked.

bold Bold text denotes items that you must select or click on in the software,

such as menu items and dialog box options. Bold text also denotes

parameter names.

italic Italic text denotes variables, emphasis, a cross reference, or an introduction

to a key concept.

monospace Text in this font denotes text or characters that you should enter from the

keyboard. This font is also used for the proper names of functions,

variables, and filenames and extensions.

monospace italic

Italic text in this font denotes text that is a placeholder for a word or value

that you must supply.

Page 5

Contents

Chapter 1

Generating Functions

with the NI 5401

About Your NI 5401......................................................................................................1-1

Connecting Signals ........................................................................................................1-2

ARB Connector...............................................................................................1-3

SYNC Connector.............................................................................................1-3

PLL Ref Connector..........................................................................................1-4

Pattern Out Connector (PCI Only)..................................................................1-5

Connector Pin Assignments....................................................... .......1-5

Signal Descriptions...........................................................................1-6

SHC50-68 50-Pin Cable Connector ................................................................1-6

Software Options for Your NI 5401 ..............................................................................1-8

Software Included with Your NI 5401 ............................................................1-8

VirtualBench.....................................................................................1-8

NI-FGEN Instrument Driver.............................................................1-9

Additional National Instruments Development Tools.....................................1-9

LabVIEW..........................................................................................1-9

LabWindows/CVI.............................................................................1-10

ComponentWorks .............................................................................1-10

Using the Soft Front Panels to Generate Waveforms....................................................1-11

Generating Standard Functions .......................................................................1-11

Generating Multiple Frequencies in a Sequence.............................................1-13

Waveform Editor.............................................................................................1-15

Power-Up and Reset Conditions....................................................................................1-16

Chapter 2

Function Generator Operation

Generating Waveforms..................................................................................................2-2

Direct Digital Synthesis (DDS) .....................................................................................2-3

Frequency Hopping and Sweeping..................................................................2-4

Triggering ......................................................................................................................2-4

Trigger Sources ...............................................................................................2-4

Modes of Operation.........................................................................................2-5

Single Trigger Mode.........................................................................2-5

Continuous Trigger Mode.................................................................2-6

Stepped Trigger Mode ........................................ ..............................2-7

Analog Output................................................................................................................2-7

©

National Instruments Corporation v NI 5401 User Manual

Page 6

Contents

SYNC Output and Duty Cycle........................................................................2-9

Output Attenuation.................................................. ........................................2-9

Output Impedance.............................................................. .............................2-10

Output Enable ..................................... .............................................. ..............2-10

Pre-Attenuation Offset.................................................................................... 2-11

Phase-Locked Loops and Board Synchronization.........................................................2-11

Analog Filter Correction................................................................................................2-13

RTSI/PXI Trigger Lines................................................................................................2-14

Calibration.....................................................................................................................2-15

Appendix A

Specifications

Appendix B

Optional Accessories

Appendix C

Frequency Resolution and Lookup Memory

Appendix D

Technical Support Resources

Glossary

Index

Figures

Figure 1-1. NI 5401 I/O Connectors........................................................................ 1-2

Figure 1-2. Output Levels and Load Termination Using a

50 Ω Output Impedance........................................................................1-3

Figure 1-3. SYNC Output and Duty Cycle..............................................................1-4

Figure 1-4. NI 5401 50-Pin Digital Connector Pin Assignments............................ 1-5

Figure 1-5. SHC50-68 68-Pin Connector Pin Assignments....................................1-7

Figure 1-6. VirtualBench-FG Soft Front Panel for Function Generation................ 1-11

Figure 1-7. VirtualBench-FG General Settings Dialog Box for the NI 5401.......... 1-12

Figure 1-8. VirtualBench-FG Signals Settings Dialog Box for the NI 5401........... 1-12

Figure 1-9. VirtualBench-FG Load Waveform Dialog Box....................................1-13

Figure 1-10. VirtualBench-FG Frequency List Editor Dialog Box...........................1-14

Figure 1-11. Waveform Editor Soft Front Panel .......................................................1-15

NI 5401 User Manual vi www.natinst.com

Page 7

Table

Contents

Figure 2-1. NI 5401 Block Diagram ........................................................................2-1

Figure 2-2. Waveform Data Path Block Diagram....................................................2-2

Figure 2-3. DDS Building Blocks............................................................................2-3

Figure 2-4. Waveform Generation Trigger Sources ................................................2-5

Figure 2-5. Single Trigger Mode .............................................................................2-6

Figure 2-6. Continuous Trigger Mode.....................................................................2-6

Figure 2-7. Stepped Trigger Mode............................... ... .........................................2-7

Figure 2-8. Analog Output and SYNC Out Block Diagram....................................2-8

Figure 2-9. Waveform and Trigger Timings............................................................2-8

Figure 2-10. Output Attenuation Chain .....................................................................2-9

Figure 2-11. PLL Architecture for the NI 5401 for PCI ............................................2-12

Figure 2-12. PLL Architecture for the NI 5401 for PXI............................................2-12

Figure 2-13. Analog Filter Correction .......................................................................2-13

Figure 2-14. RTSI Trigger Lines and Routing for the NI 5401 for PCI....................2-14

Figure 2-15. PXI Trigger Lines, 10 MHz Backplane Oscillator, and

Routing for the NI 5401 for PXI ...........................................................2-14

Table 1-1. Digital Connector Signal Descriptions..................................................1-6

©

National Instruments Corporation vii NI 5401 User Manual

Page 8

Generating Functions

with the NI 5401

The NI 5401 User Manual describes the features, functions, and operation

of the NI 5401 arbitrary function generator. This device performs

comparably to standalone instruments while providing the flexibility of

computer-based operation.

About Your NI 5401

Thank you for buying a National Instruments NI 5401 arbitrary function

generator. The NI 5401 family consists of two different devices:

• NI 5401 for PCI

• NI 5401 for PXI

Your NI 5401 device has the following features:

• One 12-bit resolution output channel

• Up to 16 MHz sine and transistor-transistor logic (TTL) waveform

output

• Software-selectable output impedances of 50 Ω and 75 Ω

• Output attenuation levels from 0 to 73 dB

• Phase-locked loop (PLL) synchronization to external clocks

• Sampling rate of 40 MS/s

• Digital and analog filter

• 32-bit direct digital synthesis (DDS) for standard function generation

• External trigger input

• Real-Time System Integration (RTSI) and PXI triggers

1

All NI 5401 devices follow industry-standard Plug and Play specifications

on both buses and offer seamless integration with compliant systems.

Detailed specifications for the NI 5401 are in Appendix A, Specifications.

©

National Instruments Corporation 1-1 NI 5401 User Manual

Page 9

Chapter 1 Generating Functions with the NI 5401

Connecting Signals

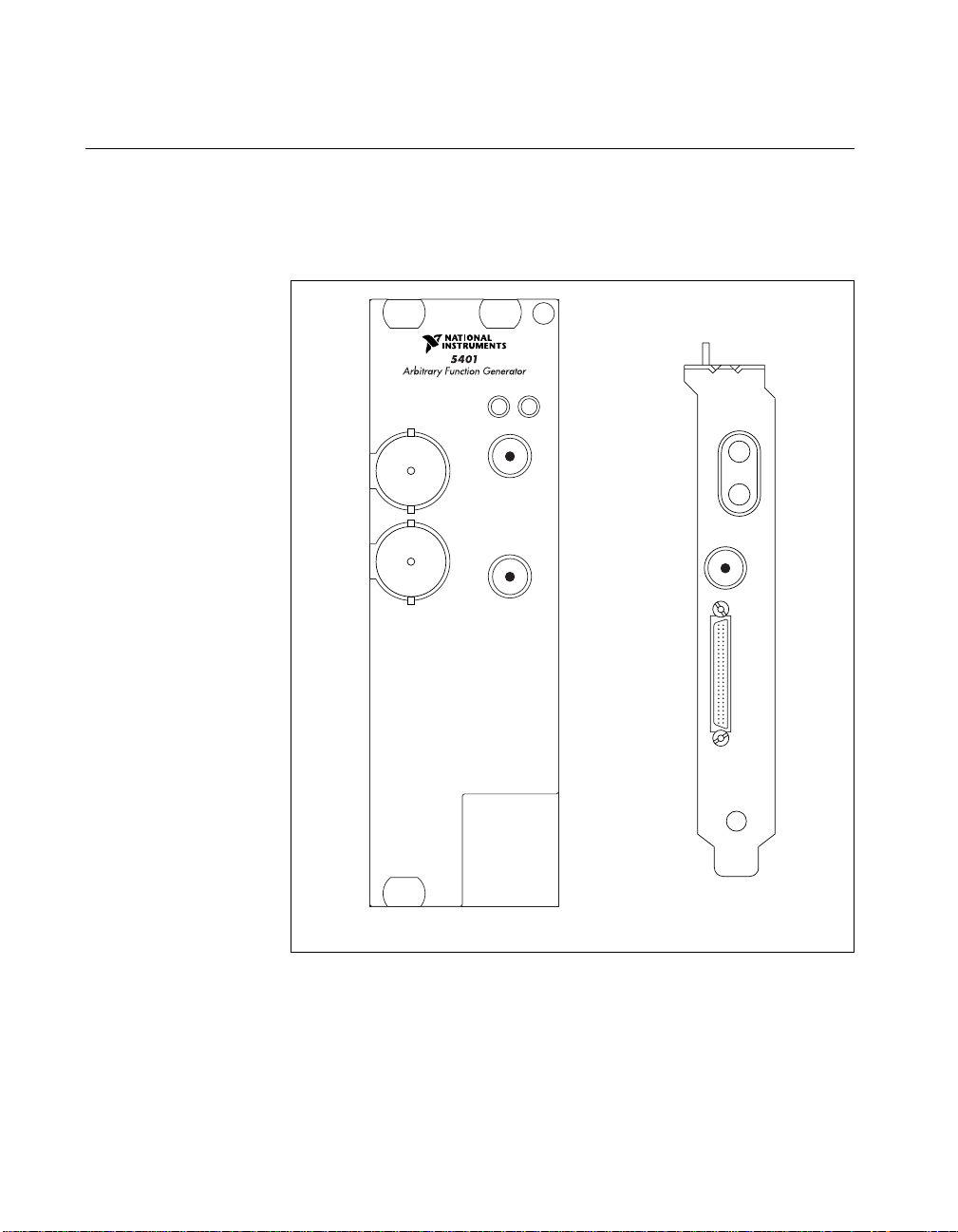

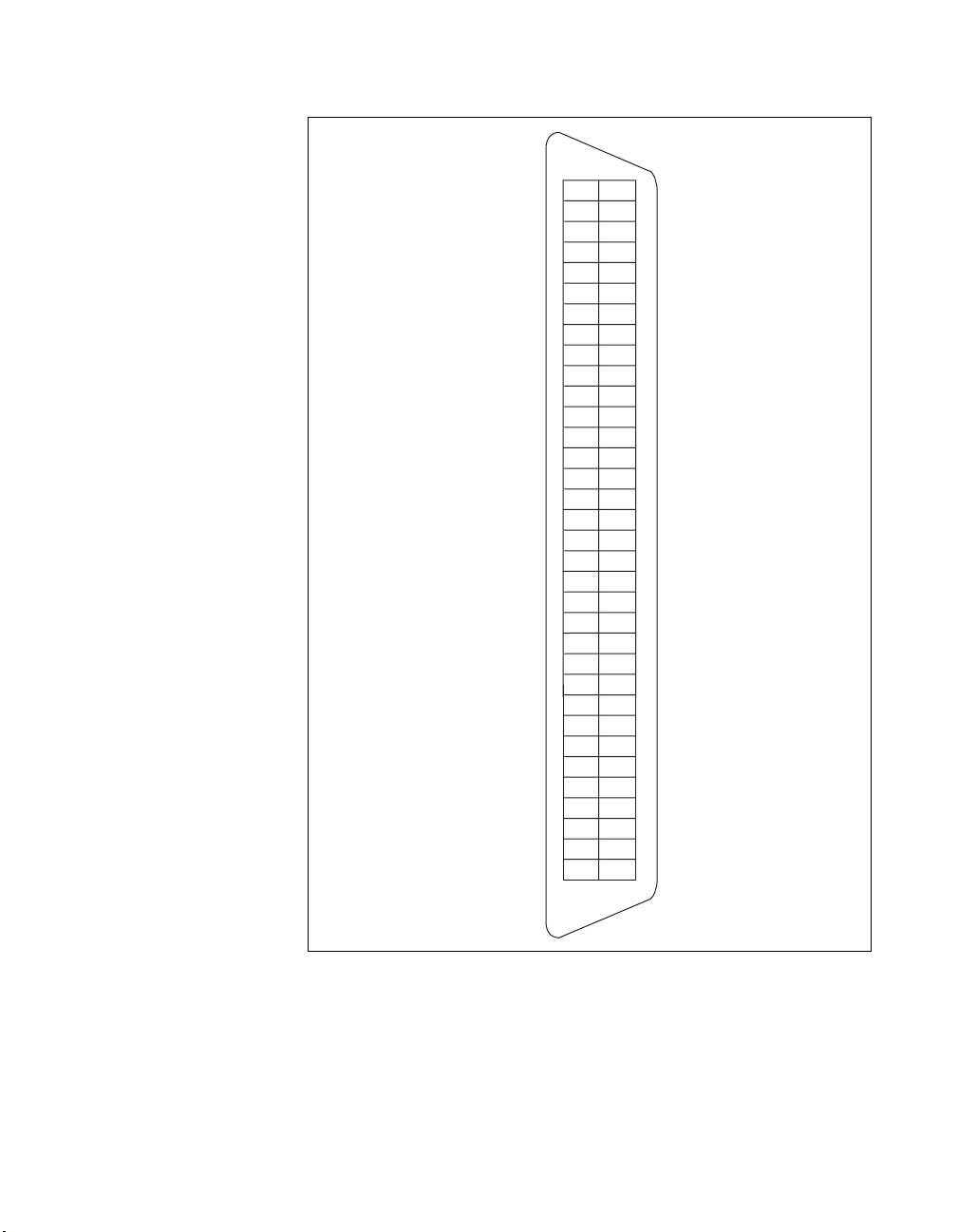

Figure 1-1 shows the front panels for the NI 5401 for the PXI and PCI

buses. The front panel contains three types of connectors: BNC, SMB, and

50-pin very high-density SCSI (VHDSCSI). The main waveform is

generated through the connector labeled ARB.

LOCK

ACCESS

ARB OUT

SYNC OUT

EXT TRIG

PLL REF

ARB

SYNC

PLL IN

PXI PCI

PATTERN OUT

Figure 1-1.

NI 5401 I/O Connectors

NI 5401 User Manual 1-2 www.natinst.com

Page 10

ARB Connector

Chapter 1 Generating Functions with the NI 5401

The ARB connector provides the waveform output. The maximum output

levels on this connector depend on the type of load termination. If the

output of your NI 5401 terminates into a 50 Ω load, the output levels are

±5 V , as sho wn in Figure 1-2. If the output of your NI 5401 terminates into

a high-impedance load (HiZ), the output levels are ±10 V. If the output

terminates into any other load, the levels are as follows:

R

L

V

out

------------------ -

RLRO+

10× V±=

where V

By default, R

Figure 1-2.

Note

Software sets the voltage output levels based on a 50 Ω load termination.

is the maximum output voltage level

out

R

is the load impedance in ohms, and

L

R

is the output impedance on the NI 5401.

O

= 50 Ω, but you can use your software to set it to 75 Ω.

O

NI 5401

ARB

50 Ω Load

RO =

Ω

50

R

50

Load

=

L

Ω

±5 V

NI 5401

ARB

RO =

50

High-Impedance Load

Output Levels and Load Termination Using a 50

For more information on waveform generation and analog output

operation, refer to Chapter 2, Function Generator Operation. For

specifications on the waveform output signal, see Appendix A,

Specifications.

Load

R

=

Ω

L

HiZ

Output Impedance

Ω

±10 V

SYNC Connector

The SYNC connector provides a TTL version of the sine waveform being

generated at the output. You can think of the SYNC output as a very

high-frequency resolution, software-programmable clock source for many

applications. You can also vary the duty cycle of the SYNC output on the

fly by software control, as shown in Figure 1-3. t

©

National Instruments Corporation 1-3 NI 5401 User Manual

is the time period of the

p

Page 11

Chapter 1 Generating Functions with the NI 5401

sine wave being generated and tw is the pulse width of the SYNC output.

The duty cycle is (t

ARB Output

SYNC Output

(50% Duty Cycle)

SYNC Output

(33% Duty Cycle)

For your NI 5401 for PCI, you can route the SYNC output to the RTSI lines

over the RTSI bus. For your NI 5401 for PXI, you can route the SYNC

output to the TTL trigger lines over the TTL trigger bus. The SYNC output

is derived from a comparator connected to the analog waveform and

provides a meaningful waveform only when you are generating a sine w ave

on the ARB output. For more information on SYNC output, see Chapter 2,

Function Generator Operation.

) × 100%.

w/tp

t

p

t

w

Figure 1-3. SYNC Output and Duty Cycle

PLL Ref Connector

The PLL Ref connector is a phase-locked loop (PLL) input connector that

can accept a reference clock from an external source and frequency lock the

NI 5401 internal clock to this external clock. The reference clock should

not deviate more than ±100 ppm from its nominal frequency . The minimum

amplitude levels of 1 V

reference clock frequencies of 1 MHz and 5–20 MHz in 1 MHz steps.

Note You can frequency lock the NI 5401 for PCI to other National Instruments devices

over the RT SI bus using the 20 MHz RTSI clock signal. You can frequency lock the

NI 5401 for PXI to other National Instruments devices using the 10 MHz backplane clock.

If no external reference clock is av ailable, the NI 5401 automatically tunes

the internal clock to the highest accuracy possible. For more information on

PLL operation, refer to Chapter 2, Function Generator Operation.

NI 5401 User Manual 1-4 www.natinst.com

are required on this clock. You can lock

pk-pk

Page 12

Pattern Out Connector (PCI Only)

This connector is used on the NI 5401 for PCI to supply the external trigger

input to the board.

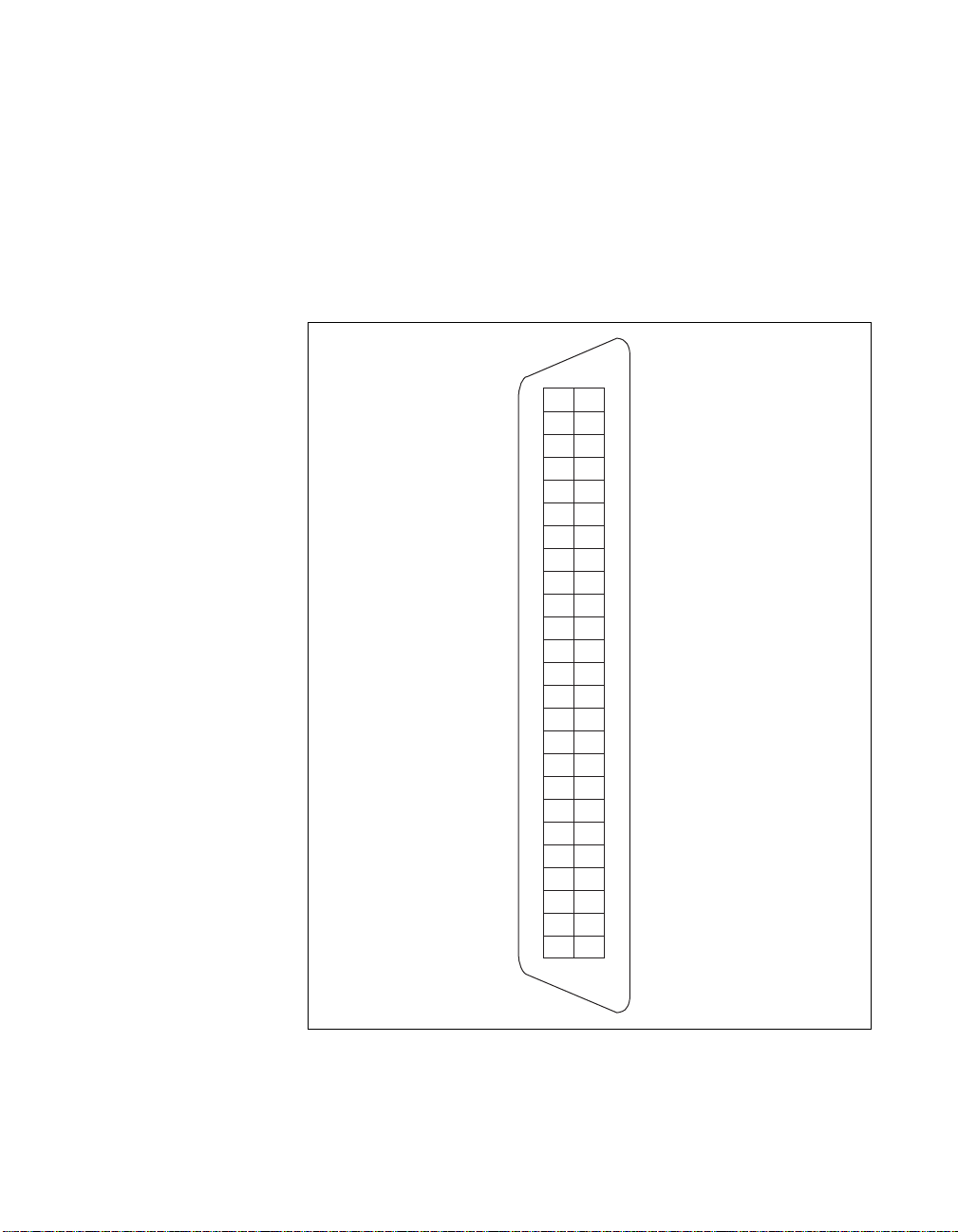

Connector Pin Assignments

Figure 1-4 shows the NI 5401 50-pin digital connector. Refer to Table 1-1

for a description of the signals.

Chapter 1 Generating Functions with the NI 5401

DGND

NC

DGND

NC

DGND

NC

DGND

RFU

DGND

RFU

DGND

RFU

DGND

RFU

DGND

RFU

DGND

RFU

DGND

RFU

DGND

RFU

DGND

RFU

DGND

50

EXT_TRIG25

2449

2348

2247

2146

2045

1944

1843

1742

1641

1540

1439

1338

1237

1136

1035

934

833

732

631

530

429

328

227

126

NC

NC

NC

NC

NC

NC

RFU

RFU

RFU

RFU

RFU

RFU

RFU

RFU

RFU

RFU

RFU

RFU

RFU

RFU

RFU

RFU

RFU

RFU

Figure 1-4.

©

National Instruments Corporation 1-5 NI 5401 User Manual

NI 5401 50-Pin Digital Connector Pin Assignments

Page 13

Chapter 1 Generating Functions with the NI 5401

Signal Descriptions

Table 1-1 shows the pin names and signal descriptions used on the NI 5401

digital output connector.

Table 1-1.

Signal Name Type Description

DGND – Digital ground

EXT_TRIG Input External trigger—The external trigger input signal is a

NC – Not connected.

RFU – Reserved for future use. Do not connect signals to this pin.

Digital Connector Signal Descriptions

TTL-level signal that you can use to start or step through a

waveform generation. For more information on trigger sources

and trigger mode, see Chapter 2, Function Generator

Operation.

SHC50-68 50-Pin Cable Connector

You can use an optional SHC50-68 50-pin to 68-pin cable for external

trigger input. The cable connects to the digital connector on the NI 5401.

Figure 1-5 shows the 68-pin connector pin assignments on the SHC50-68

cable.

Note

The SHC50-68 connector uses the same signals as the NI 5401 digital output

connector shown in Ta ble 1-1.

NI 5401 User Manual 1-6 www.natinst.com

Page 14

Chapter 1 Generating Functions with the NI 5401

RFU

RFU

RFU

RFU

RFU

RFU

RFU

RFU

RFU

RFU

RFU

RFU

RFU

RFU

RFU

RFU

RFU

RFU

RFU

RFU

RFU

RFU

RFU

RFU

NC

NC

NC

NC

NC

NC

NC

NC

NC

EXT_TRIG

26

34

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

27

28

29

30

31

32

33

1

35

2

36

3

37

4

38

5

39

6

40

7

41

8

42

9

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

DGND

DGND

DGND

DGND

DGND

DGND

DGND

DGND

DGND

DGND

DGND

DGND

DGND

DGND

DGND

DGND

DGND

DGND

DGND

DGND

DGND

DGND

DGND

RFU

DGND

DGND

DGND

DGND

DGND

DGND

DGND

DGND

DGND

DGND

Figure 1-5. SHC50-68 68-Pin Connector Pin Assignments

©

National Instruments Corporation 1-7 NI 5401 User Manual

Page 15

Chapter 1 Generating Functions with the NI 5401

Software Options for Your NI 5401

This section describes the NI-FGEN driver software and development tools

that you can use to create application software for your NI5401.

Software Included with Your NI 5401

Your NI5401 kit includes several VirtualBench soft front panels to help

you get up and running quickly with your waveform generator. These soft

front panels are an onscreen interface similar to standalone instruments. An

NI-FGEN instrument driver is also included, which you can use with a

wide variety of development tools to build applications for your NI 5401.

These software tools are discussed in the following sections.

VirtualBench

Similar to standalone instruments, VirtualBench acquires, controls,

analyzes, and presents data. However, since VirtualBench operates on your

PC, it provides additional processing, storage, and display capabilities.

VirtualBench loads and saves waveform data in a form that popular

spreadsheet programs and word processors can use. It can also generate

reports—a complement to the raw data storage—by adding timestamps,

measurements, user names, and comments. You can print the waveforms

and the settings of VirtualBench to a printer connected to thePC.

VirtualBench has two components—VirtualBench-FG and Waveform

Editor—that you can use with your NI5401. These components are

described in the following sections.

VirtualBench-FG

VirtualBench-FG transforms your PC into a fully featured function

generator that rivals desktop models by using the DDS capabilities of your

NI5401. VirtualBench-FG emulates benchtop function generators, so you

can quickly learn to use computer-based instruments.

With VirtualBench-FG, you can generate a variety of waveforms, including

five standard waveforms: sine, square, triangle, rising exponential, and

falling exponential. Using VirtualBench-FG, you load waveforms from an

ASCII text file and generate them repeatedly. You can generate these

waveforms with a resolution of approximately 10mHz and perform

frequency sweeps and shift-keying. As with all VirtualBench instruments,

you can load and save instrument settings.

NI 5401 User Manual 1-8 www.natinst.com

Page 16

Chapter 1 Generating Functions with the NI 5401

Waveform Editor

You use the Waveform Editor to create, sketch, and edit complex

waveforms that the VirtualBench-FG player can then generate. A library of

standard waveforms for creating complex waveforms is included, and you

can also write equations to create arbitrary waveforms and view the

waveforms in a time or frequency domain.

NI-FGEN Instrument Driver

To create your application, you need an industry-standard software driver

such as NI-FGEN to control your instrument. The NI-FGEN driver

includes a set of standard functions for configuring, creating, starting, and

stopping waveform generation. The instrument driver reduces your

program development time and simplifies instrument control by

eliminating the need to learn a complex programming protocol for your

instrument.

NI-FGEN is in a standard instrument driver format that works with

LabVIEW, LabWindows/CVI, and conventional programming languages

such as C, C++, and Visual Basic.

Refer to the NI-FGEN

instrument driver. This file can be launched from the

Start»Programs»National Instruments FGEN menu.

Note

An NI-FGEN Instrument Driver Quick Reference Guide is included in your NI 5401

kit. This reference guide helps you program your NI 5401.

readme.txt file for more details on the NI-FGEN

Additional National Instruments Development Tools

The following sections describe several additional tools that you can use to

develop complex applications for your NI 5401. The NI-FGEN instrument

driver exposes the Application Programming Interfaces (APIs) to these

development environments.

LabVIEW

LabVIEW is a graphical programming language for building

instrumentation systems. With LabVIEW, you quickly create front panel

user interfaces, giving you interactive control of your software system. To

specify the functionality, you assemble block diagrams—a natural design

notation for engineers and scientists. LabVIEW has all of the same

development tools and language capabilities of a standard language such

©

National Instruments Corporation 1-9 NI 5401 User Manual

Page 17

Chapter 1 Generating Functions with the NI 5401

as C, including looping and case structures, configuration management

tools, and compiled performance.

Note Use the NI-FGEN instrument driver to program and control your NI 5401 using

LabVIEW.

LabWindows/CVI

LabWindows/CVI is an interactive, ANSI C programming environment

designed for automated test applications.

LabWindows/CVI has an interacti ve drag-and-drop editor for building your

user interface and a complete ANSI C development environment for

building your test program logic. The LabWindows/CVI environment has

a wide collection of automatic code-generation tools and utilities that

accelerate your development process, without sacrificing any of the po wer

and flexibility of a language such as C. In addition, the LabWindows/CVI

run-time libraries are compatible with standard C/C++ compilers,

including Visual C++ and Borland C++ under Windows.

Note Use the NI-FGEN instrument driver to program and control your NI 5401 using

LabWindows/CVI.

ComponentWorks

ComponentWorks is a collection of 32-bit ActiveX controls for building

virtual instrumentation systems. ComponentWorks gives you the power

and flexibility of standard development tools, such as Microsoft Visual

Basic or Visual C++, with the instrumentation expertise of National

Instruments. Based on ActiveX technology, ComponentWorks controls are

easy to configure using property sheets and are easy to control from your

programs using high-level properties and methods. ComponentWorks

features instrumentation-based graphical user interface (GUI) tools,

including graphs, meters, gauges, knobs, dials, and switches.

Note Use the NI-FGEN instrument driver to program and control your NI 5401 using

ComponentWorks.

NI 5401 User Manual 1-10 www.natinst.com

Page 18

Chapter 1 Generating Functions with the NI 5401

Using the Soft Front Panels to Generate Waveforms

You use the VirtualBench soft front panels to interactively control your

NI 5401 as you would a desktop function generator.

Generating Standard Functions

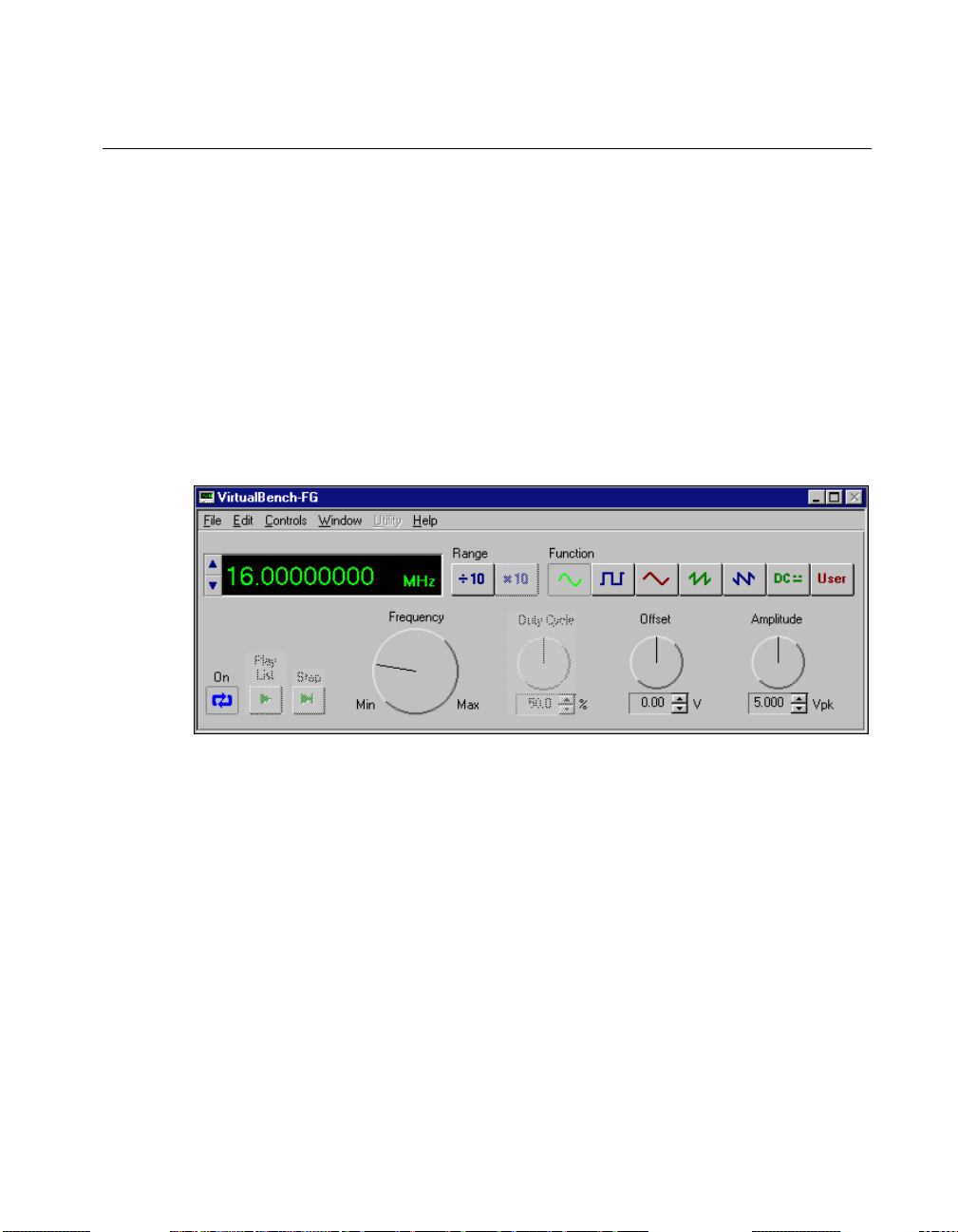

If you need to generate standard waveforms such as a sine, square, ramp,

or DC signal, you can use the VirtualBench-FG soft front panel shown in

Figure 1-6. Launch the front panel by selecting Start»Programs»National

Instruments FGEN»VirtualBench FG. You use this front panel to

control the frequency, amplitude, offset, and type of waveform generated.

The maximum sine frequency you can generate is 16 MHz. The maximum

amplitude is 5 V

the actual levels will be twice that shown on the front panel.

into a 50 Ω load. If the load is a high-impedance load,

pk

Figure 1-6.

©

National Instruments Corporation 1-11 NI 5401 User Manual

VirtualBench-FG Soft Front Panel for Function Generation

Page 19

Chapter 1 Generating Functions with the NI 5401

To control additional instrument parameters, select Edit»54xx Settings to

bring up the dialog box shown in Figures 1-7 and 1-8.

Figure 1-7. VirtualBench-FG General Settings Dialog Box for the NI 5401

Figure 1-8. VirtualBench-FG Signals Settings Dialog Box for the NI 5401

Note Refer to the online help for further information about the 54xx Settings dialog box.

NI 5401 User Manual 1-12 www.natinst.com

Page 20

Chapter 1 Generating Functions with the NI 5401

You can also load a custom waveform pattern with VirtualBench-FG. This

waveform should be a text file and should contain exactly 16,384 samples.

If the defined waveform does not contain exactly 16,384 samples, you may

see undesired effects in your wa veform output. F ollow these steps to load a

custom waveform:

1. Select File»Load Waveform to bring up the dialog box shown in

Figure 1-9.

Figure 1-9. VirtualBench-FG Load Waveform Dialog Box

2. Specify the delimiter used in the text file, the number of columns, the

start line, and the number of samples.

3. Click OK to return to the main VirtualBench-FG screen shown in

Figure 1-6.

4. Click the User button to use the information in the text file as the

source for the waveform.

5. Click the On button to generate the waveform.

Generating Multiple Frequencies in a Sequence

If desired, you can generate multiple frequencies in a sequence, which can

include frequency sweeping, hopping, and so on. You can list up to 512

different frequencies and specify the duration of generation for each of

©

National Instruments Corporation 1-13 NI 5401 User Manual

Page 21

Chapter 1 Generating Functions with the NI 5401

them using the VirtualBench-FG Frequency List Editor. Follow these steps

to create a list of multiple frequencies:

1. Select Window»Frequency List Editor from the VirtualBench-FG

soft front panel to bring up the dialog box shown in Figure 1-10.

Figure 1-10. VirtualBench-FG Frequency List Editor Dialog Box

2. Specify the frequency and duration of each function in the sequence.

3. Save the sequence by selecting File»Save.

4. To return to the main VirtualBench-FG screen shown in Figure 1-6,

select File»Close.

5. Select File»Load Frequency List to load the frequency list.

Y ou can combine the frequency list generation with diff erent trigger modes

to get the desired frequency generation.

NI 5401 User Manual 1-14 www.natinst.com

Page 22

Waveform Editor

Chapter 1 Generating Functions with the NI 5401

You can use the Waveform Editor shown in Figure 1-11 to create a custom

waveform. To launch the Waveform Editor, select Start»Programs»

National Instruments FGEN»Waveform Editor. You can select

waveforms from the function library, write equations, or draw them

manually. Each segment can have more than one waveform component in

it, and you can perform a variety of math functions on each component.

Figure 1-11.

Waveform Editor Soft Front Panel

This soft front panel is resizable so you can view the w av eforms you create

with as much precision as you wish. You can save the waveforms in the

following formats:

• Voltage (

•Text (

• Binary (

.wfm)

.txt)

.bin)

T ext wav eforms are the only format you can use with the NI 5401, and they

must contain exactly 16,384 samples to function properly.

©

National Instruments Corporation 1-15 NI 5401 User Manual

Page 23

Chapter 1 Generating Functions with the NI 5401

Power-Up and Reset Conditions

When you power up your computer, the NI 5401 is in the following state:

• The output is disabled and set to 0 V.

• The trigger mode is set to continuous.

• The trigger source is set to automatic (the software provides the

triggers).

• The digital filter is enabled.

• Output attenuation remains unchanged from its previous setting.

• The analog filter remains unchanged from its previous setting.

• Output impedance remains unchanged from its previous setting.

When you reset the board using NI-FGEN or any other application

software, your NI 5401 is in the same state as shown at power up,

previously listed, with the following differences:

• Output attenuation is set to 0 dB.

• The analog filter is enabled.

• Output impedance is set to 50 Ω.

• The PLL reference source is set to internal tuning.

• The SYNC duty cycle is set to 50%.

NI 5401 User Manual 1-16 www.natinst.com

Page 24

Function Generator Operation

This chapter describes how to use your NI 5401.

Figure 2-1 shows the NI 5401 block diagram.

RTSI/PXI Trigger Bus

2

Instruction

FIFOs

IFIFO

Control

Clock

Controls

Filter

Controls

Data Path

Bus

Interface

RTSI

Control

Waveform

Sequencer

Trigger

Control

DDS +

Lookup

Memory

DDS

Control

Analog

Control

Digital

Filter

PXI/PCI Channel

Figure 2-1.

Attenuators,

DAC

NI 5401 Block Diagram

Filter, and

Amplifier

Level

Crossing

Detector

PLL and

Clocking

ARB

SYNC

PLL Ref

©

National Instruments Corporation 2-1 NI 5401 User Manual

Page 25

Chapter 2 Function Generator Operation

The NI 5401 has several main components:

• A PXI or PCI bus interface that handles Plug and Play protocols for

assigning resources to the device and providing drivers for the data and

address bus that are local to the device

• A waveform sequencer that performs multiple functions such as

arbitrating the data buses and controlling the triggers, filters,

attenuators, clocks, PLL, RTSI switch, instruction FIFO, and DDS

• The data from the memory is fed to a digital-to-analog converter

(DA C) through a half-band interpolating digital filter . The output from

the DAC goes through the filter to the amplifiers, attenuators, and,

finally, the I/O connector.

Generating Waveforms

The NI 5401 generates waveforms using DDS, which is used for generating

standard waveforms that are repetitive in nature, such as sine, TTL, square,

and triangular waveforms. DDS mode limits you to one buffer, and the

buffer size must be exactly equal to 16,384 samples.

Figure 2-2 shows a block diagram of the data path for waveform

generation. The data for waveform generation comes from DDS lookup

memory. This data is interpolated by a half-band digital filter and then fed

to a high-speed DAC. The data has a pipeline delay of 26 update clocks

through this digital filter. Although the digital filter can be disabled through

software, there will still be a 26 update clock delay.

A

12 Bits

Digital Filter

DDS Lookup

Memory

Digital Filter

Enable

DDS

Figure 2-2.

Filter

12

MUX

B

Div/2

Waveform Data Path Block Diagram

DAC Register

80 MHz Oscillator

DAC12

On the NI 5401, the high-speed DAC is always updated at 80 MHz, but the

update clock for memory is 40 MHz.

NI 5401 User Manual 2-2 www.natinst.com

Page 26

Direct Digital Synthesis (DDS)

Direct digital synthesis (DDS) is a technique for deriving, under digital

control, an analog frequency source from a single reference clock

frequency. This technique produces high-frequency accuracy and

resolution, temperature stability, wideband tuning, and rapid and

phase-continuous frequency switching.

The NI 5401 uses a 32-bit, high-speed accumulator with a lookup memory

and a 12-bit DAC for DDS-based waveform generation. Figure 2-3 shows

the building blocks for DDS-based waveform generation.

Chapter 2 Function Generator Operation

Frequency

Time

Frequency

Time

Instruction FIFO

DDS

Sequencer

16-Bit

Counter

(14)

Lookup

Memory

Div/2

Figure 2-3.

Data Out (16)

80 MHz Oscillator

DDS Building Blocks

The lookup memory is dedicated to the DDS. Y ou can store one cycle of a

repetitive waveform—a sine, triangular, square, or arbitrary wave—in the

lookup memory . Then, you can change the frequency of that waveform by

sending just one instruction. You can use DDS mode for very fine

frequency resolution function generation. You can generate sine waves of

up to 16 MHz with the NI 5401. Waveform generation always loops back

to the beginning of the lookup memory after passing through the end of the

lookup memory.

The NI 5401 uses a lookup waveform memory for storing the waveform

buffer and FIFO memory for storing the staging list, which contains

multiple frequency list information. This FIFO is referred to as an

instruction FIFO.

©

National Instruments Corporation 2-3 NI 5401 User Manual

Page 27

Chapter 2 Function Generator Operation

Each stage is made up of two instructions: the frequency, which specifies

the frequency of the waveform to be generated, and the time, which

specifies the time for which the frequency is to be generated.

Note You cannot specify the number of iterations for a waveform to be generated.

Frequency Hopping and Sweeping

You can define a staging list for performing frequency hops and sweeps.

The entire staging list uses the same buffer loaded into the lookup memory.

All stages differ in the frequency to be generated.

Note The minimum time that a frequency should be generated is 2 µs. Therefore, the

maximum hop rate from frequency to frequency is 500 kHz.

The maximum number of stages that can be stored in the instruction FIFO

for DDS mode is 512. For more information on the waveform generation

process, refer to your software documentation.

Triggering

You use triggering to start and step through a waveform generation. The

trigger sources and modes of operation are explained in the following

sections.

Trigger Sources

Trigger sources are software selectable. By default, the software produces

the trigger sources. You can also use an external trigger from a pin on the

digital I/O connector, the RTSI trigger lines on the RTSI bus, or the TTL

trigger lines on the PXI trigger bus on the backplane. Figure 2-4 shows the

trigger sources for the NI 5401.

NI 5401 User Manual 2-4 www.natinst.com

Page 28

RTSI/PXI Trigger

Chapter 2 Function Generator Operation

RTSI/PXI Trigger

Lines <0..6>

7

RTSI Switch

Modes of Operation

External Trigger

Software Trigger

Trigger Select

Figure 2-4. Waveform Generation Trigger Sources

Digital

MUX

Start Trigger

If you need to automatically trigger the waveform generation, use software

to generate the triggers. A rising TTL edge is required for external

triggering. For more information on triggering over RTSI lines, see the

RTSI/PXI Trigger Lines section later in this chapter.

The NI 5401 has three triggering modes—single, continuous, and

stepped—described in the following sections.

Single Trigger Mode

The waveform you define in the staging list is generated only once by going

through the entire staging list. Only one trigger is required to start the

waveform generation.

In single trigger mode, after the NI 5401 receives a trigger, the waveform

generation starts at the first stage and continues through the last stage. The

last stage is generated repeatedly until you stop the waveform generation.

Figure 2-5 illustrates a single trigger mode of operation.

©

National Instruments Corporation 2-5 NI 5401 User Manual

Page 29

Chapter 2 Function Generator Operation

Start Trigger

f1, ∆T1

End of All Stages

f2, ∆T2

f3, ∆T3

Last Stage Generated

f4

Continuously Until Stopped

Figure 2-5. Single Trigger Mode

For example, assume that one cycle of a sine wave is stored in the DDS

lookup memory. F or stage 1, f1 specifies the sine frequency to be generated

for time ∆T1, f2 and ∆T2 for stage 2, and so on. If there are four stages in

the staging list, f4 will be generated continuously until the waveform

generation is stopped.

Continuous Trigger Mode

The waveform you define in the staging list is generated infinitely by

continually cycling through the staging list. After a trigger is received, the

waveform generation starts at the first stage, continues through the last

stage, and loops back to the start of the first stage, continuing until you stop

the waveform generation. Only one trigger is required to start the waveform

generation.

Figure 2-6 illustrates a continuous trigger mode of operation.

Start Trigger

(f1, ∆T1)

End of All Stages

(f2, ∆T2)

(f3, ∆T3)

(f4, ∆T4)

(f1, ∆T1)

Repeat

Until Stopped

(f2, ∆T2)

Figure 2-6. Continuous Trigger Mode

NI 5401 User Manual 2-6 www.natinst.com

Page 30

Chapter 2 Function Generator Operation

Stepped Trigger Mode

After a start trigger is received, the waveform defined by the first stage is

generated. Then, the device waits for the next trigger signal. On the next

trigger, the waveform described by the second stage is generated, and so on.

Once the staging list is exhausted, the waveform generation returns to the

first stage and continues in a cyclic fashion.

Figure2-7 illustrates a stepped trigger mode of operation. Switching from

stage to stage is phase continuous. In this mode, the time instruction is not

used. The trigger paces the waveform generation from one frequency to the

other.

Start Trigger

f1 f2

Analog Output

Note

The DAC output can be fine-tuned for gain and offset. Since the offset is adjusted

before the main attenuators and amplifier, it is referred to as pre-attenuation offset. This

fine-tuning of gain and offset is performed by separate DACs.

Start Trigger

Start Trigger

Start Trigger

f3

End of All Stages

Figure 2-7.

Stepped Trigger Mode

f4

Start Trigger

f1

Analog waveforms are generated as follows:

1. The 12-bit digital waveform data is fed to a high-speed DAC.

2. A lowpass filter filters the DAC output.

3. This filtered signal is amplified before it goes to a 10 dB attenuator.

4. The output from the 10 dB attenuator then goes to the main amplifier,

which can provide up to ±5 V levels into 50 Ω. An output relay can

switch between ground level and the main amplifier. Refer to the

Output Enable section of this document for additional information

about this relay.

5. The output of this relay goes to a series of passive attenuators.

6. The output of the attenuators goes through a selectable output

impedance of 50or75Ω to the I/O connector.

©

National Instruments Corporation 2-7 NI 5401 User Manual

Page 31

Chapter 2 Function Generator Operation

Figure 2-8 shows the essential block diagram of analog waveform

generation.

12

Clock

DAC

Lowpass

Filter

Gain

DAC

Offset

DAC

Level

DAC

Pre Amp

10 dB

Attenuator

Main Amp

Comparator

+

-

Output

Enable

50 Ω

Attenuators

(63 dB in 1 dB steps)

50 Ω

25 Ω

50 Ω/75 Ω

Selector

Figure 2-8. Analog Output and SYNC Out Block Diagram

Figure 2-9 shows the timing relationships of the trigger input and

waveform output. T

is the pulse width on the trigger signal. Td2 is the time

d1

delay from trigger to output on Arb output. Refer to Appendix A,

Specifications, for more information on these timing parameters.

Arb

SYNC

T

d1

Trigger Input Signal

(Slope: Positive, TTL)

Waveform Output

(±5 V

into 50 Ω

pp

)

T

d2

Figure 2-9. Waveform and Trigger Timings

Note

Y ou can switch off the analog lo wpass filter at any time during wav eform generation.

When you change this setting, the bouncing of electromechanical relays on the NI 5401

distorts the output signal for about 10 ms.

NI 5401 User Manual 2-8 www.natinst.com

Page 32

SYNC Output and Duty Cycle

The SYNC output is a TTL version of the sine waveform generated at the

output. The signal from the pre-amplifier is sent to a comparator, where it

is compared against a level set by the level DAC. The output of this

comparator is sent to the SYNC connector through a hysteresis buffer and

a 50 Ω series resistor to reverse terminate reflected pulses.

You can use the SYNC output as a very high-frequency resolution,

software-programmable clock source for many applications. You also can

vary the duty cycle of SYNC output, on the fly, by changing the output of

the level DAC. The SYNC output might not carry meaning for other types

of generated waveforms.

Note

You can change the duty cycle of the SYNC output at any time during waveform

generation.

Output Attenuation

Figure2-10 shows the NI5401 output attenuator chain. The output

attenuators are made of resistor networks and may be switched in any

combination. The maximum attenuation possible on the NI5401 is 73 dB.

Chapter 2 Function Generator Operation

1 dB

In

2 dB 4 dB

8 dB

Figure 2-10.

16 dB

Output Attenuation Chain

32 dB

Out

By attenuating the output signal, you keep the dynamic range of the DAC;

that is, you do not lose any bits from the digital representation of the signal

because the attenuation is done after the DAC and not beforeit.

attenuation (in decibels) = –20 log

whereV

Note

For the NI5401, Vi = ±5 V for a terminated load and ±10 V for an

= desired voltage level for the output signal

o

V

= input voltage level.

i

(Vo /Vi)

10

unterminatedload.

©

National Instruments Corporation 2-9 NI 5401 User Manual

Page 33

Chapter 2 Function Generator Operation

NI-FGEN calculates the value of the output attenuation chain, which you

can control by changing the peak-to-peak amplitude parameter. 0dB

attenuation corresponds to an amplitude of 10V

attenuation of 73dB corresponds to an amplitude of 2.24mV

amplitude less then this is coerced to this value.

Note You can change the output attenuation at any time during waveform generation.

When you change this setting, the bouncing of electromechanical relays on the NI5401

distorts the output signal for about 10 ms.

Output Impedance

As shown in Figure2-10, before the signal reaches the output connector,

you can select an output impedance of 50Ω or 75Ω. If the load impedance

is 50Ω and all the attenuators are off (an output attenuation of 0dB), the

output levels are ±5 V.

Most applications use a load impedance of 50Ω, but applications such as

video device testers require 75Ω. If the load is a very high-input impedance

load (~1 MΩ), you will see output levels up to ±10V.

Note You can change the output impedance at any time during waveform generation.

When you change this setting, the bouncing of electromechanical relays on the NI5401

distorts the output signal for about 10ms.

. The maximum

pk-pk

pk-pk

. Any

Output Enable

You can switch off the waveform generation at the output connector by

controlling the output enable relay, as shown in Figure2-8. When the

output enable relay is off, the output signal level goes to ground level.

Note Even though the output enable relay is in the off position, the waveform generation

process continues internally on the NI5401.

You can use this feature to disconnect and connect different devices to the

NI5401 on the fly.

Note You can change the output enable state at any time during waveform generation.

When you change this setting, the bouncing of electromechanical relays on the NI5401

distorts the output signal for about 10ms.

NI 5401 User Manual 2-10 www.natinst.com

Page 34

Chapter 2 Function Generator Operation

Pre-Attenuation Offset

The NI 5401 hardware supports a DC offset of up to ±2.5 V before the

attenuation chain. Unless the 10 dB attenuator is switched in, which occurs

when the amplitude is less then 3.16 V

, the waveform maximum plus

pk-pk

the offset must not exceed ±5 V into 50 Ω. If it does, the waveform is

clipped. Refer to Figure 2-8 for a diagram showing the location of the

10 dB attenuator.

NI-FGEN automatically calculates the pre-attenuation offset value based

on the DC offset and amplitude values, so the allowable DC offset range is

dependent on the amplitude. For example, if you have an amplitude of

1V

, the maximum DC offset you can apply is 0.25 V, which

pk-pk

corresponds to a pre-attenuation offset of 2.5 V.

Note

You can change the DC Offset at any time during waveform generation. Refer to

your software documentation for additional information.

Phase-Locked Loops and Board Synchronization

Figure 2-11 illustrates the block diagram for the NI 5401 for PCI PLL

circuit. Figure 2-12 illustrates the block diagram for the NI 5401 for PXI

PLL circuit. The PLL consists of a voltage-controlled crystal oscillator

(VCXO) with a tuning range of ±100 ppm. This VCXO generates the main

clock of 80 MHz.

The PLL can lock to a reference clock source from the external connector ,

from a RTSI Osc line on the RTSI bus (NI 5401 for PCI) , or fro m a

10 MHz Osc line on the PXI backplane bus (for NI 5401 for PXI). The PLL

can also be tuned internally using a calibration DAC (CalDAC). National

Instruments accurately performs this tuning during manufacturing. Refer to

the RTSI/PXI Trigger Lines section later in this manual for additional

information on using the RTSI and 10 MHz Osc lines.

The reference and VCXO clock are compared by a phase comparator

running at 1 MHz. The loop filters the error signal and sends it to the control

pin of the VCXO to complete the loop.

©

National Instruments Corporation 2-11 NI 5401 User Manual

Page 35

Chapter 2 Function Generator Operation

Board Clock (Master)

Master/Slave

RTSI Clock (Slave)

Source

Loop

Filter

RTSI

Switch

(20 MHz)

Phase

Comp

RTSI Osc

RTSI Bus

Control

Voltage

VCXO

Source

Control

Voltage

VCXO

AMUX

80 MHz

Div/4

Tune

DAC

20 MHz

14

(1 V

Board Clock

Figure 2-11. PLL Architecture for the NI 5401 for PCI

10 MHz Osc

80 MHz

AMUX

Div/8

Loop

Filter

CAL

DAC

10 MHz

Phase

Comp

(1 V

Figure 2-12. PLL Architecture for the NI 5401 for PXI

PLL Ref

pk-pk

PXI Bus

PLL Ref

pk-pk

min)

min)

Y ou can frequenc y lock to an external reference clock source of 1 MHz and

from 5–20 MHz in 1 MHz increments. The PLL can lock to a signal level

of at least 1 V

Caution Do not increase the voltage level of the clock signal at the PLL reference input

connector by more than the specified limit, 5 V

Note If two or more NI 5401 devices are locked to each other using the same reference

pk-pk

.

.

pk-pk

clock, they are frequency locked, but the phase relationship is indeterminate.

NI 5401 User Manual 2-12 www.natinst.com

Page 36

Analog Filter Correction

The NI5401 can correct for slight deviations in the flatness of the

frequency characteristic of the analog lowpass filter in its passband, as

shown in Figure2-13. Curve A shows a typical lowpass filter curve. The

response of the filter is stored in an onboard EEPROM in 1 MHz

increments up to 16 MHz. CurveC is the correction applied to the

frequency response. The resulting CurveB is a flat response over the entire

passband. If you want to generate a sine wave at a particular frequency with

filter correction applied, you have to specify that frequency through your

software.

Gain (dB)

Chapter 2 Function Generator Operation

A

B

C

Frequency (MHz)

A. Typical Analog Filter Characteristics

B. Corrected Filter Characteristics

C. Correction Applied

Figure 2-13.

Note

You can change the filter frequency correction at any time during waveform

Analog Filter Correction

generation.

©

National Instruments Corporation 2-13 NI 5401 User Manual

Page 37

Chapter 2 Function Generator Operation

RTSI/PXI Trigger Lines

The NI 5401 for PCI contains seven trigger lines and one RTSI clock line

available over the RTSI bus to send and receive NI 5401-specific

information to other boards that have RTSI connectors. Figure 2-14 shows

the RTSI trigger lines and routing of NI 5401 for PCI signals to the RTSI

switch.

SYNC

Start Trigger

RTSI Trigger

Board Clock

Master/Slave

RTSI Clock

Figure 2-14.

RTSI

Switch

RTSI Trigger Lines and Routing for the NI 5401 for PCI

RTSI 0

RTSI 1

RTSI 2

RTSI 3

RTSI 4

RTSI 5

RTSI 6

RTSI Osc

RTSI Bus

Figure 2-15 shows the PXI trigger lines and routing of NI 5401 for PXI

signals to the RTSI switch.

SYNC

Start Trigger

RTSI Trigger

BOARD_SYNC

RTSI

Switch

TRIG 0

TRIG 1

TRIG 2

TRIG 3

TRIG 4

TRIG 5

PXI STAR

PXI Bus

PXI 10MHz Osc

Figure 2-15.

PXI Trigger Lines, 10 MHz Backplane Oscillator, and Routing for the

NI 5401 for PXI

NI 5401 User Manual 2-14 www.natinst.com

Page 38

Chapter 2 Function Generator Operation

The NI 5401 can receive a hardware trigger from another board as a RTSI

trigger signal on any of the RTSI/PXI trigger lines.

You can also route signals as follows:

• Route the Start Trigger signal generated on the NI 5401 to other boards

through any of the RTSI/PXI bus trigger lines.

• Route the SYNC output generated on the NI 5401 to other boards

through any of the RTSI/PXI b u s trigger lines.You can use this signal

to give other boards an accurate and fine frequency resolution clock.

♦ NI 5401 for PCI

For frequency locking to other boards as a master, the NI 5401 sends an

onboard 20 MHz signal to the RTSI Osc line as a board clock signal. For

locking to other devices as a slave, the NI 5401 receives the RTSI Osc line

as a RTSI clock signal.

♦ NI 5401 for PXI

For frequency locking to other boards, the NI 5401 for PXI receives the

PXI backplane 10 MHz Osc as a reference clock signal. All the NI 5401s

for PXI use this common signal as the reference clock for frequency

locking.

Note Refer to your software documentation for selecting and routing signals to the

RTSI/PXI trigger bus.

Calibration

Calibration is the process of minimizing measurement errors by making

small circuit adjustments. On the NI 5401, NI-FGEN automatically makes

these adjustments by retrieving predetermined constants from the onboard

EEPROM, calculating correction values, and writing those values to the

CalDACs.

National Instruments calibrates all NI 5401 devices to the levels indicated

in Appendix A, Specifications. Factory calibration involves procedures

such as nulling the offset and gain errors. However, since offset and gain

errors may drift with time and temperature, you may need to recalibrate

your device. Contact National Instruments to recalibrate your NI 5401.

©

National Instruments Corporation 2-15 NI 5401 User Manual

Page 39

Specifications

This appendix lists the specifications for the NI 5401. These specifications

are typical at 25 °C unless otherwise stated. The operating temperature

range is 0 to 50 °C.

Analog Output

Number of channels...............................1

Resolution ..............................................12 bits

Maximum update rate ............................40 MHz

DDS accumulator................................... 32 bits

Frequency range

Sine .................................................16 MHz, max

SYNC (TTL)...................................16 MHz, max

Square .............................................1 MHz, max

Ramp............................................... 1 MHz, max

Triangle...........................................1 MHz, max

A

Frequency resolution ..............................9.31 mHz

Voltage Output

Ranges

.....................................................±5 V into a 50 Ω load

±10 V into a high-impedance load

Accuracy ................................................±0.1 dB

Output attenuation..................................0 to 73 dB

Resolution....................................... 0.001 dB steps

©

National Instruments Corporation A-1 NI 5401 User Manual

Page 40

Appendix A Specifications

Pre-attenuation offset

Range...............................................±2.5 V into 50 Ω

1

Accuracy..........................................±5 mV

Output coupling .....................................DC

Output impedance ..................................50 Ω or 75 Ω software selectable

Load impedance .....................................50 Ω or greater

Output enable..........................................Software switchable

Protection................................................Short-circuit protected

Sine Spectral Purity

Harmonic products and spurs

Up to 1 MHz....................................–60 dBc

Up to 16 MHz..................................–35 dBc

Phase noise .............................................–105 dBc/Hz at 10 kHz from

carrier

Filter Characteristics

Digital

Type.................................................Half-band interpolating

Selection..........................................Software switchable (enable or

disable)

Taps ................................................67

Filter coefficients ............................Fixed 20-bit

Data interpolating frequency ..........80 MS/s

Pipeline signal delay .......................26 sampling periods

Analog

Type.................................................7th-order L-C lowpass filter

Passband ripple................................±2 dB

1

With less than 10 dB of attenuation, signal maximum plus offset (before attenuation) must not exceed ±5 V (into 50

NI 5401 User Manual A-2 www.natinst.com

Ω)

Page 41

Triggers

Appendix A Specifications

Waveform Specifications

Memory.................................................. 16,384 16-bit samples

Segment length.......................................16,384 samples, exact

Segment linking (instruction FIFO)....... 512 links

Timing I/O

Update clock ..........................................Internal, 40 MHz only

Frequency locking

External reference sources.............. Input connector, RTSI clock line,

or internal

Reference clock frequencies........... 1 MHz, 5–20 MHz in 1 MHz steps

Frequency locking range.................±100 ppm

Digital Trigger

Compatibility ........................................ TTL

Response ...............................................Rising edge

Pulse width (T

Trigger to waveform

output delay (T

)....................................20 ns min

d1

)...................................28 sample clocks + 150 ns max

d2

RTSI

Trigger lines ..........................................7

Clock lines..............................................1

Bus Interface

Type .......................................................Slave

Operational Modes

Type .......................................................Single, continuous, stepped

©

National Instruments Corporation A-3 NI 5401 User Manual

Page 42

Appendix A Specifications

SYNC Out

Level ......................................................TTL

Duty cycle...............................................20% to 80%, software

External Clock Reference Input

Frequency ...............................................1 MHz or 5–20 MHz in 1 MHz

controllable

steps

Internal Clock

Mechanical

Amplitude...............................................1 V

Frequency ...............................................40 MHz

Initial accuracy .......................................±5 ppm

Temperature stability (0 to 5 °C)............±25 ppm

Aging (1 year).........................................±5 ppm

Connectors

ARB (output)...................................SMB/BNC

SYNC (output).................................SMB/BNC

PLL reference (input)......................SMB

External trigger in............................50-pin digital (PCI),

SMB (PXI)

Size .........................................................1 slot

Power requirements ...............................5 V, 3.5 A max

12 V, 125 mA

≤ level ≤ 5 V

pk-pk

pk-pk

NI 5401 User Manual A-4 www.natinst.com

Page 43

Optional Accessories

National Instruments offers a variety of products to use with your NI 5401,

including probes, cables, and other accessories:

• Shielded and unshielded I/O connector blocks (SCB-68, TBX-68,

CB-68)

• RTSI bus cables

For more specific information about these products, refer to your National

Instruments catalogue or Web site, or call the office nearest you.

Cabling

The following list gives recommended part numbers for cables that you can

use with your NI 5401 device:

• BNC male to BNC male, 50 Ω cable from ITT Pomona Electronics

(part number BNC-C-xx)

• BNC male to BNC male, 75 Ω cable from ITT Pomona Electronics

(part number 2249-E-xx)

• BNC female to RCA phono plug adapter, from ITT Pomona

Electronics (part number 5319)

• BNC 50 Ω feed-through terminator adapter from ITT Pomona

Electronics (part number 4119-50)

• BNC female-female adapter from ITT Pomona Electronics

(part number 3283)

B

©

National Instruments Corporation B-1 NI 5401 User Manual

Page 44

Frequency Resolution and

Lookup Memory

For DDS-based waveform generation, you must first load one cycle of the

desired waveform into the lookup memory. The size of the DDS lookup

memory is 16,384 samples. Each sample is 16 bits wide.

Note

One cycle of the waveform buffer loaded into the memory should be exactly equal

to the size of the DDS lookup memory.

= update clock for the accumulator.

F

c

C

For the NI 5401, F

F

= desired frequency of the output signal

a

N = accumulator size in bits

For the NI 5401, N = 32.

FCW = frequency control word to be loaded into the accumulator to

generate F

The frequency control word is calculated using the formula:

FCW = (2

The frequency resolution is then given by:

frequency resolution = F

For example, if you need to generate a frequency of 10 MHz, then the FCW

32

is (2

* 10E6)/40E6, which equals 1,073,741,824. If you need to generate

a frequency of 1 Hz, then the FCW is (2

Note

On the NI 5401, the maximum frequency of a sine wave you can generate reliably

is limited to 16 MHz. Other waveforms such as square or triangular waves are limited to

1MHz.

= 40 MHz.

c

.

a

N

* Fa) / F

c

/ 2N = (40 × 106) / 232 = 9.31322 mHz

c

32

* 1)/40E6, which equals 107.

©

National Instruments Corporation C-1 NI 5401 User Manual

Page 45

Appendix C Frequency Resolution and Lookup Memory

You can also synthesize arbitrary waveforms using DDS. Generating

arbitrary waveforms this way will be very limited; you are restricted to a

single buffer, and this buffer should be exactly equal to the size of the

lookup memory (16,384 samples).

T o update e v ery sample of an arbitrary w av eform in lookup memory at the

maximum clock rate of 40 MHz, the software writes an FCW value of

(N–L)

2

, where N is the size of the accumulator and L is the number of

address bits of lookup memory (L = 14 bits). Thus, the FCW value for the

NI 5401 equals 262,144. Since FCW = (2

so you would write a frequency value of (2

equals 2.441 kHz

If you want to update every sample in lookup memory at an integral

subdivision, D, of the maximum clock rate, then you want an FCW value

(N–L–D+1)

of 2

. In other words, for an effectiv e update rate of ev ery sample at

half the maximum clock rate, write a frequency value of

(32–14–2+1)

(2

×(40 × 106)) / 232, which equals 1.221 kHz.

N

* Fa) / Fc, Fa=(2

(32–14)

×(40 × 106)) / 232, which

(N–L)

*Fc)/2N,

NI 5401 User Manual C-2 www.natinst.com

Page 46

Technical Support Resources

This appendix describes the comprehensive resources available to you in

the Technical Support section of the National Instruments Web site and

provides technical support telephone numbers for you to use if you have

trouble connecting to our Web site or if you do not have internet access.

NI Web Support

To provide you with immediate answers and solutions 24 hours a day,

365 days a year, National Instruments maintains extensi ve online technical

support resources. They are available to you at no cost, are updated daily,

and can be found in the Technical Support section of our Web site at

www.natinst.com/support.

On-Line Problem-Solving and Diagnostic Resources

• KnowledgeBase—A searchable database containing thousands of

frequently asked questions (FA Qs) and their corresponding answers or

solutions, including special sections devoted to our newest products.

The database is updated daily in response to new customer experiences

and feedback.

• Troubleshooting Wizards—Step-by-step guides lead you through

common problems and answer questions about our entire product line.

Wizards include screen shots that illustrate the steps being described

and provide detailed information ranging from simple getting started

instructions to advanced topics.

• Product Manuals—A comprehensive, searchable library of the latest

editions of National Instruments hardware and software product

manuals.

• Hardware Reference Database—A searchable database containing

brief hardware descriptions, mechanical drawings, and helpful images

of jumper settings and connector pinouts.

• Application Notes—A library with more than 100 short papers

addressing specific topics such as creating and calling DLLs,

developing your own instrument driver software, and porting

applications between platforms and operating systems.

D

©

National Instruments Corporation D-1 NI 5401 User Manual

Page 47

Appendix D Technical Support Resources

Software-Related Resources

• Instrument Driver Network—A library with hundreds of instrument

drivers for control of standalone instruments via GPIB, VXI, or serial

interfaces. You also can submit a request for a particular instrument

driver if it does not already appear in the library.

• Example Programs Database—A database with numerous,

non-shipping example programs for National Instruments

programming environments. You can use them to complement the

example programs that are already included with National Instruments

products.

• Software Library—A library with updates and patches to application

software, links to the latest versions of driver software for National

Instruments hardware products, and utility routines.

Worldwide Support

National Instruments has offices located around the globe. Many branch

offices maintain a Web site to provide information on local services. You

can access these Web sites from

www.natinst.com/worldwide.

If you have trouble connecting to our Web site, please contact your local

National Instruments office or the source from which you purchased your

National Instruments product(s) to obtain support.

For telephone support in the United States, dial 512 795 8248. For

telephone support outside the United States, contact your local branch

office:

Australia 03 9879 5166, Austria 0662 45 79 90 0, Belgium 02 757 00 2 0,

Brazil 011 284 5011, Canada (Ontario) 905 785 0085,

Canada (Québec) 514 694 8521, China 0755 3904939,

Denmark 45 76 26 00, Finland 09 725 725 11, France 01 48 14 24 24,

Germany 089 741 31 30, Hong Kong 2645 3186, India 91805275406,

Israel 03 6120092, Italy 02 413091, Japan 03 5472 2 970,

Korea 02 596 7456, Mexico (D.F.) 5 280 7625,

Mexico (Monterrey) 8 357 7695, Netherlands 0348 433466,

Norway 32 27 73 00, Singapore 22658 86, Spain (Madrid) 91 640 0085,

Spain (Barcelona) 93 582 0251, Sweden 08 587 895 00,

Switzerland 056 200 51 51, Taiwan 02 2377 1200,

United Kingdom 01635 523545

NI 5401 User Manual D-2 www.natinst.com

Page 48

Glossary

Prefix Meaning Value

µ- micro- 10

m- milli- 10

k- kilo- 10

M- mega- 10

Numbers/Symbols

% percent

+ positive of, or plus

– negative of, or minus

± plus or minus

/per

–6

–3

3

6

°degree

Ω ohm

+5 V +5 V output signal

A

A amperes

amplification method of scaling the signal level to a higher level

ARB normal waveform output signal

attenuation decreasing the amplitude of a signal

©

National Instruments Corporation G-1 NI 5401 User Manual

Page 49

Glossary

B

b bit—one binary digit, either 0 or 1

B byte—eight related bits of data, an eight-bit binary number. Also used to

denote the amount of memory required to store one byte of data.

BNC a type of coaxial signal connector

buffer temporary storage for acquired or generated data

bus the group of conductors that interconnect individual circuitry in a computer.